Delta Tau 5xx-603869-xUxx User Manual

^1 HARDWARE REFERENCE MANUAL

125

^2 Brick Motion Controller

^3 Programmable Servo Amplifier

Single Source Machine Control Power // Flexibility // Ease of Use

21314 Lassen Street Chatsworth, CA 91311 // Tel. (818) 998-2095 Fax. (818) 998-7807 // www.deltatau.com

^4 5xx-603869-xUxx

^5 May 2, 2007

Copyright Information

© 2007 Delta Tau Data Systems, Inc. All rights reserved.

This document is furnished for the customers of Delta Tau Data Systems, Inc. Other uses are

unauthorized without written permission of Delta Tau Data Systems, Inc. Information contained in this

manual may be updated from time-to-time due to product improvements, etc., and may not conform in

every respect to former issues.

To report errors or inconsistencies, call or email:

Delta Tau Data Systems, Inc. Technical Support

Phone: (818) 717-5656

Fax: (818) 998-7807

Email: support@deltatau.com

Website: http://www.deltatau.com

Operating Conditions

All Delta Tau Data Systems, Inc. motion controller products, accessories, and amplifiers contain static

sensitive components that can be damaged by incorrect handling. When installing or handling Delta Tau

Data Systems, Inc. products, avoid contact with highly insulated materials. Only qualified personnel

should be allowed to handle this equipment.

In the case of industrial applications, we expect our products to be protected from hazardous or

conductive materials and/or environments that could cause harm to the controller by damaging

components or causing electrical shorts. When our products are used in an industrial environment, install

them into an industrial electrical cabinet or industrial PC to protect them from excessive or corrosive

moisture, abnormal ambient temperatures, and conductive materials. If Delta Tau Data Systems, Inc.

products are directly exposed to hazardous or conductive materials and/or environments, we cannot

guarantee their operation.

Safety Instructions

Qualified personnel must transport, assemble, install, and maintain this equipment. Properly qualified

personnel are persons who are familiar with the transport, assembly, installation, and operation of

equipment. The qualified personnel must know and observe the following standards and regulations:

IEC 364 resp. CENELEC HD 384 or DIN VDE 0100

IEC report 664 or DIN VDE 0110

National regulations for safety and accident prevention or VBG 4

Incorrect handling of products can result in injury and damage to persons and machinery. Strictly adhere

to the installation instructions. Electrical safety is provided through a low-resistance earth connection. It

is vital to ensure that all system components are connected to earth ground.

This product contains components that are sensitive to static electricity and can be damaged by incorrect

handling. Avoid contact with high insulating materials (artificial fabrics, plastic film, etc.). Place the

product on a conductive surface. Discharge any possible static electricity build-up by touching an

unpainted, metal, grounded surface before touching the equipment.

Keep all covers and cabinet doors shut during operation. Be aware that during operation, the product has

electrically charged components and hot surfaces. Control and power cables can carry a high voltage,

even when the motor is not rotating. Never disconnect or connect the product while the power source is

energized to avoid electric arcing.

After removing the power source from the equipment, wait at least 10 minutes before touching or

disconnecting sections of the equipment that normally carry electrical charges (e.g., capacitors, contacts,

screw connections). To be safe, measure the electrical contact points with a meter before touching the

equipment.

The following text formats are used in this manual to indicate a potential for personal injury or equipment

damage. Read the safety notices in this manual before attempting installation, operation, or maintenance

to avoid serious bodily injury, damage to the equipment, or operational difficulty.

WARNING:

A Warning identifies hazards that could result in personal injury or death. It

precedes the discussion of interest.

Caution:

A Caution identifies hazards that could result in equipment damage. It precedes

the discussion of interest

Note:

A Note identifies information critical to the user’s understanding or use of the

equipment. It follows the discussion of interest.

REVISION HISTORY

REV. DESCRIPTION DATE CHG APPVD

1 MANUAL CREATION 05/02/07 CP S. MILICI

Brick Motion Controller Hardware Reference Manual

Table of Contents

125 ................................................................................................................................................................................. I

Copyright Information.............................................................................................................................................. ii

Operating Conditions ............................................................................................................................................... ii

Safety Instructions.................................................................................................................................................... ii

INTRODUCTION .......................................................................................................................................................1

Brick Motion Controller Features .............................................................................................................................1

SPECIFICATIONS .....................................................................................................................................................3

Part Number ..............................................................................................................................................................3

Brick Motion Controller Options..........................................................................................................................3

RECEIVING AND UNPACKING.............................................................................................................................5

Use of Equipment......................................................................................................................................................5

SYSTEM WIRING......................................................................................................................................................7

Noise Problems.....................................................................................................................................................7

Wiring Earth-Ground ................................................................................................................................................7

Earth Grounding Paths.........................................................................................................................................7

Connectors.................................................................................................................................................................8

X1-X8: Encoder Input (1 to 8)..............................................................................................................................8

X9-10: Analog I/O Ch5 (X9) and Ch6 (X10), (Optional) ....................................................................................9

X11-12: Analog I/O Ch7 (X11) and Ch8 (X12), (Optional) ................................................................................9

X13: USB 2.0 Connector ...................................................................................................................................10

X14: RJ45, Ethernet Connector.........................................................................................................................10

X15: Watchdog ...................................................................................................................................................10

TB1: Power Connector .......................................................................................................................................11

S1: Re-Initialization on Reset Control...............................................................................................................11

S2: Firmware Reload Enable ............................................................................................................................11

J4 Limit Inputs (1-4 Axis) ...................................................................................................................................12

J5 Limit Inputs (5-8 Axis) ...................................................................................................................................13

AMP1-AMP8: Amplifier connections (1 to 8).....................................................................................................15

J6: General Purpose I/O....................................................................................................................................17

Suggested M-Variable Addressing for the General Purpose I/O (J6) ................................................................18

J7: Extra General Purpose I/O (Optional).........................................................................................................19

Suggested M-Variable Addressing for the optional General Purpose I/O (J7) ..................................................20

J8: Extra General Purpose I/O (Optional)........................................................................................................21

Suggested M-Variable Addressing for the General Purpose I/O (J8) ................................................................22

Setting up Quadrature Encoders..............................................................................................................................24

Signal Format .....................................................................................................................................................24

Hardware Setup..................................................................................................................................................24

Encoder Loss Setup.............................................................................................................................................25

Setting up the Analog Inputs (optional)..............................................................................................................26

Filtered DAC Outputs Configuration (optional) ................................................................................................26

Setting up for Pulse and Direction Output...............................................................................................................29

Software Setup ....................................................................................................................................................29

Actions on Watchdog Timer Trip........................................................................................................................33

Diagnosing Cause of Watchdog Timer Trip .......................................................................................................33

APPENDIX A.............................................................................................................................................................35

DB- Connector Spacing Specifications...................................................................................................................35

X1-8: DB-15 Connectors for encoder feedback..................................................................................................35

X9-12: DB-9 Connectors for Analog I/O............................................................................................................35

Screw Lock Size for all DB-connectors ..............................................................................................................35

Type of Cable for Encoder Wiring..........................................................................................................................36

Table of Contents i

Brick Motion Controller Hardware Reference Manual

APPENDIX B.............................................................................................................................................................38

Schematics...............................................................................................................................................................38

X15: Watchdog ..................................................................................................................................................38

J6 and J7: General Purpose I/O........................................................................................................................38

J4: Limit Inputs for Axis 1-4..............................................................................................................................40

J5: Limit Inputs for Axis 5-8..............................................................................................................................41

Dimensional Layout and Connector location.....................................................................................................42

ii Table of Contents

Brick Motion Controller Hardware Reference Manual

INTRODUCTION

The Brick Motion Controller is a fully scaleable automation controller utilizing

the intelligence and capability of its embedded Turbo PMAC2. With the ability

to store programs locally and built-in PLC execution, it is programmable for

virtually any kind of automation application. This allows for complete machine

motion and logic control.

This product has 4 or 8 (optional) axes of analog +/-10V filtered-PWM (12-bit

resolution) or pulse and direction outputs as standard. Options are available for

dual true-DAC analog outputs at 18-bit resolution or Direct-PWM with current

loop. Feedback with quadrature incremental encoders is standard. Options for

sinusoidal, resolver or serial encoders are available.

The Brick Motion Controller provides a standard I/O capability of 16 inputs

and 8 outputs at 12-24volts fully protected and isolated with separate commons

for each bank of 8 inputs. Outputs are rated for 1 ampere each and are thermalfuse protected. Outputs can be current sinking or sourcing depending on use of

common emitter or common collector connections. Additional I/O is an option

(up to 64 inputs and 32 outputs). Also an option for up to four 16 bit analog

inputs is available.

Brick Motion

Controller

The Brick Motion Controller’s functionality doesn’t stop there, but also includes features such as

extensible I/O via ModBus TCP master, or ModBus TCP slave for third party HMI hardware. Our PCbased HMI package connected through USB 2.0 or Ethernet makes the Brick Motion Controller a

powerful single-source solution.

Brick Motion Controller Features

The Brick Motion Controller is capable of controlling up to eight axes with direct-PWM commands.

• Motorola DSP 56k digital signal processor

• Turbo PMAC2 CPU (for kinematics, open servo, NC applications)

• Fully Configurable via USB2.0 and/or Ethernet TCP/IP (100 Base-T)

• Operation from a PC

• Stand-alone operation

• Linear and circular interpolation

• 256 motion programs capacity

• 64 asynchronous PLC program capability

• Rotating buffer for large programs

• 36-bit position range (± 64 billion counts)

• Adjustable S-curve acceleration and deceleration

• Cubic trajectory calculations, splines

• Set and change parameters in real time

• Torque, Velocity and Position control standard

• Small footprint saves space

• Full rated temperature cooling standard (no need for additional fans)

• 16 inputs (expandable to 32 with option) fully-protected and isolated with separate commons for

two banks of eight

• Eight thermal-fuse protected outputs (expandable to 16 with option) rated for 0.5A @ 24VDC

each (Flexible outputs allow for sinking or sourcing of current depending on whether the common

emitter or common collector is used.)

Introduction 1

Brick Motion Controller Hardware Reference Manual

• Primary encoder for each axis with TTL differential/single-ended inputs with A, B quadrature

channels and C index channel, 10 MHz cycle rate, and digital Hall-effect inputs

• Five flags per axis using DB-25: HOME, PLIM, MLIM and USER inputs; EQU compare

• Optional analog inputs and outputs, ± 5VDC

• Optional two PWM outputs.

• Optional Dual Port RAM (Required for NC)

• Optional Modbus Protocol

• Optional Sinusoidal encoder feedback

• Optional Resolver feedback

• Optional EnDat, Hiperface interfaces.

2 Introduction

Brick Motion Controller Hardware Reference Manual

SPECIFICATIONS

Part Number

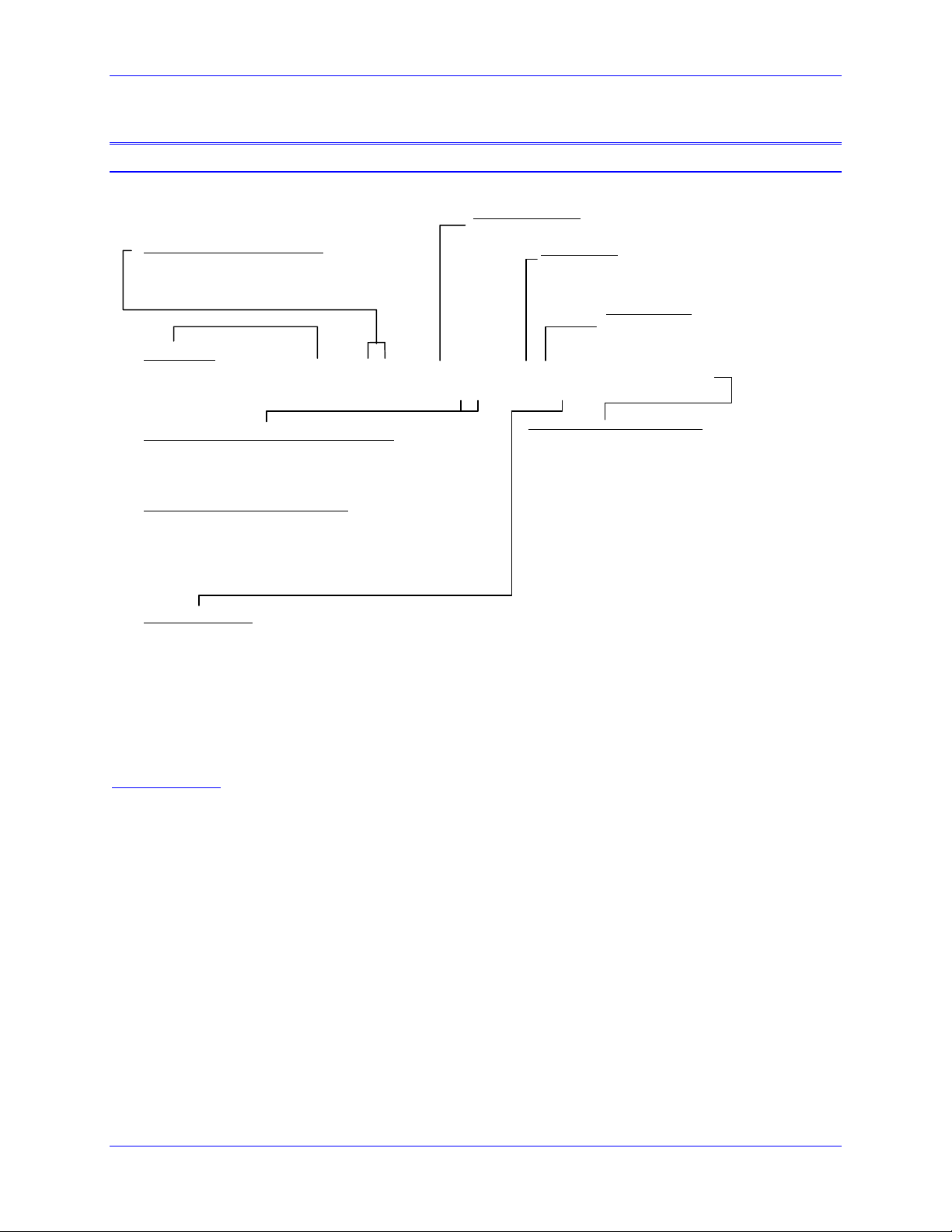

Brick Controller

Model Number Definition

CPU Options - Turbo P MAC 2 Processor

C0 : 80Mhz, 8Kx24 Internal, 256Kx24SRAM, 1MB Flash (Default)

F3: 240Mhz, 192Kx24 Internal, 1Mx24SRAM, 4MB Flash

Number of Axes

4: Four Axes (Default)

8: Eight Axes

BC4 - C0 - F00 - 000 – (0000)

Axis 1-4 Output Options

F: Filtered-PWM analog output on Channels 1-4, 12-bit resolution (default)

D: Dual true-DAC analog outputs on Channels 1-4, 18-bit resolution

Dig ital I/O Optio n

0: Digital I/O 16 inputs and 8 outputs, 0.5A, 24VDC (default)

1: Expanded digital I/O additional 16 inputs and 8 outputs, 0.5A, 24VDC

2: Expanded digital I/O additional 32 inputs and 16 outputs, 0.5A, 24VDC

Analog I/O Options

0: No Options (default)

3: Two 16-bit analog inputs

4: Four 16-bit analog inputs

Axis 5 -8 Feedback Options , apply onl y to BC4 controller

Note: For Other Feedback Options See “Special Feedback Options”

00: No added encoders or flags, 12-24V flags on Channels 1-4 (default)

02: Four added encoders (Channels 5-8), four added flag sets, 12-24V flags all channels

05: No added encoders or flags, 5V flags on Channels 1-4

07: Four added encoders (Channels 5-8), four added flag sets, 5V flags all channels

Axis 5 -8 Options , apply on ly to BC 8 controller

Note : Letter must be s ame as previous letter

F2: Filtered-PWM analog output on Channels 5-8, 12-bit resolution, 12-24V flags all channels

D2: Dual true-DAC analog outputs on Channels 5-8, 18-bit resolution, 12-24V flags all channels

F7: Filtered-PWM analog output on Channels 5-8, 12-bit resolution, 5V flags all channels

D7: Dual true-DAC analog outputs on Channels 5-8, 18-bit resolution, 5V flags all channels

Communication Options

Note: To use PMAC-NC software, DPRAM is required

0: No Options, Default

D: DPRAM option, size 32K x 16-bit wide (required for NC software)

M: ModBus Ethernet Communication Protocol (So ftware) opti on

S: DPRAM and Modbus Options Combined

R: RS232 port on 9-pin D-sub Connector

E: DPRAM & RS232 Options Combined

N: RS232 & ModBus Options Combined

T: Modbus, DPRAM & RS232 Combined

MAC RO and Sp ecial Feedback Opti ons (See Not e)

Number and Type of Special Feedback Channels

BC X - XX - XXX - XXX -XXXX

00: No Special Feedback Channels

4A: 4 Sinusoidal Encoder Feedback Channels

4B: 4 Resolver Feedback Channels

4C: 4 Serial Encoder Feedback Channels

4D: 4 Sinusoidal Encoder and Serial Encoder Feedback Channels

8A: 8 Sinusoidal Encoder Feedback Channels

8B: 8 Resolver Feedback Channels

8C: 8 Serial Encoder Feedback Channels

8D: 8 Sinusoidal Encoder and Serial Encoder Feedback Channels

Ser ial Encoder Protocols

BC X - XX - XXX - XXX -XXXX

0: No Serial Encoder Protocol (for previous digit = 0, A, or B)

1: SSI

2: Yaska wa Sigma II

3: EnDat

4: HiperFace

5: Tamagawa

MACRO Ring Interface

BC X - XX - XXX - XXX -XXX

0: No MACR O Interface

1: RJ45 MACRO Interface

2: Fi ber Opti c MACRO In terface

Note: If this portion of the model number is

present at all, an add-in board with RS-232

comms port, 2 channel "handwheel" port and 8

relay outputs for the amplifier-enable signals will

be provided, regardless of the values in this

portion of the model number. Addit ional circuits

X

are provided as specified by the codes here.

Brick Motion Controller Options

CPU Options

• Option C0 – 80MHz Turbo CPU with 8Kx24 internal memory, 1Mx24 256Kx24 SRAM, 1Mx8 flash

memory

• Option F3 – 240MHz Turbo CPU with 192Kx24 internal memory, 1Mx24 SRAM, 4Mx8 flash memory

Axis 1-4 Output Options

• Filtered-PWM analog output on Channels 1-4, 12-bit resolution (default)

• Dual true-DAC analog outputs on Channels 1-4, 18-bit resolution

Secondary Encoder Options

• Four secondary encoder inputs, and flags 12-24V.

• Four secondary encoder inputs, and flags 5V.

Digital I/O Option

• Digital I/O 16 inputs and 8 outputs, 0.5A, 24VDC (default)

• Expanded digital I/O additional 16 inputs and 8 outputs, 0.5A, 24VDC

• Expanded digital I/O additional 32 inputs and 16 outputs, 0.5A, 24VDC

Specifications 3

Brick Motion Controller Hardware Reference Manual

Analog I/O Options

• Two 16-bit analog inputs

• Four 16-bit analog inputs

Communication Options

• DPRAM option, size 32K x 16-bit wide (required for use with NC software)

• ModBus Ethernet Communication Protocol (Software) option

• DPRAM and Modbus options combined

• RS232 port on 9-pin D-sub connector

• DPRAM & RS232 options combined

• Modbus & DPRAM options combined

• Modbus, DPRAM & RS232 options combined

MACRO and Special Feedback Options

Number and Type of Special Feedback Channels

• No Special Feedback Channels

• 4 Sinusoidal Encoder Feedback Channels

• 4 Resolver Feedback Channels

• 4 Serial Encoder Feedback Channels

• 4 Sinusoidal Encoder and Serial Encoder Feedback Channels

• 8 Sinusoidal Encoder Feedback Channels

• 8 Resolver Feedback Channels

• 8 Serial Encoder Feedback Channels

• 8 Sinusoidal Encoder and Serial Encoder Feedback Channels

Serial Encoder Protocols

• No Serial Encoder Protocol (for previous digit = 0, A, or B)

• SSI Serial Absolute Encoder Interface

• Yaskawa Sigma II Serial Absolute Encoder Interface

• EnDat Serial Absolute Encoder Interface

• HiperFace Serial Absolute Encoder Interface

• Tamagawa Serial Absolute Encoder Interface

MACRO Ring Interface

• RJ45 MACRO Interface

• Fiber Optic MACRO Interface

4 Specifications

Brick Motion Controller Hardware Reference Manual

RECEIVING AND UNPACKING

Delta Tau products are thoroughly tested at the factory and carefully packaged for shipment. When the

Brick Motion Controller is received, there are several steps that should be performed immediately:

1. Observe the condition of the shipping container and report any damage immediately to the

commercial carrier that delivered the drive.

2. Remove the control from the shipping container and remove all packing materials. Check all

shipping material for connector kits, documentation, diskettes, CD ROM, or other small pieces of

equipment. Be aware that some connector kits and other equipment pieces may be quite small and

can be accidentally discarded if care is not used when unpacking the equipment. The container and

packing materials may be retained for future shipment.

3. Verify that the part number of the unit received is the same as the part number listed on the purchase

order.

4. Inspect the unit for external physical damage that may have been sustained during shipment and

report any damage immediately to the commercial carrier that delivered the drive.

5. Electronic components in this product are design-hardened to reduce static sensitivity. However, use

proper procedures when handling the equipment.

6. If the Brick Motion Controller is to be stored for several weeks before use, be sure that it is stored in a

location that conforms to published storage humidity and temperature specifications stated in this

manual.

Use of Equipment

The Brick Motion Controller is a Turbo PMAC2 controller. So parallel with this manual the user needs to

use the Turbo Software Reference Manual and the Turbo User Manual. Always download the latest

manual revision from the Delta Tau website: www.deltatau.com

Note:

If Ethernet communications are used, Delta Tau Systems strongly recommends the

use of RJ45 CAT5e or better shielded cable.

Newer network cards have the Auto-MDIX feature that eliminates the need for

crossover cabling by performing an internal crossover when a straight cable is

detected during the auto-negotiation process.

For older network cards, one end of the link must perform media dependent

interface (MDI) crossover (MDIX), so that the transmitter on one end of the data

link is connected to the receiver on the other end of the data link (a crossover/patch

cable is typically used). If an RJ45 hub is used, then a regular straight cable should

be implemented.

Maximum length for Ethernet cable should not exceed 100m (330ft).

Specifications 5

Brick Motion Controller Hardware Reference Manual

6 Specifications

Brick Motion Controller Hardware Reference Manual

SYSTEM WIRING

WARNING:

Installation of electrical control equipment is subject to many regulations including

national, state, local, and industry guidelines and rules. General recommendations

can be stated but it is important that the installation be carried out in accordance

with all regulations pertaining to the installation.

Noise Problems

When problems do occur often it points to electrical noise as the source of the problem. When this

occurs, turn to controlling high-frequency current paths. If the grounding instructions do not work, insert

chokes in the motor phases. These chokes can be as simple as several wraps of the individual motor leads

through a ferrite ring core (such as Micrometals T400-26D). This adds high-frequency impedance to the

outgoing motor cable thereby making it harder for high-frequency noise to leave the control cabinet area.

Care should be taken to be certain that the core’s temperature is in a reasonable range after installing such

devices.

Wiring Earth-Ground

Panel wiring requires that a central earth-ground location be installed at one part of the panel. This

electrical ground connection allows for each device within the enclosure to have a separate wire brought

back to the central wire location. Usually, the ground connection is a copper plate directly bonded to the

back panel or a copper strip with multiple screw locations. The Brick Motion Controller is brought to the

earth-ground via the fourth pin on the J1 connector, located at the bottom of the unit through a heavy

gauge, multi-strand conductor to the central earth-ground location.

Earth Grounding Paths

High-frequency noises from the PWM controlled power stage will find a path back to the drive. It is best

that the path for the high-frequency noises be controlled by careful installation practices. The major

failure in problematic installations is the failure to recognize that wire conductors have impedances at

high frequencies. What reads 0 Ohms on a DVM may be hundreds of Ohms at 30MHz. Consider the

following during installation planning:

1. Star point all ground connections. Each device wired to earth ground should have its own conductor

brought directly back to the central earth ground plate.

2. Use unpainted back panels. This allows a wide area of contact for all metallic surfaces reducing high

frequency impedances.

3. Conductors made up of many strands of fine conducts outperform solid or conductors with few

strands at high frequencies.

4. Motor cable shields should be bounded to the back panel using 360-degree clamps at the point they

enter or exit the panel.

5. Motor shields are best grounded at both ends of the cable. Again, connectors using 360-degree shield

clamps are superior to connector designs transporting the shield through a single pin. Always use

metal shells.

6. Running motor armature cables with any other cable in a tray or conduit should be avoided. These

cables can radiate high frequency noise and couple into other circuits.

System Wiring 7

Loading...

Loading...