Delfield MFSC-31, N14-1313-34, N10-1313-34, N10-1313-37, N14-1313-37 Service And Installation Manual

...Page 1

Milk, Ice Cream and Milk & Ice Cream Dispensers

Service and Installation Manual

Please read this manual completely before attempting to install or operate this equipment! Notify carrier of damage! Inspect all

components immediately. See page 2.

N, N6/N10/N14

Free-standing milk or

beverage dispensers

NSCF, SCF

Free-standing ice cream

dispensers and milk & ice

cream dispensers

NDF

Free-standing milk or

beverage dispensers

MF, MFSC, FF,

FFSC, RFF, RFFSC

Built-in milk or beverage,

ice cream, and milk & ice cream

dispensers

NLFAC

Free-standing milk or beverage

dispensers with air curtain

IMPORTANT INFORMATION

READ BEFORE USE

PLEASE SAVE THESE INSTRUCTIONS!

Effective June 2003

Page 2

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

3

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

CONTENTS

SERIAL NUMBER LOCATION ....................................................2

RECEIVING & INSPECTING EQUIPMENT .................................2

SPECIFICATIONS........................................................................3

REFRIGERANT NOTES...............................................................3

INSTALLATION........................................................................4-5

OPERATION................................................................................6

MAINTENANCE ..........................................................................7

WIRING DIAGRAM ....................................................................8

REPLACEMENT PARTS LISTS..............................................9-10

STANDARD LABOR GUIDELINES............................................11

STANDARD WARRANTIES .................................................12-13

AUTHORIZED PARTS DEPOTS...................................back cover

©2003 The Delfield Company. All rights reserved. Reproduction

without written permission is prohibited. “Delfield” and “Shelleymatic” are

registered trademarks of The Delfield Company.

SERIAL NUMBER LOCATION

Serial number tag locations

MF/MFSC, FF/FFSC and RFF/RFFSC — on the end above the

refrigeration system.

N, N6/N10/N14, and SCF — rear of the unit above the louver.

NDF — Front right hand corner under the lid.

NLFAC — at the rear of the unit by the power cord.

Always have the serial number of your unit available when

calling for parts or service. A complete list of authorized

Delfield parts depots is shown on the back cover of this

manual.

The units represented in this manual are for indoor use only.

RECEIVING AND INSPECTING THE EQUIPMENT

Even though most equipment is shipped crated, care should

be taken during unloading so the equipment is not damaged

while being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported

to the delivering carrier immediately.

2. If damaged, open and inspect the contents with the

carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notification should be made verbally

as well as in written form.

4. Request an inspection by the shipping company of the

damaged equipment. This should be done within 10

days from receipt of the equipment.

5. Check the lower portion of the unit to be sure casters

are not bent.

6. Also open the compressor compartment housing and

visually inspect the refrigeration package. Be sure lines

are secure and base is still intact.

7. Freight carriers can supply the necessary damage forms

upon request.

8. Retain all crating material until an inspection has been

made or waived.

Uncrating the Equipment

First cut and remove the banding from around the crate.

Remove the front of the crate material, use of some tools will

be required. If the unit is on legs remove the top of the crate

as well and lift the unit off the skid. If the unit is on casters

it can be rolled off the skid.

2

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 3

SPECIFICATIONS

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

MODEL LOADING/ AMPS NEMA BTU REF

NUMBER H.P. DISPENSING (115V) PLUG LOAD CAP. CHG.

Self-cont. free-standing milk or beverage dispensers

N-520 1/4 sliding top lids 5.0 5-15P 189 1035 16oz

N-860 1/4 sliding top lids 5.0 5-15P 259 1167 16oz

N-1200 1/4 sliding top lids 5.0 5-15P 328 1273 16oz

N-1530 1/4 sliding top lids 5.0 5-15P 398 1360 16oz

N6-1313-33 1/4 sliding top lids 5.0 5-15P 245 1167 16oz

N6-1313-37 1/4 sliding top lids 5.0 5-15P 245 1167 16oz

N10-1313-33 1/4 sliding top lids 5.0 5-15P 353 1315 16oz

N10-1313-37 1/4 sliding top lids 5.0 5-15P 353 1315 16oz

N14-1313-33 1/4 sliding top lids 5.0 5-15P 455 1422 16oz

N14-1313-37 1/4 sliding top lids 5.0 5-15P 455 1422 16oz

Self-cont. free-standing milk or beverage dispensers

NDF-12 1/4 drop front & flip top lids 5.0 5-15P 687 1204 16oz

NDF-18 1/3 drop front & flip top lids 7.0 5-15P 898 1585 24oz

Self-cont. free-standing milk or beverage dispensers with air curtain (BTU is with

lids closed.)

NLFAC-8 1/3 hinged lids w/air curtain 7.0 5-15P 668 2184 24oz

NLFAC-12 1/2 hinged lids w/air curtain 9.0 5-15P 859 2885 32oz

NLFAC-16 1/2 hinged lids w/air curtain 9.0 5-15P 1050 3193 32oz

MODEL LOADING/DISPENSING AMPS NEMA BTU REF

NUMBER H.P. BODY STYLE (115V) PLUG LOAD CAP. CHG.

Self-cont. free-standing milk and ice cream dispensers

NSCF-48 1/4 hinged top lids 6.0 5-15P 139(ref) 1596(ref) 16oz

414(frz) 796(frz)

Self-cont. free-standing ice cream dispensers

SCF-32 1/4 hinged top lids 6.0 5-15P 709 915 16oz

SCF-48 1/3 hinged top lids 8.0 5-15P 1043 1350 24oz

MODEL CUTOUT AMPS NEMA BTU REF

NUMBER H.P. DIM. (L X D) (115V) PLUG LOAD CHARGE CHG

Self-cont. built-in milk or beverage dispensers *a 2.87” space is required between each cutout

MFSC-2020 1/4 (1) 25” x 22.25” 6.5 5-15P 304 1223 16oz

MFSC-2821 1/4 (1) 10.75” x 21” 6.5 5-15P 264 1166 16oz

MFSC-31 1/4 (2) 10.75” x 21”* 6.5 5-15P 296 1212 16oz

MFSC-44 1/4 (3) 10.75” x 21”* 6.5 5-15P 408 1346 16oz

MFSC-57 1/4 (4) 10.75” x 21”* 6.5 5-15P 519 1447 16oz

MODEL RECOMMENDED CUTOUT BTU

NUMBER H.P. DIMENSIONS (L X D) LOAD

Remote built-in milk or beverage dispensers *a 2.87” space is required between each cutout

MF-2020 1/4 (1) 25.25” x 22.25” 300

MF-2821 1/4 (1) 10.75” x 21” 260

MF-31 1/4 (2)10.75” x 21”* 300

MF-44 1/4 (3)10.75” x 21”* 410

MF-57 1/4 (4) 10.75” x 21”* 520

Remote built-in ice cream dispensers *a 2.87” space is required between each cutout

FF-3324 1/4 (1) 10.75” x 21” 430

FF-2 1/3 (2)10.75” x 21”* 710

MODEL CUTOUT AMPS NEMA BTU REF

NUMBER H.P. DIMENSIONS (L X D) (115V) PLUG LOAD CAP. CHG.

Self-cont. built-in ice cream dispensers *a 2.87” space is required between each cutout

FFSC-3324 1/4 (1) 10.75” x 21” 6.0 5-15P 434 763 16oz

FFSC-2 1/3 (2) 10.75” x 21”* 8.0 5-15P 709 915 24oz

Self-cont. built-in milk & ice cream dispensers *a 2.87” space is required between each cutout

RFFSC-103 1/4 (2) 10.75” x 21”* 6.0 5-15P 139(ref) 1596(ref)

414(frz) 796(frz)

MODEL RECOMMENDED CUTOUT BTU LOAD

NUMBER H.P. DIMENSIONS (L X D) REFG. FRZ.

Remote built-in milk & ice cream dispensers *a 2.87” space is required between each cutout

RFF-103 1/3 (2) 10.75” x 21” 140 410

REFRIGERANT NOTES

MF, MFSC, N, N6/N10/N14, NDF and

NLFAC series refrigerators use HFC-134a

refrigerant.

FF, FFSC, RFF, RFFSC, SCF, and NSCF

freezers use HFC-404A refrigerant.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

3

Page 4

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

5

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

INSTALLATION

Location

Be sure the location chosen has a floor strong enough to

support the total weight of the cabinet and contents. Units in

this product line can weigh as much as 1500 pounds when it

is fully stocked. Reinforce the floor as necessary to provide for

maximum loading.

For the most efficient refrigeration, be sure to provide good air

circulation inside and out.

Inside cabinet: Do not pack unit so full that air cannot circulate.

Take care not to block air flow to the fans and allow space

along sides.

Outside cabinet: Be sure that the unit has access to ample

air. Avoid hot corners and locations near stoves and ovens.

It is recommended that the rear of the unit be no less than

two inches from any wall, partition or any other object which

will restrict exhaust air flow.

Leveling

A level cabinet looks better and will perform better because

the cabinet will not be subject to unnecessary strain due to

doors not properly lining up with door frames.

Some models have casters for ease of cleaning underneath

and for mobility. It is important that the unit be installed in a

stable condition with the front casters locked before operating.

Locking the front casters after installation is the owner’s and

operator’s responsibility.

Electrical connection

A standard self-contained unit is provided with a power cord

and three-prong grounded plug.

The unit should be plugged into a receptacle with its own

circuit protection that matches the amperage of the plug.

Refer to the amperage data on page three or the

serial tag data and your local code or the National

Electrical Code to be sure the unit is connected

to the proper power source. A protected circuit of

the correct voltage and amperage must be run for

connection to the unit.

The power supply must be disconnected

whenever performing maintenance or repairing

the equipment!

The unit must never be operated without the

louvered panel in place.

Built-in units

All self-contained units (MFSC, FFSC and RFFSC) are tested

at the factory to assure proper operation. The unit should not

be installed directly next to high heat generating equipment

(ranges, griddles, etc.).

These units are built into the counter from below and must

be supported from the bottom. The counter cut-out sizes and

power supply requirements are shown in the specifications on

page three. All refrigerators have drains located in the bottom

of the tank. An appropriate drainage area or container must

be provided by the customer. Be sure to place the unit so the

pressure control, located near the compressor, can be reached.

For installation of remote units (MF ,FF and RFF), consult a

refrigeration service company to connect refrigeration lines to

the remote condensing unit.

Self-contained refrigerated units (MFSC, FFSC

and RFFSC) require air flow to the compressor.

A louver is provided and must be installed in the

counter in front of the condenser. An equal size

opening at the rear of the cabinet must also be

provided to allow warm air to escape. Failure to

do so will void all product warranties.

Free standing units

All self-contained units (N, N6/10/14, NDF, NLFAC, SCF and

NSCF) are tested at the factory to assure proper operation. The

unit should not be installed directly next to high heat generating

equipment (ranges, griddles, etc.).

These units are free standing, either on legs or casters. The

power supply requirements are shown on page three. All free

standing units have drains located in the bottom of the tank.

An appropriate drainage area or container must be provided by

the customer.

Do not place the unit against a wall or any object that will

block air circulation through the condensing unit. If the unit

must be placed against a wall, leave a minimum of 2” of

space for air flow.

4

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 5

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

RETAINER

LO

AD TRAY

ELEVATOR HOUSINGS

RETAINER

REMOVE SCREWS,

SLIDE COVER OFF

REMOVE OR

ADD SPRINGS

AS NEEDED

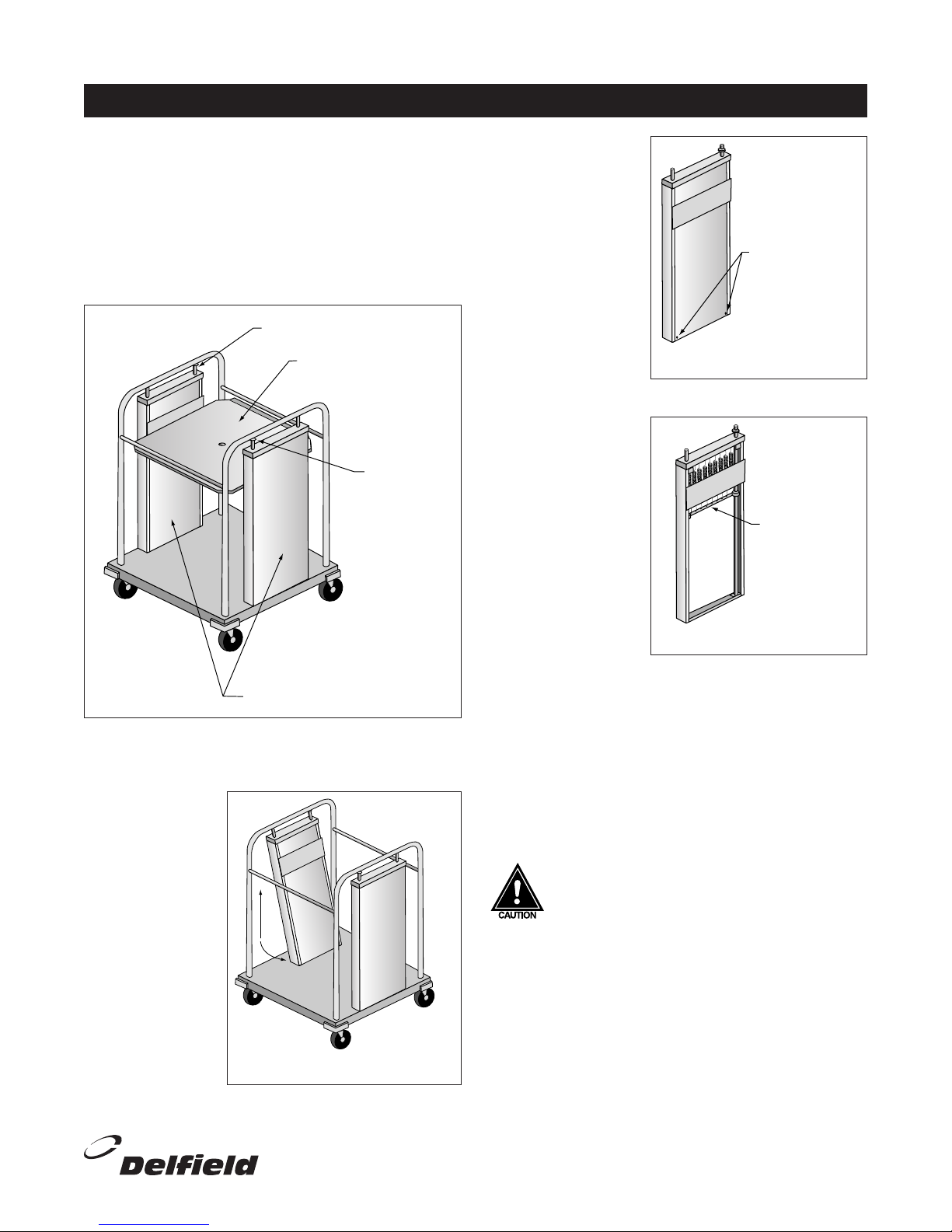

INSTALLATION CONTINUED

How to adjust self-leveling dispenser

Tools Needed: One small flat head screw driver; One Phillips

head screw driver.

1. Always wear safety glasses when adjusting your dispenser.

Also, lock brakes on mobile units before beginning.

2. Unload dispenser and remove stainless steel load tray by

lifting straight up and set it aside (see fig. 1).

(figure 1) Sample unit

3. Use small regular screw driver to loosen each retainer

mounted on stainless steel rod at top of each elevator

housing.

4. To remove

elevator housing,

lift housing

straight up to

clear the stud on

unit base. Then

gently swing the

bottom of the

housing towards

the inside of the

unit and pull

housing out of

the unit (see fig.

2). Lay housing

on flat surface.

(figure 2) Remove elevator housing

5. Use Phillips head

screw driver to

remove front panel

on the elevator

housing (see fig. 3).

6. If carrier is riding

too high, you need

to remove springs.

With carrier all the

way to the top,

gently disengage

one spring at a

time, unhooking

(figure 3) Remove front panel

bottom loop out of

carrier bracket (see

fig. 4). Remove as

many springs as

necessary.

If carrier is riding too

low, you need to add

springs. With carrier

all the way to the top,

gently engage one

spring at a time by

hooking bottom loop

of spring into carrier

bracket. Add as many

(figure 4) Remove or add springs

springs as necessary.

7. When finished, put elevator housing back in unit and put

stainless steel load tray back on elevator housings. Load

unit to test dispensing level. If spring adjustment does

not position carrier properly, repeat procedure #6 trying

different springs. If this does not work, a different set

of springs may be required. To order, call The Delfield

Company Parts and Service Department at 800.733.8829

8. If level is appropriate, put front panels back on and

tighten retainer.

CAUTION: Dispenser should not be operated

with front panels off elevator housing.

NOTE: When adjusting the elevators make sure each have the

same number and size of springs connected to the carrier on

both sides. This will prevent the load tray from binding.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

5

Page 6

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

7

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

OPERATION: N, N6/10/14, NDF, NLFAC, MF & MFSC SERIES

N, N6/10/14, NDF, NLFAC and MFSC Series milk

dispensers are set at the factory to maintain temperatures

between 36°F and 40°F. No further adjustment should be

necessary. To begin operation on self-contained models,

plug the electrical supply cord into a receptacle with the

correct voltage. Remote models will require a connection to

a separate refrigeration system.

Loading: N, MF & MFSC Series

To load, place a complete layer of cartons or bottles

standing upright on the load tray. Then place a divider tray

on top of this layer, then another layer of cartons or bottles

on this tray, then another tray and another layer, etc. As

each additional tray is loaded, the elevators gradually lower.

The last layer may be placed on top without the use of

another tray. When loading the average tall half pint bottles,

four layers may be loaded into each compartment standing

upright and the fifth layer laying down.

It is very important to use the divider trays

provided between each successive layer of

contents to assure the correct balance of the

load and the proper action of the elevating

mechanism.

Wire racks, when used, should be loaded completely. When

placing one rack on top of the other, be sure the stacking

lugs are properly aligned.

Loading: N6/10/14 Series

These cabinets are designed to dispense 13” x 13” x 11”

high (maximum dimensions) dairy cases. Place one case

loaded with milk on the carrier and then place a second case

loaded with milk on top of the first case. Press down on

the cases leaning them toward the retaining bracket located

under the top lid track, then gradually release pressure on

the cases so that the top edge of the case engages with the

retaining bracket.

The elevating mechanism is designed to keep the contents

several inches below the top of the cabinet when fully loaded.

This distance serves two purposes:

A. It keeps the top layer of milk completely refrigerated even

when the lids are removed.

B. It insures that the lids will operate without striking the

contents as successive layers are added.

Loading: NDF Series

These cabinets are designed to dispense 13” x 13” x 11”

high (maximum dimensions) dairy cases. They do not have

a self-leveling mechanism. Simply place the cases on top of

each other inside the cabinet through the wide opening in the

top and front.

Loading: NLFAC Series

These cabinets are designed to dispense 13” x 13” x 11”

high (maximum dimensions) dairy cases. Model NLFAC-8

holds eight cases; four on the bottom and four on the top.

Model NLFAC-12 holds twelve cases; six on the bottom and

six on the top. Model NLFAC-16 holds sixteen cases, eight on

the bottom and eight on the top.

Milk cases are loaded through the wide opening in the top

and front of the unit. Fold the hinged lids up and back and

rest them on the top. The cabinet interior has self-locating

guides installed to make loading easy.

OPERATION: FFSC, RFFSC, SCF & NSCF SERIES

FFSC and SCF Series ice cream dispensers are set at the

factory to maintain temperatures between -5°F and 0°F.

RFFSC and NSCF Series combination milk and ice cream

dispensers are set at the factory to maintain temperatures

between 36°F and 40°F for refrigerated product and between

-5°F and 0°F for frozen product. Each combination unit is

constructed with two tanks and separate controls. No further

adjustments should be necessary. To begin operation plug

the electrical supply cord into a receptacle with the correct

voltage.

6

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Loading

To load, place two layers of ice cream on the load tray,

then a tray, two additional layers of ice cream, then another

tray, etc. Do not stack ice cream above the frost line on

the interior of the freezer. See the instructions for the MF

units (above) for loading the refrigerated portion of the

combination units.

Page 7

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

MAINTENANCE

Cleaning the unit

The interior and exterior can be cleaned using soap and

warm water. If this is not sufficient, try ammonia and water

or a non-abrasive liquid cleaner.

The lid and lid openings should be cleaned with a sponge

and mild soap solution on a daily basis to maintain their

ability to seal.

When cleaning the exterior, always rub with

the “grain” of the stainless steel to avoid

marring the finish. Do not use an abrasive

cleaner because it will scratch the stainless

steel and plastic.

Do not use a sharp tool or knife to scrape any

gaskets as this may tear the gasket and ruin its

ability to seal.

Do not use full strength degreasing agents on

the gaskets as they could cause the gasket to

crack and become brittle.

The inside wall of these units house the

evaporator coil (cooling coil). Never use a

sharp object to remove frost or ice as this may

cause the unit to lose its freon charge and will

void all warranties.

Cleaning the NLFAC milk dispensers

The following special instructions apply to the model NLFAC

dispenser only. After cleaning the interior and exterior as

described above, be sure to return the milk case loading

tray to the bottom of the unit. The load tray is required

not only for easy self-locating of milk cases, but it also

ensures proper air flow through the evaporator coil for the

air curtain.

Any restriction to the air flow path, including

leaving the milk case load tray out of the

cabinet, will result in the voiding of your

warranties.

A drain is supplied to simplify cleaning of the interior.

Open the clamp used to close off the drain tube. Drain

accumulated liquid from the cabinet. Be sure to re-clamp

the tubing before resuming operation of the NLFAC unit.

Honeycomb Cleaning Procedure

Remove the honeycomb material from the equipment.

Soak in fresh hot dishwater for five minutes. Rinse by

spraying soap off with warm water, directing the spray into

the holes. Repeat rinsing steps until material is visibly

clean. Soak in sanitizing solution for five minutes. Replace

into equipment.

Cleaning the condenser

To maintain peak refrigeration performance, the

condenser coil fins must be cleaned of dust,

grease and food particles every 60 days.

If conditions are such that the condenser is totally blocked in

two months, the frequency of cleaning should be increased.

The condenser can be cleaned with a stiff brush or vacuum

cleaner. Using high pressure such as compressed air is

recommended to thoroughly clean the coil.

Failure to follow the recommended methods and

frequency of condenser coil cleaning will result

in reduced refrigeration efficiency and possible

damage to the equipment. It may also invalidate

your warranties.

Low pressure control settings

The factory recommended low pressure control settings

for using HFC-134a refrigerant are 30 psig cut-in with a 20

psig differential. For units using HFC-404A refrigerant, the

pressure control settings are 30 psig cut-in with a 25 psig

differential.

The temperature is controlled by an adjustable pressure

control located in the machine compartment. An adjustable

control has the word COLDER near the knob, with an arrow

to indicate the adjustment direction. These controls are

field adjustable and do not require a service agent. If you

have any questions, feel free to contact the Delfield Service

Department.

In attempting to adjust the pressure control, you can

do damage to your unit by accidentally adjusting the

differential. Please make small incremental adjustments

if a temperature adjustment is necessary, please contact

the service department at Delfield (800) 733-8829 #1, or

your local

service agent.

Delfield is not

responsible

for charges

incurred

while having

the pressure

control

adjusted.

Defrosting

If there is 3/8” accumulation of ice formation on the interior

wall, the unit must be turned off to defrost.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

7

Page 8

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

9

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

G

N

L1

PRESSURE CONTROL

CONDENSING UNIT

MODELS — MFSC, & RFFSC

G

N

L1

PRESSURE CONTROL

CONDENSING UNIT

MODELS — N, SCF, NSCF, & NDF

ON/OFF SWITCH

MODEL —NLFAC

L1 N G

DT1 CONDENSING UNIT

THERMOSTAT

EVAP. FANS

DEFROST TIMER

WIRING DIAGRAMS

8

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 9

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

PARTS REPLACEMENT

MFSC-2020

Plastic drain 3324242

1” rubber drain stopper 3234021

Lrg. elevator assy 0201737

Bearing 6320007

Extension spring .58 lbs 6150201

Extension spring .28 lbs 6150202

Retainer 6530024

Carrier 0047745

Throat collar 0044074

Lid assy 0201525

Hinge #1 extruded 6230109

Plastic hinge insert 6230110

Top lid assy 0047769

Exp. valve 3516062

Exp. valve cover 0052417

Cond. unit 3526674

Filter dryer 3516101

Pressure control 2193927

Louver 2214110003

Cord/plug assy. 2183348

MFSC-2821, MFSC-31, MFSC-44,

MFSC-57

Plastic drain 3234242

1” rubber drain stopper 3234021

Small elevator assy. 0201768

Bearing 6320007

Small elevator plate carrier 0048574

Extension spring .58 lbs 6150201

Retainer 6530024

Carrier 0048347

Large drip proof lid 3234188

Throat collar 6700029

Divider tray 0040006

Cond. unit 3526674

Filter dryer 3516101

Pressure control 2193927

Exp. valve 3516062

Exp. valve cover 0052417

Louver 2214110003

Cord/plug assy. 2183348

MF-2020

Plastic drain 3234242

1” rubber drain stopper 3234021

Large elevator assy. 0201737

Bearing 6320007

Extension spring .58 lbs 6150201

Extension spring .28 lbs 6150202

Retainer 6530024

Carrier 0047745

Throat collar 0044074

Lid assy. 0201525

Extruded hinge 6230109

Plastic hinge 6230110

Exp. valve 3516062

Exp. valve cover 0052417

MF-2821, MF-31, MF-44, MF-57

Plastic drain 3234242

1” rubber drain stopper 3234021

Small elevator assy. 0201768

Bearing 6320007

Extension spring .58 lbs 6150201

Retainer 6530024

Carrier 0048347

Large drip proof lid 3234188

Throat collar 6700029

Divider tray 0040006

Exp. valve 3516062

Exp. valve cover 0052417

FFSC-3324

Plastic drain 3234242

1” rubber drain stopper 3234021

Small elevator assy. 0201768

Bearing 6320007

Extension spring .58 lbs 6150201

Retainer 6530024

Carrier 0048347

Large drip proof lid 3234188

Throat collar 6700029

Divider tray 0040006

Cond. unit 3526709

Filter dryer 3516101

Pressure control 2193927

Exp. valve 3516273

Exp. valve cover 0051417

Louver 2214110003

Cord/plug assy. 2183348

FFSC-2

Plastic drain 3234242

1” rubber drain stopper 3234021

Small elevator assy. 0201768

Bearing 6320007

Extension spring .58 lbs 6150201

Retainer 6530024

Carrier 0048347

Large drip proof lid 3234188

Throat collar 6700029

Divider tray 0040006

Cond. unit 3526710

Filter dryer 3516101

Pressure control 2193927

Exp. valve 3516273

Exp. valve cover 0051417

Louver 2214110003

Cord/Plug Assy. 2183348

FF-3324

Plastic drain 3234242

1” rubber drain stopper 3234021

Small elevator assy. 0201768

Bearing 6320007

Extension spring .58 lbs 6150201

Retainer 6530024

Carrier 0048347

Large drip proof lid 3234188

Throat collar 6700029

Divider tray 0040006

Exp. valve 3516273

Exp. valve cover 0051417

FF-2

Plastic drain 3234242

1” rubber drain stopper 3234021

Small elevator assy. 0201768

Bearing 6320007

Extension spring .58 lbs 6150201

Retainer 6530024

Carrier 0048347

Large drip proof lid 3234188

Throat collar 6700029

Divider tray 0040006

Exp. valve 3516273

Exp. valve cover 0051417

RFFSC-103

Plastic drain 3234242

1” rubber drain stopper 3234021

Small elevator assy. 0201768

Bearing 6320007

Extension spring .58 lbs 6150201

Retainer 6530024

Carrier 0048347

Large drip proof lid 3234188

Throat collar 6700029

Divider tray 0040006

Cond. unit 3526709

Filter dryer 3516101

Pressure control 2193927

Exp. valve 1/4 low 3516225

Exp. valve 1/4 hi 3516273

Exp. valve cover 1701278

Louver 2214110003

EPR valve 3/8 inlet/outlet 3516265

Cord/Plug Assy. 2183348

RFF-103

Plastic drain 3234242

1” rubber drain stopper 3234021

Small elevator assy. 0201768

Bearing 6320007

Extension spring .58 lbs 6150201

Retainer 6530024

Carrier 0048347

Large drip proof lid 3234188

Throat collar 6700029

Divider tray 0040006

Exp. valve 1/4 low 3516225

Exp. valve 1/4 hi 3516273

Exp. valve cover 0052417

N520, N860, N1200

1” plastic drain 3234242

Cond. unit 3526674

Filter dryer 3516101

Pressure control 2193927

Exp. valve 3516062

Sensing blub holding clip 3516205

Top sliding lid assy. 0201316

4” chrome lift cover handle 3234110

Bottom sliding lid assy. 0201317

Louver 9 x 13.50 0048864

Louver 13 x 25 221411003

N-series carrier 0047121

N-series divider tray 0040005

Elevator assy. 0201768

Bearing 6320007

Ext. spring 6150201

Retainer 6230024

Elevator assy. Frzr 0201770

Louver side 13 x 13.50 0047033

Rocker switch 2190154

6” leg with remov. foot 3234645

Cord/plug assy. 2183348

3/4 valve drain 6690493

N-1530

1” plastic drain 3234242

Cond. unit 3526674

Filter dryer 3516101

Pressure control 2193927

Exp. valve 3516062

Sensing blub holding clip 3516205

Top sliding lid assy. 0201318

4” chrome lift cover handle 3234110

Bottom sliding lid assy. 0201319

Louver 9 x 13.50 0048864

Louver 13 x 25 221411003

N-series divider tray 0040005

Bearing 6320007

Ext. spring 6150201

Retainer 6230024

Sliding lid assy bottom 0201317

4” chrome lift cover handle 3234110

Louver side 13 x 13.50 0047033

Rocker switch 2190154

6” leg with remov. foot 3234645

Cord/plug assy. 2183348

3/4 valve drain 6690493

N-6-1313-37, N6-1313-34

1” plastic drain 3234242

Cond. unit 3526674

Filter dryer 3516101

Pressure control 2193927

Exp. valve 3516062

Sensing blub holding clip 3516205

Sliding lid track 6230016

Lid assy bottom 0201331

Lid assy top 0201330

Louver 13 x 13.50 0047033

Louver side 9 x 13.50 0048864

Louver 13 x 25 221411003

Milk crate carrier 0047906

Elevator assy. 0201764

Bearing 6320007

Ext. spring 6150201

Retainer 6230024

Rocker switch 2190154

6” leg with remov. foot 3234645

Cord/plug assy. 2183348

3/4 valve drain 6690493

N-10-1313-34, N-10-1313-37

1” plastic drain 3234242

Cond. unit 3526674

Filter dryer 3516101

Pressure control 2193927

Exp. valve 3516062

Sensing blub holding clip 3516205

Sliding lid track 6230016

Lid assy bottom 0201333

Top sliding lid assy. 0201332

Louver 13 x 13.50 0047033

Louver side 9 x 13.50 0048864

Louver 13 x 25 221411003

Milk crate carrier 0047906

Elevator assy. 0201764

Bearing 6320007

Ext. spring 6150201

Retainer 6230024

Rocker switch 2190154

6” leg with remov. foot 3234645

Cord/plug assy. 2183348

3/4 valve drain 6690493

N-14-1313-34

1” plastic drain 3234242

Cond. unit 3526674

Filter dryer 3516101

Pressure control 2193927

Exp. valve 3516062

Sensing blub holding clip 3516205

Sliding lid track 6230016

Lid assy bottom 0201333

Top sliding lid assy. 0201334

Louver 13 x 13.50 0047033

Louver side 9 x 13.50 0048864

Louver 13 x 25 221411003

Bearing 6320007

Ext. spring 6150201

Retainer 6230024

Rocker switch 2190154

6” leg with remov. foot 3234645

Cord/plug assy. 2183348

3/4 valve drain 6690493

Continued on the next page.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

9

Page 10

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

11

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

PARTS REPLACEMENT

N-14-1313-37

1” plastic drain 3234242

Cond. unit 3526674

Filter dryer 3516101

Pressure control 2193927

Exp. valve 3516062

Sensing blub holding clip 3516205

Sliding lid track 6230016

Lid assy bottom 0201333

Top sliding lid assy. 0201334

Louver 13 x 13.50 0047033

Louver side 9 x 13.50 0048864

Louver 13 x 25 221411003

Bearing 6320007

Ext. spring 6150201

Retainer 6230024

Milk crate carrier 0047906

Elevator assy. 0201764

Rocker switch 2190154

6” leg with remov. foot 3234645

Cord/plug assy. 2183348

3/4 valve drain 6690493

NDF-12

4” caster 3234180

Cond. unit 3526674

Filter dryer 3516101

Pressure control 2193927

Dry door tension catch 3234307

Thermometer 3516059

1” Plastic drain 3234242

Top lid assy. 0201176

Snap in gasket 6700007

Key lock 6230003

Hinge/pin assy. LH 0201178

Hinge/pin assy. RH 0201177

Front lid assy 0201181

Bumper 9321005

Corner bumper 6230170

Cord/plug assy. 2183348

Drain valve 6690493

NDF-18

4” caster 3234180

Cond unit 3526675

Filter dryer 3516101

Pressure control 2193927

Dry door tension catch 3234307

Thermometer 3516059

1” Plastic drain 3234242

Top lid assy. 0201184

Snap in gasket 6700008

Key lock 6230003

Hinge/pin assy. LH 0201178

Hinge/pin assy. RH 0201177

Front lid assy 0201185

Bumper 9321005

Corner bumper 6230170

Cord/plug assy. 2183348

Drain valve 6690493

NFLAC-8

Glass door lock assy 3234684

5” caster 3234161

Door track 6230007

Cond unit 3526675

Filter dryer 3516101

Cord/plug assy. 2183348

Thermometer dial 3516133

Rocker switch 2190154

Timer 2194345

Evap. Coil 3516065

Exp. valve 3516062

Honeycomb difuser clear 1701083

Egg crate diffuser black 1701082

Fan blade 3516172

Fan guard 3516173

Fan motor 2162691

Thermostat 2194536

Cover assy. 0202128

Lid assy front 0202130

Thimble 6230014

Alum in-between hinge 6230017

Heavy duty hinge 6230020

Plastic hinge insert 6230110

Milk crate divider 0047067

Louver 13. X 22 0060131

Louvered door frame 0048910

Louvered door front LH 0048085

Hinge ag 1” 3234067

Magnetic snap in catch 3234156

Dry door steel strike SMK01071

Bumper 9321079

NFLAC-12

Glass door lock assy 3234684

5” caster 3234161

Door track 6230008

Cond. unit 3526688

Filter dryer 3516101

Cord/plug assy. 2183348

Bushing 6190096

Thermometer dial 3516133

Rocker switch 2190154

Timer 2194345

Evap. coil 3516065

Exp. valve 3516062

Honeycomb difuser clear 1701083

Egg crate diffuser black 1701082

Fan blade 3516172

Fan guard 3516173

Fan motor 2162691

Thermostat 2194536

Cover assy. 0202132

Lid assy front 0202133

Thimble 6230014

Alum. in-between hinge 6230018

Heavy duty hinge 6230020

Plastic hinge insert 6230110

Milk crate divider 0047067

Louver 13 x 25 2214110003

Louvered door front RH 0048922

Louvered door front LH 0048097

Hinge ag 1” 3234067

Magnetic snap in catch 3234156

Dry door steel strike SMK01071

Bumper 9321079

NFLAC-16

Glass door lock assy 3234684

5” caster 3234161

Door track 6230009

Cond unit 3526689

Filter dryer 3516101

Cord/plug assy. 2183348

Bushing 6190096

Thermometer dial 3516133

Rocker switch 2190154

Timer 2194345

Evap. coil 3516065

Exp. valve 3516062

Honeycomb difuser clear 1701083

Egg crate diffuser black 1701082

Fan blade 3516172

Fan guard 3516173

Fan motor 2162691

Thermostat 2194536

Cover assy. 0202141

Lid assy front 0202142

Thimble 6230014

Alum in-between hinge 6230019

Heavy duty hinge 6230020

Plastic hinge insert 6230110

Milk crate divider 0047067

Louver 13 x 25 2214110003

Louvered door front RH 0048922

Louvered door front LH 0048097

Hinge ag 1” 3234067

Magnetic snap in catch 3234156

Dry door steel strike SMK01071

Bumper 9321079

SCF-32

1” plastic drain 3234242

1” rubber drain stopper 3234021

Exp. valve 3516225

Sensing bulb holding clip 3516205

Cond. unit 3526709

Filter dryer 3516101

Pressure control 2193927

Cord/plug assy. 2183348

Exp. valve cover 1701278

Elevator assy. 0201768

Bearing 6320007

Extension spring .058 lbs 6150201

Retainer 6230024

Carrier large 0048347

Divider tray 0040006

Large drip proof lid 3234188

Louver side 13 x 13.50 0047033

Louver 13 x 25 221411003

Louver side 9 x 13.50 0048864

Rocker switch 2190154

6” leg with removable foot 3234645

Drain valve 6690493

SCF-48

1” plastic drain 3234242

1” rubber drain stopper 3234021

Exp. valve 3516225

Sensing bulb holding clip 3516205

Cond. unit 3526710

Filter dryer 3516101

Pressure control 2193927

Cord/plug assy. 2183348

Exp. valve cover 1701278

Elevator assy. 0201768

Bearing 6320007

Extension spring .058 lbs 6150201

Retainer 6230024

Carrier large 0048347

Divider tray 0040006

Large drip proof lid 3234188

Louver side 13 x 13.50 0047033

Louver 13 x 25 221411003

Louver side 9 x 13.50 0048864

Rocker switch 2190154

6” leg with removable foot 3234645

Drain valve 6690493

NSCF-48

1” plastic drain 3234242

Cond. unit 3526709

Filter dryer 3516101

Pressure control 2193927

Exp. valve 2516225

Exp. valve 3516273

Sensing bulb holding clip 3516205

Expansion valve cover 1701278

EPR valve 3516265

Cord/plug assy. 2183348

Elevator assy. 0201768

Bearing 6320007

Extension spring .058 lbs 6150201

Retainer 6230024

Carrier large 0048347

Divider tray 0040006

Large drip proof lid 3234188

Louver side 13 x 13.50 0047033

Louver 13 x 25 221411003

Louver side 9 x 13.50 0048864

Rocker switch 2190154

6” leg with removable foot 3234645

Drain valve 6690493

SCF-50

5” caster 3234161

1” plastic drain 3234242

1” rubber drain stopper 3234021

Elevator assy. 0201768

Bearing 6320007

Extension spring .058 lbs 6150201

Retainer 6230024

Carrier large 0048347

Divider tray 0040006

Large drip proof lid 3234188

Cond. unit 3526709

Filter dryer 3516101

Pressure control 2193927

Cord/plug assy. 2183348

Louver end at 221411001

Louver front rear 221411000

Rocker switch 2190154

Drain valve 6690493

10

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 11

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

STANDARD LABOR GUIDELINES TO REPAIR OR REPLACE PARTS ON DELFIELD EQUIPMENT

Advice and recommendations given by Delfield Service Technicians do not constitute or guarantee any special coverage.

• A maximum of 1-hour is allowed to diagnose a defective component.

• A maximum of 1-hour is allowed for retrieval of parts not in stock.

• A maximum travel distance of 100 miles round trip and 2-hours will be reimbursed.

• Overtime, installation/start-up, normal control adjustments, general maintenance, glass breakage, freight damage, and/or

correcting and end-user installation error will not be reimbursed under warranty unless pre-approved with a Service Work

Authorization from Delfield. You must submit the number with the service claim.

LABOR OF 1-HOUR IS ALLOWED TO REPLACE:

• Thermostat • Contactor/Relay

• Infinite Switch • Transformer

• Door Jamb Switch • Evaporator/Condenser Fan Motor and Blade

• Solenoid Coil • Circulating Fan Motor and Blade

• Hi-limit/Thermal Protector Switch • Microprocessor Control

• Fan Delay/Defrost Termination Switch • Water Level Sensor/Probe

• Compressor Start Components and Overload Protector • Door Hinges, Locks, and Gaskets

• Defrost Timer • Condensate Element

• Thermometer • Springs/Lowerator

• Gear Box

LABOR OF 2 HOURS TO REPLACE:

• Drawer Tracks/Cartridges • Defrost Element

• Pressure Control • Heating Element

• Solenoid Valve • Locate/Repair Leak

LABOR OF 3 HOURS TO REPLACE:

• EPR or CPR Valve • Condenser or Evaporator Coil

• Expansion Valve

LABOR OF 4 HOURS TO REPLACE

• Compressor

This includes recovery of refrigerant and leak check.

$35.00 maximum reimbursement for refrigerant recovery (includes recovery machine, pump, torch, oil, flux, minor fittings,

solder, brazing rod, nitrogen, or similar fees.)

REFRIGERANTS

• R22 A maximum of $4.00/lb. or 25¢/oz. will be reimbursed.

• R134A A maximum of $5.00/lb. or 31¢/oz. will be reimbursed.

• R404A A maximum of $12.00/lb. or 75¢/oz. will be reimbursed.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

11

Page 12

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

13

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

STANDARD ONE YEAR WARRANTY (ONE YEAR PARTS, 90 DAYS LABOR.)

The Deleld Company (“Deleld”) warrants to the Original Purchaser

of the Deleld product (herein called the “Unit”) that such Unit, and all

parts thereof, will be free from defects in material and workmanship

under normal use and service for a period of one (1) year from

the date of shipment of the Unit to the Original Purchaser or, if the

Original Purchaser returns the warranty card completely lled out

including the date of installation within thirty (30) days of receipt

of the Unit, one (1) year from the date of installation. During this

one year warranty period, Deleld will repair or replace any defective

part or portion there of returned to Deleld by the Original Purchaser

which Deleld determines was defective due to faulty material or

workmanship. The Original purchaser will pay all labor, crating, freight

and related costs incurred in the removal of the Unit of defective

component and shipment to Deleld, except that during a period of

either ninety (90) days from the date of shipment of the Unit to the

Original Purchaser or, if the Original Purchaser returns the warranty

card completely lled out including the date of installation within thirty

(30) days of receipt of the Unit, ninety (90) days from the date of

installation Deleld will pay all related labor costs. Deleld will pay the

return costs if the Unit or part thereof was defective.

The term “Original Purchaser” as used herein means that person, rm,

association, or corporation for whom the Unit was originally installed.

This warranty does not apply to any Unit or part thereof that has

been subjected to misuse, neglect, alteration, or accident, such as

accidental damage to the exterior nish, operated contrary to the

recommendations specied by Deleld; or repaired or altered by anyone

other than Deleld in any way so as to, in Deleld’s sole judgement,

affect its quality or efciency. This warranty does not apply to any Unit

that has been moved from the location where it was originally installed.

This warranty also does not cover the refrigerator drier or the light

bulbs used in the Unit. The warranty is subject to the user’s normal

maintenance and care responsibility as set forth in the Service and

Installation Manual, such as cleaning the condenser coil, and is in

lieu of all other obligations of Deleld. Deleld neither assumes, nor

authorizes any other person to assume for Deleld, any other liability

in connection with Deleld’s products.

basis, with credit being issued after the part has been received and

inspected at Deleld’s plant and determined by Deleld to be within this

warranty.

Under no condition does this warranty give the Original Purchaser the

right to replace the defective Unit with a complete Unit of the same

manufacturer or of another make. Unless authorized by Deleld in

writing, this warranty does not permit the replacement of any part,

including the motor-compressor, to be made with the part of another

make or manufacturer.

No claims can be made under this warranty for spoilage of any products

for any reason, including system failure.

The installation contractor shall be responsible for building access,

entrance and eld conditions to insure sufcient clearance to allow any

hood(s), vent(s), or Unit(s) if necessary, to be brought into the building.

Deleld will not be responsible for structural changes or damages

incurred during installation of the Unit or any exhaust system.

Deleld shall not be liable in any manner for any default or delay in

performance hereunder caused by or resulting from any contingency

beyond Deleld’s control, including, but not limited to, war,

governmental restrictions or restraints, strike, lockouts, injunctions,

re, ood, acts of nature, short or reduced supply of raw materials, or

discontinuance of the parts by the original part manufacturer.

Except as provided in any Additional Four Year Protection Plan,

if applicable, and the Service Labor Contract, if applicable, the

foregoing is exclusive and in lieu of all other warranties, whether

written or oral, express or implied. This warranty supersedes

and excludes any prior oral or written representations or

warranties. Deleld expressly disclaims any implied warranties

of merchantability, tness for a particular purpose of compliance

with any law, treaty, rule or regulation relating to the discharge of

substances into the environment. The sole and exclusive remedies

of any person relating to the Unit, and the full liability of Deleld for

any breach of this warranty, will be as provided in this warranty.

Removal or defacement of the original Serial Number or Model Number

from any Unit shall be deemed to release Deleld from all obligations

hereunder or any other obligations, express or implied.

Parts furnished by suppliers to Deleld are guaranteed by Deleld only

to the extent of the original manufacturer’s express warranty to Deleld.

Failure of the Original Purchaser to receive such manufacturer’s express

warranty to Deleld. Failure of the Original Purchaser to receive such

manufacturers warranty shall in no way create any warranty, expressed

or implied, or any other obligation or liability on Deleld’s part in respect

thereof.

IF THE CUSTOMER IS USING A PART THAT RESULTS IN A VOIDED

WARRANTY AND A DELFIELD AUTHORIZED REPRESENTATIVE

TRAVELS TO THE INSTALLATION ADDRESS TO PERFORM WARRANTY

SERVICE, THE SERVICE REPRESENTATIVE WILL ADVISE CUSTOMER

THE WARRANTY IS VOID. SUCH SERVICE CALLS WILL BE BILLED

TO CUSTOMER AT THE AUTHORIZED SERVICE CENTER’S THEN

APPLICABLE TIME AND MATERIALS RATES. CONSIDER: CUSTOMER

MAY INITIATE A SERVICE AGREEMENT WITHOUT PARTS COVERAGE.

If shipment of a replacement part is requested prior to the arrival in

the Deleld factory of the part claimed to be defective, the Original

Purchaser must accept delivery of the replacement part of a C.O.D.

12

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Other than this Deleld Standard One Year Limited Warranty, any

applicable Deleld Additional Four Year Protection Plan or applicable

Deleld Service Labor Contract, the Original Purchaser agrees and

acknowledges that no other warranties are offered or provided in

connection with or for the unit or any other part thereof.

In no event will Deleld be liable for special, incidental or consequential

damages, or for damages in the nature of penalties.

IF DURING THE WARRANTY PERIOD, CUSTOMER USES A PART FOR

THIS DELFIELD EQUIPMENT OTHER THAN AN UNMODIFIED NEW

OR RECYCLED PART PURCHASED DIRECTLY FROM DELFIELD OR

ANY OF ITS AUTHORIZED SERVICE CENTERS AND/OR THE PART

BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION,

THIS WARRANTY WILL BE VOID. FURTHER, DELFIELD AND ITS

AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS DAMAGES OR

EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY

OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION

OF ANY MODIFIED PART AND/OR PART RECEIVED FROM AN

UNAUTHORIZED SERVICE CENTER. If the warranty becomes void,

Customer may purchase from Deleld, if available, a Service

Agreement or service at the then current time and materials rate.

For more information on Deleld warranty’s log on and check out the

service section of our web site at www.deleld.com.

Page 13

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

ADDITIONAL FOUR YEAR PROTECTION PLAN (FOR MOTOR-COMPRESSOR ONLY)

Installation

Deleld Model# Serial # Date

General Conditions

Deleld shall not be liable in any manner for any default or delay

in performance hereunder caused by or resulting from any

contingency beyond Deleld’s control, including, but not limited

In addition to the Standard One Year Warranty on the MotorCompressor contained in the above listed Deleld product (the

“Unit”), The Deleld Company (“Deleld”) also agrees to repair, or

exchange with similar or interchangeable parts in design and capacity

at Deleld’s option, the defective Motor-Compressor contained in the

Unit (the “Motor-Compressor), or any part thereof, for the Original

Purchaser only, at any time during the four (4) years following the

initial one (1) year period commencing on the date of installation for

the Original Purchaser. Failure of the Original Purchaser to register

the registration card containing the Original Purchasers name,

address, date of installation, model number and serial number of

the Unit containing the Motor-Compressor within 30 days from the

date of installation shall void this warranty. This additional warranty

is only available if the Motor-Compressor is inoperative due to defects

in material or factory workmanship, as determined by Deleld in

its sole judgement and discretion. The Original Purchaser shall be

responsible for returning the defective Motor-Compressor to Deleld

prepaid, F.O.B. at the address shown on the back cover of this manual.

The term “Original Purchaser” as used herein means that person, rm,

association, or corporation for whom the Unit was originally installed.

The term “Motor-Compressor” as used herein does not include unit

base, air or water cooled condenser, receiver, electrical accessories

such as relay, capacitors, refrigerant controls, or condenser fan/motor

assembly. This warranty does not cover labor charges incidental to

the replacement of parts. This warranty further does not include

any equipment to which said condensing unit is connected, such as

cooling coils, temperature controls or refrigerant metering devices.

This warranty shall be void if the Motor-Compressor, in Deleld’s

sole judgement, has been subjected to misuse, neglect, alteration

or accident, operated contrary to the recommendations specied

by the Unit manufacturer, repaired or altered by anyone other than

Deleld in any way so as, in Deleld’s sole judgment, to affect its

quality or efciency or if the serial number has been altered, defaced

or removed. This Warranty does not apply to a Motor-Compressor in

any Unit that has been moved from the location where it was originally

installed. The addition of methyl chloride to the condensing unit or

refrigeration system shall void this warranty.

to, war, governmental restrictions or restraints, strike, lockouts,

injunctions, re, ood, acts of nature, short or reduced supply

of raw materials, or discontinuance of any part or the Motor-

Compressor by the unit manufacturer.

Replacement of a defective Motor-Compressor is limited to one (1)

Motor-Compressor by us during the four (4) year period. Deleld

shall replace the Motor-Compressor at no charge.

This warranty does not give the Original Purchaser of the Motor-

Compressor the right to purchase a complete replacement Motor-

Compressor of the same make or of another make. It further does

not permit the replacement to be made with a Motor-Compressor

of another kind unless authorized by Deleld. In the event Deleld

authorizes the Original Purchaser to purchase a replacement

Motor-Compressor locally, only the wholesale cost of the Motor-

Compressor is refundable.

Expressly excluded from this warranty are damages resulting from

spoilage of goods.

Except as provided in any applicable Standard One Year Limited

Warranty or applicable Service Labor Contract, the foregoing

is exclusive and in lieu of all other warranties, whether written

or oral, express or implied. This Warranty supersedes and

excludes any prior oral or written representations or warranties.

Deleld expressly disclaims any implied warranties of

merchantability, tness for a particular purpose or compliance

with any law, treaty, rule or regulation relating to the Motor-

Compressor, and the full liability of Deleld for any breach of this

warranty, will be as provided in this warranty.

Other than any applicable Deleld Standard One year Limited

Warranty, this Deleld Additional Four Year Protection Plan and any

applicable Deleld Service Labor Contract, the Original Purchaser

agrees and acknowledges that no other warranties are offered or

provided in connection with or for the Motor-Compressor or any

part thereof.

In no event will Deleld be liable for special, incidental or

consequential damages, or for damages in the nature of penalties.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

13

Page 14

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

15

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

NOTES:

14

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 15

NOTES:

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

15

Page 16

980 S. Isabella Rd., Mt. Pleasant, MI 48804-0470, U.S.A. • (989) 773-7981 or (800) 733-8821 • Fax (800) 669-0619 • www.delfield.com

Delfield reserves the right to make changes in design or specifications without prior notice. ©2003 The Delfield Company. All rights reserved. Printed in the U.S.A.

1336 Main Street

Buffalo, NY 14209

800.722.1252

716.884.7425

716. 884.0410 FAX

serves: CT, DC, DE, MA, MD, ME,

NH, NJ, NY, PA, RI, VA, VT, WV

3) Appliance Installation Service

15024 Staff Court

Gardena, CA 90248

1.800.531.1111

1.800.782.5747

Email: orders@pacparts.com

www.pacparts.com

serves: AZ, CA, HI, NV, OR

4) Pacific Coast Parts

2916 Sidco Drive

Nashville, TN 37204

615.726.0351

800.737.0351

615.259.4100 FAX

serves: TN, AL

14) T.M.A.

14450 Ewing Ave S. #100

Burnsville, MN 55306

800.422.2823

952.894.4427

952.894.2164 FAX

serves: IA, MN, MT, ND, SD, WI

5) Contract Ice

3909 St. Timothy Lane

St. Ann, MO 63074

800.972.7670

314.427.7477

314. 427.8190 FAX

serves: AR, IA, IL, KS,

KY, MO, NE, OK, TX, NM, LA

6) E.M.C.O. Sales & Distributors

2920 N.W. 109th Avenue

Miami, FL 33172

305 994.9994

305.994.9992 FAX

International parts depot

9) Global Parts and Supplies

2120 Solona St.

PO Box 14009

Fort Worth, TX 76117-0009

1.800.433.1804 toll free

1.800.272.7358 fax

serves: AR, LA, NM, OK, TX

7) Stove Parts Supply/GCS Service

9923 S.W. 178th St.

Vashon, WA 98070

888.872.2465

206-463-1772

206.463.4431 FAX

serves: AK, HI, ID, MT, OR, WA

12) Performance Refrigeration Parts

2200 Norcross Parkway, Suite 210

Atlanta, GA 30071

800.235.6516

770.446.6177

770.446.3157 FAX

serves: FL, GA, MS, NC, SC, VA

13) Southeastern Restaurant Services

1816 West 26th Street

Erie, PA 16508-1149

800.332.3732

814.456.3732

814.452.4843 FAX

serves: MD, NJ, OH, PA, VA, WV

2) A.I.S. Commercial Parts & Service

1177 Kamato Road

Mississauga, Ontario L4W1X4

800.427.6668

800.361.7745 FAX

serves: Canada

8) Garland Group

980 South Isabella Road

Mt. Pleasant, MI 48858

800.733.8829

989.773.7981

989.773.3210 FAX

custom parts direct from Delfield

1) The Delfield Company

44792 Helm

Plymouth, MI 48170

888.828.4454

734.451.2043

734.451.3215 FAX

serves: MI, IN, WI, OH

11) MicroDine, Inc.

3000 S. Wyandot

Englewood, CO 80110

(800) 624-2117

(303) 7618861 FAX

serves: AZ, CO, KS, NE, NM, OK, UT, WY

10) Hawkins Commercial Appl. Serv.

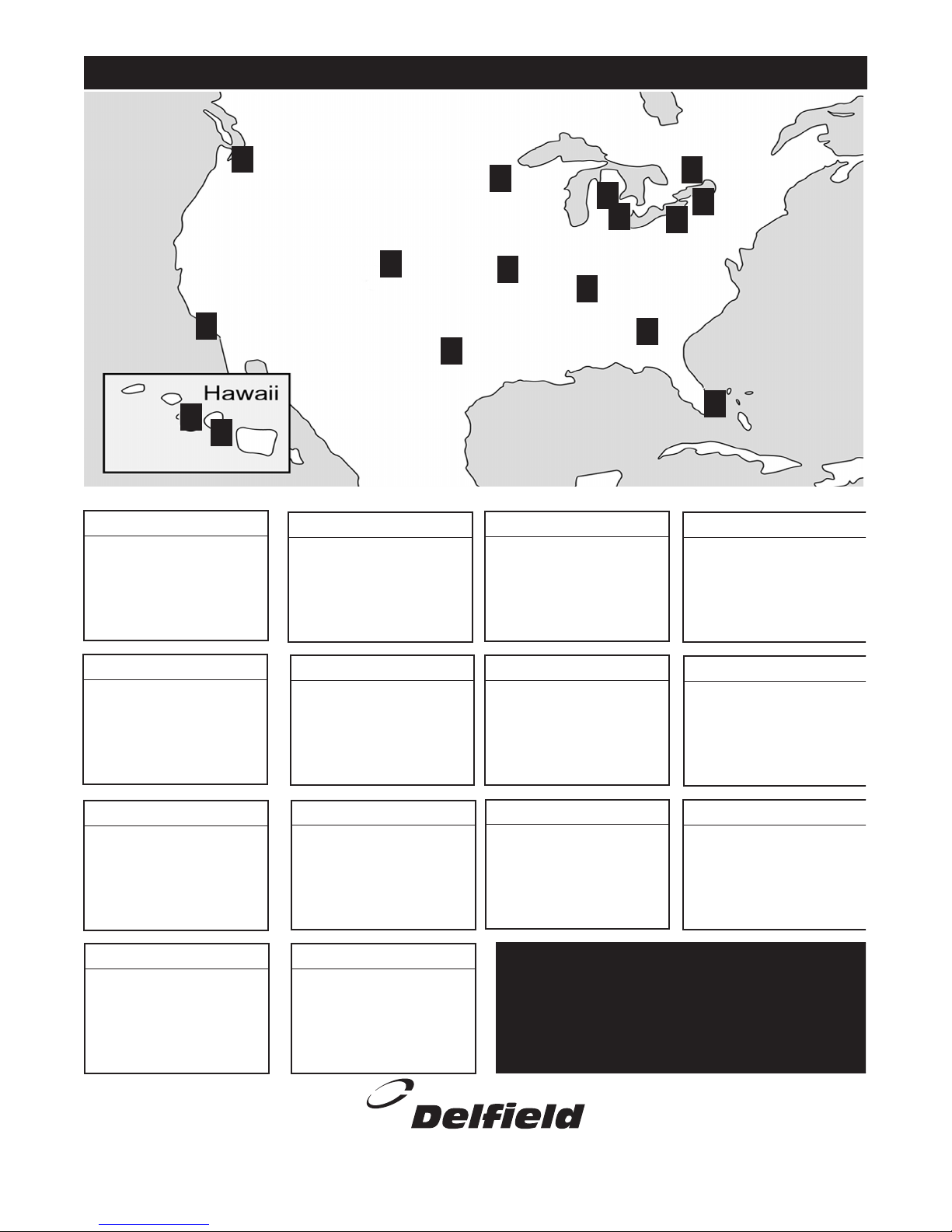

NORTH

AMERICA

4

4

12

9

10

1

11

7

6

5

14

3

13

8

2

12

Delfield has 14 conveniently located Parts Depots to

ensure parts are handled promptly and accurately.

Delfield reserves the right to update or make changes

to this list without prior notice

Please call 1-800-733-8829 or check the web at www.delfield.com

for a list of the current Parts Depots.

AUTHORIZED PARTS DEPOTS

MMMILKICE 06/03

Loading...

Loading...