Page 1

^1 USER MANUAL

^3U03U042 Geo 3U Direct PWM Drive

(New Version)

^3 Geo 3U Direct PWM Drive, 3U042

Single Source Machine Control Power // Flexibility // Ease of Use

21314 Lassen Street Chatsworth, CA 91311 // Tel. (818) 998-2095 Fax. (818) 998-7807 // www.deltatau.com

^4 5xx-603729-xUx2

^5 July 26, 2006

Page 2

Page 3

Copyright Information

© 2006 Delta Tau Data Systems, Inc. All rights reserved.

This document is furnished for the customers of Delta Tau Data Systems, Inc. Other uses are

unauthorized without written permission of Delta Tau Data Systems, Inc. Information contained in this

manual may be updated from time-to-time due to product improvements, etc., and may not conform in

every respect to former issues.

To report errors or inconsistencies, call or email:

Delta Tau Data Systems, Inc. Technical Support

Phone: (818) 717-5656

Fax: (818) 998-7807

Email: support@deltatau.com

Website: http://www.deltatau.com

Operating Conditions

All Delta Tau Data Systems, Inc. motion controller products, accessories, and amplifiers contain static

sensitive components that can be damaged by incorrect handling. When installing or handling Delta Tau

Data Systems, Inc. products, avoid contact with highly insulated materials. Only qualified personnel

should be allowed to handle this equipment.

In the case of industrial applications, we expect our products to be protected from hazardous or

conductive materials and/or environments that could cause harm to the controller by damaging

components or causing electrical shorts. When our products are used in an industrial environment, install

them into an industrial electrical cabinet or industrial PC to protect them from excessive or corrosive

moisture, abnormal ambient temperatures, and conductive materials. If Delta Tau Data Systems, Inc.

products are directly exposed to hazardous or conductive materials and/or environments, we cannot

guarantee their operation.

Page 4

Safety Instructions

Qualified personnel must transport, assemble, install, and maintain this equipment. Properly qualified

personnel are persons who are familiar with the transport, assembly, installation, and operation of

equipment. The qualified personnel must know and observe the following standards and regulations:

IEC 364 resp. CENELEC HD 384 or DIN VDE 0100

IEC report 664 or DIN VDE 0110

National regulations for safety and accident prevention or VBG 4

Incorrect handling of products can result in injury and damage to persons and machinery. Strictly adhere

to the installation instructions. Electrical safety is provided through a low-resistance earth connection. It is

vital to ensure that all system components are connected to earth ground.

This product contains components that are sensitive to static electricity and can be damaged by incorrect

handling. Avoid contact with high insulating materials (artificial fabrics, plastic film, etc.). Place the

product on a conductive surface. Discharge any possible static electricity build-up by touching an

unpainted, metal, grounded surface before touching the equipment.

Keep all covers and cabinet doors shut during operation. Be aware that during operation, the product has

electrically charged components and hot surfaces. Control and power cables can carry a high voltage,

even when the motor is not rotating. Never disconnect or connect the product while the power source is

energized to avoid electric arcing.

After removing the power source from the equipment, wait at least 10 minutes before touching or

disconnecting sections of the equipment that normally carry electrical charges (e.g., capacitors, contacts,

screw connections). To be safe, measure the electrical contact points with a meter before touching the

equipment.

The following text formats are used in this manual to indicate a potential for personal injury or equipment

damage. Read the safety notices in this manual before attempting installation, operation, or maintenance

to avoid serious bodily injury, damage to the equipment, or operational difficulty.

WARNING

A Warning identifies hazards that could result in personal injury or death. It

precedes the discussion of interest.

Caution

A Caution identifies hazards that could result in equipment damage. It precedes the

discussion of interest.

Note

A Note identifies information critical to the user’s understanding or use of the

equipment. It follows the discussion of interest.

Page 5

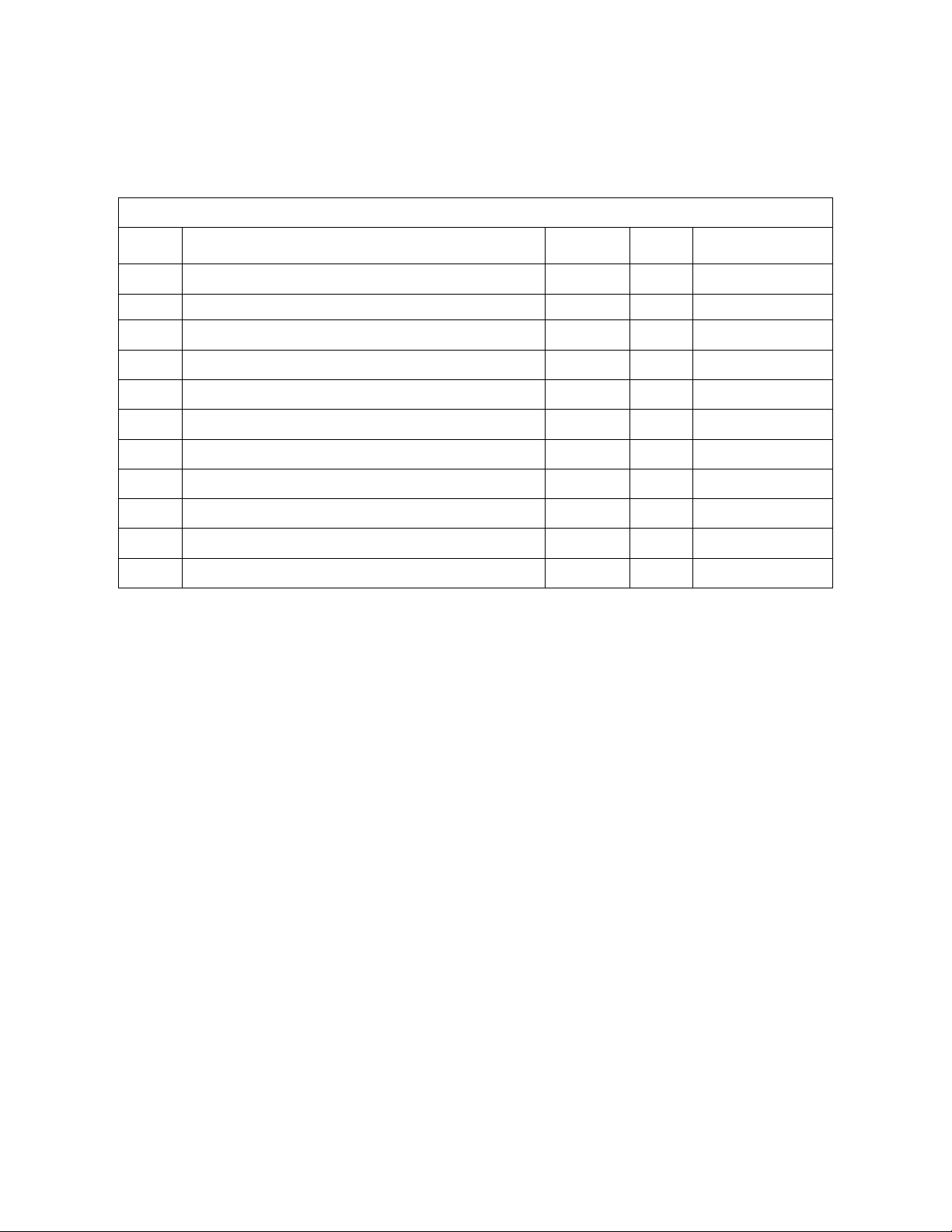

REVISION HISTORY

REV. DESCRIPTION DATE CHG APPVD

1 REPLACED COVER PRODUCT PHOTO 07/25/06 CP D.DIMITRI

Page 6

3U Servo Amplifier

Table of Contents

Copyright Information................................................................................................................................................i

Operating Conditions .................................................................................................................................................i

Safety Instructions.................................................................................................................................................... ii

INTRODUCTION .......................................................................................................................................................1

Compatible Motors....................................................................................................................................................2

Maximum Speed....................................................................................................................................................2

Torque...................................................................................................................................................................2

Motor Poles ..........................................................................................................................................................3

Motor Inductance..................................................................................................................................................3

Motor Resistance ..................................................................................................................................................3

Motor Back EMF ..................................................................................................................................................3

Motor Torque Constant ........................................................................................................................................4

Motor Inertia ........................................................................................................................................................4

Motor Cabling ......................................................................................................................................................4

RECEIVING AND UNPACKING.............................................................................................................................5

Use of Equipment......................................................................................................................................................5

Environmental Specifications....................................................................................................................................5

Electrical Specifications............................................................................................................................................6

Recommended Fusing and Wire Gauge....................................................................................................................6

Wire Sizes .............................................................................................................................................................6

Physical Specifications..............................................................................................................................................7

MOUNTING ................................................................................................................................................................8

SYSTEM WIRING......................................................................................................................................................9

Fuse and Circuit Breaker Selection......................................................................................................................9

Use of GFI Breakers.............................................................................................................................................9

Transformer and Filter Sizing ..............................................................................................................................9

Noise Problems...................................................................................................................................................10

Operating Temperature ......................................................................................................................................10

Amplifier Cooling Considerations......................................................................................................................11

Single Phase Operation ......................................................................................................................................11

Power Supply Considerations .................................................................................................................................11

Wiring AC Input......................................................................................................................................................11

Wiring Earth-Ground ..............................................................................................................................................12

Earth Grounding Paths.......................................................................................................................................12

Wiring 24 V Logic Control .....................................................................................................................................13

Regen (Shunt) Resistor Wiring ...............................................................................................................................13

Shunt Regulation.................................................................................................................................................14

Minimum Resistance Value.................................................................................................................................14

Maximum Resistance Value................................................................................................................................14

Energy Transfer Equations.................................................................................................................................14

Bonding...................................................................................................................................................................18

Filtering...................................................................................................................................................................18

CE Filtering........................................................................................................................................................18

Input Power Filtering .........................................................................................................................................18

Motor Line Filtering...........................................................................................................................................18

3U DRIVE CONNECTIONS....................................................................................................................................21

PWM Input Connector ............................................................................................................................................21

Axis #1 PWM input connector ............................................................................................................................21

P1 (36-pin Mini-D Connector) ...........................................................................................................................21

Axis #2 PWM Input connector............................................................................................................................22

P2 (36-pin Mini-D Connector) ...........................................................................................................................22

Motor Output Connector .........................................................................................................................................23

Table of Contents ii

Page 7

3U Servo Amplifier

Wiring the Motor Thermostats................................................................................................................................24

Motor Temperature Switch.................................................................................................................................24

GEO 3U PWM BACKPLANE CONNECTIONS...................................................................................................25

3UBP8A, 300-603730-10x......................................................................................................................................25

J1: 3U Geo Drive backplane slot........................................................................................................................25

J2: 24V Input Molex Connector..........................................................................................................................26

J3: FAN output Molex Connector.......................................................................................................................26

TB1: AC input Power and Regen Resistor Connector........................................................................................26

TB2: Regen Resistor Connector .........................................................................................................................26

DIRECT PWM COMMUTATION CONTROLLER SETUP ..............................................................................28

Key Servo IC Variables...........................................................................................................................................28

Key Motor Variables...............................................................................................................................................28

DC BRUSH MOTOR DRIVE SETUP WITH NON-TURBO PMAC ..................................................................29

Hardware Connection ........................................................................................................................................29

I-Variable Setup..................................................................................................................................................29

DC BRUSH MOTOR DRIVE SETUP WITH TURBO PMAC ............................................................................31

Commutation Phase Angle: Ixx72...........................................................................................................................31

Special Instructions for Direct-PWM Control of Brush Motors..............................................................................31

Testing PWM and Current Feedback Operation .....................................................................................................32

Purpose...............................................................................................................................................................33

Preparation.........................................................................................................................................................33

Position Feedback and Polarity Test..................................................................................................................34

PWM Output and ADC Input Connection ..............................................................................................................34

PWM/ADC Phase Match ....................................................................................................................................35

Synchronous Motor Stepper Action ....................................................................................................................35

Current Loop Polarity Check .............................................................................................................................35

Troubleshooting..................................................................................................................................................35

SETTING I2T PROTECTION .................................................................................................................................36

CALCULATING MINIMUM PWM FREQUENCY.............................................................................................37

PWM DRIVE COMMAND STRUCTURE.............................................................................................................38

Default Mode...........................................................................................................................................................38

Enhanced Mode.......................................................................................................................................................38

TROUBLESHOOTING............................................................................................................................................39

Error Codes .............................................................................................................................................................39

3U Drive Status Display Codes ..........................................................................................................................39

Status LEDs (for older and newer revision) 3U042............................................................................................40

Amplifier stops and displays a code....................................................................................................................41

APPENDIX A.............................................................................................................................................................42

PWM Cable Ordering Information..........................................................................................................................42

Mating Connector and Cable Kits...........................................................................................................................42

Connector and pins Part numbers ......................................................................................................................42

Motor Cable Drawing..............................................................................................................................................43

3U042 (CABKIT3C) ...........................................................................................................................................43

APPENDIX B.............................................................................................................................................................44

Regenerative Resistor: GAR78/48 .........................................................................................................................44

APPENDIX C.............................................................................................................................................................46

3U Rack DIMENSIONS .........................................................................................................................................46

Table of Contents iii

Page 8

3U Servo Amplifier

Table of Contents iv

Page 9

3U Servo Amplifier

Table of Contents v

Page 10

3U Servo Amplifier

INTRODUCTION

This document provides user data and support for the 3U Geo Direct PWM drives 3U042. Geo drives are

brushless drive amplifier modules designed and manufactured by Delta Tau Data Systems, Inc.

The 3U042 is a 3U size Geo Direct PWM amplifier designed to drive up to two axis with 4A RMS

continuous and 8A RMS peak (2 seconds). These drives are low power amplifiers designed to drive

permanent magnet brushless (rotary or linear), AC induction and DC Brush type motors from PWM

(pulse width modulated) command signals. These drive systems are designed to fit into a standard 3U

rack. The 3U Geo Direct PWM drives will operate directly off the power mains wired to the backplane,

typically 230VAC or 110VAC, three phase or single phase with the appropriate derating. An external

power supply of +24 VDC @1A (unregulated) is required for logic power allowing the user to control

motor power separately from control logic power. The amplifiers are interfaced to a PMAC controller via

ACC-24E2, ACC-24E2M, ACC-8F or ACC-8FS or other digital output servos.

These drive amplifiers are designed to receive logic-level direct digital PWM motor voltage command

from the controller and convert them to high voltage for motor control. They provide the power

conversion, motor current sense feedback to the controller, and comprehensive system protection. Each

drive also accepts motor thermal overload sensors for drive shut down on motor over temperature. The

host controller provides all other motor control functions.

Product Features:

Simple wiring •

•

High power density

•

Extensive fault protection

•

Locking motor connectors

•

Closed loop hall effect current sensors

•

Direct line connection with Soft Start

•

Separate logic and motor power control

•

3U format for small size and easy support

•

Full isolation for PMAC and user interfaces

•

Direct PWM control for best performance and cost

•

Shunt Regulator (requires external Resistor) for Bus power control

•

Auto ranging Shunt Regulator automatically selects for 115 or 230V operation

The 3U Geo Direct PWM drives consist of three basic components: 3U format Drive Module, backplane

that gives access for the power supply and associated metal work with fan for keeping the drive cool.

Both the drive modules and backplane may be purchased separately as spares. This family of products is

further supported with the availability of cable or connector kits and compatible shunt regulator resistor

(regen resistor).

The amplifier has many protection features to ensure the proper operation and protection of all of the

components connected to the unit. When the amplifier detects a fault, the unit will display a character

indicating the type of fault. Even though backup protection is provided, the PMAC controller should

have the I

2

T protection variables set up to protect the amplifier from over current over time.

The following is a list of the faults detected by the logic of the amplifier:

•

Instantaneous over current

•

Integrated current over time (I

Backplane Board 1

2

T)

Page 11

3U Servo Amplifier

Motor over temperature (input from motor) •

•

Under voltage

•

IGBT thermal failure

•

PWM fault

•

Over voltage

•

Ground fault

•

Minimum dead time protection

•

Shoot through protection

Note:

The 3U drive products are available in kit-form. The electronics on these products are

subject to damage by static electricity. Handle it as little as possible. Use ground wrist

straps when handling. Do not allow static-charge holding materials (paper, plastic, etc.)

to come in near proximity of the product.

Typically, the position feedback is fed to the PMAC controller via the available accessories and is not part

of the 3U drive amplifier. Thus, the position feedback is not to be connected to the amplifier in any

way.

Compatible Motors

The 3U Geo Direct PWM product line is capable of interfacing to a wide variety of motors. The 3U Geo

Direct PWM drives can be used with almost any type of three-phase brushless motor, including DC

brushless rotary, AC brushless rotary, induction, and brushless linear motors. Motor selection for an

application is a science in itself and cannot be covered in this manual. However, some basic

considerations and guidelines are offered. Motor manufacturers include a host of parameters to describe

their motor.

Some basic equations can help guide an applications engineer to mate a proper drive with a motor. A

typical application accelerates a load to a speed, running the speed for a while and then decelerating the

load back into position.

Maximum Speed

The motor’s maximum rated speed is given. This speed may or may not be achievable in a given system.

The speed could be achieved if enough voltage and enough current loop gain are available. Also,

consider the motor’s feedback adding limitations to achievable speeds. The load attached to the motor

also limits the maximum achievable speed. In addition, some manufacturers will provide motor data with

their drive controller, which is tweaked to extend the operation range that other controllers may be able to

provide. In general, the maximum speed can be determined by input voltage line-to-line divided by Kb

(the motor’s back EMF constant). It is wise to de-rate this a little for proper servo applications.

Torque

The torque required for the application can be viewed as both instantaneous and average. Typically, the

instantaneous or peak torque is calculated as a sum of machining forces or frictional forces plus the forces

required to accelerate the load inertia. The machining or frictional forces on a machine must be

determined by the actual application. The energy required to accelerate the inertia follows the equation: t

= JA, where t is the torque in pound-feet required for the acceleration, J is the inertia in pound-feetsecond squared, and A is in radians per second per second. The required torque can be calculated if the

desired acceleration rate and the load inertia reflected back to the motor are known. The t-JA equation

requires that the motor’s inertia be considered as part of the inertia-requiring torque to accelerate.

Once the torque is determined, the motor’s specification sheet can be reviewed for its torque constant

parameter (Kt). The torque required at the application divided by the Kt of the motor provides the peak

Backplane Board 2

Page 12

3U Servo Amplifier

current required by the amplifier. A little extra room should be given to this parameter to allow for good

servo control.

Most applications have a duty cycle in which the acceleration profile occurs repetitively over time.

Calculating the average value of this profile gives the continuous rating required by the amplifier.

Applications also concern themselves with the ability to achieve a speed. The requirements can be

reviewed by either defining what the input voltage is to the drive, or defining what the voltage

requirements are at the motor. Typically, a system is designed at a 230 or 480V input line. The motor

must be able to achieve the desired speed with this voltage limitation. This can be determined by using

the voltage constant of the motor (Kb), usually specified in volts-per-thousand rpm. The application

speed is divided by 1000 and multiplied by the motor’s Kb. This is the required voltage to drive the

motor to the desired velocity. Headroom of 20% is suggested to allow for good servo control.

Peak Torque

The peak torque rating of a motor is the maximum achievable output torque. It requires that the amplifier

driving it be able to output enough current to achieve this. Many drive systems offer a 3:1 peak-tocontinuous rating on the motor, while the amplifier has a 2:1 rating. To achieve the peak torque, the drive

must be sized to be able to deliver the current to the motor. The required current is often stated on the

datasheet as the peak current through the motor. In some sense, it can also be determined by dividing the

peak amplifier's output rating by the motor’s torque constant (Kt).

Continuous Torque

The continuous torque rating of the motor is defined by a thermal limit. If more torque is consumed from the

motor than this on average, the motor overheats. Again, the continuous torque output of the motor is subject

to the drive amplifier’s ability to deliver that current. The current is determined by the manufacturer’s

datasheets stating the continuous RMS current rating of the motor and can also be determined by using the

motor’s Kt parameter, usually specified in torque output per amp of input current.

Motor Poles

Usually, the number of poles in the motor is not a concern to the actual application. However, it should

be noted that each pole-pair of the motor requires an electrical cycle. High-speed motors with high motor

pole counts can require high fundamental drive frequencies that a drive amplifier may or may not be able

to output. In general, drive manufacturers with PWM switching frequencies (16KHz or below) would

like to see commutation frequencies less than 400 Hz. The commutation frequency is directly related to

the number of poles in the motor.

Motor Inductance

Typically, motor inductance of servomotors is 1 to 15 mH. The Geo drive product series can drive this

range easily. On lower-inductance motors (below 1mH), problems occur due to PWM switching where

heating currents flow through the motor, causing excessive energy waste and heating. If an application

requires a motor of less than 1mH, external inductors are recommended to increase that inductance.

Motors with inductance in excess of 15mH can still be driven, but are slow to react and typically are out

of the range of high performance servomotors.

Motor Resistance

Motor resistance is not really a factor in determining the drive performance, but rather, comes into play

more with the achievable torque or output horsepower from the motor. The basic resistance shows up in

the manufacturer’s motor horsepower curve.

Motor Back EMF

The back EMF of the motor is the voltage that it generates as it rotates. This voltage subtracts from the

bus voltage of the drive and reduces the ability to push current through the motor. Typical back EMF

ratings for servomotors are in the area of 8 to 200 volts-per-thousand rpm. The Geo drive product series

Backplane Board 3

Page 13

3U Servo Amplifier

can drive any range of back EMF motor, but the back EMF is highly related to the other parameters of the

motor such as the motor inductance and the motor Kt. It is the back EMF of the motor that limits the

maximum achievable speed and the maximum horsepower capability of the motor.

Motor Torque Constant

Motor torque constant is referred to as Kt and usually it is specified in torque-per-amp. It is this number

that is most important for motor sizing. When the load that the motor will see and the motor’s torque

constant is known, the drive amplifier requirements can be calculated to effectively size a drive amplifier

for a given motor. Some motor designs allow Kt to be non-linear, in which Kt will actually produce less

torque per unit of current at higher output speeds. It is wise to de-rate the systems torque producing

capability by 20% to allow headroom for servo control.

Motor Inertia

Motor inertial comes into play with motor sizing because torque to accelerate the inertia of the motor is

effectively wasted energy. Low inertia motors allow for quicker acceleration. However, consider the

reflective inertia from the load back to the motor shaft when choosing the motor’s inertial. A high ratio of

load-to-motor inertia can cause limited gains in an application if there is compliance in the transmission

system such as belt-drive systems or rubber-based couplings to the systems. The closer the rotor inertia

matches the load’s reflected inertia to the motor shaft, the higher the achievable gains will be for a given

system. In general, the higher the motor inertia, the more stable the system will be inherently.

Mechanical gearing is often placed between the load and the motor simply to reduce the reflected inertia

back to the motor shaft.

Motor Cabling

Motor cables are an integral part of a motor drive system. Several factors should be considered when

selecting motor cables. First, the PWM frequency of the drive emits electrical noise. Motor cables must

have a good-quality shield around them. The motor frame must also have a separate conductor to bring

back to the drive amplifier to help quench current flows from the motor due to the PWM switching noise.

Both motor drain wire and the cable shield should be tied at both ends to the motor and to the drive

amplifier.

Another consideration in selecting motor cables is the conductor-to-conductor capacitance rating of the

cable. Small capacitance is desirable. Longer runs of motor cable can add motor capacitance loading to

the drive amplifier causing undesired spikes of current. It can also cause couplings of the PWM noise

into the earth grounds, causing excessive noise as well. Typical motor cable ratings would be 50 pf per

foot maximum cable capacitance.

Another factor in picking motor cables is the actual conductor cross-sectional area. This refers to the

conductor’s ability to carry the required current to and from the motor. When calculating the required

cable dimensions, consider agency requirements, safety requirements, maximum temperature that the

cable will be exposed to, the continuous current flow through the motor, and the peak current flow

through the motor. Typically, it is not suggested that any motor cable be less than 14 AWG.

The motor cable’s length must be considered as part of the application. Motor cable length affects the

system in two ways. First, additional length results in additional capacitive loading to the drive. The

drive’s capacitive loading should be kept to no more than 1000 pf. Additionally, the length sets up

standing waves in the cable, which can cause excessive voltage at the motor terminals. Typical motor

cable length runs of 200 feet for 230V systems and 50 feet for 480V systems are acceptable. Exceeding

these lengths may put other system requirements in place for either a snubber at the motor end or a series

inductor at the drive end. The series inductor at the drive end provides capacitance loading isolation from

the drive and slows the rise time of the PWM signal into the cable, resulting in less voltage overshoot at

the motor.

Backplane Board 4

Page 14

3U Servo Amplifier

RECEIVING AND UNPACKING

Delta Tau products are thoroughly tested at the factory and carefully packaged for shipment. When the

3U Geo Direct PWM Drive is received, there are several things to be done immediately:

1. Observe the condition of the shipping container and report any damage immediately to the

commercial carrier that delivered the drive.

2. Remove the control from the shipping container and remove all packing materials. Check all

shipping material for connector kits, documentation, CD ROM, or other small pieces of equipment.

Be aware that some connector kits and other equipment pieces may be quite small and can be

accidentally discarded if care is not used when unpacking the equipment. The container and packing

materials may be retained for future shipment.

3. Verify that the part number of the drive received is the same as the part number listed on the purchase

order.

4. Inspect the drive for external physical damage that may have been sustained during shipment and

report any damage immediately to the commercial carrier that delivered the drive.

5. Electronic components in this amplifier are design-hardened to reduce static sensitivity. However,

use proper procedures when handling the equipment.

6. If the 3U Geo Direct PWM Drive is to be stored for several weeks before use, be sure that it is stored

in a location that conforms to published storage humidity and temperature specifications stated in this

manual.

Use of Equipment

The following restrictions will ensure the proper use of the 3U Geo Direct PWM Drive:

The components built into electrical equipment or machines can be used only as integral components

•

of such equipment.

•

The 3U Geo Direct PWM Drives are to be used only on grounded three-phase industrial mains supply

networks (TN-system, TT-system with grounded neutral point).

•

The 3U Geo Direct PWM Drives must not be operated on power supply networks without a ground or

with an asymmetrical ground.

•

If the 3U Geo Direct PWM Drives are used in residential areas, or in business or commercial

premises, implement additional filter measures.

•

The 3U Geo Direct PWM Drives may be operated only in a closed switchgear cabinet, taking into

account the ambient conditions defined in the environmental specifications.

Delta Tau guarantees the conformance of the 3U Geo Direct PWM Drives with the standards for

industrial areas stated in this manual, only if Delta Tau components (cables, controllers, etc.) are used.

Environmental Specifications

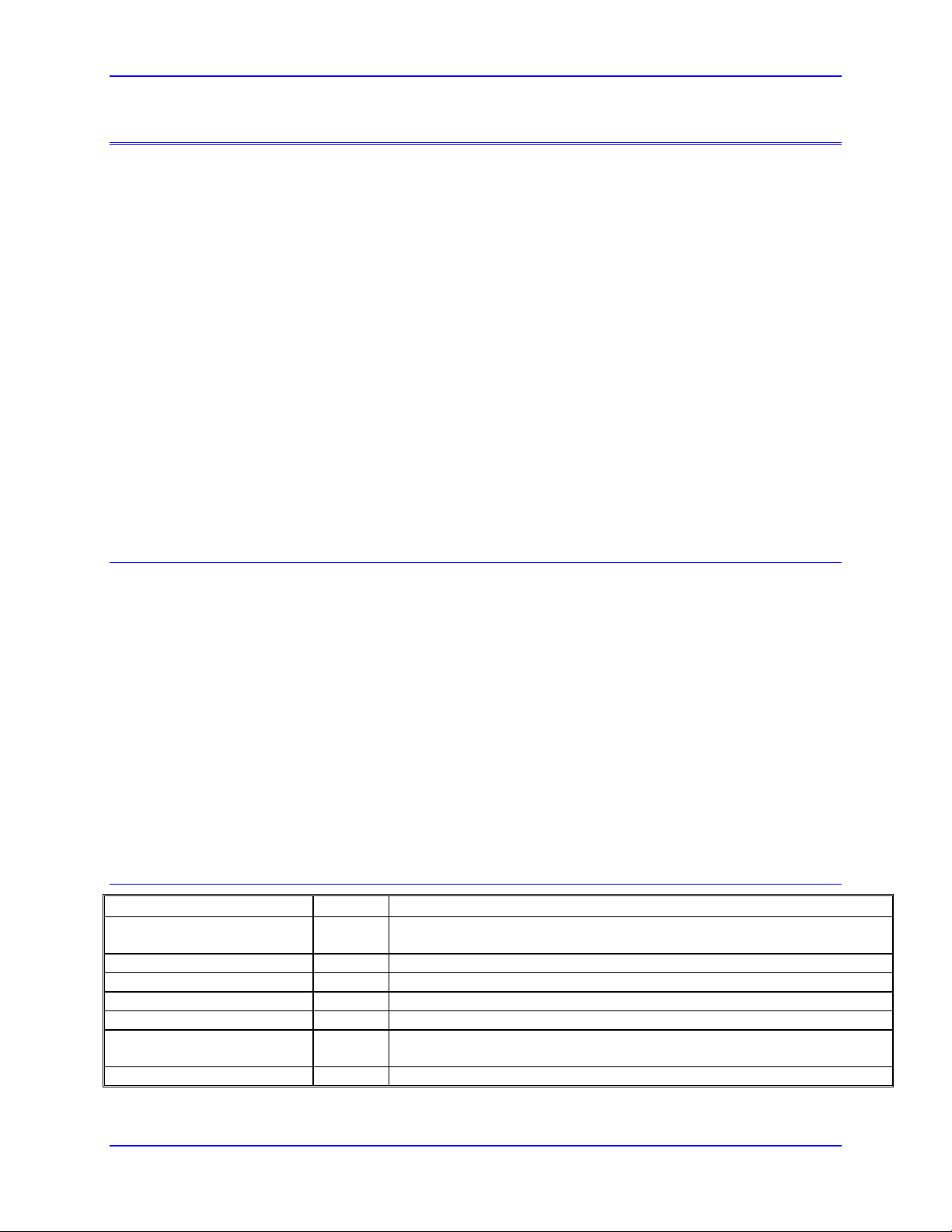

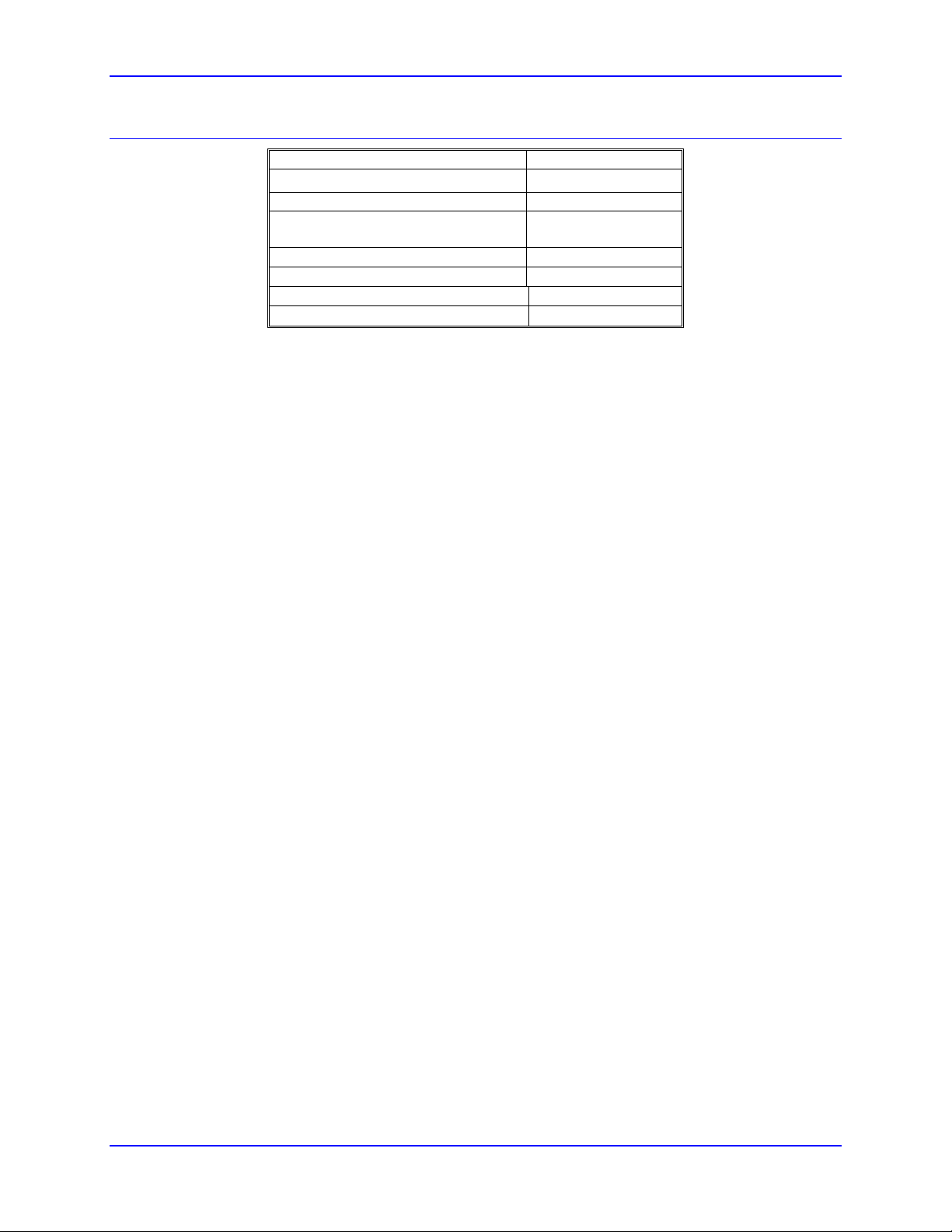

Description Unit Specifications

Operating Temperature °C +0 to 45°C. Above 45°C, derate the continuous peak output current by 2.5%

per °C above 45°C. Maximum Ambient is 55°C

Rated Storage Temperature °C -25 to +70

Humidity % 10% to 90% non-condensing

Shock Call Factory

Vibration Call Factory

Operating Altitude Feet

(Meters)

Air Flow Clearances in (mm) 3" (76.2mm) above and below unit for air flow

To 3300 feet (1000 meters). Derate the continuous and peak output current

by 1.1% for each 330 feet (100meters) above the 3300 feet

Backplane Board 5

Page 15

3U Servo Amplifier

Electrical Specifications

Output Circuits (axes)

Nominal Input Voltage (VAC)

Rated Input Voltage (VAC)

Rated Continuous Input Current (A AC

Rated Input Power (Watts)

Frequency (Hz)

Phase Requirements

Charge Peak Inrush Current (A)

Main Bus Capacitance (µf), backplane

board

Rated Output Voltage (V)

Rated Cont. Output Current per Axis

Peak Output Current (A) for 2 seconds

Rated Output Power per Axis (Watts)

Nominal DC Bus

Over-voltage Trip Level (VDC)

Under-voltage Lockout Level (VDC)

Turn-On Voltage (VDC)

Turn-Off Voltage (VDC)

Maximum Current (A)

Recommended Current (A)

Minimum Resistance (Ohms)

Maximum Power (W)

Recommended Load Resistor (300 W

Max.)

Input Voltage (VDC)

Input Current (A)

Inrush Current (A)

Resolution (bits)

Full-scale Signed Reading (±A)

Maximum PWM Frequency (kHz) @ rated

current

Minimum Dead Time (µs)

Charge Pump Time (% of PWM period.)

Recommended Fusing and Wire Gauge

RMS

)

1Φ or 3Φ

2

230

97-265

5.28

2103

50/60

940

138

4

8

956

325

410

10

392

372

GAR48

20-27

1

2

12

13.01

12

1

5

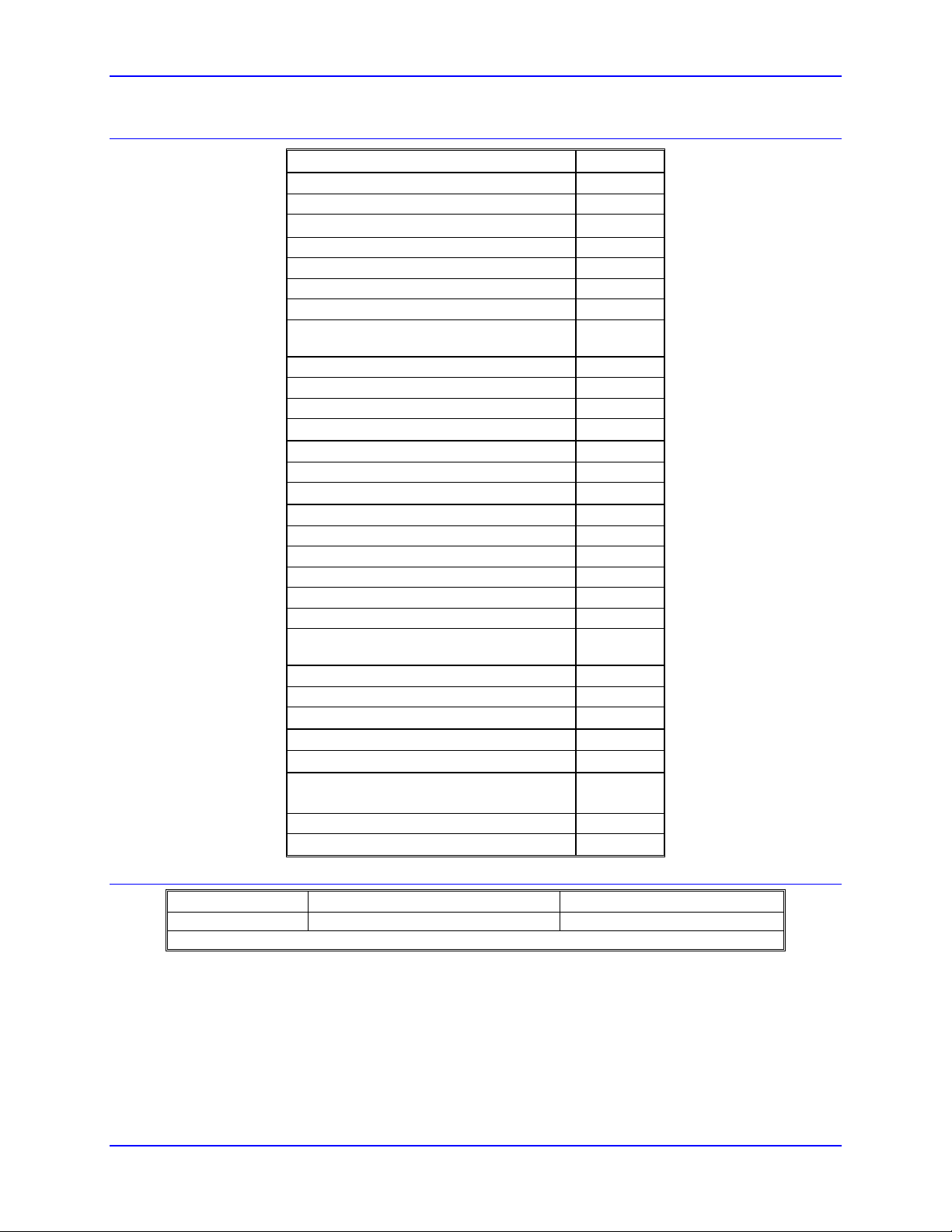

Model Recommended Fuse (FRN/LPN) Recommended Wire Gauge*

3U042 20 12 AWG

* See local and national code requirements

Wire Sizes

3U Geo Direct PWM Drive electronics create a DC bus by rectifying the incoming AC electricity. The

current flow into the drive is not sinusoidal but rather a series of narrow, high-peak pulses. Keep the

incoming impedance small so that these current pulses are not hindered. Conductor size, transformer size,

and fuse size recommendations may seem larger than normally expected. All ground conductors should

be 8AWG minimum using wires constructed of many strands of small gauge wire. This provides the

lowest impedance to high-frequency noises.

Backplane Board 6

Page 16

3U Servo Amplifier

Physical Specifications

L x W x H (inches) 6.30 x 2.40 x 5.08

Width (3U rack slots) 3

Weight: drive only with front panel

(w/o backplane and side panels)

Backplane Width (3U rack slots) 3

Backplane Weight 0.275kgs (0.6lbs)

Terminal Connections Torque to 20 in-lb

3U042

0.9kgs (2.0lbs)

Backplane 3UBP8A

Backplane Board 7

Page 17

3U Servo Amplifier

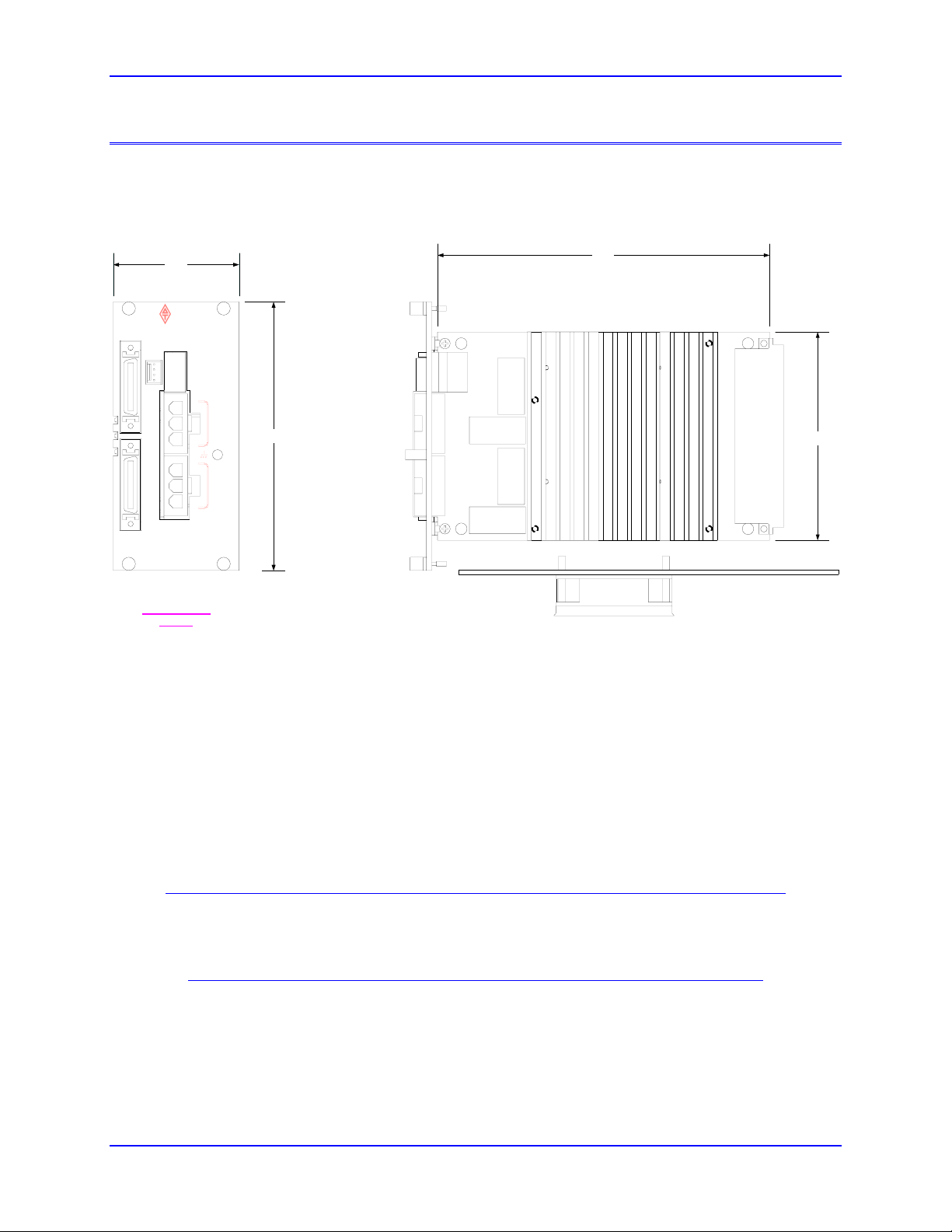

MOUNTING

The 3U Geo Direct PWM drives are designed to be installed in an enclosure whose ambient temperature

does not exceed 55 °C. It must not be exposed to conductive dust or humidity in excess of 90% noncondensing. Corrosive gasses, corrosive dust, and other contaminants must be kept out of the drive

enclosure.

2.39

DELTA

TAU

2-AXIS PWM AMPLIFIER

230 VAC INPUT -4A rms CONT/8A rms PEAK

MOTOR

O.T .

AMPLIFIER

STATUS

PWM

INPUT

1

ENA 1

ENA 2

PWR

PWM

INPUT

2

U

V

W

U

V

W

M

O

T

O

R

1

M

O

T

O

R

2

5.08

6.30

3.94

MODEL 3U42

FACEPLATE

3 SLOT

The drive rack is mounted to a back panel. The back panel should be unpainted and electrically

conductive to allow for reduced electrical noise interference. The back panel is machined to accept the

mounting bolt pattern of the drive. Make sure that all metal chips are cleaned up before the drive is

mounted so there is no risk of getting metal chips inside the drive.

The 3U rack is mounted to the back panel through 4 x 0275”x0.400” obround, user needs to provide

screws and internal-tooth lock washers to attach at the cabinet. It is important that the teeth break through

any anodization on the drive's mounting gears to provide a good electrically conductive path in as many

places as possible. Mount the 3U rack on the back panel so there is airflow (at least three inches) at both

the top and bottom areas of the drive.

If multiple 3U Geo drives are used, they can be mounted side-by-side, leaving at least one-tenth of an

inch clearance between drives in the 3U rack. It is extremely important that the airflow is not obstructed

by the placement of conduit tracks or other devices in the enclosure.

Caution:

Units must be installed in an enclosure that meets the environmental IP rating of

the end product (ventilation or cooling may be necessary to prevent enclosure

ambient from exceeding 113° F [45° C]).

Backplane Board 8

Page 18

3U Servo Amplifier

SYSTEM WIRING

MAIN

POWER

BLK

BLK

+24 V

RED

24 V RET

GARxx

SHUNT

RESISTOR

EARTH

FRAME

BLK

WHT

WHT

Twisted Wires

Twisted Wires

3U042 Geo Direct PWM drive

Motor #1

UW

BLK

V

BLU

WHT

UW

Mo tor # 2

V

300- 603730 -10 x

AC INPUT

FAN

GND

24V

TB2

EART H

GRN \YEL

BLK

BLU

WHT

3UBP8A

Backpla ne

J3

BLK

RED

SCREW HEAD

TB1

L3

L2

L1

J2

GND

+24V

SHUNT

SHUNT RTN

Motor#1

Motor#2

Optiona l

EMI FI LTER

EARTH

BLOCK

MCR

24V

POWER

SUPPLY

Fusing

WARNING:

Installation of electrical control equipment is subject to many regulations including

national, state, local, and industry guidelines and rules. General recommendations

can be stated but it is important that the installation be carried out in accordance

with all regulations pertaining to the installation.

Fuse and Circuit Breaker Selection

In general, fusing must be designed to protect the weakest link from fire hazard. Each Geo drive is designed

to accept more than the recommended fuse ratings. External wiring to the drive may be the weakest link as

the routing is less controlled than the drive’s internal electronics. Therefore, external circuit protection, be it

fuses or circuit breakers, must be designed to protect the lesser of the drive or external wiring.

High peak currents and high inrush currents demand the use of slow blow type fuses and hamper the use

of circuit breakers with magnetic trip mechanisms. Generally, fuses are recommended to be larger than

what the rms current ratings require. Remember that some drives allow three times the continuous rated

current on up to two axis of motion. Time delay and overload rating of protection devices must consider

this operation.

Use of GFI Breakers

Ground Fault Interrupter circuit breakers are designed to break the power circuit in the event that

outgoing currents are not accompanied by equal and opposite returning currents. These breakers assume

that if outgoing currents are not returning then there is a ground path in the load. Most circuit breakers of

this type account for currents as low as 10mA PWM switching in servo drives coupled with parasitic

capacitance to ground in motor windings and long cables generate ground leakage current. Careful

installation practices must be followed. The use of inductor chokes in the output of the drive will help

keep these leakage currents below breaker threshold levels.

Transformer and Filter Sizing

Incoming power design considerations for use with Geo Drives require some over rating. In general, it is

recommended that all 3-phase systems using transformers and incoming filter chokes be allotted a 25%

Backplane Board 9

Page 19

3U Servo Amplifier

over size to keep the impedances of these inserted devices from affecting stated system performance. In

general, it is recommended that all single-phase systems up to 1kW be designed for a 50% overload. All

single-phase systems over 1kW should be designed for a 200% overload capacity.

Noise Problems

When problems do occur often it points to electrical noise as the source of the problem. When this

occurs, turn to controlling high-frequency current paths. If following the grounding instructions does not

work, insert chokes in the motor phases. These chokes can be as simple as several wraps of the individual

motor leads through a ferrite ring core (such as Micrometals T400-26D). This adds high-frequency

impedance to the outgoing motor cable thereby making it harder for high-frequency noise to leave the

control cabinet area. Care should be taken to be certain that the core’s temperature is in a reasonable

range after installing such devices.

Operating Temperature

It is important that the ambient operating temperature of the 3U Geo Direct PWM drive must be kept

within specifications. The 3U Geo Direct PWM drive should be installed in an enclosure such as a

NEMA spec. cabinet. The internal temperature of the cabinet must be kept under the Geo Drive Ambient

Temperature specifications. It is sometimes desirable to roughly calculate the heat generated by the

devices in the cabinet to determine if some type of ventilation or air conditioning is required. For these

calculations the 3U Geo Direct PWM drive’s internal heat losses must be known. Budget 100W per axis

for 1.5A drives, 150W per axis for 3A drives, 200W per axis for 5A drives, 375W per axis for 10A

drives, 500W per axis for 15A drives, and 650W per axis for 20A drives (A are for continuous rating).

From 0°C to 45°C ambient no de-rating required. Above 45°C, de-rate the continuous and peak output

current by 2.5% per °C above 45°C. Maximum ambient is 55°C.

Backplane Board 10

Page 20

3U Servo Amplifier

Amplifier Cooling Considerations

The drive amplifiers produce heat that must be removed. The installation requires that a fan blows air up

through the vertical fins of the product’s heat sink. The 3U Geo Direct PWM drive systems include the

metal plates that go around the unit as part of the rack’s metal panel work and a 24VDC (2.6W) fan. The

fan must be positioned at the bottom side of the drive unit and attached to the fan connector, J3 for

3U042, on the backplane for power.

Caution:

Do not operate the amplifier without an operational fan.

Do not impede airflow through the unit.

Single Phase Operation

Due to the nature of power transfer physics, it is not recommended that any system design attempt to

consume more than 2kW from any single-phase mains supply. Even this level requires careful

considerations. The simple bridge rectifier front end of the Geo Drive, as with all other drives of this

type, require high peak currents. Attempting to transfer power from a single-phase system getting one

charging pulse each 8.3 milliseconds causes excessively high peak currents that can be limited by power

mains impedances. The 3U Geo Direct PWM Drive output voltage sags, the input rectifiers are stressed,

and these current pulses cause power quality problems in other equipment connected to the same line.

While it is possible to operate drives on single-phase power, the actual power delivered to the motor must

be considered. Never design expecting more than 1.5 HP total from any 115V single-phase system and

never more than 2.5 HP from any 230V single-phase system.

Check the table below on how to calculate how to derate at single phase.

110VAC single phase 230VAC single phase

3U042 10% Not needed

Note: Output Wattage derrates @ single phase.

Power Supply Considerations

The 3U Geo Direct PWM Amplifiers require an external mains connection to the barrier block on the

back side of the backplane to create the motor bus power. This connection can be single phase or threephase AC power at 115 or 230Vac. A single-phase system cannot provide more than 1500-2000 watts.

The form factor of the current becomes exaggerated perhaps allowing the internal rectifier bridge to be

damaged and electrical noise to interfere with other electronic equipment. These connections must be

fused with slow blow (i.e., FRN) fuses. Recommended fusing is 20A for the 3U042.

The logic power for the amplifier is derived from a separate external 24VDC @1A power supply. The

3U Drives have internal DC-to-DC converters that isolate the drive from this power supply and create all

the internally required logic voltages. Startup current from this power external power supply is isolated

with a soft start circuit

A Protective Earth Ground must be connected to the backplane (3UBP8A) and to the 3U rack itself. The

ground should be a low impedance path directly returning to the main earth distribution block within the

machine enclosure.

Wiring AC Input

The main bus voltage supply is brought to the Geo drive through connector TB1 on the backplane board.

If single phase is used, derrating needs to be calculated. It is acceptable to bring the single-phase power

into any two of the three input pins on connector TB1. Higher-power drive amplifiers require three-phase

input power. It is extremely important to provide fuse protection or overload protection to the input

power to the Geo drive amplifier. Typically, this is provided with fuses designed to be slow acting, such

Backplane Board 11

Page 21

3U Servo Amplifier

as FRN-type fuses. Due to the various regulations of local codes, NEC codes, UL and CE requirements,

it is very important to reference these requirements before making a determination of how the input power

is wired.

Additionally, many systems require that the power be able to be turned on and off in the cabinet. It is

typical that the AC power is run through some kind of main control contact within the cabinet, through

the fuses, and then fed to a Geo drive. If multiple Geo drives are used, it is important that each drive has

its own separate fuse block.

Whether single- or three-phase, it is important that the AC input wires be twisted together to eliminate

noise radiation as much as possible. Additionally, some applications may have further agency noise

reduction requirements that require that these lines be fed from an input filtering network.

The AC connections from the fuse block to the Geo drive are made via a cable that is connected at the

backplane with screw terminals.

TB1: AC Input Connector Pin-out on the backplane

Pin # Symbol Function Description Notes

1 L1 Input Line Input Phase 1 Not used for single phase input

2 L2 Input Line Input Phase 2

3 L3 Input Line Input Phase 3

3UBP8A, 300-603730-10x

If DC bus is used, use L3 for DC+ and L2 for DC return

Wiring Earth-Ground

Panel wiring requires that a central earth-ground location be installed at one part of the panel. This

electrical ground connection allows for each device within the enclosure to have a separate wire brought

back to the central wire location. Usually, the ground connection is a copper plate directly bonded to the

back panel or a copper strip with multiple screw locations. The Geo drive is brought to the earth-ground

via a wire connected to the stud on the front panel through a heavy gauge, multi-strand conductor to the

central earth-ground location.

Earth Grounding Paths

High-frequency noises from the PWM controlled power stage will find a path back to the drive. It is best

that the path for the high-frequency noises be controlled by careful installation practices. The major

failure in problematic installations is the failure to recognize that wire conductors have impedances at

high frequencies. What reads 0 ohms on a DVM may be hundreds of ohms at 30MHz. Consider the

following during installation planning:

1. Star point all ground connections. Each device wired to earth ground should have its own conductor

brought directly back to the central earth ground plate.

2. Use unpainted back panels. This allows a wide area of contact for all metallic surfaces reducing high

frequency impedances.

3. Conductors made up of many strands of fine conducts outperform solid or conductors with few

strands at high frequencies.

4. Motor cable shields should be bounded to the back panel using 360-degree clamps at the point they

enter or exit the panel.

5. Motor shields are best grounded at both ends of the cable. Again, connectors using 360-degree shield

clamps are superior to connector designs transporting the shield through a single pin. Always use

metal shells.

6. Running motor armature cables with any other cable in a tray or conduit should be avoided. These

cables can radiate high frequency noise and couple into other circuits.

Backplane Board 12

Page 22

3U Servo Amplifier

Wiring 24 V Logic Control

An external 24VDC power supply is required to power the logic portion of the 3U Geo Direct PWM

drive. This power can remain on, regardless of the main AC input power, allowing the signal electronics

to be active while the main motor power control is inactive. The 24V is wired into connector J2 at the

3UBP8A backplane. The polarity of this connection is extremely important. Carefully follow the

instructions in the wiring diagram. This connection can be made using 16 AWG wire directly from a

protected power supply. In situations where the power supply is shared with other devices, it may be

desirable to insert a filter in this connection.

The power supply providing this 24V must be capable of providing an instantaneous current of at least

0.8A to be able to start the DC-to-DC converter in the 3U Geo Direct PWM drive. In the case where

multiple drives are driven from the same 24V supply, it is recommended that each drive be wired back to

the power supply terminals independently. It is also recommended that the power supply be sized to

handle the instantaneous inrush current required to start up the DC-to-DC converter in the Geo drive.

J2: 24VDC Input Logic Supply Connector

Pin # Symbol Function Description Notes

1 +24VDC Input Control power input 24V+/-10% @ 1A

2 RET Common Control power return

Connector is located at the backplane

3UBP8A, 300-603730-10x

Regen (Shunt) Resistor Wiring

The regen circuit is also known as a shunt regulator. Its purpose is to dump power fed back into the drive

from a motor acting as a generator. Excessive energy can be dumped via an external load resistor. The

Geo product series is designed for operation with external shunt resistors of 48 Ω for the 10A, 15A and

20A.These are available directly from Delta Tau as GAR48 and GAR78, respectively. These resistors are

provided with pre-terminated cables that plug into the connector at the backplane.

Caution:

The black wires are for the thermostat and the white wires are for the regen resistor

on the external regen resistor (pictured in Appendix). These resistors can get very

hot. It is recommended that they be mounted away from other devices and near the

top of the cabinet.

The regen resistors incorporate a thermal overload protection device available through the two black leads

exiting the resistor. It is important that these two leads be wired in a safety circuit that stops the system

from operating should the thermostat open.

TB2: Regen Resistor Connector

Pin # Symbol Function Description

1 SHUNT RTN Output Regen Resistor output

2 SHUNT Output

Connector is located at the backplane

Regen Resistor Return

3UBP8A, 300-603730-10x

Backplane Board 13

Page 23

3U Servo Amplifier

Shunt Regulation

When the motor is used to slow the moving load, this is called regenerative deceleration. Under this

operation, the motor is acting as a generator consuming energy from the load while passing the energy

into the DC Bus storage capacitors. Left unchecked, the DC Bus voltage can raise high enough to

damage the drive. For this reason there are protection mechanisms built into the Geo Drive product such

as shunt regulation and over-voltage protection.

The shunt regulator monitors the DC Bus voltage. If this voltage rises above a present threshold (Regen

Turn On Voltage), the Geo Drive will turn on a power device intended to place the externally mounted

regen resistor across the bus to dump the excessive energy. The power device keeps the regen resistor

connected across the bus until the bus voltage is sensed to be below the Regen Turn Off voltage at which

time the power device removes the resistor connection.

Minimum Resistance Value

The regen resistor selection requires that the resistance value of the selected resistor will not allow more

current to flow through the Geo Drive’s power device than specified.

Maximum Resistance Value

The maximum resistor value that will be acceptable in an application is one that will not let the bus

voltage reach the drive’s stated over voltage specification during the deceleration ramp time. The

following equations defining energy transfer can be used to determine the maximum resistance value.

Energy Transfer Equations

Regen, or shunt, regulation analysis requires study of the energy transferred during the deceleration

profile. The basic philosophy can be described as follows:

The motor and load have stored kinetic energy while in motion. •

•

The drive removes this energy during deceleration by transferring to the DC bus.

•

There are losses during this transfer, both mechanical and electrical, which can be significant in some

systems.

•

The DC bus capacitors can store some energy.

•

The remaining energy, if any, is transferred to the regen resistor.

Kinetic Energy

The first step is to ascertain the amount of kinetic energy in the moving system, both the motor rotor and

the load it is driving. In metric (SI) units, the kinetic energy of a rotating mass is:

1

2

K

2

(kg-m2)

J

2

Eω=

where:

is the kinetic energy in joules, or watt-seconds (J, W-s)

E

K

J is the rotary moment of inertia in kilogram-meter

ω is the angular velocity of the inertia in radians per second (1/s)

If the values are not in these units, first convert them. For example, if the speed is in revolutions per

minute (rpm), multiply this value by 2π/60 to convert to radians per second.

When English mechanical units are used, there are additional conversion factors must be included to get

the energy result to come out in joules. For example, if the rotary moment of inertia J is expressed in lb-

2

, the following equation should be used:

ft-sec

2

E

=

K

If the rotary moment of inertia J is expressed in lb-in-sec

E

=

K

Backplane Board 14

J678.0

ω

2

, the following equation should be used:

2

J0565.0

ω

Page 24

3U Servo Amplifier

ω

=

In standard metric (SI) units, the kinetic energy of a linearly moving mass is:

1

E =

K

2

mv

2

where:

is the kinetic energy in joules (J)

E

K

m is the mass in kilograms (kg)

v is the linear velocity of the mass in meters/second (m/s)

Here also, to get energy in Joules from English mechanical units, additional conversion factors are

required. To calculate the kinetic energy of a mass having a weight of W pounds, the following equation

can be used:

E ==

K

W

678.0

2

v

g

2

Wv0211.0

where:

E

is the kinetic energy in joules (J)

K

W is the weight of the moving mass in pounds (lb)

g is the acceleration of gravity (32.2 ft/sec

2

)

v is the linear velocity of the mass in feet per second (ft/sec)

Energy Lost in Transformation

Some energy will be lost in the transformation from mechanical kinetic energy to electrical energy. The

losses will be both mechanical due to friction and electrical due to resistance. In most cases, these losses

will comprise a small percentage of the transformed energy and can be safely ignored especially because

ignoring losses leads to a conservative design. However, if the losses are significant and the system

should not be over-designed, calculate these losses.

In metric (SI) units, the mechanical energy lost due to Coulomb (dry) friction in a constant deceleration to

stop of a rotary system can be expressed as:

E

LM

t

T

d

f

2

1

ω

=

where:

ELM is the lost energy in joules (J)

T

is the resistive torque due to Coulomb friction in newton-meters (N-m)

f

ω is the starting angular velocity of the inertia in radians per second (1/s)

td is the deceleration time in seconds (s)

If the frictional torque is expressed in the common English unit of pound-feet (lb-ft), the comparable

expression is:

E

LM

T678.0

d

f

t

In metric (SI) units, the mechanical energy lost due to Coulomb (dry) friction in a constant deceleration to

stop of a linear system can be expressed as:

E =

LM

1

F

2

dvtf

where:

is the lost energy in joules (J)

E

LM

T

is the resistive force due to Coulomb friction in newtons (N)

f

v is the starting linear velocity in meters/second (m/s)

td is the deceleration time in seconds (s)

If the frictional force is expressed in the English unit of pounds (lb) and the velocity in feet per second

(ft/sec), the comparable expression is:

Backplane Board 15

Page 25

3U Servo Amplifier

=

(

−−−

=

E

LM

F678.0

dvtf

The electrical resistive losses in a 3-phase motor in a constant deceleration to stop can be calculated as:

E =

LE

2

i

rms

2

t

R

pp

d

3

where:

is the lost energy in joules (J)

E

LE

i

is the current required for the deceleration in amperes (A), equal to the required deceleration torque

rms

divided by the motor’s (rms) torque constant K

R

is the phase-to-phase resistance of the motor, in ohms (Ω)

pp

t

is the deceleration time in seconds (s)

d

T

Capacitive Stored Energy in the Drive

The energy not lost during the transformation is initially stored as additional capacitive energy due to the

increased DC bus voltage. The energy storage capability of the drive can be expressed as:

E −=

C

1

2

VC

regen

2

V

2

nom

)

where:

is the additional energy storage capacity in joules (J)

E

C

C is the total bus capacitance in Farads

V

is the DC bus voltage at which the regeneration circuit would have to activate, in volts (V)

regen

V

is the normal DC bus voltage, in volts (V)

nom

Evaluating the Need for a Regen Resistor

Any starting kinetic energy that is not lost in the transformation and cannot be stored as bus capacitive

energy must be dumped by the regeneration circuitry in to the regen (shunt) resistor. The following

equation can be used to determine whether this will be required:

LE

E

C

If E

LM

E

E

E

excess

in this equation is greater than 0, a regen resistor will be required.

excess

E

K

Regen Resistor Power Capacity

A given regen resistor will have both a peak (instantaneous) and a continuous (average) power dissipation

limit. It is therefore necessary to compare the required peak and continuous regen power dissipation

requirements against the limits for the resistor.

The peak power dissipation that will occur in the regen resistor in the application will be:

2

V

peak

regen

R

100

timeon%

P =

peak

where:

P

is peak power dissipation in watts (W)

peak

V

is the DC bus voltage at which the regeneration circuit activates, in volts (V)

regen

R is the resistance value of the regen resistor, in ohms (Ω)

However, this power dissipation will not be occurring all of the time, and in most applications, only for a

small percentage of the time. Usually, the regen will only be active during the final part of a lengthy

deceleration, after the DC bus has charged up to the point where it exceeds the regen activation voltage.

The average power dissipation value can be calculated as:

avg

P

P−=

where:

P

is average power dissipation in watts (W)

avg

Backplane Board 16

Page 26

3U Servo Amplifier

%on-time is the percentage of time the regen circuit is active

Note:

The Turn On voltage for the shunt circuitry for all Geo drives is 388.5V. There is

a Hysteresis of 20V, so if the regen turns on @ 388.5V it will not turn off until it

drops to 367.5V.

Backplane Board 17

Page 27

3U Servo Amplifier

Bonding

The proper bonding of shielded cables is imperative for minimizing noise emissions and increasing immunity

levels. The bonding effect is to reduce the impedance between the cable shield and the back panel.

Power input wiring does not require shielding (screening) if the power is fed to the enclosure via metal

conduit. If metal conduit is not used in the system, shielded cable is required on the power input wires

along with proper bonding techniques.

Filtering

CE Filtering

Apply proper bonding and grounding techniques, described earlier in this section, when incorporating

EMC noise filtering components to meet this standard.

Noise currents often occur in two ways. The first is conducted emissions passed through ground loops.

The quality of the system-grounding scheme inversely determines the noise amplitudes in the lines.

These conducted emissions are of a common-mode nature from line-to-neutral (ground). The second is

radiated high-frequency emissions that usually are capacitively coupled from line-to-line and are

differential in nature.

When mounting the filters, make sure the enclosure has an unpainted metallic surface. This allows more

surface area to be in contact with the filter housing and provides a lower impedance path between the

housing and the back plane. The back panel should have a high frequency ground strap connection to the

enclosure frame and earth ground.

Input Power Filtering

Caution:

To avoid electric shock, do not touch filters for at least 10 seconds after removing the

power supply.

The Geo Drive electronic system components require EMI filtering in the input power leads to meet the

conducted emission requirements for the industrial environment. This filtering blocks conducted-type

emissions from exiting onto the power lines and provides a barrier for power line EMI.

Adequately size the system. The type of filter must be based on the voltage and current rating of the

system and whether the incoming line is single or three-phase. One input line filter may be used for

multi-axis control applications. These filters should be mounted as close to the incoming power as

possible so noise is not capacitively coupled into other signal leads and cables. Implement the EMI filter

according to the following guidelines:

Mount the filter as close as possible to the incoming cabinet power. •

•

When mounting the filter to the panel, remove any paint or material covering. Use an unpainted

metallic back panel.

•

Filters are provided with a ground connection. All ground connections should be tied to ground.

•

Filters can produce high leakage currents; they must be grounded before connecting the supply.

•

Do not touch filters for a period of ten seconds after removing the power supply.

Motor Line Filtering

Motor filtering may not be necessary for CE compliance of Geo Drives. However, this additional

filtering increases the reliability of the system. Poor non-metallic enclosure surfaces and lengthy,

unbonded (or unshielded) motor cables that couple noise line-to-line (differential) are some of the factors

that may lead to the necessity of motor lead filtering.

Backplane Board 18

Page 28

3U Servo Amplifier

Motor lead noise is either common-mode or differential. The common-mode conducted currents occur

between each motor lead and ground (line-to-neutral). Differential radiated currents exist from one motor

lead to another (line-to-line). The filtering of the lines feeding the motor provides additional attenuation

of noise currents that may enter surrounding cables and equipment I/O ports in close proximity.

Differential mode currents commonly occur with lengthy motor cables. As the cable length increases, so

does its capacitance and ability to couple noise from line-to-line. While every final system is different

and every application of the product causes a slightly different emission profile, it may become necessary

to use differential mode chokes to provide additional noise attenuation to minimize the radiated

emissions. The use of a ferrite core placed at the Geo Drive end on each motor lead attenuates differential

mode noise and lowers frequency (30 to 60 MHz) broadband emissions to within specifications. Delta

Tau recommends a Fair-Rite P/N 263665702 (or equivalent) ferrite core.

Common mode currents occur from noise spikes created by the PWM switching frequency of the Geo

Drive. The use of a ferrite or iron-powder core toroid places common mode impedance in the line

between the motor and the Geo Drive. The use of a common mode choke on the motor leads may

increase signal integrity of encoder outputs and associated I/O signals.

Backplane Board 19

Page 29

3U Servo Amplifier

Backplane Board 20

Page 30

3U Servo Amplifier

3U DRIVE CONNECTIONS

PWM Input Connector

Axis #1 PWM input connector

P1 (36-pin Mini-D Connector)

Pin # Symbol Function Description Notes

1 FC0 Feedback 1 of 4 fault code bits

2 FC2 Feedback 1 of 4 fault code bits

3 ADC_CLK1+ Command A/D converter clock

4 ADC_STB1+ Command A/D converter strobe

5 CURRENTA+ Feedback Phase A actual current data Serial digital

6 CURRENTB+ Feedback Phase B actual current data Serial digital

7 AENA1+ Command Amplifier enable High is enable

8 FAULT1+ Feedback Amplifier fault High is fault

9 PWMATOP1+ Command Phase A top Cmd High is on command

10 PWMABOT1+ Command Phase A bottom Cmd High is on command

11 PWMBTOP1+ Command Phase B top Cmd High is on command

12 PWMBBOT1+ Command Phase B bottom Cmd High is on command

13 PWMCTOP1+ Command Phase C top Cmd High is on command

14 PWMCBOT1+ Command Phase C bottom Cmd High is on command

15 GND Common Reference voltage

16 +5V Power +5v power From controller

17 Reserved

18 Reserved

19 FC1 Feedback 1 of 4 fault code bits

20 FC3 Feedback 1 of 4 fault code bits

21 ADC_CLK1- Command A/D converter clock

22 ADC_STB1- Command A/D converter strobe

23 CURRENTA- Feedback Phase A actual current data Serial digital

CURRENTB- Feedback Phase B actual current data Serial digital

24

25 AENA1- Command Amplifier enable Low is enable

26 FAULT1- Feedback Amplifier fault Low is fault

27 PWMATOP1- Command Phase A top Cmd Low is on command

28 PWMABOT1- Command Phase A bottom Cmd Low is on command

29 PWMBTOP1- Command Phase B top Cmd Low is on command

30 PWMBBOT1- Command Phase B bottom Cmd Low is on command

31 PWMCTOP1- Command Phase C top Cmd Low is on command

32 PWMCBOT1- Command Phase C bottom Cmd Low is on command

33 GND Common Reference voltage

34 +5V Power +5v power From controller

35 Reserved

36 Reserved

A Mini-D 36-pin connector for first digital amplifier command outputs and current feedbacks. This

connector provides the interface to a fully digital amplifier for the first channel.

Note that current feedback data must be in serial digital form, already converted from analog in the

amplifier.

For Cables see Appendix A

Backplane Board 21

Page 31

3U Servo Amplifier

Axis #2 PWM Input connector

P2 (36-pin Mini-D Connector)

Pin # Symbol Function Description Notes

1 FC0 Feedback 1 of 4 fault code bits

2 FC2 Feedback 1 of 4 fault code bits

3 ADC_CLK2+ Command A/D converter clock

4 ADC_STB2+ Command A/D converter strobe

5 CURRENTA+ Feedback Phase A actual current data Serial digital

6 CURRENTB+ Feedback Phase B actual current data Serial digital

7 AENA2+ Command Amplifier enable High is enable

8 FAULT2+ Feedback Amplifier fault High is fault

9 PWMATOP2+ Command Phase A top Cmd High is on command

10 PWMABOT2+ Command Phase A bottom Cmd High is on command

11 PWMBTOP2+ Command Phase B top Cmd High is on command

12 PWMBBOT2+ Command Phase B bottom Cmd High is on command

13 PWMCTOP2+ Command Phase C top Cmd High is on command

14 PWMCBOT2+ Command Phase C bottom Cmd High is on command

15 GND Common Reference voltage

16 +5V Power +5v power From controller

17 Reserved

18 Reserved