Page 1

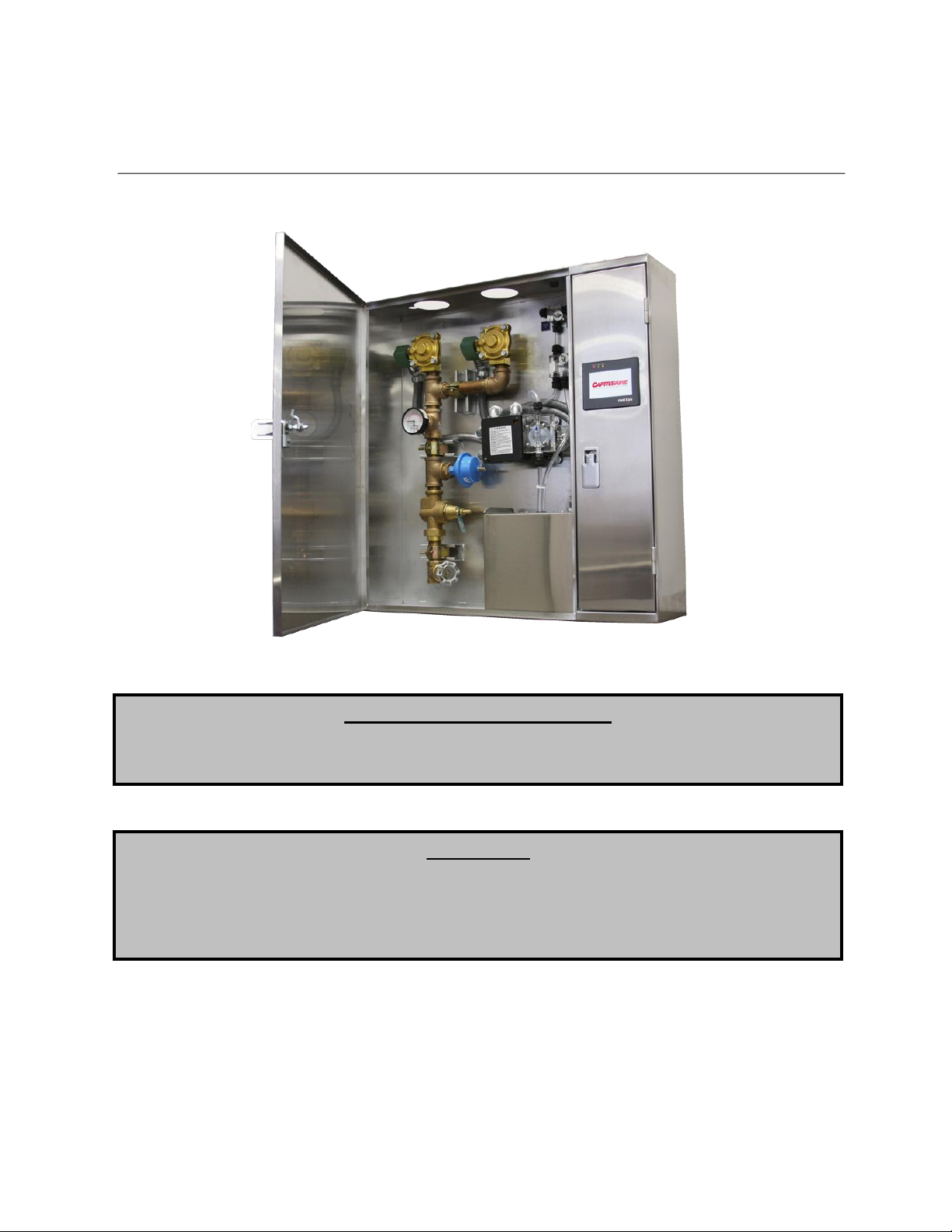

Self Cleaning System Control Panel

Installation, Operation, and Maintenance Manual

WARNING!!

Installation of this control should only be performed by a qualified professional who has read

and understands these instructions and is familiar with proper safety precautions. Improper

installation poses serious risk of injury due to electric shock, and other potential hazards.

Read this manual thoroughly before installing or servicing this equipment. ALWAYS

disconnect power prior to working on module.

RECEIVING AND INSPECTION

Upon receiving unit, check for any interior and exterior damage, and if found, report it

immediately to the carrier. Also check that all accessory items are accounted for and are

damage free.

Save these instructions. This document is the property of the owner of this equipment and is

required for future maintenance. Leave this document with the owner when installation or

service is complete.

March 2011, Rev. 2

A0017476

Page 2

TABLE OF CONTENTS

WARRANTY .................................................................................................................................................. 3

PIPING SIZE SELECTION ............................................................................................................................ 4

INSTALLATION ............................................................................................................................................. 7

Plumbing ................................................................................................................................................... 7

Site Preparation .................................................................................................................................... 7

Assembly .............................................................................................................................................. 7

Electrical ................................................................................................................................................... 7

OPERATION ............................................................................................................................................... 11

Special Tools Required ...................................................................................................................... 11

Start Up Procedure ............................................................................................................................. 11

Water Wash Cycle .............................................................................................................................. 15

Scheduling .......................................................................................................................................... 16

Special Functions ............................................................................................................................... 18

Alarms ................................................................................................................................................ 18

Diagnostics ......................................................................................................................................... 18

WEB INTERFACE ....................................................................................................................................... 19

Scheduling .......................................................................................................................................... 19

Hood Control ...................................................................................................................................... 21

MAINTENANCE .......................................................................................................................................... 22

Factory Service Department ............................................................................................................... 24

2

Page 3

WARRANTY

This equipment is warranted to be free from defects in materials and workmanship, under normal use and

service, for a period of 12 months from date of shipment. This warranty shall not apply if:

1. The equipment is not installed by a qualified installer per the MANUFACTURER’S installation

instructions shipped with the product,

2. The equipment is not installed in accordance with federal, state and local codes and regulations,

3. The equipment is misused or neglected,

4. The equipment is not operated within its published capacity,

5. The invoice is not paid within the terms of the sales agreement.

The MANUFACTURER shall not be liable for incidental and consequential losses and damages

potentially attributable to malfunctioning equipment. Should any part of the equipment prove to be

defective in material or workmanship within the 12-month warranty period, upon examination by the

MANUFACTURER, such part will be repaired or replaced by MANUFACTURER at no charge. The

BUYER shall pay all labor costs incurred in connection with such repair or replacement. Equipment shall

not be returned without MANUFACTURER’S prior authorization and all returned equipment shall be

shipped by the BUYER, freight prepaid to a destination determined by the MANUFACTURER.

3

Page 4

PIPING SIZE SELECTION

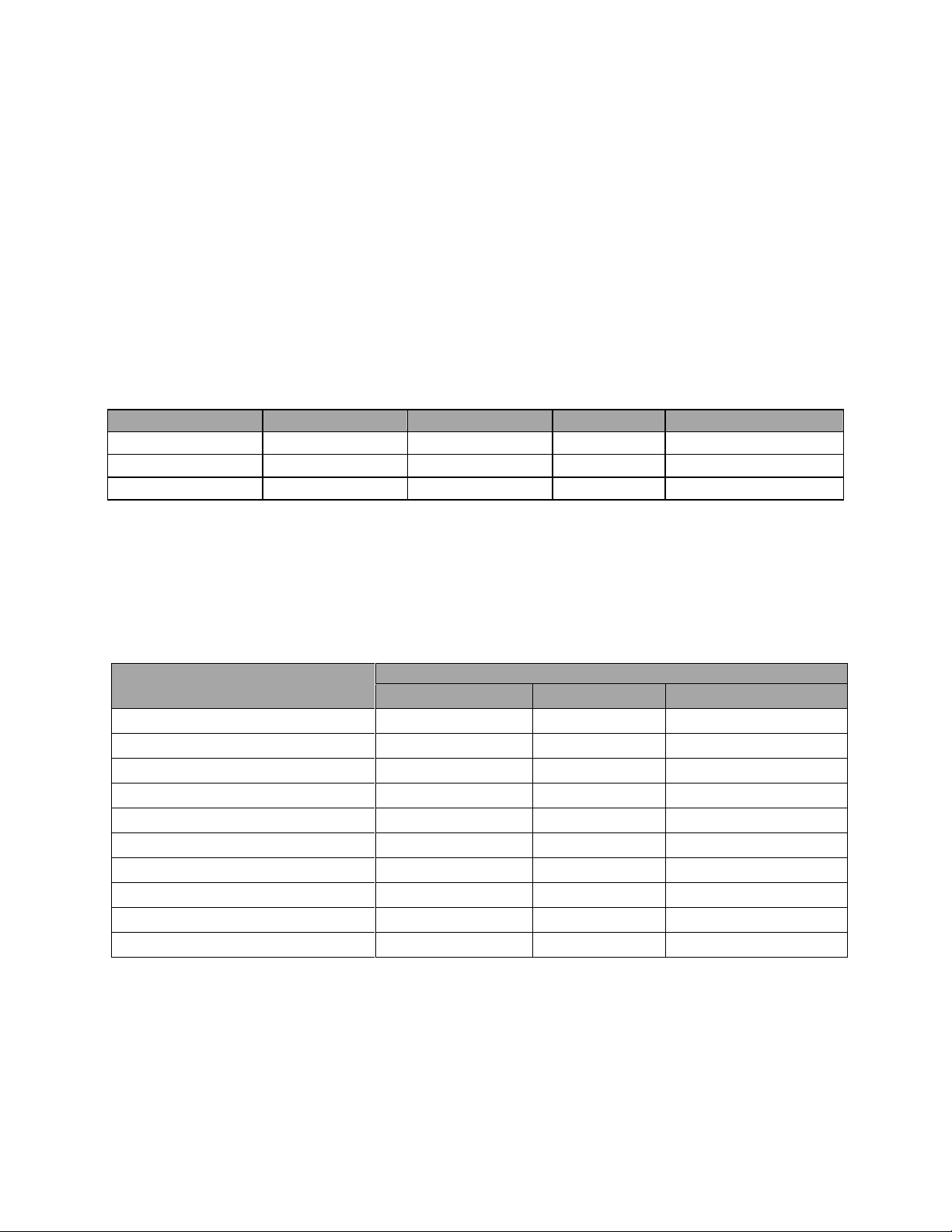

Equivalent Pipe Length For Various Pipe Fittings

Pipe Size Inches

45° Elbow

90° Elbow

Tee Thru Run

Tee Thru Branch

3/4"

1.03

2.21

1.23

4.41

1"

1.31

2.81

1.56

5.62

1 ½”

2.15

4.31

2.4

8.63

Pressure Drop (PSI) per Equivalent Foot of Waterline - Pipe Size

Gallons per Minute

Waterline Pipe Size (psi per foot of pipe)

3/4”

1”

1 1/2”

10

0.102

0.029

0.004

20

0.368

0.105

0.014

30

0.779

0.222

0.030

40

1.327

0.379

0.052

50

2.005

0.573

0.078

60

2.809

0.803

0.109

70

3.735

1.068

0.146

80

4.782

1.367

0.186

90

5.947

1.700

0.232

100

7.223

2.066

0.282

To ensure proper operation of the Self Cleaning System, a minimum of 30 PSI water operating pressure

during spraying must be achieved at the hood nozzles. For this to occur, proper sizing of the water line is

required. Use the following steps to calculate the piping minimum size.

1. Use the Minimum Pressure Requirements for Lengths of Hood chart and find the minimum PSI

required at the hood inlet. Subtract this value from the available PSI at the panel pressure gauge.

Maximum panel operating pressure is 50 psi. This will be your maximum allowable pressure drop

for field installed pipes between the panel and the hood.

2. Most fittings add an equivalent pipe length to the total run. Use the chart below to calculate the

equivalent pipe length for installed fittings. If you have multiple fittings of one type, simply multiply

the number below by the total number of the fitting and add to the total run length.

3. To calculate the total flowing pressure drop between the panel and the hood, take the total

equivalent length found in step 2 and add the total linear field installed pipe length. Multiply this

number by the value found in the table below, Pressure Drop (PSI) per Equivalent Foot of

Waterline. (Gallons per minute is calculated by multiplying the length of the hood by 0.7 gpm)

This will be the friction pressure drop between the hood and the panel.

4. Add in the pressure drop due to gravity. This must be evaluated to overcome any rise in pipe

elevation between the panel and the hood. There is .43 psi/ft of vertical rise of pressure drop.

5. Now, compare the maximum allowable pressure drop from step 1 to the calculated pressure drop

from step 3. If the calculated pressure drop exceeds the maximum allowable pressure drop,

increase the pipe size and recalculate steps 2 and 3. Continue this step until the calculated

pressure drop is below the maximum allowable.

4

Page 5

Field Pipe Pressure Drop Calculation Example

Wall mount panel installed with 30 feet of ¾” linear pipe between panel and hood. (2) 90 degree elbows

are installed in the pipe run and the pipe run has a vertical rise of 5 feet. Length of end-to-end hood

system is 32 feet.

Hood System = 32 feet. Flow rate = 32 feet * 0.7 gpm = 23 gpm

Pressure required at hood = 45 psi.

Pressure at panel gauge = 50 psi.

Allowable pressure drop between panel and hoods: 50 psi – 45 psi = 5 psi

Equivalent length of pipe = 30 + 2 * 2.21 = 34.42 feet

Friction Pressure Drop through pipe = 34.42 * 0.779 = 26.81 psi

Gravitational Pressure = 0.43 psi/ft * 5 feet = 2.15 psi

Total Pressure Drop in Field Pipe between panel and hood = 26.81 psi + 2.15 psi = 28.96 psi

Allowable pressure drop = 5 psi

This system will not work correctly because calculated pressure drop is greater then allowable pressure

drop. Pipe size will need to be change to 1-1/2 inch diameter.

Re-calculate with 1-1/2 inch pipe instead of ¾” pipe:

Equivalent length of pipe = 30 + 2 * 4.31 = 38.62 feet

Friction Pressure Drop through pipe = 38.62 * 0.030 = 1.15 psi

Gravitational Pressure = 0.43 psi/ft * 5 feet = 2.15 psi

Total Pressure Drop in Field Pipe between panel and hood = 1.15 psi + 2.15 psi = 3.30 psi

Allowable pressure drop = 5 psi

This system will work correctly because calculated pressure drop is less then allowable pressure drop.

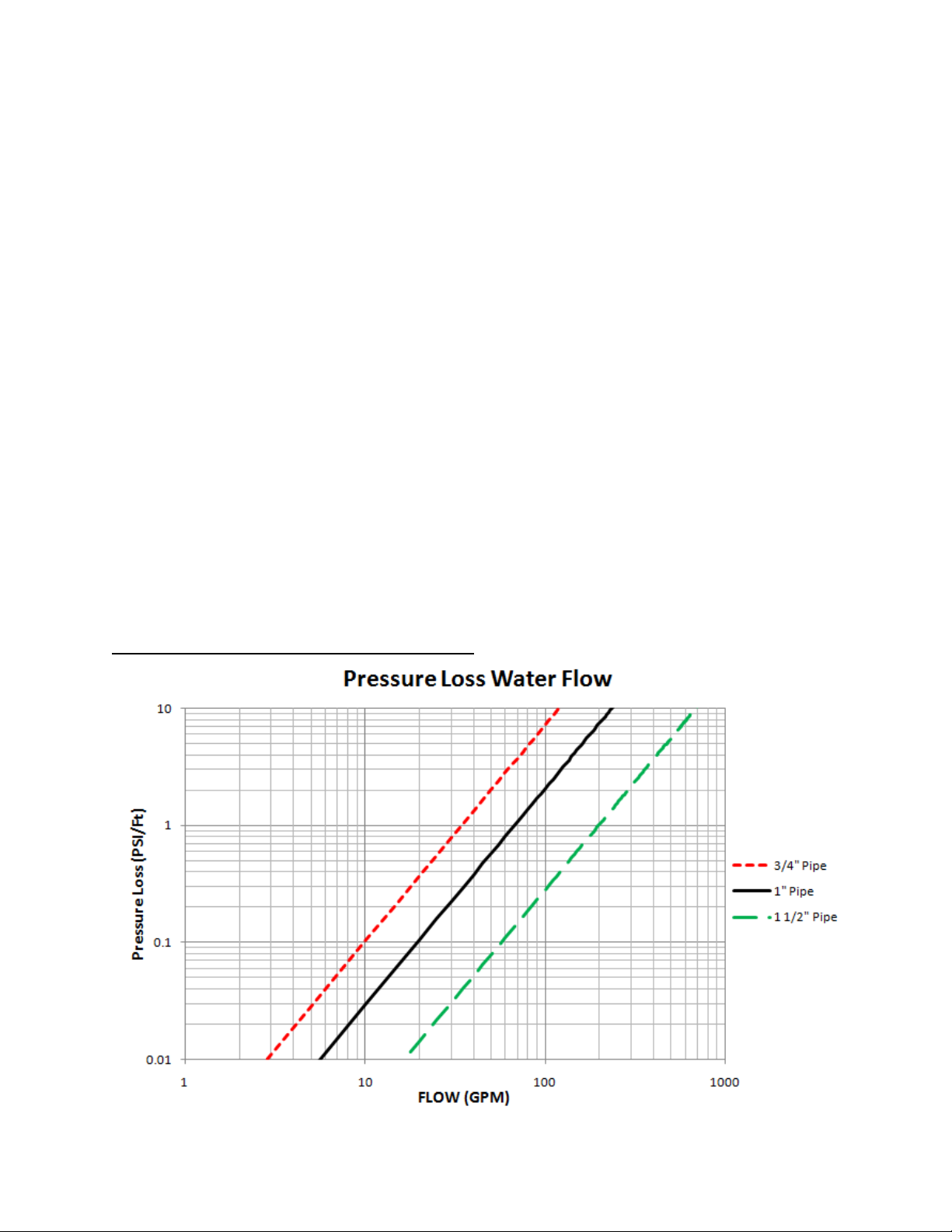

Pressure Loss Through Typical Water Pipe Chart

5

Page 6

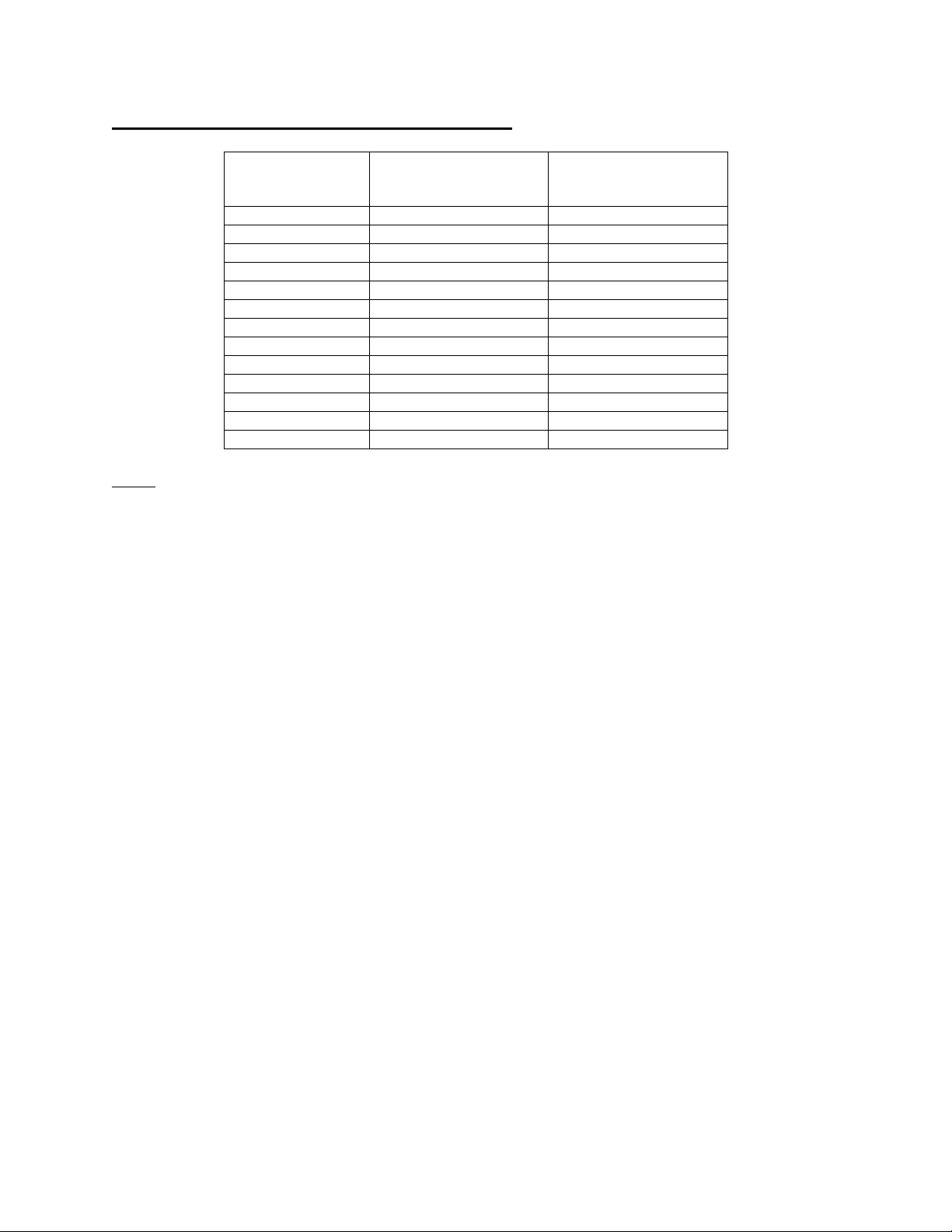

Minimum Pressure Requirements for Lengths of Hood

Length of Hood

(Ft)

Minimum Inlet Water

Pressure for Cold

Mist (PSI)

Minimum Inlet Water

Pressure for Self

Cleaning (PSI)

0

10

30 4 10

30 8 10

30

12

10

30

16

15

30

20

15

31

24

15

32

28

15

34

32

20

37

36

20

39

40

20

42

44

20

46

48

20

50

NOTE: Water pressure may not drop below 30 PSI while the hood is spraying hot water. Pressure may

not rise above 50 PSI when the hood is spraying. If the pressure is greater than 50 psi, a water regulator

must be connected. The chart above is for continuous hood installations. If you exceed the lengths above,

water line must be branched for adequate water supply.

6

Page 7

Copper Wire Ampacity

Wire Size AWG

Maximum Amps

14

15

12

20

10

30 8 50 6 65 4 85

INSTALLATION

WARNING!!

Disconnect power before

installing or servicing control.

High voltage electrical input is

needed for this equipment. This

work should be performed by a

qualified electrician.

Refer to the project blueprints for proper plumbing and electrical hookup, located on the inside of the

plumbing door. CAUTION: Do not apply power before plumbing and electrical installation is complete on

the panel. Please see drawings for the panel on the following pages.

Plumbing

Site Preparation

1. Provide clearance around installation site to safely install equipment into its final position.

2. Consider general service and installation space when locating unit.

Assembly

1. Mount the panel on the wall, or recessed in the wall with an optional trim ring if ordered,

approximately 42” from the finished floor to the bottom of the cabinet.

2. Open the cabinet and verify proper pipe size for the hot water connection. Route and connect the

hot water supply piping to the manifold connection located at the bottom of the cabinet.

3. Connect piping from the top connection of the manifold and route to the ceiling. Connect a

vacuum breaker at the highest point of the run to the hood connections.

4. Connect a tee fitting after the vacuum breaker and connect the ¼” NPT soap injection check

valve.

5. Continue the pipe to the hood, and then connect to the wash manifold connection on the hood.

6. Connect the tubing to the check valve and route tubing to the cabinet. At the cabinet, connect

tubing to the top connection on the clear block mounted on the surfactant pump.

7. Prime the surfactant pump as described under the Maintenance section of this document.

Electrical

Before connecting power to the control, read and

understand the entire section of this document. As-built

wiring diagrams are furnished with each control by the

factory, and are attached either to the door of the unit or

provided with a paperwork packet.

Electrical wiring and connections should be done in

accordance with local ordinances and the National

Electric Code, ANSI/NFPA70. Be sure the voltage and

phase of the power supply and the wire amperage

capacity is in accordance with the unit nameplate.

1. Always disconnect power before working on or near

this equipment. Lock and tag the disconnect switch or

breaker to prevent accidental power up.

7

Page 8

2. Electrical termination points are located on the right hand side compartment of the panel. One

side of these terminal blocks is internally wired. Field wiring is expected on the other side,

directions shown below. Refer to the SCS Electrical Installation Diagram.

a. 120 VAC power to the panel on terminal blocks H1 and N1.

b. Hood Lights on terminal blocks B and W.

c. Exhaust fan starter coil on terminal blocks A1 and N1. Supply fan starter coil on terminal

blocks SF1 and N1. If an electrical pre-wire package controlling the fans is also provided by

the same manufacturer in conjunction with the Self Cleaning panel, the pre-wire will contain

terminal blocks identically labeled A1, SF1 and N1. Connect the terminal blocks together from

the Self Cleaning panel to the electrical prewire panel.

d. Electrical Gas Valve if present on terminal blocks GS and N1.

e. Fire system Microswitch on terminal blocks C1, AR1 and TR1. C1 is the common, AR1 is the

armed state, and TR1 is the triggered state. Verify connections on wiring schematic. If no fire

system is required, place a jumper between terminals C1 and AR1.

f. PCU Pressure Switch if present on terminal blocks HD and P2.

g. Building Management System Dry contact if present on terminal blocks HD and BMS.

3. Duct thermostats (if present):

A duct thermostat is comprised of one RTD (resistive temperature detector) sensor mounted in

the riser and one digital temperature controller mounted in the cabinet. Each RTD is connected to

its controller through a 3 conductor 18AWG thermostat wire. The temperature controller has two

displays on it; the upper (PV) display is the current temperature in the riser. The lower (SV)

display is the temperature at which the controller will turn on the exhaust fan. The UP and DOWN

buttons are used to adjust the 85 degree default SV value up or down to the desired setting. The

controller has a default 2 degree hysteresis value so that once the rising temperature reaches the

SV value and the fan turns on, it will stay on until the temperature drops 2 degrees below the SV

value. If 2 degrees proves undesirable it can be changed, see the changing the hysteresis

example section of this document. The C1, AL1 and SV LEDs will all normally be illuminated.

The C1 LED will go out when the temperature controller turns on the fans.

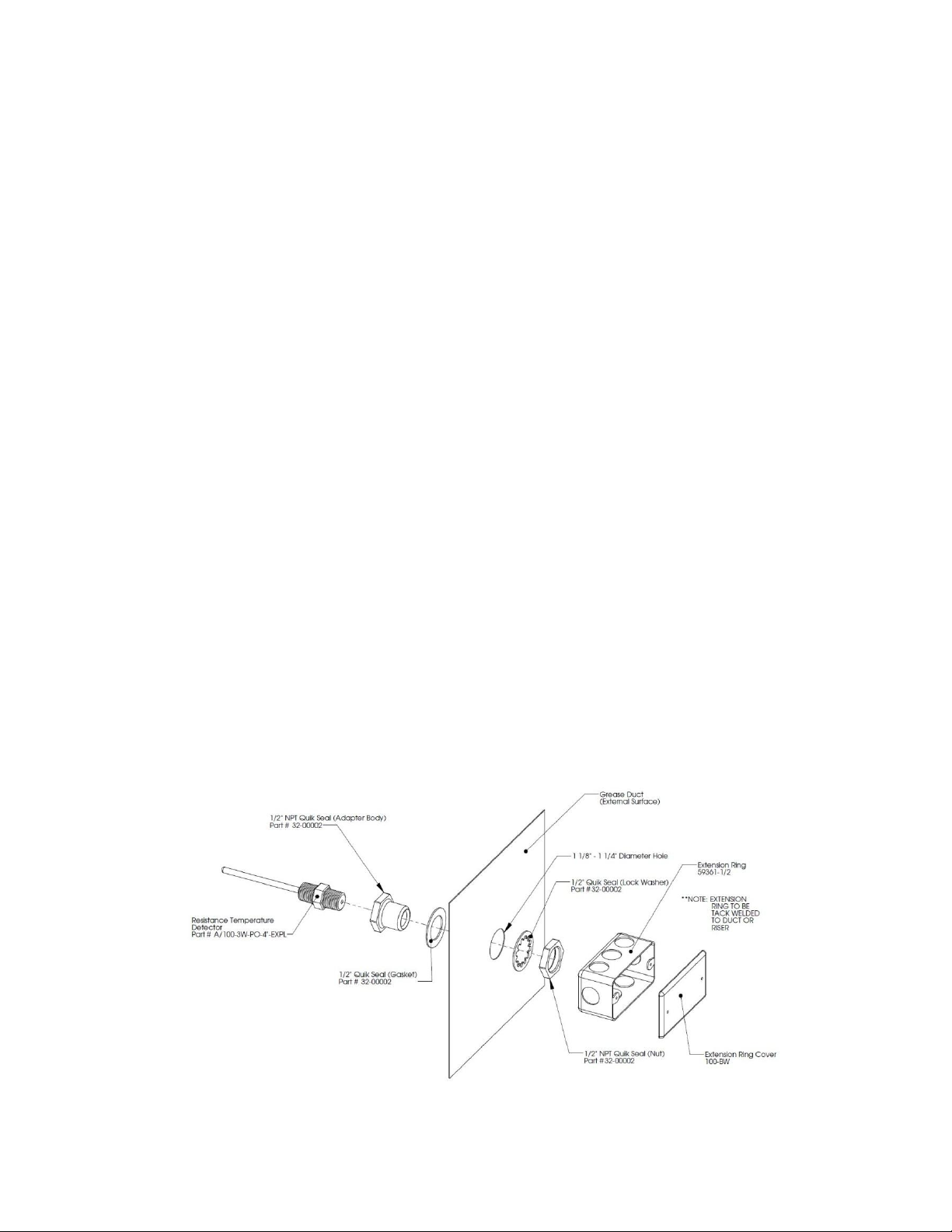

RTD Sensor Installation

RTD sensors are shipped factory installed in factory assembled hood risers. If the risers are field

cut, the sensor and other components are shipped loose for field installation as shown below. A

hole must be cut in the grease duct and the quick seal and sensor must be assembled as shown.

8

Page 9

The wire used to connect to the RTD sensor is 3 conductor 18AWG stranded plenum rated

thermostat wire with conductors that are Brown, Brown, Black. The thermostat wire is connected

to the matching color leads coming from the RTD inside the junction box. The 2 Brown leads are

interchangeable. Use the appropriate wire nuts or butt splices to make the connections as shown

below.

Temperature Controller Connection

To attach the wires from the RTD to the temperature controller, first remove all power sources

from the pre-wire, most pre-wires have more than one power source. Remove the temperature

controller from its socket by folding the blue catches down away from the controller and pulling

the controller straight out of its socket. The 3 conductor thermostat wire is connected to the 3

screw terminals in the lower right corner of the temperature controller socket as shown below.

Using a #2 Philips screwdriver attach the first Brown wire to terminal #1, attach the second Brown

wire to terminal #2 and attach the Black wire to terminal #3. Reinsert the temperature controller

into its socket and re-latch the blue catches

9

Page 10

1. Press and hold the SEL key for three seconds.

HYS will be displayed on the PV display.

2. Press the SEL key once.

The current setting (2) will flash in the SV display

3. Press the UP key twice to change the setting to 4.

4. Press the SEL key once.

The 4 will stop flashing and the new setting is saved.

5. Press and hold the SEL key for 2 seconds.

Both displays will return to their normal states.

Changing the Hysteresis from 2 to 4 Example

4. Before powering up the system, make sure that the interior of the control is free of loose debris or

shipping materials.

5. If any of the original wire supplied with the system must be replaced, it must be replaced with type

THHN wire or equivalent.

10

Page 11

OPERATION

Prior to starting up or operating the Self Cleaning system, check all fasteners and wires for tightness.

Special Tools Required

AC Voltage Meter

Amperage Meter

Standard Hand Tools

Start Up Procedure

1. Once all power, lights, inputs and outputs are connected, startup can begin. Before applying

power to the Self Cleaning System, verify that breakers CB-01 and CB-02 are turned off. Apply

power. Turn CB-01 ON then CB-02 ON. The Touch Screen Panel will power up and beep. If

that’s not the case, check all power connections.

2. Verify the COM indicator Light on top of the Touch Screen Panel is lighted green. If that is not the

case, verify the serial cable going from the back of the panel to the Controller is properly plugged

in. Make sure the Grey connector is labeled “HMI” on the side of the Touch Screen Panel and

“PLC” on the side of the controller. If there is still no communication, cycle power to the Unit once

more.

3. An alarm might be displayed on the Touch Screen Panel. You can silence it by pressing Mute or

Acknowledge on the panel.

11

Page 12

4. From the main page of the Touch Screen Panel, you can verify the basic operations of the

system.

Press the Lights button to energize the hood lights. The button should turn green. If the

lights do not come on, make sure light bulbs are installed and check the lighting circuit.

With the Mode Button set to Manual, press the Fan button to energize the fans. The Fan

and Lights button should turn green. The fan and hood lights should come on. If the

supply fan does not power up, make sure the fire system micro-switch is in the armed

position or has been connected properly. A fire system distributor should service the

micro-switch or arm the fire system.

Make sure the Hood filters are in place and with the Mode Button set to Manual, press

the Wash button. This should stop the fans and start the wash cycle.

5. The Auto/Manual Mode button allows the user to switch between the Manual and Automatic

modes. In Manual mode, the fans and wash cycle are controlled by the user through the buttons

on the main page of the Touch Screen panel. In Automatic Mode, the Fans and Wash Cycle are

controlled by the schedule configured in the system. That schedule can be programmed through

the Schedule Page or through the Web interface. These items are explained further down in this

document.

6. Press the Setup button to go to the Setup page to configure all the options associated with the

functionality of the system.

12

Page 13

Setup options

From the Setup Screen, all options and configurations can be selected.

1. Wash after Fans OFF (Factory Default: ON): When this option is turned ON, the wash cycle will

automatically start when the Fans are turned ON and then turned OFF whether in manual mode

or in automatic mode. Also this option disables the Wash Schedule in Automatic Mode. Only the

Fan schedule is then used. This option is also required if the Wash cycle needs to be controlled

by an external building Management System.

2. Number of Wash Zones (Factory Default: 1): A maximum of 3 wash zones can be set. One

water solenoid is of course required for each Wash Zone.

3. Wash Time (Min) (Factory Default: 3 min): This value is setup in Minutes with a maximum value

of 30 Min. This is the time the wash cycle will last for each wash zone.

4. Gas Valve and Gas Valve Reset with Fan (Factory Default: OFF): If the Gas Valve option is

turned ON, an additional button is displayed on the main screen to allow the user to reset or reenergize an electric gas valve connected to the panel. The gas valve is de-energized at initial

startup and when the Fire System is triggered. If the Gas Valve Reset with Fan option is also

turned ON, the gas valve will also de-energize when the fans are turned off.

5. BMS (Factory Default: OFF): If this option is turned ON, a Building Management System can turn

the fans ON and OFF remotely through a dry contact. This function only works in Manual mode.

6. Push to Prime Surfactant Pump is used to prime the pump. Refer to the “Prime the Surfactant

Pump” paragraph of this manual under the Maintenance section.

From the Setup Screen, you can navigate to the Set Clock, the Fire Options or the Change IP Screen.

7. Set Clock: The system clock can be adjusted here. Push the Save button to make it effective.

The SCS panel does not support Daylight Savings Time. The clock has to be adjusted manually.

13

Page 14

8. Fire options: This screen is Password protected and changes should not be made after passing

an inspection. When prompted, press the logon button and type user admin and password

casfire.

a. Exhaust On in Fire (Factory Default: ON): When this option is turned ON, the exhaust

fans will be turned ON in a fire condition. If the option is turned OFF, the exhaust fans will

stay in whatever state they were before the fire condition. The supply fans will always be

turned OFF in a fire condition.

b. Lights Out In Fire (Factory Default: OFF): When this option is turned ON, the hood lights

will be turned OFF in a Fire condition. If the option is turned OFF, the exhaust fans will

stay in whatever state they were before the fire condition.

9. Change IP Address: The controller has an Ethernet port that can be used to connect the SCS

panel to a local Ethernet network and get access to the web interface. The functionality of the

web interface is described in a separate chapter of this manual. The Ethernet port can also be

used for maintenance purposes, for example to download a new revision of the software or

troubleshoot a problem.

The controller comes preloaded with a factory default IP address of 192.168.1.10 and subnet

mask of 255.255.255.0.

To change those values, press on the numbers with a grey background and enter the new IP

Address and Subnet Mask. After pressing Save, a pop-up will ask the user to confirm. Press

Save again to continue. Press Cancel otherwise.

Note: The Controller will reset in order to use the new values and communication will be lost for a

few seconds. This will also cause a FALSE indication of a fire alarm. Acknowledge the alarm and

close the alarm window. Fans, hood lights, wash cycle and gas valve will also be shutdown and

will need to be manually turned on again.

14

Page 15

Water Wash Cycle

1. The Wash Cycle consists of the following sequence: For each wash zone, the duration of the

wash is set by the Wash time programmed on the Setup Page of the Touch Screen Panel

(Factory Default of 3 min). Water will be sprayed during the total duration of the cycle. The

surfactant is injected for 1 second every 1 minute of wash time. The injection occurs at the start of

each minute. This is not an adjustable time.

2. If multiple Wash Zones are setup, once zone 1 washing is complete, the wash cycle will start over

for Zone 2 and then for Zone 3.

3. The wash cycle can be initiated in multiple ways:

In manual mode, the Wash button can be pressed on the Touch Screen Panel main

page.

In Automatic mode the wash cycle will start following the schedule programmed through

the Schedule Screen. If the fans were running in automatic mode before the start of the

wash cycle, they will be stopped during the wash cycle and started back again at the end

of it.

If the “Wash After Fans OFF” option is turned ON, the wash cycle will start when the Fan

button on the Touch Screen Panel main page is turned ON and then turned OFF in

manual mode or when the fans automatically shut off in automatic mode.

If the Building Management System (BMS) option is turned ON, the BMS can turn the

fans ON and OFF and if the “Wash After Fans OFF” option is also turned ON, the Wash

can be controlled as well since the wash cycle will start when the fans go OFF. This

function only works in Manual mode.

4. If the surfactant level is too low, an alarm will be triggered on the Touch Screen Panel. If the

water wash cycle is initiated while this alarm is active, water will be sprayed but no surfactant will

be injected which will result in a poor cleaning result. Refill Surfactant as soon as possible for

best results.

15

Page 16

Scheduling

Tuesday

Program 1

Enabled

8:00

Fans On

Tuesday

Program 2

Enabled

13:00

Fans Off

Tuesday

Program 3

Enabled

14:00

Fans On

Tuesday

Program 4

Enabled

20:00

Fans Off

Tuesday

Program 5

Disabled

The SCS panel provides the ability to program when the fans and the wash cycle should operate on a 7day 24-hour schedule. To run according to the schedule, the automatic mode has to be selected on the

main page of the Touch Screen Panel. If the “Wash After Fans OFF” option is turned ON, only the fan

schedule can be programmed.

1. Fan Schedule: For each day of the week, 10 programs are available. Each program can be

enabled individually. Push on the items with a gray background to modify their value. Select the

Weekday and Program number. Press the Push to Enable to activate the program. You can then

edit the Time and Fans State. If a program is not to be used, you can disable it by pressing the

Push to Disable button. The Fans state can be set to ON or OFF for each program.

For example, if on Tuesdays, fans need to run from 8:00 am to 1:00 pm and then from 2:00 pm to

8:00 pm, the following programs would be used. Note that the time is set in military format.

16

Page 17

2. Wash Schedule: For each day of the week, 10 programs are available. Each program can be

Tuesday

Program 1

Enabled

13:30

Tuesday

Program 2

Enabled

21:00

Tuesday

Program 3

Disabled

enabled individually. Push on the items with a gray background to modify their value. Select the

Weekday and Program number. Press the Push to Enable to activate the program. You can then

edit the Time. If a program is not to be used, you can disable it by pressing the Push to Disable

button. The wash cycle will start at the time scheduled and run as described in the Water Wash

Cycle section of this document. note that if the fans are programmed to run during the same time,

they will be stopped during the wash cycle and started back again at the end of it.

For example, if on Tuesdays, Wash need to run at 1:30 pm and then at 9:00 pm, the following

programs would be used. Note that the time is set in military format.

3. Copy Schedule Function: This allows the user to copy all 10 programs for both Fan schedule

and Wash schedule from one weekday to the other.

Select the original and destination weekday and press Copy. A pop-up will ask the user to

confirm. Press Copy again to continue. Press Cancel otherwise.

17

Page 18

Special Functions

1. Duct thermostat: If a duct thermostat is wired to the Controller and detects a temperature above

it’s setpoint, the fans will be turned on unless the system is in the Wash Cycle.

2. Building Management System (BMS) Control: If the BMS option is turned on, a Building

Management System can turn the fans ON and OFF remotely through a dry contact connected to

the controller. This function only works in Manual mode. If the “Wash After Fans OFF” option is

also turned ON, the Wash can be controlled as well since the wash cycle will start when the fans

go OFF. If a Duct thermostat is wired to the Controller and detects a temperature above it’s

setpoint, the fans will be turned on regardless of the status of the BMS contact.

Alarms

When an Alarm is triggered, an audible alarm and a visual indication are generated on the Touch Screen

panel. The Audible Alarm can be silenced by pushing the Mute button. Some Alarms are automatically

acknowledged when the condition is resolved and some require a manual acknowledge on the screen.

For example, a low surfactant alarm will automatically disappear when the surfactant is refilled. However

a Fire Condition Alarm will remain on the screen until the condition is resolved and the user presses the

Acknowledge button on the alarm screen.

Diagnostics

The Diagnostics page is accessible from the Main page of the Touch Screen Panel. It gives a history of

all the alarm recorded by the system. This can be useful for troubleshooting. The log can be erased by

pressing the Clear button.

18

Page 19

WEB INTERFACE

The web interface can be access by typing the IP address of the Controller in a web browser address.

The factory default IP is 192.168.1.10. So the webpage would be located at http://192.168.1.10/ if the IP

address hasn’t been changed. To change the IP address of the controller, refer to the Change IP

Address section of this manual under Setup Options.

To properly view the webpage, you have to have the Java Platform loaded on your computer.

You can download it from http://www.java.com.

The web interface allows the user to do some of the same operations that can be accessed through the

Touch Screen panel:

- View and edit the Fan and Wash schedules.

- Manual Control of the hood like turning the fans, hood lights ON or OFF or starting a wash cycle.

Scheduling

Click On “Fan Schedule” icon: You can view the schedule for each day of the week by clicking the

weekday icons on the right hand-side.

19

Page 20

To change a schedule, click on the “Edit Schedule” icon.

Make Changes by clicking on the Yellow boxes. Enable or disable any of the 10 programs available per

weekday. For each program, specify the start time the fan state (ON or OFF). Time is displayed in Military

mode.

Click on the “Save Schedule” icon when the changes are complete.

20

Page 21

Click on the “Main” icon to go back to the main page

In a similar fashion, you can view and edit the wash cycle schedule by clicking on the “Wash Schedule”

icon.

Hood Control

You have also access to the hood controls through the webpage. You can turn the fans and hood lights

ON or OFF or start the wash cycle the same way you would do it through the Touch Screen Panel.

This can be used in case the there is a problem with the Touch Screen Panel for example or if the hood

needs to be controlled from a remote location.

21

Page 22

MAINTENANCE

To guarantee trouble free operation of this control, the manufacturer suggests following these guidelines.

Most problems associated with unit failures are directly related to poor service and maintenance.

Please record any maintenance or service performed on this equipment in the documentation section

located at the end of this manual.

First Week of Operation

1. Remove and clean the line strainer screen, located in the pressure reducing valve assembly

within the plumbing enclosure of the control panel, after the first week of operation. Clogging from

line debris, caused by new construction, will happen more frequently until lines are flushed by

repeated usage.

Weekly

1. The surfactant level should be checked to keep the surfactant pump from losing its prime. If low,

then add surfactant until full. Please see directions for priming the surfactant pump if needed.

2. Monitor the hot water temperature (140 to 170 degrees F) and pressure (30 to 50 PSI) while

ventilators are washing. Readings can be accomplished by checking the combination

temperature/pressure gauge located within the plumbing enclosure of the control panel.

Every 3 Months

1. Visually inspect the components of the control panels to ensure proper operation.

2. Check all nozzles for proper and evenly distributed water flow. If nozzles are clogged, clean or

replace.

Every 6 Months

1. The line strainer, located in the pressure reducing valve assembly, should be removed and

cleaned. Remove the bottom plug and O-ring; the strainer will be attached to the bottom plug and

will be extracted when the bottom plug is removed. Remove and clean strainer as required. If the

screen is damaged, then a replacement of 80-mesh screen is required.

2. Check all nozzles for proper and evenly distributed water flow. If nozzles are clogged, clean or

replace.

Prime the Surfactant Pump

1. Loosen the wing nut on the knurled adjustment cam nut, located behind the clear pump block.

2. Turn the pointer index to the setting number 6 (maximum flow) and then retighten the index.

3. Ensure that the strainer is below the surface of the surfactant level.

4. Loosen the tubing connection on top of the clear block. WARNING: Do not let surfactant spray

from the loose fittings. Wrap a rag around loosened fittings to prevent the surfactant from

spraying.

5. Press the Push to Prime button on the Setup page of the Touch Screen panel or rotate the

knurled nut by hand until the surfactant is drawn out of the loosed fitting with no air bubbles in the

clear block.

6. Tighten the top fitting and press the pump prime switch or rotate the knurled nut by hand to verify

that the surfactant will be pumped beyond the cleat block into the top tubing.

7. Loosen the wing nut and adjust the pointer to the 1.5 or 2 setting, and then retighten the wing nut.

The pump is primed and now ready for use.

22

Page 23

23

Page 24

Start-Up and Maintenance Documentation

Job Name

Service Company

Address

Address

City

City

State

State

Zip

Zip Phone Number

Phone Number

Fax Number

Fax Number

Contact

Contact

Purchase Date

Start-Up Date

Date

Service Performed

Job Information

Maintenance Record

Factory Service Department

Phone: 1-866-784-6900

Fax: 1-919-554-9374

24

Loading...

Loading...