Page 1

53-1002576-02

53-1002576-02

December 2012

Brocade M6505 16 Gbps

Fibre Channel SAN I/O Module

Hardware Reference Manual

®

Page 2

Copyright © 2012 Brocade Communications Systems, Inc. All Rights Reserved.

Brocade, Brocade Assurance, the B-wing symbol, BigIron, DCX, Fabric OS, FastIron, MLX, NetIron, SAN Health, ServerIron,

urboIron, VCS, and VDX are registered trademarks, and AnyIO, Brocade One, CloudPlex, Effortless Networking, ICX, NET Health,

T

OpenScript, and The Effortless Network are trademarks of Brocade Communications Systems, Inc., in the United States and/or in

other countries. Other brands, products, or service names mentioned may be trademarks of their respective owners.

Notice: This document is for informational purposes only and does not set f

any equipment, equipment feature, or service offered or to be offered by Brocade. Brocade reserves the right to make changes to

this document at any time, without notice, and assumes no responsibility for its use. This informational document describes

features that may not be currently available. Contact a Brocade sales office for information on feature and product availability.

Export of technical data contained in this document may require an export license from the United States government.

The authors and Brocade Communications Systems, Inc. shall have no liability or responsibility to any person or entity with

ct to any loss, cost, liability, or damages arising from the information contained in this book or the computer programs that

respe

accompany it.

The product described by this document may co

open source license agreements. To find out which open source software is included in Brocade products, view the licensing

terms applicable to the open source software, and obtain a copy of the programming source code, please visit

http://www.brocade.com/support/oscd.

ntain “open source” software covered by the GNU General Public License or other

orth any warranty, expressed or implied, concerning

Brocade Communications Systems, Incorporated

Corporate and Latin American Headquarters

Brocade Communications Systems, Inc.

130 Holger Way

San Jose, CA 95134

Tel: 1-408-333-8000

Fax: 1-408-333-8101

E-mail: info@brocade.com

European Headquarters

Brocade Communications Switzerland Sàrl

Centre Swissair

Tour B - 4ème étage

29, Route de l'Aéroport

Case Postale 105

CH-1215 Genève 15

Switzerland

Tel: +41 22 799 5640

Fax: +41 22 799 5641

E-mail: emea-info@brocade.com

Asia-Pacific Headquarters

Brocade Communications Systems China HK, Ltd.

No. 1 Guanghua Road

Chao Yang District

Units 2718 and 2818

Beijing 100020, China

Tel: +8610 6588 8888

Fax: +8610 6588 9999

E-mail: china-info@brocade.com

Asia-Pacific Headquarters

Brocade Communications Systems Co., Ltd. (Shenzhen WFOE)

Citic Plaza

No. 233 Tian He Road North

Unit 1308 – 13th Floor

Guangzhou, China

Tel: +8620 3891 2000

Fax: +8620 3891 2111

E-mail: china-info@brocade.com

Document History

Title Publication number Summary of changes Date

Brocade M6505 16 Gbps Fibre Channel

SAN I/O Module Hardware Reference

Manual

Brocade M6505 16 Gbps Fibre Channel

SAN I/O Module Hardware Reference

Manual

53-1002576-01 New document December 2012

53-1002576-02 Update Data Transmission

Ranges table

December 2012

Page 3

Contents

About This Document

In this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

How this document is organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Document conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Text formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Command syntax conventions . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Notes, cautions, and warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Key terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Notice to the reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Additional information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Brocade resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Other industry resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Product support documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Getting technical help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Document feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Chapter 1 Brocade M6505 Product Overview

In this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAN I/O Module overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Operating system support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Hardware features and functionality . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Software features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Optional features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Ports on Demand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ISL trunking groups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Access Gateway and Native Fabric modes . . . . . . . . . . . . . . . . . . . . . 5

Access Gateway mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Native Fabric mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Optional Brocade licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SAN I/O Module front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SAN I/O Module side view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SFP+ transceivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual iii

53-1002576-02

Page 4

Chapter 2 Installing the SAN I/O Module

Unpacking the SAN I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Items included with the SAN I/O Module . . . . . . . . . . . . . . . . . . . . . 11

System reliability guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Handling static-sensitive devices. . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Preparing the Blade Server Enclosure for the SAN I/O Module. . . .12

Inserting the SAN I/O Module in the Blade Server Enclosure . . . . .13

Handling SFP+ transceivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Inserting an SFP+ transceiver in the SAN I/O Module port . . . . . . . 15

Cabling guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Data transmission ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 3 Configuring the SAN I/O Module

In this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Items required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Modifying the SAN I/O Module IP address . . . . . . . . . . . . . . . . . . . .20

Using the CMC GUI to set the IP address. . . . . . . . . . . . . . . . . .20

Using the CMC CLI to set the IP address . . . . . . . . . . . . . . . . . .21

Using the SAN I/O Module CLI to set the IP address. . . . . . . . .22

Connecting the SAN I/O Module to the Ethernet network . . . . . . . . 24

Connecting to the SAN I/O Module using Web Tools . . . . . . . . . . . . 24

Connecting the SAN I/O Module to the fabric. . . . . . . . . . . . . . . . . . 24

Chapter 4 Operating the SAN I/O Module

In this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Interoperability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Activating Ports on Demand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Activating ports with a POD license . . . . . . . . . . . . . . . . . . . . . .30

Changing from Access Gateway mode to Native Fabric mode. . . . . 31

Disabling Access Gateway mode . . . . . . . . . . . . . . . . . . . . . . . .32

Changing from Native Fabric mode to Access Gateway mode. . . . .33

Access Gateway mode default port mapping . . . . . . . . . . . . . . . . . . 33

Accessing the SAN I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Interpreting POST results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Interpreting SAN I/O Module LED activity . . . . . . . . . . . . . . . . . . . . .35

Power-on self-test LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Normal-operation LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Removing and replacing SAN I/O Modules . . . . . . . . . . . . . . . . . . . .37

Removing and replacing SFP+ transceivers and cables . . . . . . . . .39

iv Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 5

Switch management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Viewing the configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Upgrading or downgrading firmware . . . . . . . . . . . . . . . . . . . . . . . . . 41

Changing the default account password. . . . . . . . . . . . . . . . . . . . . . 41

Changing the default account password at login . . . . . . . . . . .42

Backing up the configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Locating the serial number information . . . . . . . . . . . . . . . . . . . . . .43

Appendix A SAN I/O Module Specifications

In this appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Processor and memory specifications. . . . . . . . . . . . . . . . . . . . . . . .45

Weight and physical dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Architectural specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Supported HBAs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Fibre Channel standards compliance . . . . . . . . . . . . . . . . . . . . . . . . 47

Regulatory compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

FCC warning (US only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

BSMI statement (Taiwan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

KC statement (Republic of Korea) . . . . . . . . . . . . . . . . . . . . . . . 48

VCCI statement (Japan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

CE statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Canadian requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Laser compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

RTC battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Regulatory compliance standards . . . . . . . . . . . . . . . . . . . . . . .49

Environmental regulation compliance. . . . . . . . . . . . . . . . . . . . . . . .50

Environmental Protection Use Period (EPUP) Disclaimer . . . . . 50

China RoHS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Index

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual v

53-1002576-02

Page 6

vi Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 7

About This Document

In this chapter

•How this document is organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

•Document conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

•Notice to the reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

•Additional information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

•Getting technical help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

•Document feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

How this document is organized

This document is organized to help you find information that you want as quickly and easily as

possible. The document contains the following components:

• Chapter 1, “Brocade M6505 Product Overview,”describes the Brocade M6505 16 Gbps Fibre

Channel SAN I/O Module and explains its basic concepts and features. This chapter also

provides instructions for unpacking the SAN I/O Module from its shipping container, references

to the appropriate publication for installing the SAN I/O Module into the Dell M1000e Blade

Server Enclosure, and Fibre Channel port cabling guidelines.

• Chapter 2, “Installing the SAN I/O Module,” describes the procedures needed to unpack and

install the Brocade M6505 16 Gbps Fibre Channel SAN I/O Module for the Dell M1000e Blade

Server Enclosure.

• Chapter 3, “Configuring the SAN I/O Module,” describes how to change the IP address of the

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module, connect the module to the Ethernet

network and fabric, and connect to the Brocade M6505 16 Gbps Fibre Channel SAN I/O

Module using Web Tools.

• Chapter 4, “Operating the SAN I/O Module,” is a reference for understanding the power-on

diagnostics and LEDs supporting the Brocade M6505 16 Gbps Fibre Channel SAN I/O Module.

Also provided are details for operating and replacing the Brocade M6505 16 Gbps Fibre

Channel SAN I/O Module, removing and replacing SFP+ transceivers and cables, changing

between Access Gateway mode and Native Fabric mode, activating Ports on Demand (POD),

backing up the system, maintaining firmware, changing passwords, locating serial number

information, and viewing configurations.

• Appendix A, “SAN I/O Module Specifications,” provides product specifications and regulatory

compliance information.

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual vii

53-1002576-02

Page 8

Document conventions

This section describes text formatting conventions and important notice formats used in this

document.

Text formatting

The narrative-text formatting conventions that are used are as follows:

bold text Identifies command names

italic text Provides emphasis

code text Identifies CLI output

For readability, command names in the narrative portions of this guide are presented in mixed

lettercase: for example, switchShow. In actual examples, command lettercase is all lowercase.

Identifies the names of user-manipulated GUI elements

Identifies keywords and operands

Identifies text to enter at the GUI or CLI

Identifies variables

Identifies paths and Internet addresses

Identifies document titles

Identifies command syntax examples

Command syntax conventions

Command syntax in this manual follows these conventions:

command Commands are printed in bold.

--option, option Command options are printed in bold.

-argument, arg Arguments.

[ ] Optional elements appear in brackets.

variable Variables are printed in italics. In the help pages, values are underlined

enclosed in angled brackets < >.

...

value Fixed values following arguments are printed in plain font. For example,

| Boolean. Elements are exclusive. Example:

Repeat the previous element, for example “member[;member...]”

--show WWN

--show -mode egress | ingress

or

viii Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 9

Notes, cautions, and warnings

NOTE

ATTENTION

CAUTION

DANGER

The following notices and statements are used in this manual. They are listed below in order of

increasing severity of potential hazards.

A note provides a tip, guidance, or advice, emphasizes important information, or provides a

reference to related information.

An Attention statement indicates potential damage to hardware or data.

A Caution statement alerts you to situations that can be potentially hazardous to you or cause

damage to hardware, firmware, software, or data.

A Danger statement indicates conditions or situations that can be potentially lethal or extremely

hazardous to you. Safety labels are also attached directly to products to warn of these conditions

or situations.

Key terms

For definitions specific to Brocade and Fibre Channel, see the technical glossaries on MyBrocade.

See

“Brocade resources” on page x for instructions on accessing MyBrocade.

For definitions of SAN-specific terms, visit the Storage Networking Industry Association online

dictionary at:

http://www.snia.org/education/dictionary

Notice to the reader

This document may contain references to the trademarks of the following corporations. These

trademarks are the properties of their respective companies and corporations.

These references are made for informational purposes only.

Corporation Referenced trademarks and products

Cisco Systems Cisco

Dell, Inc. PowerEdge

Microsoft Corporation Windows, Windows 2003, Windows 2008, Windows XP

Red Hat Inc. Red Hat Enterprise Linux (RHEL)

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual ix

53-1002576-02

Page 10

Corporation Referenced trademarks and products

The Open Group UNIX

VMware SUSE Linux Enterprise Server (SLES)

XenServer XEN 6.0

Additional information

This section lists additional Brocade and industry-specific documentation that you might find

helpful.

Brocade resources

To get up-to-the-minute information, go to http://my.brocade.com to register at no cost for a user ID

and password.

White papers, online demonstrations, and data sheets are available through the Brocade web site

at:

http://www.brocade.com/products-solutions/products/index.page

For additional Brocade documentation, visit the Brocade web site:

http://www.brocade.com

Release notes are available on the Brocade Connect Web site and are also bundled with the

Fabric

OS firmware.

Other industry resources

For additional resource information, visit the Technical Committee T11 web site. This web site

provides interface standards for high-performance and mass storage applications for Fibre

Channel, storage management, as well as other applications:

http://www.t11.org

For information about the Fibre Channel industry, visit the Fibre Channel Industry Association web

site:

http://www.fibrechannel.org

Product support documents

The following documentation is available from Dell.

• Dell PowerEdge M1000e Enclosure Owner’s Manual

• Dell Chassis Management Controller Firmware Version 4.x User Guide

The following support documentation is provided on the Brocade web site.

• Fabric OS Administrator’s Guide

• Fabric OS Command Reference

x Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 11

• Fabric OS MIB Reference

NOTE

• Fabric OS Message Reference

• Access Gateway Administrator’s Guide

• SAN TECH NOTE - Preparing to Install the Brocade Access Gateway

• Web Tools Administrator’s Guide

• Fabric Watch Administrator’s Guide

• Brocade M6505 16 Gbps Fibre Channel SAN I/O Module QuickStart Guide

• Release notes for the Fabric OS version running on the SAN I/O Module

• Release notes specific to the SAN I/O Module

Refer to the latest documentation version for the most up-to-date product information.

Getting technical help

Contact your switch support supplier for hardware, firmware, and software support, including

product repairs and part ordering. To expedite your call, have the following information available:

1. General Information

• Dell service tag (listed by the CMC)

• Switch model

• Switch operating system version

• Software name and software version, if applicable

• Error numbers and messages received

• supportSave command output

• Detailed description of the problem, including the switch or fabric behavior immediately

following the problem, and specific questions

• Description of any troubleshooting steps already performed and the results

• Serial console and Telnet session logs

• Syslog message logs

2. Switch serial number

The switch serial number and corresponding bar code are provided on the serial number label,

for example:

FT00X0054E9

FT00X0054E9

3. World Wide Name (WWN).

Use the wwn or switchShow commands to display the WWN.

4. Software licenses. Use the licenseIdShow command to display the list of licenses and

corresponding license IDs available on the unit.

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual xi

53-1002576-02

Page 12

Document feedback

Quality is our first concern at Brocade and we have made every effort to ensure the accuracy and

completeness of this document. However, if you find an error or an omission, or you think that a

topic needs further development, we want to hear from you. Forward your feedback to:

documentation@brocade.com

Provide the title and version number of the document, and as much detail as possible about your

comment, including the topic heading and page number and your suggestions for improvement.

xii Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 13

Chapter

NOTE

Brocade M6505 Product Overview

In this chapter

•SAN I/O Module overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

•Operating system support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

•Hardware features and functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

•Software features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

•Ports on Demand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

•ISL trunking groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

•Access Gateway and Native Fabric modes . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

•Optional Brocade licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

•Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

•SFP+ transceivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1

SAN I/O Module overview

The Brocade M6505 16 Gbps Fibre Channel SAN I/O Module is a nonblocking, embedded switch

with up to 8 external-facing Fibre Channel ports and up to 16 internal-facing Fibre Channel ports

that is custom built for the Dell PowerEdge M1000e Blade Server Enclosure. Although the product

may ship with a specific number of ports enabled, it can be upgraded to 24

on Demand (POD) license.

The Brocade M6505 16 Gbps Fibre Channel SAN I/O Module is also referred to as the SAN I/O

Module throughout this document.

The eight external ports of the Brocade M6505 16 Gbps Fibre Channel SAN I/O Module support

hot-pluggable Small Form Factor Pluggable plus (SFP+) optical transceivers. Only Brocade-branded

optical transceivers are supported.

Each external port is independently capable of supporting speeds of 16, 8, and 4 Gbps using

auto-sensing. Internal ports support speeds of 16 and 8 Gbps. The switch module operates in

either Brocade Access Gateway (AG) or Native Fabric (full-fabric switch) mode. The default mode is

AG, which utilizes NPIV for direct connectivity to Brocade, Cisco and/or McData SANs.

ports through a Ports

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual 1

53-1002576-02

Page 14

Operating system support

1

Operating system support

Brocade Fabric OS has no specific host operating system (OS) dependencies. The Fabric OS in the

switches allows for any Fibre Channel-compliant device to attach to switches as long as it conforms

to the standards for device login, name service, and related Fibre Channel features.

The operating systems listed in Table 1 are for the host machine running Brocade management

applications outside the Fabric OS, such as Brocade Network Advisor (BNA). For the latest

information on operating system support for these applications, refer to the latest released

versions of BNA documentation.

TABLE 1 Supported operating systems for management server

Operating system Description

Microsoft • Windows 2003 SP1, 64-bit (Standard, Enterprise and Web)

Linux

VMWare VMWare ESX 4.0 (U2)

XenServer XEN 6.0

• Windows 2008 64-bit (Standard, Enterprise and Web)

• Windows Server 2008 Hyper-V R2

• Red Hat Enterprise Linux (EL) 5.5 32/64-bit (Standard and Advanced platform)

• SUSE Linux ES 11 (SP1 32/64-bit)

Hardware features and functionality

The SAN I/O Module ships in Access Gateway mode. It provides support for the following hardware

features and functionality:

• Twelve to 24 auto-negotiating Fibre Channel (FC) ports

• Diagnostic ports

• Up to eight small form-factor pluggable plus (SFP+) optical transceivers supporting speeds of

16

Gbps, 8 Gbps and 4 Gbps

• System LEDs noting system power, switch status, and management health status

• One RJ-45 connector for serial console management

• Hot pluggable—Up to 4 hot-pluggable SAN I/O Modules per Dell M1000e Blade Server

Enclosure chassis

• Runtime elements that include health monitoring, uptime, memory information, CPU usage,

user information, power, and licenses

• Two internal 100 Mbps full-duplex Ethernet ports to connect to the redundant Dell M1000e

Chassis Management Controllers (CMCs)

• One serial console port on the front panel.

2 Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 15

Software features

The Brocade M6505 16 Gbps Fibre Channel SAN I/O Module supports the following software

features. For updates to the supported feature set, refer to the Brocade Fabric OS Administrator’s

Guide and product release notes for additional information.

• Access Gateway (AG) mode and Native Fabric mode. (Refer to “Access Gateway and Native

Fabric modes” on page 5.)

The SAN I/O Module ships in Access Gateway mode, but it can support the standard Native

Fabric (Switch) mode. For detailed information about AG, refer to the Brocade Access Gateway

Administrator’s Guide.

• Brocade Fabric OS (FOS), which delivers distributed intelligence throughout the network and

enables a wide range of value-added applications, such as Brocade Advanced Web Tools and

Brocade Advanced Fabric Services (on certain models)

• Dynamic Ports on Demand (DPOD) offering the flexibility to scale from 12 ports on the

Base

• Inter-Switch Link (ISL) Trunking (licensable), which allows up to eight ports (at 16, 8, or 4 Gbps

speeds) to combine to form a single, logical ISL with a speed of up to 128 Gbps (each

direction, full duplex) for optimal bandwidth utilization, automatic path failover, and load

balancing.

• Enhanced Group Management, which enables the SAN I/O Module to be managed as a group

• Detection and resolution of duplicate WWNs

• Dell DMC, iDRAC, and CMC management

• Dual and redundant firmware images

• Service levels Class 2, Class 3, and Class F (inter-switch frames)

• Role-Based Access Control (RBAC) for managing user-permission levels

• Advanced zoning, which enables you to partition your storage area network (SAN) into logical

groups of devices that can access each other

• Zoning enhancements that allow a switch with the default zone “no access” to merge with a

fabric

• Buffer credit loss detection and automatic recovery on 16 Gbps ISLs

• Importing and exporting of configuration information, including port speeds and zoning

information

• Port mirroring to monitor ingress or egress traffic from any port within the switch

• SNMP v1, v2c, and v3. (SNMP traps log errors and alarms; logs can be exported)

• TACACS+ and RADIUS remote authentication for switch management access

• IPv4 support

• AG enhancements, such as detection of unreliable N_Port links, RADIUS and LDAP support,

Advanced Performance Monitoring (APM) capability, and F_Port static mapping

• Forward error correction (FEC), which provides method error control during data transmission

by sending redundant data to ensure error-free transmission on a specified port or port range

(enabled by default)

• IP address filtering for management access by way of Telnet, HTTP, HTTPS/SSL, SSH v2, and

SNMP

model up to 24 ports

Software features

1

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual 3

53-1002576-02

Page 16

Ports on Demand

NOTE

1

• SNMP/MIB monitoring functionality contained within the Ethernet Control MIB-II

(RFC1213-MIB)

• NTP client support (NTP V3)

• FTP support for firmware upgrades

• End-to-end optics and link validation

• Registered State Change Notification (RSCN), which notifies a device of a change within the

fabric

• Switch banner support

• Syslog remote logging capabilities

• RASlogs to indicate invalid traffic isolation zones

• Four RMON groups: history, statistics, alarms, and events

Optional features

The following optional features are available, depending on whether the SAN I/O Module is

configured in Access Gateway mode or Native Fabric mode. For detailed information on any of

these features, refer to the Brocade Fabric OS Administrator’s Guide. You can also refer to

“Optional Brocade licenses” on page 6 for additional information.

• Ports on Demand (POD) licensing

• Inter-Switch Link (ISL) Trunking

• Fabric Watch

• Advanced Performance Monitoring

• Adaptive Networking

Ports on Demand

Depending on the model, the SAN I/O Module ships with either 12 or 24 active ports.

With Dynamic Ports on Demand (DPOD), physical ports are licensed as they come online. In the

Base model port set, the first 12 ports reporting (on a first-come, first-served basis) on boot-up are

assigned licenses. In the Full and ENT model port sets, the first 24 ports reporting (on a first-come,

first-served basis) on boot-up are assigned licenses. These ports may be any combination of

external or internal Fibre Channel (FC) ports. After all licenses have been assigned, you can

manually move those licenses from one port to another.

Ports 17 and 18 are prereserved for external/SAN connectivity.

• Base model—Ships with 12 active ports. You can allocate an optional POD license to activate

the additional 12 ports.

• Full model—Ships with 24 active ports. No additional POD license is needed.

• ENT (Enterprise) model—Ships with 24 active ports. No additional POD license is needed.

4 Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 17

ISL trunking groups

NOTE

NOTE

If your SAN I/O Module has an optional Brocade ISL Trunking license, external ports can form

trunking groups of ISLs between adjacent switches. ISL Trunking optimizes the performance and

availability of SAN fabrics while simplifying ISL management.

All external ports (0, 17 through 23) can be formed into a single 8-port trunk, or any combination of

2- to 7-port trunk. For details about Brocade ISL Trunking, refer to the Fabric OS Administrator’s

Guide.

Only the external ports are available for trunking.

Access Gateway and Native Fabric modes

The SAN I/O Module can function in either Native Fabric mode or Brocade Access Gateway mode.

The SAN I/O Module is shipped in Access Gateway (AG) mode by default.

Access Gateway simplifies SAN deployment by using NPIV (N_Port ID Virtualization) technology.

AG

mode improves SAN I/O Module scalability, manageability, and interoperability. For more

information on Access Gateway, refer to the Brocade Access Gateway Administrator’s Guide.

ISL trunking groups

1

Access Gateway cannot be connected directly into a storage array unless one of the external ports

is connected to a SAN network.

Access Gateway mode

The SAN I/O Module provides support for the following when operating in AG mode:

• Up to 8 auto-sensing (4, 8, and 16 Gbps) Fibre Channel ports. These are universal and

self-configuring ports that are capable of becoming the following types:

- F_Port (fabric-enabled)

- N_Port (NPIV-enabled)

• Up to 16 internal backplane F_Ports. Each port can automatically negotiate its speed at either

16 Gbps or 8 Gbps to match the speed of attached devices

• Dynamic fabric provisioning that supports fabric-assigned WWNs

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual 5

53-1002576-02

Page 18

Optional Brocade licenses

1

Native Fabric mode

Native Fabric mode can be accessed by disabling the default AG mode. Once the SAN I/O Module is

in Native Fabric mode, it provides support for the following:

• Up to 8 external auto-sensing and auto-negotiating (4, 8, or 16 Gbps) Fibre Channel ports.

These universal and self-configuring ports are capable of becoming one of the following port

types:

- E_Port (expansion port)

- F_Port (fabric-enabled)

- U_Port (self-discovery based on switch type)

These external ports are capable of ISL trunking with appropriate licensing.

• Frame filtering that augments the hardware zoning capabilities of the Brocade ASIC, which

implements hardware zoning at the port level of the SAN I/O Module.

• Brocade ASIC expanded capabilities, including World Wide Name (WWN) and device-level

zoning.

• Hardware zoning implemented by firmware-accessible table per output port.

• Zoning enhancements that allow a switch with the default zone “no access” to merge with a

fabric.

• Buffer credit loss detection and automatic recovery on ISLs.

Optional Brocade licenses

Tab le 2 lists optional licenses that are available for use on the Brocade M6505 16 Gbps Fibre

Channel SAN I/O Module.

TABLE 2 Optional supported features

License Description

Adaptive Networking A suite of tools and capabilities that optimize behavior in the SAN. Even

Advanced Performance Monitoring Enables more effective end-to-end SAN performance analysis to enhance

Fabric Watch Continuously monitors SAN fabrics for potential faults based on thresholds

ISL Trunking Optimizes the performance and availability of SAN fabrics while simplifying

Ports on Demand Allows you to obtain additional ports by way of license key upgrade.

under the worst congestion conditions, Adaptive Networking features can

maximize the fabric behavior and provide necessary bandwidth for

high-priority, mission-critical applications and connections.

performance tuning, increase productivity, optimize resource utilization,

and reduce costs.

set for a variety of SAN fabric elements and events, automatically alerting

administrators to potential problems before they become costly failures.

ISL management.

6 Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 19

Hardware description

This section describes the Brocade M6505 16 Gbps Fibre Channel SAN I/O Module as shipped

from the factory. For specifications, such as installed memory, weight and physical dimensions,

facility requirements, and architectural specifications, refer to

Specifications”.

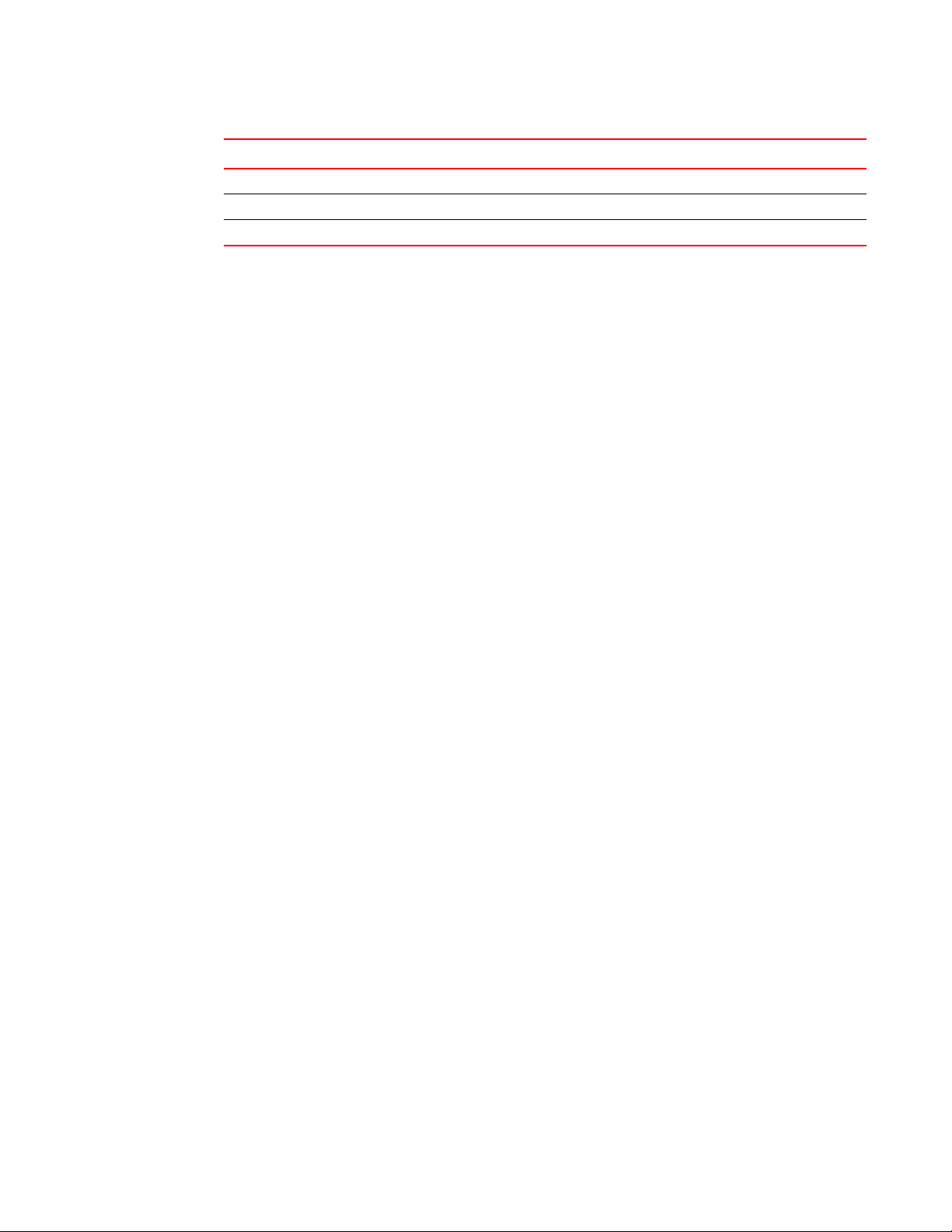

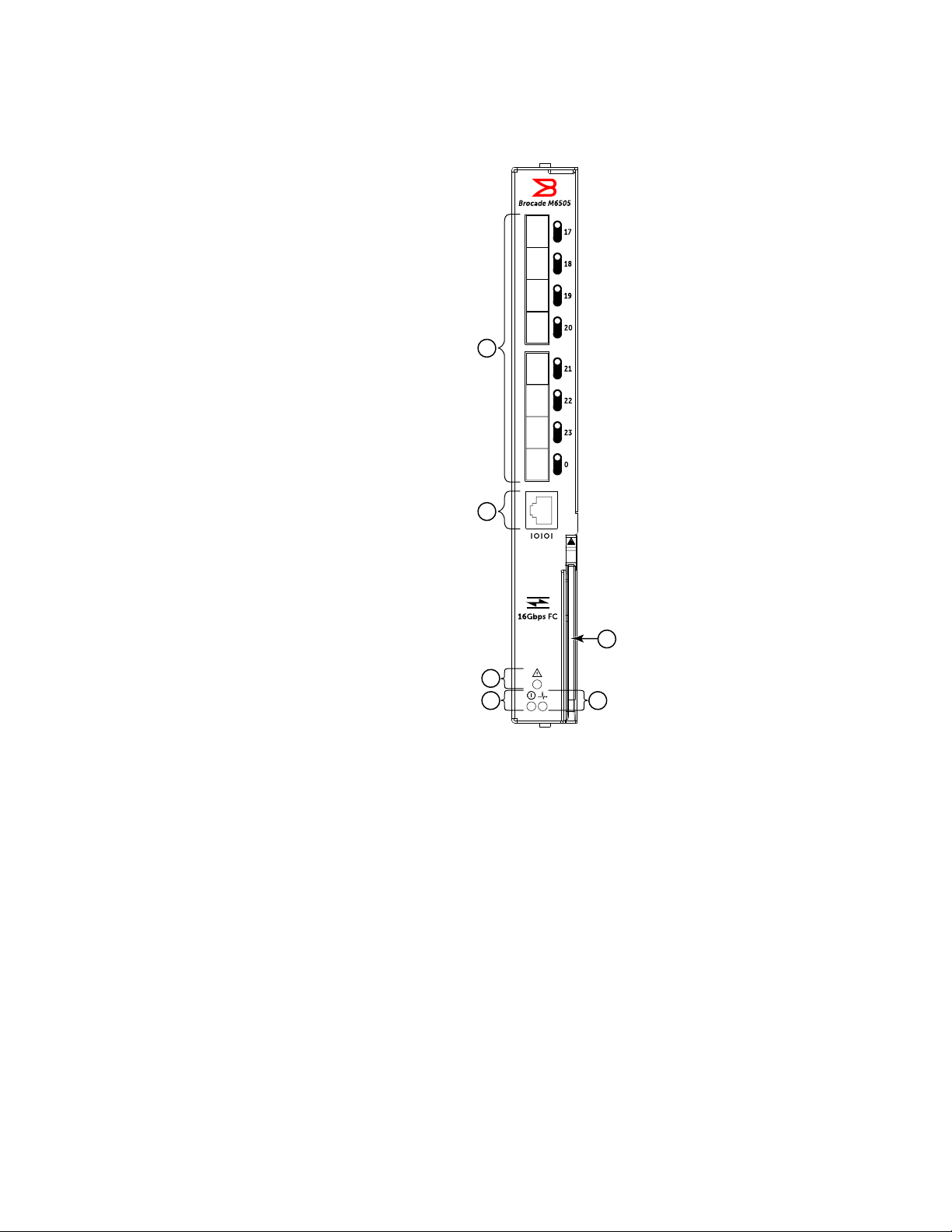

SAN I/O Module front panel

All external ports and LEDs are accessible from the front panel of the Brocade M6505 16 Gbps

Fibre Channel SAN I/O Module. The front panel faces out when the SAN I/O Module is inserted in

the I/O

module bays B or C of the Dell M1000e Blade Server Enclosure. Each external port has a

dedicated LED that identifies port status and port diagnostics. For a complete description of the

locations and interpretations of the LEDs, refer to

page 35.

Figure 1 shows details of the front panel and includes the release lever. Pressing the release latch

to open the release lever enables you to insert and remove the SAN I/O Module in and out of the

Dell M1000e Blade Server Enclosure.

Hardware description

Appendix A, “SAN I/O Module

“Interpreting SAN I/O Module LED activity” on

1

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual 7

53-1002576-02

Page 20

Hardware description

4

5

3

2

1

6

1

1 Ports with port status LEDs 4 Power status LED

2 RJ-45 console port 5 Server management status/indicator LED

3 SAN I/O Module status LED 6 SAN I/O Module release lever

FIGURE 1 Brocade M6505 16 Gbps Fibre Channel SAN I/O Module front panel

For more information on SAN I/O Module front panel LEDs, refer to “Interpreting SAN I/O Module

LED activity” on page 35.

8 Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 21

Hardware description

1

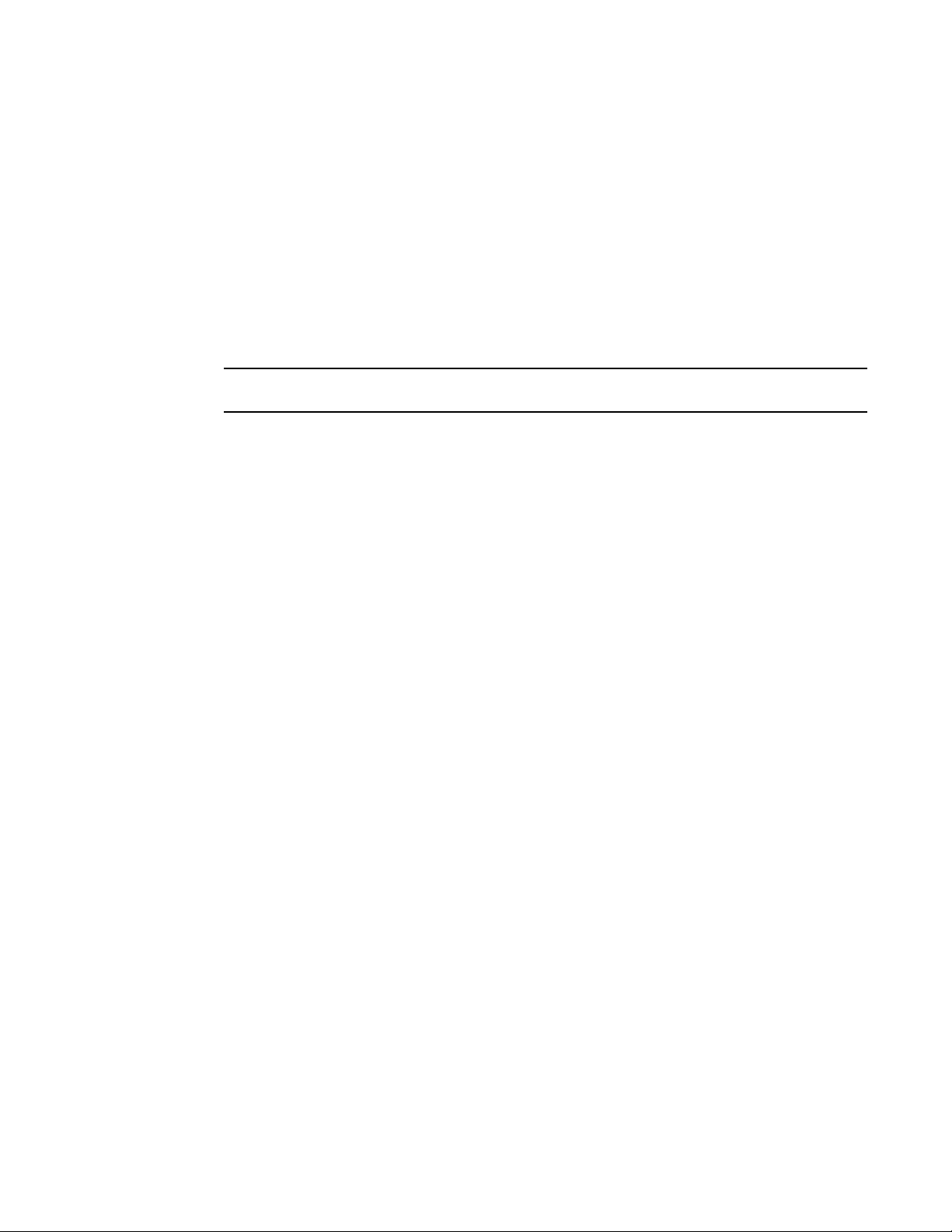

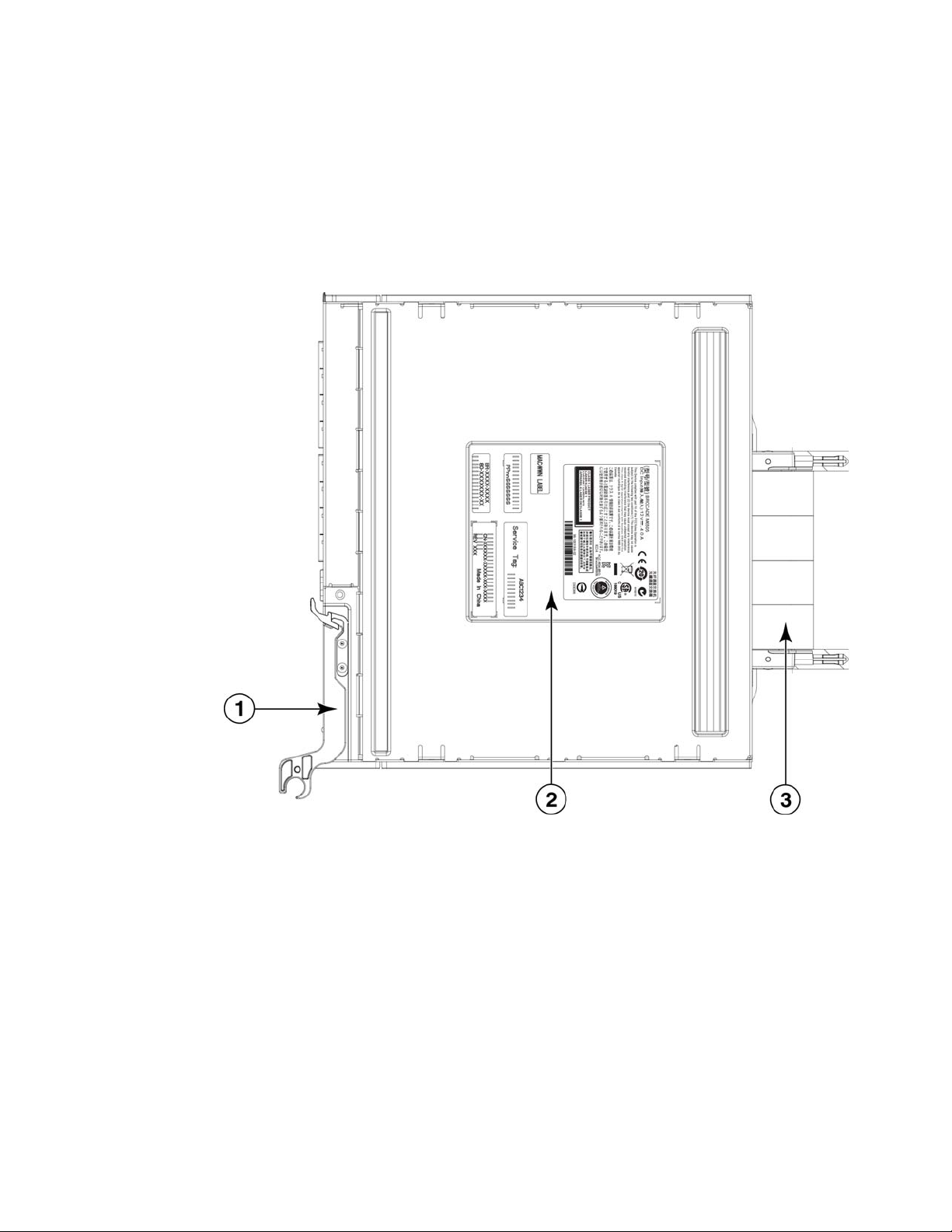

SAN I/O Module side view

The SAN I/O Module connects to the I/O module bay of the Dell M1000e Blade Server Enclosure by

way of the backplane connectors. (Refer to

the release lever is closed securely.

Once the SAN I/O Module is securely seated, the backplane connectors become active, allowing

the SAN I/O Module to be configured in the Dell M1000e Blade Server Enclosure.

Figures 2.) The SAN I/O Module seats correctly when

1Release lever

2 Product labels

3 Backplane connectors

FIGURE 2 SAN I/O Module side view

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual 9

53-1002576-02

Page 22

SFP+ transceivers

NOTE

1

SFP+ transceivers

The SAN I/O Module is designed to work exclusively with Brocade-branded small form-factor

pluggable plus (SFP+) optical transceivers. The SFP+ transceivers are hot-swappable, thus allowing

for connection to external devices without removing the SAN I/O Module from the Dell M1000e

Blade Server Enclosure.

For information on inserting or removing SFP+ transceivers, refer to “Removing and replacing SAN

I/O Modules” on page 37.

SFP+ transceivers provide optical connections to external devices for both short wavelength (SWL)

and long wavelength (LWL) connections. You can replace SFP+ transceivers with a new pluggable

SFP+ transceiver rather than replacing the SAN I/O Module.

The SAN I/O Module is shipped with 16 Gbps Brocade-branded transceivers.

• Base model—Ships with two pre-installed SFP+ transceivers. Six additional SFP+ transceivers

can be installed.

• Full model—Ships with four pre-installed SFP+ transceivers. Four additional SFP+ transceivers

can be installed.

• ENT model—Ships fully loaded with eight pre-installed SFP+ transceivers.

You can also insert pre-qualified 8 Gbps SFP+ transceivers in the SAN I/O Module.

For a list of supported SFP+ transceivers on the SAN I/O Module, refer to Table 3 on page 15.

For a complete list of Brocade-branded SFP+ transceivers and other interoperable hardware, visit

the MyBrocade website at:

http://my.brocade.com

To register at MyBrocade, go to http://my.brocade.com/wps/portal/registration.

From the main page at my.brocade.com, select the Product Portfolio tab, then select Small

Form-Factor Pluggables (SFP) from the Filter by list box. Click Brocade Optical Transceiver Modules.

10 Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 23

Chapter

Installing the SAN I/O Module

In this chapter

•Unpacking the SAN I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

•Items included with the SAN I/O Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

•System reliability guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

•Handling static-sensitive devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

•Preparing the Blade Server Enclosure for the SAN I/O Module. . . . . . . . . . 12

•Inserting the SAN I/O Module in the Blade Server Enclosure . . . . . . . . . . . 13

•Handling SFP+ transceivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

•Inserting an SFP+ transceiver in the SAN I/O Module port . . . . . . . . . . . . . 15

•Cabling guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

•Data transmission ranges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2

Unpacking the SAN I/O Module

Perform the following steps to remove the Brocade Product Name from its shipping package:

1. Open the shipping box and inspect the contents for damage.

2. Remove the foam layer that sits on top of the SAN I/O Module.

3. Remove the switch from the surrounding protective foam.

4. After ensuring that standard electrostatic discharge (ESD) precautions have been taken, slide

the SAN I/O Module from the antistatic sleeve.

Items included with the SAN I/O Module

• SFP+ transceivers: Each SAN I/O Module includes pre-installed SFP+ transceivers. The

number of pre-installed SFP+ transceivers varies based on the SAN I/O Module. The

transceivers can be activated directly out of the box.

- Base model: Two 16 Gbps SFP+ transceivers

- Full model: Four 16 Gbps SFP+ transceivers

- ENT (Enterprise) model: Eight 16 Gbps SFP+ transceivers

• Brocade M6505 16 Gbps Fibre Channel SAN I/O Module QuickStart Guide

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual 11

53-1002576-02

Page 24

System reliability guidelines

ATTENTION

2

System reliability guidelines

To help ensure proper cooling, performance, and system reliability, make sure the following

requirements are met:

• Each of the I/O module bays at the rear of the Dell M1000e Blade Server Enclosure contains

either a SAN I/O Module or a filler panel.

• A removed hot-swappable SAN I/O Module is replaced with an identical SAN I/O Module or

filler panel within 60

seconds of removal.

• You have followed the reliability guidelines in the documentation that comes with the Dell

M1000e Blade Server Enclosure.

Handling static-sensitive devices

Static electricity can damage the Dell M1000e Blade Server Enclosure and other electronic devices.

To avoid damage, keep static-sensitive devices in their static-protective packages until you are ready

to install them.

To reduce the possibility of electrostatic discharge, observe the following precautions:

• Limit your movement. Movement can cause static electricity to build up around you.

• Handle the device carefully, holding it by its edges or its frame.

• Do not touch solder joints, pins, or exposed printed circuitry.

• Do not leave the device where others can handle and damage it.

• While the device is still in its static-protective package, touch it to an unpainted metal surface

of the Dell M1000e Blade Server Enclosure or an unpainted metal surface on any other

grounded rack component in the rack in which you are installing the device for at least two

seconds. This drains static electricity from the package and from your body.

• Remove the device from its package and install it directly into the Dell M1000e Blade Server

Enclosure without setting down the device. If it is necessary to set down the device, put it back

into its static-protective package. Do not place the device on the Dell M1000e Blade Server

Enclosure or on a metal surface.

• Take additional care when you handle devices during cold weather. Heating reduces indoor

humidity and increases static electricity.

• Some types of chassis come with electrostatic discharge (ESD) connectors. If the chassis is

equipped with an ESD connector, see the documentation that comes with the Dell M1000e

Blade Server Enclosure for using the ESD connector.

Preparing the Blade Server Enclosure for the SAN I/O Module

Before the SAN I/O Module can be inserted in the Dell M1000e Blade Server Enclosure, make sure

the following conditions are met:

• The I/O module bay into which the SAN I/O Module will be inserted is ready to receive the SAN

I/O Module.

• All power requirements specific to the Dell M1000e Blade Server Enclosure are met.

12 Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 25

Inserting the SAN I/O Module in the Blade Server Enclosure

NOTE

• Any protective cover on the SAN I/O Module backside connector is removed.

• If you are replacing an existing SAN I/O Module with a new module, the new SAN I/O Module

should be ready to be inserted within 60

maintain the proper cooling level in the chassis.

seconds from the removal of the old module to

Inserting the SAN I/O Module in the Blade Server Enclosure

Complete the following steps to insert the SAN I/O Module in the Dell M1000e Blade Server

Enclosure.

1. Unpack the SAN I/O Module from its shipping box, as described in “Unpacking the SAN I/O

Module” on page 11.

2. Verify that the Dell M1000e Blade Server Enclosure I/O module bay into which the SAN I/O

Module is being inserted is empty and that any filler panel or dust cover is removed.

A maximum of four SAN I/O Modules can be installed in the Dell M1000e Blade Server

Enclosure.

The SAN I/O Module is designed to work only in I/O module bays B1/B2 and C1/C2 of the Dell

M1000e Blade Server Enclosure. Make sure to comply with installation requirements stated in

the Dell PowerEdge M1000e Enclosure Owner’s Manual.

2

3. Press the release latch on the SAN I/O Module to free the release lever, as shown in Figure 3.

1 Release latch 2 Release lever

FIGURE 3 SAN I/O Module latching mechanism (closed position)

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual 13

53-1002576-02

Page 26

Inserting the SAN I/O Module in the Blade Server Enclosure

NOTE

1

2

2

4. Ensure that the release lever is fully extended so the SAN I/O Module can be seated properly in

the Dell M1000e Blade Server Enclosure, as shown in

Figure 4.

1 Release latch 2 Release lever

FIGURE 4 SAN I/O Module latching mechanism (open position)

5. With the port side facing you and the release lever fully extended, slide the SAN I/O Module in

the Dell M1000e Blade Server Enclosure I/O module bay.

6. Press the release lever upward until the release latch clicks and locks the lever in place.

This locks the SAN I/O Module into the Dell M1000e Blade Server Enclosure I/O module bay.

Locking the SAN I/O Module into the I/O module bay provides power (if the power is on in the

Blade Server Enclosure) and activates (powers on) the switch and switch LEDs.

The switch then runs self-diagnostic tests (such as POST).

When the SAN I/O Module is inserted in the Dell M1000e Blade Server Enclosure, the physical

Ethernet connection is established through the Dell M1000e Blade Server Enclosure Chassis

Management Controller (CMC). Also, the SAN I/O Module serial port connection becomes

available through the CMC CLI connect switch-x interface.

Once inserted, the SAN I/O Module can be accessed remotely. Ensure that the SAN I/O Module

is not being modified from any other connection until configuration is complete. Refer to

Chapter 3, “Configuring the SAN I/O Module,” for additional information about configuring the

SAN I/O Module.

14 Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 27

Handling SFP+ transceivers

DANGER

DANGER

ATTENTION

Before installing an SFP+ transceiver, be aware of the following:

• The housing on the SFP+ transceiver includes an integral guide key that is designed to prevent

you from inserting the transceiver incorrectly.

• Use minimal pressure when you insert an SFP+ transceiver in the port. Forcing the transceiver

into the port can cause damage to the transceiver or the SAN I/O Module port.

• You can insert or remove an SFP+ transceiver while the Dell M1000e Blade Server Enclosure

is powered on.

• You must first insert the SFP+ transceiver in the port before connecting the cables.

• You must remove the cable from the SFP+ transceiver before you remove the SFP+ transceiver

from the SAN I/O Module.

Tab le 3 lists Brocade-branded SFP+ transceivers that are supported on the SAN I/O Module.

TABLE 3 Brocade-branded SFP+ transceivers and part numbers

Transceiver type Device support Device description Brocade part number Dell part number

SFP+ 16 Gbps FC SWL, 1-pack, BR XDL-000192 2D0N2

SFP+ 16 Gbps FC SWL, 8-pack, BR XDL-000193 MTW83

SFP+ 8 Gbps FC SWL, 1-pack, BR XDL-000163 KP1HM

SFP+ 8 Gbps FC SWL, 8-pack, BR XDL-000164 X3T03

Handling SFP+ transceivers

2

To order SFP+ transceivers, contact your sales representative.

Inserting an SFP+ transceiver in the SAN I/O Module port

All fiber-optic interfaces use Class 1 lasers.

Laser radiation. Do not view directly with optical instruments. Class 1 laser products.

Your SAN I/O Module ships from the factory with a certain number of pre-installed SFP+

transceivers. The number of pre-installed transceivers will vary based on your SAN I/O Module

model.

To insert additional SFP+ transceivers in your SAN I/O Module, complete the following procedure. If

you are replacing an SFP+ transceiver, refer to

cables” on page 39.

“Removing and replacing SFP+ transceivers and

Be sure to use only Brocade-branded SFP+ transceivers. (Refer to Table 3).

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual 15

53-1002576-02

Page 28

Cabling guidelines

NOTE

CAUTION

2

1. Review the section “Handling SFP+ transceivers” on page 15.

2. If your SAN I/O Module ships with insert plugs in the unused external ports, remove the insert

plugs from the ports to be used.

3. Insert the SFP+ transceiver into a port until it is firmly seated and the latching mechanism

clicks.

SFP+ Transceivers are keyed to ensure correct orientation. If an SFP+ transceiver does not

install easily, ensure that it is correctly oriented.

4. Connect the cable to the SFP+ transceiver. Refer to “Cabling guidelines” on page 16.

For instructions specific to the type of transceiver, visit the MyBrocade web site at:

http://my.brocade.com

The cables used in trunking groups must meet specific requirements. For a list of these

requirements, refer to the Brocade Fabric OS Administrator’s Guide.

5. After the diagnostics have completed, cable the SAN I/O Module according to instructions

provided by the manufacturer. For more information, refer to the documentation that came

with your embedded switch.

6. Configure the Ethernet IP address on the SAN I/O Module as described in “Connecting to the

SAN I/O Module using Web Tools” on page 24.

Cabling guidelines

After modifying the IP address of the SAN I/O Module, it is recommended that you cable all external

ports to fabric connections before bringing the SAN I/O Module online.

Begin by cabling the ports from the top (ports 17 and 18) and working down as needed (ports 19,

20, 21, 22, 23, and 0). At a minimum, for all licensed variants of the SAN I/O Module, ports 17 and

18 are pre-licensed at the factory as part of Dynamic Ports On Demand (DPOD).

To avoid damage to the fiber-optic cables, follow these guidelines:

• Do not route the cable along a folding cable-management arm.

• When you attach the cable to a device on slide rails, leave enough slack in the cable so that it

does not bend to a radius of less than 38 mm (1.5 in.) when the device is extended, or

becomes pinched when the device is retracted.

• Tie wraps are not recommended for optical cables because they are easily overtightened.

A 50-micron cable should not be bent to a radius less than 2 inches under full tensile load and

1.2 inches with no tensile load.

16 Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 29

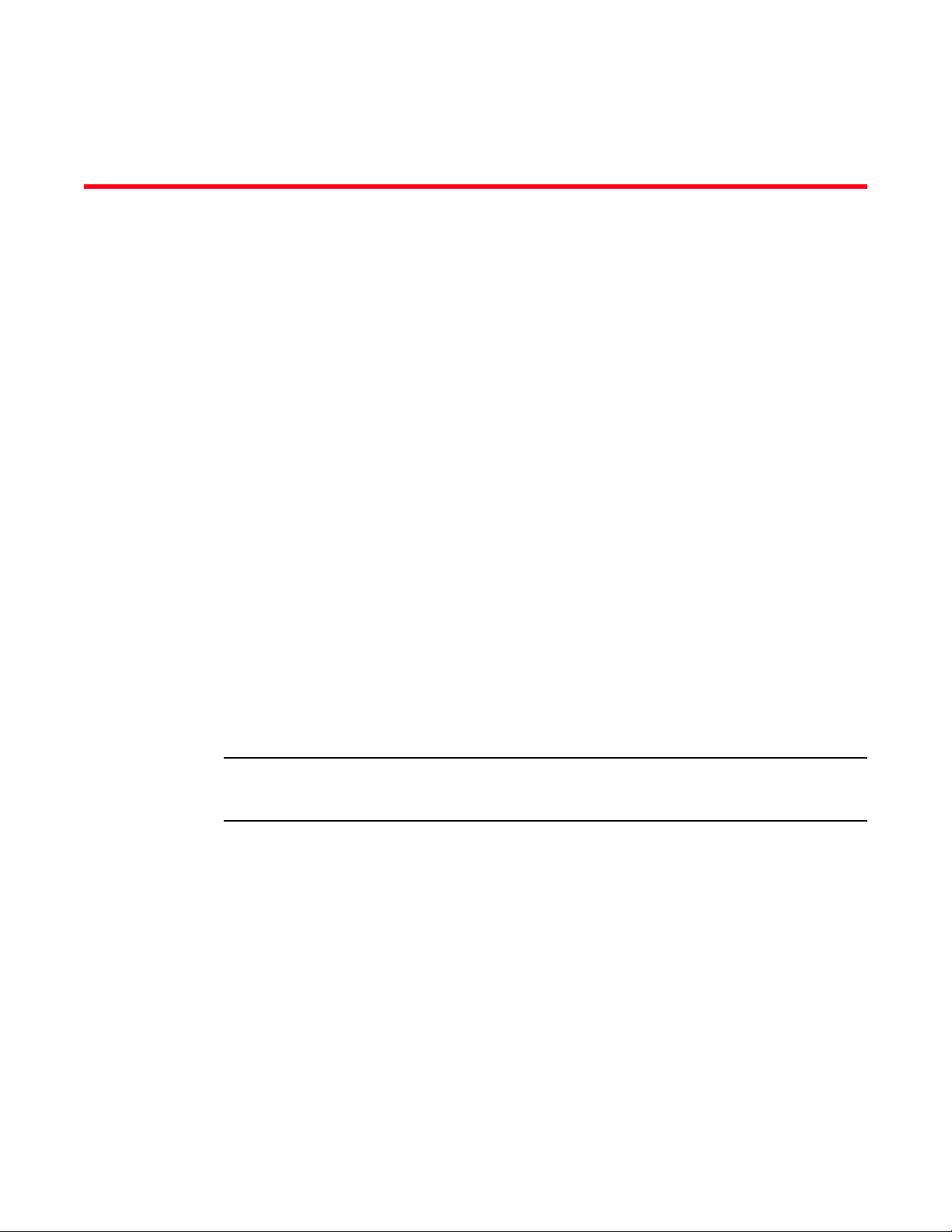

Data transmission ranges

Data transmission ranges

Tab le 4 provides the data transmission ranges for the transceivers, port speeds, and cable types.

TABLE 4 Supported optical tranceivers, speeds, cables, and distances

Transceiver

type

SWL SFP+ 2 Gbps 150 m (492 ft.) 300 m (984 ft.) 500 m (1640 ft.) N/A N/A

SWL SFP+ 4 Gbps 70 m (229 ft.) 150 m (492 ft.) 380 m (1264 ft.) 400 m (1312 ft.) N/A

SWL SFP+ 8 Gbps 21 m (68 ft.) 50 m (164 ft.) 150 m (492 ft.) 190 m (623 ft.) N/A

SWL SFP+ 16 Gbps 15 m (49 ft.) 35 m (115 ft.) 100 m (328 ft.) 125 m (410 ft.) N/A

1. 16Gb SFP+ optical transceivers support 16/8/4 Gbps speeds, and 8Gb SFP+ optical transceivers support 8/4/2 Gbps speeds.

Form

factor

Link Speed

1

Multi-node media

(50 microns)

(OM1)

Multi-mode media

(50 microns)

(OM2)

Multi-mode media

(50 microns)

(OM3)

Multi-mode media

(50 microns)

(OM4)

Single-mode

media

2

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual 17

53-1002576-02

Page 30

Data transmission ranges

2

18 Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 31

Chapter

NOTE

NOTE

Configuring the SAN I/O Module

In this chapter

•Items required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

•Modifying the SAN I/O Module IP address . . . . . . . . . . . . . . . . . . . . . . . . . . 20

•Connecting to the SAN I/O Module using Web Tools . . . . . . . . . . . . . . . . . . 24

•Connecting the SAN I/O Module to the Ethernet network . . . . . . . . . . . . . . 24

•Connecting the SAN I/O Module to the fabric . . . . . . . . . . . . . . . . . . . . . . . . 24

Although the SAN I/O Module is configured at the factory for Access Gateway (AG) mode, you can

enable it for Fabric OS Native mode. For more information, refer to

mode to Native Fabric mode” on page 31.

Items required

3

“Changing from Access Gateway

The following items are required for configuring and connecting the SAN I/O Module for use in a

network and fabric:

• The SAN I/O Module to be installed in the Dell M1000e Blade Server Enclosure.

• If required, a management workstation (computer) that has a terminal emulator (such as

HyperTerminal) or a keyboard, video, and mouse (KVM) device. This is only required if you are

not changing the SAN I/O Module IP address through the Dell M1000e Blade Server Enclosure

GUI or CLI management programs.

• An unused IP address and corresponding subnet mask and gateway address, unless DHCP is

used.

• If required, a serial cable to connect to the SAN I/O Module serial console port.

The serial cable is only required if you are not changing the SAN I/O Module IP address through

the Dell M1000e Blade Server Enclosure GUI or CLI management programs.

• Access to an FTP server for backing up the SAN I/O Module configuration.

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual 19

53-1002576-02

Page 32

Modifying the SAN I/O Module IP address

NOTE

3

• Access to the following publications:

- Dell PowerEdge M1000e Enclosure Owner’s Manual

- Dell Chassis Management Controller Firmware Version 4.x User Guide

- Brocade Fabric OS Command Reference

- Brocade Fabric OS Message Reference

- Brocade SAN TECH NOTE – Preparing to Install the Brocade Access Gateway

- Brocade Access Gateway Administrator’s Guide

- Brocade Web Tools Administrator’s Guide

- Release notes for the Fabric OS version running on the SAN I/O Module

- Release notes specific to the SAN I/O Module

Modifying the SAN I/O Module IP address

By default, the IP address for the SAN I/O Module is configured as 10.77.77.77 with a default

Ethernet subnetmask of 255.255.255.0.

Reset the IP address using any of the following three methods. The IP address values are stored on

the SAN I/O Module.

• “Using the CMC GUI to set the IP address” on page 20

• “Using the CMC CLI to set the IP address” on page 21

• “Using the SAN I/O Module CLI to set the IP address” on page 22

It is recommended that you set the IP address using the Dell M1000e Blade Server Chassis

Management Controller (CMC). From the CMC, you can set the IP address using either the GUI or the

CLI.

Using the CMC GUI to set the IP address

To modify the SAN I/O Module IP address using the CMC GUI, perform the following steps:

1. Select I/O Module Overview from the left navigation panel.

2. Click the Setup tab.

3. Enter the new information in the IP Address, Subnet Mask, and Gateway fields as appropriate,

then click Apply.

4. To enable DHCP, select DHCP Enabled, then click Apply.

Refer to Figure 5 on page 21.

20 Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 33

FIGURE 5 CMC Setup tab

Modifying the SAN I/O Module IP address

3

Refer to the Dell PowerEdge M1000e Enclosure Owner’s Manual that comes with your Dell

M1000e Blade Server Enclosure for more information.

Using the CMC CLI to set the IP address

To modify the SAN I/O Module IP address through the Chassis Management Controller (CMC) CLI,

perform the following steps:

1. Establish a Telnet session to the CMC CLI.

2. At the command prompt, enter connect switch-x where x is the bay in which the SAN I/O

Module is installed. For example, switch-x can be one of the following values:

• Switch-3 for SAN I/O Module installed in bay B1.

• Switch-4 for SAN I/O Module installed in bay B2.

• Switch-5 for SAN I/O Module installed in bay C1.

• Switch-6 for SAN I/O Module installed in bay C2.

3. Log in to the default administrative account using the following default settings:

Login: admin

Password: password

4. When prompted, either change the administrative password, or press Ctrl-C to bypass.

5. Enter the ipAddrSet command to change the IP address of the selected SAN I/O Module.

switch:admin> ipaddrset

6. Follow on-screen instructions and supply the correct information, as shown in the following

example:

switch:admin> ipaddrset

Ethernet IP Address [10.77.77.77]:10.32.53.47

Ethernet Subnetmask [255.255.255.0]:255.255.240.0

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual 21

53-1002576-02

Page 34

Modifying the SAN I/O Module IP address

3

Fibre Channel IP Addresss [none]:

Fibre Channel Subnetmask [none]:

Gateway IP Address [0.0.0.0]:10.32.48.1

DHCP [Off]:

IP address is being changed...Done.

7. E n t er ipAddrShow to verify the IP address was correctly set.

switch:admin> ipaddrshow

Ethernet IP Address: 10.32.53.47

Ethernet Subnetmask: 255.255.240.0

Fibre Channel IP Addresss: none

Fibre Channel Subnetmask: none

Gateway IP Address 10.32.48.1

DHCP: Off

Refer to the Dell PowerEdge M1000e Enclosure Owner’s Manual that comes with your Blade

Server Enclosure for information on using the CMC connect command.

Using the SAN I/O Module CLI to set the IP address

Perform the following tasks to change the IP address on the Brocade M6505 16 Gbps Fibre

Channel SAN I/O Module using the SAN I/O Module’s CLI.

Task 1: Establish a terminal session with the SAN I/O Module

Complete the following steps to establish a terminal emulation session between the SAN I/O

Module and a management workstation used for managing the SAN I/O Module. Once this session

is established, you can log in to the SAN I/O Module and use its CLI commands to manage the

module.

1. Connect a serial cable between the serial console port on the SAN I/O Module and the

management workstation that can establish a terminal emulation session with the SAN I/O

Module.

2. Disable any serial communication programs that are running on the workstation.

3. Using a terminal emulator application (such as HyperTerminal or PuTTY connection manager

on a PC or TERM in a LINUX or UNIX environment), establish a terminal session to the SAN I/O

Module from the management workstation. You will use this connection if you want to reset the

IP address of the SAN I/O Module using CLI commands and perform other configuration tasks.

For Windows 2003, 2008

a. Click Start and select Programs > Accessories > Communications.

b. Select HyperTerminal and enter a name for the connection.

c. From the HyperTerminal window, click the Connect menu and select an available COM

port.

d. Click OK.

22 Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 35

Modifying the SAN I/O Module IP address

e. From the COM Port Properties window, select the following configuration values.

Bits per second 9600

Databits 8

Parity None

Stop bits 1

Flow control None

f. Log in using the default administrative account:

Login: admin

Password: password

g. When prompted, either change the administrative password, or press Ctrl-C to bypass.

For LINUX or UNIX

a. Enter the following command at the command prompt:

tip /dev/ttyb -9600

3

b. When the terminal application stops reporting information, press Enter to display the login

prompt.

c. Log in using the default administrative account:

Login: admin

Password: password

d. When prompted, either change the administrative password, or press Ctrl-C to bypass.

Task 2: Change the IP address

1. Verify that the SAN I/O Module has completed power-on self-test (POST). When POST is

complete, the port status and SAN I/O Module power and status LEDs return to a standard

healthy state.

2. Enter the ipAddrSet command.

switch:admin> ipaddrset

3. Follow on-screen instructions and supply the correct information, as shown in the following

examples.

switch:admin> ipaddrset

Ethernet IP Address [10.77.77.77]:10.32.53.47

Ethernet Subnetmask [255.255.255.0]:255.255.240.0

Fibre Channel IP Addresss [none]:

Fibre Channel Subnetmask [none]:

Gateway IP Address [0.0.0.0]:10.32.48.1

DHCP [Off]:

IP address is being changed...Done.

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual 23

53-1002576-02

Page 36

Connecting the SAN I/O Module to the Ethernet network

NOTE

NOTE

NOTE

3

4. Enter ipAddrShow at the prompt to verify that the address was set correctly.

switch:admin> ipaddrshow

Ethernet IP Address: 10.32.53.47

Ethernet Subnetmask: 255.255.240.0

Fibre Channel IP Addresss: none

Fibre Channel Subnetmask: none

Gateway IP Address 10.32.48.1

DHCP: Off

Connecting the SAN I/O Module to the Ethernet network

Once you have successfully set the appropriate IP address of the SAN I/O Module, you can

establish an Ethernet connection through the Dell M1000e Blade Server Enclosure Chassis

Management Controller (CMC) to a remote management workstation for any additional

configuration. The management workstation must be on the same Ethernet subnet as the CMC.

Ensure that the SAN I/O Module is not being modified from any other connection until configuration

is complete.

Once an Ethernet connection is established, you can configure the SAN I/O Module by way of

Telnet/SSH using the switch CLI, or by launching Web Tools.

Connecting to the SAN I/O Module using Web Tools

Complete the following steps to connect to the Brocade M6505 16 Gbps Fibre Channel SAN I/O

Module using Web Tools.

1. On the management console, open a web browser such as Internet Explorer.

The web browser must be connected to the same network as the SAN I/O Module.

2. Enter the IP address of the SAN I/O Module in the Address field, then press Enter.

Web Tools requires any browser that conforms to HTML version 4.0, JavaScript version 1.0, and Java

Plug-in 1.6.0_24 or later.

For more information about using Web Tools, refer to the Brocade Web Tools Administrator’s Guide.

Connecting the SAN I/O Module to the fabric

Refer to “Cabling guidelines” on page 16 before beginning the following procedure.

Before beginning the following steps, determine whether the SAN I/O Module is in Brocade Access

Gateway or Native Fabric mode. This affects the configuration process. Using the Brocade M6505

16 Gbps Fibre Channel SAN I/O Module CLI, enter the ag

current operating mode.

24 Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

––modeShow command to determine the

53-1002576-02

Page 37

Connecting the SAN I/O Module to the fabric

If you are in AG mode and want to change to Native Fabric mode before connecting the SAN I/O

Module to the fabric, refer to

“Changing from Access Gateway mode to Native Fabric mode” on

page 31.

1. If the Brocade M6505 16 Gbps Fibre Channel SAN I/O Module is in Native Fabric mode,

continue to

step 2 and step 3. If the Module is in Access Gateway mode, go on to step 4.

2. Log in to the SAN I/O Module through a Telnet connection using the admin account.

3. Modify the domain ID if required using Brocade M6505 16 Gbps Fibre Channel SAN I/O

Module CLI commands.

The default domain ID is 1. If the SAN I/O Module is not powered on until after it is connected

to the fabric and the default domain ID is already in use, the domain ID for the new SAN I/O

Module is automatically reset to a unique value. If the SAN I/O Module is connected to the

fabric after it has been powered on and the default domain ID is already in use, the fabric

segments.

To find the domain IDs that are currently in use, run the fabricShow command on another SAN

I/O Module or switch in the fabric. Identify an unused domain ID:

a. Disable the SAN I/O Module being configured using the switchDisable command.

b. Enter the configure command at the root prompt.

3

The command prompts display sequentially. Enter a new value at the Domain prompt or

press Enter to accept the default value. The SAN I/O Module now has a unique domain ID

and can join the fabric. The following sample is an example of command output.

Fabric parameters (yes, y, no, n): [no] y

Data field size: (256..2112) [2112]

Sequence Level Switching: (0..1) [0]

Disable Device Probing: (0..1) [0]

Suppress Class F Traffic: (0..1) [0]

Switch PID Format: (1..2) [1]Configure...

Domain: (1..239) [1] 155

R_A_TOV: (4000..120000) [10000]

E_D_TOV: (1000..5000) [2000]

WAN_TOV: (0..30000) [0]

MAX_HOPS: (7..19) [7]

Per-frame Route Priority: (0..1) [0]

Long Distance Fabric: (0..1) [0]

BB credit: (1..27) [16]

Insistent Domain ID Mode (yes, y, no, n): [no]

Virtual Channel parameters (yes, y, no, n): [no]

F-Port login parameters (yes, y, no, n): [no]

Zoning Operation parameters (yes, y, no, n): [no]

RSCN Transmission Mode (yes, y, no, n): [no]

Arbitrated Loop parameters (yes, y, no, n): [no]

System services (yes, y, no, n): [no]

Portlog events enable (yes, y, no, n): [no]

ssl attributes (yes, y, no, n): [no]

http attributes (yes, y, no, n): [no]

snmp attributes (yes, y, no, n): [no]

rpcd attributes (yes, y, no, n): [no]

cfgload attributes (yes, y, no, n): [no]

webtools attributes (yes, y, no, n): [no]

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual 25

53-1002576-02

Page 38

Connecting the SAN I/O Module to the fabric

NOTE

NOTE

ATTENTION

3

System (yes, y, no, n): [no]

WARNING: The domain ID will be changed. The port level zoning may be

affected.

c. Re-enable the SAN I/O Module by entering the switchEnable command.

It can take up to 20 seconds for the newly added SAN I/O Module to appear in the fabric

display with its newly assigned domain ID.

4. If you must install SFP+ transceivers, install them in the external Fibre Channel ports, as

required.

a. If necessary, remove the end caps from the SFP+ transceiver.

b. Orient the SFP+ transceiver correctly and insert it in a port until it is firmly seated and the

latching mechanism clicks.

c. Repeat substeps a, b, and c for the remaining ports, as required.

Only Brocade-branded SFP+ transceivers are supported for use with the SAN I/O Module.

5. Connect the cables to the transceivers.

The transceivers are keyed to ensure correct orientation. If a transceiver does not install easily,

ensure that it is correctly oriented and that the end caps have been removed. The cables used

in trunking groups must meet specific requirements. For a list of these requirements, see the

Brocade Fabric OS Administrator’s Guide.

A cable should not be bent to a radius less than 5.08 cm (2 inches) under full tensile load and

3.048 cm (1.2 inches) with no tensile load.

Tie wraps are not recommended for optical cables because they are easily overtightened.

a. Orient a cable connector so that the key (the ridge on one side of connector) aligns with

the slot in the transceiver.

b. Insert the cable into the transceiver until the latching mechanism clicks. For instructions

specific to cable type, refer to the cable manufacturer’s documentation.

c. Repeat substeps a and b for the remaining transceivers, as required.

6. Check the LEDs to verify that all components are functional.

For information about LED patterns, refer to the “Interpreting SAN I/O Module LED activity” on

page 35.

7. Verify the correct operation of the SAN I/O Module by entering the switchShow command from

the switch Telnet session.

This command provides information about SAN I/O Module and port status.

8. Verify the correct operation of the SAN I/O Module in the fabric by entering the fabricShow

command from the switch Telnet session.

26 Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 39

Connecting the SAN I/O Module to the fabric

9. Back up the SAN I/O Module configuration to an FTP server by typing the configUpload

command and following the prompts.

This command uploads the SAN I/O Module configuration to the server, making it available for

downloading to a replacement SAN I/O Module if necessary. Brocade recommends backing up

the configuration on a regular basis to ensure that a complete configuration is available for

downloading to a replacement SAN I/O Module.

For specific instructions about how to back up the configuration, see the Brocade Fabric OS

Administrator’s Guide. The switchShow, fabricShow, and configUpload commands are

described in detail in the Brocade Fabric OS Command Reference.

3

Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual 27

53-1002576-02

Page 40

Connecting the SAN I/O Module to the fabric

3

28 Brocade M6505 16 Gbps Fibre Channel SAN I/O Module Hardware Reference Manual

53-1002576-02

Page 41

Chapter

Operating the SAN I/O Module

In this chapter

•Interoperability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

•Activating Ports on Demand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

•Changing from Native Fabric mode to Access Gateway mode . . . . . . . . . . . 33

•Changing from Access Gateway mode to Native Fabric mode . . . . . . . . . . . 31

•Access Gateway mode default port mapping . . . . . . . . . . . . . . . . . . . . . . . . 33

•Accessing the SAN I/O Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

•Interpreting POST results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

•Interpreting SAN I/O Module LED activity . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

•Interpreting POST results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

•Removing and replacing SAN I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . 37

•Removing and replacing SFP+ transceivers and cables. . . . . . . . . . . . . . . . 39

•Switch management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

•Viewing the configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

•Upgrading or downgrading firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

•Changing the default account password . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

•Backing up the configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

•Locating the serial number information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4

Interoperability

The SAN I/O Module supports interoperability for the features and functions listed in Tab le 5.

TABLE 5 Interoperability

Feature/Function Description

Link initialization The SAN I/O Module comes online automatically after it is seated securely in

one of the Dell M1000e Blade Server Enclosure I/O module bays.

Routing Fabric Shortest Path First (FSPF)—A link state path selection protocol that

directs traffic along the shortest path between the source and destination

based upon the link cost.

Registered state change

notification (RSCN)

SNMP facilities v1, v2c, and v3

Translative mode Private target support on fabrics.