Delfield 6100XL Series Service Manual

6000XL & 6100XL Series Reach Ins

Delfield

™

®

Service, Installation and Care Manual

Please read this manual completely before attempting to install or operate this equipment! Notify carrier of

damage! Inspect all components immediately. See page 2.

Refrigerators and Freezers

IMPORTANT INFORMATION

READ BEFORE USE

PLEASE SAVE THESE INSTRUCTIONS!

July 2010

6000XL Series Service and Installation Manual

Delfield

™

®

Contents

Serial Number Information ........................................................2

Receiving & Inspecting Equipment ...........................................2

Specifications .............................................................................3

Installation ...............................................................................4-5

Operation ....................................................................................6

Maintenance ............................................................................7-8

Wiring Diagrams ...................................................................9-13

Refrigeration Package Diagram ...............................................14

Replacement Parts ..............................................................15-16

Standard Labor Guidelines ......................................................17

Standard Warranties ...........................................................18-19

©2010 The Deleld Company. All rights reserved. Reproduction without written

permission is prohibited. “Deleld” is a registered trademark of The Deleld

Company.

Receiving And Inspecting The Equipment

Even though most equipment is shipped crated, care should

be taken during unloading so the equipment is not damaged

while being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported to

the delivering carrier immediately.

2. If damaged, open and inspect the contents with the

carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notification should be made verbally

Serial Number Information

The serial number of all self-contained 6000XL Series

refrigerators and freezers is located above the door under the

shroud.

Always have the serial number of your unit available when

calling for parts or service. A complete list of authorized

Delfield parts depots is available at www.delfield.com.

This manual covers standard units only. If you have a custom

unit, consult the customer service department at the number

listed below.

as well as in written form.

4. Request an inspection by the shipping company of the

damaged equipment. This should be done within 10

days from receipt of the equipment.

5. Be certain to check the compressor compartment

housing and visually inspect the refrigeration package.

Be sure lines are secure and base is still intact.

6. Freight carriers can supply the necessary damage forms

upon request.

7. Retain all crating material until an inspection has been

made or waived.

2

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

NOTE: Upon powering unit, there could be up to a

10 minute delay before unit begins to cool.

Delfield

™

®

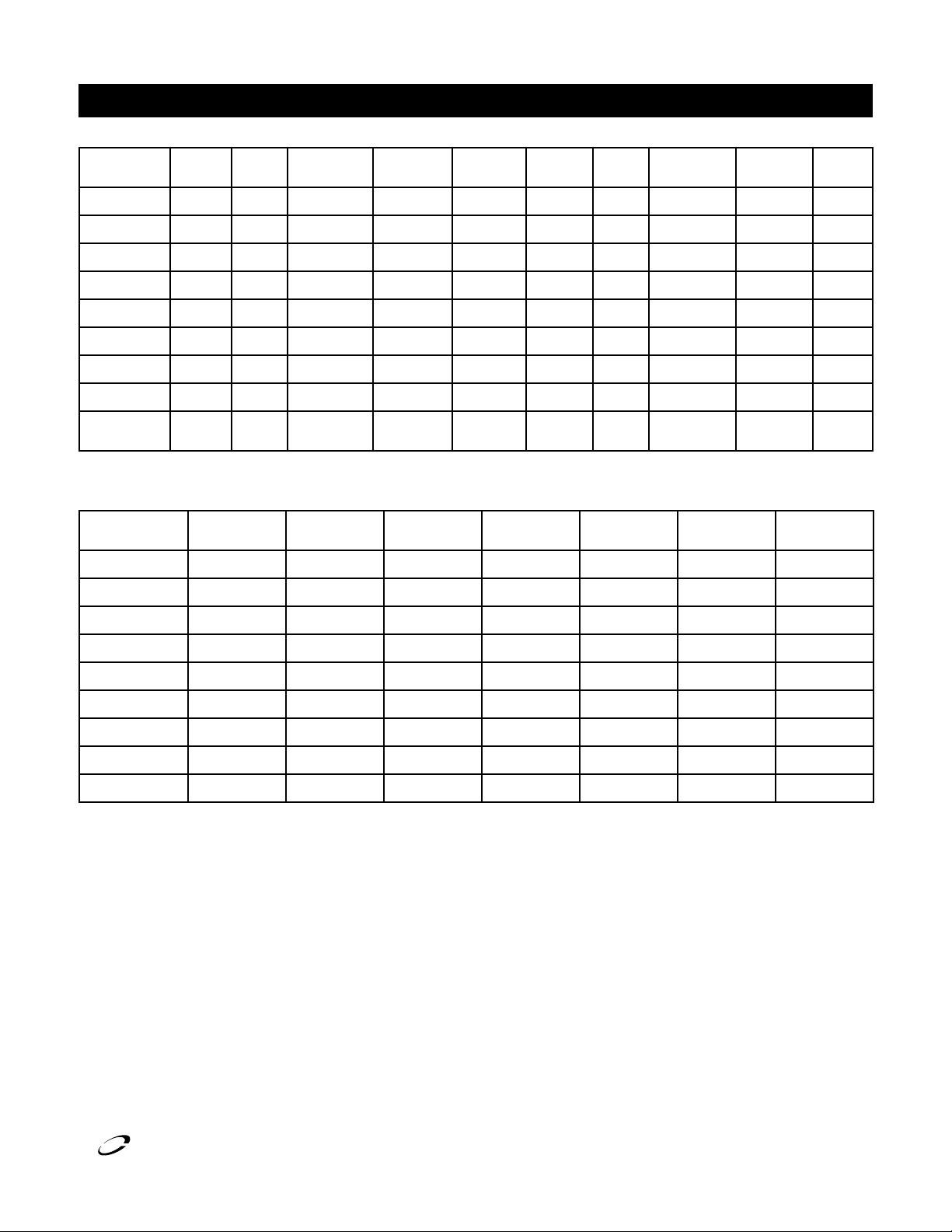

Specifications

6000XL Series Service and Installation Manual

Model Voltage Amps

6025XL-SH,S 115 6.0 20.0 15.1 1/4 2092 20˚F 12.5 274lbs/124kg 515P

6025XL-G,GH 115 6.0 20.0 15.1 1/4 2092 20˚F 12.5 338lbs/153kg 515P

6051XL-SH,S 115 8.0 43.5 33.2 1/3 2488 20˚F 12.5 454lbs/206kg 515P

6051XL-G,GH 115 8.0 43.5 33.2 1/3 2488 20˚F 12.5 548lbs/249kg 515P

6076XL-SH,S 115 16.0 66.5 48.3 1/4, 1/3 2092/2488 20˚F 12.5/12.5 622lbs/282kg 520P

6076XL-G,GH 115 16.0 66.5 48.3 1/4, 1/3 2092/2488 20˚F 12.5/12.5 774lbs/351kg 520P

6125XL-S,SH 115 9.0 20.0 15.1 1/2 2092 -20˚F 12.5 274lbs/124kg 515P

6151XL-S,SH 115 12.0 43.5 33.2 3/4 1923 -20˚F 12.5 454lbs/206kg 515P

6176XL-S,SH

Model Voltage Amps

6025XLR-SH,S 115 5.0 20.0 15.1 2092 20˚F 274lbs/124kg

6025XLR-G,GH 115 5.0 20.0 15.1 2092 20˚F 338lbs/153kg

120/208-

230

20.0 66.5 48.3 1/2, 3/4 1516/1923 -20˚F 12.5/12.5 622lbs/282kg 1420P

Storage

Capacity FT

3

Shelf

Capacity FT

Storage

Capacity FT

2

3

H.P. BTU/HR

Shelf

Capacity FT

2

Evap.

Temp

Required

BTU/HR

R-404A Charge

Oz.

Evap. Temp Shipping Weight

Shipping

Weight

Nema

Plug

6051XLR-SH,S 115 5.0 43.5 33.2 2488 20˚F 454lbs/206kg

6051XLR-G,GH 115 5.0 43.5 33.2 2488 20˚F 548lbs/249kg

6076XLR-SH,S 115 5.0 66.5 48.3 2092/2488 20˚F 622lbs/282kg

6076XLR-G,GH 115 5.0 66.5 48.3 2092/2488 20˚F 774lbs/351kg

6125XLR-S,SH 115 5.0 20.0 15.1 2092 -20˚F 274lbs/124kg

6151XLR-S,SH 115 5.0 43.5 33.2 1923 -20˚F 454lbs/206kg

6176XLR-S,SH 115 5.0 66.5 48.3 1516/1923 -20˚F 622lbs/282kg

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

3

6000XL Series Service and Installation Manual

Delfield

™

®

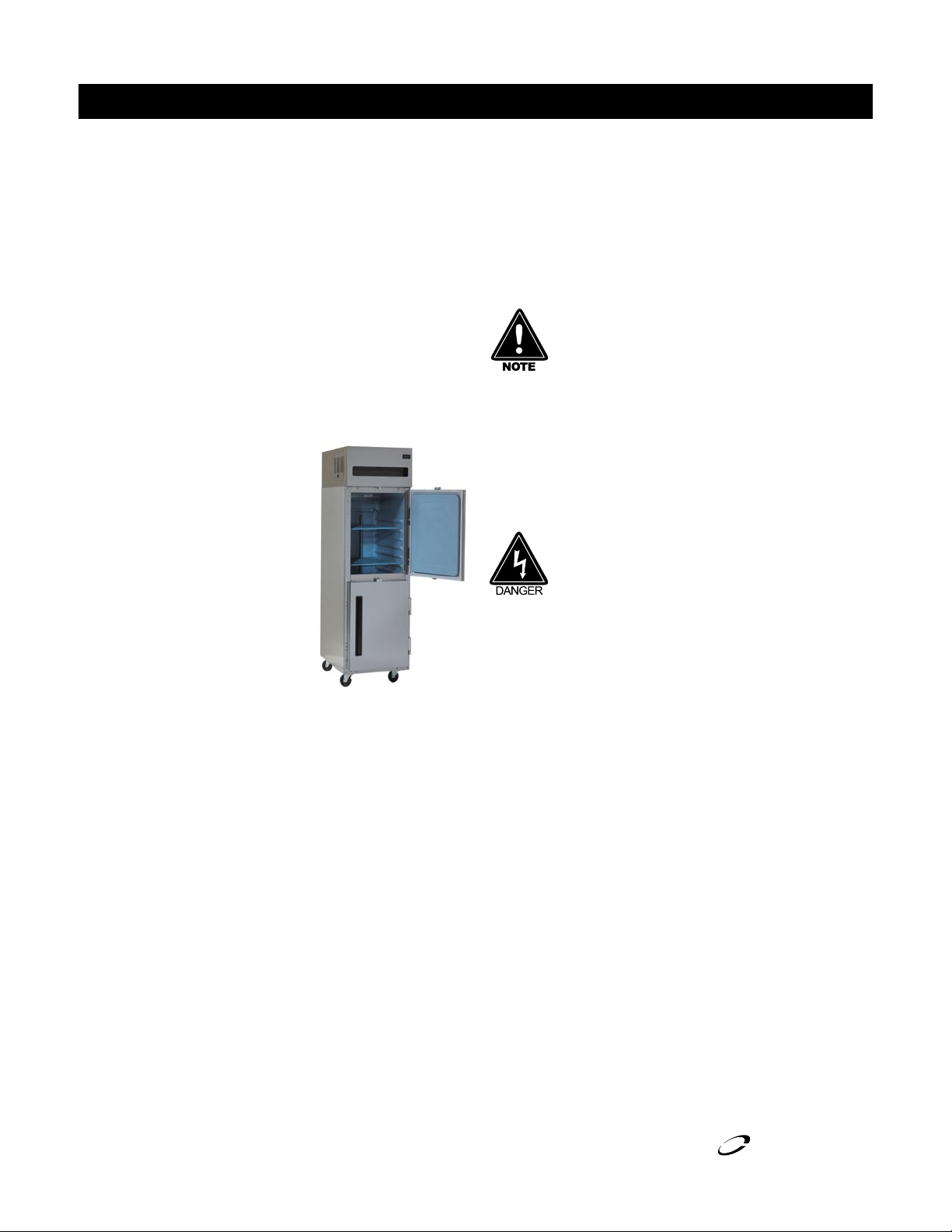

Installation

Location

Units represented in this manual are intended for indoor use

only. Be sure the location chosen has a floor strong enough

to support the total weight of the cabinet and contents. A fully

loaded 6000XL series can weigh as much as 1500 pounds.

Reinforce the floor as necessary to provide for maximum

loading. For the most efficient refrigeration, be sure to provide

good air circulation inside and out.

Inside cabinet: Do not pack refrigerator so full that air

cannot circulate. The refrigerated air is discharged at the top

rear of the unit. It is important to allow for proper air flow

from the top rear to the bottom of the unit. Obstructions to

this air flow can cause evaporator coil freeze ups and loss of

temperature or overflow of water from the evaporator drain

pan. The rear of the unit has molded ribs and the shelves

have a rear turn up on them to

prevent this. However, bags and

other items can still be located to

the far rear of the cabinet. There is

also a return air diffuser along the

top front of the cabinet interior, this

also requires proper air circulation.

Prevent obstruction by locating large

boxes and tall stacks of product to

the bottom of the cabinet.

Outside cabinet: Be sure that the

unit has access to ample air. Avoid

hot corners and locations near

stoves and ovens.

It is recommended that the unit be installed no closer than 2”

from any wall with at least 12” of clear space above the unit.

Avoid exposing glass door units to direct sunlight. Direct

sunlight through the glass doors will make the ABS liner

fade and become brittle and will greatly reduce refrigeration

efficiency.

Leveling

A level cabinet looks better and will perform better because

the doors will line up with the frames properly, the cabinet will

not be subject to undue strain and the contents of the cabinet

will not move around on the shelves. Use a level to make sure

the unit is level from front to back and side to side. Units

supplied with legs will have adjustable bullet feet to make the

necessary adjustments. If the unit is supplied with casters, no

adjustments are available. Ensure the floor where the unit is to

be located is level.

Stabilizing

Some models are supplied on casters for your convenience,

ease of cleaning underneath and for mobility. It is very

important, however, that the cabinet be installed in a stable

condition with the front wheels locked while in use.

Should it become necessary to lay the unit on its side or back

for any reason, allow at least 24 hours before start-up so as to

allow compressor oil to flow back to the sump. Failure to meet

this requirement can cause compressor failure and unit damage.

Unit repairs will not be subject to standard

unit warranties due to improper installation

procedures.

Electrical connection

Refer to the amperage data on page 3, the serial tag, your

local code or the National Electrical Code to be sure the unit is

connected to the proper power source. A protected circuit of

the correct voltage and amperage must be run for connection

of the line cord, or permanent connection to the unit.

The thermostat must be turned to OFF and

the unit disconnected from the power source

whenever performing service, maintenance

functions or cleaning the refrigerated area.

Door Reversal Procedure 6000XL

Edge-Mount Hinge

1.

Open door 90˚ and lift door straight up and off hinges.

2.

Remove the plastic screw covers on each hinge section

by prying out with a thin screwdriver.

3.

Remove two outer screws that mount each hinge to door,

loosen the center screw, rotate hinge 180˚, reinstall outer

screws and retighten center screw.

4.

Remove two screws that mount lock on top of door, turn

door up-side-down and remount lock to top of door.

5.

Remove the hinges from the cabinet face frame.

6.

Use a 3/16” drill to drill holes in cabinet face frame at the

marked hinge locations on the new hinge side.

7.

Remove the plastic cam from the hinges by pulling

straight up, then rotating the cam 180˚ and pushing back into

the hinge.

8.

Reinstall the plastic screw covers removed in step 2.

9.

Reinstall the door by reversing step 1.

10.

If plastic plugs are needed to plug old screw holes in

cabinet face frame, please contact Delfield Parts Department at

(800) 733-8821, extension 12801.

4

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

Delfield

™

®

Installation, continued

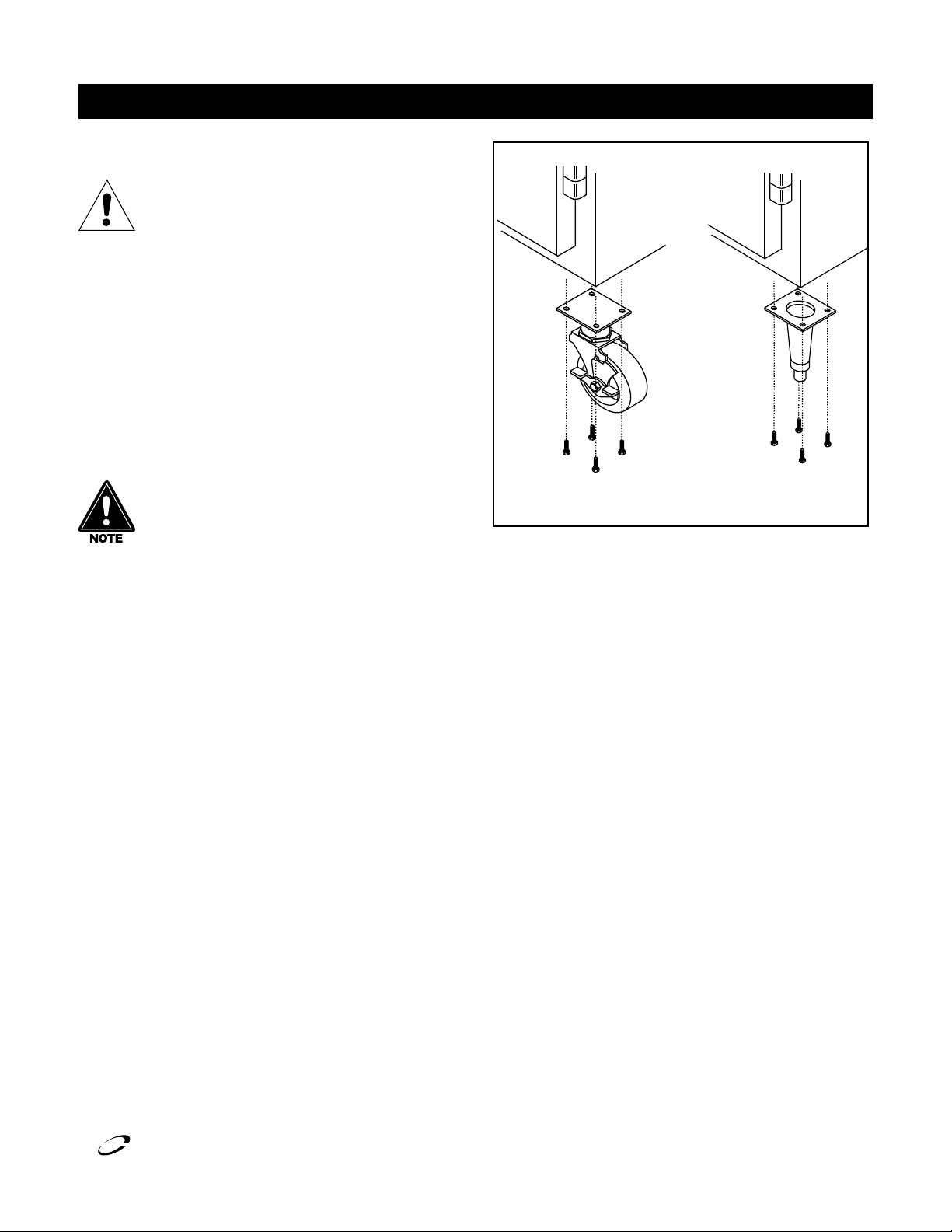

WARNING

Leg and Caster Installation

Some cabinets may weigh over 1000 lbs (450

kg). Use a lifting device capable of supporting

the unit when removing skid or installing legs or

casters.

To install the legs, or casters refer to Figure 1 and proceed as

follows:

Remove unit from skid.

1.

Raise unit to access leg/caster mounting bolts on bottom

2.

of unit.

Remove the bolts from the cabinet and use them to attach

3.

the legs or casters.

All single-section units require that the swivel

casters be mounted on the front and rigid casters

be mounted on the rear.

6000XL Series Service and Installation Manual

Figure 1. Leg or Caster Installation

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

5

6000XL Series Service and Installation Manual

Delfield

™

®

Operation

Electronic Temperature Control

Operation:

The electronic temperature control constantly monitors box

temperature as well as evaporator coil temperature to maintain

consistent product temperatures. The control also sends temperature

readings to the digital temperature display. The control circuits

continually self-check and if an error occurs, the digital display will

switch from temperature read-out to error read-out, i.e. E 1. Even

when an error is displayed, the refrigeration and controls system

should continue to function, however not at optimal performance.

Whenever the display has an error read-out, Delfield Service should

be contacted.

At initial start-up or anytime power is disconnected, then reconnected

to the unit, the control will delay all operations for a short time (up

to 10 minutes.) While in this delay period, the control initializes

the control parameters and confirms that the temperature sensors

and circuits are operational. The digital temperature display will not

display temperature OR errors until the self-check is complete and

the control has switched on the evaporator fan motor, compressor

and condenser fan motor.

IMPORTANT NOTE REGARDING FREEZERS: After initializing, the

control will immediately enter a DEFROST mode and the display

will read DEF. The compressor and condenser fan as well as the

evaporator fan will remain off until initialization defrost is complete.

This initial defrost cycle may take up to 15 minutes to complete,

at which time the freezing cycle will begin. The display will

continue to read DEF for an additional 30 minutes before displaying

temperature.

Refrigerator:

The control is located in the control box in the top of the refrigerator

behind the removable louvered panel on the left side. It is factory set

at mid-range to maintain about 38˚F (3˚C) box temperature. To adjust

for colder temperatures,

turn the knob clockwise. For warmer temperatures, turn the knob

counter-clockwise. Turn the knob fully counter-clockwise to turn

the refrigeration system off. Never turn the knob more than 1 dial

number and always allow 8 hours for temperature stabilization before

making any additional adjustments.

Freezer:

The control is located in the control box in the top of the refrigerator

behind the removable louvered panel on the left side. It is factory

set at mid-range to maintain about -3˚F (-18˚C) box temperature. To

adjust for colder temperatures, turn the knob clockwise. For warmer

temperatures, turn the knob counter-clockwise. Turn the knob fully

counter-clockwise to turn the refrigeration system off. Never turn

the knob more than 1 dial number and always allow 8 hours for

temperature stabilization before making any additional adjustments.

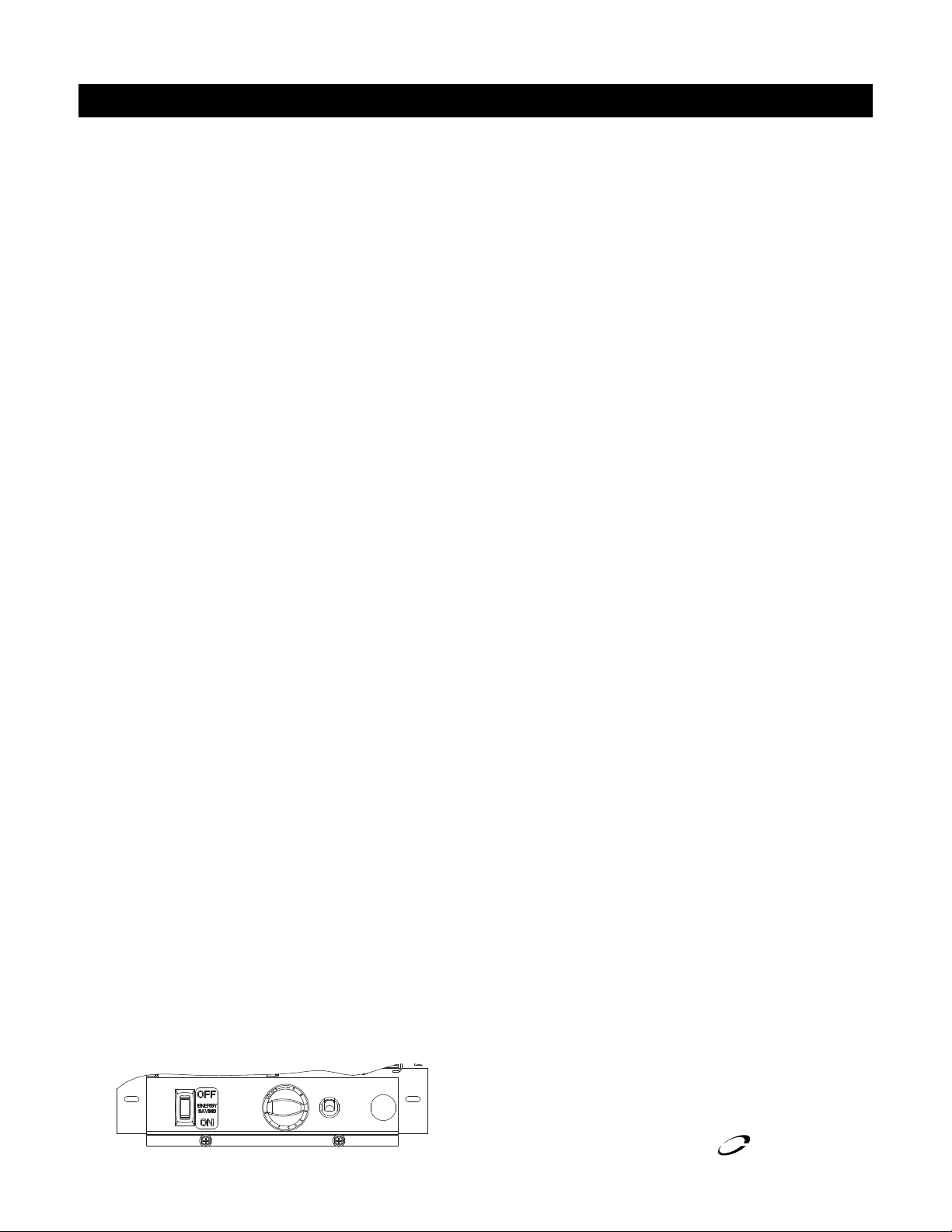

Energy Saver Switch

The energy saver switch is a rocker switch located next to the

thermostat knob that controls the amount of heat applied to the

door perimeter. The normal operating position for this switch is the

ON position, providing the least heat. If excessive condensation is

observed on the door opening, press the energy saver switch to

the OFF position, to increase the amount of heat (red portion of the

rocker switch will be visible).

Refrigeration & Defrost Cycle

Refrigerator:

Whenever the refrigerator is plugged in, and the control has

completed initializing, the evaporator fans will run continuously and

the digital temperature will display box temperature in degrees F. The

temperature control will cycle the compressor and condenser fan

motor to maintain box temperature at the control setting.

Refrigerator Defrost

The temperature control also monitors the evaporator temperature

and will turn off the compressor and condenser fan motor when

needed to allow accumulated frost on the evaporator to clear. During

this defrost cycle, the digital temperature display will read dEF. After

the defrost cycle is complete, the temperature control will return to a

normal cooling cycle, but the display will continue to read dEF until

the evaporator returns to normal cooling temperatures (up to 30

minutes).

Freezer:

Whenever the freezer is plugged in, and the control has completed

initializing including the initial defrost cycle (also see Electronic

Temperature Control Operation, on this page), the evaporator fans

will run continuously. After evaporator coil has reached operational

temperature, the digital temperature will display box temperature in

degrees F. The temperature control will cycle the compressor and

condenser fan motor to maintain box temperature at the control

setting.

Freezer Automatic Defrost

The control also monitors compressor total running time and will

enter a defrost cycle after total compressor running time is greater

than 4-hours since the last defrost cycle OR if evaporator coil

temperature drops below -34˚F (indicating excessive frost on the

coil).

Freezer Manual Defrost

If a manual defrost is desired, simply unplug the unit for several

seconds, then plug unit back in. This will cause the control to reinitialize and then enter a defrost cycle.

When the control enters the defrost mode, it switches off the

evaporator fan motor, compressor and condenser fan motor, and

switches on the defrost heater to warm the evaporator coil. Thereby

melting all frost accumulated during the previous refrigeration

cycle. The digital temperature display will now read dEF. The

control will continue the defrost cycle for a MINIMUM of 8 minutes

and a MAXIMUM of 30 minutes depending on the amount of frost

accumulated on the evaporator coil.

After the defrost cycle is complete, the control returns to a normal

refrigeration cycle, however the evaporator fan motor will not switch

on for 2 minutes AFTER the compressor and condenser fan motor

have begun operating. The digital temperature display will continue

to read dEF until the evaporator has returned to normal freezing

temperatures (up to 30 minutes).

6

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

Loading...

Loading...