Page 1

1^ USER MANUAL

^2 Accessory 14M

^3 MACRO OPTO 48 bit Input/output

^4 3Ax-603741-xUxx

^5 December 9, 2009

Single Source Machine Control Power // Flexibility // Ease of Use

21314 Lassen Street Chatsworth, CA 91311 // Tel. (818) 998-2095 Fax. (818) 998-7807 // www.deltatau.com

Page 2

Copyright Information

© 2009 Delta Tau Data Systems, Inc. All rights reserved.

This document is furnished for the customers of Delta Tau Data Systems, Inc. Other uses are

unauthorized without written permission of Delta Tau Data Systems, Inc. Information contained in

this manual may be updated from time-to-time due to product improvements, etc., and may not

conform in every respect to former issues.

To report errors or inconsistencies, call or email:

Delta Tau Data Systems, Inc. Technical Support

Phone: (818) 717-5656

Fax: (818) 998-7807

Email: support@deltatau.com

Website: http://www.deltatau.com

Operating Conditions

All Delta Tau Data Systems, Inc. motion controller products, accessories, and amplifiers contain

static sensitive components that can be damaged by incorrect handling. When installing or handling

Delta Tau Data Systems, Inc. products, avoid contact with highly insulated materials. Only

qualified personnel should be allowed to handle this equipment.

In the case of industrial applications, we expect our products to be protected from hazardous or

conductive materials and/or environments that could cause harm to the controller by damaging

components or causing electrical shorts. When our products are used in an industrial environment,

install them into an industrial electrical cabinet or industrial PC to protect them from excessive or

corrosive moisture, abnormal ambient temperatures, and conductive materials. If Delta Tau Data

Systems, Inc. products are directly exposed to hazardous or conductive materials and/or

environments, we cannot guarantee their operation.

Page 3

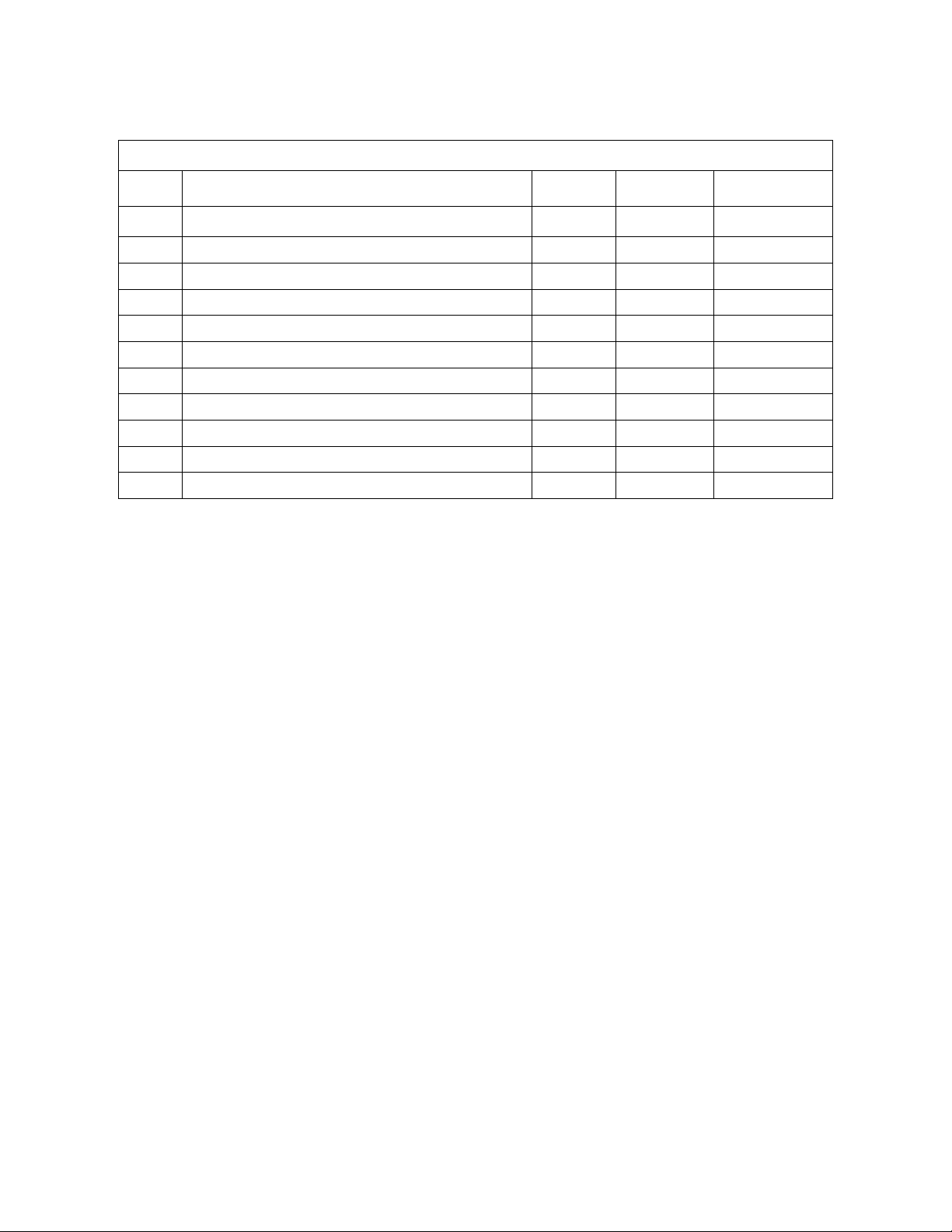

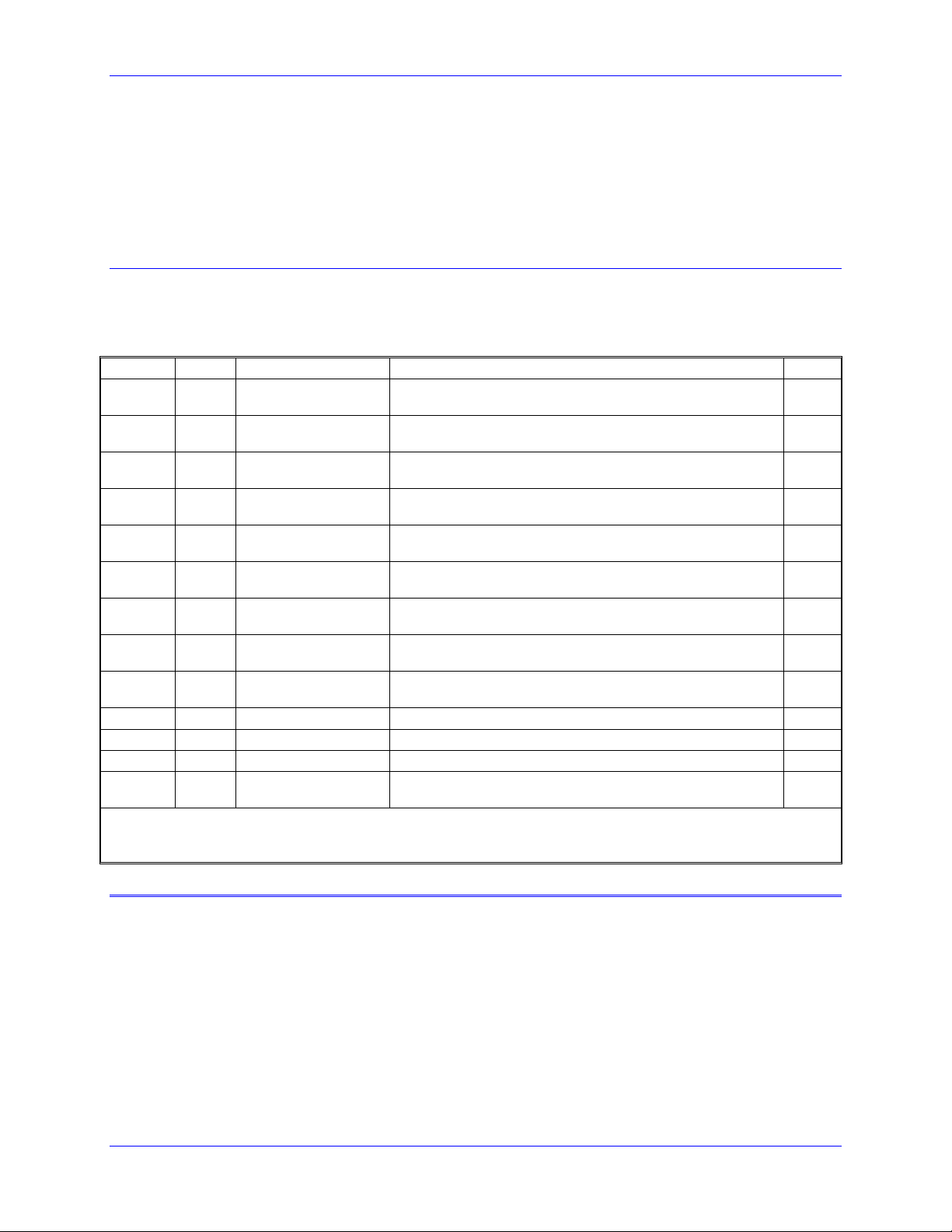

REVISION HISTORY

REV. DESCRIPTION DATE CHG APPVD

1 NEW MANUAL 07/21/09 C.PERRY S. SATTARI

2 UPDATED 16-BIT ADC OPTION 12/08/09 C.PERRY S. FIERRO

Page 4

Page 5

Accessory 14M

TABLE OF CONTENTS

INTRODUCTION .......................................................................................................................................................1

Options ......................................................................................................................................................................2

HARDWARE REFERENCE SUMMARY ...............................................................................................................3

Mechanical Layout....................................................................................................................................................3

Board Layout.............................................................................................................................................................4

Connectors and Indicators.........................................................................................................................................4

Inputs and Outputs LED Indicators......................................................................................................................4

Status LED Indicators...........................................................................................................................................4

7-Segment LED Indicator.....................................................................................................................................4

USB Connector .....................................................................................................................................................4

24V Input Connector.............................................................................................................................................4

MACRO Link Connectors .....................................................................................................................................4

DB-15 Option-1 Connector ..................................................................................................................................4

Relay Status LED Indictors...................................................................................................................................4

Inputs and Outputs Terminal Blocks (J4 and J5)..................................................................................................5

E-Point Jumper Description ......................................................................................................................................5

CONNECTORS DESCRIPTION ..............................................................................................................................6

USB Universal Serial Bus Port .................................................................................................................................6

24VDC Input.............................................................................................................................................................6

MACRO RJ-45 Copper Connectors..........................................................................................................................6

MACRO Fiber Optic Connector ...............................................................................................................................7

U17: MACRO Fiber Optic Connector (OPT A, B)...................................................................................................7

Main IO Connectors J4 and J5 ..................................................................................................................................8

J4 (50 Pin Header) ...............................................................................................................................................8

J5 (50 Pin Header) ...............................................................................................................................................9

OPT-1: DB-15 Connector .......................................................................................................................................10

SOFTWARE SETUP ................................................................................................................................................11

ACC14M MACRO 72-Bit Node (24 Inputs / 24 Outputs) FORMAT w/ Outputs high 24-bit word......................11

ACC14M MACRO 72-Bit Node (48 Outputs) FORMAT......................................................................................11

ACC14M MACRO 72-Bit Node (48 Inputs) FORMAT.........................................................................................11

ACC14M MACRO 72-Bit Node (24 Outputs / 24 Inputs) FORMAT w/ Outputs low 24-bit word.......................12

ASCII Ring Order Initial Binding of the ACC-14M Station...................................................................................14

Establishing Communications with the ACC-14M Station .................................................................................14

USING ACC-14M FOR INPUTS AND OUTPUTS................................................................................................16

MI14 Mode Setting 0 or 3 (24 inputs and 24 outputs) ADD mode 1 and 2 ........................................................16

USING OPTION 1 – ADC’S, DAC’S, RELAY’S...................................................................................................18

Using the ACC-14M ADC......................................................................................................................................18

Using the ACC-14M DAC Output..........................................................................................................................19

Using the ACC-14M Amplifier Enable Outputs.....................................................................................................20

USING ACC-14M FOR SERVO FEEDBACK.......................................................................................................21

Example Turbo Encoder Conversion Table Setup for ACC-14M...........................................................................21

ECT Setup for 18-bit Encoder without Filtering ................................................................................................21

ECT Setup for 18-bit Encoder with Filtering......................................................................................................21

Absolute Encoder Setup for ACC-14M ..................................................................................................................22

Graycode Encoder Feedback...................................................................................................................................22

FEEDBACK DATA LATCHING AND HANDSHAKING ...................................................................................23

Method 1 .............................................................................................................................................................24

Method 2 .............................................................................................................................................................24

Table of Contents i

Page 6

Accessory 14M

Method 3 .............................................................................................................................................................25

Method 4 .............................................................................................................................................................25

Method 5 .............................................................................................................................................................26

MACRO ASCII Communication Reference:..........................................................................................................27

Firmware Updates ...................................................................................................................................................28

ACC-14M MACRO STATION MI-VARIABLE REFERENCE..........................................................................29

Global MI-Variables ...............................................................................................................................................29

MS{anynode}, MI0 Station Firmware Version (Read Only)..............................................................................29

MS{anynode},MI1 Station Firmware Date (Read Only) ...................................................................................29

MS{anynode},MI2 Station ID and User Configuration Word ...........................................................................29

MS{anynode},MI3 (Reserved for Future Use)...................................................................................................30

MS{anynode},MI4 Station Status Word (Read Only) ........................................................................................30

MS{anynode},MI5 Ring Error Counter.............................................................................................................30

MS{anynode},MI6 Maximum Permitted Ring Errors in One Second................................................................31

MS{anynode},MI7 (Reserved for Future Use)...................................................................................................31

MS{anynode},MI8 MACRO Ring Check Period................................................................................................31

MS{anynode},MI9 MACRO Ring Error Shutdown Count.................................................................................31

MS{anynode},MI10 MACRO Sync Packet Shutdown Count .............................................................................32

MS{anynode},MI11 Station Order Number.......................................................................................................32

MS{anynode},MI12 Card Identification ............................................................................................................32

MS{anynode},MI13 (Reserved for Future Use).................................................................................................32

MS{anynode},MI14 Input/Output Configuration...............................................................................................33

MS{anynode},MI15 Enable MACRO PLCC......................................................................................................34

MACRO IC MI-Variables.......................................................................................................................................34

MS{anynode},MI176 MACRO IC Base Address................................................................................................34

MS{anynode},MI177 MACRO IC Address for Node 14 ....................................................................................34

MS{anynode},MI178 MACRO IC Address for Node 15 ....................................................................................34

MS{anynode},MI181–MI188 MACRO Channels 1 - 8 Address ........................................................................34

MACRO IC I/O Transfer MI-Variables..................................................................................................................34

MS{anynode},MI198 Direct Read/Write Format and Address..........................................................................35

MI198 Format Digits..........................................................................................................................................36

MS{anynode},MI199 Direct Read/Write Variable.............................................................................................38

Global MACRO Status MI-Variables .....................................................................................................................38

MS{anynode}, MI203 Phase Period ..................................................................................................................38

MS{anynode}, MI204 Phase Execution Time ....................................................................................................38

MS{anynode}, MI205 Background Cycle Time .................................................................................................38

MS{anynode}, MI206 Maximum Background Cycle Time ................................................................................38

MS{anynode}, MI208 User Ram Start...............................................................................................................38

MACRO IC MI-Variables.......................................................................................................................................39

MS{anynode},MI942 ADC Strobe Word for ADC1 and ADC2 Inputs..............................................................39

MACRO IC Setup MI-Variables.............................................................................................................................39

MS{anynode},MI970-MI973 (Reserved for Future Use)...................................................................................39

MS{anynode},MI1974 Station Display Status (Read Only)...............................................................................39

MS{anynode},MI977 Motor Nodes Reporting Ring Break................................................................................39

MS{anynode},MI978-MI989 (Reserved for Future Use)...................................................................................40

MACRO IC MI-Variables.......................................................................................................................................40

MS{anynode},MI992 MaxPhase Frequency Control.........................................................................................40

MS{anynode},MI993 Hardware Clock Control Handwheel Channels..............................................................40

MS{anynode},MI994 PWM Deadtime / PFM Pulse Width Control for Handwheel........................................42

MS{anynode},MI995 MACRO Ring Configuration/Status................................................................................42

MS{anynode},MI996 MACRO Node Activate Control ......................................................................................43

MS{anynode},MI997 Phase Clock Frequency Control .....................................................................................45

MS{anynode},MI998 Servo Clock Frequency Control......................................................................................45

MS{anynode},MI999 Handwheel DAC Strobe Word (Not Used)......................................................................46

Other ACC-14M MACRO Station Mm & MP-Variables.......................................................................................46

ii Table of Contents

Page 7

Accessory 14M

ACC-14M MACRO STATION MACPLCCS.........................................................................................................46

Requirements...........................................................................................................................................................46

Arithmetic Data Types ............................................................................................................................................46

MACRO MI Integer Variables (n = 0 – 1099)........................................................................................................46

MACRO MM and MP Integer Variables (n = 0 – 511) ..........................................................................................46

MACROPlcc Ln Integer Variables (n = 0 – 511) ....................................................................................................46

Direct Memory Addressing for Integer Ln & Ln[] Variable Definitions............................................................46

Standard MACRO Program Commands .................................................................................................................47

Valid Math, Assignment and Conditional Operators ..............................................................................................47

Valid Expressions and Arrays.................................................................................................................................47

Ln Arrays Definition Examples...............................................................................................................................47

Example Program...............................................................................................................................................47

MACRO PLCC Code Memory ...............................................................................................................................47

MAC PLCC Related ASCII Commands .................................................................................................................48

ACC-14M MACRO STATION SERIAL COMMANDS.......................................................................................48

Serial Commands ....................................................................................................................................................48

$$$ Station Reset ...............................................................................................................................................48

$$$*** Station Re-initialize...............................................................................................................................48

CHN Report Channel Number...........................................................................................................................48

CID Report Card ID Number ............................................................................................................................48

CLRF Clear Station Faults................................................................................................................................48

DATE Report Firmware Date............................................................................................................................48

DISABLE PLCC or CNTRL D Disables PLCC .................................................................................................49

ENABLE PLCC Enables PLCC.........................................................................................................................49

MI{constant} Report Station MI-Variable Value...............................................................................................49

MI{constant}={constant} Set Station MI-Variable Value .................................................................................49

MM{constant} Report Station MM-Variable Value...........................................................................................49

MM{constant}={constant} Set Station MM-Variable Value .............................................................................49

MP{constant} Report Station MP-Variable Value.............................................................................................49

MP{constant}={constant} Set Station MP-Variable Value...............................................................................49

MM{constant}-> Report Station MM-Variable Definition................................................................................49

MM{constant}->{X/Y:offset,width,format} Set Station MM-Variable Definition..............................................49

R{address} Read Station Address......................................................................................................................49

SAVE Save Station MI-Variables.......................................................................................................................50

SID Reports Serial Identification Number.........................................................................................................50

VERS Report Firmware Version........................................................................................................................50

VID Report Vendor ID Number.........................................................................................................................50

W{address},{value} Write Value to Station Address .........................................................................................50

PMAC TYPE 1 ACC-14M MACRO STATION COMMANDS ...........................................................................52

On-Line Commands ................................................................................................................................................52

MS Command .....................................................................................................................................................52

MS Variable Read...............................................................................................................................................53

MS Variable Write ..............................................................................................................................................53

MS Variable Read Copy .....................................................................................................................................53

MS Variable Write Copy.....................................................................................................................................54

Turbo PMAC PLC Commands for Type 1 ACC-14M MACRO Stations ..............................................................55

MS Variable Read Copy .....................................................................................................................................55

MS Variable Write Copy.....................................................................................................................................55

ACC-14M MACRO STATION MEMORY AND I/O MAP..................................................................................57

Internal Calculation Registers .................................................................................................................................57

Open Memory .........................................................................................................................................................57

DSPGATE2 Registers.............................................................................................................................................57

Table of Contents iii

Page 8

Page 9

Accessory 14M

INTRODUCTION

The ACC-14M can be used with a TURBO PMAC2 Ultralite or UMAC MACRO for either general

purpose digital I/O, direct connection to Opto22 style boards, or as high speed latched inputs for servo

loop position or velocity feedback. The ACC-14M can also run a Delta Tau PLCC program that allows

the user to process their IO in real time using its on-board processor without adding overhead to the Ring

Master controller.

The ACC-14M can be used as follows:

INPUTS OUTPUTS MI14 Comments

24 24 0 Default. J4 is Input Port and J5

is Output Port. Uses one IO

Node

0 48 1 Uses two IO nodes

48 0 2 Uses two IO nodes

24 24 3 J4 is Output Port and J5 is

Input Port. Uses one IO node

Whatever your intent, this manual is equipped with the necessary examples and descriptions to allow for a

rapid setup. While setup of the Acc-14M is easy for all its’ purposes it is a bit easier to setup the board

for the purpose of machine I/O than it is for the purpose of servo control. This is because configuring the

board for closed loop servo data requires a few more jumper settings, the setup of various I-variables in

the encoder conversion table, and if used for power on position the setup of certain power-on position

variables.

The encoder conversion table is setup on the controller side using variables I8000 through I8191.

Encoder conversion types are $2 and $3 for the ACC-14M and are described in the Turbo PMAC

Software Reference Manual.

If option 1 is ordered a set of analog inputs, analog outputs, and relay contacts are installed. These can be

used to control, for example, one or two inverter drives through the MACRO link.

This accessory works only with a Turbo PMAC2 controller, either in Ultralite or UMAC format.

Features:

• Two 24-bit IO ports configured as Inputs or Outputs. OPTO 22 compatible

• One 24-bit Gray Code to Binary Conversion for J4 port only

• Latching inputs

• Output Clock for Binary or Gray code encoder synchronization

Introduction 1

Page 10

Accessory 14M

Options

• OPT-A (30A-603740-OPT): Fiber Optic MACRO connectors

• OPT-C (30C-603740-OPT): RJ45 MACRO connectors

• OPT-1 (301-603740-OPT): This option includes:

o Two relay contact outputs

o Two 12-bit DAC outputs with 0-10 V voltage range

o Two 16-bit ADC inputs with 0-10 V voltage range

2 Introduction

Page 11

Accessory 14M

HARDWARE REFERENCE SUMMARY

Mechanical Layout

ACC-14M MACRO Station I/O Transfer 3

Page 12

Accessory 14M

Board Layout

Connectors and Indicators

Inputs and Outputs LED Indicators

Each of the 24 input and 24 INPUT/OUTPUT lines has an associated LED that displays its state, either

active or inactive, in the front panel of the unit.

Status LED Indicators

+24V: When lit, this LED indicates that 24V is applied to the unit.

PWR: When lit, this LED indicates that proper power is applied to the logic circuits

WD: When lit, this LED indicates that the watchdog safety circuit is activated, indicating a

failure condition.

7-Segment LED Indicator

This indicator reports the status of the unit with respect to the MACRO link. These are the possible status

codes:

0: Ring Active with no errors

1-9: NA

a: NA

b: Ring-break fault

c: Configuration change fault

d: Ring data-error fault

e: NA

f: Momentary ring fault

USB Connector

This connector is used to perform some software diagnostic procedures, or to download the operational

firmware. This connector is used in conjunction with the PEWIN32-Pro or equivalent software package.

24V Input Connector

Power is applied to the unit through this connector. The power requirement for logic is 300mA @

24VDC. The power requirement for the outputs is 50mA per each, 2.4A if all 48 are used.

MACRO Link Connectors

The unit can be ordered to use either RJ45 connectors with twisted pair copper wires or a fiber optic

connection. In either case, there will be an input and an output connector, and both are used to connect to

the MACRO link. The input connector is tied to the MACRO output connector of the previous device on

the link. The output connector connects to the input MACRO connector of the next device on the link.

DB-15 Option-1 Connector

When OPT-1 is ordered this connector provides the lines for two relay contact outputs, two 16-bit DAC

outputs with 0-10 V voltage range and two 16-bit ADC inputs with 0-10 V voltage range.

Relay Status LED Indictors

RLY1: When lit, this indicates that the first amplifier enable relay is activated.

4 ACC-14M MACRO Station I/O Transfer

Page 13

Accessory 14M

RLY2: When lit, this indicates that the second amplifier enable relay is activated.

Inputs and Outputs Terminal Blocks (J4 and J5)

Allows for the 48 bit Inputs/Outputs connections, their clocking, and errors. Each connector is a 50-pin

IDE header that allows for direct connection to Opto22 style boards.

E-Point Jumper Description

Refer to the layout diagram of ACC-14M for the location of the jumpers on the board.

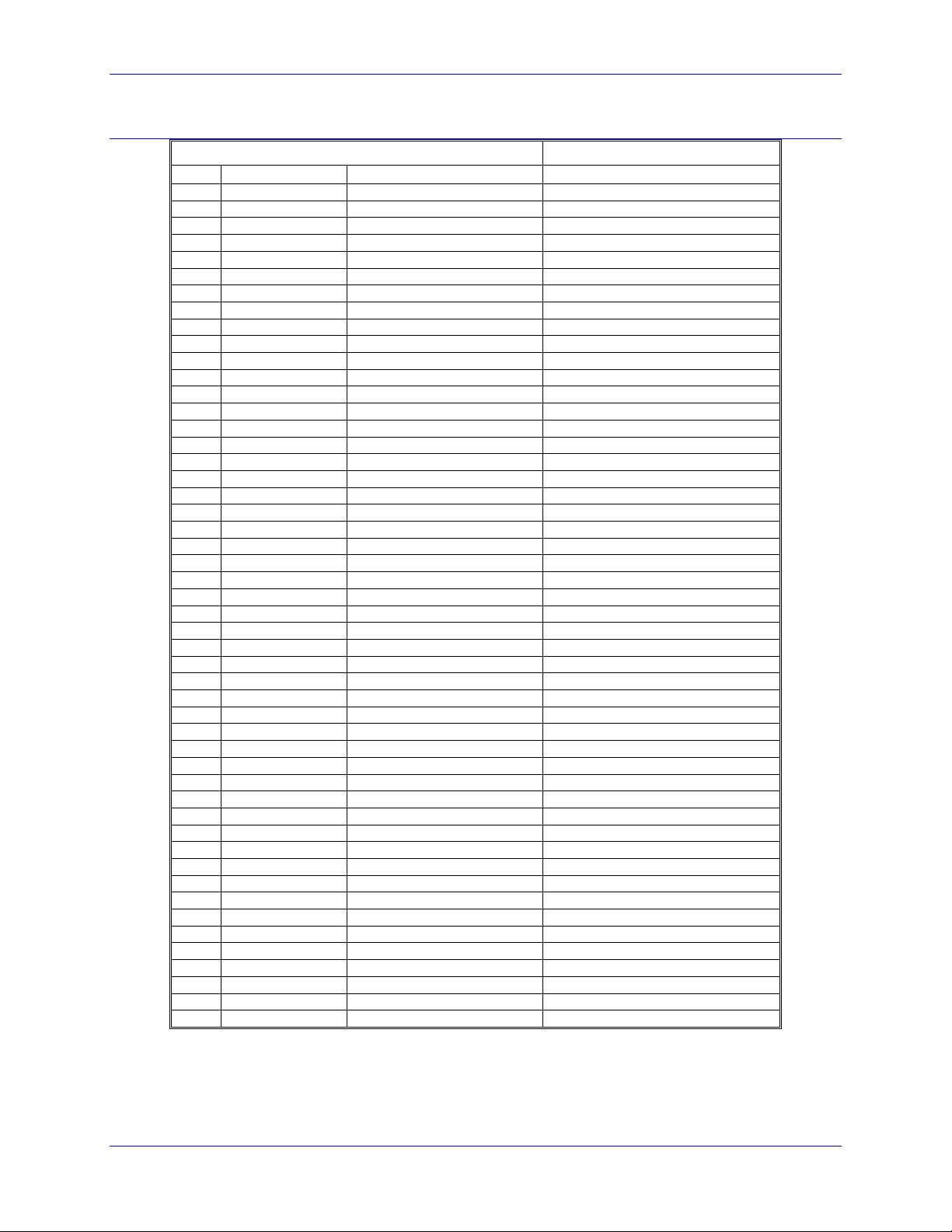

Table 1: E-Point Jumper configuration and settings

Jumper Config Description Settings

E1 1-2 Watchdog Disable ON to disable watchdog

OFF for normal operation

E2 1-2-3 BootStrap 1-2 for bootstrap mode

2-3 for normal operation

E3 1-2 Buadrate ON for 9600 Baud for USB to Serial Coverter

OFF for 38400 Baud for USB to Serial Coverter

E5 1-2-3 Output clock polarity 1-2 OCLK is sample clock-

2-3 OCLK is sample clock+

E6 1-2-3 Latch clock polarity 1-2 ENA_CLK is sample clock+

2-3 ENA_CLK is sample clock-

E7 1-2 Input latch signal for

bits 0-23

E8 1-2 Error latch signal for

bits 0-23

E9 1-2 Input latch signal for

bits 24-47

E10 1-2 Error latch signal for

bits 24-47

JP1 1-2 Board Type Reserved for ACC-65M/ACC-68M OFF

JP2 1-2 Board Type Install jumper for ACC-14M 1-2

JP3-JP6 - Reserved OFF

JP7 1-2 Re-initialization ON for re-initialization to factory defaults at power up

The E7, E8, E9, and E10 jumpers are pulled up to 5V if not using ICLK or ERR inputs from the encoder. If you are

NOT using the ICLK or ERR inputs to the ACC-14M, then you will need to jumper E7 and E8 when using J4

connector port for inputs and/or E9 and E10 when using the J5 connector port for inputs.

ON passes the ICLK1 0V input from J4 to latch Inputs 0-23

OFF passes the ICLK1 5V input from J4 to latch Inputs 0-23

ON allows a low ERR1/ input to latch Inputs 0-23

OFF allows a high ERR1/ input to latch Inputs 0-23

ON passes the ICLK2 0Vinput from J5 to latch Inputs 24-47

OFF passes the ICLK2 5Vinput from to latch Inputs 24-47

ON allows a low ERR2/ input to latch the Inputs 24-47

OFF allows a high ERR2/ input to latch the Inputs 24-47

OFF for normal operations

Default

OFF

2-3

OFF

1-2

1-2

1-2

1-2

1-2

1-2

1-2

ACC-14M MACRO Station I/O Transfer 5

Page 14

Accessory 14M

CONNECTORS DESCRIPTION

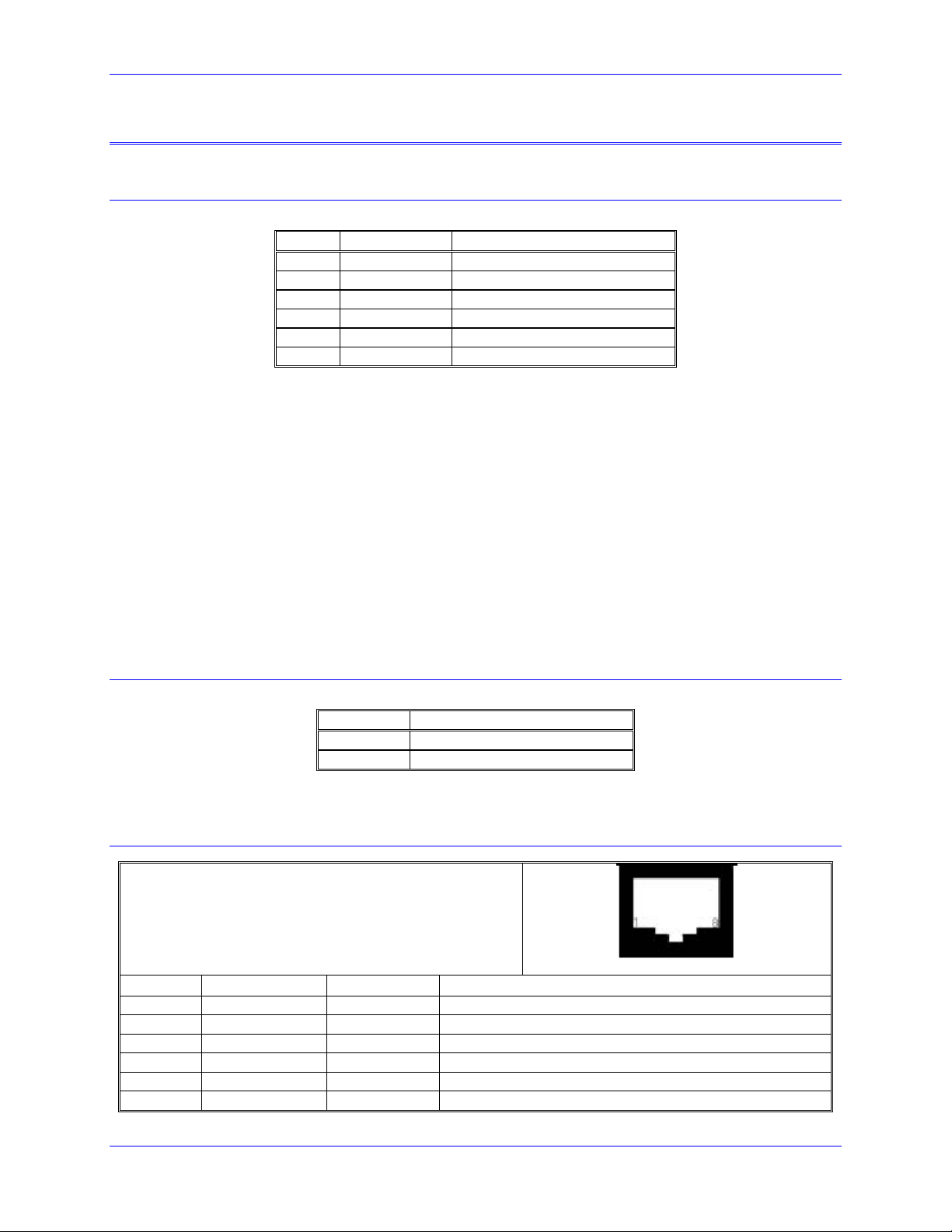

USB Universal Serial Bus Port

Pin # Symbol Function

1 VCC N.C.

2 D- DATA-

3 D+ DATA+

4 GND GND

5 SHELL SHIELD

6 SHELL SHIELD

This connector is only used to change the operational firmware, or to perform basic software diagnostic

operations. The user can user a serial port terminal window such as Microsoft HyperTerminal to

communicate to the MACRO Device. You should set your serial port communication settings as follows:

Buad Rate: 38400 for E3 not jumpered or 9600 for E3 jumpered

Data Bits: 8

Parity: None

Stop Bits: 1

Flow Control: Xon/Xoff

If you have installed PEWIN Pro software, then the USB device should be recognized by your operating

system. If the device is not recognized by Windows, please contact the factory and we can assist you.

24VDC Input

Symbol Function

24V RET AGND

+24V +24V

This connector is used to power the unit with a 25A @ 24VDC power supply.

MACRO RJ-45 Copper Connectors

Front View

Pin # Symbol Function Description

1 DATA+ Data + Differential MACRO Signal.

2 DATA- Data - Differential MACRO Signal

3 Unused Unused terminated pin

4 Unused Unused terminated pin

5 Unused Unused terminated pin

6 Unused Unused terminated pin

6 ACC-14M MACRO Station I/O Transfer

Page 15

Accessory 14M

7 Unused

Unused te

ated p

8 Unused Unused terminated pin

rmin

in

The cable used for MACRO wired connections is CAT5 verified straight-through 8 conductor. The input

connector is tied to the MACRO INPUT/OUTPUT connector of the previous device on the link. The

INPUT/OUTPUT connector connects to the input MACRO connector of the next device on the link.

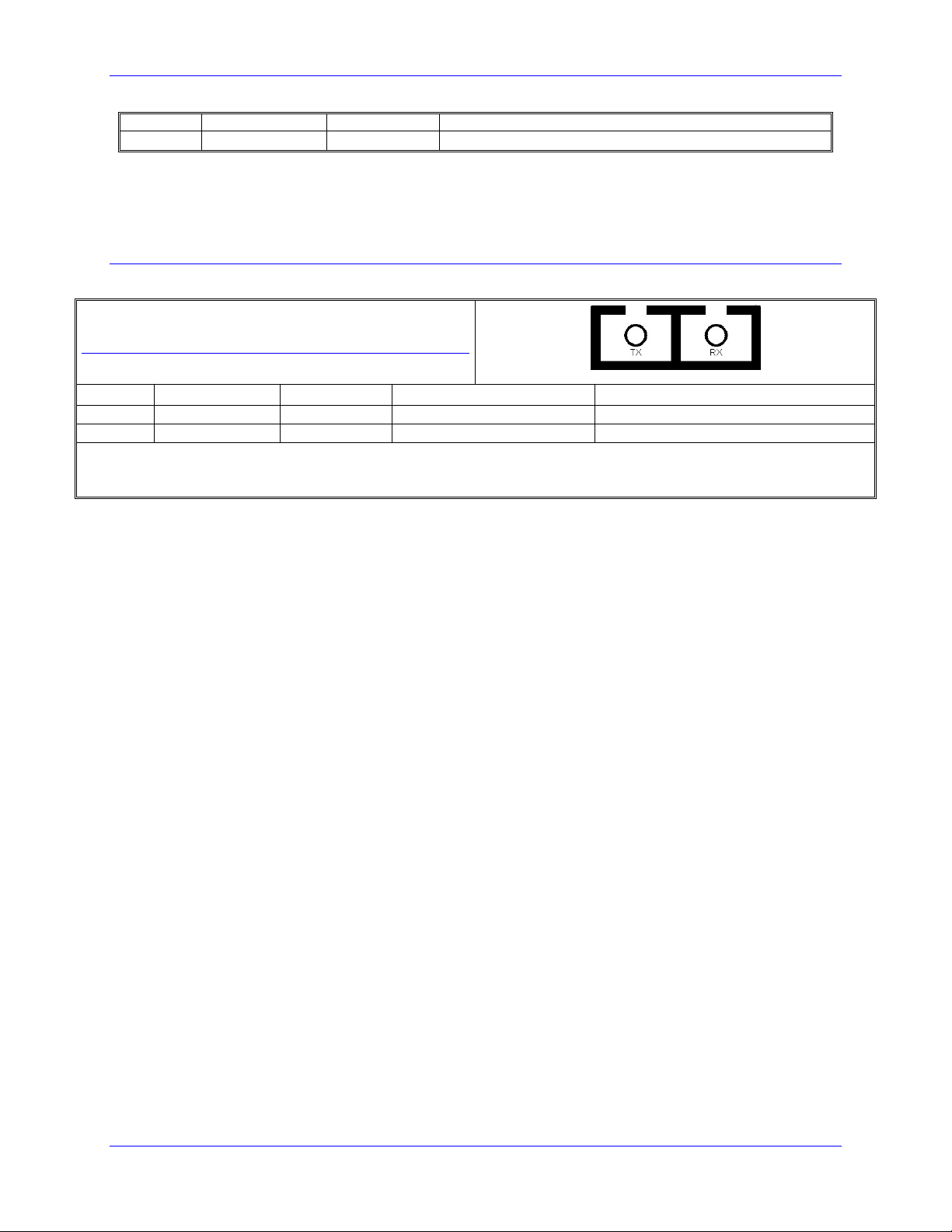

MACRO Fiber Optic Connector

U17: MACRO Fiber Optic Connector

(OPT A, B)

(2 Socket SC-Style)

Front View

Pin # Symbol Function Description Notes

1 RX Fiber Input MACRO Ring Receiver

2 TX Fiber Output MACRO Ring Transmitter

1. The fiber optic version of MACRO uses 62.5/125 multi-mode glass fiber optic cable terminated in an SC-style

connector. The optical wavelength is 1,300nm.

2. It is possible to "adapt" wire to fiber operation when using OPT B.

ACC-14M MACRO Station I/O Transfer 7

Page 16

Accessory 14M

Main IO Connectors J4 and J5

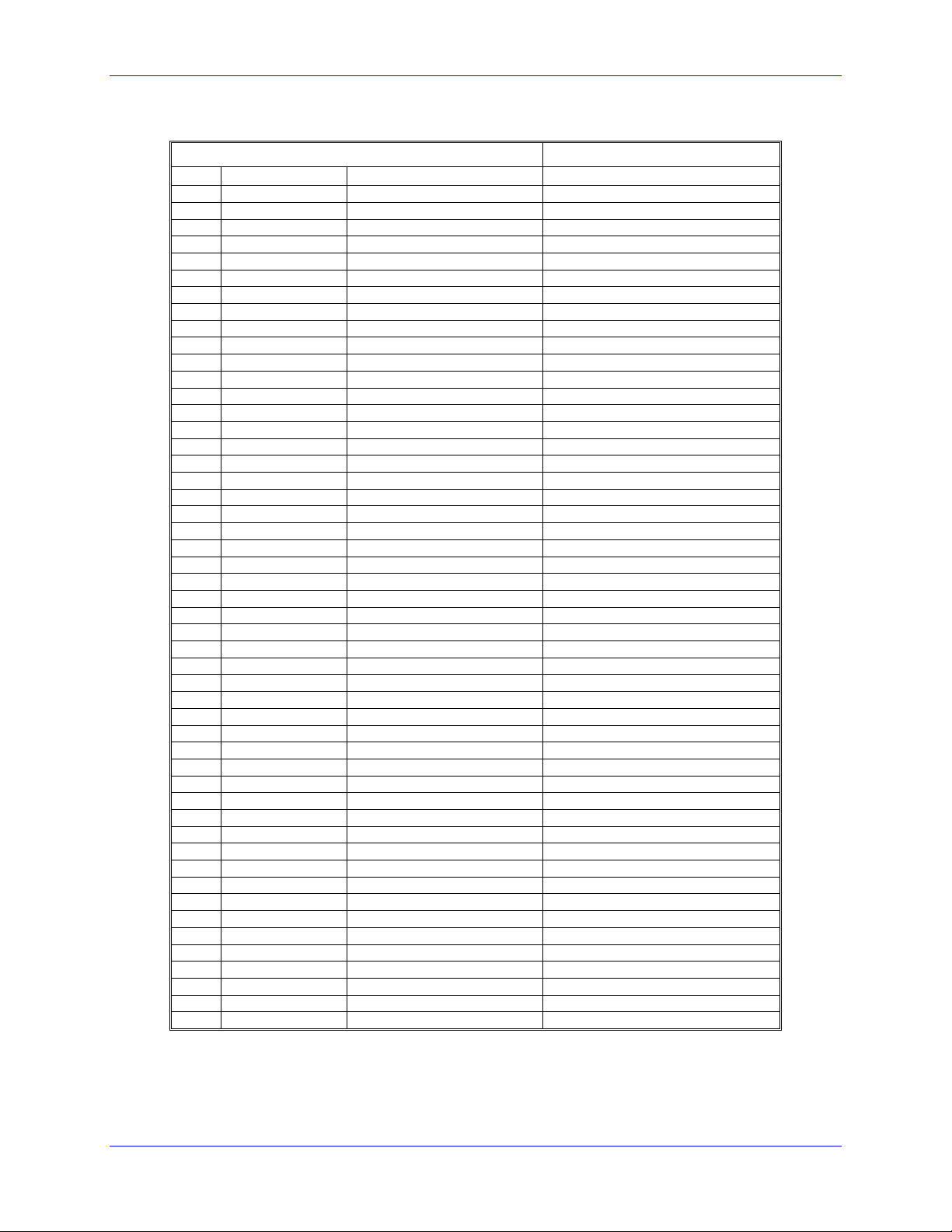

J4 (50 Pin Header)

Pin Symbol Function Description

1 MI/O23 In/out I/O at base address, bit 23

2 GND Common PMAC common

3 MI/O22 In/out I/O at base address, bit 22

4 GND Common PMAC common

5 MI/O21 In/out I/O at base address, bit 21

6 GND Common PMAC common

7 MI/O20 In/out I/O at base address, bit 20

8 GND Common PMAC common

9 MI/O19 In/out I/O at base address, bit 19

10 GND Common PMAC common

11 MI/O18 In/out I/O at base address, bit 18

12 GND Common PMAC common

13 MI/O17 In/out I/O at base address, bit 17

14 GND Common PMAC common

15 MI/O16 In/out I/O at base address, bit 16

16 GND Common PMAC common

17 MI/O15 In/out I/O at base address, bit 15

18 GND Common PMAC common

19 MI/O14 In/out I/O at base address, bit 14

20 GND Common PMAC common

21 MI/O13 In/out I/O at base address, bit 13

22 GND Common PMAC common

23 MI/O12 In/out I/O at base address, bit 12

24 GND Common PMAC common

25 MI/O11 In/out I/O at base address, bit 11

26 GND Common PMAC common

27 MI/O10 In/out I/O at base address, bit 10

28 GND Common PMAC common

29 MI/O9 In/out I/O at base address, bit 9

30 GND Common PMAC common

31 MI/O8 In/out I/O at base address, bit 8

32 GND Common PMAC common

33 MI/O7 In/out I/O at base address, bit 7

34 GND Common PMAC common

35 MI/O6 In/out I/O at base address, bit 6

36 GND Common PMAC common

37 MI/O5 In/out I/O at base address, bit 5

38 GND Common PMAC common

39 MI/O4 In/out I/O at base address, bit 4

40 GND Common PMAC common

41 MI/O3 In/out I/O at base address, bit 3

42 GND Common PMAC common

43 MI/O2 In/out I/O at base address, bit 2

44 ERR1 Input Error signal

45 MI/O1 In/out I/O at base address, bit 1

46 ICLK1 Input

47 MI/O0 In/out I/O at base address, bit 0

48 OCLK1 Output

49 +V Output 5V power

50 GND Common

8 ACC-14M MACRO Station I/O Transfer

Page 17

Accessory 14M

J5 (50 Pin Header)

Pin Symbol Function Description

1 MI/O47 In/Out I/O at base address, bit 47

2 GND Common PMAC common

3 MI/O46 In/Out I/O at base address, bit 46

4 GND Common PMAC common

5 MI/O45 In/Out I/O at base address, bit 45

6 GND Common PMAC common

7 MI/O44 In/Out I/O at base address, bit 44

8 GND Common PMAC common

9 MI/O43 In/Out I/O at base address, bit 43

10 GND Common PMAC common

11 MI/O42 In/Out I/O at base address, bit 42

12 GND Common PMAC common

13 MI/O41 In/Out I/O at base address, bit 41

14 GND Common PMAC common

15 MI/O40 In/Out I/O at base address, bit 40

16 GND Common PMAC common

17 MI/O39 In/Out I/O at base address, bit 39

18 GND Common PMAC common

19 MI/O38 In/Out I/O at base address, bit 38

20 GND Common PMAC common

21 MI/O37 In/Out I/O at base address, bit 37

22 GND Common PMAC common

23 MI/O36 In/Out I/O at base address, bit 36

24 GND Common PMAC common

25 MI/O35 In/Out I/O at base address, bit 35

26 GND Common PMAC common

27 MI/O34 In/Out I/O at base address, bit 34

28 GND Common PMAC common

29 MI/O33 In/Out I/O at base address, bit 33

30 GND Common PMAC common

31 MI/O32 In/Out I/O at base address, bit 32

32 GND Common PMAC common

33 MI/O31 In/Out I/O at base address, bit 31

34 GND Common PMAC common

35 MI/O30 In/Out I/O at base address, bit 30

36 GND Common PMAC common

37 MI/O29 In/Out I/O at base address, bit 29

38 GND Common PMAC common

39 MI/O28 In/Out I/O at base address, bit 28

40 GND Common PMAC common

41 MI/O27 In/Out I/O at base address, bit 27

42 GND Common PMAC common

43 MI/O26 In/Out I/O at base address, bit 26

44 ERR2 Input Error signal

45 MI/O25 In/Out I/O at base address, bit 25

46 ICLK2 Input

47 MI/O24 In/Out I/O at base address, bit 24

48 OCLK2 Output

49 +V Output 5v

50 GND Common

ACC-14M MACRO Station I/O Transfer 9

Page 18

Accessory 14M

OPT-1: DB-15 Connector

Pin # Symbol Function

1 GND COMMON GROUND

2 ADC1+ ANALOG INPUT 1+

3 ADC2+ ANALOG INPUT 2+

4 DAC1+ ANALOG OUTPUT 1+

5 DAC2+ ANALOG OUTPUT 2+

6 AE-NC-1 NORMALLY CLOSE RELAY 1

7 AE-COM-2 COMMON RELAY 2

8 AE-NO-2 NORMALLY OPEN RELAY 2

9 ADC1- ANALOG INPUT 1-

10 ADC2- ANALOG INPUT 2-

11 DAC1- ANALOG OUTPUT 1-

12 DAC2- ANALOG OUTPUT 2-

13 AE-COM-1 COMMON RELAY 1

14 AE-NO-1 NORMALLY OPEN RELAY 1

15 AE-NC-2 NORMALLY CLOSE RELAY 2

When OPT-1 is ordered this connector provides the lines for two relay contact outputs, two 12-bit DAC

outputs with 0-10 V voltage range and two 16-bit ADC inputs with 0-10 V voltage range.

10 ACC-14M MACRO Station I/O Transfer

Page 19

Accessory 14M

SOFTWARE SETUP

Typically, the MACRO Slave Device and MACRO Master IC (Ultralite) can support up to eight AXIS

nodes (0, 1, 4, 5, 8, 9, 12, and 13) and up to six I/O transfer nodes (2, 3, 6, 7, 10, and 11). This data

exchange goes through a MACRO IC at both points (master and slave) on the MACRO Ring. There are

three types of I/O transfers allowed that send information between the Turbo Ultralite and a MACRO

Device. These are, 48-bit I/O background data transfer, 72-bit phase rate I/O node transfer, and 48-bit

ASCII transfer.

The 48-bit I/O transfer occurs on node 15 of the MACRO ring and the 48-bit ASCII transfer occurs on

node 14 using the broadcast feature of MACRO. The 72-bit node transfer is used to exchange all

hardware I/O on the card, the 48-bit I/O transfer for MI variables and the 48-bit ASCII for Ring Order

setup of the Station. (The ACC-14M does not have switches that bind it to a certain Master and Node so

it uses Ring Order for initial binding to a Master and Node.) The Turbo PMAC2 Ultralite and the

MACRO Station enable transfer of 72 bits per I/O node with the I6841 and MI996 type variables.

Once the first node number has been established the Turbo Ultralite can control the Acc-14M through a

single I/O node, two consecutive I/O nodes, or an AXIS node depending on the type of control desired.

The data exchange format is described in the following table:

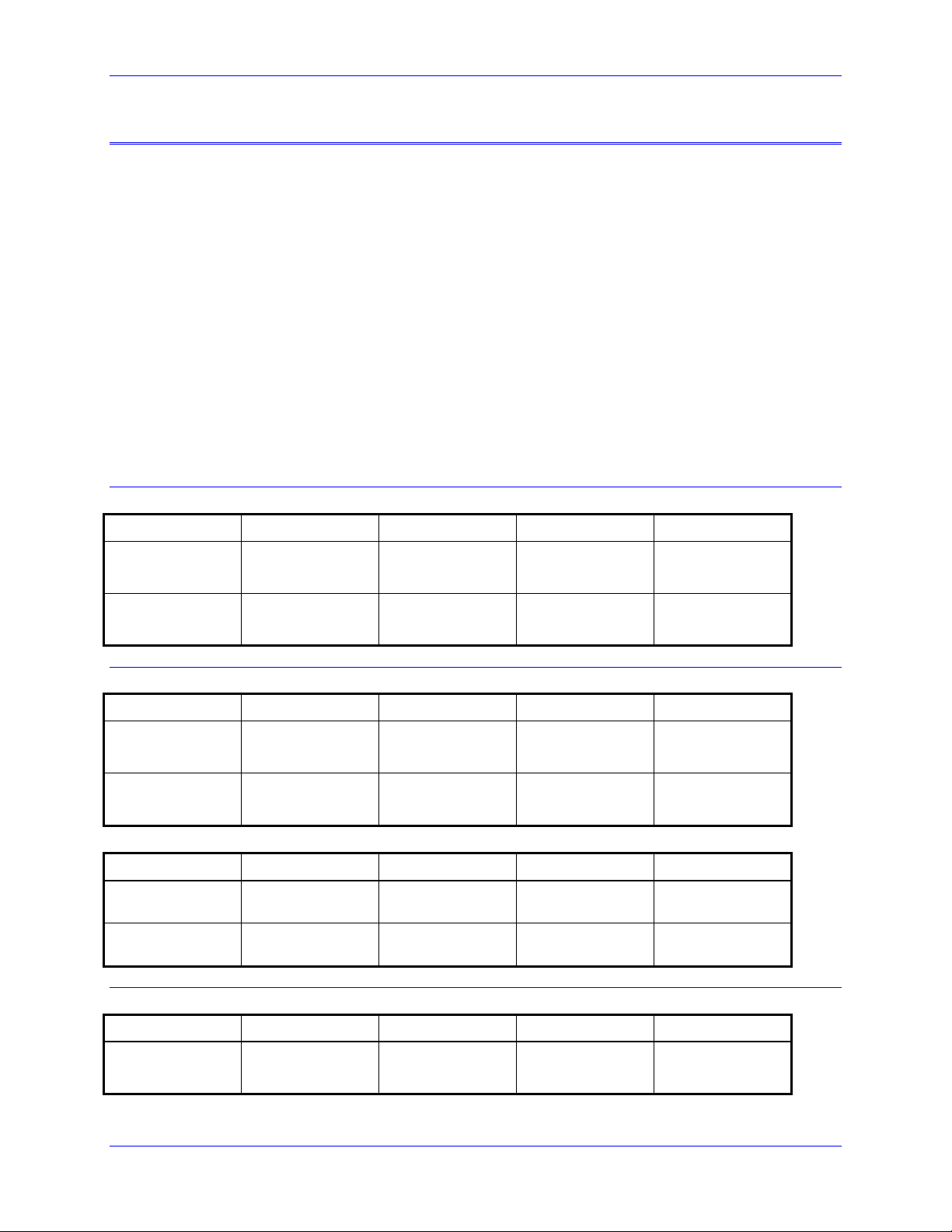

ACC14M MACRO 72-Bit Node (24 Inputs / 24 Outputs) FORMAT w/ Outputs high 24-bit word

1st X or Y: I/O Node (MI14.0 = 0, MI14.1 = 0) - One (1) I/O Node (Default)

Register # 0 ( 24 – bit ) 1 ( 16 – bit ) 2 ( 16 - bit ) 3 ( 16 - bit )

Command to

Acc-14M Station

Feedback from

Acc-14M Station

Outputs, bits 24 – 47 DAC 1

(Channel 1)

Inputs, bits 0 – 23 ADC 1 (08-23 bits)

(Channel 1)

DAC 2

(Channel 2)

ADC 2 (08-23 bits)

(Channel 2)

Flag Command

Flag Status

ACC14M MACRO 72-Bit Node (48 Outputs) FORMAT

1st X or Y: I/O Node (MI14.0 = 1, MI14.1 = 0) - Two (2) I/O Nodes (Two consecutive nodes must be enabled in MI996)

Register # 0 ( 24 – bit ) 1 ( 16 – bit ) 2 ( 16 - bit ) 3 ( 16 - bit )

Command to I/O

Station

Feedback from MI/O

Station

2nd I/O Node (Always the next consecutive X or Y: Node)

Register # 0 ( 24 – bit ) 1 ( 16 – bit ) 2 ( 16 - bit ) 3 ( 16 - bit )

Command to I/O

Station

Feedback from MI/O

Station

Outputs 0 – 23 DAC 1

(Channel 1)

Not used ADC 1 (08-23 bits)

(Channel 1)

Outputs 24 – 47 Not used Not used Not used

Not used Not used Not used Not used

DAC 2

(Channel 2)

ADC 2 (08-23 bits)

(Channel 2)

Flag Command

Flag Status

ACC14M MACRO 72-Bit Node (48 Inputs) FORMAT

1st X or Y: I/O Node (MI14.0 = 0, MI14.1 = 1) - Two (2) I/O Nodes (Two consecutive nodes must be enabled in MI996)

Register # 0 ( 24 – bit ) 1 ( 16 – bit ) 2 ( 16 - bit ) 3 ( 16 - bit )

Command to I/O

Station

Not used DAC 1

(Channel 1)

DAC 2

(Channel 2)

Flag Command

ACC-14M MACRO Station I/O Transfer 11

Page 20

Accessory 14M

Feedback from MI/O

Station

2nd I/O Node (Always the next consecutive X or Y: Node)

Register # 0 ( 24 – bit ) 1 ( 16 – bit ) 2 ( 16 - bit ) 3 ( 16 - bit )

Command to I/O

Station

Feedback from MI/O

Station

Inputs 0 – 23 ADC 1 (08-23 bits)

(Channel 1)

Not used Not used Not used Not used

Inputs 24 – 47 Not used Not used Not used

ADC 2 (08-23 bits)

(Channel 2)

Flag Status

ACC14M MACRO 72-Bit Node (24 Outputs / 24 Inputs) FORMAT w/ Outputs low 24-bit word

1st X or Y: I/O Node (MI14.0 = 1, MI14.1 = 1) - One (1) I/O Node (Default)

Register # 0 ( 24 – bit ) 1 ( 16 – bit ) 2 ( 16 - bit ) 3 ( 16 - bit )

Command to I/O

Station

Feedback from MI/O

Station

Note the 72-bit I/O can be done on a Y-Axis or X:IO Node

Outputs 0 – 23 DAC 1

(Channel 1)

Input 24 – 47 ADC 1 (08-23 bits)

(Channel 1)

DAC 2

(Channel 2)

ADC 2 (08-23 bits)

(Channel 2)

Flag Command

Flag Status

FLAG(s) Command Register

B09 - Reserved for future ring protocol control

B10 - Reserved for future ring protocol control

B11 - Reserved

B12 - Reserved

B13 - The Slave detected a MACRO Ring Break MRB & became a Ring master (Note 3)

B14 - Reserved

B15 – When B13 = 1 then B15 = 1 is a Station Fault.

B16 - Reserved for future ring protocol control

B17 - Reserved for future ring protocol control

B18 - Reserved for future ring protocol control

B19 - Fast User Defined Command Flag (UserCmd1) AENA_1 INPUT/OUTPUT

B20 - Fast User Defined Command Flag (UserCmd2) AENA_2 INPUT/OUTPUT

B21 - Fast User Defined Command Flag (UserCmd3)

B22 - Fast User Defined Command Flag (UserCmd4)

B23 - Fast User Defined Command Flag (UserCmd5)

12 ACC-14M MACRO Station I/O Transfer

Page 21

Accessory 14M

FLAG(s) Status Register

B08 - Reserved for future ring protocol status

B09 - Reserved for future ring protocol status

B10 - Reserved for future ring protocol status

B11 - Reserved

B12 - Reserved

B13 - This Node detected a MACRO Ring Break MRB (Note 3)

B14 - Reserved

B15 - Station or Real Time Data Node Fault

B16 - Reserved for future ring protocol status

B17 - Reserved for future ring protocol status

B18 - Reserved for future ring protocol status

B19 - Fast User Defined Status Flag (UserSatus1) AENA_1 INPUT/OUTPUT

B20 - Fast User Defined Status Flag (UserSatus2) AENA_2 INPUT/OUTPUT

B21 - Fast User Defined Status Flag (UserSatus3)

B22 - Fast User Defined Status Flag (UserSatus4)

B23 - Fast User Status Flag(UserSatus5)

To use this card the user will have to establish communications using the ring order method to activate the

nodes at MACRO Slave Device (ACC-14M). The user must also activate the nodes at the MACRO

Master Device (typically an Ultralite) to allow communications from the Master to the Slave. Once

communications is working properly the user can then setup the inputs and outputs or feedback devices.

The following sections will show the user how to setup:

• Ring Order Method of Communications

• General Purpose Inputs and outputs on ACC-14M

• Setting up Feedback Devices on ACC-14M

ACC-14M MACRO Station I/O Transfer 13

Page 22

Accessory 14M

ASCII Ring Order Initial Binding of the ACC-14M Station

To initially bind the ACC-14M to a MACRO Master, the Ring Order method is used. When this is used

the Ring Controller sends a command out on the Ring in the ASCII communication protocol. It is asking

to talk to the first MACRO Station that does not have a Station Number (MI11=0 or STN=0). When this

communication state is entered, the Ring Controller is now talking to the MACRO Station in an ASCII

data exchange mode. That Station can be either another Turbo PMAC MACRO Station or Slave Station

like the ACC-14M. Once communication is established, the developer at the Ring Controller binds the

Station to a Master and Node (It sets the Slave Station’s MI996). It is now setup for the normal 72-bit

and 48-bit I/O exchange between the Master and Slave Station (the ACC-14M). To come back and

communicate with this Station in the ASCII data exchange, its station number (STN) is set normally to its

order on the Ring. Once this is done, the Ring Order attempts to find the next station on the Ring that has

not been setup for Ring Order (STN=0). Control T is entered. It terminates the ASCII communication

transfer between the Ring Controller and the Station and returns to normal communication with the Ring

Controller.

At a minimum, the user must set the following I-variables to enable MACRO ASCII mode

communications.

I6840=$4030 ;to enable MACRO IC0 as sync-master and node 14 for auxiliary communications

I6841=$0FCxxx ;to enable node 15 and 14. If activating nodes 0,1,4,5 we would set I6841=$0FC033

I79=32 ;Timeout value for Node 14 Auxiliary communications

If the customer is using more than one MACRO IC, then they will setup I6890, I6891, I6940, I6941, I6990,

and I6991 appropriately. Once the communication variables are modified, they must be saved to the memory

of the controller with the save command and then reset the controller with either a “$$$” command or power

cycle the controller.

Note:

The PMAC Controller will be able to communicate to the MACRO Device in

MACRO ASCII communication mode after the unit has been reset with the

changes saved to its memory. This can be done by cycling power or by ussuing

the following commands:

mssav2 ;save settings to Macro station which has node 2 activated

ms$$$2 ;reset Macro station which has node 2 activated

Establishing Communications with the ACC-14M Station

After hooking up the Ring and 24VDC power, the user can try to read and write to the IO Device.

1. Ring Order (at the Ring Controller), enter MACSTA255. Now you can assign it a Station number by

entering STN=n where n is the Station number. If a Macro I/O error is received, make sure I6840,

I6841 and I79 are set correctly. Also make sure that the Unit has not been already assigned a Station

number.

If the Station has already been assigned a Station number, there are two options:

a) Find out the station number n and enter MACSTA<n>, where n is the station number, to initiate

MACRO ASCII communication with the Station.

b) Reset the station number of all the stations by entering MACSTA0 and then enter STN=

c) Note:

14 ACC-14M MACRO Station I/O Transfer

Page 23

Accessory 14M

This will NOT reset all the parameters in the MACRO Stations) or $$$**

Note:

This will reset all the parameters in the MACRO Stations).

Next enter ^T to exit MACRO ASCII communications. Then enter MACSTA255 to access the

first Station. Now you can assign it a Station number by entering STN=n where n is the Station

number. Enter ^T to exit MACRO ASCII Communications. Enter MACSTA255 again to

access the next station and repeat this process until you get a MACRO I/O error telling you that

there are no further unassigned stations.

2. Enter MACSTA<n> where n is the Station number. Enter I996=$F4004. (Binds to Ring Controller 0

& Node2)

3. Enter ^T. (Control-T terminates MACRO ASCII Communications)

4. Enter MSCLRF2. (Clears any faults)

5. Enter I6841=I6841 | $0FC004 (Enable Node 2).

6. Set up M-Variables for I/O as follows:

M0->X:$78420,24 ; 24 bit I/O

M1->X:$78421,8,16,S ; DAC_1 output

M2->X:$78422,8,16,S ; DAC_2 output

M3->X:$78423,0,24 ; AENA_1/2 output command

M4->X:$78421,8,16,S ; ADC_1 Input

M5->X:$78422,8,16,S ; ADC_2 Input

7. Test with the I/O (if I/O is powered properly and not connected to machine devices)

M0=$555555 ;The INPUT/OUTPUT LEDs in the 55 pattern.

M0=$AAAAAA ;The INPUT/OUTPUT LEDs in the AA pattern.

M3=$80000 ;The AENA_1 LED on and the relay closed.

M3=$100000 ;The AENA_2 LED on and the relay closed

M1=653 ;DAC_1 outputs at 1V

M2=653 ;DAC_2 outputs at 1V

M4 & M5 ;ADC_1/2 inputs

ACC-14M MACRO Station I/O Transfer 15

Page 24

Accessory 14M

USING ACC-14M FOR INPUTS AND OUTPUTS

For general purpose inputs and outputs, the ACC-14M can be used as follows:

INPUTS OUTPUTS MI14 Comments

24 24 0 Default. J4 is Input Port and J5 is Output Port.

Uses one IO Node

0 48 1 Uses two IO nodes

48 0 2 Uses two IO nodes

24 24 3 J4 is Output Port and J5 is Input Port. Uses one IO

node

The key parameter to set this up is MI14. When the user modifies MI14 on the ACC-14M, they must

issue a SAVE command to the ACC-14M and a $$$ command to the ACC-14M to activate the desired

mode. The default setting for the ACC-14M is MI14=0 and this means that the board is ready to function

as a 24 input and 24 output board when received from the factory.

MI14 Mode Setting 0 or 3 (24 inputs and 24 outputs) ADD mode 1 and 2

If MI4 is set to 0 then the ACC-14M allow the user to read and write to 24 inputs and 24 outputs. If MI14

is set to either 0 or 3 then the ACC-14M will use the 24-bit node register of the activated node to process

the inputs and outputs. The only difference between the MI4 setting of 0 and 3 is the physical location of

the inputs and outputs as shown below:

MI14 Input Output Notes

0 J4 Connector J5 Connector Default

3 J5 Connector J4 Connector

Using the IO is accomplished by writing to a node register to activate the desired outputs and reading the

same node register to read the status of the inputs. In other words the one 24-bit node register is used for

both inputs and outputs when MI14 = 0 and 3. This is efficient because it allows the 48-bits of

information to be processed using one 24-bit word and minimizes the number of nodes needed for the IO

data transfers for each MACRO Device. The only drawback to this technique is that the user will have to

keep track of the status of their outputs (see example).

Example: If the user has MI14=0 and has node 2 activated at both the Master and MACRO Device, they

can make the following definitions to read and write to the inputs and INPUT/OUTPUTs.

M3000->X:$78420,0,24 ;Actual Input/INPUT/OUTPUT Word

M4000->X:$10F0,0,24 ;Input Image Word

M4001->X:$10F1,0,24 ;Output Image word

Open PLC1 Clear

M4000=M3000 ;Input Image Word equals Actual Input Word

Process Inputs and Build image

output word (M4001)

16 ACC-14M MACRO Station I/O Transfer

Page 25

Accessory 14M

M3000=M4001 ;Set Actual output word to output Image word

Close

If the user is using another node they can be accessed at the following locations:

Table 1a Table 1b

User Node IO Word Address User Node IO Word Address

2 X:$078420,0,24 34 X:$07A420,0,24

3 X:$078424,0,24 35 X:$07A424,0,24

6 X:$078428,0,24 38 X:$07A428,0,24

7 X:$07842C,0,24 39 X:$07A42C,0,24

10 X:$078430,0,24 42 X:$07A430,0,24

11 X:$078434,0,24 43 X:$07A434,0,24

18 X:$079420,0,24 50 X:$07B420,0,24

19 X:$079424,0,24 51 X:$07B424,0,24

22 X:$079428,0,24 54 X:$07B428,0,24

23 X:$07942C,0,24 55 X:$07B42C,0,24

26 X:$079430,0,24 58 X:$07B430,0,24

27 X:$079434,0,24 59 X:$07B434,0,24

ACC-14M MACRO Station I/O Transfer 17

Page 26

Accessory 14M

USING OPTION 1 – ADC’S, DAC’S, RELAY’S

If the ACC-14M Option 1 is ordered, the ACC-14M also allows the user to use two analog inputs, two

DAC outpts, and two relay outputs.

Using the ACC-14M ADC

The MACRO Peripheral Accessories can be ordered with two analog to digital converters. These A/D

converters are 16-bit devices that are ready to be used without any software setup. Delta Tau uses the

Burr Brown ADS8361E for this circuit. This 16-bit option can be ordered on the ACC-14M (603741-

101) revision 1 and greater.

To read the A/D data from the MACRO device, the user must create the M-variable definitions to the

node associated with the MACRO device. The data received is a signed 16-bit number scaled from –10V

to +10V. The data is transferred into the upper 16-bits of the MACRO IO node registers. For example, if

the ACC-65M is associated with node 2, then the following M-variable assignment can be created:

M5000->X:$78421,8,16,S ;ADC0 upper 16 bits of IO Node 2 word1

M5001->X:$78422,8,16,S ;ADC1 upper 16 bits of IO Node 2 word2

Example Data Read: If you read a value of 20480 in M5000, then that would be approximately 6.25V. 16bit Voltage Conversion = Data×10V/32767 or for this example, 6.25V≈20480×10V/32767.

Earlier revisions of the ACC-14M used the 12-bit Burr Brown ADS7861E for this circuit. For proper

operation of the 12-bit ADC or if the users application requires 12-bit data reads then they can make the

following definitions (12-bit Voltage Conversion = Data×10V/2047):

M5000->X:$78421,12,12,S ;ADC0 upper 12 bits of IO Node 2 word1

These examples also assume that the IO nodes are activated at both the MACRO Peripheral Device

(Slave) and at the Ultralite (Master). The following table lists the locations of the ADCs if using other

node locations.

User Node ADC0 ADC1

2 X:$078421,8,16,S X:$078422,8,16,S

3 X:$078425,8,16,S X:$078426,8,16,S

6 X:$078429,8,16,S X:$07842A,8,16,S

7 X:$07842D,8,16,S X:$07842E,8,16,S

10 X:$078431,8,16,S X:$078432,8,16,S

11 X:$078435,8,16,S X:$078436,8,16,S

18 X:$079421,8,16,S X:$079422,8,16,S

19 X:$079425,8,16,S X:$079426,8,16,S

22 X:$079429,8,16,S X:$07942A,8,16,S

23 X:$07942D,8,16,S X:$07942E,8,16,S

26 X:$079431,8,16,S X:$079432,8,16,S

27 X:$079435,8,16,S X:$079436,8,16,S

34 X:$07A421,8,16,S X:$07A422,8,16,S

35 X:$07A425,8,16,S X:$07A426,8,16,S

38 X:$07A429,8,16,S X:$07A42A,8,16,S

39 X:$07A42D,8,16,S X:$07A42E,8,16,S

42 X:$07A431,8,16,S X:$07A432,8,16,S

43 X:$07A435,8,16,S X:$07A436,8,16,S

50 X:$07B421,8,16,S X:$07B422,8,16,S

51 X:$07B425,8,16,S X:$07B426,8,16,S

18 ACC-14M MACRO Station I/O Transfer

Page 27

Accessory 14M

54 X:$07B429,8,16,S X:$07B42A,8,16,S

55 X:$07B42D,8,16,S X:$07B42E,8,16,S

58 X:$07B431,8,16,S X:$07B432,8,16,S

59 X:$07B435,8,16,S X:$07B436,8,16,S

Using the ACC-14M DAC Output

The MACRO Peripheral Accessories can be ordered with two +/-10V outputs produced by filtering a

PWM signal. This technique has been used been for some time now by many of our competitors.

Although this technique does not contain the same levels of performance as a true Digital to Analog

converter, for most servo applications it is more than adequate.

Both the resolution and the frequency of the Filtered PWM outputs are configured in software on the

MACRO Peripheral Accessories through the variable MI992 (MaxPhase Setting). This MI992 variable

also effects the phase and servo interrupts. On most MACRO systems the MI992 value will be set to the

same value as the Turbo Ultrallite or UMAC ACC-5E equivalent MaxPhase I-variable

(I6800/I6850/I6900/I6950). Another key variable to be concerned about at the MACRO Peripheral

Device is MI994. MI994 is the PWM dead time specification and it is used to add dead-time to the PWM

signal as a safety feature for PMAC2 direct PWM commutation. For the DAC outputs for the MACRO

peripheral this variable (MI994) should be set to zero. For more details about these variables please refer

to the Software reference manuals for the respective hardware devices.

To write to the DAC devices at MACRO Peripheral Device the user must create the M-variable

definitions to the node associated with the MACRO device. The data received is a signed 16-bit number

scaled from –10V to +10V. The data is transferred into the upper-bits of the MACRO IO node registers.

For example if the user had the ACC-65M associated with node 2 then we could make the following Mvariable assignment:

M5000->X:$78421,8,16,S ;DAC0 bits of IO Node 2 word1

M5001->X:$78422,8,16,S ;DAC1 bits of IO Node 2 word2

MS2,MI992=6527 ;6527 is default

MS2,MI994=0

;set dead-time to zero

This example also assumes that the IO node number 2 is activated at both the MACRO Peripheral Device

(Slave) and at the Ultralite (Master).

To scale the outputs the user will have to know the relationship between MI992 and the DAC outputs. If

the user sets MI994=0, then they can assume that the maximum voltage output will be scaled relative to

MI992. For example, if MI992=6527 (default value), and if the user sets M5000=6527 then, they will

measure 10V on DAC1+ relative to AGND or 20V relative to DAC1-. Likewise, if they set

M5000=652.7 they will measure +1V on DAC1+ relative to AGND or +2V relative to DAC1-.

The following table list the locations of the DAC’s if using other node locations.

User Node DAC0 DAC1

2 X:$078421,8,16,S X:$078422,8,16,S

3 X:$078425,8,16,S X:$078426,8,16,S

6 X:$078429,8,16,S X:$07842A,8,16,S

7 X:$07842D,8,16,S X:$07842E,8,16,S

10 X:$078431,8,16,S X:$078432,8,16,S

11 X:$078435,8,16,S X:$078436,8,16,S

18 X:$079421,8,16,S X:$079422,8,16,S

19 X:$079425,8,16,S X:$079426,8,16,S

22 X:$079429,8,16,S X:$07942A,8,16,S

23 X:$07942D,8,16,S X:$07942E,8,16,S

26 X:$079431,8,16,S X:$079432,8,16,S

27 X:$079435,8,16,S X:$079436,8,16,S

ACC-14M MACRO Station I/O Transfer 19

Page 28

Accessory 14M

34 X:$07A421,8,16,S X:$07A422,8,16,S

35 X:$07A425,8,16,S X:$07A426,8,16,S

38 X:$07A429,8,16,S X:$07A42A,8,16,S

39 X:$07A42D,8,16,S X:$07A42E,8,16,S

42 X:$07A431,8,16,S X:$07A432,8,16,S

43 X:$07A435,8,16,S X:$07A436,8,16,S

50 X:$07B421,8,16,S X:$07B422,8,16,S

51 X:$07B425,8,16,S X:$07B426,8,16,S

54 X:$07B429,8,16,S X:$07B42A,8,16,S

55 X:$07B42D,8,16,S X:$07B42E,8,16,S

58 X:$07B431,8,16,S X:$07B432,8,16,S

59 X:$07B435,8,16,S X:$07B436,8,16,S

Using the ACC-14M Amplifier Enable Outputs

The MACRO Peripheral amplifier enable outputs are very similar to the amplifier enable circuits used on

other Delta Tau products. These outputs allow the user to send outputs that can be configured as either

normally open or normally closed. The amplifier enable outputs are memory mapped to the third 16-bit

node address or at the base address of the activated node +3. The AENA1 signal is at bit 19 and AENA2

signal is at bit 20. The following M-variable definitions can be made for the AENA signals at node 2

(assuming node 2 is activated at both the Master and MACRO Device).

M3003->X:$78423,8,16 ; AENA Outputs at bits 19 and 20

M3010->X:$78423,19 ;AENA1

M3011->X:$78423,20 ;AENA2

5V+

AENA

Isolation

AE_NO

AE_COM

AE_NC

The following table lists the AENA output locations for all nodes.

User Node AENA1 AENA2

2 X:$078423,19 X:$078423,20

3 X:$078427,19 X:$078427,20

6 X:$07842B,19 X:$07842B,20

7 X:$07842F,19 X:$07842F,20

10 X:$078433,19 X:$078433,20

11 X:$078437,19 X:$078437,20

18 X:$079423,19 X:$079423,20

19 X:$079427,19 X:$079427,20

22 X:$07942B,19 X:$07942B,20

23 X:$07942F,19 X:$07942F,20

26 X:$079433,19 X:$079433,20

27 X:$079437,19 X:$079437,20

34 X:$07A423,19 X:$07A423,20

35 X:$07A427,19 X:$07A427,20

20 ACC-14M MACRO Station I/O Transfer

Page 29

Accessory 14M

38 X:$07A42B,19 X:$07A42B,20

39 X:$07A42F,19 X:$07A42F,20

42 X:$07A433,19 X:$07A433,20

43 X:$07A437,19 X:$07A437,20

50 X:$07B423,19 X:$07B423,20

51 X:$07B427,19 X:$07B427,20

54 X:$07B42B,19 X:$07B42B,20

55 X:$07B42F,19 X:$07B42F,20

58 X:$07B433,19 X:$07B433,20

59 X:$07B437,19 X:$07B437,20

USING ACC-14M FOR SERVO FEEDBACK

The data ACC-14M can also be used for Servo Loop Feedback when used with a binary style or graycode

style feedback device. If using Graycode style feed back the ACC-14M can only process the data on the

J4 connector port. For Binary style feedback devices, the ACC-14M can use the inputs on both the J4

connector and J5 connector.

Delta Tau recommends using the standard IO node data transfer to the Master controller (Ultralite) and

then setup the encoder conversion at the Master controller.

For example, if the user has nodes 2 and 3 activated for feedback data then they would be receiving the

data in locations X:$78420 (node2) and X:$78424 (node3) as shown in Table 1a and 1b. Now that we

know where the data is coming from we can then process this information like any other parallel word.

Example Turbo Encoder Conversion Table Setup for ACC-14M

Two 18-bit encoders are used in an application with 10000 cts/in and a maximum velocity of 20 in/sec is

specified. Accessory 14M port A will be used for the first encoder and port B will be used for the second

encoder. The servo update rate is set at the factory default of 2258 Hz. For this example, setup an

encoder with filtering, without filtering, and with 24-bit resolution.

First, calculate the maximum velocity per servo cycle:

2010000

sec

in

sec

2258

=××=

cyc

V

max

cts

in

ECT Setup for 18-bit Encoder without Filtering

I8000=$678420 ;extended feedback entry from $078420 ($3501)

I8001=$012018 ;18-bit ($12) from $078420 base + 24 ($3502)

I8002=$678424 ;extended feedback entry from $078424 ($3503)

I8003=$012018 ;18-bit ($12) from $078424 base +24 ($3504)

I103=$3502 ;position feedback for motor 1 from $3502

I104=$3502 ;velocity feedback for motor 1 from $3502

I203=$3504 ;position feedback for motor 2 from $3504

I204=$3504 ;velocity feedback for motor 2 from $3504

ECT Setup for 18-bit Encoder with Filtering

I8000=$678420 ;extended feedback entry from $078420 ($3501)

I8001=$012018 ;18-bit ($12) from $078420 base + 24 ($3502)

I8002=$00006E ;filter 110cts/cyc (88.57*1.25) ($3503)

I8003=$678424 ;extended feedback entry from $078424 ($3504)

I8004=$012018 ;18-bit ($12) from $078424 base +24 ($3505)

I8005=$00006E ;filter 110cts/cyc (88.57*1.25) ($3506)

57.88

cyc

cts

ACC-14M MACRO Station I/O Transfer 21

Page 30

Accessory 14M

I103=$3503 ;position feedback for motor 1 from $3502

I104=$3503 ;velocity feedback for motor 1 from $3502

I203=$3506 ;position feedback for motor 2 from $3504

I204=$3506 ;velocity feedback for motor 2 from $3504

Absolute Encoder Setup for ACC-14M

(Add information Rich)

Graycode Encoder Feedback

If using a graycode style encoder with the ACC-14M the user can only use the J4 port as an input. The

processed data for the graycode encoder will be located in the Y:$C08C register in bits 0 through 23.

22 ACC-14M MACRO Station I/O Transfer

Page 31

Accessory 14M

FEEDBACK DATA LATCHING AND HANDSHAKING

When using a parallel-word absolute encoder, it is important to properly latch the encoder data to prevent

PMAC from reading the encoder data during an encoder transition. ACC-14M allows several latching

and handshaking methods to fit most types of latching schemes.

Note:

It is equally important to set up the Encoder Conversion Table Filter Word as a

software protection against bad encoder data.

PMAC reads the encoder data when it processes the Encoder Conversion Tables. This happens shortly

(approximately 2

first). Therefore, most of the following latching methods will be synchronized to the falling edge of the

servo clock.

The error signal inputs (ERR1/ and ERR2/) allow the feedback device to send a signal to the latch circuit

to interrupt the latch. Jumpers E8 and E10 are used to set the polarity for the error inputs signals. If the

feedback device does not have an error signal output, then set the jumpers E8 and E10 from 1-2 to allow

the latch circuit to work properly. See the Jumper Descriptions section of this manual for details on E8

and E10.

µ

sec) after the falling edge of the servo clock (the phase calculations are performed

ACC-14M MACRO Station I/O Transfer 23

Page 32

Accessory 14M

Method 1

This method requires the encoder inputs to be latched on the falling edge of the servo clock and no

latching to be done on ACC-14M. For latching the encoder inputs, the servo clock is accessed through

ACC-14M OCLK1 (see J4 pinout) and/or OCLK2 (see J5 pinout). If the encoder requires a rising edge

for its latch, then E5 should be jumpered 1 to 2 for OCLK1/OCLK2 respectively. If a falling edge is

required, E5 should be jumpered 2 to 3.

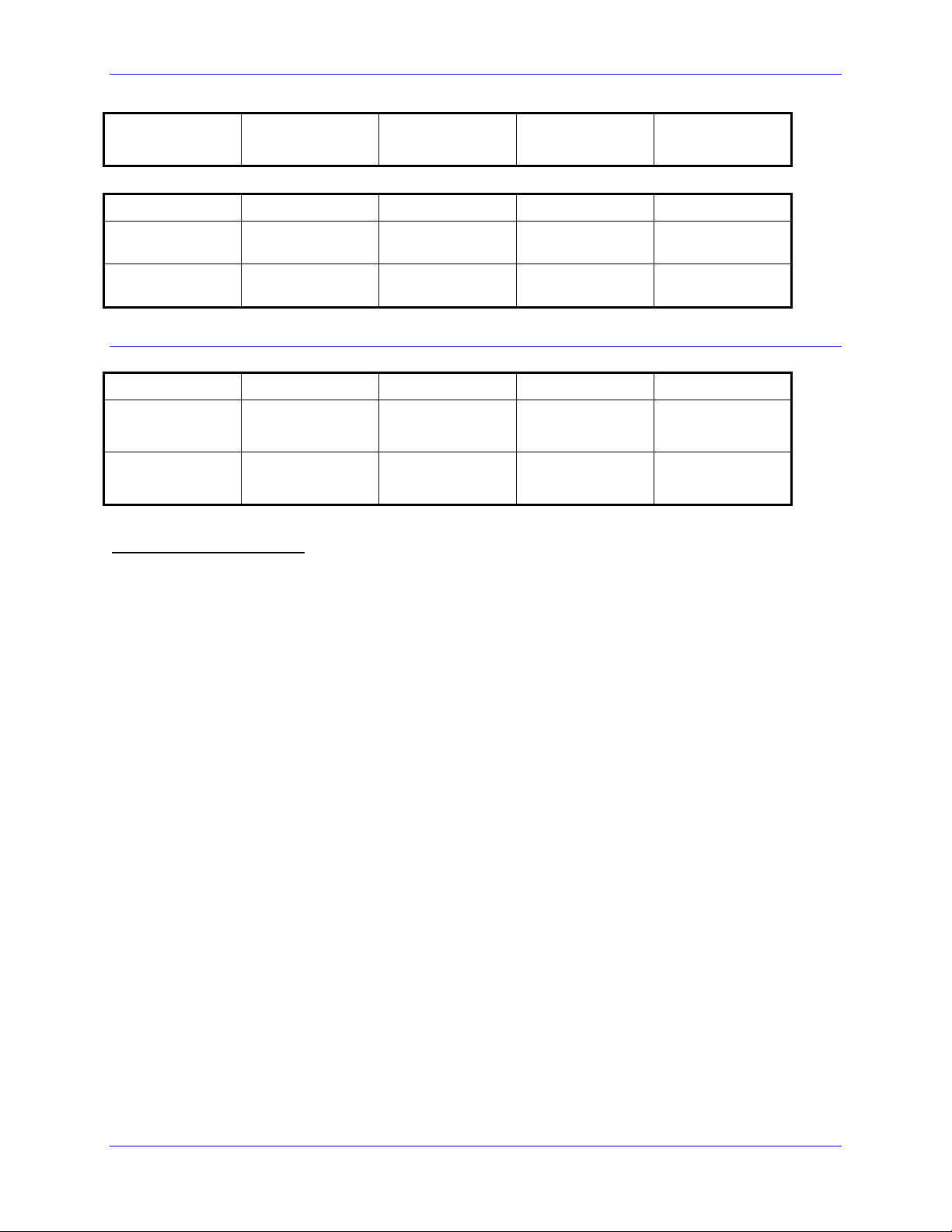

Required Signal E5 E6 E7/E9 Latch

Rising edge of OCLK 1 to 2 Don’t care Don’t care No

Falling edge of OCLK 2 to 3 Don’t care Don’t care No

The advantages and disadvantages of this method are as follows:

Advantage

Disadvantage

Easy to configure and set up.

Encoder's output latch must typically happen within 2 µsec.

Method 2

This method requires the encoder outputs to be latched on the rising edge of the servo clock and ACC14M to latch (strobe) the encoder inputs on the falling edge of the servo clock. For latching the encoder

outputs, the servo clock is accessed through ACC-14M OCLK1 (see J4 pinout ) and/or OCLK2 (see J5

pinout). If the encoder requires a rising edge for its latch, then E5 should be jumpered 1 to 2 for

OCLK1/OCLK2 respectively. If a falling edge is required, E5 should be jumpered 2 to 3. The control

words for the data must be setup for latching to allow the ACC-14M latch the data.

Required Signal E5 E6 E7/E9 Latch

Rising edge of OCLK 1 to 2 2 to 3 ON Yes

Falling edge of OCLK 2 to 3 1 to 2 ON Yes

The advantages and disadvantages of this method are as follows:

Advantage

Disadvantage

Encoder latch-time is not very critical (have almost 1 servo cycle to

latch).

Almost a 1-servo cycle delay between encoder output latch and ACC14M encoder read.

24 ACC-14M MACRO Station I/O Transfer

Page 33

Accessory 14M

Method 3

This method requires a self-latching encoder that outputs a signal that indicates it is latched and an ACC14M that latches (strobes) the encoder inputs on the falling edge of the ICLK only when the servo clock is

low. The encoder-latched indicator is brought into ACC-14M via the ICLK1/2 inputs (see J4 and/or J5

pinout). If the encoder outputs a rising edge for its latch indicator, then E7/E9 should be jumpered, so

that a rising ICLK latches the data when the servo is low. If a falling edge indicator is output, E7/E9

should not be jumpered, so that a falling ICLK latches the data when the servo is low. The control words

for the data must be setup for latching to allow the ACC-14M to latch the data.

Required Signal E5 E6 E7/E9 Latch

High ICLK means latched Don't care 2 to 3 ON Yes

Low ICLK means latched Don't care 2 to 3 OFF Yes

The advantages and disadvantages of this method are as follows:

Advantage

Disadvantage

Can only read latched encoder data.

Encoder latch is asynchronous to PMAC's servo cycle.

Method 4

This method is a combination of methods 1 and 3 above. It requires that the encoder outputs be latched

on the falling edge of the servo clock and the encoder to signal that it is latched. Also, ACC-14M must

latch (strobe) the encoder inputs on an edge of the ICLK only when the servo clock is low. For latching

the encoder outputs, the servo clock is accessed through ACC-14M OCLK1 (see J4) and/or OCLK2 (see

J5). If the encoder requires a rising edge for its latch, then E5 should be jumpered 1 to 2 for

OCLK1/OCLK2 respectively. If a falling edge is required, E5 should be jumpered 2 to 3. The encoderlatched indicator is brought into ACC-14M via the ICLK1/2 inputs (see J4 & J5 pinouts). If the encoder

outputs a rising edge for its latch indicator, then E7/E9 should be jumpered so that a rising ICLK latches

the data when the servo is low. If a falling edge indicator is output, E7/E9 should not be jumpered so that

a falling ICLK latches the data when the servo is low. The control words for the data must be setup for

latching to allow the ACC-14M to latch the data.

Required Signal E5 E6 E7/E9 Latch

High OCLK means latch

High ICLK means latched

Low OCLK means latch

High ICLK means latched

High OCLK means latch

Low ICLK means latched

Low OCLK means latch

Low ICLK means latched

1 to 2 1 to 2 ON Yes

2 to 3 1 to 2 ON Yes

1 to 2 1 to 2 OFF Yes

2 to 3 1 to 2 OFF Yes

The advantages and disadvantages of this method are as follows:

Advantage

Disadvantage

Can only read latched encoder data.

Have full handshaking between PMAC and encoder

Typically, encoder’s output latch must happen within 2 µsec.

More complex wiring and timing.

ACC-14M MACRO Station I/O Transfer 25

Page 34

Accessory 14M

Method 5

This method requires no latching on the encoder outputs and latching on the ACC-14M inputs at the

falling edge of the servo clock. For the encoder, no signals are used so the state of the OCLK does not

matter. E7/E9 must be jumpered and latching must be enabled from the control to allow ACC-14M to

latch (strobe) its inputs with the falling edge of the servo clock. The control words for the data must be set

up for latching to allow the ACC-14M to latch the data.

Required Signal E5 E6 E7/E9 Latch

Latch at Falling Edge Don't care 2 to 3 ON Yes

Latch at Rising Edge Don't care 1 to 2 ON Yes

The advantages and disadvantages of this method are as follows:

Advantage

Disadvantage

Easy to configure and set up.

The encoder data may be latched into ACC-14M at an encoder

transition causing bad encoder data for that servo cycle. Must set up

the Encoder Conversion Table Filter

26 ACC-14M MACRO Station I/O Transfer

Page 35

Accessory 14M

MACRO ASCII Communication Reference:

1. “VID” Vendor ID (Delta Tau = 1, Range=1- 65535)

2. “CID” Vendor Card ID, Part Number, (Range=1- 4,294,967,295) 32 bit unsigned.

a) Delta Tau: TURBO PMAC 2 VME = 602413 (MACRO Master)

b) Delta Tau: TURBO PMAC 2 Ultra-lite = 603182 (MACRO Master)

c) Delta Tau: UMAC TURBO = 603382 (MACRO Master)

d) Delta Tau: UMAC MACRO 8 = 602804 (MACRO Slave)

e) Delta Tau: UMAC MACRO 16 = 602??? (MACRO Slave)

3. “SID” Serial ID (Range = 64 bit unsigned, 0=Serial ID not available)

4. “$$$**” - Station to reset to default parameter with no station number and ready for Ring location

identification. Note not $$$***.

5. “SAVe” – Save station number and initialization parameters.

6. “$$$” – Reset Station to “SAVed” station number and initialization parameters.

7. “STN=n” <n=0-254> – Assigns the MACRO station number. Normally this would be its order in

the Ring. A “STN=0” resets the station number and is reserved for the Ring Controller Master.

8. Commands with STN=0 is a broadcast to all stations in Ring.

st

9. Commands with STN=255 is a request for communication with the 1

station in Ring with its

STN=0.

10. Commands with STN=1-254 is a request for communication with the station in Ring with STN=1-

254.

11. “STN” – The addressed MACRO Station responds with its station number (n).

12. “STN=n” where n=0-254 – Set the addressed MACRO Station’s STN to “n.”

Note:

The station will stop responding to you.

ACC-14M MACRO Station I/O Transfer 27

Page 36

Accessory 14M

Firmware Updates

Downloading new firmware to the MACRO IO Device is a simple process once the MACRO board is set

up properly. To download new firmware to the MACRO IO Device, obtain the following items:

• Two jumpers

• USB Cable

• Install drivers for MACRO IO USB Device from http://www.ftdichip.com. Usually PEWIN Pro will install

the driver and the board should automatically be seen by the operating system.

• MACRO Firmware Download Software (MacroFWDown.exe)

• New firmware file (MACROIO.bin)

To download the software to the MACRO Device, do the following:

1. Copy the firmware into a directory (C:\Macro\Firmware).

2. Jumper the E2 (1-2) and E1 (1-2).

3. Place the USB cable to the J2 USB connection on the MACRO Device and place the other end to the

USB port on the PC.

4. Power up the MACRO Device and then launch MacroFWDown.exe. Choose the com port and select

MACRO I/O and then press the Download FW button.

After the download is complete, power down the system and remove jumper E1 and place jumper E2

from

28 ACC-14M MACRO Station I/O Transfer

Page 37

Accessory 14M

ACC-14M MACRO STATION MI-VARIABLE REFERENCE

The ACC-14M is set up through its own set of initialization I-variables, which are distinct from the Ivariables on a Turbo PMAC2. Usually, they are referenced as MI-variables (e.g. MI900) to distinguish

them from PMAC’s own I-variables, although they can be referenced just as I-variables.

These MI-variables can be accessed through the on-line MS{node#},MI{variable#} read and

MS{node#},MI{variable#}={constant} write commands, or the

MSR{node#},MI{variable#},{PMAC variable} read-copy and

MSW{node#},MI{variable#},{PMAC variable} write-copy commands (either on-line or

background PLC), where {node#} specifies the MACRO node number (0 to 13), {variable#}

specifies the number of the Station MI-variable (0 - 1023), {constant} represents the numerical value to