Page 1

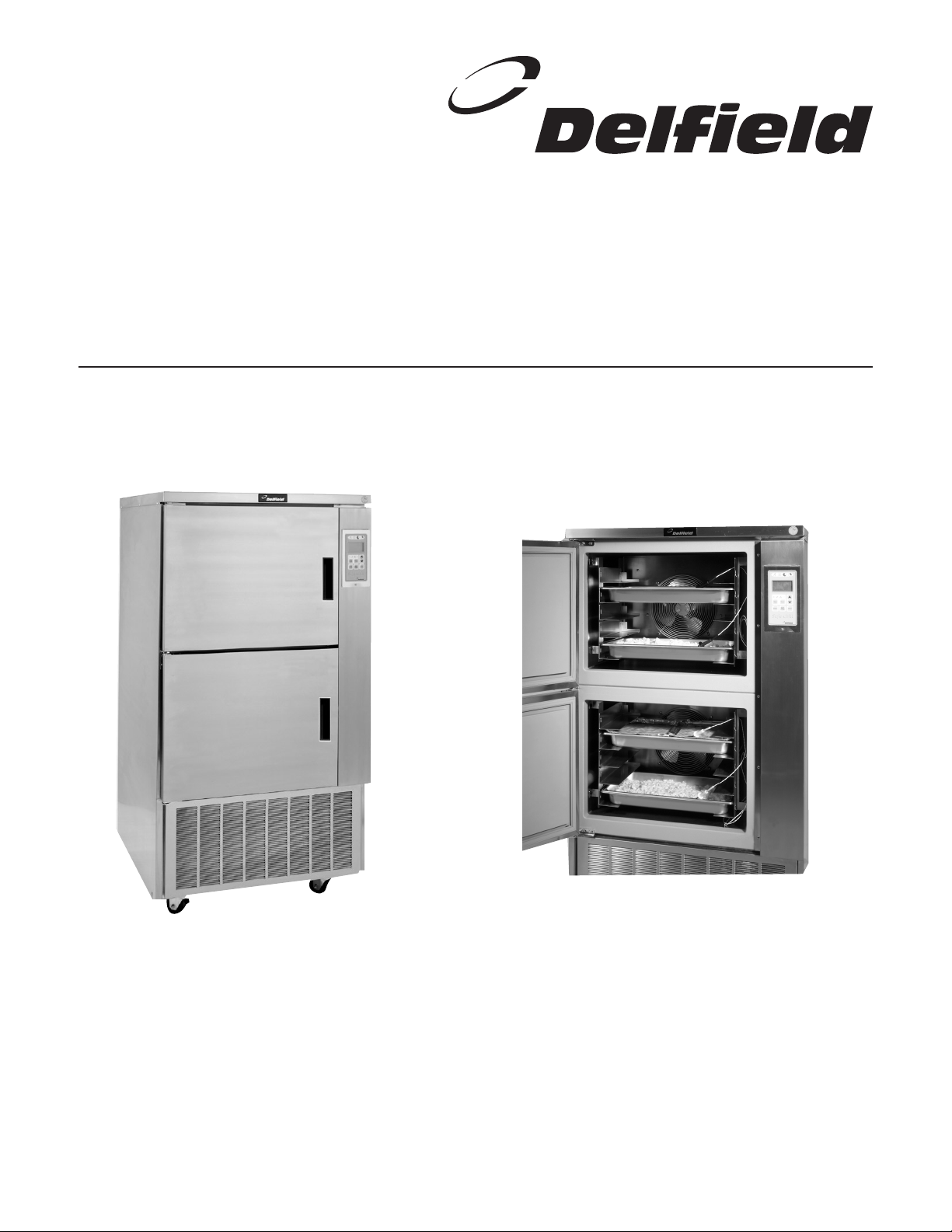

SAFE CHILL™ BLAST CHILLERS

Service, Installation and Care Manual

Please read this manual completely before attempting to install or operate this equipment! Notify

carrier of damage! Inspect all components immediately. See page 2.

Model DBC-10

EFFECTIVE JANUARY 2002

Page 2

Safe Chill™ Blast Chillers Service & Installation Manual

Contents

RECEIVING AND INSPECTING UNIT.................................. 2

MECHANICAL DATA ............................................................. 2

INSTALLATION................................................................... 3-5

OPERATION.......................................................................... 5

CONTROL............................................................................. 4

LIST OF PARAMETERS........................................................ 6

ROUTINE MAINTENANCE ................................................... 5

WIRING DIAGRAM ............................................................... 7

REPLACEMENT PARTS LIST............................................... 8

STANDARD WARRANTIES............................................ 10-11

AUTHORIZED PARTS DEPOTS ......................................... 12

Receiving and Inspecting the Equipment

Care should be taken during unloading so the equipment is not

damaged while being moved into the building.

Carefully check for any visible signs of damage to the cartons

or containers. If evidence of damage exists, the package

should be opened immediately and a joint inventory and

examination of the contents should be made by you and the

driver.

Serial Number Information

On Deleld’s Safe Chill™ Blast Chiller units, the serial tag is

located on the right hand interior side of the top cabinet.

Always have the serial number of your unit available when

calling for parts or service. A complete list of authorized

Deleld parts depots is shown on the back cover of this

manual.

This manual ©2002 The Deleld Company. All rights reserved. Reproduction

without written permission is prohibited. Safe Chill™ and Deleld are registered

trademarks of The Deleld Company.

Filing a claim

Notation of loss or damage does not constitute the ling of

a claim. You should le your claim in writing with the carrier

immediately.

Carriers will furnish the necessary form upon request. You

should also request an inspection. If a claim is led by phone,

always follow up immediately in writing.

Concealed damage

If a concealed loss or damage is discovered after you have

given the carrier a clear delivery receipt, notify the carrier in

writing immediately or within 10 days from the delivery date.

If you phone the carrier, you must follow up the call in writing

to protect your rights. You can only improve your position as

a claimant by promptly reporting such loss or damage. You

should also retain all cartons or containers, including packing

material, until an inspection has been made or waived.

Safe Chill™ Blast Chiller

Mechanical Data

MODEL # OF BTU SYS NEMA SHIP

NUMBER LENGTH DEPTH HEIGHT PANS HP AMPS REF CHG CAP PLUG WEIGHT

DBC-5 35.63 31.1 47.50 5 3/4 11/120v 56 oz. 4000 5-20P 410

DBC-5U 52.25 30.92 32 5 3/4 11/120v 56 oz. 4000 5-20P 410

DBC-10 35.63 31.1 70.50 10 (2)3/4 11 (120v/208-240v) (2) 56 oz. (2) 4000 14-20P 600

2

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Page 3

Installation

Location

Be sure the location chosen has a oor strong enough to

support the total weight of the cabinet and contents. Reinforce

the oor if necessary to provide for maximum loading.

For the most efcient operation, be sure to provide good air

circulation inside and out.

Inside cabinet: Do not pack the equipment so full that air cannot

circulate.

Outside cabinet: Be sure that the unit has access to ample air.

Avoid hot corners and locations near stoves and ovens.

Installation note: Evaporator drains are also located to the right

of the evaporator housing and run to a condensate evaporator

pan. No external drains are needed as this is all self contained.

Drain lines need to be kept free from obstruction to allow for

proper water removal.

Safe Chill™ Blast Chillers Service & Installation Manual

Stabilizing

All models are supplied on casters for your convenience, ease

of cleaning and mobility. It is very important, however, that the

cabinet be installed in a stable condition with the front wheels

locked while in use.

Should it become necessary to lay the unit on

its side or back for any reason, allow at least 24

hours before start-up so as to allow compressor

oil to ow back to the sump.

Electrical Connection

Refer to the amperage data on page 2, the serial tag, your

local code or the National Electrical Code to be sure the unit is

connected to the proper power source. A protected circuit of the

correct voltage and amperage must be run for connection of the

line cord, or permanent connection to the unit.

It is recommended that the unit be installed no closer than 2”

from any wall.

Leveling

A level cabinet looks better and will perform more efciently

when the doors line up with the door frames properly, the

cabinet will not be subject to undue strain, and the corners of

the shelves will not move around on the supports. Use a level to

make sure the unit is level from front to back and side to side.

The unit comes standard with non adjustable casters, a level

oor is very important. If it becomes necessary to level the unit

adjustable legs are available.

Operation Information

(SEE PAGE 4 FOR DIAGRAM OF CONTROL PANEL)

Operating Pressures

Normal operating pressures should be achieved during

the preservation mode, with approximately 75 of ambient

temperature. Freezer mode 15# suction and 220# discharge.

Chilling mode 55# suction and 220# discharge.

Blast Chilling (soft mode): This mode pulls the food down from

the starting temperature to food set point of 37˚F (FP1). Once

the temperature is obtained the unit sounds an alarm and either

switches to preservation mode automatically (after the alarm

times out) or manually. During pull down in soft mode, the blast

chiller maintains a box temperature of 23˚F (BT1). This mode is

primarily used for pulling down delicate foods.

The unit should be disconnected from the

power source whenever performing service,

maintenance functions or cleaning the

refrigerated area.

Be careful - the line cord is not run over by the

casters when moving the unit. This can damage

the cord.

Blast Chilling (timed mode): This mode operates in either a

soft or hard mode. The user can preset the amount of time the

chiller pulls down for up to 240 minutes (TC1). The unit will

pull down until the time is reached or the two probes hit 37˚F

(FP1). At this point the unit will sound an alarm and go into

preservation mode.

Freezer Mode: This mode pulls the food down from starting

point to 0˚F (FP3). In this mode the unit operates in a hard chill

mode until one of the two food probes reach 37˚F (FP1). At that

point the box temperature is pulled down to -25˚F (BT3) until the

food set point of 0˚F (FP3) is reached. At this point an alarm is

sounded and the unit can go into preservation mode.

Blast Chilling (hard mode): This mode operates the same way

as the soft mode except for the box temperature. During pull

down from start until one of the two food probes reaches 47˚F

(FP2) the box temperature is maintained at -5˚F (BT2), after

this point the box temperature is held at 23˚F (BT1) until the

food reaches 37˚F (FP1). This mode is for items that are harder

to pull down or if a faster chilling time is desired.

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Preservation Mode: After any of the above cycles reach their

set point, the unit will go into a preservation mode. This mode

will be held until the user terminates it. After chilling, the

food probes will maintain a temperature of 37˚F (FP1) using

a box temperature of 23˚F (BT1). After the freezing, the food

probes will maintain a temperature of 0˚F (FP3) using a box

temperature of -15˚F (BT3).

continued pg. 4

3

Page 4

Safe Chill™ Blast Chillers Service & Installation Manual

Safe Chill™ Control

Probe

Temp

Box

Temp

Time

Elapsed

Time

Remaining

OPERATION CONTINUED...

Defrost Mode: After chilling/freezing the unit will go into a

defrost mode for 15 minutes or until the coil reaches a

temperature of 70˚(DF1). During the freezer preservation mode

the defrost heater will operate for 15 minutes (DF2) or until the

coil reaches a temperature of 70˚F(DF1) every 6 hours (DF3).

Tandem Mode (DBC-10 only): In this mode, both the upper

and lower compartments will start at the same time running in

the same mode of operation (soft, hard, or freezer mode). Once

operating the compartments cycle independently. For example,

if the bottom compartment pulls down quicker than the top it will

shut down without affecting the tops operation.

Individual Mode (DBC-10 only): This mode allows operation of

the two compartments in different modes of operation starting

them at different times. For example, the top compartment can

be loaded to run in a timed soft chill cycle, and at any time the

bottom could be loaded in a freezer mode and started.

Operating the Control

1. Start Cycle (DBC-10 will start both upper and lower

units):

• Press MODE button, display will change.

• Press MODE button until desired mode (soft, hard, freeze)

appears in left hand upper corner of display.

• Press START/STOP button, unit will start cycle.

2. Start cycle in individual mode (DBC-10 only):

• Press MODE button, display will change

• Press MODE button until “Indiv” appears in left hand upper

corner of display.

• Press ENTER button.

• Press MODE button until desired mode (soft, hard, freeze)

appears in left hand upper corner of display.

• Press START/STOP button, unit will start cycle.

3. Start cycle in timed mode (DBC-10 only will start both

upper and lower units):

• Press MODE button, display will change

• Press MODE button until “Indiv” appears in left hand upper

corner of display.

• Press TIMED button, counter will appear in right hand

upper corner of display.

• Press UP/DOWN buttons to adjust timer to desired setting.

• Press START/STOP button, unit will start cycle.

4. To stop a cycle:

• Press START/STOP button for one second.

If unit is a DBC-5 or DBC-5U cycle will shut down.

DBC-10 If only one compartment is running, cycle will shut

down. If both compartments are running, display will prompt

you to shut entire unit down by pressing START/STOP

button. To shut down the individual compartments press

the UP button for the top or the DOWN button for the

bottom.

Soft

Chill

4

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Hard

Chill

Blast

Freeze

Dual

Mode

Page 5

OPERATION CONTINUED...

Safe Chill™ Blast Chillers Service & Installation Manual

5. Start cycle with one unit running (DBC-10 only):

• Press MODE button, display will change.

• Press MODE button until desired mode (soft, hard, freeze)

appears in left hand upper corner of display.

Press START/STOP button, unit will start cycle.

6. Adjusting parameters (using this function will affect

performance and should only be carried out by qualied

personnel.):

• Press and hold UP and MODE buttons until menu changes

to system menu.

• Press UP/DOWN button until “Preset Menu” is highlighted.

• Press UP/DOWN button until parameter to be adjusted is

shown.

To edit press ENTER button

Press UP/DOWN button until new setting is displayed.

Press ENTER to save.

• Press START/STOP to back out to previous menu.

7. Setting Clock.

Skip rst three steps if clock is being set from power startup

• Press and hold UP and MODE buttons until menu changes

to system menu.

• Press UP/DOWN button until “Clock setup” is highlighted.

• Press ENTER button to access Clock setup.

• Press UP/DOWN button until value to be adjusted is

highlighted.

• Press ENTER button to edit setting.

• Press UP/DOWN button until new setting is displayed.

• Press ENTER button to save setting.

• Repeat if additional settings require adjustment.

9. Alarms and Faults

The unit will sound an alarm upon the completion of a cycle

or if a fault occurs. The end of a cycle alarm is distinctively

different than the fault alarm. If a fault occurs an alarm will

sound and the display will prompt you to press the ENTER

button. The display will then show an explanation of the fault

that occurred. To end the fault message press START/STOP

button. This will repeat if there is more than one fault.

If the cycle that the fault occurred in is printed the print out

will place an “x” at the right hand side of the printout under

the letter that corresponds to that fault. See the list below for

the fault and its equivalent letter.

A .........Product Probe #1 open

B .........Product Probe #1 shorted

C .........Product Probe #2 open

D .........Product Probe #2 shorted

E .........Box temperature sensor open

F ......... Box temperature sensor shorted

G .........Defrost temperature sensor open

H .........Defrost temperature sensor shorted

I ......... Chill cycle time exceeded

J .........Food temperature below limit

K .........Power interrupted cycle

8. Printing

Print parameter (PR1) must be set to OFF (default) for unit

to print after cycle is complete. If PR1 is set to ON unit will

download information at the print intervals (PT1).

Information is downloaded to printer using the RS-232 port

under the touch pad. If information is to be downloaded to a

PC a crossed RS-232 cable must be used.

Unit will only print to an 80 character wide printer.

• The following instructions are for printing after cycle is

complete (PR1 set to OFF).

• For DBC-5 and DBC-5U press the PRINT button and unit

will begin downloading information. Print function will only

work if the selected units cycle is completed.

• Control only saves information from previous cycle; once a

new cycle is started the previous information is deleted.

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

5

Page 6

Safe Chill™ Blast Chillers Service & Installation Manual

MAINTENANCE

The interior and exterior can be cleaned using soap and warm

water. If this isn’t sufcient, try ammonia and water or a

nonabrasive liquid cleaner. When cleaning the exterior, always

rub with the “grain” of the metal to avoid marring the nish. Do

not use an abrasive cleaner because it will scratch the metal.

In order to maintain proper refrigeration performance, the condenser ns must be cleaned of dust, dirt and grease regularly.

The condenser coil is located behind the removable louvered

front and there are two coils located on the DBC-10. It is

recommended that these be cleaned at least once every three

months. If conditions are such that the condenser is totally

blocked in three months, the frequency of cleaning should

be increased. Clean the condenser with a vacuum cleaner

or stiff brush. If it’s extremely dirty, a commercially available

condenser cleaner may be required.

Door gaskets are dart style and can easily be replaced without

the use of any tools. Do not use sharp tools or knives to

scrape the bellows as this may tear the gasket and eliminate

its ability to seal. Door gaskets should be cleaned as required

to maintain their ability to seal properly. A soft bristle brush

and solution of soap and water will keep the gaskets clean. Do

not use full strength de-greasing agents on the gasket.

Pan slides are removable via the four thumb screws and are

made of stainless steel. They are dishwasher safe or can be

cleaned with soap and water.

Food Probes:

If necessary to check the probes, they are a 10,000 ohm

thermistor and it is important that they be kept away from

any high voltage wiring. There are four probes per section;

two food probes, one box probe and an evaporator probe.

Accessing the evaporator, expansion valve, and other evaporator components can be done by removing the pan slides and

pulling the evaporator housing away slowly as to not pull out

any wiring. Once access has been gained wire ties can be

cut and the housing can be removed. Food probes can be

cleaned with soap and water. For optimum use of the food

probes, do not allow the handle to rest in the food. When

removing a food probe from the food do not pull on the cable,

use the handle.

The control uses a lithium battery and may need to be

replaced approximately every ve years.

List of Parameters

PARAMETER

DESCRIPTION PARAMETER DEFAULT RANGE COMMENTS

Food probe

temperature (chilling) (FP1) 37˚F 28˚F to 40˚F

Food probe

temperature (hard chilling) (FP2) 47˚F 0˚F to 70˚F

Food probe

temperature (freezing) (FP3) 0˚F -20˚F to 10˚F

Box temperature

(soft/hard chilling) (BT1) 23˚F 20˚F to 37˚F

Box temperature

(hard chilling) (BT2) -5˚F 20˚F to 37˚F

Box temperature

(freezing hold) (BT3) -15˚F -5˚F to -30˚F

Maximum chill time (TC1) 240 minutes 0 to 240 minutes

Defrost termination

(temperature) (DF1) 55˚F 40˚F to 70˚F

Defrost termination (time) (DF2) 15 minutes 0 to 90 minutes

Defrost cycle time

(freezing) (DF3) 360 minutes 180 to 480 minutes

Print output (PR1) (PR1) OFF to PR1

Print interval (PT1) 5 minutes 0 to 480 minutes

Maximum coil temperature

(evaporator fan) (MCT) 30˚F 20˚F TO 60˚F

Chill time recall (CTR) Recall 0 to chill time alarm Stores last chill

(TC1) time /or preset

6

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Page 7

Wiring Diagram

Safe Chill™ Blast Chillers Service & Installation Manual

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

7

Page 8

Safe Chill™ Blast Chillers Service & Installation Manual

8

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Page 9

Safe Chill™ Blast Chillers Service & Installation Manual

Standard One Year Warranty

The Deleld Company (“Deleld”) warrants to the Original

Purchaser of the Deleld product (herein called the “Unit”) that

such Unit, and all parts thereof, will be free from defects in

material and workmanship under normal use and service for

a period of one (1) year from the date of shipment of the Unit

to the Original Purchaser or, if the Original Purchaser returns

the warranty card completely lled out including the date of

installation within thirty (30) days of receipt of the Unit, one

(1) year from the date of installation. During this one year warranty period, Deleld will repair or replace any defective part or

portion there of returned to Deleld by the Original Purchaser

which Deleld determines was defective due to faulty material

or workmanship. The Original purchaser will pay all labor,

crating, freight and related costs incurred in the removal of the

Unit of defective component and shipment to Deleld, except

that during a period of either ninety (90) days from the date

of shipment of the Unit to the Original Purchaser or if, the

Original Purchaser returns the warranty card completely lled

out including the date of installation within thirty (30) days of

receipt of the Unit, ninety (90) days from the date of installation

Deleld will pay all related labor costs. Deleld will pay the

return costs if the Unit or part thereof was defective.

The term “Original Purchaser” as used herein means that

person, rm, association, or corporation for whom the Unit was

originally installed.

This warranty does not apply to any Unit or part thereof

that has been subjected to misuse, neglect, alteration, or accident, such as accidental damage to the exterior nish, operated contrary to the recommendations specied by Deleld;

or repaired or altered by anyone other than Deleld in any

way so as to, in Deleld’s sole judgement, affect its quality or

efciency. This warranty does not apply to any Unit that has

been moved from the location where it was originally installed.

This warranty also does not cover the refrigerator drier or the

light bulbs used in the Unit. The warranty is subject to the

user’s normal maintenance and care responsibility as set forth

in the Service and Installation Manual, such as cleaning the

condenser coil, and is in lieu of all other obligations of Deleld.

Deleld neither assumes, nor authorizes any other person

to assume for Deleld, any other liability in connection with

Deleld’s products.

Removal or defacement of the original Serial Number or Model

Number from any Unit shall be deemed to release Deleld

from all obligations hereunder or any other obligations, express

or implied.

Parts furnished by suppliers to Deleld are guaranteed by

Deleld only to the extent of the original manufacturer’s

express warranty to Deleld.

Failure of the Original Purchaser to receive such manufacturers warranty shall in no way create any warranty, expressed

or implied, or any other obligation or liability on Deleld’s part

in respect thereof.

One year service, labor and parts.

If shipment of a replacement part is requested prior to the

arrival in the Deleld factory of the part claimed to be defective,

the Original Purchaser must accept delivery of the replacement part on a C.O.D. basis, with credit being issued after the

part has been received and inspected at Deleld’s plant and

determined by Deleld to be within this warranty.

Under no condition does this warranty give the Original Purchaser the right to replace the defective Unit with a complete

Unit of the same manufacturer or of another make. Unless

authorized by Deleld in writing, this warranty does not permit

the replacement of any part, including the motor-compressor,

to be made with the part of another make or manufacturer.

No claims can be made under this warranty for spoilage of any

products for any reason, including system failure.

The installation contractor shall be responsible for building

access, entrance and eld conditions to insure sufcient clearance to allow any hood(s), vent(s), or Unit(s) if necessary, to

be brought into the building. Deleld will not be responsible for

structural changes or damages incurred during installation of

the Unit or any exhaust system.

Deleld shall not be liable in any manner for any default

or delay in performance hereunder caused by or resulting

from any contingency beyond Deleld’s control, including, but

not limited to, war, governmental restrictions or restraints,

strike, lockouts, injunctions, re, ood, acts of nature, short or

reduced supply of raw materials, or discontinuance of the parts

by the original part manufacturer.

Except as provided in any Additional Four Year Protection

Plan, if applicable, and the Service Labor Contract, if applicable, the foregoing is exclusive and in lieu of all other warranties, whether written or oral, express or implied. This warranty

superseded and excludes any prior oral or written representations or warranties. Deleld expressly disclaims any implied

warranties of merchantability, tness for a particular purpose

of compliance with any law, treaty, rule or regulation relating

to the discharge of substances into the environment. The sole

and exclusive remedies of any person relating to the Unit, and

the full liability of Deleld for any breach of this warranty, will be

as provided in this warranty.

Other than this Deleld Standard One Year Limited Warranty,

any applicable Deleld Additional Four Year Protection Plan

or applicable Deleld Service Labor Contract, the Original

Purchaser agrees and acknowledges that no other warranties

are offered or provided in connection with or for the unit or any

other part thereof.

In no event will Deleld be liable for special, incidental or

consequential damages, or for damages in the nature of penalties.

10

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Page 10

Additional Four Year Protection Plan (for Motor-Compressors only)

Safe Chill™ Blast Chillers Service & Installation Manual

Installation

Deleld Model# Serial # Date

In addition to the Standard One Year Warranty on the MotorCompressor contained in the above listed Deleld product

(the “Unit”), The Deleld Company (“Deleld”) also agrees to

repair, or exchange with similar or interchangeable parts in

design and capacity at Deleld’s option, the defective MotorCompressor contained in the Unit (the “Motor-Compressor),

or any part thereof, for the Original Purchaser only, at any

time during the four (4) years following the initial one (1) year

period commencing on the date of installation for the Original

Purchaser. Failure of the Original Purchaser to register the

registration card containing the Original Purchasers name,

address, date of installation, model number and serial number

of the Unit containing the Motor-Compressor within 30 days

from the date of installation shall void this warranty. This

additional warranty is only available if the Motor-Compressor is

inoperative due to defects in material or factory workmanship,

as determined by Deleld in its sole judgement and discretion.

The Original Purchaser shall be responsible for returning the

defective Motor-Compressor to Deleld prepaid, F.O.B. at the

address shown on the back cover of this manual.

General Conditions

Deleld shall not be liable in any manner for any default

or delay in performance hereunder caused by or resulting

from any contingency beyond Deleld’s control, including, but

not limited to, war, governmental restrictions or restrains,

strike, lockouts, injunctions, re, ood, acts of nature, short or

reduced supply of raw materials, or discontinuance of any part

or the Motor-Compressor by the unit manufacturer.

Replacement of a defective Motor-Compressor is limited to

one (1) Motor-Compressor by us during the four (4) year

period. Deleld shall replace the Motor-Compressor at no

charge.

This warranty does not give the Original Purchaser of the

Motor-Compressor the right to purchase a complete replacement Motor-Compressor of the same make or of another

make. It further does not permit the replacement to be made

with a Motor-Compressor of another kind unless authorized

by Deleld. In the event Deleld authorizes the Original Purchaser to purchase a replacement Motor-Compressor locally,

only the wholesale cost of the Motor-Compressor is refundable.

Expressly excluded from this warranty are damages resulting

from spoilage of goods.

The term “Original Purchaser” as used herein means that

person, rm, association, or corporation for whom the Unit was

originally installed.

The term “Motor-Compressor” as used herein does not include

unit base, air or water cooled condenser, receiver, electrical

accessories such as relay, capacitors, refrigerant controls, or

condenser fan/motor assembly. This warranty does not cover

labor charges incidental to the replacement of parts. This

warranty further does not include any equipment to which said

condensing unit is connected, such as cooling coils, temperature controls or refrigerant metering devices. This warranty

shall be void if the Motor-Compressor, in Deleld’s sole judgement, has been subjected to misuse, neglect, alteration or

accident, operated contrary to the recommendations specied

by the Unit manufacturer, repaired or altered by anyone other

than Deleld in any way so as, in Deleld’s sole judgment, to

affect its quality or efciency or if the serial number has been

altered, defaced or removed. This Warranty does not apply

to a Motor-Compressor in any Unit that has been moved from

the location where it was originally installed. The addition of

methyl chloride to the condensing unit or refrigeration system

shall void this warranty.

Except as provided in any applicable Standard One Year Limited Warranty or applicable Service Labor Contract, the foregoing is exclusive and in lieu of all other warranties, whether

written or oral, express or implied. This Warranty supersedes

and excludes any prior oral or written representations or warranties. Deleld expressly disclaims any implied warranties of

merchantability, tness for a particular purpose or compliance

with any law, treaty, rule or regulation relating to the MotorCompressor, and the full liability of Deleld for any breach of

this warranty, will be as provided in this warranty.

Other than any applicable Deleld Standard One year Limited

Warranty, this Deleld Additional Four Year Protection Plan and

any applicable Deleld Service Labor Contract, the Original

Purchaser agrees and acknowledges that no other warranties

are offered or provided in connection with or for the MotorCompressor or any part thereof.

In no event will Deleld be liable for special, incidental or

consequential damages, or for damages in the nature of penalties.

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

11

Loading...

Loading...