Page 1

Service and

Installation Manual

Please read this manual completely before attempting to install

or operate this equipment! Notify carrier of damage! Inspect all

components immediately. See page 2.

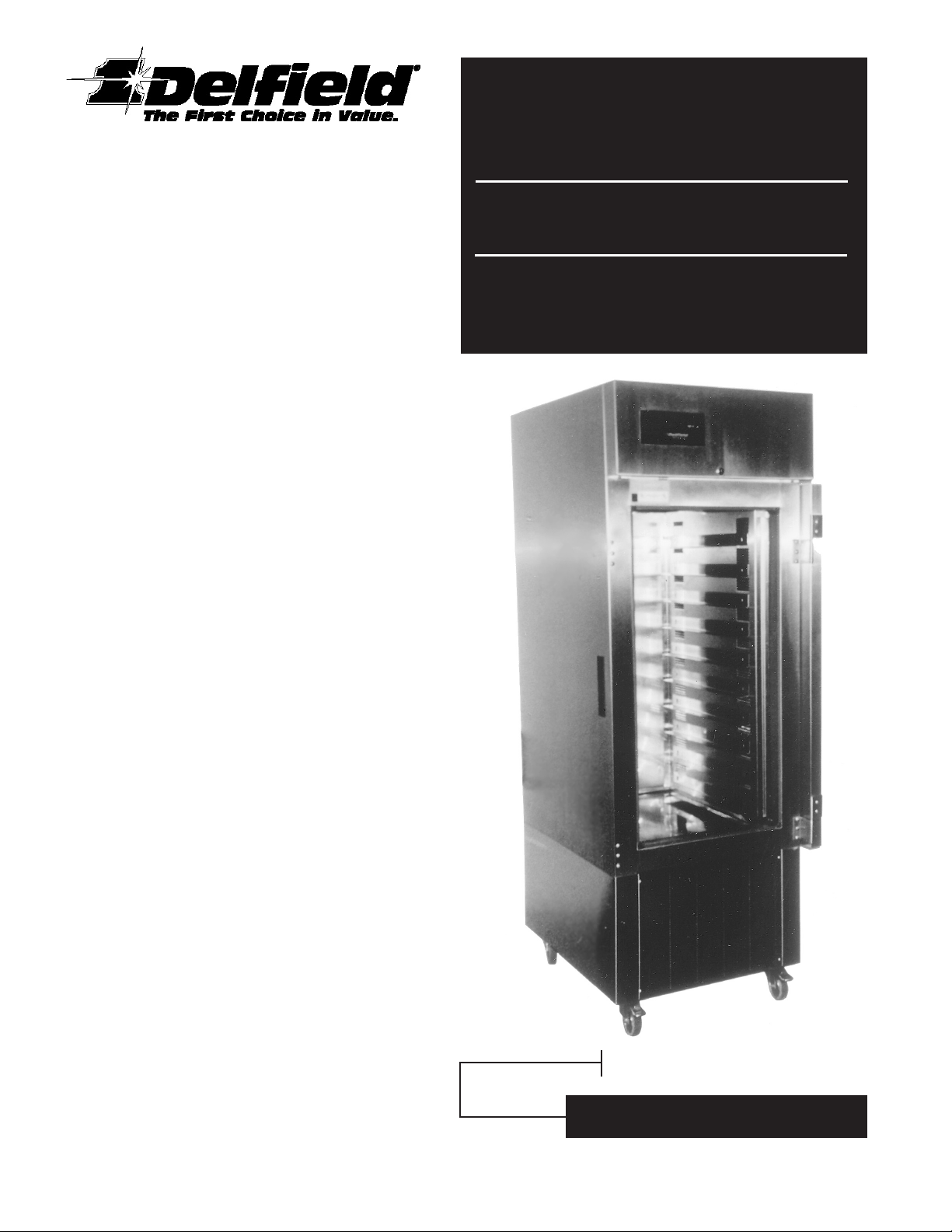

Air Curtain Refrigerator

ACR-26S

Effective September 1998

Page 2

074-2900

DELFIELD

PART NUMBER

MODEL

NUMBER

H.P.AMPS

VOLTS/HERTZ/

PHASE

STORAGE

CAPACITY

18" x 26" TRAY

CAPACITY

BTU/HR

DOOR CLOSED

BTU/HR

SYSTEM CAP.

Air Curtain Refrigerator

ACR-26S

1/2 504 3300 5-15P

SHIP

WEIGHT

NEMA

PLUG

592 lbs./266 kg.1012.0 12.5 ft

3

115V/60Hz/1ph

Contents

Serial Number Information

SERIAL NUMBER LOCATION . . . . . . . . . . . . . . . . . . . . . .2

RECEIVING AND INSPECTING . . . . . . . . . . . . . . . . . . . .2

MECHANICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

MCII Tempatrol® FUNCTION SETTINGS . . . . . . . . . . . . .4

BASIC OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

MCII TEMPATROL®

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Display functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Defrost settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Optional settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Self-diagnostic system . . . . . . . . . . . . . . . . . . . . . . . . . .10

REFERENCE CHARTS

MCII Tempatrol® CHECK SYSTEM warnings . . . . . . .10

MCII Tempatrol® diagnostic codes. . . . . . . . . . . . . . . .11

MCII Tempatrol® display . . . . . . . . . . . . . . . . . . . . . . .11

MCII Tempatrol® troubleshooting . . . . . . . . . . . . . . . .12

WIRING DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

REPLACEMENT PARTS LISTS . . . . . . . . . . . . . . . . . . . . .14

WARRANTIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

AUTHORIZED PARTS DEPOTS . . . . . . . . . . . . . back cover

To view the serial number of the ACR-26S refrigerator, open

the door of the unit. The serial number is located on the inside

back wall in the top left corner of the unit.

Always have the serial number of your unit available when call

ing for parts or service. A complete list of authorized Delfield

parts depots is shown on the back cover of this manual.

©1998 The Delfield Company. All rights reserved. Reproduction without

written permission is prohibited.

The starburst “1” symbol is a trademark and “Delfield” is a registered

trademark of The Delfield Company.

-

Receiving and Inspecting the Equipment

Even though most equipment is shipped crated, care should

be taken during unloading so the equipment is not damaged

while being moved into the building.

Carefully check for any visable signs of damage to cartons or

containers. If evidence of damage exists, the package should

be opened immediately and joint inventory and examination

of the contents should be made by you and the driver.

Concealed damage

If a concealed loss or damage is discovered after you have

given the carrier a clear delivery receipt, notify the carrier

in writing immediately or within 10 days from the

delivery date. If you phone the carrier, you must follow

up the call in writing to protect your rights. You can only

improve your position as a claimant by promptly reporting

such loss or damage. You should also retain all cartons or

containers, including packing material, until an inspection has been made or waived.

Filing a claim

Notation of loss or damage does not constitute the filing of a

claim. You should file your claim in writing with the carrier

immediately!

Carriers will furnish the necessary form upon request. You

should also request an inspection. If a claim is filed by

phone, always follow up immediately in writing.

Specifications

2

For customer service, call (800) 733-8829,

(800) 733-8821 or (517) 773-7981

Page 3

Installation

When the door is open, Delfield’s patented air curtain design

directs cold air across the cabinet opening, keeping hot air

out and cold air in for extended periods of time. The unit

will maintain a maximum of 45°F box temperature at 70°F

ambient with the door open during peak production times,

quickly returning to a normal 36°F. With the door closed,

a maximum 40°F at 100°F ambient is maintained (normal

operation) while running only 15% in an 85° room.

Location

Be sure the location chosen has a floor strong enough to support the total weight of the cabinet and contents. Reinforce

the floor if necessary to provide for maximum loading.

Don’t pack the interior of the refrigerator so full that air cannot circulate. When operating open, keep trays pushed all the

way in so that they do not disrupt the air curtain air flow.

Avoid placing unit under air conditioning vents or other ventilation fans that may affect the air curtain when door is open.

Leveling

A level cabinet looks better and will perform better because the

doors will line up with the door frames properly, the cabinet

will not be subject to undue strain, and the contents of the cabinet will not move around on the shelves. Use a level to make

sure the unit is level from front to back and side to side.

Stabilizing

The ACR-26S is supplied with casters for your convenience,

ease of cleaning underneath and for mobility. Two locking

casters allow you to stabilize the unit if you are loading or

unloading product.

Electrical connection

Refer to the amperage data shown on page 1 of this manual,

the serial tag and your local code or the National Electrical

Code for proper wire sizes. All case wiring is labeled with

the required voltage-be sure it is connected to the proper

power source. A protected circuit of the correct voltage and

amperage must be run for connection of the line cord or permanent connection to the unit.

The power switch should be turned to the OFF position and

the power cord disconnected whenever performing maintenance functions or cleaning the refrigerated cabinet area.

Reversing the door hinging

The following steps will allow you to reverse the side the

door hinges on.

1. Open the door to 180° open position.

2. Lift up door and remove door from hinges in fully open

position.

3. Remove pins from hinges.

4. Remove both hinges and relocate on the opposite side.

Tighten hinges.

5. Unscrew the lock stop tab from the top of door and

mount to the bottom in the holes provided.

6. Invert the door and mount it into the hinges in the

fully open position.

Magnetic door

Open the ACR’s door completely and the magnetic strip built

in to the frame allows the door to remain open while loading

or unloading.

Maintenance

The interior and exterior can be cleaned using soap and

warm water. If this is not sufficient, try ammonia and water

or a nonabrasive liquid cleaner. When cleaning the exterior,

always run with the “grain” of the stainless steel to avoid

marring the finish. Do not use an abrasive cleaner because it

will scratch the stainless steel and plastic.

In order to maintain proper refrigeration performance, the

condenser fins must be cleaned of dust, dirt and grease

regularly. It is recommended that this be done at least every

three months. If conditions are such that the condenser is

totally blocked in three months, the frequency of cleaning

should be increased. Clean the condenser with a vacuum

cleaner or stiff brush. If extremely dirty, a commercially

available condenser cleaner may be required.

Door gaskets should be cleaned as required to maintain their

ability to seal properly. Do not use sharp tools or knives to

scrape the bellows as this may tear the gasket and eliminate its

ability to seal. A bristle brush and solution of soap and water

should be all this is required to keep the gaskets clean. Do not

use full strength de-greasing agents on the gasket because they

could cause the gasket to crack and become brittle.

Customer service FAX (517) 773-3210

3

Page 4

MCII Function Settings

The MCII microprocessor has been preset at the factory for the following functions eliminating the need for

programming when your unit arrives. These settings

must be correct for your unit to operate properly.

1. Enter diagnostic . . . . . . . . . . Press down + time > temp

2. Enter Phase II . . . . . . . . . . . . . . . . . . . . . . . Press defrost

3. Scroll to “Basic function” . . . . . . Press up/down - go to

“012”**** - set at 0:01

4. Scroll to temperature range . . . . . . Press up/down - go to

“015” - set at 0:07

5. Scroll to defrost termination temp . . . . . Press up/down

-go to “005” - set at 0.03

6. Press reset button

7. Press temp button. . . . . . . . . . . . . Temp should read 0°F

8. Scroll up or down . . . . . . . . . . . . . . . . Set at 36°F (2°C)

***Basic function (“012”) must be set first otherwise

it will cancel out everything previously entered.

Basic Operation -

After plugging the unit in and turning the power switch to

ON, the unit will operate immediately upon start without

any programming of the MCII Tempatrol

freezer temperature is preset to 0°F and the refrigerator is

preset to 37°F. NOTE: Freezer cabinets have a built-in differ

ential; the actual interior temperature will be 0 to 3 degrees

lower than the set point.

When the unit is started, the digital display will flash, and will

continue flashing if the interior cabinet temperature is over the

set temperature range. When the cabinet is cooled to the set

For Units Built With The MCII Tempatrol

®

required. The

®

temperature range, the display will stop flashing.

When the unit is restarted after a power interruption, the digital display will flash only if the interior cabinet temperature is

over the set temperature range. When the cabinet is cooled to

-

the set temperature range, the display will stop flashing.

Every time the unit is started or restarted, the clock must be set

to the correct time of day if a custom defrost plan has been previously entered into the MCII Tempatrol. Otherwise, the clock

will resume at the time when the power was interrupted.

4

For customer service, call (800) 733-8829,

(800) 733-8821 or (517) 773-7981

Page 5

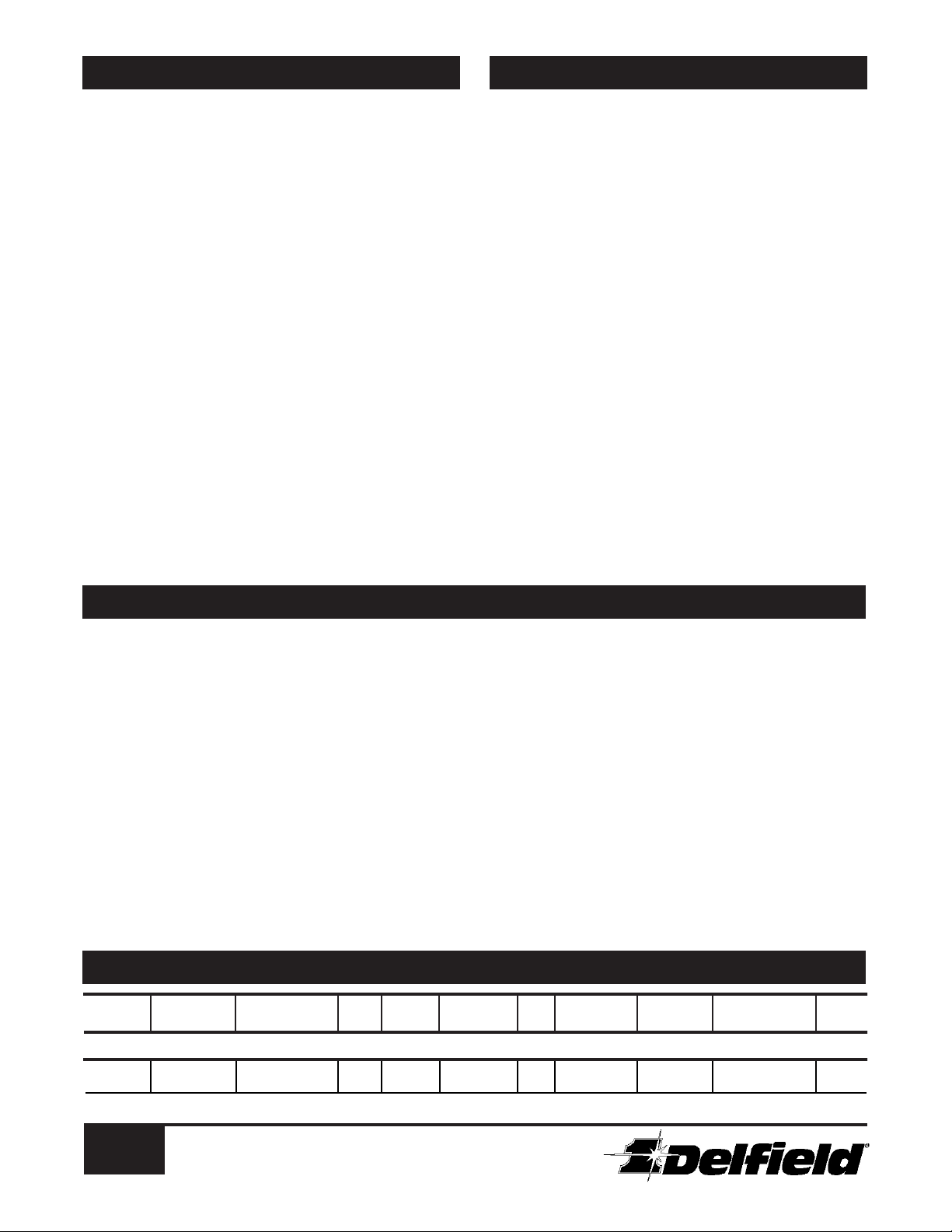

MCII Tempatrol

RESET

®

CHECK SYSTEM DEFROST

AM PM

CLEAN

CONDENSER

DOOR AJAR

ST PE SST PE S

®

Controls

RESET

• Turns off alarms

• Terminates the cur-

rent defrost cycle

• Returns display of

cabinet temperature

MCII Tempatrol

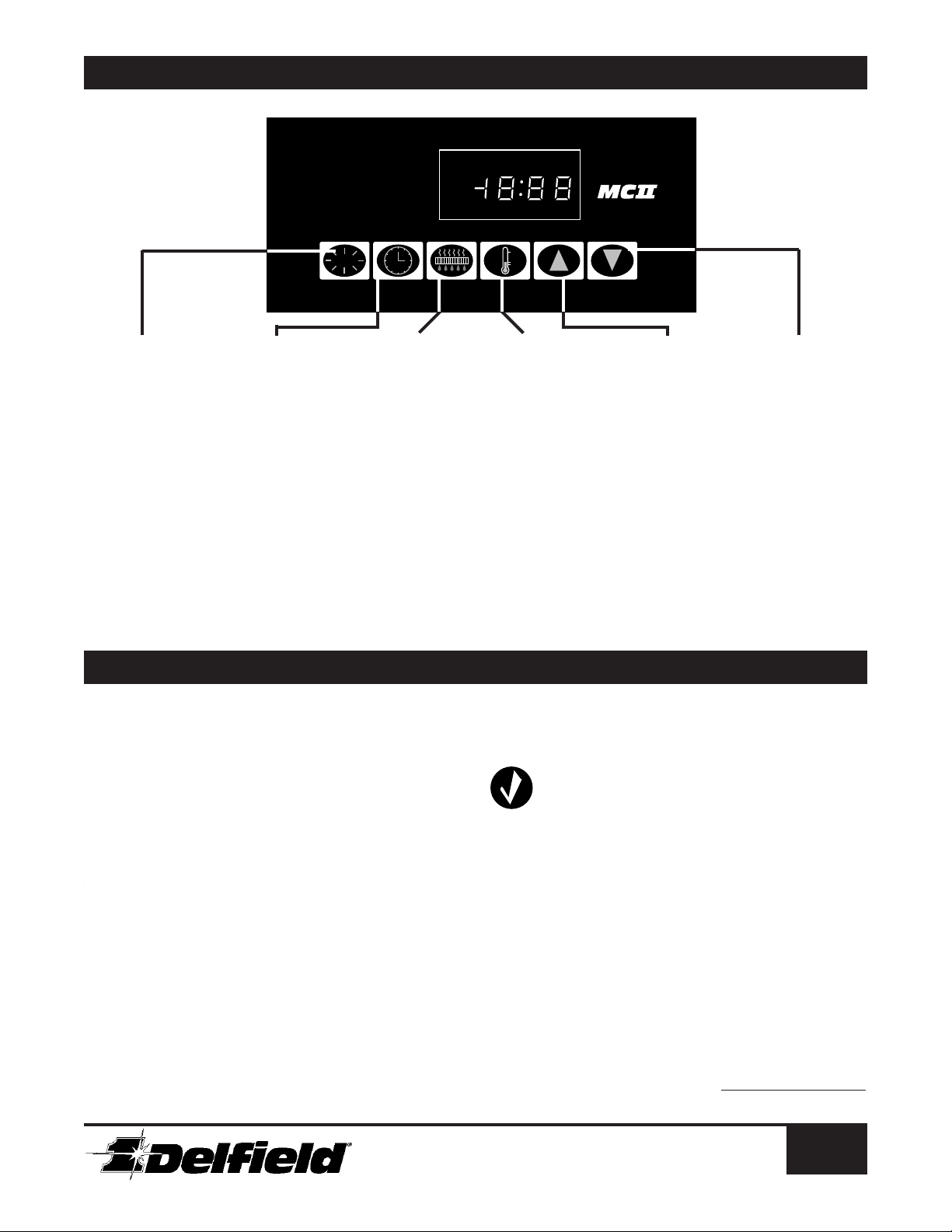

Normal display

Normal display

The normal display is the interior cabinet temperature in

The normal display is the interior cabinet temperature in

degrees Fahrenheit. (For details on changing the display

degrees Fahrenheit. (For details on changing the display

to show the temperature in degrees Celsius, see page 10.)

to show the temperature in degrees Celsius, see page 10.)

Pressing the RESET button always displays current temper-

Pressing the RESET button always displays current temperature. By pressing TEMP, you can read the set point of the

ature. By pressing TEMP, you can read the set point of the

interior cabinet. The display will automatically return to the

interior cabinet. The display will automatically return to the

current interior temperature after one minute.

current interior temperature after one minute.

It is not unusual for the interior temperature to rise rapidly

It is not unusual for the interior temperature to rise rapidly

when a door is opened. The temperature displayed is usu-

when a door is opened. The temperature displayed is usually the warmest temperature inside the unit. This is done

ally the warmest temperature inside the unit. This is done

purposely to make sure that the entire storage area is always

purposely to make sure that the entire storage area is always

represented by the display and assures that the refrigeration

represented by the display and assures that the refrigeration

system is activated quickly to return the storage area to its

system is activated quickly to return the storage area to its

correct temperature.

correct temperature.

Remember that the temperature displayed represents a pre-

Remember that the temperature displayed represents a precision measurement of the actual air temperature, not an

cision measurement of the actual air temperature, not an

average temperature. When a door is opened, the cold air

average temperature. When a door is opened, the cold air

literally “falls out” and warm air rushes in. What the display

literally “falls out” and warm air rushes in. What the display

shows is real, and provides more accurate control.

shows is real, and provides more accurate control.

TIME

• Displays the current

time (if set)

• Allows setting the

clock by pressing UP

and DOWN buttons

• Starts a manual

defrost cycle when

pressed simultaneously with

DEFROST

®

Display Functions

DEFROST

• Displays current

defrost setting

(A,3,4,6 or 8)

• Allows setting

defrost setting and

times by pressing

UP and DOWN but

tons

• Starts a manual

defrost cycle when

pressed simultaneously with TIME

TEMP

• Displays current temperature set point

• Allows modification

of set point by press

ing UP and DOWN

buttons

-

Normal display

Flashing temperature disply

The normal display is the interior cabinet temperature in

A flashing temperature display can be caused by four situadegrees Fahrenheit. (For details on changing the display to

tions, and is the first signal of a possible problem:

show the temperature in degrees Celsius, see page

1. The unit has been started, or restarted after a

10.) Pressing the RESET button always displays cur-

power loss, and has not yet reached set tempera-

rent temperature. By pressing TEMP, you can read

ture.

the set point of the interior cabinet. The display will

2. The interior cabinet is over temperature. This

automatically return to the current interior tempera-

occurs when a freezer reaches 32°F (0°C) or

ture after one minute.

when a refrigerator reaches 65°F (18°C). This

It is not unusual for the interior temperature to rise

condition will stop when the temperature returns

rapidly when a door is opened. The temperature

to a reading below these warning levels.

displayed is usually the warmest temperature inside

3. Long duty cycle. The unit has been running

the unit. This is done purposely to make sure that

for one continuous hour without a door being

the entire storage area is always represented by the

opened. This condition will stop if RESET is

display and assures that the refrigeration system is

pressed, a door is opened, or if the compressor

activated quickly to return the storage area to its cor-

shuts off.

rect temperature.

4. The door has been ajar for over one minute. This

Remember that the temperature displayed represents

condition will stop if the door is closed.

a precision measurement of the actual air tempera-

ture, not an average temperature. When a door is

opened, the cold air literally “falls out” and warm air

• When time is

• When defrost set

-

• When first defrost

• When set point is

UP

displayed, changes

time forward

ting is displayed,

moves forward

through choices

time is displayed,

moves the hour

forward

displayed, moves set

point up one degree

Continued on the next page

• When time is

displayed, changes

time backward

• When defrost set

ting is displayed,

moves backward

through choices

• When first defrost

time is displayed,

moves the hour

backward

• When set point is

displayed, moves

set point down one

degree

DOWN

-

Customer service FAX (517) 773-3210

5

Page 6

MCII Tempatrol

®

CHECK SYSTEM DEFROST

AM PM

CLEAN

CONDENSER

DOOR AJAR

®

CHECK SYSTEM DEFROST

AM PM

CLEAN

CONDENSER

DOOR AJAR

®

CHECK SYSTEM DEFROST

AM PM

CLEAN

CONDENSER

DOOR AJAR

®

CHECK SYSTEM DEFROST

AM PM

CLEAN

CONDENSER

DOOR AJAR

®

CHECK SYSTEM DEFROST

AM PM

CLEAN

CONDENSER

DOOR AJAR

ST PE S

RESET

®

CHECK SYSTEM DEFROST

AM PM

CLEAN

CONDENSER

DOOR AJAR

®

Display Functions

(continued)

Door ajar

The DOOR AJAR indicator

light will come on when a

door is opened. If the door

remains open for more than

one minute, the temperature

display will begin to flash.

After three minutes, a loud beep is emitted every three seconds. The flashing display and warning beep will stop when

RESET is pressed. If the door is not closed when RESET is

pressed, the same cycle will repeat.

Clean condenser

The CLEAN CONDENSER

indicator light is a maintenance reminder that comes

on every 90 days. It will go

off when the RESET button is

pressed.

Defrost

The DEFROST indicator light

comes on during defrosting

cycles. The defrost cycle may

be terminated by pressing the

RESET button. Warmer interior cabinet temperatures are

normal during and after defrosting.

Check system

The CHECK SYSTEM indicator light comes on when a

significant malfunction of the

unit has occurred, such as an

incomplete defrost, continuous compressor operation with

accompanying over-temperature

condition, or sensor failure. After 2™ hours in this condition, a

loud warning beep is emitted every second. The beep will stop

if RESET is pressed.

Clock display

Setting the CLOCK is not

essential to operation unless

custom defrost times have

been set on freezer units and

while not in automatic (A)

mode. If the power is interrupted, the clock may have to be

reset for correct custom defrost timing.

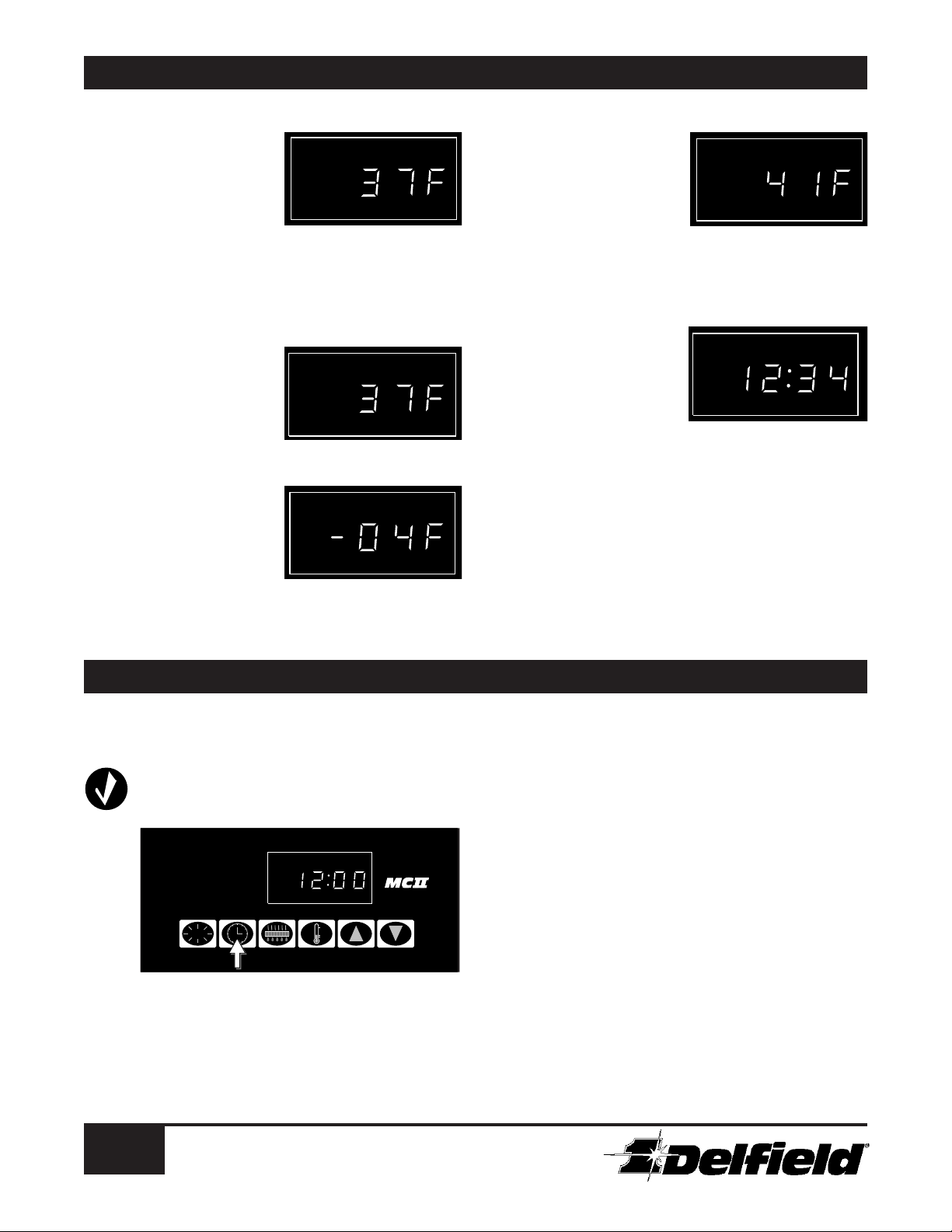

Setting the clock

To set the clock, perform the following steps:

®

MCII Tempatrol

Programming

1) Press RESET to clear the flashing display; this

must be done to make the rest of the keypad

functional.

2) Press the TIME button to show current time (set

to 12:00 a.m. when started or restarted).

6

For customer service, call (800) 733-8829,

(800) 733-8821 or (517) 773-7981

3) Press UP or DOWN to set the correct time.

Note the AM and PM indicators at the left of the

clock display.

4) Press

RESET to return to interior cabinet tem-

perature display.

If the defrost cycle starts while the clock is being set, stop

pressing the UP or DOWN button and wait a couple of

seconds before continuing. This will help to keep the time

display advancing quickly.

Page 7

®

RESET

®

CHECK SYSTEM DEFROST

AM PM

CLEAN

CONDENSER

DOOR AJAR

RESET

®

CHECK SYSTEM DEFROST

AM PM

CLEAN

CONDENSER

DOOR AJAR

RESET

®

CHECK SYSTEM DEFROST

AM PM

CLEAN

CONDENSER

DOOR AJAR

RESET

®

CHECK SYSTEM DEFROST

AM PM

CLEAN

CONDENSER

DOOR AJAR

RESET

®

CHECK SYSTEM DEFROST

AM PM

CLEAN

CONDENSER

DOOR AJAR

RESET

®

CHECK SYSTEM DEFROST

AM PM

CLEAN

CONDENSER

DOOR AJAR

ST PE S

ST PE S

MCII Tempatrol

Programming

Setting defrost cycles

Setting defrost cycles on freezer units is done via the MCII

Tempatrol. The automatic defrost cycle is preprogrammed at

“3” in the factory, and no adjustment is needed to use the unit

with this setting. A custom defrost cycle for freezers can be

programmed if desired. For information on how to determine

the proper defrost setting for your application, see page 9.

Refrigerators defrost automatically; no adjustment is needed.

Follow these steps to set or change the defrost cycle:

1) Press DEFROST. The current defrost setting (A, 3,

4, 6 or 8) will be displayed. “A” indicates the automatic “demand” defrost cycle; 3 through 8 indicate

the number of defrost cycles per 24 hours.

(continued)

however, the time of the first defrost is shown.

4) Press UP or DOWN to set the hour of the first

defrost cycle. Other defrosts will then be spaced

evenly over each 24-hour period, as determined

by the number of cycles selected.

5) Press RESET to return display to interior temperature reading.

Setting the temperature set point

Setting the temperature set point is also accomplished using

the MCII Tempatrol. The recommended storage temperature

for freezers is 0°F to –5°F (–18°C to –21°C); the set point

is preprogrammed at the factory at 0°F (–18°C). The recommended storage temperature for refrigerators is 35°F to 40°F

(2°C to 4°C); the set point is preprogrammed at the factory

at 37°F (3°C). If other ranges are selected and set, they must

be suitable for all products being stored in the unit.

2) Press UP or DOWN until desired setting appears in

the display.

3) Press DEFROST again. If you selected automatic

(A) mode, the display will return to the interior

temperature reading. If you selected 3, 4, 6 or 8,

1) Press RESET to display interior cabinet temperature, if

not already shown.

2) Press TEMP to display the current set point.

3) Press UP or DOWN to select the desired new set

point. Refrigerators are designed to maintain an

interior temperature of 34°F to 45°F (1°C to 7°C);

Customer service FAX (517) 773-3210

7

Page 8

MCII Tempatrol

ST PE S

®

Defrost Settings

Refrigerators

Refrigerators automatically defrost, using a special defrost

program in the MCII Tempatrol

whenever the MCII Tempatrol detects poor unit efficiency.

A refrigerator defrost will rarely occur. However, under certain

conditions, a defrost may be needed to assure optimum per

formance. Defrost cycles will occur more frequently at interior

temperature settings of 34°F (1°C) or less. Frequent defrosts

may also occur when room temperatures are unusually high.

Refrigerator defrosts cannot be adjusted; however, pressing

the RESET button will terminate the current defrost cycle on

either a refrigerator or a freezer.

®

. A refrigerator will defrost

-

Freezers

On freezers, an automatic (A) defrost cycle has been preset at

the factory; custom defrost cycles may be set by the user. The

last defrost program is always kept in the MCII Tempatrol’s

memory, even if power is lost. Correct setting of the clock is

essential if a custom defrost cycle is set.

Custom defrost cycles

When programming the custom defrost cycles, the display will

offer a choice of A, 3, 4, 6 or 8. The following chart has guide-

lines on selecting the proper setting.

DEFROST

SETTINGS

A

3

4

6

8

USAGE

LEVEL

variable

light

average

heavy

very heavy

FREQUENCY OF

DOOR OPENINGS

varies during the day

8 to 10 times per day

about once per hour

two or three times per hour

several times per hour

DEFROST

TIMING

automatic;

every 8 hours

every 6 hours

every 4 hours

every 3 hours

as needed

Example

Matt’s Diner wants to avoid defrost cycles during the peak

business hours around 7:00 a.m., noon and 5:00 p.m. The

freezer is used heavily during these periods, but the rest of the

day is “normal”. The humidity in the diner is high, however.

Therefore, we estimate that four defrosts are needed each day,

and they will occur every six hours.

To avoid the 7:00 a.m. rush, the first defrost time will be set

at 8:00 a.m. in this example. Subsequent defrosts then occur

at 2:00 p.m., 8:00 p.m. and 2:00 a.m., thereby missing all the

rush periods.

The first defrost should be set to follow the period of heaviest

usage during the day.

For additional instructions on using the MCII Tempatrol to set

a custom defrost cycle, see page 8.

Automatic defrost cycles

If the automatic (A) or “demand” defrost mode is selected,

the MCII Tempatrol will monitor usage and efficiency of the

unit, and will then defrost automatically only when needed.

This setting is recommended for all applications when the

time of each defrost is not important. In automatic (A) mode,

it is possible for light duty units to operate for several days

without defrosting.

By eliminating unnecessary defrosting, significant energy savings can be realized, and fewer defrosts also lead to more constant temperature control and longer product life.

The automatic defrost mode is not recommended when the

number of door openings per hour exceeds three.

For additional instructions on using the MCII Tempatrol to set

the automatic (A) defrost cycle, see page 8.

More defrosts should be added in high humidity environments.

Based on your selection, enter a time for the first defrost so that

it, and all subsequent defrosts, occur at suitable times.

®

MCII Tempatrol

Optional Settings

Changing the temperature

The temperature display can read in degrees Fahrenheit

(default setting) or Celsius (International System). To change

scales, follow these steps:

1) Press the TIME and DOWN buttons simultaneous-

ly, then press the TEMP button.

2) Press the DEFROST button. The condensing unit

will shut off, and the display will read 000.

8

For customer service, call (800) 733-8829,

(800) 733-8821 or (517) 773-7981

Manual defrost cycles

A manual defrost cycle can be initiated at any time by pressing

the DEFROST and TIME buttons simultaneously. The defrost

can be terminated by pressing RESET.

3) Hold the TIME button, and press UP or DOWN

until the display shows C for Celsius, or F for

Fahrenheit.

4) Release the TIME button. The display will blink to

indicate the command has been executed.

5) Press RESET. The condensing unit will restart, and

the display will return to the cabinet temperature,

now displayed in the new temperature scale.

Page 9

MCII Tempatrol

ST PE S

ST PE S

ST PE S

ST PE S

®

Optional Settings

(continued)

Locking control settings

You can lock the control settings so that they cannot be

changed without knowing how to unlock them. This will prevent unsupervised changes to the set point or defrost cycles.

1) Press the TIME and DOWN buttons simultaneously, then press the TEMP button.

2) Press the DEFROST button. The condensing unit

will shut off, and the display will read 000.

3) Press UP until the display reads 009.

4) Hold the TIME button, and press UP or DOWN

until the display shows L for locked, or U for

unlocked.

5) Release the TIME button. The display will blink to

indicate the command has been executed.

6) Press RESET. The condensing unit will restart,

and the display will return to the cabinet temperature. No control settings can be changed until the

locking procedure is reversed.

Over temperature alarms

You can select when the over temperature alarm will sound.

The following settings are available:

0:01 Alarm sounds when unit is over set point for 60 minutes

(default setting)

0:02 Alarm sounds when the unit is 5°F (3°C) over set point.

0:03 Alarm sounds when the unit is 10°F (6°C) over set point.

0:04 Alarm sounds when the unit is 15°F (8°C) over set point.

1) Press the TIME and DOWN buttons simultaneously, then press press the TEMP button.

2) Press the DEFROST button. The condensing unit

will shut off, and the display will read 000.

3) Press UP until the display reads 010.

4) Hold the TIME button, and press UP or DOWN

until the display shows the desired setting from

the chart above.

5) Release the TIME button. The display will blink to

indicate the command has been executed.

6) Press RESET. The condensing unit will restart, and

the display will return to the cabinet temperature.

1) Press the TIME and DOWN buttons simultaneous-

ly, then press the TEMP button.

2) Press the DEFROST button. The condensing unit

will shut off, and the display will read 000.

3) Press UP until the display reads 011.

4) Hold the TIME button, and press UP or DOWN

until the display shows the desired setting.

5) Release the TIME button. The display will blink to

indicate the command has been executed.

6) Press RESET. The condensing unit will restart, and

the display will return to the cabinet temperature.

Set point differential tolerance

The unit is set at the factory to hold the programmed set

point to within plus or minus 3°F (2°C), which is default

option 0:01. Depending on the alarm setting you have

selected, the alarm will sound when the cabinet temperature

is outside that range. You may change the differential tolerance to 2°F (1°C) by selecting option 0:02, or 1°F (0.5°C)

by selecting option 0:03.

1) Press the TIME and DOWN buttons simultaneous-

ly, then press the TEMP button.

2) Press the DEFROST button. The condensing unit

will shut off, and the display will read 000.

3) Press UP until the display reads 013.

4) Hold the TIME button, and press UP or DOWN

until the display shows the desired setting.

5) Release the TIME button. The display will blink to

indicate the command has been executed.

6) Press RESET. The condensing unit will restart,

and the display will return to the cabinet temperature.

Other programmable options

There are many other options accessible through the MCII

Tempatrol; these should be left to qualified service personnel,

however. For information on accessing the MCII Tempatrol’s

self-diagnostic mode, see the next section.

Power up display

When the unit is restarted, you can choose to have the normal

temperature display appear (option 0:01), a flashing tempera-

ture display for 3 seconds (option 0:02) or a flashing clock

display for 3 seconds (option 0:03). The flashing displays may

help remind you to check the defrost, set point or clock settings after a power interruption.

Customer service FAX (517) 773-3210

9

Page 10

MCII Tempatrol

ST PE S

ST PE S

CAUTION

®

Self-Diagnostic System

Check system indications

Whenever a CHECK SYSTEM indication

appears, a potentially serious problem has

occurred. Appropriate action should be taken

immediately to ensure proper product temperature is maintained. A qualified service agent

should be called whenever a serious problem

has occurred.

You may be able to speed up the repair process, however, by

noting the diagnostic codes provided on the digital display by

the MCII when a problem occurs.

Using the diagnostic mode

Using the following instructions, enter the diagnostic mode

and write down the codes to give to your service agent.

1) To enter the diagnostic mode, press DOWN and

TIME simultaneously, then press TEMP.

2) The diagnostic code numbers and CHECK

SYSTEM indicator should appear. If there is more

than one code number, the unit will display them

one after another, repeating the sequence continuously. By using the chart provided on page 12, you

can determine the problem area or areas to check.

3) To exit the diagnostic mode, press RESET.

The CHECK SYSTEM indicator will go out

unless there is a sensor problem. The CHECK

SYSTEM indication will reappear in one hour if

an over-temperature condition still exists.

The diagnostic codes are provided for information only; service should be left to qualified service agents only!

Clearing error codes

After the unit is repaired, the error code or codes must be

erased from the MCII. Otherwise, they will be stored and

any new errors will be added to the old list, making diagnosis of potential future problems difficult. Follow these steps to

erase all error codes from the MCII:

1) Press the TIME and DOWN buttons simultaneously, then press the TEMP button.

2) Press the DEFROST button. The condensing

unit will shut off, and the display will read 000.

3) Press UP until the display reads 08.

4) Press the TIME button. The display will blink to

indicate the command has been executed.

5) Press RESET. The condensing unit will

restart, and the display will return to the

cabinet temperature.

MCII Tempatrol

®

Check System Warnings

(Reference Chart)

10

For customer service, call (800) 733-8829,

(800) 733-8821 or (517) 773-7981

Page 11

MCII Tempatrol

®

Diagnostic Codes

(Reference Chart)

DISCONNECT ALL POWER TO YOUR DELFIELD UNIT BEFORE REPAIRING OR REPLACING THE MICROPROCESSOR OR ANY

OTHER MAINTENANCE OR REPAIR FUNCTION

MCII Tempatrol

®

Display

(Reference Chart)

Customer service FAX (517) 773-3210

11

Page 12

MCII Tempatrol

®

Troubleshooting

(Reference Chart)

12

For customer service, call (800) 733-8829,

(800) 733-8821 or (517) 773-7981

Page 13

N

#14

AWG

115V POWER CORD

PROVIDED ON

SELF-CONTAINED

MODELS

PM: POWER MODULE

PMR: POWER MODULE

RELAY

CONDENSATE EVAPORATOR

(OPTIONAL)

CABINET WIRING

MAIN WIRING

WIRING FOR

115V MODELS

AC SERIES

REFRIGERATORS

PSS

L1

PM TRANSFORMER

EVAPORATOR

PMR2

CONDENSING UNIT

FRAME HEATERS

GLASS DOOR HEATERS

ON - G MODEL ONLY

ACR-26S Wiring Diagram

Customer service FAX (517) 773-3210

13

Page 14

Replacement Parts Lists

Bumper, round, gray ........................................................................................ 323-4223

Caster, 4" diameter, plate w/brakes ................................................................... 323-4221

Coil, evaporator ................................................................................................. 351-6085

Control, MCII display ........................................................................................ 219-3967

Condensing unit, 1/2 HP, med, 404A ................................................................ 352-6731

Control, pressure, high ..................................................................................... 351-6247

Cord/plug assembly 5-15P ............................................................................... 218-3348

Door assembly .................................................................................................. 034-0011

Fan assembly, 8" diameter ................................................................................ 216-2687

Gasket, door ..................................................................................................... 170-1147

Handle assembly, rear ....................................................................................... 034-0021

Hinge, bottom half (2) ...................................................................................... 005-5292

Hinge, top half (2) ............................................................................................. 005-5291

Lock .................................................................................................................. 323-4416

Louver, back ..................................................................................................... 005-5158

Louver, front ..................................................................................................... 005-5157

Module, power, MCII ........................................................................................ 219-3987

Switch, rocker ................................................................................................... 219-0154

Valve, expansion, 404A ..................................................................................... 351-6084

14

For customer service, call (800) 733-8829,

(800) 733-8821 or (517) 773-7981

Page 15

Notes:

Customer service FAX (517) 773-3210

15

Page 16

Standard 1 Year Limited Warranty

— 1 year parts, 90 days labor

The Delfield Company (“Delfield”) warrants to the Original

Purchaser of the Delfield product (herein called the “Unit”)

that such Unit, and all parts thereof, will be free from defects

in material and workmanship under normal use and service for

a period of one (1) year from the date of shipment of the Unit

to the Original Purchaser or, if the Original Purchaser returns

the warranty card completely filled out including the date of

installation within thirty (30) days of receipt of the Unit, one

(1) year from the date of installation. During this one year war

ranty period, Delfield will repair or replace any defective part or

portion thereof returned to Delfield by the Original Purchaser

which Delfield determines was defective due to faulty mate

rial or workmanship. The Original Purchaser will pay all labor,

crating, freight and related costs incurred in the removal of the

Unit or defective component and shipment to Delfield, except

that during a period of either ninety (90) days from the date of

shipment of the Unit to the Original Purchaser or, if the Original

Purchaser returns the warranty card completely filled out includ

ing the date of installation within thirty (30) days of receipt of

the Unit, ninety (90) days from the date of installation Delfield

will pay all related labor costs. Delfield will pay the return costs

if the Unit or part thereof was defective.

The term “Original Purchaser” as used herein means that per

son, firm, association, or corporation for whom the Unit was

originally installed.

This Warranty does not apply to any Unit or part thereof that

has been subjected to misuse, neglect, alteration, or accident,

such as accidental damage to the exterior finish; operated con

trary to the recommendations specified by Delfield; or repaired

or altered by anyone other than Delfield in any way so as to,

in Delfield’s sole judgment, affect its quality or efficiency. This

Warranty does not apply to any Unit that has been moved from

the location where it was originally installed. This Warranty also

does not cover the refrigerator drier or the light bulbs used in

the Unit. The warranty is subject to the user’s normal main

tenance and care responsibility as set forth in the Service

and Installation Manual, such as cleaning the condenser

coil, and is in lieu of all other obligations of Delfield. Delfield

neither assumes, nor authorizes any other person to assume

for Delfield, any other liability in connection with Delfield’s

products.

Removal or defacement of the original Serial Number or Model

Number from any Unit shall be deemed to release Delfield from

all obligations hereunder or any other obligations, express or

implied.

Parts furnished by suppliers to Delfield are guaranteed by

Delfield only to the extent of the original manufacturer’s express

warranty to Delfield. Failure of the Original Purchaser to receive

such manufacturer’s warranty shall in no way create any war

ranty, express or implied, or any other obligation or liability on

Delfield’s part in respect thereof.

-

-

-

-

If shipment of a replacement part is requested prior to the arriv

al in the Delfield factory of the part claimed to be defective, the

Original Purchaser must accept delivery of the replacement part

on a C.O.D. basis, with credit being issued after the part has

been received and inspected at Delfield’s plant and determined

by Delfield to be within this Warranty.

Under no condition does this Warranty give the Original

Purchaser the right to replace the defective Unit with a com

-

plete Unit of the same manufacturer or of another make. Unless

authorized by Delfield in writing, this Warranty does not permit

the replacement of any part, including the motor-compressor, to

be made with the part of another make or manufacturer.

No claims can be made under this Warranty for spoilage of prod

ucts for any reason, including system failure.

The installation contractor shall be responsible for building

access, entrance and field conditions to insure sufficient clear

ance to allow any hood(s), vent(s) or Unit(s), if necessary, to be

brought into the building. Delfield will not be responsible for

structural changes or damages incurred during installation of the

Unit or any exhaust system.

Delfield shall not be liable in any manner for any default or

delay in performance hereunder caused by or resulting from any

contingency beyond Delfield’s control, including, but not limited

to, war, governmental restrictions or restraints, strikes, lockouts,

injunctions, fire, floods, acts of nature, short or reduced supply

of raw materials, or discontinuance of the parts by the original

part manufacturer.

Except as provided in any Additional Four Year Protection

Plan, if applicable, and the Service Labor Contract, if appli

cable, the foregoing is exclusive and in lieu of all other

warranties, whether written or oral, express or implied. This

Warranty supersedes and excludes any prior oral or written

representations or warranties. Delfield expressly disclaims

any implied warranties of merchantability, fitness for a par

ticular purpose or compliance with any law, treaty, rule or

regulation relating to the discharge of substances into the

environment. The sole and exclusive remedies of any person

relating to the Unit, and the full liability of Delfield for any

breach of this Warranty, will be as provided in this Warranty.

Other than this Delfield Standard One Year Limited Warranty,

any applicable Delfield Additional Four Year Protection Plan or

applicable Delfield Service Labor Contract, the Original Purchaser

agrees and acknowledges that no other warranties are offered or

provided in connection with or for the Unit or any part thereof.

In no event will Delfield be liable for special, incidental or con

sequential damages, or for damages in the nature of penalties.

-

-

-

-

-

-

-

16

For customer service, call (800) 733-8829,

(800) 733-8821 or (517) 773-7981

Page 17

Additional 4 Year Protection Plan

— for motor-compressor only

Delfield Model# Serial# Installation Date

In addition to the Standard One Year Warranty on the MotorCompressor contained in the above listed Delfield product (the

“Unit”), The Delfield Company (“Delfield”) also agrees to repair,

or exchange with similar or interchangeable parts in design and

capacity at Delfield’s option, the defective Motor-Compressor

contained in the Unit (the “Motor-Compressor”), or any part

thereof, for the Original Purchaser only, at any time during

the four (4) years following the initial one (1) year period commencing on the date of installation for the Original Purchaser.

Failure of the Original Purchaser to register the registration

card containing the Original Purchaser’s name, address, date

of installation, model number and serial number of the Unit

containing the Motor-Compressor within 30 days from the

date of installation shall void this Warranty. This additional

Warranty is only available if the Motor-Compressor is inopera

tive due to defects in material or factory workmanship, as

determined by Delfield in its sole judgment and discretion. The

Original Purchaser shall be responsible for returning the defec

tive Motor-Compressor to Delfield prepaid, F.O.B. at the address

shown on the back cover of this manual.

The term “Original Purchaser” as used herein shall be deemed

to mean that person, firm, association, or corporation for whom

the equipment was originally installed.

The term “Motor-Compressor” as used herein does not include

unit base, air or water cooled condenser, receiver, electrical

accessories such as relay, capacitors, refrigerant controls, or

condenser fan/motor assembly. This warranty does not cover

labor charges incidental to the replacement of parts. This war

ranty further does not include any equipment to which said

condensing unit is connected, such as cooling coils, temperature

controls or refrigerant metering devices. This warranty shall be

void if the Motor-Compressor, in Delfield’s sole judgment, has

been subjected to misuse, neglect, alteration or accident, oper

ated contrary to the recommendations specified by the Unit

manufacturer, repaired or altered by anyone other than Delfield

in any way so as, in Delfield’s sole judgment, to affect its quality

or efficiency or if the serial number has been altered, defaced or

removed. This Warranty does not apply to a Motor-Compressor

in any Unit that has been moved from the location where it was

originally installed. The addition of methyl chloride to the con

densing unit or refrigeration system shall void this warranty.

General Conditions

-

-

-

-

-

Delfield shall not be liable in any manner for any default or

delay in performance thereunder caused by or resulting from

any contingency beyond Delfield’s control including, but not

limited to, war, governmental restrictions or restraints, strikes,

lockouts, injunctions, fire, floods, acts of nature, short or

reduced supply of raw material or discontinuance of any part or

the Motor-Compressor by the unit manufacturer.

Replacement of a defective Motor-Compressor is limited to one

(1) Motor-Compressor by us during the four (4) year period.

Delfield shall replace the Motor-Compressor at no charge.

This Warranty does not give the Original Purchaser of the

Motor-Compressor the right to purchase a complete replacement

Motor-Compressor of the same make or of another make. It fur

ther does not permit the replacement to be made with a MotorCompressor of another kind unless authorized by Delfield. In

the event Delfield authorizes the Original Purchaser to purchase

a replacement Motor-Compressor locally, only the wholesale

cost of the Motor-Compressor is refundable.

Expressly excluded from this warranty are damages resulting

from spoilage of goods.

Except as provided in any applicable Standard One Year

Limited Warranty or applicable Service Labor Contract, the

foregoing is exclusive and in lieu of all other warranties,

whether written or oral, express or implied. This Warranty

supersedes and excludes any prior oral or written representa

tions or warranties. Delfield expressly disclaims any implied

warranties of merchantability, fitness for a particular purpose

or compliance with any law, treaty, rule or regulation relat

ing to the discharge of substances into the environment. The

sole and exclusive remedies of any person relating to the

Motor-Compressor, and the full liability of Delfield for any

breach of this Warranty, will be as provided in this Warranty.

Other than any applicable Delfield Standard One Year Limited

Warranty, this Delfield Additional Four Year Protection Plan

and any applicable Delfield Service Labor Contract, the Original

Purchaser agrees and acknowledges that no other warranties

are offered or provided in connection with or for the MotorCompressor or any part thereof.

In no event will Delfield be liable for special, incidental or con

sequential damages, or for damages in the nature of penalties.

-

-

-

-

Customer service FAX (517) 773-3210

17

Page 18

Notes:

18

For customer service, call (800) 733-8829,

(800) 733-8821 or (517) 773-7981

Page 19

Page 20

DMACR

9/98

Loading...

Loading...