Dell EMC VMAX 250F, EMC VMAX 450F, EMC VMAX 850F, EMC VMAX 950F Site Planning Manual

EMC® VMAX® All Flash

Site Planning Guide

VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F

with HYPERMAX OS

REVISION 8.2

Copyright © 2016-2017 Dell Inc. or its subsidiaries. All rights reserved.

Published August 2017

Dell believes the information in this publication is accurate as of its publication date. The information is subject to change without notice.

THE INFORMATION IN THIS PUBLICATION IS PROVIDED “AS-IS.“ DELL MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND

WITH RESPECT TO THE INFORMATION IN THIS PUBLICATION, AND SPECIFICALLY DISCLAIMS IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. USE, COPYING, AND DISTRIBUTION OF ANY DELL SOFTWARE DESCRIBED

IN THIS PUBLICATION REQUIRES AN APPLICABLE SOFTWARE LICENSE.

Dell, EMC, and other trademarks are trademarks of Dell Inc. or its subsidiaries. Other trademarks may be the property of their respective owners.

Published in the USA.

EMC Corporation

Hopkinton, Massachusetts 01748-9103

1-508-435-1000 In North America 1-866-464-7381

www.EMC.com

2 Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS

CONTENTS

Figures

Tables

Chapter 1

Chapter 2

Chapter 3

7

9

Preface 11

Revision history...........................................................................................14

Pre-planning tasks 15

Before you begin......................................................................................... 16

Tasks to review........................................................................................... 16

VMAX All Flash packaging........................................................................... 17

Delivery and transportation 19

Delivery arrangements................................................................................20

Pre-delivery considerations........................................................................ 20

Moving up and down inclines...................................................................... 20

Shipping and storage environmental requirements......................................21

Specifications 23

Radio frequency interference..................................................................... 24

Recommended minimum distance from RF emitting device........... 24

Power consumption and heat dissipation....................................................25

Adaptive cooling............................................................................ 26

Airflow........................................................................................................ 27

Air volume, air quality, and temperature..................................................... 28

Air volume specifications............................................................... 28

Temperature, altitude, and humidity ranges...................................28

Temperature and humidity range recommendations...................... 28

Air quality requirements.................................................................29

Shock and vibration....................................................................................30

Sound power and sound pressure...............................................................30

Hardware acclimation times........................................................................ 31

Optical multimode cables............................................................................32

Open systems host and SRDF connectivity................................... 32

Chapter 4

Chapter 5

Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS 3

Data Center Safety and Remote Support 35

Fire suppressant disclaimer........................................................................ 36

Remote support..........................................................................................36

Physical weight and space 39

Floor load-bearing capacity........................................................................ 40

Raised floor requirements...........................................................................40

Physical space and weight.......................................................................... 41

CONTENTS

Chapter 6

Chapter 7

Chapter 8

Position VMAX 250F Bay 43

Bay layout and dimensions..........................................................................44

Tile placement............................................................................................ 45

Casters and leveling feet............................................................................ 45

Cabinet stabilizing...................................................................................... 47

Position VMAX 450F, VMAX 850F, VMAX 950F Bays 49

System bay layouts.................................................................................... 50

Adjacent layouts, VMAX 450F, VMAX 850F, VMAX 950F .............51

Dispersed layout, VMAX 450F, VMAX 850F, VMAX 950F............. 52

Adjacent and dispersed (mixed) layout ......................................... 53

Dimensions for array layouts...................................................................... 54

Tile placement............................................................................................ 55

Caster and leveler dimensions.................................................................... 56

Power cabling, cords and connectors 59

Power distribution equipment, VMAX 250F................................................60

Power distribution unit VMAX 450F, VMAX 850F, VMAX 950F................. 62

Wiring configurations, VMAX 250F............................................................ 64

Wiring configurations, VMAX 450F, VMAX 850F, VMAX 950F.................. 68

Power interface.......................................................................................... 72

Customer input power cabling.................................................................... 72

VMAX 250F customer AC power feed cabling............................... 73

Best practices: Power configuration guidelines.......................................... 74

Power extension cords, connectors, and wiring..........................................74

Single-phase..................................................................................75

Three-phase (International (Wye))................................................80

Three-phase (North American (Delta))......................................... 83

Three-phase (Wye, Domestic).......................................................85

Chapter 9

Chapter 10

Chapter 11

EMC racking for VMAX 250F 87

Two system configurations.........................................................................88

EMC rack requirements for customer components.................................... 88

Third Party Racking Option for VMAX 250F 89

Computer room requirements, VMAX 250F............................................... 90

Customer rack requirements, VMAX 250F................................................. 90

PDU requirements for third party racks, VMAX 250F................................. 91

Component power requirements, VMAX 250F .............................. 91

Power distribution equipment for third-party rack, VMAX 250F....94

Third Party Racking Option for VMAX 450F, VMAX 850F and

VMAX 950F 95

Computer room requirements ....................................................................96

Customer rack requirements ..................................................................... 97

Third party racks with vertical PDUs — RPQ Required ............................. 99

Requirements for third party racks with vertical PDUs (rear-facing)

.....................................................................................................100

Requirements for third party racks with vertical PDUs (inward-

facing) .........................................................................................102

Chassis to chassis grounding.................................................................... 103

4 Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS

CONTENTS

Chapter 12

Appendix A

Optional kits 105

Overhead routing kit................................................................................. 106

PDU/PDP kits, VMAX 250F......................................................................106

Dispersion kits, VMAX 450F, VMAX 850F.................................................106

Dispersion kits, VMAX 950F......................................................................107

Securing kits............................................................................................. 108

GridRunner kit and customer-supplied cable trough................................. 108

Best Practices for AC Power Connections 111

Best practices overview for AC power connections................................... 112

Selecting the proper AC power connection procedure...............................113

Procedure A: Working with the customer's electrician onsite.................... 114

Procedure A, Task 1: Customer's electrician................................. 115

Procedure A, Task 2: EMC Customer Engineer ............................116

Procedure A, Task 2: EMC Customer Engineer (VMAX 250F)..... 120

Procedure A, Task 3: Customer's electrician................................ 124

Procedure B: Verify and connect.............................................................. 125

Procedure C: Obtain customer verification............................................... 126

PDU labels.................................................................................................126

PDU label part numbers................................................................126

Applying PDU labels, VMAX 250F ................................................127

Applying PDU labels, VMAX 450F, VMAX 850F, VMAX 950F...... 128

Ground the cabinet................................................................................... 128

AC power specifications............................................................................130

Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS 5

CONTENTS

6 Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS

FIGURES

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Typical airflow in a hot/cold aisle environment........................................................... 27

Cabinet dimensions and clearances ........................................................................... 44

Placement with floor tiles........................................................................................... 45

Adjacent layout, VMAX 450F, VMAX 850F, VMAX 950F............................................ 51

Dispersed layout, front view....................................................................................... 52

Adjacent and dispersed (mixed) layout, dual-engine array..........................................53

Layout Dimensions, VMAX 450F, VMAX 850F, VMAX 950F...................................... 54

Placement with floor tiles, VMAX 450F, VMAX 850F, VMAX 950F............................55

Caster and leveler dimensions.................................................................................... 56

Power distribution unit (PDU), VMAX 250F, rear view............................................... 61

Power distribution unit (PDU) without installed wire bales, rear view.........................63

Power distribution unit (PDU) with installed wire bales, rear view..............................63

PDU internal wiring, VMAX 250F................................................................................64

Single-phase, PDP internal wiring, VMAX 250F..........................................................65

Three-phase (Delta), PDP internal wiring, VMAX 250F.............................................. 66

Three-phase (Wye), PDP internal wiring, VMAX 250F............................................... 67

Single-phase, horizontal 2U PDU internal wiring, VMAX 450F, VMAX 850F, VMAX

950F...........................................................................................................................69

Three-phase (Delta), horizontal 2U PDU internal wiring, VMAX 450F, VMAX 850F,

VMAX 950F................................................................................................................ 70

Three-phase (Wye), horizontal 2U PDU internal wiring, VMAX 450F, VMAX 850F,

VMAX 950F.................................................................................................................71

Customer input power cabling for VMAX 250F...........................................................73

Single-phase: EF-PW40U-US (VMAX 450F, VMAX 850F), ET-PW40U-US (VMAX

950F), ES-PW40U-US (VMAX 250F)........................................................................ 77

Single-phase: EF-PW40URUS (VMAX 450F, VMAX 850F), ET-PW40URUS (VMAX

950F), ES-PW40URUS (VMAX 250F)....................................................................... 78

Single-phase: EF-PW40UIEC3 (VMAX 450F, VMAX 850F), ET-PW40UIEC3 (VMAX

950F), ES-PW40UIEC3 (VMAX 250F).......................................................................78

Single-phase: EF-PW40UASTL (VMAX 450F, VMAX 850F), ET-PW40UASTL (VMAX

950F), ES-PW40UASTL (VMAX 250F)......................................................................79

Single-phase: E-PW40L730........................................................................................79

Flying leads, three-phase, international: EF-PC3YAFLE (VMAX 450F, VMAX 850F),

ET-PC3YAFLE (VMAX 950F), ES-PC3YAFLE (VMAX 250F), ....................................81

Three-phase, international: EF-PCBL3YAG (VMAX 450F, VMAX 850F), ET-

PCBL3YAG (VMAX 950F), ES-PCBL3YAG (VMAX 250F)......................................... 82

Three-phase, North American, Delta: EF-PCBL3DHR (VMAX 450F, VMAX 850F), ET-

PCBL3DHR (VMAX 950F), ES-PCBL3DHR (VMAX 250F).........................................84

Three-phase, North American, Delta: EF-PCBL3DHH (VMAX 450F, VMAX 850F), ET-

PCBL3DHH (VMAX 950F), ES-PCBL3DHH (VMAX 250F)........................................ 84

Three-phase, domestic (Black and Gray): EF-PCBL3YL23P (VMAX 450F,

VMAX 850F), ET-PCBL3YL23P (VMAX 950F), ES-PCBL3YL23P (VMAX 250F)...... 86

Customer rack dimension requirements .....................................................................98

Requirements for customer rack with rear-facing, vertical PDUs..............................100

Requirements for third party rack with inward-facing, vertical PDUs........................102

Two independent customer-supplied PDUs............................................................... 112

Circuit breakers ON — AC power within specification...............................................115

Circuit breakers OFF — No AC power.......................................................................115

System bay power tee breakers (OFF = pulled out)...................................................116

Connecting AC power, single-phase...........................................................................117

Connecting AC power, three-phase........................................................................... 118

Power zone connections............................................................................................119

PDP power switches for Zone A and B ..................................................................... 120

Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS 7

FIGURES

42

43

44

45

46

47

48

Connecting AC power ............................................................................................... 121

Power zone connections........................................................................................... 122

Customer input power cabling for VMAX 250F......................................................... 123

Applying the PDU labels ........................................................................................... 127

PDU label , single-phase and three-phase................................................................. 128

Label placement— Customer PDU Information.........................................................128

Location of cabinet ground lugs................................................................................ 129

8 Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS

TABLES

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

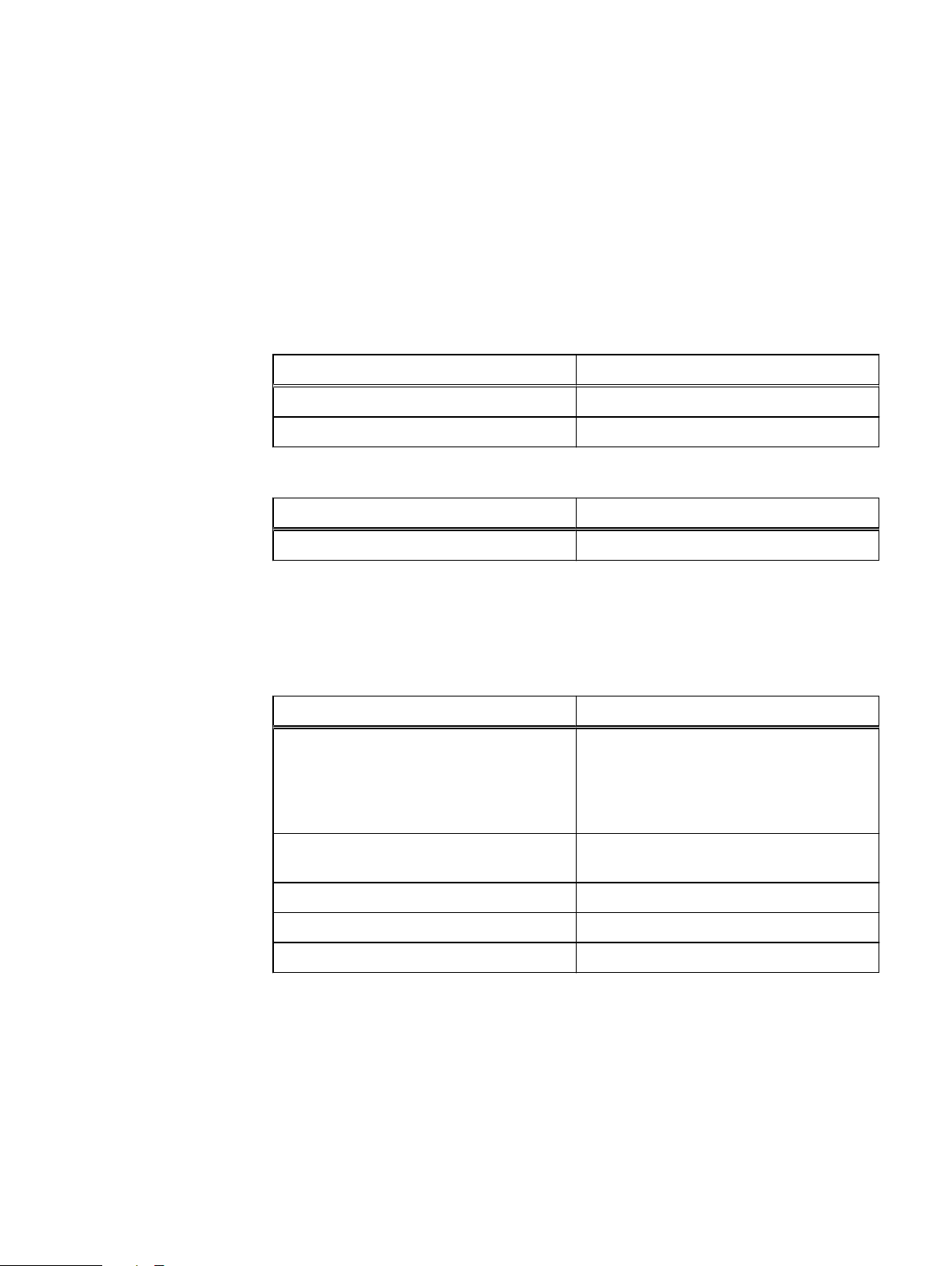

Typographical conventions used in this content.......................................................... 12

Revision history...........................................................................................................14

Before you begin......................................................................................................... 16

Shipping and storage environmental requirements...................................................... 21

Minimum distance from RF emitting devices.............................................................. 24

Power consumption and heat dissipation....................................................................25

Airflow diagram key.................................................................................................... 27

Maximum air volume, VMAX 250F..............................................................................28

Maximum air volume, VMAX 450F, VMAX 850F, VMAX 950F....................................28

Environmental operating ranges................................................................................. 28

Temperature and humidity..........................................................................................29

Platform shock and vibration......................................................................................30

Sound power and sound pressure levels, A-weighted, VMAX 250F............................ 30

Sound power and sound pressure levels, A-weighted, VMAX 450F, VMAX 850F,

VMAX 950F................................................................................................................30

Hardware acclimation times (systems and components).............................................31

OM3 and OM4 Fibre cables — 50/125 micron optical cable.......................................32

Space and weight requirements, VMAX 250F............................................................. 41

Space and weight requirements, VMAX 450F, VMAX 850F, VMAX 950F................... 41

Adjacent layout diagram key, VMAX 450F, VMAX 850F, VMAX 950F ....................... 51

Caster and leveler dimensions diagram key................................................................ 56

Extension cords and connectors options – single-phase.............................................75

Extension cords and connectors options – three-phase international (Wye)..............80

Extension cords and connectors options – three-phase North American (Delta)....... 83

Extension cords and connectors options – three-phase Wye, domestic..................... 85

Engine and 2U SPS power requirements.................................................................... 92

25 drive DAE power requirements.............................................................................. 93

Power Distribution Equipment C13 Outlet Connections required for 1 V-Brick ...........94

Power Distribution Equipment C13 Outlet Connections required for 2 V-Bricks ........ 94

Overhead routing models, VMAX 250F..................................................................... 106

Overhead routing models, VMAX 450F, VMAX 850F, VMAX 950F........................... 106

PDU/PDP kits for VMAX 250F................................................................................. 106

Dispersion kit model numbers, VMAX 450F, VMAX 850F..........................................107

Dispersion kit model numbers, VMAX 950F...............................................................107

Securing kit models, VMAX 250F..............................................................................108

Securing kit models, VMAX 450F, VMAX 850F, VMAX 950F....................................108

Bottom routing model, VMAX 250F.......................................................................... 109

Bottom routing model, VMAX 450F, VMAX 850F, VMAX 950F................................ 109

Procedure options for AC power connection ............................................................ 113

VMAX 250F label part numbers.................................................................................126

VMAX 450F, VMAX 850F, VMAX 950F label part numbers, EMC racks ...................126

Input power requirements - single-phase, North American, International, Australian

..................................................................................................................................130

Input power requirements - three-phase, North American, International, Australian

.................................................................................................................................. 131

Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS 9

TABLES

10 Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS

Preface

Note

As part of an effort to improve its product lines, EMC periodically releases revisions of

its software and hardware. Therefore, some functions described in this document

might not be supported by all versions of the software or hardware currently in use.

The product release notes provide the most up-to-date information on product

features.

Contact your EMC representative if a product does not function properly or does not

function as described in this document.

This document was accurate at publication time. New versions of this document might

be released on EMC Online Support (https://support.emc.com). Check to ensure that

you are using the latest version of this document.

Purpose

This document is intended for use by customers and/or company representatives who

want to plan the purchase and installation of a VMAX All Flash system.

Audience

This document is intended for use by customers or company representatives.

Related documentation

The following documentation portfolios contain documents related to the hardware

platform and manuals needed to manage your software and storage system

configuration. Also listed are documents for external components which interact with

your array.

EMC VMAX All Flash Product Guide for VMAX 250F, 450F, 850F, 950F with HYPERMAX

OS

Provides product information regarding the purchase of a VMAX 250F, 450F,

850F, 950F with HYPERMAX OS.

EMC VMAX Securing Kit Installation Guide

Describes how to install the securing kit on a VMAX3 Family array or VMAX All

Flash array.

EMC VMAX Best Practices Guide for AC Power Connections

Describes the best practices to assure fault-tolerant power to a VMAX3 Family

array or VMAX All Flash array.

EMC VMAX Power-down/Power-up Procedure

Describes how to power-down and power-up a VMAX3 Family array or VMAX All

Flash array.

HYPERMAX OS 5977.xxx.xxx for EMC VMAX3 Family and VMAX All Flash Release Notes

Describes new features and any known limitations.

Special notice conventions used in this document

EMC uses the following conventions for special notices:

Preface

11

DANGER

WARNING

CAUTION

NOTICE

Note

Preface

Indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Addresses practices not related to personal injury.

Presents information that is important, but not hazard-related.

Typographical conventions

EMC uses the following type style conventions in this document:

Table 1

Typographical conventions used in this content

Bold

Italic

Monospace

Monospace italic

Monospace bold

[ ] Square brackets enclose optional values

| Vertical bar indicates alternate selections - the bar means “or”

Used for names of interface elements, such as names of windows,

dialog boxes, buttons, fields, tab names, key names, and menu paths

(what the user specifically selects or clicks)

Used for full titles of publications referenced in text

Used for:

l

System code

l

System output, such as an error message or script

l

Pathnames, filenames, prompts, and syntax

l

Commands and options

Used for variables

Used for user input

{ } Braces enclose content that the user must specify, such as x or y or

z

... Ellipses indicate nonessential information omitted from the example

Where to get help

Support, product and licensing information can be obtained as follows:

12 Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS

Preface

Product information

EMC technical support, documentation, release notes, software updates, or

information about EMC products can be obtained on the https://

support.emc.com site (registration required).

Technical support

To open a service request through the https://support.emc.com site, you must

have a valid support agreement. Contact your EMC sales representative for

details about obtaining a valid support agreement or to answer any questions

about your account.

Your comments

Your suggestions help us improve the accuracy, organization, and overall quality of the

documentation. Send your comments and feedback to:

VMAXContentFeedback@emc.com

13

Preface

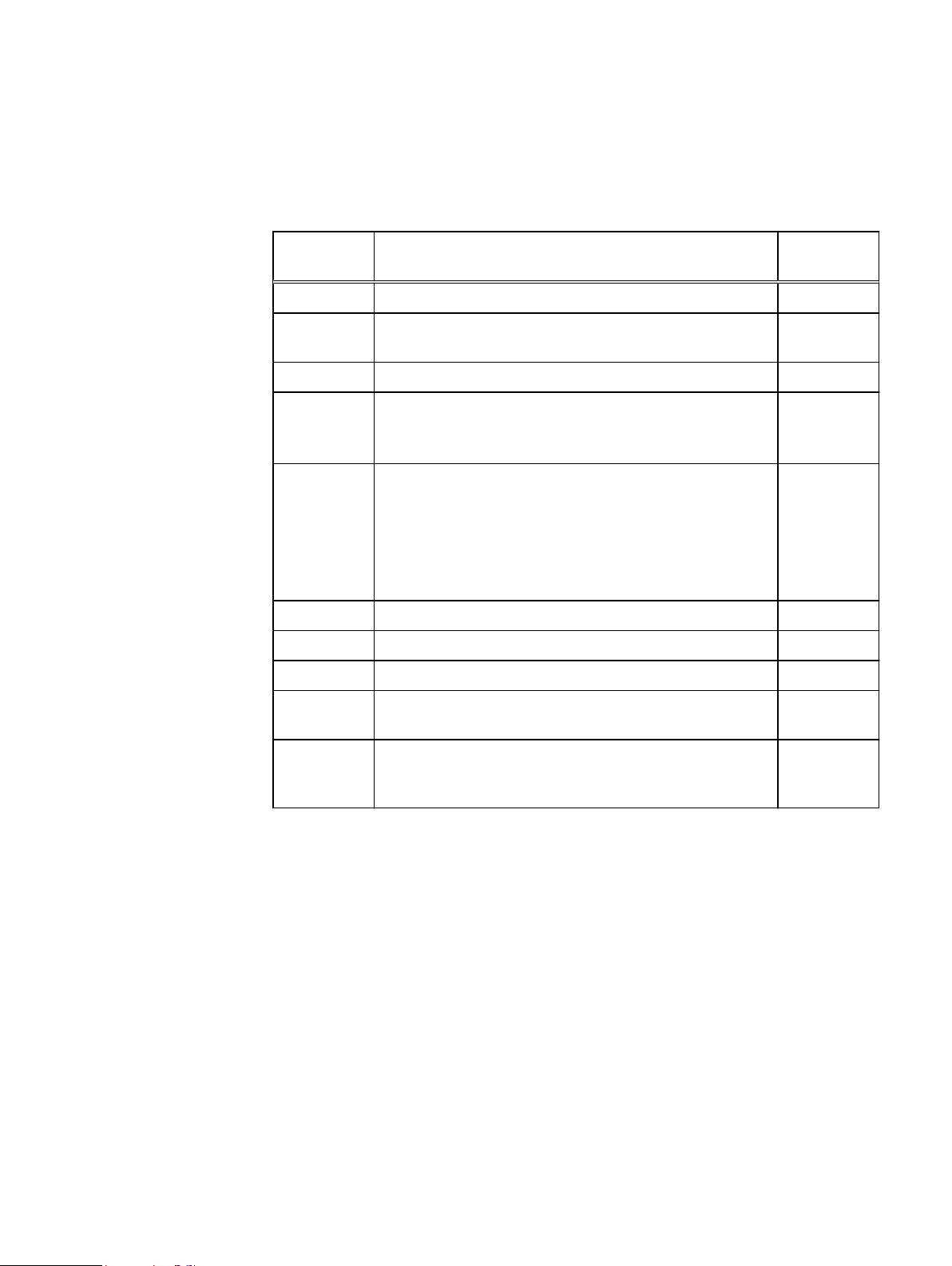

Revision history

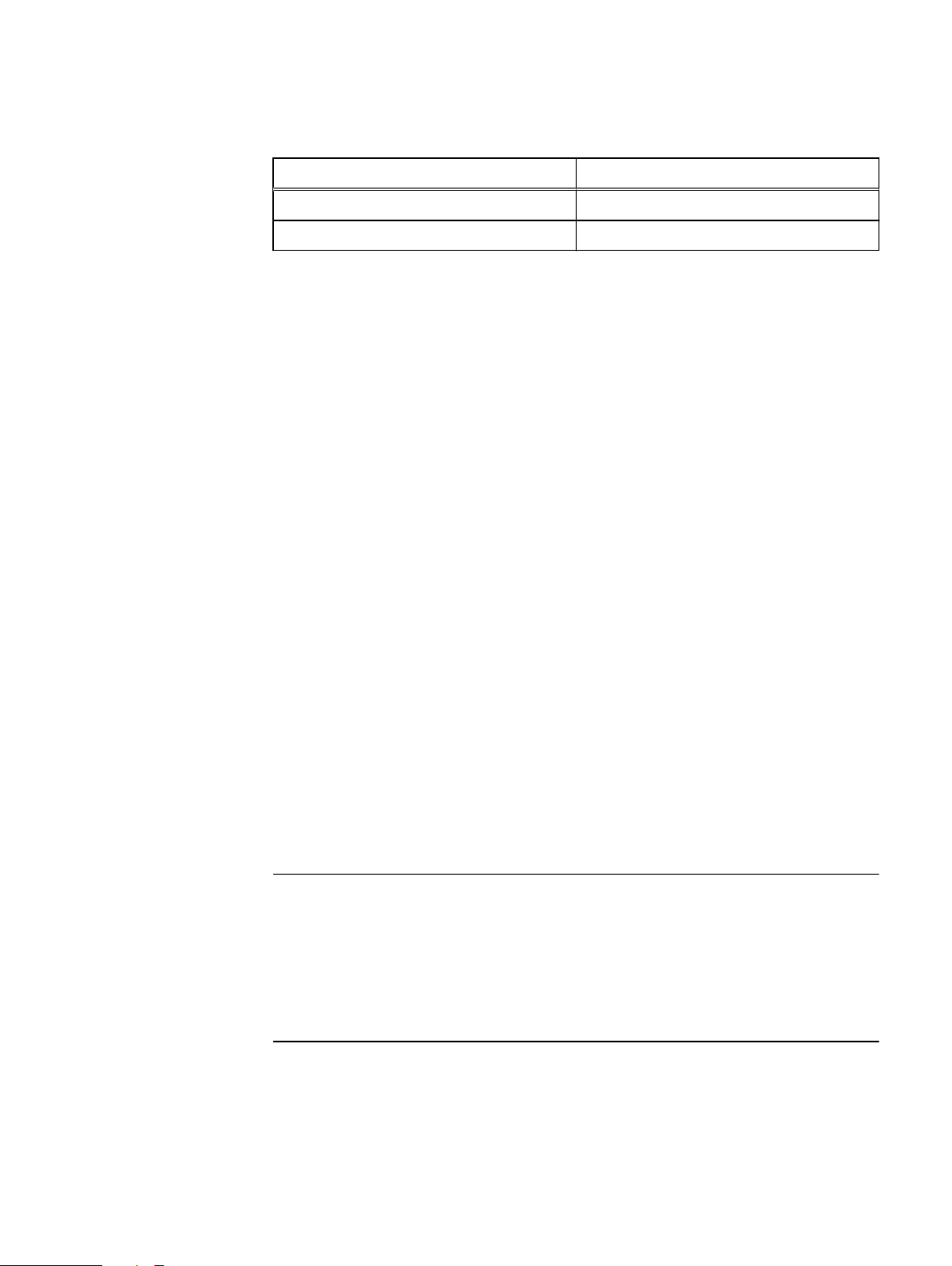

Table 2 Revision history

Revision Description and/or change Date

released

8.2 Fixed typo for single-phase PDP wiring configuration. August, 2017

8.1 Added recommendation for chassis to chassis grounding for

multiple bay systems.

8.0 Added VMAX 950F product content. May, 2017

7.0 Updated power and heat dissipation numbers for VMAX 250F.

Corrected formula for 3rd party rack cabinet width

requirements.

6.0 Added VMAX 250F product content and adjusted document

architecture for readability.

Updated wiring configuration diagrams and content for new

2U PDUs.

Updated power distribution unit recommendations for

overhead power.

5.0 In Position Bays chapter, removed an incorrect image. June, 2016

4.0 Added content to support option for 3rd-party racks. May, 2016

3.0 Modified topics to reflect Slot 9 is reserved for compression. April, 2016

2.0 Updated values in the power and heat dissipation specification

table.

1.0 First release of the VMAX All Flash with EMC HYPERMAX OS

for VMAX 450F, VMAX 450FX, VMAX 850F, and

VMAX 850FX.

June, 2017

September,

2016

August, 2016

February,

2016

February,

2016

14 Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS

CHAPTER 1

Pre-planning tasks

This chapter includes:

l

Before you begin.................................................................................................16

l

Tasks to review...................................................................................................16

l

VMAX All Flash packaging...................................................................................17

Pre-planning tasks 15

Pre-planning tasks

Before you begin

VMAX All Flash arrays are designed for installation in data centers that provide:

l

l

l

l

l

l

Raised floors are preferred.

For information regarding overhead cable routing, see: Overhead routing kit on page

106.

To prepare the site for an array, meet with your EMC Systems Engineer and EMC

Customer Engineer and determine what is needed to prepare for delivery and

installation.

One or more sessions may be necessary to finalize installation plans.

Sufficient physical space

Controlled temperature and humidity

Airflow and ventilation

Power and grounding

System cable routing facilities

Fire protection

Tasks to review

The following table provides a list of tasks to review during the planning process:

Table 3

Task Comments and/or Provide

Identify power requirements with customer and customer

electrician.

For customer-supplied third party rack support, see the

detailed physical requirements in Third Party Racking Option

for VMAX 250F on page 89 and Third Party Racking Option

for VMAX 450F, VMAX 850F and VMAX 950F on page 95.

Complete the

Survey

Installation Planning Task Sheet and Presite

in DXCX.

Before you begin

External AC power must be supplied from an independent

customer-supplied power distribution unit (PDU).

EMC recommends that the customer’s electrician be available

at the installation site for regular and third party racked

arrays.

Best Practices for AC Power Connections on page 111

provides details.

The field representative working the order must:

l

Review the requisite information regarding the third party

racking option.

l

In Sizer, select the desired configuration. In the

Hardware Options screen, under Rack Type, select

Third Party.

l

Connection for ConnectEMC to dial home to the EMC

Support Center. Data Center Safety and Remote Support

on page 35 provides additional details on remote

support.

16 Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS

Table 3 Before you begin (continued)

Task Comments and/or Provide

l

Power, cooling and ventilation, humidity control, floor

load capability, system placement, and service clearances

as required in the data center.

VMAX All Flash packaging

VMAX All Flash arrays offer the simplest packaging ever delivered for a platform. The

basic building block is an appliance-based entity called a V-Brick in open system arrays

and a zBrick in mainframe arrays. Each V-Brick or zBrick includes:

l

An engine with two directors (the redundant data storage processing unit)

l

Flash capacity in Drive Array Enclosures (DAEs):

n

VMAX 250F: Two 25-slot DAEs with a minimum base capacity of 13TBu

n

VMAX 450F, VMAX 850F: Two 120-slot DAEs with a minimum base capacity of

53TBu

n

VMAX 950F (open or mixed systems): Two 120-slot DAEs with a minimum base

capacity of 53TBu

n

VMAX 950F (mainframe systems): Two 120-slot DAEs with a minimum base

capacity of 13TBu

l

Multiple software packages are available: F and FX packages for open system

arrays and zF and zFX for mainframe arrays.

Pre-planning tasks

This document uses the term V-Brick for planning purposes. All guidelines that apply

to V-Bricks also apply to zBricks.

VMAX All Flash packaging 17

Pre-planning tasks

18 Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS

CHAPTER 2

Delivery and transportation

This chapter includes:

l

Delivery arrangements....................................................................................... 20

l

Pre-delivery considerations................................................................................20

l

Moving up and down inclines..............................................................................20

l

Shipping and storage environmental requirements............................................. 21

Delivery and transportation 19

NOTICE

Delivery and transportation

Delivery arrangements

Delivery within the United States or Canada is by air-ride truck with custom-designed

shipping material, crate, and pallet. International delivery normally involves air freight.

Unless otherwise instructed, the EMC Traffic Department arranges for delivery

directly to the customer’s computer room. To ensure successful delivery of the

system, EMC has formed partnerships with specially selected moving companies.

These companies have moving professionals trained in the proper handling of large,

sensitive equipment. These companies provide the appropriate personnel, floor

layments, and any ancillary moving equipment required to facilitate delivery. Moving

companies should check general guidelines, weights, and dimensions.

Inform EMC of any labor union-based restrictions or security clearance requirements

prior to delivery.

Pre-delivery considerations

Take into account the following considerations prior to the delivery at your site:

l

Weight capacities of the loading dock, tailgate, and service elevator if delivery is to

a floor other than the receiving floor.

l

Length and thickness of covering required for floor protection.

l

Equipment ramp availability if the receiving floor is not level with computer room

floor.

l

Set up the necessary network and gateway access to accommodate EMC Secure

Remote Support (ESRS) so that it will be available and operable for the installation

date.

Moving up and down inclines

To prevent tipping when moving up and down inclines, the following guidelines are

recommended:

l

When moving cabinets, all doors/drawers should be closed.

l

When moving the cabinet down an incline, the front of the cabinet must go first.

l

When moving the cabinet up an incline, the rear of the bay goes last.

All portions of the bay will clear ramp and threshold slopes up to 1:10 (rise to run

ratio), per Code of Federal Regulations — ADA Standards for Accessible Design, 28

CFR Part 36.

20 Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS

Delivery and transportation

Shipping and storage environmental requirements

The following table provides the environmental requirements for shipping and storage:

Table 4 Shipping and storage environmental requirements

Condition Setting

Ambient temperature -40° to 149° F (-40° to 65° C)

Temperature gradient 43.2° F/hr (24° C/hr)

Relative humidity 10% to 90% noncondensing

Maximum altitude 25,000 ft (7619.7 m)

Storage time (unpowered) Recommendation: Do not exceed 6

consecutive months of unpowered storage.

Shipping and storage environmental requirements 21

Delivery and transportation

22 Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS

CHAPTER 3

Specifications

This chapter includes:

l

l

l

l

l

l

l

l

Radio frequency interference.............................................................................24

Power consumption and heat dissipation........................................................... 25

Airflow................................................................................................................27

Air volume, air quality, and temperature.............................................................28

Shock and vibration........................................................................................... 30

Sound power and sound pressure...................................................................... 30

Hardware acclimation times................................................................................31

Optical multimode cables................................................................................... 32

Specifications

23

Specifications

Radio frequency interference

Electro-magnetic fields, which include radio frequencies can interfere with the

operation of electronic equipment. EMC Corporation products have been certified to

withstand radio frequency interference (RFI) in accordance with standard

EN61000-4-3. In Data Centers that employ intentional radiators, such as cell phone

repeaters, the maximum ambient RF field strength should not exceed 3 Volts /meter.

The field measurements should be taken at multiple points in close proximity to EMC

Corporation equipment. It is recommended to consult with an expert prior to installing

any emitting device in the Data Center. In addition, it may be necessary to contract an

environmental consultant to perform the evaluation of RFI field strength and address

the mitigation efforts if high levels of RFI are suspected.

The ambient RFI field strength is inversely proportional to the distance and power

level of the emitting device.

Recommended minimum distance from RF emitting device

The following table provides the recommended minimum distances between EMC

arrays and RFI emitting equipment. Use these guidelines to verify that cell phone

repeaters or other intentional radiator devices are at a safe distance from the EMC

Corporation equipment.

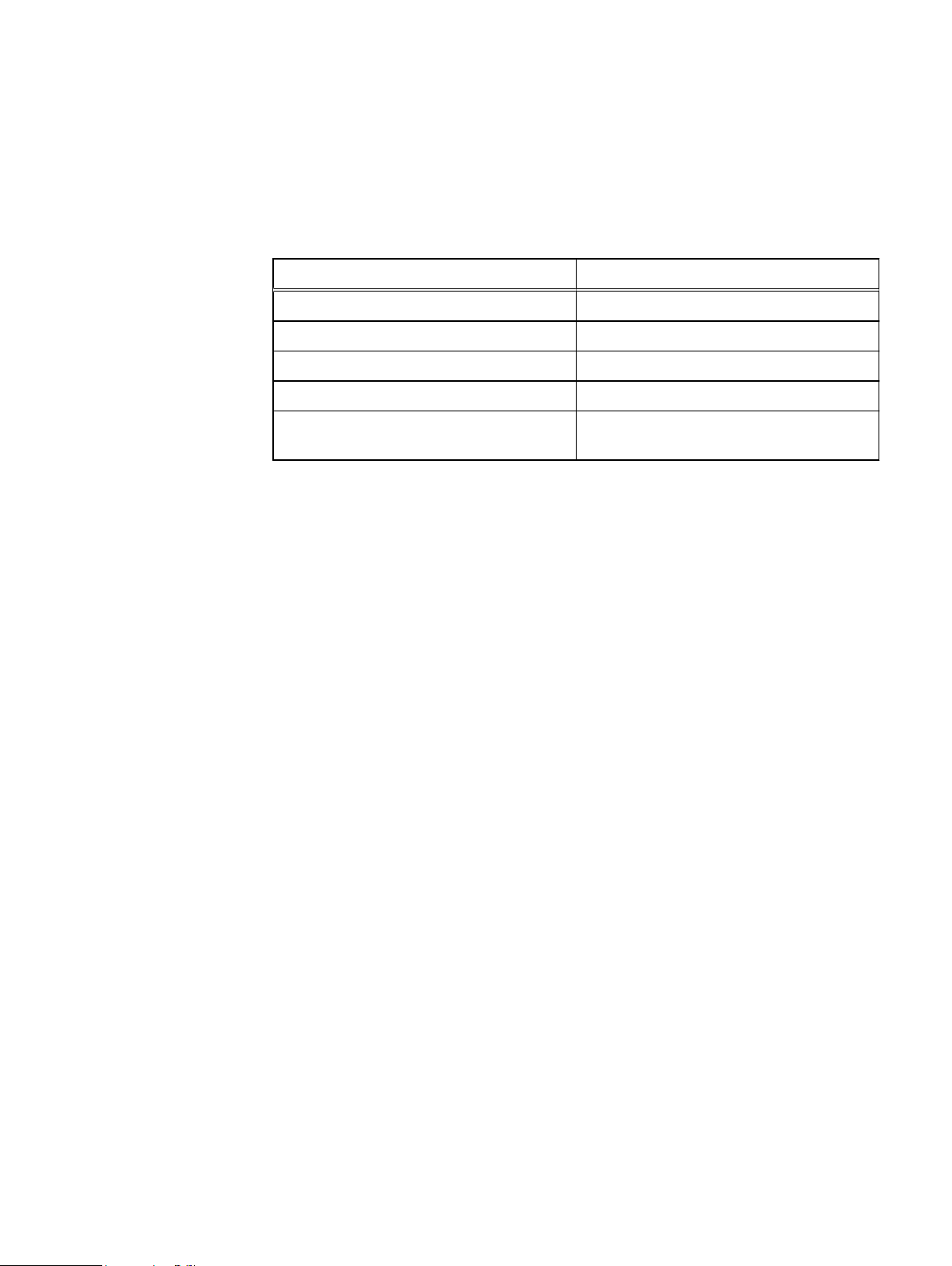

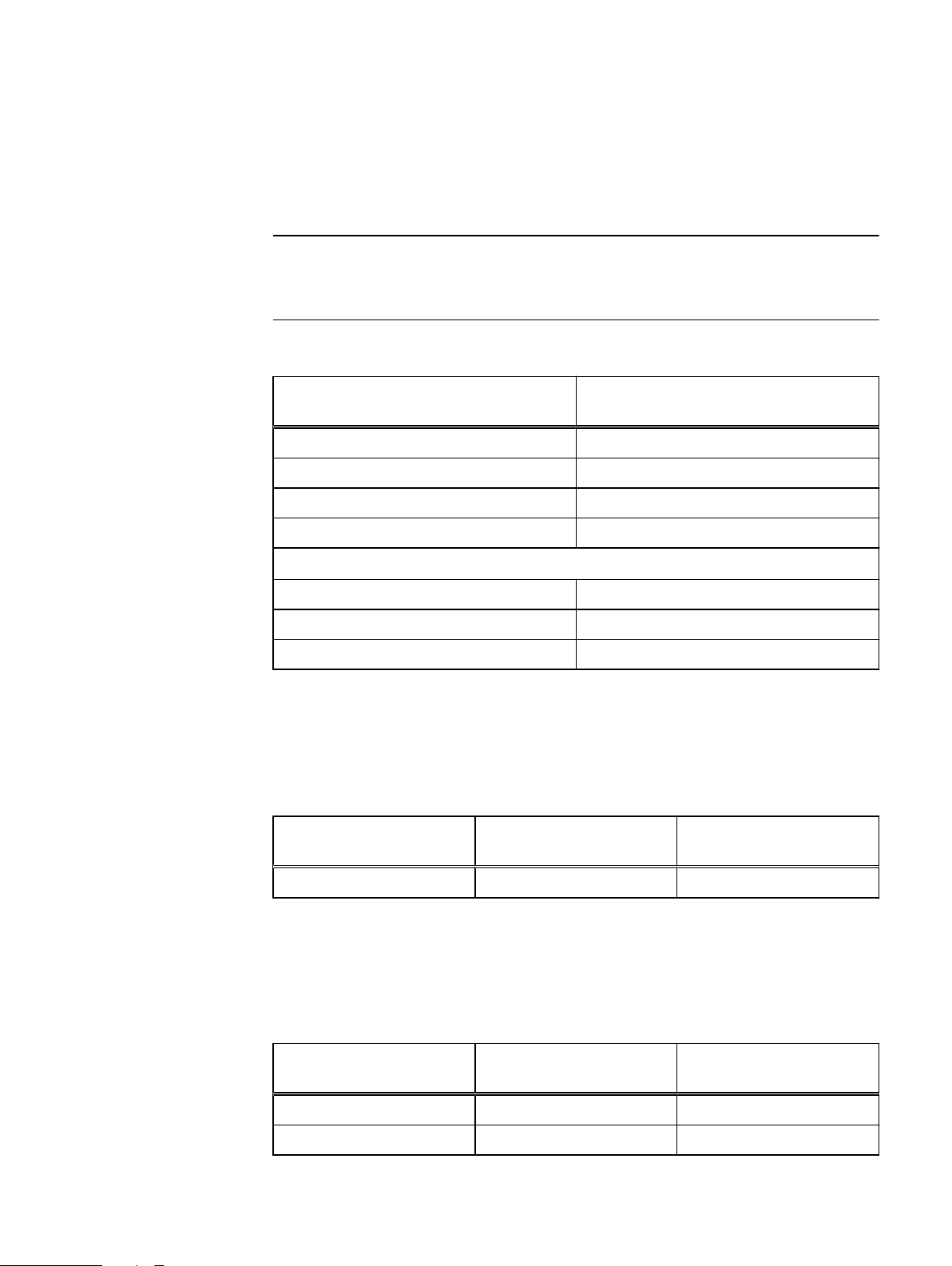

Table 5

Minimum distance from RF emitting devices

Repeater power level

1 Watt 9.84 ft (3 m)

2 Watt 13.12 ft (4 m)

5 Watt 19.69 ft (6 m)

7 Watt 22.97 ft (7 m)

10 Watt 26.25 ft (8 m)

12 Watt 29.53 ft (9 m)

15 Watt 32.81 ft (10 m)

a.

Effective Radiated Power (ERP)

a

Recommended minimum distance

24 Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS

Power consumption and heat dissipation

NOTICE

EMC provides the EMC Power Calculator to refine the power and heat figures to more

closely match your array. Contact your EMC Sales Representative or use the EMC

Power Calculator for specific supported configurations. The following table provides

calculations of maximum power and heat dissipation.

Power consumption and heat dissipation details vary based on the number of system

and storage bays. Ensure that the installation site meets these worst case

requirements.

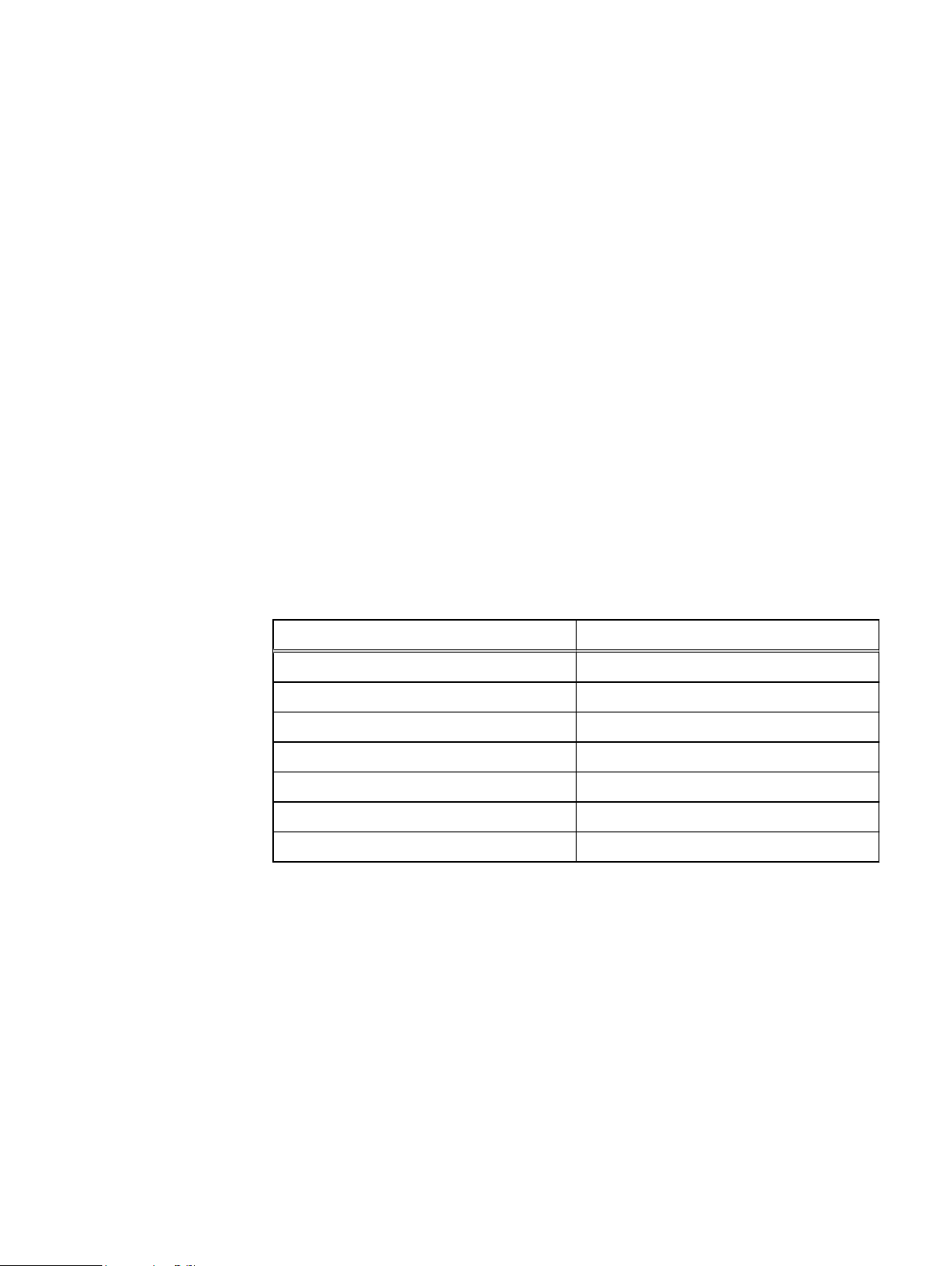

Table 6 Power consumption and heat dissipation

VMAX 250F VMAX 450F VMAX 850F VMAX 950F

Specifications

Maximum power

and heat

dissipation at

<26°C and

a

>35°C

System bay 1

Dual V-Brick

System bay 2

Dual V-Brick

b

a.

Power values and heat dissipations shown at >35°C reflect the higher power levels associated with both the battery recharge

cycle, and the initiation of high ambient temperature adaptive cooling algorithms. Values at <26°C are reflective of more steady

state maximum values during normal operation.

b.

Power values for system bay 2 and all subsequent system bays where applicable.

Maximum

total power

consumption

<26°C /

>35°C

(kVA)

4.13 / 5.19 14,090 /

N/A 6.28 / 8.38 21,415 /

Maximum

heat

dissipation

<26°C /

>35°C

(Btu/Hr)

17,698

Maximum

total power

consumption

<26°C /

>35°C

(kVA)

6.69 / 9.05 22,813 /

Maximum

heat

dissipation

<26°C /

>35°C

(Btu/Hr)

30,861

28,576

Maximum

total power

consumption

<26°C /

>35°C

(kVA)

6.94 / 9.30 23,665 /

6.49 / 8.59 22,131 /

Maximum

heat

dissipation

<26°C /

>35°C

(Btu/Hr)

31,713

29,292

Maximum

total power

consumption

<26°C /

>35°C

(kVA)

7.25 / 9.61 24,712 /

6.80 / 8.90 23,178 /

Maximum

heat

dissipation

<26°C /

>35°C

(Btu/Hr)

32,760

30,339

Power consumption and heat dissipation 25

Specifications

Adaptive cooling

The systems apply adaptive cooling based on customer environments to save energy.

Engines and DAEs access thermal data through components located within their

enclosures. Based on ambient temperature and internal activity, they set the cooling

fan speeds. As the inlet temperatures increase, the adaptive cooling increases the fan

speeds, with the resulting platform power increasing up to the maximum values shown

below. These values, along with the SPS recharge power consumption, contribute to

the maximum system power consumption values over 35°C shown in Table 6 on page

25.

VMAX 250F

l

DAE25 (25 Drives) = 7VA - 24 BTU/hr

l

Engine = 255VA - 870 BTU/hr

VMAX 450F, VMAX 850F

l

DAE120 (2.5 Drives) = 305VA - 1024 BTU/hr

l

Engine = 180VA - 614 BTU/hr

VMAX 950F

l

DAE120 (2.5 Drives) = 305VA - 1024 BTU/hr

l

Engine = 255VA - 870 BTU/hr

26 Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS

Airflow

5

6

5

4

4

8

7

9

9

1 1

22

3

Specifications

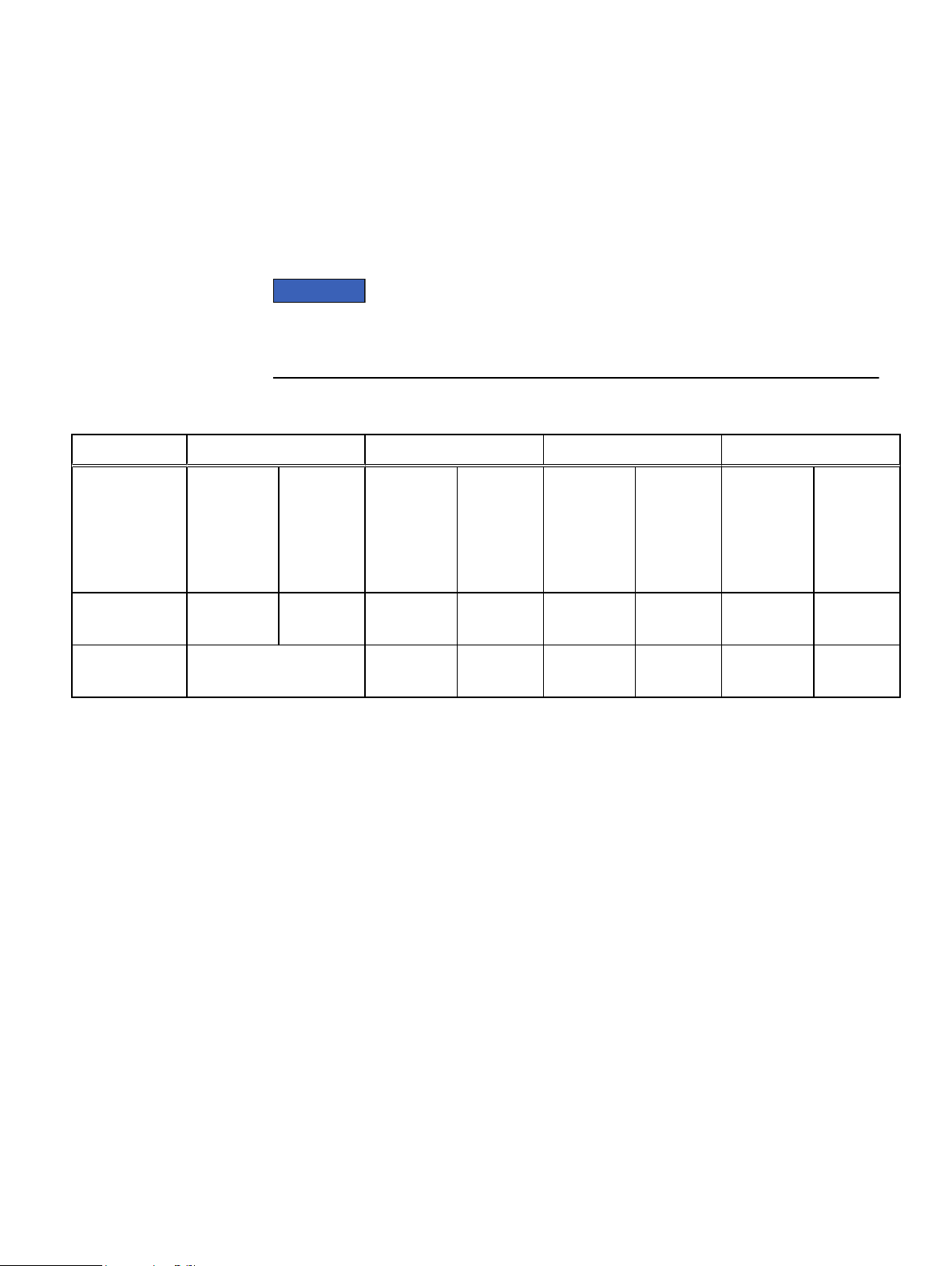

Systems are designed for typical hot aisle/cold aisle data center cooling environments

and installation:

l

On raised or nonraised floors.

l

In hot aisle/cold aisle arrangements.

The airflow provides less mixing of hot and cold air, which can result in a higher return

temperature to the computer room air conditioner (CRAC). This promotes better heat

transfer outside the building and achieves higher energy efficiency and lower Power

Usage Effectiveness (PUE). Additional efficiency can be achieved by sequestering the

exhaust air completely and connecting ducts directly to a CRAC unit or to the outside.

Best practice is to place a perforated floor tile in front of each bay to allow adequate

cooling air supply when installing on a raised floor. The following figure shows typical

airflow in a hot aisle/ cold aisle environment.

Figure 1 Typical airflow in a hot/cold aisle environment

Table 7 Airflow diagram key

# Description # Description

1 To refrigeration unit 6 Hot aisle

2 Suspended ceiling 7 Perforated rear doors

3 Air return 8 Pressurized floor

4 System bays 9 Perforated floor tile

5 Cold aisle

Airflow 27

Specifications

Air volume, air quality, and temperature

The installation site must meet certain recommended requirements for air volume,

temperature, altitude, and humidity ranges, and air quality.

Air volume specifications

The following table provides the recommended maximum amount of air volume.

Table 8 Maximum air volume, VMAX 250F

Bay Units

System bay, 1 V-Brick 490 cfm (13.9 m3/min)

System bay, 2 V-Bricks 980 cfm (27.8 m3/min)

Table 9 Maximum air volume, VMAX 450F, VMAX 850F, VMAX 950F

Bay Units

System bay 1,325 cfm (37.4 m3/min)

Temperature, altitude, and humidity ranges

The following table provides the recommended environmental operating ranges.

Table 10

Condition System

Operating temperature and operating

altitude

Operating altitude (maximum) 10,000 ft (3,048 m) 1.1° derating per 1,000

Operating relative humidity extremes 20% to 80% noncondensing

Operating rate of temperature change 9° F/Hr (5° C/Hr)

Thermal excursion 122° F (48° C) (up to 24 hours)

Environmental operating ranges

a

a.

These values apply to the inlet temperature of any component within the bay.

b.

Derating equals an operating temperature of 29.25° C

l

50° – 90° F (10° to 32° C) at 7,500 ft

(2,286 m)

l

50° – 95° F (10° to 35° C) at 3,317 ft

(950 m)

b

ft

Temperature and humidity range recommendations

The following table provides the recommended operating and humidity ranges to

ensure long-term reliability, especially in environments where air quality is a concern.

28 Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS

Table 11 Temperature and humidity

Note

Condition System

Operating temperature range 64°— 75° F (18° to 24° C)

Operating relative humidity range 40 — 55%

Air quality requirements

VMAX All Flash arrays are designed to be consistent with the requirements of the

American Society of Heating, Refrigeration and Air Conditioning Engineers (ASHRAE)

Environmental Standard Handbook and the most current revision of Thermal

Guidelines for Data Processing Environments, ASHRAE TC 9.9 2011.

The arrays are best suited for Class 1A Datacom environments, which consist of tightly

controlled environmental parameters, including temperature, dew point, relative

humidity and air quality. These facilities house mission critical equipment and are

typically fault tolerant, including the air conditioners. In a data center environment, if

the air conditioning fails and the temperature is lost, a vault may occur to protect

data.

The data center should maintain a cleanliness level as identified in ISO 14664-1, class 8

for particulate dust and pollution control. The air entering the data center should be

filtered with a MERV 11 filter or better. The air within the data center should be

continuously filtered with a MERV 8 or better filtration system. In addition, efforts

should be maintained to prevent conductive particles, such as zinc whiskers, from

entering the facility.

The allowable relative humidity level is 20–80% non condensing, however, the

recommended operating environment range is 40–55%. For data centers with

gaseous contamination, such as high sulfur content, lower temperatures and humidity

are recommended to minimize the risk of hardware corrosion and degradation. In

general, the humidity fluctuations within the data center should be minimized. It is also

recommended that the data center be positively pressured and have air curtains on

entry ways to prevent outside air contaminants and humidity from entering the

facility.

For facilities below 40% relative humidity (RH), EMC recommends using grounding

straps when contacting the equipment to avoid the risk of electrostatic discharge

(ESD), which can harm electronic equipment.

Specifications

As part of an ongoing monitoring process for the corrosiveness of the environment,

EMC recommends placing copper and silver coupons (per ISA 71.04-1985, Section 6.1

Reactivity) in airstreams representative of those in the data center. The monthly

reactivity rate of the coupons should be less than 300 Angstroms. When monitored

reactivity rate is exceeded, the coupon should be analyzed for material species and a

corrective mitigation process emplaced.

Air quality requirements 29

Note

Specifications

Shock and vibration

The following table provides the platform shock and vibration maximums and the

transportation shock and vibration levels (in the vertical direction).

Levels shown apply to all three axes, and should be measured with an accelerometer in

the equipment enclosures within the cabinet.

Table 12 Platform shock and vibration

Platform condition Response measurement level (should

Non operational shock 10 G's, 7 ms duration

Operational shock 3 G's, 11 ms duration

Non operational random vibration .40 Grms, 5-500Hz, 30 minutes

not exceed)

Operational random vibration .21 Grms, 5-500Hz, 10 minutes

Packaged system condition

Transportation shock 10 G's, 12 ms duration

Transportation random vibration 1.15 Grms, 1 hour

Frequency range 1-200 Hz

Sound power and sound pressure

VMAX 250F

Table 13

Configuration Sound power levels

System bay, 1 V-Brick 7.1 58.9

VMAX 450F, VMAX 850F, VMAX 950F

Sound power and sound pressure levels, A-weighted, VMAX 250F

(LWAd) (B)

a.

Declared noise emissions with.3B correction factor added per ISO9296.

b.

Measured at the four bystander positions per ISO7779

a

(LpA) (dB)

b

Sound pressure levels

Table 14

950F

Configuration Sound power levels

System bay (max) 7.9 66

System bay (min) 7.6 63

30 Site Planning Guide VMAX 250F, VMAX 450F, VMAX 850F, VMAX 950F with HYPERMAX OS

Sound power and sound pressure levels, A-weighted, VMAX 450F, VMAX 850F, VMAX

Sound pressure levels

(LWAd) (B)

a.

Declared noise emissions with.3B correction factor added per ISO9296.

a

(LpA) (dB)

b

Loading...

Loading...