Page 1

^1 USER MANUAL

^2 3U DIGITAL PWM AMPLIFIER

^3 3U Digital PWM Amplifier

^4 4Ax-603397-xUxx

^5 January 28, 2003

Single Source Machine Control Power // Flexibility // Ease of Use

21314 Lassen Street Chatsworth, CA 91311 // Tel. (818) 998-2095 Fax. (818) 998-7807 // www.deltatau.com

Page 2

Copyright Information

© 2003 Delta Tau Data Systems, Inc. All rights reserved.

This document is furnished for the customers of Delta Tau Data Systems, Inc. Other uses are

unauthorized without written permission of Delta Tau Data Systems, Inc. Information contained

in this manual may be updated from time-to-time due to product improvements, etc., and may not

conform in every respect to former issues.

To report errors or inconsistencies, call or email:

Delta Tau Data Systems, Inc. Technical Support

Phone: (818) 717-5656

Fax: (818) 998-7807

Email: support@deltatau.com

Website: http://www.deltatau.com

Operating Conditions

All Delta Tau Data Systems, Inc. motion controller products, accessories, and amplifiers contain

static sensitive components that can be damaged by incorrect handling. When installing or

handling Delta Tau Data Systems, Inc. products, avoid contact with highly insulated materials.

Only qualified personnel should be allowed to handle this equipment.

In the case of industrial applications, we expect our products to be protected from hazardous or

conductive materials and/or environments that could cause harm to the controller by damaging

components or causing electrical shorts. When our products are used in an industrial

environment, install them into an industrial electrical cabinet or industrial PC to protect them

from excessive or corrosive moisture, abnormal ambient temperatures, and conductive

materials. If Delta Tau Data Systems, Inc. products are exposed to hazardous or conductive

materials and/or environments, we cannot guarantee their operation.

Page 3

3U Digital PWM Amplifier User Manual

Table of Contents

INTRODUCTION.......................................................................................................................................................1

Theory of Operation..................................................................................................................................................1

Power Supply Considerations ...................................................................................................................................1

Specifications............................................................................................................................................................2

Power Stage..........................................................................................................................................................2

Environmental ......................................................................................................................................................2

3U Power Supply..................................................................................................................................................2

Amplifier Display Codes...........................................................................................................................................2

CONNECTIONS.........................................................................................................................................................3

3U Amplifier Faceplate Connections........................................................................................................................3

Power Supply Faceplate............................................................................................................................................4

Hardware Connections to the Assembly ...................................................................................................................4

Hardware Connections to the Assembly ...................................................................................................................5

Power-DC Bus......................................................................................................................................................5

Power-AC Input....................................................................................................................................................6

Amplifier Power Section Pinout (603391-10x).....................................................................................................7

3U Power Supply Layout......................................................................................................................................8

3U AMPLIFIER BACKPLANE BOARD (603435-10X) .........................................................................................9

Front Side Connectors ..........................................................................................................................................9

Back Side Connectors.........................................................................................................................................10

3U Amplifier Backplane Layout (Back)..............................................................................................................11

3U Amplifier Backplane Layout (Front).............................................................................................................11

TROUBLESHOOTING............................................................................................................................................13

USEFUL NOTES.......................................................................................................................................................15

Table of Contents i

Page 4

3U Digital PWM Amplifier User Manual

ii Table of Contents

Page 5

3U Digital PWM Amplifier User Manual

INTRODUCTION

The 3U Digital PWM Amplifier board is a 3U-size amplifier designed to drive AC Induction, Permanent

Magnet Brushless, DC Brushed type motors. This amplifier unit comes in two packages: Two 680W

continuous power amplifiers or one 1360W continuous power amplifier. The 3U Digital PWM Amplifier

may be interfaced conveniently to the PMAC controller via ACC-24E2 or ACC-8F.

Typically, the amplifier is purchased with the Delta Tau 3U power supply and backplane interface card to

distribute the power to the unit.

Part Number Description

603428-10x 170V Power Supply for 3U Amplifiers

603435-10x Backplane Assembly for 3U Amplifiers

Theory of Operation

The 3U Digital PWM Amplifier is a 3-phase direct PWM drive, utilizing the latest in smart power

technology from the world’s leading vendors and the cutting edge algorithms of the PMAC2/UMAC

controller family. The 3U Digital PWM Amplifier can drive all of the motor types commonly used in

programmable motion control in both rotary and linear forms.

The 3U Digital PWM Amplifier is based on PWM (Pulse Width Modulation), a technique employing

both frequency and phase to approximate sinusoidal currents and to control AC and DC motors.

Each axis of the 3U Digital PWM Amplifier uses a three H-bridge legs scheme. Each leg employs a top

and bottom IGBT transistor. The motor windings are connected between the center points of top and

bottom pairs. When two appropriate IGBT transistors in the bridge are turned on, the current flows

through any two motor windings. Any two (top and bottom) bridge transistors are turned on by a logic

from PMAC2 with no other conditioning necessary, except an optical isolation. The 3U Digital PWM

Amplifier performs no control functions itself; it simply accepts direct PWM commands from the

PMAC2. PMAC2 requires the position feedback and the feedback about the current fed to the motors to

commutate each controlled axis.

The current feedback is provided in digital form as a part of a serial data stream of 18 bits (12 bits report

the current feedback and remaining 6 bits report fault conditions) from the current feedback A/D

converters which are located in the 3U Digital PWM Amplifier. Each axis has its own “mask” word that

tells the PMAC2 how many bits to expect from the A/D converter. The clock and the strobe for the digital

feedback are programmable at the PMAC2.

The position feedback is generally fed to PMAC2/UMAC via ACC 8F or ACC-24E2. The position

feedback is not connected to the Quad Amp in any way.

Power Supply Considerations

The 3U Digital PWM Amplifier requires a single power supply of +50V to +170V max. The current

requirement can vary depending on the load, but should not exceed 8A (4A per channel) continuous and

16A peak (8A per channel) for a 1-second period.

The logic power for the amplifier is derived from the BUS voltage. Typically, the BUS voltage can be

brought in from the amplifier backplane assembly card.

Any shunt resistors connected to the amplifiers are connected to the amplifier backplane assembly.

Introduction 1

Page 6

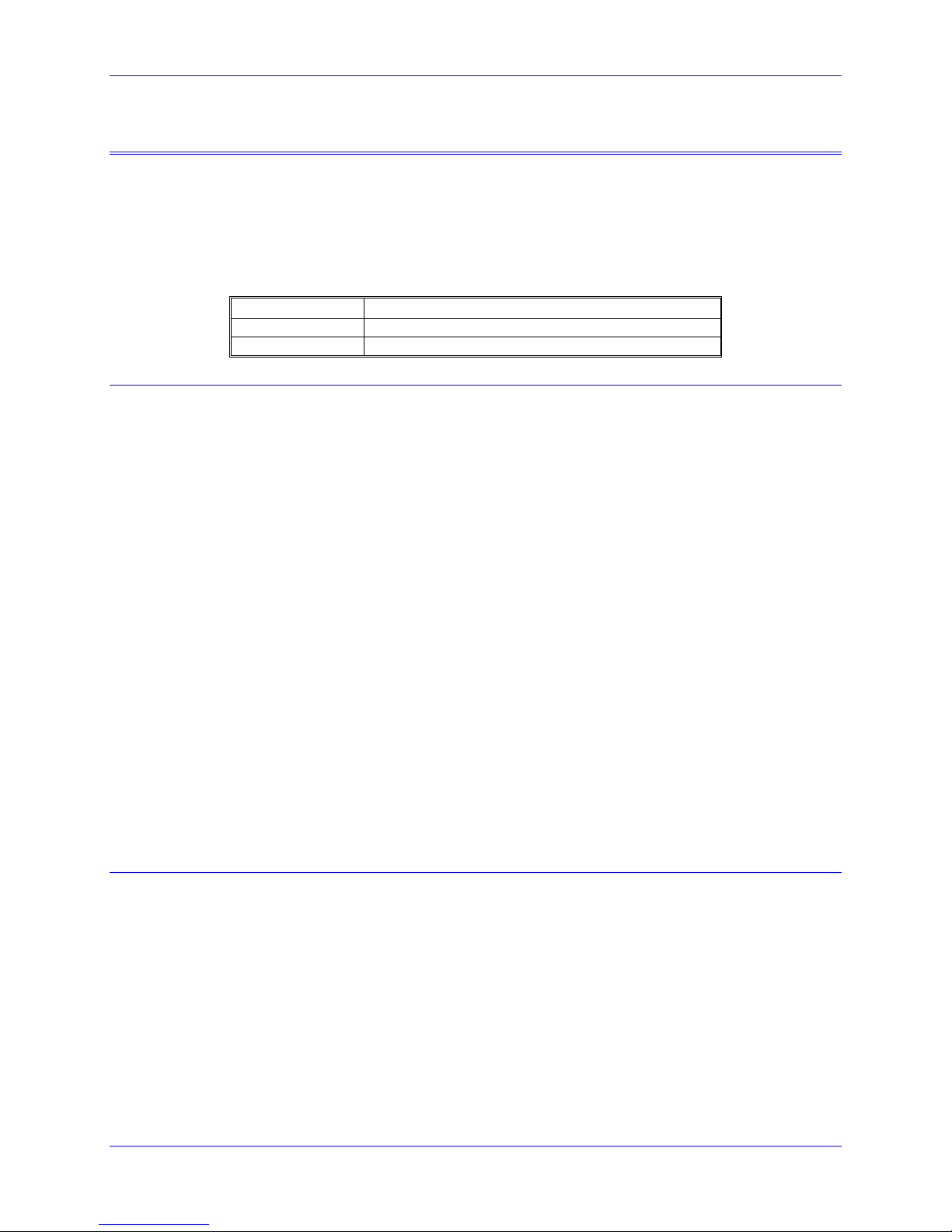

Specifications

Power Stage

BUS Voltage (standard unit) 60V DC minimum

Max Continuous Current (per amp) 4A (RMS)

MAX ADC Current Loop Feedback 12A

Environmental

3U Power Supply

3U Digital PWM Amplifier User Manual

Description Specification

170V DC maximum

Peak Current (per amp) 8A

Maximum PWM Frequency 15 KHz

Description Specification

Operating Temperature

Storage Temperature

Humidity 0% to 95%, Non-Condensing

0°C to 55°C (32°F to 135°F)

-12°C to 82°C (10°F to 180°F)

Description Specification

Main AC Input Voltage 120V AC

Frequency 50/60 Hz

Main BUS Voltage 170V

Amplifier Display Codes

The amplifier is protected against severe electrical and temperature conditions. See the table below for a

code, and explanation.

Code Description

0 Everything is OK

1 2 sec over current, axis #1

2 Short circuit, axis # 1

3 Motor over temperature fault, axis #1

4 2 sec over current, axis # 2

5 Short circuit, axis #2

6 Motor over temperature fault, axis #2

8 Under voltage, global

9 High PWM fault, global

C Over voltage, global

2 Introduction

Page 7

3U Digital PWM Amplifier User Manual

CONNECTIONS

3U Amplifier Faceplate Connections

Amplifier 1 Input/Output

Logic Power Indicator

Amplifier Status LED

Ampliier Fault

Amplifier 2 Input/Output

Connections 3

Page 8

Power Supply Faceplate

MAIN AC

3U Digital PWM Amplifier User Manual

INPUT VOLTAGE

CHASIS

GROUND

4 Connections

Page 9

3U Digital PWM Amplifier User Manual

Hardware Connections to the Assembly

Power-DC Bus

The amplifier requires an external DC bus supply. The bus can be supplied via Delta Tau Power Supply

(part of the UMAC line product), or via customer provided DC source. Such a source can be connected to

the UMAC PWM backplane, or directly to the J1 connector of the 3U power board via quick-disconnect

terminals.

The graphic below shows two 3U PWM amplifiers and a Delta Tau Power Supply in a rack. The DC bus

is distributed through the backplane.

3U 3U Power Supply

Chassis ground

AC line input

Below are shown three 3U PWM amplifiers and a Delta Tau Power Supply in a rack. The DC bus must be

connected to the backplane.

3U 3U 3U

BUS IN +

BUS IN -

Connections 5

Page 10

3U Digital PWM Amplifier User Manual

The DC bus can be connected to a stand-alone 3U amplifier via quick-disconnect terminals as shown:

BUS IN+ (pin 4)

BUS IN – (pin 6)

Power-AC Input

AC input voltage is applied to the power supply assembly ONLY. The power supply accepts three-phase

or single-phase AC voltage. For a single-phase operation, connect AC line and Neutral to any of the AC

inputs (A, B, C), and connect AC ground to Chassis GND terminal.

Typical 3U wiring diagram

Motor#1

3U

PMAC2 controller

Acc 8F

Acc 8F

Motor#2

6 Connections

Page 11

3U Digital PWM Amplifier User Manual

Amplifier Power Section Pinout (603391-10x)

J1 connector pin out J2 connector pin out

pin 1

Pin #

Description

1 Motor ground 1 Axis #1 W phase

2 Axis #1 W phase 2 Axis #1 V phase

3 Axis #2 W phase 3 Axis #1 U phase

4 Bus + 4 Axis #2 W phase

5 Shunt 5 Axis #2 V phase

6 Bus - 6 Axis #2 U phase

7 Bus + 7 Motor ground

8 Axis #1 V phase

9 Axis #2 V phase

10 Axis #1 U phase

11 Axis #2 U phase

Pin #

Description

603391-10x J2 connector pin out

J1 J2

pin 11

Connections 7

Page 12

3U Power Supply Layout

3U Digital PWM Amplifier User Manual

8 Connections

Page 13

3U Digital PWM Amplifier User Manual

3U AMPLIFIER BACKPLANE BOARD (603435-10X)

The 3U Amplifier Backplane Board allows plugging the 3U digital PWM amplifiers into an assembly that

distributes the BUS power for up to three 2-Axis 3U digital amplifiers. If the optional 170V power supply

is used in the system, you could plug two 2-axis 3U digital amplifiers into the Amplifier Backplane Board

Assembly. Any external shunts for the amplifier will be connected to the lug type connectors located on

the backside of the assembly. Typically, this assembly would be placed into a 3U Rack provided by Delta

Tau.

The backside of the assembly allows you to –

• Connect the motor leads to Molex Type connectors located on the backside of the assembly;

• Bring in an external DC BUS for the Amplifiers;

• Add a shunt resistor;

• Connect the power for external cooling fans.

The front side of the assembly simply allows the user to plug the amplifiers and power supply into the

unit.

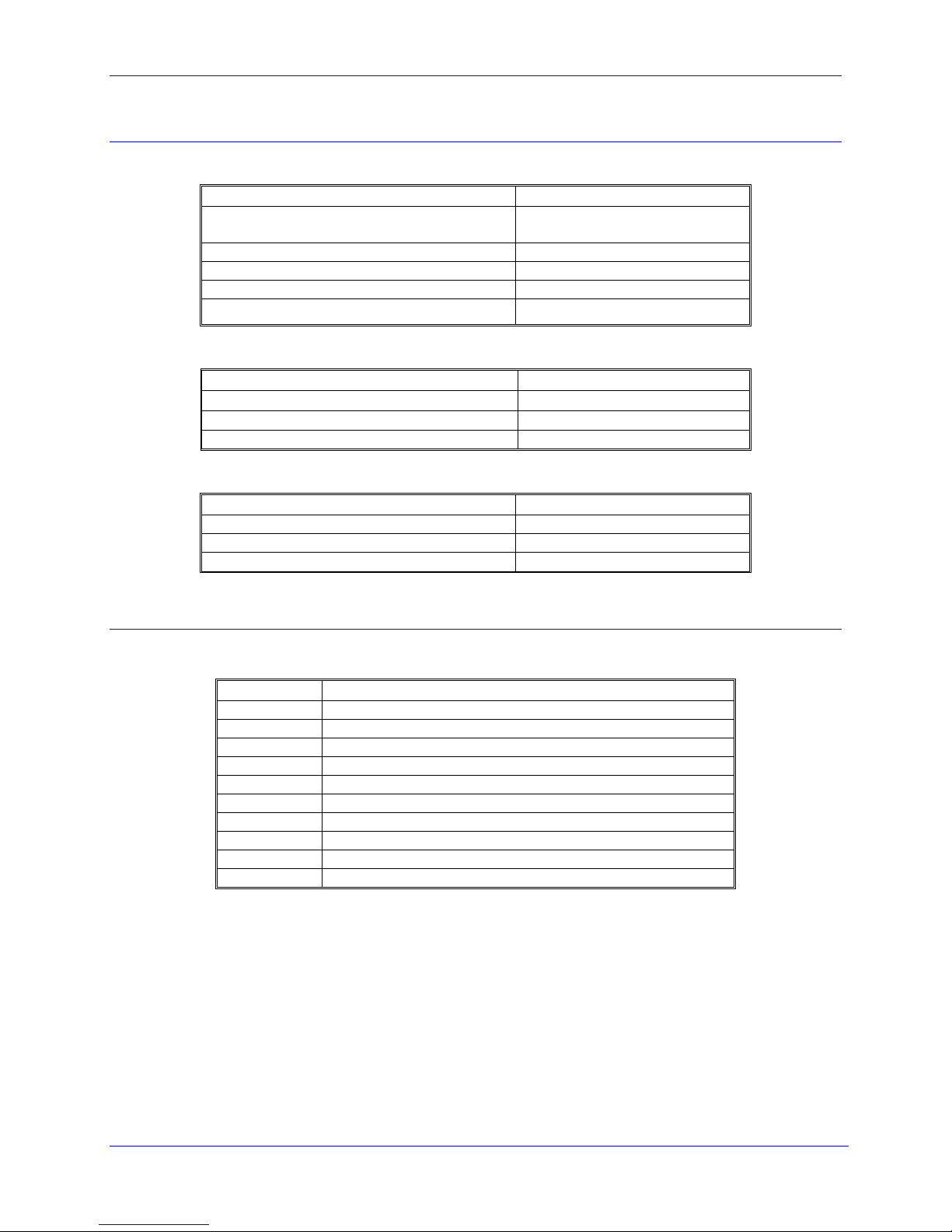

Front Side Connectors

Connector Description Notes

J3 3U Digital Amplifier Input

J4 3U Digital Amplifier Input Traditionally for Axis #3 & Axis #4

J5 170V 3U Power Supply Make sure to plug into J5 connector.

J6 3U Digital Amplifier Input Traditionally for Axis #5 & Axis #6

J3, J4, and J6 Amplifier Pinouts

Pin # Description Pin # Description

1 Motor ground 7 Bus +

2 Axis #1 W phase 8 Axis #1 V phase

3 Axis #2 W phase 9 Axis #2 V phase

4 Bus + 10 Axis #1 U phase

5 Shunt 11 Axis #2 U phase

6 Bus -

Traditionally for Axis #1 & Axis #2

3U Amplifier Backplane Board (603435-10x) 9

Page 14

J5 Power Supply Pinout

3U Digital PWM Amplifier User Manual

Pin #

1 BUS+ INPUT 7 NC

2 SHUNT 8 NC

3 BUS- INPUT 9 FAN+

4 SHUNT Return 10 FAN5 BUS+ Input 11 GND (M otor GND from

6 BUS-Input

Description Pin # Description

Back Side Connectors

Connector Description Notes

J1 Shunt Resistor Input

J2 Shunt Resistor Return

J7 Optional Axis 1 Motor Output

J8 Optional Axis 2 Motor Output

J9 Optional Axis 3 Motor Output

J10 Optional Axis 4 Motor Output

J11 Optional Axis 5 Motor Output

J12 Optional Axis 6 Motor Output

J13 Fan Power Outputs

J14 Fan Power Outputs Traditionally for the J4 Amplifier

J15 Fan Power Outputs Traditionally for the J6 Amplifier

J16 External BUS Supply Input

amp)

Traditionally for the J3 Amplifier

10 3U Amplifier Backplane Board (603435-10x)

Page 15

3U Digital PWM Amplifier User Manual

3U Amplifier Backplane Layout (Back)

SHUNT

RETURN

0.216''0.8175''

J2

J1

SHUNT

1

1

BUSIN+

BUSIN-

1

A B C

A B C

J11

AXIS 5

J12

AXIS 6

J15

1

AXIS 3

AXIS 4

J9

J10

A B C

1

A B C

1

6.25''

3U Amplifier Backplane Layout (Front)

J3 J4

J14

1

6.25''

1

1

LP1

A B C

A B C

4.92

J7

AXIS 1

J8

AXIS 2

J13

1

J5

J6

4.92

3U Amplifier Backplane Board (603435-10x) 11

Page 16

3U Digital PWM Amplifier User Manual

12 3U Amplifier Backplane Board (603435-10x)

Page 17

3U Digital PWM Amplifier User Manual

TROUBLESHOOTING

Amplifier stops and displays a code

If a 3U amplifier displays other digit than 0, please refer to a section ‘Protection’ for an explanation of

fault codes.

Amplifier is ‘dark’

If the amplifier status display, +5V, +12V, -12V, ENA1, and ENA2 are not illuminated, verify that DC

bus is connected to the 3U amplifier.

If the condition described above is present, and the 3U amp is used in a UMAC rack along with a power

supply, verify that AC line is connected to the power supply.

Motor does not move upon a command

Verify that PWM cables and motor leads are correctly connected to 3U amplifier. Is motor properly

phased?

Cannot phase a motor

Verify that PMAC is properly configured and sees the motor’s feedback.

Troubleshooting

13

Page 18

3U Digital PWM Amplifier User Manual

14 Troubleshooting

Page 19

3U Digital PWM Amplifier User Manual

5

USEFUL NOTES

If a shunt (regen) resistor is required, use the shunt terminals on the backplane. Or, the shunt resistor can

be connected directly to the 3U power board (300-603391-102) between J11 pin 5 and J11 pin 4.

The long pin on the power board connector J11 represents pin 11 (Axis #2 U phase).

If the 3U amplifier is not used in Delta Tau UMAC rack, it is a user’s responsibility to assure that the

proper cooling is provided for the IGBTs. Delta Tau suggests a fan capable of at least 100 CFM placed as

close to the heatsinks as possible.

If the bus connection to the 3U amp is not done via Delta Tau backplane, a de-coupling capacitor (about

120 µF) for + and – bus should be used.

Useful Notes

1

Page 20

3U Digital PWM Amplifier User Manual

6

Useful Notes

1

Loading...

Loading...