delem DA-52 Reference Manual

DA-52

Reference Manual

Operation of Version 1

English

Manual version V0608

Preface

This manual describes the operation of the Delem controller type DA-52 and is meant for

operators who are instructed for operation of the total machine.

Delem Limited warranty

• This manual does not entitle you to any rights. Delem reserves the right to change this

manual without prior warning.

• All rights reserved. The copyright is held by Delem. No part of this publication may be

copied or reproduced without written permission from Delem BV.

V0608, II

Table of contents

1. Operation overview and general introduction . . . . . . . . . . . . . . . . . . . . 1.1

1.1. The control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.1

1.2. Operation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.3. Programming modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.4. Other frontpanel keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

1.5. Software versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

2. Product programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1

2.1. Program selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1

2.2. Program edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2

2.2.1. General properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2

2.2.2. Parameters explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.3

2.3. Bend programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5

2.3.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5

2.3.2. Bend parameters - first page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5

2.3.3. Bend parameters - second page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.7

3. Programming of tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1

3.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1

3.2. Programming of Punches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1

3.2.1. Punch library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1

3.2.2. Punch parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2

3.3. Programming of bottom dies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2

3.3.1. Die library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2

3.3.2. Die parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3

4. Program Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1

4.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1

4.2. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1

4.3. Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3

4.4. Program settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.4

4.5. Computation settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.6

4.6. Production settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.7

4.7. Backgauge dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.9

4.8. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.10

4.9. Data transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.11

5. Manual mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1

5.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1

5.2. Parameter Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1

5.3. Zoomed values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.4

5.4. Manual operation of the axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5

5.4.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5

5.4.2. To teach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.6

6. Automatic mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1

6.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1

6.2. Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.2

6.3. Zoomed values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3

6.4. Manual operation of the axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.4

A. Parameter index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A.1

V0208, 1

V0208, 2

1. Operation overview and general introduction

1.1. The control unit

The control looks as follows:

numeric keys

screen

function keys

arrow keys

mode keys

start/stop

1.a

The precise outfit of your control may vary.

Operation of the control is done with the various keys on the front panel. A description of all

keys and their functions is given in the next section.

Beside the front panel keys, an external USB mouse can be used as a pointing device to

select menu items, parameters or softkeys. It depends on your configuration whether such a

device is available. In this manual the phrase ‘mouse’ is used to describe any of these

possible pointing devices.

V0608, 1.1

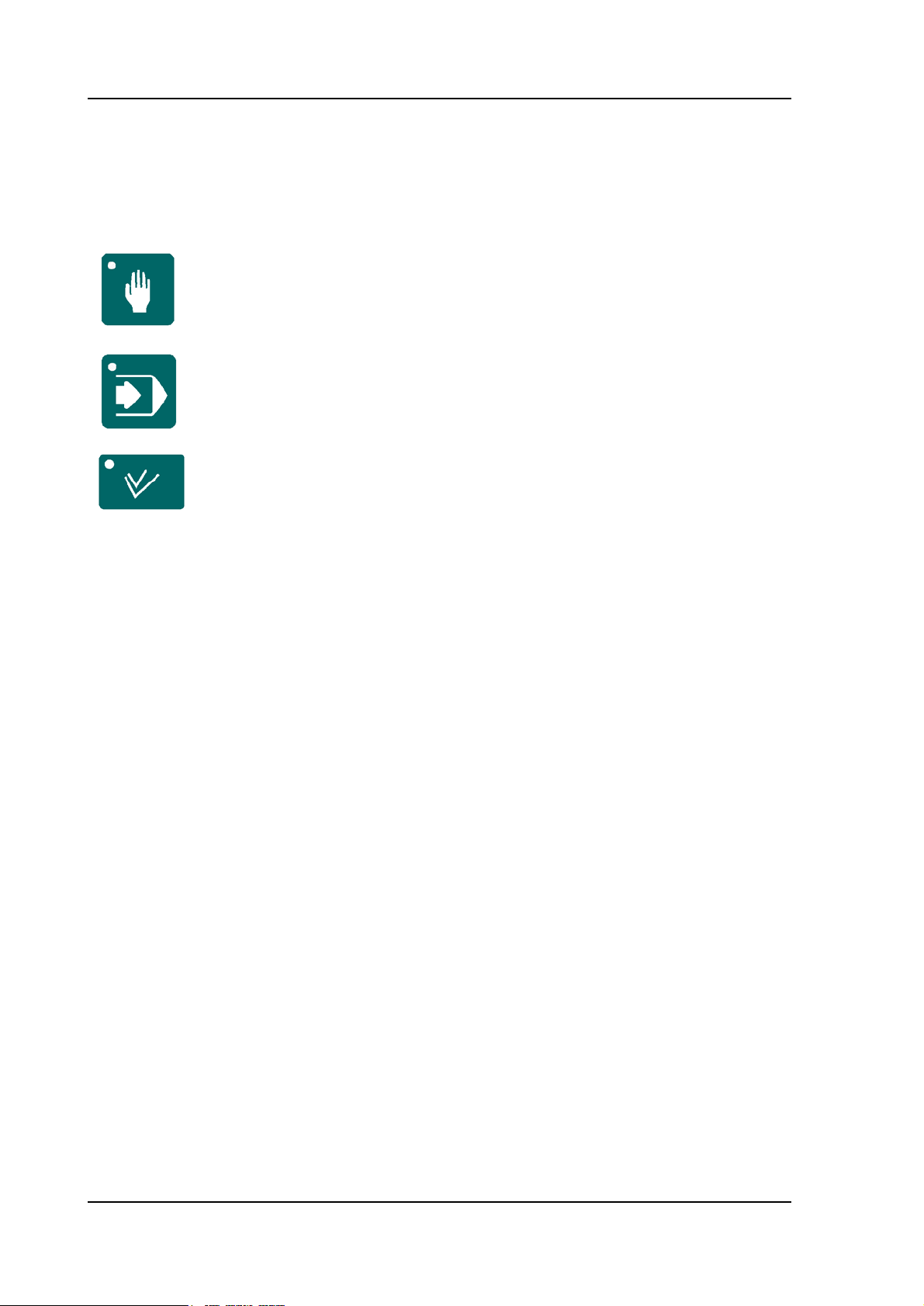

1.2. Operation modes

The control has the 3 following modes:

Manual mode In this mode it is possible to program all

parameters of just one bending. This mode

is useful for testing and for calibration.

Programming

mode

Manual

movement

Each mode can be selected by pressing the relevant push button. A LED in the push button

indicates whether or not this mode is active.

In this mode bend programs can be

programmed and executed.

In this mode any selected axis can be

moved manually with the arrow keys.

V0608, 1.2

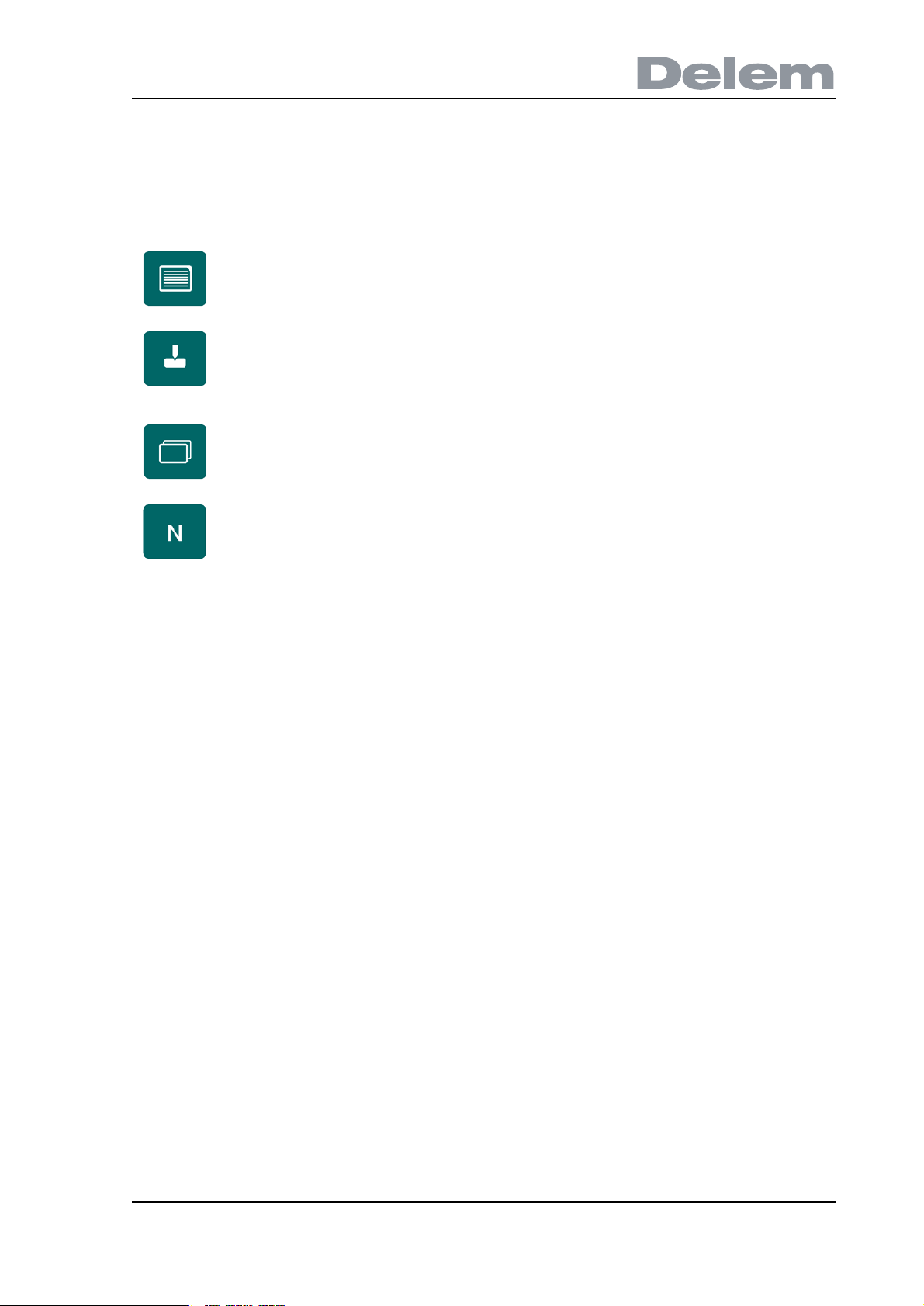

1.3. Programming modes

The control has the following programming functions:

Program

constants

Tools In this mode you program and edit the tools.

Change view Key to switch between various pages of a

Program

library

You select one of the programming modes in the manual- or automatic operation mode while

the controller is in the 'stop'-status.

In this mode you program the general

parameters for bend programming.

There are 30 different punches and 30

different dies to program in the program

memory.

bend.

It also serves to return to an active program.

Open the library with bend programs on the

control.

V0608, 1.3

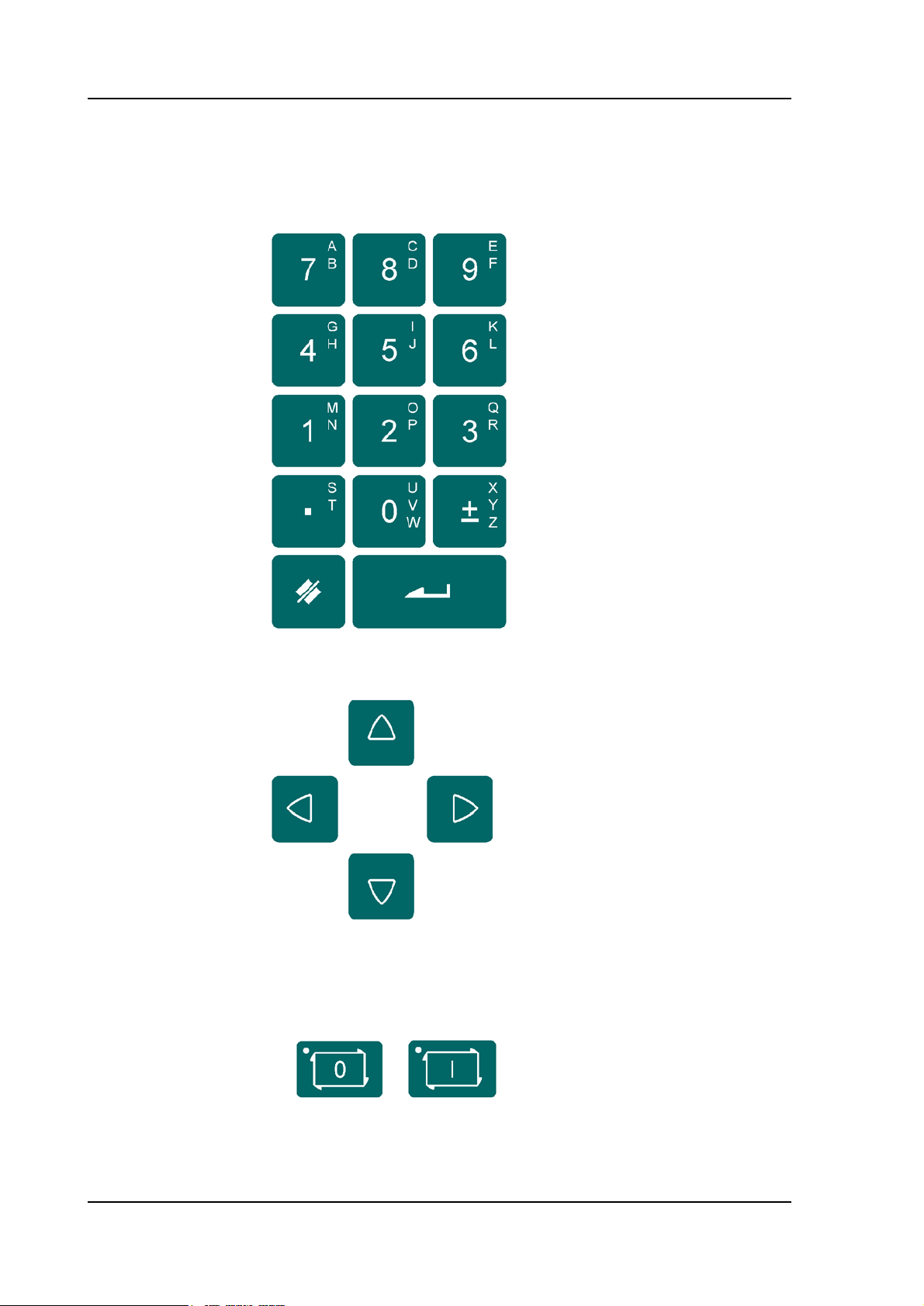

1.4. Other frontpanel keys

The frontpanel consists of the following items:

Keyboard:

decimal point

clear key: Clearance

of the input data field

in the bottom left

corner on the monitor

screen

10 numerical keys (0-

9) incl. alphanumeric

input

plus/minus toggle

enter key, to confirm a

programmed value

Cursor path control:

Stop button Start button

V0608, 1.4

Return to previous function or abort parameter edit.

Keyswitch

The control has a keyswitch to prevent uncontrolled programming. With the keyswitch in the

off position only a selected program can be executed. The parameters cannot be changed to

wrong, unwanted values.

1.5. Software versions

The version of the software in your control is displayed at the upper side of the menu screen in

the programming mode.

Example of version number:

V 1.2

V stands for version

1 is version number

2 is version level

The version number is increased when new features are added to the software, the level

number is increased when minor corrections are needed in the existing version number.

V0608, 1.5

V0608, 1.6

2. Product programming

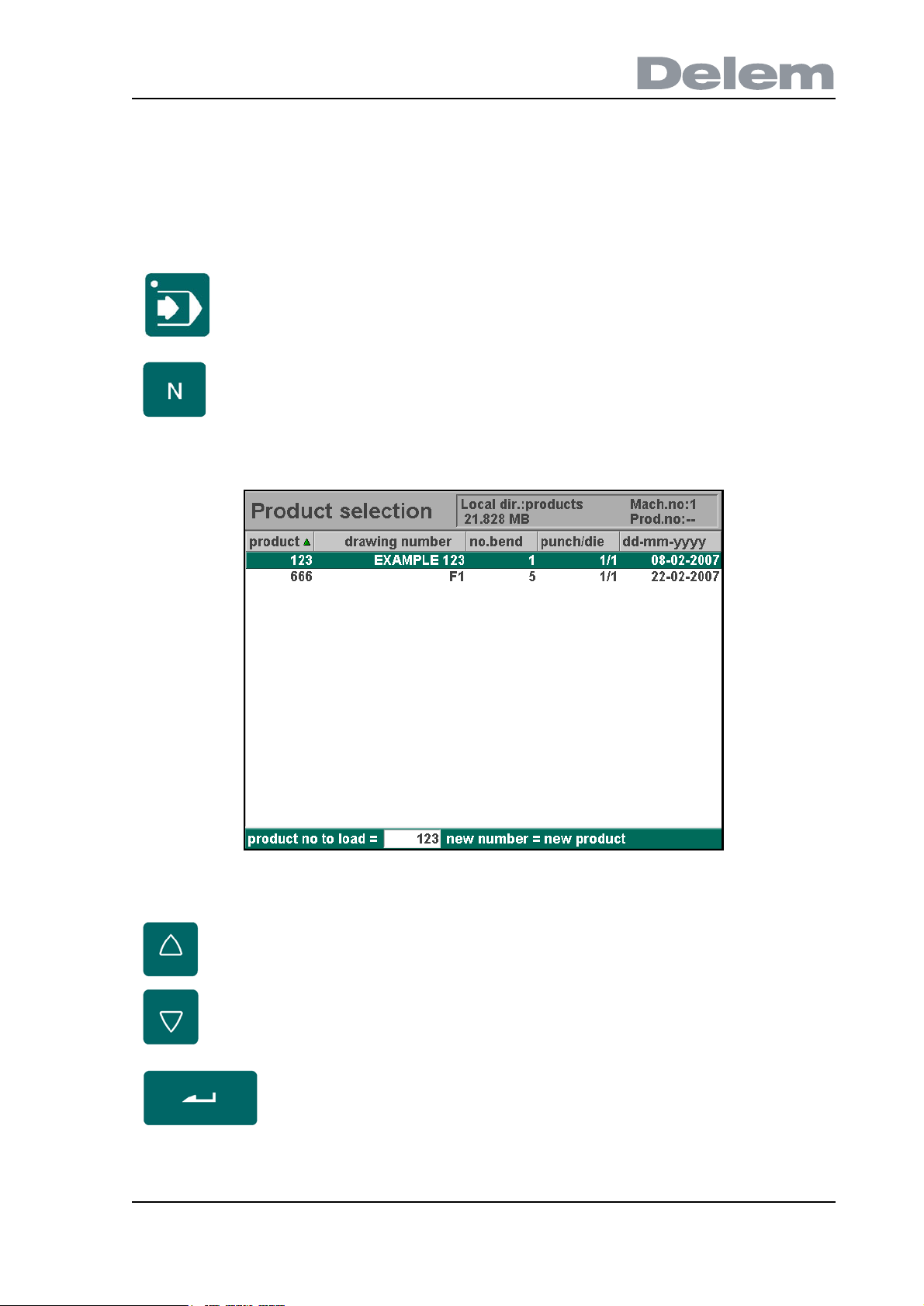

2.1. Program selection

To edit or create a program, proceed as follows:

Press this key to activate the automatic mode.

Press this key to open the program library.

The program library screen appears.

2.a

Use the arrow keys to move to the desired program in the list.

Use the ‘enter’ key to select the highlighted program.

V0608, 2.1

A program can also be selected by entering its number directly.

To create a new program:

Type a number that does not exist yet. When entered, the control asks whether or not to

create a new program.

To delete a program:

Move the cursor bar to the correct program.

Press the ‘clear’ key. The program number changes to zero.

Press the ENTER key. The control will ask if you wish to delete the

selected program. Choose yes (1) to confirm or no (0) to cancel.

2.2. Program edit

2.2.1. General properties

When a program has been selected (or created), a screen is shown with the general product

parameters. These parameters are the same for every bend of the program.

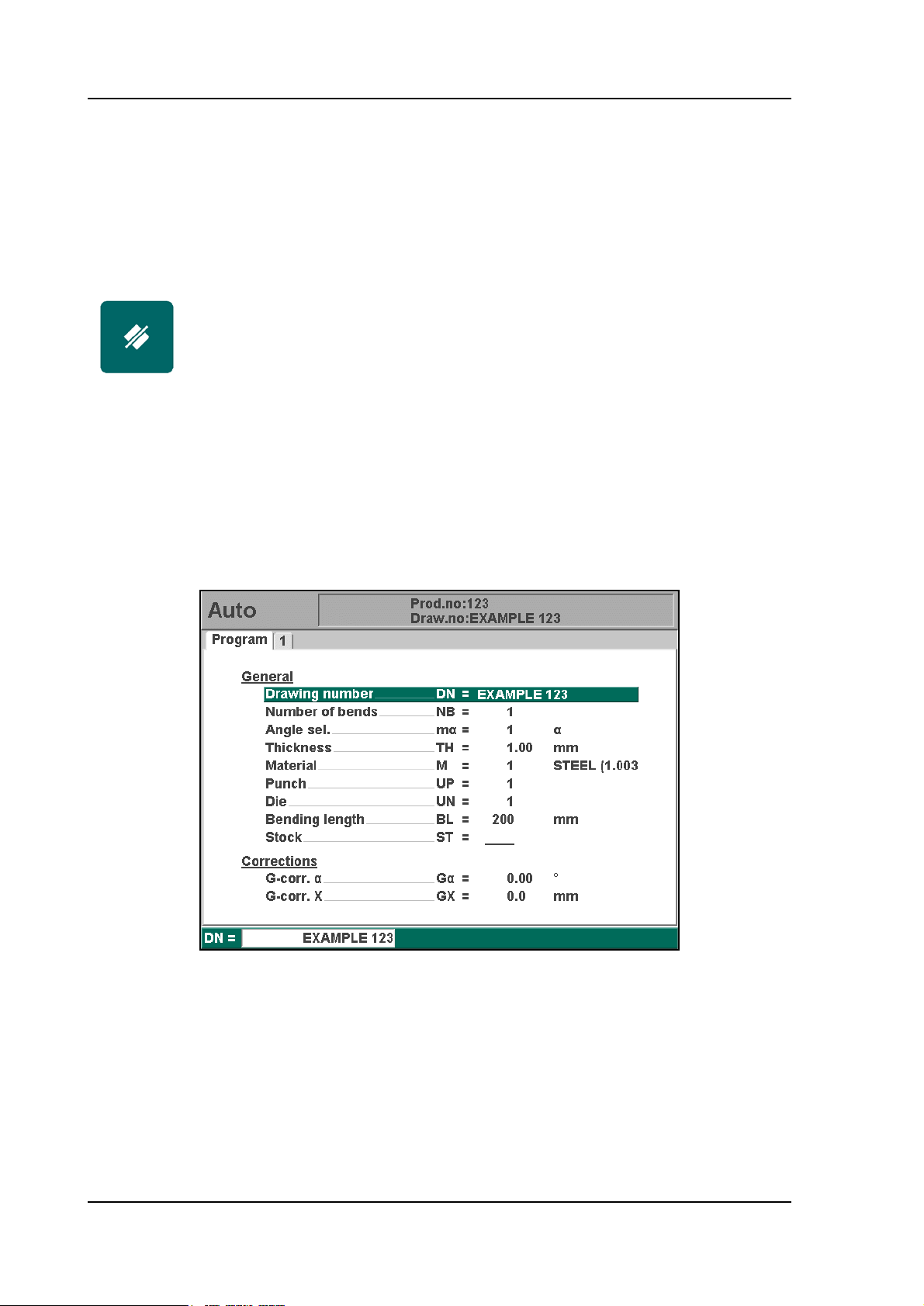

2.b

This page gives all data which are the same for every bending of the program (main data of

program).

V0608, 2.2

Use the arrow keys up/down to move the cursor to the

desired parameter.

Use the arrow keys left/right to browse between the

various pages of the bend program.

After pressing the enter key the programmed value will

be placed at the corresponding parameter.

2.2.2. Parameters explanation

Drawing number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..DN

A name or description of the program. The maximum length is 20 characters.

Number of bends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..NB

The number of bends in the current program.

When this value is increased, the additional bends are copied from the last bend.

When this value is decreased, the superfluous bends are deleted.

Angle selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..ma

Selection of the programming mode for the Y-axis.

0 = absolute: program the absolute Y-axis position for a bend.

1 = a: program the angle to bend. The required Y-axis position is computed.

Depending on this parameter, either the parameter 'angle' or the parameter 'bend

position' will appear in a bend step.

Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..TH

Thickness of the sheet.

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..M

Selection of one of the programmed materials, which are used to calculate the bending

depths. The control contains 4 preprogrammed materials and 2 programmable ones. In

total, 6 materials can be programmed on the control. See the chapter about

programming constants how to program materials.

V0608, 2.3

E-MODULE

(N/mm²)

TENSILE

STRENGTH

(N/mm²)

1 = Steel

2 = Aluminium

3 = Zinc

4 = Stainless steel

5 = Material 5

6 = Material 6

Punch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .UP

Number of punch in library.

Die . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .UN

Number of die in library.

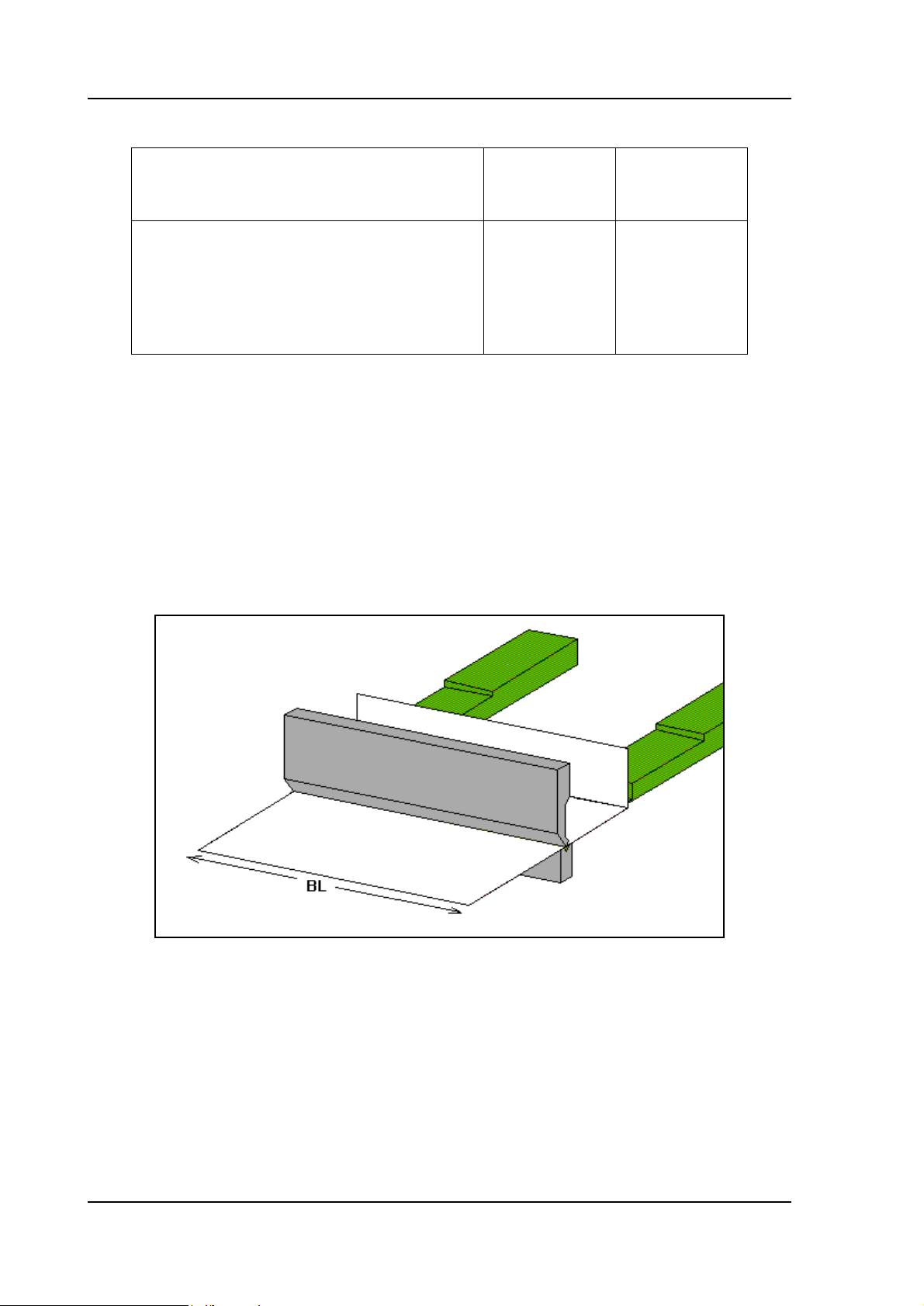

Bending length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .BL

Length of sheet between tools.

When programming a bend, it is assumed the programmed tools have the necessary length.

210.000

70.000

94.000

210.000

210.000

210.000

400

200

200

700

400

400

2.c

Stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ST

The number of products that should be created with this program.

G-Corr

G-Corr X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Gx =

V0608, 2.4

α . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Gα =

General correction of the angle, valid for each bend of the program. The value should be

programmed in the same manner as for the correction per bend.

General correction of the X-axis position, valid for each bend of the program. The value

should be programmed in the same manner as for the correction per bend.

2.3. Bend programming

2.3.1. Introduction

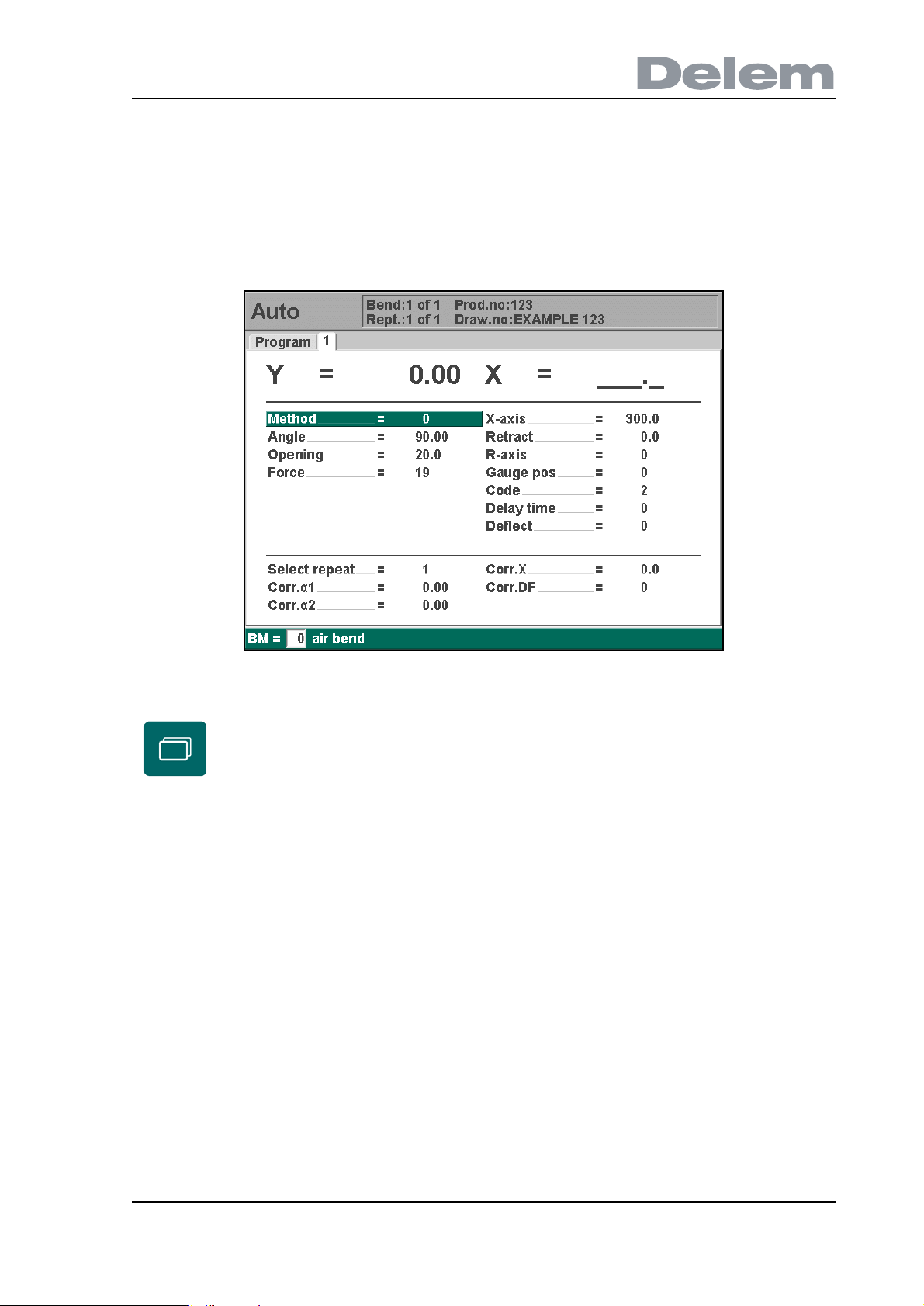

The parameters of one bend are divided over 2 screen pages. The bend number, product

number and drawing number are displayed in the top row on the screen.

2.d

Use the key ‘change view’ to switch to another page

with bend parameters.

When this key is pressed again, a screen with zoomed

values appears.

The parameters below the line are corrections. They are not necessary when programming a

product, but are used to correct the machine behaviour during production. They are described

in chapter 6.

2.3.2. Bend parameters - first page

Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..BM

Select the required bending method. The control supports 2 methods:

0 = Air bend

1 = Bottoming

Bend methods:

V0608, 2.5

Loading...

Loading...