Page 1

6000XL & 6100XL Series Reach Ins

Delfield

™

®

Service, Installation and Care Manual

Please read this manual completely before attempting to install or operate this equipment! Notify carrier of

damage! Inspect all components immediately. See page 2.

Refrigerators and Freezers

IMPORTANT INFORMATION

READ BEFORE USE

PLEASE SAVE THESE INSTRUCTIONS!

*9294254*

April 2012

Page 2

6000XL Series Service and Installation Manual

Delfield

Contents

Serial Number Information ........................................................ 2

Receiving & Inspecting Equipment ...........................................2

Specifications ............................................................................. 3

Installation .................................................................................. 4

Door Reversal Procedures ......................................................... 5

Leg & Caster Installation ............................................................5

Operation .................................................................................6-7

Evaporator Fan Matrix ................................................................ 7

Maintenance ............................................................................7-8

Wiring Diagrams ...................................................................9-13

Refrigeration Package Diagram ............................................... 14

Replacement Parts ..............................................................15-16

Standard Labor Guidelines ......................................................17

Standard Warranties ...........................................................18-19

©2012 The Delfield Company. All rights reserved. Reproduction without

written permission is prohibited. “Delfield” is a registered trademark of The

Delfield Company.

Serial Number Information

The serial number tag of all 6000XL Series refrigerators and

freezers is located inside the cabinet on the left side.

Always have the serial number of your unit available when

calling for parts or service. A complete list of authorized

Delfield parts depots is available at www.delfield.com.

This manual covers standard units only. If you have a custom

unit, consult the customer service department at the number

listed below.

Receiving And Inspecting The Equipment

Even though most equipment is shipped crated, care should

be taken during unloading so the equipment is not damaged

while being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported to

the delivering carrier immediately.

2. If damaged, open and inspect the contents with the

carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notification should be made verbally as

well as in written form.

4. Request an inspection by the shipping company of the

damaged equipment. This should be done within 10 days

from receipt of the equipment.

5. Be certain to check the compressor compartment housing

and visually inspect the refrigeration package. Be sure

lines are secure and base is still intact.

6. Freight carriers can supply the necessary damage forms

upon request.

7. Retain all crating material until an inspection has been

made or waived.

2

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

™

®

Page 3

Delfield

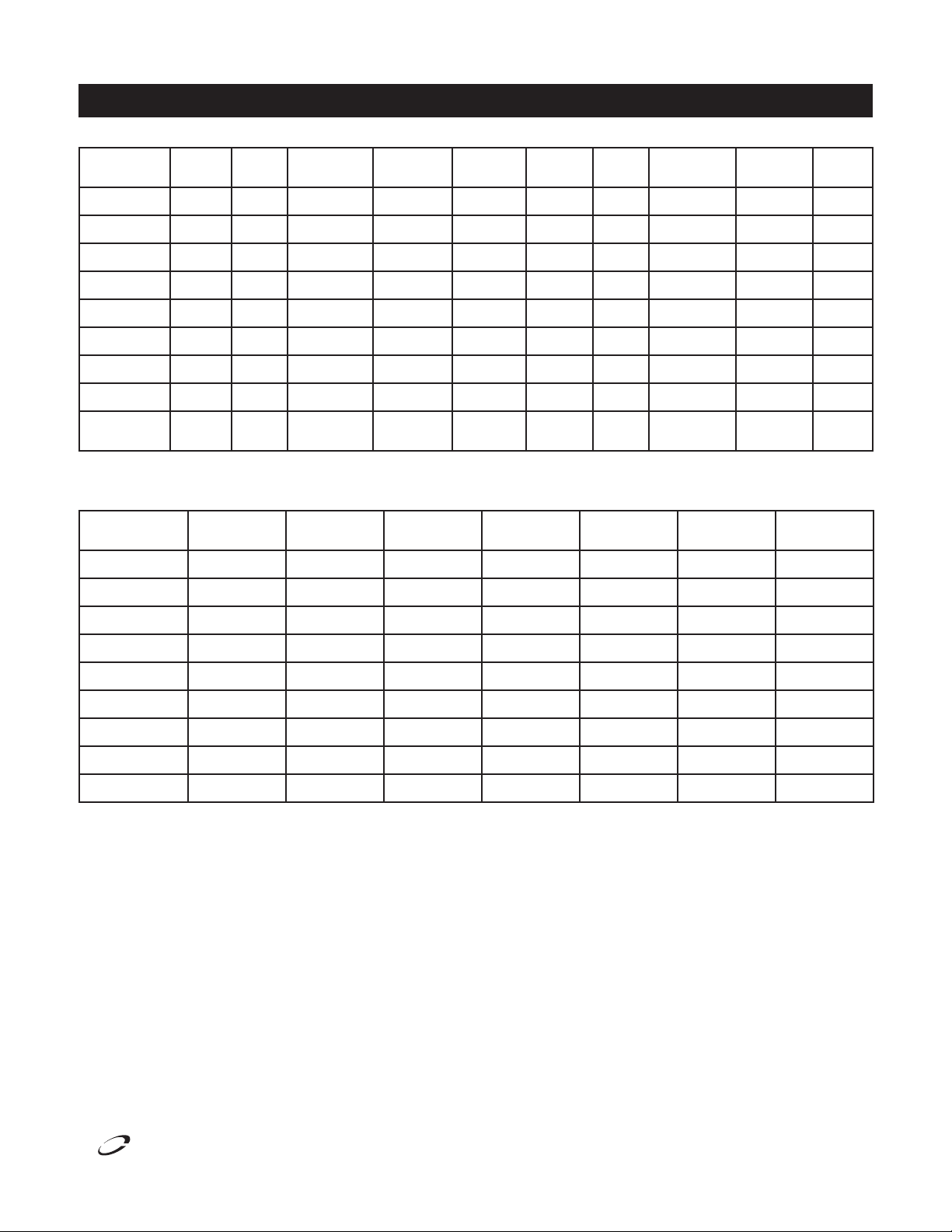

Specifications

6000XL Series Service and Installation Manual

Model Voltage Amps

6025XL-SH,S 115 6.0 20.0 15.1 1/4 2092 20˚F 12.5 274lbs/124kg 515P

6025XL-G,GH 115 6.0 20.0 15.1 1/4 2092 20˚F 12.5 338lbs/153kg 515P

6051XL-SH,S 115 8.0 43.5 33.2 1/3 2488 20˚F 12.5 454lbs/206kg 515P

6051XL-G,GH 115 8.0 43.5 33.2 1/3 2488 20˚F 12.5 548lbs/249kg 515P

6076XL-SH,S 115 16.0 66.5 48.3 1/4, 1/3 2092/2488 20˚F 12.5/12.5 622lbs/282kg 520P

6076XL-G,GH 115 16.0 66.5 48.3 1/4, 1/3 2092/2488 20˚F 12.5/12.5 774lbs/351kg 520P

6125XL-S,SH 115 9.0 20.0 15.1 1/2 2092 -20˚F 12.5 274lbs/124kg 515P

6151XL-S,SH 115 12.0 43.5 33.2 3/4 1923 -20˚F 12.5 454lbs/206kg 515P

6176XL-S,SH

Model Voltage Amps

6025XLR-SH,S 115 5.0 20.0 15.1 2092 20˚F 274lbs/124kg

6025XLR-G,GH 115 5.0 20.0 15.1 2092 20˚F 338lbs/153kg

120/208-

230

20.0 66.5 48.3 1/2, 3/4 1516/1923 -20˚F 12.5/12.5 622lbs/282kg 1420P

Storage

Capacity FT

3

Shelf

Capacity FT

Storage

Capacity FT

2

3

H.P. BTU/HR

Shelf

Capacity FT

2

Evap.

Temp

Required

BTU/HR

R-404A Charge

Oz.

Evap. Temp Shipping Weight

Shipping

Weight

Nema

Plug

6051XLR-SH,S 115 5.0 43.5 33.2 2488 20˚F 454lbs/206kg

6051XLR-G,GH 115 5.0 43.5 33.2 2488 20˚F 548lbs/249kg

6076XLR-SH,S 115 5.0 66.5 48.3 2092/2488 20˚F 622lbs/282kg

6076XLR-G,GH 115 5.0 66.5 48.3 2092/2488 20˚F 774lbs/351kg

6125XLR-S,SH 115 5.0 20.0 15.1 2092 -20˚F 274lbs/124kg

6151XLR-S,SH 115 5.0 43.5 33.2 1923 -20˚F 454lbs/206kg

6176XLR-S,SH 115 5.0 66.5 48.3 1516/1923 -20˚F 622lbs/282kg

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

3

Page 4

6000XL Series Service and Installation Manual

Delfield

Installation

Location

Units represented in this manual are intended for indoor use

only. Be sure the location chosen has a floor strong enough to

support the total weight of the cabinet and contents. A fully loaded

6000XL series can weigh as much as 1500 pounds. Reinforce

the floor as necessary to provide for maximum loading. For the

most efficient refrigeration, be sure to provide good air circulation

inside and out.

Inside cabinet: Do not pack refrigerator so full that air cannot

circulate. The refrigerated air is discharged at the top rear of

the unit. It is important to allow for proper air flow from the

top rear to the bottom of the unit. Obstructions to this air flow

can cause evaporator coil freeze ups and loss of temperature

or overflow of water from the evaporator drain pan. The rear

of the unit has molded ribs and the shelves have a rear turn

up on them to prevent this. However,

bags and other items can still be

located to the far rear of the cabinet.

There is also a return air diffuser

along the top front of the cabinet

interior, this also requires proper air

circulation. Prevent obstruction by

locating large boxes and tall stacks of

product to the bottom of the cabinet.

Stabilizing

Some models are supplied on casters for your convenience,

ease of cleaning underneath and for mobility. It is very

important, however, that the cabinet be installed in a stable

condition with the front wheels locked while in use.

Should it become necessary to lay the unit on its side or back

for any reason, allow at least 24 hours before start-up so as to

allow compressor oil to flow back to the sump. Failure to meet

this requirement can cause compressor failure and unit damage.

Unit repairs will not be subject to standard unit

warranties due to improper installation procedures.

Electrical connection

Refer to the amperage data on page 3, the serial tag, your

local code or the National Electrical Code to be sure the unit is

connected to the proper power source. A protected circuit of the

correct voltage and amperage must be run for con nec tion of the

line cord, or permanent connection to the unit.

The thermostat must be turned to OFF and

the unit disconnected from the power source

whenever performing service, maintenance

functions or cleaning the refrigerated area.

Outside cabinet: Be sure that the

unit has access to ample air. Avoid

hot corners and locations near stoves

and ovens.

It is recommended that the unit be installed no closer than

2” from any wall with at least 12” of clear space above the

unit. Avoid exposing glass door units to direct sunlight. Direct

sunlight through the glass doors will make the ABS liner

fade and become brittle and will greatly reduce refrigeration

efficiency.

Leveling

A level cabinet looks better and will perform better because the

doors will line up with the frames properly, the cabinet will not

be subject to undue strain and the contents of the cabinet will

not move around on the shelves. Use a level to make sure the

unit is level from front to back and side to side. Units supplied

with legs will have adjustable bullet feet to make the necessary

adjustments. If the unit is supplied with casters, no adjustments

are available. Ensure the floor where the unit is to be located

is level.

Power Switch

Select units are equipped with a power disconnect switch

located next to the energy saver switch and thermostat

control knob. Switch must be in the “on” position for the

unit to operate. On freezers, if the switch is turned off, then

returned to the on position, the unit will enter a defrost cycle

and the display will read “Def.”

Upon powering unit, there could be up to a 10

minute delay before unit begins to cool.

4

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

™

®

Page 5

Delfield

Door Reversal Procedures

Standard Edge-Mount Hinge

6000XL Series Service and Installation Manual

Only for Models Ordered With Re-Hinging Option

1. Open door 90˚ and lift door straight up and off hinges.

2. Remove the metal screw covers on each door-side hinge

section by sliding it down and off.

3. Remove two outer screws that mount each hinge to door,

loosen the center screw, rotate hinge 180˚, reinstall outer

screws and retighten center screw.

4. Remove two screws that mount lock on top of door, turn

door up-side-down and remount lock to top of door.

5. Use a 3/16” drill to drill holes in cabinet face frame at the

marked hinge locations on the new hinge side.

6. Remove the cabinet hinge screw covers by gently prying

them out with a small screwdriver.

7. Remove all three screws from each hinge and mount them

to the opposite side of the door opening.

8. Remove the plastic cam from the hinges by pulling straight

up, then rotating the cam 180˚ and pushing back into the

hinge.

9. Remount the door and check for proper closure and gasket

seal. Adjust hinges as needed. Once adjustment is verified,

remove the door, reinstall all hinge screw covers and set the

door back in place.

10. If plugs are needed to plug old screw holes in cabinet face

frame, please contact Delfield Parts Department at (800)

733-8821, extension 12801.

1. Open door 90˚ and lift door straight up and off hinges.

2. Remove the metal screw covers on each door-side hinge

section by sliding it down and off.

3. Remove two outer screws that mount each hinge to door,

loosen the center screw, rotate hinge 180˚, reinstall outer

screws and retighten center screw.

4. Remove two screws that mount lock on top of door, turn

door up-side-down and remount lock to top of door.

5. Pry the plugs out of the hinge mounting holes on the side

opposite the current hinge locations and set them aside.

6. Remove the cabinet hinge screw covers by gently prying

them out with a small screwdriver.

7. Remove all three screws from each hinge and mount them

to the opposite side of the door opening. Press the plugs

removed in step 5 into the screw holes from the original

hinge locations.

8. Remove the plastic cam from the hinges by pulling straight

up, then rotating the cam 180˚ and pushing back into the

hinge.

9. Remount the door and check for proper closure and gasket

seal. Adjust hinges as needed. Once adjustment is verified,

remove the door, reinstall all hinge screw covers and set the

door back in place.

10. If additional plugs are needed due to loss or damage, please

contact Delfield Parts Department at (800) 733-8821, extension 12801.

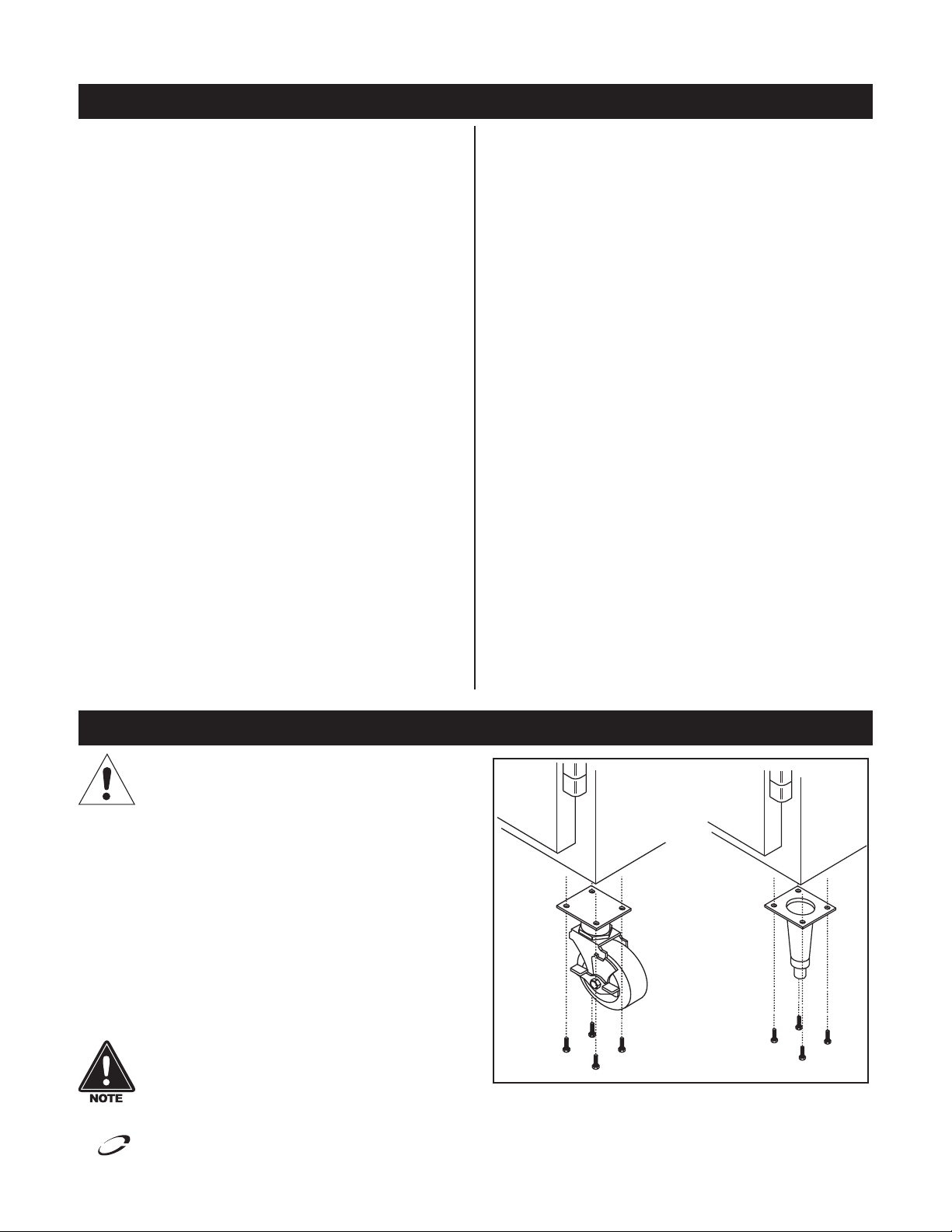

Leg & Caster Installation

Some cabinets may weigh over 1000 lbs (450 kg).

Use a lifting device capable of supporting the unit

WARNING

To install the legs, or casters refer to Figure 1 and proceed as

follows:

1. Remove unit from skid.

2. Raise unit to access leg/caster mounting bolts on bottom

of unit.

3. Remove the bolts from the cabinet and use them to attach

the legs or casters.

when removing skid or installing legs or casters.

All single-section units require that the swivel

casters be mounted on the front and rigid casters

be mounted on the rear.

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

Figure 1. Leg or Caster Installation

5

Page 6

6000XL Series Service and Installation Manual

Delfield

Operation

Electronic Temperature Control

Operation:

The electronic temperature control constantly monitors box

temperature as well as evaporator coil temperature to maintain

consistent product temperatures. The control also sends

temperature readings to the digital temperature display. The

control circuits continually self-check and if an error occurs,

the digital display will switch from temperature read-out to

error read-out, i.e. E 1. Even when an error is displayed, the

refrigeration and controls system should continue to function,

however not at optimal performance. Whenever the display has

an error read-out, Delfield Service should be contacted.

At initial start-up or anytime power is disconnected, then

reconnected to the unit, the control will delay all operations for

a short time (up to 10 minutes.) While in this delay period, the

control initializes the control parameters and confirms that the

temperature sensors and circuits are operational. The digital

temperature display will not display temperature OR errors until

the self-check is complete and the control has switched on the

evaporator fan motor, compressor and condenser fan motor.

Freezer:

The control is located in the control box in the top of the

refrigerator behind the removable louvered panel on the left

side. It is factory set at mid-range to maintain about -3˚F

(-18˚C) box temperature. To adjust for colder temperatures,

turn the knob clockwise. For warmer temperatures, turn the

knob counter-clockwise. Turn the knob fully counter-clockwise

to turn the refrigeration system off. Never turn the knob more

than 1 dial number and always allow 8 hours for temperature

stabilization before making any additional adjustments.

Power Switch

Select units are equipped with a power disconnect switch

located next to the energy saver switch and thermostat control

knob. Switch must be in the “on” position for the unit to

operate. On freezers, if the switch is turned off, then returned to

the on position, the unit will enter a defrost cycle and the display

will read “Def.”

IMPORTANT NOTE REGARDING FREEZERS: After initializing,

the control will immediately enter a DEFROST mode and the

display will read DEF. The compressor and condenser fan as

well as the evaporator fan will remain off until initialization

defrost is complete. This initial defrost cycle may take up to

15 minutes to complete, at which time the freezing cycle will

begin. The display will continue to read DEF for an additional

30 minutes before displaying temperature.

Temperature Alarm:

The alarm will flash “HI” or “LO” 90 minutes after the unit has

reached its alarm temperature point or after any power interruption

if the temperature is above or below the alarm set points.

Refrigerators are factory set at mid-range to maintain about 38ºF

(3ºC) box temperature. The high refrigerator temperature point

is 50°F (10°C). The low refrigerator temperature point is 25°F

(-4°C). Freezers are factory set at mid-range to maintain about 3ºF

(-18ºC) box temperature. The high freezer temperature point is

20°F (-7°C). Freezers do not have a low temperature point.

Refrigerator:

The control is located in the control box in the top of the

refrigerator behind the removable louvered panel on the left

side. It is factory set at mid-range to maintain about 38˚F

(3˚C) box temperature. To adjust for colder temperatures, turn

the knob clockwise. For warmer temperatures, turn the knob

counter-clockwise. Turn the knob fully counter-clockwise to

turn the refrigeration system off. Never turn the knob more

than 1 dial number and always allow 8 hours for temperature

stabilization before making any additional adjustments.

Energy Saver Switch

The energy saver switch is a rocker switch located next to

the thermostat knob that controls the amount of heat applied

to the door perimeter. The normal operating position for this

switch is the ON position, providing the least heat. If excessive

condensation is observed on the door opening, press the

energy saver switch to the OFF position, to increase the amount

of heat (red portion of the rocker switch will be visible).

Refrigeration & Defrost Cycle

Refrigerator:

Whenever the refrigerator is plugged in, and the control

has completed initializing, the digital thermostat will display

box temperature. The temperature control will cycle the

compressor, evaporator fan motor and condenser fan motor to

maintain box temperature at the control setting. See evaporator

fan matrix for more information.

Refrigerator Defrost

The temperature control also monitors the evaporator

temperature and will turn off the compressor and condenser

fan motor when needed to allow accumulated frost on the

evaporator to clear. During this defrost cycle, the digital

temperature display will read dEF. After the defrost cycle is

complete, the temperature control will return to a normal

cooling cycle, but the display will continue to read dEF until the

evaporator returns to normal cooling temperatures (up to 30

minutes).

6

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

™

®

Page 7

Delfield

Operation, continued

Freezer:

Whenever the freezer is plugged in, and the control has

completed initializing including the initial defrost cycle (also see

Electronic Temperature Control Operation, on this page). The

digital therostat will display box temperature. The temperature

control will cycle the compressor, evaporator fan motor and

condenser fan motor to maintain box temperature at the control

setting. See evaporator fan matrix for more information.

Freezer Automatic Defrost

The control also monitors compressor total running time

and will enter a defrost cycle after total compressor running

time is greater than 4-hours since the last defrost cycle OR

if evaporator coil temperature drops below -30˚F (-34°C)

(indicating excessive frost on the coil).

Freezer Manual Defrost

If a manual defrost is desired, simply unplug the unit for several

seconds, then plug unit back in. This will cause the control to

re-initialize and then enter a defrost cycle.

When the control enters the defrost mode, it switches off the

6000XL Series Service and Installation Manual

evaporator fan motor, compressor and condenser fan motor,

and switches on the defrost heater to warm the evaporator

coil. Thereby melting all frost accumulated during the previous

refrigeration cycle. The digital temperature display will now read

dEF. The control will continue the defrost cycle for a MINIMUM

of 8 minutes and a MAXIMUM of 30 minutes depending on the

amount of frost accumulated on the evaporator coil.

After the defrost cycle is complete, the control returns to a normal

refrigeration cycle, however the evaporator fan motor will not

switch on for 2 minutes AFTER the compressor and condenser

fan motor have begun operating. The digital temperature

display will continue to read dEF until the evaporator has

returned to normal freezing temperatures (up to 30 minutes).

Service Alert

During normal operation the evaporator fan may cycle

and/or pulse independently of the compressor. Consult

the service manual or contact Technical Support at

1-800-733-8829 if you are unsure of the proper function.

Evaporator Fan Matrix

Cooling Cycle Defrost Cycle

Compressor On Compressor Off Compressor Off

Evap Fan On Evap Fan Off Evap Fan On Evap Fan Off Evap Fan On Evap Fan Off

Refrigerator X Cycles On 3-Min, Off 3-Min X

Freezer X X X

Maintenance

The thermostat must be turned to OFF and the unit

disconnected from the power source whenever

performing service, maintenance functions or

cleaning the refrigerated area.

Refrigerators and Freezers

The Delrite® ABS interior and exterior can be cleaned using

soap and warm water. If this isn’t sufficient, try ammonia

and water or a nonabrasive liquid cleaner. When cleaning the

exterior, always rub with the “grain” of the stainless steel to

avoid marring the finish.

Do not use an abrasive cleaner because it will scratch the

stainless steel and plastic and can damage the breaker strips

and gaskets.

Cleaning the Condenser Coil

The condenser coil requires regular cleaning, recommended is

every 90 days. In some instances though you may find that

there is a large amount of debris and dust or grease accumulated

prior to the 90 day time frame. In these cases the condenser coil

should be cleaned every 30 days.

If the build up on the coil consists of only light dust and debris

the condenser coil can be cleaned with a simple brush, heavier

dust build up may require a vacuum or even compressed air to

blow through the condenser coil.

If heavy grease is present there are de-greasing agents available

for refrigeration use and specifically for the condenser coils.

The condenser coil may require a spray with the de-greasing

agent and then blown through with compressed air.

Failure to maintain a clean condenser coil can initially cause high

temperatures and excessive run times, continuous operation

with dirty or clogged condenser coils can result in compressor

failures. Neglecting the condenser coil cleaning procedures will

void any warranties associated with the compressor or cost to

replace the compressor.

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

7

Page 8

6000XL Series Service and Installation Manual

Delfield

Maintenance, continued

Never use a high pressure water wash for this

cleaning procedure as water can damage the

electrical components located near or at the

condenser coil.

In order to maintain proper refrigeration performance, the

condenser fins must be cleaned of dust, dirt and grease regularly.

It is recommended that this be done at least every three months.

If conditions are such that the condenser is totally blocked in

three months, the frequency of cleaning should be increased.

Clean the condenser with a vacuum cleaner or stiff brush. If

extremely dirty, a commercially available condenser cleaner may

be required.

Gasket Maintenance

Gaskets require regular cleaning to prevent mold and mildew

build up and also to keep the elasticity of the gasket. Gasket

cleaning can be done with the use of warm soapy water. Avoid

full strength cleaning products on gaskets as this can cause

them to become brittle and prevent proper seals. Also, never

use sharp tools or knives to scrape or clean the gasket which

could possibly tear the gasket and rip the bellows.

Gaskets can easily be replaced and do not require the use of

tools or authorized service persons. The gaskets are “Dart”

style and can be pulled out of the grove in the door and new

gaskets can be “pressed” back into place.

Stainless Steel Care and Cleaning

To prevent discoloration or rust on stainless steel several

important steps need to be taken. First, we need to understand

the properties of stainless steel. Stainless steel contains 70-80%

iron which will rust. It also contains 12-30% chromium which

forms an invisible passive film over the steels surface which

acts as a shield against corrosion. As long as the protective

layer is intact, the metal is still stainless. If the film is broken

or contaminated, outside elements can begin to breakdown the

steel and begin to form rust of discoloration.

Proper cleaning of stainless steel requires soft cloths or plastic

scouring pads.

NEVER USE STEEL PADS, WIRE BRUSHES OR SCRAPERS!

Cleaning solutions need to be alkaline based or non-chloride

cleaners. Any cleaner containing chlorides will damage

the protective film of the stainless steel. Chlorides are also

commonly found in hard water, salts, and household and

industrial cleaners. If cleaners containing chlorides are used be

sure to rinse repeatedly and dry thoroughly upon completion.

Routine cleaning of stainless steel can be done with soap and

water. Extreme stains or grease should be cleaned with a nonabrasive cleaner and plastic scrub pad. It is always good to

rub with the grain of the steel. There are also stainless steel

cleaners available which can restore and preserve the finish of

the steels protective layer.

Early signs of stainless steel breakdown can consist of small

pits and cracks. If this has begun, clean thoroughly and start to

apply stainless steel cleaners in attempt to restore the passivity

of the steel.

Doors/Hinges

Over time and with heavy use doors the hinges may become

loose. If it is noticed that the door is beginning to sag, it may

become necessary to tighten the screws that mount the hinge

brackets to the frame of the unit. If the doors are loose or

sagging this can cause the hinge to pull out of the frame which

may damage both the doors and the door hinges. In some

cases this can require qualified service agents or maintenance

personnel.

Drain Maintenance

Each unit has a drain located inside the unit which removes the

condensation from the evaporator coil and evaporates it at an

external condensate evaporator pan. Each drain can become

loose or disconnected from moving or bumping the drain. If you

notice excessive water accumulation on the inside of the unit be

sure the drain tube is connected from the evaporator housing

to the condensate evaporator drain pan. If water is collected

underneath the unit you may want to check the condensate

evaporator drain tube to be sure it is still located inside the

drain pan. The leveling of the unit is important as the units are

designed to drain properly when on a level surface, if your floor

is not level this can also cause drain problems. Be sure all drain

lines are free of obstructions, typically food product is found

blocking drain lines causing water to back up and overflow the

drain pans.

Fluorescent Light Bulb Replacement

Delfield recommends that fluorescent light bulbs be recycled

rather than disposed of.

8

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

Never use an acid based cleaning solution!

Many food products have an acidic content which

can deteriorate the finish. Be sure to clean the

stainless steel surfaces of ALL food products.

Common items include, tomatoes, peppers and

other vegetables.

™

®

Page 9

Delfield

Wiring Diagrams: Refrigerators

REVISIONS

INITIAL RELEASE1

REV DESCRIPTION DATE APPROVED

11"

8

1

2

"

L ENNIS

17-MAY-2011

ADDED L-2/3 DESIGNATION & H-4 FOR HEATER TERMINAL2

3 BROWN COMPRESSOR WIRE WAS BLACK (ON DIAGRAM ONLY)

26-MAY-2011

L ENNIS

REVISIONS

INITIAL RELEASE1

REV DESCRIPTION DATE APPROVED

11"

8

1

2

"

L ENNIS

02-MAY-2011

ADDED L-2/3 DESIGNATION & H-4 FOR HEATER TERMINAL2

17-MAY-2011

L ENNIS

26-MAY-2011

L ENNIS

BROWN COMPRESSOR WIRE WAS BLACK (ON DIAGRAM ONLY)3

6025XL-S, 6025XL-SH

6000XL Series Service and Installation Manual

L1

2/3

SEE NAMEPLATE FOR MAXIMUM

TEMPERATURE

CONTROL

L

CONTROL

CIRCUIT

FAN RELAY

HEATER

RELAY

COMPRESSOR

RELAY

1.1,2,3 2.1,2,3 3.1,2,3

(IF USED)

LED DISPLAY

SENSOR

EVAP COIL

SWITCH

DOOR

SWITCH

9294455

LINE VOLTAGE

115/60/1

FUSE SIZE

N

5

F

6

H

4

C

1

CABINET AIR

SENSOR

M

EVAPORATOR FAN

M

COMPRESSOR

M

CONDENSOR FAN

DOOR FRAMEENERGY SAVER

HEATER

INCANDESCENT

LIGHT

NOTES:

N

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

3) UNIT SHOWN WITH COMPRESSOR

RUNNING AND DOORS CLOSED

CONTROL

BOX

P

RED

DOOR

HINGE

SWITCH

BLK

ENERGY SAVER

SWITCH

GREY

L

H

2LC1 3

4

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

FRAME HEATERS

EVAPORATOR HOUSING

EVAP FAN

MOTOR

M

Y

DEFROST

HEATER

M

W

BLK

BRN

BLK

CONDENSER

FAN

BLK

W

INCANDESCENT

LIGHT

W

SPLICE

POWER BOX

10

11

12

START

13

WINDING

WINDING

RUN

14

COMPRESSOR

BLUE

SENSOR

SENSOR

EVAP COIL

CABINET AIR

W

W

WITH BLUE

STRIPES

W

F

5N6

W

LED DISPLAY

(IF USED)

W

START RELAY

START

CAPACITOR

COMPRESSOR

GROUND

MOTOR PROTECTOR

WIRE

NUT

PLUG

6025XL-G, 6025XL-GH

L1

™

LINE VOLTAGE

SEE NAMEPLATE FOR MAXIMUM

TEMPERATURE

CONTROL

L

CONTROL

CIRCUIT

2/3

FAN RELAY

HEATER

RELAY

COMPRESSOR

RELAY

1.1,2,3 2.1,2,3 3.1,2,3

(IF USED)

LED DISPLAY

SENSOR

EVAP COIL

SWITCH

FLUORESCENT

LAMP SWITCH

NOTES:

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

3) UNIT SHOWN WITH COMPRESSOR

RUNNING AND DOORS CLOSED

®

9294475

115/60/1

FUSE SIZE

N

5

F

6

H

4

C

1

CABINET AIR

SENSOR

EVAPORATOR FAN

COMPRESSOR

CONDENSOR FAN

DOOR FRAMEENERGY SAVER

HEATER

FLUORESCENT

LAMP BALLAST

FLUORESCENT

LAMP

FLUORESCENT

N

LAMP

SWITCH

BLK

BLK

W

FLUORESCENT LIGHT

BALLAST

RED

FLUORESCENT LAMP

FLUORESCENT LAMP ASSEMBLY

BLUE

EVAPORATOR HOUSING

EVAP FAN

SENSOR

CABINET AIR

W

CONDENSER

FAN MOTOR

Y

MOTOR

SENSOR

EVAP COIL

W

WITH BLUE

STRIPES

START RELAY

START

CAPACITOR

MOTOR PROTECTOR

PLUG

WIRE

NUT

M

W

W

W

BLK

BRN

BLK

M

BLK

W

WINDING

12

RUN

SPLICE

10

11

STAR

13

WINDING

14

COMPRESSOR

POWER BOX

COMPRESSOR

GROUND

9

M

BLUE

M

CONTROL

BOX

M

BLK

ENERGY SAVER

SWITCH

P

GREY

W

L

H

2LC1 3

5N6

4

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

FRAME HEATERS

W

F

LED DISPLAY

(IF USED)

W

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

Page 10

6000XL Series Service and Installation Manual

Delfield

REVISIONS

INITIAL RELEASE1

REV DESCRIPTION DATE APPROVED

11"

8

1

2

"

L ENNIS

02-MAY-2011

17-MAY-2011

L ENNIS

ADDED HEATER RELAY TO CONTROL & L-2/3 DESIGNATION2

BROWN COMPRESSOR WIRE WAS BLACK (ON DIAGRAM ONLY)3

26-MAY-2011

L ENNIS

REVISIONS

INITIAL RELEASE1

REV DESCRIPTION DATE APPROVED

11"

8

1

2

"

2 ADDED L-2/3 DESIGNATION & H-4 FOR HEATER TERMINAL

L ENNIS

17-MAY-2011

3 BROWN COMPRESSOR WIRE WAS BLACK (ON DIAGRAM ONLY)

26-MAY-2011

L ENNIS

Wiring Diagrams: Refrigerators

6051XL-S, 6051XL-SH

L1

2/3

SEE NAMEPLATE FOR MAXIMUM

TEMPERATURE

CONTROL

L

CONTROL

CIRCUIT

FAN RELAY

HEATER

RELAY

COMPRESSOR

RELAY

1.1,2,3 2.1,2,3 3.1,2,3

(IF USED)

LED DISPLAY

SENSOR

EVAP COIL

SWITCH

DOOR

SWITCHES

9294454

LINE VOLTAGE

115/60/1

FUSE SIZE

N

5

F

6

H

4

C

1

CABINET AIR

SENSOR

M

EVAPORATOR FAN

M

COMPRESSOR

M

CONDENSOR FAN

DOOR FRAMEENERGY SAVER

HEATERS

INCANDESCENT

LIGHT

NOTES:

N

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

3) UNIT SHOWN WITH COMPRESSOR

RUNNING AND DOORS CLOSED

CONTROL

BOX

P

RED

DOOR

HINGE

SWITCHES

BLK

ENERGY SAVER

SWITCH

GREY

H

L

4

2LC1 3

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

DOOR FRAME HEATERS

EVAPORATOR HOUSING

EVAP FAN

MOTOR

M

Y

DEFROST

HEATER

M

W

BLK

BRN

BLK

CONDENSER

FAN

BLK

W

INCANDESCENT

LIGHT

W

SPLICE

W

12

WINDING

RUN

POWER BOX

10

STAR

13

WINDING

14

COMPRESSOR

11

BLUE

SENSOR

SENSOR

EVAP COIL

CABINET AIR

W

W

WITH BLUE

STRIPES

W

F

5N6

W

LED DISPLAY

W

(IF USED)

START RELAY

START

CAPACITOR

COMPRESSOR

GROUND

MOTOR PROTECTOR

WIRE

NUT

PLUG

6051XL-G, 6051XL-GH

L1

SEE NAMEPLATE FOR MAXIMUM

TEMPERATURE

CONTROL

L

CONTROL

CIRCUIT

2/3

FAN RELAY

HEATER

RELAY

COMPRESSOR

RELAY

1.1,2,3 2.1,2,3 3.1,2,3

(IF USED)

LED DISPLAY

EVAP COIL

SWITCH

FLUORESCENT

LAMP SWITCHES

NOTES:

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

3) UNIT SHOWN WITH COMPRESSOR

RUNNING AND DOORS CLOSED

9294476

LINE VOLTAGE

115/60/1

FUSE SIZE

N

5

F

6

H

4

C

1

SENSOR

CABINET AIR

SENSOR

M

EVAPORATOR FAN

M

COMPRESSOR

M

CONDENSOR FAN

DOOR FRAMEENERGY SAVER

HEATERS

FLUORESCENT

LAMP BALLAST

FLUORESCENT

LAMP

FLUORESCENT

LAMP BALLAST

FLUORESCENT

LAMP

N

FLUORESCENT

LAMP

SWITCH

BLK

BLK W

BLK

P

GREY

1.1,2,3 2.1,2,3 3.1,2,3

RED

FLUORESCENT LAMP ASSEMBLY

CONTROL

BOX

ENERGY SAVER

SWITCH

L

H

2LC1 3

4

TEMPERATURE

CONTROL

BLK

DOOR FRAME HEATERS

FLUORESCENT LIGHT

FLUORESCENT LAMP

F

5N6

BALLAST

W

FLUORESCENT

LAMP

BLUE

SWITCH

EVAPORATOR HOUSING

EVAP FAN

MOTOR

M

Y

BLUE

SENSOR

SENSOR

EVAP COIL

CABINET AIR

W

W

WITH BLUE

STRIPES

W

W

CONDENSER

FAN MOTOR

M

LED DISPLAY

(IF USED)

BLK

FLUORESCENT LIGHT

BALLAST

POWER BOX

COMPRESSOR

GROUND

START RELAY

START

CAPACITOR

MOTOR PROTECTOR

BLUE

PLUG

WIRE

NUT

RED

FLUORESCENT LAMP ASSEMBLY

W

W

12

WINDING

RUN

FLUORESCENT LAMP

SPLICE

10

STAR

WINDING

14

COMPRESSOR

11

13

BLK

W

W

W

BLK

BRN

BLK

BLK

10

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

™

®

Page 11

Delfield

Wiring Diagrams: Refrigerators

REVISIONS

1

REV DESCRIPTION

DATE APPROVED

11"

8

1

2

"

L ENNIS

02-MAY-2011

INITIAL RELEASE

L ENNIS

17-MAY-2011

2 ADDED L-2/3 DESIGNATION & H-4 FOR HEATER TERMINAL

26-MAY-2011

L ENNIS

BROWN COMPRESSOR WIRE WAS BLACK (ON DIAGRAM ONLY)3

REVISIONS

1

REV DESCRIPTION

DATE APPROVED

11"

8

1

2

"

L ENNIS

02-MAY-2011

INITIAL RELEASE

ADDED HEATER RELAY TO CONTROL & L-2/3 DESIGNATION2

17-MAY-2011

L ENNIS

L ENNIS

26-MAY-2011

BROWN COMPRESSOR WIRE WAS BLACK (ON DIAGRAM ONLY)3

6076XL-S, 6076XL-SH

9294477

L1

LINE VOLTAGE

115/60/1

SEE NAMEPLATE FOR MAXIMUM

FUSE SIZE

TEMPERATURE

CONTROL

L

N

CONTROL

CIRCUIT

5

2/3

F

6

FAN RELAY

H

4

HEATER

RELAY

C

1

COMPRESSOR

RELAY

1.1,2,3 2.1,2,3 3.1,2,3

(IF USED)

LED DISPLAY

SENSOR

CABINET AIR

EVAP COIL

SENSOR

ENERGY SAVER

SWITCH

DOOR

SWITCH

TEMPERATURE

CONTROL

L

N

CONTROL

CIRCUIT

5

2/3

F

6

FAN RELAY

H

4

HEATER

RELAY

C

1

COMPRESSOR

RELAY

1.1,2,3 2.1,2,3 3.1,2,3

(IF USED)

LED DISPLAY

SENSOR

CABINET AIR

EVAP COIL

SENSOR

ENERGY SAVER

SWITCH

DOOR

SWITCHES

EVAPORATOR FAN

COMPRESSOR

CONDENSOR FAN

DOOR FRAME

HEATER

INCANDESCENT

LIGHT

EVAPORATOR FAN

COMPRESSOR

CONDENSOR FAN

DOOR FRAME

HEATERS

INCANDESCENT

NOTES:

N

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

3) UNIT SHOWN WITH COMPRESSOR

RUNNING AND DOORS CLOSED

M

M

M

M

M

M

LIGHT

CONTROL

BOX

P

RED

BLK

DOOR

HINGE

SWITCH

ENERGY SAVER

SWITCH

GREY

C L

1 2

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

L

H N6F

3

FRAME HEATERS

EVAPORATOR HOUSING

EVAP FAN

MOTOR

M

Y

BLUE

SENSOR

SENSOR

EVAP COIL

CABINET AIR

W

W

WITH BLUE

STRIPES

W

54

W

LED DISPLAY

(IF USED)

W

6000XL Series Service and Installation Manual

PLUG

RECEPTICAL BOX

EVAPORATOR HOUSING

EVAP FAN

MOTOR

M

W

INCANDESCENT

LIGHT

CONTROL

WIRE

BOX

SWITCHES

ENERGY SAVER

SWITCH

P

GREY

C L

L

H N6F

BLK

1 2

54

3

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

DOOR

HINGE

DOOR FRAME HEATERS

10

START

SPLICE

WINDING

14

COMPRESSOR

NUT

POWER BOX

START RELAY

START

11

CAPACITOR

COMPRESSOR

GROUND

MOTOR PROTECTOR

RED

13

W

W

BLK

BRN

BLK

12

WINDING

CONDENSER

M

FAN

RUN

BLK

Y

BLUE

W

W

LED DISPLAY

W

(IF USED)

W

SENSOR

SENSOR

EVAP COIL

CABINET AIR

INCANDESCENT

LIGHT

W

W

WITH BLUE

STRIPES

W

W

BLK

W

BRN

BLK

M

CONDENSER

FAN

BLK

WINDING

12

RUN

SPLICE

10

STAR

WINDING

14

COMPRESSOR

POWER BOX

13

WIRE

NUT

START RELAY

START

11

CAPACITOR

COMPRESSOR

GROUND

MOTOR PROTECTOR

6076XL-G, 6076XL-GH

9294478

L1

LINE VOLTAGE

115/60/1

SEE NAMEPLATE FOR MAXIMUM

FUSE SIZE

TEMPERATURE

CONTROL

L

CONTROL

CIRCUIT

2/3N5

F

M

6

FAN RELAY

EVAPORATOR FAN

H

4

HEATER

RELAY

C

M

1

COMPRESSOR

RELAY

(IF USED)

LED DISPLAY

TEMPERATURE

CONTROL

FAN RELAY

HEATER

RELAY

COMPRESSOR

RELAY

(IF USED)

LED DISPLAY

ENERGY SAVER

ENERGY SAVER

SWITCH

CONTROL

CIRCUIT

SWITCH

COMPRESSOR

M

CONDENSOR FAN

SENSOR

CABINET AIR

EVAP COIL

SENSOR

DOOR FRAME

HEATER

FLUORESCENT

LAMP BALLAST

FLUORESCENT

LAMP

N

5

F

M

6

EVAPORATOR FAN

H

4

C

M

1

COMPRESSOR

M

CONDENSOR FAN

SENSOR

CABINET AIR

EVAP COIL

SENSOR

DOOR FRAME

HEATERS

FLUORESCENT

LAMP BALLAST

FLUORESCENT

LAMP

FLUORESCENT

LAMP BALLAST

FLUORESCENT

LAMP

1.1,2,3 2.1,2,3 3.1,2,3

FLUORESCENT

LAMP SWITCH

L

2/3

1.1,2,3 2.1,2,3 3.1,2,3

FLUORESCENT

LAMP SWITCHES

N

NOTES:

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

3) UNIT SHOWN WITH COMPRESSOR

RUNNING AND DOORS CLOSED

BLK

FLUORESCENT

LAMP

SWITCH

BLK W

P

BLK

CONTROL

BOX

ENERGY SAVER

SWITCH

P

GREY

NLC L H F

5

31 2

4 6

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

DOOR FRAME HEATER

FLUORESCENT LIGHT

BALLAST

RED

FLUORESCENT LAMP

FLUORESCENT LAMP ASSEMBLY

BLUE

W

W

LED DISPLAY

(IF USED)

W

BLUE

EVAPORATOR HOUSING

EVAP FAN

MOTOR

Y

SENSOR

EVAP COIL

CABINET AIR

W

WITH BLUE

STRIPES

BALLAST

BALLAST

BLUE

BLUE

W

PLUG

FLUORESCENT

LAMP

SWITCH

FLUORESCENT

LAMP

SWITCH

RECEPTICAL BOX

BLK

FLUORESCENT LIGHT

RED

BLK

FLUORESCENT LAMP

W

BLK

FLUORESCENT LIGHT

RED

FLUORESCENT LAMP

WBLK

FLUORESCENT LAMP ASSEMBLY

EVAPORATOR HOUSING

EVAP FAN

M

SENSOR

W

W

W

W

BLK

BRN

BLK

CONDENSER

M

FAN

BLK

WINDING

SPLICE

POWER BOX

START RELAY

10

11

12

START

13

WINDING

RUN

COMPRESSOR

GROUND

14

MOTOR PROTECTOR

COMPRESSOR

START

CAPACITOR

P

BLK

CONTROL

WIRE

BOX

NUT

ENERGY SAVER

SWITCH

P

GREY

L

H

LC

F6N

4

3

21

5

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

W

DOOR FRAME HEATERS

MOTOR

M

Y

BLUE

SENSOR

SENSOR

EVAP COIL

CABINET AIR

W

W

W

WITH BLUE

STRIPES

W

W

LED DISPLAY

(IF USED)

W

W

BLK

BRN

BLK

CONDENSER

M

FAN

BLK

WINDING

10

12

START

RUN

SPLICE

WINDING

14

11

13

COMPRESSOR

POWER BOX

START RELAY

COMPRESSOR

GROUND

MOTOR PROTECTOR

START

CAPACITOR

WIRE

NUT

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

11

Page 12

6000XL Series Service and Installation Manual

Delfield

Wiring Diagrams: Freezers

6125XL-S, 6125XL-SH

12

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

™

®

Page 13

Delfield

Wiring Diagrams: Freezers

6151XL-S, 6151XL-SH

L1

POWER SWITCH

L

3

1.1,2,3 2.1,2,3 3.1,2,3

9294124

LINE VOLTAGE

115/60/1

SEE NAMEPLATE FOR MAXIMUM

FUSE SIZE

TEMPERATURE

CONTROL

CONTROL

CIRCUIT

FAN RELAY

HEATER RELAY

COMPRESSOR

RELAY

(IF USED)

LED DISPLAY

SENSOR

EVAP COIL

SWITCH

DOOR

SWITCHES

NOTES:

N

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

3) UNIT SHOWN WITH COMPRESSOR

RUNNING AND DOORS CLOSED

N

5

F

6

H

4

C

1

M

EVAPORATOR FAN

DEFROST HEATER

M

COMPRESSOR

M

CONDENSOR FAN

CABINET AIR

SENSOR

DOOR FRAMEENERGY SAVER

HEATERS

INCANDESCENT

LIGHT

RED

DOOR

HINGE

SWITCHES

CONTROL

BOX

BLK

P

POWER SWITCH

ENERGY SAVER

SWITCH

GREY

H

L

4

2LC1 3

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

DOOR FRAME HEATERS

6000XL Series Service and Installation Manual

EVAPORATOR HOUSING

EVAP FAN

MOTOR

M

Y

DEFROST

BLUE

CABINET AIR

SENSOR

W

SENSOR

EVAP COIL

W

WITH BLUE

STRIPES

HEATER

BLK

BRN

M

CONDENSER

BLK

FAN

F

W

5N6

W

LED DISPLAY

W

(IF USED)

W

BLK

HIGH TEMP

SWITCH

W

INCANDESCENT

LIGHT

LIMIT

PLUG

POWER BOX

WIRE

W

NUT

SPLICE

W

MOTOR

PROTECTOR

S

1

2

N

L

C

START

WINDING

1

2

N

L

R

MAIN WINDING

5

4

START CAPACITOR

RUN CAPACITOR

2

1

COMPRESSOR

6176XL-S, 6176XL-SH

L1

SEE NAMEPLATE FOR MAXIMUM

TEMPERATURE

CONTROL

L

CONTROL

CIRCUIT

FAN RELAY

HEATER RELAY

COMPRESSOR

RELAY

1.1,2,3 2.1,2,3 3.1,2,3

(IF USED)

LED DISPLAY

SENSOR

EVAP COIL

ENERGY SAVER

SWITCH

DOOR

SWITCH

9294127

LINE VOLTAGE

115/208-230/60/1

FUSE SIZE

N

5F3

M

6

EVAPORATOR FAN

H

4

DEFROST HEATER

C

M

1

COMPRESSOR

M

CONDENSOR FAN

CABINET AIR

SENSOR

DOOR FRAME

HEATER

INCANDESCENT

LIGHT

N

CONDENSOR FAN

M

EVAPORATOR FAN

DEFROST HEATER

M

COMPRESSOR

M

DOOR FRAME

HEATERS

INCANDESCENT

LIGHT

TEMPERATURE

CONTROL

N

5

F

6

FAN RELAY

H

4

HEATER RELAY

C

1

1.1,2,3 2.1,2,3 3.1,2,3

(IF USED)

LED DISPLAY

SWITCHES

NOTES:

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

3) UNIT SHOWN WITH COMPRESSOR

RUNNING AND DOORS CLOSED

L2

POWER SWITCH

L

CONTROL

CIRCUIT

3

CONTROL

BOX

P

COMPRESSOR

RELAY

SENSOR

CABINET AIR

EVAP COIL

SENSOR

RED

BLK

ENERGY SAVER

SWITCH

DOOR

HINGE

DOOR

SWITCH

ENERGY SAVER

SWITCH

GREY

LC

H4L

3

1 2

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

FRAME HEATERS

NEMA 14-20P PLUG

RECEPTICAL BOX

EVAPORATOR HOUSING

EVAP FAN

MOTOR

HIGH TEMP

LIMIT

M

SENSOR

EVAP COIL

WITH BLUE

STRIPES

W

M

CONDENSER

FAN

DEFROST

HEATER

W

BLK

BRN

BLK

BLK

SWITCH

W

INCANDESCENT

LIGHT

CONTROL

DOOR

HINGE

SWITCHES

BOX

BLK

P

POWER SWITCH

ENERGY SAVER

SWITCH

GREY

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

DOOR FRAME HEATERS

N F

5 6L3L2C1H4

WIRE

SPLICE

MAIN WINDING

R

COMPRESSOR

POWER BOX

5

4

START CAPACITOR

RUN CAPACITOR

2

1

NUT

RED

W

W

MOTOR

PROTECTOR

C

S

START

WINDING

1

1

2

2

N

N

L

L

Y

BLUE

SENSOR

CABINET AIR

W

W

FN

5 6

W

LED DISPLAY

(IF USED)

W

EVAPORATOR HOUSING

EVAP FAN

MOTOR

HIGH TEMP

LIMIT

M

SENSOR

EVAP COIL

W

WITH BLUE

STRIPES

M

CONDENSER

DEFROST

HEATER

W

BLK

BRN

BLK

FAN

BLK

SWITCH

W

INCANDESCENT

LIGHT

WIRE

SPLICE

MAIN WINDING

R

COMPRESSOR

RUN CAPACITOR

2

5

1

4

START CAPACITOR

NUT

POWER BOX

W

W

MOTOR

PROTECTOR

C

S

START

WINDING

1

1

2

2

N

N

L

L

Y

BLUE

SENSOR

CABINET AIR

W

W

W

LED DISPLAY

W

(IF USED)

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

13

Page 14

6000XL Series Service and Installation Manual

Delfield

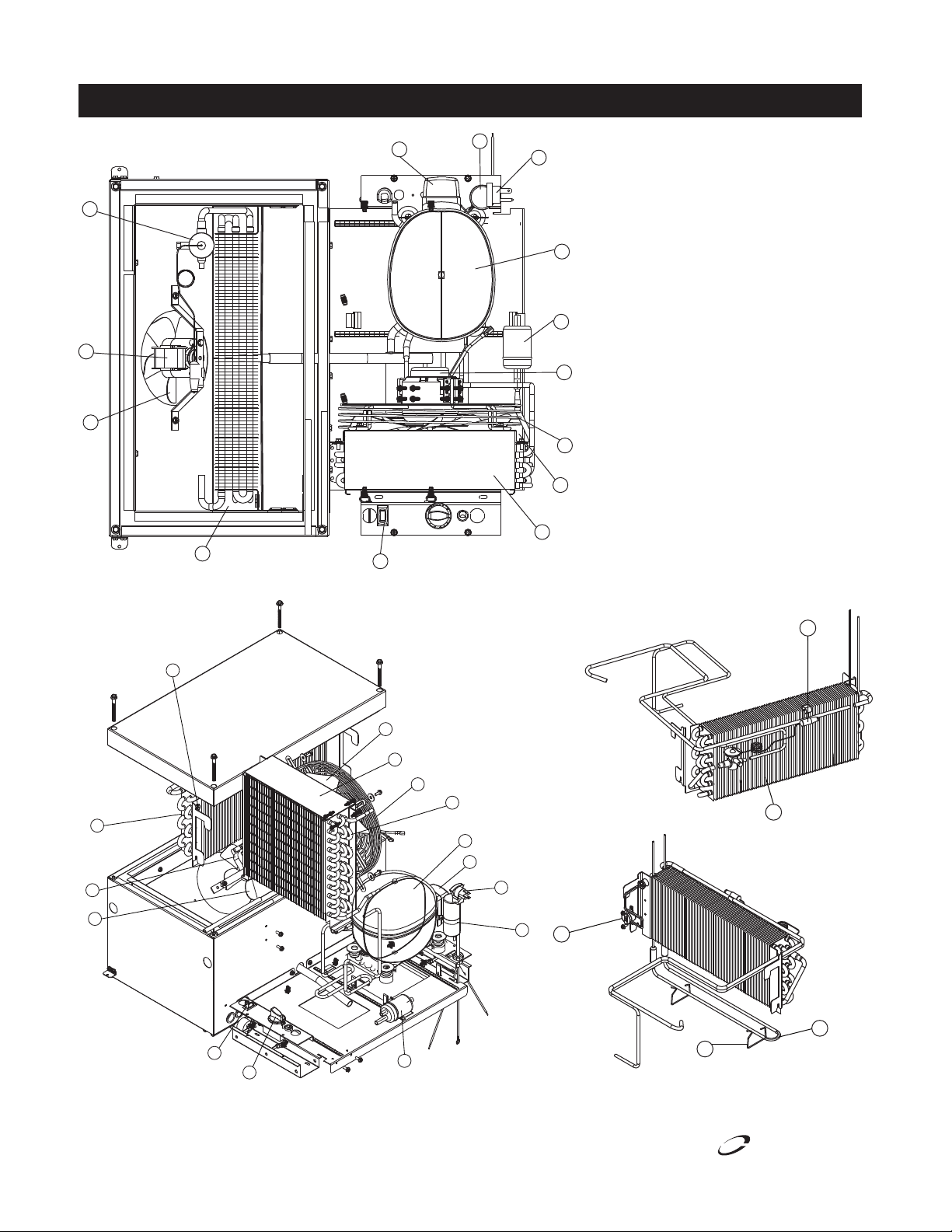

Refrigeration Package Diagram

16

17

4

7

15

18

5

12

6

14

11

9

1

3

8

21

13

9

14

11

1

5

6

3

2

18

15

16

4

17

21

20

7

19

14

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

™

®

Page 15

Delfield

Refrigeration Package - Replacement Parts

6000XL Series Service and Installation Manual

Refrigerator - 1 section & 3 section left package

Item Number Part Number 220V/50Hz

Part#

1 3516437 Coil, evaporator

2 (kit) 2194811KT 2194988KT Temperature Control

3 2190154 Switch, energy saver

4 2184181 Cord, power

5 2162715 2162719 Motor, fan, evaporator

6 3517390 Fan blade, evaporator

7 3516429 Valve, refrigerant, TXV

8 3516205 Clip, TXV bulb mounting

9 3516427 Coil, condenser

11 127-C33-0036 Shroud, condenser fan

12 2162717 2192720 Motor, fan, condenser, 9W

13 3516432 Fan blade, condenser

14 2160019 Guard, condenser fan

15 3526999 Compressor

15 3527013 Compressor, 50Hz - NL7CUX

16 3516444 Relay & overload, compressor

16 117U6002 50Hz Relay and overload, Danfoss p/n

17 2194787 Capacitor, compressor start, 280MFD

17 117U5015 50Hz Capacitor, start, 80MFD, Danfoss p/n

18 3516322 Filter-drier, refrigerant

1702795

3516041

Description

Condensate pan

Solenoid valve, used on remote units

Freezer- 1 section & 3 section left package

Item

Number

Part Number 220V/50Hz

1 3516436 Coil, evaporator

2 (kit) 2194812KT 2194964KT Control, ETC1, Kit

3 2194959 Switch, SPDT, energy saver

4 2184181 2194183 Cord, power

5 2162715 2162719 Motor, fan, evaporator

6 3517390 Fan blade, evaporator

7 3516588 Valve, refrigerant, TXV

8 3516205 Clip, TXV bulb mounting

9 3516427 Coil, condenser

11 127-C33-0036 Shroud, condenser fan

12 2162717 2162720 Motor, fan, condenser, 9W

13 3516432 Fan blade, condenser

14 2160019 Guard, condenser fan

15 3527001 Compressor

15 3527011 Compressor, 50 Hz - NL8.4CLX danfoss

16 3516441 Relay & overload, compressor

16 117U6019

17 2194789 Capacitor, compressor start, 240MFD

17

18 3516322 Filter-drier, refrigerant

19 2194785 2194967 Heater, defrost

20 9321629 Clip, defrost heater mounting

21 2194953 Switch, defrost safety, high limit

1702795

3516041

Part#

117U5017 50Hz Capacitor, start, 80MFD, Danfoss p/n

Description

50Hz Relay and overload, Danfoss p/n

Condensate pan

Solenoid valve, used on remote units

Refrigerator - 2 section & 3 section right package

Item Number Part Number 220V/50Hz

1 3516437 Coil, evaporator

2 (kit) 2194811KT 2194988KT Temperature Control

3 2190154 Switch, energy saver

4 2184181 Cord, power

5 2162715 2192719 Motor, fan, evaporator

6 3517390 Fan blade, evaporator

7 3516429 Valve, refrigerant, TXV

8 3516205 Clip, TXV bulb mounting

9 3516427 Coil, condenser

11 127-C33-0030 Shroud, condenser fan

12 2162716 2162721 Motor, fan, condenser, 16W

13 3516433 Fan blade, condenser

14 2160019 Guard, condenser fan

15 3527000 Compressor, Kit

15 3527012 Compressor, 50Hz - SC15CLX.2 danfoss

16 3516438 Relay & overload, compressor

16 117U6003 50Hz Relay and overload, Danfoss p/n

17 2194788 Capacitor, compressor start, 320MFD

17 117U5015 50Hz Capacitor, start, 80MFD, Danfoss p/n

18 3516322 Filter-drier, refrigerant

1702795

3516041

™

Part#

®

Description

Condensate pan

Solenoid valve, used on remote units

Freezer- 2 section & 3 section right package

Item

Number

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

Part Number 220V/50Hz Part# Description

1 3516436 Coil, evaporator

2 (kit) 2194812KT 2194964KT Control, ETC1, Kit

3 2194959

4 2184181 2194183 Cord, power

5 2162715 2162719 Motor, fan, evaporator

6 3517390 Fan blade, evaporator

7 3516588 Valve, refrigerant, TXV

8 3516205 Clip, TXV bulb mounting

9 3516427 Coil, condenser

11 127-C33-0030 Shroud, condenser fan

12 2162716 2162721 Motor, fan, condenser, 16W

13 3516433 Fan blade, condenser

14 2160019 G uard, condenser fan

15 3527002 Compressor, Kit

15 3527010 Compressor, 50Hz - Sc18CLX.2, danfoss

16 3516442 Relay and capacitor, compressor start, 125MFD

16

17

18 3516322 Filter-drier, refrigerant

19 2194785 2194967 Heater, defrost

20 9321629 Clip, defrost heater mounting

21 2194953 Switch, defrost safety, high limit

2190154

117U6013 50Hz Relay, Danfoss p/n

117U5012 50Hz Capacitor, start, 125MFD, Danfoss p/n

1702795

3516041

Switch, SPDT, energy saver

Switch, SPST, ON/OFF

Condensate pan

Solenoid valve, used on remote units

15

Page 16

6000XL Series Service and Installation Manual

Delfield

Replacement Parts

Miscellaneous Replacement Parts

Part Number D escription

2194791 Cable

3235514 Casters, rigid, One section only

3234778 Casters, swivel, w/o brake, Two & Three section

3234779 Casters, swivel, with brake

2194792 D isplay

3239590 D oor lock

3234791 Legs

3978270 Shelf, One Section, Three Section

3978277 Shelf LH, Two Section, Three Section

3978278 Shelf RH, Two Section, Three Section

5066440 Switch, rocker, door, SPDT-D8

3516204A

Stainless Steel Door Replacement Parts

Part Number D escription

2194005 Bulb, incandescent, 40W

2194145 Bulb, socket

000-AB9-013K Full Door, s/s, hinged left, edge mount hinges

000-AB9-013J Full Door, s/s, hinged right, edge mount hinges

000-AB9-013P Half Door, s/s, bottom left, edge mount hinges

000-AB9-013R Half Door, s/s, bottom right, edge mount hinges

000-AB9-013M Half Door, s/s, top left, edge mount hinges

000-AB9-013N Half Door, s/s, top right, edge mount hinges

3234617KT Hinge, 1-5/16" oset with adjustable housing

1702796 Gasket, full door. s/s

1702797 Gasket, half door, s/s

Vacuum breaker

Glass Door Replacement Parts

Part Number D escription

2194786 B allast

2194290 Bulb, uorescent, 18” coated, F15T8

000-AB9-013U Full door, glass, hinged left, edge mount hinges

000-AB9-013T Full door, glass, hinged right, edge mount hinges

000-AB9-013Y Half door, glass, bottom left, edge mount hinges

000-AB9-013Z Half door, glass, bottom right, edge mount hinges

000-AB9-013W Half door, glass, top left, edge mount hinges

000-AB9-013X Half door, glass, top right, edge mount hinges

3234617KT Hinge, 1-5/16" Oset with adjustable housing

1701901 Gasket, full door, glass

1701902 Gasket, half door, glass

2194289 Lampholder

16

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

™

®

Page 17

6000XL Series Service and Installation Manual

Delfield

Standard Labor Guidelines To Repair Or Replace Parts On Delfield Equipment

Advice and recommendations given by Delfield Service Technicians do not constitute or guarantee any special coverage.

•Amaximumof1-hourisallowedtodiagnose a defective component.

•Amaximumof1-hourisallowedforretrieval of parts not in stock.

•Amaximumtravel distance of 100 miles round trip and 2-hours will be reimbursed.

•Overtime,installation/start-up,normalcontroladjustments,generalmaintenance,glassbreakage,freightdamage,and/or

correcting and end-user installation error will not be reimbursed under warranty unless pre-approved with a Service Work

Authorization from Delfield. You must submit the number with the service claim.

LABOR OF 1-HOUR IS ALLOWED TO REPLACE:

•Thermostat • DoorJambSwitch

•Evaporator/CondenserFanMotorandBlade • SolenoidCoil

•Hi-limit/ThermalProtectorSwitch • FanDelay/DefrostTerminationSwitch

•CompressorStartComponentsandOverloadProtector • DoorHinges,Locks,andGaskets

•CondensateElement • Thermometer

LABOR OF 2 HOURS TO REPLACE:

•DefrostElement • SolenoidValve

•Locate/RepairLeak

LABOR OF 3 HOURS TO REPLACE:

•CondenserorEvaporatorCoil

•ExpansionValve

LABOR OF 4 HOURS TO REPLACE

•Compressor

This includes recovery of refrigerant and leak check.

$55.00 maximum reimbursement for refrigerant recovery (includes recovery machine, pump, torch, oil, flux, minor fittings,

solder, brazing rod, nitrogen, or similar fees.)

REFRIGERANTS

•R404AAmaximumof$15.00/lb.or$1.00/oz.willbereimbursed.

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

17

Page 18

6000XL Series Service and Installation Manual

Delfield

Manufacturers Limited Lifetime Warranty-ABS Liner

Delfield warrants to the original purchaser-user, subject to the

limitations and exclusions set forth below, that the ABS interior of the

Delfield models identified above will be free of manufactured defects

for as long as the equipment is owned by the original purchaser-user

and is in operation.

What is covered.

The interior liner of the 6000XL Series refrigerators are covered

against manufactured defects under normal use. For purposes of

this Warranty, interior liner is defined as the portion of the interior

liner which is made of ABS material. This warranty applies only to

products sold and installed after March 1, 2000 in the United States,

Canada, Puerto Rico, and Mexico. For purposes of this warranty,

lifetime is defined as the expected usable life for the equipment of 12

years.

Delfield’s Obligation

Limited strictly to shipping OEM replacement parts or repair kits

for any covered ABS interior. A Delfield authorized service dealer

and Delfield’s Service Department must confirm the liner defect

has occurred under normal conditions and is not due to misuse

as defined below. All decisions regarding the ABS interior shall be

made by Delfield’s Service Department and shall be binding upon

the parties. No labor or service charges or allowances are covered

by this warranty. Warranty service must be performed by a Delfield

approved authorized service agent.

User Responsibility

The product must be installed, cleaned and maintained as described

in the Service and Installation manual which is furnished with the

product. Only approved replacement parts may be used. Failure

to adhere to the requirements of this paragraph may void warranty

coverage.

Exclusions

This warranty does not cover labor, service, charges for travel time,

mileage, or premium charges. This warranty also does not include

defects resulting from:

• Operationoftheproductbeyondthespecicationsetforthinthe

Service and Installation Manual.

• Failuretocleanandmaintaintheproductasdescribedinthe

Service and Installation Manual.

•Installationoftheproductinamannerotherthanassetforthin

the Service and Installation.

• Useofinstallationofreplacementpartsnotapprovedby

Delfield; or

• TheintroductionhotitemsdirectlyontotheABSliner.

This warranty is in lieu of all other warranties or guarantees of

any kind, express or implied, except Delfield’s One Year Parts

and One year Labor Warranty. ANY IMPLIED WARRANTIES OR

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

ARE HEREBY DISCLAIMED AND EXCLUDED. IN NO EVENT SHALL

DELFIELD BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES OF ANY KIND OR NATURE, OR FOR ANY DEFECT

RESULTING IN WHOLE OR IN PART FROM MISUSE, ALTERATION,

IMPROPER INSTALLATION OR INADEQUATE MAINTENANCE OF THE

PRODUCT OR ANY PART THEREOF.

No part or assembly which has been subject to accident, alteration

or misuse, or which has not been installed or serviced in accordance

with the Operation Manual furnished with the product, or which is

from equipment on which the serial number has been altered or

removed, shall be covered by this warranty.

Procedures

All claims for replacement parts or repair kits must be made through

a Delfield Parts Depot or an authorized Delfield dealer. The defective

part invoice must be returned to Delfield within 15 days after the

date of service to be eligible for warranty coverage. All claims

must include the model number, serial number, an original date of

installation and customer identification. Use of parts other than

original Delfield replacement parts will not be covered.

18

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

™

®

Page 19

Delfield

Standard One Year Warranty (One Year Parts And Labor)

6000XL Series Service and Installation Manual

The Delfield Company (“Delfield”) warrants to the Original Purchaser

of the Delfield product (herein called the “Unit”) that such Unit, and all

parts thereof, will be free from defects in material and workmanship

under normal use and service for a period of one (1) year from

the date of shipment of the Unit to the Original Purchaser or, if the

Original Purchaser returns the warranty card completely filled out

including the date of installation within thirty (30) days of receipt

of the Unit, one (1) year from the date of installation. During this

one year warranty period, Delfield will repair or replace any defective

part or portion there of returned to Delfield by the Original Purchaser

which Delfield determines was defective due to faulty material or

workmanship. The Original purchaser will pay all labor, crating, freight

and related costs incurred in the removal of the Unit of defective

component and shipment to Delfield, except that during a period of

either ninety (90) days from the date of shipment of the Unit to the

Original Purchaser or, if the Original Purchaser returns the warranty

card completely filled out including the date of installation within thirty

(30) days of receipt of the Unit, ninety (90) days from the date of

installation Delfield will pay all related labor costs. Delfield will pay the

return costs if the Unit or part thereof was defective.

The term “Original Purchaser” as used herein means that person, firm,

association, or corporation for whom the Unit was originally installed.

This warranty does not apply to any Unit or part thereof that has

been subjected to misuse, neglect, alteration, or accident, such as

accidental damage to the exterior finish, operated contrary to the

recommendations specified by Delfield; or repaired or altered by anyone

other than Delfield in any way so as to, in Delfield’s sole judgement,

affect its quality or efficiency. This warranty does not apply to any Unit

that has been moved from the location where it was originally installed.

This warranty also does not cover the refrigerator drier or the light

bulbs used in the Unit. The warranty is subject to the user’s normal

maintenance and care responsibility as set forth in the Service and

Installation Manual, such as cleaning the condenser coil, and is in

lieu of all other obligations of Delfield. Delfield neither assumes, nor

authorizes any other person to assume for Delfield, any other liability

in connection with Delfield’s products.

basis, with credit being issued after the part has been received and

inspected at Delfield’s plant and determined by Delfield to be within this

warranty.

Under no condition does this warranty give the Original Purchaser the

right to replace the defective Unit with a complete Unit of the same

manufacturer or of another make. Unless authorized by Delfield in

writing, this warranty does not permit the replacement of any part,

including the motor-compressor, to be made with the part of another

make or manufacturer.

No claims can be made under this warranty for spoilage of any products

for any reason, including system failure.

The installation contractor shall be responsible for building access,

entrance and field conditions to insure sufficient clearance to allow any

hood(s), vent(s), or Unit(s) if necessary, to be brought into the building.

Delfield will not be responsible for structural changes or damages

incurred during installation of the Unit or any exhaust system.

Delfield shall not be liable in any manner for any default or delay in

performance hereunder caused by or resulting from any contingency

beyond Delfield’s control, including, but not limited to, war,

governmental restrictions or restraints, strike, lockouts, injunctions,

fire, flood, acts of nature, short or reduced supply of raw materials, or

discontinuance of the parts by the original part manufacturer.

Except as provided in any Additional Four Year Protection Plan,

if applicable, and the Service Labor Contract, if applicable, the

foregoing is exclusive and in lieu of all other warranties, whether

written or oral, express or implied. This warranty supersedes

and excludes any prior oral or written representations or

warranties. Delfield expressly disclaims any implied warranties

of merchantability, fitness for a particular purpose of compliance

with any law, treaty, rule or regulation relating to the discharge of

substances into the environment. The sole and exclusive remedies

of any person relating to the Unit, and the full liability of Delfield for

any breach of this warranty, will be as provided in this warranty.

Removal or defacement of the original Serial Number or Model Number

from any Unit shall be deemed to release Delfield from all obligations

hereunder or any other obligations, express or implied.

Parts furnished by suppliers to Delfield are guaranteed by Delfield only

to the extent of the original manufacturer’s express warranty to Delfield.

Failure of the Original Purchaser to receive such manufacturer’s express

warranty to Delfield. Failure of the Original Purchaser to receive such

manufacturers warranty shall in no way create any warranty, expressed

or implied, or any other obligation or liability on Delfield’s part in respect

thereof.

IF THE CUSTOMER IS USING A PART THAT RESULTS IN A VOIDED

WARRANTY AND A DELFIELD AUTHORIZED REPRESENTATIVE

TRAVELS TO THE INSTALLATION ADDRESS TO PERFORM WARRANTY

SERVICE, THE SERVICE REPRESENTATIVE WILL ADVISE CUSTOMER

THE WARRANTY IS VOID. SUCH SERVICE CALLS WILL BE BILLED

TO CUSTOMER AT THE AUTHORIZED SERVICE CENTER’S THEN

APPLICABLE TIME AND MATERIALS RATES. CONSIDER: CUSTOMER

MAY INITIATE A SERVICE AGREEMENT WITHOUT PARTS COVERAGE.

If shipment of a replacement part is requested prior to the arrival in

the Delfield factory of the part claimed to be defective, the Original

Purchaser must accept delivery of the replacement part of a C.O.D.

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

Other than this Delfield Standard One Year Limited Warranty, any

applicable Delfield Additional Four Year Protection Plan or applicable

Delfield Service Labor Contract, the Original Purchaser agrees and

acknowledges that no other warranties are offered or provided in

connection with or for the unit or any other part thereof.

In no event will Delfield be liable for special, incidental or consequential

damages, or for damages in the nature of penalties.

IF DURING THE WARRANTY PERIOD, CUSTOMER USES A PART FOR

THIS DELFIELD EQUIPMENT OTHER THAN AN UNMODIFIED NEW

OR RECYCLED PART PURCHASED DIRECTLY FROM DELFIELD OR

ANY OF ITS AUTHORIZED SERVICE CENTERS AND/OR THE PART

BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION,

THIS WARRANTY WILL BE VOID. FURTHER, DELFIELD AND ITS

AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS DAMAGES OR

EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY

OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION

OF ANY MODIFIED PART AND/OR PART RECEIVED FROM AN

UNAUTHORIZED SERVICE CENTER. If the warranty becomes void,

Customer may purchase from Delfield, if available, a Service

Agreement or service at the then current time and materials rate.

For more information on Delfield warranty’s log on and check out the

service section of our web site at www.delfield.com.

19

Page 20

™

®

Delfield

Mt. Pleasant, MI Covington, TN

Thank you for choosing Delfield!

Help is a phone call away. Help our team of professional, courteous

customer service reps by having your model number and serial number

available at the time of your call (800) 733-8829.

Model: ______________________ S/N: ______________________

Installation Date: ______________

For a list of Delfield’s authorized parts depots,

visit our website at www.delfield.com.

™

®

Delfield

980 S. Isabella Rd., Mt. Pleasant, MI 48858, U.S.A. • (989) 773-7981 or (800) 733-8829 • Fax (989) 773-3210 • www.deleld.com

Deleld reserves the right to make changes in design or specications without prior notice. ©2012 The Deleld Company. All rights reserved. Printed in the U.S.A.

DM6000XL 04/12

9294254

Loading...

Loading...