Dell E1200i ExaScale Installation Manual

E1200i ExaScale

Installation Guide

Notes, Cautions, and Warnings

NOTE: A NOTE indicates important information that helps you make better use of your computer.

CAUTION: A CAUTION indicates potential damage to hardware or loss of data if instructions are not

followed.

WARNING: A WARNING indicates a potential for property damage, personal injury, or death.

Information in this publication is subject to change without notice.

© 2010 Dell Force10. All rights reserved.

Reproduction of these materials in any manner whatsoever without the written permission of Dell Inc. is strictly forbidden.

Trademarks used in this text: Dell™, the DELL logo, Dell Precision™, OptiPlex™, Latitude™, PowerEdge™, PowerVault™,

PowerConnect™, OpenManage™, EqualLogic™, KACE™, FlexAddress™ and Vostro™ are trademarks of Dell Inc. Intel

®

Xeon

, Core™ and Celeron® are registered trademarks of Intel Corporation in the U.S. and other countries. AMD® is a registered trademark

and AMD Opteron™, AMD Phenom™, and AMD Sempron™ are trademarks of Advanced Micro Devices, Inc. Microsoft

Windows Server

States and/or other countries. Red Hat Enterprise Linux

and/or other countries. Novell

®

Oracle

is a registered trademark of Oracle Corporation and/or its affiliates. Citrix®, Xen®, XenServer® and XenMotion® are either registered

trademarks or trademarks of Citrix Systems, Inc. in the United States and/or other countries. VMware

and vSphere

®

, MS-DOS® and Windows Vista® are either trademarks or registered trademarks of Microsoft Corporation in the United

®

is a registered trademark and SUSE ™ is a trademark of Novell Inc. in the United States and other countries.

®

are registered trademarks or trademarks of VMWare, Inc. in the United States or other countries.

Other trademarks and trade names may be used in this publication to refer to either the entities claiming the marks and names or their products.

Dell Inc. disclaims any proprietary interest in trademarks and trade names other than its own.

November 2011 P/N 100-00069-04

®

, Pentium®,

®

, Windows®,

®

and Enterprise Linux® are registered trademarks of Red Hat, Inc. in the United States

®

, Virtual SMP®, vMotion®, vCenter®,

Contents

1 About This Guide

Information Symbols and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 The E1200 System

Operating Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Site Preparation

Site Selection Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cabinet Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Fans and Airflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Storing Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 Installing the AC Chassis

Unpacking the E1200 System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installing the Equipment Rack Shelf Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Standard Front Chassis Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installing the Chassis into an Equipment Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 Installing the DC Chassis

Unpacking the E1200 System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installing the Equipment Rack Shelf Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Standard Front Chassis Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Installing the Chassis into an Equipment Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6 Installing Fan Trays

7 Installing AC Power Supplies

Securing the Chassis Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installing Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

AC Power Supply and Fan Operability Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8 Installing DC Power Supplies

Cable and Connector Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Installing DC PEMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

DC Power Supply and Fan Operability Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Contents | 3

9 Installing RPMs, Line Cards, and SFM3s

Unpacking an RPM or Line Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Important Points to Remember . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Installing Line Cards and RPMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

RPMs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Line Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Blank Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Preparing and Installing RPMs and Line Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Installing a Second RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

RPM Label and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

www.dell.com | support.dell.com

Line Card LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Installing Switch Fabric Modules (SFM3s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

SFM3 Front Panel and LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Line Card Cable Management Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10 RPM Ports and Cables

RPM Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Connecting the Console and Auxiliary Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Cable and Adapter Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Accessing the Console with a DB-9 Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Accessing the Console with a DB-25 Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . 53

Accessing the Auxiliary Port by Modem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Accessing the 10/100 Ethernet Management Port . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Universal Serial Bus Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4 | Contents

11 Powering Up

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Supplying Power - AC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Supplying Power - DC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Booting to the CLI Prompt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Booting from the BOOT_USER Prompt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

12 Removing and Replacing Components

Removing and Replacing Fan Trays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Removing and Replacing AC Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Remove an AC Power Supply in a non-redundant installation. . . . . . . . . . . . . 61

Remove an AC Power Supply in a redundant installation . . . . . . . . . . . . . . . . . 61

Removing and Replacing DC Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Remove a DC Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Removing and Replacing RPMs, Line Cards, or SFM3s . . . . . . . . . . . . . . . . . . . . . 63

Removing and Replacing line cards or RPMs . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Removing and Replacing SFM3s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Removing and Replacing the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

13 Using a Flash Memory Card

External Flash Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Inserting the External Flash Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Removing the External Flash Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Formatting an External Flash Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Copying Files to the External Flash. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Displaying Files Stored on the External Flash. . . . . . . . . . . . . . . . . . . . . . . . . . 69

A System Boot

The System Boot Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

System Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Booting from the BOOT_USER Prompt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

B Alarms

Power Supplies Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

AC Power Supplies and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

SFM3s and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

C System Specifications

E1200i AC Chassis Physical Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

E1200i AC System Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

E1200i DC Chassis Physical Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

E1200i DC System Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Agency Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Safety Standards and Compliance Agency Certifications . . . . . . . . . . . . . . . . . 85

Electromagnetic Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Product Recycling and Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

D Technical Support

The iSupport Website . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Accessing iSupport Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Contacting the Technical Assistance Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Requesting a Hardware Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Contents | 5

www.dell.com | support.dell.com

6 | Contents

1

About This Guide

This guide provides site preparation recommendations, step-by-step procedures to rack mount the

Force10 Networks E1200 ExaScale chassis, as well as instructions to install its fan trays, power supplies,

route processor modules (RPMs), switch fabric modules (SFM3s), and line cards.

The E1200 system is packaged with components necessary for optimal performance, including blank

panels for RPM, SFM3, and line card slots. Blanks are required in empty slots to ensure adequate system

cooling and for EMI containment during operation.

E1200i systems run Dell Force10 OS (FTOS™) software. After you complete the hardware installation

process and power up the system, refer to the

information and the FTOS Command Reference for detailed CLI information.

Information Symbols and Warnings

FTOS Configuration Guide for software configuration

Table 1-1

Table 1-1. Information Symbols

Symbol Warning Description

defines the information symbols used throughout this guide.

Note This symbol informs you of important operational information.

Caution This symbol informs you that improper handling and installation could result in equipment

damage or loss of data.

Warning This symbol signals information about hardware handling that could result in injury.

WARNING: The installation of this equipment shall be performed by trained and qualified personnel only.

Read this guide before installing and powering up this equipment. This equipment contains two power cords.

Disconnect both power cords before servicing.

WARNING: This equipment contains optical transceivers, which comply with the limits of Class 1 laser

radiation.

WARNING: Visible and invisible laser radiation may be emitted from the aperture of the optical transceiver

ports when no cable is connected. Avoid exposure to laser radiation and do not stare into open apertures.

CAUTION: Wear grounding wrist straps when handling this equipment to avoid ESD damage.

About This Guide | 7

WARNING: Leakage Current (High Touch Current) in AC-powered systems: AC power cords are secured to

the power inlet using the provided brackets. The power cord plugs must be secured to the building outlets by

the qualified chassis installer or a qualified electrician.

See

Chapter 3, Site Preparation

for more cautions.

Related Publications

For more information about the E1200 system, refer to the following documents:

• FTOS Configuration Guide

• FTOS Command Reference

• FTOS Release Notes for the E-Series ExaScale

www.dell.com | support.dell.com

8 | About This Guide

2

The E1200 System

The Dell Force10 E1200 system is a carrier-class, high-capacity aggregation router. The 16-slot modular

system provides two slots dedicated for Route Processor Modules (RPMs) and 14 slots for line cards with

Layer 2 switching and Layer 3 and routing capabilities.

Operating Overview

The E1200 system requires a Route Processor Module (RPM), at least one line card, and at least eight

Switch Fabric Modules (SFM3s) for packet processing. The RPM is the core for routing and control

operations; all traffic destined for the E1200i terminates on the RPM. Routing table entries are built on

the RPM and directed to the forwarding information tables on the line cards.

Software processes, such as Telnet, SNMP, CLI, Layer 2, and Layer 3 functions, are divided among three

CPUs for redundancy and speed. Independent software images run on each CPU. Each CPU has its own

memory, which isolates processes from each other, increasing reliability. Operating the E1200 system

with redundant RPMs enables automatic fail-over redundancy.

Line cards perform all data forwarding operations. Each line card has at least one Force10 Networks

proprietary ASIC. The FPC accepts packets, feeds packets to input/output ports, handles packet

classification (access lists, and Layer 2 and Layer 3 lookups), and packet-marking (Diffserv or 802.1p).

The BTM is responsible for all queuing operations.

The internal flash memory device shipped with the RPM contains the boot ROM and runtime images.

Each RPM accommodates an external flash memory card and two USB ports that can be used to copy and

store system boot, software images, and configuration files. For information about using a flash card or

USB ports, refer to

Chapter 13, Using a Flash Memory Card

.

The E1200 System | 9

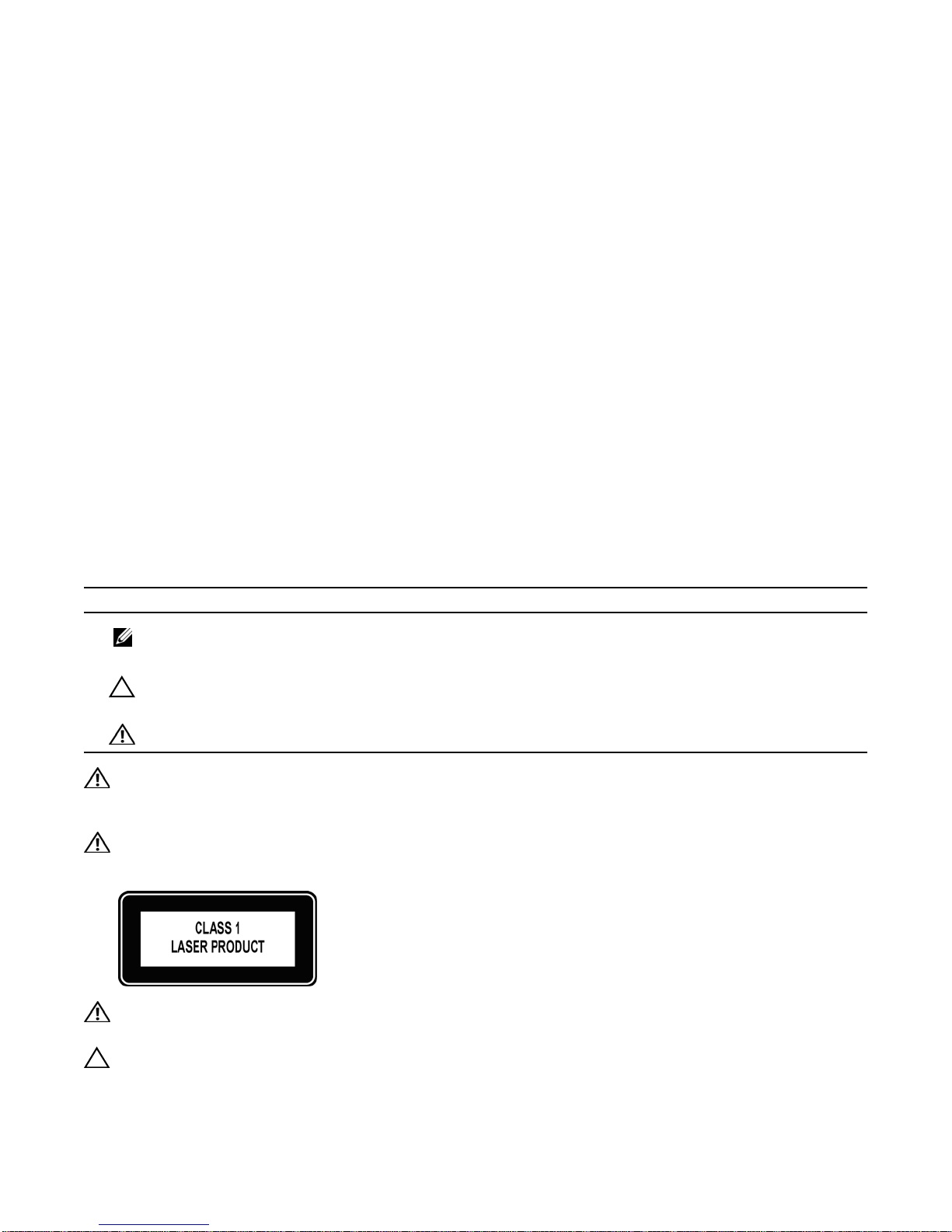

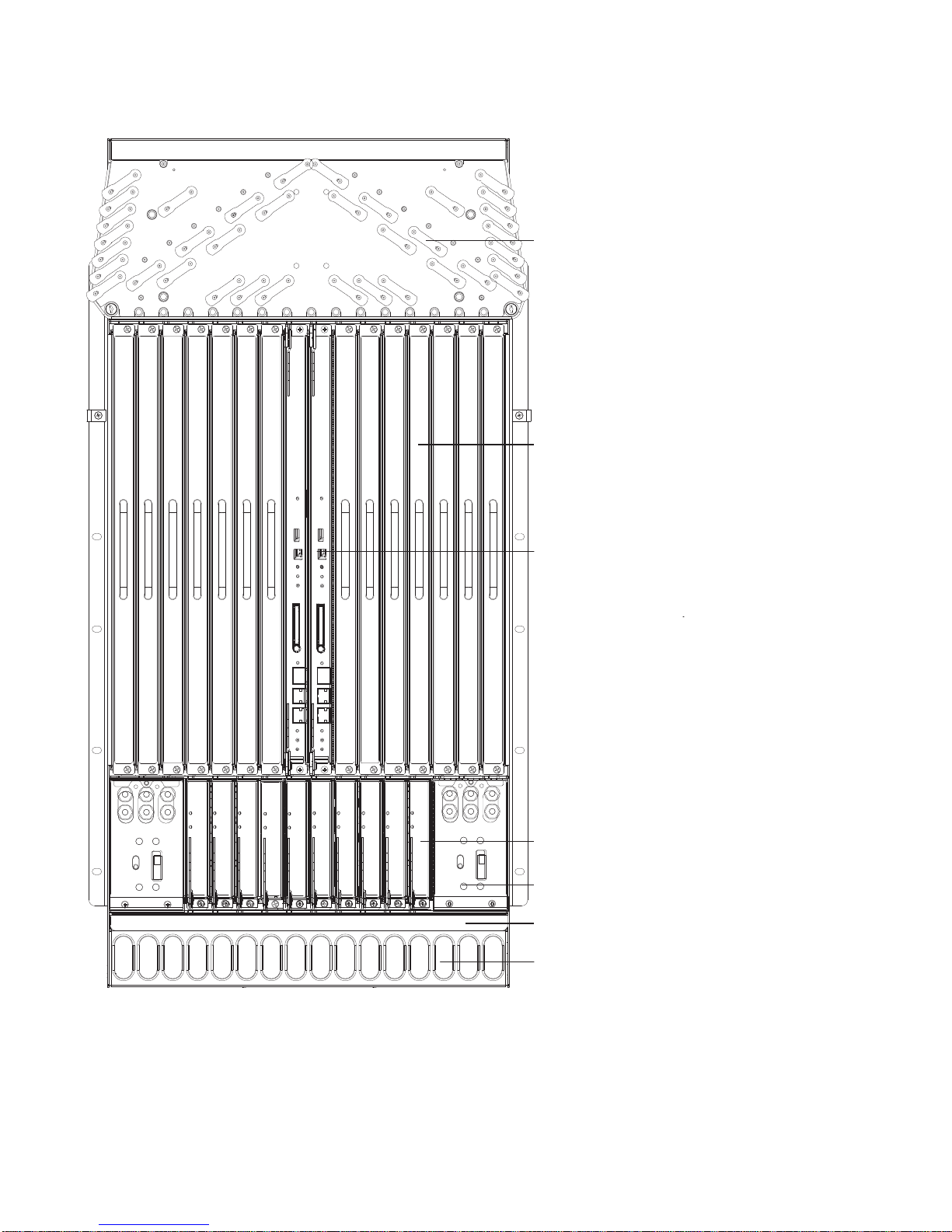

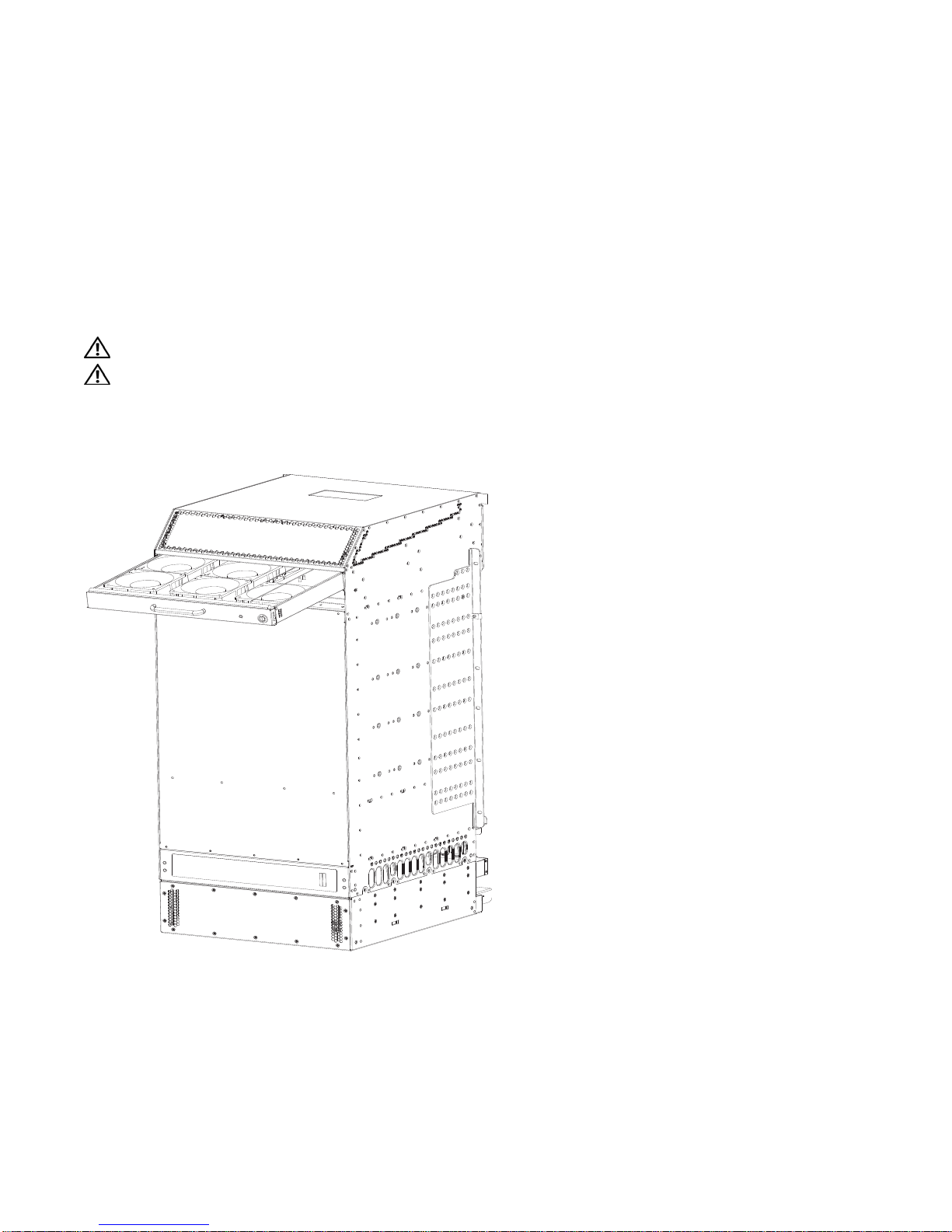

Figure 2-1. E1200i AC Chassis Front View

Cable Management

System

www.dell.com | support.dell.com

Line Card Slots

RPMs

Switch Fabric

Modules (SFM3s)

Blanks (BLNK)

Air Filter

10 | The E1200 System

Air Vents

AC Power Supplies

AC Power Plugs

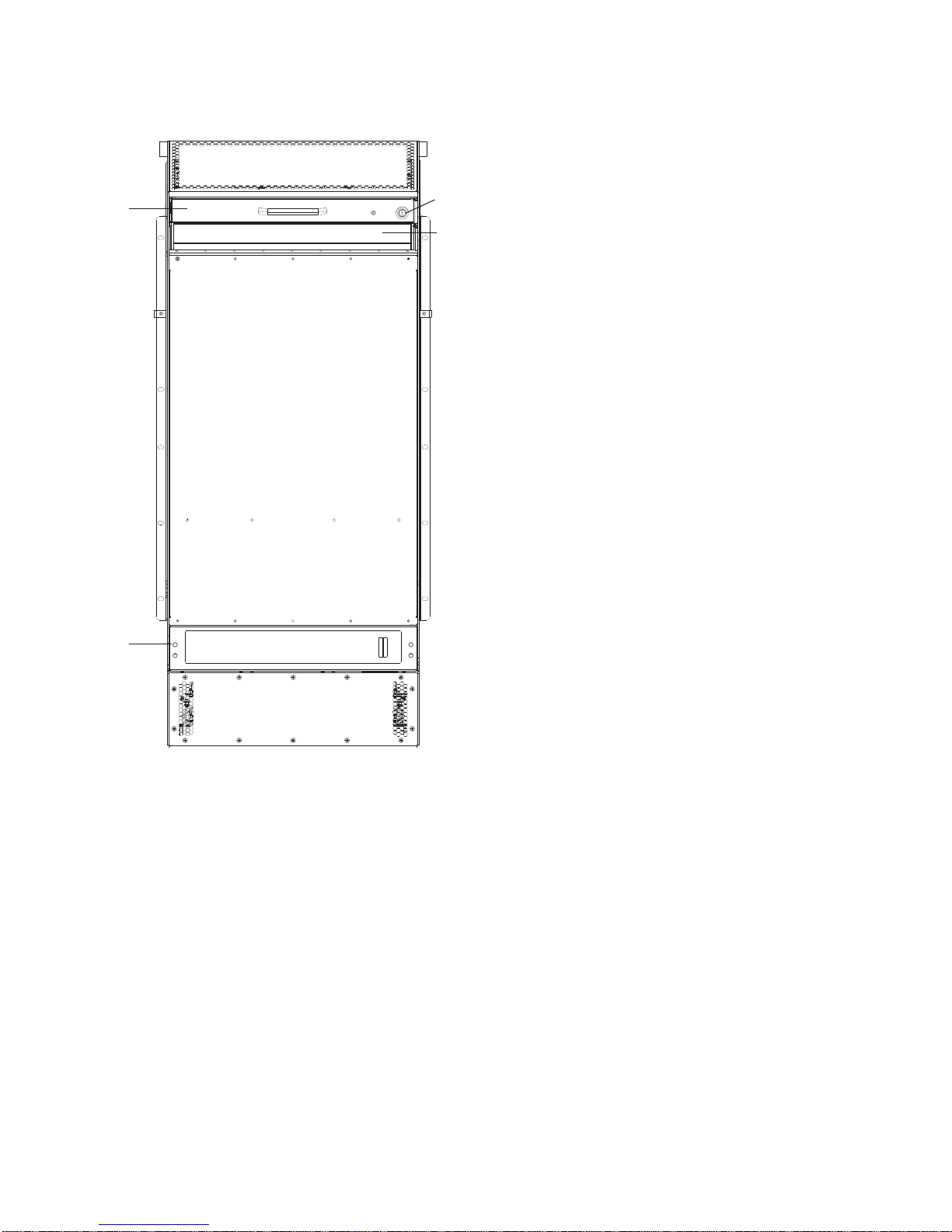

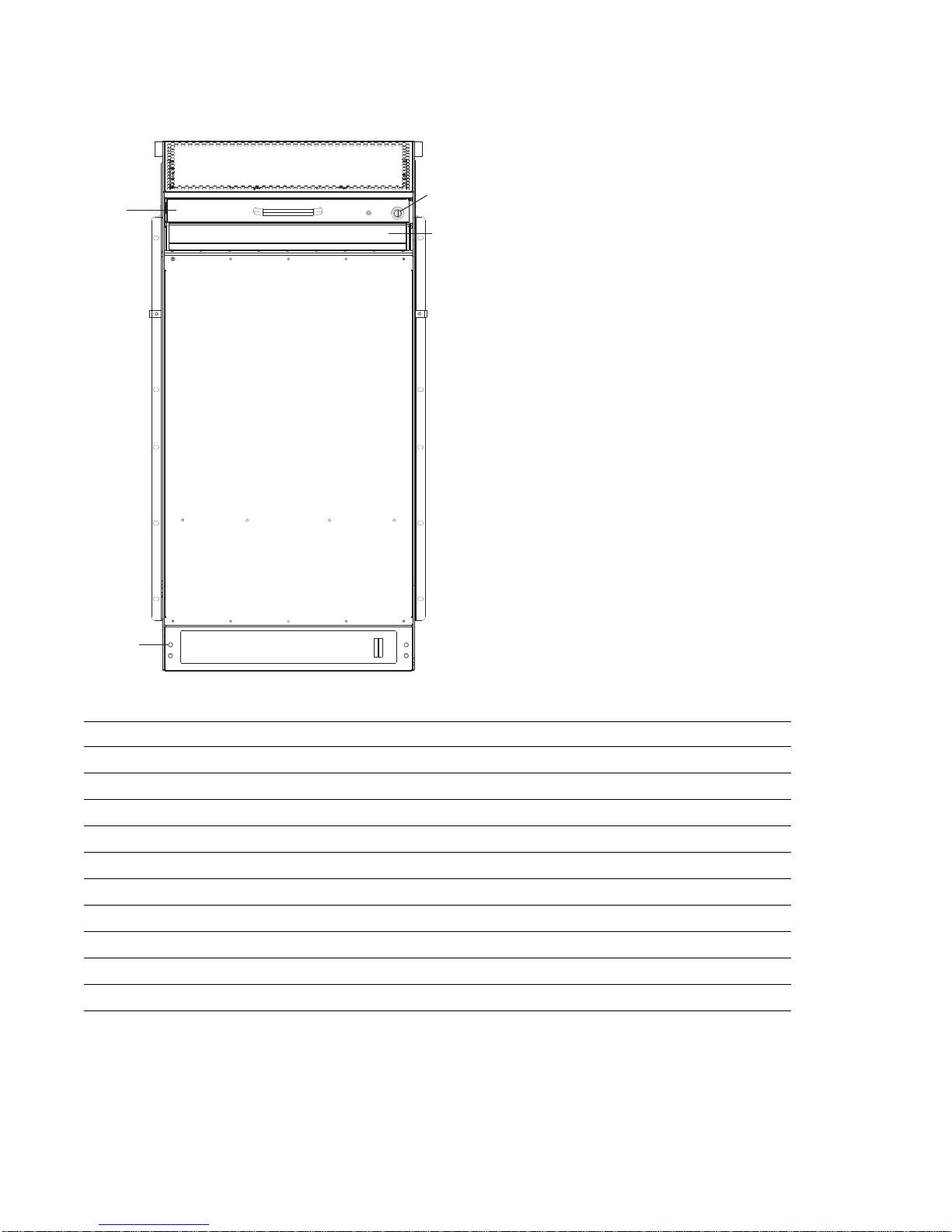

Figure 2-2. E1200 AC Chassis Rear View

Installed

Fan Tray

Locking

Screw

Empty Fan Tray

(with self-closing door)

Ground

Connection

The E1200 System | 11

Figure 2-3. E1200i DC Chassis Front View

www.dell.com | support.dell.com

Cable Management

System

Line Card

Slots

RPMs

12 | The E1200 System

Switch Fabric

Modules (SFM3s)

DC Power Supply

Air Filter

Air Vents

Figure 2-4. E1200 DC Chassis Rear View

Installed

Fan Tray

Locking

Screw

Empty Fan Tray

(with self-closing door)

Ground

Connection

Table 2-1. E1200 Hardware Component Operating Requirements Summary

Component Minimum Maximum Field-Replaceable

Backplane (factory installed) 1 1 N

Air filter (factory installed) 1 1 Y

Fan trays 2 2 Y

RPMs 1 2 Y

Line cards 1 14 Y

SFM3s 8 10 Y

AC Power Supply 3 (in a shelf) 6 Y

DC Power Supply 1 2 Y

Cable management system 0 1 Y

Cable management system cover 0 1 Y

The E1200 System | 13

To install the E1200 system:

Step Task Section

1 Prepare the site

Site Preparation

2 Unpack the AC chassis and components

Unpacking the E1200 System

or

Unpack the DC chassis and components

3 Mount the AC chassis

Unpacking the E1200 System

Standard Front Chassis Mounting

Installing the Chassis into an Equipment Cabinet

or

www.dell.com | support.dell.com

Mount the DC chassis

Standard Front Chassis Mounting

Installing the Chassis into an Equipment Cabinet

4 Install the cable management system See the instructions that come with the cable management system.

5 Install components:

• Fan trays

• Power Supplies (including power and

grounding cables)

6 Verify power supply and fan tray operability

Installing Fan Trays

Installing AC Power Supplies

Installing DC Power Supplies

AC Power Supply and Fan Operability Test

DC Power Supply and Fan Operability Test

7 Install card components:

• RPM(s) and line cards

• SFM3s

8 Connect network cable

9 Supply power to the chassis

Installing Line Cards and RPMs

Installing Switch Fabric Modules (SFM3s)

RPM Ports and Cables

Supplying Power - AC

Supplying Power - DC

10 Initial boot The initial boot operation automatically brings up the system to the

runtime CLI. To interrupt the automatic boot process, issue a break

key sequence (Ctrl^) if you experience boot problems.

The console monitor will display the default BOOT_USER # prompt.

Refer to

Chapter A, System Boot

for instructions to continue the boot

process.

14 | The E1200 System

3

Site Preparation

This chapter describes factors to consider before installing your E1200 system. The following topics are

discussed:

• Site Selection Criteria

• Rack Mounting

• Cabinet Placement

• Power

• Fans and Airflow

• Storing Components

For complete E1200 System Specifications, refer to

Chapter C, System Specifications

.

Site Selection Criteria

Before you begin the installation process, make sure that the area where you intend to install your E1200

meets the following safety requirements.

Select a site:

• In a restricted access area.

• In a dry, clean, well-ventilated and temperature-controlled room, away from nearby heat sources such as

hot air vents or direct sunlight.

• Away from sources of severe electromagnetic noise.

• Near an adequate power source. Connect the E1200 to the appropriate branch circuit protection as

defined by local electrical codes.

• Means of power disconnect must be located near the equipment.

• Position in a rack with adequate space in the front and rear, and sides of the unit for proper ventilation,

access to cables, and maintenance access. Allow

of the rack for ventilation. If placing the chassis in a cabinet, ensure that there is enough clearance

between the closed cabinet door and the cables in the cable management system on the chassis.

at least

18 inches in the front and 20 inches in the rear

• Ensure that the ambient temperature around the unit (which may be higher than the room temperature) is

within the limit specified for the unit.

• Ensure that there is sufficient airflow around the unit and that the electrical circuits are not overloaded.

Consider the nameplate rating of all the connected equipment, and ensure that there is over current

protection.

Site Preparation | 15

• Ensure that the equipment is properly grounded.

• Do not place objects on top of unit.

CAUTION: The E1200 AC shipping containers each weigh up to 400 pounds. The unpacked chassis and

pallet weigh approximately 200 pounds. Do not attempt to lift or move the chassis without the use of a hand

cart, pallet jack, or forklift.Lift the E1200 chassis either from the bottom or by the handles provided with the

front shipping cover. Lifting by the chassis shelves or fan tray openings will cause chassis damage. Do not

remove the protective front shipping cover until the chassis is secured in the equipment rack.

Rack Mounting

When you prepare your equipment rack, make sure the rack is bolted to the floor and/or braced to a wall

or ceiling.

www.dell.com | support.dell.com

When you install the chassis:

• Make sure that the rack is grounded to the grounding electrode. Each DC PEM must be grounded to the

rack or building ground bus. The equipment rack must be grounded to the same grounding electrode

used by the power service in your area. The ground path must be permanent.

• Install the E1200 chassis in the rack before you install internal components or make network and power

connections.

• In an empty rack, place the chassis in the lower half of the rack to ensure rack stability.

Cabinet Placement

The cabinet must meet the following criteria:

• Minimum cabinet size is 30 inches deep and 24 inches wide.

• Minimum air flow is 750 cubic feet per minute (CFM).

• Minimum of 3 inches between the closed doors and the front of the cable management panel, and a

minimum of 3 inches between the chassis rear and the rear of the cabinet with the cabinet door closed.

With the rear doors of the cabinet open, you will need a clearance of at least 20 inches from the rear to

access the chassis fan trays.

• Minimum of 20 inches clearance at the chassis front to access the air filter, power supplies, and cards.

Power

The E1200 requires 3 AC Power Supplies in a shelf (0, 1, 2 or 3, 4, 5) or 1 DC PEM to operate. For full

redundancy, you must have 6 AC Power Supplies (so that if one power supply fails in one shelf, the

system remains operational operates with the 3 power supplies in the other shelf) or a second 2 DC Power

Entry Module (2 total)

CAUTION: You cannot power the system with both types of power supply module installed. The system must

contain only one type of power module, either AC or DC.

16 | Site Preparation

WARNING: The E1200i AC Chassis is shipped with two tool-accessible covers preventing access into the

alternative DC PEM cavities. Do not remove these covers; they prevent unauthorized access to high direct

current locations within the chassis. The covers must remain in place at all times.

WARNING: Make your chassis ground connections first (see

grounded, excessive electromagnetic emission may result.

WARNING: Disconnect all power to the equipment rack or cabinet before chassis installation.

WARNING: Never operate the E1200 system with empty RPM, SFM3, or line card slots. Always replace

empty slots with blank panels.

Figure 2-2

). If the chassis is not correctly

Each E1200 system requires at least three AC Power Supplies or at least one DC Power Supply to operate.

Three AC units are required for power supply redundancy, and so six AC units provides full redundancy.

Two DC units are required for power supply and full facility redundancy.

WARNING: Leakage Current (High Touch Current): The AC power cords are secured to the power inlet using

the provided bracket. The AC power cord plugs must be secured to the building outlets by the chassis installer

or a qualified electrician.

Refer to

Chapter C, System Specifications

for specifications on thermal output and other power related

numbers.

Fans and Airflow

Your E1200 chassis contains two field-replaceable fan trays. Air flows through the system from a

filtered-intake vent located in the lower part of the chassis. Air circulates from the bottom front (and

sides) to the back and exhausts through a top rear vent. The variable fan speed is reduced at normal

operating temperatures and increases to full speed as operating temperatures increase, up to 104° F

(40° C).

For fan tray access, maintenance and proper ventilation, position the chassis and equipment rack or

cabinet so that:

• at least three inches clearance is around the front and side intake and exhaust vents for free air flow

• 20 inches in the rear are available to access the fan tray

• the system can operate with two fan trays.

For instructions on replacing a fan tray, refer to

Removing and Replacing Fan Trays

.

Storing Components

CAUTION: Do not transport a chassis with components (line cards, power supplies, RPMs, Fan Trays, Power

Supply, or SFM3s) installed in the chassis. Place the modules in their original ESD-preventative packaging

and attach the Front Shipping Cover on the front of the chassis prior to placing the chassis in its original

shipping crate. Shipping the chassis with components installed may damage the components and the chassis

backplane.

If you do not install your E1200 system and components right away, properly store components and all

extra field-replaceable components (spares) until you are ready to install them. Keep all components in

the original packaging during storage.

Follow these indoor storage guidelines:

• Storage temperature should remain constant ranging from -40° to 158°F (-40° to 70°C).

Site Preparation | 17

• Non-condensing relative humidity should be maintained within 5 to 95 percent.

• Store on a dry floor, away from direct sunlight, heat, and air conditioning ducts.

• Store in a dust-free environment.

www.dell.com | support.dell.com

18 | Site Preparation

4

Installing the AC Chassis

This chapter provides instructions to rack mount your E1200 system into a standard 19-inch or 23-inch

equipment rack. It contains the following sections:

• Unpacking the E1200 System

• Installing the Equipment Rack Shelf Bar

• Standard Front Chassis Mounting

• Installing the Chassis into an Equipment Cabinet

Unpacking the E1200 System

The E1200 AC system and components are shipped on a wooden pallet with a front shipping cover.

Remove the chassis from the shipping packaging, and move the chassis with a hand cart, pallet jack, or

fork lift to its rack. Do not unpack the power supplies, fan trays, air filter, or cards until the chassis is

installed.

WARNING: The E1200 AC shipping containers each weigh up to 400 pounds. The unpacked chassis and

pallet weigh approximately 200 pounds. Do not attempt to lift or move the chassis without the use of a hand

cart, pallet jack, or forklift.

CAUTION: Lift the E1200 chassis only with the handles provided or from the bottom. Lifting by the chassis

shelves will cause chassis damage. Do not remove the shipping cover during the installation process. The

cover prevents damage to the internal framework and EMI seals.

WARNING: Electrostatic discharge (ESD) damage can occur when components are mishandled. Always

wear an ESD-preventative wrist or foot-heal ground strap when handling RPMs, SFM3s, or line cards. After

you remove the original packaging, place RPMs, SFM3s, and line cards directly into the chassis, or on an

antistatic surface.

WARNING: Complete the chassis installation into the rack before you install any other component (fan trays,

power supplies, line cards, RPMs, SFM3s, cables).

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions

to ensure that the system remains stable. The following guidelines are provided to ensure your safety:

This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the

heaviest component at the bottom of the rack.

If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the unit

in the rack.

Installing the AC Chassis | 19

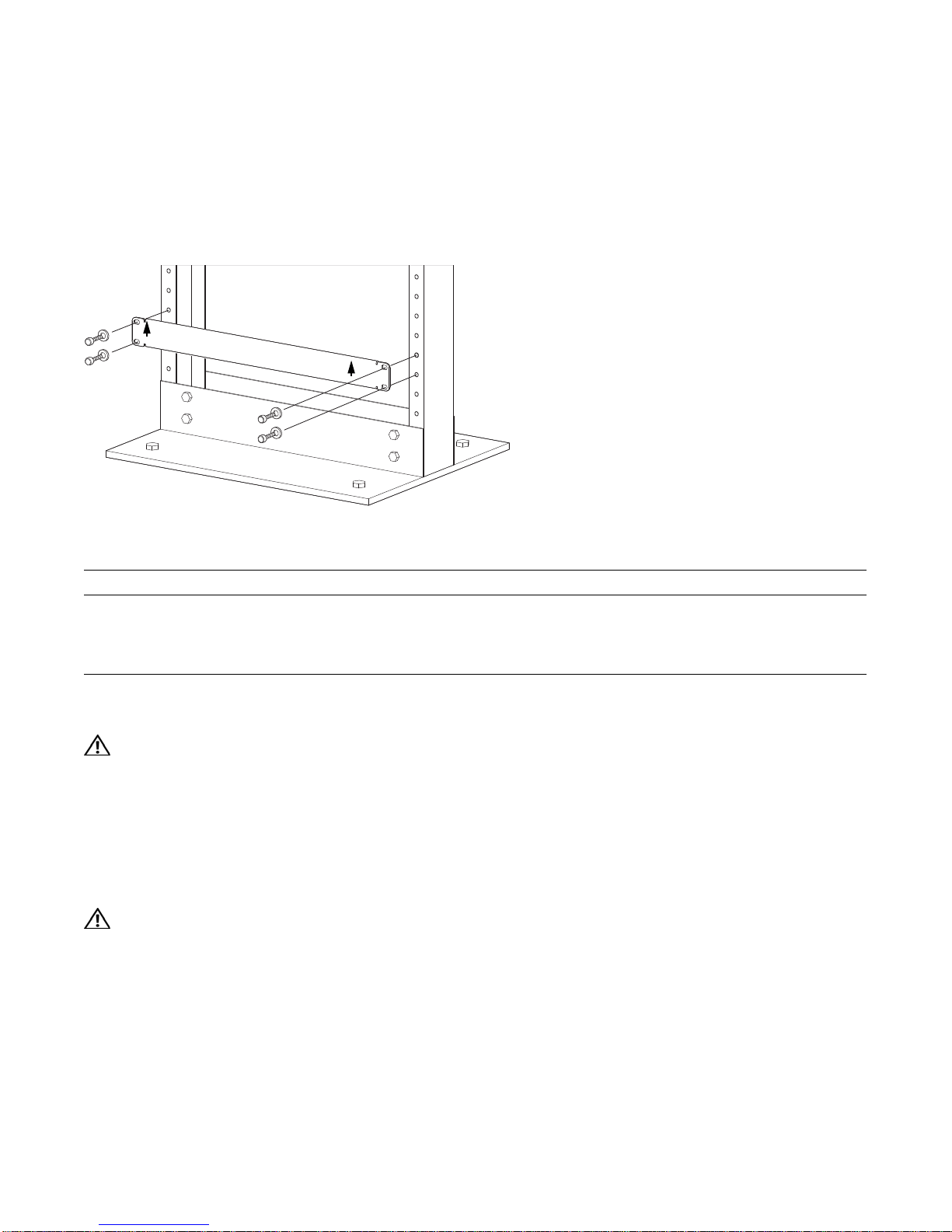

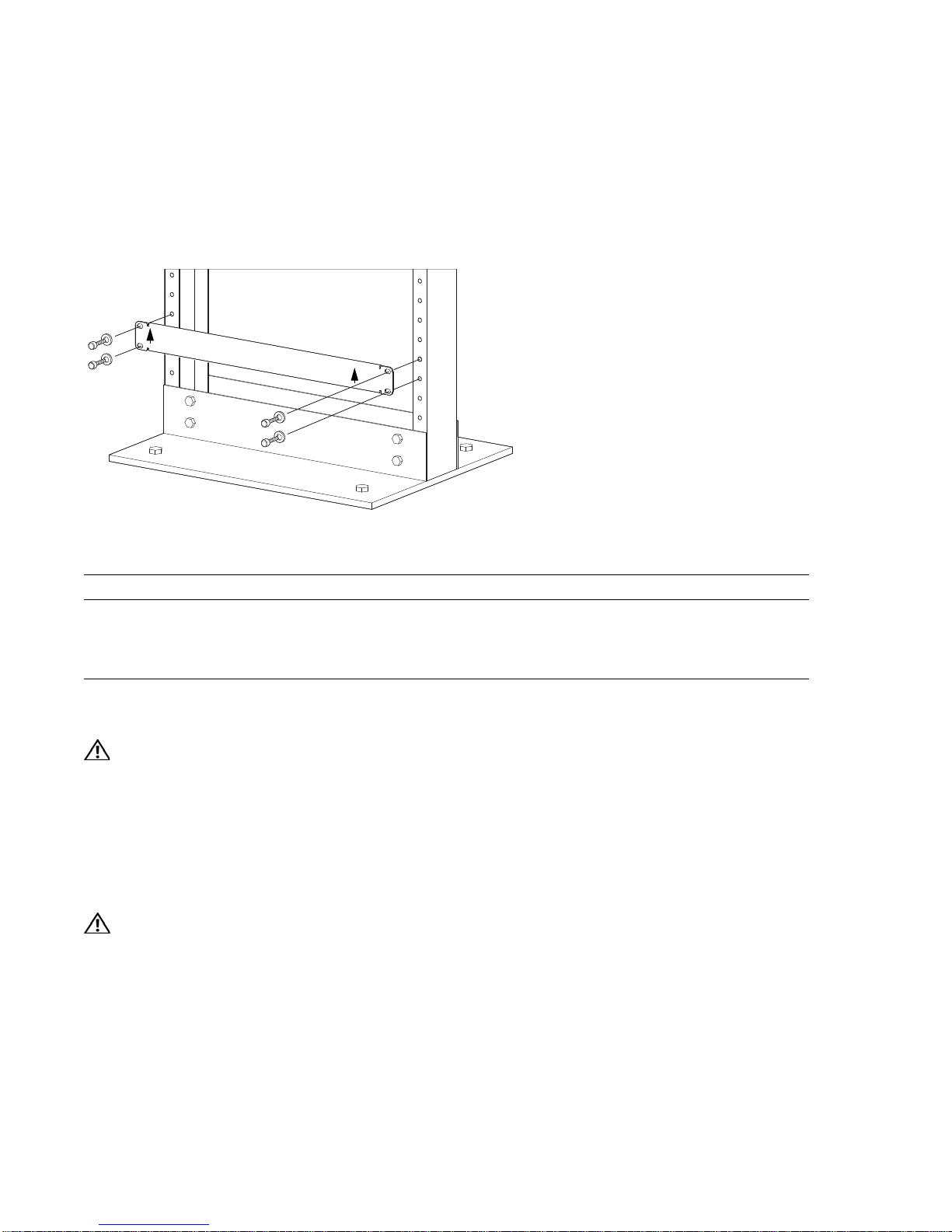

Installing the Equipment Rack Shelf Bar

The rack shelf bar (

Figure 4-1

) enables you to easily position the chassis into the rack and provides the

unit additional stability. The E1200 system must be mounted in a rack that is permanently secured to the

floor.

Figure 4-1. Rack Shelf Bar

UP

www.dell.com | support.dell.com

UP

F

To install a equipment rack shelf bar:

Step Task

1 Determine the chassis mounting location in the equipment rack.

2 Orient the bar with the arrows pointing upward. The smooth side of the bar should face outward.

3 Attach the bar to the equipment rack brackets using the mounting screws provided by the manufacturer.

Standard Front Chassis Mounting

WARNING: To prevent bodily injury when mounting or servicing this unit in a rack, you must take special

precautions to ensure that the system remains stable. The following guidelines are provided to ensure your

safety:

• This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

• When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the heaviest

component at the bottom of the rack.

• If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the unit in

the rack.

WARNING: Pour éviter toute blessure corporelle pendant les opérations de montage ou de réparation de

cette unité en casier, il convient de prendre des précautions spéciales afin de maintenir la stabilité du

système. Les directives ci-dessous sont destinées à assurer la protection du personnel:

• Si cette unité constitue la seule unité montée en casier, elle doit être placée dans le bas.

• Si cette unité est montée dans un casier partiellement rempli, charger le casier de bas en haut en plaçant

l'élément le plus lourd dans le bas.

• Si le casier est équipé de dispositifs stabilisateurs, installer les stabilisateurs avant de monter ou de

réparer l'unité en casier.

20 | Installing the AC Chassis

WARNING: Zur Vermeidung von Körperverletzung beim Anbringen oder Warten dieser Einheit in einem

Gestell müssen Sie besondere Vorkehrungen treffen, um sicherzustellen, daß das System stabil bleibt. Die

folgenden Richtlinien sollen zur Gewährleistung Ihrer Sicherheit dienen:

• Wenn diese Einheit die einzige im Gestell ist, sollte sie unten im Gestell angebracht werden.

• Bei Anbringung dieser Einheit in einem zum Teil gefüllten Gestell ist das Gestell von unten nach oben zu

laden, wobei das schwerste Bauteil unten im Gestell anzubringen ist.

• Wird das Gestell mit Stabilisierungszubehör geliefert, sind zuerst die Stabilisatoren zu installieren, bevor

Sie die Einheit im Gestell anbringen oder sie warten.

NOTE: Dell Force10 recommends that you install and operate the E1200 system in a standard 19-inch or 23-

inch equipment rack.

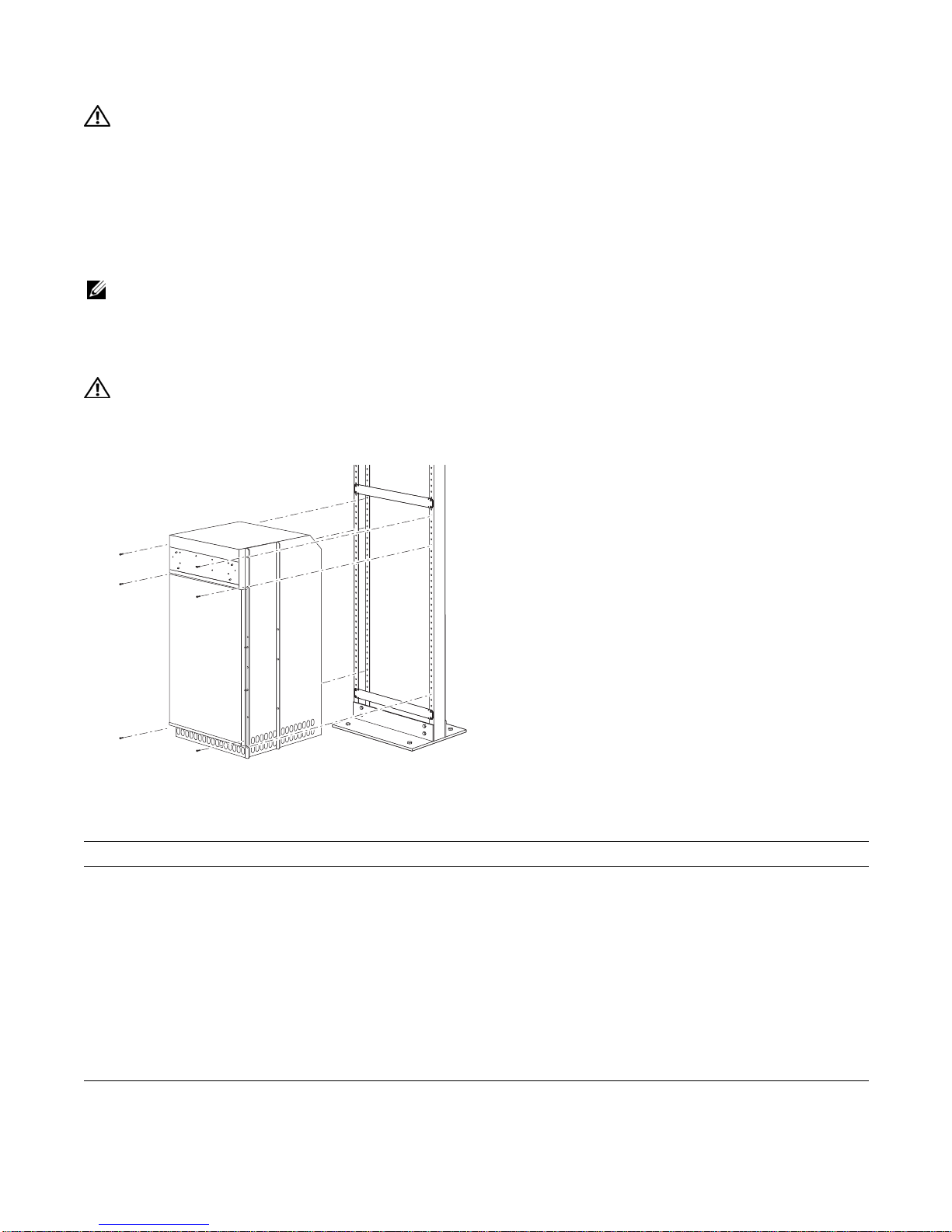

Install the E1200 system after you secure the equipment rack shelf bar. Load the chassis in the lower half

of an empty rack to avoid a top-heavy rack (

WARNING: Do not remove the Front shipping Cover during the initial installation process. The cover provides

Figure 4-2

front handles to assist in lifting and prevents damage to the internal framework and EMI seals.

Figure 4-2. Rack Mounting the Chassis

).

FN00046B

To install the chassis into a prepared rack:

Step Task

1 If you are center or rear-mounting the chassis in a 19-inch rack, adjust the chassis rack mounting brackets to the

desired position.

2 If you are mounting the chassis in a 23-inch rack, install the 23-inch adapter brackets.

3 Using a hand cart, pallet jack, or forklift, align the rack-mount holes with the equipment rack holes, situating the

chassis on top of the equipment rack shelf bar.

4 Insert rack mounting screws in the holes that are not obscured by the metal chassis shipping cover. Tighten the

screws. See

5 Loosen and remove the screws that secure the chassis Front Shipping Cover and remove the cover.

6 Insert the remaining rack mounting screws and tighten to secure the chassis in the rack.

Figure 4-2

.

Installing the AC Chassis | 21

Installing the Chassis into an Equipment Cabinet

Install the E1200 system after you secure the rack shelf bar. Load the chassis in the lower half of the

cabinet to avoid it becoming top-heavy. Make sure the cabinet is positioned with adequate space in the

front, rear, and sides of the unit for proper ventilation, access to cables, and access for maintenance.

Refer to

Chapter 3, Site Preparation

for complete requirements.

To install the chassis into an equipment cabinet:

Step Task

1 Install the equipment rack shelf bar.

2 Adjust the chassis mounting brackets to the desired front-rear position and add a 23-inch adapter brackets as

www.dell.com | support.dell.com

3 Using a hand cart, pallet jack, or forklift, align the rack-mount holes with the cabinet holes.

4 Insert rack mounting screws in the holes that are not obscured by the metal chassis shipping cover. Tighten the

5 Loosen and remove the screws attaching the chassis shipping cover. Remove the shipping cover.

6 Insert the remaining mounting screws and tighten to secure the chassis in the cabinet.

required.

screws.

22 | Installing the AC Chassis

5

Installing the DC Chassis

This chapter provides instructions to rack mount your E1200 system into a standard 19-inch or 23-inch

equipment rack. It contains the following sections:

• Unpacking the E1200 System

• Standard Front Chassis Mounting

• Installing the Chassis into an Equipment Cabinet

Unpacking the E1200 System

The E1200 DC system and components are shipped on a wooden pallet with Front Shipping cover.

Remove the chassis from the shipping packaging and move the chassis with a hand cart, pallet jack, or

fork lift to its rack. Do not unpack the power supplies, fan trays, air filter, or cards until the chassis is

installed.

WARNING: The E1200 DC shipping containers each weigh up to 400 pounds. The unpacked chassis and

pallet weigh approximately 200 pounds. Do not attempt to lift or move the chassis without the use of a hand

cart, pallet jack, or forklift.

CAUTION: Lift the E1200 chassis only with the handles provided or from the bottom. Lifting by the chassis

shelves will cause chassis damage. Do not remove the shipping cover during the installation process. The

cover prevents damage to the internal framework and EMI seals.

WARNING: Electrostatic discharge (ESD) damage can occur when components are mishandled. Always

wear an ESD-preventative wrist or foot-heal ground strap when handling RPMs, SFM3s, or line cards. After

you remove the original packaging, place RPMs, SFM3s, and line cards directly into the chassis or on an

antistatic surface.

WARNING: Complete the chassis installation into the rack before you install any other component (fan trays,

power supplies, line cards, RPMs, SFM3s, cables).

WARNING: This product relies on the building's installation for short-circuit (overcurrent) protection. Ensure

that a fuse or circuit breaker no less than 150A is used on the phase conductors (all current-carrying

conductors).

WARNING: Pour ce qui est de la protection contre les courts-circuits (surtension), ce produit dépend de

l'installation électrique du local. Vérifier qu'un fusible ou qu'un disjoncteur de 150A? est utilisé sur les

conducteurs de phase (conducteurs de charge).

WARNING: Dieses Produkt ist darauf angewiesen, daß im Gebäude ein Kurzschluß- bzw. Überstromschutz

installiert ist. Stellen Sie sicher, daß eine Sicherung oder ein Unterbrecher von nicht mehr 150A? an den

Phasenleitern (allen stromführenden Leitern) verwendet wird.

WARNING: Class 1 laser product.

WARNING: Produit laser de classe 1.

WARNING: Laserprodukt der Klasse 1.

Installing the DC Chassis | 23

Installing the Equipment Rack Shelf Bar

The rack shelf bar (

Figure 5-1

) enables you to easily position the chassis into the rack and provides the

unit additional stability. The E1200 system must be mounted in a rack that is permanently secured to the

floor.

Figure 5-1. Rack Shelf Bar

UP

www.dell.com | support.dell.com

UP

F

To install a equipment rack shelf bar:

Step Task

1 Determine the chassis mounting location in the equipment rack.

2 Orient the bar with the arrows pointing upward. The smooth side of the bar should face outward.

3 Attach the bar to the equipment rack brackets using the mounting screws provided by the manufacturer.

Standard Front Chassis Mounting

WARNING: To prevent bodily injury when mounting or servicing this unit in a rack, you must take special

precautions to ensure that the system remains stable. The following guidelines are provided to ensure your

safety:

• This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

• When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the heaviest

component at the bottom of the rack.

• If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the unit in

the rack.

WARNING: Pour éviter toute blessure corporelle pendant les opérations de montage ou de réparation de

cette unité en casier, il convient de prendre des précautions spéciales afin de maintenir la stabilité du

système. Les directives ci-dessous sont destinées à assurer la protection du personnel:

• Si cette unité constitue la seule unité montée en casier, elle doit être placée dans le bas.

• Si cette unité est montée dans un casier partiellement rempli, charger le casier de bas en haut en plaçant

l'élément le plus lourd dans le bas.

• Si le casier est équipé de dispositifs stabilisateurs, installer les stabilisateurs avant de monter ou de

réparer l'unité en casier.

24 | Installing the DC Chassis

WARNING: Zur Vermeidung von Körperverletzung beim Anbringen oder Warten dieser Einheit in einem

Gestell müssen Sie besondere Vorkehrungen treffen, um sicherzustellen, daß das System stabil bleibt. Die

folgenden Richtlinien sollen zur Gewährleistung Ihrer Sicherheit dienen:

• Wenn diese Einheit die einzige im Gestell ist, sollte sie unten im Gestell angebracht werden.

• Bei Anbringung dieser Einheit in einem zum Teil gefüllten Gestell ist das Gestell von unten nach oben zu

laden, wobei das schwerste Bauteil unten im Gestell anzubringen ist.

• Wird das Gestell mit Stabilisierungszubehör geliefert, sind zuerst die Stabilisatoren zu installieren, bevor

Sie die Einheit im Gestell anbringen oder sie warten.

NOTE: Dell Force10 recommends that you install and operate the E1200 system in a standard 19-inch or 23-

inch equipment rack.

Install the E1200 system after you secure the equipment rack shelf bar. Load the chassis in the lower half

of an empty rack to avoid a top-heavy rack (

WARNING: Do not remove the Front shipping Cover during the initial installation process. The cover provides

Figure 5-2

front handles to assist in lifting and prevents damage to the internal framework and EMI seals.

Figure 5-2. Rack-Mounting the Chassis

)

FN00046B

To install the chassis into a prepared rack:

Step Task

1 If you center- or rear-mount the chassis in a 19-inch rack, adjust the chassis rack-mounting brackets to the desired

position.

2 If you mount the chassis in a 23-inch rack, install the 23-inch adapter brackets.

3 Use a hand cart, pallet jack, or forklift to align the rack-mount holes with the equipment rack holes, situating the

chassis on top of the equipment rack shelf bar.

4 Insert rack-mounting screws in the holes that are not obscured by the metal chassis shipping cover. Tighten the

screws. See

5 Loosen and remove the screws that secure the chassis Front Shipping Cover and remove the cover.

6 Insert the remaining rack-mounting screws and tighten to secure the chassis in the rack.

Figure 5-2

.

Installing the DC Chassis | 25

Installing the Chassis into an Equipment Cabinet

Install the E1200 system after you secure the rack shelf bar. Load the chassis in the lower half of the

cabinet to avoid it becoming top-heavy. Make sure the cabinet is positioned with adequate space in the

front, rear, and sides of the unit for proper ventilation, access to cables, and access for maintenance.

Refer to

Chapter 3, Site Preparation

for complete requirements.

To install the chassis into an equipment cabinet:

Step Task

1 Install the equipment rack shelf bar.

2 Adjust the chassis mounting brackets to the desired front-rear position and add a 23-inch adapter brackets as

www.dell.com | support.dell.com

3 Using a hand cart, pallet jack, or forklift, align the rack-mount holes with the cabinet holes.

4 Insert rack-mounting screws in the holes that are not obscured by the metal chassis shipping cover. Tighten the

5 Loosen and remove the screws attaching the chassis shipping cover. Remove the shipping cover.

6 Insert the remaining mounting screws and tighten to secure the chassis in the cabinet.

required.

screws.

26 | Installing the DC Chassis

Installing Fan Trays

6

Access the fan tray slots from the rear of the chassis (

chassis. When a fan tray is not installed in the lower slot, a self-closing door will seal the slot. Panel

blanks are not required. However, to ensure fail-safe chassis operation, do not operate the chassis with

only one fan tray for more than 30 minutes.

WARNING: Install the fan trays before you supply power to the system.

WARNING: Electrostatic discharge (ESD) damage can occur when components are mishandled. Always

wear an ESD-preventative wrist or foot-heal ground strap when handling chassis components. After you

remove the original packaging, place chassis components on an antistatic surface.

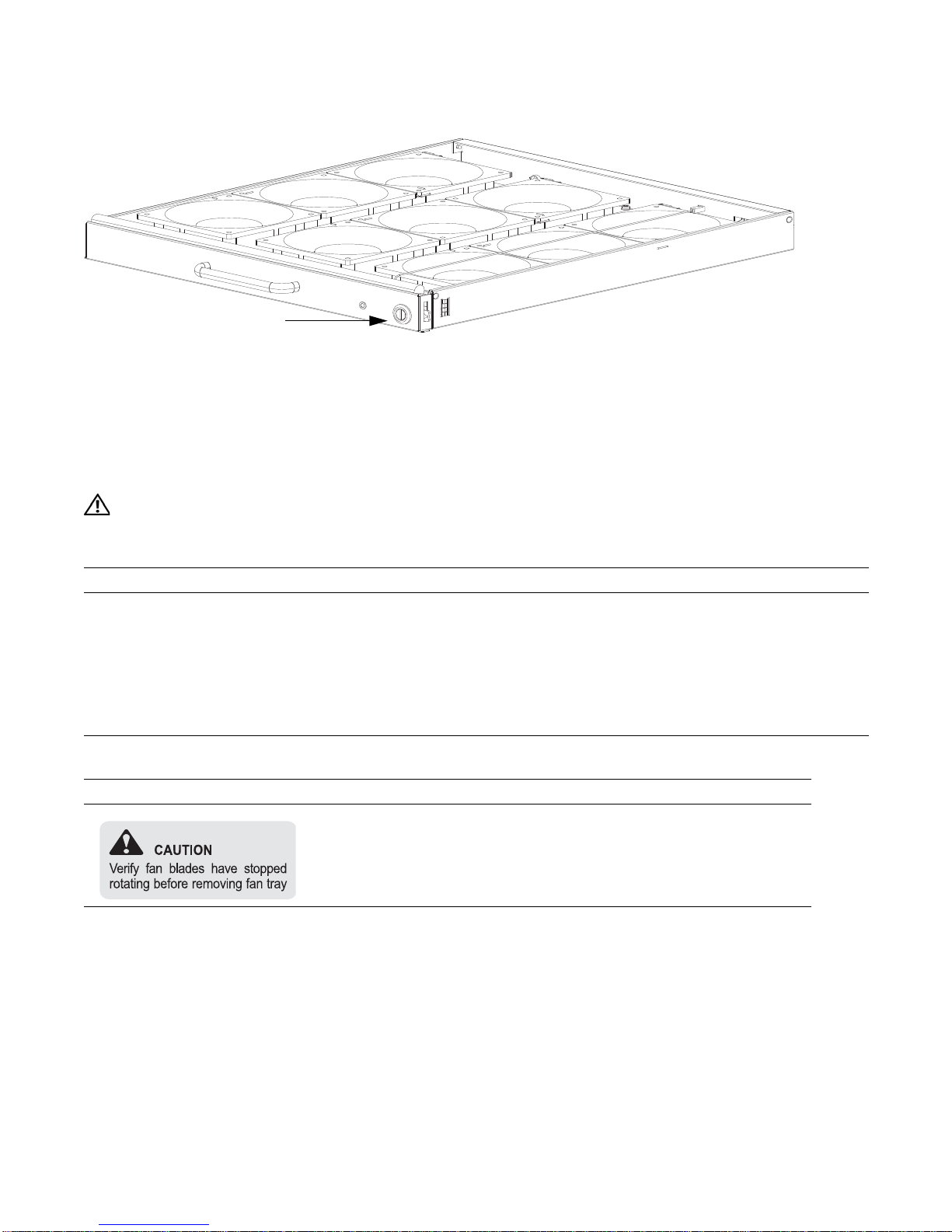

Figure 6-1. .Installing Fan Tray

Figure 6-1

). Two fan trays are required in the

Installing Fan Trays | 27

Figure 6-2. Fan Tray

screw latch

Install the fan trays after the chassis is installed securely in the equipment rack. Access the fan tray slots

www.dell.com | support.dell.com

from the rear side of the chassis. To ensure proper temperature and airflow control, all six fan trays must

be installed before you supply power to the system. You will need a #2 Phillips screwdriver to tighten the

screws that secure the fan trays to the chassis. A fan tray can be installed in any fan tray slot.

To install fan trays:

WARNING:

Table 6-1

is an illustration of the fan tray safety labels: Prevent exposure and contact with

hazardous voltages. Do not attempt to operate this system without the safety cover provided with each PEM.

Step Task

1 Unpack the fan tray.

2 Prior to inserting a fan tray, fully turn its screw latch counter-clockwise (with flathead screwdriver) until the fan

tray latching mechanism fully retracts into the fan tray (see

3 Grip the fan tray handle. Slide the connector end of each fan tray into the slot until it stops and the handle end is

Figure 6-2

).

flush with the chassis rear.

4 Secure the fan trays into place by turning the screw latch clockwise.

Table 6-1. Fan Tray Safety Labels

Label Location

Fan tray faceplate

28 | Installing Fan Trays

7

A

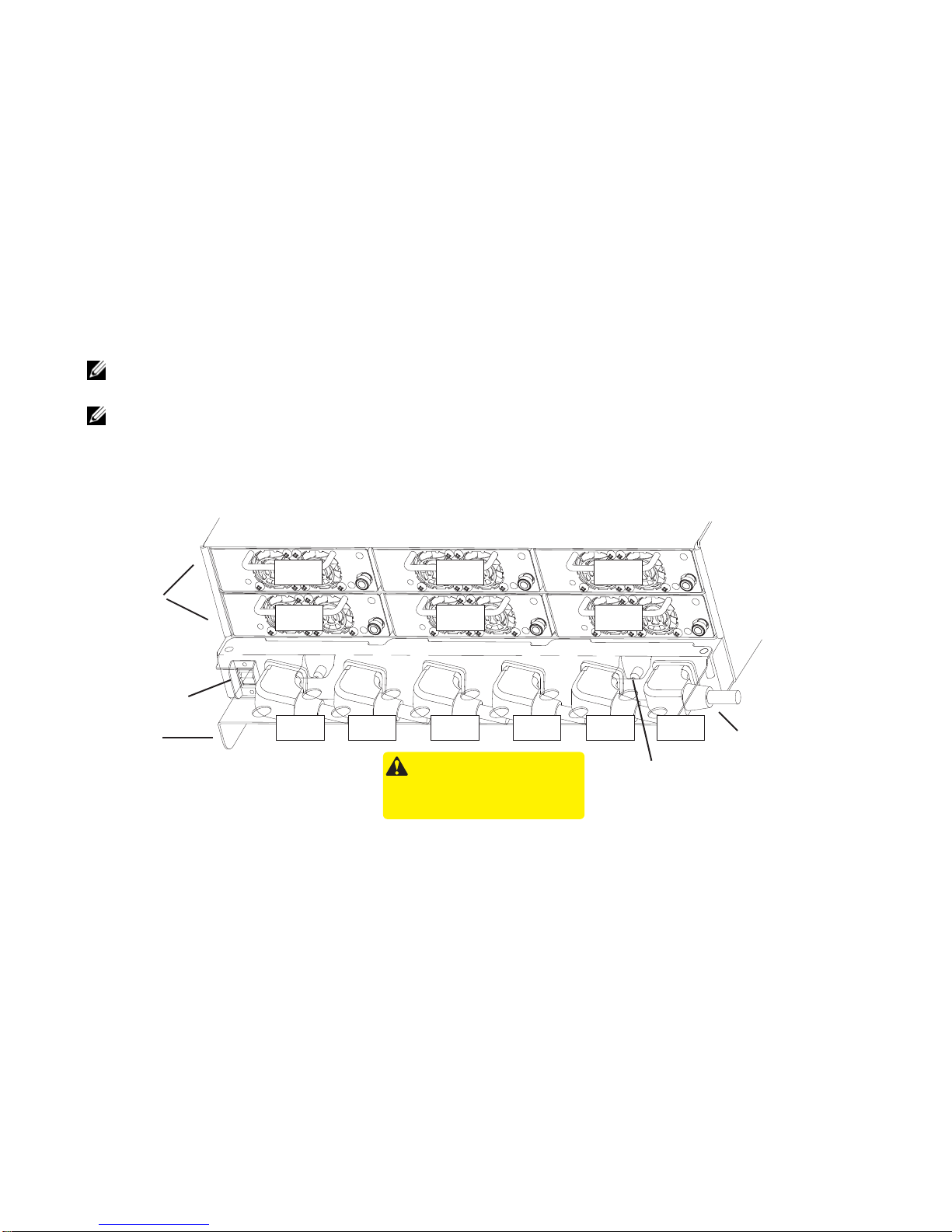

Installing AC Power Supplies

The E1200 system requires a minimum of 3 AC power supplies in a shelf (0, 1, 2 or 3, 4, 5) to operate.

For full redundancy use 6 power supplies so that if one power supply fails in one shelf, the system

remains operational operates with the 3 power supplies in the other shelf. To comply with safety agency

and EMI regulations, you must install the AC-cord retainer over all power cords. The E1200 chassis

contains 6 AC power supply slots, as shown in

NOTE: If you are installing only three power supplies, they must be installed in the same row. FTOS will

generate an error message if the three power supplies are not in the same row.

NOTE: The On/Standby switch disconnects power to the rest of the chassis from all 6 AC power supplies

slots. When the AC cord is attached, power supply fans will spin and the LEDs will indicate status while the

On/Standby switch is in Standby.

Figure 7-1. E1200i AC Power Supply Shelf

Figure 7-1

.

Power

Supplies

On/Standby

Switch

C-Cord Retainer

Safety Cover

AC- 0

AC- 3

AC- 0 AC-3 AC-1 AC-4 AC-2 AC- 5

WARNING -

HIGH LEAKAGE CURRENT. EARTH CONNECTION

ESSENTIAL BEFORE CONNECTING SUPPLY.

COURANT DE FUITE ELEVE. RAC CORDEMENT

A LA TERRE INDISPENSABLE AVANT LE

RACCOR DEMENT AU RESEAU.

This retainer must be in place during normal operation.

Do not remove except for servicing

AC- 1

AC- 4

/

/

/

AC- 2

AC- 5

Locking Screw

AC Power Plugs

Installing AC Power Supplies | 29

Loading...

Loading...