Page 1

Blended Ice Machine

Multiplex Models MS-8

Service Manual

Manufactured exclusively for

McDonald’s® By:

Manitowoc Foodservice

Tel. (888) 436-5442

Tel. (989) 773-7981

Fax (888) 779-2040

MS-8-1H, MS-8-1LH

MS-8-EH, MS-8-ELH

MS-8-AH, MS-8-ALH

MS-8-BH, MS-8-BLH

MS-8-CH, MS-8-CLH

MS-8-FH, MS-8-FLH

MS000A01, MS000A02

MS000A03, MS000A04

MS000A05, MS000A06

Blended Ice Machine

Multiplex

January 2012

Printed in

The United States of America

Page 2

Important Warning And Safety Information

WARNING READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING,

OR PERFORMING MAINTENANCE ON THE EQUIPMENT.

WARNING FAILURE TO FOLLOW INSTRUCTIONS IN THIS MANUAL CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH.

WARNING DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING UNLESS ALL COVER AND ACCESS PANELS ARE IN PLACE AND

PROPERLY SECURED, DO NOT OPERATE THIS EQUIPMENT.

WARNING THIS APPLIANCE IS NOT INTENDED FOR USE BY PERSONS WHO LACK

EXPERIENCE OR KNOWLEDGE, UNLESS THEY HAVE BEEN GIVEN

SUPERVISION OR INSTRUCTION CONCERNING USE OF THE APPLIANCE

BY A PERSON RESPONSIBLE FOR THEIR SAFETY.

WARNING THIS APPLIANCE IS NOT TO BE PLAYED WITH.

WARNING DO NOT CLEAN WITH WATER JET.

WARNING DO NOT USE ELECTRICAL APPLIANCES INSIDE THE FOOD STORAGE

COMPARTMENT OF THIS APPLIANCE.

CAUTION Observe the following:

• Minimum clearances must be maintained from all walls and combustible materials.

• Keep the equipment area free and clear of combustible material.

• Adequate clearance for air openings.

• Operate equipment only on the type of electricity indicated on the specification plate.

• Retain this manual for future reference.

We reserve the right to make product improvements at any time.

Specifi cations and design are subject to change without notice.

Page 3

General Information

Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Component Identifi cation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Heat of Rejection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Daily Preventive Maintenance Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Weekly Preventive Maintenance Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operation

How to Make a Drink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

How to Replace a Product Bag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Shaver Blade Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Energize Sequence Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Make a Drink Energized Component Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Rinsing Energized Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Manager’s Menu Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Centering the Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table of Contents

Troubleshooting

Display Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Blender And Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cabinet/Product Thermistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Ice Shaver/Ice Bin Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Product Dispensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Rinsing And Water Dispensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Refrigeration Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Will Not Run Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Weight Beam Diagnostic Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Ice Shaver Will Not Run Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Component Check Procedures

ON/OFF Rocker Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Control Board Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

IO (Input/Output) Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

LCD Touchscreen & Microprocessor Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Cabinet Temperature Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Product Chase Temperature Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Chase Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1/12 3

Page 4

Table of Contents (continued)

Component Check Procedures, continued

Evaporator Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Condenser Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Ice Bin Lid Microswitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Product Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Solenoid Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Shaver Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Blender Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Manual Rinse Push Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Compressor Electrical Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Discharge Pressure High Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Discharge Pressure Low Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Suction Pressure High Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Suction Pressure Low Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Recovery/Evacuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Assembly & Replacement Parts List

Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Duct Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Top Valve & Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Lower Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

VitaMix Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Condensing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Evaporator Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Refrigerant Recovery/Evacuation & Charging Procedures

Charging Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

System Contamination Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Mild System Contamination Cleanup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Severe System Contamination Cleanup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

R-290 Service Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Filter-Driers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Total System Refrigerant Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Operating Pressures Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Specifi cations/Wiring Diagrams/Schematics

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Blender Scale & Shaver Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Electronic Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

BIM Warranty Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4 1/12

Page 5

General Information

Model Numbers

This manual covers the Blended Ice Machine, model

numbers MS-8-1H, MS-8-1LH, MS-8-EH, MS-8-ELH,

MS-8-AH, MS-8-ALH, MS-8-BH, MS-8-BLH, MS-8CH, MS-8-CLH, MS-8-FH, MS-8-FLH, MS000A01,

MS000A02, MS000A03, MS000A04, MS000A05 and

MS000A06.

Serial Number Location

This number is required when requesting information

from your local distributor. The serial number is listed

on the SERIAL NUMBER DECAL affi xed to the middle

of the lower back panel on the Blended Ice Machine. A

second decal is located on the front right side of cup

dispenser.

General Warranty Information

Your Blended Ice Machine comes with a three-year

warranty on parts and labor and a fi ve-year warranty on

compressor. Consult your local Multiplex Distributor for

terms and conditions of your warranty. Your warranty

specifi cally excludes all general adjustments, cleaning,

accessories and related servicing.

The warranty card must be returned to activate the

warranty on this equipment. If a warranty card is not

returned, the warranty period can begin when the

equipment leaves the Multiplex factory.

No equipment may be returned to without a written

Return Materials Authorization (RMA). Equipment

returned without an RMA will be refused at dock and

returned to the sender at the sender’s expense.

Please contact your local distributor for return

procedures.

The following Warranty outline is provided for your

convenience. For a detailed explanation, read the

warranty bond shipped with each product.

Contact your local Multiplex representative or Multiplex

if you need further warranty information.

PARTS

Multiplex warrants Blended Ice Machine parts against

defects in materials and workmanship, under normal

use and service for three (3) years from the date of

original installation.

The compressor is covered by an additional two (2) year

part only warranty beginning on the date of the original

installation.

LABOR

Labor required to repair or replace defective

components is covered for three (3) years from the date

of original installation.

EXCLUSIONS

The following items are not included in the Blended Ice

Machine warranty coverage:

Normal maintenance, adjustments and cleaning as

outlined in this manual.

Repairs due to unauthorized modifi cations to the

Blended Ice Machine or use of non-standard parts

without prior written approval from Multiplex.

Damage caused by improper installation of the Blended

Ice Machine, electrical supply, water supply or drainage,

or damage caused by fl oods, storms, or other acts of

God.

Premium labor rates due to holidays, overtime, etc.;

travel time; fl at rate service call charges; mileage and

miscellaneous tools and material charges not listed

on the payment schedule. Additional labor charges

resulting from the inaccessibility of equipment are also

excluded.

Parts or assemblies subjected to misuse, abuse,

neglect or accidents.

Damage or problems caused by installation, cleaning

and/or maintenance procedures inconsistent with the

technical instructions provided in this manual.

AUTHORIZED WARRANTY SERVICE

To comply with the provisions of the warranty, a

refrigeration service company qualifi ed and authorized

by your Multiplex Distributor, or a Contracted Service

Representative must perform the warranty repair.

SERVICE CALLS

Normal maintenance, adjustments and cleaning

as outlined in this manual are not covered by the

warranty. If you have followed the procedures listed in

this manual, and the Blended Ice Machine still does

not perform properly, call your Local Distributor or the

Multiplex Service Department.

1/12 5

Page 6

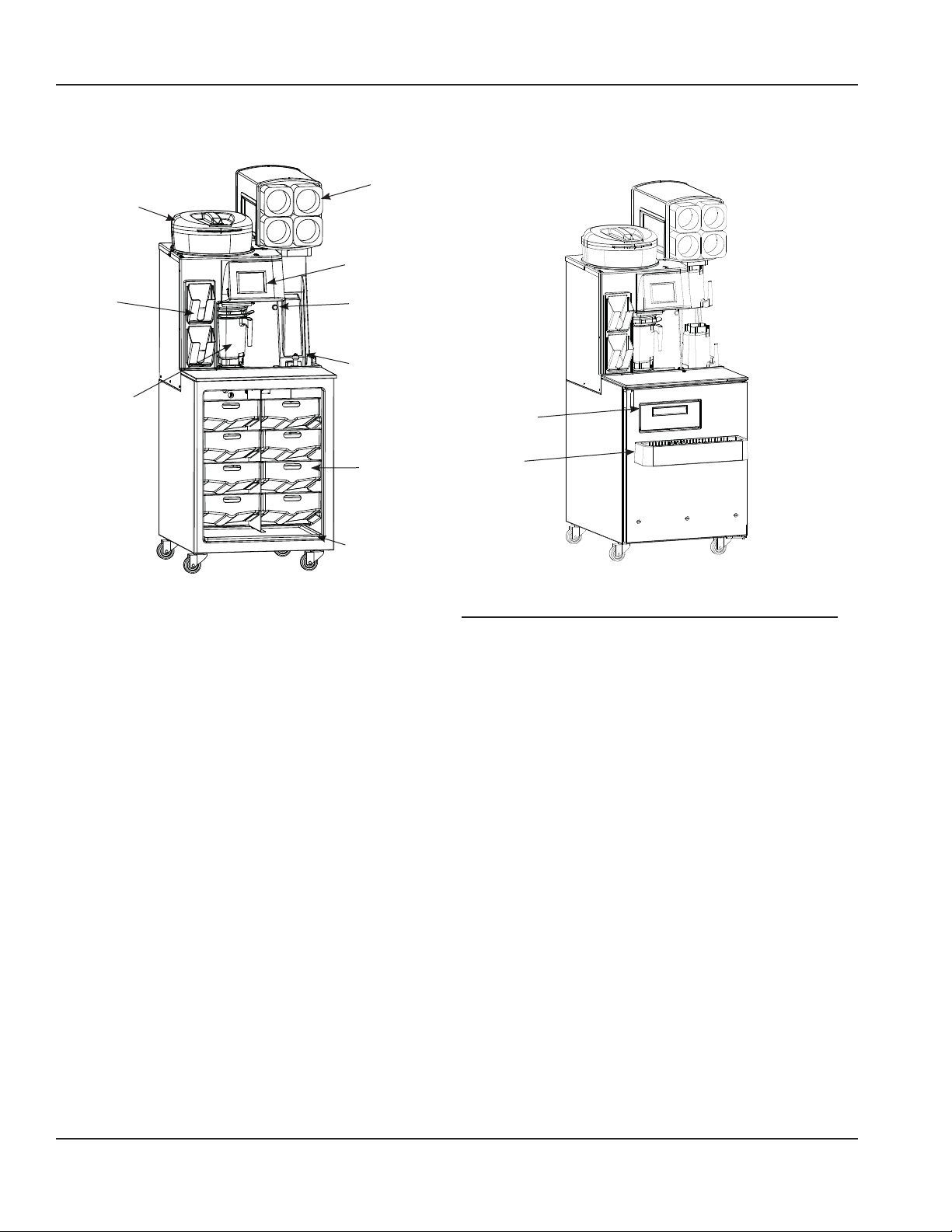

Component Identifi cation

Cup

Dispenser

Ice Hopper Lid

(VMP00133)

(1706175)

Touch

Screen

Lid

Dispenser

(1706142)

Blender Fill

Pitcher

Manual Rinse

Button

Blender Rinse

Location

Product

Bins

(1706268)

Pull Out Tray

(076-CDZ-0000)

General System Overview

The Blended Ice Machine is a self-contained dispensing

unit that allows the operator to make fl avor combinations

of blended ice drinks. It contains product fl avoring in a

reach-in enclosure, a refrigeration system and an ice

shaving machine.

The operator controls and accesses the unit using

a lighted touch screen. Icons on the Drink Selection

screen represent the primary fl avor combinations for

the blended ice drinks. A second screen provides drink

size options (S, M, L) and ingredient options, such as

“no yogurt.” Menu changes and additions are uploaded

using a USB mass storage device.

On-screen instructions also include operator procedures

for cleaning/sanitizing, checking inventory, replacing

product bags, selecting drink sizes and manually

preparing drinks. Managers and technicians have

access to menu/software updates, diagnostics and

other service screens.

Whipped

Cream Door

(000-187-0016)

Syrup Rail

(1706194)

Syrup Rail Divider

(1706195)

Part Description Number

Cleaning Kit 000-BIC-0008

Cleaning Pitcher 3239631

Cup Dispenser 1706175

Gasket, Door 1706208

Gasket, Whipped Cream Door 1706209

Hinge Kit RF000066

Ice Hopper Lid VMP00133

Lid Dispenser 1706142

Product Bin 1706268

Pull Out Tray 076-CDZ-0000

Syrup Rail 1706194

Syrup Rail Divider 1706195

Whipped Cream Door 000-187-0016

6 1/12

Page 7

Electrical

GENERAL

!

Warning

All wiring must conform to local, state and national

codes.

MINIMUM CIRCUIT AMPACITY

The minimum circuit ampacity is used to help select

the wire size of the electrical supply. (Minimum circuit

ampacity is not the Blended Ice Machine’s running amp

load.) The wire size (or gauge) is also dependent upon

location, materials used, length of run, etc., so it must

be determined by a qualifi ed electrician.

ELECTRICAL REQUIREMENTS

Refer to Blended Ice Machine Model/Serial Plate for

voltage/amperage specifi cations. A dedicated electrical

circuit is required.

MINIMUM CIRCUIT AMPERAGE CHART

Important

Due to continuous improvements, this information is

for reference only. Please refer to the serial number

tag to verify electrical data. Serial tag information

overrides information listed on this page.

Model

Numbers

MS-8-1H,

MS-8-1LH,

MS-8-FH,

MS-8-FLH,

MS000A05,

MS000A06

MS-8-BH

MS-8-BLH

MS-8-AH,

MS-8-ALH,

MS-8-CH,

MS-8-CLH,

MS-8-EH,

MS-8-ELH,

MS000A01,

MS000A02,

MS000A03,

MS000A04

Voltage/Cycle

115/60/1 16.0 20A

230-240/60/1 9.8 16A

230-240/50/1 9.8 16A

Total

Amps

Breaker

Size

GROUNDING INSTRUCTIONS

!

Warning

The machine must be grounded in accordance with

national and local electrical codes.

This appliance must be grounded. In the event of

malfunction or breakdown, grounding provides a path

of least resistance for electric current to reduce the

risk of electric shock. This appliance is equipped with

a cord having an equipment-grounding conductor

and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed

and grounded in accordance with all local codes and

ordinances.

EXPORT NOTE: For export models replace the supply

2

cord with a 1.5mm

minimum, 3 conductor H05VV-F

harmonized cord.

1/12 7

Page 8

Clearance Requirements

Model Air Cooled

Top 8" (20 cm)

Sides 6" (15 cm)

Back 6" (15 cm)

Front 30" (76 cm)

Heat of Rejection

Heat of Rejection

Air Conditioning

BTUh/kW

2100/0.62 2600/0.76

Peak

General Specifi cations

Temperature Control Setting 36°F setpoint 4°F differential

2°C setpoint 2°C differential

controlled by software

Ice Capacity 23 lbs (10 kg)

Shipping Weight 430 lbs (195 kg)

Product Bin Capacity 19.8lbs (9kg) per bin

CO

Regulator Setting 40psi (276 kPa)

2

Water Regulator Setting 30psi (207 kPa)

Location

The location selected for the Blended Ice Machine must

meet the following criteria.

• The air temperature must be at least 40°F (4°C), but

must not exceed 90°F (32°C), climate class 4.

• The location must not be near heat-generating

equipment or in direct sunlight and must be

protected from weather.

• Water temperature min/max = 40°F/110°F

(4°C/43°C).

• Water pressure min/max = 20 psi/40 psi

(138kPa/276kPa)

• Always use the water supply line supplied when

installing this appliance. Never reuse an old supply

line.

• Main supply CO

Machine regulator min/max = 55 psi/150 psi

(379kPa/1034kPa)

Carbon Dioxide (CO2) displaces oxygen. Exposure

to a high concentration of CO2 gas causes tremors,

which are followed rapidly by loss of consciousness

and suffocation. If a CO2 gas leak is suspected,

particularly in a small area, immediately ventilate

the area before repairing the leak. CO2 lines and

pumps must not be installed in an enclosed space.

An enclosed space can be a cooler or small room

or closet. This may include convenience stores with

glass door self serve coolers. If you suspect CO2

may build up in an area, venting of the B-I-B pumps

and / or CO2 monitors must be utilized.

pressure to Blended Ice

2

!

Warning

8 1/12

Page 9

Maintenance

Door Gasket Maintenance

Door gaskets require regular cleaning to prevent mold and

mildew build up and also to retain the elasticity of the gasket.

Gasket cleaning can be done with the use of warm soapy water.

Avoid full strength cleaning products on gaskets as this can

cause them to become brittle and crack. Never use sharp tools

or knives to scrape or clean the gasket. Gaskets can be easily

replaced and do not require the use of tools or an authorized

service person. The gaskets are “Dart” style and can be pulled

out of the groove in the door and new gaskets can be “pressed”

back into place.

Drain Maintenance - Base

Each unit has a drain located inside the unit that removes

the condensation from the evaporator coil and routes it to an

external condensate evaporator pan. Each drain can become

loose or disconnected during normal use. If you notice water

accumulation on the inside of the unit be sure the drain tube

is connected to the evaporator drain pan. If water is collecting

underneath the unit make sure the end of the drain tube is in

the condensate evaporator in the machine compartment. The

leveling of the unit is important as the units are designed to

drain properly when level. Be sure all drain lines are free of

obstructions.

Caster Maintenance

Wipe casters with a damp cloth monthly to prevent corrosion.

The power switch must be turned to OFF and the

unit disconnected from the power source whenever

performing service, maintenance functions or

cleaning the refrigerated area.

Refrigerators

The interior and exterior can be cleaned using soap and

warm water. If this isn’t suffi cient, try ammonia and water or a

nonabrasive liquid cleaner. When cleaning the exterior, always

rub with the “grain” of the stainless steel to avoid marring the

fi nish. Do not use an abrasive cleaner because it will scratch the

stainless steel and can damage the breaker strips and gaskets.

Stainless Steel Care and Cleaning

To prevent discoloration or rust on stainless steel several

important steps need to be taken. First, we need to understand

the properties of stainless steel. Stainless steel contains 70- 80%

iron, which will rust. It also contains 12-30% chromium, which

forms an invisible passive fi lm over the steel’s surface, which

acts as a shield against corrosion. As long as the protective

layer is intact, the metal is still stainless. If the fi lm is broken

or contaminated, outside elements can begin to breakdown the

steel and begin to form discoloration or rust. Proper cleaning of

stainless steel requires soft cloths or plastic scouring pads.

NEVER USE STEEL P ADS, WIRE BRUSHES OR SCRAPERS!

Cleaning solutions need to be alkaline based or non-chloride

cleaners. Any cleaner containing chlorides will damage

the protective fi lm of the stainless steel. Chlorides are also

commonly found in hard water, salts, and household and

industrial cleaners. If cleaners containing chlorides are used be

sure to rinse repeatedly and dry thoroughly. Routine cleaning

of stainless steel can be done with soap and water. Extreme

stains or grease should be cleaned with a non-abrasive cleaner

and plastic scrub pad. Always rub with the grain of the steel.

There are stainless steel cleaners available which can restore

and preserve the fi nish of the steels protective layer. Early signs

of stainless steel breakdown are small pits and cracks. If this

has begun, clean thoroughly and start to apply stainless steel

cleaners in attempt to restore the passivity of the steel.

Never use an acid based cleaning solution! Many

food products have an acidic content, which can

deteriorate the fi nish. Be sure to clean the stainless

steel surfaces of ALL food products. Common items

include, tomatoes, peppers and other vegetables.

Cleaning the Condenser Coil

In order to maintain proper refrigeration performance, the

condenser fi ns must be cleaned of dust, dirt and grease

regularly. It is recommended that this be done at least every

three months. If conditions are such that the condenser is totally

blocked in three months, the frequency of cleaning should be

increased. Clean the condenser with a vacuum cleaner or stiff

brush. If extremely dirty, a commercially available condenser

cleaner may be required.

Failure to maintain a clean condenser coil can initially cause high

temperatures and excessive run times. Continuous operation

with a dirty or clogged condenser coil can result in compressor

failure. Neglecting the condenser coil cleaning procedures will

void any warranties associated with the compressor and cost to

replace the compressor.

Never use a high-pressure water wash for this

cleaning procedure as water can damage the

electrical components located near or at the

condenser coil.

Doors/Hinges

Over time and with heavy use doors the hinges may become

loose. If this happens tighten the screws that mount the hinge

brackets to the frame of the unit. Loose or sagging doors can

cause the hinges to pull out of the frame, which may damage

both the doors and the hinges. In some cases this may require

qualifi ed service agents or maintenance personnel to perform

repairs.

Do not place hot pans on/against the blue ABS

liner. Do not throw items into the storage area.

Failure to follow these recommendations could

result in damage to the interior of the cabinet or

to the blower coil. Overloading the storage area,

restricting the airfl ow, and continuous opening and

closing of the doors and drawers will hamper the

units ability to maintain operational temperature.

Preventing blower coil corrosion

To help prevent corrosion of the blower coil, store all acidic

items, such as pickles and tomatoes, in sealable containers.

Immediately wipe up all spills.

Continuous opening and closing of the doors will hamper the

unit’s ability to maintain optimum refrigeration temperature. Top

section is not intended for overnight storage. Product should be

removed from pans. Pans can remain in unit while empty.

1/12 9

Page 10

Clean Blended Ice Machine (BIM-8)

Why

Time required

Time of day

Hazard icons

To break the bacteria cycle

5 minutes to prepare 15 minutes to complete

At close For 24-hour restaurants: During low-volume periods

Chemicals

Daily BE 23 D1

Blended Ice Machine Models MS-8-1H, MS-8-1LH, MS-8-EH, MS-8-ELH, MS-8-BH, MS-8-BLH, MS-8-CH, MS-8-CLH, MS000A03, MS000A04

Precaution:

Hazard Communication Standard (HCS) –The procedures on this card include the use of chemical products.

These chemical products will be highlighted with bold face letters followed by the abbreviation (HCS) in the

tools portion of the procedure. See the Hazard Communication Standard (HCS) manual for the appropriate

Material Safety Data Sheet(s) (MSDS).

Tools and supplies

Bucket, clean and

sanitized towels

Scoop Bucket, soiled towels KAY 5Sanitizer

Procedure

Cycle touch pad to cleaning.

1

On the Menu Screen press

Cleaning, then Daily

Cleaning.

Gather items shown.

2

solution (HCS)

KAY Beverage

Equipment Cleaner

5

No-Scratch Pad

Remove parts for cleaning and

sanitizing.

Remove the following items

and take them back to the 3

compartment sink to wash,

rinse and sanitize.

x Blender pitchers

x Ice hopper lid

x Syrup rail

x Drip pan

x Splash guard

Do not place parts in “Power

Soaker” or dishwasher.

Empty ice hopper.

3

continued X

Remove ice hopper lid. Use

an ice scoop and an empty

bucket to remove as much ice

as possible from above the ice

shelf. Replace ice hopper lid.

Manually dispense ice.

4

Daily BE 23 D1

Place a blend pitcher on the

pitcher pad. Press Manual Ice

Dispense button until ice

hopper is empty. Remove

blender pitcher of ice and

discard in back sink.

©McDonald’s Corporation · Planned Maintenance Manual · October2011 Page 1of 2

10 1/12

Page 11

Clean Blended Ice Machine (BIM-8)(continued)

With the blender pitchers at

6

the 3-compartment sink, clean

pitchers.

Place one KAY Beverage

Equipment Cleaner packet

into the first pitcher and fill

with hot water from the back

sink. Allow the product to

soak in the pitcher for 5

minutes. Use a no-scratch pad

to remove any film build-up.

Pour the solution into the

second pitcher and soak for 5

minutes. Once this is done,

discard solution, rinse and

sanitize bot h pitchers in t he 3compartment sink. Allow to

air dry.

KAY Beverage Equipment

Cleaner

Sanitize ice chute

7

Use a spray bottle with

Sanitizer solution and a

sanitized towel to sanitize:

x Above and around the

ice chute

x Inside the ice chute

KAY 5 Sanitizer

Re-install all components.

9

Blend pitchers, ice hopper lid,

syrup rails, drip pan and

splash guard.

Clean with APSC the interior of

10

the blended ice machine with a

clean, sanitized towel

dampened with KAY 5

Sanitizer solution:

x Clean inside the

machine.

x Pull out the whipped

cream holder and clean

the holder and sides

inside the machine that

hold the holder

x Clean all door gaskets

KAY 5 Sanitizer

Clean with APSC the exterior

11

of the blended ice machine

with a clean, sanitized towel

dampened with KAY 5

Sanitizer solution:

x Clean lid holders, cup

holder tubes, cabinet,

front of door, top of

work surface, touch

screen, outside of ice

hopper

Blended Ice Machine Models MS-8-1H, MS-8-1LH, MS-8-EH, MS-8-ELH, MS-8-BH, MS-8-BLH, MS-8-CH, MS-8-CLH, MS000A03, MS000A04

Clean pitcher pad and drain

8

area.

x Use coffee pot of hot

water from the back

sink to rinse drain

area and drain.

x Spray the drain area

with Sanitizer

solution and wipe

with a clean sanitize

towel.

x Clean top and sides

of the pad.

KAY 5 Sanitizer

KAY 5 Sanitizer

Daily BE 23 D1

©McDonald’s Corporation · Planned Maintenance Manual · October2011 Page 2of 2

1/12 11

Page 12

Clean Blended Ice Machine (BIM-8)

Why

Time required

Time of day

Hazard icons

To break the bacteria cycle

10 minutes to prepare 50 minutes to complete

At close For 24-hour restaurants: During low-volume periods

Electricity

Chemicals

Weekly BE 23 W1

Blended Ice Machine Models MS-8-1H, MS-8-1LH, MS-8-EH, MS-8-ELH, MS-8-BH, MS-8-BLH, MS-8-CH, MS-8-CLH, MS000A03, MS000A04

Sharp Objects/Surfaces

Precaution:

Hazard Communication Standard (HCS) –The procedures on this card include the use of chemical products.

These chemical products will be highlighted with bold face letters followed by the abbreviation (HCS) in the

tools portion of the procedure. See the Hazard Communication Standard (HCS) manual for the appropriate

Material Safety Data Sheet(s) (MSDS).

Tools and supplies

Cleaning Pitcher Cleaning Tubes Bucket with SolidSense All

Bucket, clean,

sanitizer-soaked towels

Bucket, soiled towels KAY 5SanitizerSolution Scoop Empty bucket KAY Beverage Equipment

Purpose Super Concentrate

(APSC)

Procedure

Cycle touch pad to cleaning.

1

On the Menu screen press

Cleaning, then Weekly

Cleaning.

Bucket with 2 KAY5

Sanitizer (HCS) packet

4

Bucket with rinse water Bio-Shield Dispenser Bio-Shield Tower Drain

Cleaner

Cleaner

Taylor Lube HP or

Carpigiani Carpilub e

Manually dispense ice.

Place a blend pitcher on the

pitcher pad. Press Manual Ice

Dispense button until ice

hopper is empty. Remove

blender pitcher of ice and

discard in back sink.

Fill each labeled bucket to the

5

fill line with the appropriate

solution and bring to machine.

Fill APSC bucket with hot

SolidSense APSC from

Gather items shown.

2

Empty ice hopper.

3

Remove ice hopper lid. Use

an ice scoop and an empty

bucket to remove as much ice

as possible from above the ice

shelf. Replace ice hopper lid.

dispenser at 3-compartment

sink.

Fill RINSE bucket with

warm, clean water.

Fill SANITIZE bucket with 5

gallons of lukewarm water

and 2 packets of

KAY 5

Sanitizer and mix thoroughly.

continued X

©McDonald’s Corporation · Planned Maintenance Manual · October2011 Page 1of 5

Weekly BE 23 W1

12 1/12

Page 13

Clean Blended Ice Machine (BIM-8)(continued)

Remove product bins and

6

bags.

Remove each product bag

from the product bin and

place in walk-in cooler. Take

product bins to 3compartment sink and wash,

rinse and sanitize. Allow to

air dry.

Connect cleaning tubes.

7

Connect one tube from the

cleaning tubes to each inlet

line. Insert the free end of the

tubes into the bucket of clean

SolidSense APSC solution.

All lines must be cleaned

including unused.

Chemicals

SolidSense APSC solution

Place black cleaning pitcher

8

on pitcher pad.

Press Next.

9

The message window will

display: “APSC cleaning of

Strawberry Banana

then change to the next flavor

until all lines have been

cleaned. If cleaner solution

runs low, press Pause, refill

the bucket with cleaner

solution and press Resume.

After the last line is cleaned,

the next cleaning screen will

appear.

Line”,

Press Next.

11

The message window will

display: “Rinse of

Banana Line”, then change to

the next flavor until all lines

have been rinse d. If water

runs low, press Pause, refill

the bucke t with warm wa t er

and press Resume. After the

last line is cleaned, the next

cleaning screen will appear.

Remove tubes from RINSE

12

bucket and place into the

warm water SANITIZE bucket.

Chemicals

KAY 5 Sanitizer

Press Next.

13

The message window will

display: “Sanitizer fill of

Strawberry Banana

then change to the next flavor

until all lines have been

sanitized. If sanitizer solution

runs low, press Pause, refill

the bucket with sanitizer

solution and press Resume.

Sanitize Hold

14

After the last line is sanitized,

“Sanitize Hold” will appear,

and then the next cleaning

screen will appear.

Remove tubes from Sanitize

15

solution and lay across the top

rim of the bucket.

BleBlended Ice Machine Models MS-8-1H, MS-8-1LH, MS-8-EH, MS-8-ELH, MS-8-BH, MS-8-BLH, MS-8-CH, MS-8-CLH,MS000A03, MS000A04

Strawberry

Line”,

Remove tubes from the APSC

10

bucket and place into the

warm water RINSE bucket.

Press Next.

16

The message window will

display: “Auto purge of

Strawberry Banana

then change to the next flavor

until all lines have been

purged. The next cleaning

screen will appear.

Disconnect the cleaning tubes

17

from each product line.

©McDonald’s Corporation · Planned Maintenance Manual · October2011 Page 2of 5

Line”,

continued X

Weekly BE 23 W1

1/12 13

Page 14

Clean Blended Ice Machine (BIM-8)(continued)

Lube each product line.

18

Use either Taylor Lube HP or

Carpigiani Carpilube. Put a

small amount of lube around

each product line.

Pull the bottom drain pan from

19

inside the machine.

Reconnect product bins and

20

bags.

Retrieve product bags from

walk-in cooler. Install product

bags into the product bins.

Position the rear groove of the

spout on the product bag into

the front slot of the product

bin. Make sure it’s properly

snapped into place. Then

install each product bin into

its proper location.

Replace black cleaning pitcher

21

with blending pitcher.

Place discharged product in

trash or back sink.

Remove Ice hopper lid.

22

Use clean sanitizer-soaked

26

towel to clean inside of

hopper.

Use caution when wip i ng ne ar

the shaver blade.

Sharp Objects/Surfaces

Rinse ice hopper with clean

27

water.

Fill a blend pitcher with clean

water. Slowly pour the clean

water into the ice hopper in a

circular motion, as close to

and as high up the inside

walls as possible, without

splashing outside the unit.

Repeat if needed for a

thorough rinse.

Remove black cleaning pitcher

28

from the pitcher pad, be

careful not to splash any

remaining solution from the

pitcher.

Spray interior of ice hopper

29

with Sanitizer Solution.

Allow to air dry.

Sharp Objects/Surfaces

Use caution when ne ar the

shaver blade.

KAY 5 Sanitizer

BleBlended Ice Machine Models MS-8-1H, MS-8-1LH, MS-8-EH, MS-8-ELH, MS-8-BH, MS-8-BLH, MS-8-CH, MS-8-CLH,MS000A03, MS000A04

Remove parts for cleaning and

30

sanitizing.

Place black cleaning pitcher

23

on the pitcher pad.

Fill a blend pitcher with

24

SolidSense APSC.

Chemicals

SolidSense APSC

Pour in SolidSense APSC.

25

Slowly pour the SolidSense

APSC into the ice hopper in a

circular motion, as close to

and as high up the inside

walls as possible, without

splashing solution outside the

unit.

Remove the following items

and take them back to the 3compartment sink to wash,

rinse and sanitize:

x Blend pitchers

x Scale overflow tray

x Ice hopper lid

x Syrup rail

x Drip pan

x Splash guard

Do not place parts in “Power

Soaker” or dishwasher.

continued X

©McDonald’s Corporation · Planned Maintenance Manual · October2011 Page 3of 5

Weekly BE 23 W1

14 1/12

Page 15

Clean Blended Ice Machine (BIM-8)(continued)

With the blender pitchers at

31

the 3-compartment sink:

Place one KAY Beverage

Equipment Cleaner packet

into the first pitcher and fill

with hot water from the back

sink. Allow the product to

soak in the pitcher for 5

minutes. Use a no-scratch pad

to remove any film build-up.

Pour the solution into the

second pitcher and soak for 5

minutes. Once this is done,

discard solution and rinse and

sanitize bot h pitchers in t he 3compartment sink. Allow to

air dry.

KAY Beverage Equipment

Cleaner

Sanitize ice chute

32

Use a spray bottle with

Sanitizer solution and a

sanitized towel to sanitize:

x Above and around the

ice chute

x Inside the ice chute

Clean with APSC the interior of

35

the blended ice machine with a

clean, sanitized towel

dampened with KAY 5

Sanitizer solution:

x Clean inside the

machine.

x Pull out the whipped

cream holder and clean

the holder and sides

inside the machine that

hold the holder

x Clean all door gaskets

KAY 5 Sanitizer

Clean with APSC the exterior

36

of the blended ice machine

with a clean, sanitized towel

dampened with KAY 5

Sanitizer solution:

x Clean lid holders, cup

holder tubes, cabinet,

front of door, top of

work surface, touch

screen, outside of ice

hopper

BleBlended Ice Machine Models MS-8-1H, MS-8-1LH, MS-8-EH, MS-8-ELH, MS-8-BH, MS-8-BLH, MS-8-CH, MS-8-CLH,MS000A03, MS000A04

KAY 5 Sanitizer

Clean pitcher pad and drain

33

area.

x Use coffee pot of hot

water from the back

sink to rinse drain

area and drain.

x Spray the drain area

with Sanitizer

solution and wipe

with a clean sanitize

towel.

x Clean top and sides

of the pad.

KAY 5 Sanitizer

Re-install all components.

34

Blend pitchers, scale overflow

tray, ice hopper lid, syrup

rails, drip pan and splash

guard.

KAY 5 Sanitizer

Slowly pour two full pitchers of

37

hot water from the back sink

into the rinse area.

On top of the BIO-SHIELD®

38

dispenser open the pressure

relief knob by turning the knob

counter clockwise.

Remove the cap from the BIO-

39

SHIELD® dispenser.

Weekly BE 23 W1

continued X

©McDonald’s Corporation · Planned Maintenance Manual · October2011 Page 4of 5

1/12 15

Page 16

Clean Blended Ice Machine (BIM-8)(continued)

4

4

4

4

4

4

4

Pour two full pitchers of hot

0

water from the back sink into

the dispenser.

Quickly pour one packet of

1

BIO-SHIELD Beverage Tower

Drain Cleaner into the

dispenser.

Immediately replace and

tighten the cap. Then on top

of the BIO-SHIELD®

dispenser close the pressure

relief knob by turning the

knob clockwise. Shake the

dispenser to dissolve the

cleaner.

Drain Cleaner.

Carefully purge a small

2

amount of solution from the

dispenser into the back sink or

utility sink.

This helps prevent

“sputtering” of solution and

possible splashing ba ck onto

clothing or eyes.

Rinse the BIO-SHIELD®

6

dispenser.

Rinse the BIO-SHIELD®

dispens er wi th warm wa te r

and return the dispenser to the

proper storage area.

IMPORTANT! Do not use

the drain for at least four

hours after cleaning. But

the machine can still be

used.

BleBlended Ice Machine Models MS-8-1H, MS-8-1LH, MS-8-EH, MS-8-ELH, MS-8-BH, MS-8-BLH, MS-8-CH, MS-8-CLH,MS000A03, MS000A04

Carefully spray the solution

3

into the rinser sink drain hole.

Open the pressure relief knob

4

again by turning the knob

counter clockwise on top of

the BIO-SHIELD® dispenser.

Remove the cap from the BIO-

5

SHIELD® dispenser.

Weekly BE 23 W1

©McDonald’s Corporation · Planned Maintenance Manual · October2011 Page 5of 5

16 1/12

Page 17

Operation

Procedure to Make a Drink

NOTE: Ice must be present in the ice bin and product

must be connected and primed to produce a drink.

Size and Option Touch Screen

3. Select drink options:

Drink Selection Touch Screen

1. Place a clean blend container on the container pad.

2. Press the touch screen to select the type of drink

desired from list of main menu items. The screen

will advance and list the selection. (If the selection

is incorrect, press return and reselect).

- Select Return to view the previous screen.

- The yogurt button toggles between including and

leaving out the yogurt.

- Select the Multiple button if you want to make

multiple drinks of the same fl avor.

- Select drink size(s).

NOTE: A green box will highlight the selections.

4. The machine will add the proper amount of

ingredients, blend and stop automatically.

5. Pour the drink into a properly sized cup for the drink

selection.

6. Place container in rinse position – container is

automatically rinsed.

1/12 17

Page 18

Procedure to Replace a Product Bag

These instructions can be found on the Touch Screen in

the Help Menu under “Replace Product”.

1. Touchscreen will indicate the bag is empty “Drink

making paused, check product supply”.

2. Press “Replace product”.

3. Use the arrows and the Confi rm button to select the

product to be replaced.

8. Return product bin to its position in cabinet.

9. Press OK on touchscreen panel. This will reset

inventory.

10. Procedure complete. Use the arrows and the

Confi rm button to select another product to be

replaced. Press Return to display the previously

active screen.

4. Remove product bin from cabinet and discard

empty bag.

5. Wipe the inside of the product bin with a clean

sanitize towel.

6. Place bag in product bin with spout down. Position

product bag with the spout facing down. Position

the rear groove of the spout on the product bag

into the front slot of the product bin. Make sure it’s

properly snapped into place.

7. Open the cap on the product bag and tear it off.

18 1/12

Page 19

Shaver Blade Replacement

WARNING: To reduce the risk of injury, unplug the unit before beginning any repair or upgrade

work.

WARNING: Shaver and Blender Blades are sharp! Handle with caution to avoid injury.

NOTE: Actual components may differ slightly in appearance from those shown in this Update.

1. Unplug the unit from its power source.

2. Remove the Lid and the Ice Shelf from the Ice Bin.

3. Remove the Shaver Wheel. To do so, hold the Shaver Wheel fi rmly with one hand while

turning the Paddle nut counterclockwise with the other hand, as shown in Figure A. If the

Paddle Nut is too tight to loosen by hand, use a pair of pliers. After removing the Paddle Nut,

pull the Shaver Wheel up and off of the shaft.

4. The Ice Shaver Blade should now be exposed. Remove the two screws that secure the

blade, as shown in Figure B. Note that the screw holes in the Shaver blade are recessed to

allow the mounting screws to fi t fl ush with the top surface of the blade. When installing the

new Shaver Blade, be sure to mount it with the recessed side facing upward. Also note the

number and type of shims underneath the blade (See Figure C.). The two different types of

shims are easily distinguishable by their thickness. There may be a number of different shim

combinations based on the vintage of your unit, including but not limited to one thin shim

alone, one thick shim alone and one thick shim in combination with up to fi ve thin shims. Be

sure to note this accurately when you remove the blade.

5. The Ice Shaver Blade Replacement Kit, shown in Figure D, includes:

• (1) Shaver Blade (STM519) NOTE: The replacement Shaver Blade may differ in

appearance from the blade currently installed.

• (1) Thick Shim (STM517)

• (4) Thin Shims (STM514)

• (2) Mounting Screws (FST527) NOTE: Mounting Screws may be a different length than

the screws that you currently use.

Replace the old blade with the blade from the kit, along with the same combination of shims

that existed when you removed the old blade. You can reuse the old shims or use the shims

provided in the kit as long as the combination is the same as the original. Be sure to mount

the blade so that the side with recessed screw holes is facing up.

6. Secure the new blade with the new screws provided. The new screws should be compatible

with any shim confi guration even if they are longer than the original screws.

7. Replace the shaver wheel and secure the paddle nut as tightly as possible BY HAND. No

tools should be required to tighten the paddle nut.

8. MAKE SURE THAT THE PADDLE NUT IS TIGHT AND ROTATE THE SHAVER WHEEL

COUNTERCLOCKWISE BY HAND. THERE SHOULD BE NO INTERFERENCE BETWEEN

THE SHAVER WHEEL AND THE ICE SHAVER BLADE. IF THERE IS ANY EVIDENCE

OF INTERFERENCE SUCH AS A SCRAPING NOISE OR DIFFICULTY TURNING THE

SHAVER WHEEL, REMOVE THE SHAVER WHEEL AND THE ICE SHAVER BLADE. YOU

CAN LOWER THE BLADE HEIGHT BY REMOVING SHIMS. START BY REMOVING THE

THIN SHIMS FIRST, ONE AT A TIME. CHECK FOR INTERFERENCE AFTER REMOVING

EACH SHIM. PROCEED TO THE NEXT STEP ONLY WHEN NO INTERFERENCE EXISTS.

FAILURE TO ENSURE CLEARANCE CAN RESULT IN DAMAGE TO THE ICE SHAVER

BLADE AND/OR THE SHAVER WHEEL.

9. Replace the ice shelf.

10. Fill the ice bin about one-third to one-half full of ice and replace the lid.

11. Plug the unit in.

12. Press the Dispense Ice Button for 10 seconds. The unit should dispense between 12 and 25

ounces of ice during the 10 second period. If the unit dispenses less than this, thin shims can

be added one at a time to increase the shave rate. ALWAYS BE AWARE OF CLEARANCE

BETWEEN THE SHAVER WHEEL AND THE ICE SHAVER BLADE. FAILURE TO DO SO

CAN DAMAGE THE MACHINE.

1/12 19

Page 20

Energize Sequence

Power up

nti sweat

htrs

Rocker sw.

on

Transformer

primary

Transformer

secondary

Duct fan

motor

energizes

Evap. Fan mtr.

energizes

L2

Compressor

Evap. – cond.

fans

IO brd

LCD

powers

Duct

thermistor

indicates temp

Warm

alarm

Ice bin sw.

indicates

position

L1

Open alarm

3 minute

delay

Cabinet thermistor

indicates cabinet

temp

Main Control board

energizes comp./cond.

fan motor relay on I.O.

board

IO brd energizes

compressor

Thermistor indicates

set point temp.

attained

De –energizes comp.

3 min. delay

At set point

Comp. off

War

m

Above set point

23

Energize Sequence Flowchart

20 1/12

Page 21

Make a Drink Energized Component

Flowchart

time period

within max.

screen

menu

Main

Select

drink

Verify weight

time based on selections

Pitcher on pad

2x size

solenoid valve &

solenoid valve &

product pump

De-energize

within max.

Verify weight

within time

period

When selected

solenoid valve

and product

energize

yogurt

pump

Energize blender motor for

predetermined amount of

shaver motor

Energize

solenoid valve &

product pump

De-energize

time period

within max.

Verify weight

time period

product pump

Verify weight

Energize

Size and

option

screen

Making a Drink Energized

Component Flow Chart

2

1/12 21

Page 22

i

nco

r

r

e

c

t

Reselect drink

Energizes

solenoid valve

and product

pump

De-energize

solenoid valve and

product pump

When selected

energize yogurt

solenoid valve

and product

pump

De-energize

solenoid valve &

product pump

MAKE A DRINK ENERGIZED COMPONENT

FLOWCHART - CONTINUED

3

Size and

option screen

22 1/12

Page 23

Errors and Corrections

Adjust banana

weight to 3 oz

incorrect

time period

within max.

drink type

Reselect

c

o

rre

c

t

Verify weight

screen

menu

Main

Select

drink

i

n

time based on selections

Pitcher on pad

2x size

solenoid valve &

product pump

De-energize

Verify weight

within time

period

When selected

solenoid valve

and product

energize

yogurt

pump

time period

within max.

Verify weight

Incorrect

Energize solenoid

valve & product

pump

Component Flow Chart

Size and

option

screen

Making a Drink Energized

Energize blender motor for

predetermined amount of

solenoid valve &

Energize

product pump

De-energize

time period

within max.

Verify weight

shaver motor

product

Error out of

4

1/12 23

Page 24

Rinsing Energized

Flow Chart

Try a different

pitcher

Control board energizes water inlet

valve coil

Water valve opens

Valve de-energizes after

predetermined time period

24 1/12

Page 25

Rinsing Energized Flow Chart

and errors / corrections

Replace

relay brd

Check water

supply

Place pitcher in rinse position

Replace magnet or

pitcher

Replace wire

Pitcher magnet closes reed

y

e

s

Check for

no

power at relay

board

no

Manual rinse

button

operates

n

o

Test reed switch

resistance

no

no

Control Board energizes water

switch

inlet valve coil

Water valve opens

Valve de-energizes after

predetermined time period

Switch doesn’t close

Try a different

pitcher

1/12 25

Page 26

Manager’s Menu Screen

After selecting Managers Menu, the pass code

screen appears.

Managers password is 3312 or 71360.

The screen features:

• Upload New Menu and Recipe Data

• F/C Temperature Units

• Update System Parameters

- Date and Time Settings

- Refrigeration Settings

- Valid Weight Ranges

- Specifi c Product Settings

- Ice Dispense Settings

- Water Dispense Settings

- Cleaning Process Settings

- Service Intervals

- Return

• Return

Service password is 89531.

The screen features:

• Update System Parameters

• Scale Calibration

• Periodic Maintenance

• Fault and Diagnostic History

• Input/Output Test

• Smart Equipment Commission

• Return

Factory Service password is 54221.

The screen features:

• Asset and Operation History

• System Parameters

• Blender Motor Replaced

• Shaver Motor Replaced

• Blender Spindle Replaced

• Blender Control Replaced

• Blender Control Fan Replaced

Reset functions password is 93078.

The screen features:

• Reset Inventory

• Reset Hardware History

• Reset Date of Manufacture

• Reset System Parameters

• Reset Born on Date

• Reset Cleaning Timer

Centering Scale Instructions

1. Remove drive coupler.

2. Loosen plate.

3. Center drive coupler to plate.

• Scale Beam Replaced

• Compressor Replaced

• Install New Firmware

• Return

4. Tighten plate screws.

26 1/12

Page 27

Troubleshooting

Display Assembly

Symptom: Potential Cause: Remedy / Checks:

Display Does not turn

on.

The Display turns on

and does not respond

to touches.

Spots on the display,

or display not as

expected.

No Power

Improper /

Disconnected Power

Wiring

I/O Board

Display Assembly

Touch-screen Display

Bad / Disconnected

Touch-screen Display

not seated in enclosure

correctly.

Something is activating

the touch-screen.

Dirty Display 1. Follow the cleaning instructions for the machine.

Display Bad /

Compromised.

1. Verify that the machine is plugged into a working outlet that is rated for the

machine.

2. Verify that the power switch is ON.

3. If the power switch is ON, verify that LED17 and LED 18 of the I/O board are ON,

and LED15 (MICROPROCESSOR) is ON-Flashing.

4. If ALL LEDs are off, remove AC power and verify the wiring/connection to the

24VAC connector (J19) on the I/O board. This includes the main power switch, and the

120/24VAC power transformer.

Caution! High voltage! Be sure to disconnect power to the machine before servicing!

5. If possible, measure the 24VAC input to the I/O board.

6. If the 24VAC input is good, replace the I/O board.

7. If the 24VAC input to the I/O board is bad, Measure the voltages at the transformer.

8. If the 120VAC input is good, and the 24VAC output is bad, replace the transformer.

9. If there is no 120VAC to the transformer, verify 120VAC at outlet.

10. If there is 120VAC to outlet, replace main power switch.

11. If the LED17 and LED18 are ON, and LED15 is OFF, check the ribbon cable

connection to the I/O board.

12. If the ribbon cable connection to the I/O board is good, the cable may have come

disconnected inside the display enclosure. Replace the Display Assembly.

13. If LED17 and LED18 are ON, LED 15 is fl ashing, and the display is not ON, the

display may have become disconnected inside the Display Assembly. Replace the

Display Assembly.

1. Ensure that there is nothing on or resting against the display.

*Note: Issues with the touch-response require that the Display Assembly is

returned for service.

2. Replace the Display Assembly.

*Note: Care should be taken not to spray the display directly or to over-saturate

the display with fl uid as this may damage the display.

1. If there are spots or artifacts associated with the operation of the display, the

display is bad and the Display Assembly needs to be replaced.

Cannot update

Application Software

via USB Flash Drive.

Application Software

on the USB Flash drive

is non-existent, wrong

format, or corrupt.

Incompatible flash

drive.

1. Verify that the fi les on the USB Flash drive are correct. There should be two fi les in

the root directory (eg. “F:” when viewing the USB Flash Drive on a PC.)

File 1: “fi rmware.S19”

File 2: “mfscrc.txt” (or “mfscrc” if the extension is hidden).

2. These fi les MUST be labeled as above, and they MUST be paired from the

released code revision.

*Note: These fi les are paired in the released Application Software .zip fi le. In order

to ensure that they are paired, you will have to get the fi les from the Application

Software .zip fi le.

3. If the fi les are correct, try to load the fi les with a different USB Flash Drive.

4. If the code will not load, replace the Display Assembly.

1/12 27

Page 28

Blender and Scale

Symptom: Potential Cause: Remedy / Checks:

Blender

Communication Error:

“Communication Lost

With Blender. Reset

Power to Machine”

“Lost Connection with

Blender – Restart

Machine”

Blender not spinning.

Scale Reading Wrong

• “Blend Container

Not in Place”

• “Check Blend

Container and

Pad. Valid

Container weight

exceeded.”

No Power to Blender

Control

Blender Cable /

Connection

Blender Control Board

I/O Board

Display Assembly

Stuck / Jammed

Blender

Blend Container Bad

Blender

Scale out of calibration

/ not calibrated

Scale not accurate /

bad.

*Note: If the blender communication is good, LED14 on the I/O board will be ON.

1. Check power connections to Blender Control

2. Check serial cable connection between blender control and I/O board.

3. If the connection is good, replace the serial cable.

4. If possible, check the serial communication to a separate blender control.

5. If the error is removed with separate Blender Control, replace the Blender Control

on unit.

6. If the error remains, replace the I/O board.

7. If the error remains, replace the Display Assembly.

1. Remove the blend container from the scale.

2. Ensure that the blades of the blend container rotate freely.

3. If the blades do not rotate, remove the obstruction or replace the blend container.

4. If the blend container is good, ensure that there is nothing obstructing the operation

of the blender mechanism.

5. From the startup screen, select

6. Enter code “89531”.

7. Select [Test I/O].

8. Select [Blender Ramp].

9. If the blender does not respond, replace the blender assembly.

1. From the startup screen, select [Menu] à [Managers Menu].

2. Enter code “89531”.

3. Select [Calibrate Scale].

4. Follow the on-screen directions exactly to complete calibration.

Note: For best results, ensure that the water used for calibration is measured

accurately.

1. Ensure that there is nothing on the scale or affecting the operation of the scale.

2. From the startup screen, select [Menu] à [Managers Menu].

3. Enter code “89531”.

4. Select [Test I/O].

5. Place an empty pitcher on the scale.

6. Ensure that the pitcher is positioned on the scale correctly.

7. Record the “Scale weight”. ______

8. Measure 8 oz of water and add it to the pitcher.

9. Record the “Scale weight”. ______

10. Subtract the pitcher weight from the pitcher weight with 8oz of water. _______

11. Verify that the resulting weight is 8 oz ± 0.5 oz.

12. If the weight is not as expected, re-calibrate the scale.

13. If, after the second try, the scale is still wrong, replace the scale beam assembly.

[Menu] à [Managers Menu].

28 1/12

Page 29

Cooling

Symptom: Potential Cause: Remedy / Checks:

Faulty Temperature

Thermistor

1. See Product/Cabinet Thermistor debug section.

Cabinet Temperature

Low / Product

Freezing

Product Temperature

High, cabinet temperature good.

• “High Temperature

Alarm”

Compressor not turning off

I/O Board

Faulty Temperature

Thermistor

Duct fan obstructed /

not operating

I/O Board

1. From the startup screen, select

2. Enter code “89531”.

3. Select [Test I/O].

4. The compressor relay should be OFF.

5. If the compressor is still ON, verify that LED1 on the I/O board is OFF.

6. Verify operation of the compressor relay by cycling the relay control on and off

several times.

If the relay is good, the relay activation will have an audible “click”.

7. If the LED is cycling ON and OFF, but the relay is not ‘clicking’ replace the I/O

board.

2. See Product/Cabinet Thermistor debug section.

1. The duct fan should be ON in all modes of operation.

2. Apply power to the Smoothie Machine.

3. Open the cabinet door and observe the duct fan (upper right at the rear of the

cabinet).

4. Verify that the duct fan is not obstructed.

5. If the duct fan is OFF, check the connections from the duct fan to the I/O

Board, J8.

6. If the connections are good, replace the duct fan.

Cabinet / Product Thermistors

Symptom: Potential Cause: Remedy / Checks:

High/Low Product or

Cabinet temperature

reading.

• “Product Sensor

Open Failure”

• “Product Sensor

Short Failure”

• “Cabinet Sensor

Open Failure”

• “Cabinet Sensor

Short Failure”

Faulty Temperature

Thermistor

Bad or loose wiring

I/O Board

Display Assembly

1. From the startup screen, select [Menu] à [Inventory]

2. Record the reading for the product thermistor and the cabinet thermistor.

• An open thermistor will read -20.

• A shorted thermistor will read 140.

3. Check the connections to the I/O board.

4. If the connections are good, swap the cabinet thermistor and the product thermistor

connections on the I/O board.

5. If the problem (open/short/high reading/low reading) follows the thermistor, replace

the faulty thermistor. (Be sure to connect the correct thermistor to the correct connector.)

6. If the problem remains on either the cabinet or product reading, replace the I/O

board.

[Menu] à [Managers Menu].

1/12 29

Page 30

Ice Shaver / Ice Bin Cover

Symptom: Potential Cause: Remedy / Checks:

Ice Bin Lid not in place. 1. Ensure that the Ice Bin Lid is positioned properly on the Ice Bin.

2. See “Ice Bin Lid” for debugging Ice Bin Lid issues.

Ice Shaver does not

activate

• “Not Enough

Shaved Ice in

Container Drink

Preparation

Paused

Fill Ice Bin or Clear

Ice Passageway”

Ice Bin Lid:

• “Ice bin lid not

in place. Secure

ice bin cover to

restore operation”

Ice Shaver breaker

tripped.

Ice Shaver motor bad.

I/O Board bad.

Ice Bin Switch Bad /

Stuck

Cable connection to I/O

board bad.

I/O Board 1. Cycle power to the system to remove the error message and enter the Service

1. Check the breaker at the rear of the machine.

2. Ensure that the Ice Shaver is not jammed.

3. Reset the breaker if necessary.

1. From the startup screen, select

2. Enter code “89531”.

3. Select [Test I/O].

4. Ensure the “Ice Bin Cover” is ON when the cover is in place.

5. Turn ON the shaver motor.

6. If the shaver motor does not turn on, Check LED3 on I/O board.

7. If LED 3 is ON, and the shaver is not operating, remove power to the system

and check wire connections to the shaver motor.

Caution! The Shaver Motor wiring is high voltage! Be sure to disconnect

power to the machine before servicing!

8. If the connections are good, replace shaver assembly

9. If LED 3 is OFF, replace I/O board

1. Secure the Ice bin Lid.

2. If the lid is secure, and the error does not go away, remove the lid and attempt

to activate the SW using a screwdriver or a fl at, dull knife.

3. While attempting to activate the switch, listen and feel for the switch

activation.

4. If the mechanical operation of the switch is bad, Replace the switch or switch

components.

5. If the switch seems like it’s activating, but the error is not removed, check the

switch connection to the I/O board.

6. If the connection is good, check the operation of the I/O board.

1. Check the switch connection to the I/O board.

2. If the connection is good, check the operation of the I/O board.

Menu

2. From the startup screen, select [Menu] à [Managers Menu].

3. Enter code “89531”.

4. Select [Test I/O].

5. Remove the cable connector from J3 (ICE COVER) of the I/O Board.

6. Using a piece of or wire, short pin 1 to pin 3 of J3.

7. Verify that while the short is applied, the display indicates that the Ice Cover is

ON.

8. If the display indicates that the Ice Cover is still OFF, replace the I/O Board.

9. If the display indicates that the Ice Cover is ON, replace the Ice Cover switch.

[Menu] à [Managers Menu].

30 1/12

Page 31

Product Dispensing

Symptom: Potential Cause: Remedy / Checks:

Product Not

Dispensing:

• “Drink Making

Paused”

• “Check Hose at

Pump Location”

• “Product dispense

fault – Check

Product Pomp

Lines and Nozzle”

Air line disconnected

Insufficient air pressure

Regulator Bad

Solenoid Valve Bad or

wiring disconnected /

bad.

I/O Board

Product tubing obstruction

1. Verify that a pressurized air line is connected to the air inlet on the back of the

system.

2. Verify that the air regulator at the rear of the machine is between TBD and

TBD psi.

3. If the Air Line to the system is good, and the regulator is not reading air

pressure, replace the regulator.

1. From the startup screen, select

2. Enter code “89531”.

3. Select [Test I/O].

4. While listening inside the cabinet, turn the suspect valve ON.

The valve will make an audible “click” when activated.

5. If the valve does not activate, ensure that the wiring to the valve is correct.

6. Check the relay operation on the I/O board.

If the relay is good, the relay activation will have an audible “click” and the

corresponding LED will be ON.

7. If the relay is good, and the wiring is good, replace the solenoid valve.

8. If the relay does not activate, replace the I/O board.

1. Follow the maintenance procedures for clearing an obstruction.

[Menu] à [Managers Menu].

1/12 31

Page 32

Rinsing and Water Dispensing

Symptom: Potential Cause: Remedy / Checks:

Blend Container

Rinse does not

activate

Water is not connected or turned

on.

Ensure water is connected and

turned ON (water pressure

gauge)

Blend container is not properly

positioned over the rinse mechanism or improper blend container

being used.

Reed Switch 1. From the startup screen, select

Rinse Valve Bad / Stuck 1. From the startup screen, select [Menu] à [Managers Menu].

I/O Board 1. From the startup screen, select

Turn on the water source and ensure that all water connections are tight.

Ensure that the water pressure is above 30 psi.

Ensure that blend container (with embedded magnet) is positioned properly over

the rinse mechanism.

[Menu] à [Managers Menu].

2. Enter code “89531”.

3. Select [Test I/O].

4. Ensure the “Rinse Reed Switch” is ON when the blend container is present.

5. If the “Rinse Reed Switch” is OFF, ensure that the blend pitcher is properly

positioned.

6. Check the connection from the Reed Switch to J4 of the I/O board.

7. If the connection is good, replace the reed switch.

2. Enter code “89531”.

3. Select [Test I/O].

4. With the “Rinse Reed switch” ON, from the service screen, turn on the

“Rinse Solenoid”.

5. If no water, ensure that LED4 of the I/O board is ON.

6. If LED is ON, check cable connection to rinse valve.

7. If the connections are good, replace the valve.

[Menu] à [Managers Menu].

2. Enter code “89531”.

3. Select [Test I/O].

4. With the Hall Effect switch ON (blend container present), turn on the “Rinse

Solenoid”.

5. Verify that LED4 on the I/O board is ON.

6. If the LED does not activate, replace the I/O board.

Water is not connected or turned

on.

Ensure water is connected and

turned ON (water pressure

gauge)

Water Valve Bad / Stuck 1. From the startup screen, select [Menu] à [Managers Menu].

Manual Water dispense does not

activate. (Service

Menu Only)

I/O Board 1. From the startup screen, select [Menu] à [Managers Menu].

Turn on the water source and ensure that all water connections are tight.

Ensure that the water pressure is above 30 psi.

2. Enter code “89531”.

3. Select [Test I/O].

4. Turn on the “Water Solenoid”.

5. If no water, ensure that LED5 of the I/O board is ON.

6. If LED is ON, check cable connection to water valve.

7. If the connections are good, replace the valve.

2. Enter code “89531”.

3. Select [Test I/O].

4. Turn on the “Water Solenoid”.

5. Verify that LED5 on the I/O board is ON.

6. If the LED does not activate, replace the I/O board.

32 1/12

Page 33

Refrigeration Operation

Default temperature setpoint = 36°F (2.2°C) with a 4°F

(2.2°C) Differential

Normal Operation

The microprocessor control board controls the cabinet

temperature based on the input received from the

cabinet temperature thermistor. The thermistor value

is compared to the control board setpoint. When the

reach-in temperature is equal or greater than the

setpoint (plus half the differential) the compressor relay

closes provided the following conditions are satisfi ed:

1. Power has been uninterrupted to the control board

for a 3 minute period.

OR

1. The 3 minute compressor time delay has expired.

The delay period starts after the compressor has

run and then cycles off.

2. The blender motor is off - If the blender motor is

operating the compressor relay closes when the

blender motor stops (provided # 1 above is true).

The compressor relay opens when the reach-in

temperature is less than the setpoint (minus half the

differential).

Evaporator and Condenser Fan Motor Operation

The condenser fan motor and compressor share the

same relay. The evaporator fan motor relay is energized

continuously and the evaporator fan cycles off only

during cleaning cycle.

Operation in the Clean/Sanitize cycle

During the weekly cleaning/sanitize cycle the evaporator

fan motor relay and the condenser fan motor/

compressor relay are de-energized. The relays cannot

energize until the clean/sanitize cycle is complete.

Upon completion of the clean/sanitize cycle the relays

will energize provided the conditions listed in normal

operation are satisfi ed.

Maximum Compressor Run Time

After 180 minutes of cumulative compressor run time,

the compressor will be de-energized for fi fteen (15)

minutes.

High Temp Alarm

High temp alarm will display when product thermistor

is above 42ºF (5.6°C) for 30 minutes and following

conditions are satisfi ed

3 hours since power is applied

1 hour since cleaning cycle