Page 1

Dell PowerVault TL1000 Tape Autoloader

User's Guide

Page 2

Page 3

Dell PowerVault TL1000 Tape Autoloader

User's Guide

Page 4

Information in this document is subject to change without notice.

© 2014 Dell Inc. All rights reserved.

Reproduction in any manner whatsoever without the written permission of Dell Inc. is strictly forbidden.

Trademarks used in this text: Dell, the DELL logo and PowerVault are trademarks of Dell Inc.

Other trademarks and trade names might be used in this document to refer to either the entities claiming the marks

and names or their products. Dell Inc. disclaims any proprietary interest in trademarks and trade names other than

its own.

|

Type: 3572 Model: S3H/S4H/S5H/S6H

Printed August 2014

Page 5

Read this first

Contacting Dell

For customers in the United States, call 800-WWW-DELL (800-999-3355).

Note: If you do not have an active Internet connection, you can find contact

information about your purchase invoice, packing slip, bill, or Dell product

catalog.

Dell provides online and telephone-based support and service options. Service

availability varies by country and product, and some services might not be

available in your area. To contact Dell for sales, technical support, or customer

service issues follow the steps that are listed:

1. Visit http://dell.com/support.

2. Verify your country or region in the Choose A Country/Region menu at the

bottom of the page.

3. Click Contact Us on the left side of the page.

4. Select the appropriate service or support link that is based on your need.

5. Choose the method of contacting Dell that is convenient for you.

iii

Page 6

iv Dell PowerVault TL1000 Tape Autoloader User's Guide

Page 7

Contents

Read this first ............iii

Contacting Dell .............iii

Figures ..............vii

Tables ...............ix

Safety and environmental notices . . . xi

Safety notices ..............xi

Laser safety and compliance.........xii

Performing the safety inspection procedure....xii

Rack safety ..............xiii

Preface ..............xv

Chapter 1. Product description ....1-1

Front panel ..............1-2

Cartridge magazine ...........1-4

Rear panel ..............1-5

Bar code reader .............1-6

SAS host interface ............1-6

Encryption ..............1-6

Supported Internet Protocols ........1-7

Simple Network Management Protocol (SNMP)

messaging ..............1-7

Network Time Protocol ..........1-7

Ultrium tape drives ...........1-8

Media ................1-8

Logical Unit Number (LUN) scanning .....1-9

Location coordinates and element addresses . . . 1-9

Library specifications ..........1-10

Product environment ..........1-11

Supported device drivers .........1-12

Chapter 4. Operations ........4-1

The Operator Panel ...........4-3

Monitoring the library .........4-3

Managing the library ..........4-4

Configuring the library .........4-9

Servicing the library ..........4-14

The Web User Interface ..........4-16

Monitoring the library .........4-17

Managing the library .........4-20

Configuring the library .........4-23

Servicing the library ..........4-34

Chapter 5. Media ..........5-1

Data cartridges .............5-2

Cartridge compatibility .........5-3

Write once, read many (WORM) cartridges . . . 5-3

WORM media ............5-3

Data security on WORM media ......5-4

WORM media errors ..........5-4

Requirements for WORM capability .....5-4

Cleaning cartridge ............5-4

Bar code labels .............5-5

Guidelines for the use of bar code labels . . . 5-6

Write-Protect switch ...........5-6

Cartridge care and handling ........5-7

Provide training ...........5-7

Ensure proper packaging ........5-8

Provide proper acclimation and environmental

conditions .............5-8

Perform a thorough inspection.......5-9

Handle the cartridge carefully .......5-9

Examples of cartridge problems ......5-10

Environmental and shipping specifications for

tape cartridges .............5-10

Chapter 2. User interfaces ......2-1

Operator Panel .............2-1

Web User Interface............2-5

Chapter 3. Installation and

configuration............3-1

Choosing a location ...........3-1

Installing in a rack ............3-2

Removing the accessor locking screw .....3-7

Attaching the library to a server .......3-8

Configuring the library ..........3-10

Configuring your library with the Web User

Interface ..............3-11

Configuring your library with the Operator

Panel ...............3-24

Populating the library with cartridges .....3-27

Verifying library and drive operation .....3-28

Taking the Library Online .........3-29

Registering for support notification ......3-29

Chapter 6. Troubleshooting .....6-1

How the library reports problems.......6-1

Library error message content ........6-2

Diagnosing a problem ..........6-3

Isolating problems ............6-6

Installation and configuration problems.....6-8

Interpreting front panel LEDs ........6-8

Reseating cables ............6-10

Emailing logs .............6-10

Chapter 7. Service procedures ....7-1

ITDT-DCR..............7-1

||

Contacting Dell technical support .......7-2

||

Chapter 8. Removal and replacement

procedures ............8-1

Required tools .............8-1

Replacing a defective cartridge magazine ....8-1

Unlocking the cartridge magazine manually . . . 8-1

v

Page 8

Appendix A. Error codes ......A-1

Library error codes ...........A-1

Drive error codes ...........A-11

Web User Interface error messages ......A-11

Trap definitions (types) .........A-14

Library sense data ............C-1

Tape drive sense data ..........C-3

Appendix D. Library Configuration

Form ...............D-1

Appendix B. TapeAlert flags .....B-1

TapeAlert flags supported by the library ....B-1

TapeAlert flags supported by the Ultrium tape

drive ................B-3

Appendix C. Sense data .......C-1

Sense Key definitions...........C-1

Accessibility ............E-1

Glossary .............F-1

Index ...............X-1

vi

Dell PowerVault TL1000 Tape Autoloader User's Guide

Page 9

Figures

1-1. TL1000 Tape Autoloader .......1-1

|

1-2. Front panel components .......1-2

1-3. Cartridge Magazine .........1-4

1-4. Cartridge magazine (top view) .....1-4

1-5. Rear panel components........1-5

1-6. Ultrium half-high tape drive ......1-8

1-7. Location coordinates ........1-10

2-1. Operator Panel components ......2-1

2-2. Library ready screen ........2-4

2-3. Password entry screen ........2-4

2-4. Screen elements ..........2-5

2-5. Confirmation screen .........2-5

2-6. Java security warning message .....2-6

2-7. Login page ............2-6

2-8. User account window ........2-7

2-9. Superuser account window ......2-7

2-10. Administrator account window .....2-8

3-1. Rack mount screw locations for front and

|

rear vertical rails ..........3-3

3-2. Attaching the front brackets to the library

|

||

||

chassis .............3-4

3-3. Attaching the rear brackets to the rails 3-4

3-4. Creating the rail assemblies ......3-5

3-5. Installing the rail assemblies ......3-6

3-6. Securing the front of the library in the rack 3-6

3-7. Securing the rear of the library in the rack 3-7

3-8. The cables at the rear of the library 3-7

3-9. accessor locking screw ........3-8

3-10. Interface cable connection .......3-8

3-11. Java security warning message .....3-12

3-12. Web User Interface login screen 3-13

3-13. System summary .........3-13

3-14. Logical library mode settings .....3-14

3-15. Cartridge assignment settings .....3-15

3-16. Network settings .........3-16

3-17. Date and time settings .......3-17

3-18. Encryption settings.........3-18

3-19. Encryption enabled settings ......3-19

3-20. Email notifications .........3-20

3-21. Trap notifications .........3-21

3-22. Trap list settings .........3-22

3-23. SNMPv3 user list settings ......3-22

3-24. User access settings ........3-23

3-25. Add User dialog .........3-23

3-26. Save configuration .........3-24

3-27. Cartridge release gate ........3-27

3-28. Cartridge orientation ........3-28

4-1. Operator Panel top menus

4-2. Configuration settings ........4-3

4-3. Current information .........4-4

4-4. Firmware revision .........4-4

4-5. Unlock I/O station command .....4-4

4-6. I/O station unlocked ........4-5

4-7. Unlock magazine command ......4-5

4-8. Move cartridge command .......4-6

4-9. Unload command .........4-6

......4-3

4-10. Clean Drive command ........4-6

4-11. Inventory command.........4-7

4-12. Online/Offline command .......4-7

4-13. Move to Ship Position command ....4-7

4-14. Reboot Drive command .......4-8

4-15. Reboot Library command .......4-8

4-16. Logout command .........4-8

4-17. Auto Cleaning settings ........4-9

4-18. Active slot count settings .......4-9

4-19. Library access mode settings .....4-10

4-20. Date and time settings .......4-11

4-21. Network settings .........4-12

4-22. Operator Panel settings .......4-13

4-23. Factory default settings .......4-13

4-24. Error status menu .........4-14

4-25. Run Library Verify command .....4-14

4-26. Drive diagnostic procedures......4-15

4-27. Web User Interface menu ......4-16

4-28. System Summary screen .......4-17

4-29. Library Map screen ........4-18

4-30. Move Cartridges screen .......4-20

4-31. Unload Drive screen ........4-21

4-32. Clean Drive screen .........4-21

4-33. Library State screen ........4-21

4-34. Inventory screen .........4-22

4-35. Inventory progress bar .......4-22

4-36. Unlock magazine .........4-22

4-37. User Access screen .........4-23

4-38. Physical library settings screen .....4-24

4-39. Logical library settings screen .....4-24

4-40. Network settings screen .......4-26

4-41. Encryption settings screen

4-42. Encryption settings enabled screen 4-28

4-43. Date and time settings screen .....4-28

4-44. Email settings screen ........4-30

4-45. SNMP settings screen ........4-31

4-46. Save/Restore configuration with cookies 4-33

4-47. Save/Restore screen ........4-33

4-48. Operator interventions screen .....4-34

4-49. View Library Logs screen ......4-35

4-50. Traces screen ...........4-36

4-51. Download Drive Logs screen .....4-36

4-52. Download Library Logs screen .....4-37

4-53. Reset library and drive screen .....4-37

4-54. Firmware Update screen .......4-38

4-55. Usage Statistics screen........4-39

5-1. The LTO Ultrium Data Cartridge ....5-1

5-2. Ultrium data and WORM tape cartridges 5-4

5-3. Sample bar code label on the LTO Ultrium 6

Tape Cartridge ..........5-6

5-4. Setting the write-protect switch .....5-7

5-5. Double-boxing tape cartridges for shipping 5-8

5-6. Checking for gaps in the seams of a

cartridge ............5-9

6-1. Front panel LEDs .........6-8

8-1. Cartridge magazine lock release access hole 8-2

......4-27

vii

Page 10

viii Dell PowerVault TL1000 Tape Autoloader User's Guide

Page 11

Tables

1. Class I Laser Product ........xii

1-1. Data capacity and recording format 1-2

1-2. Front panel component descriptions 1-2

1-3. Rear panel component descriptions 1-5

1-4. Ultrium data and cleaning cartridge

compatibility with Ultrium tape drive . . . 1-9

1-5. Physical specifications ........1-10

1-6. Electrical specifications .......1-10

1-7. Environmental specifications .....1-10

1-8. Operational specifications ......1-11

1-9. Acoustical specifications .......1-11

2-1. Operator Panel component descriptions 2-1

3-1. Location criteria ..........3-1

3-2. Default library configuration settings 3-10

5-1. Cartridge types and colors ......5-2

5-2. Cartridge Data Capacity and Recording

Formats .............5-2

5-3. Nominal cartridge life: Load/unload cycles 5-3

5-4. Ultrium data cartridge compatibility with

Ultrium tape drive .........5-3

5-5. Cartridges and VOLSERs compatible with

the Ultrium Tape Drives .......5-5

5-6. Location of the write-protect switch 5-7

5-7. Environment for operating, storing, and

shipping the LTO Ultrium Tape Cartridge . 5-10

6-1. Front Panel LED indicators ......6-9

A-1. Library error codes .........A-1

A-2. Drive error codes .........A-11

A-3. Web user error messages ......A-11

A-4. Trap list ............A-14

B-1. TapeAlert flags supported by the library B-1

B-2. TapeAlert flags supported by the Ultrium

tape drive ............B-3

C-1. Sense key definitions ........C-1

C-2. Library sense data .........C-1

C-3. Ultrium Tape drive sense data .....C-3

C-4. Ultrium Tape drive sense data - Bytes 12

and13.............C-4

ix

Page 12

x Dell PowerVault TL1000 Tape Autoloader User's Guide

Page 13

Safety and environmental notices

Safety notices and environmental notices for this product are shown and described.

Safety notices

Observe the safety notices when this product is used. These safety notices contain

danger and caution notices. These notices are sometimes accompanied by symbols

that represent the severity of the safety condition.

Most danger or caution notices contain a reference number (Dxxx or Cxxx).

The sections that follow define each type of safety notice and give examples.

Danger notice

A danger notice calls attention to a situation that is potentially lethal or extremely

hazardous to people. A lightning bolt symbol always accompanies a danger notice

to represent a dangerous electrical condition. A sample danger notice follows:

DANGER: An electrical outlet that is not correctly wired could place

hazardous voltage on metal parts of the system or the devices that

attach to the system. It is the responsibility of the customer to ensure

that the outlet is correctly wired and grounded to prevent an electrical

shock. (D004)

Caution notice

A caution notice calls attention to a situation that is potentially hazardous to

people because of some existing condition, or to a potentially dangerous situation

that might develop because of some unsafe practice. A caution notice can be

accompanied by one of several symbols:

If the symbol is... It means...

A hazardous electrical condition with less severity than

electrical danger.

A hazardous condition that is not represented by other

safety symbols.

This product contains a Class II laser. Do not stare into the

beam. (C029) Laser symbols are always accompanied by the

classification of the laser as defined by the U. S.

Department of Health and Human Services (for example,

Class I, Class II).

A hazardous condition due to mechanical movement in or

around the product.

xi

Page 14

If the symbol is... It means...

Laser safety and compliance

Table 1. Class I Laser Product

The library might contain a laser assembly that complies with the performance

standards set by the US Food and Drug Administration for a Class I laser

product. Class I laser products do not emit hazardous laser radiation. The

library has the necessary protective housing and scanning safeguards to ensure

that laser radiation is inaccessible during operation or is within Class I limits.

External safety agencies have reviewed the library and have obtained approvals

to the latest standards as they apply.

This part or unit is heavy but has a weight smaller than 18

kg (39.7 lb). Use care when lifting, removing, or installing

this part or unit. (C008)

A hazardous condition due to the unit's susceptibility to

electrostatic discharge.

Performing the safety inspection procedure

Before you service the unit, complete the following safety inspection procedure.

1. Stop all activity between the host and the library’s tape drive.

2. Turn off the power to the library by switching the Power button on the rear of

the tape library to the Off position.

3. Disconnect the tape drive’s SAS cable.

4. Unplug the library’s power cord from the electrical outlet and the library’s

power supply unit.

5. Check the library’s power cords for damage, such as a pinched, cut, or frayed

cord.

6. Check the tape drive’s SAS cable for damage.

7. Check the cover of the library for sharp edges, damage, or alterations that

expose its internal parts.

8. Check the cover of the library for proper fit. It should be in place and secure.

9. Check the product label at the rear of the library to make sure that it matches

the voltage at your outlet.

xii Dell PowerVault TL1000 Tape Autoloader User's Guide

Page 15

Rack safety

The following general safety information must be used for all rack mounted

devices.

DANGER

v Always lower the leveling pads on the rack cabinet.

v Always install stabilizer brackets on the rack cabinet.

v To avoid hazardous conditions because of uneven mechanical loading,

always install the heaviest devices in the bottom of the rack cabinet.

Always install servers and optional devices, starting from the bottom

of the rack cabinet.

v Rack mounted devices are not to be used as a shelf or workspace. Do

not place any object on top of rack mounted devices.

v Each rack cabinet might have more than one power cord. Be sure to

disconnect all power cords in the rack cabinet before you service any

device in the rack cabinet.

v Connect all devices that are installed in a rack cabinet to power

devices installed in the same rack cabinet. Do not plug a power cord

from a device that is installed in one rack cabinet into a power device

that is installed in a different rack cabinet.

v An electrical outlet that is not correctly wired might place hazardous

voltage on the metal parts of the system or the devices that attach to

the system. It is the responsibility of the customer to ensure that the

outlet is correctly wired and grounded to prevent an electrical shock.

CAUTION:

(R001)

v Do not install a unit in a rack where the internal rack ambient

temperatures might exceed the manufacturer's recommended ambient

temperature for all your rack mounted devices.

v Do not install a unit in a rack where the air flow is compromised.

Ensure that air flow is not blocked or reduced on any side, front, or

back of a unit that is used for air flow through the unit.

v Consideration must be given to the connection of the equipment to

the supply circuit so that overloading of the circuits does not

compromise the supply wiring or overcurrent protection. To provide

the correct power connection to a rack, refer to the rating labels on the

equipment in the rack to determine the total power requirement of the

supply circuit.

v (For sliding drawers) Do not pull out or install any drawer or feature

if the rack stabilizer brackets are not attached to the rack. Do not pull

out more than one drawer at a time. The rack might become unstable

if you pull out more than one drawer at a time.

v (For fixed drawers) This drawer is a fixed drawer and must not be

moved for servicing unless specified by the manufacturer. Attempting

to move the drawer partially or out of the rack might cause the rack

to become unstable or cause the drawer to fall out of the rack.

Safety and environmental notices xiii

Page 16

CAUTION:

Removing components from the upper positions in the rack cabinet

improves rack stability during relocation. Follow these general

guidelines whenever you relocate a populated rack cabinet within a

room or building:

v Reduce the weight of the rack cabinet by removing equipment,

starting at the top of the rack cabinet. When possible, restore the rack

cabinet to the configuration of the rack cabinet as you received it. If

this configuration is not known, you must do the following:

– Remove all devices in the 32U position and above.

– Ensure that the heaviest devices are installed in the bottom of the

rack cabinet.

– Ensure that there are no empty U-levels between devices that are

installed in the rack cabinet below the 32U level.

v If the rack cabinet you are relocating is part of a suite of rack cabinets,

detach the rack cabinet from the suite.

v Inspect the route that you plan to take to eliminate potential hazards.

v Verify that the route that you choose can support the weight of the

loaded rack cabinet. Refer to the documentation that comes with your

rack cabinet for the weight of a loaded rack cabinet.

v Verify that all door openings are at least 760 x 2032 mm (30 x 80 in.).

v Ensure that all devices, shelves, drawers, doors, and cables are secure.

v Ensure that the four leveling pads are raised to their highest position.

v Ensure that there is no stabilizer bracket that is installed on the rack

cabinet during movement.

v Do not use a ramp that is inclined at more than 10 degrees.

v When the rack cabinet is in the new location:

– Lower the four leveling pads.

– Install stabilizer brackets on the rack cabinet.

– If you removed any devices from the rack cabinet, repopulate the

rack cabinet from the lowest position to the highest position.

v If a long-distance relocation is required, restore the rack cabinet to the

configuration of the rack cabinet as you received it. Pack the rack

cabinet in the original packaging material, or equivalent. Also, lower

the leveling pads to raise the casters off the pallet and bolt the rack

cabinet to the pallet.

(R002)

xiv Dell PowerVault TL1000 Tape Autoloader User's Guide

Page 17

Preface

|

This manual contains information and instructions necessary for the setup,

operation, and servicing of the Dell™PowerVault™TL1000 Tape Library.

xv

Page 18

xvi Dell PowerVault TL1000 Tape Autoloader User's Guide

Page 19

Chapter 1. Product description

“Front panel” on page 1-2

“Cartridge magazine” on page 1-4

“Rear panel” on page 1-5

“Bar code reader” on page 1-6

“SAS host interface” on page 1-6

“Encryption” on page 1-6

“Supported Internet Protocols” on page 1-7

“Simple Network Management Protocol (SNMP) messaging” on page 1-7

“Network Time Protocol” on page 1-7

“Ultrium tape drives” on page 1-8

“Media” on page 1-8

“Logical Unit Number (LUN) scanning” on page 1-9

“Location coordinates and element addresses” on page 1-9

“Library specifications” on page 1-10

“Product environment” on page 1-11

“Supported device drivers” on page 1-12

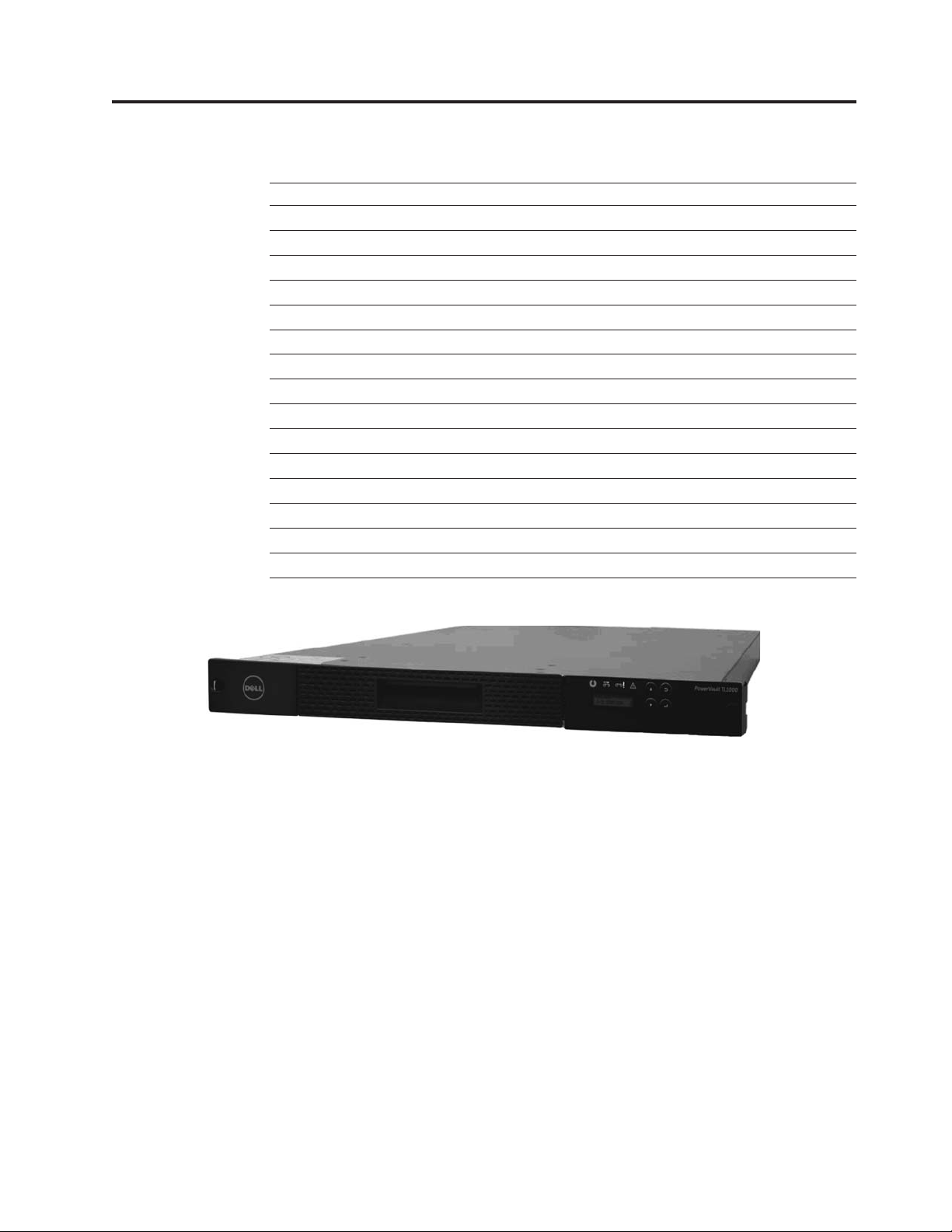

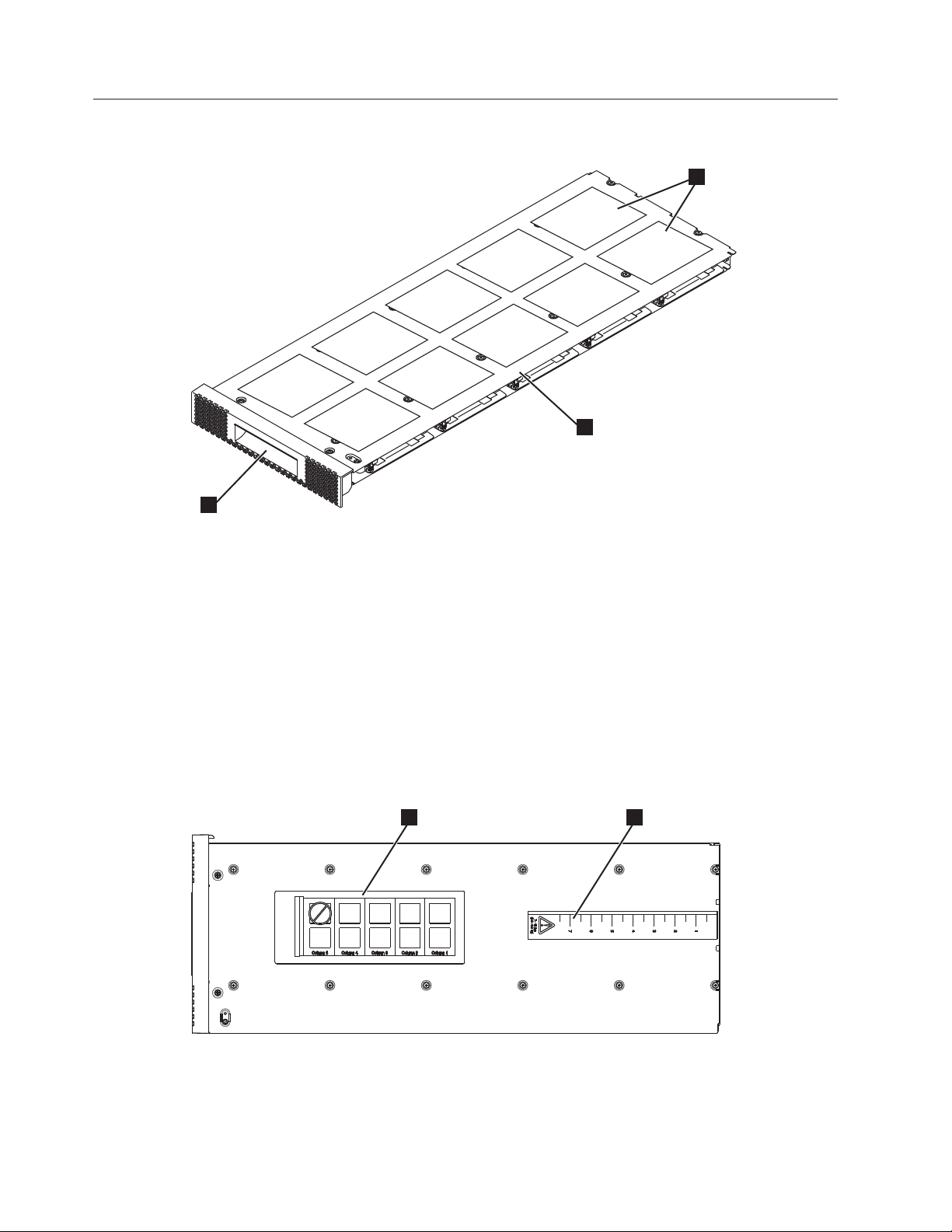

Figure 1-1. TL1000 Tape Autoloader

|

The Dell™PowerVault™TL1000 Tape Autoloader provides compact, high-capacity,

low-cost solutions for simple, unattended data backup. The library has a compact

1U form factor with easy access to tape cartridges with a removable magazine. The

|

TL1000 Tape Autoloader is an external stand-alone or rack-mountable unit that

incorporates an Ultrium 6 Half-High Tape Drive (Model S6H), Ultrium 5 Half-High

|

Tape Drive (Model S5H), or Ultrium 4 Half-High Tape Drive (Model S4H). It is

equipped with a SAS (Serial Attached SCSI) host adapter attachment that has a

data transfer rate of up to 6.0 Gbps.

|

The TL1000 Tape Autoloader has a 10-position removable cartridge magazine,

providing a maximum of 9 data cartridge positions, or a maximum of 8 data

cartridge positions with a configurable 1-slot I/O station. One position is reserved

as the tape drive exchange position and can be accessed by the library only. Tape

|

cartridges that are supported in the TL1000 Tape Autoloader include the 2500 GB

native physical capacity LTO Ultrium Tape Cartridge (Ultrium 6), 1500 GB native

physical capacity LTO Ultrium Tape Cartridge (Ultrium 5), 800 GB native physical

capacity LTO Ultrium Tape Cartridge (Ultrium 4), 400 GB Tape Cartridge (Ultrium

a29z0176

1-1

Page 20

Front panel

3), 200 GB Tape Cartridge (Ultrium 2), and WORM (Ultrium 6, Ultrium 5, Ultrium

4). The library data storage capacity can be further increased by using hardware

compression.

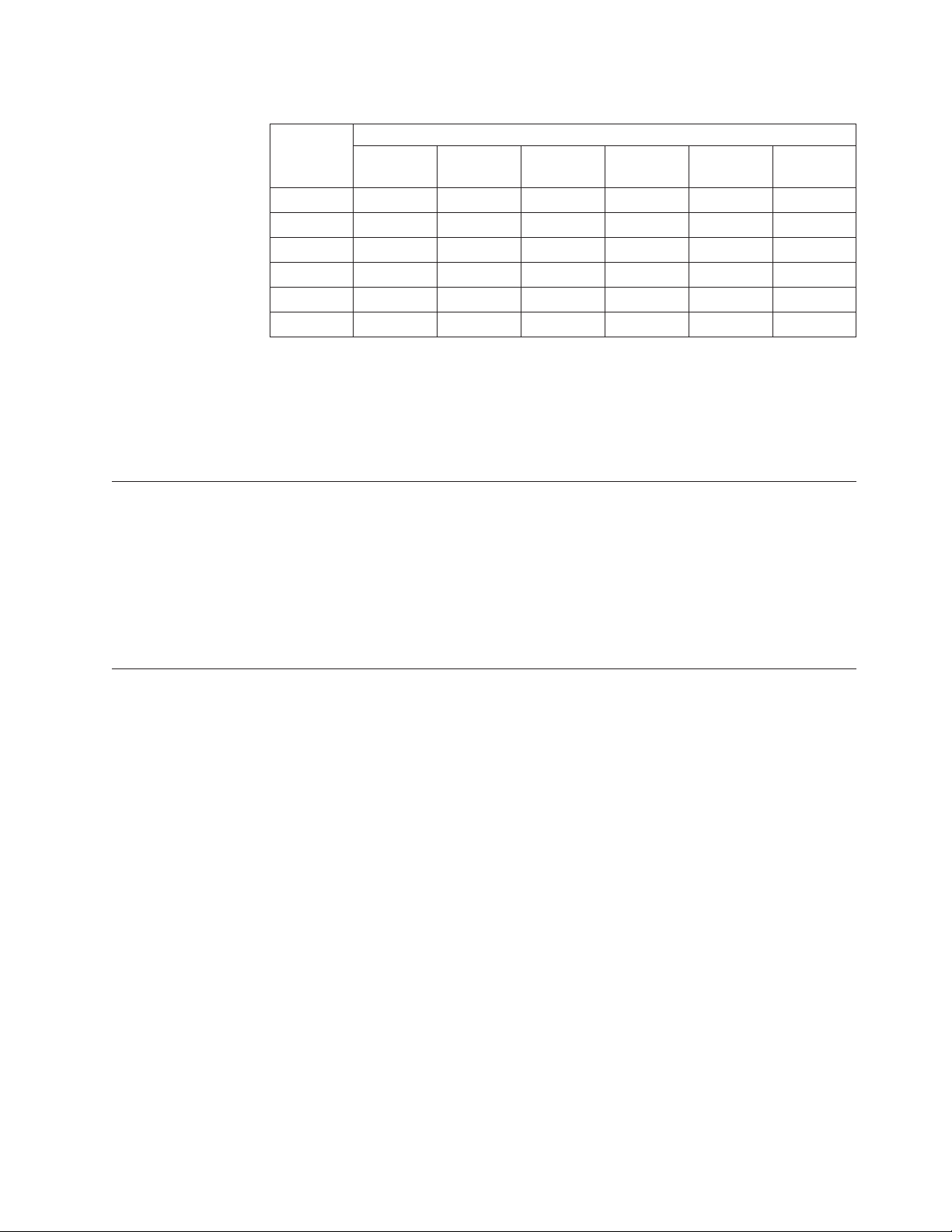

Table 1-1. Data capacity and recording format

Type Native Data Capacity Recording Format

Ultrium 6 2500 GB (6250 GB at 2.5:1

compression)

Ultrium 5 1500 GB (3000 GB at 2:1

compression)

Ultrium 4 800 GB (1600 GB at 2:1

compression)

Ultrium 3 400 GB (800 GB at 2:1

compression)

Ultrium 2 200 GB (400 GB at 2:1

compression)

Ultrium 1 100 GB (200 GB at 2:1

compression)

Reads and writes data on

2176 tracks, 16 tracks at a

time.

Reads and writes data on

1280 tracks, 16 tracks at a

time.

Reads and writes data on 896

tracks, 16 tracks at a time.

Reads and writes data on 704

tracks, 16 tracks at a time.

Reads and writes data on 512

tracks, 8 tracks at a time.

Reads and writes data on 384

tracks, 8 tracks at a time.

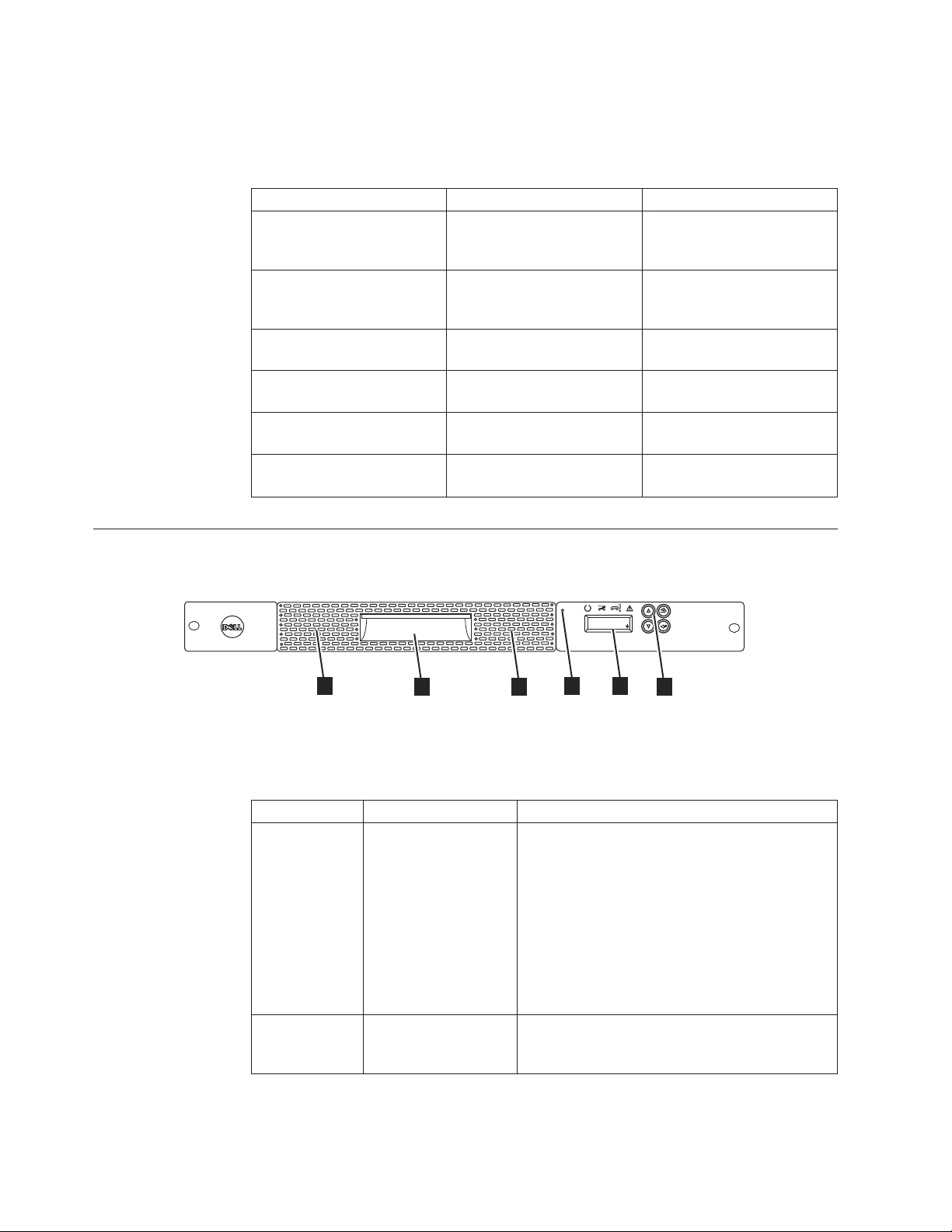

Figure 1-2. Front panel components

2

Table 1-2. Front panel component descriptions

Number Component Description

1 Operator Panel The Operator Panel features a monochrome

2 Control keys The control keys are located to the right of the

2

PowerVault TL1000

a29z0175

UNLOCK

I/O STATION

5

3

5

4

1

16-character LCD graphic display that is on the

front of the library. Library operations and

service functions are completed from this screen.

The Web User Interface offers some of the same

functionality as the Operator Panel with a web

browser for remote access to the library. For

information about the Operator Panel and the

Web User Interface, see Chapter 2, “User

interfaces,” on page 2-1.

Operator Panel LCD display on the front of the

library.

1-2 Dell PowerVault TL1000 Tape Autoloader User's Guide

Page 21

Table 1-2. Front panel component descriptions (continued)

Number Component Description

3 Cartridge magazine The tape library has a single cartridge magazine

that can hold up to 9 data cartridges, or 8 data

cartridges with a 1-slot I/O station. See

Figure 1-3 on page 1-4.

Column 5/Tier 1 in the cartridge magazine can

be configured as a 1-slot I/O station. Column

5/Tier 2 in the cartridge magazine is reserved

for the exchange position and can be accessed by

the library only. The I/O station is used to

import and export cartridges without

interrupting normal library operation. Beginning

with Column 4, a minimum of one column can

be reserved for cleaning cartridges. Cleaning

cartridges are used to clean the tape drive heads.

For configuration details, see Chapter 3,

“Installation and configuration,” on page 3-1.

4 Cartridge magazine

release

|

5 Air vents These vents draw cooler air into the library

Emergency cartridge magazine lock release.

When the I/O station is locked, insert a large,

straightened paper clip twice or hold the paper

clip in place while the cartridge magazine slides

past the I/O station lock.

enclosure and allow warm air to escape which

helps keep the library at a normal operating

temperature.

Chapter 1. Product description 1-3

Page 22

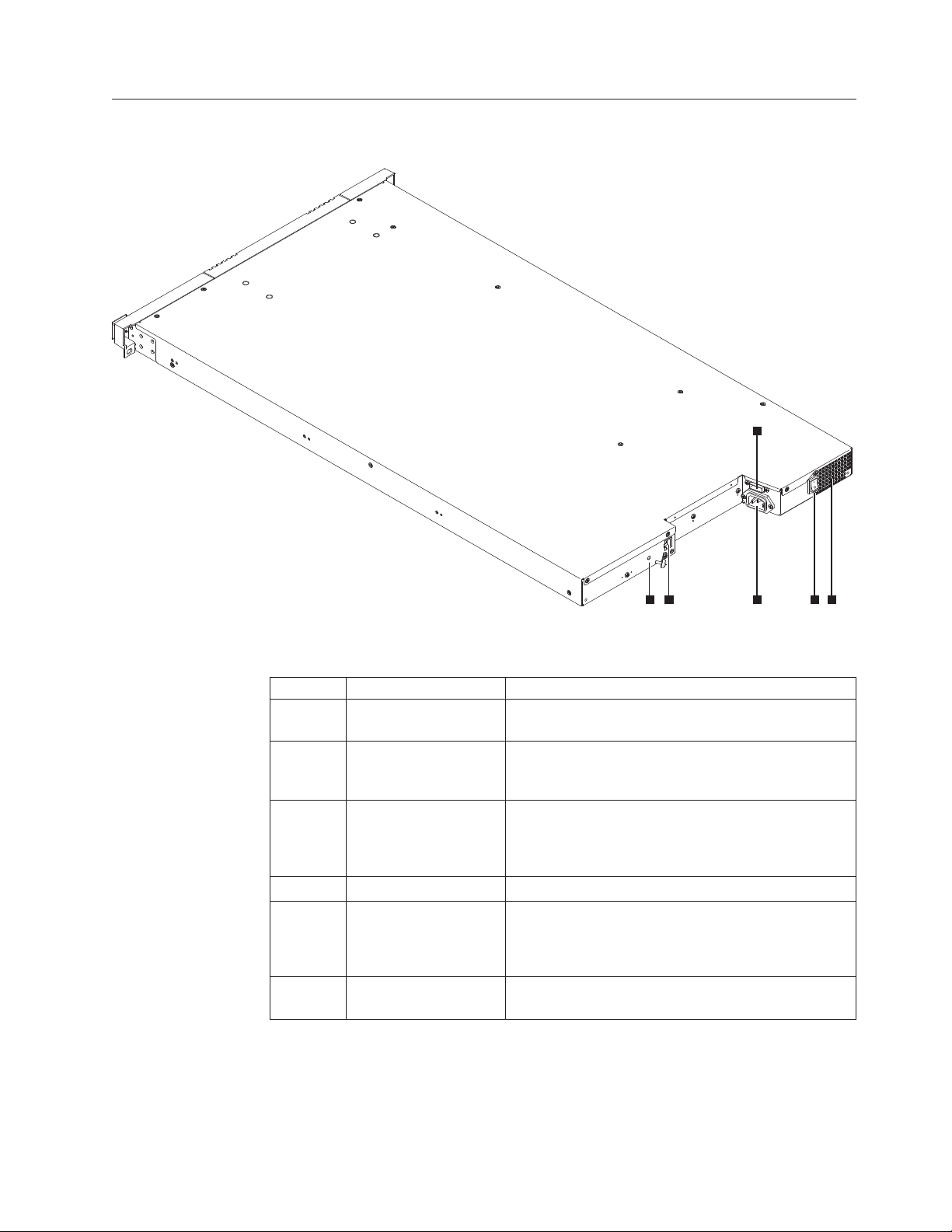

Cartridge magazine

Column 5

Tier 2

Column 4

Tier 2

Column 3

Tier 2

Column 4

Tier 1

Column 2

Tier 2

Column 3

Tier 1

Column 1

Tier 2

Column 2

Tier 1

Column 1

Tier 1

1

3

Figure 1-3. Cartridge Magazine

1 Cartridge locations as they appear

Figure 1-4 shows the cartridge location label 1 and ruler 2 that appears on the

cartridge magazine. The ruler provides an indication of the distance, when the

magazine is opened or withdrawn, to the end of the magazine before it clears the

front edge of the library. To prevent dropping the magazine, support both ends of

the magazine before it clears the front edge of the library.

Column 5

Tier 1

in the Library Map.

Note: These labels are for reference

only and do not display on the

magazine.

2

a29z0025

2 Cartridge magazine

3 Magazine handle

21

Figure 1-4. Cartridge magazine (top view)

1-4 Dell PowerVault TL1000 Tape Autoloader User's Guide

a29z0057

Page 23

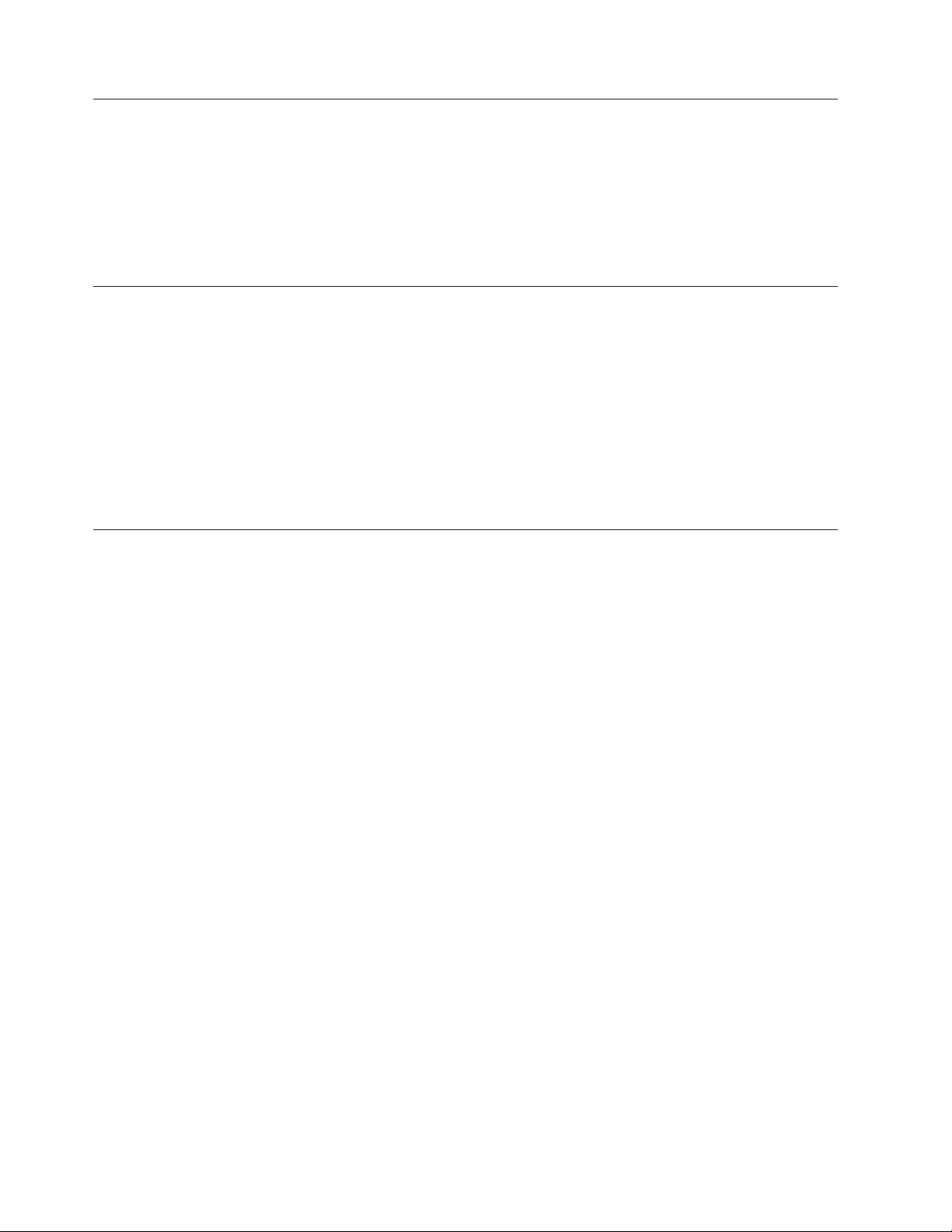

Rear panel

3

Figure 1-5. Rear panel components

Table 1-3. Rear panel component descriptions

Number Component Description

1 Power connector The library connects to a 110/220 volt ac power

2 Power switch The library is powered ON when the power supply

3 SAS host interface

4 Ethernet port This port is used to connect the library to a network.

5 Accessor locking screw The accessor locking screw is used to lock the

6 Air vent These vents allow air to escape from the power

connector

45 1 2 6

supply.

switch on the rear panel is ON (|). The library has no

independent power switch on the front panel.

Serial-attached SCSI host interface cable connection.

The Ultrium 4, 5, and 6 SAS drives use the SFF-8088

connection at the drive end and SFF-8088 or SFF-8470

at the host adapter end.

accessor in place during transportation.

Important: Remove the accessor locking screw before

the library is powered ON.

supply and tape drive sled.

a29z0003

Chapter 1. Product description 1-5

Page 24

Bar code reader

SAS host interface

|

|

|

Encryption

The bar code reader is a part of the library accessor. The bar code reader reads

each cartridge bar code label that identifies the types of cartridge magazines and

tape drive that is installed in the library. It also provides inventory feedback to the

host application, Operator Panel, and Web User Interface. The library stores the

customized inventory data in memory. Library firmware supportsa6or

8-character volume serial number (VOLSER) on the bar code label on the tape

cartridge.

The Ultrium 4, Ultrium 5, and Ultrium 6 Half-High Tape Drives support the Serial

Attached SCSI (SAS) interface. The SFF-8088 SAS connector on the Ultrium 4,

Ultrium 5, and Ultrium 6 is compatible with SAS-1 or SAS-2 cables.

A drive with a SAS (Serial Attached SCSI) interface is linked directly to controllers.

SAS is a performance improvement over traditional SCSI. SAS enables multiple

devices (up to 128) of different sizes and types to connect simultaneously with

thinner and longer cables. Its full-duplex signal transmission supports 6.0 Gb/s

(S4H, S5H, and S6H). In addition, the TL1000 Tape Autoloader is hot-plugged, if

necessary. SAS drives can auto-negotiate speed.

The LTO Ultrium 6, Ultrium 5, and Ultrium 4 Tape Drives support host

Application Managed Encryption (AME) with T10 encryption methods, for SAS

drives. Data encryption is supported by LTO Ultrium 6, Ultrium 5, and Ultrium 4

Data Cartridges only.

Note: Application Managed Encryption (AME) does not require a key.

The encryption enabled drive contains the necessary hardware and firmware to

encrypt and decrypt host tape application data. Encryption policy and encryption

keys are provided by the host application or host server. A drive digital certificate

is installed at manufacturing time. Each drive receives a unique serial number and

certificate. The T10 application validates each drive instance by checking the

drive’s digital certificate.

The LTO Ultrium encryption environment is complex and requires knowledge

beyond that of product trained Service Support Representatives (SSRs). The

Encryption function on tape drives (desktop, stand-alone, and within libraries) is

configured and managed by the customer. In some instances, SSRs are required to

enable encryption at a hardware level when service access or service password

controlled access is required. Customer setup support is by Field Technical Sales

Support (FTSS), customer documentation, and software support for encryption

software problems. Customer 'how to' support is also provided by way of support

line contract.

The encryption-capable library firmware allows the user to select None or

Application Managed encryption from the Web User Interface. The factory default

is None.

1-6 Dell PowerVault TL1000 Tape Autoloader User's Guide

Page 25

Supported Internet Protocols

|

The TL1000 Tape Autoloader supports the Internet protocols:

v IPv4

v IPv6

To learn more about IPv4, visit http://www.iana.org/. To learn more about IPv6,

visit http://www.ipv6.org/..

Simple Network Management Protocol (SNMP) messaging

Occasionally, the library might encounter a situation that you want to know about,

such as an open magazine or a fault that causes the library to stop. The library

provides a standard TCP/IP protocol called Simple Network Management Protocol

(SNMP) to send alerts about conditions (such as need for operator intervention)

over a TCP/IP LAN network to an SNMP monitoring station. These alerts are

called SNMP traps. With the information supplied in each SNMP trap, the

monitoring station (together with customer-supplied software) can alert operations

personnel of possible problems or operator interventions that occur.

SNMP traps

SNMP Traps are alerts or status messages that can be collected, monitored, and

used to proactively manage attached libraries with SNMP protocol with the SNMP

monitoring stations. In summary, each trap provides the following information:

v Product Identification such as product name, description, manufacturer, model

number, firmware level, and the URL that the trap is designated for.

v Product Status such as the severity of the trap, status (current and previous) and

the time the trap occurred.

v Library State (physical device status) such as identification and status of devices

that is monitored. It would include enclosure, power supply, controller,

magazine status, drive count, cartridge slot count, and I/O station count. Also

included would be certain library statistics, and where appropriate, the fault FSC

(fault symptom code) including the severity and description of that fault.

v Drive Status such as the identification of each drive in the library, firmware

level, serial number, and other address and status information.

v Trap Definitions such as library status change, open magazine, I/O accessed,

hard fault information, requests to clean the drive, excessive retries, and

returning to normal operations.

v SNMP MIBs: The library's Management Information Base (MIB) contains units

of information that specifically describe an aspect of the system, such as the

system name, hardware number, or communications configuration. When with

|

SNMP to monitor your TL1000 Tape Autoloader, make sure that the TL1000 MIB

file is loaded on your SNMP monitoring station. SNMP traps are sent to the

SNMP monitoring stations that are defined for your library (see “Configuring

SNMP trap notifications” on page 4-31).

Network Time Protocol

NTP is an Internet standard protocol that assures accurate synchronization of

computer clock times in a network of computers. Running as a continuous

background client program on a computer, NTP sends periodic time requests to a

server, obtaining server time stamps, and with them to adjust the client’s clock.

Chapter 1. Product description 1-7

Page 26

Ultrium tape drives

|

Figure 1-6. Ultrium half-high tape drive

The TL1000 Tape Autoloader supports the Ultrium 4 (S4H), Ultrium 5 (S5H), and

Ultrium 6 (S6H) half-high tape drives.

The Ultrium 4, Ultrium 5, and Ultrium 6 half-high tape drives support the Serial

Attached SCSI (SAS) interface. They have one Mini-SAS (SFF-8088) connector.

Speed matching

a80hh015

Media

|

|

To improve system performance, the Ultrium 4, Ultrium 5, and Ultrium 6 Tape

Drives use a technique that is called speed matching to dynamically adjust its

native (uncompressed) data rate to the slower data rate of the attached server.

Channel calibration

The channel calibration feature of the Ultrium 4, Ultrium 5, and Ultrium 6 Tape

Drives customizes each read/write data channel for optimum performance. The

customization enables compensation for variations in the recording channel

transfer function, media characteristics, and read/write head characteristics.

Power management

The Ultrium 4, Ultrium 5, and Ultrium 6 Tape Drives feature a power management

function. This function controls the drive’s electronics so that part of the electronics

completely turns OFF when circuit functions are not needed for the drive’s

operation.

The TL1000 Tape Autoloader uses Ultrium tape cartridges that provide up to

2500-GB native capacity (up to 6250 GB with 2.5:1 hardware data compression) for

Ultrium 6 tape drives, 1500-GB native capacity (up to 3000 GB with 2:1 hardware

data compression) for Ultrium 5 tape drives, and 800-GB native capacity (up to

1600 GB with 2:1 hardware data compression) for Ultrium 4 tape drives.

1-8 Dell PowerVault TL1000 Tape Autoloader User's Guide

Page 27

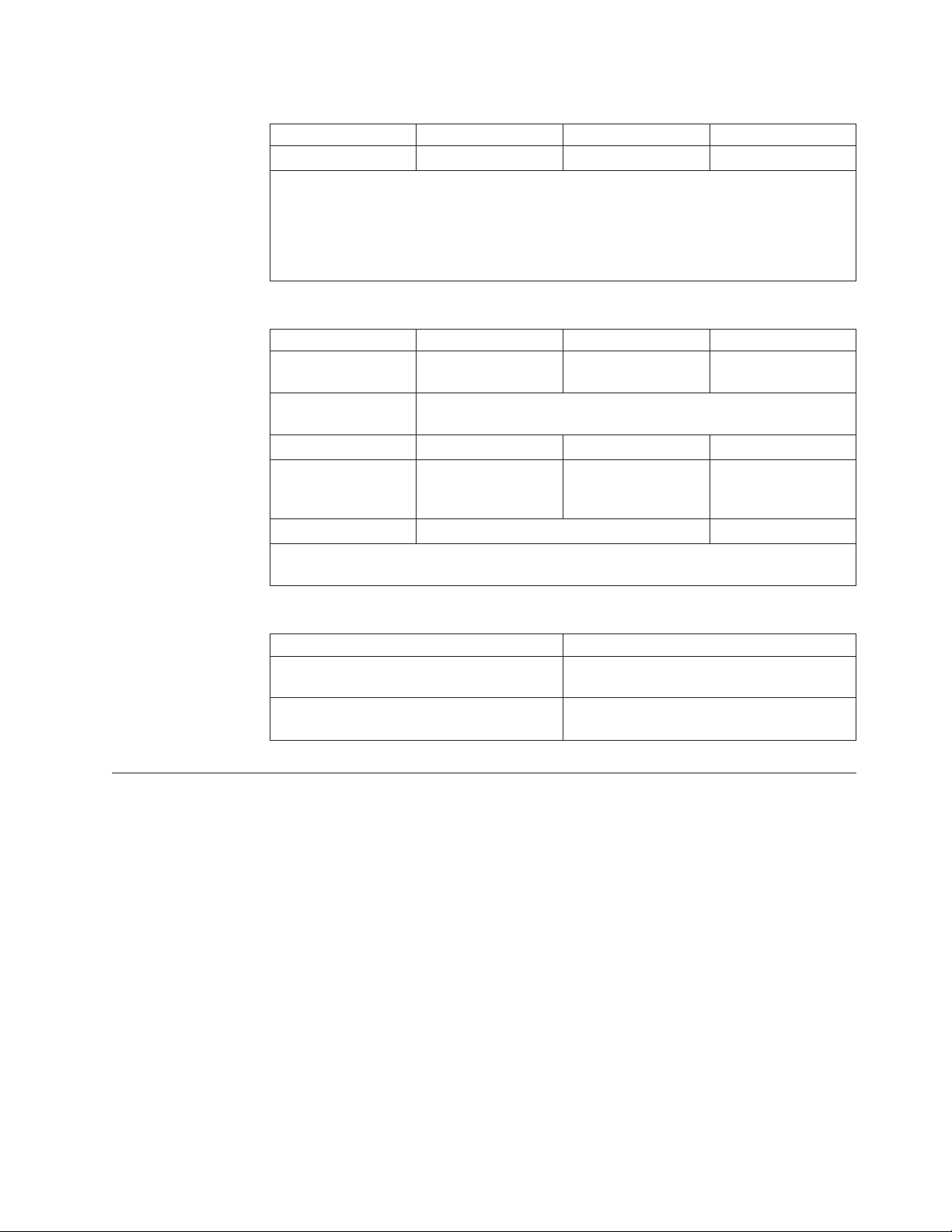

Table 1-4. Ultrium data and cleaning cartridge compatibility with Ultrium tape drive

Ultrium

Tape Drive

Ultrium 6 Read/Write Read/Write Read only

Ultrium 5 Read/Write Read/Write Read only

Ultrium 4 Read/Write Read/Write Read only

Ultrium 3 Read/Write Read/Write Read only

Ultrium 2 Read/Write Read/Write

Ultrium 1 Read/Write

2500 GB

(Ultrium 6)

1500 GB

(Ultrium 5)

LTO Ultrium Data Cartridges

800 GB

(Ultrium 4)

400 GB

(Ultrium 3)

200 GB

(Ultrium 2)

100 GB

(Ultrium 1)

|

Note: The TL1000 Tape Autoloader supports the Ultrium 4 (S4H), Ultrium 5 (S5H),

and Ultrium 6 (S6H) Tape Drives only.

For more information about media compatibility, see Chapter 5, “Media,” on page

5-1.

Logical Unit Number (LUN) scanning

|

The TL1000 Tape Autoloader uses a single SCSI ID and dual LUNs to control the

tape drive (LUN 0) and library accessor (LUN 1). The library requires a Host Bus

adapter (HBA) that supports LUN scanning. If it is not enabled, your host system

cannot scan beyond LUN 0 and fails to detect the library. It sees only the tape

drive.

Important: Some HBAs, such as RAID controllers, do not support LUN scanning.

Location coordinates and element addresses

|

The TL1000 Tape Autoloader incorporates patented high-density (HD) slot

technology, which allows multiple cartridges to be stored in a tiered architecture.

The depth of a cartridge location in a high-density slot is known as a tier.

High-density slots are designed to contain multiple cartridges in Tiers 1 and 2.

Note: Each column has a spring-loaded mechanism that pushes a tape cartridge

into Tier 1 when it is the only cartridge in that column. A single cartridge in

a column takes on the Tier 2 element address even though it is physically in

Tier 1.

Chapter 1. Product description 1-9

Page 28

Front Rear

Reserved slot

Column 5

Tier 2

Column 5

Tier 1

Figure 1-7. Location coordinates

A storage element address is assigned to each cartridge at the time the cartridge is

inserted. Storage element addresses range from 4097 to 4105 (0x1001 to 0x1009)

when the I/O station is not enabled, and from 4097 to 4104 (0x1001 to 0x1008)

when the I/O station is enabled.

Library specifications

Table 1-5. Physical specifications

Front panel width (chassis/bezel) 445 mm (17.52 in.)/483 mm (19.02 in.)

Depth 850 mm (33.46 in.)

Height 44 mm (1.73 in.)

Weight (library only) 13 kg (28.66 lbs)

Column 4

Tier 2

Column 4

Tier 1

Column 3

Tier 2

Column 3

Tier 1

Column 2

Tier 2

Column 2

Tier 1

Accessor

Column 1

Tier 2

Column 1

Tier 1

Drive

Parameter Measurement

Table 1-6. Electrical specifications

Parameter Measurement

Voltage 100 - 240 Vac. (4.0 to 1.5 A)

Frequency 50 - 60 Hz

Power consumption 110 W

For more information about installation specifications, see Chapter 3, “Installation

and configuration,” on page 3-1.

Table 1-7. Environmental specifications

Parameter Operating (see Note) Storage Shipping

Temperature

Temperature

variation

10-38°C(50-100

10 °C/hour

(maximum)

Relative humidity 20 - 80% 10 - 90% 10 - 90%

Wet bulb temperature

26 °C (78.8 °F)

1-10 Dell PowerVault TL1000 Tape Autoloader User's Guide

°F)

maximum

1 - 60 °C (34 - 140 °F)

10 °C/hour

(maximum)

29 °C (84 °F)

maximum

-40 to 60 °C (-40 to

140 °F)

10 °C/hour

(maximum)

29 °C (84 °F)

maximum

Page 29

Table 1-7. Environmental specifications (continued)

Parameter Operating (see Note) Storage Shipping

Altitude (meters) 0 - 2,500 0 - 2,500 0 - 2,500

Note: The operating environment of the library must not conflict with the media storage

requirements. The library can operate at elevated temperatures for an extended period.

However, the temperature might shorten the useful life of media that is stored in the

library. If media is stored in the library for more than 10 hours, the storage temperature

requirements for media are met. It is assumed that media stored in the library is

approximately 2 degrees above ambient temperature when the library is powered ON.

Table 1-8. Operational specifications

Parameter Model S6H Model S5H Model S4H

Maximum storage

capacity

Maximum number of

data cartridges

Drive types Ultrium 6 Half High Ultrium 5 Half High Ultrium 4 Half High

Sustained native data

transfer rate

Interface 6 Gb/s SAS 3 Gb/s SAS

Note: The Ultrium 4 Half-High tape drive in S4H libraries that are manufactured after

March 2011 support 6.0 Gb/s and a sustained native data rate of 120 Gb/s.

22.5 TB (56.2 TB with

2.5:1 compression)

9 (including an optional I/O Station)

160 MB/s (320 MB/s

with 2:1

compression)

13.5 TB (27 TB with

2:1 compression)

140 MB/s (280 MB/s

with 2:1

compression)

7.2 TB (14.4 TB with

2:1 compression)

120 MB/s (240 MB/s

with 2:1

compression)

Table 1-9. Acoustical specifications

Idling acoustical noise sound power level

LwAD in Bels (1 Bel = 10 dB)

Maximum acoustical noise sound power

level LwAD in Bels (1 Bel = 10 dB)

Product environment

|

The TL1000 Tape Autoloader is designed to operate in a general business

environment.

The library meets the acoustical requirements for general business area category

2D. Category 2D states that the library can be installed a minimum of 4 m (13 ft.)

from a permanent work station.

To allow for service access, install the library a minimum of 0.9 m (3 ft.) from all

obstacles.

The library is a precision computer peripheral device. To ensure maximum

longevity of your library, locate the library away from dust, dirt, and airborne

particulates, as follows:

v Keep the library away from high-traffic areas, especially if the floor is carpeted.

Parameter Measurement

6.6

6.8

Carpeting harbors dust and walking on the carpet can cause the carpet fibers

and the dust to become airborne.

Chapter 1. Product description 1-11

Page 30

v Keep the library out of printer and copier rooms because of toner and paper

dust. Additionally, do not store paper supplies next to the library.

v Keep the library away from moving air caused by doorways, open windows,

fans, and air conditioners.

Ensure that the machine covers are always kept closed to minimize any

contamination from airborne particles.

Supported device drivers

Device drivers enable the drive to interact with various servers. For applications

that use device drivers, see the application’s documentation to determine which

drivers to use.

Note: If you do not have Internet access and you need information about device

drivers, contact your sales representative.

1-12 Dell PowerVault TL1000 Tape Autoloader User's Guide

Page 31

Chapter 2. User interfaces

“Operator Panel”

“Web User Interface” on page 2-5

The library has a local interface, the Operator Panel, and a remote Web User

Interface (UI).

The Operator Panel is on the front of the library and allows users to work locally

on the library. The Web User Interface allows users and administrators to view and

perform some library functions from remote sites.

The Web User Interface is implemented as a Java

browser from any PC on the network. The Java Applet requires that Java 1.5.0 or

higher is installed on your host computer for full functionality, and is best viewed

with Internet Explorer 6.0 or higher. Internet Explorer 7.0 or higher is required for

IPv6.

Operator Panel

The Operator Panel is on the front bezel of the library. The Operator Panel displays

library information and menu commands that are used to run library management

functions in response to the control keys on the right of the LCD display.

™

Applet that runs in a web

6

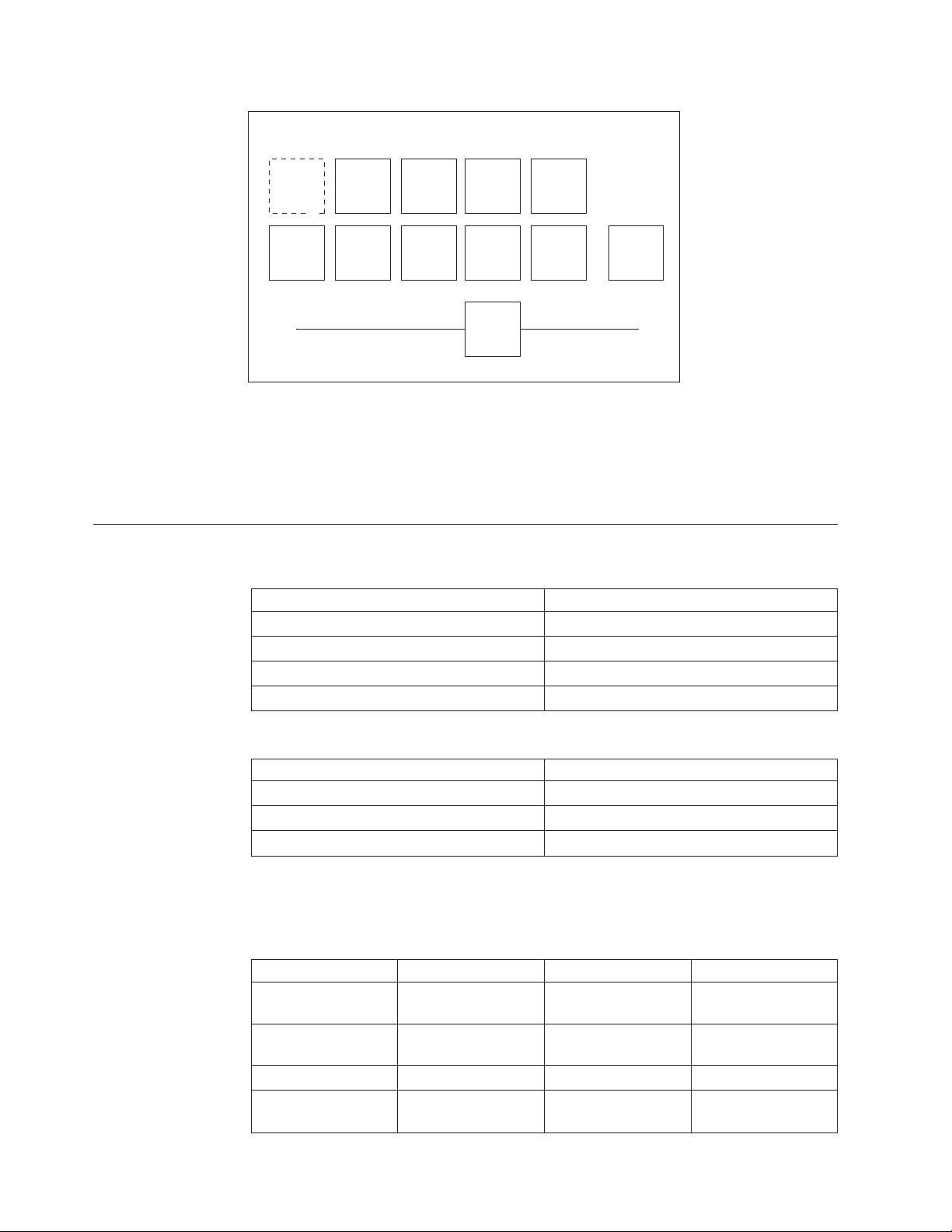

Figure 2-1. Operator Panel components

Table 2-1. Operator Panel component descriptions

Number Component Description

1 LCD display 16-character LCD graphic display

|

|

2 Up key (Δ) Button that is used to navigate upward (↑) through the menu

3 Down key (∇) Button that is used to navigate downward (↓) through the

7

8

1

9

items

menu items

2

3

4

5

a29z0177

2-1

Page 32

Table 2-1. Operator Panel component descriptions (continued)

Number Component Description

4 Cancel key Button that is used to cancel a user action and return to the

last menu item

5 Enter key Button that is used to display a submenu or to select a user

action

6 Ready/Activity

LED

7 Clean Drive

LED

8 Attention LED Amber LED lit when a cartridge is incompatible with the

9 Error LED Amber LED lit when there is an unrecoverable library or

Green LED lit when the unit is powered ON. The LED

flashes when there is any library activity or the library is

offline.

Amber LED lit when the drive needs cleaning. The LED

turns OFF after the drive is cleaned successfully.

drive, marginal, or invalid. The LED turns OFF when the

media is removed from the drive. The LED might also be lit

when there is a power supply problem.

drive failure. The corresponding error message displays on

the LCD display.

The Operator Panel operates in two basic modes:

v User Interaction mode - Mode that is employed when a user is pushing keys on

the Operator Panel.

v System Driven mode - Normal mode of operation where the Operator Panel

displays status in response to commands issued from the drive's internal

interface.

When an Operator Panel key is pressed and released, the Operator Panel

automatically changes to User Interaction mode. User Interaction mode continues

until 3 minutes after a user stops pushing keys, or the requested accessor action

stops, whichever is longer. Then, the Operator Panel returns to System Driven

mode.

If necessary, the Operator Panel automatically changes to System Driven mode.

When this change occurs, the library remembers what the user was doing before

the display mode changed.

Any operational conflict between commands that are received over the host

interface or the Web User Interface and those commands that are entered by way

of the Operator Panel are avoided with a reservation mechanism on a first-come,

first-served basis. Operator Panel commands are canceled by an Operator Panel

logout or timeout.

Library firmware does not allow a user to select an impossible request. Those

situations include, but are not limited to -

v Moving a cartridge from any source to a position occupied by another cartridge

v Moving a cartridge from an empty cartridge position

v Loading a cartridge from any source to a full drive

v Unloading a cartridge from an empty drive

Any error that is detected by the library or drive controller and not recoverable

through predetermined firmware algorithms is considered unrecoverable. When an

error occurs, an error code is displayed on the Operator Panel display and the

2-2 Dell PowerVault TL1000 Tape Autoloader User's Guide

Page 33

error LED is ON. The error code remains on the Operator Panel until a key is

pressed, which causes the Operator Panel to return to the Home Screen. Numeric

error codes are used for unrecoverable errors. Otherwise, text status messages are

displayed.

When the library powers ON or resets, it goes through several internally controlled

initialization processes, called the Power-On-Self-Test (POST).

Front panel LEDs

All LEDs are updated during power ON and reset sequences. At power ON or

software reset, all LEDs turn ON as soon as POST allows. When initialization

starts, all LEDs turn OFF and the Ready/Activity LED flashes at a rate of

approximately 2 seconds per cycle. When the mechanical initialization is complete,

the Ready/Activity LED stops flashing and turns ON.

If a library failure occurs, the Ready/Activity LED turns OFF and the Error LED

turns ON. The Operator Panel also displays an appropriate error code to help

identify the failure.

The following are more operational details of LEDs:

v The Ready/Activity LED (6 in Figure 2-1 on page 2-1) turns ON any time the

unit is powered ON and functional. The Ready/Activity LED flashes whenever

there is library. This LED also flashes when the library is offline.

v The Clean Drive LED (7 in Figure 2-1 on page 2-1) turns ON when a

“cleaning required” command is issued by the drive. The LED turns OFF after a

successful drive cleaning operation.

v The Attention LED (8 in Figure 2-1 on page 2-1) turns ON to indicate that a

piece of media is bad/marginal, or invalid. The LED turns OFF when all

marginal and invalid cartridges are exported from the library. The Attention LED

also turns ON if Autoclean is enabled and no cleaning cartridge is in a cleaning

position.

v The Error LED (9 in Figure 2-1 on page 2-1) turns ON when there is an

unrecoverable drive or library failure. An error message is displayed on the

screen and the LED remains ON until the error state is resolved.

For information, see “Interpreting front panel LEDs” on page 6-8.

Input modes

There are several ways to enter values in the different menu items. These values

are selectable predefined values, toggle values (for example, ON/OFF) and

numerical values like network addresses.

Selecting predefined values

1. To set the predefined values, press the Enter key to select the menu item.

2. With the Plus and Minus keys, select one of the various predefined values for

that item.

3. As soon as the Operator Panel display shows the correct value, press the Enter

key to apply the value.

Toggling values

Toggle values are used to switch between two different states like ON and OFF.

Chapter 2. User interfaces 2-3

Page 34

1. After you navigate to the menu item, press the Enter key to select the menu

item.

2. With the Plus and Minus keys, select one of the various predefined states for

that item.

3. Press the Enter key to apply the new state.

Entering numerical values

Numerical values are needed for network addresses, password entries, and other

configuration entries.

1. After you navigate to the menu item, the current value is displayed and the

cursor highlights the first digit of the value that can be changed.

2. For each digit to be changed in the value:

a. Use the Plus and Minus keys to increment or decrement the digit.

b. Press the Enter key to highlight the next editable digit.

3. Press the Enter key at the last digit to apply the complete entry. Press the

Cancel key to cancel the whole edit process and maintain the original value.

Logging in

At power ON or software reset, the library ready screen displays when POST

initialization completes successfully.

Figure 2-2. Library ready screen

To log in to the Operator Panel, press the Enter key. The password entry screen

displays.

Figure 2-3. Password entry screen

Press the UP and DOWN arrow keys to change the current digit. Press the Enter

key to advance to the next digit. The default password is 0000. When you are

logged in, you can change the password with the Change Login Password

command. See “Configuring Operator Panel settings” on page 4-13.

a29z0028

a29z0029

2-4 Dell PowerVault TL1000 Tape Autoloader User's Guide

Page 35

Screen elements

Figure 2-4. Screen elements

The Operator Panel displays a single menu item (1 in Figure 2-4) on each screen.

The existence of other menu items above and below the currently displayed item is

indicated by the arrows (2 in Figure 2-4) on the right side of the screen.

In the Configuration menu, the current configuration setting is indicated by an

asterisk (3 in Figure 2-4) on the right side of the screen. For example, in

Figure 2-4, the I/O station is enabled. When a configuration setting is changed, the

confirmation screen in Figure 2-5 displays. Press the Enter key to confirm, or

Cancel to return to the previous screen.

Figure 2-5. Confirmation screen

1

2

3

a29z0030

a29z0032

Web User Interface

|

The Web User Interface Java Applet requires Java 1.5.0 or higher be installed on

your host computer for full function, and is best viewed with Internet Explorer 6.0

or higher. Internet Explorer 7.0 or higher is required for IPv6. If your computer

does not have Java installed or you must upgrade your installation, download the

latest version of the Java Runtime Environment (JRE) for your platform from

http://www.java.com/. Follow the instructions that are provided to enable and

configure the Java Runtime Environment for your browser.

The Web User Interface can also be used to update the library and drive firmware,

and to download error logs, drive memory dumps, and other library data.

Before the TL1000 Tape Autoloader can be managed over a network with the Web

User Interface, set up the initial network configuration of the library with the

Operator Panel. For information, see “Configuring network settings” on page 3-24.

Logging in

To log in to the Web User Interface from Internet Explorer, you must enter the IP

address of the library. The IP address can be obtained with the View Settings

command from the Operator Panel. For example, http://192.168.1.1.

When the applet starts, the following warning message displays. This message is

normal and does not indicate a problem.

Chapter 2. User interfaces 2-5

Page 36

Figure 2-6. Java security warning message

After the Web User Interface is started, the login window is displayed.

4

a29z019

Figure 2-7. Login page

The factory default account login and password for an Administrator account is

v Account: admin

v Password: secure

The account name and password are case-sensitive. After your account name and

password are entered, use your mouse to click Login or press the Enter key.

For information about account privileges, see “User privileges” on page 2-8.

Common header elements

All Web User Interface windows (except for the Login screen) contain the

following common elements in the header

v Help - Click to read context-sensitive help for the associated page.

2-6 Dell PowerVault TL1000 Tape Autoloader User's Guide

a29z0195

Page 37

v Logoff - Click to log out of the Web User Interface.

Menus available from the Web User Interface

Figure 2-8 shows the Web User Interface window for a User account, Figure 2-9

shows the window for a Superuser account, and Figure 2-10 on page 2-8 shows the

window for an Administrator account.

Figure 2-8. User account window

Figure 2-9. Superuser account window

a29z0196

a29z0197

Chapter 2. User interfaces 2-7

Page 38

Figure 2-10. Administrator account window

For a complete description of all Web User Interface menu options, see Chapter 4,

“Operations,” on page 4-1.

User privileges

User privilege levels are manually assigned to user accounts created within the

library. Controlling access to screens and operations within the library preserves

the integrity of the library and the data that is stored within the library.

There are three types of user privileges in the library.

v Users are allowed to monitor the library, but not complete actions that affect the

physical library.

v Superusers are allowed to operate the physical and logical library, but not

complete actions that affect the library configuration.

v Administrator users are allowed access to the entire physical library and logical

library, including configuration. Only one administrator user must be assigned

the login name admin.

User privileges include

v Multiple users can be logged in at one time on the Web User Interface.

v Any user can be logged in to only one interface at a time.

a29z0198

2-8 Dell PowerVault TL1000 Tape Autoloader User's Guide

Page 39

Chapter 3. Installation and configuration

“Choosing a location”

|

“Installing in a rack” on page 3-2

“Removing the accessor locking screw” on page 3-7

“Attaching the library to a server” on page 3-8

“Configuring your library with the

Web User Interface” on page 3-11

“Configuring your library with the

Operator Panel” on page 3-24

“Populating the library with cartridges” on page 3-27

“Verifying library and drive operation” on page 3-28

“Taking the Library Online” on page 3-29

“Registering for support notification” on page 3-29

“Logging in to the Web User Interface” on page 3-12

“Checking firmware level” on page 3-13

“Configuring library settings” on page 3-14

“Configuring network settings” on page 3-16

“Configuring date and time settings” on page 3-17

“Configuring encryption settings” on page 3-18

“Configuring email notifications” on page 3-20

“Configuring trap notifications” on page 3-21

“Managing user access” on page 3-23

“Saving the library configuration” on page 3-24

“Logging in to the Operator Panel” on page 3-24

“Configuring network settings” on page 3-24

“Configuring library settings” on page 3-26

|

To install and configure a TL1000 Tape Autoloader, complete these procedures in

the order they are presented.

Choosing a location

Table 3-1. Location criteria

Criteria Definition

Room temperature 16 - 32 °C (60 - 90 °F)

Voltage 100 - 240 Vac. (4.0 to 1.5 A)

Note: The power switch is on the rear of the

library and must be easily accessible.

Frequency 50 - 60 Hz

Relative humidity 20 - 80% non-condensing

Air quality The library must be placed in an area with

minimal sources of particulate

contamination. Avoid areas near frequently

used doors and walkways, stacks of supplies

that collect dust, printers, and smoke-filled

rooms. Excessive dust and debris can

damage cartridges and the tape drive.

3-1

Page 40

Table 3-1. Location criteria (continued)

Criteria Definition

Clearance

Rack requirements Standard EIA 19-inch rack: 1U space

Installing in a rack

v Back: Minimum of 15 cm (6 in.)

v Front: Minimum of 30 cm (12 in.)

v Sides: Minimum of 5 cm (2 in.)

|

The TL1000 Tape Autoloader can be easily installed into a standard 19-inch rack

system. A standard 19-inch rack system contains multiple mounting locations that

are called EIA units as defined by the Electronics Industries Association. Each EIA

unit contains three square or round holes that are used to mount rack designed

equipment. The library requires 1 EIA unit (1U) of rack space. Each unit is

separated by a small space.

When you decide on a location in your rack for the library, consider that the

Operator Panel has a small LCD screen. The library must be positioned to allow

for easy viewing. The rear of the library must be free from any obstructions to

allow easy access to the power switch and other rear panel components.

Note: Before you begin the rack installation of the library, read the safety

information in “Rack safety” on page xiii. Also, verify that no desktop feet

are attached to the bottom of the library.

To install the library in a rack:

1. Verify that your rack kit includes all the necessary contents.

2. Determine the location in your rack for your library to be installed. With a

pencil, mark the location on the front vertical rails and rear vertical rails

(Figure 3-1 on page 3-3) in your rack.

3-2 Dell PowerVault TL1000 Tape Autoloader User's Guide

Page 41

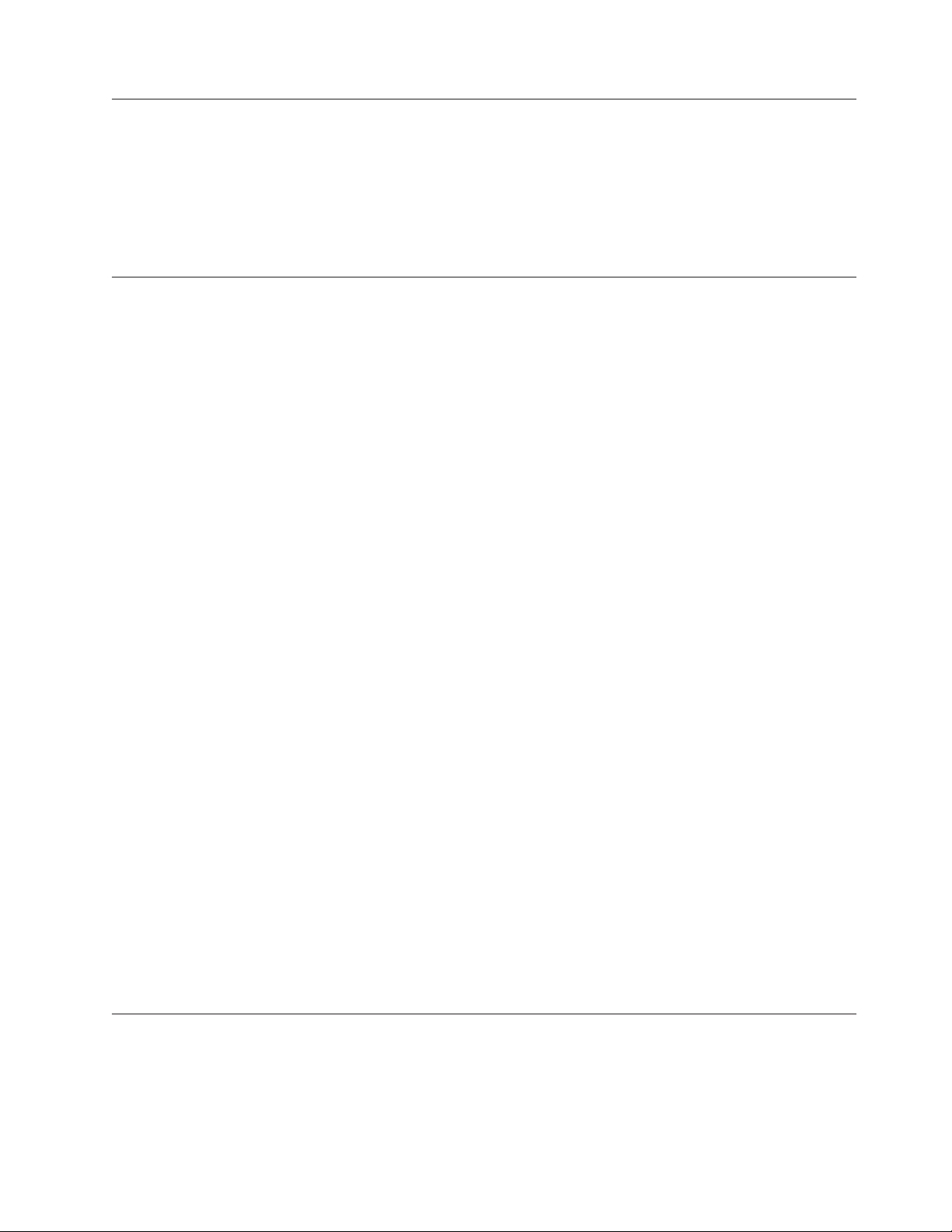

Figure 3-1. Rack mount screw locations for front and rear vertical rails

|

a29z0015

|

3. Place the screws 11 into the left and right brackets.

|

|

|

4. Attach the left 3 and right 4 (Figure 3-2 on page 3-4) front brackets to the

front of the library chassis with 2 flat-head screws 8 on each side. Use the

|

|

top two screw holes on each side. The flange of each bracket with the inserted

screws (11) fits into the cutout on each side of the bezel.

Chapter 3. Installation and configuration 3-3

Page 42

|

8

|

Figure 3-2. Attaching the front brackets to the library chassis

|

3

11

|

5. Attach the left 1 and right 2 rear brackets to the left 5 and right 6

front rails with 2 round-head screws 10 on each side (Figure 3-3).

4

8

a29z0185

1

Figure 3-3. Attaching the rear brackets to the rails

Important: Do NOT tighten these screws completely.

6. Slide in the rear rails 7 from back to front, to create the rail assemblies.

Ensure that the screw holes face outwards (Figure 3-4 on page 3-5).

12

2

10

5

6

a29z0019

3-4 Dell PowerVault TL1000 Tape Autoloader User's Guide

Page 43

Figure 3-4. Creating the rail assemblies

7. Install the rail assemblies into the rack (Figure 3-5 on page 3-6). Ensure the 3

holes in the front of the unit align with the 1U space marked on the vertical

rails in Step 2. Secure the rails to the rack with 4 flat-head screws 9 on each

|

|

side of the rack. Use the top and bottom screw locations on the front and rear

of the rack rail (Figure 3-1 on page 3-3)).

7

a29z0018

Chapter 3. Installation and configuration 3-5

Page 44

9

Figure 3-5. Installing the rail assemblies

9

a29z0020

|

|

|

8. Slide the library chassis into the rack. The heads of the large screws 11

appear through the oval openings on each side of the bezel. Use a Phillips

screwdriver to attach these screws to the rack (Figure 3-6).

|

|

Figure 3-6. Securing the front of the library in the rack

|

|

3-6 Dell PowerVault TL1000 Tape Autoloader User's Guide

a29z0186

Page 45

9. Secure the rear of the library to the rack with a round-head screw 10 on

each rear bracket (Figure 3-7). Tighten the other rear bracket screws to secure

the library to the rack.

Figure 3-7. Securing the rear of the library in the rack

10. Run the SAS cable, power cable, and Ethernet cable through the

hook-and-loop fastener strap 12. Leave enough slack to reach the

corresponding connectors, then tighten the strap (Figure 3-8).

1010

a29z0022

12

Figure 3-8. The cables at the rear of the library

Note: For information about converting and relocating the library, see

Chapter 8, “Removal and replacement procedures,” on page 8-1.

Removing the accessor locking screw

Important: The accessor locking screw prevents the library accessor from moving

during shipment and must be removed before the library is powered

ON.

Remove the accessor locking screw, located on the rear panel of the library (1 in

Figure 3-9 on page 3-8).

a29z0023

Chapter 3. Installation and configuration 3-7

Page 46

Figure 3-9. accessor locking screw

Attaching the library to a server

The drive is attached to a server with the Serial Attached SCSI (SAS) interface. The

Web User Interface accesses the library with an ethernet interface.

Connecting the Host Interface cables

To connect the host interface cable to the library:

Note: It is recommended that you shut down and turn OFF the associated server

before you connect the SAS interface cable. Turn ON the associated server

after the SAS interface cable is connected to the library and server, the

library is powered ON, and the library completed the initialization.

1

a29z0102

1 2 3

Figure 3-10. Interface cable connection

1. Attach an ethernet cable to the ethernet port (1 in Figure 3-10)

Note: On rack mount installations, run the cable through the hook-and-loop

fastener strap on the right rear bracket.

3-8 Dell PowerVault TL1000 Tape Autoloader User's Guide

29z0100

Page 47

2. Attach the host end of the SAS cable to the drive’s SAS connector (2 in

Figure 3-10 on page 3-8). See “SAS host interface” on page 1-6 for information

about the type of SAS connector that is required for attachment to the drive.

Note: On rack mount installations, run the cable through the hook-and-loop

fastener strap on the right rear bracket.

3. Attach the other end of the host SAS interface cable to the host or to an

interposer if required.

4.

v Method 1: Plug the ethernet cable into your server or PC to access the Web

User Interface directly. This method modifies your server or PC network

settings to match the library default settings. You can also use the library

Operator Panel to change the library network settings to match the server or

PC network settings before you use the Web User Interface to access the

library. If the ethernet connection is directly attached to a server or a PC, a

crossover ethernet cable might be required.

v Method 2: Plug the ethernet cable into an ethernet switch or router to access

the Web User Interface on a LAN (local area network). The library network

settings must be entered with the Operator Panel before the Web User

Interface is used to access the library.

Connecting the power cord

Important: This product can ONLY be used with an approved power cord for your

specific geographic region. Use of an unapproved power cord might result in

v Not meeting individual country-specific safety requirements

v Overheating with potential personal injury or property damage

v A fracture that results in internal contacts that are exposed, which might subject

the user to a shock hazard

To connect a power cord:

1. Plug one end of the power cord or rack PDU power cord into the power

connector (3 in Figure 3-10 on page 3-8) on the rear panel of the library.

Note: On rack mount installations, run the rack PDU power cord through the

hook-and-loop fastener strap on the right rear bracket, and tighten the

strap. The rack PDU power cord is a special power cord that plugs into a

rack power strip.

2. Plug the other end of the power cord into the nearest properly grounded

power outlet. On rack mount installations, plug the other end of the rack PDU

power cord into the nearest rack PDU.

3. Power ON the library by toggling the power switch on the power supply to the

ON (|) position.

4. Wait for the library to initialize.

During initialization, the library completes a Power ON Self Test (POST) to

ensure that the library hardware is functional. The library also tests

communications with the tape drive over the internal bus.

Note: If the Operator Panel does not initialize, check all cable connections, and

ensure that the cartridge magazine is closed and in the locked position.

Ensure that the power supply switch is in the ON position. If the Operator

Panel still does not initialize, see Chapter 6, “Troubleshooting,” on page 6-1.

Chapter 3. Installation and configuration 3-9

Page 48

Important: To disconnect all power from the library, turn the power switch to the

Note: When the library is power-cycled, wait 10 seconds after the power is OFF

before the library is powered ON again.

Configuring the library

The library can be configured with the Web User Interface or the Operator Panel.

The preferred method for configuring your library is by using the Web User

Interface. See “Configuring your library with the Operator Panel” on page 3-24

and “Configuring your library with the Web User Interface” on page 3-11.

For complete detailed information about all of the functions available on the

library with the Operator Panel and the Web User Interface, see Chapter 4,

“Operations,” on page 4-1.

The default library configuration settings are listed in Table 3-2.

Table 3-2. Default library configuration settings

Ethernet link speed Auto

SSL security Disabled

IPv4 settings Enabled

DHCP (Dynamic Host Configuration

Protocol)

Static IP address Disabled

IPv4 address 0.0.0.0

Subnet mask 255.255.255.0

Gateway 0.0.0.0

IPv6 settings Disabled

DHCP (Dynamic Host Configuration

Protocol)

Stateless auto-configuration Enabled

Static IP address Disabled

IPv6 address 0:0:0:0:0:0:0:0

Prefix length 64

Gateway 0:0:0:0:0:0:0:0

DNS setting Disabled

DNS IP address 0.0.0.0

Library name (Blank)

Auto Cleaning Disabled

Bar code label length 8 characters

OFF position, then remove the power cord from the outlet. The power

switch removes power from portions of the library and the drive, but

the power supply still has ac power at its input.

Configuration Item Default Setting

NETWORK

Enabled

Enabled

PHYSICAL

LOGICAL

3-10 Dell PowerVault TL1000 Tape Autoloader User's Guide

Page 49

Table 3-2. Default library configuration settings (continued)

Configuration Item Default Setting

Library mode Random

Loop Enabled

Auto Load Enabled

Active slots 9 + 0

ENCRYPTION

Encryption method None

DATE and TIME

NTP server Disabled

NTP server address 0.0.0.0

Time zone (GMT) +00:00

Date (MM/DD/YYYY) 01/08/2008

Auto adjustment by PC Every 1 minute

NOTIFICATIONS

SMTP (mail) settings

Mail server address 0.0.0.0

Mail event Error events enabled

SNMP (trap) settings

Community Public

Trap event Error events enabled

SNMPv3 engine ID (Set by library firmware)

Static library network settings must be entered with the Operator Panel before the

library can be accessed remotely with the Web User Interface. If your system is

serviced by a Dynamic Host Configuration Protocol (DHCP) server, the network

parameters are automatically set. Once remote access is established, you can

complete the configuration of your library remotely.

If you choose to use the Operator Panel to configure your library, go to

“Configuring your library with the Operator Panel” on page 3-24.

Configuring your library with the Web User Interface

If you choose to use the Web User Interface to configure your library, first enter

your library network settings with the Operator Panel (see “Configuring network

settings” on page 4-12).

To configure your library with the Web User Interface:

1. Install Java 1.5.0 or higher on your host computer. Download the latest

version of the Java Runtime Environment (JRE) for your platform from

http://www.java.com/.

2. “Logging in to the Web User Interface” on page 3-12

3. “Checking firmware level” on page 3-13

4. “Configuring library settings” on page 3-14

5. “Configuring network settings” on page 3-16

6. “Configuring date and time settings” on page 3-17

Chapter 3. Installation and configuration 3-11

Page 50

7. “Configuring encryption settings” on page 3-18

8. “Configuring email notifications” on page 3-20

9. “Configuring trap notifications” on page 3-21

10. “Managing user access” on page 3-23

11. “Saving the library configuration” on page 3-24

Logging in to the Web User Interface

To log in to the Web User Interface:

1. If necessary, obtain the IP address of the library on the Operator Panel.

a. From the top menu of the Operator Panel, press the Minus key to select

View Current Information, and press Enter.

b. Press the Minus key until the IP Address setting is displayed and make a

note of the IP address.

c. Press the Cancel key repeatedly to log out of the Operator Panel.

2. Open Internet Explorer on your server or PC to access the Web User Interface.

3. In the browser address field, enter your library's IP address URL to start the

Web User Interface applet in the browser window. For example,

http://192.168.1.1

When the applet launches, the warning message in Figure 3-11 displays. This

message is normal and does not indicate a problem.

4. Click Run.

Figure 3-11. Java security warning message

5. On the Web User Interface login screen, enter the administrator login account

name and default password.

v Account: admin

v Password: secure

3-12 Dell PowerVault TL1000 Tape Autoloader User's Guide

4

a29z019

Page 51

Figure 3-12. Web User Interface login screen

6. Click Login.

Checking firmware level

a29z0099

Figure 3-13. System summary

Check the current level of library firmware that is displayed in the System

Summary. If an updated level of firmware is available, download and update the

library firmware before normal operation starts. See “Updating library and drive

firmware” on page 4-38.

3

a29z019

Chapter 3. Installation and configuration 3-13

Page 52

Configuring library settings