Page 1

Hardware Maintenance

Hardware Maintenance

Page 2

Copyright © 2007 EqualLogic, Inc.

May 2007

EqualLogic is a registered trademark of EqualLogic, Inc.

All trademarks and registered trademarks mentioned herein are the property of their

respective owners.

Possession, use, or copying of the documentation or the software described in this

publication is authorized only under the license agreement.

EqualLogic, Inc. will not be held liable for technical or editorial errors or omissions

contained herein. Information in this document is subject to change.

Part Number: 110-0041-R3

ii

Page 3

Table of Contents

Preface ..................................................................................................................v

Audience ..........................................................................................................v

Organization ....................................................................................................v

Conventions ....................................................................................................vi

Documentation and Technical Support ..........................................................vi

Warranty Information ....................................................................................vii

Restricted Access Requirement .....................................................................vii

Regulatory Agency Notices ........................................................................ .viii

1 Basic Array Information............................................................................... 1-1

Array Front and Back Panels........................................................................ 1 -1

Interpreting Operations Panel LEDs ............................................................ 1-2

Using an Electrostatic Wrist Strap ............................................................... 1-4

Shutting Down and Restarting an Array ...................................................... 1-4

2 Maintaining Disks.......................................................................................... 2-1

Interpreting Disk LEDs................................................................................ 2-1

Disk Handling Requirements ....................................................................... 2-2

Identifying Failed Disks................................................... ..... .... ..... .............. 2-3

Removing Disks........................................................................................... 2-3

Installing Disks.............................................................................................2-5

3 Maintaining Control Modules...................................................................... 3-1

Supported Control Modules ......................................................................... 3-1

Interpreting Control Module LEDs.............................................................. 3-2

Control Module Handling Requirements..................................................... 3-3

Identifying Control Module Failures............................................................ 3-3

Understanding Failover Behavior ................................................................ 3-3

Maintaining Control Module Firmware....................................................... 3-4

Connecting Network Cables......................................................................... 3-5

Removing a Control Module........................................................................ 3-7

Installing a Control Module ......................................................................... 3-9

Replacing the Compact Flash Card............................................................ 3-11

4 Maintaining Power Supply and Cooling Modules...................................... 4-1

Interpreting Power Supply and Cooling Module LEDs............................... 4-1

Identifying Power Supply and Cooling Module Failures............................. 4-2

Removing a Power Supply and Cooling Module......................................... 4-2

iii

Page 4

PS3000 Series Hardware Maintenance Table of Contents

Installing a Power Supply and Cooling Module .......................................... 4-4

A Environmental, Power, and Other Specifications......................................A-1

Index............................................................................................................Index-1

iv

Page 5

Preface

This manual describes how to maintain the hardware for PS3000 Series arrays

from EqualLogic. Each array contains hot-swappable power supply and cooling

modules, up to sixteen RAID-protected disks, and single or dual

hot-swappable control modules.

With one or more PS Series arrays, you can create a PS Series group—a selfmanaging, iSCSI storage area network (SAN) that is affordable and easy to use,

regardless of scale. To install hardware, see the PS3000 Series QuickStart.

Audience

This manual is designed for the administrators responsible for maintaining

PS3000 Series hardware. Administrators are not required to have extensive

network or storage system experience. However, it may be useful to understand:

• Basic networking concepts

• Current network environment

• User disk storage requirements

• RAID configurations

• Disk storage management

Note: Although this manual provides examples of using PS Series arrays in some

common network configurations, detailed information about setting up a

network is beyond its scope.

Organization

This manual is organized as follows:

• Chapter 1, Basic Array Information, describes the PS3000 Series array front

and back panels, how to interpret LEDs, how to use an electrostatic wrist

strap, and how to shut down and restart an array.

• Chapter 2, Maintaining Disks, describes how to install and remove disks.

• Chapter 3, Maintaining Control Modules, describes how to install and

maintain control modules and replace the compact flash card. It also describes

the best way to connect network cables to control modules for high

performance and availability.

v

Page 6

PS3000 Series Hardware Maintenance Preface

• Chapter 4, Maintaining Power Supply and Cooling Modules, describes how to

install and remove one of the modules that provides both power and cooling.

• Appendix A, Environmental, Power, and Other Specifications, describes the

specifications for a PS3000 Series array.

Conventions

Conventions used in the manual are shown in the following table.

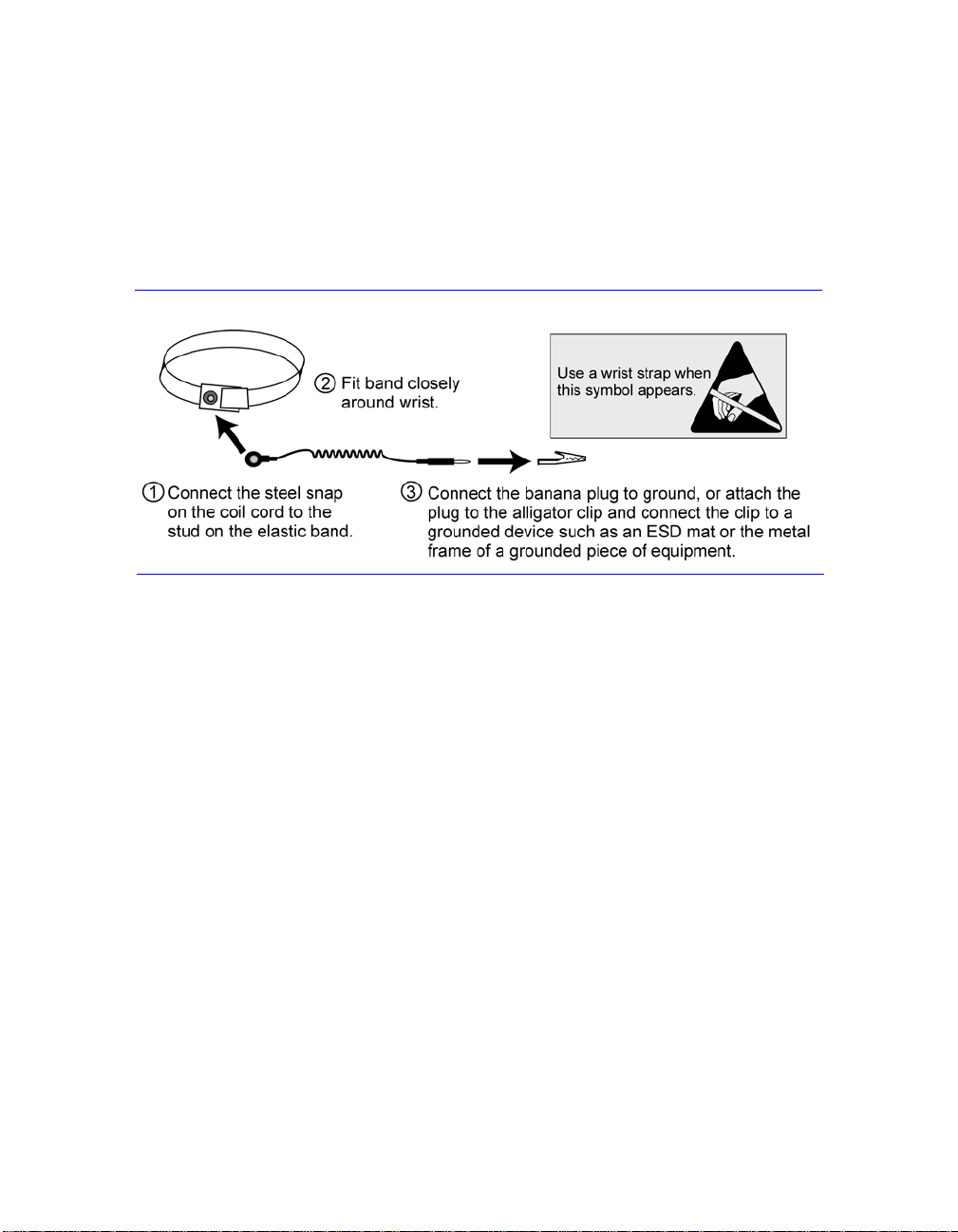

Convention Usage

When displayed, indicates that you must attach an electrostatic

wrist strap to your wrist and a grounded device to prevent

electrostatic discharge.

When displayed, indicates a potential personal injury hazard.

Documentation and Technical Support

For detailed information about PS Series storage arrays, groups, and volumes, see

the following documentation:

• Release Notes. Provides the latest information about PS Series storage arrays.

• QuickStart. Describes how to set up the storage array hardware and create a

PS Series group. Be sure to use the manual for your array model.

• Group Administration. Describes how to use the Group Manager graphical

user interface (GUI) to manage a PS Series group. This manual provides

comprehensive information about product concepts and procedures.

• CLI Reference. Describes how to use the Group Manager command line

interface (CLI) to manage a PS Series group and individual arrays.

• Hardware Maintenance. Provides information about maintaining the storage

array hardware. Be sure to use the manual for your array model.

vi

Page 7

PS3000 Series Hardware Maintenance Preface

• Online help. In the GUI, expand Tools in the far left panel and then click

Online Help for help on both the GUI and the CLI. See Obtaining Online

Help on page 2-16.

The QuickStart and Hardware Maintenance manuals are printed and shipped with

the product. They are also located on the PS Series documentation CD-ROM that

is shipped with the product, along with the Group Administration and CLI

Reference manuals and the Group Manager online help.

®

In addition, the Host Integration Tools for Microsoft

Windows® systems are

available on the Host Integration Tools CD-ROM that is shipped with the product.

Technical support on EqualLogic products is available for customers with arrays

under warranty and customers with a valid support contract. To obtain support:

• Visit the EqualLogic Customer Support website to download the latest

documentation and firmware. Go to

www.equallogic.com and log in to

your support account. If you do not have an account, register for an account.

• From the Customer Support website, you can submit a service request.

• In the United States, call toll-free 877-887-7337. Outside the United States,

call +1 919-767-5729. If the issue is urgent, ask to speak with a member of the

EqualLogic Customer Support team.

Warranty Information

The PS3000 Series array warranty is included in the shipping box. For

information about registering a warranty, visit the EqualLogic website,

www.equallogic.com.

Restricted Access Requirement

PS Series arrays must be installed in a restricted access location. A restricted

access location is an area that is intended only for qualified or trained personnel.

vii

Page 8

PS3000 Series Hardware Maintenance Preface

Regulatory Agency Notices

PS Series arrays have been tested and found to comply with the limits for a Class

A digital device, pursuant to part 15 of the FCC rules and other international

standards. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, which the user will be required to

correct at his or her own expense.

Regulatory Agency Notes

Service Note

Disconnect all PS Series storage array power cables before

servicing to avoid electric shock.

There is a danger of explosion if a PS Series storage array control

module cache battery is incorrectly replaced. Replace a battery only

with the same or equivalent battery, as recommended by the

manufacturer, and use the instructions in this document. Discard

used batteries according to the manufacturer’s instructions.

viii

Page 9

1 Basic Array Information

This chapter includes basic information about PS3000 Series arrays:

• Array Front and Back Panels on page 1-1

• Interpreting Operations Panel LEDs on page 1-2

• Using an Electrostatic Wrist Strap on page 1-4

• Shutting Down and Restarting an Array on page 1-4

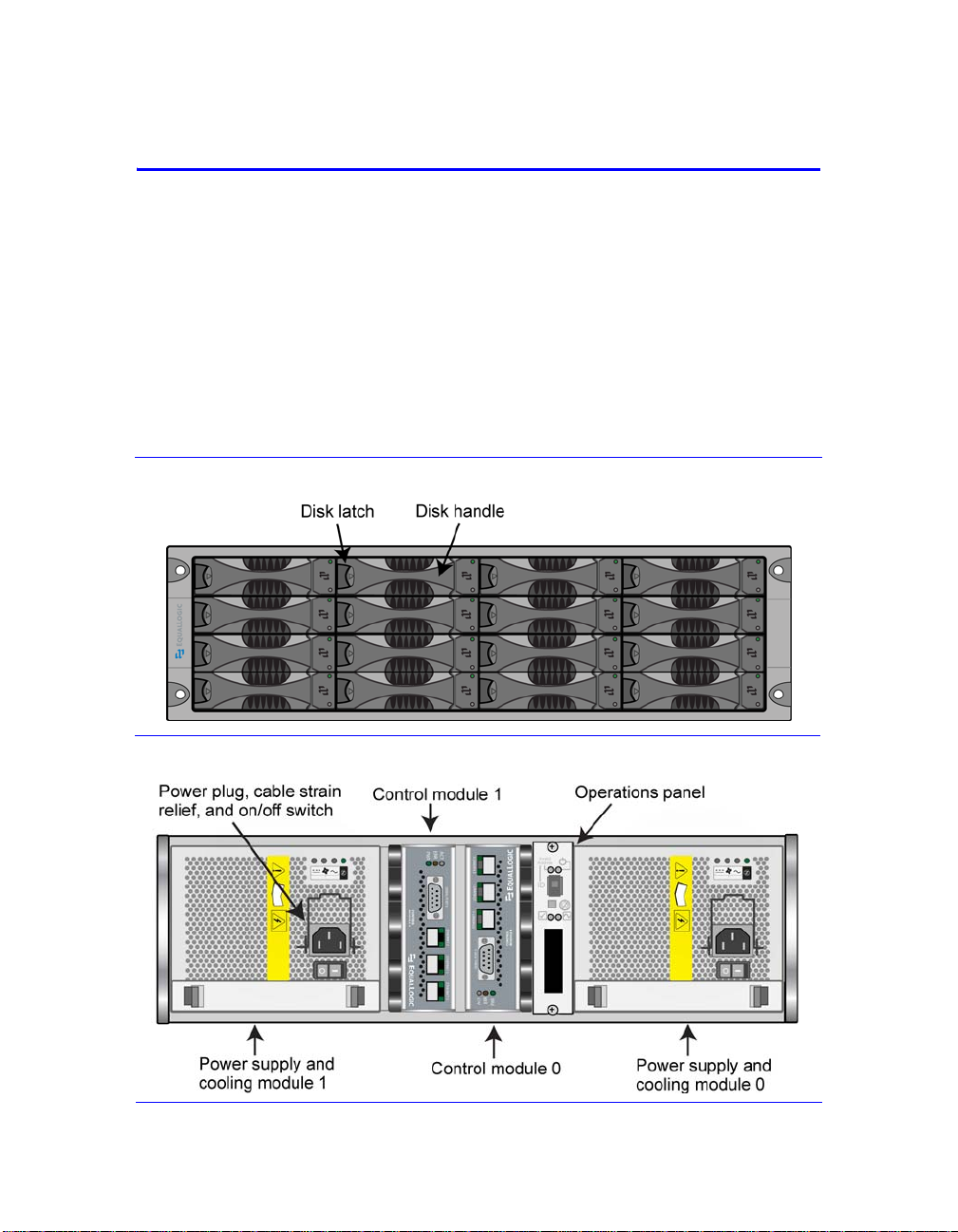

Array Front and Back Panels

The front and back panels of a PS3000 Series array are shown below.

Figure 1-1: PS3000 Series Front Panel

Figure 1-2: PS3000 Series Back Panel

1–1

Page 10

PS3000 Series Hardware Maintenance Basic Array Information

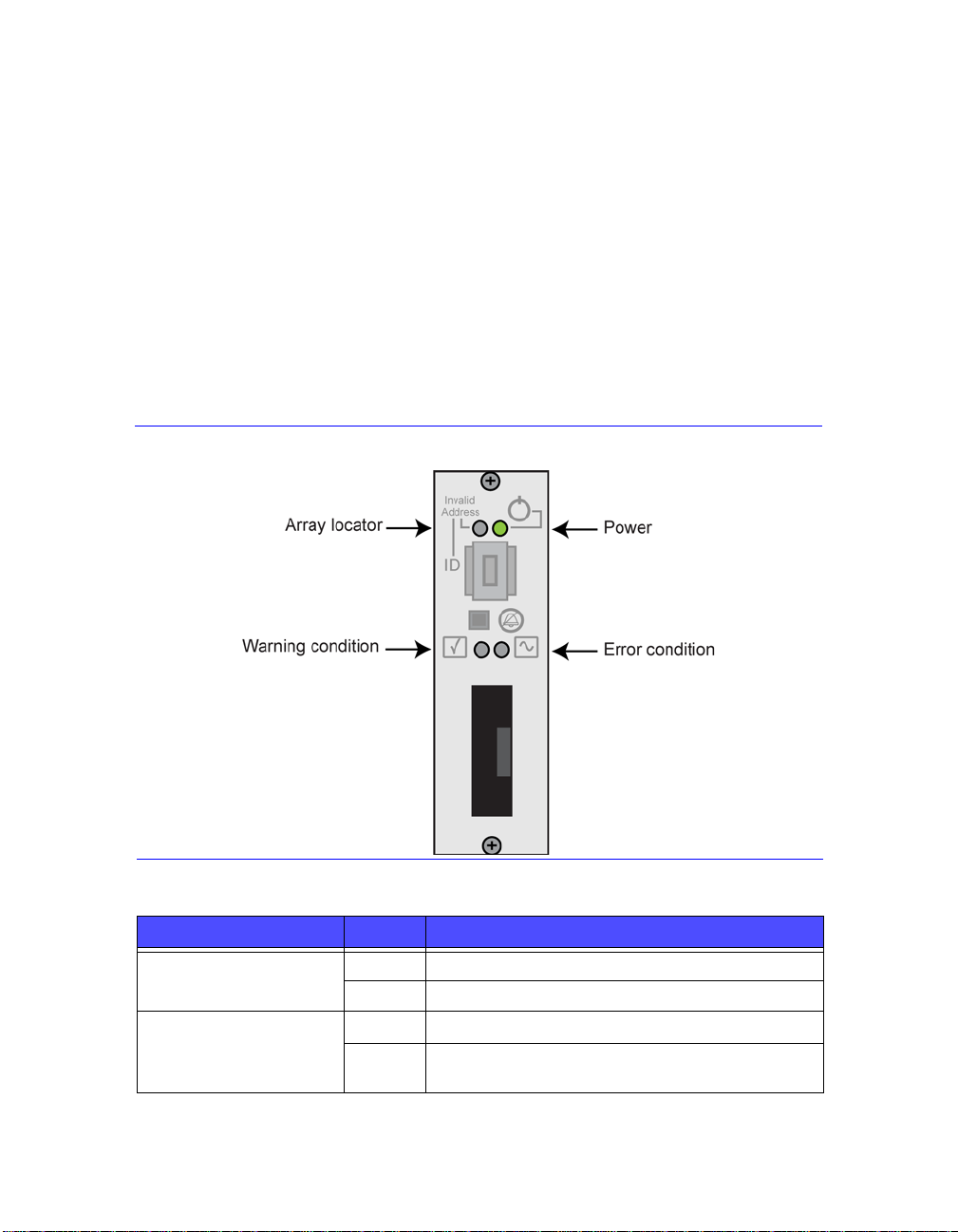

Interpreting Operations Panel LEDs

The operations panel is used to monitor PS3000 Series hardware components. The

panel is not redundant, but an array can continue to operate if it fails. See your PS

Series array service provider for information about servicing the panel.

Figure 1-3 and Table 1-1 describe the LEDs on the PS3000 Series array

operations panel, which can alert you to errors and conditions that require your

attention. Serious problems should be reported to your PS Series service provider.

For information about other LEDs, see Interpreting Disk LEDs on page 2-1,

Interpreting Control Module LEDs on page 3-2, and Interpreting Power Supply

and Cooling Module LEDs on page 4-1.

Figure 1-3: Operations Panel LEDs

Table 1-1: Operations Panel LED Descriptions

Operations LED Color Description

Power (upper right) Off No power.

Green Power.

Array locator (upper left) Off No power or normal condition.

Flashing

orange

1–2

Administrator enabled the array locator function.

Page 11

PS3000 Series Hardware Maintenance Basic Array Information

Table 1-1: Operations Panel LED Descriptions (Continued)

Operations LED Color Description

Warning condition

(lower left)

Error condition (lower

right)

Off No power or normal condition.

Flashing

orange

Off No power or normal condition.

Flashing

orange

One or more of the following has occurred:

• RAID set is degraded but still functioning.

• RAID set (volume level) has lost blocks.

• Component temperature is near a limit.

• Fan failed or fan RPMs exceed limit.

• Power supply is not installed or has no power.

• Only one control module installed or control

module has failed over.

• Control module has insufficient RAM.

• Syncing active and secondary control modules.

• No communication between control modules.

• Installed spare disk does not have enough

capacity to replace a disk in a RAID set.

• A non-critical hardware component failed.

• Real-time clock battery is low.

One or more of the following has occurred:

• RAID is not functioning.

• Lost block table is full.

• Temperature exceeds upper or lower limit.

• Control module cache has lost data.

• A cooling module is not installed.

• Both fans on a cooling module have failed.

• Cache battery has less than 72 hours charge or

temperature is too high to charge battery.

• NVRAM coin cell battery failed.

• Cache contains data that does not belong to any

of the installed disks.

• More than one valid RAID set exists in array.

• Control modules are different models.

• A critical hardware component has failed.

• Operations panel failed or not installed.

• Storage enclosure processor that monitors

array components has experienced a failure.

1–3

Page 12

PS3000 Series Hardware Maintenance Basic Array Information

Using an Electrostatic Wrist Strap

When handling the array chassis, disks, or control modules, you must use an

electrostatic protection device to prevent electrostatic discharge.

An electrostatic wrist strap is included in the shipping box.

Figure 1-4: Using an Electrostatic Wrist Strap

Shutting Down and Restarting an Array

A PS3000 Series array includes redundant, hot-swappable disks, power supplies,

and control modules (if a dual control module array). Y ou can remove a redundant

component without affecting operation if a functioning component is available.

Otherwise, it is recommended that you cleanly shut down the array and turn off

power before removing a component.

Note: When an array is shut down, any volumes with data on the array will be set

offline until the array is successfully restarted. This may affect initiators

that are connected to the volumes.

To shut down an array, follow these steps:

1. Do one of the following:

• Use telnet or SSH to connect to a functioning IP address assigned to a

network interface on the array. Do not connect to the group IP address.

• Use the null modem cable shipped with the array to connect Serial Port 0

on the active control module (ACT LED is green) to a console or a

computer running a terminal emulator.

1–4

Page 13

PS3000 Series Hardware Maintenance Basic Array Information

Serial line characteristics are as follows:

- 9600 baud

-One STOP bit

- No parity

- 8 data bits

- No hardware flow control

2. Log in to an account with read-write access, such as the

3. Enter the

Login: grpadmin

Password: xxxxxxx

> shutdown

shutdown command, as shown next.

Welcome to Group Manager

Copyright 2001-2007 EqualLogic, Inc.

grpadmin account.

If you are using a serial connection to shut down an array, it is safe to turn off

power when the “press any key” message appears. (Pressing any key will restart

both control modules.)

If you are using a network connection, the session will be disconnected before the

array is fully shut down. Confirm that the ACT LED on each control module is off

(not lit) before turning off power to the array.

After performing array maintenance, you can turn on power to the array . When the

array restart completes, the member and volumes will be set online.

1–5

Page 14

Page 15

2 Maintaining Disks

Each PS3000 Series array includes up to 16 hot-swappable disks. Disk

maintenance topics include:

• Interpreting Disk LEDs on page 2-1

• Disk Handling Requirements on page 2-2

• Identifying Failed Disks on page 2-3

• Removing Disks on page 2-3

• Installing Disks on page 2-5

Interpreting Disk LEDs

Figure 2-1shows how disks are numbered in a PS3000 Series array.

Figure 2-1: PS3000 Series Disk Numbering

Figure 2-2 shows the disk LEDs. Table 2-1 describes the LEDs.

Figure 2-2: PS3000 Series Disk LEDs

2–1

Page 16

PS3000 Series Hardware Maintenance Maintaining Disks

Table 2-1: PS3000 Series Disk LED Descriptions

Disk LEDs Color Description

Top Off No power or error condition.

Green Power.

Flashing green Disk activity.

Bottom Off No power or normal condition.

Red Error condition.

Disk Handling Requirements

You must adhere to the following disk handling requirements:

• Store disks properly. S tore replacement disks in the packaging in which they

were shipped. Do not stack disks or place anything on top of a disk.

• Protect disks from electrostatic discharge. Wear an electrostatic wrist strap

when handling a disk, unless it is protected from electrostatic discharge.

• Handle disks carefully. Hold a disk only by the plastic part of the carrier or

the handle. Do not drop or jolt a disk or force a disk into a disk slot.

• Warm replacement disks to room temperature before installation. For

example, let a disk sit overnight before installing it in an array.

• Do not leave disk slots empty. Each disk slot in an array must contain a disk

drive assembly or a blank carrier. Operating an array with an empty disk slot

will void your warranty and support contract.

• Do not remove a disk from its carrier. This action will void your warranty

and support contract.

• Keep shipping material. Return a failed disk to your PS Series array service

provider in the packaging in which the replacement disk was shipped.

Shipping disks in unauthorized packaging may void your warranty.

2–2

Page 17

PS3000 Series Hardware Maintenance Maintaining Disks

Identifying Failed Disks

Disks in a PS3000 Series array are numbered from 0 to 15 (from left to right, top

row to bottom row). A disk failure is indicated by:

• The disk’s error LED (bottom) is red, and the power LED (top) is off. See

Interpreting Disk LEDs on page 2-1.

• A message on the console, in the event log, or in the Group Manager GUI

Alarms panel describes a disk failure.

• The GUI Member Disks window or the CLI

command shows a disk failure.

member select show disks

Handling Failed Disks

How an array handles a disk failure depends on whether a spare disk is available

and whether the RAIDset containing the failed disk is degraded. For example:

• If a spare disk is available, it replaces the failed disk. Performance is normal

after reconstruction completes.

• If a spare disk is not available and the failed disk is in a RAIDset with no

previous disk failure, the RAIDset becomes degraded. Performance may be

impaired.

• If a spare disk is not available and the failed disk is in a RAIDset that is

already degraded, data may be lost and must be recovered from a backup.

Removing Disks

Before removing a disk or blank carrier from an array, attach an electrostatic

protection device, as described in Using an Electrostatic Wrist Strap on page 1-4.

Notes: Replace a failed disk as soon as possible to ensure the highest availability .

Do not remove a disk from a slot, unless you have another disk or a blank

carrier to replace it. Each slot must contain a disk or blank carrier.

Do not remove a functioning disk from an array , unless the disk is a spare;

otherwise, a RAIDset may become degraded. If you remove a spare,

replace the disk as soon as possible.

Before completely removing a functioning disk from an array slot, wait

30 seconds to allow the disk to stop spinning and the heads to land.

Store replacement disks in the packaging in which they were shipped.

2–3

Page 18

PS3000 Series Hardware Maintenance Maintaining Disks

Figure 2-3 shows how to remove a disk from a PS3000 Series array. Instructions

for removing a blank carrier are similar, except you do not have to wait 30

seconds.

Figure 2-3: Removing a Disk

2–4

Page 19

PS3000 Series Hardware Maintenance Maintaining Disks

Installing Disks

Before installing a disk or blank carrier in an array, attach an electrostatic

protection device, as described in Using an Electrostatic Wrist Strap on page 1-4.

Notes: Install only disks of the same type, speed, and spin rate in an array. The

color of the handle release button indicates the disk type.

You can use disks with different sizes in an array. However, the smallest

disk in the array will determine how much space can be used on each disk.

For example, if the smallest disk is 400GB, only 400GB of space will be

available for use on each disk.

Be sure to insert a disk fully in the chassis before pushing in the handle.

When correctly installed, the disk carrier should not protrude from the

chassis. After installation, make sure the disk power LED (top) is green or

flashing green.

There is a two-minute delay between the time you insert a disk and the

time the disk is automatically configured into a RAIDset. This time

interval allows multiple disks to be simultaneously configured in an array ,

which is more efficient than installing a single disk, configuring it, and

then repeating the process. For example, when you install a disk, the timer

starts. If no other disks are installed, the disk is configured after a delay of

two minutes. If you install another disk before two minutes have elapsed,

the timer is restarted.

If you install a disk during RAID reconstruction or verification, the new

disk will not be configured until the operation completes.

2–5

Page 20

PS3000 Series Hardware Maintenance Maintaining Disks

Figure 2-4 shows how to install a disk in an array. Use the same instructions for

installing a blank carrier.

Notes: Make sure the disk is oriented in the position shown below, with the

handle release button to the left.

When correctly installed, a disk will be level with the front of the array. If

the disk is protruding from the array, reinstall the disk.

Figure 2-4: Installing a Disk

Verify that the new disk is operational by checking the LEDs on the front panel, as

described in Interpreting Disk LEDs on page 2-1. The top LED should be green or

flashing green, and the bottom LED should be off.

In addition, the GUI Member Disks window and the CLI

disks

command output should show that the new disk is operational.

2–6

member select show

Page 21

3 Maintaining Control Modules

A PS3000 Series array includes one or two hot-swappable control modules. Each

control module includes a field-replaceable compact flash card (running PS Series

firmware), in addition to cache and NVRAM batteries. For information about

replacing a cache or NVRAM battery, contact your PS Series service provider.

Control module maintenance topics include:

• Supported Control Modules on page 3-1

• Control Module Handling Requirements on page 3-3

• Identifying Control Module Failures on page 3-3

• Understanding Failover Behavior on page 3-3

• Maintaining Control Module Firmware on page 3-4

• Connecting Network Cables on page 3-5

• Removing a Control Module on page 3-7

• Installing a Control Module on page 3-9

• Replacing the Compact Flash Card on page 3-11

Supported Control Modules

At the time of this release, PS3000 arrays support both Type 3 and Type 4 control

modules, which are functionally equivalent and distinguished only by color.

Always check the latest Release Notes for information about additional supported

control modules.

This manual shows arrays with T ype 4 control modules (gray), but the informatio n

also applies to arrays with Type 3 control modules (blue). However, do not mix

control module types in an array.

Figure 3-1: Type 3 Control Module (Blue)

Figure 3-2: Type 4 Control Module (Gray)

3–1

Page 22

PS3000 Series Hardware Maintenance Maintaining Control Modules

Interpreting Control Module LEDs

Control modules have LEDs that enable you to determine the status of the control

module (active or secondary) and identify problems. In addition, each network

interface on a control module also has LEDs.

Figure 3-3: Control Module LEDs

Note: Control modules are installed vertically in a PS3000 Series array, with the

latch mechanism facing the power supply and cooling module.

Table 3-1: Control Module LED Descriptions

Control Module LEDs Color Description

ACT Off No power, secondary control module is not

synchronized with active control module, or

error condition.

Green Active control module (serving network I/O).

Orange Secondary control module; cache is

synchronized with active control module.

ERR Off No power or no error condition.

Red Array is starting up or error condition.

PWR Off No power.

Green Power.

Table 3-2: Network Interface LED Descriptions

Network Interface LEDs Color Description

Left (as shown in

Figure 3-3)

Right (as shown in

Figure 3-3)

3–2

Off

Green Connected to network.

Off No power or not transmitting.

Green Transmitting.

No power or not connected to network.

Page 23

PS3000 Series Hardware Maintenance Maintaining Control Modules

Control Module Handling Requirements

You must adhere to the following control module handling requirements:

• Protect control modules from electrostatic discharge. Always wear an

electrostatic wrist strap when handling a control module, as described in

Using an Electrostatic Wrist Strap on page 1-4. When not installed, store a

control module in an antistatic bag or place it on a surface protected from

electrostatic discharge.

• Do not remove a control module from an array while the contro l modules

are synchronizing. When synchronization completes, a console message will

appear. Also, the ACT LED on the secondary control module will be orange.

• Do not leave a control module slot empty. In an array with one control

module, always attach a blank face plate to the empty control module slot.

Identifying Control Module Failures

A failure in a control module can be indicated by the following:

• A control module’s ERR LED is red or the PWR LED is off but there is

power to the array. See Interpreting Control Module LEDs on page 3-2.

• The ACT LED on one control module is green, but the ACT LED on the other

control module is off instead of orange.

• A message on the console, in the event log, or in the Group Manager GUI

Alarms panel describes a control module failure.

• The GUI Member Controllers window or CLI

controllers

CM0 refers to the control module to the right, when viewing the array back panel.

CM1 refers to the control module to the left.

command shows the control module as not installed.

member select show

Understanding Failover Behavior

A PS3000 Series array can have one to three active network connections. In a dual

control module array, only one control module is active (serving network traffic)

at one time. Each control module includes a battery-backed write cache for storing

recently-used data. For redundancy, the cache on the secondary control module

mirrors the data that is stored in the cache on the active control module.

Each control module has three ports: Ethernet 0, Ethernet 1, and Ethernet 2. The

active control module can use a network interface only if there is a cable

3–3

Page 24

PS3000 Series Hardware Maintenance Maintaining Control Modules

connected to the port on the active control module. Therefore, you should connect

a cable to the network interface port on each control module to ensure that both

control modules can access an interface.

A PS3000 Series array provides two types of network failure protection:

• Network connection failover. If multiple network interfaces are configured

and one network interface fails, iSCSI initiators that were connected to the

failed interface can reconnect to the group IP address and be redirected to a

functioning interface. For example, in a single control module array, if

Ethernet 0 and Ethernet 1 are connected to a network, and Ethernet 0 fails,

initiators that were connected to Ethernet 0 can be redirected to Ethernet 1.

• Control module failover. In a dual control module array, if the active control

module fails, the secondary automatically takes over and becomes active. If a

cable is connected to the port on the newly active control module, network I/O

can continue through that interface. Control module failover is transparent to

applications, but iSCSI initiators must reconnect to the group IP address.

Maintaining Control Module Firmware

A PS3000 Series array includes one or two control modules, each with a compact

flash card running the array firmware. You should run the latest firmware version

to take advantage of new product features and enhancements.

Caution: In a dual control module array, both control modules must be running

the same firmware version; otherwise, only one control module will be

functional. When you use the

update command procedure, both

control modules are updated to the same firmware version.

Group members should run the same firmware version; otherwise, only

functionality common to all versions will be available in the group. See the

PS Series Release Notes for information about mixed-firmware groups.

If you are upgrading to a dual control module array or replacing a failed compact

flash card, be sure to order the correct firmware version from EqualLogic. If you

are replacing a failed control module, remove the compact flash card from the

failed control module and install it in the replacement control module. This will

ensure that you retain the correct firmware.

A new compact flash card will show the firmware version on the label. To display

the firmware version running on an array, examine the GUI Member Controllers

window or use the CLI

member select show controllers command. If the

firmware on a compact flash card does not match the firmware running on an

array, do not install it. Instead, contact your PS Series array service provider.

3–4

Page 25

PS3000 Series Hardware Maintenance Maintaining Control Modules

Connecting Network Cables

A PS3000 Series array must have at least one and can have up to three active

network connections at one time. Multiple network connections are recommended

for performance and availability.

Connect cables to network interfaces as follows:

• For copper-based networks, use Category 5E or Category 6 cables with RJ45

connectors. Use Category 5 cables if they meet the TIA/EIA TSB95 standard.

• Connect interfaces in this order: Ethernet 0, Ethernet 1, and Ethernet 2.

• Connect interfaces to different network switches.

• In a dual control module array, to ensure connectivity if a control module

fails, connect a cable to the interface port on each control module. For

example, connect a cable to Ethernet 0 on CM0 and Ethernet 0 on CM1.

See the PS Series QuickStart and the Technical Report on the EqualLogic

Customer Support website for network requirements and recommendations.

For a single control module array, the minimum network configuration is one

network connection to Ethernet 0. However, the single network connection is a

potential point of failure. Therefore, it is recommended that you connect multiple

network interfaces to different network switches.

For example, if you connect cables as shown in Figure 3-4, and Ethernet 0 fails,

initiators can be redirected to another functioning interface. This configuration

provides the maximum network bandwidth.

Figure 3-4: Recommended Single Control Module Configuration

3–5

Page 26

PS3000 Series Hardware Maintenance Maintaining Control Modules

For a dual control module array, the minimum network configuration is a network

connection to Ethernet 0 on both control modules. Although this configuration

protects against control module failover, it is still a potential point of failure (for

example, if the network cable connected to the active control module is

disconnected). Therefore, it is recommended that you connect multiple network

interfaces to different switches.

Figure 3-5 shows the minimum network configuration for a dual control module

PS3000 Series array. Cables are connected to Ethernet 0 on both control modules.

Figure 3-5: Minimum Dual Control Module Configuration

Figure 3-6 shows the recommended network configuration for a dual control

module PS3000 Series array. This configuration provides the highest network

availability and the maximum network bandwidth.

3–6

Page 27

PS3000 Series Hardware Maintenance Maintaining Control Modules

Figure 3-6: Recommended Dual Control Module Configuration

Removing a Control Module

If a control module fails, you should remove it and replace it with a functioning

control module. You also ma y need to temporarily remove a control module to

replace a compact flash card.

In a dual control module PS3000 Series array, you can remove a contro l module

without shutting down the array, if the remaining control module has at least one

connected and functioning network interface. However, if you remove the active

control module (the LED labeled ACT will be green), there will be a short

interruption as failover to the secondary control module occurs.

Caution: Do not remove a control module from an array while the control

modules are still synchronizing. A message will appear on the console

when synchronization completes. The ACT LED on the secondary

control module will be orange when synchronization completes.

Before removing a control module:

• If you have a single control module array, if possible, cleanly shut down the

array before removing the control module to protect against cache data loss.

See Shutting Down and Restarting an Array on page 1-4.

• Disconnect any serial or network cables attached to the control module. If you

have a dual control module array, you may want to re-attach the network

cables to the functioning control module to ensure uninterrupted data access.

• Attach an electrostatic wrist strap, as described in Using an Electrostatic W rist

Strap on page 1-4.

3–7

Page 28

PS3000 Series Hardware Maintenance Maintaining Control Modules

To remove a control module, follow the instructions in Figure 3-7.

Note: If you are removing a failed control module, you must remove the compact

flash card from the failed control module, as described in Replacing the

Compact Flash Card on page 3-11. Then, install the card in the

replacement control module. This will ensure that the new control module

is running the correct firmware.

Figure 3-7: Removing a Control Module

Once you remove a control module, place it on a surface that is protected from

electrostatic charge.

3–8

Page 29

PS3000 Series Hardware Maintenance Maintaining Control Modules

If the array will permanently operate with only one control module, you must

install a blank control module in the empty slot. You can order a blank from your

PS Series array service provider. For proper cooling, do not leave a control

module slot empty.

Installing a Control Module

You may need to install a control module as part of an upgrade from a single

control module array to a dual control module array or for control module

maintenance, such as replacing a failed control module.

Notes: You can upgrade to a dual control module array without shutting down the

array.

Only install control modules of the same type in a PS3000 Series array.

Do not mix control module types in an array.

Before removing a control module:

• Make sure the firmware on the control module’s compact flash card matches

the firmware running on the already-installed control module. See

Maintaining Control Module Firmware on page 3-4.

If you are replacing a failed control module, be sure to remove the compact

flash card from the failed control module and install it in the replacement

control module. This will ensure that the new control module is running the

correct firmware.

• If you are upgrading to a dual control module array, remove the blank control

module from the slot. See the instructions in Figure 3-7 for opening the latch.

• Attach an electrostatic wrist strap (see Using an Electrostatic Wrist Strap on

page 1-4).

To install a control module, refer to the instructions in Figure 3-8.

3–9

Page 30

PS3000 Series Hardware Maintenance Maintaining Control Modules

Figure 3-8: Installing a Control Module

After installing a control module, connect network cables to the control module,

as described in Connecting Network Cables on page 3-5. Then, if the array was

shut down, turn on power to the array.

Check the LEDs, as described in Interpreting Control Module LEDs on page 3-2.

Also, check the GUI Member Controllers window or invoke the CLI

select show controllers

active (if there is only one control module) or secondary.

either

command. The control module status will be

member

If two control modules are installed but only one appears in the GUI or CLI, the

control module may not be properly installed. Re-seat the control module. If both

control modules still do not appear in the GUI or CLI, they may not be running the

same firmware, and you should contact your PS Series array service provider.

3–10

Page 31

PS3000 Series Hardware Maintenance Maintaining Control Modules

Note: Once connected, a control module cache battery may begin to charge. If

you have a dual control module array and the low-battery-safe cache

policy is enabled (the default), the array will operate in write-through

mode until the cache battery is fully charged.

However, if you need optimal performance before the battery is fully

charged, once the battery status is

good/charging, you can temporarily

disable the low-battery-safe policy and force the array to operate in writeback mode. Be sure to re-enable the low-battery-safe policy when the

battery is fully charged. See the Group Administration manual for

information about cache policies.

Replacing the Compact Flash Card

Each control module includes a compact flash card running the PS Series array

firmware. There are two reasons why you may need to replace a compact flash

card:

• The compact flash card fails on an otherwise functioning control module. Be

sure to order a replacement card with the same firmware version as the failed

card. See Maintaining Control Module Firmwar e on pag e 3-4 for information

about identifying firmware.

• The control module fails, but the compact flash card is still functioning. If this

occurs, remove the compact flash card from the failed control module and

install the card in the replacement control module. This will ensure that the

new control module is running the correct firmware.

To access the compact flash card, you can remove a control module in a dual

control module array without shutting down the array, if the remaining control

module has at least one connected and functioning network interface. If you

remove the active control module (the LED labeled ACT will be green), there will

be a short interruption as failover to the secondary control module occurs.

Before replacing a compact flash card:

• If you have a single control module array, if possible, cleanly shut down the

array before removing the control module. See Shutting Down and Restarting

an Array on page 1-4.

• Attach an electrostatic wrist strap, as described in Using an Electrostatic W rist

Strap on page 1-4.

•See Removing a Control Module on page 3-7 for instructions on removing a

control module.

3–11

Page 32

PS3000 Series Hardware Maintenance Maintaining Control Modules

• You can access the compact flash card by sliding the control module partially

from the slot. If you completely remove the control module, place it on a

surface that is protected from electrostatic discharge.

Figure 3-9 on page 3-12 shows how to remove a compac t flash card from a

control module and also how to install a card.

After you replace the compact flash card, see Installing a Control Module on

page 3-9 for instructions on installing a control module.

Figure 3-9: Removing and Installing a Compact Flash Card

After installing the control module, if the array was shut down, turn on power.

To ensure that the control module is operational, check the LEDs, as described in

Interpreting Control Module LEDs on page 3-2. Also, check the GUI Member

Controllers window or invoke the CLI

command. The control module status will be either

3–12

member select show controllers

active or secondary.

Page 33

4 Maintaining Power Supply and Cooling Modules

A PS3000 Series array includes two hot-swappable, combination power supply

and cooling modules.

Maintenance topics include:

• Interpreting Power Supply and Cooling Module LEDs on page 4-1

• Identifying Power Supply and Cooling Module Failures on page 4-2

• Removing a Power Supply and Cooling Module on page 4-2

• Installing a Power Supply and Cooling Module on page 4-4

Interpreting Power Supply and Cooling Module LEDs

Use the power supply and cooling module LEDs, shown in Figure 4-1and

described in Table 4-1, to determine the module status and identify problems.

Figure 4-1: Power Supply and Cooling Module LEDs

Table 4-1: Power Supply and Cooling Module LED Descriptions

Power Supply and

Cooling Module LED

_ _ _

____

~

Color Description

Off No power or normal condition.

Orange DC power failure.

Off No power or normal condition.

Orange Fan failure.

Off No power or normal condition.

Orange AC power failure.

Off No power.

Green Normal array operation.

4–1

Page 34

PS3000 Series Hardware Maintenance Maintaining Power Supply/Cooling Modules

Identifying Power Supply and Cooling Module Failures

A failure on a power supply and cooling module can be indicated by the

following:

• A power supply and cooling module LED is orange. See Interpreting Power

Supply and Cooling Module LEDs on page 4-1.

• Message on the console, in the event log, or in the Group Manager GUI

Alarms panel describes a power supply and cooling module failure.

• GUI Member Enclosure window or the CLI

enclosure

Power supply and cooling module 0 refers to the module on the right side of the

array back panel (when facing the back of the array). Power supply and cooling

module 1 refers to the module on the left side. See Figure 1-2 on page 1-1 for

details.

command shows a power supply and cooling module failure.

member select show

Removing a Power Supply and Cooling Module

If a power supply and cooling module fails, you must replace the module as soon

as possible, although an array can operate with only one working module. To

ensure proper cooling, do not remove a failed module until you are ready to

replace it.

You can remove a power supply and cooling module from an array without

affecting array operation if the second module is installed and functioning.

Otherwise, if possible, cleanly shut down the array before removing the module,

as described in Shutting Down and Restarting an Array on page 1-4.

Caution: After installing a power supply and cooling module, wait until the new

module initializes before removing the other module. New module

initialization can take from one to ten seconds. Completion is indicated

by the green power LED and event log messages stating that fans have

returned to their normal speed.

Figure 4-2 shows how to remove a power supply and cooling module from an

array.

4–2

Page 35

PS3000 Series Hardware Maintenance Maintaining Power Supply/Cooling Modules

Figure 4-2: Removing a Power Supply and Cooling Module

4–3

Page 36

PS3000 Series Hardware Maintenance Maintaining Power Supply/Cooling Modules

Installing a Power Supply and Cooling Module

To install a power supply and cooling module in an array, refer to Figure 4-3.

Figure 4-3: Installing a Power Supply and Cooling Module

If your PS Series array was shipped with a power cable, use this cable to meet

safety requirements.

Be sure to use the cable strain relief to secure the power cable to the array, as

shown in Figure 4-4.

4–4

Page 37

PS3000 Series Hardware Maintenance Maintaining Power Supply/Cooling Modules

Figure 4-4: Using the Cable Strain Relief

Turn on power to the power supply and cooling module (press –). Initialization

generally can take from one to ten seconds. Completion is indicated by the green

power LED and event log messages stating that fans have returned to their normal

speed.

To ensure that the new module is operational, check that there are no red LEDs.

Also, check the GUI Member Enclosure window or invoke the CLI

select show enclosure

command.

member

4–5

Page 38

Page 39

A Environmental, Power, and Other Specifications

Table A-2 describes the environmental, power, and physical specifications for a

PS3000 Series array.

Table A-2: PS3000 Series Array Specifications

Component Requirement

Weight of fully-loaded array 77.6 pounds or 35 kilograms

Operating temperature 41 to 95 degrees F / 5 to 35 degrees C

Storage temperature -22 to 140 degrees F / -30 to 60 degrees C

Maximum operating altitude 10,000 feet (3048 meters)

Operational relative humidity 20 to 80% non-condensing

Thermal output (fully-loaded array) 1700 BTU/hour

Operational shock 5 G for 10 ms 1/2 sin

Operational vibration Random 0.21grms 5 - 500 Hz

Input voltage 100 to 240 VAC (auto-sensing)

Input frequency 48 - 62 Hz

System input power 530 VA (maximum)

Power supplies Dual, 450 watts DC output

Maximum input power: 0.7 KVA

Input current: 7 – 3.5A

Height/Width/Depth 5.12” x 19” x 21.7” (13 x 48.26 x 55.1 cm)

A–1

Page 40

Page 41

Index

A

array

back panel

batteries 3-1

control module restriction 3-9

control modules 3-1

cooling 4-1

disks 2-1

environmental requirements A-1

failure indications 1-2

fans 4-1

firmware 3-4

front panel 1-1

LEDs 1-2, 2-1, 3-2, 4-1

maximum network availability 3-6

maximum network bandwidth 3-5,

1-1

3-6

power supplies 4-1

protecting from discharge 1-4

shutdown procedure 1-4

specifications A-1

B

batteries

charging

servicing 3-1

3-11

C

cable strain relief, using 4-5

cables (network), connecting 3-5

cables (power), connecting 4-4

cables (serial), connecting 1-4

compact flash card

firmware requirements

identifying firmware 3-4

moving 3-8, 3-9, 3-11

replacing 3-4, 3-11

control modules

3-4

batteries

charging cache battery 3-11

checking proper installation 3-10

compact flash card moving 3-8,

3-1

3-9, 3-11

compact flash card replacement

3-4, 3-11

failover behavior 3-3

failure indications 3-3

firmware identification 3-4

firmware requirements 3-4, 3-9,

3-11

handling requirements 3-3

installing in array 3-9

LEDs 3-2

locating 3-3

removing from array 3-7

restriction on mixing 3-9

synchronizing 3-3

types 3-9

verifying operational status 3-10

cooling

indications of failure

initialization 4-2

installing module in array 4-4

LEDs 4-1

locating modules 4-2

removing module from array 4-2

verifying operational status 4-5

4-2

D

disks

failure behavior

failure indications 2-3

handling requirements 2-2

installing in array 2-6

LEDs 2-1

locating 2-3

protecting 2-2

2-3

Index-1

Page 42

PS3000 Series Hardware Maintenance Index

removing from array 2-3

verifying operational status 2-6

E

electrostatic protection, using 1-4

environmental requirements A-1

F

failover

control module

network connection 3-4

port 3-4

failure indications

1-2

array

control modules 3-3

cooling 4-2

disks 2-3

power 4-2

fans

failure indications

initialization 4-2

installing module in array 4-4

LEDs 4-1

locating modules 4-2

maintaining 4-1

removing module from array 4-2

verifying operational status 4-5

firmware

identifying

requirements 3-4, 3-11

3-3, 3-4

4-2

3-4

L

LEDs

control module

cooling modules 4-1

disks 2-1

network interfaces 3-2

operations panel 1-2

power supplies 4-1

3-2

N

network

cable connections

configuration examples 3-5

failure protection 3-4

increasing availability 3-5

increasing performance 3-5

maximum availability 3-6

maximum bandwidth 3-5, 3-6

recommendations 3-5

requirements 3-5

network interfaces, LEDs 3-2

3-5

O

operations panel

1-2

LEDs

servicing 1-2

P

physical requirements A-1

power cables

restriction

using strain relief 4-4

power supplies

cable strain relief

indications of failure 4-2

initialization 4-2

installing module in array 4-4

LEDs 4-1

locating modules 4-2

maintaining 4-1

removing module from array 4-2

verifying operational status 4-5

4-4

4-5

R

requirements

array handling

control modules 3-3

cooling 4-2

disks 2-2

environmental A-1

firmware 3-4

network 3-5

physical A-1

1-4

Index-2

Page 43

PS3000 Series Hardware Maintenance Index

power 4-2

power cables 4-4

S

serial connection, making 1-4

shutting down an array 1-4

specifications, array A-1

U

upgrading to dual control modules 3-4

Index-3

Page 44

Page 45

Page 46

Loading...

Loading...