Page 1

Shelleymatic

®

by Deleld

Dispensing Models

Service and Installation Manual

Please read this manual completely before attempting to install or operate this equipment! Notify carrier of damage! Inspect all

components immediately. See page 2.

DIS

Drop-in dish dispensers

TT

Mobile tray/rack

dispensers

CAB

Mobile enclosed dish

dispensers

CD

Disposable cup

dispensers

Also in this manual: ND, CP, CPB, CM,

CMB, T-H, T2, TGH AND F2-SN

CT

Mobile cantilever tray/rack

dispensers

TG

Built in tray and rack

dispensers

LT

Drop-in tray dispensers

WCT

Wall mounted cantilever

tray and rack dispensers

IMPORTANT INFORMATION

READ BEFORE USE

PLEASE SAVE THESE INSTRUCTIONS!

April 2010

Page 2

Dispensing Models Service and Installation Manual

CONTENTS

RECEIVING & INSPECTING EQUIPMENT..................................2

SPECIFICATIONS .....................................................................3-5

INSTALLATION ..........................................................................6

OPERATION .............................................................................7-8

WIRING DIAGRAMS .............................................................9-10

MAINTENANCE ........................................................................11

TROUBLESHOOTING REFERENCE CHART .............................12

ADJUSTING SELF-LEVELING DISPENSER .............................13

REPLACEMENT PARTS LIST ..............................................14-16

STANDARD LABOR GUIDELINES ............................................17

STANDARD WARRANTY .....................................................18-19

©2010 The Delfield Company. All rights reserved. Reproduction without written

permission is prohibited. “Delfield” & “Shelleymatic” are registered trademarks of

The Delfield Company.

SERIAL NUMBER LOCATION

Dish Dispensers: The serial number is located on the

dispenser housing. Non-heated equipment are not assigned

serial numbers.

Tray & Rack Dispensers: The serial number is located on the

back of the unit or the underside of the flange.

Mobile & Built in Chilled Plate & Mug dispensers: The

serial number is located near the compressor.

Always have the serial number of your unit available when

calling for parts or service.

The units represented in this manual are intended for indoor

use only.

RECEIVING AND INSPECTING THE EQUIPMENT

Even though most equipment is shipped crated, care should

be taken during unloading so the equipment is not damaged

while being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported

to the delivering carrier immediately.

2. If damaged, open and inspect the contents with the

carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notification should be made verbally

as well as in written form.

4. Request an inspection by the shipping company of the

damaged equipment. This should be done within 10

days from receipt of the equipment.

5. Check the lower portion of the unit to be sure the casters

are not bent.

6. Retain all crating material until an inspection has been

made or waived.

Uncrating the Equipment

First cut and remove the banding from around the crate.

Remove the front of the crate material, use of some tools will

be required. If the unit is on legs remove the top of the crate

as well and lift the unit off the skid. If the unit is on casters

it can be rolled off the skid.

2

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 3

SPECIFICATIONS

MODEL MAXIMUM VOLTAGE NEMA

NUMBER LENGTH DEPTH HEIGHT DISH DIA. (60Hz/1Ø) AMPS PLUG

Dish Dispensers — Mobile Two Stack

CAB2-500 28.25 17 36 5 N/A N/A N/A

CAB2-575 28.25 17 36 5.75 N/A N/A N/A

CAB2-650 28.25 17 36 6.5 N/A N/A N/A

CAB2-725 28.25 17 36 7.25 N/A N/A N/A

CAB2-813 32.25 17 36 8.12 N/A N/A N/A

CAB2-913 32.25 17 36 9.12 N/A N/A N/A

CAB2-1013 32.25 17 36 10.12 N/A N/A N/A

CAB2-1200 37 19 36 12 N/A N/A N/A

CAB2-1450 45 21.5 36 14.5 N/A N/A N/A

CAB2-500-ET 28.25 17 36 5 120 15.0 5-15P

CAB2-575-ET 28.25 17 36 5.75 120 15.0 5-15P

CAB2-650-ET 28.25 17 36 6.5 120 15.0 5-15P

CAB2-725-ET 28.25 17 36 7.25 120 15.0 5-15P

CAB2-813-ET 32.25 17 36 8.12 120 15.0 5-15P

CAB2-913-ET 32.25 17 36 9.12 120 15.0 5-15P

CAB2-1013-ET 32.25 17 36 10.12 120 15.0 5-15P

CAB2-1200-ET 37 19 36 12 120 15.0 5-15P

CAB2-1450-ET 42 21.5 36 14.5 120 15.0 5-15P

CAB2-813-QT 32.25 17 36 8.12 120 15.0 5-20P

CAB2-913-QT 32.25 17 36 9.12 120 15.0 5-20P

CAB2-1013-QT 32.25 17 36 10.12 120 15.0 5-20P

CAB2-1200-QT 37 19 36 12 120 15.0 5-20P

CAB2-1450-QT 42 21.5 36 14.5 120 15.0 5-20P

Dish Dispensers — Mobile Three Stack

CAB3-500 41.25 17 36 5 N/A N/A N/A

CAB3-575 41.25 17 36 5.75 N/A N/A N/A

CAB3-650 41.25 17 36 6.5 N/A N/A N/A

CAB3-725 41.25 17 36 7.25 N/A N/A N/A

CAB3-813 47.25 17 36 8.12 N/A N/A N/A

CAB3-913 47.25 17 36 9.12 N/A N/A N/A

CAB3-1013 47.25 17 36 10.12 N/A N/A N/A

CAB3-1200 53.25 19 36 12 N/A N/A N/A

CAB3-1450 62 21.5 36 14.5 N/A N/A N/A

CAB3-500-ET 41.25 17 36 5 208 9.0 6-20P

CAB3-575-ET 41.25 17 36 5.75 208 9.0 6-20P

CAB3-650-ET 41.25 17 36 6.5 208 9.0 6-20P

CAB3-725-ET 41.25 17 36 7.25 208 9.0 6-20P

CAB3-813-ET 47.25 17 36 8.12 208 9.0 6-20P

CAB3-913-ET 47.25 17 36 9.12 208 9.0 6-20P

CAB3-1013-ET 47.25 17 36 10.12 208 9.0 6-20P

CAB3-1200-ET 53.25 19 36 12 208 9.0 6-20P

CAB3-1450-ET 62 21.5 36 14.5 208 9.0 6-20P

CAB3-813-QT 47.25 17 36 8.12 208 13.0 6-20P

CAB3-913-QT 47.25 17 36 9.12 208 13.0 6-20P

CAB3-1013-QT 47.25 17 36 10.12 208 13.0 6-20P

CAB3-1200-QT 53.25 19 36 12 208 13.0 6-20P

CAB3-1450-QT 62 21.5 36 14.5 208 13.0 6-20P

Dispensing Models Service and Installation Manual

MODEL MAXIMUM VOLTAGE NEMA

NUMBER LENGTH DEPTH HEIGHT DISH DIA. (60Hz/1Ø) AMPS PLUG

Dish Dispensers — Mobile Four Stack

CAB4-500 27 27 36 5 N/A N/A N/A

CAB4-575 27 27 36 5.75 N/A N/A N/A

CAB4-650 27 27 36 6.5 N/A N/A N/A

CAB4-725 27 27 36 7.25 N/A N/A N/A

CAB4-813 32.25 32.25 36 8.12 N/A N/A N/A

CAB4-913 32.25 32.25 36 9.12 N/A N/A N/A

CAB4-1013 32.25 32.25 36 10.12 N/A N/A N/A

CAB4-1200 36 36 36 12 N/A N/A N/A

CAB4-1450 42 42 36 14.5 N/A N/A N/A

CAB4-500-ET 27 27 36 5 208 17.0 6-20P

CAB4-575-ET 27 27 36 5.75 208 17.0 6-20P

CAB4-650-ET 27 27 36 6.5 208 17.0 6-20P

CAB4-725-ET 27 27 36 7.25 208 17.0 6-20P

CAB4-813-ET 32.25 32.25 36 8.12 208 17.0 6-20P

CAB4-913-ET 32.25 32.25 36 9.12 208 17.0 6-20P

CAB4-1013-ET 32.25 32.25 36 10.12 208 17.0 6-20P

CAB4-1200-ET 36 36 36 12 208 17.0 6-20P

CAB4-1450-ET 42 42 42 14.5 208 17.0 6-20P

CAB4-813-QT 32.25 32.25 36 8.12 208 17.0 6-20P

CAB4-913-QT 32.25 32.25 36 9.12 208 17.0 6-20P

CAB4-1013-QT 32.25 32.25 36 10.12 208 17.0 6-20P

CAB4-1200-QT 36 36 36 12 208 17.0 6-20P

CAB4-1450-QT 42 42 42 14.5 208 17.0 6-20P

All dimensions shown in specifications are in

inches. For centimeters, multiply by 2.54.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

3

Page 4

Dispensing Models Service and Installation Manual

SPECIFICATIONS

MODEL FLANGE CUTOUT MAXIMUM VOLTAGE NEMA

NUMBER DIA. HEIGHT DIA. DISH DIA. (60Hz/1Ø) AMPS PLUG

Dish Dispensers — Drop-In

DIS-500 8.37 28 7.75 5 N/A N/A N/A

DIS-575 9.12 28 8.5 5.75 N/A N/A N/A

DIS-650 9.87 28 9.25 6.5 N/A N/A N/A

DIS-725 10.62 28 10 7.25 N/A N/A N/A

DIS-813 11.5 28 10.87 8.12 N/A N/A N/A

DIS-913 12.5 28 11.87 9.12 N/A N/A N/A

DIS-1013 13.5 28 12.87 10.12 N/A N/A N/A

DIS-1200 15.37 28 14.75 12 N/A N/A N/A

DIS-1450 17.88 28 17.25 14.5 N/A N/A N/A

Dish Dispensers — Drop-In/Heated

DIS-500-ET 8.37 28 7.75 5 120 8.0 5-15P

DIS-575-ET 9.12 28 8.5 5.75 120 8.0 5-15P

DIS-650-ET 9.87 28 9.25 6.5 120 8.0 5-15P

DIS-725-ET 10.62 28 10 7.25 120 8.0 5-15P

DIS-813-ET 11.5 28 10.87 8.12 120 8.0 5-15P

DIS-913-ET 12.5 28 11.87 9.12 120 8.0 5-15P

DIS-1013-ET 13.5 28 12.87 10.12 120 8.0 5-15P

DIS-1200-ET 15.37 28 14.75 12 120 8.0 5-15P

DIS-1450-ET 17.88 28 17.25 14.5 120 8.0 5-15P

Dish Dispensers — Drop-In/Heated/Quick Temp

DIS-813-QT 11.5 28 10.87 8.12 120 8.0 5-15P

DIS-913-QT 12.5 28 11.87 9.12 120 8.0 5-15P

DIS-1013-QT 13.5 28 12.87 10.12 120 8.0 5-15P

DIS-1200-QT 15.37 28 14.75 12 120 8.0 5-15P

DIS-1450-QT 17.88 28 17.25 14.5 120 8.0 5-15P

MODEL CUTOUT MAXIMUM

NUMBER SIZE RACK/TRAY SIZE LENGTH DEPTH HEIGHT

Tray/Rack Dispensers

LT-2020 22.75 X 26 20 X 20 26.75 27.13 27.5

LT2-1221 27 X 27.75 10 X 20 31.75 28.13 27.5

LT2-1014 23.75 X 21 12 X 16 23.13 31.75 27.5

LT2-1216 27.75 X 22 14 X 21 31.75 28.13 27.5

T-2020 N/A 20 X 20 27.75 28.13 36

TT2-2020 N/A 20 X 20 26.25 25.75 37.75

LT-1014 11.75 X 21 10 X 15 15.75 22.13 27.5

LT-1216 17.75 X 21 12 X 16 21.75 19.13 27.5

LT-1222 19.75 X 21 12 X 21 26.75 19.13 27.5

LT-1418 23.75 X 21 16 X 22 23.75 21.13 27.5

LT-1422 23.75 X 20 14 X 22 27.75 21.13 27.5

LT-1622 27.75 X 21 18 X 26 27.75 23.13 27.5

LT-1826 23.75 X 21 10 X 14 31.75 25.13 27.5

CT-1216 N/A 12 X 16 13 N/A 37

CT-1221 N/A 12 X 21 15 N/A 37

CT-1418 N/A 14 X 18 15 N/A 37

CT-1422 N/A 14 X 22 15 N/A 37

CT-1622 N/A 16 X 22 17.25 N/A 37

CT-1826 N/A 18 X 26 21 N/A 37

CT-2020 N/A 20 X 20 21 N/A 37

T-1014 N/A 10 X15 23.13 16.75 36

T-1216 N/A 12 X 16 22.75 20.13 36

T-1221 N/A 12 X 21 27.25 20.13 36

T-1418 N/A 14 X 18 24.75 22.13 36

T-1422 N/A 14 X 22 28.75 22.13 36

T-1622 N/A 16 X 22 28.75 24.13 36

T-1826 N/A 18 X 26 32.75 26.13 36

T-2020 N/A 20 X 20 27.75 28.13 36

T2-1014 N/A 10 X 15 27.75 22.13 36

T2-1216 N/A 12 X 16 32.75 24.13 36

T2-1221 N/A 12 X 21 32.75 29.13 36

TT-1014 N/A 10 X 14 21.25 15.25 37.75

TT-1216 N/A 12 X 16 18.25 20.75 37.75

TT-1221 N/A 12 X 22 18.25 26.75 37.75

TT-1418 N/A 14 X 18 20.25 22.75 37.75

TT-1422 N/A 14 X 22 21.25 26.75 37.75

TT-1622 N/A 16 X 22 22.25 26.75 37.75

TT-1826 N/A 18 X 26 24.26 30.75 37.75

TT-2020 N/A 20 x 20 26.25 25.75 37.7

TT2-1014 N/A 10 X14 21.25 26.75 37.75

TT2-1216 N/A 12 X 16 36.5 20.75 37.75

TT2-1221 N/A 12 X 22 36.5 25.75 37.75

TT2-1418 N/A 14 X 18 40.5 22.75 37.75

TT2-1422 N/A 14 X 22 40.5 26.75 37.75

TT2-1622 N/A 16 X 22 44.5 26.75 37.75

TT2-1826 N/A 18 X 26 48.5 30.75 37.75

TT2-2020 N/A 20 x 20 52.5 25.75 37.75

All dimensions shown in specifications are in

inches. For centimeters, multiply by 2.54.

4

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 5

SPECIFICATIONS

MODEL FLANGE CUTOUT DISH SHIP

NUMBER DIAMETER HEIGHT DIAMETER DIAMETER WEIGHT

DISPOSABLE CUP DISPENSERS

CD 7.38” 24.5” 5.12” 2.5”-4.63” —

BREAD DISPENSERS

SB-1 6.63” 6.63” 28” 5.87” X 5.87" 15

MODEL CUTOUT NAPKIN SHIP

NUMBER L D H DIMENSION DIMENSIONS WEIGHT

NAPKIN DISPENSERS

ND-45 7.62” 6” 24” 7” X 5.62” 4” X 5.37” 12

ND-47 9.37” 6.25” 24” 8.75” X 5.87” 4.25” X 7.12” 12

ND-48 10.25” 6.25” 24” 9.62” X 6.12” 4.5” X 8” 12

ND-57 9.25” 7.12” 24” 8.62” X 6.75” 5.12” X 7” 12

ND-59 11” 6.75” 24” 10.37” X 6.37” 4.75” X 7.75” 12

ND-67 9.37” 8.17” 24” 8.75” X 8.5” 6.87” X 7.12” 12

MODEL SHIP

NUMBER L D H CAPACITY H.P. AMP WEIGHT

MOBILE CHILLED PLATE DISPENSERS

CP-2 32.5” 28” 36” 100 1/3 10.0 410

CP-4 48” 28” 36” 200 1/3 10.0 485

CP series include a 8" cord with nema 5-15p plug.

BUILT-IN CHILLED PLATE DISPENSERS

CPB-2 32” 27.75” 29.63” 100 1/3 10.0 360

CPB-4 47.5” 27.75” 29.63” 200 1/3 10.0 385

CPB series include a 8" cord with nema 5-15p plug.

MOBILE CHILLED MUG DISPENSERS

CM-2 48” 28” 36” 60 1/3 10.0 485

CM series include a 8" cord with nema 5-15p plug.

BUILT-IN CHILLED MUG DISPENSERS

CMB-2 47.5” 27.5” 29.63” 60 1/3 10.0 385

CMB series include a 8" cord with nema 5-15p plug.

MODEL SHIP

NUMBER L D H CAPACITY AMP WEIGHT

HEATED MOBILE ENCLOSED TRAY AND RACK DISPENSERS

T-1221H 27.75” 20.12” 36” 12” X 21” 7.0 127

T-1418H 24.75” 22.12” 36” 14” X 18” 7.0 155

T-1221H and T-1418H Includes a 5’ cord with nema 5-15p plug.

T-1422H 28.75” 22.12” 36” 14” X 22” 14.0 155

T-1826H 32.75” 26.12” 36” 18” X 26” 14.0 195

T-2020H 27.75” 28.12” 36” 20” X 21” 14.0 185

T-1422H, T-1826H and T-2020H Includes a 5’ cord with nema 5-20p plug.

Dispensing Models Service and Installation Manual

MODEL CUTOUT MAXIMUM SHIP

NUMBER L D H DIMENSION TRAY SIZE AMP WEIGHT

BUILT-IN TRAY AND RACK DISPENSERS

TG-1014

21.38” 14” 28” 16.88” X 11.5” 10” X 15” — 120

TG-1216

18.38” 20” 28” 13.88” X 17.5” 12” X 16” — 128

TG-1221

18.38” 25” 28” 13.88” X 22.5” 12” X 21” — 137

TG-1418

20.38” 22” 28” 15.88” X 19.5” 14” X 18” — 128

TG-1422

26” 20.38” 28” 23.5” X 15.88” 14” X 22” — 121

TG-1622

22.38” 26” 28” 17.88” X 23.5” 16” X 22” — 152

TG-1826

30” 24.38” 28” 27.5” X 19.88” 18” X 26” — 164

TG-2020

25” 26.38” 28” 22.5” X 21.88” 20” X 21” — 159

TWO STACK BUILT-IN TRAY AND RACK DISPENSERS

TG2-1014

21.38” 25.63” 28” 16.88” X 23.12” 10” X 15” — 152

TG2-1216

22.38” 29.63” 28” 17.88” X 27.12” 12” X 16” — 152

TG2-1221

29.63” 29.38” 28” 27.12” X 22.88” 12” X 21” — 159

BUILT-IN HEATED TRAY AND RACK DISPENSERS

TG-1221H

25” 20.38” 28” 22.5” X 13.88” 12” X 21” 7.0 121

TG-1418H

22” 22.38” 28” 19.5” X 15.88” 14” X 18” 7.0 174

TG-1422H

26” 22.38” 28” 23.5” X 15.88” 14” X 22” 7.0 174

TG-1826H

30” 26.38” 28” 27.5” X 19.88” 18” X 26” 14.0 184

TG-2020H

25” 28.38” 28” 22.5” X 21.88” 20” X 21” 14.0 169

TGH series include a 9" cord with nema 5-15p plug.

TWO STACK HEATED BUILT-IN TRAY AND RACK DISPENSERS

TG2-1221H

TG2-H unit include a 9" cord with nema 5-15p plug

MODEL MAXIMUM SHIP

NUMBER L D H TRAY SIZE WEIGHT

WALL-MOUNTED CANTILEVER TRAY AND RACK DISPENSERS

WCT-1216 13” 22.25” 32” 12” X 16” 81

WCT-1221 13” 27.25” 32” 12” X 21” 95

WCT-1418 15” 24.25” 32” 14” X 18” 98

WCT-1422 15” 28.25” 32” 14” X 22” 101

WCT-1622 17.25” 28.25” 32” 16” X 22” 109

WCT-1826 21” 32.25” 32” 18” X 26” 119

WCT-2020 21” 27.25” 32” 20” X 21” 110

MODEL MAXIMUM SHIP

NUMBER L D H TRAY SIZE WEIGHT

TWO STACK, MOBILE OPEN FRAME TRAY AND RACK DISPENSERS

with silverware bin and napkin dispensers

FT2-SN-1216* 43.75” 22.12” 56.38” 12” X 16” 289

FT2-SN-1418* 47.75” 22.12” 56.38” 14” X 18” 298

FT2-SN-1622* 51.75” 22.12” 56.38” 16” X 22” 306

*Add 1.75” for each dimension to account for bumpers.

29.63” 29.38” 28” 27.13” X 22.88” 12” X 21” 7.0 169

TWO STACK, HEATED MOBILE ENCLOSED TRAY AND RACK DISPENSERS

T2-1221H 32.75” 29.12” 36” 12” X 21” 14.0 185

T2-H series include a 5’ cord with nema 5-20p plug.

All dimensions shown in specifications are in

inches. For centimeters, multiply by 2.54.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

5

Page 6

Dispensing Models Service and Installation Manual

DA RNGE

DA RNGE

DA RNGE

INSTALLATION: DISH DISPENSERS

Location

Drop-in units require a counter cutout of a specific size

for proper fit. Refer to specification data on page three for

the proper dimensions.

Heated units must have minimum 1” (2.5cm) air

gap between the bottom of the dispensing tube and

any surface or objects below. Make sure the tube

will have proper clearance when installing it into a

counter or another piece of equipment.

Stabilizing

CAB models are supplied with casters for your convenience,

for ease of cleaning underneath and mobility.

The unit must be installed in a stable condition

with the front wheels locked. Locking the front

casters after installation is the owner’s and

operator’s responsibility.

Electrical Connection

All heated DIS and CAB models are tested at the factory to

assure proper operation.

Refer to the amperage data on page three, the serial tag, your

local or the National Electrical Code to be sure the unit is

connected to the proper power source. A protected circuit of

the correct voltage and amperage must run for connection of

the line cord.

DIS models plug into a wall receptacle when used as drop-in

models; if they are grouped together in a CAB model, all of the

individual DIS power cords are plugged into the receptacle in

the CAB cabinet. The master power cord on CAB models plugs

into a wall receptacle.

The unit must be disconnected from the

power source whenever performing service or

maintenance functions.

INSTALLATION: MOBILE AND BUILT-IN CHILLED PLATE AND MUG DISPENSERS

Location

For built-in models (CPB & CMB) be sure the location

chosen has a floor strong enough to support the total

weight of the cabinet and contents. Units in this product

line can weigh as much as 1500 pounds when fully

loaded. Reinforce the floor as necessary to provide for

maximum loading.

Cutout dimensions for CPB-2 and CPB-4 are 13.25” x 23/

25”; two cutouts, 2.125” apart are required on the CPB-4.

Cutout dimensions for the CMB-2 are 25.25” x 22.25”

For the most efficient refrigeration, be sure to provide

good air circulation inside and out. On the CP and CM

mobile units, allow 3.50” clearance for air circulation.

For built in units be sure there is ample air flow from front and

rear of unit with ventilation openings equivalent to one square

foot of opening.

INSTALLATION: NAPKIN/CUP DISPENSERS

Napkin and cup units require a counter cutout of a specific

size for proper fit. Refer to specification data on page three

for the proper dimensions.

Refer to the amperage data on page three, the

serial tag, your local or the National Electrical Code

to be sure the unit is connected to the proper power

source. A protected circuit of the correct voltage and

amperage must run for connection of the line cord.

The unit must be disconnected from the

power source whenever performing service or

maintenance functions.

6

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 7

Spring Requirements

MODEL

SPRING TENSION

DIS-500, 575, 650, 725

DIS-813

DIS-913

DIS-1013

DIS-1200

DIS-1450

LIGHT

3

3

3

6

6

6

MEDIUM

3

3

6

6

6

6

HEAVY

0

3

3

3

6

6

DA RNGE

W ARE

DA RNGE

TUBE

FRAME

CARRIER

BRACKET

SPRINGS

H

= HIGH TENTION SPRING

M

= MEDIUM TENTION SPRING

L

= LOW TENSION SPRING

TYPICAL EXAMPLE OF SPRING

PLACEMENT. NOTE THAT EACH OF THE

THREE SECTIONS HAS THE SAME

NUMBER AND TYPE OF SPRINGS AND

THAT THE SPRINGS ARE INSTALLED

IN THE SAME ORDER IN EACH

SECTION.

OPERATION DISH DISPENSERS

Field adjustment

The dispensing height may be adjusted, by following these

instructions in order:

Always wear safety glasses when adjusting

your dispenser. Springs under tension may

recoil when released.

If adjusting a heated model, unplug the unit. Allow

the unit to cool completely before handling.

1) Lock brakes on mobile units before beginning.

2) Unload the dispenser. Remove dispensers from the unit

by grasping the black plastic guide posts and lifting the

dispenser completely out of the unit.

3) There are minimum of six springs per dispenser. When

adjusting, make sure each section has the same number

and size of springs connected to the tube and make sure the

springs are attached in the same order in each section (see

diagram 1). This will prevent the load of dishes from binding.

Dispensing Models Service and Installation Manual

Parts and Service Department). Gently disengage one spring

at a time, unhooking the bottom loop out of the carrier

bracket first, the unhooking the top loop from the tube frame.

(see diagram 2). Remove as many springs as necessary.

6) If level is appropriate, return tube to cart or counter. If

spring adjustment does not position carrier properly, repeat

procedure trying different springs. If this does not work,

a different set of springs may be required. To order call

Loading instructions

After adjusting for dispensing height, you are ready to load

your dishes.

Only load a manageable stack of dishes at a time —

approximately 4” (10.2cm) to 5” (12.7cm). Each DIS model

dispensing tube will accommodate a 26” (66cm) stack of plates

or bowls.

4) If the dispensing

5) If the dishes are resting too high in the unit, remove springs

(diagram 1)

height is too low, add

springs or replace

current springs with

higher tension springs

(springs with higher

tension may be

ordered from Delfield’s

Parts and Service

Department). Gently

engage one spring at

a time by hooking

the top loop of

Dish dispenser spring attachments

(diagram 2)

the spring into the

bracket on the tube frame. Then hook the bottom loop of the

spring into the carrier bracket (see diagram 2). Add as many

springs as necessary.

or replace current springs with lower tension springs

(springs with lower tension may be ordered from Delfield’s

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Keep fingers clear from the edge of

the opening

If the stack is over the guide posts and is bottomed out, it is

full. If stack is over guide posts and not bottomed out (the

stack will bounce up and down), adjust the springs. See “Field

adjustment” instructions on page eight.

Temperature adjustment – ET & QT models only

ET (even-temp) models have a 400 watt heating element

and an adjustable thermostat. The factory setting for

thermostat is “A” which gives an operating temperature

of about 165°F (74°C) and effective plate temperatures of

between 110°F (43°C) to 120°F (49°C) after about two to

three hours of pre-warming.

QT (quick-temp) models have a 700 watt heating element

and an adjustable thermostat. The factory setting for

thermostat is “E” which gives an operating temperature

of about 205°F (96°C) and effective plate temperatures of

between 130°F (54°C) to 150°F (66°C) after about two to

three hours of pre-warming.

(Continued on the next page.)

7

Page 8

Dispensing Models Service and Installation Manual

DA RNGE

Heated Unit Thermostat Settings

Temperature Setting

Operating Temperature (°F)

Operating Temperature (°C)

"A"

165

74

"B"

175

79

"C"

185

85

"D"

195

91

"E"

205

96

OPERATION: DISH DISPENSERS (CONTINUED)

The thermostat is located on the bottom of the unit near

the fan motor. Use the following directions to adjust.

Unplug the unit and allow the unit to cool

completely before handling.

1) Lock brakes on mobile units before beginning.

2) Unload the dispenser. Remove dispensers from the unit

by grasping the black plastic guide posts and lifting the

dispenser completely out of the unit. It is not necessary to

remove the steel jacket from the dispensing tube.

3) Turn the unit on its side.

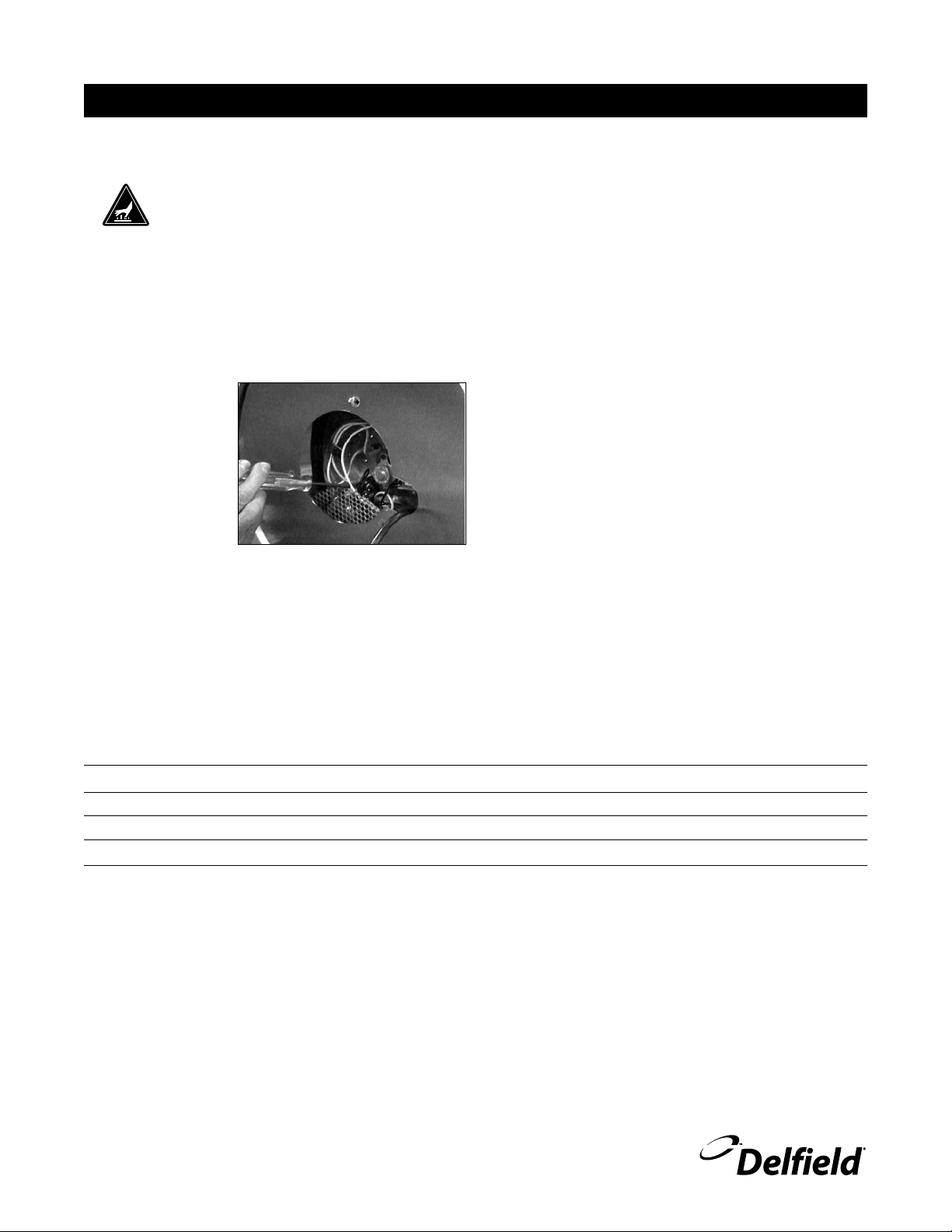

4) Remove filter from

bottom of unit. It

is not necessary

to remove the

perforated screen.

The screen has

access holes in it to

allow adjustment

of the thermostat.

The screen is

shown removed in

Location of thermostat adjustment screw

diagram 3 to show

the location of the thermostat adjustment screw only.

5) Use a small screw-driver to reach the adjustment screw

located under the perforated screen (see diagram 3). Turn

the screw to the desired setting based on the “thermostat

settings chart” shown below.

6) Reattach the filter before operating the unit again.

(diagram 3)

8

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 9

MOTOR

ON/OFF

SWITCH

CORD &

PLUG

THERMOSTAT LIMIT

HEATER

DIS, T-H, & TG-H

MODELS

DIS

DIS

DIS

DIS

CAB MODELS CONTAIN

SEVERAL DIS UNITS WIRED TOGETHER

CAB

MODELS

WIRING DIAGRAMS: HEATED DISH DISPENSERS

Dispensing Models Service and Installation Manual

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

9

Page 10

Dispensing Models Service and Installation Manual

L1

N

CONDENSING UNIT

ON/OFF SWITCH

G

PRESS

EVAP

FANS

TIMER

42

1

X

N

SWITCH

PURPLE

ORANGE

ORANGE

WHITE

RED

FAN

DELAY

BLACK/

DEFROST

HEATER

3

C1

C1

C1

C1

HEATER

CONDENSATE

WIRING DIAGRAMS: CP, CM, CMB, CPB MODELS DISPENSERS

10

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 11

DA RNGE

DA RNGE

MAINTENANCE: DISH DISPENSERS

Dispensing Models Service and Installation Manual

Unheated dish dispensers

Lift the dispenser out of the counter or CAB cart by grasping

the black dish guides and lifting straight up and out. Remove

any debris that may be in the assembly with a damp cloth.

Clean the stainless steel by using a soft cloth, soap and

warm water. If this is not sufficient, try ammonia and water

or a non-abrasive liquid cleaner. Rub with the grain of the

stainless steel to avoid marring the finish. When cleaning

is completed, insert the dispenser assembly back into the

counter or CAB cart.

The bottom rails on the CAB cart should be cleaned

occasionally. They may be accessed most easily through the

bottom of the unit.

Do not use abrasive cleaner because it will scratch

the stainless steel and plastic.

Mobile and built in chilled plate and mug

dispensers

The interior and exterior can be cleaned using soap and

swarm water. If this is not sufficient, try ammonia and water

or a non-abrasive liquid cleaner. When cleaning the exterior,

always rub with the “grain” of the stainless steel to avoid

marring the finish. Do not use an abrasive cleaner because it

will scratch the stainless steel and plastic.

In order to maintain proper refrigeration performance, the

condenser fins must be cleaned of dust, dirt and grease

regularly. It is recommended that this be done at least every

three months. If conditions are such that the condenser is

totally blocked in three months, the frequency of cleaning

should be increased. Clean the condenser with a vacuum

cleaner or stiff brush. If extremely dirty, a commercially

available condenser cleaner may be required.

Heated dish dispensers

Heated units must be disconnected from the main

power source and allowed to cool down before

cleaning. Cords on DIS models used as drop-ins

into a counter or into another piece of equipment

are directly connected to the power source. On

CAB units there is a cord from each individual

DIS tube to a central receptacle on the cart and

a separate cord from that receptacle to the main

power source. Never hose down units with water.

Lift the dispenser out of the counter or CAB cart by grasping

the black dish guides and lifting straight up and out. Remove

any debris that may be in the assembly with a damp cloth.

Clean the stainless steel by using a soft cloth, soap and warm

water. If this is not sufficient, try ammonia and water or a nonabrasive liquid cleaner. Rub with the grain of the stainless steel

to avoid marring the finish. When cleaning is completed, insert

the dispenser assembly back into the counter or CAB cart.

The bottom rails on the CAB cart should be cleaned occasionally.

They may be accessed most easily through the bottom of the

unit.

Do not use abrasive cleaner because it will scratch

the stainless steel and plastic.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

11

Page 12

Dispensing Models Service and Installation Manual

Problem Possible Cause Solutions

No Heat

Not Hot

Enough

Too Hot

Noisy

Power cord disconnected

Disconnected ON/OFF switch or ON/OFF switch

in the OFF position

Defective heating element

Air circulating fan defective or blocked

Check power source to unit and receptacle at the

underside of the cabinet. Reset GFCI receptical position

Replace ON/OFF switch; turn ON/OFF switch to on

position

Replace element

Replace motor, or remove blockage from fan

Unit plugged into incorrect voltage

Thermostat set too low

Air circulating fan partially blocked

Not waiting long enough for pre-heating

Check volatge supply and compare to unit's voltage

rating

Adjust thermostat to a higher setting

Remove blockage

90 minutes is a good average pre-heat on DIS

models

Defective air circulating motor

Obstruction at air circulating motor

Loose fan blade

Replace motor

Free obstruction

Tighten blade

Thermostat set too high Adjust thermostat to a lower setting

1a) GFCI tripped

Thermostat defective

Replace Thermostat

TROUBLESHOOTING REFERENCE CHART: HEATED DISH DISPENSERS

12

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 13

Dispensing Models Service and Installation Manual

CAUTION

ADJUSTING SELF-LEVELING DISPENSERS

Adjusting the self-leveling dispenser

Tools Needed: One small flat head screw driver;

One Phillips head screw driver

1. Always wear safety glasses when adjusting your dispenser.

Also, lock brakes on mobile units before beginning.

2. Unload dispenser and remove stainless steel load tray by

lifting straight up and set it aside (see fig. 1). For Models

LT skip to step #6.

(figure 1) Sample unit

3. Use small regular screw driver to loosen each retainer

mounted on stainless steel rod at top of each elevator

housing.

4. To remove

elevator housing,

lift housing

straight up to

clear the stud on

unit base. Then

gently swing the

bottom of the

housing towards

the inside of the

unit and pull

housing out of

the unit (see fig.

2). Lay housing

on flat surface.

(figure 2) Remove elevator housing

5. Use Phillips head

screw driver to remove

front panel on the

elevator housing (see

fig. 3).

6. If carrier is riding

too high, you need

to remove springs.

With carrier all the

way to the top, gently

disengage one spring

at a time, unhooking

bottom loop out of

(figure 3) Remove front panel

carrier bracket (see fig.

4). Remove as many

springs as necessary.

If carrier is riding too

low, you need to add

springs. With carrier

all the way to the top,

gently engage one

spring at a time by

hooking bottom loop

of spring into carrier

bracket. Add as many

springs as necessary.

(figure 4) Remove or add springs

7. When finished, put

elevator housing back in unit (except on models LT) and

put stainless steel load tray back on elevator housings.

Load unit to test dispensing level. If spring adjustment

does not position carrier properly, repeat procedure #6

trying different springs. If this does not work, a different

set of springs may be required. To order, call The Delfield

Parts and Service Department.

8. If level is appropriate, put front panels back on and

tighten retainer.

Dispenser should not be operated with front

panels off elevator housing.

When adjusting the elevators make sure each have the

NOTE:

same number and size of springs connected to the carrier on

both sides. This will prevent the load tray from binding.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

13

Page 14

Dispensing Models Service and Installation Manual

REPLACEMENT PARTS LIST

Models T, T2

1014 units

0201735 Elevator assembly, small

6150201 Spring, extension, 0.58lbs/in

6230170 Bumper, corner, small pvc

6320257 Bearing, elev, o.375ID

M3234180 Polyolefin caster 4” with brake

M3234185 Polyolefin caster 4” without brake

1216/1222/1418/ 1422/1520/

1622/1826/2020 units

0201709 Elevator assembly, large

6150202 Spring, extension, 0.28lbs/in

6230170 Bumper, corner, small pvc

6320257 Bearing, elev, o.375ID

M3234180 Polyolefin caster 4” with brake

M3234185 Polyolefin Caster 4” without brake

Models T-H, TG-H

1221-H units

0201740 Large elevator

6230007 Bearing

6150201 Extension spring, heavy tension

6150202 Extension spring, med tension

0048542 Carrier

0201046 Heat module assy

6190269 Heating element

0047140 Motor housing

0047153 Motor housing screen

6190181 Thermostat

6190180 High limit switch

6160024 Motor

6160007 Fan blade

6190085 Cord/plug

6230314 Air filter

1418-H units

3234180 4” Caster

0201046 Heat module assy

6190269 Heating element

0047153 Motor housing screen

6190181 Thermostat

6190180 High limit switch

6160024 Motor

6160007 Fan blade

6190085 Cord/plug

6230314 Air filter

2183347 Cord/plug

6230170 Corner bumper

6230007 Bearing

0047621 Carrier

6150202 Extension spring, med tension

1422-H units

3234180 4” Caster

0201046 Heat module assy

6190269 Heating element

0047153 Motor housing screen

6190181 Thermostat

6190180 High limit switch

6160024 Motor

6160007 Fan blade

6190085 Cord/plug 18-3

6230314 Air filter

2183347 Cord/plug 14-3

6230170 Corner bumper

0201709 Large elevator assy

6230007 Bearing

0048583 Carrier

6150202 Extension spring, med tension

1826-H units

3234180 4” caster

0201046 Heat module assy

6190269 Heating element

0047153 Motor housing screen

6190181 Thermostat

6190180 High limit switch

6160024 Motor

6160007 Fan blade

6190085 Cord/plug

6230314 Air filter

2183347 Cord/plug

6230170 Corner bumper

0681855 LT-1826 tray/rack dispenser

0201709 Large elevator assembly

6230007 Bearing

0048584 Carrier

6150202 Extension spring, med tension

2020-H units

3234180 4” caster

0201046 Heat module assy

6190269 Heating element

0047153 Motor housing screen

6190181 Thermostat

6190180 High limit switch

6160024 Motor

6160007 Fan blade

6190085 Cord/plug 18-3

6230314 Air filter

2183347 Cord/plug 14-3

6230170 Corner bumper

0681811 LT-2020 tray/rack dispenser

0201709 Large elevator assy

6230007 Bearing

0048503 Carrier

6150202 Extension spring, med tension

Models TT, TT2

1014 units

0201731 Elevator assembly, small 27.5

6150201 Spring, extension, 0.58lbs/in

6230170 Bumper, corner, small pvc

6230188 Polyolefin caster 4” without brake

6230218 Polyolefin caster 4” with brake

6320257 Bearing, elev, 0.375ID

1216/1222/1418/1422/1520/

1622/1826/2020 units

0201734 Elevator assembly, large

6150202 Spring, extension, 0.28lbs/in

6230170 Bumper, corner, small pvc

6230188 Polyolefin caster 4” without brake

6230218 Polyolefin caster 4” with brake

6320257 Bearing, elev, 0.375ID

Models LT, TG, TG2

1014 units

0201735 Elevator assembly, small

6150201 Spring, extension, 0.58lbs/in

6320257 Bearing .375ID

1216/1222 units

0201709 Elevator assembly, large

6150201 Spring, extension, 0.58lbs/in

6320257 Bearing .375ID

1418/1422/1520/1622/1826/2020 units

0201709 Elevator assembly, large

6150202 Spring, extension, 0.28lbs/in

6320257 Bearing .375ID

Models T2-H, TG2-H

1221 units

3234180 4” caster

0201046 Heat module assy

6190269 Heating element

0047153 Motor housing screen

6190181 Thermostat

6190180 High limit switch

6160024 Motor

6160007 Fan blade

6190085 Cord/plug

6230314 Air filter

2183347 Cord/plug

6230170 Corner bumper

0681852 LT2-1221 Tray/Rack Dispenser

0201735 Elevator assy

6230007 Bearing

0048708 Carrier

6150201 Extension spring, heavy tension

Models DIS

All units

6230314 Filter, air, 6” diameter (DDS)

6230244 Guide post

6150201 Spring, heavy tension

6150202 Spring, medium tension

6150203 Spring, light tension

500 units

6200121 Spinning head

6970011 Wire head

575 units

6200122 Spinning head

6970012 Wire head

650 units

6200123 Spinning head

6970013 Wire head

725 units

6200124 Spinning head

6970014 Wire head

813 units

6200125 Spinning head

6970015 Wire head

14

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 15

REPLACEMENT PARTS LIST

Dispensing Models Service and Installation Manual

913 units

6200126 Spinning head

6970016 Wire head

1013 units

6200127 Spinning head

6970017 Wire head

1200 units

6200128 Spinning head

6970018 Wire head

1450 units

6200129 Spinning head

6970026 Wire head

Model DIS-ET, DIS-QT

All units

6230314 Filter, air, 6” diameter

6230244 Guide post

6150201 Spring, heavy tension

6150202 Spring, medium tension

6150203 Spring, light tension

6190085 Cord with plug, NEMA 5-15P 5’

6160024 Motor, 115V 50-60Hz

6190180 Switch, high-limit, 245°F

2190154 Switch rocker

6190181

Thermostat, automatic 165°F - 205°F

500/575/650/725 ET units

6160008 Fan blade, 3” diameter

6190250 Heating element, 120V/327W

0201044 Heating module

813/913/1013/1200/1450 ET & QT units

6160007 Fan blade, 4” diameter (QT models)

6160008 Fan blade, 120V/327W (ET models)

6190254 Heating element,

120V/327W

6190269 Heating Element

120V/700W (QT models)

0201045 Heating module (ET models)

0201046 HTG Module (QT models)

(ET models)

Model CAB, CAB-ET,

CAB-QT

3234180 Caster, 4” with brake (2 needed)

3234185 Caster, 4” without brake (2 needed)

6230314 Filter, air, 6” diameter

6230244 Guide post

6150202 Spring, medium tension

6150203 Spring, light tension

6190085 Cord with plug, NEMA 5-15P 3’

6160024 Motor, 115V 50-60Hz

6190180 Switch, high-limit, 245°F

2190154 Switch rocker

6190181

500/575/650/725 ET units

6160008 Fan blade, 3” diameter

6190250 Heating element, 120V/327W

0201044 Heating module

All units

Thermostat, automatic 165°F - 205°F

813/913/1013/1200/1450 ET & QT units

6160007 Fan blade, 4” diameter (QT models)

6160008 Fan blade, 120V/327W (ET models)

6190254 Heating element,

120V/327W

6190269 HTG element,

120V/700W (QT models)

0201045 Heating module (ET models)

0201046 HTG module (QT models)

(ET models)

CAB2-ET units

2183348 Cord with plug, NEMA 5-15P 6’

CAB2-QT units

2183347 Cord with plug, NEMA 5-20P 6’

CAB3-ET, CAB4-ET, CAB3-QT, CAB4-QT

units

6190079 Cord with plug, NEMA 6-20P 6’

Model SB

0201196 Spring head assy

6150024 Dish spring

0201198 Hinged lid assy

Model ND

ND-45

0047225 Cover

0047226 Head

6150203 Extension spring

ND-47

0047127 Cover

0047152 Head

6150203 Extension spring

ND-48

0047227 Cover

0047229 Head

6150203 Extension spring

ND-57

0047239 Cover

0047241 Head

6150203 Extension spring

ND-59

0047237 Cover

0047247 Head

6150203 Extension spring

ND-47

0047250 Cover

0047251 Head

6150203 Extension spring

Model CP - mobile and built in

3234180 4” caster

6230019 Aluminum hinge

9321122 Snap bushing 1.50 black

9321198 Bushing 1.00 snap

3516070 Low temp cooler

3516225 Expansion valve

3526710 Condensing unit

3516101 Filter dryer

2193927 Pressure control

0100049 Electric condensate evap. pan

2194199 Heating element

2194151 Paragon timer

6700027 Throat collar

6230186 Snap in w/screen vent

6200068 Spinning head

6230233 Spring head adjustment

6150077 Spring compression

0201603 Lid assy

6230109 Extruded hinge

6230110 Plastic insert hinge

3234110 Lift cover chrome handle

2214110003 Louver 13.00 x 25.00

0047033 Side louver 13.00 x 13.50

0048864 Side louver 9.00 x 13.50

2190154 Rocker switch

6230172 Corner bumper

2183348 Cord/plug

Model CM - mobile and built in

3516070 Unit cooler

3516225 Expansion valve

3234180 4” caster

9321122 Bushing 1.50 black

9321198 Bushing 1.00 snap

3526710 Condensing unit

3516101 Filter dryer

2193927 Pressure control

0100049 Electric condensate evap. pan

2194199 Heating element

2194151 Paragon timer

0044074 Throat collar

0201737 Large elevator assy

6320007 Bearing .50

6150201 Extension spring .58

6150202 Extension spring .28

6230024 Retainer

0047745 Carrier

0201525 Lid assy

6230109 Extruded hinge

6230110 Plastic insert hinge

3234110 Lift cover chrome handle

2214110003 Louver 13.00 x 25.00

0047033 Side louver 13.00 x 13.50

0048864 Side louver 9.00 x 13.50

2190154 Rocker switch

6230172 Corner bumper

2183348 Cord/plug

Model CT - WCT Series

6230170 Small bumper corner

3234180 4” caster (CT series only)

6230068 Bearing

6150206 Extension spring

In addition to the above parts

CT/WCT-1216

0047481 Carrier 12.50 x 16.50

CT/WCT-1221

0047486 Carrier 12.50 x 21.50

CT/WCT-1418

0047490 Carrier 14.56 x 18.56

CT/WCT-1422

0047491 Carrier 14.50 x 22.50

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

15

Page 16

Dispensing Models Service and Installation Manual

REPLACEMENT PARTS LIST

CT/WCT-1622

0047496 Carrier 16.56 x 22.56

CT-1821 and WCT-2020

0047499 Carrier 20.56 x 21.56

CT/WCT-1826

0047498 Carrier 18.56 x 26.56

Model FT2-SN

All units

6230170 Corner bumper

6230218 4” caster

0201734 Large elevator

6320007 Bearing

6150201 Extension spring .58

6150202 Extension spring .28

6230024 Retainer

0680934 ND-napkin dispenser

6150203 Extension spring .16

0047241 Head ND-57

0047239 Cover ND-57

3234052 Silverware container

In addition to the above parts

FT2-SN-1216

0048492 Carrier 1216

FT2-SN-1418

0047621 Carrier 1418

FT2-SN-1622

0047568 Carrier 1622

16

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 17

Dispensing Models Service and Installation Manual

STANDARD LABOR GUIDELINES TO REPAIR OR REPLACE PARTS ON DELFIELD EQUIPMENT

Advice and recommendations given by Delfield Service Technicians do not constitute or guarantee any special coverage.

• A maximum of 1-hour is allowed to

• A maximum of 1-hour is allowed for

• A maximum

• Overtime, installation/start-up, normal control adjustments, general maintenance, glass breakage, freight damage, and/or

correcting and end-user installation error will not be reimbursed under warranty unless pre-approved with a Service Work

Authorization from Delfield. You must submit the number with the service claim.

LABOR OF 1-HOUR IS ALLOWED TO REPLACE:

• Thermostat • Contactor/Relay

• Infinite Switch • Transformer

• Door Jamb Switch • Evaporator/Condenser Fan Motor and Blade

• Solenoid Coil • Circulating Fan Motor and Blade

• Hi-limit/Thermal Protector Switch • Microprocessor Control

• Fan Delay/Defrost Termination Switch • Water Level Sensor/Probe

• Compressor Start Components and Overload Protector • Door Hinges, Locks, and Gaskets

• Defrost Timer • Condensate Element

• Thermometer • Springs/Lowerator

• Gear Box

LABOR OF 2 HOURS TO REPLACE:

• Drawer Tracks/Cartridges • Defrost Element

• Pressure Control • Heating Element

• Solenoid Valve • Locate/Repair Leak

travel distance of 100 miles round trip and 2-hours will be reimbursed.

diagnose a defective component.

retrieval of parts not in stock.

LABOR OF 3 HOURS TO REPLACE:

• EPR or CPR Valve • Condenser or Evaporator Coil

• Expansion Valve

LABOR OF 4 HOURS TO REPLACE

• Compressor

This includes recovery of refrigerant and leak check.

$55.00 maximum reimbursement for refrigerant recovery (includes recovery machine, pump, torch, oil, flux, minor fittings,

solder, brazing rod, nitrogen, or similar fees.)

REFRIGERANTS

• R22 A maximum of $4.00/lb. or 25¢/oz. will be reimbursed.

• R134A A maximum of $5.00/lb. or 31¢/oz. will be reimbursed.

• R404A A maximum of $15.00/lb. or $1.00/oz. will be reimbursed.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

17

Page 18

Dispensing Models Service and Installation Manual

STANDARD ONE YEAR WARRANTY (ONE YEAR PARTS, 90 DAYS LABOR.)

The Delfield Company (“Delfield”) warrants to the Original Purchaser

of the Delfield product (herein called the “Unit”) that such Unit, and all

parts thereof, will be free from defects in material and workmanship

under normal use and service for a period of one (1) year from

the date of shipment of the Unit to the Original Purchaser or, if the

Original Purchaser returns the warranty card completely filled out

including the date of installation within thirty (30) days of receipt

of the Unit, one (1) year from the date of installation. During this

one year warranty period, Delfield will repair or replace any defective

part or portion there of returned to Delfield by the Original Purchaser

which Delfield determines was defective due to faulty material or

workmanship. The Original purchaser will pay all labor, crating, freight

and related costs incurred in the removal of the Unit of defective

component and shipment to Delfield, except that during a period of

either ninety (90) days from the date of shipment of the Unit to the

Original Purchaser or, if the Original Purchaser returns the warranty

card completely filled out including the date of installation within thirty

(30) days of receipt of the Unit, ninety (90) days from the date of

installation Delfield will pay all related labor costs. Delfield will pay the

return costs if the Unit or part thereof was defective.

The term “Original Purchaser” as used herein means that person, firm,

association, or corporation for whom the Unit was originally installed.

This warranty does not apply to any Unit or part thereof that has

been subjected to misuse, neglect, alteration, or accident, such as

accidental damage to the exterior finish, operated contrary to the

recommendations specified by Delfield; or repaired or altered by anyone

other than Delfield in any way so as to, in Delfield’s sole judgement,

affect its quality or efficiency. This warranty does not apply to any Unit

that has been moved from the location where it was originally installed.

This warranty also does not cover the refrigerator drier or the light

bulbs used in the Unit. The warranty is subject to the user’s normal

maintenance and care responsibility as set forth in the Service and

Installation Manual, such as cleaning the condenser coil, and is in

lieu of all other obligations of Delfield. Delfield neither assumes, nor

authorizes any other person to assume for Delfield, any other liability

in connection with Delfield’s products.

basis, with credit being issued after the part has been received and

inspected at Delfield’s plant and determined by Delfield to be within this

warranty.

Under no condition does this warranty give the Original Purchaser the

right to replace the defective Unit with a complete Unit of the same

manufacturer or of another make. Unless authorized by Delfield in

writing, this warranty does not permit the replacement of any part,

including the motor-compressor, to be made with the part of another

make or manufacturer.

No claims can be made under this warranty for spoilage of any products

for any reason, including system failure.

The installation contractor shall be responsible for building access,

entrance and field conditions to insure sufficient clearance to allow any

hood(s), vent(s), or Unit(s) if necessary, to be brought into the building.

Delfield will not be responsible for structural changes or damages

incurred during installation of the Unit or any exhaust system.

Delfield shall not be liable in any manner for any default or delay in

performance hereunder caused by or resulting from any contingency

beyond Delfield’s control, including, but not limited to, war,

governmental restrictions or restraints, strike, lockouts, injunctions,

fire, flood, acts of nature, short or reduced supply of raw materials, or

discontinuance of the parts by the original part manufacturer.

Except as provided in any Additional Four Year Protection Plan,

if applicable, and the Service Labor Contract, if applicable, the

foregoing is exclusive and in lieu of all other warranties, whether

written or oral, express or implied. This warranty supersedes

and excludes any prior oral or written representations or

warranties. Delfield expressly disclaims any implied warranties

of merchantability, fitness for a particular purpose of compliance

with any law, treaty, rule or regulation relating to the discharge of

substances into the environment. The sole and exclusive remedies

of any person relating to the Unit, and the full liability of Delfield for

any breach of this warranty, will be as provided in this warranty.

Removal or defacement of the original Serial Number or Model Number

from any Unit shall be deemed to release Delfield from all obligations

hereunder or any other obligations, express or implied.

Parts furnished by suppliers to Delfield are guaranteed by Delfield only

to the extent of the original manufacturer’s express warranty to Delfield.

Failure of the Original Purchaser to receive such manufacturer’s express

warranty to Delfield. Failure of the Original Purchaser to receive such

manufacturers warranty shall in no way create any warranty, expressed

or implied, or any other obligation or liability on Delfield’s part in respect

thereof.

IF THE CUSTOMER IS USING A PART THAT RESULTS IN A VOIDED

WARRANTY AND A DELFIELD AUTHORIZED REPRESENTATIVE

TRAVELS TO THE INSTALLATION ADDRESS TO PERFORM WARRANTY

SERVICE, THE SERVICE REPRESENTATIVE WILL ADVISE CUSTOMER

THE WARRANTY IS VOID. SUCH SERVICE CALLS WILL BE BILLED

TO CUSTOMER AT THE AUTHORIZED SERVICE CENTER’S THEN

APPLICABLE TIME AND MATERIALS RATES. CONSIDER: CUSTOMER

MAY INITIATE A SERVICE AGREEMENT WITHOUT PARTS COVERAGE.

If shipment of a replacement part is requested prior to the arrival in

the Delfield factory of the part claimed to be defective, the Original

Purchaser must accept delivery of the replacement part of a C.O.D.

18

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Other than this Delfield Standard One Year Limited Warranty, any

applicable Delfield Additional Four Year Protection Plan or applicable

Delfield Service Labor Contract, the Original Purchaser agrees and

acknowledges that no other warranties are offered or provided in

connection with or for the unit or any other part thereof.

In no event will Delfield be liable for special, incidental or consequential

damages, or for damages in the nature of penalties.

IF DURING THE WARRANTY PERIOD, CUSTOMER USES A PART FOR

THIS DELFIELD EQUIPMENT OTHER THAN AN UNMODIFIED NEW

OR RECYCLED PART PURCHASED DIRECTLY FROM DELFIELD OR

ANY OF ITS AUTHORIZED SERVICE CENTERS AND/OR THE PART

BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION,

THIS WARRANTY WILL BE VOID. FURTHER, DELFIELD AND ITS

AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS DAMAGES OR

EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY

OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION

OF ANY MODIFIED PART AND/OR PART RECEIVED FROM AN

UNAUTHORIZED SERVICE CENTER. If the warranty becomes void,

Customer may purchase from Delfield, if available, a Service

Agreement or service at the then current time and materials rate.

For more information on Delfield warranty’s log on and check out the

service section of our web site at www.delfield.com.

Page 19

Dispensing Models Service and Installation Manual

ADDITIONAL FOUR YEAR PROTECTION PLAN (FOR MOTOR-COMPRESSOR ONLY)

Installation

Delfield Model# Serial # Date

General Conditions

Delfield shall not be liable in any manner for any default or delay

in performance hereunder caused by or resulting from any

contingency beyond Delfield’s control, including, but not limited

In addition to the Standard One Year Warranty on the MotorCompressor contained in the above listed Delfield product (the

“Unit”), The Delfield Company (“Delfield”) also agrees to repair, or

exchange with similar or interchangeable parts in design and capacity

at Delfield’s option, the defective Motor-Compressor contained in the

Unit (the “Motor-Compressor), or any part thereof, for the Original

Purchaser only, at any time during the four (4) years following the

initial one (1) year period commencing on the date of installation for

the Original Purchaser. Failure of the Original Purchaser to register

the registration card containing the Original Purchasers name,

address, date of installation, model number and serial number of

the Unit containing the Motor-Compressor within 30 days from the

date of installation shall void this warranty. This additional warranty

is only available if the Motor-Compressor is inoperative due to defects

in material or factory workmanship, as determined by Delfield in

its sole judgement and discretion. The Original Purchaser shall be

responsible for returning the defective Motor-Compressor to Delfield

prepaid, F.O.B. at the address shown on the back cover of this manual.

The term “Original Purchaser” as used herein means that person, firm,

association, or corporation for whom the Unit was originally installed.

The term “Motor-Compressor” as used herein does not include unit

base, air or water cooled condenser, receiver, electrical accessories

such as relay, capacitors, refrigerant controls, or condenser fan/motor

assembly. This warranty does not cover labor charges incidental to

the replacement of parts. This warranty further does not include

any equipment to which said condensing unit is connected, such as

cooling coils, temperature controls or refrigerant metering devices.

This warranty shall be void if the Motor-Compressor, in Delfield’s

sole judgement, has been subjected to misuse, neglect, alteration

or accident, operated contrary to the recommendations specified

by the Unit manufacturer, repaired or altered by anyone other than

Delfield in any way so as, in Delfield’s sole judgment, to affect its

quality or efficiency or if the serial number has been altered, defaced

or removed. This Warranty does not apply to a Motor-Compressor in

any Unit that has been moved from the location where it was originally

installed. The addition of methyl chloride to the condensing unit or

refrigeration system shall void this warranty.

to, war, governmental restrictions or restraints, strike, lockouts,

injunctions, fire, flood, acts of nature, short or reduced supply

of raw materials, or discontinuance of any part or the Motor-

Compressor by the unit manufacturer.

Replacement of a defective Motor-Compressor is limited to one (1)

Motor-Compressor by us during the four (4) year period. Delfield

shall replace the Motor-Compressor at no charge.

This warranty does not give the Original Purchaser of the Motor-

Compressor the right to purchase a complete replacement Motor-

Compressor of the same make or of another make. It further does

not permit the replacement to be made with a Motor-Compressor

of another kind unless authorized by Delfield. In the event Delfield

authorizes the Original Purchaser to purchase a replacement

Motor-Compressor locally, only the wholesale cost of the Motor-

Compressor is refundable.

Expressly excluded from this warranty are damages resulting from

spoilage of goods.

Except as provided in any applicable Standard One Year Limited

Warranty or applicable Service Labor Contract, the foregoing

is exclusive and in lieu of all other warranties, whether written

or oral, express or implied. This Warranty supersedes and

excludes any prior oral or written representations or warranties.

Delfield expressly disclaims any implied warranties of

merchantability, fitness for a particular purpose or compliance

with any law, treaty, rule or regulation relating to the Motor-

Compressor, and the full liability of Delfield for any breach of this

warranty, will be as provided in this warranty.

Other than any applicable Delfield Standard One year Limited

Warranty, this Delfield Additional Four Year Protection Plan and any

applicable Delfield Service Labor Contract, the Original Purchaser

agrees and acknowledges that no other warranties are offered or

provided in connection with or for the Motor-Compressor or any

part thereof.

In no event will Delfield be liable for special, incidental or

consequential damages, or for damages in the nature of penalties.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

19

Page 20

Delfield

™

®

Mt. Pleasant, MI Covington, TN

Delfield

™

®

Thank you for choosing Delfield!

Help is a phone call away. Help our team of professional, courteous

customer service reps by having your model number and serial number

available at the time of your call (800) 733-8829.

Model: ____________________ S/N: ___________________

Installation Date: ____________

For a list of Delfield’s authorized parts depots,

visit our website at www.delfield.com.

980 S. Isabella Rd., Mt. Pleasant, MI 48858, U.S.A. • (989) 773-7981 or (800) 733-8829 • Fax (989) 773-3210 • www.delfield.com

Delfield reserves the right to make changes in design or specifications without prior notice. ©2010 The Delfield Company. All rights reserved. Printed in the U.S.A.

DMDISH 04/10

Loading...

Loading...