Page 1

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

Wall-hung gas condensation boilers

English

08/06/06

Technical

instructions

Page 2

Contents

Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Symbols used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Important recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1 Package list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2 Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

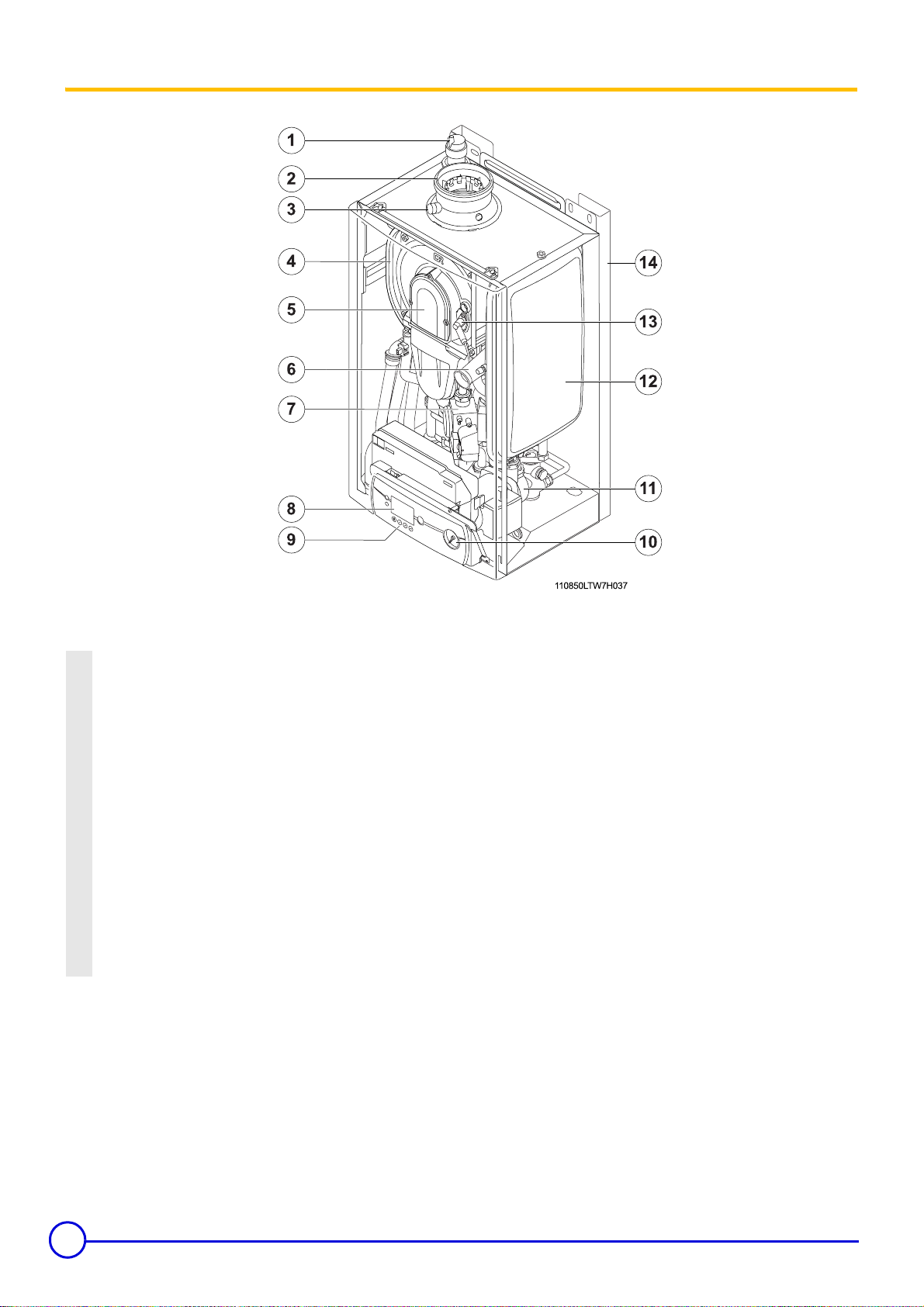

3 Main parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

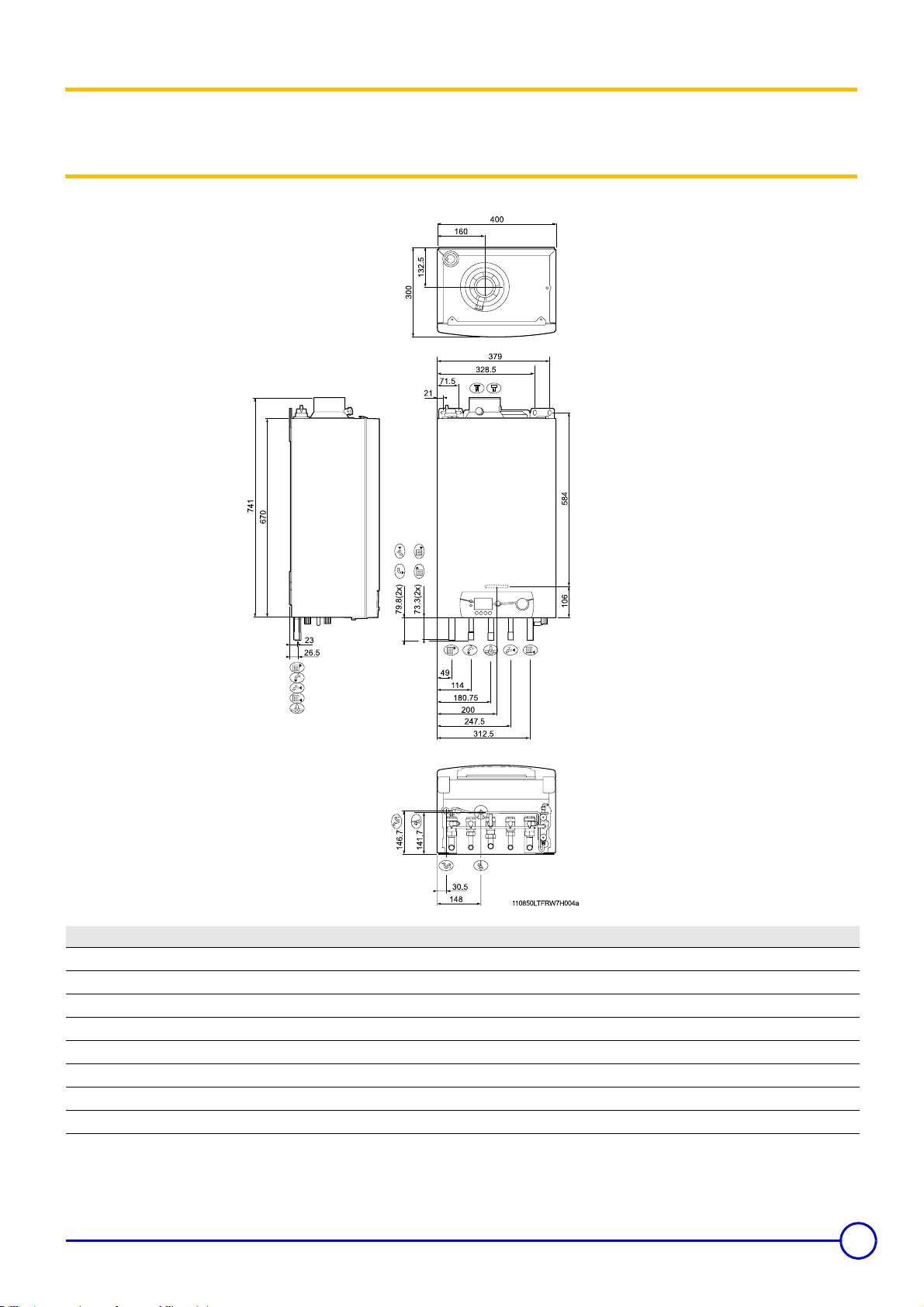

Main dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1 Package list (Standard delivery). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2 Serial number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3 Mounting frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4 Boiler installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

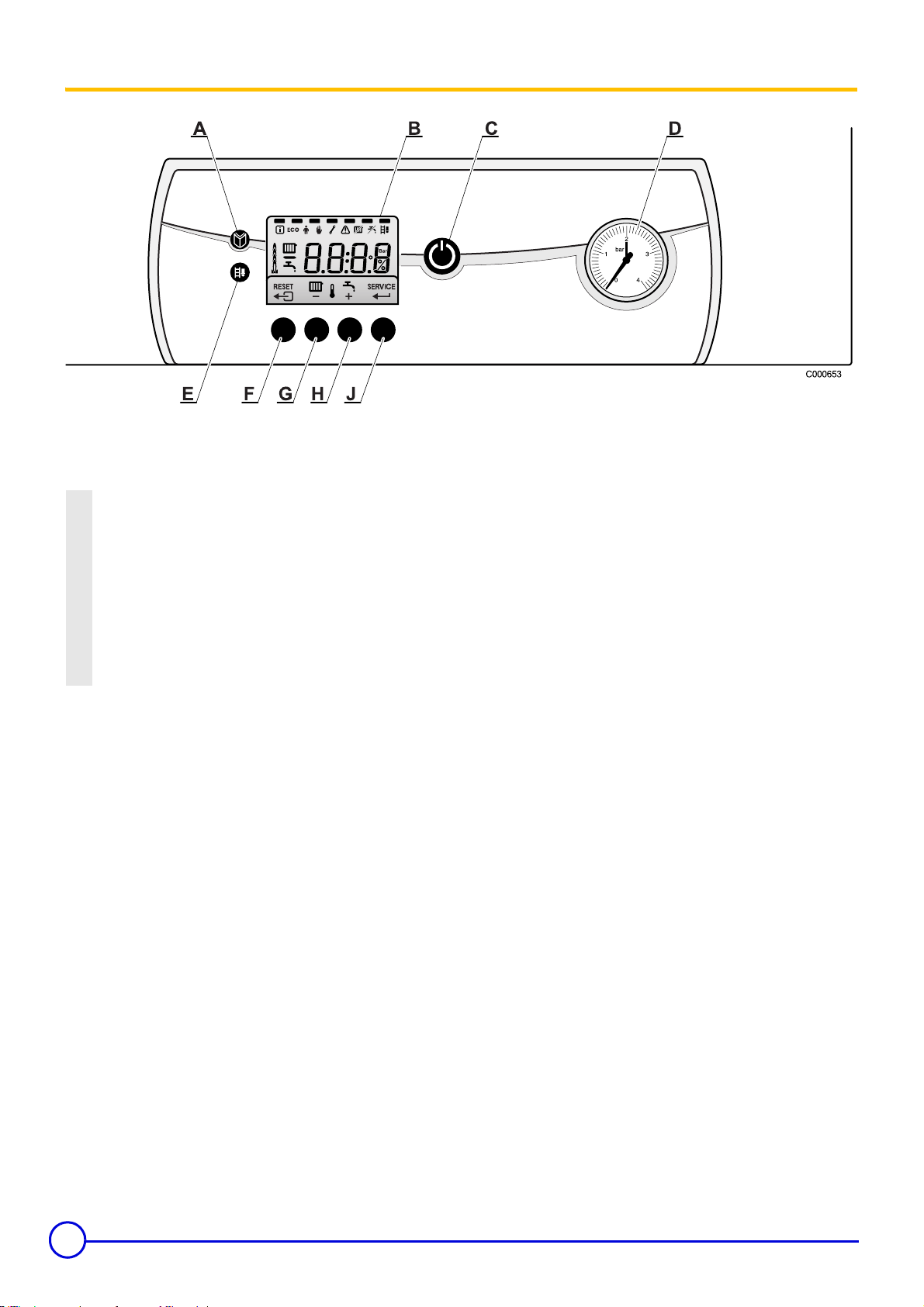

1 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2 Parameter display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Hydraulic specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

1 Boiler pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2 Expansion chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

1 Water treatment and connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

2 Connecting the options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3 Connecting the external controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

4 Connection of the domestic hot water sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

5 Antifreeze protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6 Safety contact. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

7 Connection of a remote alarm transfer and boiler operation indication system (Not proposed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

8 Pump logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Commissionning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

1 Commissionning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

2 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Adapting to another gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

1 Switching from Natural Gas to Propane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

2 Setting the control unit parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

1 Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

2 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Breakdown codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Spare parts - MCR 24, 24/28 MI, 30/35 MI, 34/39 MI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 3

Declaration of compliance

1

Declaration of compliance A.R. 8/1/2004 - BE

Manufacturer DE DIETRICH THERMIQUE S.A.S.

57 rue de la Gare

F - 67580 MERTZWILLER

+33 3 88 80 27 00

*

+33 3 88 80 27 99

+

Issued by See end of notice

We hereby certify that the series of appliances specified hereinafter is in compliance with the standard model described in the EC declaration

of compliance, and that it is manufactured and marketed in compliance with the requirements and standards of the following European

Directives:

Product type Wall-hung gas boilers

Formats MCR 24

MCR 24/28 MI

MCR 30/35 MI

MCR 34/39 MI

Standard applied - 90/396/EEC Gas Appliance Directive

Reference Standards : EN 437; EN 483; EN 625; EN 677

- 73/23/EEC Low Voltage Directive

Reference Standards : EN 60.335.1

- 89/336/EEC Electromagnetic Compatibility Directive

Generic standards : EN1000-6-3 ; EN 61000-6-1

- 92/42/EEC Efficiency Directive ****

Inspecting organisation Gastec (Netherland)

Values: Standards EN 297 A3 NOx < 114 (mg/kWh) 65 ppm; CO < 65 (mg/kWh) 65 ppm

Date 22/06/04

Signature Technical Director

Mr Bertrand SCHAFF

1

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

3

Page 4

Symbols used

Caution danger

Risk of injury and damage to equipment. Attention must be

paid to the warnings on safety of persons and equipment

Important information

Information must be kept in mind to maintain comfort

Important recommendations

MCR boilers must be installed :

- in a frost-free room;

- as close as possible to draw-off points in order to minimise energy

losses through the pipes.

Installation must be carried out in accordance with the prevailing

regulations, the codes of practice and the recommendations in these

instructions.

Keep this document close to the place where the tank is

installed.

The first start-up is to be performed by your installation engineer.

Only original spare parts must be used.

Any intervention on the appliance and heating equipment must be

carried out by a qualified technician. Please confirm to the user of the

installation that you have carried out a leak tightness check on the

gas circuit.

For the application of article 25 of the modified decree dated 02/08/

1977 and of article 1 of the modifed decree dated 05/02/1999, the

installation engineer must be in possession of the certificates of

compliance approved by the Ministries in charge of construction and

gas safety.

Any work on the gas valve unit is authorised only if carried out

by a qualified professional.

Reference

Z

Refer to another manual or other pages in this instruction

manual

DHW:Domestic hot water

The manufacturer is not liable for any improper use of the

appliance or failure to maintain or install the unit correctly

(the user shall take care to ensure that the system is

installed by a qualified fitter).

Work on electrical equipment must be carried out by a qualified

professional in compliance with the prevailing legislation.

We shall not accept any responsibility for any damage and

disturbance arising from not following these instructions.

Service the appliance regularly to ensure that it operates

correctly.

Belgium

The installation and maintenance of the boiler must be done by a

qualified professional in compliance with the prevailing local and

national regulations.

The boiler is preset in the factory to operate on natural gas.

It is formally prohibited to interfere with the gas block.

Other countries

The installation and maintenance of the boiler must be done by a

qualified professional in compliance with the prevailing local and

national regulations.

For Belgium: The operations required to switch from one gas

to another must be carried out by a SERV'elite technician.

Prior to commissioning, compare the factory settings of the appliance

with the local power supply conditions. If the settings have to be

modified, this must be carried out by a qualified professional.

Condensation boilers require a flue gas evacuation system or a fresh

air inlet specially adapted to the method of operation. Its execution

depends on the place of installation and the building.

Compliance with a minimum distance between the flue gas

evacuation system in forced flue mode or the boiler with combustible

substances is not necessary (For Belgium: Comply with the NBN

B61-002 standard). At nominal output, the temperature of the

components does not exceed 85 °C.

4

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 5

Description

MCR boilers are gas condensing boilers; they handle :

- central heating using radiators or underfloor heating

(MCR 24);

- central heating and instant domestic hot water production

(MCR ... MI).

The boilers operate on natural gas or propane. They are factory set

for natural gas H.

If converting to propane :

See "Adapting to another gas"

Z

The MCR 24 boiler can be connected to a 80 or 130 litre tank to

produce domestic hot water.

For Belgium: Any intervention on the gas valve unit is

strictly forbidden.

For use with natural gas L or propane, it is necessary to adjust the

boiler.

Boilers MCR 24 MCR 24/28 MI MCR 30/35 MI MCR 34/39 MI*

No. CE PIN 0063BQ3009

B

Type

Flue gas evacuation Forced flue

Ignition Automatic

Gas Natural gas / Propane

23P

, B33, C

13(x)

, C

33(x)

, C

43(x)

, C53, C

63(x)**

, C

83(x)

* Italy: Not proposed ** Except Belgium

1 Package list

- Boiler package with mounting frame. Can be used to make the

water, gas and water evacuation connections: Safety valve,

- Accessories package, dependent on the type and length of the

forced flue

disconnector, condensates run-off.

2 Certifications

User country FR ES, GB, GR, IE, IT, PT BE PL

Category

Gas

Supply pressure

User country CZ HU RO, SI

Category

Gas

Supply pressure

II

2Esi3P

GN H Propane GN H Propane G20/25 E (G20) Ls

GN L G31 Lw G31

20 mbar 37 mbar 20 mbar 29 mbar 20/25 mbar 20 mbar 13 mbar

25 mbar 37 mbar 20 mbar 36 mbar

II

2H3P

GN H Propane GN H Propane G20

20 mbar 50/29 mbar 25 mbar 28-30/50 mbar 20 mbar

30/37/50 mbar 30 mbar

II

2H3P

II

2H3P

I

2E(S)B

, I

3P

II

2ELwLs3P

II

G31

2H3P

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

5

Page 6

3Main parts

Automatic bleed valve

1.

Smoke nozzle

2.

Outlet for measuring combustion hygiene

3.

Heat exchanger

4.

Air/gaz canal

5.

Fan air inlet

6.

Gas block

7.

Display

8.

Control panel

9.

Pressure gauge

10.

Circulating pump

11.

Expansion chamber (only for MCR 24,MCR24/28 MI,MCR 30/35 MI)

12.

Ignition/ionisation electrode

13.

Stand off mounting frame (optional)

14.

Expansion chamber (optional): only for MCR 34/39 MI

6

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 7

4 Technical data

Boilers MCR 24 MCR 24/28MI MCR 30/35MI MCR 34/39MI

Nominal useful output 40/30 (Heating mode) (min./max) kW 6.3/25 6.3/25 6.6/31.3 6.8/35.5

Nominal useful output 80/60 (min./max) kW 5.5/23.6 5.5/23.6 5.7/29.5 5.9/33.3

Nominal useful output (DHW mode) (min./ max) kW - 27.4 34.3 38.2

Nominal input power (heatin g an d DH W modes) kW 24/24 24/28 30/35 34/39

Minimum useful output 40/30 (Heating mode) kW 6.3 6.3 6.6 6.8

Minimum input power (heating and DHW modes) kW 5.8 5.8 6.1 6.3

Gas flow rate à Pn (à 15°C - 1013 mbar):

Natural gas H

Natural gas L

Propane

PCI efficiency, Load and water temperature efficiency:

100% Nominal power, Average temperature: 70°C

100% Nominal power, Return temperature: 30°C

30% Nominal power, Return temperature: 30°C

Maximum temperature (Safety thermostat cut-off) °C 110 110 110 110

Losses when off (∆T = 30 °C) W30302928

Losses through the outer casing % 1.1 1.1 0.9 0.5

Water capacity l 1.7 1.8 2 2.2

Weight without water, without mounting frame, without cladding kg 29 30.5 32 31.5

kW

3

m

3

m

Kg/h

%

%

%

/h

/h

24

2.4

2.8

1.9

98.3

104.4

108.7

Specifications of the heating circuit

Nominal water flow (∆T = 20 K) l/h 1.03 1.03 1.29 1.47

Rated net head (∆T = 20 K) mbar >200 >200 >200 >200

Flow temperature °C 75 75 75 75

Maximum pressure bar3333

Expansion chamber l8 8 8 -

Initial pressure of the expansion tank bar1111

Minimum operating pressure bar 0.8 0.8 0.8 0.8

Domestic hot water specifications

Instruction set outlet temperature °C 55 55 55 55

Specific hot water flow (∆T = 30 K) l/min - 14 16 19

Nominal max cold water pressure bar8888

Minimum pressure (11 l/min) bar - 1.4 0.4 0.4

Combustion products circuit

Connecting

Mass flue gas flow rate (min./max) Kg/h 10/40 10/47 10/59 10/62

Flue gas temperature 80/60 °C 78 78 74 71.5

Pressure available at the flue gas nozzle Pa 50 100 100 140

Condensation water pH 50/30 - 1-7 1-7 1-7 1-7

diameter

(mm)

60/100 60/100 60/100 60/100

Electrical specifications

Power supply voltage (50 Hz) V 230 230 230 230

Power consumption W 115 115 150 180

Electrical output circulating pump W 90 90 125 135

Auxiliary electrical output (Nominal power, ex circulating pump) W25252545

Insulation class IPX4D IPX4D IPX4D IPX4D

24

2.4

2.8

1.9

98.3

104.4

108.7

35

3.5

4.1

2.7

98.2

104.4

109.7

39

3.9

4.5

3.0

98

104.4

110.5

1 mbar = 100 Pa - 1 daPa ~ 1 mm H

O

2

Cold water temperature: 10 °C; Domestic hot water temperature:

85 °C

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

7

Page 8

Main dimensions

1 Package list (Standard delivery)

• France + Other countries

Boiler package Forced flue package

Boilers

MCR 24 HG1 DY847 CX50

MCR 24/28MI HG2 DY847 CX50

MCR 30/35MI HG3 DY847 CX50

MCR 34/39MI HG4 DY847 CX50

• Belgium

Boiler package Forced flue package

Boilers

MCR 24 BE HG5 DY847 CX50

MCR 24/28MI BE HG6 DY847 CX50

MCR 30/35MI BE HG7 DY847 CX50

MCR 34/39MI BE HG8 DY847 CX50

Horizontal

(diameter 60/100)

Horizontal

(diameter 60/100)

Vertical

(diameter 80/125)

Vertical

(diameter 80/125)

2 Serial number

The serial number can be found on the boiler's rating plate.

C000655

8

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 9

3 Mounting frame

A stand off frame is an option for easy and fast upward piping behind the boiler; a pipework kit is an option for a upward piping in

combination with the stand off frame.

4 Boiler installed

MCR 24

France + Other countries Belgium + Germany + Poland

Return connection (Inside diameter 18 mm) Return connection (External diameter 22 mm)

Flow connection (Inside diameter 18 mm) Flow connection (External diameter 22 mm)

Gas connection (Inside diameter 18 mm) Gas connection (External diameter 22 mm)

Combustion air inlet (diameter 100) Combustion air inlet (diameter 100)

Flue gas discharge duct (diameter 60) Flue gas discharge duct (diameter 60)

Return storage tank (Inside diameter 16 mm) Return storage tank (External diameter 15 mm)

¢ Outlet storage tank (Inside diameter 16 mm) ¢ Outlet storage tank (External diameter 15 mm)

Condensates evacuation pipe (3/4") Condensates evacuation pipe (3/4")

º Safety valve (diameter 15) º Safety valve (diameter 15)

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

9

Page 10

MCR 24/28MI, 30/35MI, 34/39MI

France + Other countries Belgium + Germany + Poland

Return connection (Inside diameter 18 mm) Return connection (External diameter 22 mm)

Flow connection (Inside diameter 18 mm) Flow connection (External diameter 22 mm)

Gas connection (Inside diameter 18 mm) Gas connection (External diameter 22 mm)

Combustion air inlet (Ø 100 mm) Combustion air inlet (Ø 100 mm)

Flue gas discharge duct (Ø 60 mm) Flue gas discharge duct (Ø 60 mm)

Return storage tank (Inside diameter 16 mm) Return storage tank (External diameter 15 mm)

¢ Outlet storage tank (Inside diameter 16 mm) ¢ Outlet storage tank (External diameter 15 mm)

Condensates evacuation pipe (3/4") Condensates evacuation pipe (3/4")

º Safety valve (Ø 15 mm) º Safety valve (Ø 15 mm)

10

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 11

MCR boilers are equipped with a control panel with electronic

regulation including security and flame surveillance by ionisation

probe.

The boiler is not sensitive to phase reversal. The normal maximum

absorbed power is between 115 W and 130 W. The boiler is entirely

pre-wired. All external connections can be made with terminal block

X9.

Boiler MCR power can be regulated in several ways:

Dry contact room thermostat (Commutation without power): The

boilers internal control will modulate the output to achieve the flow

temperature set point of the boiler. The contact is on the X9 terminal

strip (low voltage only).

All connections on terminal block X1,X2,X4,X5,X6,X7 are in

230 V.

All connections on terminal block X9 are low voltage only.

The MCR is a modular boiler whose temperature can be regulated

using one of the following solutions:

- Regulation as a function of room temperature:

- Easymatic,Easyradio communicating room regulation + Interface

PCB (AD 221)

- Regulation: Outside sensor alone

- Regulation as a function of the outside temperature + Outside

sensor alone:

- Easymatic,Easyradio + Outside sensor + Interface PCB (AD 221)

- Regulation as a function of the outside temperature with a 3channel valve circuit:

- Easymatic or Easyradio + Outside sensor + Interface PCB (AD

222)

Operation

The MCR boiler is fitted with an electronic temperature regulator with

outlet and return temperature sensors. The outlet temperature can be

set between 20 and 85. The boiler increases or lowers power as a

function of instructions.

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

11

Page 12

1 Control panel

The control panel of the MCR boiler has 6 function keys, an on/off

switch and a screen. The function keys are used to read or modify

parameters and temperatures.

A Menu key

BDisplay

C Main ON/OFF switch

D Pressure gauge

E Sweep key

F "Escape" or "Reset" key

G Heating temperature adjustment key or -

H DHW temperature adjustment key or +

J Maintenance key or enter

The display includes 4 positions and several symbols which indicate

the operating status of the control panel and any disturbances.

Figures, points and/or letters may be displayed.

The symbols located above the function keys indicate their current

function.

Pressing on any key will display the current status of the boiler and

the current command code. If there is a malfunction, the

corresponding code continues to be displayed.

12

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 13

2 Parameter display

The following parameters can be displayed in the information menu

:

- t1 = Flow temperature (°C)

- t2 = Return temperature (°C)

- t3 = Tank sensor (°C)

- t4 = Outside temperature (°C)

- FL = Ionisation current (µA)

- nF = Fan speed (rpm)

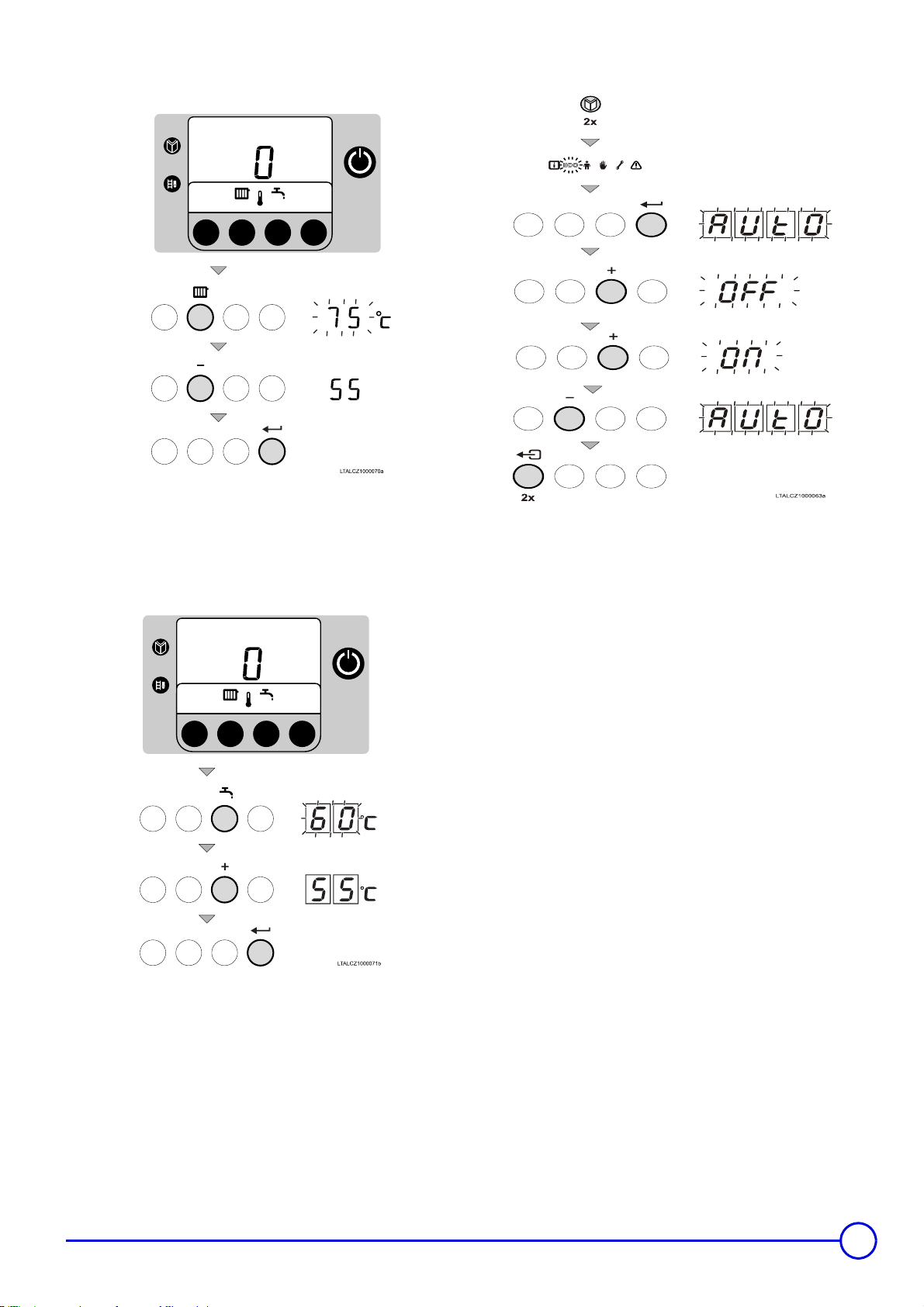

2.1 Setting the manual mode ()

- Press the Ä key. The symbol flashes. To access the

parameters, press key l.

- Press the + key successively to scroll down the various

parameters.

- Press key Ä several times until the symbol flashes on the

menu bar.

- Press the l key. The minimum outlet temperature P1 or the text

Auto is displayed if an outside temperature sensor is installed.

- Press the + key to increase the outlet temperture manually.

- To confirm, press the l key.

The installation is in manual mode.

- Press key 1 time to deactivate the manual mode.

- Press key 1 time to return to the current operating mode.

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

13

Page 14

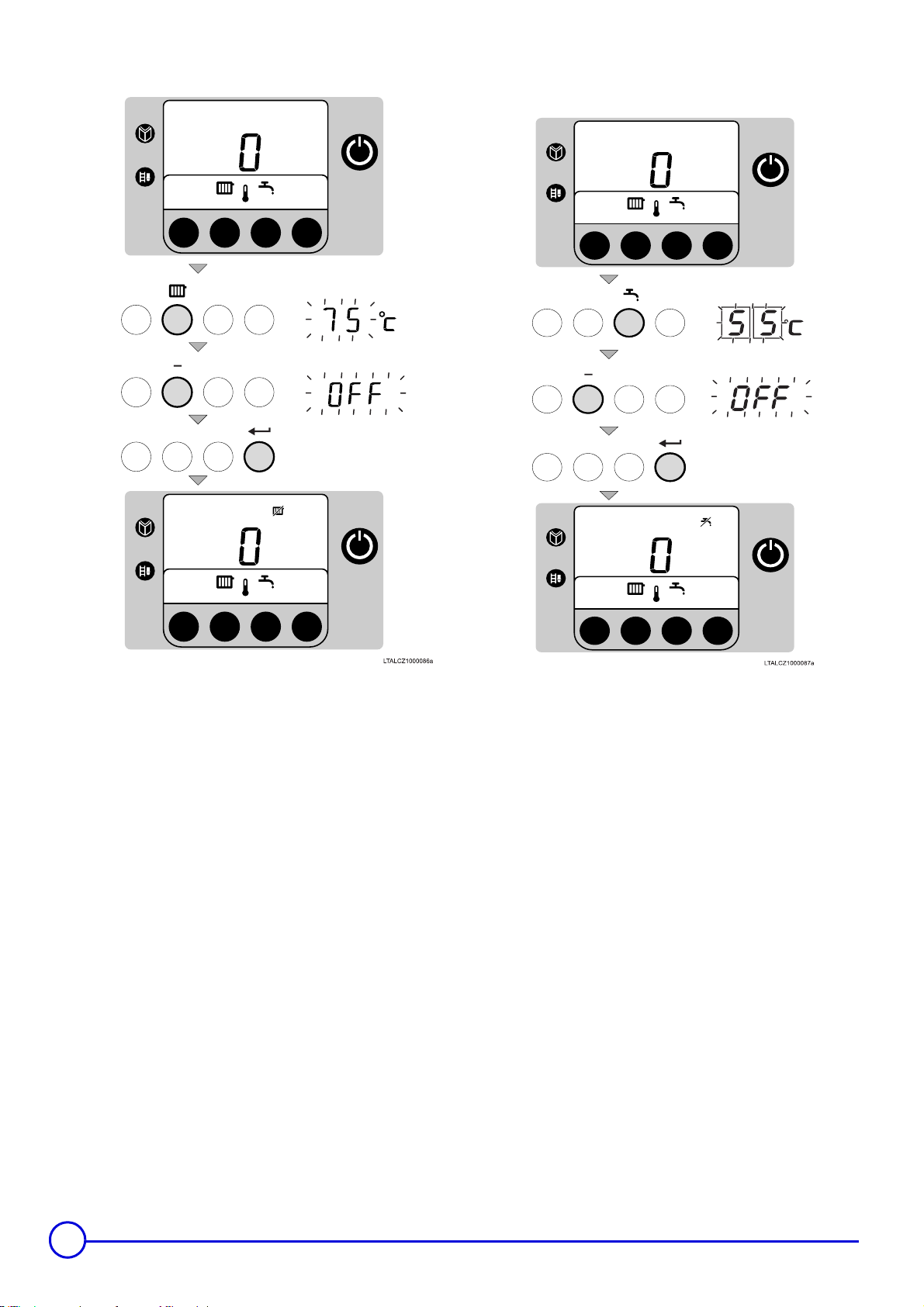

2.2 Switching off the central heating (In summer mode)

2.3 Switching off the domestic hot water()

- Starting from the current operating status, press key .

- The symbol and the current temperature are displayed.

- Press the - key until the OFF symbol is displayed.

- Press the l key to modify the setting.

- The symbol appears.

production of domestic hot water: activated.

- Starting from the current operating status, press key .

- The symbol and the current temperature are displayed.

- Press the - key until the OFF symbol is displayed.

- Press the l key to modify the setting.

- The symbol appears.

14

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 15

2.4 Modifying the water outlet temperature in the heating

installation

- Starting from the current operating status, press key .

- The symbol and the current temperature are displayed.

- Press the + or - key to modify the value.

- To confirm, press the l key.

2.5 Setting the domestic hot water temperature

2.6 Modifying the comfort setting (ECO)

The user can consult or modify the following 3 settings:

- ON = Activation of the energy-saving setting.

- OFF = Activation of the comfort setting

- AUTO = Setting dependent on the control unit (=Factory setting).

- Press the Ä key. The symbol flashes.

- Press the Ä key a second time. The symbol ECO flashes.

- To confirm, press the l key.

- The current operating status is shown on the display: ECO.

- Press the key to return to the ECO menu or press the + key

to modify the status.

- To confirm, press the l key.

- Press key 1 time to return to the current operating mode.

In ECO mode: I

If the ECO mode is set to I, when the boiler is used with an

external hot water tank, the water is not heated. If the hot water

tank is empty, the tap water will therefore be cold.

In Auto mode

If the setting is on Auto and the control unit is fitted with a ECO

function, the appliance adapts to the control unit setting.

For example: The ECO setting is tripped at night during reduced

temperature operation.

- Starting from the current operating status, press key .

- The symbol and the current temperature are displayed.

- Press the + or - key to modify the value.

- To confirm, press the l key.

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

15

Page 16

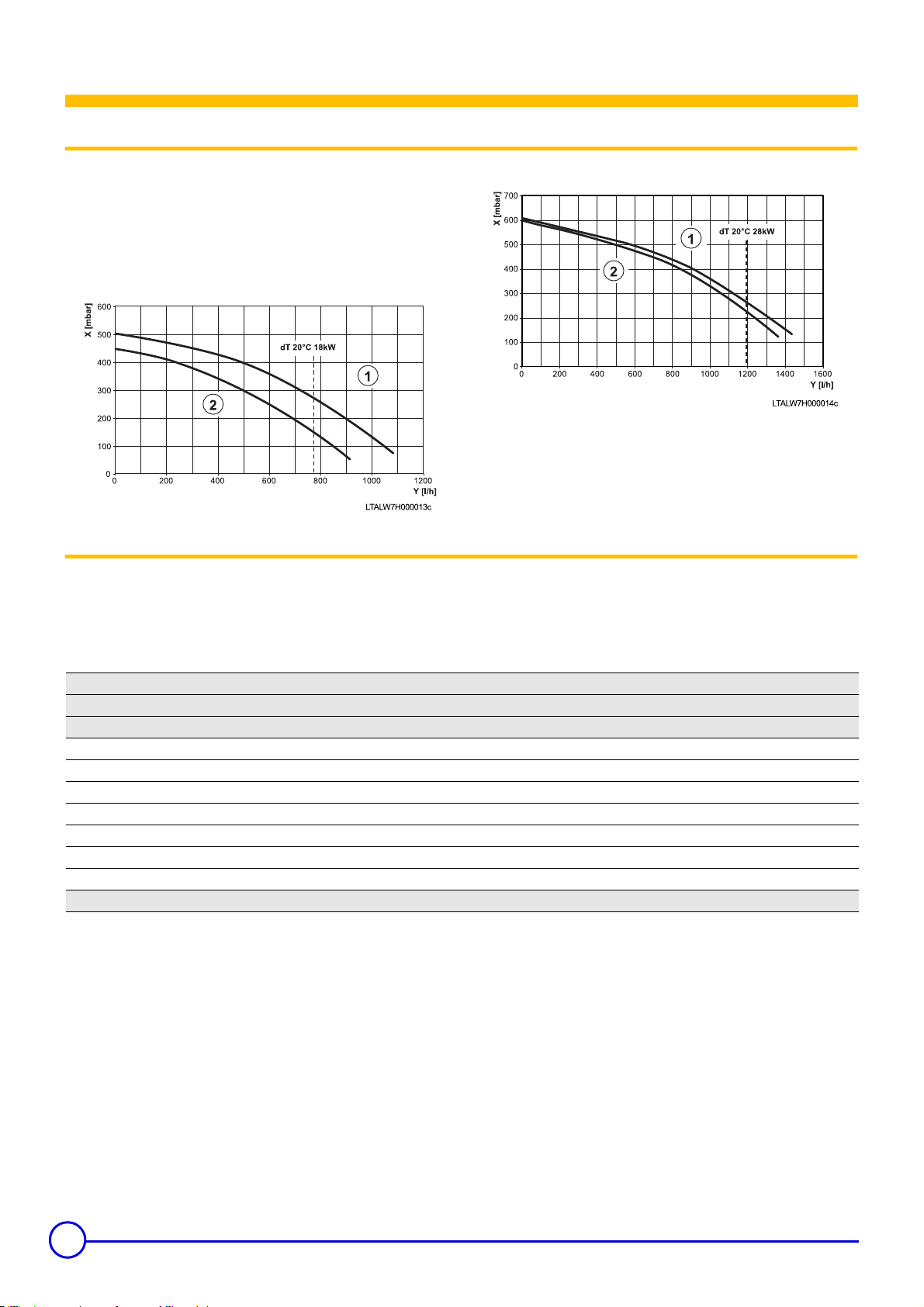

1 Boiler pump

Hydraulic specifications

Depending on the flow, the following diagrams represent::

manometric heights available at boiler outlet.

For a fixed flow, the manometric height available at the boiler outlet

is obtained by taking the difference between the manometric height

of the circulator pump and the loss of load in the boiler.

• MCR 24, MCR 24/28 MI

2 Expansion chamber

The boiler is fitted as standard with an 8-litre expansion tank (except

MCR34/39 MI) (Initial pressure of the expansion tank 1 bar). The total

water volume is determined according to the static height of the

installation and for an average water temperature of 80°C (Outlet :

80; Return : 60).

• MCR 34/39 MI

X: Rated net head

Y: Flow rate

: High manometric pump

: Low pressure pump

Pressure: Safety valve 3

Initial pressure of the expansion tank (bar) 0.5 1 1.5

Total water volume (litres) Volume of the expansion vessel (litres)

100 4.8 8 13.3

125 6 10 16.6

150 7.2 12 20

175 8.4 14 23.3

200 9.6 16 26.6

250 12 20 33.3

300 14.4 24 39.9

To obtain other volumes, multiply the volume of the system by one of the factors: 0.048 0.080 0.133

If the water volume is greater than 100 litres or the static height of the

system exceeds 5 metres, an additional expansion tank must be

fitted.

16

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 17

Installation

Residential buildings for France

Statutory terms and conditions of installation and maintenance

The installation and maintenance of the appliance must be carried

out by a qualified professional in compliance with the statutory texts

of the codes of conduct in force, particularly :

- Order of 2 August 1977

Technical and safety rules applicable to combustible gas and

liquefied hydrocarbon installations situated inside residential

buildings and their annexes.

- NF P 45-204 standards

Gas installation, (formerly DTU 61-1, gas installations: April 1982,

addendum no 1: July 1984).

- Local Sanitary Regulations

For appliances connected to the electricity network:

- NF C 15-100 standards Low voltage electrical installation - Rules.

Establishments open to the public (France)

Statutory terms and conditions of installation

The installation and maintenance of the appliance must be carried

out in compliance with the statutory texts and rules of the codes of

conduct in force, particularly:

- Safety regulations against fire and panic in establishments open to

the public:

a. General regulations

For all appliances:

- Articles GZ - Installations operating on combustible gases and

liquefied hydrocarbons

Then, depending on use:

- Articles CH-Heating, ventilation, refrigeration, air conditioning and

production of steam and domestic hot water

b. Instructions specific to each type of establishment open to

the public (hospitals, stores, etc.)

Belgium

The boiler installation and gas connection must be carried out by a

qualified professional in compliance with the NBN D 51.003, NBN D

30.003, NBN B 61.001, NBN B 61.002 and NBN D 51.006 standards.

An ARGB approved stop valve must be fitted in the pipe leading to

and close to the boiler.

Electrical connections must comply with the instructions in the

general regulations on electrical installations (RGIE).

Belgium:the cross-section of the aeration vents, which are

compulsory in the room in which the boiler is installed, must comply

with the NBN D 51-003 standard.

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

17

Page 18

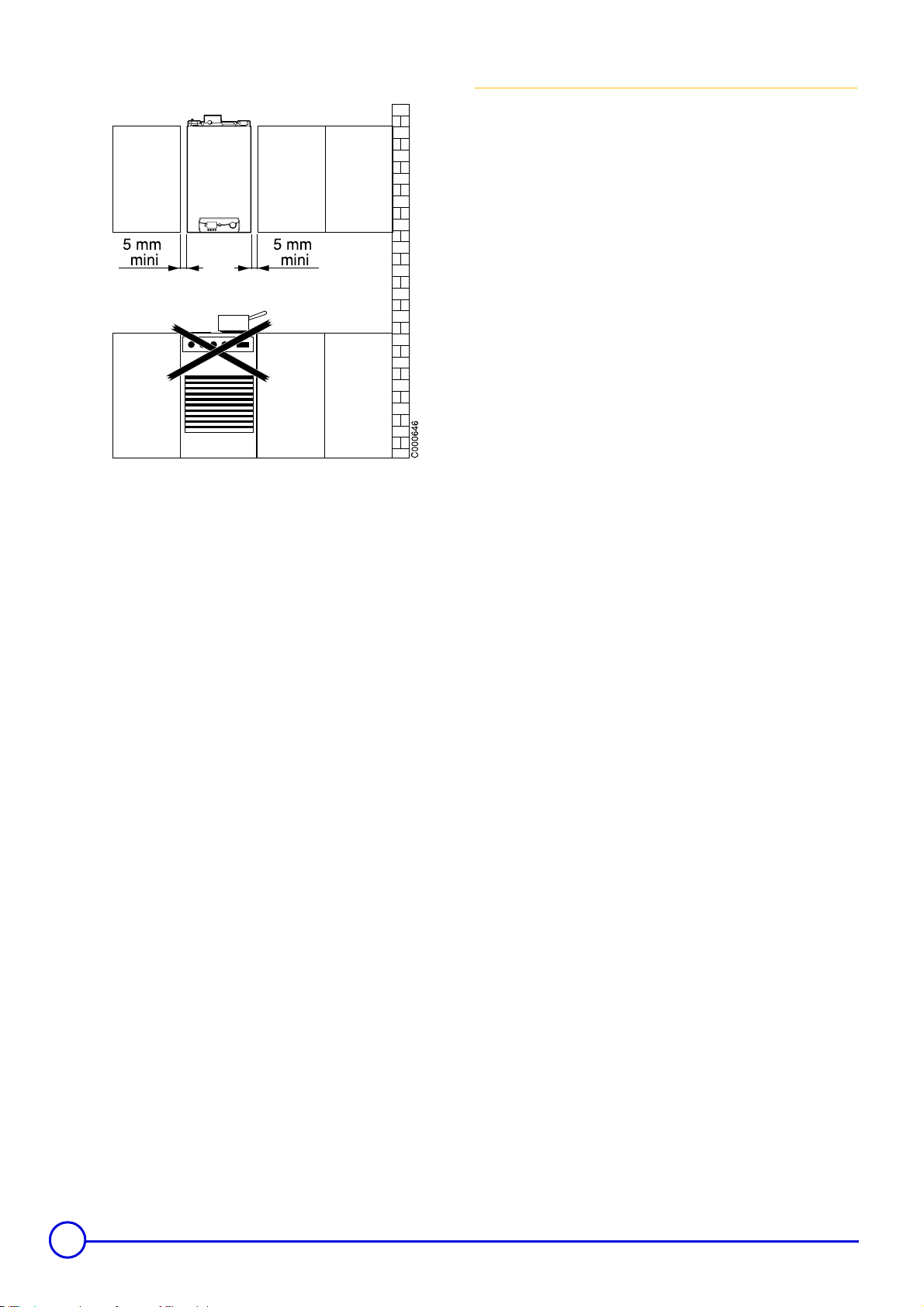

The boiler must not be positioned above a heat source or a

cooking appliance

- The boiler must be fixed to a solid surface, capable of bearing the

weight of the appliance and other equipment when full of water.

- To enable removal and replacement of the cladding, a space of 5

mm is sufficient on either side of the boiler.

- The IPX4D protection index authorises installation in bathrooms,

except for protection volumes 1 and 2 however.

Certificate of compliance

For the application of article 25 of the modified decree dated 02/08/

1977 and of article 1 of the modifed decree dated 05/02/1999, the

installation engineer must be in possession of the certificates of

compliance approved by the Ministries in charge of construction and

gas safety:

- Different forms (forms 1, 2 or 3) for a new gas installation,

- "Model 4" in particular after replacing a furnace with a new one.

In order to avoid damage to the boilers, it is necessary to

prevent the contamination of combustion air by chlorine

and/or fluoride compounds, which are particularly

corrosive. These compounds are present, for example, in

aerosol sprays, paints, solvents, cleaning products,

washing products, detergents, glues, snow clearing salts,

etc.

Therefore:

- Do not suck in air evacuated from premises using such

products: hairdressing salons, dry cleaners, industrial

premises (solvents), premises containing refrigeration

systems (risk of refrigerant leakage), etc.

- Do not stock such products close to the boilers.

If the boiler and/or peripheral equipment are corroded by

such chloride or fluoride compounds, the contractual

guarantee cannot be applied.

Comply with current regulations.

If using thermostatic valves, it is not necessary to fit them to every

radiator.

Never fit radiators in the room in which the room

temperature thermostat is installed with thermostatic

valves.

18

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 19

1 Water treatment and connections

Fill the heating system only with non-treated drinking water (pH

between 6 and 9). If you require more information on specific

subjects, do not hesitate to contact our technical department.

If used correctly water treatment can improve the boilers efficiency

and increase the anticipated life expectancy of the boiler.

As most systems contain a variety of metals, it is considered good

practice to provide some frome of water treatment in order to prevent

or reduce the following (metallic corrosion, formation of scale and

sludge, microbiological contamination, chemical changes in the

untreated system water.

Suitable chemicals and their use should be discussed with a

specialist water treatment company prio to carrying out any work

(environmantal aspects, health aspects). Specification, age and state

of the installation, as well as manufacturer recommendations must be

considered. Think of cleaning old water installations to remove any

corrosive residue, especially black iron oxide sludge.

The boiler must not operate if chemical products are used

for cleaning.

1.1 Fitting the mounting frame

Refer to the assembly instructions supplied with the mounting

Z

frame package.

The exchanger will have to be descaled, if need be, in order to

maintain optimum performance.

It is especially important to check the concentration of inhibitors after

installing them, make the necessary modifications to the installation,

inject water in the installation and perform all maintenance operations

conform to these instructions.

To know the suitable dosage as well as which inhibitors to use with

your boiler and to acquire further information on water processing or

cleaning of the installation contact the technical service directly.

Minimum water flow

The MCR boiler is equipped with a system protection against low

flows that depends on temperature reading. By reducing boiler power

as soon as there is a risk of insufficient flow, the boiler can continue

operating. However, if the temperature difference between the out

and return heating is greater than 45°C or if the rise in heating outlet

temperature is greater than 1 °C/second, the boiler cuts for 10

minutes before authorizing start-up again. If there is no water in the

boiler or if the pump is not operating, the boiler shuts itself down

(code E7) and needs to be restarted manually.

1.2 Positioning the boiler

See "Installation instructions"

Z

1.3 Filling the siphon

products will overflow into the waste water discharge

network.

To do this, fill the siphon with water via the combustion products

discharge conduit until it overflows.

Operation while the condensation water siphon is empty

may damage the boiler. There is a danger that combustion

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

19

Page 20

1.4 Stove fitting connections

- Horizontal flue gas conduits must be installed with a zero gradient. The

run-off of condensates to the boiler is handled by the eccentricity of the

horizontal terminal. The terminal must be oriented according to the

figure below.

Use the mounting template provided with the boiler to position

holes to be drilled for the outlet of the horizontal forced flue.

- Static test overpressure : 1000 Pa

- Maximum leak rate : 50 l/hm2 depending on the internal surface

of the flue gas pipe

- A diameter 60 = 0.18 m

- A diameter 100 = 0.31 m

2

/m, A diameter 80 = 0.25 m2/m,

2

/m, A diameter 130 = 0.40 m2/m.

`On concentric (forced flue) flue gas evacuation systems, the

CO2 content in the annular space on the measurement pipe

can also be checked. The installation of the flue gas evacuation

is considered leak tight if the CO2 content measured is less

than 0.2%.

The cross section of the ventilation inlet in the premises for type B

connections (i.e. intake of combustive air into the premises) must be

in compliance with the prevailing standard.

- Type C appliances can only be installed with the systems

mentioned in these technical instructions (particularly concentric

pipes, terminal connection parts).

- As connections of type B

chimney conduits and type C

23

conduits are pressurised, they must be either installed outside or

in a ventilated brick sheath.

Ventilation must be ensured :

- by an opening located in the lower section, taking the air either

from the common ventilated areas or directly from outside, and

- by an opening in the upper section connected directly with the

outside.

The minimum cross section of the air vent and the openings to be

provided must be 100 cm

2

(clear cross section).

The parts of this sheath which can be dismantled must allow for

inspection of the flue gas conduit along its entire length.

Belgium

: The boiler installation and gas connection must be carried out

by a qualified professional in compliance with the NBN D 51.003, NBN D

30.003, NBN B 61.001, NBN B 61.002 and NBN D 51. 006 standards.

23

53

110850LTW7H030

Comply with the installation instructions and the information on the

authorised lengths of the flue gas pipes.

`Mount the flue gas pipe or the fresh air/flue gas evacuation

system in compliance with the assembly instructions.

`Check the tightness of the flue gas pipe.

20

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 21

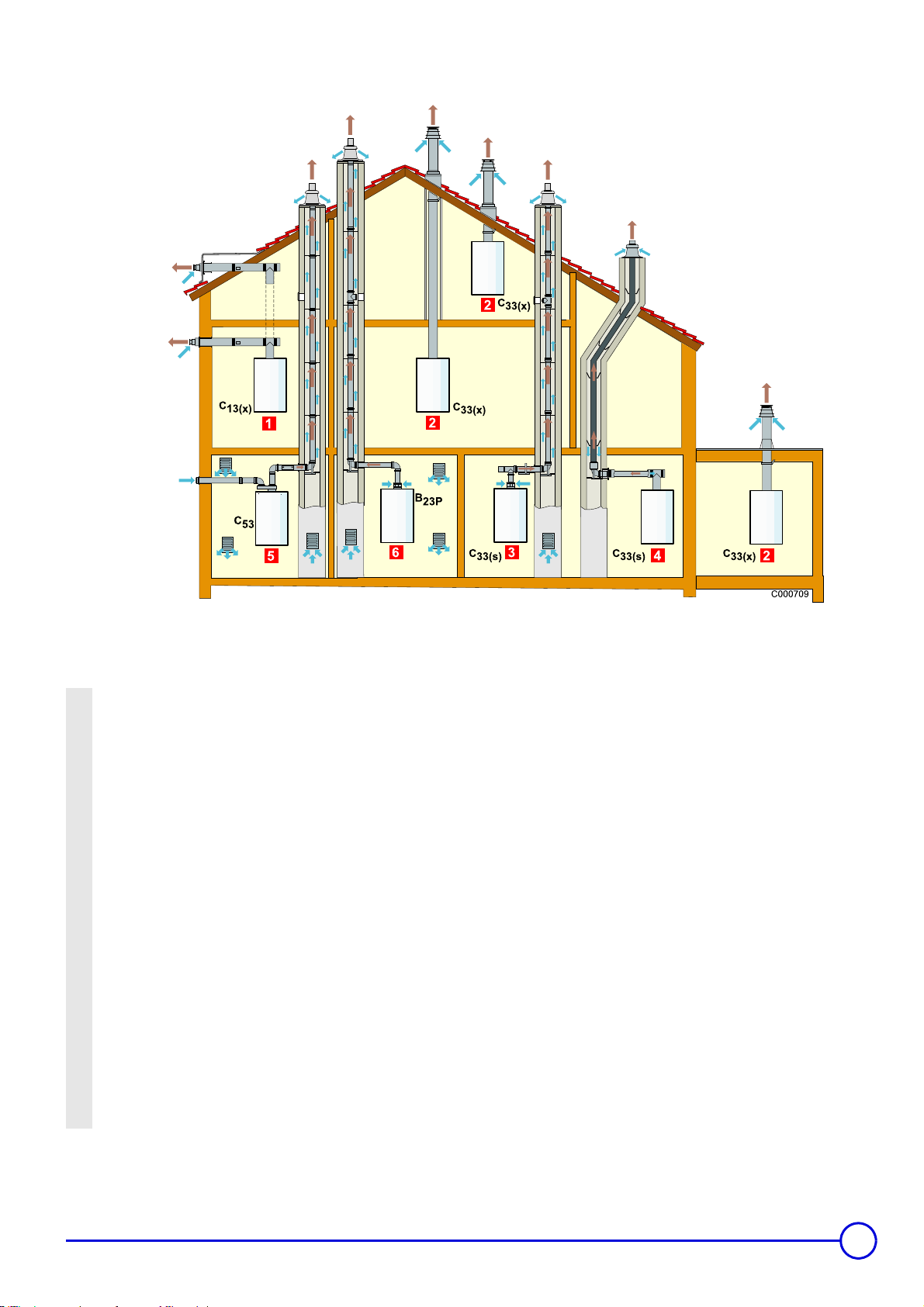

1.5 Classification

(s) Valid only for Belgium

(x) For Germany only

1 Homologation C

concentric pipes to a horizontal terminal (so-called forced flue)

2 Homologation C

concentric pipes to a vertical terminal (roof outlet)

or

3 Air/flue gas connection by concentric pipes in the boiler room and

single pipes in the chimney (combustive air in counter current in the

chimney)

or

4 Air/flue gas connection by concentric pipes in the boiler room and

single "flex" in the c himney (combustive air in counter current in the

chimney)

For Belgium:

Homologation C

connecting the boiler and the terminal. The clear section must

comply with the standard. The chimney must be swept before the

installation of the evacuation conduit.

5 Homologation C

means of a bi-flow adapter and single pipes (combustive air taken

from outside)

6 Homologation B

from the boiler room)

7 Homologation B

: Air/flue gas connection by means of

13(x)

: Air/flue gas connection by means of

33(x)

: Only factory components are authorised for

33(s)

: Air and flue gas connection separated by

53

: Chimney connection (combustive air taken

23P

: Cascade installation

23P

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

21

Page 22

1.6 Lengths of the air/flue gas pipes

Type of air/flue gas connection Maximum length of the connection pipes (metres)

MCR 24 MCR 24/28 MI MCR 30/35 MI MCR 34/39 MIDiameter

Concentric pipes connected to a horizontal

terminal ((Alu))

Concentric pipes connected to a vertical

terminal ((Alu))

Concentric pipes in the boiler room

Single pipes in the chimney (combustive air in

counter current) ((Alu))

Concentric pipes in the boiler room

"Flex" pipes in the chimney (combustive air in

counter current) (PPS)

Bi-flow adapter + Separate single air/flue gas

pipes (combustive air taken from outside)

((Alu))

Chimney (rigid or flexible) (combustive air

taken in the premises) (PPS)

C

13(x)

C

33(x)

C

33(s)

C

33(x)

C

33(s)

C

33(x)

C

53

B

23P

60/100mm 6 7 4 6

80/125 mm 31 32 22 29

60/100mm 6 7 4 6

80/125mm 31 32 22 29

60/100 mm 80 mm

(rigid)

80/125 mm 80 mm

(rigid)

60/100 mm 80 mm

(flexible)

80/125 mm 80 mm

(flexible)

60/100mm

2x80 mm

80 mm (rigid) 33 37 19 22

80 mm (flexible) 23 27 22.5 24.5

18 23.5 10 12

- - 24 25.5

15.5 19 7 9

- - 18 20

44 48 30 32.5

(s) Valid only for Belgium (x) For Germany only

Lmax is measured by adding the lengths of the air/flue gas pipes and the equivalent lengths of the other elements.

Length of the reductions (Alu) (m) Ø 60/100 Ø 60 Ø 80/125 Ø 80

Elbow87° 1.1 1.1 1.0 1.2

Elbow45° 0.8 0.6 0.8 0.9

Elbow30° 0.7 0.9 0.6 0.6

Elbow15° 0.5 0.6 0.4 0.3

Inspection T 2.2 2.9 2.1 2.8

Right inspection tube 0.7 0.3 0.7 0.5

Length of the reductions PPS (m) Ø 60/100 Ø 60 Ø 80/125 Ø 80

Elbow87° 1.1 1.1 1.5 1.2

Elbow45° 0.8 0.6 1.0 1.4

Elbow30° 0.7 0.9 - 0.6

Elbow15° 0.5 0.6 0.4 0.3

Inspection T 2.2 2.9 2.6 2.8

Right inspection tube 0.7 0.3 0.6 0.5

Inspection tube for flexible pipe - - - 0.3

Belgium

:Boilers can only be installed with the stove fittings provided by the constructor. For the list of parts, refer to the current price list.

1.7 Assembly horizontal or vertical forced flue and forced flue accessories

Refer to the instructions delivered with the package.

Z

22

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 23

• Horizontal forced flue Ø 60/100 mm (type C

Connection to an outside wall or roof outlet.

connection)

13x

A Flue gases

B Combustive air

• Connection C

- Concentric vertical forced flue

33x

Connection to a sloping or flat roof.

A Flue gases

B Combustive air

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

23

Page 24

• Connection C

33x

( C

: For Belgium) - Concentric pipes in the boiler room - Single pipes in the chimney (combustive air in

33s

counter current)

Discharge via conduit, fresh air in counter current.

A Flue gases

B Combustive air

C Horizontal section (Maximum length 1 m)

• Connection C

counter current)

33x

( C

: For Belgium) - Concentric pipes in the boiler room - Inspection tube for flexible pipe (combustive air in

33s

24

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 25

• Separate air and flue gas connection Ø 60/100 mm over 2xØ80 mm (type C53 connection)

A Ventilation (100 cm2 minimum)

B Casing classified (M1)

C Leak proof rose

D Inspection hatch

E Openings (5 0 cm2)

• Connection to a chimney Ø 80 mm type B23 connection)

Chimney conduit fitting into a chimney, combustive air taken in the

premises.

A Flue gases

B Horizontal section (max 1 m)

C Chimney connection kit

D Combustive air

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

25

Page 26

1.8 Electrical connection (230 V)

The boilers are delivered pre-fitted with a 3-conductor power supply

cable with an available length of around 1.5 metres.

The appliance must be powered by a circuit containing an omnipolar

switch with an opening distance 3 mm.

Only qualified professionnals may carry out electrical

connections, always with the power off.

When connecting to the mains, be sure to respect live for the brown

wire, neutral for the blue wire and earth for the green/yellow wire.

For Belgium + Certain European countries

If you use a two-phase electrical grid, jumper must be removed

(130 V: Lane/Neutral).

The boiler is not sensitive to phase reversal.

26

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 27

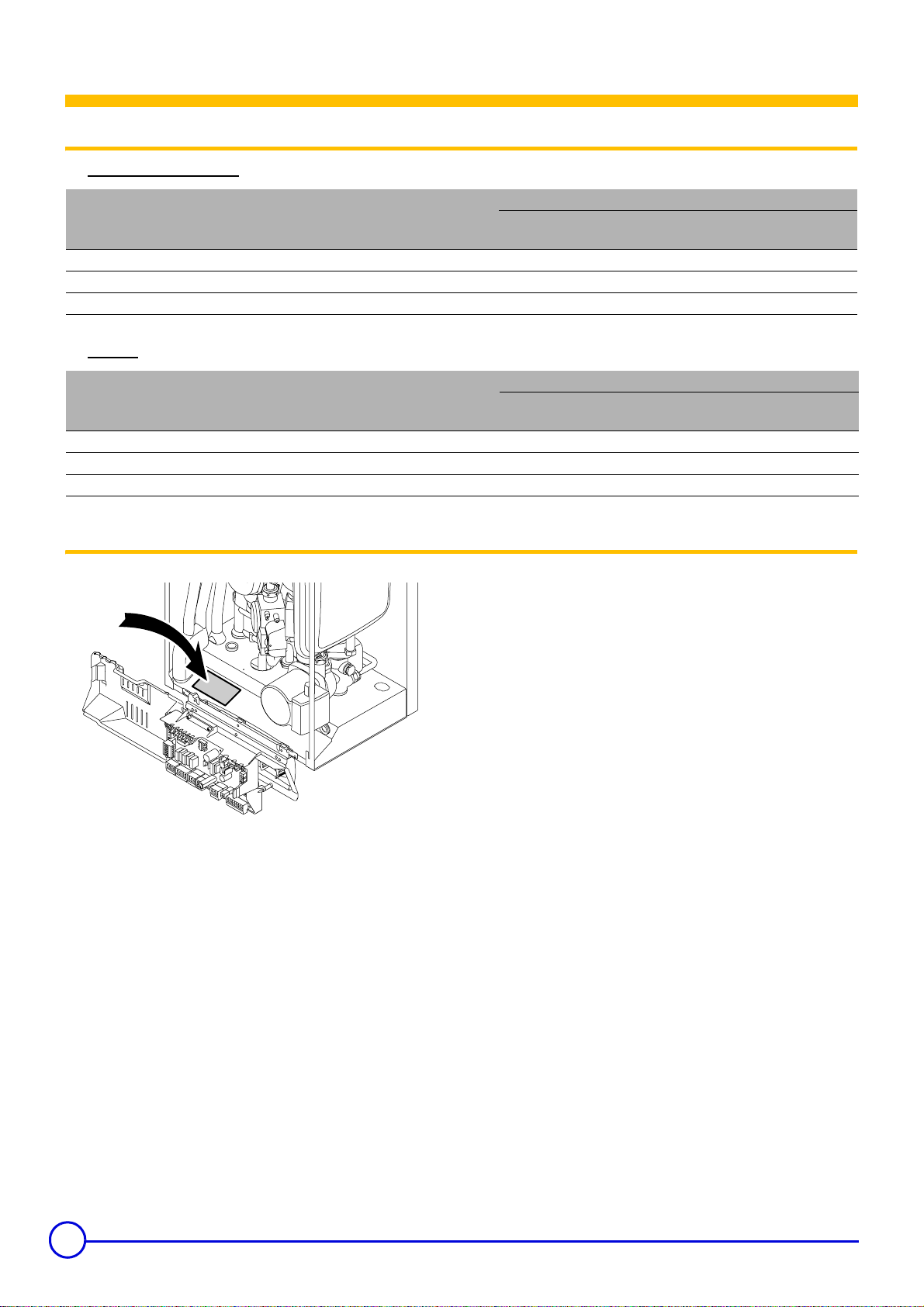

2 Connecting the options

Optional equipment can be connected to the connectors on the

control panel.

`Tilt the flap on the control panel.

`Open the protective hood.

`Make the connections according to the optional equipment you

are using.

Programmable room temperature thermostat (Package AD

137) or Wireless settable ambient thermostat (Package AD

200) or Non settable ambient thermostat (Package AD 140).

Refer to the instructions delivered with the thermostat.

Z

Outside sensor (Package AD 225)

Refer to the instructions delivered with the package.

Z

Communicating remote controller: Easymatic (Package FM

50) or Easyradio (Package AD 201) with or without external

sensor (Package AD 225) + Interface PCB (AD 221)

The connection can be made either by a 2-wire telephone

cable, or by an electric cable with a cross-section that may be

up 2 x 1.5 mm

Refer to the instructions delivered with the package.

Z

2

.

Underfloor heating: Easymatic (FM 50)/Easyradio (AD 201) +

Outside sensor (AD 225) + Interface PCB (AD 222)

Refer to the instructions delivered with the package.

Z

If you have underfloor heating: Connect the security thermostat

in the external electrical connection box (See: Package AD

222).

Accessories

- Stand of frame (Package HG19)

- Pipework kit for stand of frame (Package HG20)

- Cover pipes (Package HG21)

- Replacement kit (ELM - Package HG23); (Saunier Duval Package HG24); (Chaffoteaux et Maury - Package HG25);

(Vaillant - Package HG26)

- Mounting frame + Disconnector (Package HG27)

Standard delivery. Possibility of separate orders for the preinstallation.

- Neutralisation station (Package HC33)

- Wall support (Neutralisation station) (Package HC34)

- 2 kg refill to neutralisation (Package HC35)

- Flow collector (For Belgium+Poland)

Refer to the instructions delivered with the package.

Z

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

27

Page 28

3 Connecting the external controls

- Unscrew the 2 screws.

- Remove the front panel of the cladding.

- Run the cables in the cable clamps.

- Connect the cables to the connectors (See drawing opposite).

Switch off the mains electricity supply before carrying out

any work.

28

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 29

3.1 ON/OFF room thermostat

: Existing bridge

: Cable BUS: AD 221 or AD 222

MCR boilers can be connected to a 2-wire on/off room thermostat.

Choose a location in a "reference" room representative of the

room temperature to be taken into account if the remote control is

used as a room sensor.

1. Lane 230 V - Intensity in Amperes: 3

2. Power supply - Neutral

3. Common alarm (Contact closed)*

4. Boiler in use (Contact open)*

5. Neutral

6. Tap open: DHW

7. Tap open: Heating

8. Outside sensor connection

9. Connecting the tank sensor (Remove bridge)

10. Boiler blockage input (Remove bridge)

11. Existing bridge

12. Cable BUS: AD 221 or AD 222 (Remove bridge)

13. Not connected

14. Switch: Domestic hot water (To use this function, remove the

bridge between terminals 4 and 3)

15. Existing bridge. To be used when room thermostat is connected.

16. Switch: Heating (To use this function, remove the bridge between

terminals 4 and 1)

*Depending on parameter settings

Connect terminals 7 and 8 on the thermostat to the terminals on

connector X9.

If you are using a room thermostat with anticipation resistance,

parameter P5 must no longer be defined as 0 but as 1.

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

29

Page 30

3.2 Easymatic,Easyradio regulation connection

: Existing bridge

: Cable BUS: AD 221 or AD 222

Modulating thermostats can be connected without further adaptation.

Choose a location in a "reference" room representative of the

room temperature to be taken into account if the remote control is

used as a room sensor.

- Connect the regulation on the interface PCB (J7).

- Connect connector J6 to the interface PCB on the X9 connector.

Refer to the instructions delivered with the package.

Z

3.3 External temperature probe connection

: Existing bridge

: Outside sensor connection

An outside temperature sensor can be connected to connectors 1

and 2 on terminal X9.

(Adjustment parameter P27, from 0 to 60°C)

- Outlet temperature setting point at a minimum outside temperature

= 20 °C

(Adjustment parameter P1, from 20 to 85°C)

: Factory setting

The boiler will regulate output using the setting point on the internal

heating curve:

- Minimum temperature setting point = -15 °C

(Adjustment parameter P29, from 0 to -30°C)

- Maximum temperature setting point = 20 °C

(Adjustment parameter P28, from 0 to 40°C)

- Outlet temperature setting point at a maximum outside

temperature = 20 °C

30

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 31

4 Connection of the domestic hot water sensor

: Existing bridge

: Connecting the tank sensor

5 Antifreeze protection

If an external domestic hot water tank is used with the MCR boiler,

the probe without power from the domestic hot water tank can be

connected to connectors 3 and 4 of terminal block X9.

The control unit automatically detects the presence of an external

sensor.

- When the water temperature is above 10 °C, the boiler is switched

off and the circulation pump runs for another 15 minutes.

If a room thermostat, connected via connectors 7 and 8, is

activated, the boiler will operate permanently until it

reaches the outlet setting point.

: Existing bridge

: Cable BUS: AD 221 or AD 222 or Thermostat ON/OFF

MCR boilers must be installed in a frost-free environment

If the temperature of the central heating water in the boiler falls too

much, the integrated protection device switches itself on:

- If the water temperature is lower than 7°C, the circulating pump is

activated,

- If the water temperature is lower than 3°C, the boiler is activated,

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

31

Page 32

6 Safety contact

: Existing bridge

: Safety contact

7 Connection of a remote alarm transfer and boiler operation indication system (Not proposed)

The boiler is equipped with a 3 pin connector without power on

terminal block X7. The terminal block can be used to connect to an

external gas valve, a remote alarm transfer and boiler operation

indication system.

- Connect the alarm transfer system to pins 1 and 2 of terminal block

X7. Contact is closed in the event of a shutdown.

To do so: Set parameter 24 to 1.

- Connect the boiler operation indication system to pins 1 and 3 of

terminal block X7. If heating is required, the boiler thermostat

closes the contact.

To do so: Set parameter 24 to 2.

- Connect an external gas valve to pins 1 and 3 of terminal block X7.

The contact is closed when the gas valve is activated.

To do so: Set parameter 24 to 3.

MCR boilers are equipped with a security switch. A voltage-free

switching device (e.g. an external gas pressure switch or a safety

thermostat for underfloor heating) can be connected to connectors 5

and 6 on terminal X9 after disconnecting all of the cables. When the

contact is open, the boiler turns off indicating code 9; it will start again

once the contact is closed.

: Common alarm (Contact closed)

: Boiler in use (Contact open)

32

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 33

8 Pump logic

-In mode (domestic hot water) or with Easymatic in

(Summer), the pump operates during the production of domestic

hot water. With an Easymatic, the pump shuts down after the pump

flow switch-off delay. The heating/domestic hot water reversal

valve remains in the DHW position.

- With room temperature thermostat

- The pump switches off 2 minutes after the contact with the room

temperature thermostat is opened. After the production of

domestic hot water, if the room temperature thermostat is open,

the pump switches off after 5 seconds and the heating/domestic

hot water reversal valve remains in the DHW position.

With Easymatic or Easyradio

- When the desired room temperature is not reached, the pump

operates continually. When the room temperature is too high, the

pump is shut down after the pump switch-off delay (See

"Easymatic"). If the room temperature is too high after domestic hot

water production, the pump shuts down after the pump switch-off

delay; the heating/DHW reversal valve remains in the DHW

position (See "Easymatic").

- Easymatic and outside temperature sensor or Outside sensor

alone

Refer to the instructions delivered with the package.

Z

- If necessary, when the boiler temperature falls below 10°C, the

pump starts up to ensure that the boiler is protected from frost.

#

mode

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

33

Page 34

The first start-up is to be performed by your installation

engineer.

1 Commissionning

Commissionning

The boiler is preset in the factory to operate on natural gas. Operating

pressure: 20 mbar.

For Belgium: Operating pressure: 25 mbar.

1.1 Final checks before commissioning

The first start-up is to be performed by your installation

engineer.

Before start-up, the heating installation must be completely emptied

and rinsed.

Fill the installation with water.

Check that the equipment is properly set for the type of gas

used.

For Belgium: Any intervention on the gas valve unit is

strictly forbidden.

Cut the power supply to the boiler

Unscrew the 2 screws.

Remove the front panel.

Disconnect the 2 ignition electrodes from the connector/ignition on

the gas valve.

34

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 35

1.2 Water and gas connections

First check that the water is circulating in the boiler (water pressure

in the heating circuit, outlet and return valves open, valves and

radiators open, etc.).

Opening the valve

Measuring point on the gas block (C)

Open the gas valve.

Checking the gas supply pressure: Measurement point C.

Recommended pressure: See "Certifications".

Z

Carry out a gas tightness check. Maximum pressure: 60 mbar.

For Belgium: Maximum pressure: 100 mbar.

Open the valves on all radiators connected to the heating system.

Fill the installation with water (Minimum pressure: 1 bar, Maximum

pressure: 2.5 bar).

When filling, air may escape from the system via the automatic air

bleed and the pump.

Use the bleed plugs provided, which are attached to the gas

valve unit in the event of water leakage.

Do not allow water to get into the boiler.

Check the condensates discharge siphon; it must be filled with clean

water up to the mark.

Check the boiler pump. Remove the central chrome screw to bleed

the pump.

Carry out a water tightness check.

Bleed the gas supply pipe by unscrewing the measuring point on the

gas valve unit. Tighten the measuring point when the pipe has been

sufficiently bled.

Check the seals on the gas and water connections.

Check the electrical connections.

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

35

Page 36

Check the electrical connections to the thermostat and the other

external controls. Checking tightness (hydraulics, combusted gas

discharge and gas).

1.3 Switching the boiler on

Turn the boiler on (230 V).

Set the boiler regulation according to the heating request.

The boiler will begin an automatic venting-programm (which lasts

approx. 3 minutes) and will do this every time the power supply is

isolated.

The boiler is now ready to operate. The current operating status is

shown on the display. The display shows O.

1.4 Setting the gas/air ratio (Full load)

Belgium: Any intervention on the gas valve unit is strictly

forbidden.

Values: Setting

Boiler type Fan speed (rpm)* CO2 (%) CO2 (%)

Full load H:3

Natural gas Propane Natural gas Propane

24 ca. 4600 ca. 4400 8.8 ±0.1 10.5 ±0.3

24/28MI ca. 5500 ca. 5200 8.8 ±0.1 10.5 ±0.3

30/35MI ca. 6300 ca. 6000 8.8 ±0.1 10.5 ±0.3

34/39MI ca. 6700 ca. 6400 8.8 ±0.1 10.5 ±0.3

*In the event of forced operation at low speed, the second figure indicates

the operating code.

Unscrew the flue gas requirement plug.

Connect the combusted gas analyser.

Set the boiler to full load.

Press the key. The display shows H:3: The full load is set.

Measure the O

If this rate does not match the parameter value, correct the gas/air

ratio using the adjustment screw A on the gas valve unit.

If the rate is too high, turn the screw A clockwise to reduce the gas

flow.

If the rate is too low, turn the screw A anti clockwise to increase the

gas flow.

Check the flame via the flame detection cell. It must not go out.

Check that the analysis probe is leakproof against gas at the

sampling level point, the extremity of the probe is in the centre

of the smoke evacuation pipe.

or CO2 content in the flue gases.

2

The boiler is preset in the factory to operate on natural gas.

36

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 37

1.5 Setting the gas/air ratio (Part load)

Values: Setting

Boiler type Fan speed (rpm)* CO2 (%) CO2 (%)

Part load: L:3

Natural gas Propane Natural gas Propane

24 ca. 1300 ca. 2000 8.8 ±0.1 10.5 ±0.3

24/28MI ca. 1300 ca. 2000 8.8 ±0.1 10.5 ±0.3

30/35MI ca. 1300 ca. 2000 8.8 ±0.1 10.5 ±0.3

34/39MI ca. 1300 ca. 2000 8.8 ±0.1 10.5 ±0.3

Set the boiler to part load.

Press the - key until the L:3 symbol is displayed: The part load is set.

Measure the O

If this rate does not match the parameter value, correct the gas/air

ratio using the adjustment screw B on the gas valve unit.

If the rate is too high, turn the screw B clockwise to reduce the gas

flow.

If the rate is too low, turn the screw B anti clockwise to increase the

gas flow.

or CO2 content in the flue gases.

2

1.6 Final checks before commissioning

Remove the analysis sensor

Replace the plastic plug onto the measuring tube.

Put the upper front panel in place. Tighten the screws

To return to normal configuration, press briefly on button .

if you do not press any keys, return to normal confiuration after

15 minutes.

Check the water pressure in the installation. Top up with more water

if necessary.

.

.

Check the flame via the flame detection cell. It must not go out.

Check that the analysis probe is leakproof against gas at the

sampling level point, the extremity of the probe is in the centre

of the smoke evacuation pipe

Repeat the high speed test and the low speed test as often as

necessary until the correct values are obtained without having to

make additional adjustments.

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

37

Page 38

Write down the type of gas on the sticker on the inside of the flap.

38

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 39

2 Commissioning

• Switch on the boiler. Activate the main switch in the installation.

• Commissioning cycle

Screen display:

- F XX: Software version

• The boiler will begin an automatic venting-programm (which

lasts approx. 3 minutes) and will do this every time the power

supply is isolated. The version numbers are displayed

alternately.

- P XX: Parameter version

The current operating status is shown on the display:

Heating only: production of domestic hot water:

1: Fan ON 1: Fan ON

2: Boiler is igniting 2: Boiler is igniting

3: Operation: Heating mode 4: Operation: Domestic hot water mode

Heating only: condition satisfactory production of domestic hot water: condition satisfactory

1: Post-ventilation 1: Post-ventilation

6: Pump operation (Heating mode) 7: Pump operation (Domestic hot water mode)

0: Stand-by 0: Stand-by

2.1 Display

• No display:

- Check that the boiler is switched on (230 V),

- Check the electrical connections,

- Check the fuse (F2 = 2 AT, 230 V).

• Breakdown codes:

- The symbol

m

flashes,

- A malfunction code indicates the nature of the breakdown (for

E10

example:

),

- Correct the error if possible,

- Press key

After an E1, E2, E7, E10 or E13 error, the 3-minute air venting

cycle will take place before the boiler starts up.

for 2 seconds: The boiler restarts.

2.2 Parameter display (See "Control panel")

2.3 Boiler setting

• "User" settings

Parameters P1 to P6 can be modified by the user in order to meet

central heating and DHW comfort needs.

• "Installer" settings

Parameters P17 to dF must only be modified by a qualified

professional.

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

39

Page 40

2.4 Setting different parameters (with access code)

To get acces to the error memory, the acces code 12 must be

entered.

Parameter Description Comments Factory setting

P17 Maximum ventilator speed

(Heating)

P18 Maximum ventilator speed (DHW) Do not modify 46 55 63 67

P19 Minimum ventilator speed

(Heating+DHW)

P20 Start up speed for the ventilator Do not modify 25 25 28 30

P21

P22 Operating time: Pump (Heating) 1 to 99minutes 2

P23 Connection with the heat

P24

P25

P26 DHW cut-in temperature 2 to 15 °C 5

P27 Heat curve set point: Flow

P28 Heat curve set point: Outside

P29 Heat curve set point: Outside

P30

P31 Temperature, for which the

PdF (PdU)

Setting the pump speed

recuperation unit

Remote alarm

(Terminal X7)

The regulator includes legionella

protection function, that can be

actived

temperature

temperature (Max)

temperature (Min)

Boiler type

production of domestic hot water

is stopped, exceeded

Factory setting

10-70

X 100 rpm

Do not modify

0 = Part load

1 = Full load

0 = No connection

1 = Connection

0 = Stop "OFF" (Connectors 1 and 2 closed)

1 = Alarm messages (Connectors 1 and 3 closed)

2 = Operating light (Connectors 1 and 3 closed)

3 = External gas valve (Connectors 1 and 3

closed)

0 = Stop

1 = Start

2 = Automatic (After commissioning, the boiler will

operate once a week at 65°C for DHW) 1000

0 to 60 °C

0 to 30 °C

-40 to 0 °C

0 = MCR 1024

1 = MCR ... Combi (Heating only)

0 to 20 °C

Parameter dFX appears on the identification

plate; if this parameter is set as X, the factory

parameters will be reinstated

Parameter dUY appears on the identification

plate; if this parameter is set as Y, the factory

parameters will be reinstated

Adjustment must be done by a qualified professional.

24 24/28 MI 30/35 MI 34/39 MI

37 37 41 47

13 13 13 13

0

0

0

20

20

-15**

1 0 0 0

15

X

Y

**The character - is not displayed.

40

Modification of the factory parameters may be detrimental

to the functioning of the boiler.

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 41

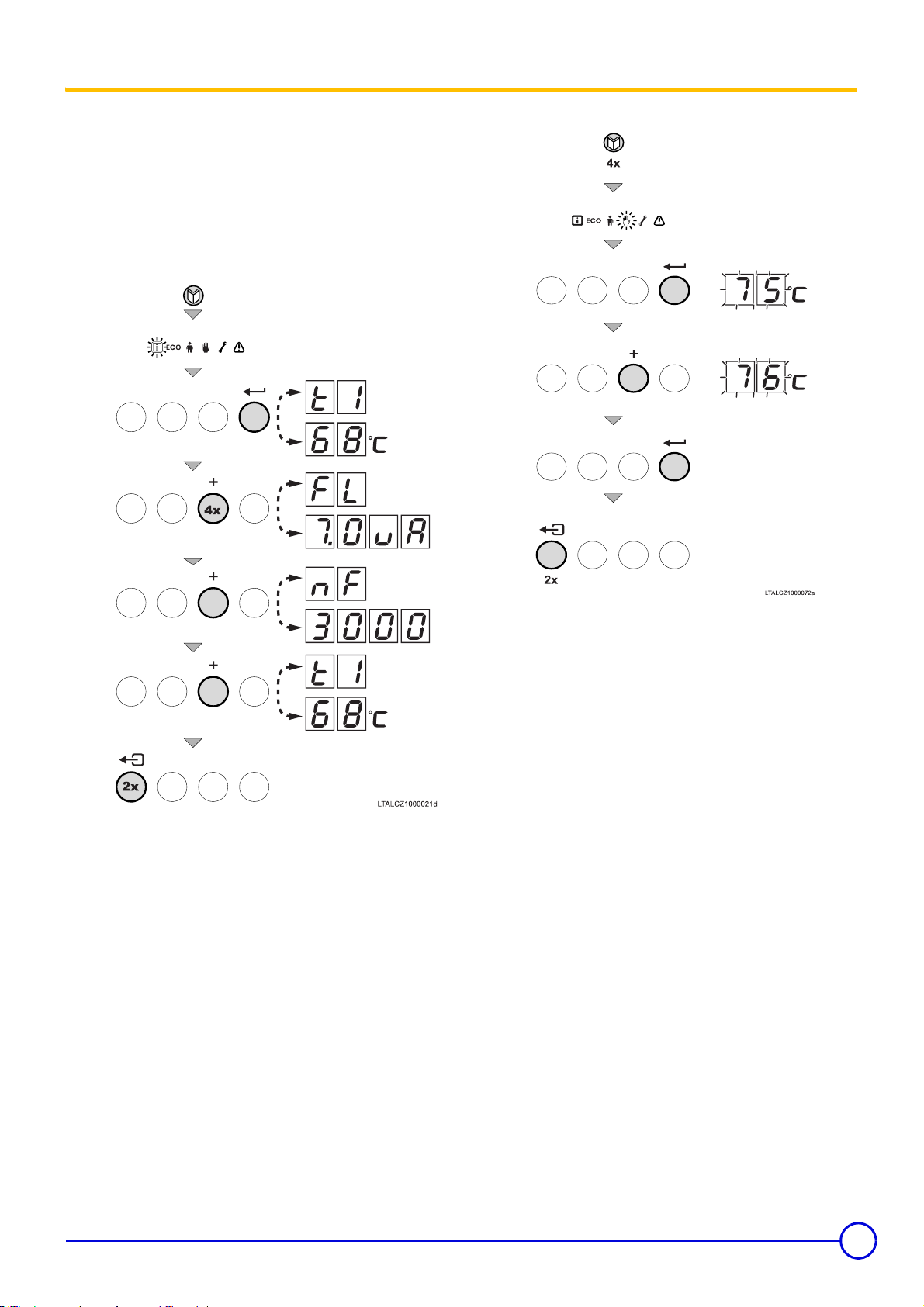

2.5 Modify parameters

• MCR 24

• MCR 24/28 MI

- Press the Ä key until the symbol is displayed.

- Select the fitter menu using the l key. The symbol COdE

appears.

- Enter the fitter code 0012 using the - or + key.

- To confirm, press the l key. The symbol P:1 appears.

- Press the l key a second time. The symbol 75°C appears

(Factory setting).

- Lower the value to 60°C using the - key.

- To confirm, press the l key

- To confirm, press the l key. The symbol P:1 appears.

- If necessary, set other parameters by selecting them using the - or

+ keys.

- Press key 2 time to return to the current operating mode.

If no selections are made in the various modes for 10 minutes,

the boiler resumes the settings prior to manipulation.

• MCR 30/35 MI, MCR 34/39 MI

X: Boiler power (kW)

Y: Fan rotation speed (rpm)

2.6 Setting the maximum output (Hi): Heating

Parameter P17 (maximum fan speed) is used to modify maximum

central heating output.

Fan speed/boiler output ratio

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

41

Page 42

2.7 Return to the factory settings "Reset Param"

2.8 Manual operation ()

- Press the + key until the P:dF symbol is displayed.

- Press the l key. The symbol dF:X appears.

To reinstate the factory settings, enter the value X using the - or +

key.

- Press the l key. The symbol dU:Y appears.

To reinstate the factory settings, enter the value Y using the - or +

key.

- To confirm, press the l key.

- Press key Ä several times until the symbol flashes on the

menu bar.

- Press the l key. The symbol AUtO appears (if outside sensor

connected).

The outlet temperature is determined by the internal heating curve.

Minimum outlet temperature: Press the + key to modify the setting.

- To confirm, press the l key.

The installation is in manual mode.

- Press key 1 time to deactivate the manual mode.

42

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 43

2.9 Switching off

Before any work is carried out on the equipment / heating system, the

power supply must be disconnected (by means of the appropriate

fuse or main switch, for example) and warning must be given before

any reconnection.

2.10 Antifreeze protection

We recommend setting the boiler thermostat to a value lower than

10°C if using a classic installation.

Define parameter P4 as 1 (energy-saving mode); the heat retention

function will be deactivated.

Installation and room antifreeze protection is guaranteed if you are

absent.

2.11 If the central heating system is not used for a long

period, we recommend switching the boiler off

Switch the boiler off.

Cut the power supply to the boiler.

Cut the gas supply.

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

43

Page 44

Adapting to another gas

For Belgium: Only SERV’élite is authorised to carry out the

conversion of this appliance.

MCR boilers are preset in the factory for natural gas H.

The actions described below must be carried out by a

qualified technician.

1 Switching from Natural Gas to Propane

The conversion from Natural Gas to Propane requires only the

adjustment of the burner and the fan speed.

2 Setting the control unit parameters

For conversion to propane

To obtain the gas valve setting used to start up with propane, use the

following instructions:

- GN (G20) to G31: Turn the high speed adjustment screw 2

rotations clockwise

or

- Turn high speed screw clockwise until it is closed. Turn high speed

adjustment screw 3.5 - 4 rotations counter clock wise.

Parameter Nominal fan

speed

(rpm)

MCR 24

Natural gas H

(Factory setting :

Gn by default)

Propane (Factory

setting : Pr)

Nominal power

h3

Minimum output

L3

Maximum DHW

speed

H3

Nominal power

h3

Minimum output

L3

Maximum DHW

speed

H3

P17 3700 3700 4100 4700 8.8±0.3

P19 1300 1300 1300 1300 8.8±0.3

P18 4600 5500 6300 6700 8.8±0.3

P17 3500 3500 3900 4500 10.5±0.3

P19 2000 2000 2000 2000 10.5±0.3

P18 4400 5200 6000 6400 10.5±0.3

For Belgium: The boiler installation and gas connection

must be carried out by a qualified professional in

compliance with the NBN D 51.003, NBN D 30.003, NBN B

61.001, NBN B 61.002 and NBN D 51.006 standards.

After this setting, the boiler will not have an optimum setting for

propane.

For the precise setting, use a CO

measuring device and apply the

2

settings procedures:

See "Modify parameters" and "Setting the gas/air ratio - Full

Z

load + Part load"

Nominal fan speed

(rpm)

MCR 24/28MI

Nominal fan

speed

(rpm)

MCR 30/35MI

Nominal fan

speed

(rpm)

MCR 34/39MI

CO

2

%

44

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 45

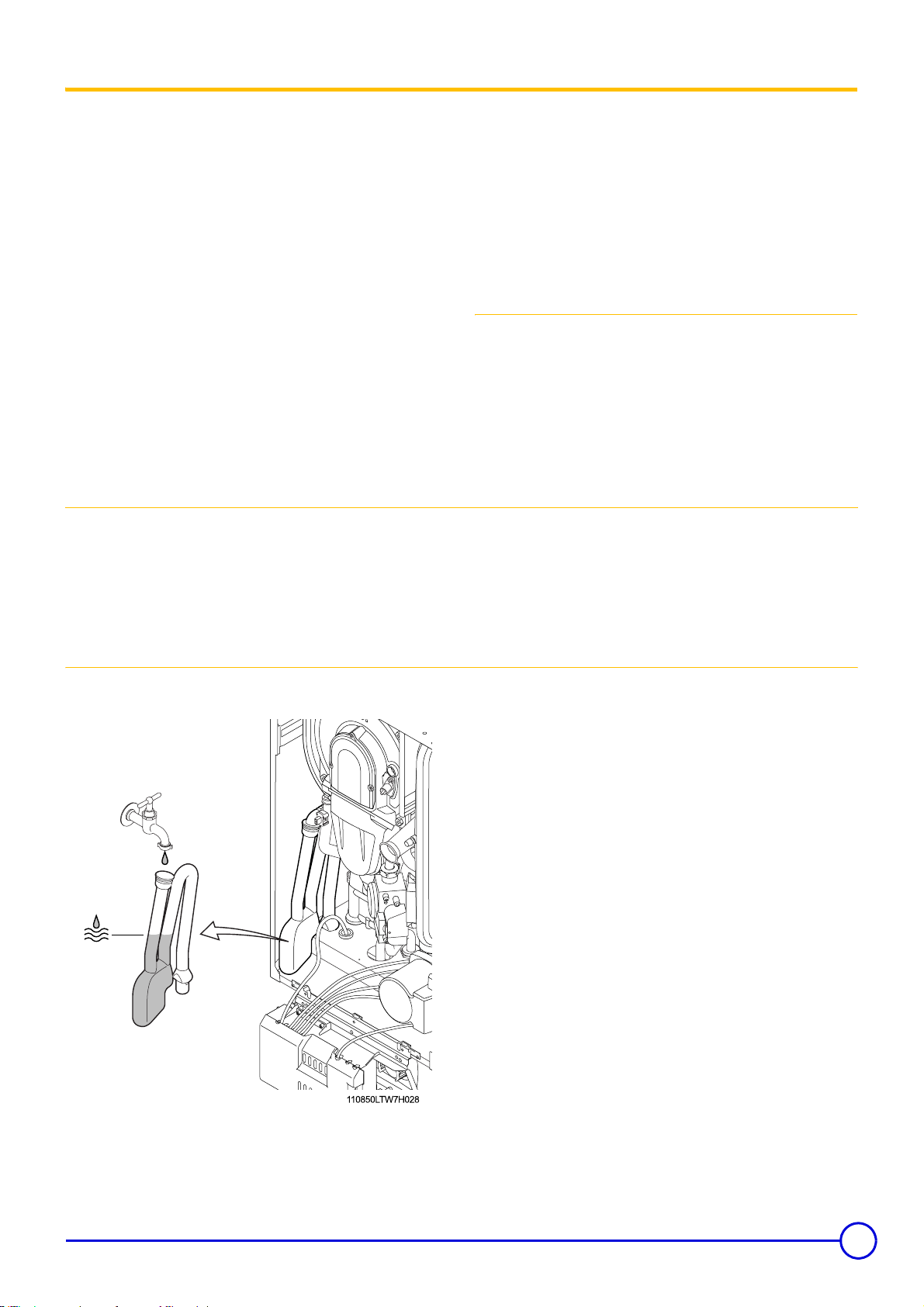

2.1 Adjusting the gas valve

110850LTW7H030

See "Setting the gas/air ratio".

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

45

Page 46

Maintenance

MCR boilers require little maintenance. An annual inspection is

compulsory.

Maintenance operations must be done by a qualified

professional.

If, on annual inspection, the combusted gas analysis is not in

compliance, a setting combustion operation must be carried

out.

1Inspection

Cut the power supply to the boiler.

Cut the gas supply to the boiler.

If the ionisation current is less than 3, check the ignition/

ionisation electrode as well as the ignition line and the earth

connection.

Only original spare parts must be used.

1.1 Checking the hydraulic pressure

46

Minimum pressure: 1 mbar. Add water to the installation if necessary.

Carry out a visual check for the presence of any water leaks.

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 47

1.2 Check the fresh air inlet and flue gas discharge ducts

(or the forced flue)

1.4 Checking the ignition electrode

The conduits must allow no leakage of flue gases and be resistant to

corrosion.

1.3 Checking condensates discharge (Siphon)

- Wipe off all traces of deposits using an abrasive cloth.

- Check the gap between the electrodes (3 to 4 mm).

- Check the leak proof seal.

- Check the ionisation current. If the ionisation current is less than

3µA, check the ignition/ionisation electrode as well as the ignition

line and the earth connection.

- Refit the ignition electrode .

The ignition cable is fixed to the ignition electrode and therefore

may not be removed.

Check the condensates discharge siphon; it must be filled with clean

water up to the mark.

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

47

Page 48

1.5 Checking combustion

Measure the content of O

/CO2 and the burnt gas temperature at the

2

flue gas sampling level point.

- Unscrew the upper part of the flue gas measuring point.

- Measure the O2 or CO2 content in the flue gases.

Check that the analysis probe is leakproof against gas at the

sampling level point, the extremity of the probe is in the centre

of the smoke evacuation pipe.

Values: Checks (Natural gas H

Boiler type

24 ca. 4600 ca. 1300 8.8 ±0.3 9.5 ±0.3

24/28MI ca. 5500 ca. 1300 8.8 ±0.3 9.5 ±0.3

30/35MI ca. 6300 ca. 1300 8.8 ±0.3 9.5 ±0.3

34/39MI ca. 6700 ca. 1300 8.8 ±0.3 9.5 ±0.3

Boiler type Fan speed (rpm)* CO2 (%)

24 ca. 4400 ca. 2000 10.5±0.3

24/28MI ca. 5200 ca. 2000 10.5±0.3

30/35MI ca. 6000 ca. 2000 10.5±0.3

34/39MI ca. 6400 ca. 2000 10.5±0.3

Full load H:3 Part load L:3

Fan speed (rpm)*

Values: Checks (Propane)

Full load H:3 Part load L:3

If the measured values differ from those given in the table, an

adjustment is necessary. Check the setting of the gas/air ratio and, if

necessary, correct it.

If you still do not manage to reach the values indicated, a

complete service of the boiler is required.

See "Maintenance".

Check the flame through the viewport; it must be stable and

blue in colour, with orange particles around the edges of the

burner (Full load).

CO2 (%)

For Belgium

CO2 (%)

48

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 49

2 Maintenance

Cut the power supply to the boiler.

Cut the gas supply to the boiler.

2.1 Open

Unscrew the 2 screws.

Remove the front panel. Disconnect the 2 ignition electrodes from

the connector/ignition on the gas valve (

).

2.3 Remove the front plate from the combustion chamber

Disconnect the ignition electrode from the transformer.

Disconnect the electrical connection from the gas valve unit.

Remove the gas block connection nut.

Disconnect the electrical connection to the fan.

Remove the nuts from the inspection hatch on the front of the heat

exchanger.

Then remove the inspection hatch, the fan and the gas valve unit.

2.2 Checking the ignition electrode / ionisaton sensor

- Dismantle the electrode pin and the earth cable.

- Unscrew the 2 screws. Remove the unit.

- Clean or replace the ignition electrodes.

08/06/06 - 300008460-001-B MCR 24, 24/28 MI, 30/35 MI, 34/39 MI

49

Page 50

2.4 Burner maintenance

Clean the burner with a brush, a vacuum cleaner or a blower.

Inspect the burner to detect any damage or cracks in the surface. If

the burner is damaged, replace it.

2.5 Maintenance of the heat exchanger

- Check the burner seal.

- Check the insulating component between the front plate and the

thermal exchanger.

A damaged or hardened seal must always be replaced.

Handle the front plate and the rear plate of the thermal

exchanger with care; they must not come into contact with

water.

- Descale the exchanger in order to maintain its performance levels.

- Clean the inside of the heat exchanger using a stiff brush

(optional).

50

MCR 24, 24/28 MI, 30/35 MI, 34/39 MI 08/06/06-300008460-001-B

Page 51

2.6 Cleaning the plate exchanger (for MCR ... MI)

Maintenance and cleaning of the heater must be carried out

at least once a year by a qualified technician.

Cut off the cold water supply and drain the DHW tank.

Bleed the boiler.

Unscrew the 2 screws.

Remove the exchanger.

Clean the plate heat exchanger with a descaling product (citric