Delem DA-52s Installation Manual

Delem

V0614, 1.1

DA-52s

Installation Manual

V 3

Delem

V0614, 1.2

Preface

This manual contains information necessary for installation of a DA-52s control on a

pressbrake machine. It is meant for service people who are authorised for service and

installation of the machine.

Limited guarantee

• The equipment is supplied by Delem without safety features. The machine manufacturer

has to ensure a safe environment.

• This equipment must be installed and used in accordance with Delem's specifications.

The guarantee on the equipment is invalidated in the event of improper installation and/or

use of this equipment.

• The General Terms and Conditions of Delivery of Delem shall apply to this product.

These conditions are available from Delem on request.

• This manual does not entitle you to any rights. Delem reserves the right to change this

manual without prior warning.

• All rights reserved. The copyright is held by Delem. No part of this publication may be

copied or reproduced without written permission from Delem BV.

Version history

The control software is updated regularly to increase performance and add new functionality.

This manual is also updated as a result of changes in the control software. The following

overview shows the relation between software and manual versions.

Software version Manual version Description

V3 V0713 first issue V3

V3 V0813 update V3

V3 V0614 update V3

This manual is valid for software version 3.

Delem

V0614, 1.3

Table of contents

PAR T I - HARDWARE DESCRIPTION .................................................................................. 5

1. INTRODUCTION ............................................................................................................ 6

2. SPECIFICATIONS .......................................................................................................... 7

2.1. Physical dimensions ................................................................................................ 7

2.2. Technical specifications .......................................................................................... 8

3. SYSTEM I/O ................................................................................................................... 9

3.1. Introduction ............................................................................................................. 9

3.2. Power supply ........................................................................................................ 10

3.3. USB connector ...................................................................................................... 10

3.4. Valve connector .................................................................................................... 11

3.5. Analog A ............................................................................................................... 12

3.6. Analog B ............................................................................................................... 13

3.7. Digital I/O .............................................................................................................. 13

3.8. Encoders ............................................................................................................... 16

4. SPARE PARTS ............................................................................................................ 17

4.1. Introduction ........................................................................................................... 17

5. SCHEMATICS .............................................................................................................. 18

PART II - MACHINE SETTINGS ............................................................................................ 1

1. THE MACH INE PARAMETE RS ..................................................................................... 2

1.1. Machine parameters menu ...................................................................................... 2

1.2. Update control ......................................................................................................... 3

1.2.1. Update procedure ............................................................................................ 3

1.2.2. Backup/restore the application ........................................................................ 7

1.2.3. Modify the update ............................................................................................ 8

1.3. Option installation ................................................................................................. 10

1.3.1. Request option on the control ........................................................................ 10

1.3.2. Request option code at Delem ...................................................................... 13

2. WINDOWS TASKS ...................................................................................................... 16

2.1. Windows introduction ............................................................................................ 16

2.2. Directory structure ................................................................................................. 18

2.3. Important files ....................................................................................................... 19

2.4. Editing the autoexec.bat ........................................................................................ 23

2.5. Control Rescue procedure .................................................................................... 25

2.6. Sequencer adjustment .......................................................................................... 29

2.7. Analysis program .................................................................................................. 31

PART III - THE DIAGNOSTIC PROGRAM ............................................................................. 1

1. GENERAL REMARKS ................................................................................................... 2

1.1. Valve outputs .......................................................................................................... 2

1.2. Components check ................................................................................................. 2

Delem

V0614, 1.4

2. TEST-MENU ................................................................................................................... 3

2.1. Start diagnostic mode ............................................................................................. 3

2.2. The menu ................................................................................................................ 3

3. KEY TEST ...................................................................................................................... 4

4. SCREEN TEST............................................................................................................... 5

5. I/O TEST......................................................................................................................... 7

5.1. Test screen ............................................................................................................. 7

5.2. Testing the valve deflection ..................................................................................... 9

APP E N DIX A - REFERE NCE L IST ........................................................................................ 1

Delem

V0614, 1.5

Part I - Hardware description

This section contains the hardware specifications of a Delem control DA-52s.

Delem

V0614, 1.6

1. Introduction

This manual contains information necessary for installation of a DA-52s control. Such a

control is the heart of a pressbrake control system with which a pressbrake machine is

controlled.

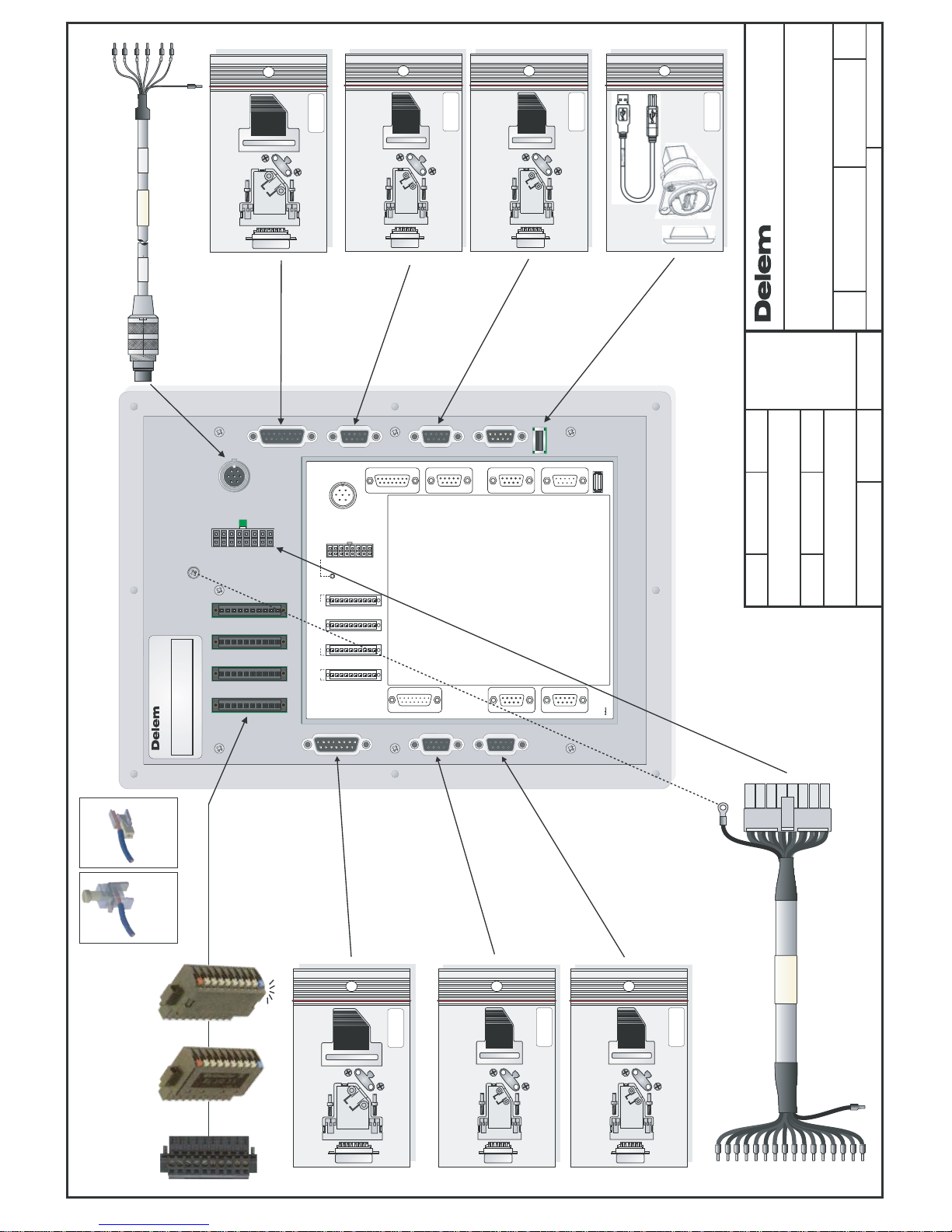

Figure 1.a

A DA-52s control combines different tasks in one unit:

- programming products and tools;

- axis control during bending;

- adjustment of machine settings.

Product programming and control operation is described in the user manual [3] of the control.

Delem

V0614, 1.7

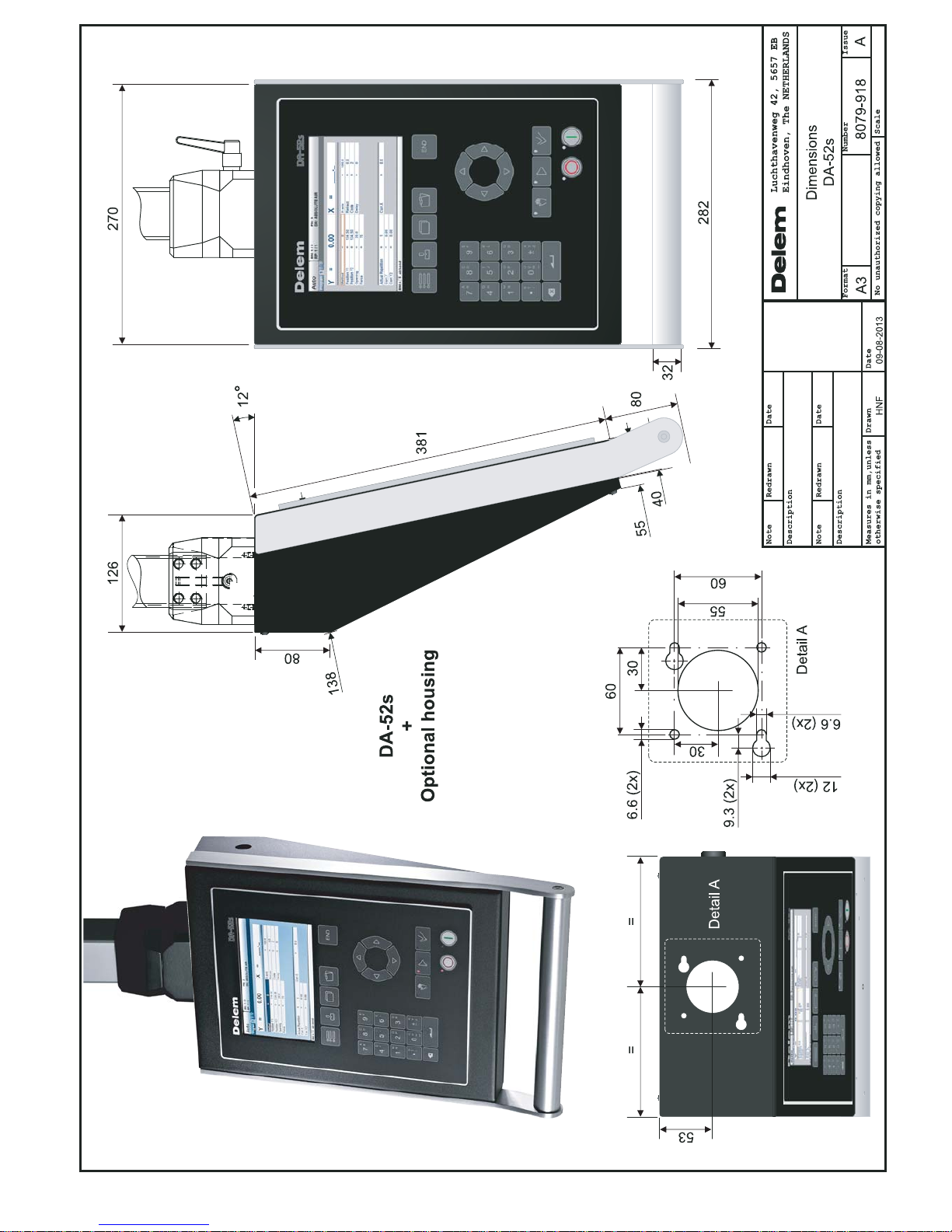

2. Specifications

2.1. Physical dimensions

For the dimensions of the DA-52s control, see the included drawings at the end of this

section.

The following environment specification values are valid for a DA-52s control:

Ambient temperature

5 - 45°C

Warning:

Avoid long-term exposure of the control to direct

sunlight. Otherwise, the temperature inside the

control will rise above tolerance levels.

Operation of the control should be carried out

indoors.

Storage temperature

min. -20°C

max. 70°C

Relative humidity

max. 90 % non-condensing

EMC

designed and built to meet the following standards:

EN50081-2

EN60082-2

Enclosure

designed and built to meet the following standards:

IP20 (without optional enclosure)

IP54 (with optional enclosure)

Delem

V0614, 1.8

2.2. Technical specifications

Power supply

18 - 28 VDC

80 W

Display

LCD/TFT colour

7” Widescreen

800 x 480

Interfaces

Valve connector

(see chapter 3)

Analog A/B

4 x Encoder

1 x RS-232

1 x USB

digital I/O

Memory

Flash memory, 64 MB embedded

Delem

V0614, 1.9

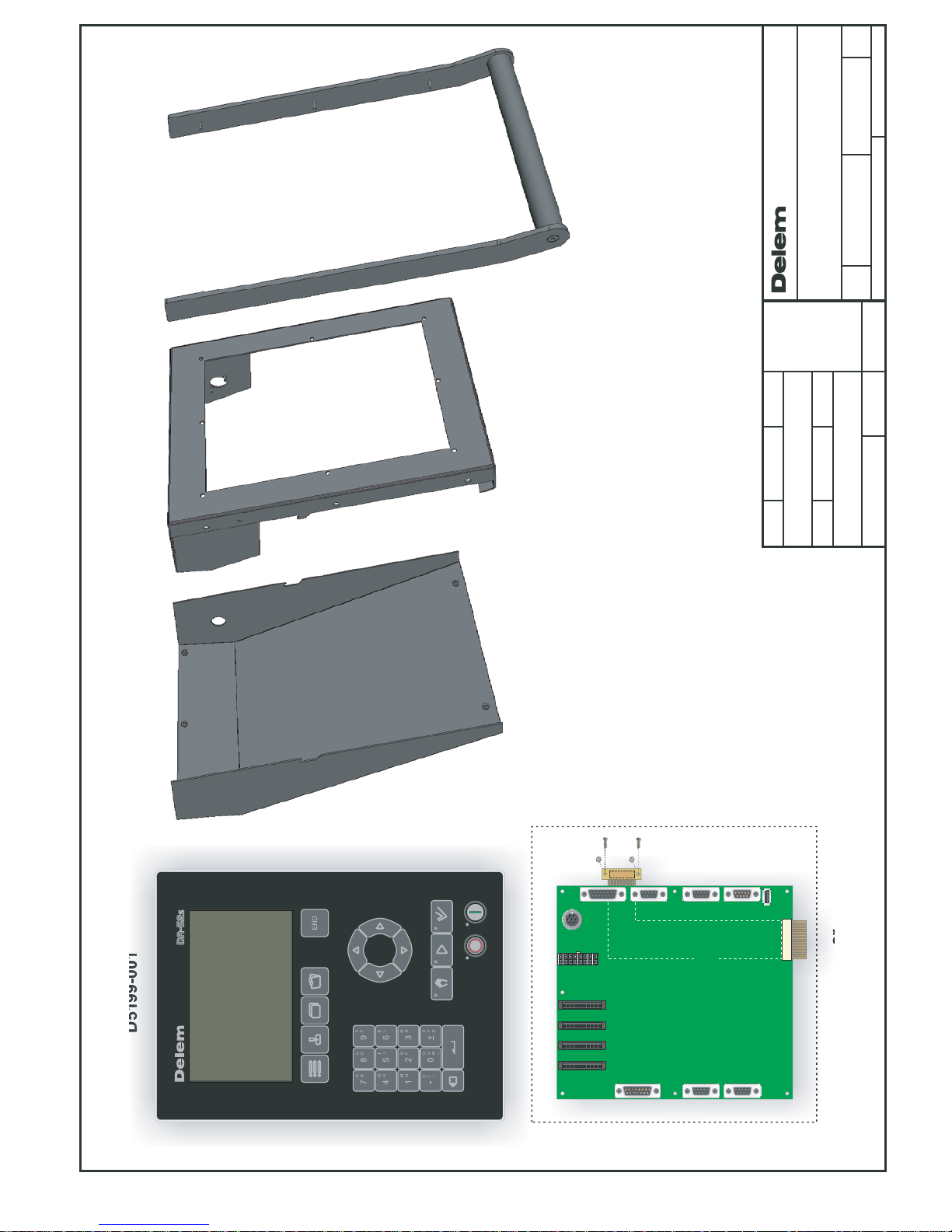

3. System I/O

3.1. Introduction

Figure 3.a

The DA-52s control is equipped with a large set of connectors for various functions:

- valve control

- system I/O

- encoder feedback

- communication

- USB

The various connectors are discussed in the following sections.

Warning:

Connectors may not be plugged or unplugged when power is ON. Connectors may only be

connected or disconnected when power is OFF.

The only exception to this rule is the USB connector.

Delem

V0614, 1.10

3.2. Power supply

7-pole male binder connector

3.3. USB connector

The control has been equipped with one standard USB connector, according to the USB 1.1

specification.

Delem

V0614, 1.11

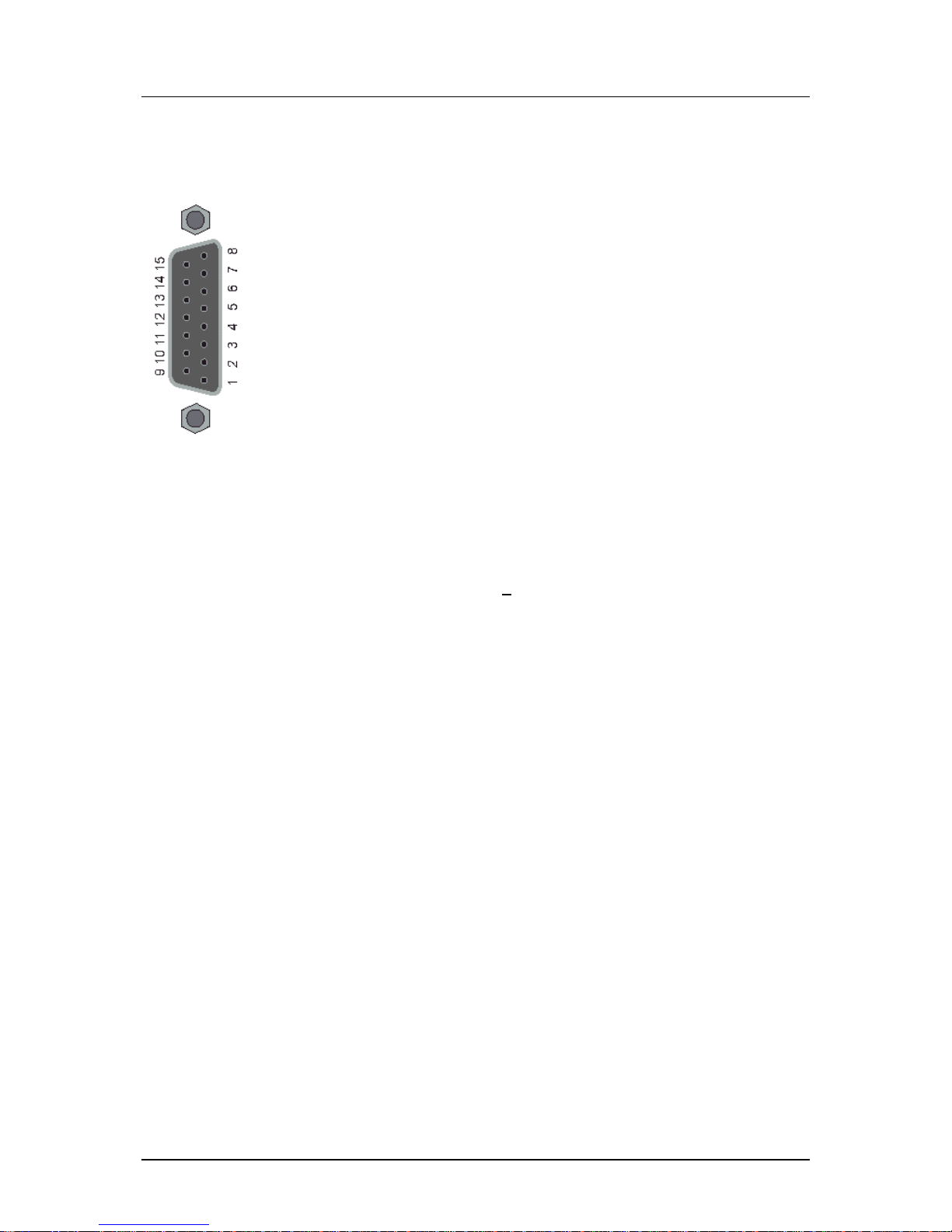

3.4. Valve connector

16-pin connector for valve control.

Standard: P-VA

The connector is used for pressure valve control. The control signals for the valve amplifiers

run through connector Analog B. An example of the required wiring is given in diagram 8061-

102.

Optional: Y-VA

The connector is used for direct control of the proportional valves.

An example of the required wiring for direct valve control is given in diagram 8061-101. This

schematic also includes a pin description of the connector. The position feedback from the

valve transducers (LVDT) is connected to connector Analog B.

See section 3.4 for more information about connector Analog B.

Analogue outputs:

Prop. Valve: Y1/Y2 4 x 3A max.

Pressure valve: P 1.5 A max.

Analogue inputs:

24V Power Supply 18-30V DC

ripple +/- 2V max.

max. 13A

Shielding of cables should be connected to the available M3 ground plug beside the

connector.

Delem

V0614, 1.12

3.5. Analog A

Connector Analog A provides several analog signals, two analog

outputs and four analog inputs.

See schematic 8061-101 for connection details.

Specifications for Analog I/O

Analogue inputs (4x)

0-10V, input impedance 44 kΩ

Reference voltage (2x)

10V + 2%

Analogue outputs (2x)

+/- 10V

10mA max.

maximum load 1 kΩ

Delem

V0614, 1.13

3.6. Analog B

Connector Analog B provides several analog signals, two analog

outputs and two analog inputs. It also includes power supply for

possible valve position transducers (LVDT).

See schematic 8061-101 for connection details.

Specifications for Analog I/O

Analogue inputs (2x)

0-12V / -10V ... +10V,

input impedance 44 kΩ

Supply voltage 24V + 2%

Analogue outputs (2x)

+/- 10V

10mA max.

maximum load 1 kΩ

Analogue output (1x)

0 - 10V (ext. pressure amplifier)

Power outputs (6x)

2x -12V

2x +12V

2x 24V

100 mA max. for each transducer

Notes:

• Used power supply depends on transducer specifications (+/-12V or 24V).

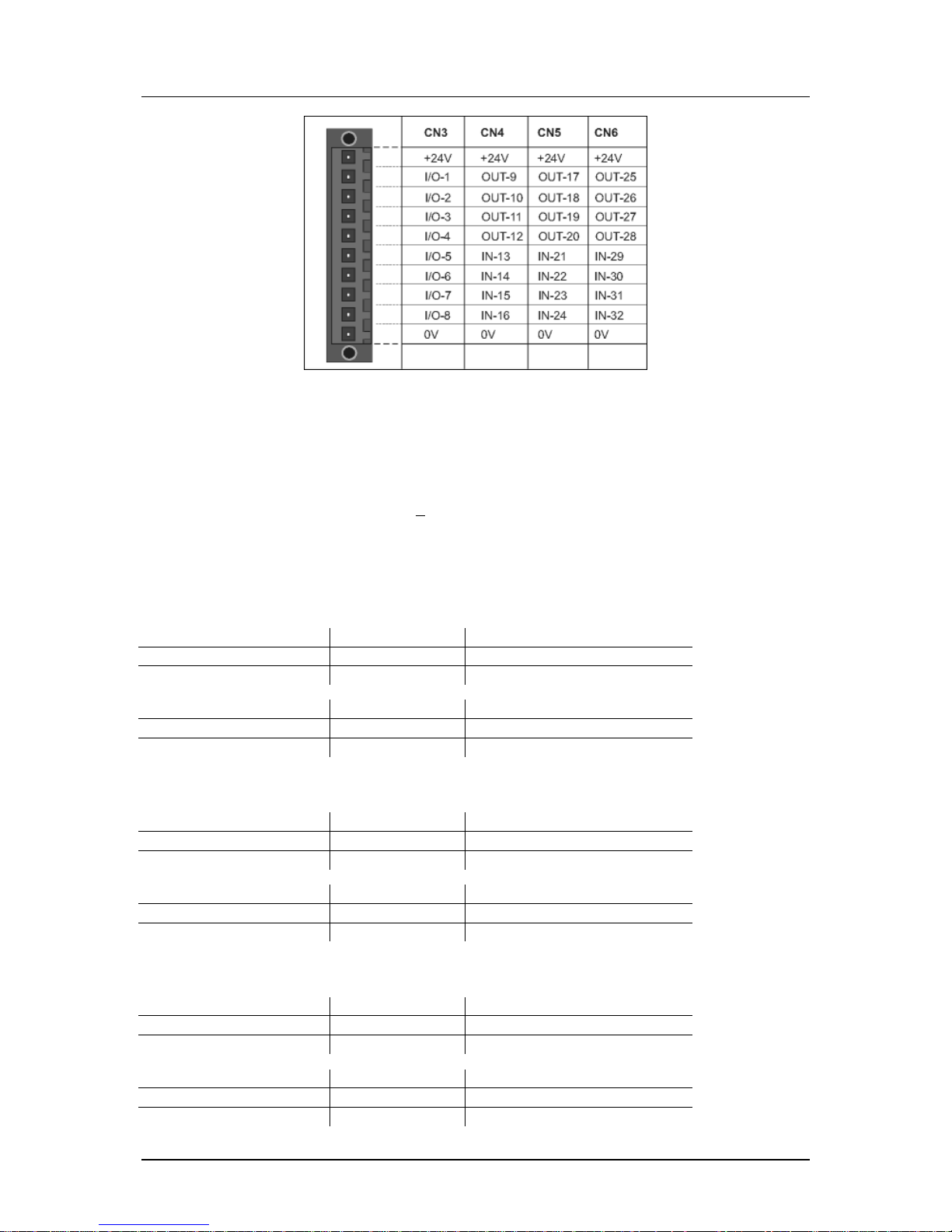

3.7. Digital I/O

12 inputs, 12 outputs, 8 programmable I/O.

Delem

V0614, 1.14

Figure 3.b

See schematic 8061-101 for connection details.

The use of I/O pins depends on the application and machine settings. For the purpose of all

assigned I/O signals we refer to the Delem machine parameter manual.

I/O power supply: 24 V DC + 20%

10A m ax.

CN3: Pins 1 - 8

Programmable Digital In-/Outputs (8x):

Digital Output

Voltage

Current

ON state

20-28 V DC

0.5 A max.

OFF state

-

0.1 mA max. (leakage current)

Digital Input

Voltage

Current

ON state

9-28 V DC

20mA max.

OFF state

0-4 V DC

1 mA max.

CN4: Pins 9 - 16

Digital Outputs (4x)

Voltage

Current

ON state

20-28 V DC

0.5 A max.

OFF state

-

0.1 mA max. (leakage current)

Digital Inputs (4x)

Voltage

Current

ON state

9-28 V DC

20mA max.

OFF state

0 - 4 V DC

1 mA max.

CN5: Pins 17 - 24

Digital Outputs (4x)

Voltage

Current

ON state

20-28 V DC

0.5 A max.

OFF state

-

0.1 mA max. (leakage curr ent)

Digital Inputs (4x)

Voltage

Current

ON state

9-28 V DC

20mA max.

OFF state

0 - 4 V DC

1 mA max.

Delem

V0614, 1.15

CN6: Pins 25 - 32

Digital Outputs (4x)

Voltage

Current

ON state

20-28 V DC

0.5 A max.

OFF state

-

0.1 mA max. (leakage current)

Digital Inputs (4x)

Voltage

Current

ON state

9-28 V DC

20mA max.

OFF state

0 - 4 V DC

1 mA max.

Notes:

• The sum of all output currents should not exceed 10A.

• All digital outputs are short-circuit proof.

• To guarantee a defined state during power on or off, the load of the outputs should

comply with IEC 61131.

Delem

V0614, 1.16

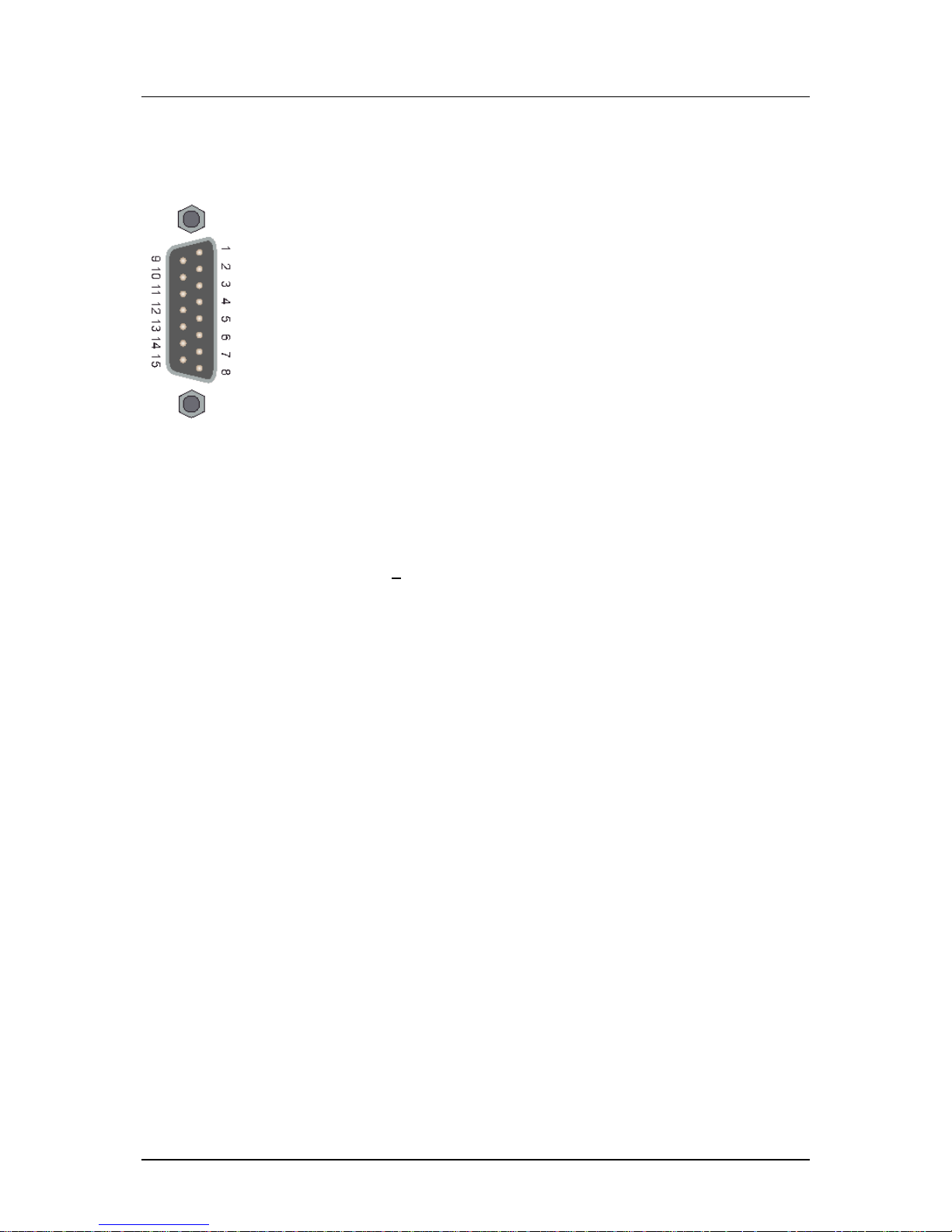

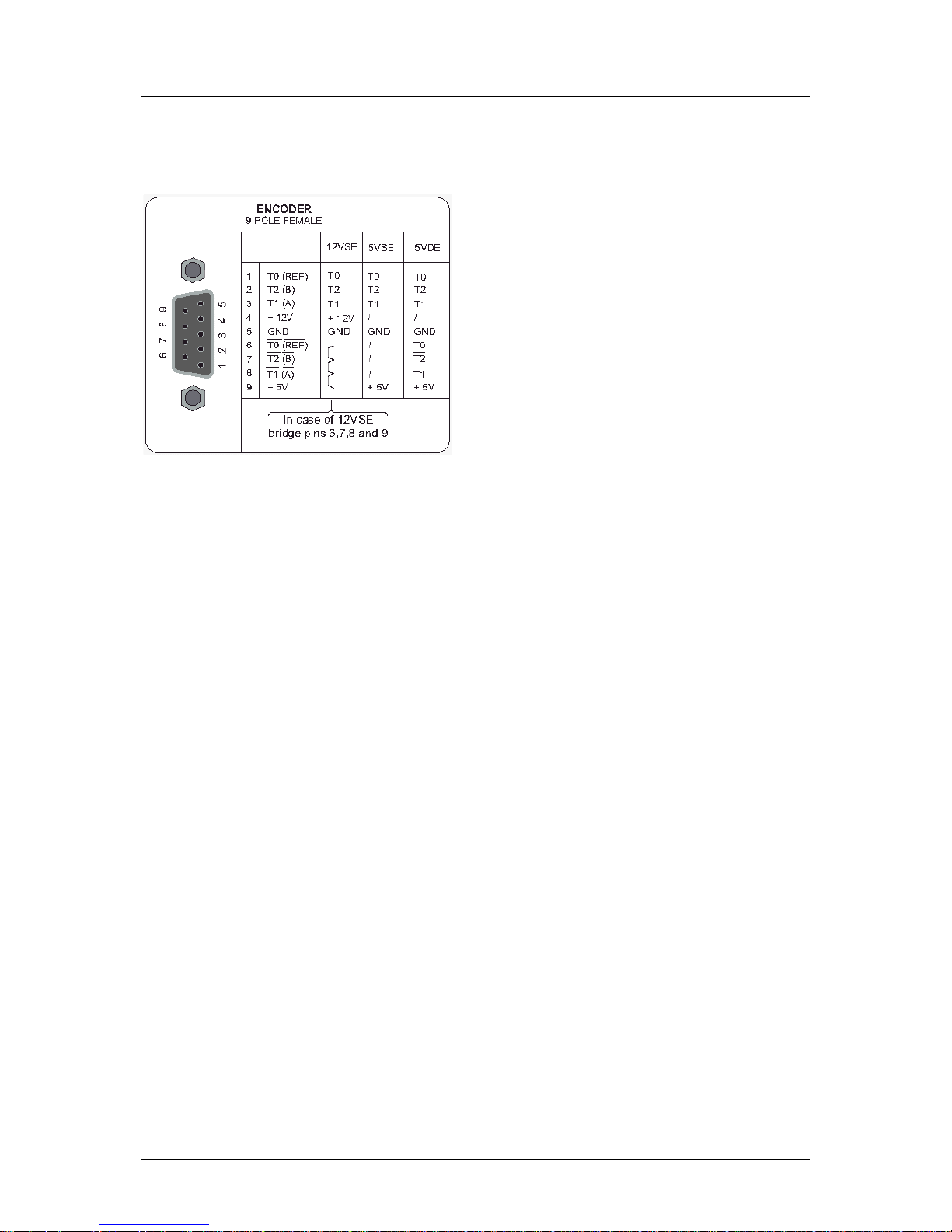

3.8. Encoders

9-pole SUBD female encoder interface

5V DC/250 mA or 12V DC/200 mA

12 V or 5 V single ended or 5 V

differential

Max. count frequency 1 MHz

See schematic 8061-101 for connection details.

Notes:

• In case of 12VSE encoder, connect pins 6, 7, 8 and 9 with each other.

Delem

V0614, 1.17

4. Spare parts

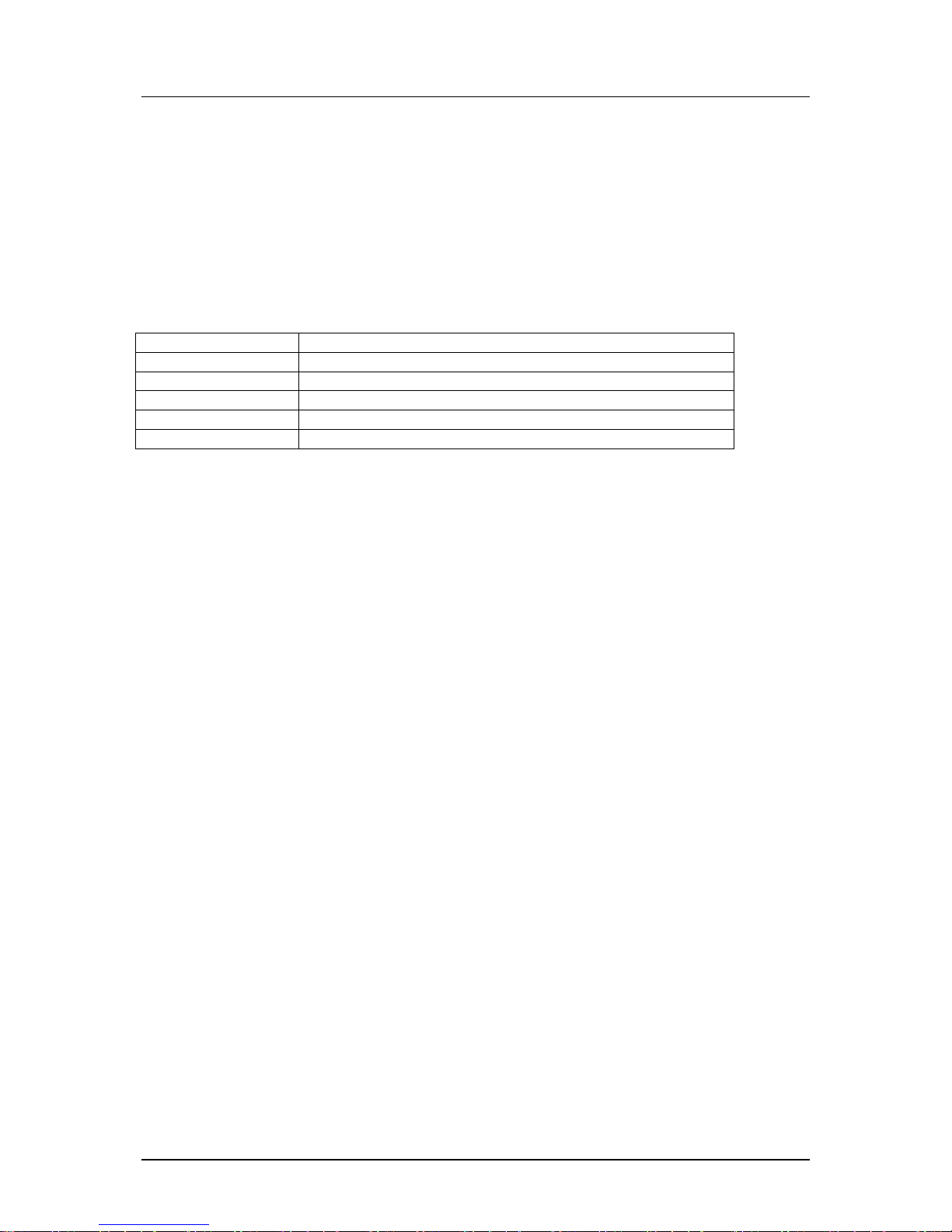

4.1. Introduction

The following table gives an overview of the available spare parts for the DA-52s controls.

The next chapter contains an exploded view of a DA-52s control, in which the same spare

part numbers are used.

Number

Description

D5199-001

DA-52s frontpanel

D5180-003

Mainboard

D6194-002

Frame

D6195-002

Cover

D5195-003

Grip

Delem

V0614, 1.18

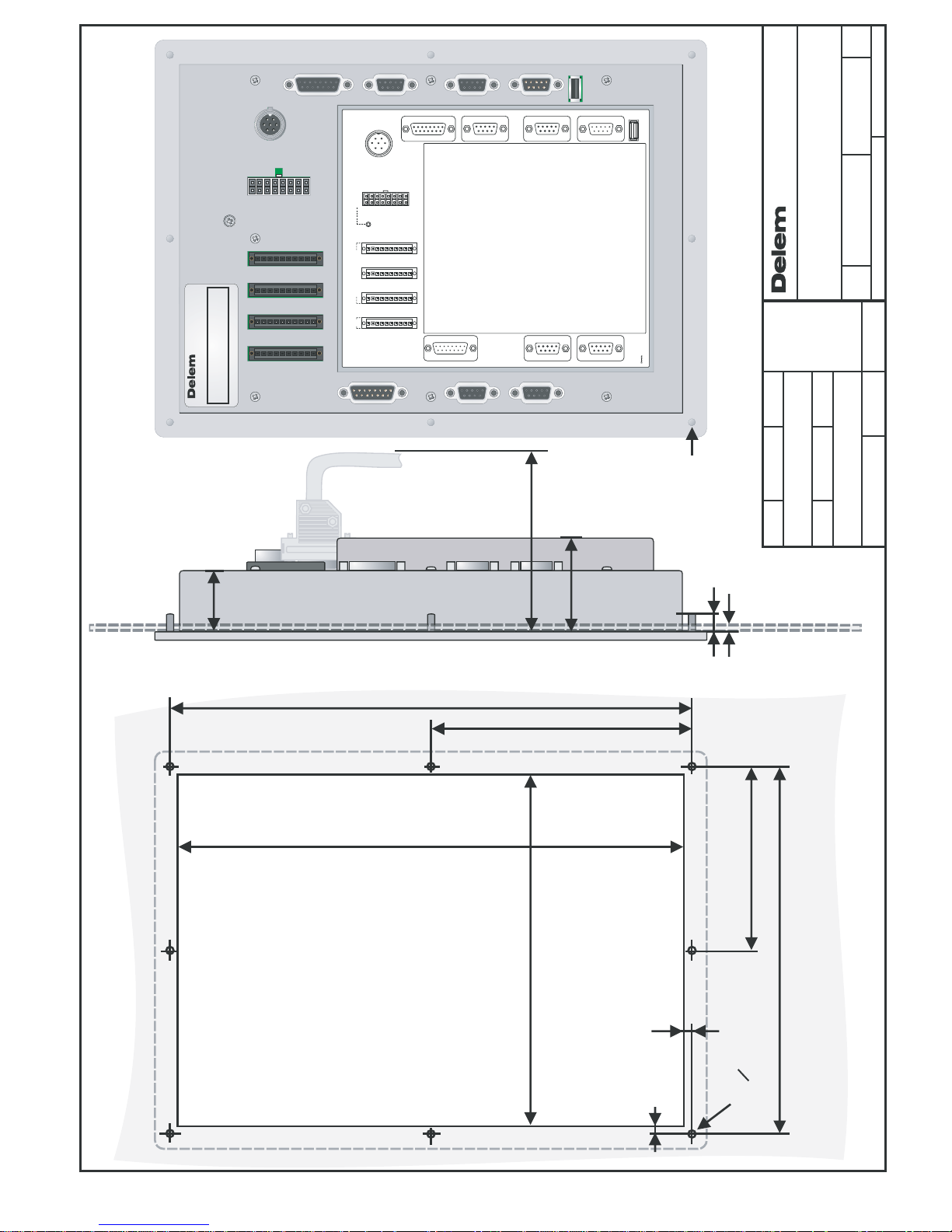

5. Schematics

The following pages show several schematics about the DA-52s control.

Note Redrawn

Redrawn

Date

Date

Date

Description

Description

Note

DrawnMeasures in mm,unless

otherwise specified

No unauthorized copying allowed

Format Number Issue

Scale

Luchthavenweg 42, 5657 EB

Eindhoven, The NETHERLANDS

A3

HNF 20-06-2012

DA-52s

Spare parts

HNF 27-11-2012B

FRU Partnumbers changed / added

8079-903

B

D5199-001

D6194-002

Frame

D5195-003

Grip

D6195-002

Cover

D5180-003 Mainboard DA-52s

18

3

ar

d

5

2s

Mainboard

+

Cable-LCD

999-9-9-9-9-

9-

FRONT - 52s

Note Redrawn

Redrawn

Date

Date

Date

Description

Description

Note

DrawnMeasures in mm,unless

otherwise specified

No unauthorized copying allowed

Format Number Issue

Scale

Luchthavenweg 42, 5657 EB

Eindhoven, The NETHERLANDS

Mounting dimensions

A3

HNF 20-06-2012

ANALOG B

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15

ANALOG A

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15

1 2 3 4 5

6 7 8 9

COM

1 2 3 4 5

6 7 8 9

ENCODER Y2

VALVE

1 2 3 4 5 6 7 8

POWER

1

2

3

4

5

6

7

1 2 3 4 5

6 7 8 9

ENCODER AUX. 1

1 2 3 4 5

6 7 8 9

ENCODER AUX. 2

1 2 3 4 5

6 7 8 9

ENCODER Y1

I/O

T

USB

9 10 11 12 13 14 15 16

I/O1

I/O2

I/O3

I/O4

I/O5

I/O6

I/O7

I/O8

+24V

0V

+24V +24V

0V

+24V

0V 0V

OUT9

OUT10

OUT11

OUT12

IN13

IN14

IN15

IN16

OUT17

OUT18

OUT19

OUT20

IN21

IN22

IN23

IN24

OUT25

OUT26

OUT27

OUT28

IN29

IN30

IN31

IN32

INPUTS / OUTPUTS

CN3 CN4 CN5 CN6

CN1

CN2

CN7

CN8

CN9

CN10

CN12

CN14

CN16

CN20

5885-011/-

Eindhoven

POWER 24V DC

Type:

DA-52s

Serial number:

Made in the Netherlands8079-00N

NNNNN

8079-901

DA-52s

DA-52s

A

34.0 mm

(8 x) M4

9.0 mm

TOP

BACKSIDE

FRONT

M4

M4

(Max. 4.0 mm)

FRONTVIEW

TOP

CUT OUT DIMENSIONS DIMENSIONS

100.0 mm

48.0 mm

M4

8 x O 4.2 mm

BOTTOM

(4.5 mm)

(4.5 mm)

209 mm

297 mm

200 mm

288 mm

104.5 mm

148.5 mm

No unauthorized copying allowed

Format Number Issue

Note Redrawn

Redrawn

Date

Date

Date

Description

Description

Note

DrawnMeasures in mm,unless

otherwise specified

Scale

Luchthavenweg 42, 5657 EB

Eindhoven, the NETHERLANDS

A3

HNF

20-06-2012

DA-52s cables & connectors

8079-902 A

ANALOG B

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15

ANALOG A

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15

1 2 3 4 5

6 7 8 9

COM

1 2 3 4 5

6 7 8 9

ENCODER Y2

VALVE

1 2 3 4 5 6 7 8

POWER

1

2

3

4

5

6

7

1 2 3 4 5

6 7 8 9

ENCODER AUX. 1

1 2 3 4 5

6 7 8 9

ENCODER AUX. 2

1 2 3 4 5

6 7 8 9

ENCODER Y1

I/O

T

USB

9 10 11 12 13 14 15 16

I/O1

I/O2

I/O3

I/O4

I/O5

I/O6

I/O7

I/O8

+24V

0V

+24V +24V

0V

+24V

0V 0V

OUT9

OUT10

OUT11

OUT12

IN13

IN14

IN15

IN16

OUT17

OUT18

OUT19

OUT20

IN21

IN22

IN23

IN24

OUT25

OUT26

OUT27

OUT28

IN29

IN30

IN31

IN32

INPUTS / OUTPUTS

CN3 CN4 CN5 CN6

CN1

CN2

CN7

CN8

CN9

CN10

CN12

CN14

CN16

CN20

5885-011/-

Eindhoven

POWER 24V DC

Type:

DA-52s

Serial number:

Made in the Netherlands8079-00N

NNNNN

ANALOG B

ENCODER Y1

ENCODER Y2

ANALOG A

5060-005

15p.SubD Female

DC-SUBD-15-F-CP

5060-004

15p.SubD Male

DC-SUBD-15-M-CP

DC-161586 DC-177988 DC-178909

Clamping-yoke

connection

(screw)

Spring connection Spring connection

+ Led indication

1 x Power LED

8 x I/O LED

DC-SUBD-9-M-CP

5060-001

9p.SubD Male

DC-SUBD-9-M-CP

5060-001

9p.SubD Male

DC-SUBD-9-M-CP

5060-001

9p.SubD Male

DC-SUBD-9-M-CP

5060-001

9p.SubD Male

ENCODER AUX 1

ENCODER AUX 2

I/O, INPUTS & OUTPUTS

DK-1079-003 4.0 m

Full version:

or

Pressure control version only:

DK-1079-007

1079-003/-

4.0 m

DK-1079-004 6.0 m

DK-1079-005 9.0 m

DK24-N40 4.0 m

DK24-N50 5.0 m

DK24-N100 10.0 m

1128-00N/n

POWER 24VDC

Clamping-yoke

connection

(screw)

Spring

connection

DK-1079-008 6.0 m

DK-1079-009 9.0 m

EXTERNAL USB

DC-USB

5181-001

USB-A/B-cable 0.65 M

Loading...

Loading...