Page 1

17" Floor Model

Drill Press

Perceuse à

colonne de

17-959L

432 mm (17 po),

modèle sur pied

Prensa de taladro

de 432 mm (17"),

modelo de apoyo

sobre el suelo

Instruction Manual

Manuel d’Utilisation

Manual de Instrucciones

FRANÇAIS (21) ESPAÑOL (39)

www.deltamachinery.com

(800) 223-7278 - US

(800) 463-3582 - CANADA

Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY GUIDELINES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

GENERAL SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ADDITIONAL SPECIFIC SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CARTON CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

WARRANTY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

FRANÇAIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

ESPAÑOL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

IMPORTANT SAFETY INSTRUCTIONS

Read and understand all warnings and operating instructions before using any tool or equipment.

When using tools or equipment, basic safety precautions should always be followed to reduce the risk of

personal injury. Improper operation, maintenance or modification of tools or equipment could result in serious

injury and property damage. There are certain applications for which tools and equipment are designed. DELTA

Machinery strongly recommends that this product NOT be modified and/or used for any application other than

for which it was designed.

If you have any questions relative to its application DO NOT use the product until you have written DELTA

Machinery and we have advised you.

Online contact form at www.deltamachinery.com

Postal Mail: Technical Service Manager

DELTA Machinery

4825 Highway 45 North

Jackson, TN 38305

(IN CANADA: 125 Mural St. Suite 300, Richmond Hill, ON, L4B 1M4)

Information regarding the safe and proper operation of this tool is available from the following sources:

Power Tool Institute

1300 Sumner Avenue, Cleveland, OH 44115-2851

www.powertoolinstitute.org

1121 Spring Lake Drive, Itasca, IL 60143-3201

American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org

ANSI 01.1 Safety Requirements for Woodworking Machines, and the U.S. Department of Labor regulations www.osha.gov

National Safety Council

SAVE THESE INSTRUCTIONS!

2

Page 3

SAFETY GUIDELINES – DEFINITIONS

It is important for you to read and understand this manual. The information it contains relates to protecting

YOUR SAFETY and PREVENTING PROBLEMS. The symbols below are used to help you recognize this

information.

indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

indicates a potentially haz ard ous situation which, if not avoided, may result in minor or mod er ate injury.

NOTICE

damage.

indicates a practice not related to personal injury which, if not avoided, may result in property

CALIFORNIA PROPOSITION 65

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other masonry products, and

• Arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals: work in a well-ventilated area, and work with approved safety equipment, such as those dust masks

that are specially designed to filter out microscopic particles.

3

Page 4

GENERAL SAFETY RULES

Failure to follow these rules may result in serious personal injury.

1. FOR YOUR OWN SAFETY, READ THE INSTRUCTION

MANUAL BEFORE OPERATING THE MACHINE. Learning

the machine’s application, limitations, and specific hazards

will greatly minimize the possibility of accidents and injury.

2. WEAR EYE AND HEARING PROTECTION. ALWAYS

USE SAFETY GLASSES. Everyday eyeglasses are NOT

safety glasses. USE CERTIFIED SAFETY EQUIPMENT.

Eye protection equipment should comply with ANSI Z87.1

standards. Hearing equipment should comply with ANSI

S3.19 standards.

3. WEAR PROPER APPAREL. Do not wear loose clothing,

gloves, neckties, rings, bracelets, or other jewelry which may

get caught in moving parts. Nonslip protective footwear is

recommended. Wear protective hair covering to contain long

hair.

4. DO NOT USE THE MACHINE IN A DANGEROUS

ENVIRONMENT. The use of power tools in damp or wet

locations or in rain can cause shock or electrocution. Keep

your work area well-lit to prevent tripping or placing arms,

hands, and fingers in danger.

5. MAINTAIN ALL TOOLS AND MACHINES IN PEAK

CONDITION. Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing

accessories. Poorly maintained tools and machines can further

damage the tool or machine and/or cause injury.

6. CHECK FOR DAMAGED PARTS. Before using the machine,

check for any damaged parts. Check for alignment of moving

parts, binding of moving parts, breakage of parts, and any

other conditions that may affect its operation. A guard or any

other part that is damaged should be properly repaired or

replaced with DELTA or factory authorized replacement parts.

Damaged parts can cause further damage to the machine

and/or injury.

7. KEEP THE WORK AREA CLEAN. Cluttered areas and benches

invite accidents.

8. KEEP CHILDREN AND VISITORS AWAY. Your shop is a

potentially dangerous environment. Children and visitors can be

injured.

9. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make

sure that the switch is in the “OFF” position before plugging

in the power cord. In the event of a power failure, move the

switch to the “OFF” position. An accidental start-up can

cause injury. Do not touch the plug’s metal prongs when

unplugging or plugging in the cord.

10. USE THE GUARDS. Check to see that all guards are in place,

secured, and working correctly to prevent injury.

11. REMOVE ADJUSTING KEYS AND WRENCHES BEFORE

STARTING THE MACHINE. Tools, scrap pieces, and other

debris can be thrown at high speed, causing injury.

12. USE THE RIGHT MACHINE. Don’t force a machine or

an attachment to do a job for which it was not designed.

Damage to the machine and/or injury may result.

13. USE RECOMMENDED ACCESSORIES. The use of

accessories and attachments not recommended by DELTA

may cause damage to the machine or injury to the user.

14. USE THE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an extension

cord, be sure to use one heavy enough to carry the current

your product will draw. An undersized cord will cause a drop

in line voltage, resulting in loss of power and overheating. See

the Extension Cord Chart for the correct size depending on

the cord length and nameplate ampere rating. If in doubt, use

the next heavier gauge. The smaller the gauge number, the

heavier the cord.

15. SECURE THE WORKPIECE. Use clamps or a vise to hold the

workpiece when practical. Loss of control of a workpiece can

cause injury.

16. FEED THE WORKPIECE AGAINST THE DIRECTION OF

THE ROTATION OF THE BLADE, CUTTER, OR ABRASIVE

SURFACE. Feeding it from the other direction will cause the

workpiece to be thrown out at high speed.

17. DON’T FORCE THE WORKPIECE ON THE MACHINE.

Damage to the machine and/or injury may result.

18. DON’T OVERREACH. Loss of balance can make you fall into

a working machine, causing injury.

19. NEVER STAND ON THE MACHINE. Injury could occur if the tool

tips, or if you accidentally contact the cutting tool.

20. NEVER LEAVE THE MACHINE RUNNING UNATTENDED.

TURN THE POWER OFF. Don’t leave the machine until it comes

to a complete stop. A child or visitor could be injured.

21. TURN THE MACHINE “OFF”, AND DISCONNECT THE

MACHINE FROM THE POWER SOURCE before installing

or removing accessories, changing cutters, adjusting or

changing set-ups. When making repairs, be sure to lock the

start switch in the “OFF” position. An accidental start-up can

cause injury.

22. MAKE YOUR WORKSHOP CHILDPROOF WITH

PADLOCKS, MASTER SWITCHES, OR BY REMOVING

STARTER KEYS. The accidental start-up of a machine by a

child or visitor could cause injury.

23. STAY ALERT, WATCH WHAT YOU ARE DOING, AND

USE COMMON SENSE. DO NOT USE THE MACHINE

WHEN YOU ARE TIRED OR UNDER THE INFLUENCE

OF DRUGS, ALCOHOL, OR MEDICATION. A moment of

inattention while operating power tools may result in injury.

24. USE OF THIS TOOL CAN GENERATE

AND DISPERSE DUST OR OTHER AIRBORNE

PARTICLES, INCLUDING WOOD DUST, CRYSTALLINE

SILICA DUST AND ASBESTOS DUST. Direct particles away

from face and body. Always operate tool in well ventilated

area and provide for proper dust removal. Use dust collection

system wherever possible. Exposure to the dust may cause

serious and permanent respiratory or other injury, including

silicosis (a serious lung disease), cancer, and death. Avoid

breathing the dust, and avoid prolonged contact with dust.

Allowing dust to get into your mouth or eyes, or lay on your

skin may promote absorption of harmful material. Always use

properly fitting NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure, and wash exposed areas

with soap and water.

4

Page 5

ADDITIONAL SPECIFIC SAFETY RULES

FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS INJURY.

1. DO NOT OPERATE THIS MACHINE until it is completely

assembled and installed according to the instructions. A

machine incorrectly assembled can cause serious injury.

2. OBTAIN ADVICE from your supervisor, instructor, or

another qualified person if you are not thoroughly familiar

with the operation of this machine. Knowledge is safety.

3. FOLLOW ALL WIRING CODES and recommended

electrical connections to prevent shock or electrocution.

4. SECURE THE MACHINE TO A SUPPORTING SURFACE.

Vibration can cause the machine to slide, walk, or tip over.

5. NEVER START THE MACHINE BEFORE CLEARING

THE TABLE OF ALL OBJECTS (tools, scrap pieces,

etc.). Debris can be thrown at high speed.

6. NEVER START THE MACHINE with the drill bit, cutting

tool, or sanding drum against the workpiece. Loss of

control of the workpiece can cause serious injury.

7. PROPERLY LOCK THE DRILL BIT, CUTTING TOOL, OR

SANDING DRUM IN THE CHUCK before operating this

machine.

8. REMOVE THE CHUCK KEY BEFORE STARTING THE

MACHINE. The chuck key can be thrown out at a high

speed.

9. TIGHTEN ALL LOCK HANDLES before starting the

machine. Loss of control of the workpiece can cause

serious injury.

10. USE ONLY DRILL BITS, CUTTING TOOLS, SANDING

DRUMS, OR OTHER ACCESSORIES with shank size

recommended in your instruction manual. The wrong

size accessory can cause damage to the machine and/or

serious injury.

11. USE ONLY DRILL BITS, CUTTING TOOLS, OR

SANDING DRUMS that are not damaged. Damaged

items can cause malfunctions that lead to injuries.

12. USE RECOMMENDED SPEEDS for all operations. Other

speeds may cause the machine to malfunction causing

damage to the machine and/or serious injury.

13. AVOID AWKWARD OPERATIONS AND HAND

POSITIONS. A sudden slip could cause a hand to move

into the bit.

14. KEEP ARMS, HANDS, AND FINGERS away from the bit.

Serious injury to the hand can occur.

15. HOLD THE WORKPIECE FIRMLY AGAINST THE

TABLE. Do not attempt to drill a workpiece that does

not have a flat surface against the table, or that is not

secured by a vise. Prevent the workpiece from rotating

by clamping it to the table or by securing it against the

drill press column. Loss of control of the workpiece can

cause serious injury.

16. TURN THE MACHINE “OFF” AND WAIT FOR THE DRILL

BIT, CUTTING TOOL, OR SANDING DRUM TO STOP

TURNING prior to cleaning the work area, removing

debris, removing or securing workpiece, or changing

the angle of the table. A moving drill bit, cutting tool, or

sanding drum can cause serious injury.

17. PROPERLY SUPPORT LONG OR WIDE workpieces.

Loss of control of the workpiece can cause severe injury.

18. NEVER PERFORM LAYOUT, ASSEMBLY OR SET-UP

WORK on the table/work area when the machine is

running. Serious injury can result.

19. TURN THE MACHINE “OFF”, disconnect the machine

from the power source, and clean the table/work area

before leaving the machine. LOCK THE SWITCH IN THE

“OFF” POSITION to prevent unauthorized use. Someone

else might accidentally start the machine and cause

serious injury to themselves.

20. ADDITIONAL INFORMATION regarding the safe and

proper operation of power tools (i.e., a safety video)

is available from the Power Tool Institute, 1300

Sumner Avenue, Cleveland, OH 44115-2851 (www.

powertoolinstitute.com). Information is also available

from the National Safety Council, 1121 Spring Lake

Drive, Itasca, IL 60143-3201. Please refer to the

American National Standards Institute ANSI 01.1 Safety

Requirements for Woodworking Machines and the

U.S. Department of Labor OSHA 1910.213 Regulations.

ADDITIONAL SAFETY RULES FOR THE LASER

EYE INJURY – LASER LIGHT

Do not stare into beam aperture, or into a reflection from a mirror-like surface.

Do not use optical tools such as a telescope or transit to view the laser beam.

EYE INJURY – LASER LIGHT

Do not operate the laser around children or allow children to operate the laser.

Store idle laser out of reach of children and other untrained persons.

Turn the laser off when it is not in use.

Do not disassemble laser module. The class II laser output could be exceeded if the unit is disassembled. Laser complies with 21

CFR 1040.10 and 1040.11.

hazardous radiation exposure.

flammable liquids, gases, or dust. A spark could ignite the dust or fumes.

NOTE: Do not remove or deface warning labels.

Use of controls or adjustments or performance of procedures other than those specified herein may result in

EXPLOSION HAZARD. Do not operate the laser or drill press in explosive atmospheres such as in the presence of

5

Page 6

POWER CONNECTIONS

A separate electrical circuit should be used for your machines. This circuit should not be less than #12 wire and should

be protected with a 20 Amp time lag fuse. If an extension cord is used, use only 3-wire extension cords which have

3-prong grounding type plugs and matching receptacle which will accept the machine’s plug. Before connecting the

machine to the power line, make sure the switch is in the “OFF” position and be sure that the electric current is of the

same characteristics as indicated on the machine. All line connections should make good contact. Running on low

voltage will damage the machine.

Do not expose the machine to rain or operate the machine in damp locations.

MOTOR SPECIFICATIONS

Your machine is wired for 120/240 V, 60 Hz alternating current. Before connecting the machine to the power source,

make sure the switch is in the “OFF” position.

GROUNDING INSTRUCTIONS

This machine must be grounded while in use to protect the operator from electric shock.

1. All grounded, cord-connected machines:

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to

reduce the risk of electric shock. This machine is equipped with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided – if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in risk of electric shock. The conductor with

insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor.

If repair or replacement of the electric cord or plug is necessary, do not connect the equipment-grounding conductor

to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood,

or if in doubt as to whether the machine is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding type plugs and matching 3-conductor receptacles that

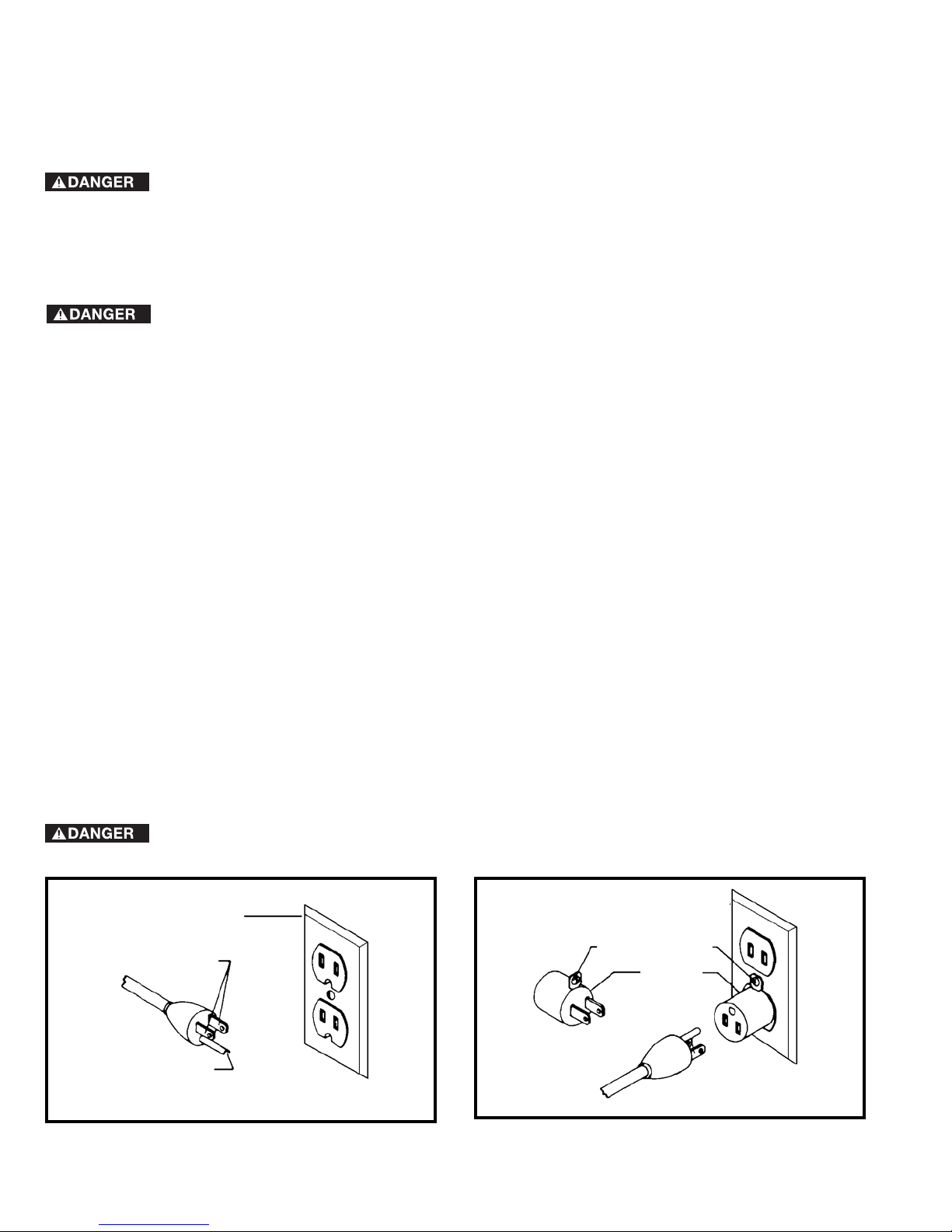

accept the machine’s plug, as shown in Fig. A.

Repair or replace damaged or worn cord immediately.

2. Grounded, cord-connected machines intended for use on a supply circuit having a nominal rating less than

150 volts:

If the machine is intended for use on a circuit that has an outlet that looks like the one illustrated in Fig. A, the

machine will have a grounding plug that looks like the plug illustrated in Fig. A. A temporary adapter, which looks like

the adapter illustrated in Fig. B, may be used to connect this plug to a matching 2-conductor receptacle as shown

in Fig. B if a properly grounded outlet is not available. The temporary adapter should be used only until a properly

grounded outlet can be installed by a qualified electrician. The green-colored rigid ear, lug, and the like, extending

from the adapter must be connected to a permanent ground such as a properly grounded outlet box. Whenever the

adapter is used, it must be held in place with a metal screw.

NOTE: In Canada, the use of a temporary adapter is not permitted by the Canadian Electric Code.

In all cases, make certain that the receptacle in question is properly grounded. If you are not sure,

have a qualified electrician check the receptacle.

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

Fig. A

GROUNDING MEANS

ADAPTER

Fig. B

6

Page 7

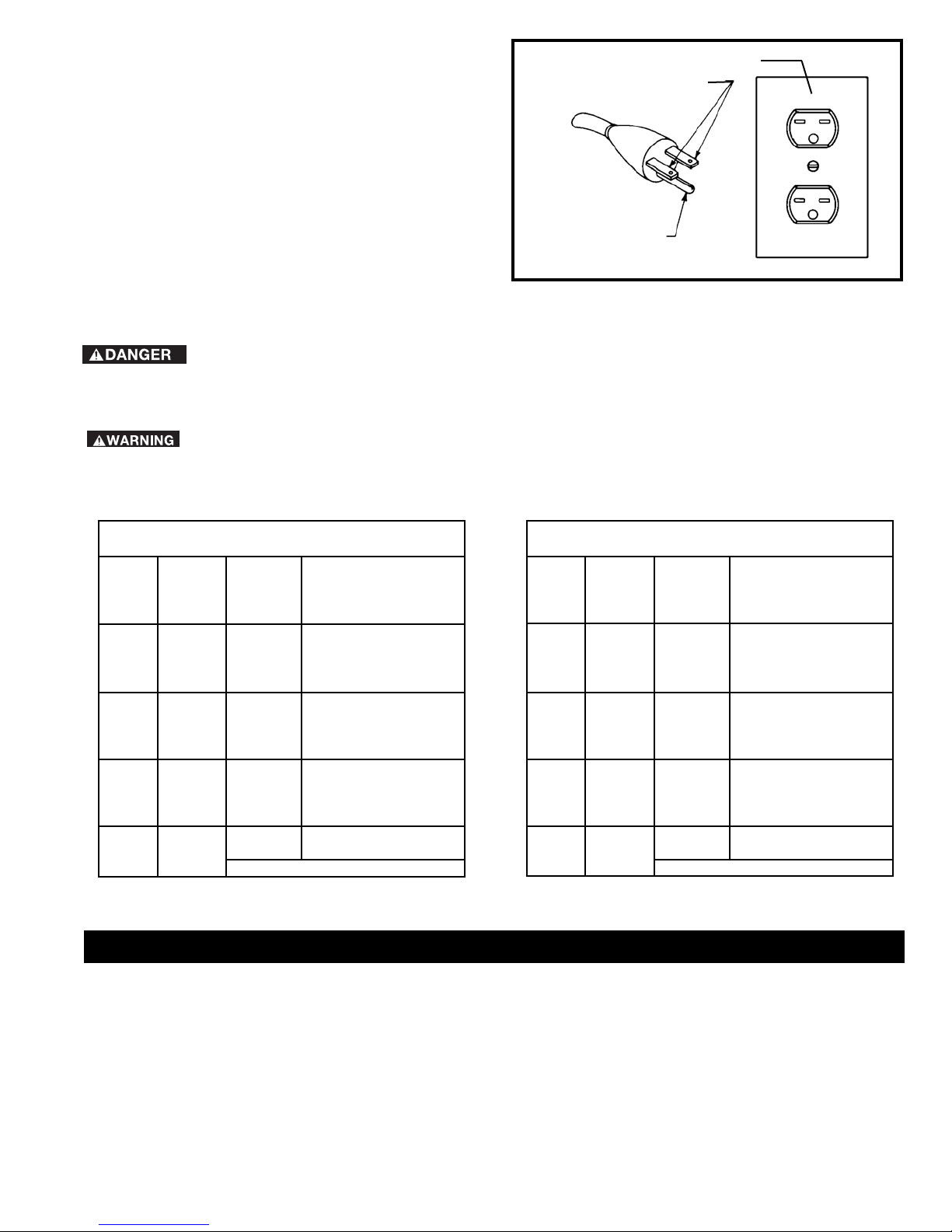

3. 240 VOLT SINGLE PHASE OPERATION

The motor supplied with your machine is a dual voltage,

120/240 volt motor. It is shipped ready-to-run for 120

volt operation. However, it can be converted for 240 volt

operation.

A qualified electrician should do the conversion, or the

machine can be taken to an Authorized DELTA Service

Center. When completed, the machine must conform to the

National Electric Code and all local codes and ordinances.

The machine is converted by re-wiring the motor for 240

volts, installing a 240 volt plug on the power supply cord

and replacing the switch with one that is rated for 240 volt

operation.

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

Be sure the 240 volt plug is only used in an outlet having the same

configuration as the plug illustrated in Fig. C. No adapter should

be used with the 240 volt plug.

In all cases, make certain that the receptacle in question is properly grounded. If you are not sure, have a

qualified electrician check the receptacle.

Fig. C

EXTENSION CORDS

which has a 3-prong grounding type plug and matching receptacle which will accept the machine’s plug. When using an extension

cord, be sure to use one heavy enough to carry the current of the machine. An undersized cord will cause a drop in line voltage,

resulting in loss of power and overheating. Fig. D-1 or D-2, shows the correct gauge to use depending on the cord length. If in doubt,

use the next heavier gauge. The smaller the gauge number, the heavier the cord.

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere

rating Volts

0-6 120

0-6 120 25-50 16 AWG

0-6 120 50-100 16 AWG

0-6 120 100-150 14 AWG

6-10 120

6-10 120 25-50 16 AWG

6-10 120 50-100 14 AWG

6-10 120 100-150 12 AWG

10-12 120

10-12 120 25-50 16 AWG

10-12 120 50-100 14 AWG

10-12 120 100-150 12 AWG

12-16 120

12-16 120 25-50 12 AWG

12-16 120

Use proper extension cords. Make sure your extension cord is in good condition and is a 3-wire extension cord

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Total

length of

cord in

feet

up to

25 18 AWG

up to

25 18 AWG

up to

25 16 AWG

up to

25 14 AWG

GREATER THAN 50 FEET NOT RECOMMENDED

Gauge of

extension cord

Fig. D-1

Ampere

rating Volts

0-6 240

0-6 240 50-100 16 AWG

0-6 240 100-200 16 AWG

0-6 240 200-300 14 AWG

6-10 240

6-10 240 50-100 16 AWG

6-10 240 100-200 14 AWG

6-10 240 200-300 12 AWG

10-12 240

10-12 240 50-100 16 AWG

10-12 240 100-200 14 AWG

10-12 240 200-300 12 AWG

12-16 240

12-16 240 50-100 12 AWG

12-16 240

Total

length of

cord in

feet

up to

50 18 AWG

up to

50 18 AWG

up to

50 16 AWG

up to

50 14 AWG

GREATER THAN 50 FEET NOT RECOMMENDED

Gauge of

extension cord

Fig. D-2

FUNCTIONAL DESCRIPTION

FOREWORD

DELTA Model 17-959L is a 17" floor model drill press. This heavy-duty machine has a 3/4 HP, 120/240V induction motor,

5/8" capacity chuck and key, cast iron table, rack and pinion elevation mechanism, and external depth stop. The 17-959L

has a tilting table for angle drilling. Side edges and parallel slots are provided for fast workpiece clamping.

NOTICE: The photo on the manual cover illustrates the current production model. All other illustrations contained in

the manual are representative only and may not depict the actual color, labeling, or accessories, and are intended to

illustrate technique only.

7

Page 8

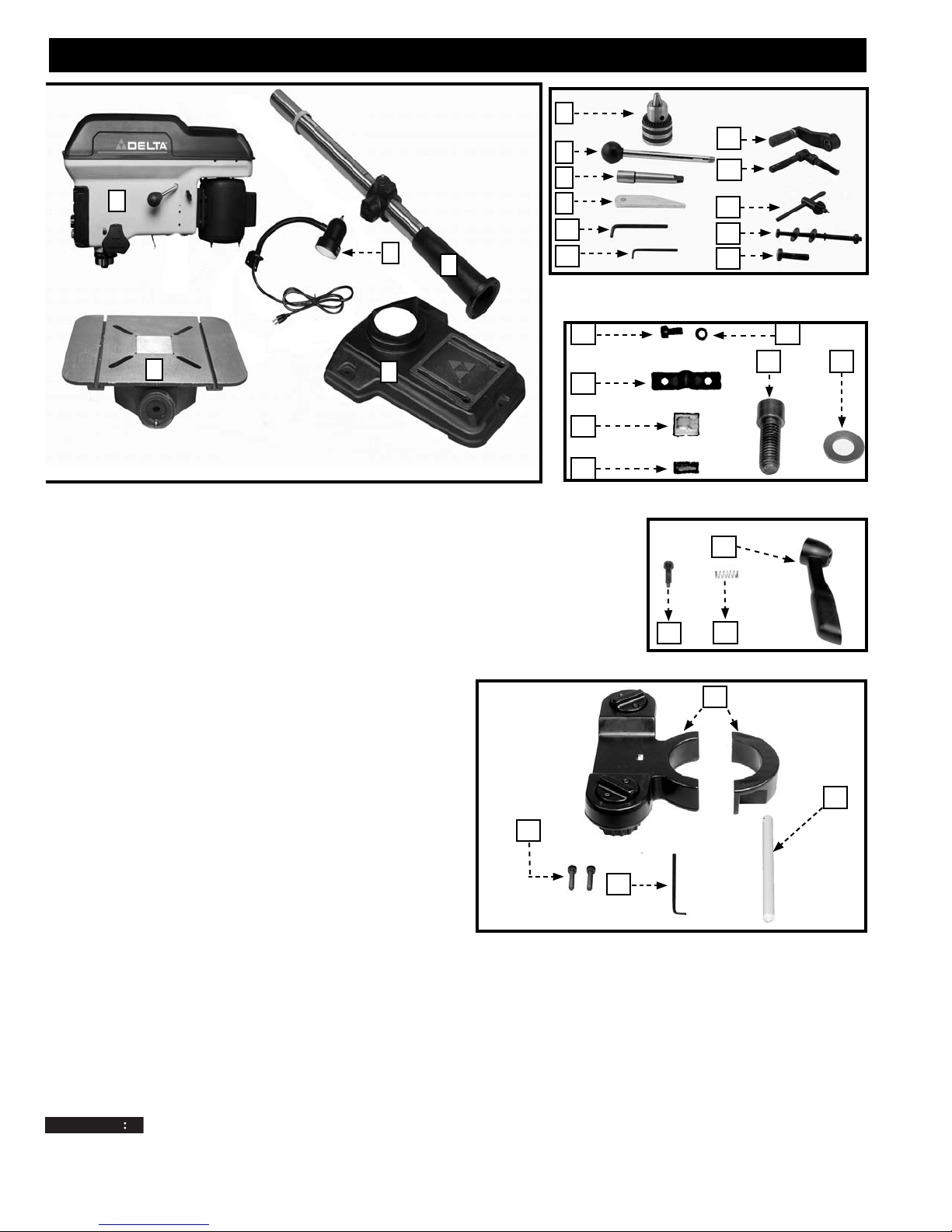

CARTON CONTENTS

6

7

8

1

4

3

9

10

11

12

13

14

15

16

2

1. Drill Press Head

2. Table

3. Table Bracket and Column

4. Light

5. Base

6. Chuck

7. Handle (3)

8. Spindle Adapter

9. Drift Key

10. 5mm Hex Wrench

11. 3mm Hex Wrench

12. Table Raising and Lowering Handle

13. Table Clamp Handle

14. Chuck Key

15. (3) M8 x 1.25 x 125mm carriage head screws,

(4) flat washers, (2) lockwashers, and (2) hex nuts

(for fastening drill press to a supporting surface)

16. M10 x 1.5 x 40mm Hex Head Screws (4)

17. M6 x 1 x 12mm Hex Cap Head Screw (2)

18. 1/4" Washer

19. Cord Strain Relief

20. Cord Clamp (2)

21. Cord Bushing

22. 12mm Hex Head Bolt

23. Flat Washer

24. Screws (2)

25. Springs (2)

26. Forward tilt levers

27. Laser

28. Laser Alignment Rod

29. 4mm Hex Wrench

30. Hex Head Cap Screws (2)

31. 12mm Hex Wrench (Not Shown)

5

30

17

19

20

21

29

24

18

22 23

26

25

27

28

UNPACKING AND CLEANING

Carefully unpack the machine and all loose items from the shipping container(s). Remove the rust-preventative oil from

unpainted surfaces using a soft cloth moistened with mineral spirits, paint thinner or denatured alcohol.

NOTICE

thinner for cleaning your machine. Such materials can easily catch fire. After cleaning, cover the unpainted surfaces

with a good quality household floor paste wax.

FIRE HAZARD. Do not use highly volatile solvents such as gasoline, naphtha, acetone or lacquer

8

Page 9

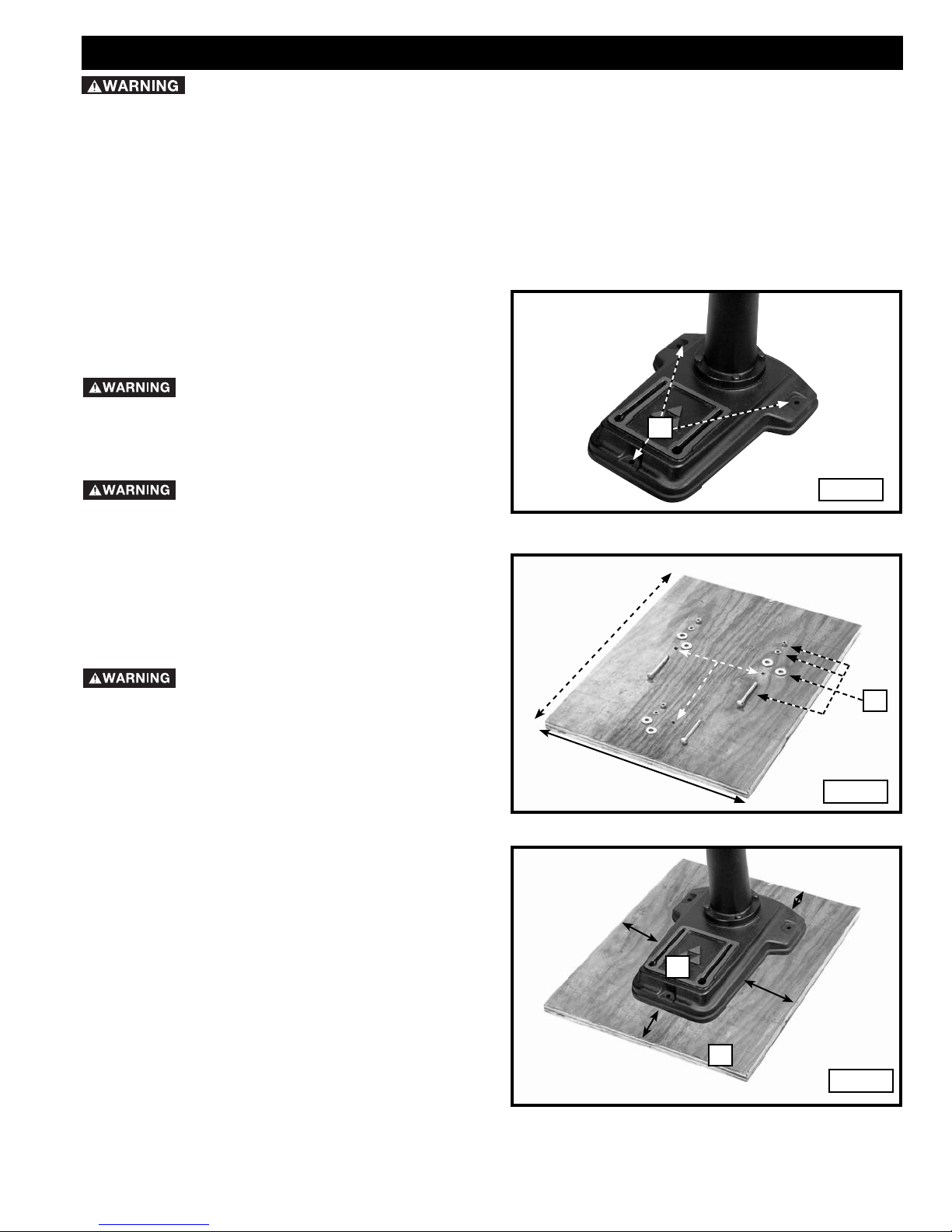

ASSEMBLY

RISK OF UNSAFE OPERATION. For your own safety, do not connect the machine to the power source

until the machine is completely assembled and you read and understand the entire instruction manual.

ASSEMBLY TOOLS REQUIRED

3mm and 5mm hex wrench (supplied)

10mm, 17mm, 24mm open end or socket wrenches (not supplied)

ASSEMBLY TIME ESTIMATE

Assembly for this machine takes approximately 30 minutes to 1 hour.

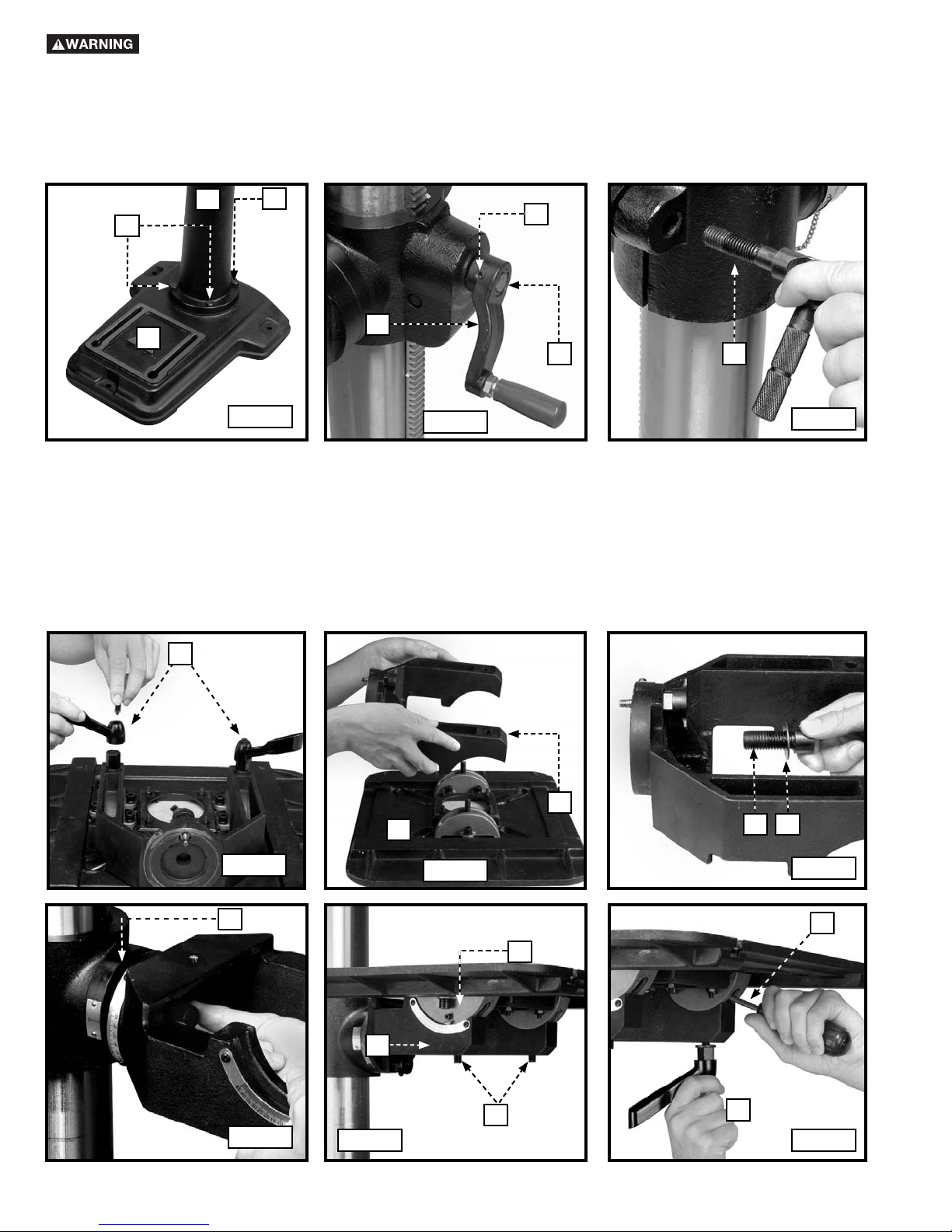

1. If you plan to use your drill press in a permanent

location, you must secure the drill press base to the

supporting surface with fasteners through the three

mounting holes (A) Fig. 1 in the drill press base.

RISK OF UNSAFE OPERATION. If you

do not fasten your drill press in a permanent manner,

you must fasten the drill press to a plywood mounting

board to prevent the drill press from tipping over

during normal use.

A

RISK OF UNSAFE OPERATION. Use

a good grade of plywood with a minimum 3/4"

thickness. Do not make the mounting board from

particle board since particle board breaks easily.

2. Use a plywood board base with the minimum

dimensions as shown in Fig. 2 for mounting the drill

press base to a supporting surface.

3. Place the drill press base (D) Fig. 3 centered on the

supporting surface (E).

RISK OF UNSAFE OPERATION. Make

sure that the plywood extends a minimum of 3" on all

four sides of the base as shown in Fig. 3.

4. Drill three 3/8" diameter holes through the holes (A)

Fig. 1 in the drill press base, and in the supporting

surface (E) Fig. 3.

NOTE: Place a piece of scrap wood underneath the

supporting surface when drilling the through holes so

that the drill bit will not damage the material beneath

the supporting surface.

5. Fasten the drill press base to the mounting board

using the carriage bolts, flat washers, lockwashers,

and hex nuts (C) Fig. 2 furnished with your drill

press. Countersink the holes for the carriage bolt

heads and flat washers under the board so that

the bolt heads are flush with or below the bottom

surface of the board. Use a flat washer, lock washer,

and hex nut above the drill press base.

28"

MINIMUM

21" MINIMUM

3" MINIMUM

3" MINIMUM

Fig. 1

C

Fig. 2

3" MINIMUM

D

3" MINIMUM

E

Fig. 3

9

Page 10

RISK OF UNSAFE OPERATION. You must secure the plywood base to the floor or supporting

surface if the drill press has any tendency to vibrate, slide, or walk during normal operation.

6. Attach the column (A) Fig. 4 to the base (B) using the four M10 x 40mm hex head screws (C), three of which are

shown.

7. Attach the table adjusting handle (D) Fig. 5 to the worm gear shaft (E). Tighten the screw (F) against the flat on the

shaft with the 3mm wrench supplied.

8. Thread the table clamp handle (G) Fig. 6 in the hole in rear of table bracket.

A

C

C

F

D

B

Fig. 4

E

Fig. 5

G

Fig. 6

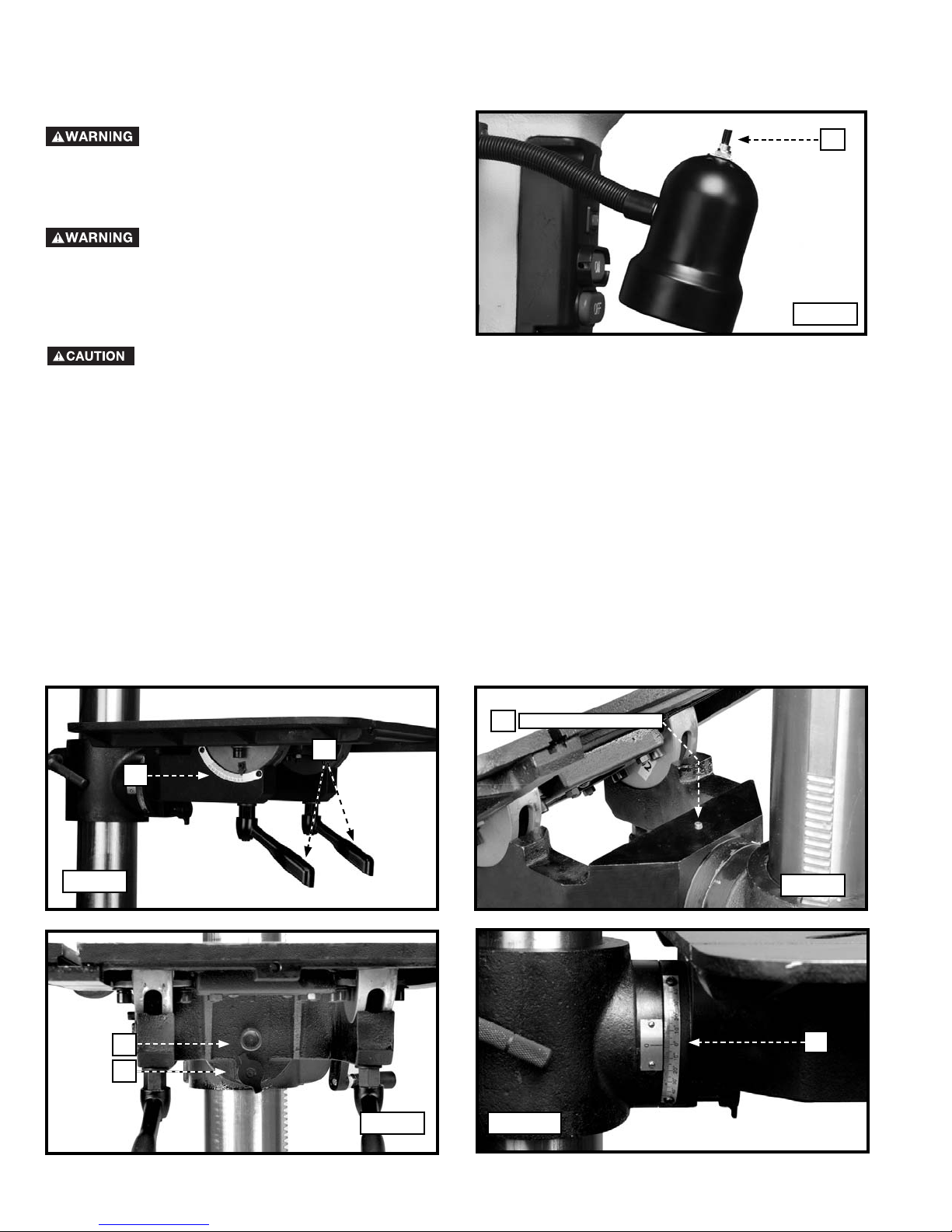

9. Attach the levers to the underside of the table by turning the screw in the lever clockwise (Fig. 7).

10. Remove both entire lever assemblies (A) Fig. 7 by turning them counter-clockwise. Remove the washers.

11. Lift the table support (B) Fig. 8 from the table (C).

12. Place the flat washer (D) Fig. 9 with the raised side against the 12mm bolt (E).

13. Insert the bolt into the table support, then into the hole in the knuckle (G) Fig. 10. Tighten securely.

14. Align the bolts (H) in the trunnion (J) with the holes in the table support (K).

15. Replace the washers and lever assemblies that were removed in STEP 10. Tighten securely.

NOTE: The bolts in the trunnion are moveable. To make the replacing of the levers easier, insert a athead screwdriver

(L) Fig. 12 in the opening of the trunnion against the bolts to steady them.

A

B

D

E

Fig. 9

L

Fig. 7

G

C

Fig. 8

J

K

Fig. 10

Fig. 11

10

H

G

Fig. 12

Page 11

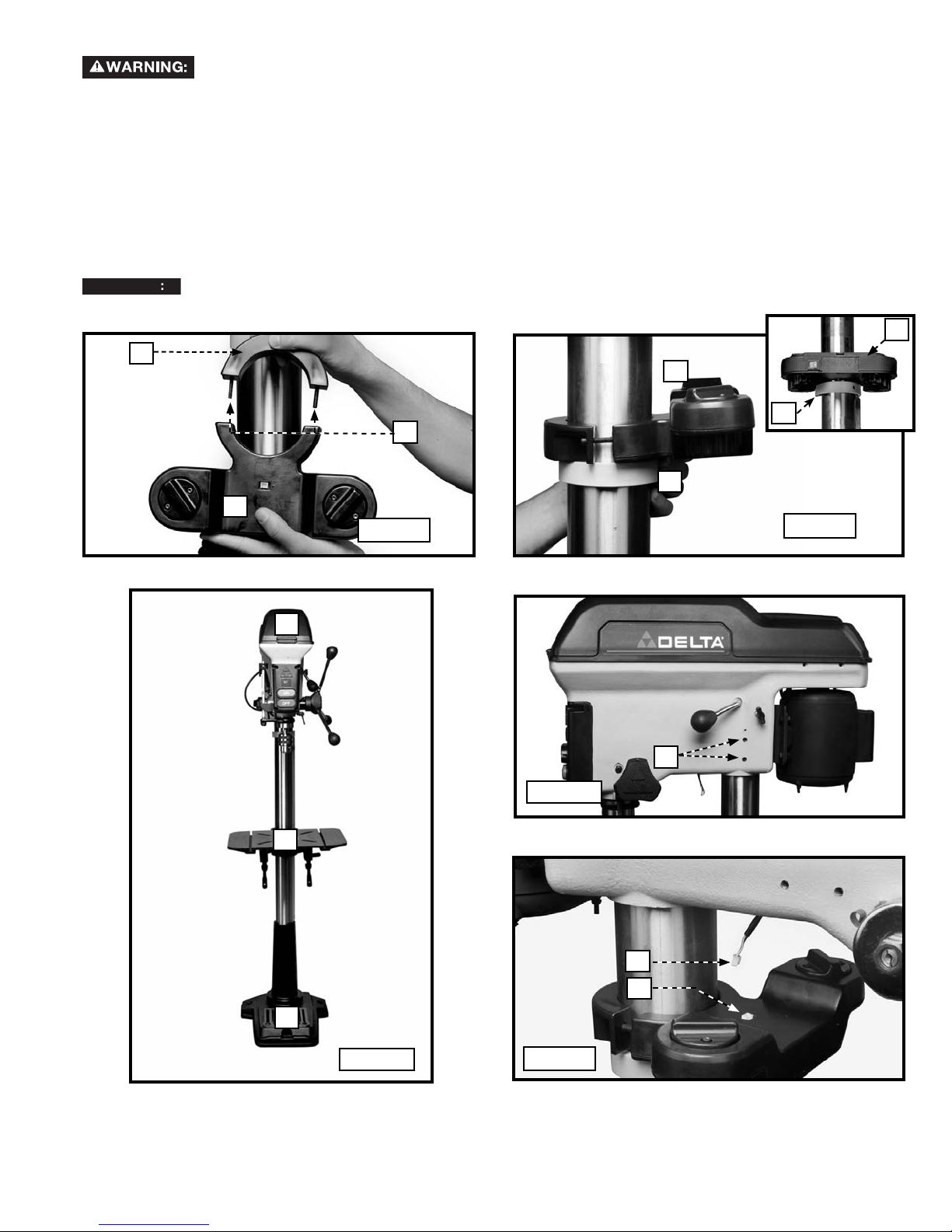

ATTACHING THE LASER AND HEADSTOCK TO THE COLUMN

EYE INJURY – LASER LIGHT. Do not stare into the laser beam or aperture or into a reflection

from a mirror-like surface.

1. Use the two socket head cap screws (C) Fig. 13 included in laser packaging and the supplied 4mm hex wrench to

attach the front laser housing (A) Fig. 13 to the rear laser housing (B) loosely.

2. Place this laser housing assembly on the drill press column (D) Fig. 14. Rest it on the collar (E) Fig. 14.

3. Place the drill press head (K) Fig. 15A on the column as far as it will go. Align the head (K) Fig. 15A with the table

(L) and the base (M). Tighten the two head-locking screws (N) Fig. 15B with the 5mm wrench supplied.

4. Slide the laser up on the column until you can plug the power wire (F) Fig. 16 into the socket of the laser (G)

Fig. 16.

5. Slide the laser up flush against the headstock.

6. Tighten the screws on the laser just enough to prevent movement.

NOTICE

B

Overtightening the laser screws can damage the laser.

C

A

Fig. 13

K

D

D

E

E

Fig. 14

L

M

Fig. 15A

N

Fig. 15B

F

G

Fig. 16

11

Page 12

INSTALLING THE CHUCK

IMPORTANT: Make certain that the tapered hole in the

bottom of the spindle (T) Fig. 17, and the taper on the

spindle adapter (U) are clean and free of grease, lacquer,

or rust-preventive coatings.

NOTE: Household oven cleaner can effectively remove

these coatings from the spindle and spindle adapter.

However, carefully follow the manufacturer’s safety rules

regarding its use.

Push the spindle adapter (U) Fig. 17 into the spindle (T).

making certain that the tang (V) engages the mating slot

inside the spindle (T).

RISK OF PROPERTY DAMAGE. To avoid damage to the laser, prevent the cleaning solution from

coming in contact with the laser pod. You can clean the laser pod with a dry cotton cloth.

IMPORTANT: Make certain the spindle taper (O) Fig. 18,

and tapered hole in chuck (P) are clean and free of any

grease, lacquer, or rust preventive coatings.

NOTE: Household oven cleaner can effectively remove

any substance from the chuck. However, carefully follow

the manufacturer's safety rules concerning its use.

Fig. 17

V

P

T

U

O

IMPORTANT: Open the chuck jaws as wide as possible,

making sure that the chuck jaws are inside the chuck.

Hold the chuck on the taper of the spindle. Tap it with

a soft-tip hammer (Q) Fig. 19 or a block of wood and

hammer to set the chuck.

RISK OF PROPERTY DAMAGE. To avoid damage to the chuck, NEVER drive the chuck on the

spindle with a metal hammer.

ATTACHING THE PINION SHAFT HANDLES

Fig. 18

Q

Fig. 19

Thread the three pinion shaft handles (R) in the three

holes located in the pinion shaft hub (S) Fig. 20.

R

S

Fig. 20

12

Page 13

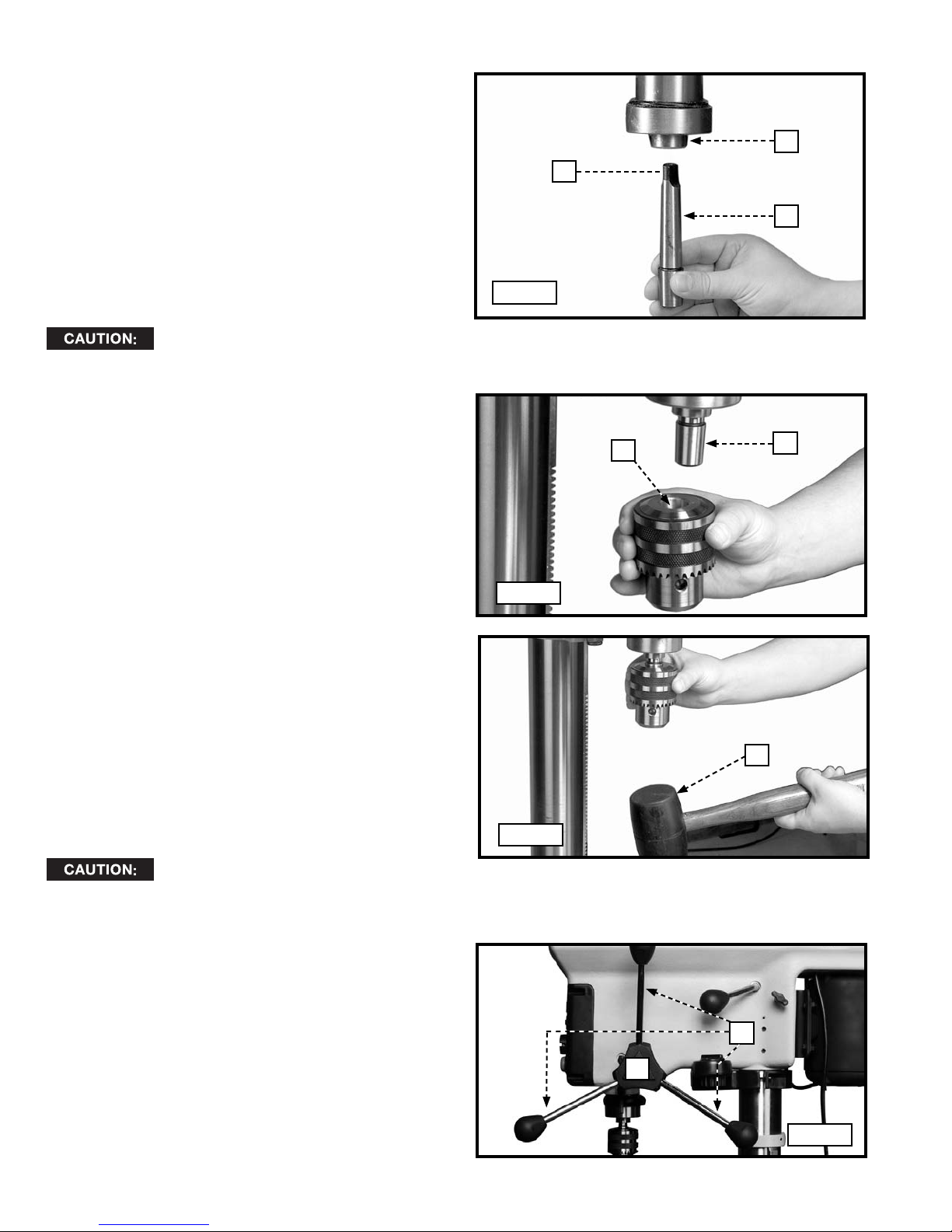

ATTACHING THE LAMP CORD BRACKET

1. Align the two holes in the lamp cord bracket (A) Fig. 21, with the two holes (B) on the side of the drill press head.

2. Place the cord bushing (inset) Fig. 21, around the top of the lamp cord.

3. Align the two holes in the lamp cord bracket with the two holes in the cord strain relief bracket and drill press head.

4. Place a 1/4" washer on an M6 x 1 x 12mm cap head screw. Insert the screw through the hole in the cord strain

relief bracket and the lamp cord bracket. Thread the screw into the drill press head (Fig. 22). Repeat this process

for the remaining hole in the cord strain relief bracket and tighten both screws securely.

A

Fig. 22

B

Fig. 21

H

5. Peel the backing from the cord clamps (H) Fig. 23,

and apply the clamps at the locations shown. Make

certain that the lamp cord is routed out of the way

of the drill, then secure the cord (J) to cord clamp (H)

Fig. 23.

J

Fig. 23

OPERATION

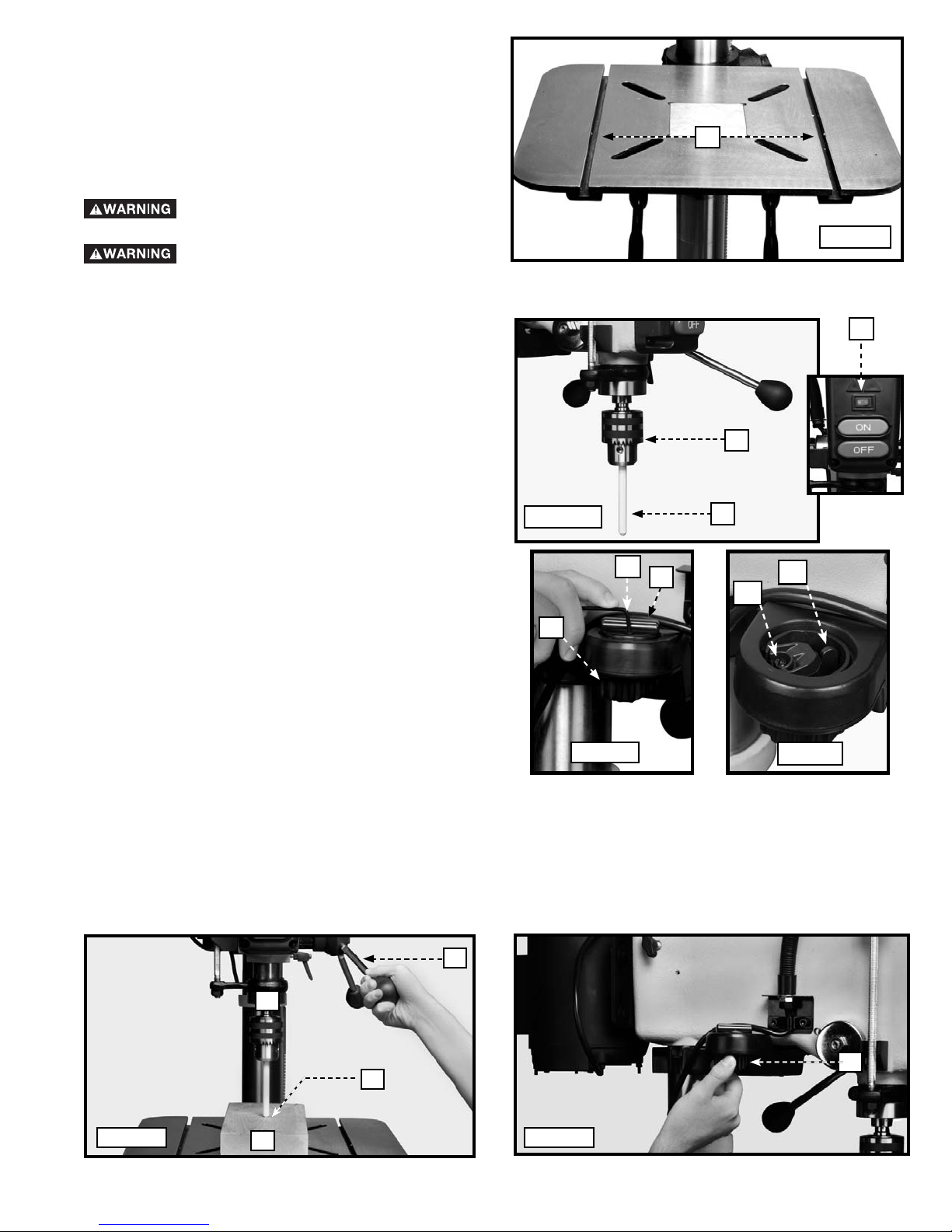

OPERATIONAL CONTROLS AND ADJUSTMENTS

STARTING AND STOPPING THE DRILL PRESS

1. The on/off switches (A and B) Fig. 24 are located on the front of the drill press. To turn the machine “ON”, depress the

“ON” switch.

2. To turn the machine “OFF”, depress the “OFF” switch.

Make sure that the switch is in the “OFF” position before plugging in the power cord. In the event of a

power failure, depress the “OFF” switch. An accidental start-up can cause injury.

IMPORTANT: When the machine is not in use, lock the switch in the “OFF” position to prevent unauthorized use, using a

padlock (A) Fig. 25 with a 3/16" diameter shackle.

A

A

B

Fig. 24 Fig. 25

13

Page 14

FLEXIBLE LAMP

The flexible lamp op er ates in de pen dent ly of the drill press. To turn the lamp “ON” and “OFF”, rotate switch (A) Fig. 26.

FIRE HAZARD. To reduce the risk of fire,

use a 40 watt or less, 120 volt, reflector track-type

light bulb (not supplied). DO NOT USE a standard

house hold light bulb. Do not allow the reflector tracktype light bulb to extend below the lamp shade.

RISK OF PERSONAL INJURY. Disconnect

the machine from the power source before making

any adjustments.

TABLE ADJUSTMENTS

RISK OF PERSONAL INJURY. Make sure that nothing is on the table and that the workpiece is clamped

down. Falling objects can cause an injury.

You can tilt the table forward from zero (0) to 45 degrees. To adjust:

1. Loosen the two forward tilt levers (A) Fig. 27.

2. Adjust the table to your desired angle. The scale (B) Fig. 27 is located on the side of the table support.

3. Tighten the levers (A) Fig. 27.

4. A positive stop (C) Fig. 28 is provided to return the table to the zero position. Adjust this stop by turning the screw/

stop (C), located under the table. Tighten the locknut to secure the stop.

You can tilt the table right or left. Positive stops are included for 0, 45 and 90 degrees. To adjust:

1. Loosen the table bolt (E) Fig. 29 approximately 1/4 turn with the supplied 12mm hex wrench.

2. Pull out the spring-loaded detent pin (F).

3. Rotate the table to your desired angle. The tilt scale (G) Fig. 30 is located on the knuckle behind the table. Use this

scale for accuracy. You can allow the detent pin to slide in to the positive stops (0, 45, and 90 degrees), but check

your scale to be sure of the exact angle.

4. Tighten the table bolt.

A

Fig. 26

Fig. 27

Located under table

C

A

B

Fig. 28

E

F

Fig. 29

Fig. 30

G

14

Page 15

T-SLOTS

The drill press table is fitted with two T-slots (L) Fig. 31

for use with various drill press accessories (stop blocks,

fences, or clamps). Use 5/16" T-bolts when attaching

your accessory to the table.

ADJUSTING THE LASERS

Disconnect the machine from the

power source.

LASER LIGHT. Do not stare into the

beam, aperture, or into a reflection from a mirror-like

surface.

L

Fig. 31

MAKING THE LASERS PARALLEL

1. Install the alignment pin (A) Fig. 32 in the chuck (B).

Make sure that the pointed end of the alignment pin

is down. The black scribed line on the pin should

face toward the left laser.

2. Turn on the lasers using the switch (C-inset) Fig. 32

on the front of the headstock.

3. With the supplied hex wrench, remove the two

screws (F) Fig. 33 and the cap (G) above the left side

of the laser housing.

4. Loosen the laser retainer screw (H) Fig. 34.

5. Move the laser lever (I) Fig. 34 so that the laser is

shining on the alignment pin. Adjust the lever (I) until

the laser is parallel with the black line.

NOTE: You may have to move the laser holder (J) Fig. 33

in order to shine the laser on the alignment pin. Adjust

the laser with the lever (I).

6. Tighten the laser retainer screw (H) Fig. 34. Replace

the cap (G) Fig. 33 and loosely tighten the two

screws (F).

7. Repeat for the other side.

MAKING THE LASERS INTERSECT

Fig. 32

J

Fig.33

C

B

A

F

G

H

I

Fig. 34

1. Place a piece of wood (A) Fig. 35 on the table and clamp it in place.

2. Use the handle (B) to lower the quill (C). Make an indentation in the wood with the alignment pin (D) Fig. 35.

3. Turn on the laser and adjust both beams to intersect at that point by rotating the laser holder (A) Fig. 36.

4. Ensure that the lasers align at different heights. Raise or lower the table, make a new indentation, and turn on the

lasers. If the lasers do not align at different heights, check the parallel adjustment.

5. Tighten the screws on each side of the laser housing, one of which is shown at (F) Fig. 33.

C

Fig. 35

A

B

A

D

Fig. 36

15

Page 16

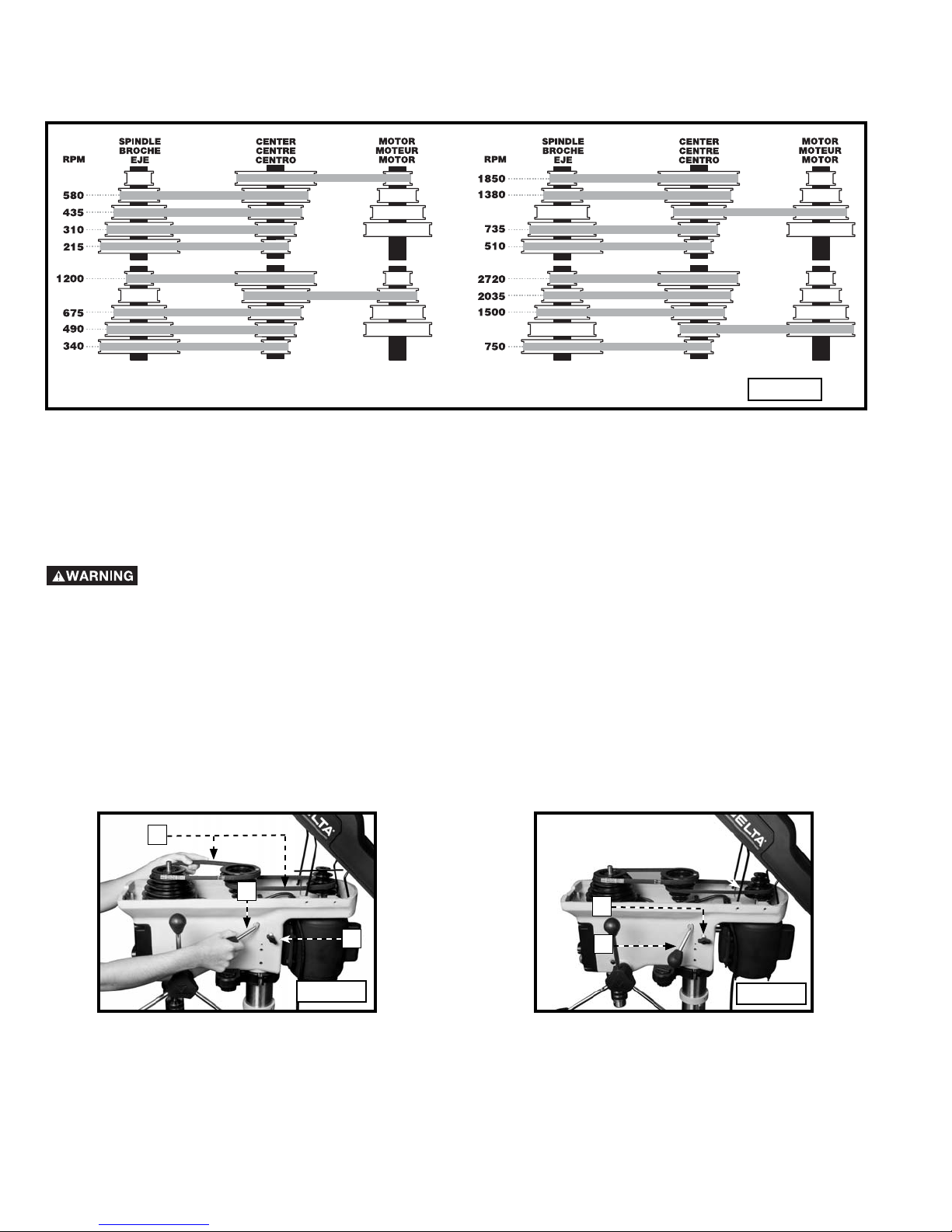

SPINDLE SPEEDS

Sixteen spindle speeds are available on the drill press. Fig. 37 illustrates the belt positions and the corresponding

speeds.

Fig. 37

CHANGING SPEEDS AND ADJUSTING BELT TENSION

NOTE: Sixteen spindle speeds are available on the drill press. A belt-positioning speed chart is located on the inside top

cover of the drill press.

DISCONNECT THE MACHINE FROM THE POWER SOURCE!

1. Open the top cover.

2. Loosen the lock-knob (A) Fig. 38 and the tension knob (located on the other side of the head casting). Move the tension

lever (B) forward.

3. Position both belts (C) Fig. 38 on the spindle pulley, center pulley, and motor pulleys according to the chart.

4. Move the tension lever (B) Fig. 39 to the rear to tension the belts.

NOTE: The belt should be just tight enough to prevent slipping. Excessive tension will reduce the life of the belt, pulleys, and

bearings. Tension is correct when you can flex the belt about 1" out of line, midway between the pulleys, using light finger

pressure.

5. Tighten the two tension lock knobs (A), one of which is shown.

C

B

A

A

B

Fig. 38

Fig. 39

16

Page 17

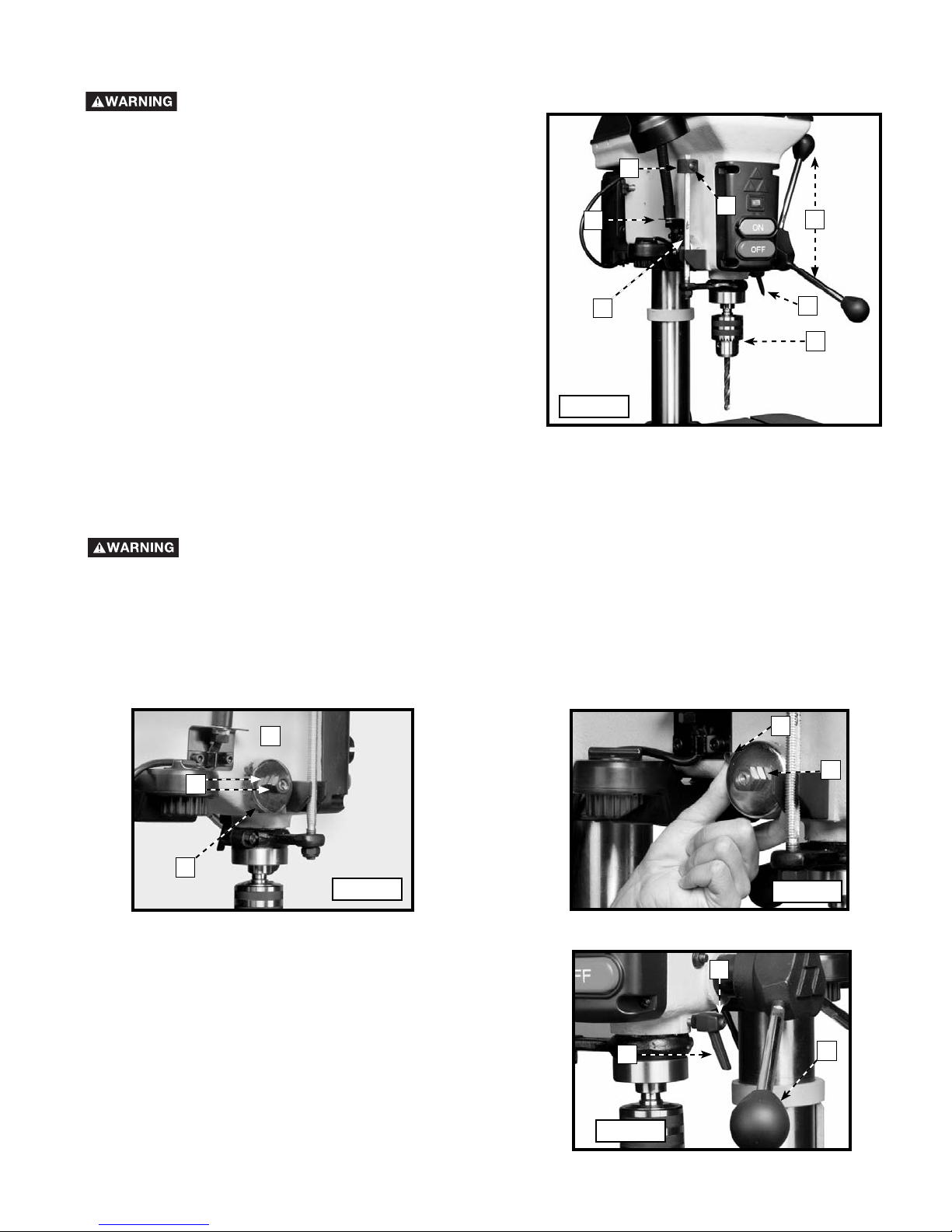

DRILLING HOLES TO DEPTH

When you want to drill a number of holes to the same depth, use the stop nut (A) Fig. 40 on the threaded stop rod (B).

DISCONNECT MACHINE FROM POWER SOURCE.

1. Insert the bit into the chuck.

2. Lower the chuck (G) Fig. 40, and the drill bit to your

chosen depth by rotating the pinion shaft handles (C).

Lock the quill in position by tightening the quill locking

lever (D).

NOTE: The quill locking lever (D) is spring-loaded. Change

it by pulling out on the handle and repositioning the hub of

the handle on the nut located underneath the hub.

3. Depress the spring-loaded button (E) Fig. 40 and move

the stop nut (A) until the bottom of the nut contacts the

stop (F). Loosen the quill locking-lever (D) to allow the

chuck and drill bit to return to the up position.

4. Connect the machine to the power source and drill

a test hole to check the adjustment. Readjust, if

necessary, by rotating the stop nut (A) Fig. 40 for fine

adjustment. You do not have to depress the button (E)

to rotate the stop nut (A).

Fig. 40

A

E

F

B

C

D

G

ADJUSTING THE SPINDLE RETURN SPRING

The spindle will automatically return slowly to its upper position when the handle is released. However, to adjust, if necessary:

DISCONNECT THE MACHINE FROM THE POWER SOURCE!

1. Loosen the nuts (B) Fig. 41, but do not remove. Make sure that the spring housing (A) remains engaged with head casting (C).

2. While firmly holding the spring housing (Fig. 42), pull out the housing and rotate it (counter-clockwise to increase or

clockwise to decrease) until the boss (D) is engaged with the next notch on the housing. Tighten the two nuts (B)

Fig. 41 to hold the housing in place.

IMPORTANT: The inside nut (E) Fig. 42 should not contact the spring housing (A) Fig. 41.

C

D

E

B

A

Fig. 41

Fig. 42

C

R

AISING AND LOWERING THE SPINDLE

Raise and lower the spindle with the pinion handles (A)

Fig. 43. You can lock the quill at any point in its travel by

tightening locking lever (B).

B

A

NOTE: The quill locking lever (B) is spring-loaded. Pull

outward on handle and reposition it on its hub (C).

Fig. 43

17

Page 18

MACHINE USE

NOTE: Use drill bits with shank diameters of 5/8" or less.

NOTE: After installing a drill bit, use the supplied key to tighten all three locations on the chuck.

The use of accessories and attachments not recommended by DELTA may result in risk of injury.

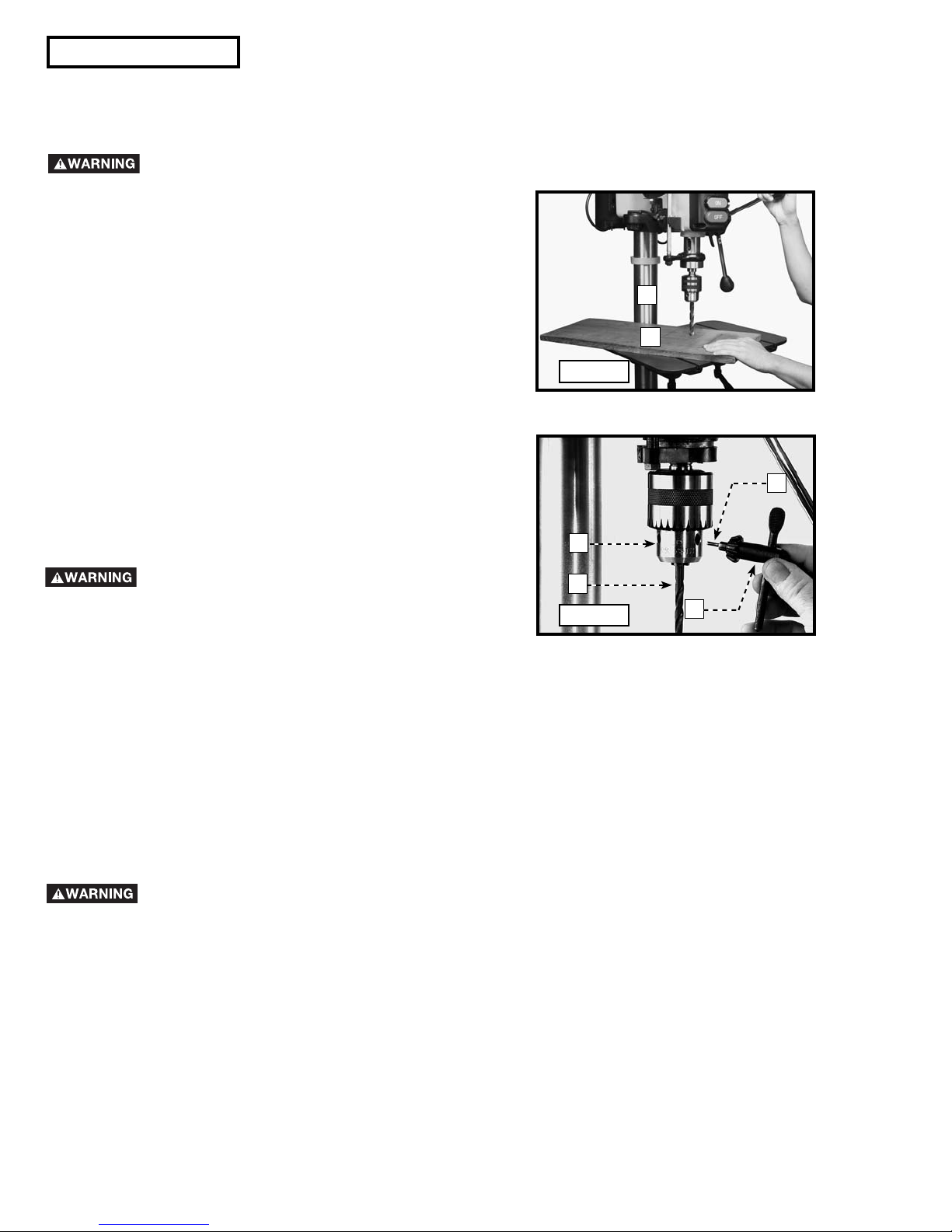

IMPORTANT: When the workpiece (A) Fig. 44 is long

enough, position it on the table with one end against the

left side of the column (B) to prevent the workpiece from

rotating. If it is not possible to support the workpiece

against the column, clamp the workpiece to the table.

Fig. 44

B

A

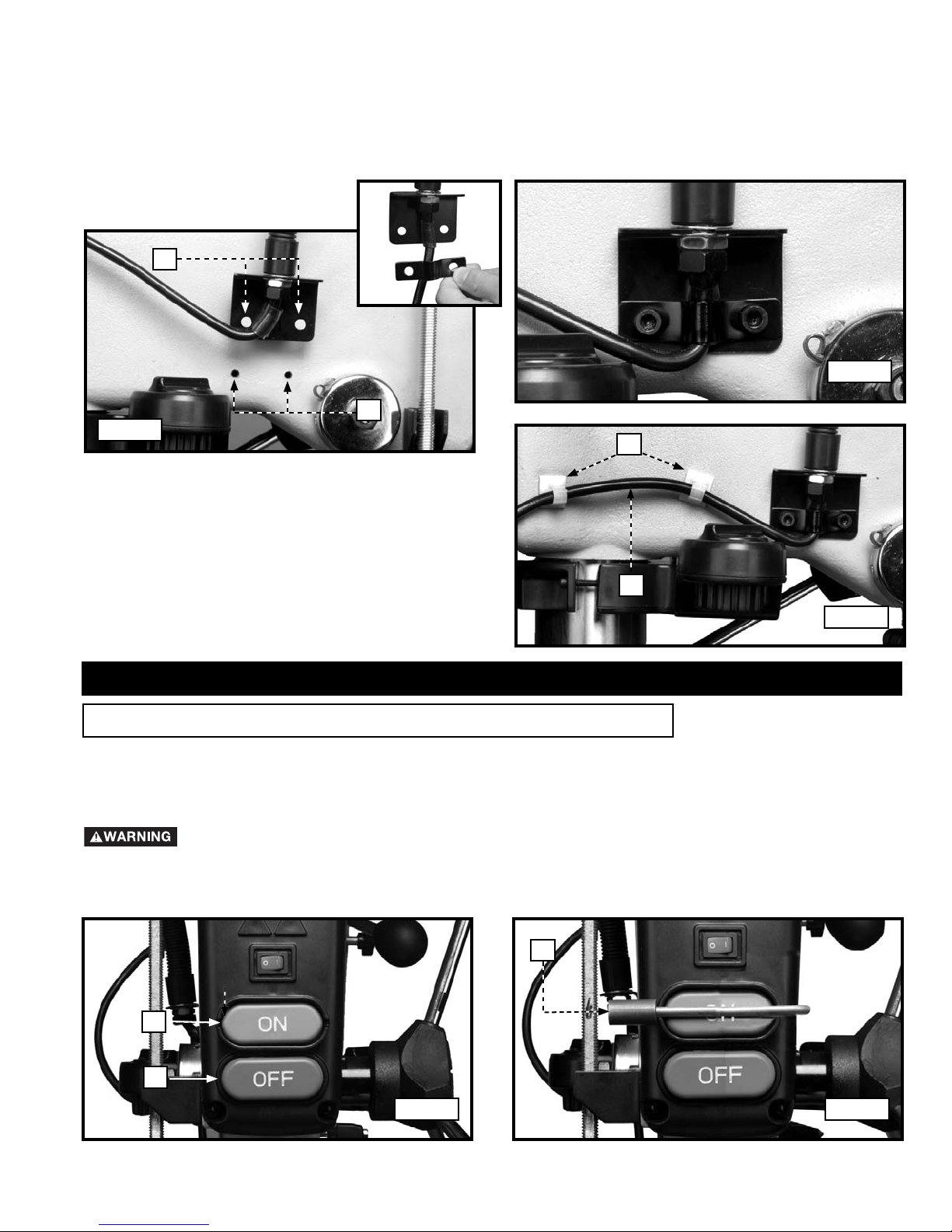

INSTALLING AND REMOVING DRILL BITS

NOTE: Use drill bits with a shank of 5/8" or less in diameter.

D

B

DISCONNECT THE MACHINE FROM THE

POWER SOURCE!

1. Insert the smooth end of drill bit (A) Fig. 45 in the chuck (B) as far as it will go, and then back the bit out 1/16" (or

up to the flutes for small bits).

2. Center the drill bit (A) Fig. 45 in the chuck (B) before tightening the chuck with the key (C).

3. Turn the chuck key (C) Fig. 45 clockwise to tighten and counter-clockwise to loosen the chuck jaws.

4. Tighten all three chuck jaws to secure the drill bit sufficiently to prevent slipping.

5. Remove the chuck key (C) Fig. 45 from the chuck before starting the drill press. The chuck key (C) is equipped with

a self-ejecting pin (D) which helps minimize the potential for the key to be left in the chuck.

A

Fig. 45

C

CORRECT DRILLING SPEEDS

Factors that determine the correct speed are 1) the workpiece, 2) the size of the hole, 3) the type of bit or other cutter,

and 4) the quality of cut.

Use the recommended speed for the the drill press bit and workpiece.

DRILLING WOOD

Twist drills, usually intended for metal drilling, can also be used for boring holes in wood. However, machine spur bits

are generally preferred for working in wood. These bits cut a flat-bottom hole and are designed for removal of wood

chips. Do not use hand bits (screw tip). At drill press speeds, they lift and rotate the workpiece.

For through boring, align the workpiece so that the bit will go through the center hole in the table. Scribe a vertical line

on the front of the column and a matching mark on the table bracket and the drill press head, so that the table and

drill press head can be clamped in the center position at any height.

Feed the workpiece slowly when the bit is close to cutting through the wood to prevent splintering the bottom face.

Use a scrap piece of wood as a base block under the work to reduce splintering and to protect the point of the bit.

18

Page 19

DRILLING METAL

Use clamps to hold metal workpieces. Never hold the workpiece in your bare hand. The drill bit can seize the work at

any time, especially when breaking through the workpiece and cause damage to the machine or injury to you. The drill

bit will break if the workpiece strikes the column.

Clamp the workpiece firmly. Any tilting, twisting, or shifting results not only in a rough hole, but also in bit breakage.

For flat work, lay the workpiece on a wooden base and clamp it firmly against the table to prevent it from turning. If

the workpiece is of irregular shape and cannot lay flat on the table, securely block or clamp it.

TROUBLESHOOTING

For assistance with your machine, visit our website at www.deltamachinery.com for a list of service centers or call the

DELTA Machinery help line at 1-800-223-7278 (In Canada call 1-800-463-3582).

MAINTENANCE

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp

cloth. NEVER use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

Wear certified safety equipment for eye, hearing and respiratory protection while using compressed air.

FAILURE TO START

Should your machine fail to start, check to make sure the prongs on the cord plug are making good contact in the

outlet. Also, check for blown fuses or open circuit breakers in the line.

LUBRICATION & RUST PROTECTION

Apply household floor paste wax to the machine table, extension table or other work surface weekly. Or use a

commercially available protective product designed for this purpose. Follow the manufacturer’s instructions for use

and safety.

To clean cast iron tables of rust, you will need the following materials: a sheet of medium Scotch-Brite™ Blending Hand

Pad, a can of WD-40® and a can of degreaser. Apply the WD-40® and polish the table surface with the Scotch-Brite

pad. Degrease the table, then apply the protective product as described above.

SERVICE

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our website at

You can also order parts from your nearest factory-owned branch, or by calling our Customer Care Center at 1-800-223-7278

to receive personalized support from highly-trained technicians.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information about DELTA Machinery, its

factory-owned branches, or an Authorized Warranty Service Center, visit our website at www.deltamachinery.com or call

our Customer Care Center at 1-800-223-7278. All repairs made by our service centers are fully guaranteed against defective

material and workmanship. We cannot guarantee repairs made or attempted by others.

servicenet.deltamachinery.com.

You can also write to us for information at DELTA Machinery, 4825 Highway 45 North, Jackson, Tennessee 38305 - Attention:

Product Service. Be sure to include all of the information shown on the nameplate of your tool (model number, type, serial

number, etc.)

19

Page 20

FREE WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call

1-800-223-7278

for a free replacement.

ACCESSORIES

Since accessories other than those offered by DELTA have not been tested with this product,

use of such accessories could be hazardous. For safest operation, only DELTA recommended accessories

should be used with this product.

A complete line of accessories is available from your DELTA Supplier, Porter-Cable • DELTA Factory Service Centers,

and DELTA Authorized Service Stations. Please visit our website www.deltamachinery.com for a catalog or for the

name of your nearest supplier.

WARRANTY

To register your tool for warranty service visit our website at www.deltamachinery.com.

Two Year Limited New Product Warranty

DELTA will repair or replace, at its expense and at its option, any new DELTA machine, machine part, or machine accessory which in normal

use has proven to be defective in workmanship or material, provided that the customer returns the product prepaid to a DELTA factory

service center or authorized service station with proof of purchase of the product within two years and provides DELTA with reasonable

opportunity to verify the alleged defect by inspection. For all refurbished DELTA product, the warranty period is 180 days. DELTA may require

that electric motors be returned prepaid to a motor manufacturer’s authorized station for inspection and repair or replacement. DELTA will

not be responsible for any asserted defect which has resulted from normal wear, misuse, abuse or repair or alteration made or specifically

authorized by anyone other than an authorized DELTA service facility or representative. Under no circumstances will DELTA be liable for

incidental or consequential damages resulting from defective products. This warranty is DELTA’s sole warranty and sets forth the customer’s

exclusive remedy, with respect to defective products; all other warranties, express or implied, whether of merchantability, fitness for purpose,

or otherwise, are expressly disclaimed by DELTA.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America, see country specific

warranty information contained in the packaging, call the local company or see website for warranty information.

20

Page 21

LES INSTRUCTIONS IMPORTANTES DE SURETE

n’importe quel outil ou n’importe quel équipement. En utilisant les outils ou l’équipement, les précautions de sûreté

fondamentales toujours devraient être suivies pour réduire le risque de blessure personnelle. L’opération déplacée,

l’entretien ou la modification d’outils ou d’équipement ont pour résultat la blessure sérieux et les dommages de

propriété. Il y a de certaines applications pour lequel outils et l’équipement sont conçus. La DELTA Machinery

recommande avec force que ce produit n’ait pas modifié et/ou utilisé pour l’application autrement que pour lequel il

a été conçu.

Si vous avez n’importe quelles questions relatives à son application n’utilisent pas le produit jusqu’à ce que vous avez écrit

Porter-Cable et nous vous avons conseillé.

(EN CANADA: 125 Mural St. Suite 300, Richmond Hill, ON, L4B 1M4)

Information en ce qui concerne l’opération sûre et correcte de cet outil est disponible des sources suivantes:

American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org

ANSI 01.1 Safety Requirements for Woodworking Machines, and the U.S. Department of Labor regulations www.osha.gov

Lire et comprendre toutes instructions d’avertissements et opération avant d’utiliser

La forme en ligne de contact à www.deltamachinery.com

Courrier Postal: Technical Service Manager

DELTA Machinery

4825 Highway 45 North

Jackson, TN 38305

Power Tool Institute

1300 Sumner Avenue, Cleveland, OH 44115-2851

www.powertoolinstitute.org

National Safety Council

1121 Spring Lake Drive, Itasca, IL 60143-3201

CONSERVEZ CES INSTRUCTIONS!

MESURES DE SÉCURITÉ - DÉFINITIONS

Ce guide contient des renseignements importants que vous deviez bien saisir. Cette information porte sur

VOTRE SÉCURITÉ et sur LA PRÉVENTION DE PROBLÈMES D’ÉQUIPEMENT. Afin de vous aider à identifier

cette information, nous avons utilisé les symboles ci-dessous.

indique une situation dangereuse imminente qui, si elle n’est pas évitée, causera la mort ou des

blessures graves.

indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait se solder par

un décès ou des blessures graves.

indique une situation potentiellement dangereuse qui, si elle n’est pas évitée pourrait se solder par

des blessures mineures ou modérées.

AVIS

n’est fait pour l’éviter, pourrait poser des risques de dommages matériels.

LA PROPOSITION DE CALIFORNIE 65

produire des poussières contenant des produits chimiques reconnus par l’État californien pour causer cancers,

malformations congénitales ou être nocifs au système reproducteur. Parmi ces produits chimiques, on retrouve:

• le plomb dans les peintures à base de plomb;

• la silice cristallisée dans les briques et le ciment ou autres articles de maçonnerie; et

• l’arsenic et le chrome dans le bois ayant subi un traitement chimique (ACC).

Le risque associé à de telles expositions varie selon la fréquence à laquelle on effectue ces travaux. Pour réduire toute

exposition à ces produits: travailler dans un endroit bien aéré, en utilisant du matériel de sécurité homologué tel un

masque antipoussières spécialement conçu pour filtrer les particules microscopiques.

indique une pratique ne posant aucun risque de dommages corporels mais qui par contre, si rien

Les scies, meules, ponceuses, perceuses ou autres outils de construction peuvent

21

Page 22

RÈGLES DE SÉCURITÉ GÉNÉRALES

l’inobservation de ces règles peut conduire à des blessures graves.

1. POUR SA SÉCURITÉ PERSONNELLE, LIRE LA NOTICE

D’UTILISATION, AVANT DE METTRE LA MACHINE EN

MARCHE, et pour aussi apprendre l’application et les limites de

la machine ainsi que les risques qui lui sont particuliers ainsi, les

possibilités d’accident et de blessures seront beaucoup réduites.

2. PORTEZ DES DISPOSITIFS DE PROTECTION DES YEUX

ET DE L’OUÏE. UTILISEZ TOUJOURS DES LUNETTES DE

SÉCURITÉ. Des lunettes ordinaires ne constituent PAS des

lunettes de sécurité. UTILISEZ DES ÉQUIPEMENTS DE SÛRETÉ

HOMOLOGUÉS. Les dispositifs de protection des yeux doivent

être conformes aux normes ANSI Z87.1. Les dispositifs de

protection de l’ouïe doivent être conformes aux normes ANSI

S3.19.

3. PORTER UNE TENUE APPROPRIÉE. Pas de cravates, de

gants, ni de vêtements amples. Enlever montre, bagues et autres

bijoux. Rouler les manches. Les vêtements ou les bijoux qui

se trouvent pris dans les pièces mobiles peuvent entraîner des

blessures.

4. NE PAS UTILISER LA MACHINE DANS UN

ENVIRONNEMENT DANGEREUX. L’utilisation d’outils

électriques dans des endroits humides ou sous la pluie peut

entraîner des décharges électriques ou une électrocution. Garder

la zone de travail bien éclairée pour éviter de trébucher ou

d’exposer les doigts, les mains ou les bras à une situation

dangereuse.

5. GARDER LES OUTILS ET LES MACHINES EN PARFAIT

ÉTAT. Garder les outils affûtés et propres afin d’obtenir le meilleur

et le plus sûr rendement. Suivre les instructions pour lubrifier

et changer les accessoires. Les outils et les machines mal

entretenus peuvent se dégrader davantage, et/ou entraîner des

blessures.

6. INSPECTER LES PIÈCES POUR DÉCELER TOUT

DOMMAGE. Avant d’utiliser la machine, la vérifier pour voir

s’il n’y a pas de pièces endommagées. Vérifier l’alignement

des pièces mobiles et si ces pièces ne se coincent pas, la

rupture de pièces, ou toute autre condition pouvant en affecter

le fonctionnement. Toute pièce ou protecteur endommagé doit

être réparé ou remplacé. Les pièces endommagées peuvent

dégrader davantage la machine et/ou entraîner des blessures.

7. GARDER L’AIRE DE TRAVAIL PROPRE. Les zones et établis

encombrés favorisent les accidents.

8. GARDER LES ENFANTS ET LES VISITEURS À DISTANCE.

L’atelier est un lieu potentiellement dangereux. Les enfants et les

visiteurs peuvent se blesser.

9. ÉVITER LE DÉMARRAGE ACCIDENTEL. S’assurer que

l’interrupteur est sur « OFF » (ARRÊT) avant de brancher le

cordon. En cas de coupure de courant, placer l’interrupteur

à la position « OFF » (ARRÊT). Un démarrage accidentel peut

entraîner des blessures.

10. UTILISER LES DISPOSITIFS PROTECTEURS. Vérifier que tous

les dispositifs protecteurs sont bien en place, bien fixés et en

bon état de marche pour éviter les blessures.

11. ENLEVER LES CLÉS DE RÉGLAGE ET CELLES DE

SERRAGE AVANT DE METTRE LA MACHINE EN MARCHE.

Les outils, les chutes et les autres débris peuvent être projetés

violemment et blesser.

12. UTILISER LA BONNE MACHINE. Ne pas forcer la machine ou

l’accessoire à faire un travail pour lequel il n’a pas été conçu.

Des dommages à la machine et/ou des blessures pourraient

s’ensuivre.

13. UTILISER LES ACCESSOIRES RECOMMANDÉS. L’utilisation

d’accessoires non recommandés par DELTA peut endommager

la machine et blesser l’utilisateur.

14. UTILISER LE CORDON PROLONGATEUR APPROPRIÉ.

S’assurer que le cordon prolongateur est en bon état. Lorsqu’un

cordon prolongateur est utilisé, s’assurer que celui-ci est d’un

calibre suffisant pour l’alimentation nécessaire à la machine. Un

cordon d’un calibre insuffisant entraînera une perte de tension

d’où une perte de puissance et surchauffe. Voir le tableau sur

les cordons prolongateurs pour obtenir le calibre approprié selon

la longueur du cordon et l’ampérage de la machine. S’il y a un

doute, utiliser un cordon d’un calibre supérieur. Plus le chiffre est

petit, plus le fil est gros.

15. FIXER LA PIÈCE.

l’objet si pratique. La perte de commande d’un objet peut

causer des dommages.

16. AVANCER LA PIÈCE DANS LE SENS CONTRAIRE À

LA ROTATION DE LA LAME, DE LA FRAISE OU DE LA

SURFACE ABRASIVE. L’alimentation dans l’autre sens peut

entraîner une projection violente de la pièce.

17. NE PAS FORCER LA MACHINE EN AVANÇANT LA PIÈCE

TROP VITE. Des dommages et/ou des blessures peuvent

s’ensuivre.

18. NE PAS SE PENCHER AU-DESSUS DE LA MACHINE. Une

perte de l’équilibre peut entraîner une chute sur la machine en

marche et causer des blessures.

19. NE JAMAIS MONTER SUR LA MACHINE. On peut se

blesser gravement si la machine bascule ou si l’on touche

accidentellement son outil tranchant.

20. NE JAMAIS LAISSER LA MACHINE EN MARCHE SANS

SURVEILLANCE. COUPER LE COURANT. Ne pas quitter la

machine tant qu’elle n’est pas complètement arrêtée. Un enfant

ou un visiteur pourrait se blesser.

21. METTRE LA MACHINE À L’ARRÊT « OFF » ET LA

DÉBRANCHER avant d’installer ou d’enlever des accessoires,

d’ajuster ou de changer des montages, ou lors des réparations.

Un démarrage accidentel peut entraîner des blessures.

22. METTRE L’ATELIER À L’ABRI DES ENFANTS AU MOYEN

DE CADENAS, D’INTERRUPTEURS PRINCIPAUX OU EN

ENLEVANT LES BOUTONS DES DISPOSITIFS DE MISE EN

MARCHE. Le démarrage accidentel de la machine par un enfant

ou un visiteur peut entraîner des blessures.

23. RESTER VIGILANT, ATTENTIF, ET FAIRE PREUVE DE BON

SENS. NE PAS UTILISER LA MACHINE LORSQUE L’ON EST

FATIGUÉ OU SOUS L’INFLUENCE DE DROGUES, D’ALCOOL

OU DE MÉDICAMENTS. Un instant d’inattention lors de

l’utilisation d’outils électriques peut entraîner des blessures

graves.

24.

PEUT PRODUIRE ET DISPERSER DE LA POUSSIÈRE OU

D’AUTRES PARTICULES EN SUSPENSION DANS L’AIR,

TELLES QUE LA SCIURE DE BOIS, LA POUSSIÈRE DE

SILICIUM CRISTALLIN ET LA POUSSIÈRE D’AMIANTE.

Dirigez les particules loin du visage et du corps. Faites

toujours fonctionner l’outil dans un espace bien ventilé et

prévoyez l’évacuation de la poussière. Utilisez un système

de dépoussiérage chaque fois que possible. L’exposition à

la poussière peut causer des problèmes de santé graves et

permanents, respiratoires ou autres, tels que la silicose (une

maladie pulmonaire grave) et le cancer, et même le décès de

la personne affectée. Évitez de respirer de la poussière et de

rester en contact prolongé avec celle-ci. En laissant la poussière

pénétrer dans vos yeux ou votre bouche, ou en la laissant

reposer sur votre peau, vous risquez de promouvoir l’absorption

de substances toxiques. Portez toujours des dispositifs de

protection respiratoire homologués par NIOSH/OSHA,

appropriés à l’exposition à la poussière et de taille appropriée, et

lavez à l'eau et au savon les surfaces de votre corps qui ont été

exposées.

Utilisez les brides ou un étau pour tenir

L’UTILISATION DE CET OUTIL

22

Page 23

RÈGLES SPÉCIFIQUES ADDITIONNELLES DE SÛRETÉ

l’inobservation de ces règles peut conduire à des blessures graves.

1. NE PAS FAIRE FONCTIONNER CETTE MACHINE

AVANT QU’ELLE NE SOIT ENTIÈREMENT ASSEMBLÉE

ET INSTALLÉE CONFORMÉMENT À CES DIRECTIVES.

Une machine mal assemblée peut provoquer des blessures

graves.

2. DEMANDER CONSEIL à un superviseur, instructeur, ou

toute autre personne qualifiée si vous ne maîtrisez pas

parfaitement l’utilisation de cette machine. La connaissance

est synonyme de sécurité.

3. SUIVRE TOUS LES CODES DE CÂBLAGE et les

connexions électriques recommandées afin d’éviter tout

choc électrique ou électrocution.

4. FIXER LA MACHINE SUR UNE SURFACE DE SUPPORT.

Les vibrations sont susceptibles de faire glisser, « marcher »,

ou basculer la machine.

5. NE JAMAIS DÉMARRER LA MACHINE AVANT DE

RETIRER DE LA TABLE TOUT OBJET (outils, morceaux de

déchet de découpe, etc.). Les débris peuvent être projetés à

grande vitesse.

6. NE JAMAIS DÉMARRER LA MACHINE avec une mèche,

un outil de coupe ou un cylindre de contact contre l’ouvrage.

La perte de contrôle de l’ouvrage peut provoquer de graves

blessures.

7. VERROUILLER CORRECTEMENT LA MÈCHE, L’OUTIL

DE COUPE OU LE CYLINDRE DE CONTACT DANS LE

MANDRIN avant d’utiliser cette machine.

8. RETIRER LA CLÉ DU MANDRIN AVANT DE DÉMARRER

LA MACHINE. La clé du mandrin risque d’être projetée à

grande vitesse.

9. SERRER TOUTES LES POIGNÉES DE VERROUILLAGE

avant de démarrer la machine. La perte de contrôle de

l’ouvrage peut provoquer de graves blessures.

10. UTILISER SEULEMENT DES MÈCHES, OUTILS

DE COUPE, CYLINDRES DE CONTACT OU AUTRES

ACCESSOIRES avec une queue à la dimension

recommandée dans le mode d’emploi. Un accessoire

de la mauvaise taille peut endommager la machine et/ou

provoquer de graves blessures.

11. UTILISER SEULEMENTS DES MÈCHES, OUTILS DE

COUPE OU CYLINDRES DE CONTACT intacts. Des articles

endommagés peuvent provoquer des défaillances qui

mèneraient à des blessures.

12. UTILISER LES VITESSES RECOMMANDÉES pour toutes

opérations.

D’autres vitesses peuvent provoquer des défaillances de la

machine qui endommageraient celle-ci et/ou provoqueraient

de graves blessures.

13. ÉVITER LES OPÉRATIONS MALADROITES ET ÉVITER

D’AVOIR LES MAINS MAL PLACÉES. En glissant

inopinément, votre main pourrait percuter la mèche.

14. TENIR LES BRAS, MAINS ET DOIGTS éloignés de la

mèche. De graves blessures à la main peuvent survenir.

15. TENIR FERMEMENT L’OUVRAGE CONTRE LA TABLE.

Ne pas percer un ouvrage si celui-ci ne repose pas sur un

côté plat contre la table ou s’il n’est pas fixé dans un étau.

Empêcher l’ouvrage de tourner en le rattachant à la table

ou en le fixant contre la colonne de la perceuse. La perte de

contrôle de l’ouvrage peut provoquer de graves blessures.

16. ÉTEINDRE LA MACHINE ET ATTENDRE QUE LA MÈCHE,

L’OUTIL DE COUPE OU LE CYLINDRE DE CONTACT

S’ARRÊTE COMPLÈTEMENT avant de nettoyer la zone

de travail, d’enlever des débris, de retirer ou de fixer un

ouvrage ou de changer l’angle de la table. Une mèche, un

outil de coupe ou un cylindre de contact en mouvement peut

provoquer de graves blessures.

17. SOUTENIR CORRECTEMENT LES OUVRAGES LONGS

OU LARGES. La perte de contrôle de l’ouvrage peut

provoquer de graves blessures.

18. NE JAMAIS EFFECTUER D’OPÉRATIONS DE TRAÇAGE,

D’ASSEMBLAGE, OU DE RÉGLAGE sur la table/l’espace

de travail lorsque la machine est en marche. De graves

blessures pourraient survenir.

19. ÉTEINDRE LA MACHINE, la débrancher, et nettoyer

la table/l’espace de travail avant de laisser la machine.

VERROUILLER L’INTERRUPTEUR EN POSITION D’ARRÊT

afin d’éviter toute utilisation non autorisée. Il se peut que

quelqu’un démarre accidentellement la machine et se blesse

gravement.

20. DES INFORMATIONS SUPPLÉMENTAIRES (i.e., une

vidéo sur la sécurité), indiquant comment utiliser des

outils électriques correctement et en toute sécurité, sont

disponibles auprès du Power Tool Institute, 1300 Sumner

Avenue, Cleveland, OH 44115-2851, États-Unis (www.

powertoolinstitute.com). Vous pouvez également vous

procurer des informations auprès du National Safety Council,

1121 Spring Lake Drive, Itasca, IL 60143-3201, États-Unis.

Veuillez vous reporter à la norme ANSI 01.01 de l’American

National Standards Institute concernant les machines de

travail du bois, ainsi que la réglementation OSHA 1910.213.

du département américain du travail.

RÈGLES ADDITIONNELLES DE SÛRETÉ POUR LE LASER

BLESSURE AUX YEUX – RAYONNEMENT LASER

Ne pas fixer du regard l’ouverture du faisceau ou le reflet du rayon sur une surface réfléchissante.

Ne pas utiliser d’outils optiques comme un télescope ou un théodolite pour regarder le faisceau laser.

BLESSURE AUX YEUX – RAYONNEMENT LASER

Ne pas utiliser le laser près des enfants et ne pas laisser les enfants utiliser le laser.

Ranger le laser inutilisé hors de la portée des enfants et des personnes sans expérience.

Arrêtez le laser en fin d’utilisation.

Ne pas démonter le module laser. Le rayonnement de classe II, produit par l’appareil, pourrait dépasser la limite si l’appareil est

démonté. Laser conforme aux normes 21 CFR 1040.10 et 1040.11.

L’utilisation de commandes ou de réglages ou l’exécution de procédures autres que celles précisées

dans la présente peut entraîner une exposition au rayonnement dangereux.

RISQUE D’EXPLOSION. Ne pas faire fonctionner le laser ou la perceuse de colonne dans un milieu

déflagrant, comme en présence de liquides, de gaz ou de poussières inflammables. Une étincelle pourrait enflammer les

poussières ou les vapeurs.

REMARQUE : Ne pas enlever ni altérer les étiquettes de mises en garde.

23

Page 24

RACCORDEMENTS ÉLECTRIQUES

Un circuit électrique séparé doit être utilisé pour les machines. Les fils de ce circuit doivent être au moins de calibre 12. Ce circuitdoit

être protégé par un fusible temporisé de 20 A. Si on utilise un cordon prolongateur, ce cordon doit être à trois fils, avoir unefiche à trois

broches et une prise de courant à trois cavités, mise à la terre qui correspond à la fiche de la machine. Avant debrancher la machine,

s’assurer que l’interrupteur se trouve en position « OFF » (ARRÊT) et que le courantélectrique présente les mêmes caractéristiques

que celles qui sont inscrites sur la machine. Toutes les connexions électriquesdoivent établir un bon contact. Le fonctionnement sur

une basse tension endommagera la machine.

Ne pas exposer la machine à la pluie, et ne pas l’utiliser dans des endroits humides.

SPÉCIFICATIONS DU MOTEUR

Cette machine est câblée pour un fonctionnement sur un courant alternatif de 120/240 volts, 60 Hz. Avant de brancher la machine,

s’assurer que l’interrupteur se trouve à la position « OFF » (ARRÊT).

INSTRUCTIONS DE MISE À LA TERRE

Cette machine doit être mise à la terre pendant son emploi, afin de protéger l’utilisateur des décharges

électriques.

1. Toutes les machines avec cordon mis à la terre: Dans l’éventualité d’un mauvais fonctionnement ou d’une panne, la mise à la

terre fournit un trajet de moindre résistance permettant de réduire le risque de décharge électrique. Cette machine est dotée d’un

cordon électrique possédant un conducteur de mise à la terre de l’équipement ainsi que d’une fiche mise à la terre. La fiche doit

être branchée dans une prise de courant correspondante, installée de façon adéquate et mise à la terre conformément à tous les

codes et règlements locaux.

Ne pas modifier la fiche fournie – si elle ne s’adapte pas à la prise de courant, il faut faire installer une prise de courant

convenable par un électricien compétent.

Un mauvais raccordement du conducteur de mise à la terre de l’équipement peut entraîner un risque de décharge électrique. Le

conducteur possédant un isolant avec surface extérieure de couleur verte, avec ou sans rayures jaunes, est le conducteur de

mise à la terre de l’équipement. Si une réparation ou un remplacement du cordon électrique s’avère nécessaire, ne pas brancher

le conducteur de mise à la terre de l’équipement à une borne sous tension.

Consulter un électricien compétent ou le personnel de service après-vente si on ne comprend pas entièrement les instructions de

mise à la terre, ou si l’on doute que la machines oit correctement mise à la terre.

Utiliser seulement des cordons prolongateurs à trois fils dotés d’une fiche mise à la terre, à trois broches, et de prises à trois

cavités convenant à la fiche de la machine, comme l’illustre la figure A.

Réparer ou remplacer sans délai tout cordon endommagé ou usé.

2. Machines avec cordon mis à la terre prévues pour une utilisation sur une alimentation nominale inférieure à 150 volts:

Si cette machine est prévue pour être utilisée sur un circuit qui comporte une prise semblable à celle illustrée à la figure A, la

machine devra comporter une fiche mise à la terre semblable à celle illustrée à la figure A. Un adaptateur temporaire semblable à

celui illustré à la figure B, peut être utilisé pour raccorder cette fiche à une prise à deux cavités comme celle illustrée à la figure B,

si une prise correctement mise à la terre n’est pas disponible. L’adaptateur temporaire ne doit être utilisé que jusqu’au moment

où une prise correctement mise à la terre est installée par un électricien compétent. L’oreille rigide ou autre dispositif semblable

de couleur verte, sur le dessus de l’adaptateur, doit être connecté sur une mise à la terre permanente comme, par exemple une

boîte à prises correctement mise à la terre. Quand un adaptateur est utilisé, celui-ci doit être retenu en place par une vis en métal.

REMARQUE: Au Canada, le Code canadien de l’électriciténe permet pas l’emploi d’un adaptateur temporaire.

électricien compétent de vérifier la prise.

Dans tous les cas, s’assurer quela prise en question est bien mise à la terre. Dans le doute, demander à un

BOÎTE À PRISES MISE À LA TERRE

BROCHES

CONDUCTRICES DE

COURANT

LA BROCHE DE MISE

À LA TERRE EST LA PLUS

LONGUE DES TROIS

Fig. A

OREILLE DE MISE À

LA TERRE

ADAPTATEUR

Fig. B

24

Page 25

3. FONCTIONNEMENT MONOPHASÉ À 240 VOLTS: Le

moteur fourni avec la machine est un moteur bitension de

120/240 volts. Il est livré, prêt à fonctionner, sous tension de

120 volts. Toutefois, il peut être converti au fonctionnement

sous 240 volts.

Un électricien professionnel devrait effectuer la conversion

ou utiliser les services d’un centre de réparations agréé

DELTA. Suite à la conversion, la machine doit être conforme

au Code électrique national et à tous les codes et à toutes les

ordonnances à l’échelle locale.

La conversion exige un recâblage du moteur pour 240 volts

grâce à l’installation d’une fiche de 240 volts sur le cordon

d’alimentation et le remplacement de l’interrupteur (le cas

échéant) avec un autre homologué pour un fonctionnement à

240 volts.

S’assurer que la fiche de 240 volts s’insère seulement dans une

prise ayant la même configuration que la fiche illustrée à la fig. C.

N’utiliser aucun adaptateur avec une fiche de 240 volts.

LA BOITE FONDE DE SORTIE

COURANT

PORTER

LA LAME FONDANT EST LA PLUS

LONGUE DES 3 LAMES

Fig. C

électricien compétentde vérifier la prise.

Dans tous les cas, s’assurer quela prise en question est bien mise à la terre. Dans le doute, demander à un

CORDON DE RALLONGE

état. En utilisant une corde de prolongation, soyez sûr d’employer un assez lourd pour porter le courant de la machine. Une corde

trop petite causera une baisse dans la tension secteur, ayant pour résultat la perte de puissance et de surchauffe. Fig. D-1 ou D-2,

expositions la mesure correcte à employer selon la longueur de corde. En cas de doute, utilisez la prochaine mesure plus lourde. Plus

le nombre de mesure est petit, plus la corde est lourde.

MESUR MINIMUM DE CORDE D’EXTENSION

TAILLES RECOMMANDÉES POUR L’USAGE AVEC STATIONNAIRES ÉLECTRIQUES LES OUTILS

Estimation

ampère Volts

0-6 120

0-6 120 25-50 16 AWG

0-6 120 50-100 16 AWG

0-6 120 100-150 14 AWG

6-10 120

6-10 120 25-50 16 AWG

6-10 120 50-100 14 AWG

6-10 120 100-150 12 AWG

10-12 120

10-12 120 25-50 16 AWG

10-12 120 50-100 14 AWG

10-12 120 100-150 12 AWG

12-16 120

12-16 120 25-50 12 AWG

12-16 120

Employez les cordes appropriées de prolongation. S’assurent votre corde de prolongation est en bon

MESUR MINIMUM DE CORDE D’EXTENSION

TAILLES RECOMMANDÉES POUR L’USAGE AVEC STATIONNAIRES ÉLECTRIQUES LES OUTILS

Longueur

totale de

corde en

pieds

jusqu’à

25 18 AWG

Mesure de corde d’am

d’extension

Estimation

ampère Volts

0-6 240

Longueur

totale de

corde en

pieds

jusqu’à

50 18 AWG

Mesure de corde d’am

d’extension

0-6 240 50-100 16 AWG

0-6 240 100-200 16 AWG

0-6 240 200-300 14 AWG

jusqu’à

25 18 AWG

6-10 240

jusqu’à

50 18 AWG

6-10 240 50-100 16 AWG

6-10 240 100-200 14 AWG

6-10 240 200-300 12 AWG

jusqu’à

25 16 AWG

10-12 240

jusqu’à

50 16 AWG

10-12 240 50-100 16 AWG

10-12 240 100-200 14 AWG

10-12 240 200-300 12 AWG

jusqu’à

25 14 AWG

12-16 240

jusqu’à 50

14 AWG

12-16 240 50-100 12 AWG

50 PI PLUS GRANDS QUE NON RECOMMANDES

12-16 240

50 PI PLUS GRANDS QUE NON RECOMMANDES

Fig. D-1 Fig. D-2

DESCRIPTION FONCTIONNELLE

AVANT-PROPOS

Le modèle DELTA 17-959L est une perceuse à colonne sur pied de 432 mm (17 po). Cette machine industrielle comprend

un moteur à induction 120/240 V, 3/4 hp, une ouverture de mandrin de 15,9 mm (5/8 po) et une clé, une table en fonte,

un mécanisme de relèvement à pignon et crémaillère et une butée de profondeur extérieure. Le modèle 17-959L est doté