Page 1

Delem

DA-69W

Reference Manual

Operation

of Version V2

Manual version V0404

Page 2

PREFACE

This manual describes the operation of the Delem controller type DA-69W and is meant for

operators who are instructed for operation of the total machine.

Only authorised people should be able to create new or edit existing programs, as well as programming or editing of the tooldata. Therefore the controller has a keyswitch to prevent

uncontrolled programming. With the keyswitch in the off position the operator can only execute a selected program. The operator cannot change the parameters to wrong, unwanted values.

V0404, 0.2

Page 3

Delem

Table of contents

Table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.3

1. Operation overview and general introduction . . . . . . . . . . . . . . . . 1.1

1.1. The control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.1

1.2. Operation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.2

1.3. Frontpanel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.3

1.4. Programming mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.6

1.4.1. The main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.6

1.4.2. Help text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.8

1.4.3. Listbox functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.10

1.5. Graphical programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.11

1.5.1. Control keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.12

1.6. Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.14

1.7. Software versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.14

1.8. Delem Limited warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.16

1.9. End user license agreement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.17

2. Product drawing/Product edit for 2-dimensional products . . . . . . 2.1

2.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.1

2.2. Delete an angle/line or insert an angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.5

2.3. Precision selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.5

2.4. Big Radius (Bumping) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.7

2.5. Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.8

• Parameter explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.10

• Parameter explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.11

• Parameter explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.14

2.6. Bend sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.15

• Restoring a bend sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.21

• Minimum bending length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.22

• Machine/Tool selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.23

• Turn indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.23

• Production time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.24

• Screen data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.24

• Function- and control keys summary . . . . . . . . . . . . . . . . . . . . . . . . . .2.25

• Bend sequence computation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.26

• Store . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.27

2.7. Variants programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.27

3. Drawing/editing a product in 3D . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1

3.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.1

3.1.1. Product data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.1

3.2. The 3D drawing of a product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.2

• Unfolded product. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.4

• Product data overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.5

• Extending or rotating the product. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.6

V0404, 0.3

Page 4

3.3. Changing the shape of a surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.8

3.4. Bend sequence 3D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.15

3.4.1. Start bend simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.16

3.4.2. Tool / machine visualisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.18

3.4.3. Manual select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.20

3.4.4. Unbend product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.21

3.4.5. Move product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.22

3.4.6. Move fingers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.23

3.4.7. Show bendsequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.25

3.5. Creating two bends simultaneously . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.25

3.6. New tool configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.28

• Selecting the machine upperside . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.29

• Programming the uppertool set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.29

• Adding uppertools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.33

• Programming uppertools with heel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.35

• Programming the undertoolset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.36

• Selecting machine lowerside . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.37

3.7. Assignments 3D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.41

4. Data preparation/Data edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1

4.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1

• Parameters explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3

4.2. Bend programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.5

• Axis functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.6

• Parameter explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.7

• Parameter explication (second page) . . . . . . . . . . . . . . . . . . . . . . . . . . 4.11

• Slave axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.15

• List of bendings of the prepared program . . . . . . . . . . . . . . . . . . . . . . . 4.16

• Ending data preparation/data editing . . . . . . . . . . . . . . . . . . . . . . . . . . 4.18

4.3. Special edit function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.19

4.4. Edit notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.19

5. Product selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1

5.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1

• Graphical directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.3

• Expanded directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.3

• Search function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.4

5.2. Directories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.6

6. Programming of tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1

6.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1

6.2. Programming of Punches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1

6.2.1. The punch menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1

• Graphical directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3

• Edit punch drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.4

• Drawing orientation of the punch on the screen . . . . . . . . . . . . . . . . . . . 6.5

6.2.2. Specific Punch Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.5

6.3. Programming of bottom dies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.9

V0404, 0.4

Page 5

Delem

6.3.1. The die menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.9

• Graphical directory dies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.11

6.3.2. Specific die data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.13

6.4. Machine upper side and lower side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.16

6.5. Saving/loading of tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.19

7. Products and tools back-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.1

7.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.1

7.2. Product backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.2

7.3. Tool back-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.5

8. Program Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.1

8.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.1

8.2. Bendsequence parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.17

• Backgauge dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.18

• Part support dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.20

• Critical dimension boundaries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.22

• Speed Y-axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.23

8.3. Backup path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.24

8.4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.25

9. Manual mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.1

9.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.1

• Parameter Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.3

• Zoom function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.6

9.2. Manual operation of the axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.7

• To teach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.8

10. Automatic / step by step mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.1

10.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10.1

• Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10.3

• Functions screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10.5

• Graphical visualisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10.5

• Zoomed values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10.6

• Bumping correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10.7

• Manual positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10.8

10.2. Step mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10.9

A. Parameter index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A.1

V0404, 0.5

Page 6

V0404, 0.6

Page 7

1. Operation overview and general introduction

1.1. The control unit

The control looks as follows:

Delem

screen

function keys

wheel

em. stop

button

touchpad

1.a

The precise outfit of your control may vary.

Operation of the control is done with the various keys on the front panel. A description of all

keys and their functions is given in the next section.

Beside the front panel keys, a built-in touchpad or external USB mouse can be used as a pointing device to select menu items, parameters or softkeys. It depends on your configuration

whether such a device is available. In this manual the phrase ‘mouse’ is used to describe any of

these possible pointing devices.

arrows

mode keys

start/stop

num. keys

V0404, 1.1

Page 8

1.2. Operation modes

The control has the 4 following modes:

Manual mode In this mode it is possible to program all parameters of

just one bending. After pushing the start button all parameters are active and the backgauge will go into position. It

is also possible to move the axes manually.

Programming

mode

Automatic

mode

Step by step

mode

Each mode can be selected by pressing the relevant push button. A LED in the push button

indicates whether or not this mode is active.

In this mode bend programs can be made or edited and

also be written to or read from disk.

The selected program can be executed automatically.

The selected program can be executed bend by bend.

V0404, 1.2

Page 9

Delem

1.3. Frontpanel

The frontpanel, besides the 4 operation mode buttons, consists of the following items :

Keyboard:

decimal point

clear key: Clearance

of the input data field

in the bottom left corner on the monitor

screen

10 numerical keys (0-

9) incl. alphanumeric

input

plus/minus toggle

enter key, to confirm a

programmed value

Cursor path control:

Stop button Start button

V0404, 1.3

Page 10

Handwheel; Manual control of any axis (Y + backgauge

axes)

Emergency stop button, to be implemented by machine

manufacturer.

Softkeys; The function of these keys is stated at the bottom side of the monitor screen.

End of menu program.

It is also possible to leave a menu by pressing <ESC> on

an external keyboard or clicking with the mouse on the

menu symbol in the upper left corner.

On the screen pages where you find the "?" symbol you

can press the "?" to get an explanation of the respective

function or parameter to program.

V0404, 1.4

Page 11

Delem

Integrated touchpad

The control can be equipped with a touchpad, which

functions as mouse. The two buttons beneath it function

as mouse buttons.

V0404, 1.5

Page 12

1.4. Programming mode

1.4.1. The main menu

Programming

mode

The main menu in programming mode looks as follows:

Select the programming mode.

1.b

Each of these menu items can be selected in several ways:

- enter the menu number and press ENTER

- use the arrow keys to scroll to the desired menu item and press ENTER

- click with the mouse once on the desired menu item

Explanation of menu items:

To draw your product on the screen and compute the

1

V0404, 1.6

bendsequence (graphical).

Page 13

Delem

To edit your product drawing and compute the bendse-

2

3

4

5

6

7

quence (graphical).

Creation of a new CNC-program by data entry (numerical).

To edit an existing CNC-program by data entry (numerical).

To select a program out of the product library.

Write programs to or read programs from a back-up

medium.

To program the dimensions of the upper tools.

8

9

10

11

12

To program the dimensions of the under tools.

To program the dimensions of the upper side of your

machine.

To program the dimensions of your machine table.

To program specific programming data.

Write or read tooling data and machine shapes to or from

a back-up medium.

V0404, 1.7

Page 14

1.4.2. Help text

The control has been equipped with an online help text possibility. This help text is available

when the question mark ‘<?>’ appears on the screen (lower right corner).

1.c

To activate a help window for a parameter:

- press the question mark key (‘?’) on the frontpanel or

- click with the mouse on the help symbol.

A pop-up window appears with information on the active parameter.

V0404, 1.8

Page 15

Delem

1.d

The help window can be used as follows:

If the text is located in a single window, remove the window by pressing any key.

If there is a lot of text across multiple windows, an arrow sign appears below the help symbol.

Use the left and right arrow keys or click on the arrow symbols to browse back and forth

through the help text.

V0404, 1.9

Page 16

1.4.3. Listbox functionality

Several parameters on the control have a limited number of possible values. Beside such

parameters, the sign appears.

This means that the key can be pressed to get a listbox with possible values of this

parameter.

This listbox can also be opened by clicking with the mouse on the symbol.

V0404, 1.10

Page 17

Delem

1.5. Graphical programming

From the main menu you can select one of the programming possibilities.

In order to design or edit a new product, the graphical programming facility is present.

This facility is a complete product design tool that allows you to draw the profile of your product. It consists of a machine-and tool-library which allows you fast automatic, interactive or

manual bending sequence computations with display of possible product/tool/machine collisions and developed length.

The graphic design tool provides a way of selecting the most optimal bend sequence for a

product, keeping in mind the minimum production time and manipulation possibilities of the

product.

Features of the design tool

- Graphical design of product shapes in 2D and 3D (if available)

- Auto scaling

- Horizontal and vertical projected dimensions can be entered

- Blank length computation

- Real scale tool design

- 10 different upper side shapes and 10 different under side shapes (tables)

- Changing of lengths and angles

- Bumping (big radius)

- Adding or deleting of bends

- Existing products can be copied, changed and stored as a new product

- Production time indication

- Closing dimension or highest precision tolerance selection

- Connecting 2D programs for 3D-production

Bending sequence computation

- Fast automatic computation for minimum production time

- Interactive bending sequence fixation

- Manual bending sequence fixation

- Collision visualisation of product with tools and machine

- Free tool and machine shape selections

- Assignments of turn times, backgauge speed etc.

- Bending sequence simulation

- Free selection of R-axis position

Postprocessing of drawings

The postprocess facility computes:

- Fully automatic

- Machine adjustment such as:

• Y-axis position

• Decompression

• X-axis position

• X-axis retract

• Y-opening

•R-axes

V0404, 1.11

Page 18

• Z-axes

Axes according to the machine configuration

The 2D-programming will be explained in chapter 2.

The 3D-programming (if available) will be explained in chapter 3.

1.5.1. Control keys

The drawing software uses several function keys on the front panel. The function depends on

the type of control (2D or 3D functionality)

- S1 thru 8

- Drawing cursor control with:

- Zoom function:

At bendsimulation overview in case of 2D-products (bendsequence menu and automatic

mode):

Enlargement

Reducement

At bendsimulation overview in case of 3D-products (bendsequence menu and automatic

mode):

Enlargement

V0404, 1.12

Reducement

Page 19

Delem

- Turnfunction for 3D-products

and to turn over the vertical axis

and to turn over the horizontal axis

- Drawing cursor control for 2D-products

In case you are drawing the profile of your product or tools the cursor keys can be used to give

directly multiples 45 degree angles. e.g.:

a = 135°

a = 45°

a = -90°

a = 90°

- Horizontal or vertical projections for 2D-products

After you entered the length of the line interval you can specify if this line interval is either the

nominal length, horizontal or vertical projection. The given length dimension in the enter field

is the line length L if the drawing cursor is in the concerning line.

Horizontal projection with or key

Vertical projection with or key

V0404, 1.13

Page 20

L is normal entered line length

V is vertical projected line length

H is horizontal projected line length

It will be noted on the screen if projection is not possible.

1.6. Ethernet

The CNC control is equipped with a network interface. The network function offers the operators the possibility to import product files directly from the network directories or to export the

finished product files to the required network directory.

1.e

Chapter 7 contains more information about networking possibilities.

1.7. Software versions

The version of the software in your control is displayed at the upper side of the menu screen in

the programming mode.

Example of version number:

VA 2 .1

VA stands for version

2 is version number

1 is version level

V0404, 1.14

Page 21

Delem

The version number is increased when new features are added to the software, the level number is increased when minor corrections are needed in the existing version number.

V0404, 1.15

Page 22

1.8. Delem Limited warranty

1 The DA-control has no safety provisions with respect to operator or machine. Applica-

tion of the DA-control is totally for the responsibility of the machine manufacturer.

Safety measures must be taken outside the DA-control in order to guarantee safe operation for the machine operator, also in case of any malfunctioning of the DA-control.

Delem cannot be held responsible for possible damages, caused directly or indirectly by

the DA-control in normal operation or even when it fails to function according to its

specifications.

2 Delem provides the manual "as is" without warranty of any kind, either expressed or

implied; including but not limited to the particular purpose. Delem may make improvements and/or changes in the product(s) and or program(s) described in the manual at any

time. This manual could include technical inaccuracies or typographical errors. Changes

are periodically made in its information. These changes will be incorporated in new editions of the publication. Requests for copies of this product and for technical information

about the products can be made to Delem employees authorised to give this information.

V0404, 1.16

Page 23

Delem

1.9. End user license agreement

License

- You have acquired a device (“DEVICE”) that includes software licensed byDelem from

Microsoft Licensing Inc. or its affiliates (“MS”). Those installed software products of

MS origin, as well as associated media, printed materials, and “online” or electronic documentation (“SOFTWARE”) are protected by international intellectual property laws

and treaties. The SOFTWARE is licensed, not sold. All rights reserved.

- IF YOU DO NOT AGREE TO THIS END USER LICENSE AGREEMENT (“EULA”),

DO NOT USE THE DEVICE OR COPY THE SOFTWARE. INSTEAD, PROMPTLY

CONTACT DELEM FOR INSTRUCTIONS ON RETURN OF THE UNUSED

DEVICE(S) FOR A REFUND. ANY USE OF THE SOFTWARE, INCLUDING BUT

NOT LIMITED TO USE ON THE DEVICE, WILL CONSTITUTE YOUR AGREEMENT TO THIS EULA (OR RATIFICATION OF ANY PREVIOUS CONSENT).

- GRANT OF SOFTWARE LICENSE. This EULA grants you the following license:

• You may use the SOFTWARE only on the DEVICE.

• NOT FAULT TOLERANT. THE SOFTWARE IS NOT FAULT TOLERANT. DELEM HAS

INDEPENDENTLY DETERMINED HOW TO USE THE SOFTWARE IN THE DEVICE, AND MS

HAS RELIED UPON DELEM TO CONDUCT SUFFICIENT TESTING TO DETERMINE THAT

THE SOFTWARE IS SUITABLE FOR SUCH USE.

• NO WARRANTIES FOR THE SOFTWARE. THE SOFTWARE is provided “AS IS” and with all

faults. THE ENTIRE RISK AS TO SATISFACTORY QUALITY, PERFORMANCE,

ACCURACY, AND EFFORT (INCLUDING LACK OF NEGLIGENCE) IS WITH YOU.

ALSO, THERE IS NO WARRANTY AGAINST INTERFERENCE WITH YOUR

ENJOYMENT OF THE SOFTWARE OR AGAINST INFRINGEMENT. IF YOU HAVE

RECEIVED ANY WARRANTIES REGARDING THE DEVICE OR THE SOFTWARE, THOSE

WARRANTIES DO NOT ORIGINATE FROM, AND ARE NOT BINDING ON, MS.

• Note on Java Support. The SOFTWARE may contain support for programs written in Java. Java

technology is not fault tolerant and is not designed, manufactured, or intended for use or resale as

online control equipment in hazardous environments requiring fail-safe performance, such as in the

operation of nuclear facilities, aircraft navigation or communication systems, air traffic control, direct

life support machines, or weapons systems, in which the failure of Java technology could lead directly

to death, personal injury, or severe physical or environmental damage. Sun Microsystems, Inc. has

contractually obligated MS to make this disclaimer.

• No Liability for Certain Damages. EXCEPT AS PROHIBITED BY LAW, MS SHALL HAVE NO

LIABILITY FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL OR INCIDENTAL

DAMAGES ARISING FROM OR IN CONNECTION WITH THE USE OR PERFORMANCE

OF THE SOFTWARE. THIS LIMITATION SHALL APPLY EVEN IF ANY REMEDY FAILS

OF ITS ESSENTIAL PURPOSE. IN NO EVENT SHALL MS BE LIABLE FOR ANY

AMOUNT IN EXCESS OF U.S. TWO HUNDRED FIFTY DOLLARS (U.S.$250.00).

• Limitations on Reverse Engineering, Decompilation, and Disassembly. You may not reverse

engineer, decompile, or disassemble the SOFTWARE, except and only to the extent that such activity

is expressly permitted by applicable law notwithstanding this limitation.

• SOFTWARE Transfer allowed but with restrictions. You may permanently transfer rights under this

EULA only as part of a permanent sale or transfer of the Device, and only if the recipient agrees to this

EULA. If the SOFTWARE is an upgrade, any transfer must also include all prior versions of the

SOFTWARE.

• EXPORT RESTRICTIONS. You acknowledge that SOFTWARE is of US-origin. You agree to

comply with all applicable international and national laws that apply to the SOFTWARE, including the

U.S. Export Administration Regulations, as well as end-user, end-use and country destination

restrictions issued by U.S. and other governments. For additional information on exporting the

SOFTWARE, see http://www.microsoft.com/exporting/.

V0404, 1.17

Page 24

V0404, 1.18

Page 25

Delem

2. Product drawing/Product edit for 2-dimensional products

2.1. Introduction

With Menu selection 1 you can draw a new product.

With Menu selection 2 you can make changes in an existing product.

On this page you have to enter first the product number and then the drawing number. The

drawing number may also contain alphanumeric characters, which can be entered with the help

of the function key ‘alphanum’ (S6).

If an existing product number is entered, a warning appears that this product already exists.

You are asked whether to replace that existing product with the new product or not. If you

choose ‘yes', the existing product is erased. If you choose ‘no', you must enter a new number.

The "±" key prompts a "-" character and the "." key prompts a "/" character in the drawing

number.

2.a

If 3D is available on the control, it is first required to confirm whether the drawing programming will be effectuated in 2D or 3D. 3D drawing is explained in chapter 3.

After finishing this input you have to enter specific product data. Then you can start drawing

the product.

In the edit mode you also have the possibility to make a copy of the active product. A special

function key ‘copy product’ appears.

V0404, 2.1

Page 26

2.b

Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TH=

Thickness of the material of the plate in millimeters (mm).

Material. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .M=

Selection of the material type. The control contains 4 preprogrammed materials. In total,

99 materials can be programmed on the control. See chapter 8 how to program materials.

Press the key to select the required setting.

Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .L=

The Z-length of the plate in millimeters (mm).

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D1=

Determine the use of the outside(A) or the inside(B) dimensions in the product drawing.

V0404, 2.2

Page 27

Delem

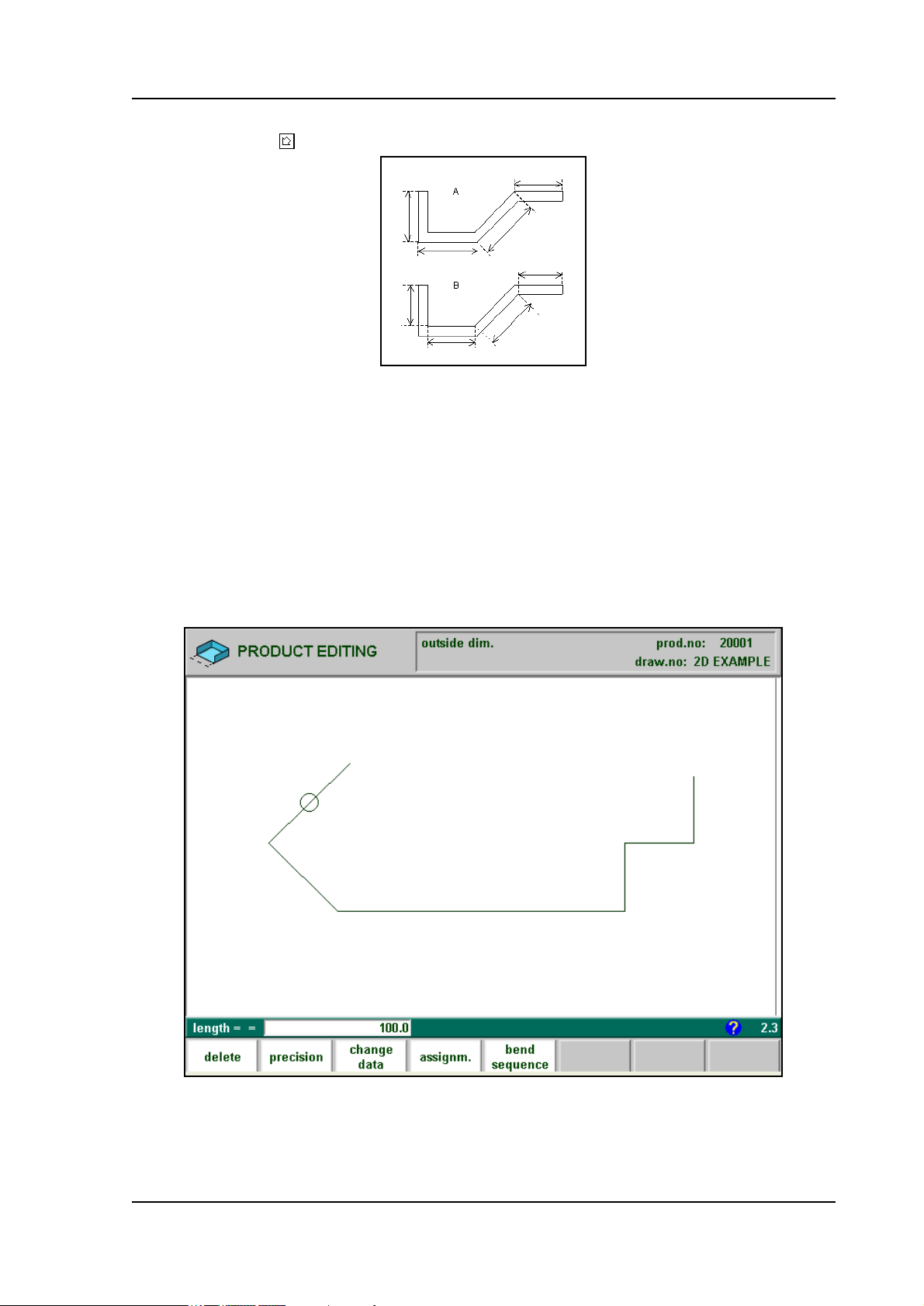

Fig. 2.c gives the definition of both the dimensions.

Press the key to select the required setting.

2.c

After entering the general product data the drawing screen appears. In the upper information

row you will find the information about product number, drawing number and inside/outside

dimensions selection.

You create now the bending profile of the product. First you enter the value of the basic length

of the product. Then you enter the angle of the next side followed by the length of that side.

This procedure continues until the product has the desired profile. A circle indicates the actual

position. With the cursor control keys you move this circle to an other position (angle or

length). During the drawing of the profile of the product the graphical software always displays the product at relative scale.

2.d

For creating the product drawing you have to enter the length of a line and the angle to bend or

you can use the cursorkeys for angles of multiple 45 degrees.

V0404, 2.3

Page 28

In ‘product drawing’ or ‘product edit’ of a 2D product you can program up to a maximal of 25

bendings per product (graphical programming).

Function keys:

insert /

delete

precision To define selected line segment, with round cursor, for

bumping Bumping: when the cursor is on an angle you can create

change

data

assignments

bend

sequence

Delete an angle/line or insert an angle, depending on the

drawing cursor position (section 2.2).

high precision or if it is to be a "closing" dimension (section 2.3).

an angle with a big radius (section 2.4).

To page with product data.

To select assignments for bending sequence computations

(section 2.5).

Program bend sequence (section 2.6).

Return to main menu

These functions will be explained in the sections as indicated in the abovementioned overview.

V0404, 2.4

Page 29

Delem

2.2. Delete an angle/line or insert an angle

The function of softkey (S1) depends on the position of the drawing cursor.

- If the cursor is within a line segment, it is possible to insert a new angle to bend, in combination with the enter key.

- If the cursor is positioned on a bend, it is possible to delete that bend.

- If the cursor is at an end line of the product, the line can be deleted.

2.3. Precision selection

When the drawing cursor (small circle) is on a line segment, with S2 high precision or closing

dimension can be selected. With S2 these functions will be toggled giving 3 possibilities (high

precision - closing dimension - normal situation).

2.e

- High precision:

At bend sequence computation the backgauge stop position will be chosen to get the highest

possible precision of this line interval.

- Closing dimension:

At bend sequence computation the backgauge stop position will be chosen to get the resulting

tolerances in this line interval.

V0404, 2.5

Page 30

Example:

2.f

Line interval marked with the open circle should be, if possible, directly placed between back

stop and the centre of the die.

Notes:

Specifying line intervals with high precision and closing dimensions may result in longer production time.

Also it will have priority over the "front extend ratio", if that is set to "comply if possible". See

section 2.5.

V0404, 2.6

Page 31

Delem

2.4. Big Radius (Bumping)

When the cursor is on an angle you can select bumping. You are prompted to program the following parameters.

radius = the desired radius in mm

segments = number of segments to create the radius.

The more segments you select, the more bendings will be used to create the programmed

radius within a smaller tolerance. With a high number of segments you will need a smaller Vdie opening to be able to bend in a proper way. Which value is acceptable as maximum for the

V-opening of the die is calculated and displayed on the screen.

For the definition of the line lengths to be programmed in the part connected to a bump radius

segment, see figure 2.g.

2.g

Lengths L1 and L2 must be equal or bigger than the radius R.

After programming these parameters the radius is drawn in the product and the maximal V-die

opening which can be used is displayed on the screen.

When the cursor is on a radius and S2 is pressed again the radius will be deleted and changed

back to a single angle (toggle function). For the screen information see figure 2.h.

V0404, 2.7

Page 32

2.h

Specification items:

Radius input:

min. value = 0.1 mm

max. value = 2500.0 mm

In the ‘assignments’ menu, it is possible to modify the way the radius bend is divided into segments. See section 2.5 for more information.

2.5. Assignments

Pressing ‘Assignments’ results in the parameter pages.

If Variants programming is active (indication 'Variants On' in the title bar), a warning is given

that corrections will be lost. Press 'Yes' to proceed with the assignments or 'No' to go back to

the edit screen.

See section 2.8 for more information about variants progamming.

Automatic bend sequence computation works with several criteria in order to find an optimum

between a minimum production time, handling possibilities without product/machine and

product/tool collision.

In order to find one of the optimums you must program several computation parameters with

which the bend sequence can be computed.

Some of these parameters are machine related, axis speeds a.o. and some are related to handling possibilities and turn times.

There are three screens with parameters for 2D programming.

V0404, 2.8

Page 33

Delem

Function keys:

previous

page

next page

load

defaults

save as

defaults

2.i

To load default assignment settings. It is possible to

determine a set of assignments which have the most optimal values to work within your surrounding. This set can

be stored into the internal memory by pressing softkey S4

(save as default). While programming another product

you can recall this previous fixed set by loading the values via softkey S3.

Save as default assignments settings

end To go back to the drawing.

V0404, 2.9

Page 34

• Parameter explanation

Optimalisation Degree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .OD=

Range 1-5

The number of alternative sequences to be computed for each bending must be entered

here.

The higher this number the more alternatives are to be examined by the processor, so the

longer the computing time will be.

Front Extend Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FR=

Range 0.0 - 1.0

This is the ratio of the minimum allowable length of your product which extends in front

of the press to the total blank length of the product. You must have a minimum length of

your product in front of the press to be able to handle the product.

Front Extend Ratio Accept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FA=

- In case programmed 0 (comply if possible) :

This means that when possible the computer tries to comply to the front extend ratio and

only when this will result in no solutions to be found it will accept that the length in front

is smaller than the specified ratio.

- In case programmed 1 (comply always) :

The computer will always comply to the front extend ratio. This may result in no solutions to be found.

Press the key to select the required setting.

V0404, 2.10

Page 35

• Parameter explanation

Backgauge possibilities

Delem

2.j

Backstop against sharp angle allowed . . . . . . . . . . . . . . . . . . . . . . . . .SA=

0 if not allowed

1 if allowed

Press the key to select the required setting.

Specify if backstop may be placed against an angle smaller than 90°.

2.k

V0404, 2.11

Page 36

Backstop die, intermediate bend . . . . . . . . . . . . . . . . . . . . . . . . . . . . .IB=

Set to allow if there may be a bend between the die and backstop.

2.l

Selection possibilities:

0 = permitted

1 = avoid: tries to avoid with low priority

2 = if not avoidable permitted: if it results that no solutions are to be found, than it is permitted

3 = prohibited: never allowable

Press the key to select the required setting.

Edge tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ET=

In case backstop is against flat plate an angle tolerance is allowed (deviation from horizontal).

To be programmed in degrees of tolerance (0 - 90° input)

2.m

V0404, 2.12

Page 37

Delem

90 Degree tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CT =

The maximum allowed deviation from vertical (90°), when the backgauge is against a

bent angle which is not 90°.

2.n

Lay-on backstop limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .BL=

This parameter (mm) is usefull in case the pressbrake has been equiped with backgaugefingers on a moving R-axis, having a so-called “lay-on” construction.

When the length of the plate at the backside of the machine is greater than this limit, the

X-axis and R-axis positions will be corrected automatically so the plate will rest on the

backgauge finger. (0 - 3200.0 mm)

This is only possible if an automatic R-axis is enabled.

2.o

V0404, 2.13

Page 38

• Parameter explanation

2.p

Blank length computation

After postprocessing, the controller calculates the developed length of your product and the

bend allowance.

Important for the developed length calculation and the bend allowance is the inner radius of

the bends.

For each of these computations a correction factor can be programmed (RF and AF).

Radius factor blank length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RF=

The computed inner radius is multiplied by this factor to correct the total developed

length of the product. The initial value of RF is 1.

Radius factor X-axis position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .AF=

The computed inner radius is multiplied by this factor to correct the X-axis position in

order to have a correct product dimension after each specific bend (bend allowance).

This factor can be checked by making a product with just one bend and a certain product

dimension e.g. 100 mm (outer dimension). See figure 2.q.

The controller computes the X-axis position necessary to obtain L=100 as shown in fig. 2.q.

The accuracy of the length L is dependent on the material parameters like thickness, strength

and kind of material. In order to have a correction possibility with the radius factor AF you can

optimise this computation.

RF and AF do not influence each other. It is recommended that first you optimise the AF factor

V0404, 2.14

Page 39

Delem

for your product and thereafter find the correct value for the developed length correction RF.

2.q

Minimum Y-axis opening. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YM=

During postprocessing of the programmed product, the control always computes an optimal opening of the pressbeam to handle your product. Here you can program a minimum

required opening. The programmed value is the distance above the speed change point

MUTE.

X-allowance DIN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .XA =

For the calculation of the developed length and bend-allowance during the postprocessing of a graphical 2D product, a Delem formula is used. It is also possible to select the

standard DIN-formula (DIN6935).

0 = Delem formula (OFF)

1 = DIN formula (ON)

Default setting is zero for the Delem formula. Press the key to select the required setting.

Equal sized bumping segments enabled . . . . . . . . . . . . . . . . . . . . . . . .EB=

When a product has a radius bend, the segment size is computed from the number of segments, which has been defined by the user. Standard the first and last segment are calculated half the size of the mid segments to obtain a better result. However, it can be a

problem selecting a die suitable to bend these small segments. Therefore the control can

calculate an equal size for all segments. This can be defined with this parameter.

0 = disabled (no equal sizes)

1 = enabled (equal sizes)

Press the key to select the required setting.

When this parameter is set to 1, all segments will have an equal size.

If it is set to 0 the calculation is as before, including half size segments. If in this case a

problem with the size of the V die is detected in the bend sequence menu, the user is

asked whether or not to select a re-calculation with equal size segments.

2.6. Bend sequence

After completion of your drawing, with function key S5 you select the "bend sequence" mode.

You will have to enter the number of the machine lowerside, the die, the machine upperside

and the punch first. This number corresponds with the number in the respective tool libraries

(menu number 7, 8, 9 and 10).

If the number entered is not known, the controller prompts the message "not programmed".

You have to program the machine parts and tools before you can compute the bend sequence.

Programming can be done via the respective selections in the program menu. The several tools

V0404, 2.15

Page 40

as available in the respective tool libraries can be shown on the screen with S2 (show library).

This selection will give an overview of the tools including the main properties of each tool.

2.r

If this overview is not sufficient to select a tool, press the function key ‘view’ and the key

‘graph. dir’ to get a graphical overview of available tools.

V0404, 2.16

Page 41

Delem

2.s

In your machine and tool library you can program 10 different machine uppersides, 10 different machine undersides (tables), 99 different dies and 99 different punches. One of each must

be selected, and can also be changed during the bending sequence determination. These selections are prompted in the lower left corner of the screen. Within the bend sequence screen, the

softkey ‘show library’ will remain available to get a graphical overview of the tool library as

shown above.

After specifying machine part and tools the product and machine will be drawn on the screen.

V0404, 2.17

Page 42

2.t

The product, as it was drawn, is placed directly under the punch, at one of the last bending

positions possible.

The shape of your product before this last bend is placed on top of the die. A bigger circle on

an angle indicates that this bending is also possible without collision.

A complete overview of available softkeys in this screen is given on page 2.25. The function

key ‘MORE>>’ serves to switch between the primary and secondary row with function keys.

With these keys you can select any of the other bendings which you

If the product has collision with the tools or machine it will be indicated via a warning message

on the screen.

prefer to be the last bending. The bends possible are indicated with

the round cursor.

V0404, 2.18

Page 43

Delem

With this function key you can switch the collision protection check

on or off.

This is indicated at the top of the screen. When you have selected

collision "off" you can also select other bends which will give collision with the tools or machine parts.

The inner radius resulting after this bend is displayed at the top of

the screen.

To enlarge or reduce the complete drawing.

After pressing "unbend" the position of the bending is indicated by a small circle, see figure

2.u.

2.u

Note:

A big radius (bumping) is shown during bend sequence computation but is treated as a single

bending.

The CNC-data of the bendings necessary to produce the radius are computed during postprocessing.

V0404, 2.19

Page 44

The bendsequence computation can be activated from the last bending upwards to the first, but

it is also possible to activate for instance the last 2 bendings manually and to compute the optimal bendsequence for the rest of the bendings. This computation will start from the bending

indicated with an asterisk. With this possibility and with help of the swap function you can

compute several possibilities.

During the automatic bendsequence computation you can always

interrupt the computation by pressing "Abort computation".

If the computation is interrupted, the computer will give most of the

times a suggestion for the bendsequence. It is possibly not the most

optimal solution.

When a bendsequence has been determined, a CNC program can be

calculated and stored. This process is called postprocessing. When

postprocessing is finished, the ‘blank length’ of the product is displayed.

Open a graphical overview of the bend sequence, in order to have a

visual check.

2.v

The images in this graphical overview can be zoomed-in or zoomed-out with the cursor- up

and cursor- down key. The function keys S7 and S8 enlarge or reduce the number of images

that is displayed on the screen at once (minimal 4 and maximal 25).

V0404, 2.20

Page 45

Function keys:

Delem

Swap bends Let two bends exchange place in the bend sequence.

Move bend Move a certain bend to another place in the bend

sequence.

Enlarge Enlarge all bend pictures, thereby decreasing the number

of bends shown on the screen.

Reduce Shrink the bend pictures, thereby increasing the number

of bends shown on the screen.

Move bend

In the graphical overview of the bendsequence, it is possible to change the order of bends simply by moving a bend to another place. Press the button ‘Move bend’ and the number of the

first bend is highlighted. Use the arrow keys to move this cursor to the bend that must be

moved. When the correct bend number is highlighted, press the enter key to select this bend.

Now use the arrow key to move the bend to the right place in the sequence. If the bend is on the

correct place, press 'enter' to confirm.

Swap Bends

With this command, two bends can change place in the bend sequence. Press the ‘swap bends’

button. Move the cursor to one of the required bends and press the ‘swap’ button or press enter.

Then move the cursor to the bend with which it must be swapped and press the enter key or the

‘swap’ button. Now the bends have been swapped. If for any reason the action must be cancelled, press the softkey ‘abort swap’ during the procedure.

• Restoring a bend sequence

A (partly) determined bend sequence is not automatically reset after leaving the bend sequence

menu.

After you re-enter the bend sequence menu it is possible to continue with the existing bend

sequence.

If you re-enter the bend sequence menu you have the following options:

V0404, 2.21

Page 46

2.w

‘new’ start new bend sequence, the existing bend sequence is

reset

‘continue’ continue with current bend sequence, the existing (par-

tial) bend sequence is restored and shown on the screen

If you have loaded a drawing from which a postprocessed bending program already exists,

there is a third option when you enter the bend sequence menu:

‘restore’ restore bend sequence from postprocessed program, the

bend sequence is restored from this postprocessed bending program and shown on the screen

If you have drawn a new product in the menu "Product drawing" and you enter the bend

sequence menu for the first time, there is no existing bend sequence and postprocessed program yet, these previously mentioned selections are not shown.

• Minimum bending length

The minimum possible bending length will be calculated from the V-opening parameter (½ V),

but also depends on the angle to bend and the thickness of the material to be bend, see figure

2.x. If the programmed value for the wanted product does not correspond with the minimum

possible length, you will get a warning message on the screen.

2.x

V0404, 2.22

Page 47

Delem

• Machine/Tool selection

At each bend you can select one of the tools or machine shapes which are present in your

library. The displayed number is the number of the tool and machine part which is presently

selected.

Entering a new number will select another tool or machine part which will be drawn directly

on the screen.

With the "enter" key you can toggle between punch-, die-, machine upper- and lower part number.

It is also possible to turn the punch and die with respect to the machine shapes. To achieve this,

the tool number must be programmed negative.

2.y

In order to get a graphical overview of the available tools while you are in the bend sequence

menu, press the function key 'show library' (S2). If pressed, an overview appears of available

tools.

Which type of tools is shown depends on which type was prompted in the bend sequence

screen: punch, die, machine upper- or lowerside.

• Turn indication

In the lower left corner a bend turn indication is displayed at each bend of bend sequence.

V0404, 2.23

Page 48

2.z

The asterisk indicates which bend is presently displayed.

• Production time

At the top of the turn information (before the first bend) the total production time is indicated.

This time is calculated from the following settings:

- X-axis speed

- Y-opening and Y-axis speeds

- R-axis speed

- Turn time programmed in the turn time table of the assignment

With automatic bend sequence computation the controller tries to find the minimum production time.

• Screen data

On top of the screen some general important data is displayed.

Col.prot.on Collision and backgauge checks on or off

Punch: 1 Punch number selected

die: 1 Die number selected

R-in = 1.3 Inner radius of the bend to be obtained with selected die

Variants On Variants programming enabled: the product has a valid CNC pro-

gram that can be modified from the graphical menu.

V0404, 2.24

Page 49

• Function- and control keys summary

Function keys:

Delem

unbend/

next

bend/previous

shift gauge Select backgauge position

swap Front to back turn of the product.

protection

on/off

compute The sequence calculation starts from the bend number

To unbend the graphical product

To bend the graphical product

To switch the collision detection with collision warning

On or Off.

presently selected. This feature gives you the unique possibility to fix the bending sequence interactively, e.g.

partly manual partly automatic.

store Automatic computation of all axes positions (complete

MORE>> The softkeys for this mode are divided in two rows. Press

end To go back to the drawing.

Function keys secondary row:

show.

bendseq.

CNC program) and storage in the product library of the

postprocessed product.

this key to switch from one row to another.

To show a mosaic screen with a step-by-step graphical

overview of the bendsequence.

V0404, 2.25

Page 50

Function keys secondary row:

show

library

Control keys:

Zoom enlargement

Zoom reducement

Softkey to get a graphical overview of the tool library.

• Bend sequence computation

With ‘compute’ the bend sequence can be computed automatically.

The computation is done only with one set of tools. These are the tools selected at the last

bend.

The computation of the bend sequence starts always at the bend which is indicated with the *

at the lower left corner of the screen.

Example: Product with 7 bends

2.aa

In the first example the bend no. 7 and no. 6 are chosen manually, from 5 up to 1 thereafter are

V0404, 2.26

Page 51

Delem

computed automatically.

In the second example the complete bend sequence is computed (7 up to 1).

During the computation all assignments are important so you must be sure before starting the

bend order computation that all assignments are set correctly.

•Store

After you have completed the bend sequence a CNC-program can be generated. This generated

program will be stored in the controller program memory.

2.7. Variants programming

The term ‘Variants programming’ means that the operator can make modifications to an existing program in the graphic menu, without having to build a new CNC program from scratch.

An existing program can be altered without loss of existing corrections and bendsequence. If

such an existing program contains proper axis values and product positions then this information can stay intact, only the latest changes (angle, sheet length) are recalculated and entered

into the program.

For instance, when a side length has been altered in the graphical bend overview and the

‘store’ command is given, then a question appears how to compute a CNC program.

2.ab

When update (S4) is chosen, the existing CNC program is changed with regard to modified

values (angle, length), but other values of bend parameters stay the same. The expression ‘reuse corrections’ refers to the corrections that may have been entered in one of the production

modes. These production modes are explained in chapter 10.

When new (S5) is chosen, a new CNC program is calculated. Corrections in the existing CNC

V0404, 2.27

Page 52

program are lost.

In order to keep the existing program, check that the indication ‘Variants On’ remains in the

title bar. When you start an action or command that would seriously change the program, a

warning is issued by the control:

2.ac

If you choose 'yes' (S4), the indication 'Variants On' will disappear from the title bar. This

means that the next time when a new 'postprocess' command is started, a new CNC program is

built and old corrections will be lost. When 'No' (S5) is chosen, the action is cancelled and

'Variants on' remains.

The message "CNC program and corrections will be lost" is not literally true. The CNC program is still present, but it cannot be updated anymore from the graphical menu. If the old

CNC program must be stored, it is still possible to go to ‘data edit’ mode and store the program

under a different product number.

V0404, 2.28

Page 53

Delem

3. Drawing/editing a product in 3D

3.1. Introduction

When selecting 1 in the main menu, you can prepare a product with a drawing in 3D by entering <3> at the parameter for the 2D/3D selection.

3.a

The drawing tool for 3D part drawing works according to the same principle as described for

the 2D part drawing, except that in 3D a surface is added where in 2D a line segment is added.

The 3D drawing tool can handle complex product drawings with holes and surfaces which

have more than four sides. Such product drawings could be generated, for instance, by CAD

software.

3.1.1. Product data

Before you start drawing you have to program the main product data like the thickness and

kind of material. This is the same as for 2D products.

V0404, 3.1

Page 54

3.2. The 3D drawing of a product

3.b

The 3D drawing screen starts with a base surface and a double cursor (line), see Fig. 3.b.

The side indicated by the cursor is the line segment to be defined. Start your dawing by entering the length and width of the base surface. When entered, the menu bar at the bottom of the

screen appears. From this point forward, the drawing can be edited as necessary. You can add

surfaces and change the shape of surfaces (including the base surface).

Each new surface (base or added) starts with the double cursor, see Fig.3.c. After entering the

extended length the cursor is transformed into a single line and the rectangle can be reshaped.

See section 3.3.: "Changing the shape of a surface".

A new surface can be added by entering the connection angle and length of a surface. If a new

surface has an angle of 45 degrees or a multiple of 45 with the current surface, you can use the

arrow keys to add a surface.

V0404, 3.2

Page 55

Delem

Function keys:

3.c

next surface

prev. side Move cursor to previous side (counterclockwise) for sur-

next side Next side. Moves the cursor clockwise along the sides of

change

lenght

del. surface Delete the surface with cursor. Only possible when the

Moves cursor to next surface.

faces without holes or move cursor to next hole for surfaces with holes

a surface.

Changes the length of a side so that the surfaces can be

reshaped into many forms. See section 3.3., ‘changing the

shape of a surface’.

surface has just one other connecting surface and the surface is not the base surface.

[un]fold Toggles between drawing in folded or unfolded form.

Functions do not change, meaning that you can also complete a drawing in the unfolded presentation.

V0404, 3.3

Page 56

Function keys:

bend

simul.

END Back to ‘3D change data’

Bendsimulation. To create a “Bend sequence”, see section 3.4.

• Unfolded product.

It is possible to toggle between the folded and the unfolded product presentation.

3.d

In figure. 3.e. you see an example of a product in the unfolded part presentation.

V0404, 3.4

Page 57

Delem

3.e

• Product data overview.

With the END-key in the drawing screen it is possible to adjust the product data.

3.f

V0404, 3.5

Page 58

• Extending or rotating the product.

In the figures 3.g and 3.h you will find respectively the cursor position for extending the product and rotating the product. The function of the cursor is displayed by a description in the

header (‘Add surface’ or ‘rotate’).

3.g

V0404, 3.6

Page 59

Delem

3.h

V0404, 3.7

Page 60

3.3. Changing the shape of a surface

Each product to be developed consists of surfaces, starting with the base surface.

Shapes with four corners such as a square, a rectangle, a trapezium, a parallelogram or any random quadrangle are possible.

With the drawing tool you can execute the following manipulations:

1. Add surface

2. Delete surface

3. Change side length

4. Change angle between two connected surfaces

1. Add surface

Adding a new surface is only possible at a side of the outline with a free side (see also text in

the header). At each side one other surface can be connected. Adding is done by entering an

angle and a length in this sequence, expanding with one rectangle. The value of the angle

entered must be between either plus or minus 180 degrees.

Besides the outline of a surface also the contour of a hole is considered as an outline with the

same possibilities. A hole must be entirely in one surface and can have any shape.

A surface or total product can contain more than one hole. Holes can not be added with the

drawing tool. According to the possibility of more than four sides and the presence of holes the

active surface of figure 3.e has 64 outline sides (43 surface outline sides and 21 hole outline

sides) which can be selected.

2. Delete surface

Deleting a surface is only possible when the surface has just one other connecting surface and

the surface is not the base surface.

V0404, 3.8

Page 61

Delem

3. Changing the length of a side

Before changing the length of a side you have to select the side to be changed. This can be

done with S3 (next side) or S2 (next hole), moving the cursor along the sides of the active surface.

The actual length value is displayed in the enter field.

3.i

Then you can press S4 (change length) to give in the new length. A pop-up window appears in

which with function key S5 can be defined how to change the length of the side: from both the

ends or from only one of the ends.

Enter a negative value to shorten the length with the programmed value or a positive value as

the new length.

V0404, 3.9

Page 62

Example:

3.j

By entering a negative value of -20 you get the same results.

The new side length is in all three the cases the same. However, the resulting shapes are different by the fact that the extension or shortening starts at different ends.

V0404, 3.10

Page 63

3.k

Delem

Changing the length of a side is allowed in case this change has only effect on the shape of the

active surface (one end or both ends belong exclusively to the active surface) or in case both

ends belong to a bendline and there is at least one end that has no side connected that is in line

with the bendline direction.

Changing the length of a side is not allowed in case both ends belong to the bendline and both

ends have a side that is in line with the direction of the bendline. That is why in figure 3.l both

ends of side number 3 can be moved whilst this is not possible for side number 2 of figure 3.m.

Imagine figure 3.m without side 1 and/or 3 then the length of side number 2 can also be

changed.

V0404, 3.11

Page 64

3.l

Side 1: Both ends can be moved in both directions (both ends belong exclusively to the active

surface)

Side 2: Only the end that is no part of the bendline can be moved (moving the other end causes

also another shape of the other surface (direction of the bendline changes) ).

Side 3: Both ends can be moved in both directions (No sides connnected to ends that are in line

with the direction of the bendline)

Side 4: Only the end that is not part of the bendline can be moved.

3.m

Side 1: Only the end that is no part of the bendline can be moved.

Side 2: None of the ends can be moved (Sides connected to both ends which are in line with

the direction of the bendline)

Side 3: Only the end that is no part of the bendline can be moved.

Side 4: Both ends can be moved in both directions (both ends belong exclusively to the active

surface)

Side 5: Both ends can be moved in both directions (both ends belong exclusively to the active

surface)

Side 6: Both ends can be moved in both directions (both ends belong exclusively to the active

surface)

The next picture explains two ways to create a hexagon. Both options start with a base of two

rectangles with an angle of 180 degrees.

V0404, 3.12

Page 65

Delem

3.n

Some other examples of special shapes by making the sides shorter or longer.

3.o

V0404, 3.13

Page 66

You can convert a new surface into lip shaped surface (smaller than the length of the previous

side) in two steps. See next figure.

3.p

4. Changing the angle between to surfaces.

You can change the angle between surfaces into any other angle between -180° and 180° without constraints. The drawing tool always displays the product at relative scale. Collision of surfaces due to another angle is also shown at relative scale.

V0404, 3.14

Page 67

3.4. Bend sequence 3D

Delem

3.q

The bending sequence is started with the tool configuration.

The tool configuration screen appears after selecting ‘bend simulation’ in the 3D drawing

mode.

The last used configuration will appear on the screen (frontview). With the cursor-up and cursor-down keys you can select the tool you want to change. The selected tool is displayed (side

view) in the separate window (see in figure 3.q. the machine upperside shape). See section 3.6

for adjusting the tool configuration.

Function keys:

new config. New tool configuration see section 3.6

assignm. Assignments, see section 3.7

show

library

Show library

V0404, 3.15

Page 68

Function keys:

bend sim. Start bend simulation

END Back to drawing screen.

After selecting the required tool configuration you can start the bendsimulation.

3.4.1. Start bend simulation

3.r

On this screen the product appears between the tools in a possible last bend position. The prod-

uct can be zoomed in or out with the cursor keys and .

Press ‘unbend’ to fix a bend.

V0404, 3.16

Page 69

Function keys:

Delem

unbend/

next

bend/previous

shift gauge Shift the product manually (section 3.4.5.) or shift the

man. select Manual selection of a bend line. Additional possibility to

tools/mach. Toggle between three possible ways of displaying the

tool config. To change the tool configuration or assignments.

These function toggle keys between to step forward and

backwards through the bending sequence (section.

3.4.4.).

gauge manually (section 3.4.6.).

determine the bendsequence (see section 3.4.3.).

product/tool configuration. Useful in case of collision

visualisation. See section 3.4.2.

show bendseq

store Store a sequence. Only the unbended part is stored. The

END Back to drawing.

Show bendsequence. To show a mosaic screen with a

step-by-step graphical overview of the bendsequence.

control displays a message when the product is completely unbended.

V0404, 3.17

Page 70

3.4.2. Tool / machine visualisation

It is possible to visualise the product only, the product including tools or the product including

tools and machineshapes. This can be selected at any moment during the bendsequence determination.

3.s

Each time you press S5 the visualisation of the configuration switches between one of the three

possibilities.

V0404, 3.18

Page 71

Delem

3.t

By pressing the function key S5 a second time you get a screen with product and tools.

3.u

By pressing the function key S5 a third time you get a screen with the product, the tools and the

V0404, 3.19

Page 72

machine shapes.

3.4.3. Manual select

The control always proposes the next bending in sequence. This is computed by the control

depending on the programming assignments and of course the product shape and applied tools.

The bending sequence can also be changed/determined via manual select [S4].

For production reasons it can be necessary to choose by way of manual select another bend line

for the bending sequence.

Function keys:

V0404, 3.20

3.v

next surface

next hole Move the cursor to the next hole.

next side Move the cursor to the next side.

Move the cursor to the next surface.

Page 73

Function keys:

swap By pressing this key the product can be rotated 180°

no change Leaves manual select without changes.

accept By pressing this key the product will be placed with the

END The same result as ‘accept’.

3.4.4. Unbend product

Delem

between the tools (swap).

manually chosen bend-line under the uppertool.

In order to generate a CNC-part program the bend sequence must be known. To achieve this

repeat pressing [S1] until the product is completely unbended. Press [S8] to generate and store

the CNC-part program into the memory.

3.w

V0404, 3.21

Page 74

3.4.5. Move product

3.x

In the bend selection menu, the control computes the next bend possible to unbend. The product is placed between the tools, where there is no collision with the tools or the machine. In

case you want to shift the product under the toolset (which is mounted), you can move the

product by pressing [S3] (shift product). A pop-up window displays the product transparent.

Function keys:

jump left Jump product to another toolset combination.

jump right Jump product to another toolset combination.

shift left Shift product to the left within the same toolset. The step

size is displayed at the command line prompt and can be

changed.

V0404, 3.22

shift right Shift product to the right within the same toolset. The

step size is displayed at the command line prompt and

can be changed.

Page 75

Function keys:

tools/mach. Toggle the display mode of the tools/machine configura-

no change Ignore the new product position and return to the simula-

accept Accept the new product position and return to the simula-

END The same result as ‘accept’.

3.4.6. Move fingers

Delem

ton.

tion menu. (no change)

tion menu.

3.y

The control automatically computes at each bend the X-axes, R-axes and Z-axes positions.

It takes into account the values of the option assignments and searches for a solution without

collision of the fingers with the product. In order to be able to select your own positions, you

can move in the unbend state the fingers by pressing ‘shift gauge’. A pop-up window displays

the backgauge fingers with one finger highlighted. The fingers can be moved by means of the

V0404, 3.23

Page 76

function keys S1 through S4. The step size of the finger can be changed by entering the desired

value. The higher the value of the step size, the bigger is the displacement.

Move the fingers by:

Function keys:

select finger

change side Change side. Move the selected finger to another side of

shift left Shift the selected finger to the left. The step size is dis-

shift right Shift the selected finger to the right. The step size is dis-

Select the finger to move.

the product behind the machine. In the example there are

two possible finger positions to choose.

This way is only possible and will only be accepted if the

required axes are enabled in the control (like X1 and X2)

played at the command line prompt and can be changed.

played at the command line prompt and can be changed.

lay on finger

no change Ignore the new finger positions and return to the simula-

accept Accept the new finger positions and return to the simula-

END The same result as ‘accept’.

Toggle between lay product on selected finger or not.

This option is only selectable in case you have R-axes in

your machine.

tion menu.

tion menu.

V0404, 3.24

Page 77

Delem

3.4.7. Show bendsequence

Before the product is completely unbended you can enter the ‘show bendsequence’ menu.

3.z

This menu option can be called at any time after the first unbend has been made. The graphical

overview displays the determined bends as well as the not yet determined bends (question

mark sign).

The images in the graphical mosiac overview can separately be enlarged or reduced with the

cursor and keys.

The images can also separately be rotated with the cursor arrow keys.

3.5. Creating two bends simultaneously

When the system meets a situation like in fig. 3.aa., it will try to bend the two surfaces simultaneously. This can only happen when all the tools have the right length and both the bends must

have the same angle.

V0404, 3.25

Page 78

3.aa

3.ab

The combined bends are shown by the double cursor (line).

V0404, 3.26

Page 79

Delem

3.ac

To select additional bendings manually, press MANUAL SELECT, followed by [S4] COMBINATIONS.

V0404, 3.27

Page 80

3.6. New tool configuration

3.ad

With a new product, the last used configuration will appear on the screen.

With an existing product, the configuration, which was saved with this product, will appear on

the screen. The active tool or machine shape is indicated by a contour line in a different colour.

Function keys:

new config. To start a new toolconfiguration.

assignm. Assignments. 3D backstop assignments. See section 3.7.

show

library

bend sim. Bend simulation. Determining the bend sequence with

the programmed configuration.

V0404, 3.28

Page 81

Delem

Function keys:

END Return to previous screen (3D drawing).

If you want to reconfigure the tool / machine set-up you can modify the actual configuration.

You can also start all over again with ‘new config’. Programming a new configuration will be