Page 1

Dell EMC PowerEdge MX7000 Enclosure

Installation and Service Manual

Regulatory Model: E44S Series

Regulatory Type: E44S001

May 2020

Rev. A06

Page 2

Notes, cautions, and warnings

NOTE: A NOTE indicates important information that helps you make better use of your product.

CAUTION: A CAUTION indicates either potential damage to hardware or loss of data and tells you how to avoid the

problem.

WARNING: A WARNING indicates a potential for property damage, personal injury, or death.

© 2018 2020 Dell Inc. or its subsidiaries. All rights reserved. Dell, EMC, and other trademarks are trademarks of Dell Inc. or its

subsidiaries. Other trademarks may be trademarks of their respective owners.

Page 3

Contents

1 About this document.....................................................................................................................6

2 Next Generation Modular overview................................................................................................ 7

PowerEdge MX architecture overview.............................................................................................................................10

3 Enclosure overview......................................................................................................................11

Front view of the enclosure................................................................................................................................................12

Control panel...................................................................................................................................................................12

PSU indicators................................................................................................................................................................ 15

Fan module indicator codes.......................................................................................................................................... 15

Back view of the enclosure.................................................................................................................................................16

Management module indicator codes..........................................................................................................................17

Locating the information tag of your system................................................................................................................... 17

4 Initial system setup and configuration.......................................................................................... 19

Setting up your enclosure................................................................................................................................................... 19

Management module configuration...................................................................................................................................19

Options to set up the management module IP address............................................................................................19

Log in to the management module..............................................................................................................................20

Methods to download firmware and drivers....................................................................................................................20

Downloading drivers and firmware....................................................................................................................................20

LCD touch panel...................................................................................................................................................................21

LCD features...................................................................................................................................................................21

Assigning an IP address out-of-the-box...........................................................................................................................22

Configuring the Static IP address using the LCD......................................................................................................23

Configuring the DHCP IP address using the LCD..................................................................................................... 23

KVM features.......................................................................................................................................................................24

5 Installing and removing system components.................................................................................26

Safety instructions.............................................................................................................................................................. 26

Before working inside your enclosure...............................................................................................................................26

After working inside your enclosure..................................................................................................................................26

Hot plug and Non-hot plug devices...................................................................................................................................27

Storage and compute sleds................................................................................................................................................27

Removing a sled blank...................................................................................................................................................27

Installing a sled blank..................................................................................................................................................... 28

Removing a compute or storage sled from the enclosure....................................................................................... 29

Installing a compute or storage sled into the enclosure............................................................................................ 31

Cooling fan modules............................................................................................................................................................33

Removing a front fan module.......................................................................................................................................33

Installing a front fan module.........................................................................................................................................33

Removing a rear fan module........................................................................................................................................ 34

Installing a rear fan module...........................................................................................................................................35

Power supply units .............................................................................................................................................................35

Contents 3

Page 4

Removing a power supply unit.....................................................................................................................................35

Installing a power supply unit....................................................................................................................................... 36

Acoustic baffle..................................................................................................................................................................... 37

Removing the air baffle.................................................................................................................................................37

Installing the air baffle................................................................................................................................................... 38

Fabrics and modules............................................................................................................................................................39

Removing a blank from Fabric A or B slot..................................................................................................................39

Installing a blank in Fabric A or B slot..........................................................................................................................39

Removing a module from Fabric A or B slot.............................................................................................................. 40

Installing a module in Fabric A or B slot....................................................................................................................... 41

Removing a MX7000 blank from Fabric C slot..........................................................................................................42

Installing a MX7000 blank in Fabric C slot..................................................................................................................42

Removing a MX7000 module from Fabric C slot...................................................................................................... 43

Installing a MX7000 module into Fabric C slot.......................................................................................................... 44

Removing a management module blank.....................................................................................................................45

Installing a management module blank....................................................................................................................... 46

Removing a management module............................................................................................................................... 47

Installing a management module..................................................................................................................................48

Support information for GPU.............................................................................................................................................49

6 Technical specifications..............................................................................................................50

Component guidelines ....................................................................................................................................................... 50

Population rules............................................................................................................................................................. 50

PSU redundancy and population rules.........................................................................................................................51

Chassis dimensions..............................................................................................................................................................52

Chassis weight.....................................................................................................................................................................52

Fan specifications................................................................................................................................................................53

PSU specifications.............................................................................................................................................................. 53

Ports and connectors specifications.................................................................................................................................53

USB ports....................................................................................................................................................................... 53

Mini DisplayPort.............................................................................................................................................................53

PowerEdge MX modules ports and connectors..............................................................................................................54

PowerEdge MX740c.....................................................................................................................................................54

PowerEdge MX840c.....................................................................................................................................................54

MX7116n Fabric Expander Module.............................................................................................................................. 54

MX9116n Fabric Switching Engine.............................................................................................................................. 54

MX9002m Management Module................................................................................................................................ 55

MX5108n Ethernet Switch...........................................................................................................................................55

MXG610s Fibre Channel Switch..................................................................................................................................55

PowerEdge MX 10GBASE-T Ethernet Pass-Through Module............................................................................... 55

PowerEdge MX 25 Gb Ethernet Pass-Through Module..........................................................................................56

Video specifications............................................................................................................................................................ 56

Environmental specifications............................................................................................................................................. 56

Standard operating temperature................................................................................................................................. 57

Expanded operating temperature................................................................................................................................57

Particulate and gaseous contamination specifications ............................................................................................58

7 Getting help...............................................................................................................................60

Recycling or End-of-Life service information..................................................................................................................60

4

Contents

Page 5

Contacting Dell EMC.......................................................................................................................................................... 60

Documentation feedback....................................................................................................................................................61

Accessing system information by using QRL................................................................................................................... 61

Quick Resource Locator for PowerEdge MX7000 enclosure.................................................................................. 61

Receiving automated support with SupportAssist ......................................................................................................... 61

8 Documentation resources........................................................................................................... 62

Contents 5

Page 6

About this document

This document provides an overview about the PowerEdge MX7000, information about installing and replacing components, technical

specifications, and guidelines to follow while installing components.

1

6 About this document

Page 7

2

Next Generation Modular overview

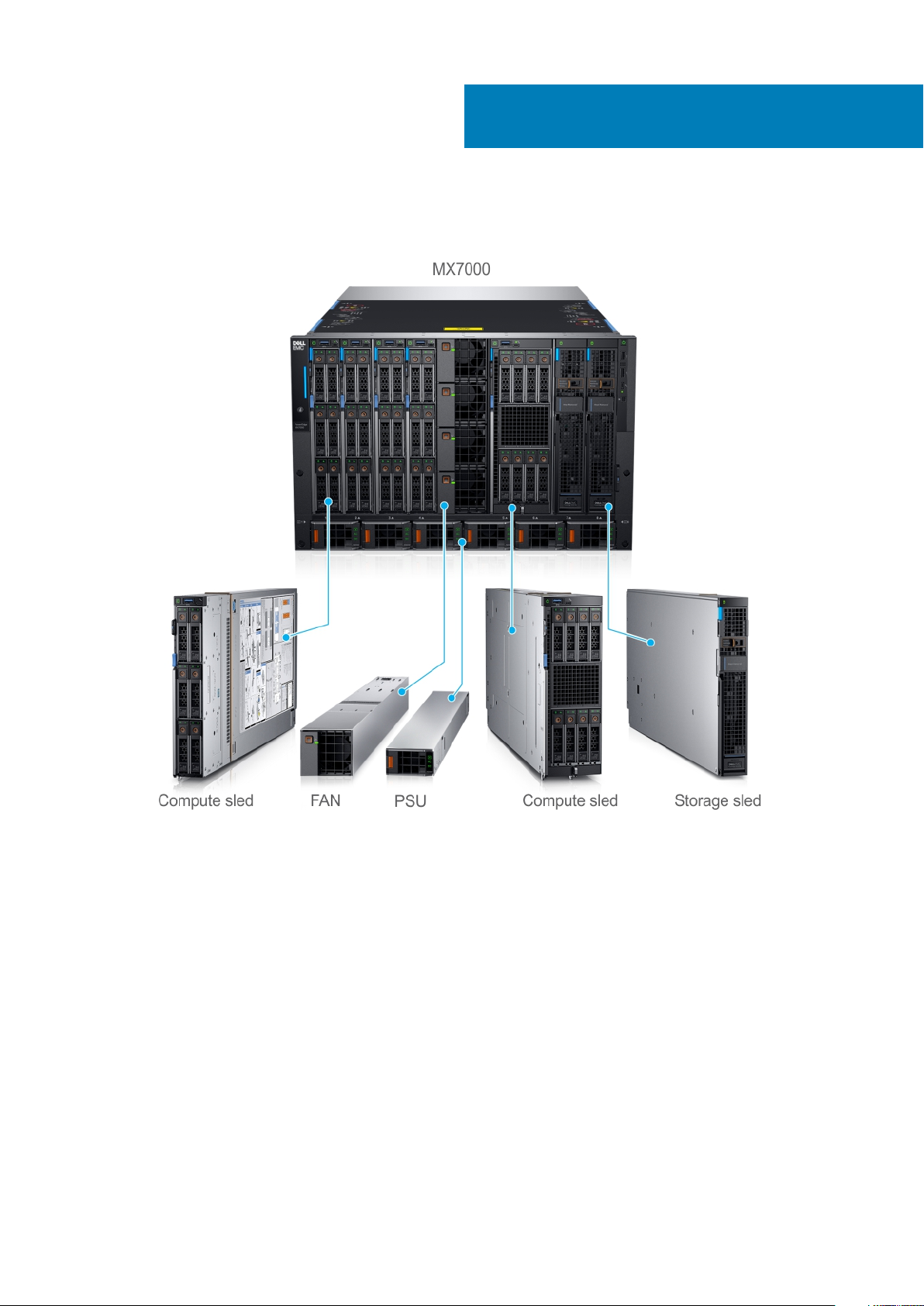

Figure 1. Next Generation Modular - Front view

• Compute sleds - MX740c, and MX840c

• Storage sled - MX5016s

Next Generation Modular overview 7

Page 8

Figure 2. Next Generation Modular - Back view

The Dell EMC PowerEdge MX7000 enclosure supports the following sleds and I/O modules:

• I/O modules -

○ Dell EMC Networking MX7116n Fabric Expander Module

○ Dell EMC Networking MX9116n Fabric Switching Engine

○ Dell EMC Networking MX5108n Ethernet Switch

○ Dell EMC Networking MXG610s Fibre Channel Switch

○ Dell EMC M9002m Management Module

○ Dell EMC PowerEdge MX5000s SAS Switch

• Ethernet Pass-Through Module -

○ Dell EMC PowerEdge MX 10GBASE-T Ethernet Pass-Through Module

○ Dell EMC PowerEdge MX 25 Gb Ethernet Pass-Through Module

• MX740c

The PowerEdge MX740c is a single-width compute sled that supports:

○ Up to two Intel Xeon Scalable Processors

○ Up to 24 DIMM slots

○ Up to six 2.5-inch SAS, SATA, SSD, or NVMe drives

• MX840c

The PowerEdge MX840c is a double-width compute sled that supports:

○ Up to four Intel Xeon Scalable Processors

○ Up to 48 DIMM slots

○ Up to eight 2.5-inch SAS, SATA, SSD, or NVMe drives

• MX5016s

8

Next Generation Modular overview

Page 9

The PowerEdge MX5016s is a single-width storage sled that provides disk expansion for the PowerEdge MX series compute sleds that

support:

○ Up to 16 hot-swappable 2.5-inch SAS drives

○ Two hot-swappable expanders providing dual SAS paths for all drives

○ Dual x4 SAS links to the MX platform infrastructure

○ 12 Gb/s SAS

• Dell EMCManagement Module M9002m

The Dell EMC MX9002m Management Module controls the overall chassis power, cooling, and hosts the OpenManage EnterpriseModular (OME-M) console. Two external 1G-BaseT Ethernet ports are provided to enable management connectivity and to connect

more PowerEdge MX7000 chassis into a single logical chassis. The PowerEdge MX7000 chassis supports two PowerEdge MX9002m

management modules for redundancy. The Management module offers:

• Two x 1G-BaseT Ethernet ports

• One x Micro-B USB port

• Dell EMC Networking MX7116n Fabric Expander Module

The Dell EMC Networking MX7116n Fabric Expander Module operates as an unmanaged Ethernet repeater to connect servers to the

MX9116n Fabric Switching Engine using QSFP28-DD connections. The Expander Module offers:

○ Sixteen 25 GE server-facing ports

○ Two QSFP28-DD ports for connection to a Fabric Switching Engine

• Dell EMC Networking MX9116n Fabric Switching Engine

The Dell EMC Networking MX9116n Fabric Switching Engine is a scalable L2/L3 switch designed that provides high-bandwidth, lowlatency 25 GbE networking. This high-end switch offers:

○ Sixteen 25 GE server-facing ports

○ 12 QSFP28-DD ports that you can use to connect to Fabric Expanders or break out to: 8x10GE or 8x25GE ports for connection to

rack servers or other Ethernet devices, or 2x40GE/2x100GE ports for uplinks, connection to SAN storage, and switch

interconnects

○ Two QSFP28 uplink ports that can operate in 1x100GE, 1x40GE, 4x25GE, 2x50GE, or 4x10GE mode

○ Two QSFP28 unified ports that operate in Ethernet or Fibre Channel 1x100GE, 1x40GE, 4x25GE, 4x10GE, 2x50GE, or

8x8/16/32GFC mode

• Dell EMC Networking MX5108n Ethernet Switch

The Dell EMC Networking MX5108n Ethernet Switch is a basic L2/L3 switch that is designed to provide high-performance, lowlatency networking for the PowerEdge MX7000 installations. It provides FCoE transit, but no native Fibre Channel functionality, and

offers:

○ Eight 25 GE server-facing ports

○ Two 100 GE QSFP28 uplink ports

○ One 40 GE QSFP28 uplink port

○ Four 10GBASE-T uplink ports

• Dell EMC Networking MXG610s Fibre Channel Switch

The Dell EMC Networking MXG610s Fibre Channel Switch provides the following hardware features:

○ Up to 16 external FC ports to connect with external FC storage or an FC switch

○ Up to 16 internal backplane FC ports to connect with the FC controller on the sleds

○ A dual-core T1022E processor operating at 1.2 GHz delivers high performance, scalability, and advanced fabric vision functionality

○ Two 32 Gbps short wavelength (SWL) optical SFP+ transceivers in the entry-level 8-port model

○ Four 32 Gbps SWL optical SFP+ transceivers in the midlevel 16-port model

○ Eight 32 Gbps SWL optical SFP+ transceivers in the enterprise 16-port model

• Dell EMC PowerEdge MX5000s SAS Switch

The Dell EMC PowerEdge MX5000s SAS Switch IOM provides the following hardware features:

○ Up to 8 internal 12Gbit/sec x4 SAS connections

○ Internal SAS Fabric that enables the connectivity without any need for attached cables

• Dell EMC PowerEdge MX 10GBASE-T Ethernet Pass-Through Module

The Dell 10 Gb Ethernet pass-through module II supports 10 Gb connections. It provides a direct connection between the optional

internal Ethernet mezzanine card in the sled and an external Ethernet device. The Ethernet pass-through modules are hot-swappable.

Next Generation Modular overview

9

Page 10

The 10 Gb Ethernet pass-through module enables you to use optical SFP+ (short reach or long reach) and direct- attached copper

(DCA) SFP+ modules.

NOTE: The Ethernet pass-through module does not support 1G mezzanine cards in the sleds.

• Dell EMC PowerEdge MX 25 Gb Ethernet Pass-Through Module

To better address high-performance network and scalability requirements, we are increasingly implementing 25 GbE for their

customers. These implementations capitalize on the 25GbE specification of the 25 Gigabit Ethernet Consortium. The specification

uses a single-lane 25 Gbps Ethernet links and is based on the existing IEEE 100 GbE standard. The 25 GbE is an easier upgrade path

from 10 GbE as it fits into the existing model. It requires half the number of PCIe lanes that are compared to 40 GbE. It leads to better

PCIe bandwidth utilization, and lower power consumption. The 25GbE SFP28 physical interface specification also supports various

form factors, enabling flexible configuration options.

Benefits of deploying 25 GbE:

○ Maximize performance and scalability

○ Lower capital and operating expenses

○ Future upgrade path

For more information about these modules and sleds, see www.dell.com/poweredgemanuals.

Topics:

• PowerEdge MX architecture overview

PowerEdge MX architecture overview

The PowerEdge MX portfolio delivers a fully managed, high-performance system that frees up valuable IT resources and personnel so you

can focus on innovation. It enables you to work beyond silos and routine, daily, and time consuming operational management to realize

your IT and digital business transformations. With the kinetic architecture and Agile management, the MX portfolio dynamically configures

compute, storage, and fabric, increases team effectiveness and accelerates operations. The responsive design delivers the innovation and

longevity customers of all sizes need for their IT and digital business transformations.

The PowerEdge MX infrastructure provides:

Flexible architecture

• A flexible architecture – Nondisruptive provisioning, on-demand allocation of compute, storage, and networking resource pools

• A scalable fabric – Cost-effective multichassis architecture with a broad array of open networking options and upgrade simplicity for

future I/O flexibility

• Granular storage – Dense, highly flexible, hot swappable, scale-out Direct Attached Storage sled with front access bays

Agile management

• End-to-end life cycle management and single point authentication for all devices from a single interface

• Simplified set-up/updates with no specialized training needed, and with multiple at-the-box management options

• An operational template methodology and comprehensive Rest API

Responsive design

• An industry-leading fabric, system thermal architecture, mechanical design, and control algorithms for dense configurations with future

compatibility

• A hardened design to protect, detect, and recover underlying infrastructure from cyber attacks

For more information about these modules and sleds, see their documents which are available at www.dell.com/poweredgemanuals.

10

Next Generation Modular overview

Page 11

3

Enclosure overview

The Dell EMC PowerEdge MX7000 is the next-generation M1000e follow-on chassis and a revolutionary architecture set to be the future

foundation of modular architecture.

The PowerEdge MX7000 enclosure is a 7U chassis that supports:

• Up to eight standard height, single-width sleds, or four standard height, double-width sleds.

Up to seven Storage sleds can be populated in the enclosure.

NOTE: One compute node must be present and it must be mapped to a storage node.

• Up to six hot swappable power supply units.

• Up to two hot swappable management modules.

• Up to six I/O modules:

○ Four Fabric-A/B type IOMs

○ Two Fabric-C type IOMs

• Four front accessible hot swappable cooling fans.

• Five rear accessible hot swappable cooling fans.

For more information about dual management modules, see Technical specifications.

Topics:

• Front view of the enclosure

• Back view of the enclosure

• Locating the information tag of your system

Enclosure overview 11

Page 12

Front view of the enclosure

Figure 3. Front view of the enclosure

Left control panel 2. Single-width compute sled

1.

3. Sled blank 4. Front fan (4)

5. Double-width compute sled 6. Single-width storage sled

7. Right control panel 8. Information tag

9. Power supply unit (6)

Control panel

Left control panel

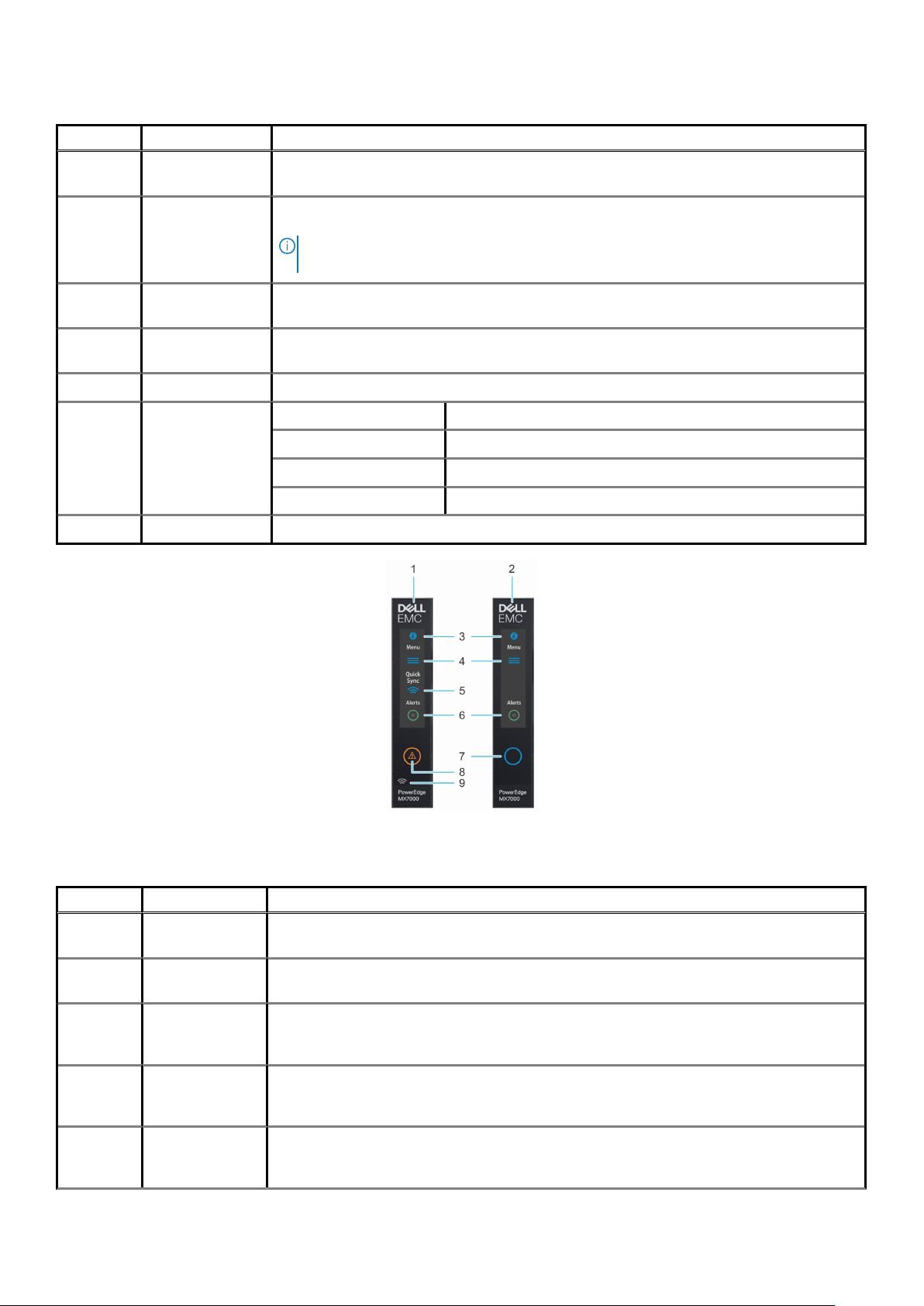

Figure 4. Left control panel - Status LED

12

Enclosure overview

Page 13

Table 1. Left control panel - LED indicator description

Indicator Description Status

1 System health Blinks amber for 2 seconds and is OFF for 1 second when the chassis health has degraded. By

default, the LED is unlit.

2 System

temperature

3 I/O module health Blinks amber for 2 seconds and is OFF for 1 second when an I/O module is faulty. By default the

4 Fan health Blinks amber for 2 seconds and is OFF for 1 second when a front or rear mounted fan fails or has a

5 Stack or group Indicates that the enclosure is a member of a group.

6 LED status bar Indicator status Description

7 System ID button Allows you to identify the system or the installed sleds.

Blinks amber for 2 seconds and is OFF for 1 second when a thermal fault exists on the enclosure. By

default, the LED is unlit.

NOTE: A thermal fault includes excessive ambient temp, I/O modules thermal status,

PSU thermal status, and fan status.

LED is unlit.

warning. By default, the LED is unlit.

Solid blue Indicates that the enclosure is healthy.

Blinking blue Indicates that the system ID mode is active.

Blinking amber Indicates that the system is experiencing a fault.

Figure 5. Left control panel - LCD options

Table 2. Left control panel - LCD panel description

Indicator Description Status

1 LCD with Quick

Sync

2 LCD without Quick

Sync

3 System ID

indicator on LCD

panel

4 Settings This option button provides access to the inventory and configuration data of the MX7000

5 Optional

QuickSync

indicator (Only for

LCD enabled with Quick Sync module

LCD without Quick Sync module

This option is a button/indicator on the LCD panel to identify the chassis, or choose specific sleds to

identify.

enclosure. It includes the Network Settings, System Information, (Model, Asset Tag, Service Tag),

and Language Settings.

Enables access to QuickSync related controls and connection information.

Enclosure overview 13

Page 14

Table 2. Left control panel - LCD panel description(continued)

Indicator Description Status

LCD with

QuickSync 2.0)

6 System alerts

indicator

7

8 Error indicator The error indicator is displayed on the LCD when there are any critical/warning alerts on the

9 Optional Quick

LCD activation

button/

System ID

indicator/

Identification

indicator

Sync wireless

status indicator

NOTE: QuickSync feature allows you to manage your system using mobile devices.

This feature is only available on certain configurations.

NOTE: If not ordered at the time of purchase, the QuickSync module will not be

available on the enclosure.

System ID Indicator status Description

Solid green The chassis has no degraded or critical alerts.

Solid amber The chassis has critical or degraded health alerts.

NOTE: This option button/indicator shows an amber colored alert icon and a combined

critical and degraded alert count. Pressing the button takes the user to the alert

details menu.

Allows you to identify the enclosure.

NOTE: Press the button to activate the LCD.

System ID Indicator status Description

Blinking blue System ID is active.

Blinking amber Chassis alerts are present.

enclosure.

Displays the connection status of the enclosure with any QuickSync enabled device.

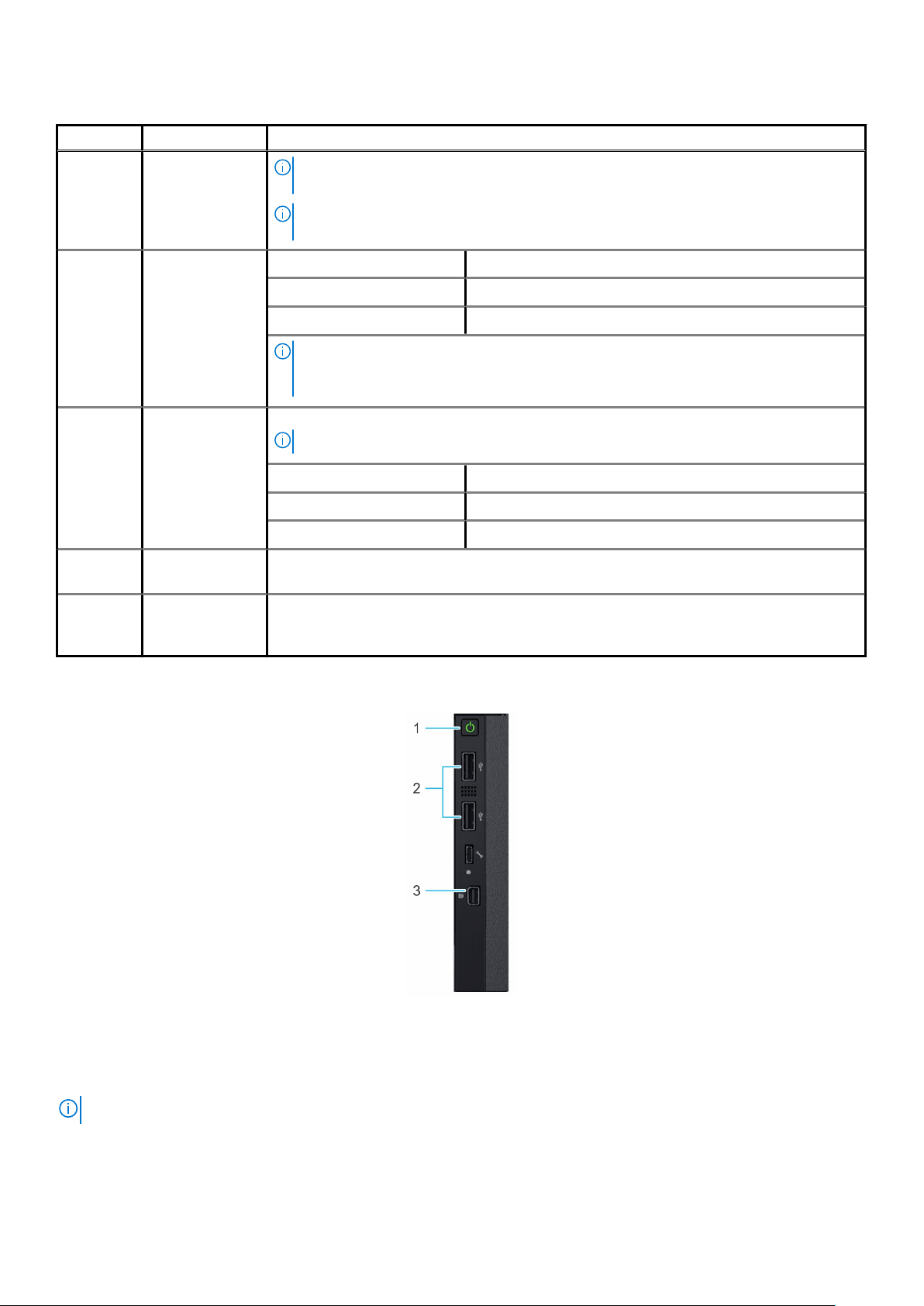

Right control panel

Figure 6. Right control panel

1. Power button

2. USB 2.0 port (2)

3. Mini DisplayPort

NOTE: For more information on the ports, see Technical specifications.

14 Enclosure overview

Page 15

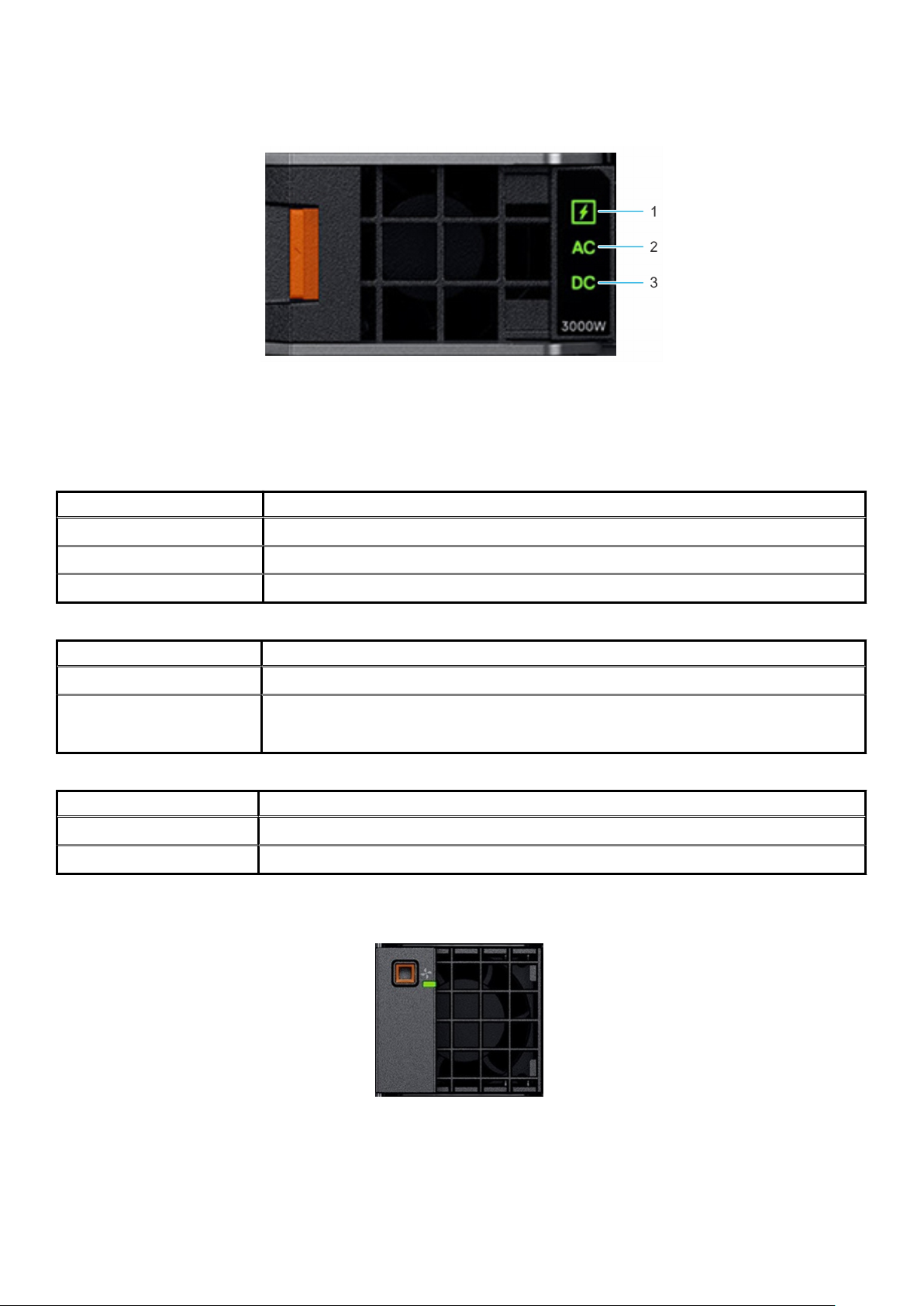

PSU indicators

Figure 7. PSU indicators

1. PSU health indicator

2. AC supply status indicator

3. DC output status indicator

Table 3. PSU health indicator codes

PSU health indicator Indicator state

PSU functioning normally Green

PSU faulty Blinking amber

PSU mismatch ON for 1 second, and then 5 blinks and OFF (non-repeating cycle).

Table 4. AC indicator codes

AC indicator Indicator state

AC source available ON

AC source unavailable or

power cable unplugged

OFF

Table 5. DC indicator codes

DC indicator Indicator state

DC output available ON

DC output unavailable OFF

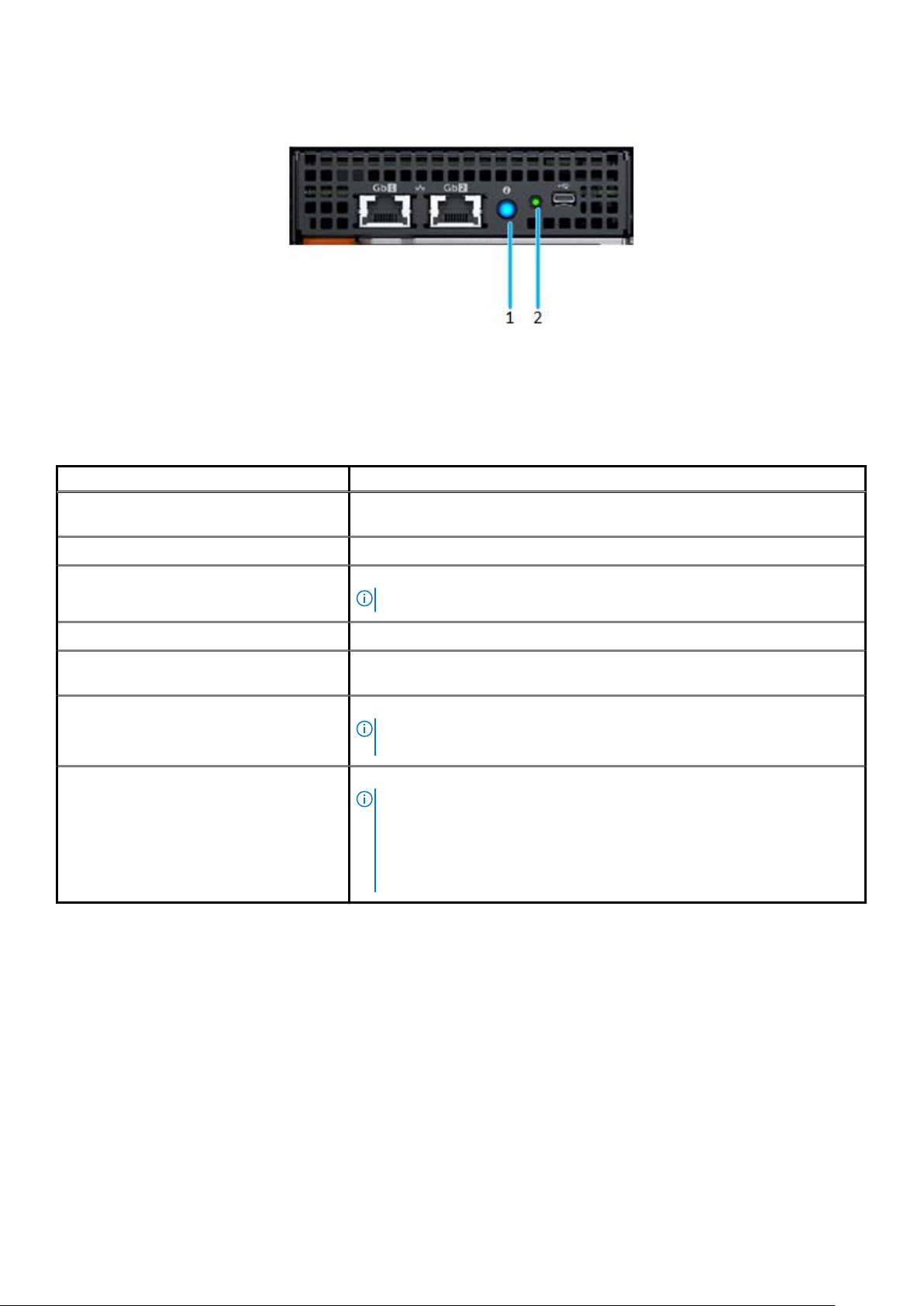

Fan module indicator codes

Figure 8. Front fan module

Enclosure overview

15

Page 16

Figure 9. Rear fan module

Table 6. Fan module indicator codes

Fan indicators Indicator state

Fan functioning normally - Front/ Rear Solid green

Fan failure Blinks amber 2 seconds and 1 second OFF

NOTE: When the chassis is powered off with the AC connection that is powered on, only the rear fans are powered off.

Back view of the enclosure

Figure 10. Back view of the enclosure

1.

Slot for Fabric A1 2. Slot for Fabric A2

3. Rear fans (5) 4. Slot for Fabric B1

5. Slot for Fabric B2 6. Slot for Fabric C2

7. Power cable connection status LED 8. C22 Power inlet connectors (6)

9. Management Module 2 10. Management Module 1

11. Slot for Fabric C1

NOTE: For more information about the ports and connectors, see Technical specifications.

16 Enclosure overview

Page 17

Management module indicator codes

Figure 11. Management module indicators

1. Status indicator, Identification button/ Indicator Dual color: Blue and amber

2. Power indicator - Green

Table 7. Management module indicator behavior

Status Indicator combination

Healthy chassis/ Management module

(Standby)

Healthy chassis/ Management module (Active) Power indicator ON (green), status indicator blue ON

Healthy chassis/ Management module

(Identifying mode)

Faulty chassis/ Management module (Active) Power indicator ON (green), status indicator amber blinking

Faulty chassis/ Management module

(Identifying mode)

Failed chassis/ Management module: Mode 1 Power indicator OFF, status indicator OFF

Failed chassis/ Management module: Mode 2 Power indicator OFF, status indicator Amber-solid

Power indicator ON (green), status indicator OFF

Power indicator ON (green), status indicator blue blinking

NOTE: Available only when the management module is active.

Power indicator ON (green), status indicator blue blinking

NOTE: Hardware failure prevents the management module from

powering.

NOTE:

• The management module starts boot but is unable to boot to one or

more operating system partitions.

• The management module boots but detects a failure such as a network

switch failure, or a voltage regulator failure.

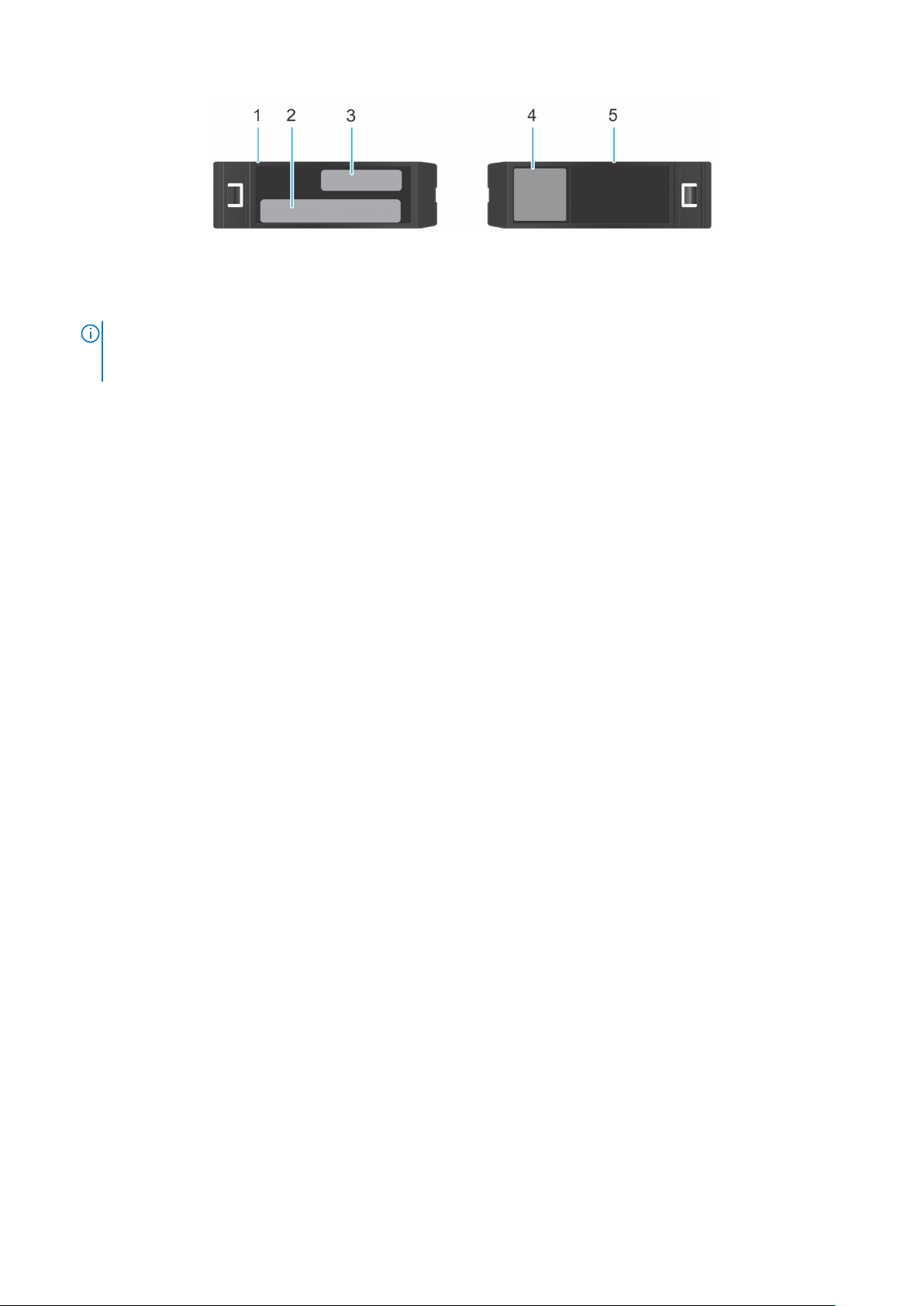

Locating the information tag of your system

You can identify your system using the unique express service code and Service Tag. Pull out the information tag in front of the system to

view the express service code and Service Tag. Alternatively, the information may be on a sticker on the back of the system chassis. The

mini Enterprise Service Tag (EST) is found on the back of the system chassis. Dell uses this information to route support calls to the

appropriate personnel.

Enclosure overview

17

Page 18

Figure 12. Locating the information tag of your system

1. Information tag (Top view)

2. MAC address and secure password label

NOTE: If you have opted for default access to the management module, the default password is available on the

Information tag. This label is blank, if you have not opted for secure default access, then the default username and

password are root and calvin.

3. Express Service Tag

4. Quick resource locator

5. Information tag (Bottom view)

18 Enclosure overview

Page 19

Initial system setup and configuration

Setting up your enclosure

Complete the following steps to set up your enclosure:

Steps

1. Unpack the enclosure.

2. Install the enclosure into the rack. For more information, see the Rail Installation Guide at www.dell.com/poweredgemanuals.

3. Connect the peripherals to the enclosure.

4. Connect the enclosure to its electrical outlet.

5. Power on the enclosure by pressing the power button.

NOTE: You can configure the static or DHCP IP address using the touch panel on the chassis.

6. Power on the attached peripherals.

For more information about setting up your enclosure, see the Getting Started Guide that shipped with your enclosure.

Management module configuration

4

Using the management module (MM), you can manage SAS storage subsystem, drive assignments, and monitor the health status for the

associated SAS devices. You can manage SAS fabric by using the OpenManage Enterprise-Modular user interface to view inventory,

storage event logs and manage drive or enclosure assignments. For more information about managing the SAS fabric using OpenManage

Enterprise-Modular, see OpenManage Enterprise-Modular User's Guide available at www.dell.com/openmanagemanuals > Chassis

Management Controllers.

Options to set up the management module IP address

Configure the initial network settings on your network infrastructure to enable the communication to and from the management module.

NOTE: For static IP configuration, you must request for it at the time of purchase.

Use the OpenManage Essentials Quick Deploy feature to assign a static or DHCP IP address.

Interfaces

Dell Deployment

Toolkit

Dell Lifecycle

Controller

OpenManage

Enterprise

Modular

Server LCD panel See the LCD touch-panel section.

Management

module and Quick

Sync 2 (optional)

Document/Section

See Dell Deployment Toolkit User’s Guide at www.dell.com/openmanagemanuals > OpenManage Deployment

Toolkit

See Dell Lifecycle Controller User’s Guide at www.dell.com/idracmanuals > Lifecycle Controller

See Dell OpenManage Enterprise-Modular User’s Guide at www.dell.com/openmanagemanuals > Chassis

Management Controllers

See Dell Integrated Dell Remote Access Controller User's Guide at www.dell.com/idracmanuals

NOTE: To access the management module, ensure that all the management modules are connected to the network. You

can also access the management module through the shared LOM mode, if you have opted for a system that has the

shared LOM mode enabled.

Initial system setup and configuration 19

Page 20

Log in to the management module

You can log in to management module as:

• Management module user

• Microsoft Active Directory user

• Lightweight Directory Access Protocol (LDAP) user

If you have opted for secure default access to management module, the management module secure default password is available on the

information tag available on the front of the enclosure. If you have not opted for secure default access to management module, then the

default user name and password are root and calvin. You can also log in by using Single Sign-On or Smart Card.

NOTE: You must have the management module credentials to log in to management module.

NOTE: Ensure that you change the default username and password after setting up the management module IP address.

For more information about logging in to the management module, see the Dell EMC OpenManage Enterprise Modular User's Guide at

www.dell.com/manuals.

Methods of setting up and configuring the IP address for the management module

You can configure management module IP using the following:

1. Management module web interface

2. Remote Access Controller ADMin (RACADM)

3. Remote Services that include Web Services Management (WS-Man)

Methods to download firmware and drivers

You can download the firmware and drivers by using any of the following methods:

Table 8. Firmware and drivers

Methods Location

From the Dell EMC support site www.dell.com/support/home

Using Dell Repository Manager (DRM) www.dell.com/openmanagemanuals > Repository Manager

Using Dell OpenManage Essentials www.dell.com/openmanagemanuals > OpenManage Essentials

Using Dell OpenManage Enterprise www.dell.com/openmanagemanuals > OpenManage Enterprise

Using Dell Server Update Utility (SUU) www.dell.com/openmanagemanuals > Server Update Utility

Using OpenManage Enterprise Modular www.dell.com/openmanagemanuals > OpenManage Enterprise

Modular

Downloading drivers and firmware

Dell EMC recommends that you download and install the latest BIOS, drivers, and systems management firmware on your system.

Prerequisites

Ensure that you clear the web browser cache before downloading the drivers and firmware.

Steps

1. Go to www.dell.com/support/home.

2. In the Drivers & Downloads section, type the Service Tag of your system in the Enter a Service Tag or product ID box, and then

click Submit.

20

Initial system setup and configuration

Page 21

NOTE: If you do not have the Service Tag, select Detect Product to allow the system to automatically detect the

Service Tag, or click View products, and navigate to your product.

3. Click Drivers & Downloads.

The drivers that are applicable to your system are displayed.

4. Download the drivers to a USB drive, CD, or DVD.

LCD touch panel

The LCD touch panel (optional) is on the left control panel of your enclosure.

The LCD touch panel displays the following options:

• System information

• System status

• Error messages

• QuickSync options - Available on the optional QuickSync LCD panel only.

NOTE: The LCD touch panel is not a hot swappable module. Before you replace the module, power off the enclosure and

disconnect the AC power from the chassis.

The LCD touch panel enables you to scroll or swipe on the screen. The options available on the LCD touch panel are:

• Welcome Screen - Enables you to select your native language and the default LCD home page.

• Main Menu - Enables you to access the LCD functionality such as Identify, Settings, QuickSync, Alerts, Help, and Powered off.

• QuickSync - Enables you to connect OpenManage Mobile to the enclosure.

• Alerts - Enables you to view a list of all the critical and warning alerts of the enclosure.

• Network Settings - View and configure the chassis management IP address.

• LCD Configuration - Enables you to configure the LCD options such as View and Modify, View only, Disabled, Present, and Not

present.

• Settings - Enables you to edit the Network settings, LCD Language, and Home screen.

• Service Interaction - Displays the impact on drive mapping when a server or sled is replaced in the enclosure.

• System Info - Displays the Model number, Asset tag, and Service tag of the enclosure.

• Chassis Power Off - Enables you to perform a Shutdown or Graceful shutdown.

LCD features

Multi-Chassis Management group

About this task

The PowerEdge MX7000 enclosures LCD allows you to manage the enclosures Multi-Chassis Management (MCM) group. In this

management feature, a lead enclosure will manage a subset of enclosures.

The MCM groups management feature allows you to perform the actions mentioned below:

• Viewing the group status

• Creating a group

• Joining a group

• Leaving a group

• Deleting a group

Viewing the group status

To view a group status

Steps

1. From the selected home screen, tap Settings.

2. Tap Manage Group.

Initial system setup and configuration

21

Page 22

Creating a group

To create a stand-alone chassis group

Steps

1. From the selected home screen, tap Settings.

2. Tap Manage Group.

3. To create a group, tap Select Group.

NOTE: A confirmation message is displayed.

NOTE: It may take several minutes to update the available group names.

Joining a group

To join a stand-alone chassis group

Steps

1. From the selected home screen, tap Settings.

2. Tap Manage Group.

3. To join a group, tap Join Group.

NOTE: If no available groups, an error message is displayed.

NOTE: If there are available groups, a list of available group names is displayed.

Leaving a group

To leave a member chassis group

Steps

1. From the selected home screen, tap Settings.

2. Tap Manage Group.

3. To exit a group, tap Leave Group.

NOTE: A confirmation message is displayed.

Deleting a group

To delete a lead chassis group

Steps

1. From the selected home screen, tap Settings.

2. Tap Manage Group.

3. To exit a group, tap Leave Group.

NOTE: A confirmation message is displayed.

Assigning an IP address out-of-the-box

About this task

The PowerEdge MX7000 enclosure offers out-of-the-box IP address assignment using the LCD touch panel. For more information about

the LCD, see LCD touch panel.

22

Initial system setup and configuration

Page 23

Steps

1. To set up the IP address out-of-the-box:

1. Select the Language, and tap Next.

The select Home Page screen is displayed.

2. Tap Preview, to view the default Home page view.

The available Home page views are:

• Main Menu

• IP Settings

• System Info

• Custom Text String

The Home Page Preview screen is displayed.

3. Tap Save to store the settings.

NOTE: You can tap Home Pages to view the selected Home Page screen.

Configuring the Static IP address using the LCD

Steps

1. The PowerEdge MX7000 enclosures LCD touch panel enables you to configure the Static or the DHCP IP address.

To configure the Static IP address:

1. From the selected home screen, tap Settings.

2. Tap Network Settings.

3. Select IPv4, and tap Edit.

The Change IP settings from DHCP to Static? screen is displayed.

4. Tap Yes.

5. Update the IPv4 octet, and tap Next.

6. Edit the Mask octet, and tap Next.

7. Edit the Gateway octet, and tap Save.

The Success screen is displayed.

NOTE: If the IP address is incorrect, an Error screen is displayed.

Configuring the DHCP IP address using the LCD

Steps

1. To configure the DHCP IP address:

1. From the selected home screen, tap Settings.

2. Tap Network Settings.

3. Select IPv6 and, tap Edit.

The Change IP settings from DHCP to Static? screen is displayed.

4. Tap Yes.

5. The network IP address is automatically updated in the enclosure.

The Success screen is displayed.

NOTE: If the IP address is incorrect an Error screen is displayed.

Initial system setup and configuration 23

Page 24

KVM features

The PowerEdge MX7000 supports Keyboard, Video, Mouse (KVM) which provides access to the servers via the management modules.

KVM functionality

The keyboard, video, mouse (KVM) solution from Dell includes an LED screen, a keyboard, and a touch pad mouse, all contained in a

space-saving 1U package. The KVM provides access to the servers via the management modules. The management module receives the

keyboard/mouse events and redirects the input to the virtual USB keyboard/mouse to the compute sled iDRAC. The management module

automatically redirects the chassis console output to the front panel display port.

The KVM accessibility keys are:

• Open the OSD menu - Press the PrintScreen key twice to enable the On Screen Display (OSD).

• Navigation - Use the Up or Down arrow keys to scroll through the list of available sled.

• Access a sled - Press the Enter key to select a sled.

• Exit a sled - Press the Escape key to exit the OSD/sled selection menu.

KVM supported ports

The KVM solution supported ports for the PowerEdge MX7000 enclosure are:

• Mini display port

• Mini display port to VGA adapters

• Mini display port to display port cables

Out of the box IP setup using the KVM

To setup the IP address out of the box using the KVM:

1. Connect the keyboard and mouse to the USB ports on the right control panel.

2. Connect the display port or the display port adapter to the display port on the right control panel.

The KVM selection menu is displayed.

3. Select OME Modular from the list.

The OME credentials page is displayed.

4. Enter the login credentials and login to the OME user interface.

The RACADM CLI screen is displayed.

KVM supported RACADM commands

Table 9. KVM supported RACADM commands

Command Description

help

help <subcommand>

?

? <subcommand>

arp

Displays a list of RACADM subcommands.

Displays the usage summary for a subcommand.

Displays a list of RACADM subcommands.

Displays the usage summary for a subcommand.

Displays the networking ARP table.

getmodinfo

chassisaction

chassislog

cmcchangeover

connect

24 Initial system setup and configuration

Displays the module configuration and status information.

Performs a chassis power on/off or power cycle/reset operation.

Displays the chassis log messages.

Toggles the redundant state of the CMC between active/standby.

Connects the switch or blade serial console.

Page 25

Table 9. KVM supported RACADM commands(continued)

Command Description

debug

Enables the debug authorization commands.

deploy

faultlist

getniccfg

getsensorinfo

getsysinfo

getpminfo

getpbinfo

racreset

racresetcfg

swinventory

serveraction

setniccfg

traceroute

traceroute6

ifconfig

ping

Deploys the blade or IOM with specified properties.

Displays the active messages in the chassis subsystem.

Displays the current network settings.

Displays the system sensor information.

Displays the general management module and system information.

Displays the power management status information.

Displays the power budget status information.

Performs a management module reset operation.

Performs a management module factory reset operation.

Displays the list of software's installed on the chassis.

Perform a server or storage power management operation.

Modify the network configuration properties.

Displays the route packets trace to network host.

Displays the IPv6 route packets trace to network host.

Displays the network interface information.

Sends ICMP echo packets on the network.

ping6

getconfig

config

chassisgroup

Sends IPv4 ICMP echo packets on the network.

Displays the management module configuration properties.

Modify the management module configuration properties.

Enables multiple chassis management.

KVM limitations

The KVM features are disabled in the following scenarios:

• If the iDRAC is undergoing a reset process.

• If the management module is undergoing a reset process or not active.

• The OSD is blank until the management module is active.

• DP - DVI and DP - HDMI are not supported by the PowerEdge MX7000 KVM solution.

• The maximum resolution that is supported by the PowerEdge MX7000 are:

○ 1920 x 1200, 32 bits per pixel @ 60 Hz

○ 1600 x 1200, 32 bits per pixel @ 75 Hz

For more information about the PowerEdge MX7000 at the box serial access feature of the chassis management firmware , see

PowerEdge MX7000 At-the-Box Serial Access to Management Firmware

For more information about the PowerEdge MX7000 supported RACADM Commands, see Dell EMC OpenManage Enterprise Modular

Edition Version 1.00.01 for PowerEdge MX7000 Chassis

Initial system setup and configuration

25

Page 26

Installing and removing system components

Safety instructions

WARNING: To avoid injury, do not attempt to lift the enclosure by yourself. Dell recommends that a minimum of two

people lift the enclosure.

WARNING: Opening or removing the cover while the enclosure is powered on may expose you to a risk of electric shock.

CAUTION: Many repairs may only be done by a certified service technician. You should only perform troubleshooting and

simple repairs as authorized in your product documentation, or as directed by the online or telephone service and

support team. Damage due to servicing that is not authorized by Dell is not covered by your warranty. Read and follow

the safety instructions that are shipped with your product.

NOTE: Dell recommends ESD protection while working on components inside the enclosure.

CAUTION: For proper operation and cooling for all the sleds, module bays, power supply units, and system fans must be

populated with a component or a blank.

5

Before working inside your enclosure

Prerequisites

Follow the safety guidelines listed in Safety instructions.

Steps

1. Power off the compute sleds, the storage sleds, and then the attached peripherals.

2. Disconnect the sleds, and the peripherals from the enclosure.

3. Power off the enclosure.

4. Disconnect the enclosure from the electrical outlet.

5. Remove the enclosure from the rack.

For more information, see the Rack Installation Guide at www.dell.com/poweredgemanuals.

After working inside your enclosure

Prerequisites

Follow the safety guidelines listed in Safety instructions.

Steps

1. Install the enclosure into the rack, if removed.

For more information, see the Rack Installation Guide at www.dell.com/poweredgemanuals.

2. Connect the enclosure to the electrical outlet.

3. Power on the enclosure.

4. Reconnect the sleds, and the peripherals into the enclosure.

5. Power on the attached peripherals, the storage sleds, and then the compute sleds.

26 Installing and removing system components

Page 27

Hot plug and Non-hot plug devices

Table 10. Hot plug devices

Hot plug devices Non-hot plug devices

Cooling fans Main distribution board

Power supply units Vertical power distribution board

Management services modules Rear fan board

Fabric A/ B/ C input output modules Left and right control panels

Sleds

NOTE: Ensure that the sled is powered off before

removing it from the enclosure.

Storage and compute sleds

Removing a sled blank

Prerequisites

1. Follow the safety guidelines listed in Safety instructions.

Steps

1. Press the release button to release the sled blank.

2. Pull the sled blank out of the enclosure.

CAUTION:

overheating.

Ensure to install a sled blank in all the empty bays. Operating the enclosure without a blank results in

Installing and removing system components 27

Page 28

Figure 13. Removing a sled blank

Next steps

1. Install a sled or sled blank.

Installing a sled blank

Prerequisites

1. Follow the safety guidelines listed in Safety instructions.

Steps

1. Align the sled blank with the bay in the enclosure.

2. Insert and push the sled blank, until it locks into place.

NOTE: Install two sled blanks when a double-width sled is removed.

28 Installing and removing system components

Page 29

Figure 14. Installing a sled blank

Removing a compute or storage sled from the enclosure

Prerequisites

1. Follow the safety guidelines listed in Safety instructions.

2. Power off the sled.

CAUTION: Ensure the compute sleds mapped to the storage sleds are powered off.

CAUTION: Remove the storage sled only when the hard drive LED is off.

NOTE: If the storage sled drive LED indicator is off, it indicates that all the compute sleds mapped to the storage

sled are powered off.

NOTE: If there are two Fabric C SAS IOMs in powered on state, the management module in the enclosure powers on

the storage sleds automatically.

Steps

1. To remove a storage or compute sled:

NOTE: The procedure to remove a single-width and double-width compute sled is the same.

For a storage sled,

a. Open the sled removal hatch on the front panel of the sled.

b. To release the sled release lever, push the blue release button to the unlock position.

For a compute sled,

a. To release the sled release lever, push the blue release button on the sled.

2. Hold the sled release lever, pull the sled out of the enclosure.

NOTE: Ensure that you install a sled blank if you are removing the sled permanently.

Installing and removing system components 29

Page 30

CAUTION: Operating the enclosure without a blank, for an extended time can result in overheating.

CAUTION: Ensure that the sled is supported with both hands while you are removing the sled.

Figure 15. Removing a storage sled from an enclosure

Figure 16. Removing a single-width compute sled from the enclosure

3. Install the I/O connector cover on the sled.

30

Installing and removing system components

Page 31

Next steps

1. Install a sled or a sled blank.

Installing a compute or storage sled into the enclosure

Prerequisites

1. Follow the safety guidelines listed in Safety instructions.

2. Ensure that the sled release lever is in the open position.

Steps

1. Remove the I/O connector cover from the sled.

Figure 17. Removing the I/O cover

2. Hold and align the sled with the bay in the enclosure.

3. Push the sled into the bay in the enclosure.

NOTE: The procedure to install a single-width and double-width sled is the same.

4. Close the release lever to lock the sled in place.

Installing and removing system components

31

Page 32

Figure 18. Installing a single-width compute sled into the enclosure

Figure 19. Installing a storage sled into the enclosure

Next steps

1. Power on the sled.

32

Installing and removing system components

Page 33

Cooling fan modules

NOTE: The system must be populated with the full set of fans to support the airflow requirements of the chassis.

Removing a front fan module

Steps

1. Press the release button to release the fan module.

2. Hold and pull the fan module out of the fan bay.

Figure 20. Removing a front fan module

Next steps

1. Install a front fan module.

Installing a front fan module

Steps

1. Insert the fan module into the fan bay.

2. Push the fan module into the fan bay, until it locks into place.

Ensure that the green LED on the fan module is illuminated, indicating that the module is functioning

NOTE:

properly.

Installing and removing system components 33

Page 34

Figure 21. Installing the front fan module

Removing a rear fan module

Steps

1. Press the release button to release the fan module.

2. Hold and pull the fan module out of the fan bay.

Figure 22. Removing a rear fan module

34

Installing and removing system components

Page 35

Next steps

1. Install the rear fan module.

Installing a rear fan module

Steps

1. Insert the fan module into the fan bay.

2. Push the fan module into the fan bay, until it locks into place.

NOTE: Ensure that the green LED on the fan module is illuminated, indicating that the module is functioning

properly.

Figure 23. Installing a rear fan module

Power supply units

Removing a power supply unit

Prerequisites

CAUTION: At least two power supply units (PSUs) must be installed for the enclosure to function properly.

1. Follow the safety guidelines listed in Safety instructions.

2. Disconnect the power cable from the power connector associated to the PSU you intend to remove.

Steps

1. Press the orange release button to open the PSU release lever.

2. Hold the release lever, pull the PSU out of the enclosure.

CAUTION: Ensure that you install a PSU blank if you are removing a PSU permanently.

Installing and removing system components 35

Page 36

Figure 24. Removing a power supply unit

Next steps

1. Install a PSU or a PSU blank.

Installing a power supply unit

Prerequisites

1. Follow the safety guidelines listed in Safety instructions.

Steps

1. Push the PSU into the enclosure until it is seated firmly.

2. Close the PSU release lever to secure the PSU in the bay.

36

Installing and removing system components

Page 37

Figure 25. Installing a power supply unit

Next steps

1. Connect the power cable to the corresponding PSU connector on the rear of the chassis.

NOTE:

When installing or hot swapping a PSU, wait for 15 seconds for the system to recognize the PSU and

determine its status. The PSU redundancy may not occur until discovery is complete. Wait until the new PSU is

discovered and enabled before you remove any PSU. The PSU status indicator turns green to indicate that the PSU

is functioning properly.

Acoustic baffle

NOTE: Ensure to install the air baffle to reduce the noise level of the enclosure.

Removing the air baffle

Steps

1. Press the release latch to detach the air baffle from the enclosure.

2. Pull the air baffle to remove it from the enclosure.

Installing and removing system components

37

Page 38

Figure 26. Removing the air baffle

Installing the air baffle

Steps

1. Align the air baffle with the enclosure.

2. Push the air baffle, until it locks into place.

Figure 27. Installing the air baffle

38

Installing and removing system components

Page 39

Fabrics and modules

There are several connections on the Main Distribution Board to enable communication between the IOMs. Between each pair of IOMs

(C1 and C2), there is a link for intermodule communication. This link is referred as Fabric-V in the schematics. This link supports a x1

connection with each lane operating up to 10 Gbps per direction. In addition to the Fabric-V, there are handshake signals between the two

modules to facilitate redundancy/failover or other module to module communication. The usage of these interconnects depends on the

IOM design and its particular requirements.

There are three fabrics connections available in MX7000 enclosure.

• General purpose (2) - Fabric A and B

• Storage (1) - Fabric C

• Fabric module A or B

• Fabric module C

• Management module

Removing a blank from Fabric A or B slot

Steps

1. Press the blue release button to release the blank.

2. Pull the blank out of the enclosure.

NOTE: To maintain proper airflow, ensure that the blanks are installed if the IOMs are not installed.

Figure 28. Removing a blank from Fabric A or B slot

Next steps

1. Install a module in the Fabric A or B slot or a blank.

Installing a blank in Fabric A or B slot

Prerequisites

1. Follow the safety guidelines listed in Safety instructions.

Installing and removing system components

39

Page 40

2. Remove the module from Fabric A or B slot.

Steps

1. Align and insert the blank in the empty slot.

2. Push the blank, until it locks into place.

Figure 29. Installing a blank in Fabric A or B slot

Removing a module from Fabric A or B slot

Prerequisites

1. Follow the safety guidelines listed in Safety instructions.

2. Disconnect the cables that are connected to the modules.

Steps

1. Press the orange release button on the module to open the release levers.

2. Hold the release levers, and pull the module out of the enclosure.

NOTE: Ensure that you install an IOM blank if you are removing a module permanently.

40 Installing and removing system components

Page 41

Figure 30. Removing a module from Fabric A or B slot

Next steps

1. Install a module into Fabric A or B slot or a blank.

Installing a module in Fabric A or B slot

Prerequisites

1. Follow the safety guidelines listed in Safety instructions.

Steps

1. Align and push the I/O module into the enclosure.

2. Close the release lever to lock the module in place.

Figure 31. Installing a module into Fabric A or B slot

Installing and removing system components

41

Page 42

Next steps

1. Connect the cables to the module.

Removing a MX7000 blank from Fabric C slot

Steps

1. Press the release button to release the blank.

2. Pull the blank out of the enclosure.

NOTE: To maintain proper airflow, ensure that the blanks are installed if the MX7000 IOMs is not installed.

Figure 32. Removing a blank from Fabric C slot

Next steps

1. Install the module in the Fabric C slot or a blank.

Installing a MX7000 blank in Fabric C slot

Prerequisites

1. Follow the safety guidelines listed in Safety instructions.

2. Remove the module from Fabric C slot.

Steps

1. Align and insert the blank in the empty slot.

2. Push the blank until it locks into place.

42

Installing and removing system components

Page 43

Figure 33. Installing a blank in Fabric C slot

Removing a MX7000 module from Fabric C slot

Prerequisites

1. Follow the safety guidelines listed in Safety instructions.

2. Disconnect the cables that are connected to the modules.

Steps

1. Press the orange release button on the module to open the release lever.

2. Hold the release lever, and pull the I/O module out of the enclosure.

NOTE: Ensure that you install MX7000 an IOM blank if you are removing a module permanently.

Installing and removing system components 43

Page 44

Figure 34. Removing a MX7000 module from Fabric C slot

Next steps

1. Install a module into Fabric C or Install a blank.

2. Connect the cables to the module.

Installing a MX7000 module into Fabric C slot

Prerequisites

1. Follow the safety guidelines listed in Safety instructions.

Steps

1. Align and push the I/O module into the enclosure.

2. Close the release lever to lock the module in place.

44

Installing and removing system components

Page 45

Figure 35. Installing a MX7000 module into Fabric C slot

Next steps

1. Connect the cables to the module.

NOTE:

Ensure that the SAS IOMs have the same firmware version. The OpenManage-Enterprise modular User interface

allows you to view the firmware details. For more information, see

OpenManage Enterprise-Modular User's Guide

Removing a management module blank

Steps

1. Press the release button to release the blank.

2. Pull the blank out of the enclosure.

NOTE: To maintain proper airflow, ensure that the blanks are installed if the management module is not installed.

.

Installing and removing system components 45

Page 46

Figure 36. Removing a management module blank

Next steps

1. Install the management module or Install a blank.

Installing a management module blank

Prerequisites

1. Follow the safety guidelines listed in Safety instructions.

2. Remove the management module.

Steps

1. Align and insert the blank in the empty slot.

2. Insert and push the blank until it locks into place.

Figure 37. Installing a management module blank

46

Installing and removing system components

Page 47

Removing a management module

Prerequisites

1. Follow the safety guidelines listed in Safety instructions.

2. Disconnect the cables that are connected to the modules.

Steps

1. Press the orange release button on the module to open the release lever.

2. Hold the release lever, and pull the management module out of the enclosure.

NOTE: Ensure that you install a IOM blank if you are removing a module permanently.

Figure 38. Removing a management module

Next steps

1. Install the management module or Install a blank.

2. Connect the network cables to the module.

Disabling a forgotten Management Module password

The software security feature of the system includes a Management Module password. The Management Module password jumper

enables or disables Management Module password features and clears any Management Module passwords in use.

Prerequisites

CAUTION:

simple repairs as authorized in your product documentation, or as directed by the online or telephone service and

support team. Damage due to servicing that is not authorized by Dell is not covered by your warranty. Read and follow

the safety instructions that are shipped with your product.

Steps

1. Power off the system, including any attached peripherals, and disconnect the system from the electrical outlet.

2. Remove the Management Module.

3. Move the jumper on the Management Module from pins 2 and 3 to pins 1 and 2.

Many repairs may only be done by a certified service technician. You should only perform troubleshooting and

Installing and removing system components

47

Page 48

Figure 39. Management Module jumper

4. Replace the Management Module.

The existing Management Module passwords are not disabled (erased) until the system boots with the jumper on pins 1 and 2.

However, before you assign a new system and/or setup Management Module password, you must move the jumper back to pins 2

and 3.

NOTE:

If you assign a new system and/or setup Management Module password with the jumper on pins 1 and 2, the

system disables the new Management Module password the next time that it boots.

5. Reconnect the system to its electrical outlet, and turn on the system, including any attached peripherals.

6. Power off the system, including any attached peripherals, and disconnect the system from the electrical outlet.

7. Remove the Management Module.

8. Move the jumper on the Management Module from pins 1 and 2 to pins 2 and 3.

9. Replace the Management Module.

10. Reconnect the system to its electrical outlet, and turn on the system, including any attached peripherals.

11. Assign a new system and/or setup Management Module password.

Installing a management module

Prerequisites

1. Follow the safety guidelines listed in Safety instructions.

Steps

1. Align and push the management module into the enclosure.

2. Close the release lever to lock the module in place.

48

Installing and removing system components

Page 49

Figure 40. Installing a management module

Next steps

1. Reconnect the network cables to the management module.

Support information for GPU

The MX7000 system can support up to 16 T4 GPUs through the vendor module, Amulet Hotkey CoreModule. If you choose to install the

Amulet Hotkey core modules, they could be installed in the Fabric B slots of the MX7000 chassis, however support for the vendor

modules from Amulet Hotkey comes from Amulet Hotkey. The following list shows the email addresses by region for Amulet Hotkey's

technical support:

• eurosupport@amulethotkey.com

• ussupport@amulethotkey.com

• latamsupport@amulethotkey.com

• apsupport@amulethotkey.com

Installing and removing system components

49

Page 50

Technical specifications

The technical and environmental specifications of your system are outlined in this section.

Topics:

• Component guidelines

• Chassis dimensions

• Chassis weight

• Fan specifications

• PSU specifications

• Ports and connectors specifications

• PowerEdge MX modules ports and connectors

• Video specifications

• Environmental specifications

Component guidelines

Population rules

6

System modules must be populated as described in the following table:

Table 11. MX7000 population rules

Category Maximum population

Blanks All the empty slots in the MX7000 enclosure must be populated with blanks (Sled, IOM, EC, and PSU). This is

required for proper cooling of the enclosure and components.

Fans All system fans must be populated in the enclosure.

Power supply

units

Power cable One C21/C20 power cable must be connected to the C22 plug corresponding to each populated PSU.

Management

module

Control panel The right control panel and one of the left control panel configurations (LCD or LED) must be present on the

Compute sled Up to eight single-width or four double-width sleds or a combination can be populated. The double-width sleds must

The number of power supply units that are required is dependent upon system configuration and redundancy mode,

and the minimum recommended quantity is two. The six PSUs are organized into two groups: Grid A consists of

PSUs 1, 2, 3, and Grid B consists of PSUs 4, 5, 6. It is recommended to populate the PSUs in the following order: 1,

4, 2, 5, 3, 6 where an equal number of PSUs on each grid is optimized for Grid Redundancy. PSU redundancy and No

Redundancy options do not have any PSU population requirements.

A Management module must be present to control and manage the enclosure.

NOTE: If a single Management module crashes, the system functions normally.

NOTE: The enclosure cannot be managed or controlled until the Management module is replaced.

MX7000 enclosure.

be in slots 1, 3, 5, 7 due to the enclosures design.

Storage Sled

I/O Module Only Brocade and SAS IOM are supported in Fabric-C.

50 Technical specifications

Up to seven Storage sleds can be populated in the enclosure.

NOTE: One compute node must be present and it must be mapped to a storage node.

One Fabric-C SAS IOM must be present and powered ON.

Page 51

Table 11. MX7000 population rules(continued)

Category Maximum population

Only one type of IOM can be offered in Fabric-C (Fibre Channel or SAS IOM, not mixed).

Only one type of switch can be offered in Fabric-B (HPCC or Ethernet).

Two Fabric-C SAS IOMs must be installed if the enclosure contains a Storage Node.

Mix Speed of pass-through in same fabric is not enabled.

Mezzanine cards If the enclosure contains a storage node, Fabric-C MiniMezzanine card (HBA330 or Jumbo PERC) must be installed

in one compute node.

Dual Port or quad port mezzanine cards must be installed for redundant IOM/Pass-through configurations.

The second processor must be installed on the compute node to support Fabric-B Mezzanine / IOM and Fabric-C

Mezzanine / IOM.

PSU redundancy and population rules

The number of PSUs required depends on the enclosure configuration and redundancy required. The minimum requirement is two PSUs.

The enclosure supports one of the following redundancy modes:

• No redundancy: This mode distributes the enclosure power load across all PSUs. There are no specific PSU population requirements

for No redundancy. The intent of this mode is to have the highest possible limit for power enablement of devices that are added to the

enclosure. If there are single or multiple PSU failures, then the enclosure limits performance to operate within the power capabilities of

the remaining PSUs.

• Grid redundancy: This mode distributes the enclosure power load across all PSUs. The six PSUs are organized into two groups: Grid

A consisting of PSUs 1, 2, 3, and Grid B consists of PSUs 4, 5, 6. For grid redundancy, PSUs should be populated in the following

order: 1, 4, 2, 5, 3, 6. The grid with the largest PSU capacity determines the limit for power enablement of devices that are added to

the enclosure. If there is a grid or PSU failure, then the enclosure power is distributed among the remaining PSUs with the intent that

a single healthy grid continues to provide power to the system without degraded performance.

• PSU redundancy: This mode distributes the enclosure power load across all PSUs. There are no specific PSU population

requirements for PSU redundancy. PSU redundancy is optimized for a population of six PSUs, and the enclosure limits the power

enablement of devices to fit within five PSUs. If there is a single PSU failure, then the enclosure power is distributed among the

remaining PSUs without degraded performance. If there are fewer than six PSUs, then the enclosure limits the power enablement of

devices to fit within all populated PSUs. If there is a single PSU failure, then the enclosure limits performance to operate within the

power capabilities of the remaining PSUs.

Table 12. PSU population rules

PSU count Population order

2 1, 4 (Optimized for Grid Redundancy 1+1, and Hot Spare)

3 1, 4, 2

4 1, 4, 2, 5 (Optimized for Grid Redundancy 2+2, and Hot Spare)

5 1, 4, 2, 5, 3

6 1, 4, 2, 5, 3, 6 (Optimized for Grid Redundancy 3+3, PSU

Redundancy 5+1, and Hot Spare)

Hot Spare:

PSU and one PSU in sleep mode while the enclosure power consumption is low, and the three PSU pairs meet all the power requirements

for the enclosure. This enables efficient power utilization when the overall enclosure power requirement is low. The partner PSU wakes

the paired PSU from sleep mode by sending a WAKE signal when the enclosure power requirement increases. The PSU pairs for MX7000

are—1 & 4, 2 & 5, and 3 & 6.

The MX7000 PSUs support the Hot Spare feature with three PSU pairs. This feature enables a PSU pair to have one active

Technical specifications

51

Page 52

Chassis dimensions

Figure 41. Dimensions of the PowerEdge MX7000

Table 13. Dimensions of the PowerEdge MX7000

Description Dimension

Xa 482 mm (18.98 inches)

Xb 445 mm (17.52 inches)

Y 307.4 mm (12.11 inches)

Zb 816.6 mm (32.15 inches)

Zc 811.6 mm (31.96 inches)

Chassis weight

Table 14. Chassis weight

Enclosure Minimum weight Maximum weight (fully populated)

PowerEdge MX7000 82 kg (180 lbs) 182 kg (400 lbs)

52 Technical specifications

Page 53

Fan specifications

The PowerEdge MX7000 enclosure supports four front accessible hot-swap cooling fans and five rear accessible hot-swap cooling fans.

The cooling fan assembly ensures that the key components of the server such as the sleds, Fabrics, and I/O modules get adequate air

circulation to keep them cool. A cooling fan failure can result in overheating and may lead to damage.

Table 15. Supported fans

Fan location Front Rear

Size 60 mm 80 mm

Number of fans 4 5