Page 1

DO 9704

INSTRUCTIONS MANUAL

Page 2

1

20

2

3

4

6

5

7

8

9

10

11

12

13

14

15

16

17

18

19

22

21

23

24

25

26

27

28

29

30

31

32

33

34

35

36

DO 9704

Page 3

67

DO 9704

PRESSURE AND TEMPERATURE - DATA-LOGGER

ENGLISH

Page 4

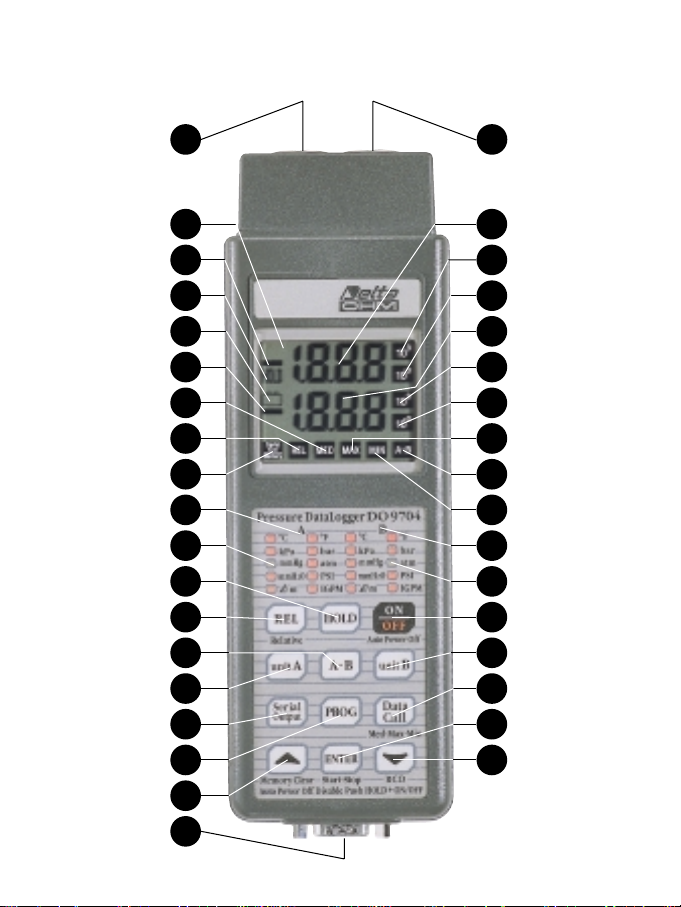

1 Input A, DIN 8-pole connector for pressure, flow rate or temperature.

2 Display.

3 Negative symbol input A.

4 HOLD symbol.

5Hsymbol: flashes during RECORD function, permanently lit if the battery is running low.

6 Negative symbol input B.

7 The display shows the Mean values.

8 REL symbol, indicates that the instrument is making a relative measurement.

9 Memory/Serial Out. Fixed symbol: the instrument is storing. Flashing symbol: serial output is

enabled.

10 Measurement units that may be selected at input A.

11 Measurement unit selected at input A.

12 HOLD key for blocking the reading.

13 REL key, the value shown is related to the indication at the moment in which the REL key was

pressed.

14 A-B key. The instrument displays the difference between the inputs.

15 Unit A: Key for selecting the measurement unit for input A.

16 Serial Output: enables unloading of data at the RS 232C serial output.

17 Prog: this key is pressed to enter the routine for programming the various functions of the

instrument.

18skey. When enabled, this key increases the displayed parameter.

19 Output for RS 232C (SUB D male 9-pole).

20 Input B, DIN 8-pole connector for pressure, flow rate or temperature.

21 Input A indication.

22 Multiplication channel for channel A 10

3

.

23 Multiplication channel for channel A 10

–3

.

24 Input B indication.

25 Multiplication channel for channel B 10

3

.

26 Multiplication channel for channel B 10

–3

.

27 The display shows the Maximum values.

28 The display shows the difference in value between inputs A or B.

29 The display shows the Minimum values.

30 Measurement units that may be selected at input B.

31 Measurement unit selected at input B.

32 Key for switching the instrument on and off.

33 Unit B. Key for selecting the measurement unit for input B.

34 When pressed in sequence, the display indicates the Maximum peak value, the Minimum value

and the Mean value.

35 The key has various functions: it starts and stops storage, confirms the set parameters.

36tkey. When enabled, this key decreases the displayed values, starts and stops the RECORD

function.

ENGLISH

68

Page 5

INTRODUCTION

The DELTA OHM DO 9704 pressure gauge and data logger has been designed for detecting pres-

sure, flow rate and temperature, physical values which are very important in industrial and chemical

processes.

The instrument has two inputs, A and B, and automatically recognises the probes connected,

whether they be pressure or temperature probes or turbines for measuring flow rate, and displays

the difference between the two inputs.

As the probes are interchangeable, it is possible to choose the most suitable combination for all

applications without having to recalibrate the instrument. The operating principle of the pressure

sensor is based on the bending of a membrane in a watertight chamber in contact with the flow of

which you want to measure the pressure. The flow may be liquid or gas. The flow rate measurement is based on the number of impulses or the frequency of a small fan.

The DO 9704 is able to measure differential or relative pressure for air or non corrosive gases,

absolute and relative pressure for measurements in contact with liquids or gases, in 6 different

measurement units; temperature (in °C or °F); flow rate in the range for 2 to 2000 litres/minute with

a turbine in the measurement units LPM (litres per minute) or IGPM (Imperial Gallons per Minute).

The instrument’s Data Logger function enables it to store up to 30,000 readings. The sampling

period is variable from 1 second to 12 hours.

The data acquired may later be transferred to a Personal Computer or a printer by means of the

opto-insulated serial line RS 232C. For each value stored the date and time of acquisition are indicated; each acquisition block is ended with a report which provides the maximum (peak), minimum

and mean values

With the Serial Output function it is possible to obtain the instantaneous values measured by the

instrument at the output of the serial line RS 232C, in order to send them to a printer or a computer.

Other functions such as HOLD (which blocks the display), REL (for taking relative measurements)

and RECORD (for storing the maximum, minimum and mean values) further enrich the instrument’s

performance.

Thanks to its versatility and to its storage capacity, the instrument is particularly suitable for pressure measurements in hydraulics, fluidodynamics, in chemical plants and process controls, in pumping plants; it is also useful in particular sectors such as moulding and presses for plastics and

thermosetting materials, chimney draught, compressors; it may also be used for flow rate and level

measurements.

ENGLISH

69

Page 6

ENGLISH

70

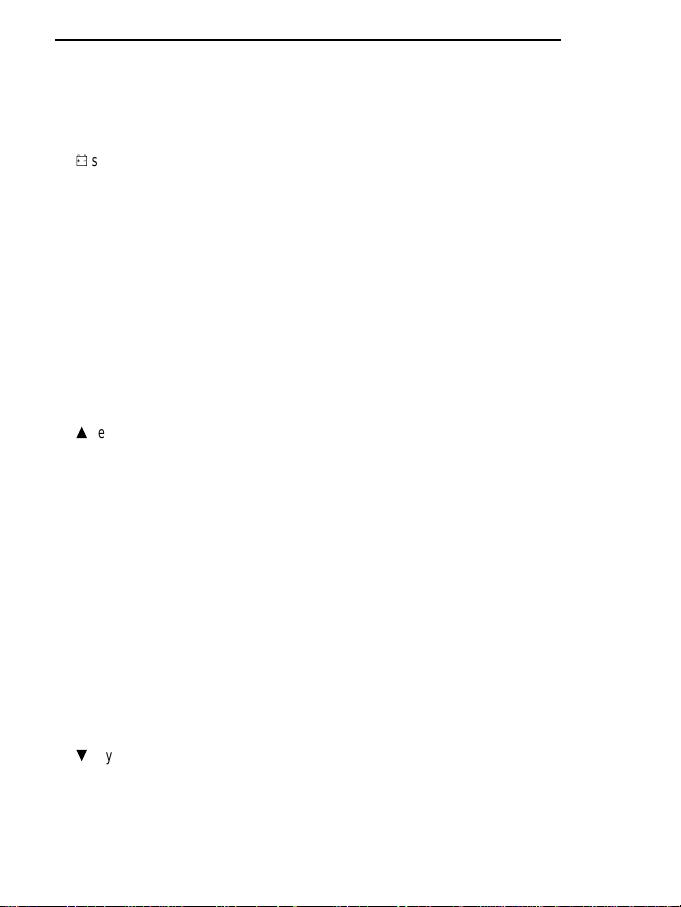

ON/OFF

HOLD + ON/OFF

HOLD

ON/OFF key. Press this key

repeatedly to switch the instrument on or off.

The instrument has a cut-out

system (Auto Power Off) which

switches off automatically after

about 8 minutes.

HOLD and ON/OFF key. If this

key is pressed and held down

together with the ON/OFF key

while switching on, for the duration of the switching-on routine,

the self cut-out function (Auto

Power Off) is disactivated.

The battery symbol flashes at a

frequency of 1 Hz.

The instrument can be switched

off only by pressing the ON/OFF

key.

When this key is pressed during

normal operation the value shown

on the display is frozen and the

HOLD symbol lights up; updating

of the internal data continues.

When the key is pressed for the

second time the instrument

returns to normal operation and

the HOLD symbol goes off.

All the symbols are lit for a few

seconds after pressing the

ON/OFF key.

Complete display.

The Hsymbol flashes to indicate

that Auto Power Off is disabled.

KEY SIMBOLS LIT BESIDES

THE NUMBERS

FUNCTION

DESCRIPTION

KEYBOARD

+

Page 7

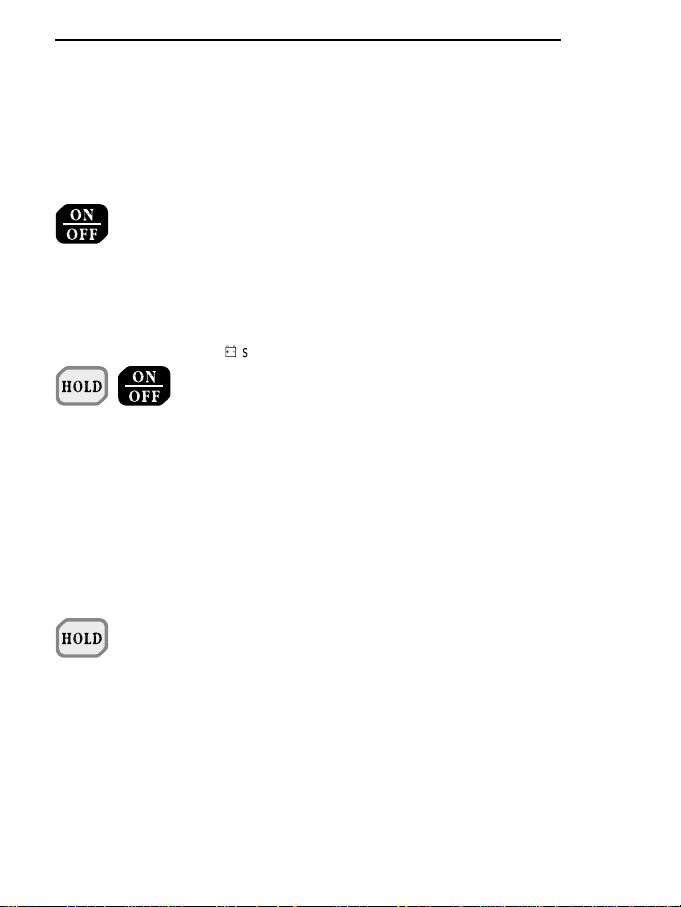

REL

UNIT A

UNIT B

ENGLISH

71

KEY SIMBOLS LIT BESIDES

THE NUMBERS

FUNCTION

DESCRIPTION

The REL key allows you to

display or store relative values or

send them immediately onto the

serial line.

The values for comparison are

stored at the precise moment in

which the key is pressed.

Data may be stored when the

REL button is active.

After data has been sent onto the

serial line, in immediate or remote

mode from the instrument’s internal memory, obtained with the

REL function active, a report will

be provided giving the maximum,

minimum and mean relative

values and the reference values

on which the calculation of the

relative values was based.

When the Unit A key is pressed,

input A, any of the following measurement units may be chosen:

kPa, bar, mmHg, atm, mmH2O,

psi, l/m, IGPM. The led corresponding to the unit chosen lights

up. The indication at the top of the

display corresponds to input A.

When the Unit B key is pressed,

input B, any of the following measurement units may be chosen:

kPa, bar, mmHg, atm, mmH2O,

psi, l/m, IGPM. The led corresponding to the unit chosen lights

up. The indication at the top of the

display corresponds to input B.

REL

3

10

3

10

Page 8

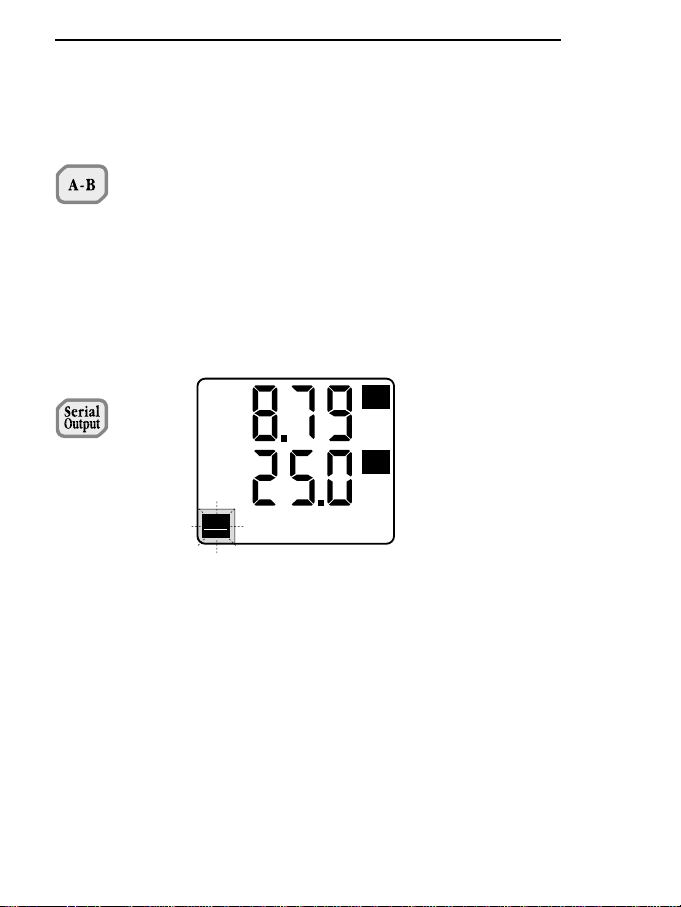

A-B

SERIAL OUTPUT

ENGLISH

72

KEY SIMBOLS LIT BESIDES

THE NUMBERS

FUNCTION

DESCRIPTION

Pressing A-B obtains the difference between the values indicated

for input A minus the values of

input B. The full-scale value of

the two probes must be the

same and they must be operating with the same measurement units, otherwise an ERR

message is given. The value of

the difference appears at the bottom of the display.

Serial Output key. The Serial

Output key sends the data being

acquired onto the serial line

immediately, according to the set

programming parameters. The

Serial Out symbol flashes.

Note:

The choice of the Baud Rate

influences the speed at which the

data are sent onto the serial line.

With a data transmission speed of

300 Baud (the character being

composed of 10 bit: 1 start bit + 8

character bit + 1 stop bit), the time

taken to send 80 characters on

the serial line is: 80 / (300/10) =

2.7 sec.

Serial

Out

Memory

3

10

3

10

Page 9

ENGLISH

73

KEY SIMBOLS LIT BESIDES

THE NUMBERS

FUNCTION

DESCRIPTION

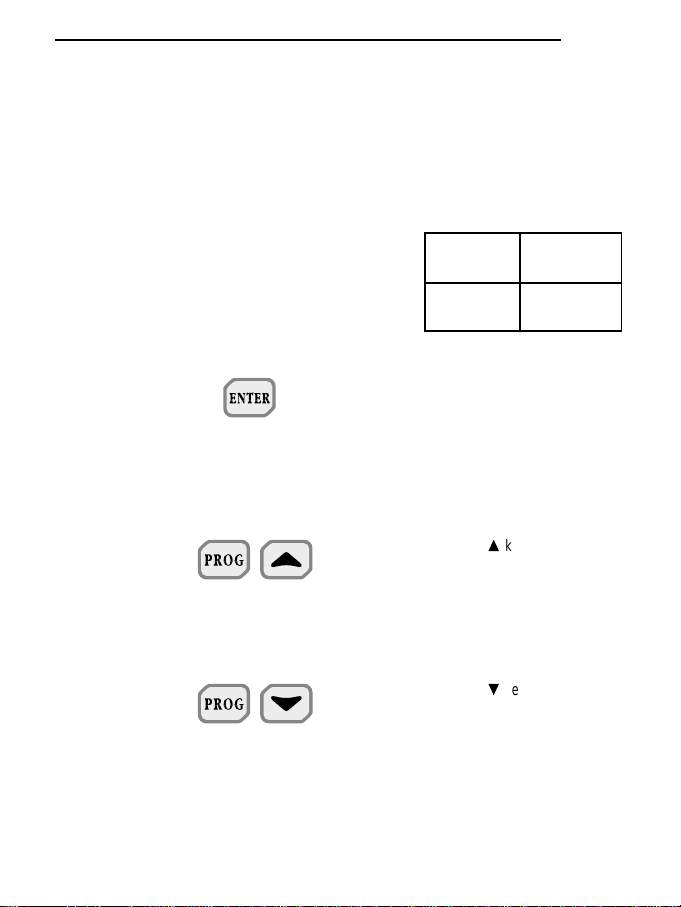

P0+

+

+

There is therefore a limit on the

minimum time that may be set as

a function of the Baud Rate chosen:

- P0 -

When ENTER is pressed with P0

on the display, the instrument

returns to normal operating mode

without storing any parameter.

Press the PROG key to move on

to step P1.

When the skey is pressed with

P0 on the channel A display it

resets the offset of the connected

probe (only for probes for relati-

ve or differential measurements).

When the tkey is pressed with

P0 on the channel B display it

resets the offset of the connected

probe (only for probes for relati-

ve or differential measurements).

BAUD

RATE

300 Baud

600 Baud

> 600 Baud

MINIMUM

SETTABLE

TIME

4 sec.

2 sec.

1 sec.

Page 10

ENGLISH

74

KEY SIMBOLS LIT BESIDES

THE NUMBERS

FUNCTION

DESCRIPTION

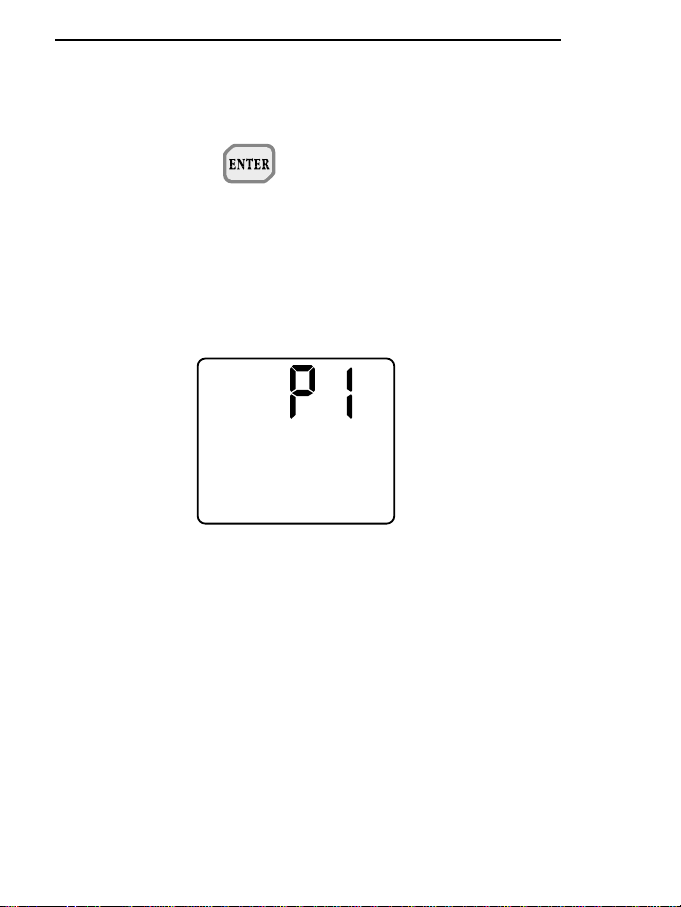

P1+ = data dump

- P1 -

When ENTER is pressed with P1

on the display, the data stored in

the memory of the instrument are

unloaded (DUMP); press the

PROG key to move on to step P2.

During data dumping the message P1 appears on the upper

display of the instrument. At the

end the instrument automatically

returns to normal operating mode.

The unloading of data from the

instrument memory may be

momentarily stopped by pressing

the ENTER key. Press the

ENTER key again to reactivate

data unloading.

When the PROG key is pressed,

data unloading is finally concluded.

At the end of each block the

report is sent with the maximum

(peak), minimum and mean

values calculated on the block.

During the DUMP phase the

instrument does not switch off

automatically, all the key functions

are disabled except the ENTER,

PROG and ON/OFF keys.

Note:

The block is defined at the

moment of storage as a group of

consecutive recordings. The first

interruption of storage ends and

determines the block.

Page 11

ENGLISH

75

KEY SIMBOLS LIT BESIDES

THE NUMBERS

FUNCTION

DESCRIPTION

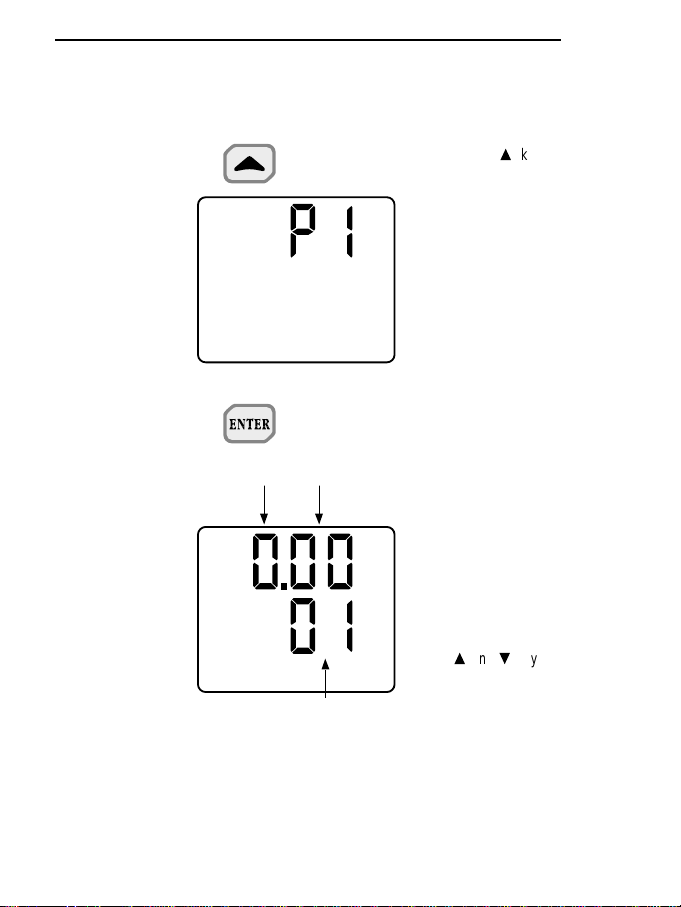

When the skey (MEMORY

CLEAR sub-function) is pressed

with P1 on the display, all the stored data are erased.

The instrument will display the

message P1. At the end the

instrument automatically returns

to normal operating mode.

- P2 -

When ENTER is pressed with P2

on the display, the storage time

parameter may be modified.

This parameter is used for the following two functions:

1. Logging time, or time elapsing

between two consecutive data

storages in the internal memory

of the instrument.

2. Data dump interval, or time elapsing between two immediate

data dumps on the serial line.

The sand tkeys are used to

define the desired intervention

time.

At bottom right of the display the

instrument indicates the seconds

(1 - 59).

At top right of the display the

instrument indicates the minutes

(1 - 59).

At top left of the display the instrument indicates the hours (1 - 12).

P1+ = erase memory

storage

P2+ = interval

programming

hours minutes

seconds

Page 12

ENGLISH

76

KEY SIMBOLS LIT BESIDES

THE NUMBERS

FUNCTION

DESCRIPTION

After defining the storage time,

press ENTER to return to normal

operation, or press the PROG key

to move on to step P3.

In the storage function the instrument is able to store more than

30,000 acquisitions.

The indicative time taken to fill the

memory completely is a function

of the recording interval and may

be obtained from the following

table:

Once the memory has been filled

the instrument automatically stops

and quits storage status. The flashing FUL message appears. The

instrument switches off after 8

minutes.

RECORDING INTERVAL

1 sec

1 min

1 hour

TIME TO FILL

THE MEMORY

8 hours

20 days

1250 days

Page 13

ENGLISH

77

KEY SIMBOLS LIT BESIDES

THE NUMBERS

FUNCTION

DESCRIPTION

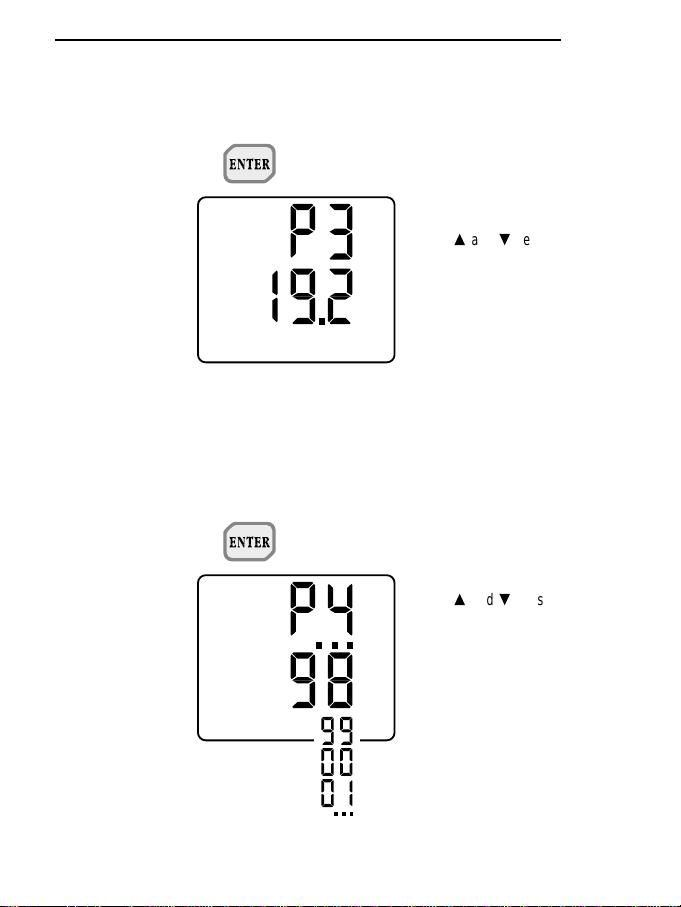

P3+ = set Baud Rate

P4+ = set year

- P3 -

When ENTER is pressed with P3

on the display, the Baud Rate of

the RS 232C serial transmission

may be modified.

The sand tkeys are used to

select the desired value.

The possible values are:

19.2 = 19200 Baud

9.6 = 9600 Baud

4.8 = 4800 Baud

2.4 = 2400 Baud

1.2 = 1200 Baud

0.6 = 600 Baud

0.3 = 300 Baud

Finally press ENTER to return to

normal operation, or press the

PROG key to move on to step P4.

- P4 -

When ENTER is pressed with P4

on the display, the year value may

be set or changed.

The sand tkeys are used to

select the desired year.

Then press PROG to move on to

step P5 (the ENTER key is not

active).

Page 14

ENGLISH

78

KEY SIMBOLS LIT BESIDES

THE NUMBERS

FUNCTION

DESCRIPTION

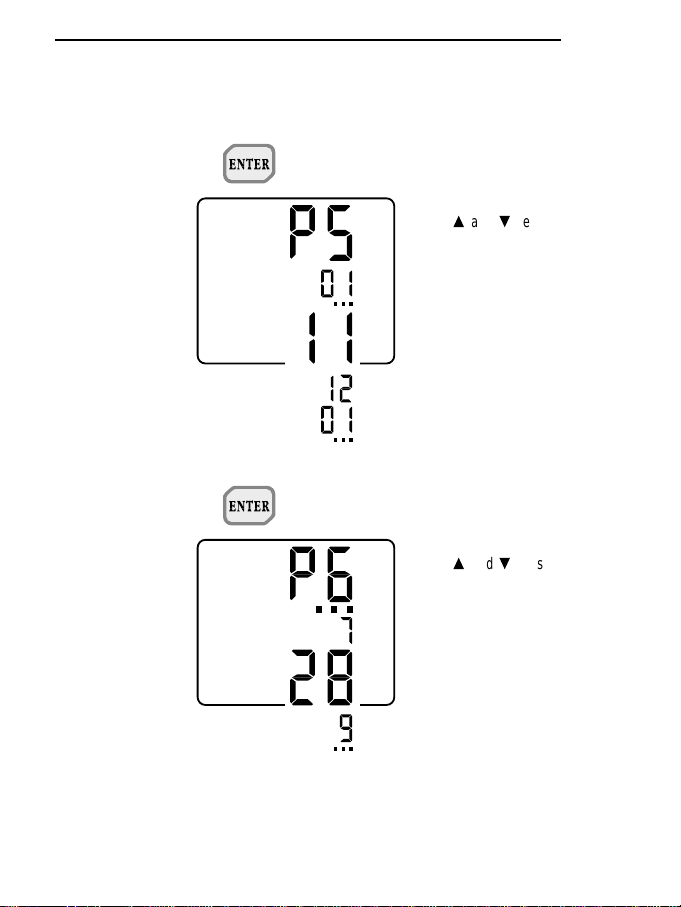

P5+ = set month

P6+ = set day

- P5 -

When ENTER is pressed with P5

on the display, the month may be

set or changed..

The sand tkeys are used to

select the desired month.

Then press PROG to move on to

step P6 (the ENTER key is not

active).

- P6 -

When ENTER is pressed with P6

on the display, the day may be set

or changed.

The sand tkeys are used to

select the desired day.

Then press PROG to move on to

step P7 (the ENTER key is not

active).

Page 15

ENGLISH

79

KEY SIMBOLS LIT BESIDES

THE NUMBERS

FUNCTION

DESCRIPTION

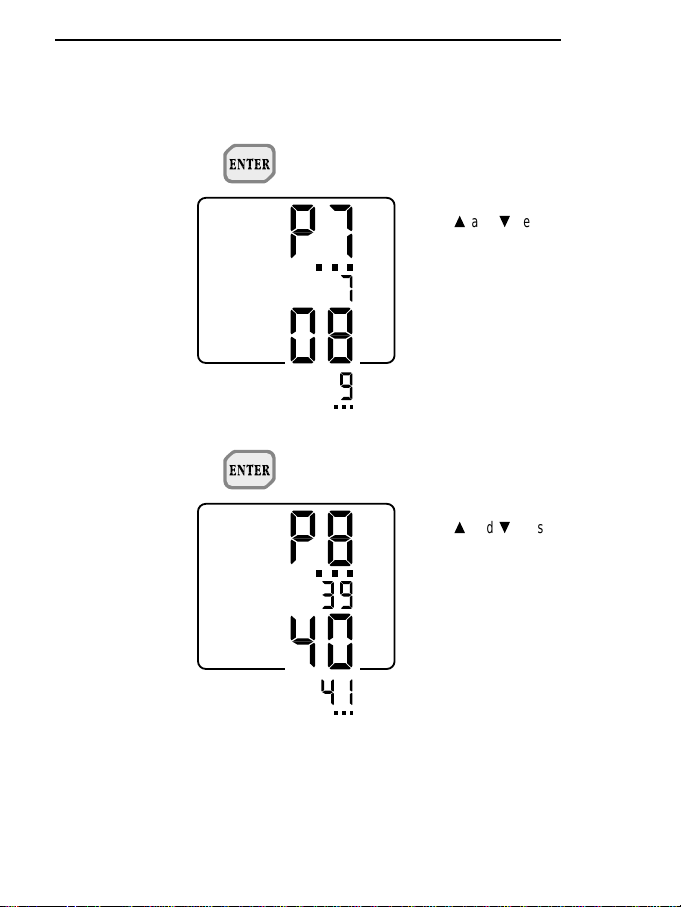

P7+ = set hours

P8+ = set minutes

- P7 -

When ENTER is pressed with P7

on the display, the hour may be

set or changed.

The sand tkeys are used to

select the desired hour.

Then press PROG to move on to

step P8 (the ENTER key is not

active).

- P8 -

When ENTER is pressed with P8

on the display, the minutes may

be set or changed.

The sand tkeys are used to

select the desired minutes.

Then press ENTER to return to

normal operating mode or PROG

to move on to step P9, without

updating the internal clock.

Quitting with the ENTER key

updates the internal clock with

the date and time just set, setting the seconds at zero at the

time of quitting.

Page 16

ENGLISH

80

KEY SIMBOLS LIT BESIDES

THE NUMBERS

FUNCTION

DESCRIPTION

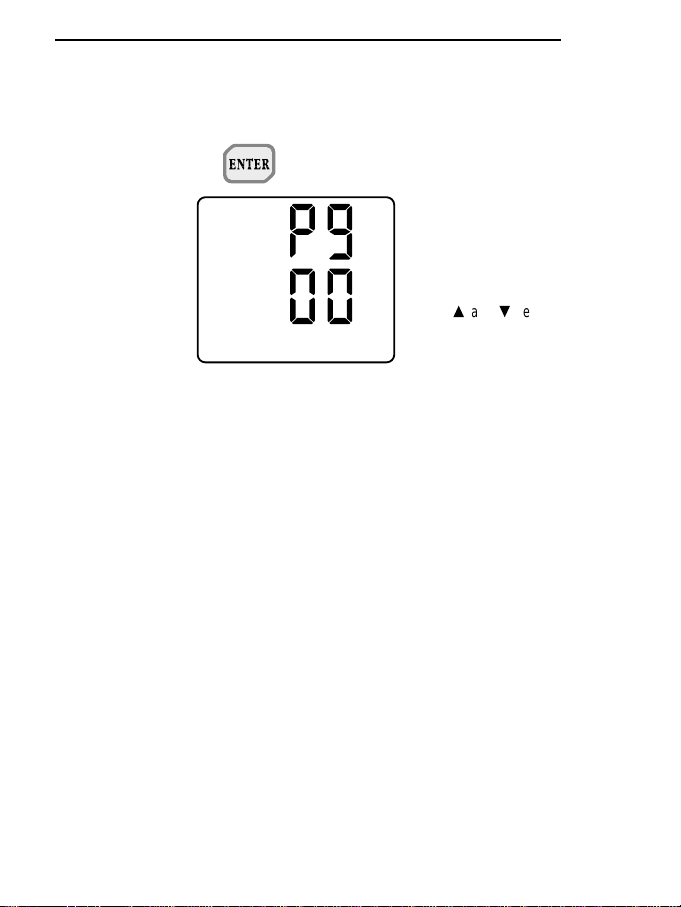

P9+ =

enable/disable

self cut-out

- P9 -

When ENTER is pressed with P9

on the display, the instrument

enters the program which enables

or disables the self cut-out function when it is in storage mode

and with a set storage interval

higher than or equal to 1 minute.

The sand tkeys are used to

select the value 00 or 01.

00 With a set storage interval

lower than 1 minute, the

instrument does not switch off

automatically; it always

remains lit.

When the ON/OFF key is

pressed, storage stops and

the instrument switches off.

00 With a set storage interval

higher than 1 minute, the

display switches off automatically after about 8 minutes. At

each set storage interval there

is a beep and the display switches on for a few seconds..

The display can be switched

on or off by pressing the

ON/OFF key. The instrument

keeps on storing if you keep it

switched on. The display switches off automatically after

about 8 minutes.

To stop storage, press the

ON/OFF key (if the instrument

is off). Press the ENTER key.

01 With a set storage interval

lower than 1 minute, the

instrument does not switch off

Page 17

ENGLISH

81

KEY SIMBOLS LIT BESIDES

THE NUMBERS

FUNCTION

DESCRIPTION

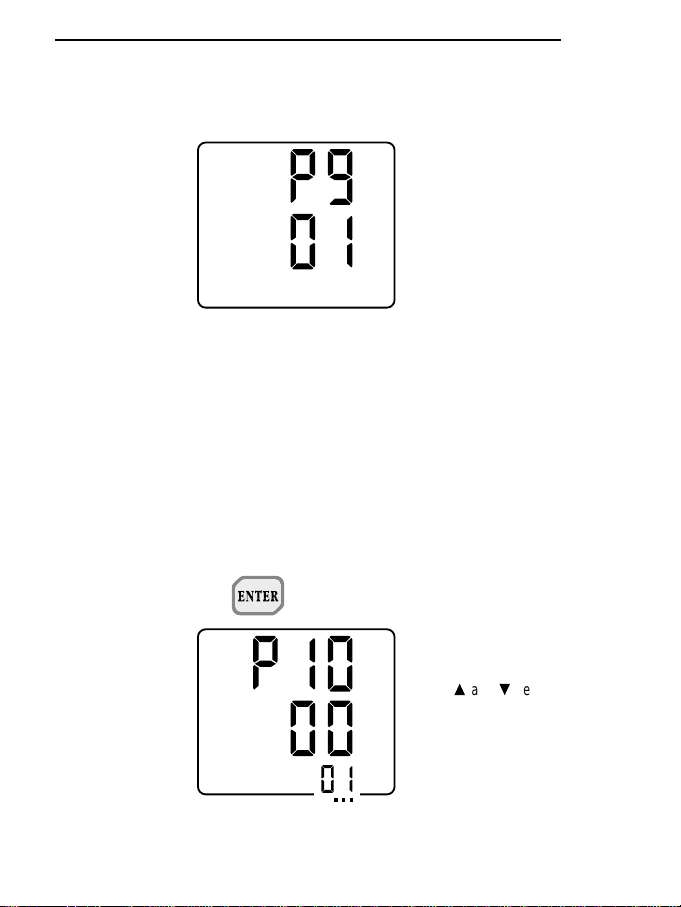

P10+ =

select type

of printing

automatically.

When the ON/OFF key is

pressed, storage is interrupted

and the instrument switches

off.

01 With a set storage interval

higher than 1 minute, the

display does not switch off

automatically; it remains

always lit and goes on storing.

When the ON/OFF key is

pressed the display stops till

the next acquisition. Then it

switches on again and

remains lit.

To stop storage, press the

ENTER key.

The ENTER key is used to return

to normal operating mode, while

pressing the PROG key moves on

to step P10.

- P10 -

When ENTER is pressed with

P10 on the display it is possible to

select complete or reduced data

printing.

The sand tkeys are used to

select the desired printing format.

01: complete printing

00: reduced printing

The ENTER key is used to return

to normal operating mode, while

pressing the PROG key moves on

to step P11.

Page 18

ENGLISH

82

KEY

SIMBOLS LIT BESIDES

THE NUMBERS

FUNCTION

DESCRIPTION

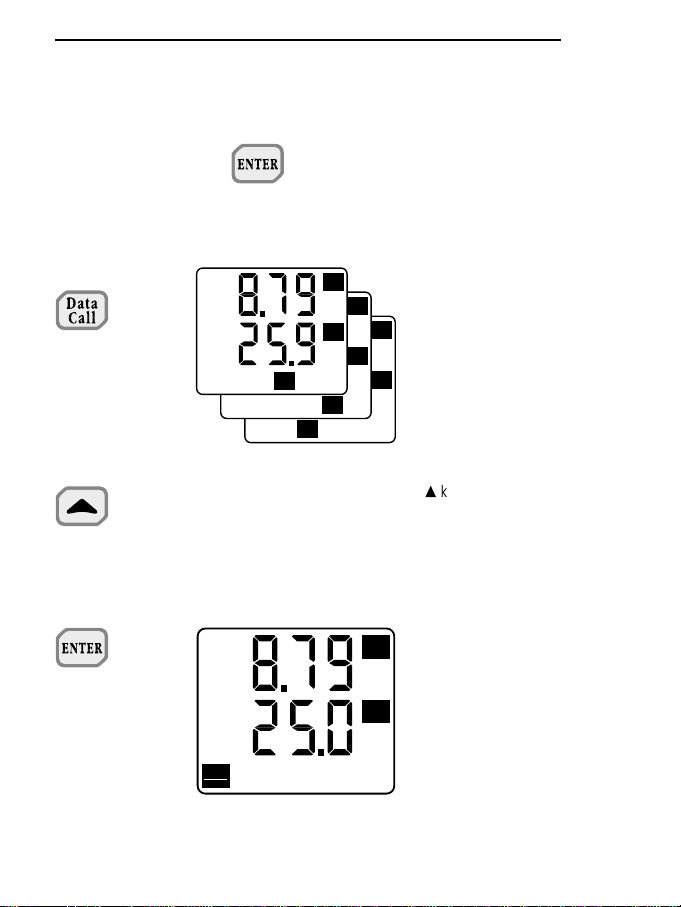

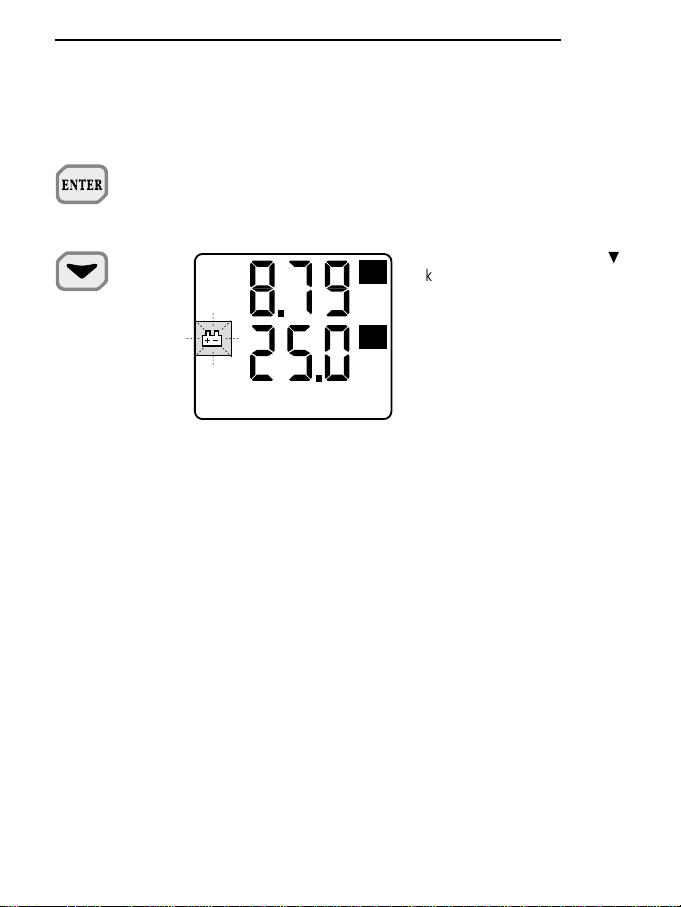

DATA CALL

P11+

- P11 -

When ENTER is pressed with

P11 on the display, the instrument

enters the program for calibrating

the instrument.

DATA CALL key (Mean - Max Min).

When the DATA CALL key is

pressed repeatedly, the Max

(Peak), Min and Mean values

measured for both measuring

channels are shown on the

display.

s

key. When enabled it increases

the values, in function P0 it

resets the probe offset of channel A (only for relative or differen-

tial probes), with P1 it enables the

memory clear function.

ENTER key (Start-Stop sub-function).

The ENTER key is used alternatively to start or stop storage of a

new block of data to be kept in the

memory of the instrument. Data

storage is performed at the rate

set during programming of step

P2.

The data stored between one

start and the following stop form a

block.

+ Start-Stop

3

10

3

10

3

3

10

10

3

10

3

10

MIN

3

10

3

10

Memory

MAX

MED

Serial

Out

Page 19

ENGLISH

83

KEY SIMBOLS LIT BESIDES

THE NUMBERS

FUNCTION

DESCRIPTION

Different blocks can thus be formed, all ending (during unloading)

with the report giving the maximum, minimum and mean values.

The Serial Out/Memory symbol

remains lit for the whole storage

period. The Auto Power Off function is active and the instrument

switches itself off after about 8

minutes of inactivity. It is restarted

automatically by the clock interrupt control which reactivates the

instrument for only the time needed for all the acquisition and storage operations. Once this has

been done the instrument switches itself off again.

During this phase the instrument

appears to be off, but it is active in

operating mode.

If the Serial Out/Memory symbol

lights up when switching on the

instrument with the ON/OFF key,

this means that the instrument

was in storage status.

In this stage the Serial Out and

PROG keys are not enabled.

When this operative mode

is disactivated the Serial

Out/Memory symbol is not lit.

The total memory capacity available is 512 kbyte, with the possibility of storing more than 30,000

readings.

Page 20

ENGLISH

84

KEY SIMBOLS LIT BESIDES

THE NUMBERS

FUNCTION

DESCRIPTION

ENTER

with RCD

During programming this key is

used both to enter the desired

program and to confirm the value

of the parameter considered.

When pressed repeatedly, the

t

key, sub-function RCD, starts and

stops the record function, which

calculates and stores the maximum, minimum and mean values.

When the RCD key is held down

the instrument emits a short beep

followed by a long one. This confirms that the max., min. and

mean values stored previously

are being erased from the

memory and a new series of

recordings is started which will be

used as the basis on which to calculate and store new max., min.

and mean values

After resetting of the max., min.

and mean values, the RCD function has a duration of about

30,000 readings, that is about 4

hours. At the end, the RCD function is automatically interrupted

and the max. min. and mean

values calculated up till then are

maintained.

During RCD mode the Auto

Power Off function is disabled and

the battery symbol flashes at a

frequency of 2 Hz.

Attention:

If the battery symbol does not fla-

10

3

3

10

Page 21

ENGLISH

85

KEY SIMBOLS LIT BESIDES

THE NUMBERS

FUNCTION

DESCRIPTION

sh at a frequency of 2 Hz when

the RCD key is pressed, it means

that the RCD function has stored

more than 30,000 acquisitions

and cannot continue any further.

After having taken note of the

max. min. and mean values calculated up till then, reset the RCD

function and restart it.

t

key. During programming or

calibration, this key is used to

decrease the value of the parameter being considered. In func-

tion P0 it resets the probe offset of channel B (only for relative

or differential probes).

Page 22

PROBE CONNECTION

One or two pressure probes, one or two temperature probes may be connected to the DO 9704

pressure and temperature gauge - data logger. The pressure probes of the TP 704 series have a

1/4” BSP male threaded coupling and must be screwed into the fitting in which the pressure is to be

measured; the probes of the TP 705 series have a ∅ 5 mm. coupling to which will be connected a

suitable tube for taking the desired measurement; take great care with the pressure seal of the

fitting, if necessary using gaskets and suitable fittings. The threaded coupling is protected by a plastic cap; put the cap back after use, as it protects the pressure cell against foreign bodies. IT IS

VERY IMPORTANT to ensure that the full scale value of the probe is higher than the pressure that

is to be measured. If you do not know the value, start off using probes with high capacities. Using

the CPA cable, connect the pressure probe to the instrument and then take the measurement. The

same operations are carried out when using two temperature probes at the same time. The temperature probe must be connected to input A or B of the instrument or to both if there are two probes;

then measure the temperature with the sensitive part of the probe. Depending on the case, immersion, contact, penetration or air probes will be used.

The same applies to probes for measuring flow rate; in this case ensure that the connection cable

is specifically configured for the flow rate or for the number of impulses of the turbine.

HOW TO MEASURE

1. Press the ON/OFF key to switch on the instrument.

* This operation enables the automatic cut-out timer.

If you wish power supply without automatic interruption, when switching on, press the HOLD

and ON/OFF keys simultaneously and keep the HOLD button held down for the duration of the

switching-on routine. The battery symbol flashes at a frequency of 1 Hz, indicating that the Auto

Power Off function is disabled.

* When the instrument is switched on all the numbers and symbols light up for a few moments,

allowing you to check that all the display segments are working.

* After a few moments it moves on to normal operation.

2. Checking display.

* After all the segments are lit, the instrument is ready to measure in the engineering unit (Pa,

bar, psi, atm, mmHg, mH2O) set before the instrument was switched off.

* If a probe is broken or is not properly connected, the Err signal appears. In this case the sensor

part and/or the connector must be checked.

3. Selection of the measuring unit.

* Press the Unit A key repeatedly to show, at the top of the display, the measurement of the pro-

be connected to input A in the desired measuring unit; press the Unit B key repeatedly to show,

at the top of the display, the measurement of the probe connected to input B in the desired

ENGLISH

86

Page 23

measuring unit.

* Press the Unit A or B key to select the temperature measuring unit in °C or °F.

4. Switching off the instrument.

* The instrument is switched off by pressing the ON/OFF key.

* Because of the Auto Power Off function the instrument may switch itself off during measure-

ments. In this case press the ON/OFF key to switch it on again.

* The instrument usually switches off automatically after 8 minutes of inactivity, with the following

exceptions:

a) Instrument in RCD status.

b) Instrument in Auto Power Off Disabled status.

In these two cases the instrument switches off only when the ON/OFF key is pressed.

c) Instrument during unloading of stored data.

d) Instrument during Serial Output of immediate data.

e) Instrument in storage function.

In the last three cases the instrument switches off automatically 8 minutes after the low

battery warning and interrupts storage and unloading of data.

When it switches on again there are two possibilities:

1. If the battery is definitively low, even when the instrument switches on again LOU appears on

the display together with the battery symbol.

The PROG key (P1+ENTER) enables the activation of the unloading of stored data even

when the battery is low.

2. If the battery has had time to recover and when the instrument switches on its charge seems,

even just a little, higher than the minimum value, LOU appears on the display without the battery symbol for a short period of time (about 4 seconds), after which the instrument returns to

normal operation; this is to remind the user that the instrument was previously in storage function and that this procedure was interrupted by the low battery warning.

5. Various operations.

* For operations such as HOLD display, relative measurements, RCD storage, DATA CALL,

Serial Output, storage in the internal memory, unloading of stored data, erasing of the internal

memory, setting of the working parameters, see the description of the instrument keyboard.

Attention when using the keyboard

The use of the keys is relatively simple, but care must be taken to avoid setting it by mistake in an

undesired mode. Ensure that HOLD, RCD, REL, MAX, MIN, MED, Serial Out/Memory are not

displayed during normal operation.

ENGLISH

87

Page 24

TEMPERATURE MEASUREMENT

Immersion temperature measurements are performed by introducing the probe to a minimum

depth of 60 mm into the liquid in which you want to take the measurement; the sensor is housed in

the end of the probe.

To take measurements in air, the probe must be pointed in a transverse direction to the air flow.

In both cases, to ensure correct measurement avoid contact of the probe with the walls of the container holding the liquid or of the duct in which the air to be measured is passing.

When taking penetration measurements the tip of the probe must be inserted at a depth of at least

60 mm; the sensor is housed in the end of the probe. When taking measurements on frozen blocks

it is convenient to use a mechanical tool to make a cavity in which to insert the pointed probe.

To perform a contact measurement correctly the surface must be flat and smooth and the probe

must be perpendicular to the measuring plain.

To obtain a correct measurement, the application of a little heat-conductive paste or a drop

of oil (water or solvents must absolutely not be used) helps to improve the response time.

METHOD OF USING THE INSTRUMENT AND WARNINGS

1. Do not expose the probes to gases or liquids that could corrode the material of the sensor or

the probe; clean the probe carefully after use.

2. Do not bend the connectors applying upward or downward force.

3. Do not bend or force the contacts when inserting the probe connector in the instrument.

4. Do not bend, deform or drop the probes as this could cause irreparable damage.

5. Always use the most suitable probe for the measurement to be taken.

6. Be careful with the range of use of the probe, measurements at limit values are possible only

for short periods.

7. Do not use the temperature probes in the presence of corrosive gases or liquids; the container

in which the sensor is housed is made of stainless steel AISI 316, while the container for the

contact probe is of AISI 316 plus silver. Do not let the surfaces of the probe come in contact

with sticky surfaces or with substances that can corrode or damage the probe. If the sensor

breaks or becomes faulty it must be replaced. In this case the probe must be recalibrated.

8. Above 400°C, avoid violent blows or thermal shock to the Pt100 temperature probes as these

could cause irreparable damage.

9. To obtain a reliable temperature measurement, too fast temperature variations must be avoided.

10. Temperature probes for surface measurements must be held in a vertical position with respect

to the surface. Apply a drop of oil or heat-conductive paste between the surface and the sensor

so as to improve contact and reduce the reading time. Do not use water or solvents to do this.

11. Temperature measurements on non-metal surfaces require a great deal of time on account of

ENGLISH

88

Page 25

their low heat conductivity.

12. The probes are not insulated from their external casing. Be very careful not to come

into contact with live parts (above 48V) as this could be dangerous not only for the

instrument but also for the operator, who could suffer an electric shock.

13. Avoid taking measurements in the presence of high frequency sources, microwaves or large

magnetic fields, as the results would not be very reliable

14. Always clean the probes carefully after use.

15. After taking a pressure measurement, clean the probe pressure chamber accurately; do not let

the fluid that comes in contact with the membrane leave any deposits or scale, with time these

could cause errors in measurement.

16. Avoid inserting sharp points or nails in the pressure chamber; a sudden blow could accidentally

break the membrane.

17. To secure the probes use a suitably sized spanner and, if necessary, sealing gaskets.

18. Great care must be taken when installing probes in pressurised containers or in

pipes. Take care when choosing the full scale range of the probes. Apart from causing irreparable damage to the probe, an error could cause quite serious physical

harm to the operator and to objects in the vicinity. There should always be a stop key

upstream from the probe. Ensure that there are no abnormal and sudden variations

in the fluid under pressure.

19. The instrument is resistant to water but it is not watertight and should not therefore be immersed in water. If it should fall into the water, take it out immediately and check that no water has

infiltrated. The instrument must be handled in such a way that water cannot get in through the

connector side.

INSTRUMENT SIGNALS AND MALFUNCTIONS

ENGLISH

89

Err On the upper display indicates:

* Error in reading the signal present at input A or B or A-B;

* Error when, with A-B, the probes inserted do not have the same full scale value and

are not of the same type.

FUL Memory full.

LOU When switching on this indicates that the instrument has switched off because the bat-

tery voltage was too low when it was in storage or serial output status. Change the battery even if there are no low battery signals.

Page 26

LOW BATTERY WARNING AND BATTERY REPLACEMENT

When the battery has run down and its voltage has reached the limit value of 7.2 Volts, the symbol

H

appears permanently on the display and an alarm beep sounds at regular intervals of about 15

seconds. In these conditions the battery should be replaced as soon as possible.

If you continue to use the instrument and the battery voltage falls as low as 6.5V the instrument is

no longer able to ensure correct measurement.

AFTER CHANGING THE BATTERY YOU MUST UPDATE THE CLOCK AND THE SET PARAMETERS.

To change the battery turn the instrument retaining screw in an anti-clockwise direction. After replacing it (with an ordinary 9V alkaline battery) close the instrument, inserting the tag into the slot provided, and turn the screw in a clockwise direction.

The stored data will not be lost even if the instrument remains without batteries as long as the

working routines have been completed.

Ensure that the instrument is switched off before changing the battery.

The symbol Happears fixed to indicate that the battery is low. This indication prevails over all the

other signals which make use of the symbol

H

. In RCD function the symbol Hflashes at a fre-

quency of 2 Hz. In Auto Power Off function the symbol

H

flashes at a frequency of 1 Hz. The fla-

shing of the RCD function prevails over the flashing of Auto Power Off.

ENGLISH

90

Page 27

FAULTY OPERATION WHEN SWITCHING ON AFTER CHANGING THE

BATTERY

Repeat the battery changing procedure, waiting for a few minutes to allow the circuit condenser

capacities to be completely discharged, then insert the battery.

WARNING ON USE OF THE BATTERIES

* If the instrument is not to be used for a long time the battery must be removed.

* If the battery is flat it must be replaced immediately.

* Take steps to avoid leakage of liquid from the battery.

* Use good quality leakproof batteries, alkaline if possible.

STORAGE OF THE INSTRUMENT

Instrument storage conditions:

* Temperature: -10...+50°C.

* Humidity: less than 90% relative humidity, avoid the formation of condensation.

* Do not store the instrument in places where:

1. There is a high degree of humidity.

2. The instrument is exposed to direct sunlight.

3. The instrument is exposed to a source of high temperature.

4. There are strong vibrations.

5. There is steam, salt and/or corrosive gas.

The instrument body is made of ABS plastic so it must not be cleaned with solvents which can spoil

plastic.

SERIAL INTERFACE RS 232C

The instrument is equipped with the standard serial interface RS 232C, galvanically insulated;

it is supplied with the adapter cable CP RS 232C. The following signals are available on the

SUB D 9-pin male connector of the instrument:

NOTE: The deflector on the connector of the adapter cable CP RS 232C must be turned to COM-

PUTER or PRINTER position, depending on the chosen connector (this may not be true on

some computers or printers).

The signals present in pins 2 and 3 are at logic levels compatible with the standard RS 232C.

ENGLISH

91

PIN SIGNAL DESCRIPTION

3 TD Datum transmitted by the instrument

2 RD Datum received by the instrument

5 GND Reference logic mass

Page 28

The transmission parameters with which the instrument is supplied are:

* Baud Rate 19200 Baud

* Parity None

* N. bit 8

* Stop bit 1

* Protocol Xon/Xoff

The data transmission speed may be changed by pressing the PROG key on the instrument to alter

the set-up parameter P3. The possible Baud Rates are: 19200, 9600, 4800, 2400, 1200, 600, 300.

The other transmission parameters are fixed.

All the messages reaching and leaving the instrument must be inserted in a “Communication frame” with the following structure:

Record-cr

where:

-Record- constitutes the message

-cr- Carriage Return (ASCII 0D)

HOST COMMANDS

COMMAND TYPE REPLY

AA Type of terminal MANOMETER – DL

AG Firmware Version Vx Rx

AH Firmware Date dd/mm/yy

A* ?

SA Request Input A

SB Request Input B

SC Request Input A-B

SI Measurement MANOMETER - DL

S* NC

It is possible to unload data onto a computer using the Xon/Xoff protocol to control the data flow:

The character Xoff (hex 13) on the serial line stops the data unloading in progress.

The character Xon (hex 11) reactivates the suspended data unloading in progress.

Dumping data from the memory

Press the PROG key twice until P1 appears on the display.

Press the ENTER key.

The instrument continues to show P1 on the display and dumps the data from the instrument’s

internal memory through the serial line.

ENGLISH

92

Page 29

At the end of data dumping the instrument returns to normal display.

It is possible to stop and resume data dumping by repeatedly pressing the ENTER key.

Once data dumping has been stopped it may be terminated by pressing the PROG key.

Memory clear

Press the PROG key twice until P1 appears on the display.

Press the skey (memory clear sub-function).

The instrument will erase the internal memory, showing P1 on the display.

At the end of the operation the instrument returns to normal display.

ENGLISH

93

COMPUTER PRINT

COMPUTER

PRINT

NC

NC

NC

NC

TEST

NC

NC

6789

RTS

RXD

CTS

DSR

DCD

GND

NC

RC

NC

NC

NC

NC

DTR

12345678910111213

141516171819202122232425

NC

TXD

SCR

12345678910111213

14 15 16 17 18 19 20 21 22 23 24 25

TC

NC

12345

Page 30

ENGLISH

94

DIAGRAM DO 9704

Probe A

Probe B

PRINTER

WITH SERIAL

Pressure or temperature

Pressure or temperature

INPUT

SERIAL/

PARALLEL

CONVERTER

PRINTER

WITH PARALLEL

INPUT

Page 31

EXAMPLE OF A REPORT PRINTED BY THE INSTRUMENT

ENGLISH

95

Page 32

ENGLISH

96

Page 33

INSTRUCTIONS FOR CONNECTING DELTA OHM INSTRUMENTS TO A PC

WITH WINDOWS OPERATIVE SYSTEM

Hardware connection:

1. The measuring instrument must be switched off.

2. Connect the serial gate of the measuring instrument to a free serial gate on the PC

(COM1/COM2) using the special Delta Ohm CP RS 232C cable.

Note: the CP RS 232C cable ends in a female 25-pin connector; if your PC does not have a

compatible connector, use the adapters normally found on the market to make the connection.

3. Turn the switch on the CP RS 232C cable to COMPUTER position.

Software connection with WINDOWS 3.1:

A) Start WINDOWS

B) Select ACCESSORIES (double click)

C) Select TERMINAL and activate the communications program (double click)

ENGLISH

97

Page 34

D) To alter the communication settings of the terminal, in order to make them compatible with those

of the measuring instrument used (unless a terminal setting file has already been saved):

select SETTINGS in the terminal window (one click)

select COMMUNICATIONS from the menu (one click)

the COMMUNICATIONS window for setting the communication procedures will appear on

the screen; set:

TRANSMISSION SPEED: 19200 which must correspond to the speed set on the instrument (one click)

DATA BITS: 8 (one click)

STOP BITS: 1 (one click)

PARITY: None (one click)

FLOW CONTROL: Xon/Xoff (one click)

CONNECTOR: COM1 or COM2 depending on the gate used for connection (one click)

CHECK PARITY and SHOW CARRIER must remain unmarked

OK to confirm the setting (one click)

ENGLISH

98

Page 35

E) To set the correct character type:

select SETTINGS from the terminal window (one click)

on the pull-down menu select TERMINAL PREFERENCES... (one click)

the TERMINAL PREFERENCES window appears on the monitor, set:

Mark local Echo (one click)

Character type: Terminal (or equivalent)

Leave the rest unchanged

OK to confirm the setting (one click)

ENGLISH

99

Page 36

F) If you want to save this terminal setting:

select FILE from the terminal window (one click)

select SAVE AS from the pull-down menu and the SAVE FILE AS window will appear (one

click)

type the name of the terminal setting file (max. 8 characters) on the line provided

OK to confirm and save the setting (one click)

ENGLISH

100

Page 37

G) To receive and store data from an instrument:

select TRANSFER from the terminal window (one click)

select RECEIVE TEXT FILE from the pull-down menu and the window will appear (one click)

type the name of the file in which data are to be stored (max. 8 characters) on the line

provided

OK to confirm and start storage (one click)

At this point the terminal is ready to receive data from the measuring instrument. Everything sent

by the measuring instrument will be stored in the file indicated previously

ENGLISH

101

Page 38

H) Switch on the measuring instrument

When the instrument has completed the switching-on routine, activate the immediate unloading

of data at the set rate, pressing the SERIAL OUTPUT button, or activate the unloading of the

data stored in the internal memory with the program P1 (press the PROG button twice) and

press the ENTER button.

I) End of storage of the data sent by the instrument

select TRANSFER from the terminal window (one click)

to end storage, select END from the pull-down menu (one click)

The software returns to the terminal window

L) End use of the TERMINAL:

select FILE from the terminal window (one click)

select QUIT from the pull-down menu (one click)

The text file, containing the data received from the measuring instrument connected to the PC, is

now stored in our computer. To read and process the file obtained we can use any text or table processing program in the Windows environment (WORD, EXCEL, WORKS, etc.)

ENGLISH

102

Page 39

Software connection with WINDOWS 95.

A) After starting WINDOWS 95, select START, PROGRAMS, ACCESSORIES, HYPERTERMINAL.

Run HYPERTRM (double click)

B) Name of the communication

In the window “Description of connection”, give a name to the communication that you want to

activate and choose an icon (in subsequent communications it will be possible to activate directly the icon chosen in place of HYPERTRM, automatically recovering all the settings saved with

the icon).

OK to confirm

Cancel in the next window

ENGLISH

103

Page 40

C) Setting communication

- select FILE from the Hyper Terminal window (one click)

- select PROPERTIES from the pull-down menu (one click) and the “Properties” window will

appear

- on the “telephone number” card, for the Connect property, choose “directly to COM1” or

“COM2”, depending on the serial gate that you intend to use for communication with the measuring instrument

- on the “telephone number” card, select CONFIGURE (one click) and the “Gate settings” card

will appear

- on the “Gate settings” card select:

BITS PER SECOND: 19200

DATA BITS: 8

PARITY: None

STOP BITS: 1

FLOW CONTROL: Xon/Xoff

OK to confirm the gate setting (one click)

ENGLISH

104

Page 41

ENGLISH

105

Page 42

- select SETTINGS to display the “Settings” card

- on the “Settings” card, for the “Emulation” property, select: TTY

- OK to confirm the “Properties” set (one click)

ENGLISH

106

Page 43

D) To set the correct character type:

- select DISPLAY from the Hyper Terminal window (one click)

- select CHARACTER from the pull-down menu (one click) and the window for selecting the character will appear; set:

- Terminal (or equivalent)

- OK to confirm (one click)

ENGLISH

107

Page 44

E) To receive and store data from an instrument:

- select CALL from the Hyper Terminal window (one click)

- select CONNECT from the pull-down menu

- In this way it is possible to receive the characters from the instrument on the monitor

ENGLISH

108

Page 45

F) To receive and store data from an instrument:

- select TRANSFER from the Hyper Terminal window (one click)

- select CAPTURE TEXT from the menu (one click) and the window will appear where you have

to set the name of the file in which to store the data received from instrument

- type the name of the file in which data are to be stored on the line provided

- OK to set the name of the receiving file (one click)

At this point the Hyper Terminal software is able to receive data from the measuring instrument and

store them in the set file

ENGLISH

109

Page 46

G) To end receiving data from an instrument:

select TRANSFER from the Hyper Terminal window (one click)

select CAPTURE TEXT from the menu (one click)

select END from the pull-down sub-menu (one click)

At this point data reception from the instrument is ended and the file stored in the computer can be

used with any of the software packages used with WINDOWS 95.

H) To quit running the Hyper Terminal:

select FILE from the Hyper Terminal window

select QUIT from the pull-down menu

ENGLISH

110

Page 47

CALIBRATING THE INSTRUMENT DO 9704

Apply a voltage of 465.5 mVdc between pin 6 (GND) and pin 1 (OUT) of the DIN 8-pole connector

at input A.

Select step 11 with the PROG key; press the ENTER key, the display shows

Using the sand tkeys, make the value shown on the display coincide with 196.0. Confirm by

pressing the ENTER key; P11 appears on the display; press PROG: P0 appears; press ENTER:

this quits the instrument calibration function.

ENGLISH

111

Instrument

7

3

5

6

8

Vdc=465.5

1

4

DO 9704

BA

2

Page 48

FLOW RATE MEASUREMENTS

A selection resistance sets the conversion factor of the connected turbine.

The instrument automatically recognises 5 fixed flow rate values plus a sixth which may be configured by the user.

*The instrument can read a reduced measuring range, it has the same selection resistance.

The connection cable of the configurable turbine will end with a DIN 8-pole connector; connect a

121 kΩ resistance between pin 3 and pin 7.

Active probe for measuring flow rate with a turbine 2 to

2000 litres/minute.

*A coil which generates impulses with a minimum of

100 mV p-p is connected to pins 4 and 6.

ENGLISH

112

FLOW RATE PROBES

Measuring range Selection Output Indication

resistance kΩ frequency PPL lt/min.

LT 5 5 l/min. 90.9 5 5

(LT10)* 95.3 5 20

LT20 20 l/min.

(LT50)* 100 0.5 125

LT125 125 l/min.

(LT250)* 105 0.1 400

(LT300)*

LT400 400 l/min.

LT500 500 l/min. 110 0.04 500

LT750 750 l/min. 115 0.04 750

LT configurable 2000 l/max 121 configurable PPL

1

2

6

1

4

7

3

8

5

N.C.

N.C.

R. Select.

5 73 4 6

N.C.

8

N.C.

2

*

Page 49

Connect the probe to the turbine that you want to configure and switch on the instrument; the message PPL will appear on the display corresponding to input A or B.

Press the PROG key, P0 will appear on the display; using the

s

and tkeys, select the input to

which the turbine probe is connected; the previously set number of impulses per litre will appear on

the display. Using the sand tkeys, set the number of impulses per litre corresponding to the

number of impulses per litre of the turbine that is being configured. Confirm by pressing the ENTER

key; P0 appears on the display. Press ENTER: this quits the procedure for configuring a turbine

with any number of impulses per litre.

CONNECTION OF PROBES TO THE PRESSURE GAUGE DATA LOGGER

DO 9704

One or two pressure probes of the series TP 704 or TP 705 may be connected to the instrument,

one or two temperature probes of the series TP 870, turbine probes for measuring flow rate or

impulse probes for measuring flow rate.

Probe connection diagram

1° 500mV

^

–

F.S.Pressure

2° Reserved

3° JP2Configuration (Selec. R towards 7)

4° Flow rate input

5° Reserved

6° GND (Ref. Flow rate)

7° +5 Vdc

8° -5 Vdc~

ENGLISH

113

Instrument

BA

7

3

5

6

8

2

DO 9704

1

4

7

3

5

6

1

8

4

2

Page 50

ENGLISH

114

6

1

4

7

3

5

8

2

+5V

7

GND

6

OUT

2.375mV/°C

1

-5V

8

6

1

4

7

3

5

8

2

6

1

4

7

3

5

8

2

N.C.

1

N.C.

5 73 4 6

N.C.

R. Select.

2

N.C.

8

*

500mV

F.S. Pressure

1

N.C.4N.C.

5

GND

6

-5V

8

+5V

7

Probe series TP 704, TP 705

Turbine probe for measuring flow rate

Active probe Pt100

series TP 870

Active probe TP 704, TP 705 Active turbine probe for measuring

flow rate.

2 to 2000 litres/minute

* A coil which generates impulses with a

minimum of 100 mV p-p is connected

between 4 and 6.

Probe series TP 870

N.C.

2

R. Select.

Verso 7

3

SEL R. PPL Turbine

(WEBSTER)

90 k9 5

95 k3 5

100 k 0.5

105 k 0.1

110 k 0.04

115 k 0.04

Probe for measuring flow rate with impulses

6

1

4

1 43

2 7

121K3K9

N.C.

N.C.

Active probe with NPN output for measuring

flow rate with impulses

8

2

7

3

5

5

N.C.

ln4148

86

N.C.

Page 51

CLASSIFICATION OF PRESSURE MEASUREMENTS

Pressure measurements are relative and therefore refer to a reference pressure. There are four

types of pressure measurement which enable the reference pressure to be defined immediately.

- Absolute pressure (A) – Pressure with respect to absolute zero, the ideal vacuum reference; the

pressure measured is always higher than the reference pressure.

- Gauge (G) – Pressure measured with respect to atmospheric pressure, environment pressure is

the reference; the pressure measured is always higher than the reference pressure.

- Vacuum (V) – Pressure with reference to atmospheric pressure, environment pressure is the

reference; the pressure measured is always lower than the reference pressure.

- Differential pressure (D) – Pressure measured with respect to any reference pressure; the pressure measured may be higher or lower than the reference pressure.

ENGLISH

115

The case G is similar to the case D

where the reference P = atmospheric P

Absolute Relative

(GAUGE)

VACUUM

Vacuum

P. to be

measured

Absolute pressure A

Reference

P.

Differential

Atm. P.

Relative pressure (gauge) G

Differential pressure D

Atmospheric

pressure

Zero

pressure

P. to be

measured

P. to be

measured

Page 52

CONVERSION FACTORS AND TABLES

°F-32

Temperature: °C =

___________

; °F = (1.8 x °C) + 32

1.8

Pressure measurement: mm = 0.03937 in in = 25.4 mm

cm = 0.3937 in in = 2.54 cm

m = 39.37 in in = 2.54 x 10–2m

f force

p =

___________

= pressure =

___________

m

2

surface

According to the international system, pressure measurement is expressed in Pascal 1 Pa = 1 N/m

2

=

1 Newton/square metre.

The principal engineering units for measuring pressure are:

Pascal = Pa (N/m2), kPa = 103Pa, Mpa = 106Pa

Bar = bar, mbar = bar x 10

–3

Metres of column of water 4°C = mH

2

O, mmH2O = mH2O x 10

–3

Millimetres of column of mercury 0°C = mmHg, Torr

Theoretic atmosphere = at (kp/cm2)

Physical atmosphere = atm

Inches of column of water at 4°C = in H2O

Inches of column of mercury at 0°C = in Hg

Micro of column of mercury at 0°C = µm Hg

Pounds per square inch = psi

1 bar = 100,000 Pa Pa = 10–5x bar

1 bar = 14.5038307 psi psi = 0.0689473023 x bar

1 bar = 0.986923 atm atm = 1.01325 x bar

1 bar = 755.7299444 mmHg mmHg = 0.001323224 x bar

1 bar = 10.19716213 mH2OmH

2

O = 0.0980665 x bar

psi = in of H2O x (3.6127 x 10–2) in of H2O = psi x 27.68

psi = mm of H2O x (1.4223 x 10–3) mm of H2O = psi x 703.1

psi = cm of H2O x (1.4223 x 10–3) cm of H2O = psi x 70.3

psi = in of Hg x 0.49118 in of Hg = psi x 2.036

psi = mm of Hg x (1.9339 x 10–2) mm of Hg = psi x 51.71

psi = Kg/cm2x 14.223 Kg/cm2= psi x 0.0703

psi = bar x 14.503 bar = psi x 0.0689

psi = mbar x (1.4503 x 10–2) mbar = psi x 68.95

ENGLISH

116

Page 53

psi = Pa x (1.4503 x 10–4) Pa = psi x 6895

psi = kPa x (1.4503 x 10–1) kPa = psi x 6.895

1 atm = 1,013 x 105Pa

1 bar = 1,000 x 105Pa

1 dyne/cm

2

= 1,000 x 10–1Pa

1 inch of Hg (0°C) = 3,386 x 103Pa

1 inch of H2O (4°C) = 2,491 x 102Pa

1 Kg/m

2

= 9,806 Pa

1 pound/inch2(psi) = 6,895 x 10

3

1 pound/foot

2

= 4,788 x 10

1

1 Torr (mm de Hg 0°C) = 1,333 x 10

2

ENGLISH

117

Page 54

ENGLISH

118

2

psi

Ipf / in

Microns

Hg

inch

O

2

H

inch

atm

2

at

kp / cm

Torr

mmHg

O

2

O mmH

2

mH

kPa MPa bar mbar

2

PA

N / m

–6

145.05

0.14505

45.05 - 10

6

7501

7.501

7.501 - 10

–4

295.3

0.2953

2.953 - 10

–3

4016

4.016

4.016 - 10

–3

9.869

9.869 - 10–69.869 - 10

–6

–3

10.20

10.20 - 10

10.20 - 10

–3

7501

7.501

7.501 - 10

3

102.0

0.1020

102.0 - 10

–3

102.0

0.1020

0.1020 - 10

4103

–2

10

10

10

–2

10

10–510

–610–3

1

10

3

–3

1

10

10

3106105

1

10

–3

14.505

14.505 - 10

3

750.1

750.1 - 10

–3

29.53

29.53 - 10

401.6

0.4016

–3

0.9869

0.9869 - 10

–3

1.020

1.020 - 10

750.1

0.7501

3

10.20

10.20 - 10

–3

10.20

10.20 - 10

1

–3

1

10

–4

0.1

10

0.1

100

100

–3

1.4224

–3

73.56 - 10

2.896

39.37

–3

96.78 - 10

0.1

73.56

–3

10

1

98.07

98.07 - 10–398.07 - 10–61.333 - 10

9.807 - 10–39.807 - 10

9.807

9807

14.224

0.01934

1.4224 - 10

–3

–3

10

73.56

735.6 - 10

–2

28.96

2.896 - 10–33.937 - 10

393.7

0.5351

0.03937

–3

0.9678

96.78 - 10–61.316 - 10

–3

–4

1

10

1.359 - 10

–3

1

735.6

73.56 - 10

4

1

10

13.59

–3

–3

10

10

13.59 - 10

–3

1.333

980.7

98.07 - 10

–3

0.9807

–6

–6

–3

98.07 - 10

133.32 - 10

3

98.07

0.13332

9.807 - 10

3

9.807

133.32

98.07 - 10

–3

14.68

0.4912

36.126 - 10

–3

3

3

760 - 10

25.4 - 10

1.868 - 10

–2

1

29.92

7.355 - 10

406.7113.60

–3

1

3.342 - 10–21.316 - 10

2.458 - 10

–3

1.033

2.54 - 10

3.453 - 10–61.359 - 10–670.31 - 10

760

25.4

1.8684

3

25.4

345.3

10.33 - 10

–3

10.33

0.3453

25.4 - 10

1013

2.491

33.86

–3

1.013

2.491 - 10

3.386 - 10–21.333 - 10

–3

–3

0.1013

3.386 - 10

0.2491 - 10

101.3

3.386

0.2491

5

3386

249.1

1.013 - 10

–5

1

1.934 - 10

1

51.715

–5

2.036

3.937 - 10

–3

27.68

0.5351 - 10

–3

–6

6.8948 - 10

–3

–3

10

51.715

–3

703.1

13.59 - 10

–6

0.7031

13.59 - 10

–3

68.948

1.333 - 10

–2

–6

6.8948 - 10

–3

0.1333 - 10–66.8948 - 10

–6

6.8948

133.32 - 10

6894.8

0.13332

Page 55

INSTRUMENT TECHNICAL DATA

Inputs / type of measurement 2 / pressure, flow rate or temperature

Connector DIN 45326 8-pole

No. conversions per second 2

Working temperature -5...+50°C

Working relative humidity 0...90% R.H. (no condensation)

Serial output RS 232C 300...19200 Baud (galvanically insulated)

Display Double LCD 12.5 mm

Functions Auto power off, Autorange, Hold, Record, Peak (5 ms),

Minimum, Mean, Relative, A-B (differential)

Memory 512 kB (FLASH) corr. to 30000 measurements

Power supply 9 Vdc alkaline battery

Autonomy Approx. 50 hours (continuous duty)

Weight / dimensions 320 gr. / 215x73x38 mm

ENGLISH

119

INSTRUMENT PRECISION

Amb. T 18 to 25°C Amb. T -5...18 Measure

or 25...50°C

Pressure measurements

0.1% FS + 0.1% RDG 0.1% FS + 0.1% RDG +100ppm/°C RDG=

measured value

Flow rate measurements

0.2% FS + 0.5% RDG 0.2% FS + 0.5% RDG + 100ppm/°C RDG=

measured value

Temperature

0.4°C 0.4°C + 0.01°C/°C (measures –200...-50°C)

measurements

with TP 870 0.2°C 0.2°C + 0.01°C/°C (measures –50...+200°C)

3°C 3°C + 0.01°C/°C (measures +200...+800°C)

Page 56

ENGLISH

120

∅i= 5 mm TUBE

∅i= 5 mm TUBE

∅i= 5 mm TUBE

∅i= 5 mm TUBE

∅i= 5 mm TUBE

1

/4 BSP

∅i= 5 mm TUBE

1

/4 BSP

∅i= 5 mm TUBE

1

/4 BSP

∅i= 5 mm TUBE

1

/4 BSP1/4 BSP1/4 BSP1/4 BSP1/4 BSP1/4 BSP1/4 BSP1/4 BSP

0÷60°C

0÷60°C

0÷60°C

0÷60°C

0÷60°C

0÷80°C

0÷60°C

0÷80°C

0÷60°C

0÷80°C

0÷60°C

0÷80°C

0÷80°C

0÷80°C

0÷80°C

0÷80°C

0÷80°C

0÷80°C

0÷80°C

0.024

0.024

0.024

0.012

0.012

0.015

0.012

0.015

0.012

0.015

0.012

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.50% FSO

0.50% FSO

0.50% FSO

0.25% FSO

0.12% FSO

0.20% FSO

0.12% FSO

0.20% FSO

0.12% FSO

0.20% FSO

0.12% FSO

0.40% FSO

0.40% FSO

0.40% FSO

0.40% FSO

0.40% FSO

0.40% FSO

0.50% FSO

0.50% FSO

TP704-200MBGI

TP704-500MBGI

TP704-1 BGI

TP704-2BGI

TP704-10BGI

TP704-20BGI

TP704-50BGI

TP704-2BAI

TP704-10BAI

TP704-20BAI

TP704-50BAI

TP704-100BAI

TP704-200BAI

TP704-500BAI

TP704-1000BAI

TP705-10MBD

TP705-20MBD

TP705-50MBD

TP705-100MBD

TP705-200MBD

TP705-500MBD

TP705-1BD

TP705-2BD

TP705BARO

20.0 mbar

40.0 mbar

100 mbar

200 mbar

400 mbar

1000 mbar

2.00 bar

4.00 bar

20.0 bar

40.0 bar

100.0 bar

200 bar

400 bar

750 bar

1100 bar

10.0 mbar

20.0 mbar

50.0 mbar

100 mbar

200 mbar

500 mbar

1.00 bar

2.00 bar

10.0 bar

20.0 bar

50.0 bar

100 bar

200 bar

500 bar

1000 bar

CONNECTIONS

WORKING

TEMP.

TEMPE-

RATURE

DRIFT

AT 25°C

%FS

•

1°C

PRECISION

20÷25°C

Rated

pressure

Maximum

over-pressure

DIFFERENTIAL

RELATIVE

rear of sensor

connected to

GATE 2

ABSOLUTE

ABSOLUTE

rear of sensor

connected to

vacuum

GAUGE

RELATIVE

rear of sensor

connected to

ambient

INSULATED

MEMBRANE

ABSOLUTE

ABSOLUTE

rear of sensor

connected to

vacuum

INSULATED

MEMBRANE

N.B.: Differential probes may be used also for relative measurements (use only the socket marked +).

Differential probes may be used also for two-pole measurements (with pressure on the bottom socket marked + and pressure on the socket marked –).

The BAROMETRIC probe may be used also for measurements up to 0 bar (vacuum).

PROBE PRECISION

Page 57

ENGLISH

121

USE

COD. °C max.

τ

**

sec.

Pt100 SENSOR PROBES

HD 9010

HD 8602

HD 8705

HD 8706

HD 8804

HD 8901

HD 9117

HD 9021

DO 9406

DO 9505

DO 9417

DO 9704

DO 9709

-50

3"TP 870P

+400

-50

3”TP870A

+300

-50

3"

TP 871

+200

-50

3"TP 870

+400

-50

12”TP 870C

+400

4030

➛

➛

➛

➛

70

➛

➛

∅

3

➛

➛

∅

15

➛

➛

∅

12

➛

➛

∅

3

➛

➛

230

∅

4

➛

➛

230

➛

➛

➛

➛

∅

4

➛

➛

150

➛

➛

∅

4

➛

➛

230

➛

➛

DIMENSIONS

Page 58

ORDER CODES

DO 9704 K Pressure gauge - thermometer - data logger kit composed of a diplomatic carrying

case, instrument DO 9704, series of fittings, 1 CPA 8-pole din 45326 connecting

cable between instrument and probe, manual, 9 Vdc alkaline battery.

NOTE: The pressure or temperature probes must be ordered separately to suit the

customer’s requirements.

TP 870 Immersion temperature probe, Pt100 sensor, diam. 3 x 230 mm, measuring range

-50°C...+400°C.

TP 870/C Contact temperature probe, Pt100 sensor, diam. 4 x 230 mm, measuring range

-50°C...+400°C.

TP 870/P Penetration temperature probe, Pt100 sensor, diam. 4 x 150 mm, measuring range

-50°C...+400°C.

TP 870/A Air temperature probe, Pt100 sensor, diam. 4 x 230 mm, measuring range

-50°C...+300°C.

Pressure probes: contact surface with Allumina pressurised fluid, stainless steel body AISI

304, male threaded coupling 1/4” BSP, 8-pole DIN 45326 male connector.

TP 704-200MBGI Pressure probe, full scale 200 mbar relative.

TP 704-500MBGI Pressure probe, full scale 500 mbar relative.

TP 704-1BGI Pressure probe, full scale 1 bar relative.

TP 704-2BGI Pressure probe, full scale 2 bar relative.

TP 704-10BGI Pressure probe, full scale 10 bar relative.

TP 704-20BGI Pressure probe, full scale 20 bar relative.

TP 704-50BGI Pressure probe, full scale 50 bar relative.

TP 704-2BAI Pressure probe, full scale 2 bar absolute.

TP 704-10BAI Pressure probe, full scale 10 bar absolute.

TP 704-20BAI Pressure probe, full scale 20 bar absolute.

TP 704-50BAI Pressure probe, full scale 50 bar absolute.

TP 704-100BAI Pressure probe, full scale 100 bar absolute.

TP 704-200BAI Pressure probe, full scale 200 bar absolute.

TP 704-500BAI Pressure probe, full scale 500 bar absolute.

TP 704-1000BAI Pressure probe, full scale 1000 bar absolute.

The probes in the series TP 705 are suitable for measuring the low pressure of non-corrosive gases and dry air, fitting diam. 5 mm.

TP 705-10MBD Pressure probe, full scale 10 mbar relative.

TP 705-20MBD Pressure probe, full scale 20 mbar relative.

TP 705-50MBD Pressure probe, full scale 50 mbar relative.

TP 705-100MBD Pressure probe, full scale 100 mbar relative.

TP 705-200MBD Pressure probe, full scale 200 mbar relative.

TP 705-500MBD Pressure probe, full scale 500 mbar relative.

ENGLISH

122

Page 59

TP 705-1BD Pressure probe, full scale 1 bar relative.

TP 705-2BD Pressure probe, full scale 2 bar relative.

TP 705-BARO Pressure probe, full scale 1 bar absolute barometric.

GUARANTEE

This instrument is strictly inspected before being sold. However if there should be any defect due to

manufacture and/or transport, apply to the dealer from whom you bought the instrument. The guarantee period is 2 (two) years from the date of purchase. During this period all defects found by us

will be repaired free of charge, excluding those due to incorrect use and careless handling. The

probes are not covered by the guarantee, as they can be irreparably damaged after only a few

minutes of incorrect use.

ENGLISH

123

Page 60

EXAMPLES OF USE OF THE KEYBOARD

1. Switches the instrument on or off.

2. Blocks or resets updating of the display.

Display blocked Display reset

3. Allows the display, storage or sending of the relative values immediately onto the

serial line.

Display or relative values Display of absolute values

ENGLISH

124

°C

10

3

°C

10

3

3

HOLD

10

°C

3

10

°C

REL

Page 61

4. Pressing DATA CALL repeatedly gives:

1.

The Maximum value of the probes connected to the inputs

2.

The Minimum value of the

probes connected to the inputs

3.

The Mean value of the probes

connected to the inputs

4.

Returns to normal operating

mode

ENGLISH

125

MED

3

10

°C

MAX

3

10

°C

MIN

3

10

°C

3

10

°C

Page 62

ENGLISH

126

5. Instrument programming.

10

3

=

=

+

++

++

+

=

=

+

=

++

+

=

Returns to normal operating mode, without

storing the changed

values.

Confirms the selected

value and returns to

normal operating

mode

Unloads data from the memory

Returns to normal operating mode

Erases memory (Memory Clear)

Returns to normal operating mode

=

++ +

=

Confirms the selected

value and returns to

normal operating

mode

Sets

Baud Rate

Sets reading or storage interval (from 1 sec. to 12 hours)

Resets relative probes

offset on channel A

Resets relative probes

offset on channel B

3

10

3

10

Page 63

ENGLISH

127

Sets year

00, 01, 02 ... 99

Example: 2000

=

++ +

Sets month

01, 02, 03 ... 12

Example: 01 January

=

++ +

Sets day

01, 02, 03 ... 31

Example: 01

=

++ +

Sets hour

00, 01, 02 ... 23

Example: 00 midnight

=

++ +

Page 64

Enables self cut-out

during storage with an

intervention time equal to

or greater than 1 minute

The instrument does not cut out

automatically during storage

=

++

+

=

Confirms the selected

value and returns to

normal operating mode

+

=

Confirms the selected

value and returns to

normal operating mode

Data printing is complete

Data printing is reduced

=

++

ENGLISH

128

Sets minutes

00, 01, 02 ... 59

Example: 01 minutes

=

++ +

=

Confirms the selected

value and returns to

normal operating

mode, storing the set

date and time

Page 65

ENGLISH

129

=

=

=

++

Returns to normal

operating mode

=

+=

Enters calibration

function

++

6. Activation or disactivation of the serial output.

Serial output active Serial output ended

7. Activation or disactivation of the Record function.

When the key is pressed the instrument

gives a beep and starts storing and updating

the MAX, MIN and MEAN value

When the key is held down for more than one second,

the instrument gives a short beep followed by a long one.

The Maximum, Minimum and Mean values have been reset

and the instrument starts updating these values again.

RCD

RCD

RCD

mg/l

°C

Serial

Out

Memory

mg/l

°C

mg/l

°C

Page 66

ENGLISH

130

8. Activation and disactivation of the storage function.

Storage phase active Storage phase ended

Start-Stop

Start-Stop

°C

10

3

Start-Stop

3

10

°C

Serial

Out

Memory

Page 67

INDEX

TECHNICAL DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

KEYBOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

PROBE CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

HOW TO MEASURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Attention when using the keyboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

TEMPERATURE MEASUREMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

METHOD OF USING THE INSTRUMENT AND WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

INSTRUMENT SIGNALS AND MALFUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

LOW BATTERY WARNING AND BATTERY REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Faulty operation when switching on after changing the battery . . . . . . . . . . . . . . . . . . . . . . 91

Warning on use of the batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

STORAGE OF THE INSTRUMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

SERIAL INTERFACE RS 232C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Host commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

DIAGRAM DO 9704 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

EXAMPLE OF A REPORT PRINTED BY THE INSTRUMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 95

INSTRUCTIONS FOR CONNECTING DELTA OHM INSTRUMENTS TO A PC

WITH WINDOWS OPERATIVE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Hardware connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Software connection with WINDOWS 3.1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Software connection with WINDOWS 95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

CALIBRATING THE INSTRUMENT DO 9704 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

FLOW RATE MEASUREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

CONNECTION OF PROBES TO THE PRESSURE GAUGE DATA LOGGER DO 9704 . . . . . . 113

ENGLISH

131

Page 68

Probe connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Classification of pressure measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Conversion factors and tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

INSTRUMENT TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Instrument precision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Probe precision. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

ORDER CODES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

GUARANTEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

EXAMPLES OF USE OF THE KEYBOARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

ENGLISH

132

Page 69

CE CONFORMITY

Safety EN61000-4-2, EN61010-1 level 3

Electrostatic discharge EN61000-4-2 level 3

Electric fast transients EN61000-4-4 level 3

Voltage variations EN61000-4-11

Electromagnetic interference

sucseptibility

IEC1000-4-3

Electromagnetic interference

emission

EN55020 class B

DELTA OHM SRL