Page 1

Disconnect negative ( - ) battery cable.

Manual

RacerGaugeΦ52and60mm

SI & Imperial SeriesSI & Imperial Series

DF06501〜DF06506,DF06601〜DF06606,DF06701〜DF06706,DF06801〜DF06806,

DF07004〜DF07006,DF11501〜DF11506,DF11601〜DF11606,DF11701〜DF11706,

DF11801〜DF11806,DF11901〜DF11903

Thank you very much for purchasing our product.

This product is an additional product for providing information to automobile users about engine conditions

and other important factors. Before installing and using the product, please read this manual and the

warranty card thoroughly. All sections are for customers and installation personnels. After installation,

please keep this manual and the warranty card for future reference. In the event that this product (or the

vehicle in which it is installed) is lent to or transferred to another person, please be sure this operation

manual and warranty card accompany the product.

Defi will not be held responsible for accidents or damages related to installation of this product.

When installing and operating this product, be sure to read the cautionary items in the operation manual for

the vehicle in which this product will be installed in addition to the manual of this product. Please obtain a

full understanding of the cautionary items and use the product accordingly. Before using the product,

please confirm all the components are included in the package.

http://www.defi-shop.com/

Safety Warning 【Please read carefully.】

In this manual, the degree of hazard arising from actions such as improper operation is separated into the 3

levels "Danger," "Warning," and "Caution." In addition, instructions that must be followed for safe and

proper use of this product as well as practices that must be maintained are marked with a "Confirmation"

heading. Please read and become familiar with these sections.

Danger

Warning

Caution

Confirmation

Propertiesforsafetywarning

Prohibited

Before handling (for installation personnel)

Ensure that the vehicle will remain stationary and turn off the engine before installing this product. Failure to do so

could result in a fire, and could make the vehicle move during installation.

Remove the key from the ignition and disconnect the negative (-) battery terminal prior to installation of this product.

Failure to do so could result in a fire caused by an electrical short circuit.

Take care not to install this product in a way that interferes with safety equipment such as seat belts and air bag

systems or vehicle operation equipment such as engine controls, steering wheel or brake systems. Interference

with normal operation of the vehicle can result in an accident or fire.

Solder or use a solderless connector for wiring connections and make sure connections are insulated. In areas

where there could be tension or sudden impacts on the wiring, safeguard the wiring with corrugated tubing or other

shock absorbent material. Accidental shorts can cause fires.

When wiring power supply wire, to avoid the risk of electrical shock or fire, be sure to confirm that there is no

disconnection or breakage of wire. Poor connection can result in short-circuit, electrical shock, fire, or other hazards.

Discontinue use of this product if a blowout of the fuse has occurred. Continued use while the condition exists could

result in an accident, fire, or damage to the vehicle.

Use the fuse of regulated capacity when the fuse of the power wire is changed. Using a fuse that exceeds regulated

capacity may cause fire and may affect the accuracy.

Do not install the product at the wet places. It may result in a fire caused by an electrical short circuit.

Carefully consider the installation location and driver's operation of the product before installation. Do

not install the product where it interrupts driving and the safety deices of vehicle such as the airbag

system. Be sure not to install the unit where it could fall. Improper installation or operation could

cause the product to fall and damage the vehicle or cause serious danger by impeding driving.

Do not disassemble or modify this product. Such actions will not only void the warranty but also

damage or destroy the product.

Do not perform installation of this product immediately after the engine has been switched off. The

engine and exhaust system are extremely hot at this time and can cause burns if touched.

Ensure that the wiring of this product does not have an adverse impact on the other wiring of the vehicle. Any

controlling devices or other electronic components of the vehicle could be damaged.

Discontinue use of this product if the product doesn't operate or operates improperly. Continued use while the

condition exists could result in an accident or fire.

Please keep children and infants away from the installation area. Children may swallow small parts or be injured in other ways.

Do not install this product in the area where safety equipment such as airbags are mounted. This may cause more

injuries in the event of an accident.

This product is designed for use on 12V vehicles. Do not install this product on vehicles with 24V systems.

Insulate any unused wires. If any wires or connectors loosen during installation, please make sure

they are correctly reattached.

Do not drop any of the components of this product. It may result in damage to the product.

Do not apply excessive force on switches/terminals. It may result in damage to the product.

Do not use wires other than the provided wires.

Do not attach wires on the body of the vehicle or engine parts as this may result in damage to the product.

Install wires away from ignition and also radio signal frequency interference as this could cause the gauges to malfunction.

Do not place wires near the engine, exhaust pipe or turbine. It may result in damage or fusion of wires.

Make sure the waterproof processing is done when diverging wires in the engine compartment.

When installing the sensor, do not bend the wire near the sensor body.

Wear gloves to avoid burns when soldering and cuts when installing wires, sharp edges of parts.

Install sensors away from hot or wet places.

When using sunshade, put sunshade between products and windshield to avoid direct sun exposure .

Use the dried soft cloth for cleanup. Do not use the cleaner except for the neutral detergent. It result in the trouble.

Do not share single fuse with multiple gauges. Every gauge requires independent fuse for IGN and +B line.

Do not pull the wires out of connectors forcefully. The connectors may be broken and the

wires may be cut. When pulling out the wires, press the lock firmly and unclip the locks of

connectors.

Do not install gauges into the passenger side or center of the dashboard. It doesn't meet

vehicle safety standards.

Be sure to follow all instructions in this manual to ensure safe installation and operation of the product.

When the negative (-) battery terminal is disconnected, equipment such as clocks and audio components having

internal memory may lose their memory data. Follow the operation manual of each component to reset data after

installation of this product.

Do not lay the gauge face down due to oil leakage. Angle "A" must be more than 90 degrees.

After installation is complete, return this operation manual, warranty card, and the package to

the customer along with the warranty.

The gauge pointer may not be in the proper position when you purchase the product. Normal

function will resume when power is connected.

Please confirm with the maintenance book on the car that the manufacturer issued when installing and detaching

genuine parts.

Before tapping wires, check the voltage of the existing wire. After tapping the wire, check the voltage of the tapped

wire again to confirm whether you have tapped into the proper place.

If car navigation system or car television is installed in vehicle, gauges and wires of this product need to be kept as

far away as possible from the wiring and installing positions of car navigation system or car television. Failure to do

so may result in interference of television display.

On no event will Nippon Seiki Co., Ltd. be liable to you for any damages or losses of genuine parts for your vehicle

while installing.

Indicates the imminent dangerous situation of death or serious injury if the product is

mishandled.

Indicates the possibility of death or serious injury if the product is mishandled.

Indicates a conceivable source of personal injury or damage to equipment if the product

is improperly operated.

Indicates an instruction that must be performed or practice that must be maintained.

Indicates attention needs to be paid. (Including warnings)

Indicates restricted actions. (PROHIBITED actions)

Must

Indicates actions that need to be carried out. (MUST actions)

Danger

Warning

Caution

Confirmation

'12.07-2

IMPORTANT

WEAR

SAFETY GLASSES

disassemble/

modify

24V

Over90°

A

About Installation and Operation(for customer and installation personnel)

Warning

Please have this product installed by the retail store or dealer where it was purchased. Installation by the customer

will void the warranty.

Do not disassemble or modify this product. Such actions will not only void the warranty but also damage or destroy the product.

In order to ensure safe driving, check the information on the gauge only for short periods of time. Looking at the

display for long periods of time could distract adequate attention from the road and result in an accident.

Discontinue use of this product if the gauge doesn't operate, water gets into the unit, or smoke or a strange odor

comes from the unit. If such a condition occurs, contact the sales outlet or installation personnel as soon as

possible. Continued use while the condition exists could result in an accident or fire.

Do not operate during driving.

Fix the switch unit and other parts tightly to the vehicle to avoid that children swallow those.

Caution

On no event will Nippon Seiki Co., Ltd. be liable to you for any damages arising out of the use or inability to use the

product, even if Nippon Seiki Co., Ltd. has been advised of the possibility of such damage.

Do not pull the wires out of connectors forcefully. The connectors may be broken and

the wires may be cut. When pulling out the wires, press the lock firmly and unclip the

locks of connectors.

Confirmation

This product cannot be linked to either the ADVANCE System or the Defi-Link System.

The information displayed on this product are for reference purposes only. Please drive according to the indication

of vehicle's originally equipped instruments.

This product uses high luminance LEDs. When several gauges are lined up, there might be color difference in the

LED production tolerance, but it is not malfunction.

Please check the installed product regularly. Durability might deteriorate according to use conditions, etc.

Lineup (for customer)

SI models

Illumination color

Size(mm)

TURBO

PRESS.

TEMP.

EXT.T.

VOLT

Blue Red White

Φ52

DF06504

DF06604

DF06704

DF06804

DF07004

Φ60

DF11504

DF11604

DF11704

DF11804

DF11901

Φ52

DF06505

DF06605

DF06705

DF06805

DF07005

Φ60

DF11505

DF11605

DF11705

DF11805

DF11902

Φ52

DF06506

DF06606

DF06706

DF06806

DF07006

Φ60

DF11506

DF11606

DF11706

DF11806

DF11903

Display Range

-100kPa〜+200kPa

0〜1000kPa

30〜150℃

200〜1100℃

10〜15V

Imperial models

Illumination color

Size(mm)

BOOST

PRESS.

TEMP.

E.G.T.

VOLT

Blue Red White

Φ52

DF06501

DF06601

DF06701

DF06801

DF07004

Φ60

DF11501

DF11601

DF11701

DF11801

DF11901

Φ52

DF06502

DF06602

DF06702

DF06802

DF07005

Φ60

DF11502

DF11602

DF11702

DF11802

DF11902

Φ52

DF06503

DF06603

DF06703

DF06803

DF07006

Φ60

DF11503

DF11603

DF11703

DF11803

DF11903

Display Range

-30inHg〜30PSI

0〜140PSI

100〜300°F

400〜2000°F

10〜15V

Main Features (for customer)

■Stepping motor "STEP MASTER VS-2" provides smooth operation.

■Ignition ON initiates self-luminescence gauge.

■Illumination using high-brightness LEDs

■Lightning-like Opening / Closing mode

■Self-diagnostics function monitors both sensor disconnection and short-circuiting during startup.

a) Sensor disconnection check

This function reports any in-proper connections, broken or disconnected sensor or sensor

wire. The pointer will wave between 250 and 260 degrees.

b) Short-circuiting check

This function indicates any short circuit on the sensor or sensor wire.

The pointer will wave between 10 and 20 degrees.

■Full 270°sweep dial provides ultimate visibility.

■A mounting bracket and instrument case is provided with the product.

■The red triangle of the regular position bezel can be used as a warning indicator and others.

Product Specifications(for customer and installation personnel)

■Power-supply voltage: 10V to 15V DC (12V vehicles only)

■Current consumption: +B line: MAX 120mA (Dark current 0mA)

IGN line: MAX 120mA

ILM line: MAX 2mA

■Temperature range (humidity is assumed to be 80% or lower) Unit: °C(°F)

Temperature range for storage Temperature range for operation

Gauge -30(-22) ~ +80(176) -20(-4) ~ +60(140)

Boost sensor -30(-22) ~ +100(212) -30(-22) ~ +80(176)

Pressure sensor -30(-22) ~ +140(284) -30(-22) ~ +120(248)

Temperature sensor -30(-22) ~ +150(302) -20(-4) ~ +150(302)

Exhaust temperature sensor -30(-22) ~ +130(266) -30(-22) ~ +130(266)

*The upper temperature limit of sensor connectors is 105℃(221°F).

*The sensing part of exhaust temp. sensor is not included in the temperature range above.

■Dial color: Black (invisible until the ignition is turned on)

■Illumination color: Blue, red, and white *The color cannot be switched.

■Dimensions: See reverse side.

Installation (for customer and installation personnel)

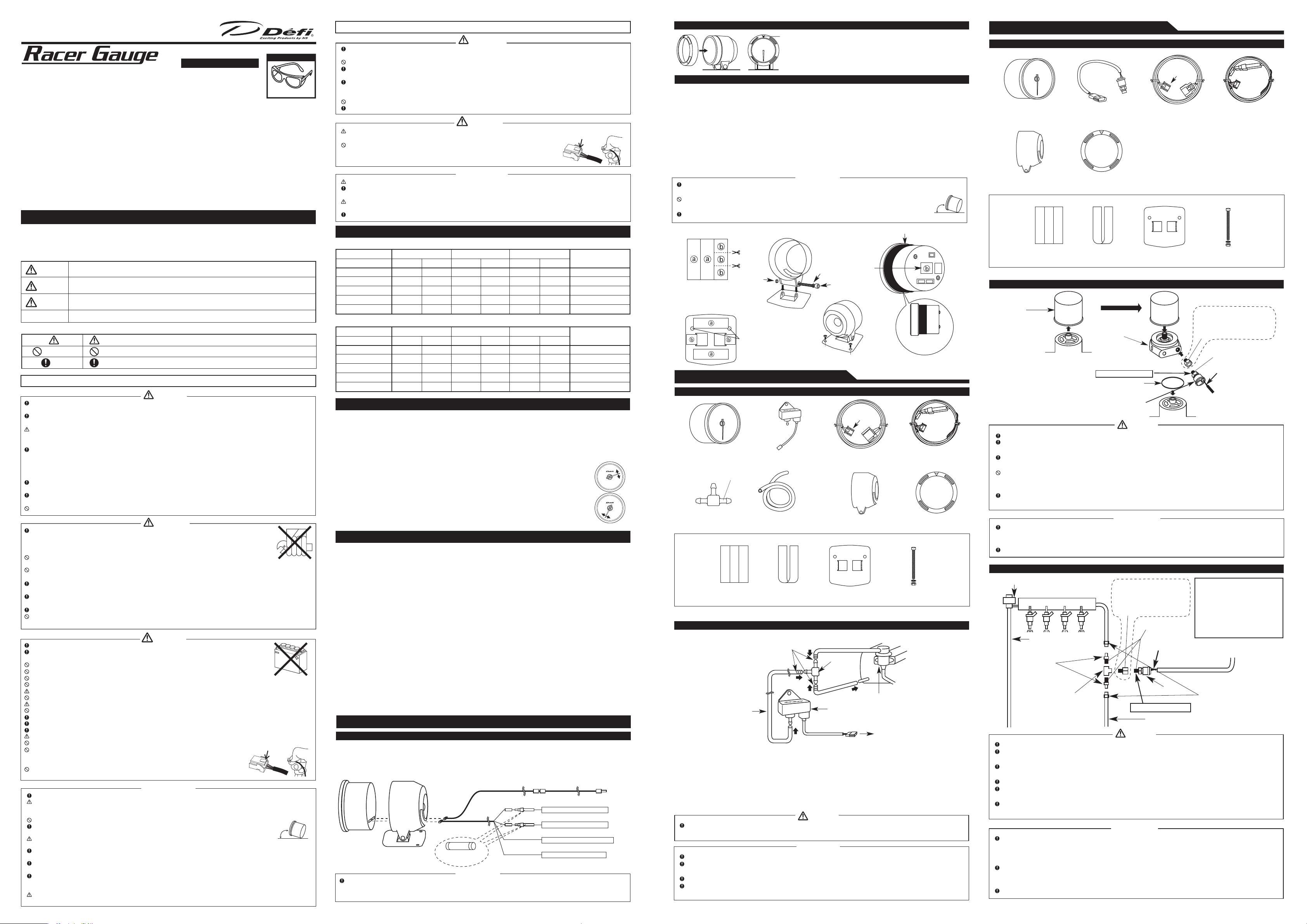

■How to wire the power supply wire

1) Disconnect negative ( - ) battery cable.

2) Connect the power supply wire as shown below.

3) Connect each sensor. Refer to "How to attach sensor" sections. (Except the Volt gauge)

4) Connect the sensor wire.

5) Reconnect negative ( - ) battery cable.

Sensor wire Sensor

Orange wire:IGN (Ignition)

To 12V wire when ignition on

Power supply wire

+B 0.3A

Fuse

IGN 0.3A

Confirmation

When several gauges are installed into a vehicle, use each power supply wire to connect gauges to

the vehicle independently. Do not join multiple power supply wires. Do not share single fuse with

multiple gauges. Every gauge requires independent fuse for IGN and +B line.

Red wire:+B (12V Battery)

To 12V battery wire

White wire:+ILM(Illumination)

To 12V wire when small lamp on

Black wire:GND (Ground)

To ground or negative battery terminal

(a)

(b)

■How to use the regular position bezel

Red triangle

●The red triangle can be used as an warning indicator.

●To move the position of the red triangle, remove the bezel

once and then adjust the position and attach it again.

■How to attach Mounting bracket set

1) Cut the double sided tape as shown in figure 1.

2) Insert convex part of the mounting bracket over the legs of the meter cup. Attach the mounting

bracket to the meter cup with the bolt, nut, and washer included in the kit as shown in figure 2.

3) Attach one piece of double sided tape and the buffer on the gauge as shown in figure 3. (Cut the

buffer into suitable length when installing

Φ 52(2 1/16”) series.)

4) Pass the power supply wire and the sensor wire through the hole of the meter cup and connect them

to the gauge.

5) Place the gauge in the meter cup making sure that the wires are not sandwiched.

6) Attach double sided tape on the back of the mounting bracket as shown in figure 4. Bend the

mounting bracket to conform to the structure of the location where you intend to attach it.

Confirmation

Use appropriate dashboard cleaning liquids (commercially available) to clean the area

where the double sided tape will be attached.

Do not lay the gauge face down due to oil leakage. Angle "A" must be more than 90

degrees.

Over90°

A

If the adherence of double sided tape is not enough, use commercial tapping screws.

【figure 1】【figure 3】【figure 2】

Nut

【figure 4】

Mounting bracket

Washer

Double

sided tape

Bolt

[In case using screws]

Buffer

(rear side)

Holes for screws

(Φ4.4mm)

Attaching position

of buffer

Use screws commercially available as needed.

TURBO (DF065, DF115 series)

■Components

Light blue

3pins

Gauge 1pc Boost sensor 1pc Sensor wire (2.5m,8 1/5ft)

1pc

Φ4mm x 3

Inside

diameter

Φ4mm

Three way joint

1pc

Rubber hose (0.5m, 1 3/5ft)

1pc

Meter cup 1pc Regular position

Mounting bracket set

Double sided

tape 1pc

Operation manual (this sheet) and warranty card are included other than the parts listed above. Keep them at hand.

Buffer

1pc

Mounting

bracket 1pc

■How to attach boost sensor

Attach with clamps.

(commercially available)

Three-way joint

(a)

(c)

(b)

Fuel regulator

Rubber hose

Sensor

*Be sure to be installed facing side the

hole down.

To sensor wire

1) The rubber hose attached to the sensor should be as short as possible. Attach the sensor with bolts

(M6) in the engine compartment in an area where it will not be subject to excess heat or vibration.

2) Access to the air pressure intake may be obtained between the surge tank and the fuel regulator.

(A)Detach the vacuum hose from the surge tank side that has less pressure oscillations and connect

it to the point (a) or (b) of the three way joint.

(B)In order to connect the surge tank with three way joint, cut the required length of the hose from

the included rubber hose.

(C)Use the remaining rubber hose to connect the sensor to the three way joint.

Warning

To avoid disconnection of rubber hose and air leak, attach hose clamps or use tie-wraps to secure the

adjacent hose in the engine compartment. Disconnected hose or air leak could cause damage to the engine.

Confirmation

The length of the included rubber hose is 0.5m. Please adjust appropriately.

The included three-way joint can be used only for the piping inner diameter of Φ 4 between the surge

tank and fuel pressure regulator. In case of other than

Φ4, use another joint that fits properly.

The sensor must be installed being the rubber hose connection side faced down.

For vehicles which have a solenoid valve between the surge tank and the fuel pressure regulator,

place a three-way joint closer to the surge tank side than to the solenoid side.

Power supply wire

(1m, 3 1/3ft) 1pc

bezel 1pc

M4 bolt, nut,

washer 1pc

Surge tank

PRESS. (DF066, 116 series)

■Components

Red

3pins

Gauge 1pc Pressure sensor

(1/8PT) 1pc

Meter cup 1pc Regular position

bezel 1pc

Mounting bracket set

Double sided

tape 1pc

Operation manual (this sheet) and warranty card are included other than the parts listed above. Keep them at hand.

Buffer

1pc

■How to attach pressure sensor for oil pressure (Use a commercial sensor attachment.)

Detach the original

element.

Sensor attachment

(commercially available)

Engine

Thread size 1/8PT

(provided with commercial parts)

Be sure the sensor wire is not twisted when installing the sensor. The sensor wire will be cut.

Oil spills by the installation work. Please replenish the engine with oil. The engine might overheat

when oil is too little.

To avoid oil leaks by installing of the sensors, use Teflon tape. Before driving, inspect oil blocks for

leaks. Leaks could cause a fire or damage the engine.

Do not install the sensor near oil pump. Do not install the sensor to pressure switch directly. Failure to

do so could damage the sensor because the pressure pulsation is too big and exceed three times

full-scale momentarily.

To avoid the damage of the sensor wire, please fix the waterproof connector on the vehicle body and

do not bend the sensor wire near the sensor.

The thread size of the pressure sensor is 1/8PT. Use a sensor attachment of 1/8PT. If the thread

size of the sensor attachment for the pressure sensor is 1/8NPT, use a conversion adapter available

from hardware stores.

Tighten the sensor into the sensor attachment and then connect it to the sensor wire.

■How to attach pressure sensor for fuel pressure (Use a commercial three-way joint and hose unions.)

Fuel pressure regulator

Use a commercial

conversion adapter in case

the inlet of the three-way

joint is 1/8NPT.

Fuel return pipe

(low pressure)

Hose union

(commercially

available)

Three-way joint

(commercially available)

Be sure the sensor wire is not twisted when installing the sensor. The sensor wire will be cut.

Before cutting the fuel feed pipe, be certain to remove the gas cap to relieve any pressure built up in the

fuel tank.

When cutting the fuel feed pipe, be certain to discharge static electricity. Otherwise, there is a possibility

of the ignition in gasoline.

Wear glasses to protect eyes when cutting the fuel filter pipe.

To avoid fuel leaks during installation of the sensor, use Teflon tape. Attach hose connection and fuel

feed tubing with clamps. Inspect pipes and hose connections for leaks before driving.

To avoid the damage of the sensor wire, please fix the waterproof connector on the vehicle body and

do not bend the sensor wire near the sensor.

Confirmation

The sensor must be installed on the feed (high pressure) pipe side between the fuel tank and the

fuel pressure regulator.

*It is not possible to obtain accurate fuel pressure from the return (low pressure) side at the rear of the

fuel pressure regulator.

The thread size of hose unions and the three-way joint need to be 1/8PT. Use hose unions and a

three-way joint of 1/8PT. If the thread size of the three-way joint is 1/8NPT,

available from hardware stores.

Tighten the sensor into the sensor attachment and then connect it to the sensor wire.

Sensor wire (2.5m, 8 1/5ft)

Mounting

bracket 1pc

O ring

Sensor

Engine

Warning

Confirmation

Wind Teflon tape.

Be sure not to twist.

Sensor

Thread size 1/8PT

Fuel feed pipe (high pressure)

Warning

1pc

Power supply wire

(1m, 3 1/3ft) 1pc

M4 bolt, nut,

washer 1pc

Use a commercial

conversion adapter in case

the inlet of the sensor

attachment is 1/8NPT.

Wind Teflon tape.

Be sure not to twist.

To sensor wire

→

*Cut the fuel feed pipe and

install hose unions.

*If the material used for the

inner surface of fuel feed

pipe is resin, a hose union

may not be fixed. Check the

material before cutting the

fuel feed pipe.

To sensor wire

↑

Fix tightly with clamps.

(commercially available)

use a conversion adapter

Page 2

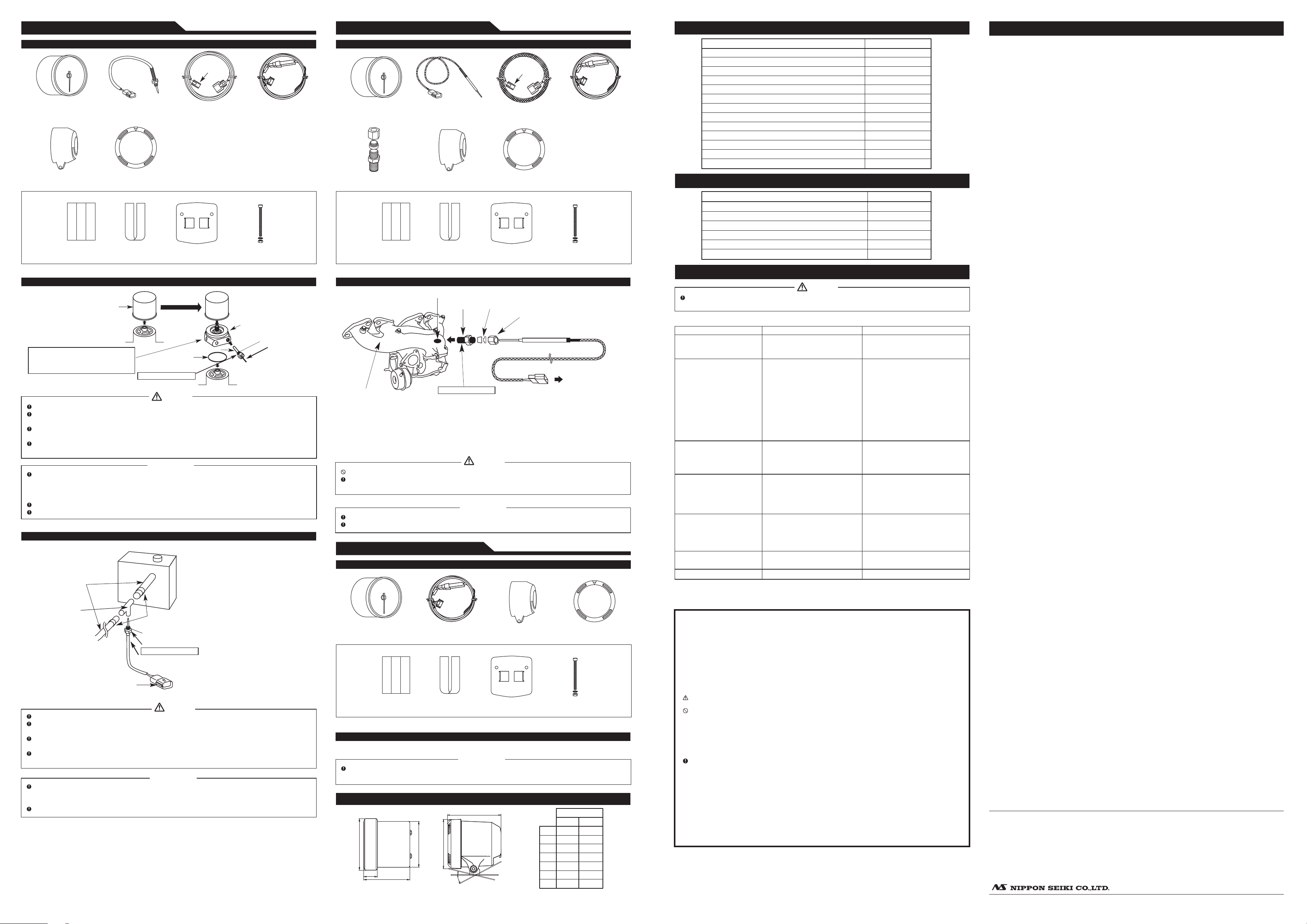

TEMP. (DF067, 117 Series)

■Components

Red

2pins

Gauge 1pc Temperature sensor

(1/8PT) 1pc

Meter cup 1pc Regular position

bezel 1pc

Mounting bracket set

Double sided

tape 1pc

Operation manual (this sheet) and warranty card are included other than the parts listed above. Keep them at hand.

■

How to attach temperature sensor for oil temperature (Use a commercial sensor attachment.)

Buffer

1pc

Detach the original element.

Engine

Do not put the sensor in the side hole.

The depth of the hole for the sensor

must be more than 30mm (1.2”).

(provided with

commercial parts)

Thread size 1/8PT

Be sure the sensor wire is not twisted when installing the sensor. The sensor wire will be cut.

Oil spills by the installation work. Please replenish the engine with oil. The engine might overheat

when oil is too little.

To avoid oil leaks by installing of the sensors, use Teflon tape. Before driving, inspect oil blocks for

leaks. Leaks could cause a fire or damage the engine.

To avoid the damage of the sensor wire, please fix the waterproof connector on the vehicle body and

do not bend the sensor wire near the sensor.

Confirmation

The thread size of the temperature sensor is 1/8PT. Use a sensor attachment of 1/8PT. If the thread

size of the sensor attachment for the temperature sensor is not 1/8PT, and you use a conversion

adapter available from hardware store, note that the temperature is displayed lower than the actual

value.

The depth of the hole for the sensor must be more than 30mm (1.2”).

Tighten the sensor into the sensor attachment and then connect it to the sensor wire.

■How to attach temperature sensor for water temperature (Use a commercial sensor attachment.)

Radiator

Upper hose

Sensor attachment

(commercially available)

Attach tightly with clamps.

(commercially available)

Wind Teflon tape.

Thread size 1/8PT

Be sure not to twist.

Sensor

Be sure the sensor wire is not twisted when installing the sensor. The sensor wire will be cut.

Coolant spills by the installation work. Please replenish the engine with coolant and bleed the air

from the system, or the engine might overheat.

To avoid water leaks during installation of the sensors, use Teflon tape. Attach the sensor

attachment and upper hose with clamps. Inspect hose connections for leaks before driving.

To avoid the damage of the sensor wire, please fix the waterproof connector on the vehicle body and

do not bend the sensor wire near the sensor.

Confirmation

The thread size of the temperature sensor is 1/8PT. Use a sensor attachment of 1/8PT. If the thread

size of the sensor attachment for the temperature sensor is not 1/8PT, and you use a conversion adapter

available from hardware store, note that the temperature is displayed lower than the actual value.

Tighten the sensor into the sensor attachment and then connect it to the sensor wire.

Sensor wire (3m, 10ft)

1pc

Mounting

bracket 1pc

Sensor

O ring

Engine

Warning

*Cut the upper hose and connect the

sensor attachment between hoses.

→To sensor wire

Warning

Power supply wire

(1m, 3 1/3ft) 1pc

M4 bolt, nut,

washer 1pc

Sensor attachment

(commercially available)

Wind Teflon tape.

Be sure not to twist.

To sensor wire

→

EXT.T. (DF068, 118 series)

■Components

Black

2pins

Gauge 1pc Exhaust temperature

sensor 1pc

Sensor wire (2.5m,8 1/5ft)

1pc

Power supply wire

(1m, 3 1/3ft) 1pc

Meter cup 1pcFitting (1/8PT) 1pc Regular position

bezel 1pc

Mounting bracket set

Double sided

tape 1pc

Operation manual (this sheet) and warranty card are included other than the parts listed above. Keep them at hand.

Buffer

1pc

Mounting

bracket 1pc

M4 bolt, nut,

washer 1pc

■How to attach exhaust temperature sensor for exhaust temperature

Make a threaded screw

hole (1/8PT).

Fitting(a)

Bushing

Fitting(b)

Exhaust temperature sensor

Sensor wire

Exhaust manifold

Thread size 1/8PT

1) Make a 1/8PT threaded screw hole in the exhaust manifold pipe. (Weld if the pipe wall thickness is not enough)

2) Dismantle the fitting. Do not crush the bushing inside the fitting.

3) Tighten the fitting(a) to the hole of the exhaust manifold.

4) Pierce the sensor through the fitting(b) and the busing.

5) Insert the edge of the sensor into the fitting(a) and position it at the center of the exhaust pipe.

6) Tighten the fitting(b).

Warning

To avoid personal injury, do not install the exhaust temperature sensor while the engine is hot.

When making a hole, make sure no chip remains in the exhaust pipe or turbine. It may result in

damage to the engine, exhaust pipe, or turbine.

Confirmation

The thread size of the fitting is 1/8PT. Make a threaded screw hole of 1/8PT.

Tighten the sensor into the sensor attachment and then connect it to the sensor wire.

VOLT (DF070, 119 series)

■Components

Gauge 1pc Power supply wire

(1m, 3 1/3ft) 1pc

Mounting bracket set

Double sided

tape 1pc

Operation manual (this sheet) and warranty card are included other than the parts listed above. Keep them at hand.

Buffer

1pc

■How to attach Volt gauge

Volt is displayed by connecting the power supply wire.

Confirmation

Use the tube fuse of repair part when the fuse of the power supply wire is changed. Using a

commercial fuse may affect the accuracy.

Dimensions in mm (1mm=0.039in)

D

ΦA

Gaugediameter

C

B

ΦE

F

G

Meter cup 1pc Regular position

bezel 1pc

Mounting

bracket 1pc

M4 bolt, nut,

washer 1pc

Gaugediameter

Φ52

58.3

A

51.8

B

15.2

C

67.9

D

61.9

E

15°

F

25°

G

Φ60

66.3

52.2

15.5

70.2

70.5

15°

32°

Repair Parts (for customer)

Item Model Number

Fuse 0.3A (2pcs)

PDF06508G

Mounting Bracket set for Φ52mmgauge PDF06507G

Mounting Bracket set for Φ60mmgauge

Power Supply wire

Boost Sensor

Boost Sensor wire

Pressure Sensor(1/8PT)

Pressure Sensor wire

Temp. Sensor(1/8PT)

Temp. Sensor wire

Exhaust Temp. Sensor

Exhaust Temp. Sensor wire

1/8PT Fitting for Exhaust Temp. Sensor

PDF07809G

PDF06504H

PDF06503S

PDF06505H

PDF00703S

PDF06603H

PDF00903S

PDF05602H

PDF01103S

PDF06803H

PDF01105G

Optional Parts (for customer)

Item Model Number

Boost Sensor extension wire 1m(3 1/3ft.)

Pressure Sensor extension wire 1m(3 1/3ft.)

Pressure Sensor extension wire 2m(6 3/5ft.)

Temp. Sensor extension wire 1m(3 1/3ft.)

Temp. Sensor extension wire 2m(6 3/5ft.)

Exhaust Temp. Sensor extension wire 2m(6 3/5ft.)

PDF06002H

PDF06013H

PDF00707H

PDF06014H

PDF00906H

PDF01107H

Troubleshooting (for customer and installation personnel)

Warning

If operation of the product seems unusual, inspect the product to confirm that there is no malfunction.

If an operational problem has occurred, it could result in an accident.

※In addition to a general inspection of the product, use the following table to confirm proper operation of the unit.

Condition Possible Cause Corrective Action

○A gauge lapses into the

disconnection check mode.

(Except VOLT gauge)

○A gauge lapses into the short

circuit check mode. (Except

VOLT gauge)

○A gauge doesn't operate.

○A gauge doesn't perform the

opening mode.

○A gauge doesn't perform the

closing mode.

○Dimmer is not working.

○Malfunctioning operation

○Disconnection of sensor or sensor wire

○Connector is unhooked.

○Incorrect wiring

○Sensor or sensor wire has a short

circuit.

○Sensor or sensor wire is shorted to

the vehicle body.

○Fuse on the power supply wire is

blown out.

○Wiring of IGN wire or GND wire of

the power supply wire to the vehicle

is wrong.

○Fuse on the IGN wire of the power

supply wire is blown out.

○Wiring of constant battery+ wire of

the power supply wire to the vehicle

is wrong.

○Fuse on the constant battery+ wire of

the power supply wire is blown out.

○Wiring of ILM wire of the power

supply wire to the vehicle is wrong.

○Wrong wiring of the power supply wire

※If the problem is not solved after the remedies mentioned above are tried:

⇒Ask the installation personnel or the shop you purchased the gauge for inspection.

⇒Purchase new parts for replacing wear-out parts .

Maintenance & Check/Warranty & Servicing

■Warranty card・Terms and conditions

This product is delivered with this operation manual and a warranty card. Please read terms and conditions in

this manual thoroughly and keep the warranty card in a safe place. Failure to show this warranty will void the

warranty.

■Warranty period

Limited one year warranty. The warranty period starts at the date of retail purchase by the original end-user

purchase. Please confirm the warranty card is provided with the information of retail store where purchased.

Please refer to Limited Warranty for details.

Except in the case of defects, we shall not be liable for any trouble including violation, accident or improper

wiring resulting from using this product.

The warranty does not cover any unauthorized repair performed or caused to be performed by the end user.

Such action can destroy or damage this product.

■Inspection

Please ask the shop you purchased the product for inspection if any defect in product is suspected. We don't

accept the order of fixing because Defi products require installation and wiring to the vehicle. In case you cannot

go to the shop you purchased because of move-out or closure of shop, please ask the nearest Defi Distributor

listed in the Defi website.

For a repair/inspection service, take the warranty card and customer contact information with you.

■Label

The label sticked on the product is for the product traceability. Do not peel it off.

■Repairing

When a repair is necessary, we will return the inspection result report through the store to you. After receiving a

repair service request, we start repairing. Ask the store how much it costs and how long it takes to repair.

■Discarding the products

Please dispose products in accordance with disposal laws, state laws and local government. A recycle label on

the package indicates that the package is recyclable.

○Check the disconnection of connectors

and wires.

○Look for the point of short circuit with the

following procedures.

【Step 1】 Unplug the sensor from sensor wire.

<1> The gauge lapses into the

disconnection check mode.

→Short circuit of the sensor.

<2> The short circuit check mode

continues. →Go to 【Step 2】

【Step 2】Unplug the sensor wire from the gauge.

<1> The gauge lapses into the

disconnection check mode.

→ Sensor wire has a short circuit.

○Check the wiring.

○Do not share single fuse with multiple

gauges. Every gauge requires

independent fuse for IGN and +B line.

○Check the wiring.

○Replace the fuse of the power supply

wire.

○Check the wiring.

○Replace the fuse of the power supply

wire.

○Check the wiring.

○Check the wiring.

Terms and Conditions (for customer)

LIMITED PRODUCT WARRANTY AND LIMITED PRODUCT LIABILITY

A. Limited Warranty

a. Our sole obligation to you after the sale of a product is to replace, without charge, the product or any

component thereof discovered to bee defective within a period of one (1) year from the purchasing

date(the "Warranty Period"). You accept sole responsibility for the proper assembly operation and

regular maintenance of the product. This limited warranty is void if any product is damaged by

accident, misuse, improper installation, or abuse, including tampering or damage in transit. Further,

this limited warranty is void if you sell or otherwise transfer a product to a third party, regardless of

whether the transfer takes place within the Warranty Period.

b. Out liability to you resulting from the sale of any product, including liability for any latent defects found

within the Warranty Period, shall not exceed the total purchase price paid for the product by you.

c. YOU UNDERSTAND AND AGREE THAT WE MAKE NO REPRESENTATIONS OR WARRANTIES OF

ANY KIND, EXPRESS OR IMPLIED AS TO ANY MATTER WHATSOEVER, INCLUDING THE

CONDITION OF THE PRODUCT OR ANY COMPONENT PARTS THEREOF, ITS

MERCHANTABILITY OR ITS FITNESS FOR ANY PARTICULAR PURPOSE AND YOU ACCEPT IT,

"AS IS," "WHERE IS."

d. You also understand that we are not granting any express warranties, other than those stated herein.

These include only those warranties enumerated in paragraph A. a. There are no other express

warranties granted anywhere in these terms and conditions of sale, and you understand and agree to

this fact as part of the bargained for exchange of this sale. Nowhere else, except as stated in this

paragraph, in this contract is there intended, by either party, for there to be any express warranties

granted to you.

e. EXCEPT AS OTHERWISE PROVIDED HEREIN, WE SHALL NOT BE LIABLE FOR DAMAGES,

INCLUDING SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES WHETHER IN CONTRACT

OR IN TORT ARISING OUT OF OR IN CONNECTION WITH THE PERFORMANCE OF ANY

PRODUCT OR ANY COMPONENT PART THEREOF OR ITS USE BY YOU, AND WE SHALL NOT

BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF

OR IN CONNECTION WITH YOUR USE OF THE PRODUCT.

f. The warranty on this product is void if the product is modified, changed, adjusted or damaged. This

product is to be used only in the ways for which it is designed and marketed for, any deviations from

the intended uses will void the warranty and will excuse any possible liability of ours.

g. You accept sole responsibility for the proper assembly, operation and regular maintenance of the

product. This limited warranty is void if the product is damaged, changed, altered, or modified by

accident, misuse, improper installation , or abuse, including tampering or damage in transit or while in

use. YOU HAVE MADE AN INDEPENDENT INVESTIGATION OF THE PURCHASED

COMPONENTS AND HAVE RELIED SOLELY ON YOU OWN INVESTIGATION, BARGAINING AND

JUDGMENT IN REFERENCE THERETO. YOU ACKNOWLEDGE THAT YOU ARE NOT RELYING

ON OUR SKILL OR JUDGMENT TO SELECT OR FURNISH GOODS SUITABLE FOR ANY

PARTICULAR PURPOSE IN PURCHASING OUR PRODUCTS, YOU HAVE NOT RELIED OR

ACTED UPON ANY REPRESENTATIONS OR WARRANTIES ON OUR PART NOT SPECIFICALLY

SET FORTH HEREIN.

h. This limited warranty gives you specific legal rights. You may also have other rights which vary from

state to state. Some states do not enforce contractual limitations on how long an implied warranty

lasts, when an action may be brought, or the exclusion or limitation of incidental or consequential

damages, so the above limitations or exclusions may not apply to you.

B. Modification Strictly Prohibited

You understand and agree that any modification whatsoever , of the product, is strictly prohibited. You

also agree not to modify the product in any manner regardless of whether such modification is

material or immaterial. You also acknowledge that any modification of the product will void your

limited warranty and bar you from any recovery or any remedy in a court of law or equity. Modification

is strictly forbidden unless expressly authorized by our prior written approval. You agree not to make

any modifications to the product and agree not to use any parts, components, or accessories in

connection with the installation and use of the product that are not authorized and approved by us.

C. Indemnity and Release

a. You understand and agree that many factors beyond our control affect the operational safety of the

product, including but not to limited to the installation of the product according to the instructions

provided with the product.

b. You also understand and agree that the installation of the product may involve the use of tools,

equipment and construction methods which may present safety hazards which are beyond our

control. You also understand and agree that the use of some of our products may create hazards and

lower your ability to control your vehicle.

c. You agree, as part of the bargained for exchange, to protect, indemnify, save harmless and release

us, our authorized agents, employees, officers, directors and shareholders from and against all

liabilities, obligations, claims, damages, penalties, causes of action, costs and expenses, imposed

upon or incurred by or asserted against us or any assignees of ours, by you or any third party by

reason of the occurrence or existence (or alleged occurrence or existence) of any use, installation,

assembly, possession or operation of the product, any loss, damage or destruction of the product as

of and after delivery(a "casualty occurrence"), and any other act or event relating to or caused by the

product, including but not limited to, consequential or of the terms and conditions hereof, or any and

all liability for property loss or damage, or any and all damage resulting from death or personal

injuries, including loss of services which any person may sustain on account of, arising out of, or in

connection with any use, maintenance, possession or operation of the product. In the event that any

action, suit or proceeding is brought against us or any of our authorized agents, employees, officers,

directors or shareholders by reason of any such occurrence, you will, upon our request and at your

expense, resist and defend such action, suit or proceeding or cause the same to be resisted and

defended by counsel designated and approved by us.

Racer Gauge Φ52,Φ60 Operation Manual

■

Issue First edition: September, 2011 Second edition: July, 2012

■

ManufacturerNippon Seiki Co., Ltd.

■

Contact Information Nippon Seiki Co., Ltd. Defi Business Division

【Address】 190-1 Fujihashi 1-chome, Nagaoka-shi, Niigata 940-2141 JAPAN

【URL】 http://www.defi-shop.com/

Patent pending PAT. 3624865 PAT. 3365604

Loading...

Loading...