Delfield 536-SRR68 Service Manual

536-SR68 & 536-SRR68 Dual View Display Case

Delfield

™

®

Service, Installation and Care Manual

Please read this manual completely before attempting to install or operate this equipment! Notify carrier

of damage! Inspect all components immediately. See page 2.

IMPORTANT INFORMATION

READ BEFORE USE

PLEASE SAVE THESE INSTRUCTIONS!

536-SR68

Effective Date June 2008

Dual View Series Service and Installation Manual

Delfield

™

®

Contents

Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . 2

Receiving and Inspecting the Equipment. . . . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Display Case Glass Replacement . . . . . . . . . . . . . . . . . . 3

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Pressure Control Settings . . . . . . . . . . . . . . . . . . . . . . . 5

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Replacement Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . 6

Standard Warranties. . . . . . . . . . . . . . . . . . . . . . . . . . .7-9

Receiving And Inspecting The Equipment

Even though most equipment is shipped crated, care should

be taken during unloading so the equipment is not damaged

while being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported to

the delivering carrier immediately.

2. If damaged, open and inspect the contents with the

carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notification should be made verbally as

well as in written form.

4. Request an inspection by the shipping company of the

damaged equipment. This should be done within 10 days

from receipt of the equipment.

Serial Number Location

The serial number is located on the rear of the unit on the

bottom right hand side.

Always have the serial number available when calling for

parts or service.

©2008 The Delfield Company. All rights reserved. Reproduction

without written permission is prohibited. “Delfield” is a registered

trademark of The Delfield Company.

5. Also open the compressor compartment housing and

visually inspect the refrigeration package. Be sure lines

are secure and base is still intact.

6. Freight carriers can supply the necessary damage forms

upon request.

7. Retain all crating material until an inspection has been

made or waived.

Uncrating the Equipment

First cut and remove the banding from around the crate.

Remove the front of the crate material, use of some tools will

be required.

Warning: While uncrating do not lay unit on side.

If compressor is set on side, return to upright

position for 24 hours to allow for all compressor

oil to drain back into compressor.

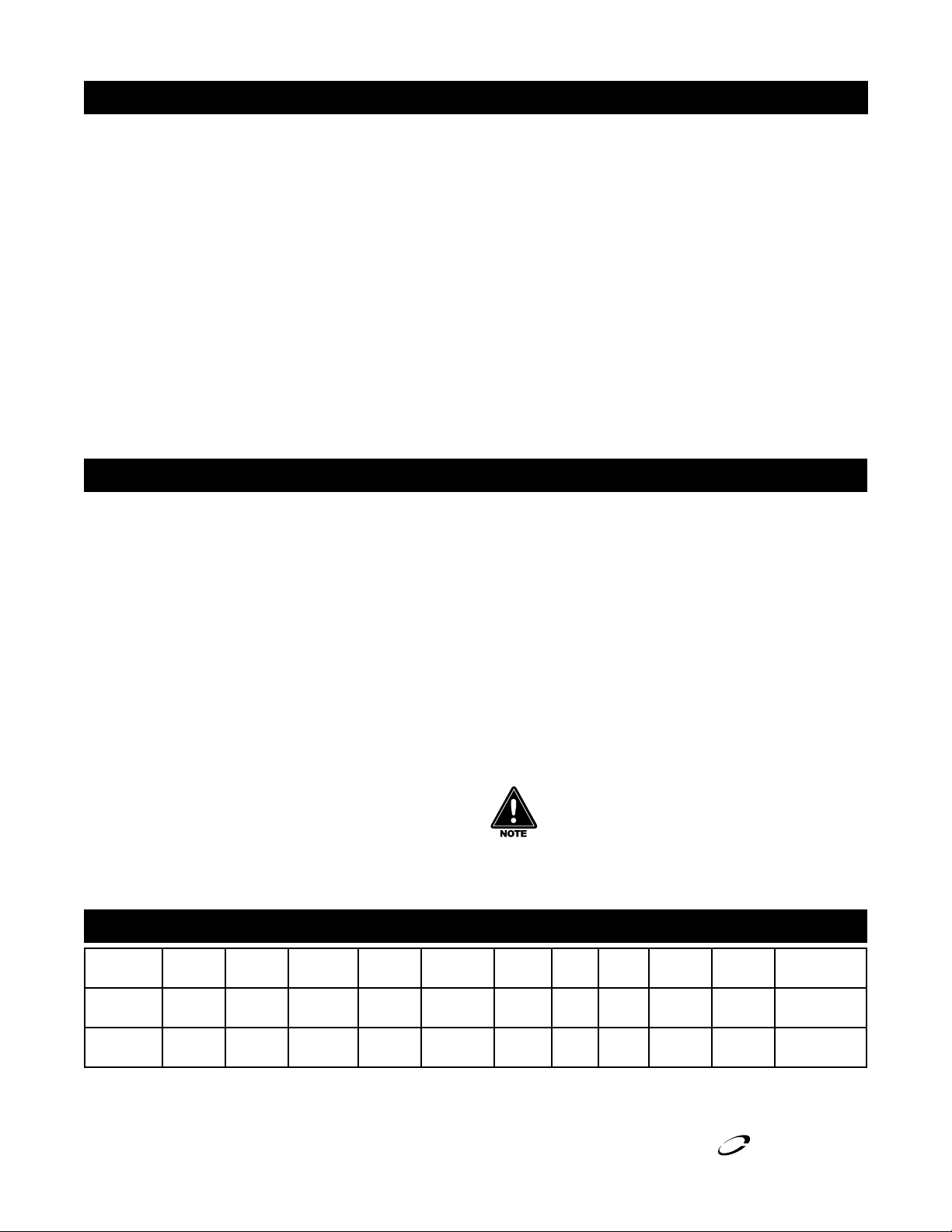

Specifications

Model Length Overall

536-SR68 36”

536-SRR68 36”

2

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

(91.4cm)

(91.4cm)

Depth

28”

(71.1cm)

28”

(71.1cm)

Height Shelf

Area

68”

(172.7cm)

68”

(172.7cm)

19.9ft

19.9ft

2

2

Storage

Capacity

21.8ft

21.8ft

Design

Load

3

1286 1/2 120 12.0 5-15P 600lbs/272kg

3

1286 N/A 120 5.0 N/A 575lbs/261kg

H.P. Volts Amps NEMA

Plug

Ship Weight

Delfield

™

®

CAUTION

Installation

Dual View Series Service and Installation Manual

Location

These units are intended for indoor use only. Be sure the

location chosen has a floor strong enough to support 1000

pounds of the cabinet and contents. Reinforce the floor as

necessary to provide for maximum loading.

For the most efficient refrigeration, be sure to provide good

air circulation inside and out.

Inside cabinet: Do not pack refrigerator so full that air

cannot circulate.

Outside cabinet: Be sure that the unit has access to ample

air. Avoid hot corners and locations near stoves and ovens.

Leveling

A level cabinet looks better and will perform better because:

1. The drain pan will drain properly.

2. The doors will line up with the frames properly.

3. The cabinet will not be subject to undue strain.

To meet NSF standards, this unit must be sealed to the

floor.

Installation of glass shelves

1. Remove stainless steel shelf bracket assemblies by

sliding key slots over shoulder bolts on inside edges of

posts.

2. Plug light cords into receptacles.

3. Place 0.25” safety glass shelves on brackets.

Installation of dry section front & side glass

1. Remove (2) acorn nuts on bottom side of shelf.

2. Remove top of stainless steel shelf by lifting shelf off

subtop.

3. Place 0.25” thick side glass pieces into bottom channel

and lower rear of stainless steel shelf.

4. Place 0.25” thick front glass piece into bottom channel

and lower front of stainless steel shelf over top edge of

glass.

5. Replace acorn nuts on bottom side of shelf.

Plumbing

Self-contained models are standard with a condensate

evaporator. If the evaporator fails, the unit’s drain must have

an outlet to an appropriate drainage area or container.

Moisture collecting from improper drainage

can create a slippery surface on the floor

and a hazard to employees. It is the owner’s

responsibility to provide a container or outlet for

drainage.

Electrical connection

Refer to the wattage data on page 2, the serial tag and your

local code to be sure the unit is connected to the proper

power source. A protected circuit of the correct voltage

and amperage must run for connection of the line cord, or

permanent connection to the unit.

Self-contained units have an ON/OFF switch located in the base

of the unit. Simply turn the switch to ON to begin operation.

The power switch must be turned OFF and

the unit disconnected from the power source

whenever performing service or maintenance

functions.

Operation Information

On self-contained models, after turning the ON/OFF switch

to ON, the unit’s compressor will begin operating. Delfield

display cases are designed to maintain an operation

temperature of 36°F to 40°F at ambient room temperature of

75°F and relative humidity of 55%.

Do not load the storage area in a way that restricts the air

flow. Overloading will result in a loss of temperature.

Continuous opening and closing of the doors will hamper

the units ability to maintain operational temperature.

Display Case Glass Replacement

Delfield professionally packages the glass in the crate

to minimize the risk of freight damage. However, during

shipment glass damage can happen and breakage is not

covered under warranty. If your Delfield unit arrives with

broken glass in the top dry section, we recommend that you

purchase replacement glass locally. The table to the right lists

replacement sizes for the dry top section only.

Please call your Delfield service or sales representative if you

have any questions on glass replacement.

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

Shelves Front Sides

(Top)

34.0” x 15.84”

(Center)

34.0” x 17.24”

(Bottom)

32.50” x 15.43”

*** All glass shelving is .25” thick safety glass.***

24.95” x 35.0”

Two Each Required:

24.57” tall;

19.38” at bottom

15.04” at top

3

Dual View Series Service and Installation Manual

Delfield

™

®

Maintenance

Door Gasket Maintenance

Door gaskets require regular cleaning to prevent mold and mildew

build up and also to retain the elasticity of the gasket. Gasket cleaning

can be done with the use of warm soapy water. Avoid full strength

cleaning products on gaskets as this can cause them to become brittle

and crack. Never use sharp tools or knives to scrape or clean the

gasket. Gaskets can be easily replaced and do not require the use of

tools or an authorized service person. The gaskets are “Dart” style and

can be pulled out of the groove in the door and new gaskets can be

“pressed” back into place.

Caster Maintenance

Wipe casters with a damp cloth monthly to prevent corrosion.

The power switch must be turned to OFF and the

unit disconnected from the power source whenever

performing service, maintenance functions or cleaning

the refrigerated area.

Refrigerators and Freezers

The interior and exterior can be cleaned using soap and warm water.

If this isn’t sufficient, try ammonia and water or a nonabrasive liquid

cleaner. When cleaning the exterior, always rub with the “grain” of

the stainless steel to avoid marring the finish. Do not use an abrasive

cleaner because it will scratch the stainless steel and can damage the

breaker strips and gaskets.

Stainless Steel Care and Cleaning

To prevent discoloration or rust on stainless steel several important

steps need to be taken. First, we need to understand the properties of

stainless steel. Stainless steel contains 70- 80% iron, which will rust.

It also contains 12-30% chromium, which forms an invisible passive

film over the steel’s surface, which acts as a shield against corrosion.

As long as the protective layer is intact, the metal is still stainless.

If the film is broken or contaminated, outside elements can begin to

breakdown the steel and begin to form discoloration or rust. Proper

cleaning of stainless steel requires soft cloths or plastic scouring

pads.

NEVER USE STEEL PADS, WIRE BRUSHES OR SCRAPERS!

Cleaning the Condenser Coil

In order to maintain proper refrigeration performance, the condenser

fins must be cleaned of dust, dirt and grease regularly. It is recommended

that this be done at least every three months. If conditions are such

that the condenser is totally blocked in three months, the frequency

of cleaning should be increased. Clean the condenser with a vacuum

cleaner or stiff brush. If extremely dirty, a commercially available

condenser cleaner may be required.

Failure to maintain a clean condenser coil can initially cause high

temperatures and excessive run times. Continuous operation with

a dirty or clogged condenser coil can result in compressor failure.

Neglecting the condenser coil cleaning procedures will void any

warranties associated with the compressor and cost to replace the

compressor.

Never use a high-pressure water wash for this cleaning

procedure as water can damage the electrical components

located near or at the condenser coil.

Doors/Hinges

Over time and with heavy use doors the hinges may become loose. If

this happens tighten the screws that mount the hinge brackets to the

frame of the unit. Loose or sagging doors can cause the hinges to pull

out of the frame, which may damage both the doors and the hinges. In

some cases this may require qualified service agents or maintenance

personnel to perform repairs.

Do not place hot pans on/against the blue ABS liner. Do not

throw items into the storage area. Failure to follow these

recommendations could result in damage to the interior of

the cabinet or to the blower coil. Overloading the storage

area, restricting the airflow, and continuous opening and

closing of the doors and drawers will hamper the units

ability to maintain operational temperature.

Preventing blower coil corrosion

To help prevent corrosion of the blower coil, store all acidic items,

such as pickles and tomatoes, in sealable containers. Immediately

wipe up all spills.

Cleaning solutions need to be alkaline based or non-chloride cleaners.

Any cleaner containing chlorides will damage the protective film of

the stainless steel. Chlorides are also commonly found in hard water,

salts, and household and industrial cleaners. If cleaners containing

chlorides are used be sure to rinse repeatedly and dry thoroughly.

Routine cleaning of stainless steel can be done with soap and water.

Extreme stains or grease should be cleaned with a non-abrasive

cleaner and plastic scrub pad. Always rub with the grain of the

steel. There are stainless steel cleaners available which can restore

and preserve the finish of the steels protective layer. Early signs of

stainless steel breakdown are small pits and cracks. If this has begun,

clean thoroughly and start to apply stainless steel cleaners in attempt

to restore the passivity of the steel.

Never use an acid based cleaning solution! Many food

products have an acidic content, which can deteriorate the

finish. Be sure to clean the stainless steel surfaces of ALL

food products. Common items include, tomatoes, peppers

and other vegetables.

4

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

Units with pans should be operated with pans in place.

Operating the unit without all pans in place will lower

efficiency and may damage the unit.

Continuous opening and closing of the doors will hamper the unit’s

ability to maintain optimum refrigeration temperature. Top section is

not intended for overnight storage. Product should be removed from

pans. Pans can remain in unit while empty.

Cleaning the condensate evaporator (remote models only)

The stainless steel condensate evaporator pan should be cleaned

every six months. Use a vacuum cleaner or damp cloth to remove

dust that may have accumulated. This will prevent corrosion of the

stainless steel.

Loading...

Loading...