Page 1

46-464 MIDI-LATHE STAND EXTENSION

FOR USE WITH DELTA MIDI-LATHES 46-455 AND 46-460 AND LATHE STAND 46-462

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY DELTA MACHINERY ACCESSORY, CALL US TOLL FREE AT

800-223-7278.

SAFETY INSTRUCTIONS

To reduce the risk of injury, read the tool instruction

manual before using any accessory. Failure to heed these warnings

may result in personal injury and serious damage to the tool and

the accessory. When servicing this tool, use only identical replacement parts.

disconnect it from power source before installing and removing

accessories, before adjusting or when making repairs. An

accidental start-up can cause injury.

used with Delta midi-lathes 46-455 and 46-460 and Delta lathe

stand 46-462 and Delta lathe extension bed 46-463.

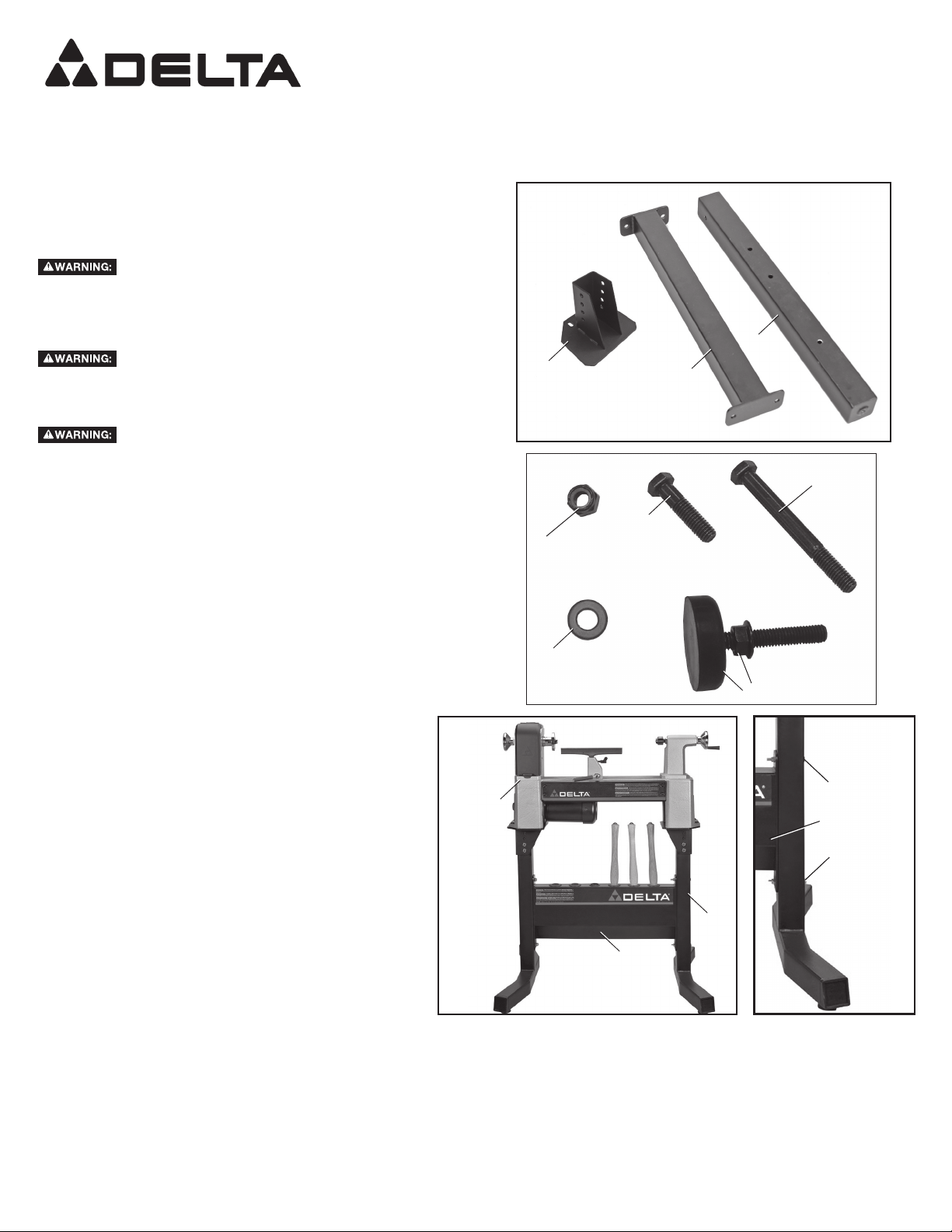

46-464 PARTS (FIG. 1, FIG. 2)

A. Lathe stand platform (1)

B. Extension cross brace (1)

C. Center support leg (1)

D. 3/8-16 x 1-1/2" (38 mm) hex head bolt (2)

E. 3/8-16 x 3-1/2" (89 mm) hex head bolt (5)

F. 3/8-16 nylock nut (7)

G. 3/8 flat washer (14)

H. Leveling foot and jam nut (1)

NOTE: If you are assembling both the 46-462 Lathe Stand and

this 46-464 Lathe Stand Extension at the same time, refer to the

46-462 instruction sheet before proceeding to section Assembly

of Extension with the Stand in this sheet as directed.

To reduce the risk of injury, turn tool off and

To reduce risk of injury this product should only be

A

FIG. 1

F

G

N039890 - JULY09 - REV0

C

B

E

D

H

FIG. 2

ASSEMBLY

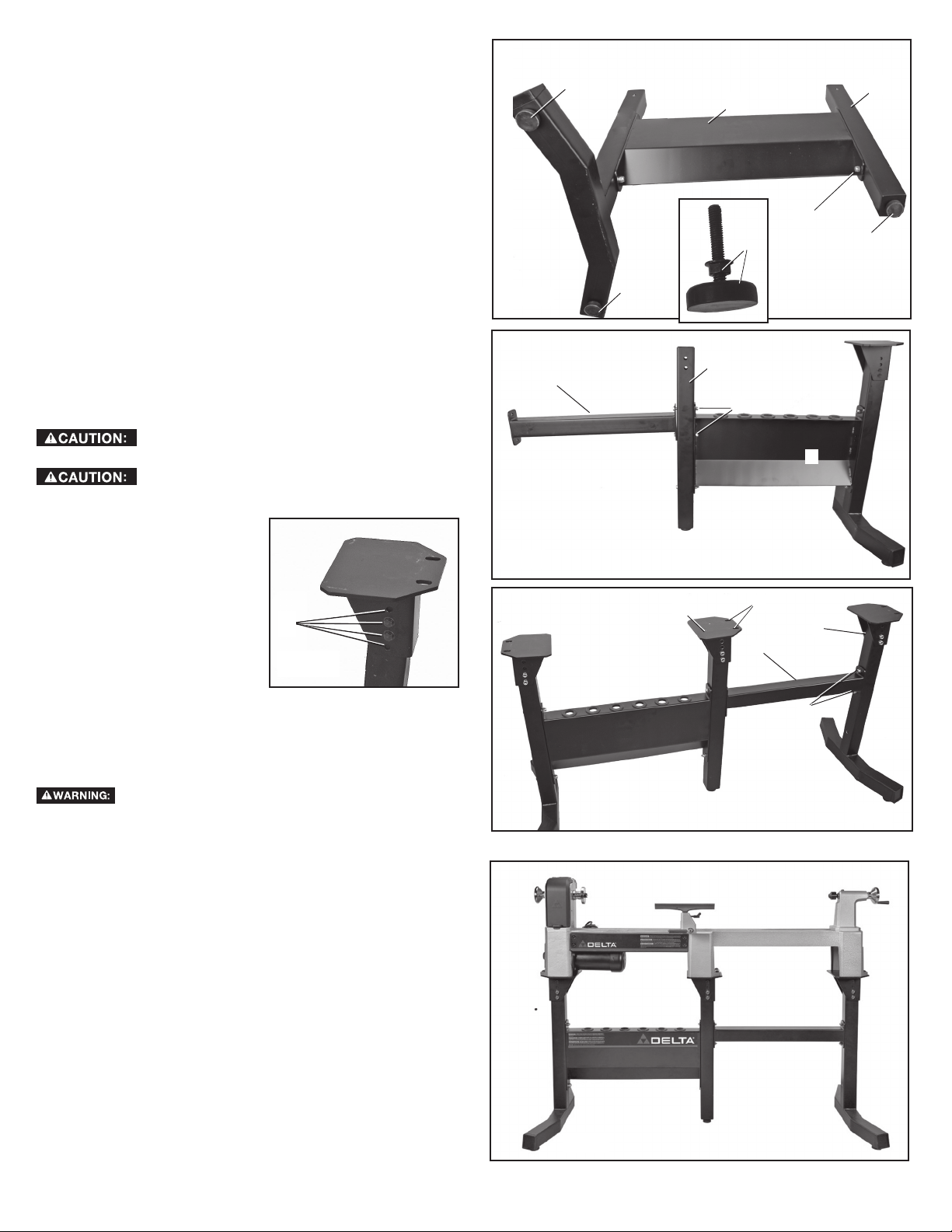

DISASSEMBLY OF THE STAND

1. Remove the lathe (I) Fig. 3 from the stand (J).

2. Remove the right side leg (K) Fig. 3 by removing both

sets of bolts, washers and nuts, located at (L) Fig. 4, that

attach leg to cross brace / tool holder (M).

3. Set aside these parts to re-attach later on the very end of

the stand extension.

ASSEMBLY OF EXTENSION WITH THE STAND

NOTE: For ease of alignment, do not fully tighten nuts

until assembly is complete.

1. Bolt center support leg (C) Fig. 5 to cross brace/tool

holder (M) in bottom hole only (shown at (N)) using one

3/8-16 x 3-1/2" (89 mm) hex head bolt (E) Fig. 2, two 3/8

flat washers (G) Fig. 2 and one 3/8-16 nylock nut (F) Fig.

2.

2. Place flat washer on bolt and insert it through center support leg

(C) Fig. 5 and then through the hole (N) in tool holder. Place a

second flat washer on the bolt and fasten with the nylock nut.

3. Make sure jam nut is on rubber leveling foot (H) Fig. 5 (inset)

as shown. Screw in rubber leveling foot (H) as shown in Fig. 5.

Tighten all the way down. Height can be adjusted later.

4. Attach extension brace (B) Figure 6 to center support leg (C) and

cross brace / tool holder (M) in two top holes (P) as shown, using

two 3/8-16 x 3-1/2" (89 mm) hex head bolts (E) Fig. 2, four 3/8

FIG. 3

L

I

M

L

K

J

FIG. 4

flat washers (G) Fig. 2 and two 3/8-16 nylock nuts (F) Fig. 2.

5. For each hole (P) Fig. 6, place washer on bolt and insert the bolt

through hole in extension brace (B), then through hole in center

support leg (C) and then through the cross brace / tool holder (M).

Place a second flat washer on the bolt and fasten with nylock nut.

NOTE: Figure 6 is shown from back of lathe stand.

NOTE: An additional Lathe Stand Extension can be attached in a

similar manner using steps above. Do not attach more than two

Lathe Stand Extensions.

Page 2

6. Attach right side leg assembly (K) Fig. 7 to the right side of

extension brace (B) in two holes (Q) as shown using two 3/8-16 x

3-1/2" (89 mm) hex head bolts (E) Fig. 2, four 3/8 flat washers (G)

Fig. 2 and two 3/8-16 nylock nuts (F) Fig. 2. Remember to orient

leg as shown in Fig. 7.

7. Attach lathe stand platform (A) Fig. 7 to center support leg using

two 3/8-16 x 3-1/2" (89 mm) hex head bolts (E) Fig. 2, four 3/8 flat

washers (G) Fig. 2 and two 3/8-16 nylock nuts (F) Fig. 2.

NOTE: The stand height is adjustable by placing two bolts through

two of the four holes (R) Fig. 8 in the lathe stand platform. Be sure

the lathe mounting holes (S) Fig. 7 in top of the platform are facing to

outside, away from tool holder as shown.

8. To attach lathe stand platform (S), place 3/8 flat washers on two

bolts and insert bolts through desired two holes (R) Fig. 8. Place

3/8 flat washers on the bolts after insertion and then tighten with

3/8-16 nylock nuts.

NOTE: Be sure each lathe stand platform is set at the same height.

NOTE: Do not tighten completely.

9. Attach extension bed to your lathe. Refer to the instruction sheet

with your DELTA 46-463 Midi-Lathe Extension Bed for attaching

the bed to your lathe. Lift lathe and extension bed onto lathe

stand platforms as shown in Fig. 9.

Risk of unsafe operation. Make sure hardware on

lathe and lathe extension bed is tight.

Risk of unsafe operation. Use two people when

lifting the lathe and lathe bed extensions.

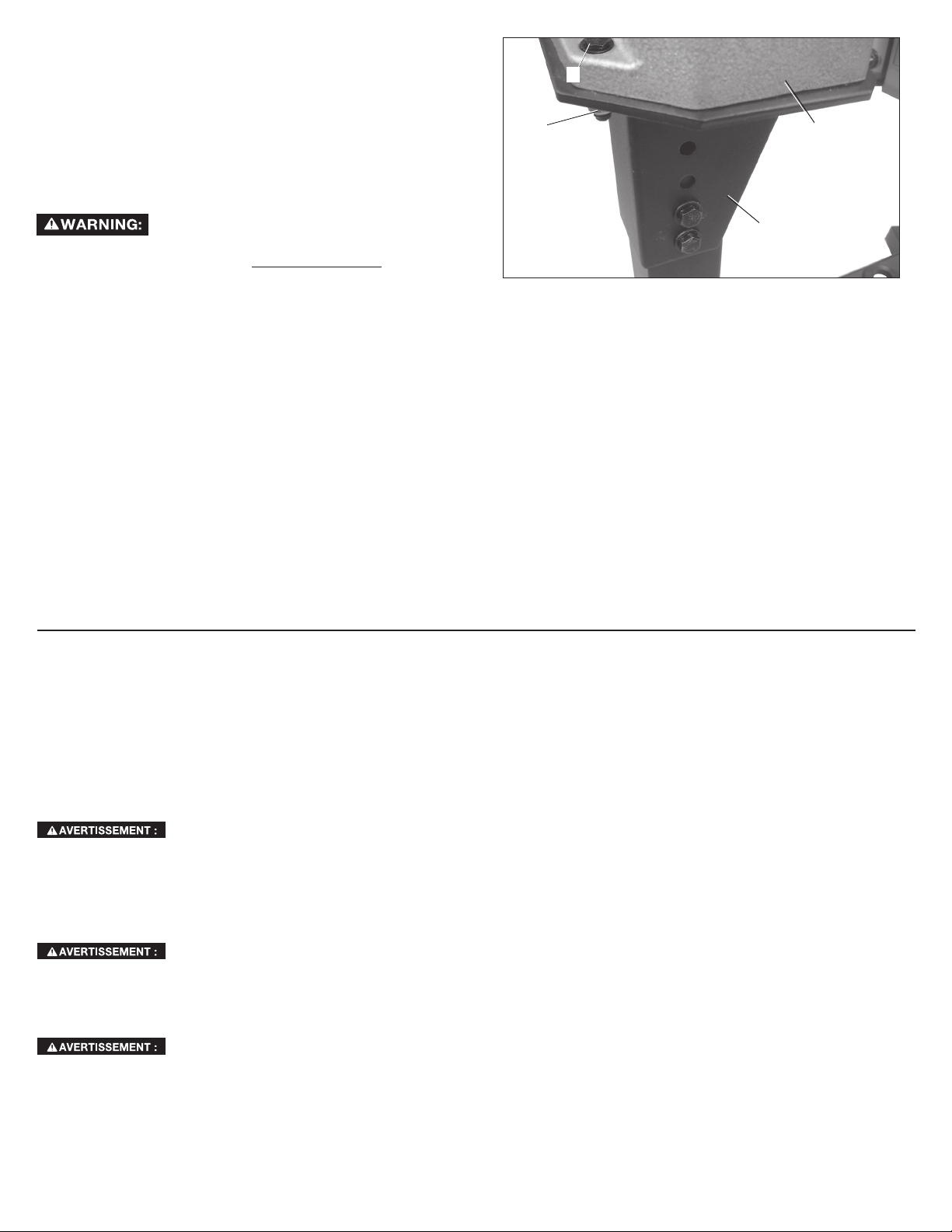

10. Match up holes in lathe

base with holes in platform.

Attach lathe to stand at these

holes using four 3/8-16 x 1-1/2"

(38 mm) hex head bolts (B)

Figure 10, eight 3/8 flat washers

and four 3/8-16 nylock nuts (A).

11. For each hole, place a washer

on the hex head bolt and insert

it down through the hole at (B)

R

FIG. 8

Fig. 10. Place a second washer

on bolt underneath and tighten

securely using nylock nut.

12. Tighten all lathe stand hardware firmly at this point.

13. Adjust all leveling feet so the lathe stand rests securely on the

floor without rocking or tilting. Then tighten all four jam nuts.

Refer to the instruction sheet with your DELTA 46-463

Midi-Lathe Extension Bed for all relevant safety rules when using the

lathe with the extension.

FIG. 5

FIG. 6

H

M

N

H

H

C

B

P

M

A

S

K

B

Q

C

H

FIG. 7

TROUBLESHOOTING

For assistance w i t h your machine, visit o u r w e b s i t e

at www.deltaportercable.com for a list of service centers or call the

DELTA Machinery help line at 1-800-223-7278 (In Canada call 1-800-

463-3582).

SERVICE

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts,

visit our website at www.deltaportercableservicenet.com. You can

also order parts from your nearest factory-owned branch, Authorized

Warranty Service Center or by calling End User Services at (800) 2237278 to receive personalized support from one of our highly-trained

representatives.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement

of parts. For information about DELTA Machinery, its factory-owned

branches, or to locate an Authorized Warranty Service Center, visit

our website at www.deltaportercable.com or call our End User

Services at (800) 223-7278. All repairs made by our service centers

FIG. 9

2

Page 3

are fully guaranteed against defective material and workmanship. We

cannot guarantee repairs made or attempted by others. By calling

this number you can also find answers to most frequently asked

questions 24 hours/day.

You can also write to us for information at DELTA Machinery, PO

Box 2468, Jackson, Tennessee 38302-2468 - Attention: End User

Services. Be sure to include all of the information shown on the

nameplate of your tool (model number, type, serial number, date

code, etc.)

ACCESSORIES

Since accessories other than those offered

by DELTA have not been tested with this product, use of such

accessories could be hazardous. For safest operation, only DELTA

recommended accessories should be used with this product.

A complete line of accessories is available from your DELTA Supplier,

DELTA Factory Service Centers, and DELTA Authorized Service

Stations. Please visit our Web Site www.deltaportercable.com for a

catalog or for the name of your nearest supplier.

WARRANTY

To register your tool for warranty service visit our website at www.

deltaportercable.com.

FIVE YEAR LIMITED NEW PRODUCT WARRANTY

DELTA will repair or replace, at its expense and at its option, any

new DELTA machine, machine part, or machine accessory which in

normal use has proven to be defective in workmanship or material,

provided that the customer returns the product prepaid to a DELTA

factory service center or authorized service station with proof of

purchase of the product within five years and provides DELTA with

reasonable opportunity to verify the alleged defect by inspection.

For all refurbished DELTA product, the warranty period is 180 days.

DELTA will not be responsible for any asserted defect which has

resulted from normal wear, misuse, abuse or repair or alteration

made or specifically authorized by anyone other than an authorized

B

A

F

FIG. 10

DELTA service facility or representative. Under no circumstances will

DELTA be liable for incidental or consequential damages resulting

from defective products. Some states do not allow the exclusion

or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This warranty is DELTA’s

sole warranty and sets forth the customer’s exclusive remedy,

with respect to defective products; all other warranties, express or

implied, whether of merchantability, fitness for purpose, or otherwise,

are expressly disclaimed by DELTA. For further detail of warranty

coverage and warranty repair information, visit www.deltaportercable.

com or call (888) 848-5175. This warranty gives you specific legal

rights and you may have other rights which vary in certain states or

provinces.

LATIN AMERICA: This warranty does not apply to products sold in

Latin America. For products sold in Latin America, see country specific warranty information contained in the packaging, call the local

company or see website for warranty information.

P

RALLONGE DE BANC DE

TOUR À BOIS MOYEN 46-464

À UTILISER AVEC LES TOURS À BOIS MOYENS DELTA, MODÈ-

LES 46-455 ET 46-460, ET LE BANC DE TOUR À BOIS 46-462

POUR TOUTE QUESTION RELATIVE À CET ACCESSOIRE OU

TOUT AUTRE ACCESSOIRE DELTA, COMPOSER GRATUITEMENT

LE : 800-223-7278.

CONSIGNES DE SÉCURITÉ

Pour réduire tout risque de dommages

corporels, lire le manuel de l’utilisateur respectif à l’outil

avant l’utilisation de tout accessoire. Tout manquement à ces

avertissements augmente les risques de blessures, et les risques

de sérieusement endommager l’appareil et ses accessoires. Lors

de l’entretien de cet outil, n’utiliser que des pièces de rechange

identiques.

corporels, arrêter et débrancher l’outil du secteur avant d’installer

ou retirer tout accessoire, avant tout réglage ou pour faire toute

réparation. Tout démarrage accidentel comporte des risques de

dommages corporels.

corporels, ce produit ne devrait être utilisé qu’avec les tours à

bois moyens Delta, modèles 46-455 et 46-460, les bancs de tour

Delta 46-462 et les extensions de banc de tour Delta 46-463.

PIÈCES DE LA 46-464 (Fig. 1, Fig. 2)

A. Plateforme du banc de tour à bois (1)

B. Barre transversale de rallonge (1)

C. Pied de support central (1)

Pour réduire tout risque de dommages

Pour réduire tout risque de dommages

D. Boulons à tête hexagonale de 38 mm (3/8-16 x 1-1/2 po), (2)

E. Boulons à tête hexagonale de 89 mm (3/8-16 x 3-1/2 po), (5)

F. Écrous nylock 3/8-16 (7)

G. Rondelles plates de 3/8 (14)

H. Pied réglable avec contre-écrou (1)

REMARQUE : Si vous effectuez en même temps, l’installation

du banc de tour 46-462 et celle de la rallonge de banc de tour

46-464, reportez-vous aux directives d’utilisation du 46-462 avant

de passer à la section Montage de la rallonge au banc de tour de

ces directives.

MONTAGE

DÉMONTAGE DU BANC

1. Retirez le tour (I), fig. 3, du banc (J).

2. Retirez le pied droit (K), fig. 3, en retirant les deux jeux de boulons,

rondelles et écrous, situés sur (L), fig. 4, et qui rattachent le pied à

la barre transversale/porte-outils (M).

3. Mettez l’ensemble de ces pièces de côté pour les rattacher plus

tard, à l’extrémité de la rallonge de banc.

MONTAGE DE LA RALLONGE AU BANC

REMARQUE : Pour faciliter l’alignement, ne pas resserrer

complètement les écrous tant que le montage n’est pas terminé.

1. Arrimez le pied de support central (C), fig. 5, à la barre

transversale/porte-outils (M) par le trou inférieur seulement (illustré

par N), à l’aide d’un boulon à tête hexagonale de 89 mm (3/816 x 3-1/2 po) (E), fig 2, deux rondelles plates de 3/8 (G), fig. 2, et

un écrou nylock de 3/8-16 (F), fig. 2.

2. Placez une rondelle sur un boulon puis insérez-le dans le pied de

support central (C), fig. 5, puis dans le trou (N) du porte-outils.

Insérez une deuxième rondelle plate sur le boulon puis resserrez

avec un écrou nylock.

3

Page 4

3. Assurez-vous que le contre-écrou est bien inséré sur le pied

de réglage en caoutchouc (H), fig. 5 (encadré), comme illustré.

Vissez le pied réglable en caoutchouc (H), comme illustré en fig.

5. Resserrez à fond. La hauteur pourra être ajustée plus tard.

4. Rattachez la barre transversale de rallonge (B), fig. 6, au pied de

support central (C) et à la barre transversale/porte-outils (M) par

les deux trous supérieurs (P), comme illustré, à l’aide de deux

boulons à tête hexagonale de 89 mm (3/8-16 x 3-1/2 po) (E), fig.

2, quatre rondelles plates de 3/8 (G), fig. 2, et deux écrous nylock

de 3/8-16 (F), fig. 2.

5. Pour chacun des trous (P), fig. 6, placez une rondelle sur un

boulon puis insérez-le dans le trou de la barre transversale de

rallonge (B) puis dans le trou du pied de support central (C) et

enfin dans la barre transversale/porte-outils (O). Insérez une

deuxième rondelle plate sur le boulon puis resserrez avec un

écrou nylock.

REMARQUE : La figure 6 montre l’arrière du banc de tour.

REMARQUE : Une rallonge de banc de tour supplémentaire peut

être rattachée de la même manière en suivant la procédure ci-dessus.

Ne pas rattacher plus de deux rallonges de banc de tour.

6. Rattachez le dispositif du pied droit (K), fig. 7 sur l’extrémité droite

de la barre transversale de rallonge (B) par deux trous (Q), comme

illustré, à l’aide de deux boulons à tête hexagonale de 89 mm

(3/8-16 x 3-1/2 po) (E), fig. 2, quatre rondelles plates de 3/8 (G),

fig. 2, et deux écrous nylock de 3/8-16 (F), fig. 2. N’oubliez pas

de bien orienter le pied comme illustré.

7. Rattachez la plateforme (A) du banc de tour, fig. 7, au pied de

support central à l’aide de deux boulons à tête hexagonale de

89 mm (3/8-16 x 3-1/2 po) (E), fig. 2, quatre rondelles plates de

3/8 (G), fig. 2, et deux écrous nylock de 3/8-16 (F), fig. 2.

REMARQUE : On peut régler la hauteur du banc en plaçant deux

boulons au travers de deux des quatre trous (R), fig. 8, sur la

plateforme du banc de tour. S’assurer que les trous d’installation du

tour (S), fig. 7, sur la plateforme sont orientés vers l’extérieur, et non

pas vers le porte-outils, comme illustré.

8. Pour le rattacher, placez deux rondelles plates de 3/8 sur deux

boulons, puis insérez les boulons dans les trous (R) désirés, fig. 8.

Placez des rondelles plates de 3/8 sur les boulons après insertion

puis resserrez avec des écrous nylock de 3/8-16.

REMARQUE : S’assurer que toutes les plateformes du banc de tour

sont bien à la même hauteur.

REMARQUE : Ne pas encore serrer complètement.

9. Rattachez l’extension de banc au tour. Reportez-vous aux

directives d’utilisation incluses avec l’Extension de banc de tour à

bois moyen DELTA 46-463 pour rattacher le tour au banc. Placez

le tour et l’extension de banc sur les plateformes du banc de tour,

comme illustré en figure 9.

Conditions d’utilisation dangereuses.

S’assurer que les fixations sur le tour et l’extension de banc de

tour sont soigneusement serrées.

Conditions d’utilisation dangereuses.

Soulever le tour et les extensions de banc de tour à deux

personnes.

10. Alignez les trous sur la base du tour avec les trous de la plateforme.

Rattachez le tour au banc par ces trous à l’aide de quatre boulons

à tête hexagonale de 38 mm (3/8-16 x 1-1/2 po) (B), fig. 10, huit

rondelles plates de 3/8 et quatre écrous nylock de 3/8-16 (A).

11. Pour chacun des trous, placez une rondelle sur les boulons à tête

hexagonale puis insérez ces derniers dans les trous (B), fig. 10.

Placez une deuxième rondelle dessous, sur chaque boulon, puis

resserrez soigneusement à l’aide d’un écrou nylock.

12. Resserrez alors fermement toutes les fixations sur le banc de

tour.

13. Ajustez tous les pieds réglables de façon à ce que le banc de tour

s’appuie en toute sécurité, fermement et à plat, sur le sol. Puis

resserrez les quatre contre-écrous.

avec l’Extension de banc de tour à bois moyen DELTA 46-463 pour

toute consigne de sécurité pertinente à l’utilisation du tour avec une

extension.

Se reporter aux directives d’utilisation incluses

DEPANNAGE

Pour l'assistance avec votre outil, visiter notre site web à

www.deltaportercable.com pour une liste de centres de maintenance

ou appeler la ligne d'aide de DELTA Machinery à 1-800-223-7278.

(Canada: 1-800-463-3582).

SERVICE

PIÈCES DE RECHANGE

Utiliser seulement des pièces de rechange identiques. Pour obtenir

une liste des pièces de rechange ou pour en commander, consulter

notre site Web au www.deltaportercableservicenet.com. Il est

aussi possible de commander des pièces auprès d’une succursale

d’usine ou un centre de réparation sous garantie autorisé ou en

communiquant avec le service à la clientèle au 800-223-7278 pour

recevoir un soutien personnalisé de l’un de nos représentants bien

formés.

ENTRETIEN ET RÉPARATION

Tous les outils de qualité finissent par demander un entretien ou un

changement de pièce. Pour de plus amples renseignements à propos

de DELTA Machinery, ses succursales d’usine ou pour trouver un

centre de réparation sous garantie autorisé, consulter notre site Web

au www.deltaportercable.com ou communiquer avec notre service

à la clientèle au 800-223-7278. Toutes les réparations effectuées

dans nos centres de réparation sont entièrement garanties contre les

défauts de matériaux et de main-d’œuvre. Nous ne pouvons garantir

les réparations effectuées en partie ou totalement par d’autres.

En composant ce numéro à toute heure du jour ou de la nuit, il est

également possible de trouver les réponses aux questions les plus

courantes.

Pour de plus amples renseignements, écrire également à DELTA

Machinery, PO Box 2468, Jackson, Tennessee 38302-2468, É.-U. à l’attention de : End User Services. S’assurer d’indiquer toutes les

informations figurant sur la plaque signalétique de l’outil (numéro du

modèle, type, numéro de série, code de date, etc.).

ACCESSOIRIES

offertspar DELTA n'ont pas été testés avec ce produit, utilisation

de tels accessoires a pu être dangereux. Pour l'exploitation

sûre, seulement DELTA a recommandé des accessoires devrait

être utilisé avec ce produit.

Une ligne complète des accessoires est fournie des centres

commerciaux d'usine de par votre de DELTA fournisseur, de DELTA,

et des stations service autorisées. Veuillez visiter notre site Web

www.deltaportercable.com pour un catalogue ou pour le nom de

votre fournisseur plus proche.

Depuis des accessoires autre que ceux

GARANTIE

Pour enregistrer votre outil pour la garantie service la visite notre site

Web à www.deltaportercable.com.

GARANTIE LIMITÉE DE CINQ ANS

DELTA réparera ou remplacera, à ses frais et à sa discrétion, toute

nouvelle machine DELTA, pièce de rechange ou tout accessoire

qui, dans des circonstances d'utilisation normale, s'est avéré

défectueux en raison de défauts de matériau ou de fabrication,

à condition que le client retourne le produit (transport payé

d'avance) au centre de réparation de l'usine DELTA ou à un centre

de réparation autorisé accompagné d'une preuve d'achat et dans

les cinq ans de la date d'achat du produit, et fournisse à DELTA

une opportunité raisonnable de vérifier le défaut présumé par une

inspection. La période de garantie des produits DELTA réusinés

est de 180 jours. DELTA ne peut être tenu pour responsable des

défauts résultants de l'usure normale, de la mauvaise utilisation,

4

Page 5

de l'abus, de la réparation ou de la modification du produit, sauf

en cas d'autorisation spécifique d'un centre de réparation ou

d'un représentant DELTA autorisé. En aucune circonstance DELTA

ne peut être tenu pour responsable des dommages accidentels

ou indirects résultant d'un produit défectueux. Certains États

ou provinces ne permettent pas l’exclusion ou la restriction de

dommages accessoires ou indirects, auquel cas, les exclusions

ou limitations ci-dessus pourraient ne pas être applicables. Cette

garantie constitue la seule garantie de DELTA et le recours exclusif

des clients en ce qui concerne les produits défectueux ; toutes les

autres garanties, expresses ou implicites, de qualité marchande,

d'adéquation à un usage particulier, ou autre, sont expressément

déclinées par DELTA. Pour obtenir de plus amples renseignements

sur les pièces ou les réparations couvertes par la présente garantie,

visiter le site www.deltaportercable.com ou composer le (888)

848-5175. Cette garantie confère des droits légaux particuliers à

l’acheteur, mais celui-ci pourrait aussi bénéficier d’autres droits

variant d’un état ou d’une province à l’autre.

AMÉRIQUE LATINE : Cette garantie ne s’applique aux produits

vendus en Amérique latine. Pour ceux-ci, veuillez consulter les

informations relatives à la garantie spécifique présente dans

l’emballage, appeler l’entreprise locale ou consulter le site Web pour

les informations relatives à cette garantie.

EXTENSIÓN 46-464 DEL

SOPORTE PARA TORNOS

MEDIANOS

COMPATIBLE CON TORNOS MEDIANOS 46-455 Y 46-460 Y CON

EL SOPORTE PARA TORNOS 46-462 MARCA DELTA

SI TIENE ALGUNA PREGUNTA ACERCA DE ESTE O CUALQUIER

OTRO ACCESORIO PARA MAQUINARIAS DELTA, LLÁMENOS

GRATUITAMENTE AL 800-223-7278.

INSTRUCCIONES DE SEGURIDAD

Para reducir el riesgo de lesiones, lea el manual

de instrucciones de la herramienta antes de usar cualquiera de los

accesorios. De no seguir estas advertencias podrían producirse

lesiones corporales y graves daños a la herramienta y al accesorio.

Cuando realice el mantenimiento de esta herramienta, utilice

únicamente repuestos idénticos.

herramienta y desenchúfela antes de instalar y quitar accesorios,

y antes de realizar ajustes o reparaciones. Un arranque accidental

puede causar lesiones.

producto sólo debe utilizarse con los tornos medianos 46-455 y

46-460 marca Delta, con el soporte 46-462 marca Delta para tornos,

y con el asiento de la extensión 46-463 marca Delta para tornos.

PIEZAS DEL 46-464 (FIG. 1, FIG. 2)

A. Plataforma del soporte para tornos (1)

B. Soporte transversal de la extensión (1)

C. Base de apoyo central (1)

D. Pernos hexagonales de 38 mm (3/8-16 x 1-1/2 pulg.) (2)

E. Pernos hexagonales de 89 mm (3/8-16 x 3-1/2 pulg.) (5)

F. Tuercas de seguridad Nylock de 3/8-16 (7)

G. Arandelas planas de 3/8 (14)

H. Pata niveladora con tuerca de bloqueo (1)

NOTA: Si está ensamblando el soporte para tornos 46-462

y la extensión 46-464 del soporte para tornos al mismo

tiempo, remítase a la hoja de instrucciones del 46-462 antes

de remitirse a la sección Ensamblaje de la extensión con el

soporte que aparece en esta hoja, según se indique.

ENSAMBLAJE

DESMONTAJE DEL SOPORTE

1. Retire el torno (I) Fig. 3 del soporte (J).

2. Quite ambos juegos de pernos, arandelas y tuercas de (L) Fig.

4 que fijan la base derecha (K) Fig. 3 al soporte transversal /

sujeta herramientas (M).

Para reducir el riesgo de lesiones, apague la

Para reducir el riesgo de lesiones, este

3. Ponga a un lado estas piezas para volverlas a instalar una

vez que la extensión del soporte esté casi completamente

instalada.

ENSAMBLAJE DE LA EXTENSIÓN CON EL SOPORTE

NOTA: Con el fin de facilitar el alineamiento, no ajuste

completamente los pernos y las tuercas hasta no finalizar el

ensamblaje.

1. Fije la base de apoyo central (C) Fig. 5 al soporte transversal

/ sujeta herramientas (M) con un perno hexagonal de 89 mm

(3/8-16 x 3-1/2 pulg.) (E) Fig. 2, dos arandelas planas de 3/8

(G) Fig. 2 y una tuerca de seguridad Nylock de 3/8-16 (F) Fig. 2

instalados sólo en el orificio inferior (que aparece en (N)).

2. Coloque una arandela plana en el perno e insértelo en la base

de apoyo central (C) Fig. 5 y luego en el orificio (N) del sujeta

herramientas. Coloque una segunda arandela plana en el

vástago del perno y termine de fijarlo con la tuerca de seguridad

Nylock.

3. Verifique que la pata niveladora de goma (H) Fig. 5 (recuadro)

tenga una tuerca de bloqueo como aparece en la imagen.

Atornille la pata niveladora de goma (H) como lo muestra la

Fig. 5. Enrósquela completamente hasta abajo. Podrá ajustar la

altura después.

4. Utilice dos pernos hexagonales de 89 mm (3/8-16 x 3-1/2

pulg.) (E) Fig. 2, cuatro arandelas planas de 3/8 (G) Fig. 2 y dos

tuercas de seguridad Nylock de 3/8-16 (F) Fig. 2 para fijar el

soporte de la extensión (B) Figura 6 a la base de apoyo central

(C) y al soporte transversal / sujeta herramientas (M) por los dos

orificios superiores (P) como aparece.

5. Coloque una arandela en cada uno de los pernos hexagonales

e insértelos en los orificios correspondientes (P) Fig. 6 del

soporte de la extensión (B), luego por el orificio de la base de

apoyo central (C) y luego por el soporte transversal / sujeta

herramientas (O). Coloque una segunda arandela plana en el

vástago del perno y termine de fijarlo con la tuerca de seguridad

Nylock.

NOTA: La Figura 6 muestra la parte posterior del soporte para

tornos.

NOTA: Si desea instalar una extensión adicional en el soporte

para tornos, siga los pasos anteriores. No instale más de dos

extensiones al soporte para tornos.

6. Utilice dos pernos hexagonales de 89 mm (3/8-16 x 3-1/2

pulg.)(E) Fig. 2, cuatro arandelas planas de 3/8 (G) Fig. 2 y

dos tuercas de seguridad Nylock de 3/8-16 (F) Fig. 2 para fijar

la base derecha (K) Fig. 7 al lado derecho del soporte de la

extensión (B) usando los dos orificios (Q) como aparece en la

imagen. Recuerde orientar la base como aparece en la imagen.

7. Utilice dos pernos hexagonales de 89 mm (3/8-16 x 3-1/2

pulg.) (E) Fig. 2, cuatro arandelas planas de 3/8 (G) Fig. 2 y dos

tuercas de seguridad Nylock de 3/8-16 (F) Fig. 2 para fijar la

plataforma del soporte para tornos (A) Fig. 7 a la base de apoyo

central.

5

Page 6

NOTA: Para ajustar la altura del soporte, inserte dos pernos

hexagonales en dos de los cuatro orificios (R) Fig. 8 de la

plataforma del soporte para tornos. Verifique que los orificios

de montaje del torno (S) Fig. 7 que está encima de la plataforma

queden orientados hacia afuera, en dirección opuesta al sujeta

herramientas, como aparece en la imagen.

8. Para fijarlo, coloque dos pernos, cada uno con una arandela

plana de 3/8, en los dos orificios deseados (R) Fig. 8. Coloque

otra arandela plana de 3/8 en el vástago de cada perno y

termine de fijarlo con tuercas de seguridad Nylock de 3/8-16.

NOTA: Verifique que ambas plataformas del soporte para tornos

estén a la misma altura.

NOTA: No ajuste completamente.

9. Fije el asiento de la extensión a su torno. Remítase a la hoja

de instrucciones que vino con su Asiento de extensión DELTA

46-463 para tornos medianos para ver cómo fijar el asiento a su

torno. Levante el torno y el asiento de la extensión y colóquelos

sobre las plataformas del soporte para tornos como aparece en

la Fig. 9.

Riesgo de peligro durante su operación.

Verifique que los accesorios de montaje del torno y del asiento

de la extensión para tornos estén bien ajustados.

Riesgo de peligro durante su operación. Se

requieren dos personas para levantar el torno y los asientos de

la extensión para tornos.

10. Alinee los orificios de la base del torno con los de la plataforma.

Fije el torno al soporte con cuatro pernos hexagonales de 38 mm

(3/8-16 x 1-1/2 pulg.) (B) Figura 10, ocho arandelas planas de

3/8 y cuatro tuercas de seguridad Nylock de 3/8-16 (A) en estos

orificios.

11. Coloque una arandela en cada uno de los pernos hexagonales e

insértelos en los orificios correspondientes (B) Fig. 10. Coloque

una segunda arandela en el vástago de cada uno de los pernos

y termine de fijarlos con las tuercas de seguridad Nylock.

12. Ajuste bien todos los accesorios de montaje del soporte para

tornos.

13. Ajuste las patas niveladoras de modo que el soporte para

tornos quede estable sobre el suelo, sin mecerse o inclinarse.

Luego, termine de ajustar las cuatro tuercas de bloqueo.

Cuando utilice el torno con la extensión,

remítase a la hoja de instrucciones que vino con su Asiento de

extensión DELTA 46-463 para tornos medianos para ver todas las

reglas de seguridad relevantes.

LOCALIZACION DE FALLAS

Para obtener asistencia para su máquina, visite nuestro sitio Web en

www.deltaportercable.com para tener acceso a una lista de centros

de servicio o llame a la línea de ayuda de DELTA Machinery al 1-800223-7278. (En Canadá, llame al 1-800-463-3582.)

SERVICIO

PIEZAS DE REPUESTO

Utilice sólo piezas de repuesto idénticas. Para obtener una lista

de las piezas o para solicitarlas, visite nuestro sitio Web en www.

deltaportercableservicenet.com. También puede solicitar piezas

en una de nuestras sucursales o centros de mantenimiento con

garantía autorizados más cercanos, o llamando a End User Services

(Servicios para el usuario final) al (800) 223-7278 para obtener

asistencia personalizada de uno de nuestros representantes

altamente capacitados.

MANTENIMIENTO Y REPARACIONES

Con el paso del tiempo, todas las herramientas de calidad requieren

mantenimiento o reemplazo de las piezas. Para obtener información

acerca de DELTA Machinery y sus sucursales o para localizar un

centro de mantenimiento con garantía autorizado, visite nuestro

sitio Web en www.deltaportercable.com o llame a End User

Services (Servicios para el usuario final) al (800) 223-7278. Todas

las reparaciones realizadas en nuestros centros de mantenimiento

están completamente garantizadas en relación con los materiales

defectuosos y la mano de obra. No podemos otorgar garantías en

relación con las reparaciones ni los intentos de reparación de otras

personas. Si llama a este número, también encontrará las respuestas

a las preguntas más frecuentes durante las 24 horas del día.

Asimismo, para obtener información puede escribirnos a DELTA

Machinery, PO Box 2468, Jackson, Tennessee 38302-2468 Attention: End User Services. Asegúrese de incluir toda la información

mencionada en la placa de la herramienta (número de modelo, tipo,

número de serie, código de fecha, etc.)

ACCESORIOS

Puesto que los accesorios con excepción

de ésos ofrecidos por DELTA no se han probado con este

producto, el uso de tales accesorios podría ser peligroso. Para

la operación más segura, solamente el DELTA recomendó los

accesorios se debe utilizar con este producto

Una línea completa de accesorios está disponible de su surtidor

de DELTA, centros de servicio de la fábrica de DELTA, y estaciones

autorizadas delta. Visite por favor nuestro Web site www.

deltaportercable.com para un catálogo o para el nombre de su

surtidor más cercano.

PÓLIZA DE GARANTÍA

IDENTIFICACIÓN DELPRODUCTO:

Sello o firma del Distribuidor.Nombre del producto: ___________

Mod./Cat.: Marca: Núm. de serie: (Datos

para ser llenados por el distribuidor) Fecha de compra y/o

entrega del producto: Nombre y domicilio del

distribuidor donde se adquirió el producto:____________________

Este producto está garantizado por tres años de garantía limitada a partir

de la fecha de entrega, contra cualquier defecto en su funcionamiento,

así como en materiales y mano de obra empleados para su fabricación.

Nuestra garantía incluye la reparación o reposición del producto y/o

componentes sin cargo alguno para el cliente, incluyendo mano de

obra, así como los gastos de transportación razonablemente erogados

derivados del cumplimiento de este certificado. Para hacer efectiva esta

garantía deberá presentar su herramienta y esta póliza sellada por el

establecimiento comercial donde se adquirió el producto, de no contar

con ésta, bastará la factura de compra.

EXCEPCIONES

Esta garantía no será válida en los siguientes casos:

•Cuando elproductosehubieseutilizadoencondicionesdistintasa

las normales;

•Cuando el producto no hubiese sido operado de acuerdo con el

instructivo de uso que se acompaña;

•Cuandoelproductohubiesesidoalteradooreparadoporpersonas

distintas a las enlistadas al final de este certificado.

Anexo encontrará una relación de sucursales de servicio de fábrica,

centros de servicio autorizados y franquiciados en la República

Mexicana, donde podrá hacer efectiva su garantía yadquirir partes,

refacciones y accesorios originales.

6

Page 7

PARA REPARACIÓN Y SERVICIO DE SUS

HERRAMIENTAS ELÉCTRICAS, FAVOR DE DIRIGIRSE

AL CENTRO DE SERVICIO MÁS CERCANO

CULIACAN, SIN

Blvd.Emiliano Zapata 5400-1 Poniente

Col. San Rafael (667) 717 89 99

GUADALAJARA, JAL

Av. La Paz #1779 - Col. Americana Sector Juárez (33) 3825 6978

MEXICO, D.F.

Eje Central Lázaro Cárdenas No. 18

Local D, Col. Obrera (55) 5588 9377

MERIDA, YUC

Calle 63 #459-A - Col. Centro (999) 928 5038

MONTERREY, N.L.

Av. Francisco I. Madero 831 Poniente - Col. Centro (818) 375 23 13

PUEBLA, PUE

17 Norte #205 - Col. Centro (222) 246 3714

QUERETARO, QRO

Av. San Roque 274 - Col. San Gregorio (442) 2 17 63 14

SAN LUIS POTOSI, SLP

Av. Universidad 1525 - Col. San Luis (444) 814 2383

TORREON, COAH

Blvd. Independencia, 96 Pte. - Col. Centro (871) 716 5265

VERACRUZ, VER

Prolongación Díaz Mirón #4280 - Col. Remes (229) 921 7016

VILLAHERMOSA, TAB

Constitución 516-A - Col. Centro (993) 312 5111

PARA OTRAS LOCALIDADES:

Si se encuentra en México, por favor llame al (55) 5326 7100

Si se encuentra en U.S., por favor llame al

(800) 223-7278

GARANTIA

Para registrar la herramienta para obtener el mantenimiento cubierto

por la garantía de la herramienta, visite nuestro sitio web en www.

deltaportercable.com.

GARANTÍA LIMITADA DE CINCO AÑOS PARA PRODUCTOS NUEVOS

DELTA reparará o reemplazará, a expensas y opción propias, cualquier

máquina nueva, pieza de máquina nueva o accesorio de máquina

nuevo DELTA que durante el uso normal haya presentado defectos de

fabricación o de material, siempre que el cliente devuelva el producto con

el transporte prepagado a un centro de servicio de fábrica DELTA o una

estación de servicio autorizado DELTA, con un comprobante de compra

del producto, dentro del plazo de cinco años y dé a DELTA una oportunidad

razonable de verificar el supuesto defecto mediante la realización de

una inspección. Para todos los productos DELTA reacondicionados, el

período de garantía es de 180 días. DELTA no será responsable de ningún

defecto alegado que haya resultado del desgaste normal, uso indebido,

abuso o reparación o alteración realizada o autorizada específicamente

por alguien que no sea un centro de servicio autorizado DELTA o un

representante autorizado DELTA. DELTA no será responsable en ninguna

circunstancia de los daños incidentales o emergentes que se produzcan

como resultado de productos defectuosos. Algunos estados no permiten

la exclusión o limitación de los daños incidentales o resultantes, por lo

que la limitación o exclusión anterior puede no aplicarse a usted. Esta

garantía es la única garantía de DELTA y establece el recurso exclusivo del

cliente en lo que respecta a los productos defectuosos; DELTA rechaza

expresamente todas las demás garantías, expresas o implícitas, tanto

de comerciabilidad como de idoneidad para un propósito o de cualquier

otro tipo. Para mayores detalles sobre la cobertura de la garantía e

información acerca de reparaciones realizadas bajo garantía, visítenos en

www.deltaportercable.com o dirígase al centro de servicio más cercano

(888) 848-5175. Esta garantía no aplica a accesorios o a daños causados

por reparaciones realizadas o intentadas por terceros. Esta garantía le

otorga derechos legales específicos, además de los cuales puede tener

otros dependiendo del estado o provincia en que se encuentre.

AMÉRICA LATINA: Esta garantía no se aplica a los productos que

se venden en América Latina. Para los productosque se venden

en América Latina, debe consultar la información de la garantía

específica del país que viene en el empaque, llamar a la compañía

local o visitar el sitio Web a fin de obtener esa información.

SOLAMENTE PARA PROPÓSITO DE MÉXICO:

IMPORTADO POR: DELTA S.A. DE C.V.

BOSQUES DE CIDROS, ACCESO RADIATAS NO.42

3A. SECCIÓN DE BOSQUES DE LAS LOMAS

DELEGACIÓN CUAJIMALPA,

05120, MÉXICO, D.F.

TEL. (52) 555-326-7100

R.F.C.: BDE810626-1W7

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

7

Page 8

Delta Machinery, PO Box 2468, Jackson, TN 38302-2468 (800) 223-7278 - U.S. (800) 463-3582 - CANADA

www.deltaportercable.com Copyright © 2008 Delta Machinery

Loading...

Loading...