Page 1

Delem

DAC-250

OPERATION MANUAL

VA 3

L:\Documentation\MANUAL\DAC\DAC-250\V3\250OMGB.WPD

Manual version V1299

Page 2

INTENTIONALLY

LEFT

BLANK

0.2

Page 3

PREFACE

Delem

This manual remains the property of Delem

Delem bv

DelemDelem

bv and will be placed at your disposal free of

bv bv

charge. It is not allowed to multiply the contents of this manual, in whole or in part, or to disclose

the contents to third parties without written consent of Delem

Delem bv

DelemDelem

bv It is not allowed to use the

bv bv

contents of this manual and incorporate them in other designs without Delem's written consent.

Delem bv

Delem bv, Holland

Delem bvDelem bv

LIMITED WARRANTY

1 The DAC-250 offers no protection against the operator and contains no built-in machine

safety.

Therefore, application of the DAC-250 controller is the entire responsibility of the

customer. Safety measures must be taken outside the DAC-250 controller in order to

guarantee safety for the operator, even in case of possible malfunctioning of the DAC-250

controller.

Delem

Delem bv

DelemDelem

bv cannot be held responsible for any damage caused directly or indirectly by

bv bv

the DAC-250 controller in normal operation or even if it fails to function according to its

specifications.

2 Delem

Delem bv

DelemDelem

implied; including, but not limited to the particular purpose. Delem

bv provides this manual without warranty of any kind, either expressed or

bv bv

Delem bv

DelemDelem

bv reserves the

bv bv

right at any time to make improvements and/or changes in their product(s) and/or

program(s) described in this manual.

This manual may include technical inaccuracies or typographical errors but as it is subject

to periodical updatings the necessary corrections will be incorporated in new editions of

this publication.

Requests for copies of this manual and for technical information about products can be

Delem bv

directed to

Delem bv employees authorized to give this information.

Delem bvDelem bv

0.3

Page 4

INTENTIONALLY

LEFT

BLANK

0.4

Page 5

Delem

CONTENTS PAGE

CONTENTS ...............................................................0.5

1. INTRODUCTION ...................................................2.1

2. HARDWARE .......................................................2.1

2.1. Frontpanel ....................................................2.1

2.1.1. Displays and LEDs .............................................2.2

2.1.2. Keyboard .....................................................2.2

2.2. Memory ......................................................3.1

3. OPERATING MODES ...............................................3.1

3.1. General ......................................................3.1

3.1.1. Start/stop parameter readout ......................................3.2

3.2. Manual mode ..................................................3.2

3.3. Automatic mode ...............................................3.3

3.4. Semi-automatic mode ...........................................4.1

4. PARAMETER PROGRAMMING ......................................4.1

4.1. Identification of a step ...........................................4.1

4.2. Programmable Parameters .......................................4.2

4.2.1. Programming a value ...........................................4.4

4.2.2. Backgauge position Xm .........................................4.4

4.2.3. Actual position readout Xp .......................................4.4

4.2.4. COR(rection) ..................................................4.4

4.2.5. Retract distance DX ............................................4.5

4.2.6. Function Outputs F .............................................4.5

4.2.7. Repetition CY .................................................4.6

4.2.8. Code C(haining) ...............................................4.7

4.2.9. Stock Counter # ................................................4.8

4.2.10. Inch/mm selection ..............................................4.8

4.2.11. Programming key lock ..........................................4.8

4.2.12. Range checking ................................................5.1

5. PROGRAMMING EXAMPLES ........................................6.1

6. MACHINE FUNCTIONS .............................................6.1

6.1. Selecting machine functions ......................................6.1

6.2. Position adjustment .............................................6.2

6.3. Counting (#) mode .............................................7.1

7. MACHINE PARAMETERS ...........................................7.1

7.1. List of machine parameters .......................................7.2

7.2. Description of the machine parameters ..............................8.1

0.5

Page 6

8. INSTALLATION ....................................................8.1

8.1. Connection example ............................................8.1

8.2. Encoder Voltage ...............................................8.1

9. DIAGNOSTIC PROGRAM DAC-150/DAC-250 ..........................9.1

9.1. Introduction ...................................................9.1

9.2. Starting the diagnostic program ...................................9.2

9.2.1. A1: Ram memory ..............................................9.2

9.2.2. A2: displays ...................................................9.3

9.2.3. A3: frontpanel keys and LEDs ....................................9.4

9.2.4. A4: digital inputs and outputs .....................................9.4

9.2.5. A5: analog output deflection (DC-version only) .......................9.5

9.3. Ending the diagnostic program ....................................9.5

0.6

Page 7

Delem

1. INTRODUCTION

The DAC-250 is a universal programmable controller, designed to control machinery based on

incremental displacement of certain machine functions such as the backgauge control of an

industrial shear. For a better understanding the backgauge will be referred to throughout this manual

but remember, any machine section with a movement, measured by an incremental encoder, could

be meant instead. The DAC-250 is not confined to axis positioning but can program parameters,

related to other machine functions, as well.

It is possible to program several steps which can be combined to programs. The DAC-250 is capable

of controlling servo-loop systems, a one- or two-speed AC or DC drive system.

1.1

Page 8

INTENTIONALLY

LEFT

BLANK

1.2

Page 9

Delem

2. HARDWARE

The DAC-250 consists of two printed circuit boards and a frontpanel. The two PCBs are:

- I/O board;

- Computer board containing all LEDs, character displays and keyboard interface.

2.1. Frontpanel

Unfold the drawing at the end of this manual, which shows a representation of the front panel with

a description of the function keys.

2.1.1. Displays and LEDs

Displays

The DAC-250 has eight character displays. These are 7-segment displays. The eight displays are

divided as follows:

- two displays for number and step indication (N,ST).

- six displays for parameter value display.

LEDs

The control panel contains thirteen LEDs:

- nine LEDs indicating the selected parameters;

(Xm, Xp, COR, DX, F, CY, C, # and I);

- one LED to indicate that the CH-function is active;

- one LED in the stop key, indicating that the DAC-250 is stopped;

- one LED in the Semi-automatic mode key, indicating that the DAC-250 has been started

in semi-automatic mode.

- one LED in the Automatic mode key, indicating that the DAC-250 has been started in

Automatic mode;

2.1

Page 10

2.1.2. Keyboard

The keyboard contains the following keys:

- 10 numerical keys (0 - 9)

- decimal point

- plus/minus toggle

- clear key, to clear a parameter value

- cursor key, to select the next parameter

- N, program number increment key

- ST, step increment key

- manual movement low speed up key (+)

- manual movement low speed down key (-)

- manual movement high speed key (x key in combination with + or - key)

- stop key (0)

- semi automatic start key

- automatic mode start key

2.2. Memory

The following (external) memory is available:

- 32 Kbyte EPROM for program code (optional 64K)

-8 Kbyte RAM

- 2 Kbyte EEPROM for step and machine parameter storage.

2.2

Page 11

Delem

3. OPERATING MODES

3.1. General

The DAC-250 has three operating modes: Manual mode, Automatic mode and Semi-automatic

mode.

Manual mode is selected if N = 0 and ST = 0.

Automatic and semi-automatic mode are both selected with a key on the frontpanel. These keys also

serve as start buttons.

When the automatic or semi-automatic key is pressed the DAC-250 will position the backgauge

according to the programmed parameters in the selected step.

The LED of the corresponding key (either automatic or semi-automatic) will light up.

When the stop button (O) is pressed the DAC-250 will control the backgauge at its actual position.

The LED of the stop button will light up.

In some situations the "stop" is forced by the DAC-250 itself. In that case the LED of the relevant

start button extinguishes and the LED of the stop button lights up.

In the following paragraphs the three operating modes are described.

First the parameter readout after pressing start and stop is described.

Paragraph 3.1.1. describes the inputs and outputs which have a direct relationship with an operating

cycle.

3.1.1. Start/stop parameter readout

When the start button is pressed the cursor moves automatically to Xp. This means that when the

start button is pressed always the actual position is displayed.

When the stop button is pressed again the cursor moves to Xm.

There are two exceptions:

1. When the cursor is at the parameter # it will stay at # when the start or stop button is

pressed.

2. When the counter (#) is used in the downcounting mode the cursor automatically moves

to # when the value 0 is reached. In this case the DAC-250 also goes to stop.

3.1

Page 12

3.2. Manual mode

Manual mode can only be selected if N = 0 and ST = 0.

In Manual Mode all parameters can be programmed. Only the program flow part of code (C) and

step repetition (CY) have no meaning. However, Stock Counter (#) can be used.

When the automatic or semi-automatic key is pressed (start function) in manual mode the backgauge

moves to the programmed position.

The stock counter (#) will be either incremented or decremented at each manual cycle, depending

on the setting (refer to chapter 4.2.8).

When the stock counter reaches zero in downcounting mode the DAC-250 stops. The cursor

automatically goes to the #-LED).

If the LED of the stop button is lit the backgauge can be moved manually by pressing the manual

movement keys on the frontpanel. These keys are:

+ = slow speed in counting up direction

- = slow speed in counting down direction

X = high speed, must be pressed together with the + or - key.

3.3. Automatic mode

In Automatic Mode a program can be executed.

When the automatic key is pressed the backgauge moves to the programmed position of the

current step (N,ST).

A new step (N,ST) is loaded at each change of the status of the START input.

If the value for step repetition CY is higher than 1, only the value of CY in the current step is decremented by 1 and no new step will be loaded.

Note:

A step with CY = 0 will be skipped.

In some situations the DAC-250 stops instead of moving to the new backgauge position. This

depends on the program flow code (C) (refer to chapter 4.2.7).

3.2

Page 13

Delem

3.4. Semi-automatic mode

The execution cycle in Semi-automatic Mode is mainly equal to the Automatic Mode.

In semi-automatic mode the DAC-250 stops at the end of a cycle.

If the programmed value for CY is higher than 1 a number of cycles equal to this value must have

been executed before the DAC-250 stops.

3.3

Page 14

INTENTIONALLY

LEFT

BLANK

3.4

Page 15

Delem

4. PARAMETER PROGRAMMING

The DAC-250 is a programmable backgauge controller.

The DAC-250 can also program parameters, related to other machine functions.

One such set of parameters is referred to as a "step".

Several steps can be combined to build a program. During the execution of the program the steps

within a program are executed one after another in an automatic cycle.

4.1. Identification of a step

A step is identified by a 2-digit number in the range 0-99.

This means that up to 100 steps can be programmed and stored into memory.

The number of the selected step is displayed on two character displays. The digit, highest in order

(left-hand), is called "N", the lowest in order (right-hand) is called "ST".

The keys N and ST are used to increment the value of N and ST. If N or ST = 9 it will become 0

after the next increment. If you pass the required numeral you can only increment until this numeral

appears again, i.e. you cannot decrement.

Holding the keys N and ST will speed up the effect.

If in manual mode two LEDs light up:

- the selected parameter;

- the LED at the right of the ST-display.

Note:

"N" can be considered as a program number and "ST" as a step number within the program.

This definition enables the programming of 10 programs of maximum 10 steps each.

However, you are free to make programs consisting of more than 10 steps or to let a

program start at every N,ST combination.

The current N,ST is memorized after power down. At power up this step is automatically

loaded again.

4.2. Programmable Parameters

A parameter can be programmed upon selection. The selected parameter is indicated by a LED. Each

parameter is represented by its own LED. Selecting a parameter is done by pressing the < key. The

actual value of the selected parameter is displayed on the 6-character display.

There are five step dependant parameters and two general parameters. The function Xp, which is

also indicated by a LED, is not a programmable parameter. If Xp is selected the actual position of

the backgauge is displayed.

4.1

Page 16

The step dependant parameters are:

- Xm = position of the backgauge

- COR = correction of the position of the backgauge

- DX = retraction of the backgauge

- F = function outputs

- CY = number of (step) repetitions

- C = code

The general parameters are:

# = Stock counter: counting of products

I = inch/mm selection

Each time the < key is pressed the next parameter becomes active. The sequence is as follows:

< Xm < Xp < COR < DX < F < CY < C < # < I ... < Xm and so on.

Holding the key < will speed up the effect.

4.2.1. Programming a value

When a parameter is selected its value can be programmed.

To program a value the following keys are available:

- 10 numerical keys (0-9)

- decimal point

- plus/minus

- clear key ( )

When programming a value each new digit is added as follows:

- left of the decimal point:

all existing digits are shifted one place to the left, the last programmed digit will be the

least significant.

- right of the decimal point:

the digits appear from the left to the right

4.2

Page 17

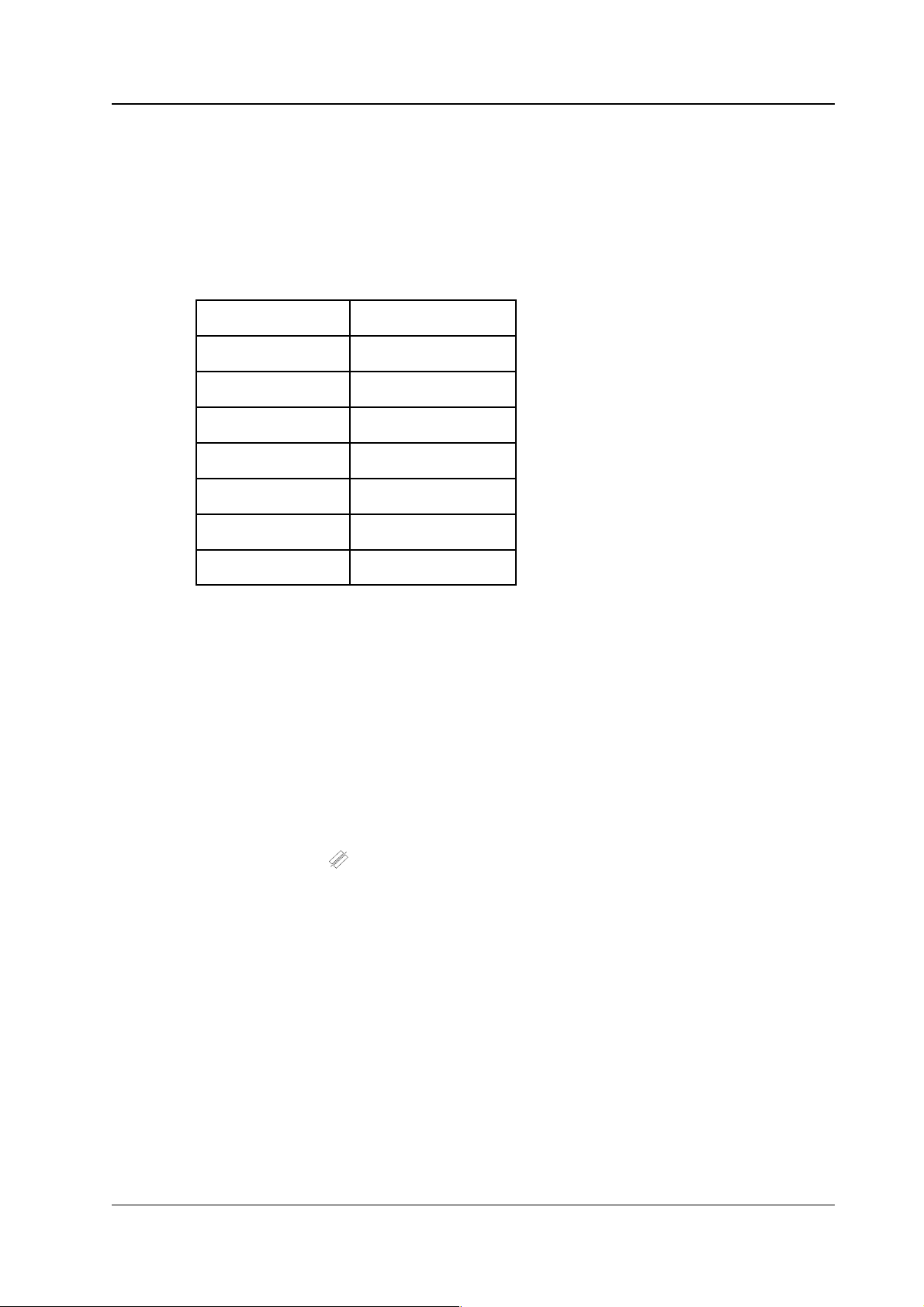

Example:

Suppose the value 367.25 has to be programmed. The table below shows the order of the

keys to be pressed. The number of decimals depends on the setting of the machine

parameter and may as well be limited to only one digit.

Delem

key pressed value on display

0.00

3 3.00

6 36.00

7 367.00

. 367.00

2 367.20

Plus/minus key:

If the plus/minus key is pressed a minus sign is displayed in the first free digit left of the

value. If the plus/minus key is pressed and all the digits are already used the minus sign is

placed in the leftmost digit (the leftmost digit of the value is blanked out).

If the plus/minus key is pressed a second time the value becomes positive again (toggle

function).

Clear key:

When the clear key ( ) is pressed the value on the display is set to zero.

The value which is displayed after clear is one "0" left of the decimal point. The number

of zeros at the right of the decimal point depends on the parameter format. The minus sign

is also reset after clear.

Example:

5 367.25

A parameter with two digits right of the decimal point is displayed as "0.00" after clear.

The range of values which can be programmed is machine dependant and will be discussed

in the next paragraphs.

4.3

Page 18

4.2.2. Backgauge position Xm

When the cursor is at Xm a value is displayed with a format depending on the installed machine

parameter.

This format represents the stepping resolution of the backgauge movement.

Note 1:

The backgauge position can also be programmed negative if chaining is used (see chapter

4.2.8).

Note 2:

If the cursor is at Xm and a correction (COR) has been programmed (see chapter 4.2.4) this

will be indicated by a flashing "COR" LED.

4.2.3. Actual position readout Xp

If Xp is selected the actual backgauge position is displayed.

If the reference has not passed yet only small squares are displayed: the lower four segments of each

display are lit.

4.2.4. COR(rection)

Correction on the programmed backgauge position.

The value to be programmed at COR appears in the same resolution as Xm.

Default: 0

4.2.5. Retract distance DX

In some cases it may be necessary to clear (retract) the material from the backgauge. This may occur

at the moment when the mechanical action begins. The retract distance is a programmable

displacement of the motor axis in the upcounting direction.

The value at DX appears in the same resolution as Xm.

Default: 5

4.4

Page 19

Delem

4.2.6. Function Outputs F

There are two function (on/off) outputs: F1 and F2.

These outputs can be used in two ways:

1.) The value of these two outputs can be programmed as one parameter.

2.) They can be used by the stroke length limitation function as a warning signal.

Use machine parameter 28 to select one of these functions.

1.) In case the outputs are programmed as one parameter, there are four combinations:

Value F2 F1

00 off off

01 off on

10 on off

11 on on

Default: 00 (both off)

A combination can be programmed with function F.

The digital outputs will be set to the programmed value when the start-enable input

becomes high while the DAC has been started. The outputs stay at the actual value during

the program step and will be reset when the DAC is stopped.

2.) In case the stroke length limitation function is programmed through machine parameter 28,

the function outputs have a different function. Then the machine has a maximum stroke

length, dimensioned in seconds. With function F, you can program a stroke length as a

percentage of that maximum stroke length. When the desired time has elapsed, output F1

will become active. Output F2 is not used in this function and remains inactive.

4.2.7. Repetition CY

Step repetition: the number of times a step is repeated before the next step is executed.

Range : 0 - 9999

Default: 1

Note 1:

Note 2:

The value 0 means that the step must be skipped.

This parameter has no meaning in Manual mode and is equal to 0.

4.5

Page 20

4.2.8. Code C(haining)

This parameter is a combination of two functions:

- Chaining indication

- Program flow code

Chaining:

0 = The programmed backgauge value (Xm) is an absolute position.

1 = The programmed backgauge value (Xm) is a chain value.

This means that the new value is obtained by adding or subtracting the programmed value to/from

the previous position. Consequently the value may be negative as well.

Program flow code:

5 = Start of program: this indicates the first step of a program.

6 = Program end code: after this step has been completed the first step (= code 5) is loaded

and the DAC-250 stops. The program counter will be adjusted.

7 = Program end code: after this step has been completed the first step (= code 5) is loaded

and the program is executed again as long as the stock counter (#) is not equal to 0.

After each completion of the program the repetition counter is decremented (if

decrement mode is selected). On reaching value 0 the DAC-250 stops.

8 = Program end code: after this step has been completed the first step (= code 5) is loaded

and the program is executed again. This is repeated endlessly.

9 = Program end code: after this step has been completed the DAC-250 stops.

The chaining code can be combined with a program flow code. In that case two digits have to be

programmed. The order in which these digits are programmed is not important.

Example:

If the programmed backgauge position in a step must be a chain value and it is the last step,

the value for the code (C) can be 16 or 61. Both combinations have the same meaning (code

1 and code 6).

Note 1:

If the chain/absolute code is omitted the position is assumed to be an absolute backgauge

position.

Note 2:

If the chaining code is set (code = 1) in a step it will be indicated by the " " LED (at

the right of the upper display).

4.6

Page 21

Delem

Note 3:

If the first step of a program is searched the first step with code = 5 with a lower N,ST

number will be loaded. If no step with code = 5 is found step N,ST = 01 will be loaded.

Default: 0

4.2.9. Stock Counter #

Range : 0 - 9999

Default: 9999

Stock counter determines the number of times that the selected program will be repeated (product

counter).

There are two operation modes for the product counter:

- downcounting

- upcounting

This mode can be selected by a special operator selectable parameter (see chapter 6).

In the downcounting mode this counter has only meaning if the code in the last step of the selected

program is equal to 6 or 7, or if the Manual mode (N,ST = 00) has been selected. In all other cases

this counter is not used. During execution of a program the #-value will be decremented each time

a program has been executed once. When the #-value reaches zero the DAC-250 stops and the

cursor will automatically move to the #-LED.

If in the downcounting mode the value zero has been reached (DAC-250 to stop) the programmed

value is reloaded if the start button is pressed.

In the upcounting mode the #-value is incremented by 1 each time a program has been executed

once. The programmed #-value is the counter preset. When the #-value reaches 9999 the next value

will be zero.

This actual #-value will always be displayed. In the upcounting mode the original programmed value

is lost after one or more steps have been executed.

Note:

If in Manual mode code= 8 is programmed in downcounting mode the #-value will not be

decremented (endless mode).

4.7

Page 22

4.2.10. Inch/mm selection

Programming unity for backgauge position (Xm), actual position of the backgauge (Xp), correction

(COR) and retraction (DX).

0 = mm

1 = inches

Default: 0

Resolution:

In case of programming in inches the decimal point moves two positions to the left. If possible the

total number of digits is incremented by 1. The parameters, influenced by this conversion, are Xm,

Xp, COR and DX. The conversion follows the machine-installed resolution.

4.2.11. Programming key lock

If the programming key lock is off it is impossible to change the value of the parameters. If you try

to change a value the LED indicating the selected parameter flashes. This happens if one of the

following keys is pressed:

- 0 thru 9

- decimal point

- clear

- plus/minus

There are a few exceptions:

- In manual mode (N = 0, ST = 0) all parameters can always be programmed, even if

lock is in the OFF-position.

- The correction COR can always be programmed.

- Program repetition # can always be programmed.

4.2.12. Range checking

Each programmed parameter is checked against its minimum and maximum value. If a programmed

value is invalid the display starts flashing.

If the display is flashing and one of the following keys is pressed the value will be limited at its

minimum or maximum value:

- Cursor key <

- N

- ST

- Automatic start

- Semi-automatic start

4.8

Page 23

Delem

5. PROGRAMMING EXAMPLES

Before the actual programming starts it may be useful to do some exercising on the front panel. The

following sequences do not necessarily represent an actual situation on your machine.

With these exercises it will be easy to make your own sequences. It may require a final check but

once the sequences are correct we recommend to keep record. In case of repeat orders it will be

possible to recall the sequence (program) related to the product to be made.

We start with the contents of a complete program, followed by the list of entries.

Example 1

This program is based on a resolution of 0.1 mm.

N ST Xm COR DX F CY C Comment

1 0 100.0 0.0 0.0 00 1 5 Start of program

Move the backgauge to 100.0 mm

1 1 75.0 0.0 0.0 00 2 1 Move the backgauge to 75.0 with

respect to the former position

(chaining)

Make this step twice.

1 2 200.0 2.5 0.0 01 1 0 Move the backgauge to 200.0 mm

+ 2.5 mm and activate F1.

1 3 275.0 0.0 5.0 00 1 0 Move the backgauge to 275.0 mm

and then 5.0 mm if retraction is

necessary

1 4 300.0 0.0 0.0 00 1 8 Move the backgauge to 300.0 mm

and return to step 10 (N = 1, ST =

0).

5.1

Page 24

Entries

Displays

Key 2-D 6-D LEDs Comment

on

0 0 50.0 Xm Initial backgauge position

N 1 0 999.0 Xm Start of program

Backgauge is at position 999.0

Change position to 100.0

1 1 0 1.0 Xm Enter 1st digit of value 100.0

0 1 0 10.0 Xm Enter 2nd digit of value 100.0

0 1 0 100.0 Xm Enter 3rd digit of value 100.0

< 1 0 50.0 Xp Press cursor

< 1 0 0.0 COR Press cursor

< 1 0 0.0 DX Press cursor

< 1 0 00 F Press cursor

< 1 0 1 CY Press cursor

< 1 0 0 C Press cursor

5 1 0 5 C Enter flow code (see chapter 4.2.7 where

code 5 is explained).

< 1 0 9934 # Press cursor

< 1 0 0 I Press cursor

< 1 0 100.0 Xm Press cursor

ST 1 1 999.0 Xm Backgauge is at position 999.0

Change position to 75.0

7 1 1 7.0 Xm Enter 1st digit of value 75.0

5 1 1 75.0 Xm Enter 2nd digit of value 75.0

< 1 1 50.0 Xp Press cursor

< 1 1 0.0 COR Press cursor

< 1 1 0.0 DX Press cursor

< 1 1 00 F Press cursor

< 1 1 1 CY Press cursor

2 1 1 2 CY Enter value of repetition

< 1 1 0 C Press cursor

1 1 1 1 C Enter 1 for C(haining) mode

< 1 1 9934 #, CH Press cursor

< 1 1 0 I, CH Press cursor

< 1 1 75.0 Xm, CH Press cursor

ST 1 2 999.0 Xm Backgauge is at position 999.0

Change position to 200.0

5.2

Page 25

Delem

Displays

Key 2-D 6-D LEDs Comment

on

2 1 2 2.0 Xm Enter 1st digit of value 200.0

0 1 2 20.0 Xm Enter 2nd digit of value 200.0

0 1 2 200.0 Xm Enter 3rd digit of value 200.0

< 1 2 50.0 Xp Press cursor

< 1 2 0.0 COR Press cursor

2 1 2 2.0 COR Enter 1st digit of value 2.5

. 1 2 2.0 COR Enter decimal point

5 1 2 2.5 COR Enter decimal of value 2.5

< 1 2 0.0 DX Press cursor

< 1 2 00 F Press cursor

1 1 2 01 F Enable output F1

< 1 2 1 CY Press cursor

< 1 2 0 C Press cursor

< 1 2 9934 # Press cursor

< 1 2 0 I Press cursor

< 1 2 200.0 Xm Press cursor

ST 1 3 999.0 Xm Backgauge is at position 999.0

Change position to 275.0

2 1 3 2.0 Xm Enter 1st digit of value 275.0

7 1 3 27.0 Xm Enter 2nd digit of value 275.0

5 1 3 275.0 Xm Enter 3rd digit of value 275.0

< 1 3 50.0 Xp Press cursor

< 1 3 0.0 COR Press cursor

< 1 3 0.0 DX Press cursor

5 1 3 5.0 DX Enter necessary retraction value

< 1 3 00 F Press cursor

< 1 3 1 CY Press cursor

< 1 3 0 C Press cursor

< 1 3 9934 # Press cursor

< 1 3 0 I Press cursor

< 1 3 275.0 Xm Press cursor

ST 1 4 999.0 Xm Backgauge is at position 999.0

Change position to 300.0

5.3

Page 26

Displays

Key 2-D 6-D LEDs Comment

on

3 1 4 3.0 Xm Enter 1st digit of value 300.0

0 1 4 30.0 Xm Enter 2nd digit of value 300.0

0 1 4 300.0 Xm Enter 3rd digit of value 300.0

< 1 4 50.0 Xp Press cursor

< 1 4 0.0 COR Press cursor

< 1 4 0.0 DX Press cursor

< 1 4 00 F Press cursor

< 1 4 1 CY Press cursor

< 1 4 0 C Press cursor

8 1 4 8 C Enter flow code (see chapter 4.2.7 where

code 8 is explained).

< 1 4 9934 # Press cursor

< 1 4 0 I Press cursor

< 1 4 300.0 Xm Press cursor

End of program 1

5.4

Page 27

Delem

Example 2

This time the resolution is set at 0,01 mm.

N ST Xm COR DX F CY C Comment

2 0 50.00 0.00 0.00 00 1 5 Start of program

Move the backgauge to 50.00 mm

2 1 65.00 0.00 0.00 00 0 0 Skip this step

2 2 80.00 0.05 0.00 10 1 0 Move the backgauge to 80.0 mm +

0.05 mm and activate F2.

2 3 100.00 0.00 2.50 00 1 9 Move the backgauge to 100.00 mm

and stop the program.

Entries

Displays

Key 2-D 6-D LEDs Comment

on

0 0 50.00 Xm Initial backgauge position

N 2 0 999.00 Xm Start of program

Backgauge is at position 999.00

Change position to 50.00

5 2 0 5.00 Xm Enter 1st digit of value 50.00

0 2 0 50.00 Xm Enter 2nd digit of value 50.00

< 2 0 50.00 Xp Press cursor

< 2 0 0.00 COR Press cursor

< 2 0 0.00 DX Press cursor

< 2 0 00 F Press cursor

< 2 0 1 CY Press cursor

< 2 0 0 C Press cursor

5 2 0 5 C Enter flow code (see chapter 4.2.7 where

code 5 is explained).

< 2 0 9934 # Press cursor

< 2 0 0 I Press cursor

< 2 1 65.00 Xm No changes; continue with next step

5.5

Page 28

Displays

Key 2-D 6-D LEDs Comment

on

ST 2 2 999.00 Xm Backgauge is at position 999.00

Change position to 80.00

8 2 2 8.00 Xm Enter 1st digit of value 80.00

0 2 2 80.00 Xm Enter 2nd digit of value 80.00

< 2 2 80.00 Xp Press cursor

< 2 2 0.00 COR Press cursor

. 2 2 0.00 COR Enter decimal point

0 2 2 0.00 COR Enter 1st decimal of correction

5 2 2 0.05 COR Enter 2nd decimal of correction

< 2 2 0.00 DX Press cursor

< 2 2 00 F Press cursor

1 2 2 10 F Enable output F2

< 2 2 1 CY Press cursor

< 2 2 0 C Press cursor

< 2 0 9934 # Press cursor

< 2 2 0 I Press cursor

ST 2 3 999.00 Xm Backgauge is at position 999.00

Change position to 100.00

1 2 3 1.00 Xm Enter 1st digit of value 100.00

0 2 3 10.00 Xm Enter 2nd digit of value 100.00

0 2 3 100.00 Xm Enter 3rd digit of value 100.00

< 2 3 100.00 Xp Press cursor

< 2 3 0.00 COR Press cursor

< 2 3 2.50 DX Press cursor

< 2 3 00 F Press cursor

< 2 3 1 CY Press cursor

< 2 3 0 C Press cursor

9 2 3 9 C Enter flow code (see chapter 4.2.7 where

code 9 is explained).

< 2 3 9934 # Press cursor

< 2 3 0 I Press cursor

< 2 3 100.00 Xm Press cursor

End of program 2

5.6

Page 29

Delem

6. MACHINE FUNCTIONS

6.1. Selecting machine functions

Most of the machine functions can only be modified by authorized personnel and only with a special

access code.

These functions are discussed in chapter 7.

The machine functions which are accessible by the operator are discussed in chapter 6.2 and 6.3.

6.2. Position adjustment

If no reference encoder is used the backgauge position is adjusted by programming a special

machine function. The value which must be programmed is the real backgauge position. This programmed position will be copied to the actual position read-out parameter Xp. This is only valid if

machine parameter 10 is programmed at the value 3.

The machine function can be entered if N = 0, ST = 0

Move the cursor to CY; the LED lights up.

Enter the special code 2345.

Press the ST-key once (N = 0, ST = 0). The LEDs at Xm, Xp and CY light up, indicating that this

parameter has been selected.

Enter the real backgauge position.

Return to normal programming mode by pressing the cursor key <.

If operating without a reference encoder the actual backgauge position read out will be memorized

after power down.

6.1

Page 30

6.3. Counting (#) mode

The stock counter (#) can operate in two modes:

- downcounting

- upcounting

This machine function is accessed as follows:

Make N = 0 and ST = 0

Move the cursor to CY; the LED lights up.

Enter the special code 1111. Press the ST-key once.

The LEDs #, CY and I will light up.

The counter mode can be programmed as follows:

0 = downcounting

1 = upcounting

Default: 0

Return to the normal programming mode by pressing the cursor key <.

If by accident another numeral than 0 or 1 should be pressed the display starts flashing.

Press the clear key ( ) and try again.

6.2

Page 31

Delem

7. MACHINE PARAMETERS

7.1. List of machine parameters

The machine parameters are only accessible with a special entry code. We recommend that machine

parameters should preferably be adjusted by authorized personnel. Make N = O and ST = O, move

the cursor to CY and enter the special code 8520. Once the entry code has been entered the different

machine parameters can be selected with the N and ST keys; all parameter LEDs light up. An N-ST

com-bination selects one machine parameter, so theoretically up to 100 machine parameters can be

defined. However, only 50 machine parameters are used.

Return to the normal programming mode by pressing the cursor key <.

The following list shows all machine parameters which are available. Chapter 7.2 gives a full

description and the way to change them, but only of the active combinations.

In cases where combinations are not used the display shows a zero.

N = 0 ST = 0 not used

N = 0 ST = 1 Software version

N = 0 ST = 2 type of drive

N = 0 ST = 3 Counter pulse division factor

N = 0 ST = 4 Counter pulse multiplying factor

N = 0 ST = 5 Decimal point position

N = 0 ST = 6 Reference position

N = 0 ST = 7 Maximum backgauge position

N = 0 ST = 8 Minimum backgauge position

N = 0 ST = 9 not used

N = 1 ST = 0 Auto indexing

N = 1 ST = 1 Spindle allowance

N = 1 ST = 2 Positioning tolerance (AC-drive only)

N = 1 ST = 3 Retract holdtime

N = 1 ST = 4 Chaining mode

N = 1 ST = 5 Backgauge position offset

N = 1 ST = 6 Safety breakpoint fast speed at maximum position

N = 1 ST = 7 Safety breakpoint fast speed at minimum position

N = 1 ST = 8 not used

N = 1 ST = 9 not used

N = 2 ST = 0 Breakpoint fast speed BFS (AC drive only)

N = 2 ST = 1 Breakpoint slow speed BSS (AC drive only)

N = 2 ST = 2 Stop time T (AC drive only)

N = 2 ST = 3 Overrun OR (AC drive only)

N = 2 ST = 4 overrun wait time

N = 2 ST = 5 DC motor slow speed

N = 2 ST = 6 DC motor high speed

N = 2 ST = 7 AC-output definition

N = 2 ST = 8 Maximum stroke length

7.1

Page 32

N = 2 ST = 9 not used

N = 3 ST = 0 Servo motor gain (DC servo drive only)

N = 3 ST = 1 Servo motor switch (DC servo drive only)

N = 3 ST = 2 Servo motor braking ramp (DC servo drive only)

N = 3 ST = 3 Servo motor acceleration ramp (DC servo drive only)

N = 3 ST = 4 Manual movement slow speed

N = 3 ST = 5 Manual movement high speed

N = 3 ST = 6 Reference search speed

N = 3 ST = 7 In-position tolerance

N = 3 ST = 8 Reference search procedure

N = 3 ST = 9 not used

N = 4 ST = 8 EEPROM write access count

N = 4 ST = 9 Memory erase code

7.2. Description of the machine parameters

The following machine parameters are defined:

N = 0, ST = 1: Software version

Selecting this N-ST combination brings the number of the software version on the display.

N = 0, ST = 2: Type of drive

Range : 1 - 3

Default : 2

1 = 1-speed AC or DC drive

2 = 2-speed AC or DC drive

3 = servo motor drive

The next two parameters, 03 and 04, are meant to set a correct scaling between the encoder and the

display. The encoder gives an exact number of pulses over a mm displacement, the display ‘counts’

the pulses and shows a certain number of millimeters per pulse, according to the Display Resolution.

Parameters 03 and 04 are used to adjust the scaling.

7.2

Page 33

Delem

N = 0, ST = 3: Counter pulse division factor

Range : 1 - 100

Default : 2

This value is the software division factor.

N = 0, ST = 4: Counter pulse multiplying factor

Range : 1 - 100

Default : 1

Software multiplying factor.

For determining the multiply- and division factors to get a correct encoder scaling the following

procedure is advised:

1. use the formular F= DR x NP

SPP

in which: - DR = Display resolution (1 / 0.1 / 0.01)

- NP = Number of encoder pulses per revolution of the spindle

- SPP = Spindle pitch in mm

2. Write this Factor F as a fraction :

F= multiply factor

division factor

3. Program the division factor value at parameter 03 and

program the multiply factor value at parameter 04.

Example:

- a display resolution of 0.1 mm

- number of encoder pulses 100 ppr

- spindle pitch of 10 mm

results in F= 0.1 x 100 = 1

10

This means a value of 1 at parameters 03 and 04.

7.3

Page 34

N = 0, ST = 5: Decimal point position

Range : 0 - 3

Default : 1

0 = 1 mm resolution

1 = 0.1 mm resolution

2 = 0.01 mm resolution

3 = 0.001 mm resolution *

* This resolution is used if spindles dimensioned in inches are used. (parameter I must be set

to zero, refer to 4.2.10).

This is the resolution for programmed position Xm, position readout Xp, correction COR and

retraction DX.

N = 0, ST = 6: Reference position

Range : 0 - 999999 display units

Default : 1000

This position must appear on the display when the reference has passed. The reference encoder must

generate a pulse from low to high on the reference input.

N = 0, ST = 7: Maximum backgauge position

Range : 0 - 999999 display units

Default : 9999

Maximum backgauge dimension. This value is a soft limit. Programmed values for Xm and DX are

checked against this value.

During execution (DAC-250 started) the end position (combination of Xm, DX and COR) is also

checked.

If a programmed (end) position is too large it will automatically be limited at the maximum position.

7.4

Page 35

Delem

N = 0, ST = 8: Minimum backgauge position

Range : 0 - 999999 display units

Default : 0

Minimum backgauge dimension. This value is a soft limit.

Programmed values for Xm and DX are checked against this value.

During execution (DAC-250 started) the end position (combination of Xm, DX and COR) is also

checked.

If a programmed (end) position is too small it will automatically be limited at the minimum position.

N = 1, ST = 0: Auto indexing

Range : 0 - 3

Default : 1

Each time the supply voltage is switched on, the reference-switch must be passed. This passing for

the first time of the reference switch can be done automatically or manually.

Settings, which are possible:

0 = no automatic passing (with reference encoder), in this case the reference point can be

passed by pressing the manual pushbutton.

1 = automatic reference passing, the motor will be controlled after pushing the start button in

the downcounting direction.

2 = automatic reference passing, the motor will be controlled after pushing the start button in

the upcounting direction.

3 = no reference encoder used, the actual backgauge position will be memorized after power

down.

Adjustment of the backgauge position is done by programming the real value in a machine

parameter (see chapter 6.2).

7.5

Page 36

N = 1, ST = 1: Spindle allowance

Range : 0 - 1

Default : 1

0 = one-side positioning

1 = two-side positioning

Note: One-side positioning is also possible with a servo drive (drive type = 3)

In case of one-side positioning the positioning direction is from a larger to a smaller position.

N = 1, ST = 2: Positioning tolerance

Range : 0 - 9999 display units

Default : 0

The backgauge will position to the new programmed position if the difference between the actual

position and the new position is greater than this tolerance.

If the difference is smaller the backgauge will stay at its actual position.

This parameter is only used in combination with one- or two-speed drives (type 1 or 2). This

parameter has no meaning if a servo drive (type = 3) has been selected.

N = 1, ST = 3: Retract holdtime

Range : 0 - 999.9 sec.

Default : 1.0 sec

Backgauge holdtime at retract position after the START input goes high.

N = 1, ST = 4: Chaining mode

Range : 0 - 1

Default : 0

In case of chaining the programmed Xm value is relative to the previous backgauge position. The

new position can be computed relative to the previous programmed position or relative to the

previous actual position. This can be programmed with this parameter.

0 = new position is computed relative to the previous programmed position (including

correction).

1 = new position is computed relative to the previous actual position.

7.6

Page 37

Delem

N = 1, ST = 5: Backgauge position offset

A backgauge position offset can be programmed. This offset will be added to the displacement of

the backgauge. This facility can be seen as tool thickness compensation in certain applications where

there is material loss.

In case the offset is used, the backgauge position is calculated as follows:

Xp = Xm + cor + X-offset

Xp = backgauge position

Xm = programmed backgauge position

cor= programmed correction

X-offset= position offset

In case of chaining the position will be calculated as follows:

a) Xm programmed positive = larger position

Xp = Xp + Xm + cor + X-offset

b) Xm programmed negative = smaller position

Xp = Xp + Xm + cor - X-offset

When the X-offset is not needed the value must be programmed 0.

N = 1, ST = 6: Safety Breakpoint Fast Speed at maximum position

Range : 0 - 9999 Display units

Default : 0

7.7

Page 38

N = 1, ST = 7: Safety Breakpoint Fast Speed at minimum position

Range : 0 - 9999 Display units

Default : 0

These parameters are available for 2-speed control, AC and DC. They can be used to program safety

zones near the minimum and maximum backgauge position, in which the backgauge can only move

with low speed and not with high speed.

These parameters are related to the maximum and minimum positions of the backgauge. They do

not indicate exact positions, but indicate the distances to the outer positions.

Min. Max.

position position

Zone Zone max.

min.

Parameter 17 Parameter 16

Fig. 7.1

These zone-parameters can be used to prevent collision of the backgauge construction with some

other mechanics parts while moving in high speed.

In case of a DC-drive is slow speed programmed with parameter 21.

7.8

Page 39

Delem

Breakpoint for one- and two-speed drives

Fig. 7.2 explains the meaning of the parameters BFS, BSS, T and OR. The indications HS and SS

represent the high and low speed of the backgauge. The Breakpoint Slow Speed (BSS) and the stop

time (T) serve to position the backgauge. When the backgauge approaches the programmed position

at slow speed and comes within the range of the BSS, the controller will switch off and the

backgauge will come to a stop. If the resulting position is not correct, try altering the BSS.

When the BSS is not accurate enough to reach the programmed position, use the stop time (T) to

delay the moment of switching off the controller.

In the case of a 2-speed drive, you can program the Breakpoint Fast Speed (BFS) to define areas for

high speed and low speed. When the backgauge is moving to a programmed position at high speed,

it will slow down to slow speed when it is within the range of the BFS.

The advised procedure is to leave the BFS at its high default value and first program BSS and T

correctly. Once that has been done, try adjusting the BFS to reduce the production time without

positioning inaccuracies.

N = 2, ST = 0: Breakpoint Fast Speed BFS

Range : 0 - 9999 count units

Default : 100

Switch point from high speed to slow speed.

N = 2, ST = 1: Breakpoint Slow Speed BSS

Range : 0 - 9999 count units

Default : 10

Slow speed switch-off point.

Fig. 7.2

7.9

Page 40

N = 2, ST = 2: Stop time T

Range : 0 - 99 (5 msec units)

Default : 0

Delay time before switching off low speed after BSS has been reached.

N = 2, ST = 3: Overrun OR

Range : 0 - 9999 count units

Default : 50

Overrun distance in case of one side positioning.

Overrun is always in the upcounting direction.

Note: This parameter must also be programmed if one-side positioning is used in combination

with a servo drive (type = 3).

N = 2, ST =4: Overrun wait time

Range : 0 - 999 5msec units

Default : 100

Wait time at overrun position before the backgauge starts positioning in the opposite direction.

Output deflections for two speed with DC-motor:

N = 2, ST = 5: DC-motor Slow speed SS

The parameter SS must be programmed if 2-speed DC motor drives are used.

Range : 1 - 100% of maximum output deflection (10 V)

Default : 4%

N = 2, ST = 6: DC-motor high speed HS

The parameter HS must be programmed if 2-speed DC motor drives are used.

Range : 1 - 100% of maximum output deflection (10 V)

Default : 80%

7.10

Page 41

Delem

N = 2, St = 7 AC output definition

Range : 0 - 1

Default : 0

It is possible to drive an AC-motor with 3-outputs instead of 4-outputs as set by default.

The output setting is then as follows:

0 = 4 outputs used:

++ = high speed opening (backwards)

+ = low speed opening (backwards)

-- = high speed closing (forwards)

- = low speed closing (forwards)

1 = 3 outputs used:

++ = output off: low speed

output on : high speed

+ = opening

- = closing

-- = not used

N = 2, ST = 8: Maximum Stroke Length

Range : 0 - 9999 seconds of maximum stroke length

Default : 0

With this parameter, it is possible to set a maximum stroke length in seconds. When that

programmed time has elapsed, function output F1 will become active.

This means that when you use the stroke function, it will not be possible to use the F1, F2 digital

function outputs anymore.

The meaning of this machine parameter is as follows:

value = 0, stroke limitation disabled, normal function of F1 F2 outputs

value > 0, stroke limitation active with the programmed value in seconds for the

maximum stroke length.

The user can program the desired stroke length as a percentage (0-100%) of the maximum machine

parameter time. This percentage value can be programmed in every step by selecting the F-led.

When the percentage value is programmed zero then the stroke limitation is not active in that step.

In this case the F1 output will not be activated.

7.11

Page 42

The following timing diagram is valid:

Start

pressed Start cut

Start enable

input

1

F1 = Stroke

limitation 0

Stroke reached

Percentage of programmed time.

Fig. 7.3

Note: When the DAC-250 is stopped, the F1 output will be off.

Parameters for servo drive adjustment

Fig. 7.4 explains the meaning of the following parameters to be adjusted with DC-servo control:

GAIN, SWITCH, BRAKING RAMP, ACCELERATION RAMP

Fig. 7.4

7.12

Page 43

N = 3, ST = 0: Servo motor gain

Range : 1 - 15

Default : 9

N = 3, ST = 1: Servo motor switch

Range : 0 - 999 count units

Default : 3

Switching point from ramp to gain

N = 3, ST = 2: Servo motor braking ramp

Range : 1 - 15

Default : 7

Delem

N = 3, ST = 3: Servo motor acceleration ramp

Range : 5 - 1275 msec

Default : 5

This parameter defines the time needed to reach the full speed output.

N = 3, ST = 4: Manual movement slow speed

Range : 1 - 99 mm/sec

Default : 1 mm/sec

N = 3, ST = 5: Manual movement high speed

Range : 1 - 99 mm/sec

Default : 10 mm/sec

N = 3, ST = 6: Reference search speed

Range : 1 - 100% of maximum output deflection (10 V)

Default : 50%

N = 3, ST = 7: In-position tolerance

Range : 0 - 999 count units

Default : 4

The "in-position output" (Ip) becomes active if the difference between the actual position and the

programmed position is smaller than this tolerance.

7.13

Page 44

N = 3, ST = 8: Reference Search Procedure

Range : 0 - 1

Default : 0

0 = System 1: standard reference search system without Reference Search Direction switch

(RSD-switch).

1 = System 2: reference search system with RSD-switch

Two systems for reference search are implemented:

1. Without Reference Search Direction switch

2. With Reference Search Direction switch

System 1 is the standard reference search system. For this system the motor drive must be equipped

with a direction sensitive enable/disable input.

System 2 Now the motordrive does not need any direction sensitive enable/disable input anymore.

Also you are free where you place the reference search direction switch (RSD). It may be the same

switch; EOT-switch.The advantage of the reference search cycle with system 2 is that in case the

RSD switch is mounted in the middle of the X-axes stroke, the DA-control senses the status of this

switch. In case the X-axis is between the zero-position and RSD switch a normal reference search

cycle is initiated.

In case the X-axis is between the RSD and EOT+ switch the status of the RSD switch indicates that

reference search can start in the direction of the RSD switch (forward). Overall you will have shorter

reference search cycle time. Another advantage is the fact that it is not needed to mount the limit

switches for ref.-search.

Fig. 7.5

7.14

Page 45

The reference search cycle is as follows:

No RSD switch With RSD switch

Delem

Move to the selected

reference search

direction

EOT switch activated:

motordrive stops

movement

No more movement

detected by the

control

RSD

Active ?

No

Move to the selected

reference search

direction

RSD switch activated:

stop movement by the

control

Yes

The control enables

reference input

Move in opposite

direction until

reference found

after ref. found the

control disables ref.

input, move to prog.

pos.

Moves in opposite

direction

RSD switch

disactivated:

enable reference input

Ref. found: the

control disables ref.

input, move to prog.

pos.

7.15

Page 46

Note 1: Reference switch activated means RSD (EOT) input is low. Reference switch not activated

means input is high (+24V).

Note 2: To be sure that the Ref.-switch (RSD) is mounted, the DAC-control will only move the

backgauge over the following distance for taking reference. This in case the RSD-switch

input is active (low) at the start of the reference search cycle.

A) Ref. search direction backwards:

1.5 x (max. position - ref. position)

B) Ref. search direction forwards:

1.5 x (ref. position - min. position)

N = 4, ST = 8: EEPROM write access count

The EEPROM write access count is displayed.

Some important parameters are saved in the EEPROM each time at power down. The number of

times this will happen is counted and visualized at this machine parameter position. The parameters

which are saved are described in the memory management specification.

If the count exceeds the value 9900 the message 'E2Err' appears on the display each time at power

up. Press any key and this message will disappear.

According to the specifications of the EEPROM chips each location can only be rewritten 10.000

times.

N = 4, ST = 9: Memory erase code

Default : 0

Working in the memory erase mode may destroy valuable information. Read the following

instructions before pressing one of the buttons. Be sure of the relevant button before pressing it.

0 = no memory erase

1 = complete erase of memory, including step memory and machine parameters. The machine

parameters are loaded with the default values.

2 = only the machine parameters are loaded with their initial values. The step memory is not

affected.

3 = only the (complete) step memory is erased. The machine parameters are not affected.

10 = erase of program steps N = 0, ST = 1 thru 9

11 = erase of program steps N = 1, ST = 0 thru 9

12 = erase of program steps N = 2, ST = 0 thru 9

19 = erase of program steps N = 9, ST = 0 thru 9

7.16

Page 47

Delem

To make the erase effective the following steps must be performed:

a) program the required code at N = 4, ST = 9.

b) exit the machine parameters by pressing the cursor key <

c) switch off the power

d) switch the power on again

After the erase and initialization is ready the erase code is reset to zero.

If these steps are not performed in this order the erase code will be reset to zero without any erasing

taking place.

7.17

Page 48

INTENTIONALLY

LEFT

BLANK

7.18

Page 49

Delem

8. INSTALLATION

8.1. Connection example

To connect the DAC-250 to your backgauge system you will find an example in the appendix.

8.2. Encoder Voltage

Both DAC-150 and DAC-250 are equipped with a power supply circuit for the encoder. This circuit

can supply a voltage of 5V or 12V. The controller is delivered with the required power supply

voltage for the encoder as is noted on the controller itself.

If necessary, it is possible to change the voltage. To do so, the power supply circuit can be adjusted

by replacing several components.

Tables 1 and 2 on the next page contain a list of components that must be (re)placed in order to

change the encoder voltage, one way or the other.

The placement of these components can be found on the enclosed component lay-out, drawing nr.

7353-201. As far as the encoder supply is concerned, this lay-out is valid for both types of

controllers.

When changing from 12 to 5 V, the RA1-component must be placed. Beware of the correct

mounting position on the I/O board:

Fig. 8.1

Abbreviations

In the next two tables, the following abbreviations are used:

R = Resistor

RA= Resistor Array

C = Capacitor

J = Jumper (shortcut between connection points)

8.1

Page 50

- = Component is not placed

F = Farad

K = Kilo-Ohm

1K2 = 1200 Ohm

2N2F = 2.2 Nanofarad

390PF = 390 Picofarad

Table 1: Change voltage from 5 to 12 V

Component Type Old value Required value action

RA1 resistor array,

4 resistors, 5-

pins

R1 resistor 1K2 22K replace resistor

R2 resistor 1K2 22K replace resistor

R3 resistor 1K2 22K replace resistor

R4 resistor - 22K place resistor

R5 resistor - 22K place resistor

R6 resistor - 22K place resistor

C20 capacitor 2N2F 1NF replace capacitor

C21 capacitor 2N2F 1NF replace capacitor

C22 capacitor 1NF 390PF replace capacitor

J1 jumper 2-3 1-2 change connection

Table 2: Change voltage from 12 to 5 V

Component Type Old value Required value action

RA1 resistor array,

4 resistors,

5-pins

R1 resistor 22K 1K2 replace resistor

R2 resistor 22K 1K2 replace resistor

R3 resistor 22K 1K2 replace resistor

R4 resistor 22K - remove component

R5 resistor 22K - remove component

R6 resistor 22K - remove component

C20 capacitor 1NF 2N2F replace capacitor

C21 capacitor 1NF 2N2F replace capacitor

C22 capacitor 390PF 1NF replace capacitor

J1 jumper 1-2 2-3 change connection

4 times 2K2 - remove component

- 4 times 2K2 place component

8.2

Page 51

Delem

9. DIAGNOSTIC PROGRAM DAC-150/DAC-250

9.1. Introduction

The DAC-150 and DAC-250 are equipped with a diagnostic program. This diagnostic program

contains several tests. With each of these tests a certain part of the hardware can be tested. With

input and output tests also the interaction with the complete system (machine) can be verified.

The selected test is always displayed in the two leftmost digits of the display. The other four

digits are used to display test dependent information.

When the diagnostic program is selected test number 1 (A1) will be active.

Another test can be selected by pressing the cursor key (<). Pressing this key increments the test

number by one.

9.2. Starting the diagnostic program

The diagnostic program can be activated by pressing the keys 7, 8 and 9 simultaneously when

the power is switched on. Automatically test A1 is selected.

The diagnostic program contains the following tests:

A1: Ram memory

A2: displays

A3: frontpanel keys and LEDs

A4: digital inputs and outputs

A5: analog output deflection

9.1

Page 52

9.2.1. A1: Ram memory

The memory is tested by writing a test pattern. After this pattern has been written all bytes are

read back and checked.

The complete memory is tested.

The test is started by pressing the Start key.

During the test the display will be blank. When the memory test is completed a code will be

displayed. When the memory is found OK the value 0 is displayed otherwise the digit 1 will be

displayed.

Continue to the next test by pressing <.

9.2.2. A2: displays

With this test all the digits of all the displays are tested.

This test is divided into several phases. By pressing the Start key the first one is started. A next

phase is selected each time the Start key is pressed. When all phases are selected once and the

Start key is pressed again the indication A2 appears on the display again.

The phases of which this test consists are:

1. All segments of all displays are lid

2. All segments of all displays are off

3. One segment of each display is lid for about 1 second. Then the next segment is lid

etc.

4. All segments of one display are lid for about 1 second. Then the next display is lid

etc.

5. All available decimal points are lid.

Continue to the next test by pressing <.

9.2

Page 53

Delem

9.2.3. A3: frontpanel keys and LEDs

With this test all frontpanel keys and LEDs can be tested separately.

When a key is pressed a corresponding code will be displayed on the two rightmost digits of the

display. By pressing some of the keys also a LED will lid. See table.

Key Code LED

11 Xm

22 Xp

3 3 COR (DAC-250 only)

4 4 DX (DAC-250 only)

5 5 F (DAC-250 only)

6 6 CY (DAC-250 only)

7 7 C (DAC-250 only)

88 #

99 I

0 0 (DAC-250 only)

.16

+/- 11 (DAC-250 only)

Clear 18

N 148 (DAC-250 only)

St 147 (DAC-250 only)

Stop 12 Stop

Auto./Start 17 Automatic

Semi-auto 14 Semi-automatic (DAC-250 only)

X13

+15

-10

Continue to the next test by pressing <.

9.3

Page 54

9.2.4. A4: digital inputs and outputs

A digital output can be made active by pressing a key corresponding to the following table:

Key Output

3 ++ (AC-version only)

6 + (AC-version only)

9 - (AC-version only)

0 -- (AC-version only)

2IP

5 EOC (DAC-250 only)

7 F1 (DAC-250 only)

8 F2 (DAC-250 only)

When an input is made active a LED will light corresponding to the following table:

Input LED

EOT Xm

START Xp

R#

KEY-lock/count I

Continue to the next test by pressing <.

9.2.5. A5: analog output deflection (DC-version only)

With this test a certain analog output deflection can be set.

The output voltage is in the range of -10V to +10V.

The deflection can be changed by pressing the + key (greater value) or - key (smaller value).

The current output deflection will be displayed (as % of maximal deflection).

The possible values are:

-100% -80% -20% -5% -0% +0% +5% +20% +80% +100%

--------> + key

<-------- - key

9.4

Page 55

Delem

Offset-adjustment

By means of this test you can set the offset voltage of the speed output as follows:

- set output to 0%

- measure the speed output voltage on connectionpoints 24 and 23

- Adjust the output voltage to zero volt with help of potentiometer RP1 on the I/O

board type 7353. See also included components lay-out schematics.

9.3. Ending the diagnostic program

You can end the diagnostic program by switching off the power of the controller and switch it on

again to return in the normal programming mode.

9.5

Page 56

INTENTIONALLY

LEFT

BLANK

9.6

Page 57

Page 58

Page 59

Page 60

Keep encodercable away from

power- and relaiswires.

Connect shielding from

encodercable to earth on

both sides

20

21

REF

19

+ 12V

18

22

24

T2

T1

0V

SPEED OUTPUT +/- 10V

DAC250

RELAIS OUTPUTS

23

ONLY FOR AC

Connect diodes (fast transient types)

as close as possible to the relais terminals

spd -

T1T2M+

spd +

DC321/

E

DC322

ENCODER

M

M-

EXAMPLE

9005-101 D

Scale

Luchthavenweg 42, 5657 EB

Eindhoven, the NETHERLANDS

CONNECTIONS DAC250

servo drive

A3

No unauthorized copying allowed

Format Number Issue

Date

ONLY FOR DC

Date

Note Redrawn

Date

Redrawn

-

-

Description

Note

VW 01-07-1996

DrawnMeasures in mm,unless

-

-

Description

otherwise specified

CONNECTION TERMINALS

F2 F1 EOC IP -- - + ++CEOT

0V

C

1000 uF

24V Supply isolated

24VT2

start

INPUTS

enable

OPTO-COUPLED

R

24V DC

1

2

3

1000 uF

+

Program key

FUSE 2A

220V AC

T1

from other supplies

Keep supply-wires to linefilter as far as

possible from wires to the transformer.

220V AC

Page 61

Keep encodercable away from

power- and relaiswires.

Connect shielding from

encodercable to earth on

both sides

20

21

REF

19

+ 12V

18

22

24

T2

T1

0V

SPEED OUTPUT +/- 10V

DAC250

RELAIS OUTPUTS

23

spd -

T1T2M+

spd +

DC321/

E

DC322

ENCODER

M

M-

EXAMPLE

9005-102 B

Scale

Luchthavenweg 42, 5657 EB

Eindhoven, the NETHERLANDS

CONNECTIONS DAC250

servo drive

A3

No unauthorized copying allowed

Format Number Issue

Date

ONLY FOR DC

Date

Note Redrawn

Date

Redrawn

-

-

Description

Note

VW 01-07-1996

DrawnMeasures in mm,unless

-

-

Description

otherwise specified

CONNECTION TERMINALS

F2 F1 EOC IP -- - + ++CEOT

Connect diodes (fast transient types)

as close as possible to the relais terminals

C

start

INPUTS

enable

OPTO-COUPLED

R

24V DC

1

2

3

1000 uF

+

Program key

FUSE 2A

T1

0V

1000 uF

24V Supply isolated

24VT2

from other supplies

220V AC

Keep supply-wires to linefilter as far as

possible from wires to the transformer.

220V AC

Page 62

20

21

REF

+ 12V

19

T2

18

222324

T1

0V

EXAMPLE

Luchthavenweg 42, 5657 EB

Eindhoven, the NETHERLANDS

9005-103 -

Scale

SPEED OUTPUT +/- 10V

DAC250

RELAIS OUTPUTS

CONNECTION TERMINALS

INPUTS

OPTO-COUPLED

start

FAST

+

F2 F1 EOC IP -- -

CEOT

C

enable

R

ONLY FOR AC

Connect diodes (fast transient types)

as close as possible to the relais terminals

FAST

CONNECTIONS DAC250

Format Number Issue

A3

No unauthorized copying allowed

+

-

ONLY FOR AC

Date

Note Redrawn

Date

Redrawn

-

-

Description

Note

Date

VW 01-07-1996

DrawnMeasures in mm,unless

-

-

Description

otherwise specified

0V

1000 uF

24V Supply isolated

24VT2

from other supplies

24V DC

1

2

3

1000 uF

+

Program key

FUSE 2A

220V AC

T1

Keep supply-wires to linefilter as far as

possible from wires to the transformer.

220V AC

Page 63

20

21

REF

+ 12V

19

T2

18

222324

T1

0V

FAST

FAST

EXAMPLE

Luchthavenweg 42, 5657 EB

Eindhoven, the NETHERLANDS

CONNECTIONS DAC250

9005-104 -

Scale

RELAIS OUTPUTS

A3

No unauthorized copying allowed

Format Number Issue

SPEED OUTPUT +/- 10V

DAC250

RELAIS OUTPUTS

CONNECTION TERMINALS

INPUTS

OPTO-COUPLED

start

+

F2 F1 EOC IP -- -

CEOT

C

enable

R

+

-

F F F

ONLY FOR AC

Connect diodes (fast transient types)

as close as possible to the relais terminals

F F F F F F F F

ONLY FOR AC

Date

Note Redrawn

Date

Redrawn

-

-

Description

Note

Date

VW 05-02-1997

DrawnMeasures in mm,unless

-

-

Description

otherwise specified

0V

1000 uF

24V Supply isolated

24VT2

from other supplies

24V DC

1

2

3

1000 uF

+

Program key

FUSE 2A

220V AC

T1

Keep supply-wires to linefilter as far as

possible from wires to the transformer.

220V AC

Page 64

Keep encodercable away from

power- and relaiswires.

Connect shielding from

encodercable to earth on

both sides

20

21

REF

+ 12V

19

T2

18

T1

22

0V

24

SPEED OUTPUT +/- 10V

23

spd -

T1T2M+

spd +

DC321/

E

DC322

ENCODER

M

M-

EXAMPLE

9005-105 -

Scale

Luchthavenweg 42, 5657 EB

Eindhoven, the NETHERLANDS

CONNECTIONS DAC250

RELAIS OUTPUTS(servo drive)

A3

No unauthorized copying allowed

Format Number Issue

Date

ONLY FOR DC

Date

-

Date

Redrawn

-

-

-

VW 05-02-1997

DrawnMeasures in mm,unless

DAC250

CONNECTION TERMINALS

24V DC

1

2

1000 uF

+

RELAIS OUTPUTS

F2 F1 EOC IP -- - + ++CEOT

C

start

INPUTS

enable

OPTO-COUPLED

R

3

T1

Note Redrawn

Connect diodes (fast transient types)

as close as possible to the relais terminals

Description

Description

Note

otherwise specified

0V

1000 uF

24V Supply isolated

24VT2

from other supplies

FUSE 2A

Program key

220V AC

Keep supply-wires to linefilter as far as

possible from wires to the transformer.

220V AC

Page 65

9042-103 D

Scale

24

X-AXIS

depends on

desired direction

18speed +

AU-

EOT F-

EOT B-

STOP

EMERGENCY

FORWARDS

TRAVEL

END OF

BACKWARDS

TRAVEL

END OF

AU+

44A

))

EOT F+

211A

EOT B+

3

32

31

speed output +/- 10V

+/- 10V

Internal connection on

)

30

23

17

speed -

printed circuit board

23+12V

screen on chassis

AGND

24-12V

7359

DC322

MOTORDRIVE

29 TRAFOT1

DAC150/250

U

26 TRAFOT2

U

T2

15

T1

14

M-

25

M+

28

27 TRAFOT3

screen on chassis

18T1

19T2

20REF

21V+21220V

0V

V+

T2

T1

REF

Reference signal may

also be signal from

reference switch

E

M

ENCODER

Luchthavenweg 42, 5657 EB

Eindhoven, the NETHERLANDS

Date

-

Note Redrawn

Description

CONNECTIONS DC322 (DAX50)

X-AXISuniversal diagram

Format Number Issue

Date

23-04-1997

Redrawn

-

Description

Note

-

-

A3

No unauthorized copying allowed

Date

VW 02-07-1996

DrawnMeasures in mm,unless

otherwise specified

0V

+24V

24V DC

FUSE 10A

FUSE

FUSE

380V

FUSE 10A

Metal baseplate must take very good

galvanic contact against relaisbox base

(ground)!

EXAMPLE DIAGRAM NO WARRANTY

Loading...

Loading...