Page 1

Dell

®

®

PowerEdge

PowerEdge

®

®

2100/180 and 2100/200 Syst emsDell

2100/180 and 2100/200 Syst ems

SERVICE MANUAL

®

Model MMM

Page 2

Page 3

Dell® PowerEdge® 2100/180 and 2100/200 Systems

SERVICE MANUAL

®

Page 4

Information in this document is sub jec t to change without notice.

1996 Dell Computer Corporation. A ll ri ghts reserve d .

Reproduction in any man ne r w ha tsoe ve r w ithout the written permission of Dell Com put er Corporation is strictly forbidden.

Trademarks used in this text: Dell, the DELL logo, and PowerEdge are registered trademarks of Dell Computer Corporation; MS-DOS and

Microsoft are registered trademarks of Microsoft Corporation; IBM is a registered trademark of Inte rnational Business Machines Corporation;

Intel, LANDesk, and Pentium are registered trademarks of Intel Corporatio n .

Other trademarks and trade names may be used in this document to refer to either the entities claiming the marks and names or their products.

Dell Computer Corporat ion disclaims any proprietary inter est in tr ade marks and trade names other than its own .

September 1996 P/N 82502

Page 5

Index

B

battery, removal

beep codes

bezel, removal

boot routine, observing when

troubleshooting

bracket, hard-disk drive, removal

, 4-18

, 3-1

, 4-4

, 2-3

, 4-10

C

cables, DC power

CD-ROM drive

access indicator location

location

removal

, 1-4, 4-7

, 4-8

computer

back/left side internal view

cover removal

front/right side internal view

orientation

technical specifications

configuration guidelines, SCSI drives

, 1-12

, 1-3

, 1-5

, 4-3

, 1-4

, 1-3

, 1-19

, 1-7

D

DC power distribution diagram

DIMMs

ECC

, 1-6

installation

removal

, 4-15

, 4-15

socket population rules

diskette drive

access indicator location

location

removal

, 1-4, 4-7

, 4-8

diskette-based diagnostics

DREQ line assignments, list of

drives

boot device

, 1-8

externally-accessible drive bays

location of

, 4-7

SCSI configuration guidelines

SCSI ID numbers

, 1-8

SCSI termination jumper examples

SCSI termination jumpers

, 1-13

, 1-6

, 1-3

, 2-6

, 1-18

, 1-8

E

, 1-3

, 1-7

, 1-9

connectors, locations

, 1-14, 4-14

control panel assembly

location

removal

, 1-4

, 4-6

ECC

, 1-6

EISA expansion cards

, 1-6

error messages, system, list of

expansion subsystem

, 1-6

, 3-3

Index 1

Page 6

expansion-card slots

expansion-cards, removal

external visual inspection

, 1-6

, 4-11

, 2-2

externally-accessible drives, removal

, 4-8

J

jumpers

list of

, 1-16

location on system board

, 1-15

F

front bezel

features

insert removal

removal

, 1-3

, 4-5

, 4-4

H

hard-disk SCSI drives

bracket removal

location

, 4-7

, 4-10

hard-disk drives, SCSI

configurations

, 1-7

hard-disk-drive access indicator

help, getting

, 2-6

I

ID numbers, SCSI devices

indicators

, 1-3

, 1-8

, 1-3

M

memory, system

messages, error

microprocessor removal

, 1-6

, 3-3

, 4-16

P

PCI expansion cards

Plug and Play ISA expansion cards

POST beep codes

power button

, 1-3

power indicator

power supply

cables

connectors

, 1-10

, 1-12

, 1-10

DC voltage ranges

illustrated

, 1-12

power distribution diagram

removal

, 4-12

precautionary measures

, 1-6

, 3-1

, 1-3

, 1-10

, 1-13

, 4-2

, 1-6

initial procedures

initialization, system error messages

, 2-1

, 3-3

R

insert removal, front bezel

integrated

SCSI controller

, 1-7

server management

video controller

, 1-7

interrupt assignments, list of

2 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

, 4-5

reset button

resource conflicts, eliminating

, 1-6

, 1-17

, 1-3

, 2-5

Page 7

S

T

SCSI controller, integrated

SCSI devices, ID numbers

, 1-7

, 1-8

SCSI hard-disk drives. See also drives

specifications, technical

subsystems, advanced expansion

system battery removal

, 1-19

, 1-6

, 4-18

system board

component locations

illustrated

removal

, 1-14

, 4-19

system cooling fan, removal

system error messages, list of

system power supply

, 4-14

, 4-13

, 3-3

, 1-10

System Setup program

advanced menu

boot options submenu

exit menu

key functions, list of

main menu

menus

, A-1

screen color combinations

screen conventions

security menu

starting

, A-1

, A-6

, A-5

, A-10

, A-2

, A-3

, A-3

, A-1

, A-8

technical specifications

, 1-19

termination jumpers

SCSI drives

, 1-8

troubleshooting

boot routine, observing

, 2-3

external visual inspection

initial procedures

initial user contact

, 2-1

, 2-1

internal visual inspection

U

user contact, initial

, 2-1

V

video controller, integrated

visual inspection

external

internal

, 2-2

, 2-4

, 2-2

, 2-4

, 1-7

system unit. See computer

Index 3

Page 8

Figures

Figure 1-1. Computer Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Figure 1-2. Front-Bezel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

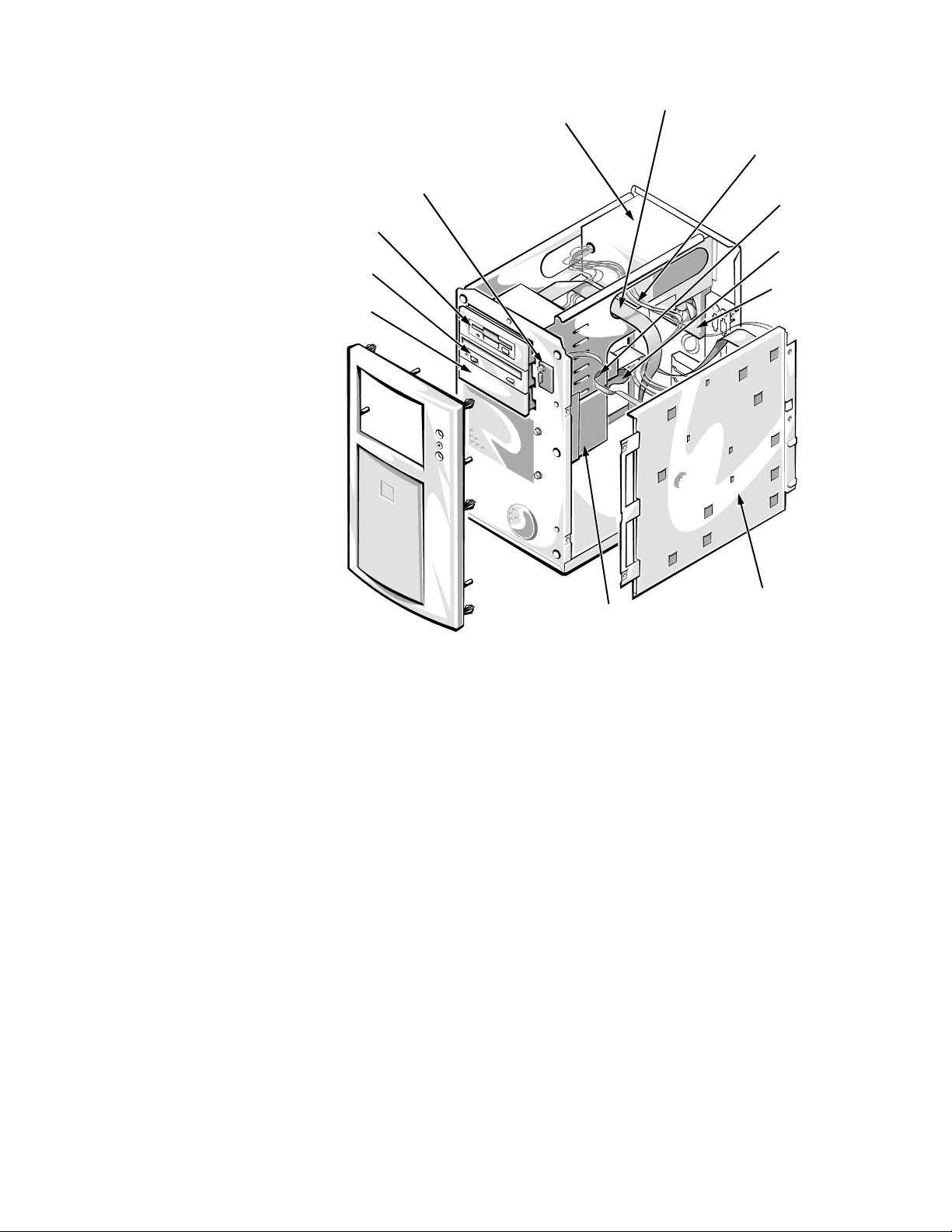

Figure 1-3. Front/Right Side Internal View . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

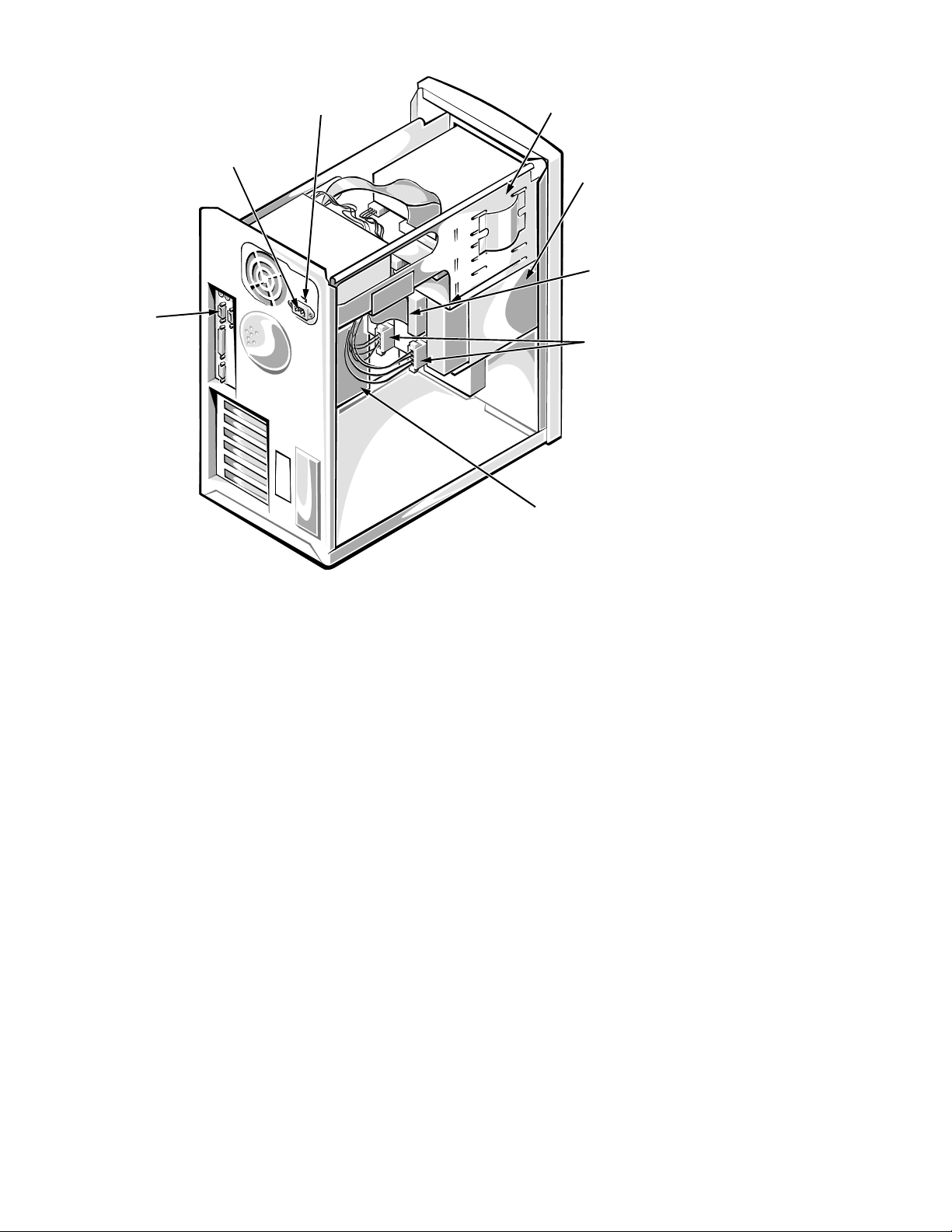

Figure 1-4. Back/Left Side Internal View . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Figure 1-5. SCSI Termination Jumper Examples. . . . . . . . . . . . . . . . . . . . . . 1-9

Figure 1-6. DC Power Connector P1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Figure 1-7. DC Power Connectors P2, P3, P4, P5, and P6. . . . . . . . . . . . . . 1-11

Figure 1-8. DC Power Connectors P7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Figure 1-9. DC Power Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Figure 1-10. DC Power Distribution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Figure 1-11. System Board Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Figure 1-12. System Board Jumpers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Figure 4-1. Computer Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4-2. Front Bezel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Figure 4-3. Front-Bezel Insert Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Figure 4-4. Control-Panel Assembly Removal. . . . . . . . . . . . . . . . . . . . . . . . 4-6

Figure 4-5. Drive Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Figure 4-6. Externally Accessible Drives Removal . . . . . . . . . . . . . . . . . . . . 4-8

Figure 4-7. Drive-Mounting Rails and Extensions Removal . . . . . . . . . . . . . 4-9

Figure 4-8. Hard-Disk Drive Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Figure 4-9. Expansion Card Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Figure 4-10. Power Supply Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Figure 4-11. System Cooling-Fan Removal. . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Figure 4-12. System Board Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Figure 4-13. DIMM Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Figure 4-14. DIMM Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Figure 4-15. Microprocessor Securing Clip Removal . . . . . . . . . . . . . . . . . . 4-16

Figure 4-16. Microprocessor/Heat Sink Assembly. . . . . . . . . . . . . . . . . . . . . 4-17

Figure 4-17. System Battery Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Figure 4-18. System Board Assembly Removal. . . . . . . . . . . . . . . . . . . . . . . 4-19

Figure 4-19. System Board Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Figure A-1. Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

DELL CONFIDENTIAL Preliminary 4/19/00

xi

Page 9

Figure A-2. Boot Options Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Figure A-3. Advanced Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Figure A-4. Security Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Figure A-5. Exit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

xii

DELL CONFIDENTIAL Preliminary 4/19/00

Page 10

Tables

Table 1-1. DC Voltage Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Table 1-2. Jumper Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Table 1-3. Interrupt Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Table 1-4. DREQ Line Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Table 1-5. Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Table 3-1. POST Beep Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Table 3-2. System Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Table A-1. Main Menu Categories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Table A-2. Boot Options Submenu Categories . . . . . . . . . . . . . . . . . . . . . . . A-5

Table A-3. Advanced Menu Categories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Table A-4. Security Menu Categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Table A-5. Exit Menu Categories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

DELL CONFIDENTIAL Preliminary 4/19/00

xiii

Page 11

xiv

DELL CONFIDENTIAL Preliminary 4/19/00

Page 12

Contents

Chapter 1

System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

System Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Advanced Expansion Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Integrated Server Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Video Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Integrated SCSI Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

SCSI Hard-Disk Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

SCSI Configuration Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

SCSI ID Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Device Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

System Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

System Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Pin Assignments for the DC Power Connectors. . . . . . . . . . . . . . . . . . 1-10

DC Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

System Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

System Board Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Interrupt Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

DMA Channel Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Technical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

v

Page 13

Chapter 2

Basic Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Initial User Contact. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

External Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Observing the Boot Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Internal Visual Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Eliminating Resource Conflicts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Running the Diskette-Based Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Getting Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Chapter 3

Beep Codes and Error Messages. . . . . . . . . . . . . . . . . . . . 3-1

POST Beep Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

System Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Chapter 4

Removing and Replacing Parts . . . . . . . . . . . . . . . . . . . . . 4-1

Recommended Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Precautionary Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Computer Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Front-Bezel Inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Control Panel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Externally Accessible Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Hard-Disk Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Expansion Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

System Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

System Cooling Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

System Board Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

DIMMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Microprocessor/Heat Sink Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

System Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

System Board Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

System Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

vi

Page 14

Appendix A

System Setup Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

System Setup Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Screen Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Key Function Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Screen Color Combinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Boot Options Submenu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Advanced Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Security Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Exit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Index

Figures

Figure 1-1. Computer Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Figure 1-2. Front-Bezel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Figure 1-3. Front/Right Side Internal View . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Figure 1-4. Back/Left Side Internal View . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Figure 1-5. SCSI Termination Jumper Examples. . . . . . . . . . . . . . . . . . . . . . 1-9

Figure 1-6. DC Power Connector P1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Figure 1-7. DC Power Connectors P2, P3, P4, P5, and P6. . . . . . . . . . . . . . 1-11

Figure 1-8. DC Power Connectors P7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Figure 1-9. DC Power Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Figure 1-10. DC Power Distribution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Figure 1-11. System Board Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Figure 1-12. System Board Jumpers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Figure 4-1. Computer Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4-2. Front Bezel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Figure 4-3. Front-Bezel Insert Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Figure 4-4. Control-Panel Assembly Removal. . . . . . . . . . . . . . . . . . . . . . . . 4-6

Figure 4-5. Drive Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Figure 4-6. Externally Accessible Drives Removal . . . . . . . . . . . . . . . . . . . . 4-8

vii

Page 15

Figure 4-7. Drive-Mounting Rails and Extensions Removal . . . . . . . . . . . . . 4-9

Figure 4-8. Hard-Disk Drive Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Figure 4-9. Expansion Card Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Figure 4-10. Power Supply Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Figure 4-11. System Cooling-Fan Removal. . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Figure 4-12. System Board Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Figure 4-13. DIMM Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Figure 4-14. DIMM Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Figure 4-15. Microprocessor Securing Clip Removal . . . . . . . . . . . . . . . . . . 4-16

Figure 4-16. Microprocessor/Heat Sink Assembly. . . . . . . . . . . . . . . . . . . . . 4-17

Figure 4-17. System Battery Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Figure 4-18. System Board Assembly Removal. . . . . . . . . . . . . . . . . . . . . . . 4-19

Figure 4-19. System Board Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Figure A-1. Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Figure A-2. Boot Options Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Figure A-3. Advanced Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Figure A-4. Security Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Figure A-5. Exit Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Tables

Table 1-1. DC Voltage Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Table 1-2. Jumper Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Table 1-3. Interrupt Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Table 1-4. DREQ Line Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Table 1-5. Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Table 3-1. POST Beep Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Table 3-2. System Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Table A-1. Key Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Table A-2. Main Menu Categories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Table A-3. Boot Options Submenu Categories . . . . . . . . . . . . . . . . . . . . . . . A-5

Table A-4. Advanced Menu Categories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Table A-5. Security Menu Categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Table A-6. Exit Menu Categories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

viii

Page 16

ix

Page 17

R

ead This First

A prerequisite for using this manual to service Dell computer systems is a

basic knowledge of IBM®-compatible PCs and prior training in IBM-

compatible PC troubleshooting techniques. In addition to information provided in this manual and the

provides the

cedures and instructions on using the Dell diagnostics to test the computer

system.

W

arnings, Cautions, and Notes

Throughout this manual, there may be blocks of text printed in bold type or in italic

type. These blocks are warnings, cautions, and notes, and they are used as follows:

WARNING: A WARNING indicates the pote ntial for bodi ly har m and pr ovide s

instructions for how to avoid the problem.

CAUTION: A CAUTION indicates either pot entia l damage t o hardware or loss

of data and provides instructions for how to avoid the problem.

Diagnostics and T roubleshooting Guide

User’s Guide

that came with the system, Del l

for troubleshooting pro-

NOTE: A NOTE provides helpful information about using the computer system.

x

Page 18

Chapter 1

System Overview

he Dell

T

ual are high-speed, upgradable, server systems, which use the Intel® Pentium®

Pro family of microprocessors. PowerEdge 2100 systems incorporate the highperformance peripheral component interconnect (PCI) local bus as well as the

extended industry-standard architecture (EISA) expansion bus. These buses are

built into the system board, which also integrates a Pentium Pro microprocessor and all

other elements of the basic computer sy stem.

The microprocessor module is installed in a zero insertion force (ZIF) socket on

the system board. This allows upgrading of the system board to a faster, more

powerful microprocessor when one becomes available. Contact Dell for information about Dell-supported microprocessor upgrades.

The Pentium Pro microprocessor contains a built-in clock multiplier circuit,

which increases the internal operating frequency to a multiple of the system

clock frequency. The microprocessors for each of these systems and their operating frequencies are as follows:

Dell PowerEdge 2100/180 system — 180 MHz derived from a system clock

•

frequency of 60 MHz

Dell PowerEdge 2100/200 system — 200 MHz derived from a system clock

•

frequency of 66 MHz

®

PowerEdge® 2100/180 and 2100/200 systems, covered in this man-

System Overview 1-1

Page 19

S

ystem Features

In addition to the standard features found in a traditional personal computer,

Dell PowerEdge 2100 systems include the following new and/or advanced

features:

256 KB of cache memory internal to the Pentium Pro module

•

16 MB of 72-bit wide, buffered, extended-data output (EDO)-type main

•

memory, upgradable to 256 MB

Memory error correction code (ECC) feature is built into the memory con-

•

troller on the system board

Advanced combination EISA and PCI expansion subsystem

•

Three EISA and three PCI expansion-card slots (none of the expansion-card

•

slots are shared)

Integrated VGA-compatible video subsystem attached to the PCI bus with

•

1 MB video memory standard

BIOS in upgradable flash memory attached to the EISA bus

•

Integrated super I/O controller attached to the EISA bus, provides a

•

bidirectional parallel port, two serial ports, and the diskette drive interface

Integrated ultra (fast-20) wide small computer system interface (SCSI)

•

controller

Integrated server management circuitry that monitors operation of the sys-

•

tem cooling fan for running or not, as well as critical system voltages and

temperatures

3.5-inch diskette drive and a CD-ROM drive standard in externally accessi-

•

ble drive bays

Recessed power and reset buttons to prevent accidental system interruptions

•

New quick-test feature in the diskette-based diagnostics (for more informa-

•

tion about

Chapter 2.)

All of these features, except the new quick-test feature, are briefly described in

this chapter. For a c om ple te list of system features, see “Technical Specifications”

found later in this chapter.

QUICK TEST

, see “Running the Diskette-Based Diagnostics” in

1-2 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 20

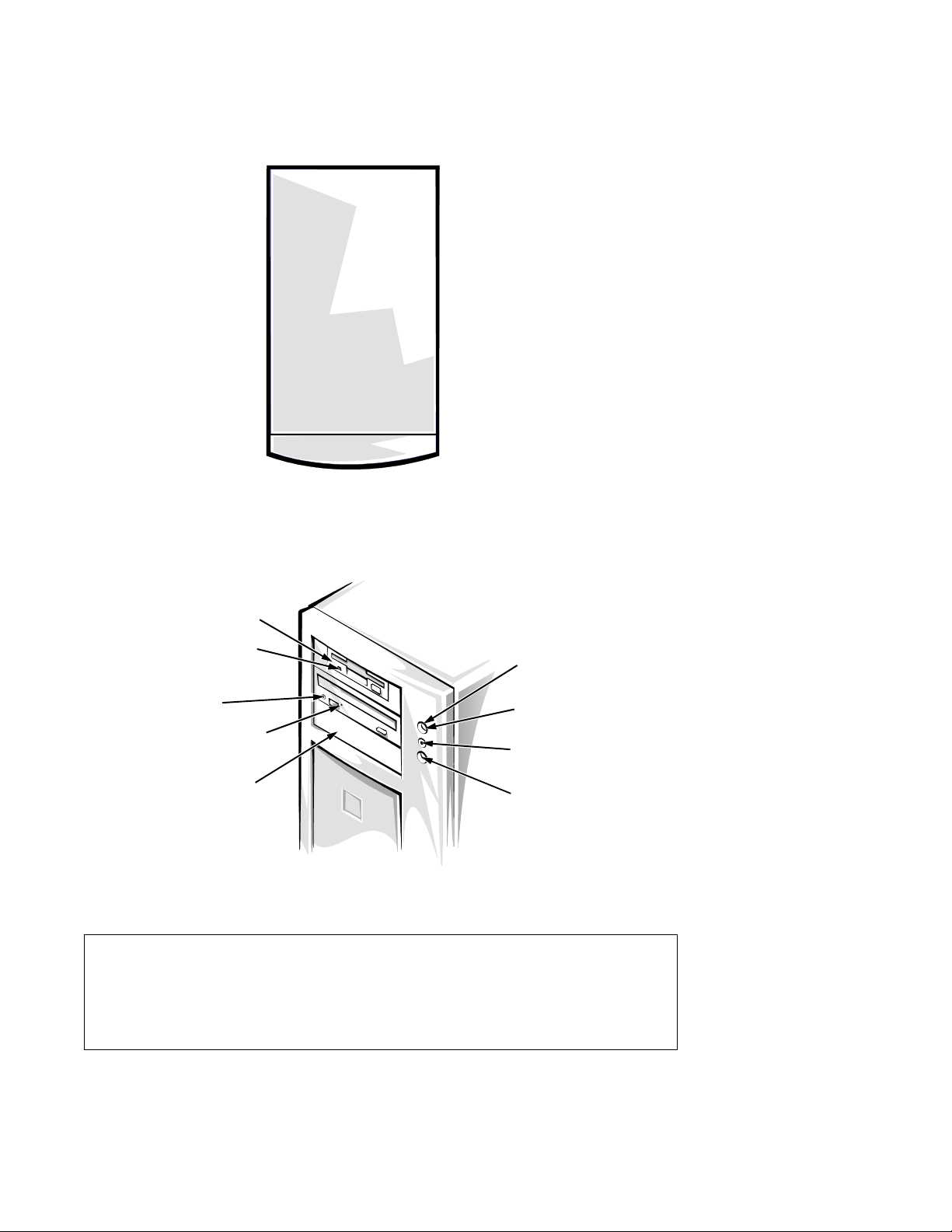

When following the text in this manual, assume that the location or direction

relative to the computer is as shown in Figure 1-1.

back of computer

left side

front of computer

Figure 1-1. Computer Orientation

3.5-inch diskette drive

diskette-drive access

indicator

CD-ROM drive

CD-ROM–drive access

indicator (BUSY)

third drive bay

right side

power button

power indicator

hard-disk-drive

access indicator

reset button

Figure 1-2. Front-Bezel Features

CAUTION: To avoid possible data or file structure corruptions, the

front-bezel reset button should be used only when the system cannot be

rebooted by pressing

<CTRL><ALT><DEL>

. Before you use the reset

button to initiate a hardware reset, close any open application program

and any files if possible.

System Overview 1-3

Page 21

Figure 1-3. Front/Right Side Internal View

system power supply

diskette controller

cable

system board

mounting plate

diskette drive

power cables

system cooling

fan

control panel

cable

SCSI cable

CD-ROM drive

internal hard-disk

drive cage

third drive bay

control panel

assembly

1-4 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 22

voltage selection switch

AC power input connector

I/O panel

connectors

externally-accessible

drive bays (3)

SCSI hard-disk

drive cage

SCSI cable

hard-disk-drive

power cables

system board

Figure 1-4. Back/L eft Side Internal View

System Overview 1-5

Page 23

System Memory

System memory has a minimum of 16 MB of 72-bit wide, buffered, EDO-type

memory . The system memory capacity can be expanded up to 256 MB by using

combinations of 16-, 32-, and 128-MB buffered, EDO-type dual in-line memory

modules (DIMMs).

The system board has four, 168-pin DIMM sockets. The DIMMs can be mixed.

The socket population rules are as follows:

Populate the DIMM sockets in order from DIMM_A (lower) to DIMM_D

•

(upper).

The DIMMs should be rated at 60 nanoseconds (ns) or faster. All of the sys-

•

tem memory operates at the speed of the slowest DIMM installed.

The largest capacity DIMM should be in socket DIMM_A with the smaller

•

capacity DIMMs installed in decreasing sizes toward socket DIMM_D.

The 72-bit wide, buffered, EDO DIMMs support the ECC feature that detects

memory errors and corrects single-bit memory errors. The ECC feature provides more reliable memory and less downtime. The ECC feature is built into

the memory controller on the system board.

See “DIMMs” in Chapter 4 for information on removing and replacing DIMMs.

Advanced Expansion Subsystem

The computer system offers advanced expansion subsystems that can support a

mixture of traditional EISA expansion cards, Plug and Play ISA expansion cards,

and PCI expansion cards. The EISA Configuration Utility included with the system

provides a means of avoiding resource conf licts that might arise from such an

arrangement.

After all legacy cards have been configured with the EISA Configuration Utility,

the system automatically assigns any required memory space, IRQ lines, and

DMA channels to any installed Plug and Play ISA expansion cards and PCI

expansion cards the next time the system is rebooted. Chapter 5, “Using the

EISA Configuration Utility,” in the User’s Guide describes the EISA Configura-

tion Utility and provides instructions for using it to configure the system.

The six expansion-card slots include three EISA expansion-card connectors and

three PCI expansion-card connectors. The expansion-card connectors are

located on the system board (see Figure 1-11).

Integrated Server Management

The system board contains integrated server management circuitry that monitors whether the system cooling fan is running, as well as critical system

voltages and temperatures. The integrated server management circuitry works

in conjunction with the Intel LANDesk® Server Management suite.

1-6 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 24

Video Controller

The video subsystem is built into the system board a nd consists of a high-speed,

high-resolution VGA-compatible video subsystem. The video controller is connected to the PCI local bus. The standard video subsystem contains 1 MB of

video memory (the video memory size is not upgradable).

Maximum noninterlaced resolutions are 640 x 480 pixels with 16.7 million colors or 800 x 600 pixels with 65,536 colors.

Maximum interlaced resolution is 1024 x 768 pixels with 256 colors.

Integrated SCSI Contro lle r

A single-integrated SCSI controller provides an ultra (fast-20) wide, SCSI interface through a 68-pin connector on the system board. The integrated SCSI

controller attaches to the PCI bus to provide a high-performance SCSI bus.

The integrated SCSI controller provides control for the three SCSI hard-disk

drives in the SCSI hard-disk drive cage, the CD-ROM drive in the middle

externally-accessible drive bay and a SCSI drive installed in the lower

externally-accessible drive bay.

SCSI Hard-Disk Drives

A SCSI hard-disk drive cage is located under the externally-accessible drive bays at

the front of the computer (see Figure 1-4). The SCSI hard-drive cag e can contain up

to three, 1.6-inch-high, SCSI hard-disk drives (either fast/wide or ultra [fast-20]

wide). These SCSI hard-disk drives mount vertically . The SCSI hard-disk drive bays

are populated from left to right (facing the front of the computer), so that the SCSI

terminator jumper is accessible on the leftmost drive installed (last drive on the SCSI

channel).

NOTE: The externally-accessible drive bays at the front of the computer are

normally used for diskette drives, CD-ROM drives, and/or tape drives. Harddisk drives should be installed in the SCSI hard-disk drive cage. For detailed

information about installing externally-accessible drives, see Chapter 8, “Installing

Drives in the External Bays,” in the User’s Guide. For detailed information about

installing SCSI hard-disk drives, see Chapter 9, “Installing Drives in the Internal

Bays,” in the User’s Guide.

SCSI Configuration Guidelines

Although SCSI devices are installed essentially the same way as other devices,

their configuration requirements are different. To configure your SCSI subsystem, follow the general guidelines offered in the following subsections.

System Overview 1-7

Page 25

SCSI ID Numbers

Each device attached to the SCSI host adapter must have a unique SCSI ID

number from 0 to 15. See Chapter 9, “Installing Drives in the Internal Bays” in

the User’s Guide for additional SCSI addressing information.

NOTE: Any narrow SCSI devices installed in the external drive bays will

require SCSI ID numbers less than 7.

When SCSI devices are shipped from Dell, the default SCSI ID numbers are

assigned as follows:

The computer’s built-in SCSI controller is configured through the BIOS as

•

SCSI ID 7 (the default ID number for a host adapter) if the system includes

a CD-ROM or tape drive.

NOTE: If only wide SCSI hard-disk drives ar e connected to the built-in SCSI

controller (no CD-ROM or tape drives), it may be configured as SCSI ID

15.

A SCSI CD-ROM drive (installed in an externally-accessible drive bay) is

•

configured as SCSI ID 5.

A SCSI tape drive (if installed) is configured as SCSI ID 6.

•

The drive you intend to use as your boot device should be configu red as SCSI

•

ID 0. You can configure any additional hard-disk drives to any of the stillavailable SCSI ID numbers.

If Dell installs additional SCSI hard-disk drives in the system, they will be

•

configured as SCSI ID 1 and SCSI ID 2.

NOTE: There is no requirement that SCSI ID numbers be assigned sequentially or

that devices be attached to the cable in or der by ID number.

Device Termination

Before installing SCSI devices, you must configure the termination on the

device(s) and for the built-in SCSI controller according to the guidelines listed

in the following text.

SCSI logic requires that termination be enabled for the two devices at opposite

ends of the SCSI chain and disabled for all devices in between. To that end,

regardless of whether you are installing internal or external devices, use the following guidelines:

The built-in SCSI controller has active termination — no action is required.

•

When the SCSI hard-disk drives are installed by Dell, termination is set to

•

enabled on the SCSI hard-disk drive installed in the left bay of the SCSI

hard-disk drive cage. Termination should be disabled on any other drives

installed in the SCSI hard-disk drive cage. Figure 1-5 shows some examples

of SCSI termination jumpers.

1-8 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 26

If you install an optional SCSI controller card to control the CD-ROM drive

•

and any other SCSI device in the externally-accessible drive bays, you must

enable termination for the SCSI controller card and the SCSI device at the

end of the SCSI interface cable (preferably the CD-ROM drive). See the

documentation that came with your SCSI controller card for instructions.

Figure 1-5 shows an example of a SCSI termination jumper on a CD-ROM

drive.

NOTE: When you install or remove a termination jumper, do not move or

remove any other jumpers installed on the drives.

termination jumper

example CD-ROM drive

termination jumper

example hard-disk drive (back view)

example hard-disk drive (bottom view)

termination jumper

jumpered unjumpered

Figure 1-5. SCSI Termination Jumper Examples

System Overview 1-9

Page 27

System Unit

The following subsections provide service-related information about the

computer.

System Power Supply

The 230-W system power supply can operate from an AC power source of

115 VAC at 60 Hz or 230 VAC at 50 Hz. The system power supply provides the

DC operating voltages and currents listed in Table 1-1.

NOTE: The power supply produces DC voltages only under its loaded condition. Therefore, when you measure these voltages, the DC power connectors

must be connected to their corresponding pow er input connectors on the s ystem

board or drives.

.

Table 1-1. DC Voltage Ranges

Voltage Range

Maximum Output

Current

1

+3.3 VDC +3.15 to +3.45 VDC 14.0 A

+5 VDC +4.75 to +5.25 VDC 29.0 A

+12 VDC +11.40 to +12.60 VDC

6.0 A

2

–12 VDC –10.80 to –13.20 VDC 0.3 A

–5 VDC –4.50 to –5.50 VDC 0.3 A

+5 VFP

1

Maximum continuous DC output power shall not exceed 230 W. Maximum combined load on

2

3

VFP (volts flea power) — sometimes called “standby power.”

3

+5 VDC and +3.3 VDC shall not exc eed 170 W.

The total power of all voltages other than +12 VDC must not exceed 158 W.

+4.75 to +5.25 VDC 10 mA

Pin Assignments for the DC Power Connectors

The power-supply output voltages can be measured at the back (wire side) of

the connectors without disconnecting them. Figures 1-6, 1-7, and 1-8 show the

wire side of the connectors.

1-10 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 28

–5 VDC (white)

common (black)

common (black)

common (black)

1

PSON#

(grey)

11

12 13 14 15 16 17 18 19 20

+5 VDC (red)

+5 VDC (red)

+5 VDC (red)

not used (brown)

+5 VDC (red)

P1

234 5678 910

1

+5 VDC (red)

common (black)

+5 VDC (red)

common (black)

PWRGOOD

1

Pin 11 — PSON# should measure between +4 and +5 VDC except when the power button on the front

2

(orange)

panel is pressed, taking PSON# to its active-low state.

2

Pin 5 — PWRGOOD should measure between +4 and +5 VDC when the power supply is on and oper-

ating to indicate that all power-supply output voltages are within ranges specified in Table 1-1.

common (black)

common (black)

–12 VDC (blue)

+12 VDC (yellow)

+5 VFP (purple)

Figure 1-6. DC Power Connector P1

P2, P3, P5, P6

1234

+5 VDC (red)

common (black)

common (black)

+12 VDC (yellow)

P4

1234

+12 VDC (yellow)

common (black)

common (black)

+5 VDC (red)

Figure 1-7. DC Power Connectors P2, P3, P4, P5, and P6

System Overview 1-11

Page 29

Figure 1-8. DC Power Connectors P7

1234

+3.3 VDC (blue/white)

common (black)

common (black)

5

P7

6

+3.3 VDC (blue/white)

+3.3 VDC (blue/white)

common (black)

P7

P6

P5

P4

P3

P2

P1

DC Power Distribution

Figures 1-9 and 1-10 provide the following information about DC power

distribution:

Power-supply connector identification

•

Power cable connections for diskette, tape, CD-ROM, and hard-disk drives

•

Power distribution to sockets and connectors on the system board

•

Figure 1-9. DC Power Cables

1-12 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 30

keyboard

controller

system board

+3 VDC

system

power supply

optional

drive

CD-ROM

drive

3.5-inch

diskette drive

internal

hard-disk drive

internal

hard-disk drive

P1

POWER

PWRGOOD

PSON#

PSON#

+5 VFP +5 VFP

+5 VDC

–5 VDC

+12 VDC

–12 VDC

P7

+5 VDC

–5 VDC

+12 VDC

–12 VDC

POWER3V

+3.3 VDC

main memor y

P2

sockets

DIMM_D

P3

P4

DIMM_C

DIMM_B

DIMM_A

P5

MICROPROCESSOR

P6

+3.3 VDC

power

management

logic

RTC/

NVRAM

processor core

core VCC (+2.1 to +3.5 VDC)

battery

regulator

+3.3 VDC

+5 VDC

+12 VDC

–12 VDC

+5 VDC

–5 VDC

+12 VDC

–12 VDC

battery (+3 VDC)

+3.3 VDC

+5 VFP

PWRGOOD

+12 VDC

+5 VFP

+5 VDC

+5 VDC

fuse

+5 VDC

+5 VDC

PCI4

through

PCI6

EISA1

through

EISA3

SRV_MGT

FAN

PANEL

SPKR

KYBD

MOUSE

internal

Y-cable

hard-disk drive

Figure 1-10. DC Power Distribution

System Overview 1-13

Page 31

System Board Layout

keyboard (bottom) and

mouse (top) connectors (KYBD / MOUSE)

video connector

(JVGA)

parallel port connector

(PARALLEL)

serial port 1 (bottom)

and serial port 2 (top)

connectors (SERIAL)

diskette/tape drive interface

connector (FLOPPY)

control-panel connector

(PANEL)

battery socket

(BATTERY)

top of the computer

microprocessor socket

EISA connectors (EISA1

[lower], EISA2, and EISA3)

fan connector (FAN)

power connector (POWER)

3-volt power connector

(POWER3V)

auxiliary fan connector

(AUXFAN)

DIMM connectors (DIMM_A

[lower], DIMM_B, DIMM_C,

and DIMM_D)

PCI connectors (PCI4

[lower], PCI5, and

PCI6)

server management

connector (SRV_MGT)

integrated SCSI port

connector (SCSI)

The subsections that follow provide service-related information about the system board components.

Figure 1-11. System Board Components

1-14 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 32

System Board Jumper

200 MHZ

180 MHZ

PASSWD

EISA

VGA

CARDBIOS

jumpered

unjumpered

Figure 1-12. System Board Jumpers

System Overview 1-15

Page 33

Table 1-2. Jumper Descriptions

Jumper Description Settings

200MHZ Microprocessor speed Installed if the micro-

processor’s internal speed is

200 MHz, otherwise, not

installed.

180MHZ Microprocessor speed Installed if the micro-

processor’s internal speed is

180 MHz, otherwise, not

installed.

PASSWD Password enable/disable Jumper installed to activate

boot password feature.

EISA Clear EISA configuration

settings

Install the jumper and boot

the system to clear the configuration settings.

Remove the jumper and use

the EISA Configuration Utility to configure the system.

VGA Integrated VGA controller

enable/disable

Install to enable the integrated VGA controller.

CARDBIOS Used for trouble shooting Install the jumper to boot

system from BIOS expansion card.

Remove the jumper to allow

normal boot operation from

BIOS.

1-16 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 34

Interrupt Assignments

Table 1-3. Interrupt Assignments

IRQ Line Used By/Available

IRQ0 Generated by system timer.

IRQ1 Generated by keyboard controller to indicate that keyboard’s out-

put buffer is full.

IRQ2 Generated internally by interrupt controller to enable IRQ8

through IRQ15.

IRQ3

and

IRQ4

Generated by super I/O controller to indicate that device connected to corresponding serial port requires service (IRQ3 for

COM2 or COM4; IRQ4 for COM1 or COM3).

IRQ5 Available for use by expansion card unless this IRQ line is used

by secondary parallel port.

IRQ6 Generated by super I/O controller to indicate that diskette or tape

drive requires service.

IRQ7 Generated by super I/O controller to indicate that device con-

nected to parallel port requires service.

IRQ8 Generated by keyboard controller for each tick of RTC.

IRQ9 Available for use by expansion card.

IRQ10 Available for use by expansion card.

IRQ11 Available for use by expansion card.

IRQ12 Generated by keyboard controller to indi cate that mouse’s output

buffer is full.

IRQ13 Generated by math coprocessor to indicate coprocessor error.

IRQ14 Available for use.

IRQ15 Available for use.

System Overview 1-17

Page 35

DMA Channel Assignments

Table 1-4. DREQ Line Assignments

DREQ Line Used By/Available

DREQ0 Available

DREQ1 Available

DREQ2 Generated by super I/O controller to initiate DMA cycle for

attached diskette drive

DREQ3 Available

DREQ4 Generated by bus controller chip to activate second DMA con-

troller

DREQ5 Available

DREQ6 Available

DREQ7 Available

1-18 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 36

T

echnical Specifications

Table 1-5. Technical Specifications

Microprocessor

Microprocessor type . . . Intel Pentium Pro microprocessor

Microprocessor speed . . 200 or 180 MHz

Internal cache . . . . . . . . 256 KB

Math coprocessor . . . . . internal to the microprocessor

System Information

System chip set . . . . . . . Intel 440FX controller chip set

Data bus width . . . . . . . 64 bits

Address bus width. . . . . 32 bits

Expansion Bus

Bus types. . . . . . . . . . . . PCI and EISA

Bus speed . . . . . . . . . . . PCI: 30 MHz with the 180 MHz microprocessor;

33 MHz with the 200 MHz microprocessor

EISA: 7.5 MHz with the 180 MHz microprocessor;

8.33 MHz with the 200 MHz microprocessor

PCI expansion-card

connectors. . . . . . . . . . . three (no shared expansion-card slots)

EISA expansion-card

connectors. . . . . . . . . . . three (no shared expansion-card slots)

System Clocks

System clock. . . . . . . . . 60 or 66 MHz (matches external processor speed)

Diskette/communica-

tions ports . . . . . . . . . . . 24 MHz from the system clock

Memory

Architecture . . . . . . . . . 72-bit (64 data bits plus 8 parity bits), noninter-

leaved, buffered, EDO-type memory

DIMM sockets . . . . . . . four 168-pin sockets

DIMM capacities . . . . . 16, 32, a nd 128 MB (D IMM s a re 60 ns o r f as te r, ED O)

Standard RAM . . . . . . . 16 MB

Maximum RAM . . . . . . 256 MB

BIOS address . . . . . . . . F000:0000h–F000:FFFFh

System Overview 1-19

Page 37

Table 1-5. Technical Specifications

Integrated SCSI Controller

(Continued)

Type . . . . . . . . . . . . . . . Adaptec AIC-7880 ultra wide SCSI controller with

integrated 68-pin SCSI connector on the system

board

Drives

Externally accessible

bays. . . . . . . . . . . . . . . . one 5.25-inch bay (upper bay) dedicated to a

3.5-inch diskette drive; one 5.25-inch bay (middle

bay) containing a CD-ROM drive; one 5.25-inch

bay (lower bay) for a tape drive or CD-ROM drive

Internally accessible

bays. . . . . . . . . . . . . . . . three hard-disk drive bays for SCSI hard-disk

drives up to 1.6-inch-high

Ports

Externally accessible:

Serial (DTE). . . . . . two 9-pin connectors; 16550-compatible

Parallel . . . . . . . . . . one 25-hole connector (bidirectional)

Video . . . . . . . . . . . one 15-hole connector (VGA compatible)

PS/2-style key-

board. . . . . . . . . . . . 6-pin mini-DIN

PS/2-compatible

mouse . . . . . . . . . . . 6-pin mini-DIN

Internally accessible:

SCSI controller. . . . one 68-pin ultra (fast-20) wide connector

Diskette drive . . . . . 34-pin connector

Controls and Indicators

Reset control. . . . . . . . . push button

Power control . . . . . . . . push button

Power indicator. . . . . . . green LED

Diskette-drive access

indicator . . . . . . . . . . . . green LED

Hard-disk drive access

indicator . . . . . . . . . . . . green LED

CD-ROM drive access

indicator . . . . . . . . . . . . green LED

1-20 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 38

Table 1-5. Technical Specifications

Video

(Continued)

Video type. . . . . . . . . . . ATI mach64 (264VT) PCI video controller with

integrated VGA connector

Video memory

(standard) . . . . . . . . . . . 1 MB (not upgradable)

Power

DC power supply:

Wattage . . . . . . . . . . 230 W

Voltage . . . . . . . . . . 90 to 135 V at 60 Hz;

180 to 265 V at 50 Hz

Backup battery . . . . . . . 3.0-V CR2032 lithium coin cell

Physical

Height . . . . . . . . . . . . . . 44.45 cm (17.5 inches)

Width. . . . . . . . . . . . . . . 24.13 cm (9.5 inches)

Depth. . . . . . . . . . . . . . . 41.91 cm (16.5 inches)

Weight (maximum). . . . 17.68 kg (39.0 lb)

Environmental

Temperature:

Operating . . . . . . . . 10° to 35°C (50° to 95°F)

Storage . . . . . . . . . . -40° to 65°C (-40° to 149°F)

Relative humidity . . 8% to 80% (noncondensing)

Maximum vibration:

Operating . . . . . . . . 0.25 G at 3 to 200 Hz for 30 min

Storage . . . . . . . . . . 0.5 G at 3 to 200 Hz for 30 min

Maximum shock:

Operating . . . . . . . . half-sine wave form: 50 G for 2 ms

Storage . . . . . . . . . . half-sine wave form: 110 G for 2 ms;

square wave form: 27 g for 15 ms

Altitude:

Operating . . . . . . . . -16 to 3048 m (-50 to 10,000 ft)

Storage . . . . . . . . . . -16 to 10,600 m (-50 to 35,000 ft)

z

System Overview 1-21

Page 39

1-22 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 40

Chapter 2

Basic Troubleshooting

his chapter describes basic troubleshooting procedures that can help you

T

diagnose a computer system problem. These procedures can often reveal the

source of a problem or indicate the correct starting point for troubleshooting the

system. A brief explanation of how to load and start the diskette-based diagnostics is located at the end of the chapter. Dell recommends that you perform the

following procedures in the order they are presented in this manual.

I

nitial User Contact

When you first contact a user who has a problem, ask the user to describe the

problem and the conditions under which it occurs. A verbal description can

often indicate the cause of a problem or indicate the appropriate troubleshooting

procedure to use. After the user describes the problem, follow these steps:

1. Ask the user to back up any data on the hard-disk drive if the system’s condition permits.

Appendix C, “Maintaining the System,” in the User’s Guide provides infor-

mation about backing up data.

2. Ask the user to try to duplicate the problem by r epeating the operations

he or she was performing at the time the problem occurred.

Can the user duplicate the problem?

.

Proceed to step 3.

Yes

.

Proceed to the next section, “External Visual Inspection.”

No

3. Observe the user to determine if he or she is making an error, such as

typing an incorrect key combination or entering a command

incorrectly.

Is the problem a result of user error?

.

Instruct the user in the proper procedure, or direct him or her to the

Yes

appropriate user documentation for the correct procedure.

.

Proceed to the next section, “External Visual Inspection.”

No

Basic Troubleshooting 2-1

Page 41

E

xternal Visual Inspection

The external visual inspection is a quick inspection of the exterior of the system

unit, the monitor, the keyboard, any peripherals, and cables. While performing

the visual inspection, make any necessary corrections. To perform the external

visual inspection, follow these steps:

1. Turn off the system unit, the monitor, and all peripherals.

2. Verify that all power cables are properly connected to the system unit,

the monitor and peripherals, and their power sources.

3. Verify that the keyboard and mouse interface cables are firmly

attached to the proper connectors on the back of the system unit.

For a PS/2-compatible mouse, the keyboard and mouse interface cable connectors are identical except for their labels. If needed, see “System

Features” in Chapter 1.

For a serial mouse, the mouse interface cable must be firmly attached to one

of the serial port connectors, and its captive screws must be secure enough

to ensure a firm connection.

4. If present, verify that any network cables are attached properly.

5. Verify that any devices attached to the serial and parallel port connectors are properly connected.

Each of the serial and parallel interface cables must be firmly attached to an

appropriate connector on the back of the system unit as well as to the interface connector on the device. The captive screws that secure these

connectors at each end of the interface cable must be secure enough to

ensure a firm connection.

6. Verify that the video interface cable is firmly attached to the connector

on the back panel or to a video expansion card and to the connector on

the back of the monitor.

For proper connection of the video monitor, see the documentation for the

monitor.

7. Inspect all external monitor controls for any obvious damage or improper settings.

For proper settings of the video monitor controls, see the documentation for

the monitor.

8. Inspect the keyboard to ensure that no keys are sticking.

If one or more keys are sticking, it may be necessary to replace the

keyboard.

2-2 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 42

9. Inspect the exterior of the system unit, including all controls and indicators, and all user-accessible data storage devices for any signs of

physical damage.

Does the inspection reveal any problems?

.

Proceed to the appropriate procedure in Chapter 4, “Removing and

Yes

Replacing Parts.”

.

Proceed to the next section, “Observing the Boot Routine.”

No

O

bserving the Boot Routine

After you have performed an external visual inspection as described in the previous section, you should boot the system and, while the boot routine is

running, observe the system for any indications of problems.

NOTE: Most of the steps in this procedure require observation of system functions and indications, some of which can occur simultaneously. It may be

necessary to reboot the system several times in order to complete all of these

steps.

To observe problem indications during the boot routine, follow these steps:

1. Insert the diagnostics diskette into drive A. Turn on all peripherals and

the system unit. If the system unit is already on, press the reset button

or <

CTRL><ALT><DEL

2. Check the power supply fan.

Does the fan run normally?

Proceed to step 3.

Yes.

Troubleshoot the system power supply.

No.

3. Watch the Num Lock, Caps Lock, and Scroll Lock indicators on the

upper-right corner of the keyboard. After all three indicators flash

momentarily, the Num Lock indicator should light up and remain on.

Do these indicators flash on and off within approximately ten seconds after

the boot routine starts?

Proceed to step 4.

Yes.

Troubleshoot the system power supply. If the troubleshooting procedure

No.

indicates that the system power supply is operational, troubleshoot the

memory.

> to reboot the system.

Basic Troubleshooting 2-3

Page 43

4. During the boot routine, observe the system for any of the following:

Diskette-drive and hard-disk drive access indicators: These indicators

•

light up in response to data being transferred to or from the drives. If

either of these indicators fails to light up during the boot routine, troubleshoot the diskette drive or hard-disk drive subsystem, as appropriate.

System error messages: These messages can indicate problems or pro-

•

vide status information. If a system error message is displayed, see

Table 3-2.

Beep codes: A beep code is a series of beeps that indicates an error con-

•

dition. If the system emits a beep code, see Table 3-1.

NOTE: The system beeps once during the boot ro utine. This single beep is

normal and is not a beep code.

5. Observe the monitor screen for the Diagnostics Menu.

Does the Diagnostics Menu appear?

See “Running the Diskette-Based Diagnostics” found later in this

Yes.

chapter.

Proceed to step 6.

No.

6. Insert another copy of the diagnostics diskette into the diskette drive, and reboot the system.

Does the Diagnostics Menu appear?

See “Running the Diskette-Based Diagnostics” found later in this

Yes.

chapter.

Proceed to the next section, “Internal Visual Inspection.”

No.

I

nternal Visual Inspection

CAUTION: Before you proceed with the internal visual inspection descri bed i n

this sectio n, ensure that the user has s aved all open files and ex ited all open

application programs if possible.

A simple visual inspection of a system unit’s interior hardware can often lead to the

source of a problem, such as a loose expansion card, cable conn ector, or mou nting screw .

When you perform the visual inspection, refer to “Sy stem Features” in Chapter 1 to locate

components in the inspection procedure.

To perform the internal visual inspection, follow these steps:

1. Turn off the system, including any attached peripherals, and disconnect

all the AC power cables from their power sources.

2. Remove the system unit cover.

2-4 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 44

3. Verify that the microprocessor, DIMMs, and expansion cards, are fully

seated in their sockets or connectors.

WARNING: The microprocessor can get extremely hot. Be sure the chip

has had sufficient time to cool before you touch it.

While reseating the microprocessor, wear a wrist grounding strap or maintain contact with a metal surface on the chassis.

To reseat the microprocessor, remove it from its socket and reinstall it as

described in “Microprocessor/Heat Sink Assembly” in Chapter 4.

To reseat a DIMM, remove it from its socket and reinstall it as described in

“DIMMs” in Chapter 4.

If you need to reseat an expansion card, use a

the screw that secures the card-mounting bracket. Grasp the card by its top

corners, and carefully pull it out of its connector. Reinsert the card in its

connector, and carefully push it in until it is fully seated. Then reinstall the

card-mounting bracket’s retaining screw.

4. Verify that all jumpers are set correctly.

For information about these jumpers, see “System Board Jumpers” in Chapter 1.

5. Check all cable connectors inside the system unit to verify that they are

firmly attached to their appropriate connectors.

6. Reinstall the system unit cover.

7. Reconnect the system unit and any attached peripherals to their power sources, and turn them on.

Does the problem appear to be resolved?

No further steps are necessary. Terminate the procedure.

Yes.

Proceed to the next sections, “Eliminating Resource Conflicts,” “Run-

No.

ning the Diskette-Based Diagnostics,” and to “Getting Help.”

-inch nut driver to remove

1/4

E

liminating Resource Conflicts

Devices within the system unit may require dedicated memory spaces, interrupt

levels, or DMA channels, all of which must be allocated during installation of

the devices. Because a device may be installed at a different time, it is possible

that the same resource is assigned to two or more devices.

Resource conflicts can result in disorderly or erratic system operation or system

failure. If you suspect that resource conflicts might exist, check the system and

reassign the resources as necessary.

For additional information, see Chapter 5, “Using the EISA Configuration Utility” in the User’s Guide.

Basic Troubleshooting 2-5

Page 45

R

unning the Diskette-Based Diagnostics

The diskette-based diagnostics (included with the system) contain tests that aid

in troubleshooting all major components of the computer system.

CAUTION : To prevent dam age to th e orig inal diag nostics disket te, alway s use

a backup copy of the diagnostics diske tte when servicing a user’s system. Dell recommends that users make several copies of this diskette to ensure that one is always

available.

To start the diagnostics, turn off the system unit, insert a diagnostics diskette

into drive A, and then turn on the system unit.

Starting the diagnostics causes the Dell logo screen to appear on the monitor

screen, followed by a message indicating that the diagnostics is loading. Before

the diagnostics loads, a program tests the portion of main memory (RAM)

required for loading the diagnostics. If a main memory error is detected, a message appears on the screen telling you which DIMM has failed.

If no errors are found in main memory, the diagnostics loads and the Diagnostics Menu appears. This menu lets you choose the following options or exit to

the Microsoft

®

MS-DOS® prompt:

RUN QUICK TESTS

•

locate a failure or to indicate where further testing is needed to isolate a

failure

RUN ALL TESTS

•

RUN SPECIFIC TESTS

•

G

etting Help

If none of the troubleshooting procedures in this chapter or the tests in the diskette-based diagnostics reveals the source of the problem or leads to the proper

troubleshooting steps for determining the source of the problem, call Dell for

technical assistance. For instructions, see the chapter titled “Getting Help” in

the Diagnostics a nd T r ou bleshooti ng Guide .

— Runs selected tests from all test groups to quickly

— Runs all tests for a thorough test of the system

— Tests a particular area or subsystem

2-6 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 46

Chapter 3

Beep Codes and Error Messages

his chapter describes beep codes and system error messages that can occur

T

during POST or, in the case of some failures, during normal system operation.

The tables in this chapter list faults that can cause a beep code or system error

message to occur and the probable causes of the fault in each case.

If a faulty system does not emit beep codes or display syste m error message s to

indicate a failure, you should use the diskette-based diagnostics to run the

appropriate tests to help isolate the source of the problem. See “Running the

Diskette-Based Diagnostics” in Chapter 2.

P

OST Beep Codes

If the monitor cannot display error messages during the POST, the system may

emit a series of beeps that identifies the problem or that can help you identify a

faulty component or assembly . Table 3-1 lists the beep codes that may be generated during the POST. Most beep codes indicate a fatal error that prevents the

system from completing the boot routine until the indicated condition is

corrected.

When the system emits a beep code, record the code and then find it in

Table 3-1. If the table does not lead to the source of the problem, run the appropriate tests in the diskette-based diagnostics to assist in troubleshooting the

problem.

Table 3-1. POST Beep Codes

Beep Code Error Probable Causes

1-2 Invalid Expansion-

card-ROM checksum

1-2-2-3 Invalid BIOS ROM

checksum

1-3-1-1 DRAM refresh failure Defective DIMMs or sys-

Improperly seated expansion card or the system

needs rebooted.

Corrupted BIOS firmware

or defective system board.

tem board. Reseat the

DIMMs or replace the system board.

Beep Codes and Error Messages 3-1

Page 47

Table 3-1. POST Beep Codes

Beep Code Error Probable Causes

(Continued)

1-3-1-3 Keyboard controller

error

Defective DIMMs or system board. Reseat the

DIMMs or replace the system board.

1-3-3-1 No DIMM memory

installed

Defective DIMMs or system board. Reseat the

DIMMs or replace the system board.

1-3-4-1 DRAM failure Defective DIMMs or sys-

tem board. Reseat the

DIMMs or replace the system board.

1-3-4-3 DRAM failure Defective DIMMs or sys-

tem board. Reseat the

DIMMs or replace the system board.

1-4-1-1 DRAM failure Defective DIMMs or sys-

tem board. Reseat the

DIMMs or replace the sys-

tem board.

1-4-2-1 CMOS failure Defective system board.

1-4-3-1 Memory controller or

DIMM failure

Defective DIMMs or sys-

tem board. Reseat the

DIMMs or replace the sys-

tem board.

2-1-2-3 Invalid ROM copy-

Defective system board.

right notice

2-2-3-1 Unexpected interrupt Improperly seated expan-

sion card or the system

needs rebooted.

3-2-2-1 Gate A20 failure Defective system board.

4-2-4-3 Keyboard controller

error

Defective DIMMs or sys-

tem board. Reseat the

DIMMs or replace the sys-

tem board.

4-2-4-4 Gate A20 failure Defective system board.

3-2 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 48

S

ystem Error Messages

Table 3-2 lists (in alphabetical order) system error messages that can appear on

the monitor screen. These messages can help you find the source of a problem.

Some of these error messages indicate fatal errors. When a fatal error occurs,

the system cannot usually be rebooted until an appropriate hardware change has

been made.

Table 3-2. System Error Messages

Message Definition Probable Causes

System battery is dead

- Replace

and run

Setup

System CMOS

checksum

bad - Run

Setup

Incorrect

drive A type

- Run Setup

Incorrect

drive B type

- Run Setup

Keyboard

error

The system battery

is dead.

The configuration

data is corrupted.

The diskette drive

does not match the

diskette drive type

stored in the configuration data.

The diskette drive

does not match the

diskette drive type

stored in the configuration data.

A cable may be

loose, or the keyboard may be faulty.

Replace the battery

and run the System

Setup program.

Run the System Setup

program to restore your

system configuration.

Run the System Setup

program to restore your

system configuration.

Run the System Setup

program to restore your

system configuration.

Defective keyboard,

keyboard cable, or

system board.

Stuck key

System/

Shadow RAM

failed at

offset:

A cable may be

loose, or the keyboard may be faulty.

One or more

DIMMs may be

improperly seated or

faulty.

Defective keyboard or

keyboard cable.

Reseat the DIMMs or

replace the DIMMs.

Beep Codes and Error Messages 3-3

Page 49

Table 3-2. System Error Messages

Message Definition Probable Causes

(Continued)

Operating

system not

found

System

cache error

- Cache disabled

System

timer error

Real-time

clock error

Keyboard

controller

error

The system did not

find a bootable operating system.

The microprocessor

chip malfunctioned.

A chip on the system board malfunctioned.

The real-time clock

on the system board

malfunctioned.

A cable may be

loose, the keyboard

may be faulty , or the

keyboard controller

is defective.

Use a diskette with a

bootable operating

system on it in drive

A, or load a bootable

operating system

from the hard-disk

drive.

Defective microprocessor or system

board.

Defective microprocessor or system

board.

Defective microprocessor or system

board.

Defective keyboard,

keyboard cable, or

system board.

EISA configuration

NVRAM bad

EISA configuration

error

Invalid CPU

speed

detected Check jumpers

Memory size

limit

exceeded

The EISA jumper

may have been accidentally installed.

The EISA configuration data in

NVRAM does not

match the installed

EISA expansion

cards.

The microprocessor

speed jumper plug

may be absent or

installed on the

wrong jumper pins.

The size of installed

DIMM memory is

greater than

256 MB.

Be sure the EISA

jumper is removed;

then reboot the system, and restore the

EISA configuration.

Be sure the EISA

expansion cards are

properly seated; then

run the EISA configuration utility.

Check the microprocessor speed

jumpers.

Verify that the total

installed DIMM

memory does not

exceed 256 MB.

3-4 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 50

Table 3-2. System Error Messages

Message Definition Probable Causes

(Continued)

Resource

conflict

Warning:

IRQ not initialized

Expansion

ROM not

initialized

System configuration

data write

error

The BIOS de tected a

resource conflict

while configuring a

Plug and Play ISA

or PCI expansion

card.

The BIOS de tected a

resource conflict

while configuring a

Plug and Play ISA

or PCI expansion

card.

The BIOS de tected a

resource conflict

while configuring a

Plug and Play ISA

or PCI expansion

card.

The system board

may be malfunctioning.

See “Eliminating

Resource Conflicts”

in Chapter 2.

See “Eliminating

Resource Conflicts”

in Chapter 2.

See “Eliminating

Resource Conflicts”

in Chapter 2.

Defective system

board.

System memory size has

changed Run Configuration

Utility

A DIMM was added

or removed. The

DIMMs are improperly seated.

Reseat the DIMMs or

replace the DIMMs.

Beep Codes and Error Messages 3-5

Page 51

3-6 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 52

Chapter 4

Removing and Replacing Parts

his chapter provides procedures for removing the components, assemblies,

T

and subassemblies in the computer. Unless otherwise noted, each procedure

assumes the following:

You have performed the steps in “Precautionary Measures” found later in

•

this chapter.

You have removed the computer cover.

•

You can replace or reinstall a part by performing the removal procedure in

•

reverse order unless additional information is provided.

R

ecommended Tools

Most of the procedures in this chapter require the use of one or more of the following tools:

Small flat-blade screwdriver

•

Wide flat-blade screwdriver

•

Number 1 and number 2 Phillips-head screwdrivers

•

•

•

Also, use a wrist grounding strap as explained in the next section, “Precautionary Measures.”

-inch nutdriver

1/4

Tweezers or long-nose pliers

Removing and Replacing Parts 4-1

Page 53

P

recautionary Measures

Before you perform any of the procedures in this chapter, take a few moments

to read the following warning for your personal safety and to prevent damage to

the computer from ESD.

WARNING FOR YOUR PERSONAL SAFETY AND PROTECTION

OF THE EQUIPMENT: Before you start to work on the computer, perform the following steps in the sequence listed.

1. Turn off the computer and any attached peripherals.

2. Disconnect the computer and any attached peripherals from their

power sources to reduce the potential for personal injury.

3. Disconnect any communications cables.

4. Wear a wrist grounding strap, and clip it to an unpainted metal sur-

face, such as the system power supply’s fan guard, on the computer

chassis.

If a wrist grounding strap is not available, touch the fan guard or

some other unpainted metal sur face on the back of the computer to

discharge any static charge from your body.

4-2 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 54

C

omputer Cover

cover-mounting

screws (4)

handle

Figure 4-1. Computer Cover Removal

To remove the computer cover, follow these steps:

1. Remove the four cover-mounting screws at the back of the computer.

2. Slide the cover backward about one inch, then grasp the front of the

cover and the handle at the back of the cover and lift the cover straight

up off the chassis.

Removing and Replacing Parts 4-3

Page 55

F

alignment holes (5)

retaining clips (6)

retaining holes (6)

alignment pins (5)

ront Bezel

Figure 4-2. Front Bezel Removal

To remove the front bezel, follow these steps:

1. Remove the computer cover.

2. Pry the front bezel loose with your finger tips and remove it from the chassis.

As you pry the front bezel loose, pry at different points around the bezel to

keep the opening between the front bezel and the computer chassis equal on

all sides to prevent damage to the bezel alignment pins.

4-4 Dell PowerEdge 2100/180 and 2100/200 Systems Service Manual

Page 56

F

ront-Bezel Inserts

latch

tab

front-bezel insert

Figure 4-3. Front-Bezel Insert Removal

To remove a front-bezel insert, follow these steps:

1. Remove the front bezel.

2. With the inside of the front bezel facing you; grasp the front bezel with

both hands and place your fingers on the outside of the front-bezel

insert.

3. Push on the outside of the front-bezel insert (indicated by the two

arrows); then twist the sides of the front bezel outward until the frontbezel insert is released.

To replace a front-bezel insert, position one end of the insert in place under its

latch; then press the other end into place until the tab snaps under the latch.

Removing and Replacing Parts 4-5

Page 57