Page 1

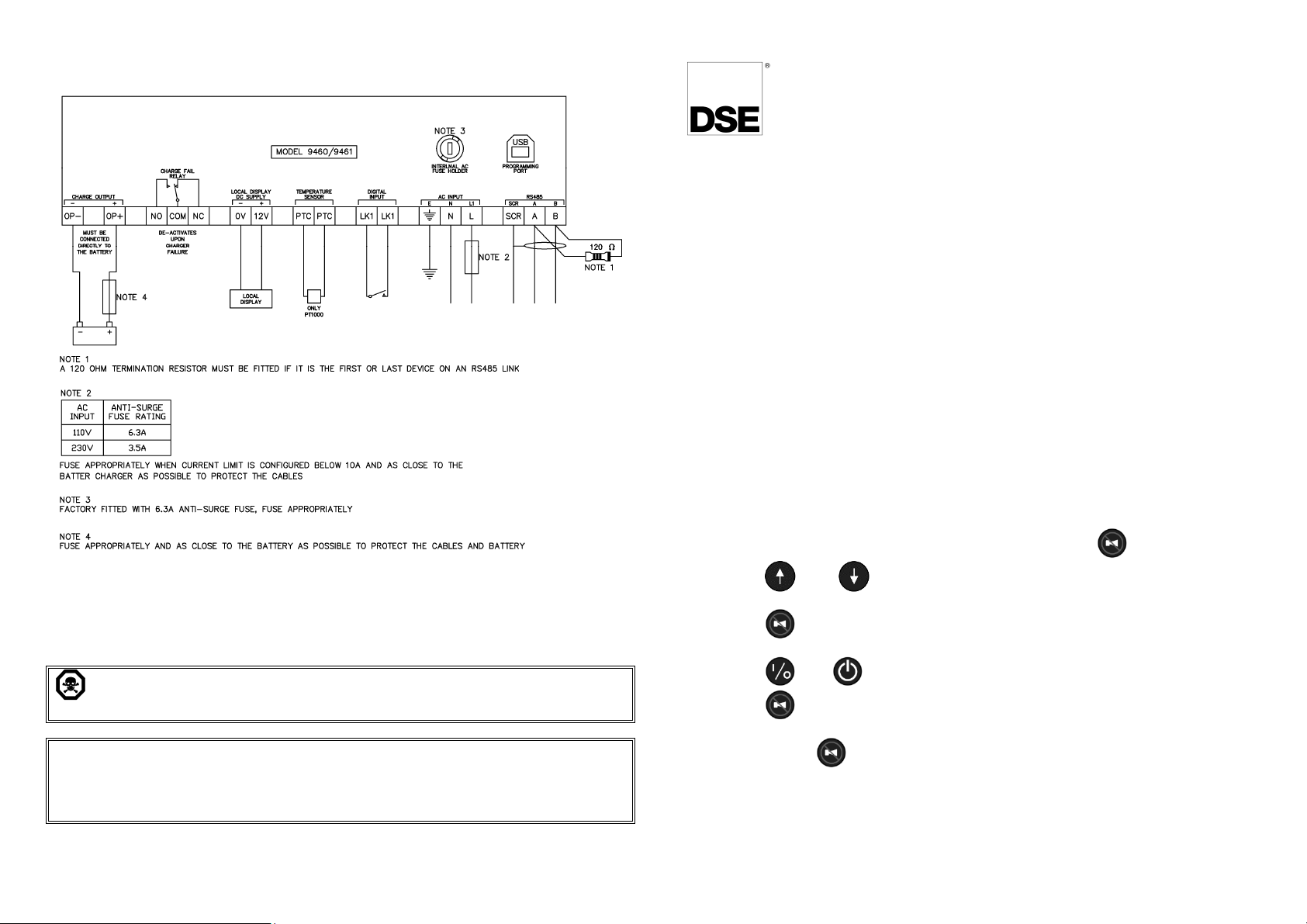

TYPICAL WIRING DIAGRAM

Deep Sea Electronics Inc.

DEEP SEA ELECTRONICS

053-147

ISSUE 4

DSE9460 & DSE9461

INSTALLATION INSTRUCTIONS

INSTALLATION

The battery chargers are wall mounted via four holes on the back of the enclosure. Dimension and

mounting details are given overleaf.

The battery charger is fit-and-forget. It can be permanently connected to the supply and the load, with

no requirement to disable the charger during times of heavy load (such as engine cranking) or when in

parallel with a charging alternator.

BATTERY SUITABILITY

The battery charger is factory set by DSE to suit Lead Acid batteries but can be adjusted to suit other

battery types using the Configuration Suite PC Software.

Care must be taken to ensure the batteries connected to the charger are of the correct ‘technology’ to

suit the setting of the charger.

INDICATIONS

The Battery Charger features an LCD display and depending on the variant, additional voltage and

current meters may be fitted.

BOOST MODE

Boost mode is operated automatically or by activation of the digital input (if configured to perform this

function). This raises the battery charger voltage to the boost voltage setting

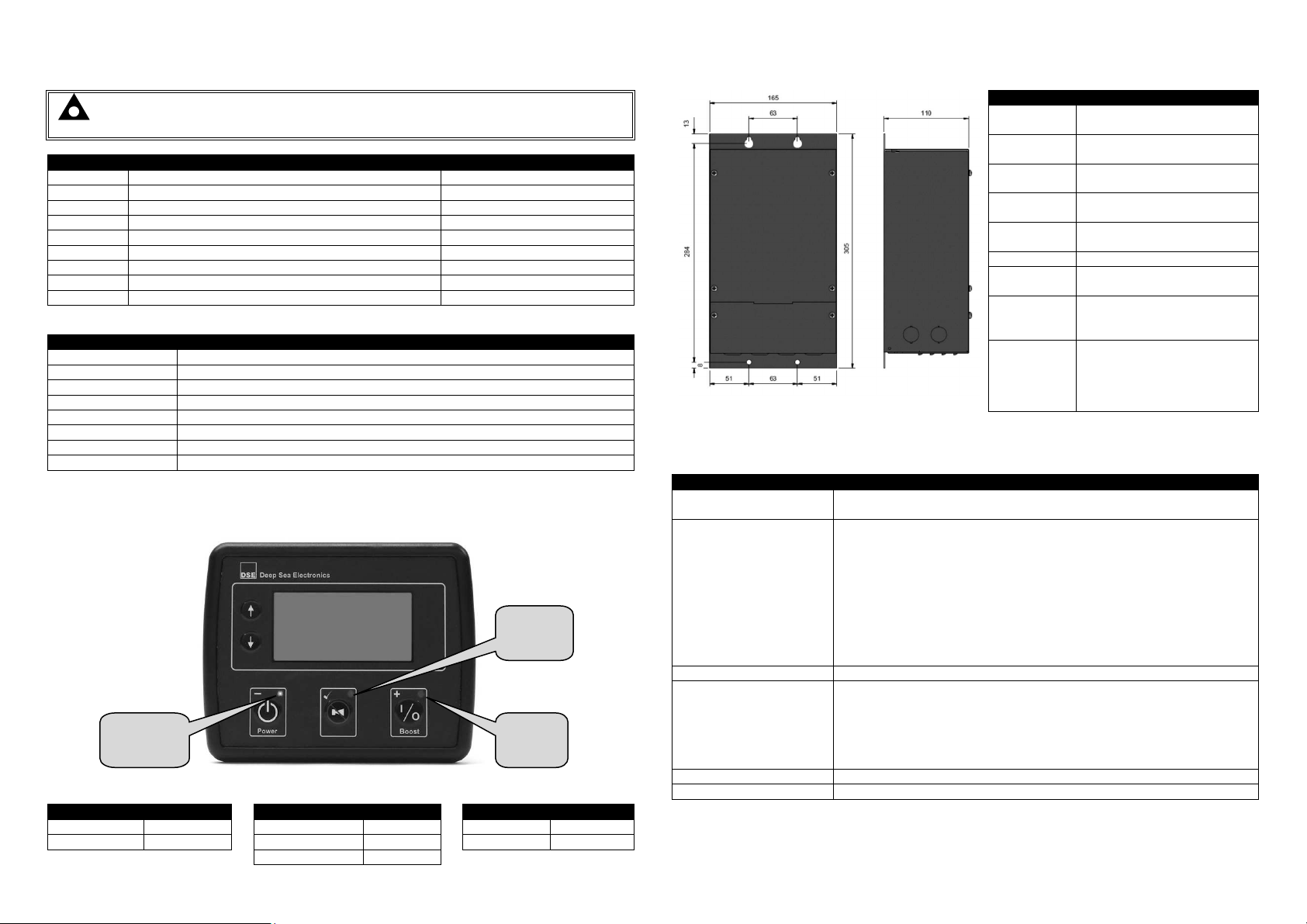

ACCESSING THE FRONT PANEL EDITOR

.

DANGER OF DEATH: LIVE PARTS exist within the enclosure. The enclosure cover must

not be removed when connected to an AC supply

Deep Sea Electronics Plc.

Tel:+44 (0)1723 890099

Fax: +44 (0)1723 893303

Email: support@deepseaplc.com

Web: www.deepseaplc.com

Tel: +1 (815) 316 8706

Fax: +1 (815) 316 8708

Email: support@deepseausa.com

Web: www.deepseausa.com

• The Front Panel Editor (FPE) is accessed by pressing and holding the () button.

• Press the (up) or (down) button to cycle through the Adjustable Parameters listed

overleaf.

• Press the () button to edit a parameter when it is being viewed on the screen. The value

flashes to show edit mode is in progress.

• Press the (+) or (-) button to change the parameter to the required value.

• Press the () button to save the currently selected value. The value ceases flashing to show

editing is complete.

• Press and hold the () button to exit the editor

Page 2

ADJUSTABLE PARAMETERS

Index

Parameter

Value

Value

Home Page List

CHARGER STATUS

FAULT STATUS

BOOST MODE

Condition

LED State

Condition

LED State

Condition

LED State

Parameter

Comment

Parameter

Comment

•

•

Fault

DIMENSIONS AND MOUNTING

NOTE: On later versions of the DSE2541 display, only parameters 100 to 108 are available

for configuration.

100 Contrast 0 %

101 Temperature Units °C, °F

102 Slave ID 1 to 255

103 Baud Rate 4800 to 115200

104 Enable Alarm Popup Screen Enable, Disable

105 Home Page Configuration 0 to 8 (Home Page List)

106 Home Page Timeout 0 s

107 Sleep Mode Timeout 0 s

108 Enable Engineering Page Enable, Disable

Parameter 105 – Home Page Configuration has the following possible selections:

0 Analogue Meters

1 Output Voltage And Current

2 Output Power And Battery Charger Temperature

3 Battery Sensed Voltage And Battery Temperature

4 Mains AC Voltage And Frequency

5 Battery Charger Model And Charger Software Version

7 Control Page

8 Alarms Page

DISPLAY LED INDICATIONS

Status

Charger

Status

Charger Off Off No Fault Off Boost Off Off

Charger On On Warning Fault On Boost On On

Shutdown Fault Flashing

Boost

Mode

Cabinet

Type

Overall Size

Material

Surface

Finish

Protection

Category

Weight 2.3 kg (5 lb 1 oz)

Mounting

Type

Mounting

Holes

Operating

Temperature

(With

Deratings)

Custom cabinet for indoor

use only

165 mm X 305 mm X 110 mm

(6.5 ” X 12.0 ” X 4.3 ”)

Sheet steel enclosure of allround solid construction

Powder-coated black

IP20, NEMA 1

Wall mounted with terminals

to bottom.

Diameter 6 mm (0.2 ”)

63 mm X 284 mm

(3.4 ” x 11.2 ”) centres

-30 °C to +80 °C

(-22 °F to +176 °F)

Measurements in mm

REQUIREMENTS FOR UL CERTIFICATION

Screw Terminal

Tightening Torque

Conductors

Communication Circuits Must be connected to communication circuits of UL Listed equipment

Mounting

Operating Temperature -22 ºF to +131 ºF (-30 ºC to +55 ºC)

Storage Temperature -40 ºF to +176 ºF (-40 ºC to +80 ºC)

4.5 lb-in (0.5 Nm)

Terminals suitable for connection of conductor size 12 AWG – 26 AWG

(0.5 mm² to 2.0 mm²).

• Conductor protection must be provided in accordance with NFPA 70,

Article 240

• Low voltage circuits (35 V or less) must be supplied from the engine

starting battery or an isolated secondary circuit.

• The communication, sensor, and/or battery derived circuit conductors

shall be separated and secured to maintain at least ¼” (6 mm)

separation from the generator and mains connected circuit conductors

unless all conductors are rated 600 V or greater.

Suitable for use in type 1 Enclosure Type rating with surrounding air

temperature -22 ºF to +131 ºF (-30 ºC to +55 ºC)

• Suitable for pollution degree 3 environments when voltage sensing

inputs do not exceed 300 V. When used to monitor voltages over 300 V

device to be installed in an unventilated or filtered ventilation enclosure

to maintain a pollution degree 2 environment.

Loading...

Loading...