Page 1

Instruction booklet

of your range cooker

Range cookers models

DCM671XE, DCV671XE, DCM672XE, DCV672XE,

DCM690XE, DCM691XE, DCM692XE, DCV690XE,

DCM6100XE, DCM6101XE, DCM6102XE, DCV6100XE,

DCM6121XE, DCM6122XE

Page 2

Thank you for choosing our product. From now on, cooking will always be

pleasantly creative with your new cooker.

We recommend carefully reading all the instructions in this manual, which

includes detailed information about the most suitable conditions for using the

cooker correctly and safely. These instructions also help you to become familiar

with each component.

Useful advice is given for using recipients, utensils, positions of guides and control

settings.

The correct cleaning operations contained in this manual allow you to maintain the

cooker's performance unchanged over time.

The individual sections are set out in order to allow you to become familiar with all

the functions in the cooker. The text is easy to comprehend and is accompanied

with detailed images and simple pictograms.

Reading this manual thoroughly will provide you with the answer to any question

that may arise regarding the correct use of your new cooker.

INSTRUCTIONS FOR THE INSTALLER: for the qualified technician who is in

charge of adequately checking the gas system, installing, commissioning and

testing the appliance.

INSTRUCTIONS FOR THE USER: include suggestions, the description of the

controls and the correct cleaning and maintenance operations for the appliance.

Page 3

Contents

1. General information ______________________________________ 5

1.1 Technical service _________________________________________________________ 5

2. Warnings for safety and use ________________________________ 6

3. Installation______________________________________________ 8

3.1 General warnings _________________________________________________________ 8

3.2 Fitting the front moulding ___________________________________________________ 9

3.3 Fitting the adjustable feet ___________________________________________________ 9

3.4 Electric connection _______________________________________________________ 10

3.5 Power consumption of the vitroceramic hob____________________________________ 12

3.6 Power consumption of the volcanic rock grill ___________________________________ 12

3.7 Ventilation requirements___________________________________________________ 13

3.8 Gas connection__________________________________________________________ 13

3.9 Stability chain ___________________________________________________________ 14

3.10 Gas regulations _________________________________________________________ 15

3.11 Connecting to LPG _______________________________________________________ 15

4. Final operations ________________________________________ 16

4.1 Fixing the free-standing cooking hob _________________________________________ 16

4.2 Levelling the cooker to the floor _____________________________________________ 16

5. Description of controls ___________________________________ 17

5.1 The front panel __________________________________________________________ 17

6. Using the cooking hob ___________________________________ 23

6.1 Switching on the burners __________________________________________________ 23

6.2 Switching off the burners __________________________________________________ 23

7. Using the deep fryer _____________________________________ 24

7.1 Before switching on the deep fryer ___________________________________________ 24

7.2 How to fry ______________________________________________________________ 24

7.3 Indicative frying times _____________________________________________________ 25

7.4 Switching off ____________________________________________________________ 25

8. Using the fry-top / steak grill _______________________________ 26

8.1 Before switching on the fry-top / steak grill _____________________________________ 26

8.2 Switching on ____________________________________________________________ 26

8.3 Energy regulator table ____________________________________________________ 26

8.4 Switching off ____________________________________________________________ 26

9. Using the volcanic rock grill _______________________________ 27

9.1 Before switching on the grill ________________________________________________ 27

9.2 Switching on ____________________________________________________________ 27

9.3 Energy regulator table ____________________________________________________ 28

9.4 Switching off ____________________________________________________________ 28

10. Using the vitroceramic hob _______________________________ 29

10.1 General warnings ________________________________________________________ 29

10.2 Switching on ____________________________________________________________ 29

10.3 Switching off ____________________________________________________________ 29

3

Page 4

11. Using the ovens _______________________________________ 30

11.1 General warnings ________________________________________________________ 30

11.2 Drawer and storage compartment ___________________________________________ 30

11.3 Using the electric multifunction oven _________________________________________ 30

11.4 Using the auxiliary oven with natural convection ________________________________ 32

11.5 Using the convection electric oven ___________________________________________ 33

11.6 Using the grill oven with natural convection ____________________________________ 34

Contents

12. Cooking suggestions____________________________________ 35

12.1 Suggestions for using the hob burners correctly ________________________________ 35

12.2 Suggestions for using the deep fryer correctly __________________________________ 35

12.3 Suggestions for using the fry-top / steak grill correctly ____________________________ 35

12.4 Suggestions for using the volcanic rock grill correctly ____________________________ 35

12.5 Suggestions for using the vitroceramic hob correctly _____________________________ 36

12.6 Suggestions for using the oven correctly ______________________________________ 36

13. Cleaning and maintenance _______________________________ 39

13.1 Cleaning stainless steel surfaces ____________________________________________ 39

13.2 Cleaning enamelled surfaces _______________________________________________ 39

13.3 Cleaning the knobs and the control panel _____________________________________ 39

13.4 Cleaning the grids and burners _____________________________________________ 39

13.5 Cleaning the igniter plugs and thermocouples __________________________________ 40

13.6 Cleaning the deep fryer ___________________________________________________ 40

13.7 Cleaning the fry-top / steak grill _____________________________________________ 40

13.8 Cleaning the volcanic rock grill ______________________________________________ 41

13.9 Cleaning the vitroceramic hob ______________________________________________ 41

13.10 Cleaning the oven________________________________________________________ 42

13.11 Replacing the oven light bulb _______________________________________________ 42

14. Special maintenance____________________________________ 43

14.1 Removing the oven door __________________________________________________ 43

14.2 Removing the side rack-holder frames________________________________________ 44

14.3 Removing and cleaning the inside oven fan____________________________________ 44

4

Page 5

Warnings

This user’s manual is an integral part of the product purchased. The user must conserve the manual

correctly so that it is always available for consultation during the use and maintenance of the

product. Keep this user’s manual for future reference. If the product is resold, the manual must be

transferred to any subsequent owner or user of the product.

CLASSES OF APPLIANCES

The cooking appliances described in this operating manual belong to the following installation

classes:

• Class 1: non-flush-mounted cooking appliance;

• Class 2 – subclass 1: cooking appliance flush-mounted between two

units, made up of a single unit, but which can also be installed so that the

side walls are accessible.

1. General information

This product conforms to the requirements of the following European directives:

• 73/23/EEC for "Low Voltage".

• 89/336/EEC for "Electromagnetic Disturbance".

• 90/396/EEC for "Gas Appliances".

• 89/109/EEC for "Material in contact with Food".

The above mentioned directives also conform to Machine directive 98/37/EC.

1.1 Technical service

Before leaving the factory, this appliance has been tested and set up by qualified, specialist

personnel, so as to guarantee the best operating results. Each repair or adjustment that may

subsequently be necessary must be carried out with the utmost care and attention. We therefore

recommend always contacting the Dealer where the appliance was purchased or your nearest

Service Centre, specifying the type of problem and the appliance model.

5

Page 6

Warnings

2. Warnings for safety and use

THIS MANUAL IS AN INTEGRAL PART OF THE APPLIANCE. IT SHOULD BE KEPT IN GOOD CONDITION AND CLOSE

TO THE APPLIANCE FOR THE WHOLE LIFECYCLE OF THE COOKER. WE RECOMMEND READING THIS MANUAL

VERY CAREFULLY BEFORE USING THE COOKER. IN CASE AN ADDITIONAL JETS KIT IS GIVEN AS ACCESSORY

TO THE COOKER, WE RECOMMEND KEEPING AND PRESERVING IT. THE INSTALLATION MUST BE CARRIED OUT

BY QUALIFIED PERSONNEL AND IN COMPLIANCE WITH CURRENT STANDARDS. THIS APPLIANCE IS FOR

DOMESTIC USE AND CONFORMS TO THE EEC DIRECTIVES CURRENTLY IN FORCE. THE APPLIANCE IS BUILT

FOR CARRYING OUT THE FOLLOWING FUNCTION: COOKING AND HEATING FOOD; ANY OTHER USE IS TO BE

CONSIDERED IMPROPER. THE MANUFACTURER DECLINES ANY RESPONSIBILITY SHOULD THE APPLIANCE BE

USED FOR PURPOSES OTHER THAN THOSE INDICATED.

AT THE MOMENT OF PURCHASE, THE USER ASSUMES DIRECT RESPONSIBILITY FOR THE PRODUCT AND MUST

THEREFORE MAKE SURE THAT, WITH NORMAL USE, NO INSTABILITY, DEFORMATION, BREAKAGE OR WEAR

OCCURS OVER TIME THAT WOULD REDUCE PRODUCT SAFETY.

THIS PRODUCT IS DESIGNED AND MANUFACTURED TO OPERATE SAFELY AND DOES NOT POSE ANY DANGERS

TO PEOPLE, ANIMALS, AND OBJECTS.

DO NOT LEAVE ANY PIECES OF THE PACKING UNATTENDED IN THE HOME. SEPARATE THE VARIOUS PACKING

MATERIALS AND DELIVER THEM TO THE NEAREST RECYCLING CENTRE.

THE EARTH CONNECTION IS OBLIGATORY CONFORMING TO THE MODALITIES ENVISAGED BY THE SAFETY

STANDARDS OF THE ELECTRICAL WIRING SYSTEM.

THE PLUG TO BE CONNECTED TO THE POWER SUPPLY CABLE AND THE RELATIVE SOCKET MUST BE THE

SAME TYPE AND MUST COMPLY WITH CURRENT STANDARDS. AFTER INSTALLING THE APPLIANCE MAKE SURE

THAT THE PLUG IS ACCESSIBLE TO ALLOW THE PERIODICAL CHECK-UP.

DO NOT PULL OUT THE PLUG BY PULLING THE CABLE.

SHOULD THE GAS TAPS BE DIFFICULT TO ROTATE, LUBRICATE THEM USING A SPECIFIC PRODUCT FOR HIGH

TEMPERATURES.

CONTACT THE TECHNICAL SERVICE FOR THIS OPERATION.

IMMEDIATELY AFTER INSTALLATION, TEST THE APPLIANCE BRIEFLY BY FOLLOWING THE INSTRUCTIONS

SHOWN BELOW. IN THE EVENT OF A MALFUNCTION, DISCONNECT THE APPLIANCE FROM THE MAINS AND

CONTACT YOUR NEAREST TECHNICAL SERVICE CENTRE.

DO NOT ATTEMPT TO REPAIR THE APPLIANCE.

EACH TIME YOU FINISH USING THE COOKING HOB, ALWAYS CHECK THAT THE CONTROL KNOBS ARE IN "ZERO"

POSITION (OFF).

6

NEVER PUT INFLAMMABLE OBJECTS INTO THE OVEN: SHOULD IT BE ACCIDENTALLY SWITCHED ON, A FIRE

MAY BREAK OUT. IN THE EVENT OF A FIRE: CLOSE THE MAIN GAS SUPPLY AND CUT OFF THE ELECTRIC

CURRENT. DO NOT THROW WATER ON BURNING OR FRYING OIL. DO NOT STORE INFLAMMABLE OBJECTS OR

AEROSOL CANS NEAR THE APPLIANCE AND DO NOT SPRAY NEAR THE BURNERS WHEN SWITCHED ON. DO

NOT WEAR BAGGY CLOTHES OR ACCESSORIES THAT ARE NOT CLOSE TO THE BODY WHEN THE BURNERS

ARE SWITCHED ON: SERIOUS INJURIES CAN BE CAUSED BY BURNING FABRIC.

Page 7

Warnings

DO NOT REST SAUCEPANS THAT DO NOT HAVE A PERFECTLY SMOOTH, EVEN BASE ON THE COOKING HOB.

DO NOT USE RECIPIENTS OR STEAK GRILLS THAT EXCEED THE OUTER PERIMETER OF THE COOKING HOB.

THE IDENTIFICATION PLATE WITH THE TECHNICAL DATA, SERIAL NUMBER AND THE MARK IS CLEARLY VISIBLE

ON THE BACK OF THE APPLIANCE.

THE PLATE MUST NEVER BE REMOVED.

THE APPLIANCE SHOULD ONLY BE USED BY ADULTS. DO NOT ALLOW CHILDREN TO APPROACH OR PLAY

WITH THE APPLIANCE. NEVER STORE ITEMS THAT CHILDREN MAY ATTEMPT TO REACH ABOVE THE

APPLIANCE. THE HEATING UP OF SOME PARTS OF THE APPLIANCE AND OF THE USED PANS MAY BE A

DANGER, SO DURING FUNCTIONING AND DURING ALL THE TIME NECESSARY FOR THE COOOLING DOWN, TAKE

CARE TO POSITION THE HOT PANS IN A WAY TO PREVENT BURNS OR OVERTURNING. AVOID LEAVING THE

OVEN DOOR OPEN DURING FUNCTIONING OR IMMEDIATELY SOON AFTER THE SWITCHING OFF. AVOID

TOUCHING THE HEATING ELEMENTS INSIDE THE OVEN AND GRILLS AS WELL.

RESTING OR SITTING ON THE OPEN OVEN DOOR, DRAWERS OR STORAGE COMPARTMENT CAN OVERTURN

THE APPLIANCE, AND CONSEQUENTLY CAUSE HARM. THE DRAWERS HAVE A DYNAMIC CAPACITY OF 25 KG.

IF THE COOKER IS SET ON A PEDESTAL, APPROPRIATE MEASURES MUST BE TAKEN TO PREVENT IT FROM

SLIDING OFF THE PEDESTAL.

WHEN THE APPLIANCE IS DECOMMISSIONED, IT MUST BE DISPOSED OF IN A SUITABLE RECYCLING CENTRE.

CUT OFF THE MAINS POWER CORD AFTER UNPLUGGING IT FROM THE WALL OUTLET, AND MAKE SAFE ANY

COMPONENTS WHICH MIGHT BE DANGEROUS FOR CHILDREN (DOORS, ETC.).

THIS APPLIANCE IS MARKED ACCORDING TO THE EUROPEAN DIRECTIVE 2002/96/EC ON WASTE ELECTRICAL

AND ELECTRONIC EQUIPMENT (WEEE).

BY ENSURING THIS PRODUCT IS DISPOSED OF CORRECTLY, YOU WILL HELP PREVENT POTENTIAL NEGATIVE

CONSEQUENCES FOR THE ENVIRONMENT AND HUMAN HEALTH, WHICH COULD OTHERWISE BE CAUSED BY

INAPPROPRIATE WASTE HANDLING OF THIS PRODUCT.

THE SYMBOL

ON THE PRODUCT, OR ON THE DOCUMENTS ACCOMPANYING THE PRODUCT, INDICATES

THAT THIS APPLIANCE MAY NOT BE TREATED AS HOUSEHOLD WASTE. INSTEAD IT SHALL BE HANDED OVER TO

THE APPLICABLE COLLECTION POINT FOR THE RECYCLING OF ELECTRICAL AND ELECTRONIC EQUIPMENT.

DISPOSAL MUST BE CARRIED OUT IN ACCORDANCE WITH LOCAL ENVIRONMENTAL REGULATIONS FOR WASTE

DISPOSAL. FOR MORE DETAILED INFORMATION ABOUT TREATMENT, RECOVERY AND RECYCLING OF THIS

PRODUCT, PLEASE CONTACT YOUR LOCAL CITY OFFICE, YOUR HOUSEHOLD WASTE DISPOSAL SERVICE OR

THE SHOP WHERE YOU PURCHASED THE PRODUCT.

The manufacturer declines any responsibility for damage incurred by persons or objects

that is caused by not following the above guidelines or by tampering with any part of the

appliance or by using non-original spare parts.

7

Page 8

Instructions for the installer

3. Installation

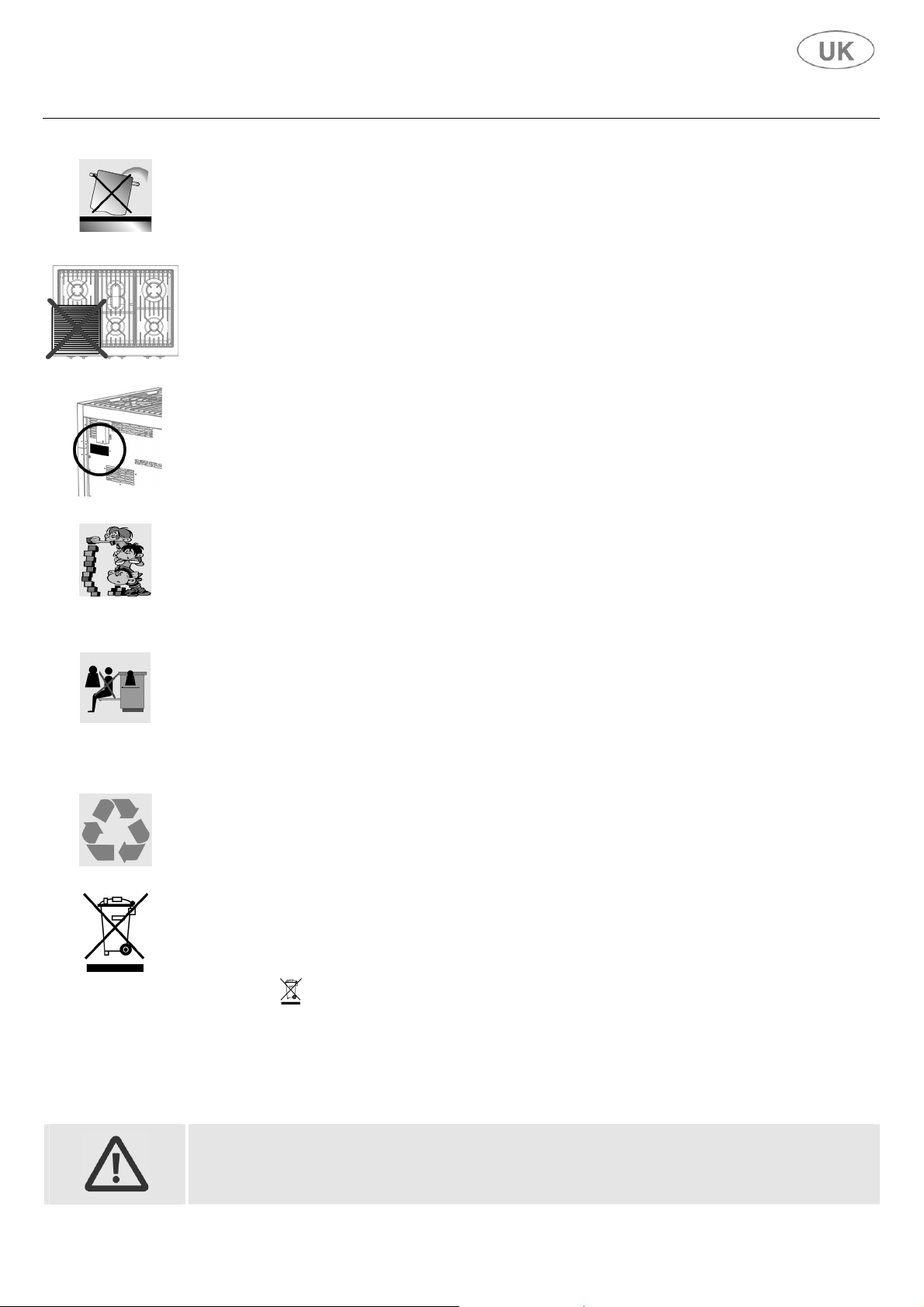

DIMENSIONS OF THE FREE-STANDING COOKING HOBS

DIMENSIONS OF THE COOKING HOBS

DIMENSIONS OF THE COOKERS

8

3.1 General warnings

It is the law that a competent person installs all gas appliances. In the UK Corgi gas

installers are approved to work to safe and satisfactory standards. The cooker must be

installed in accordance with BS 6172. Failure to install the cooker correctly could invalidate

the warranty liability claims could and could lead to prosecution.

The manufacturer declines any responsibility for damage incurred by persons, animals or

objects that is caused by not following the above guidelines (cfr. chapter “2. Warnings for

safety and use”).

The technical data is indicated on the plate located on the back of the appliance. The adjustment

conditions are shown on a label applied to the packing and the appliance.

Do not use the oven door handle for handling the appliance, or for removing the appliance

from the packing.

Page 9

Instructions for the installer

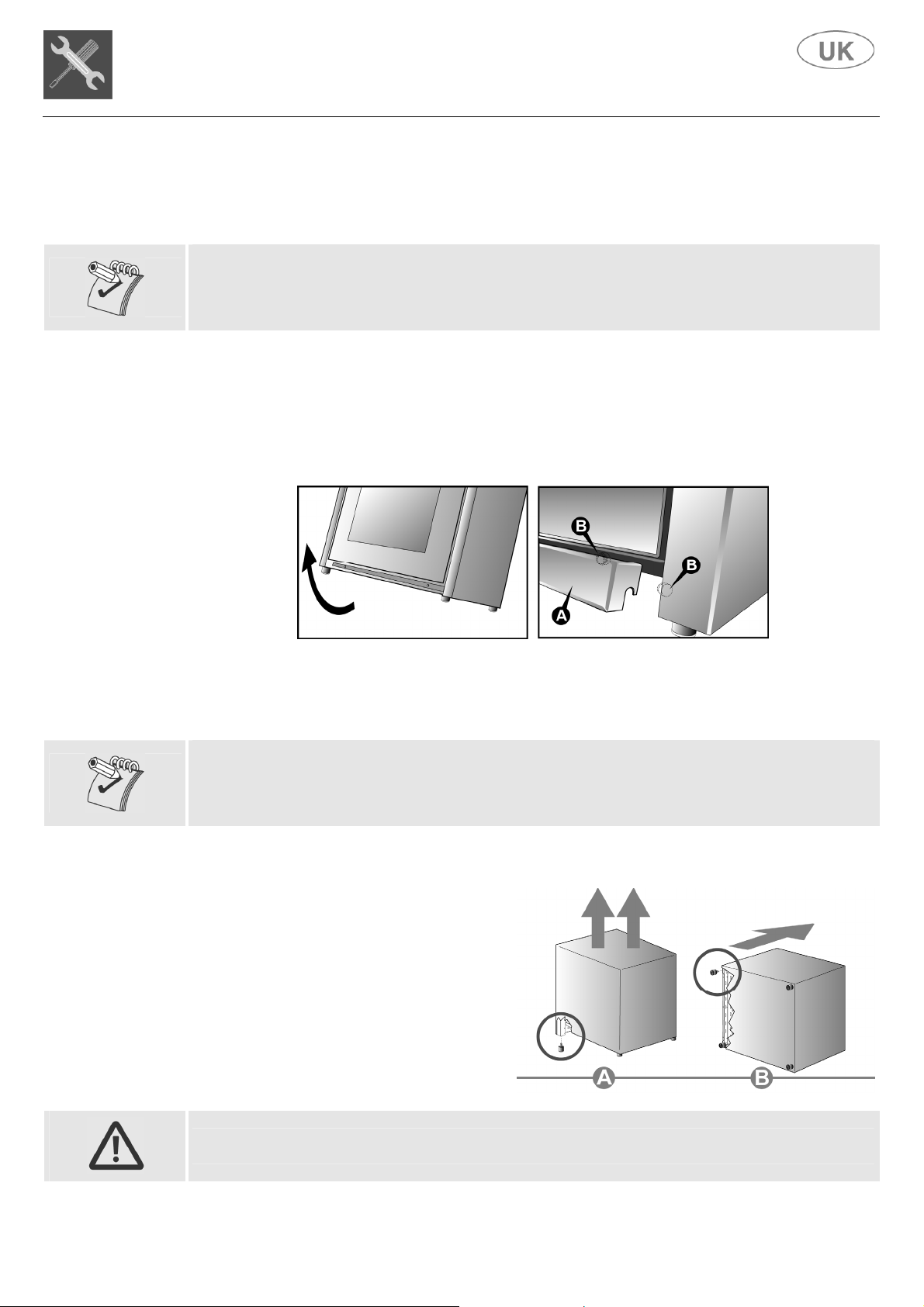

3.2 Fitting the front moulding

For the 70 cm model with double oven, a front moulding is included as standard supply to

complete the aesthetic lines of the cooker.

Before turning the cooker over, we recommend removing all the parts that are not stably attached

to it, in particular the cooking hob grids and burners. To lighten the weight of the cooker, the

accessories inside the oven may also be removed, thereby preventing accidental damage during

the overturning operation.

To assemble, proceed as follows:

• Tilt the cooker backwards.

• Align the moulding A with the mounting position as shown in the illustration.

• Apply the moulding until it fits into the mounting position.

• Pull the moulding downward so that it hooks onto the 4 pins B (2 for each end) present on the

cooker.

3.3 Fitting the adjustable feet

Before turning the cooker over, we recommend removing all the parts that are not stably attached

to it, in particular the cooking hob grids and burners. To lighten the weight of the cooker, the

accessories inside the oven may also be removed, thereby preventing accidental damage during

the overturning operation.

The cooker is delivered with the feet removed. Before moving and hooking up the cooker, take the

feet from the packing and screw them onto the cooker. This can be done in one of two ways:

A Lifting the cooker off the floor.

B Laying the cooker on its back.

The final regulation of the feet to level the

cooker to the floor will be done after the

gas and electric hook-ups have been

made.

Should it be necessary to drag the cooker, screw the feet in completely and carry out the final

regulation only when the other operations are completed.

9

Page 10

Instructions for the installer

3.4 Electric connection

Make sure that the voltage and the size of the mains corresponds to the specifications shown on

the plate located on the back of the appliance.

The plate must never be removed.

The plug at the end of the power supply cable and the wall socket must be the same type and must

comply with current electric standards. Check that the mains is adequately earthed. Once the

appliance has been installed make sure that the plug is accessible to allow the periodical check-up.

The power supply cable should conform to BS6004.

Prepare an omni-polar cutoff device on the power supply line of the appliance with a contact

opening distance equal to or more than 3 mm, located in a convenient position near the appliance.

Do not use reducers, adapters or shunts.

Before making the electric connection, make sure of the efficiency of the earthing.

Make sure that the relief valve and the home wiring system are able to withstand the appliance

load.

The yellow/green earth cable must not be subject to cutoffs.

The electric cable must not come into contact with parts whose temperature is more than 50°C

higher than room temperature.

The cooker should be installed in accordance with the latest edition of the IEE regulations.

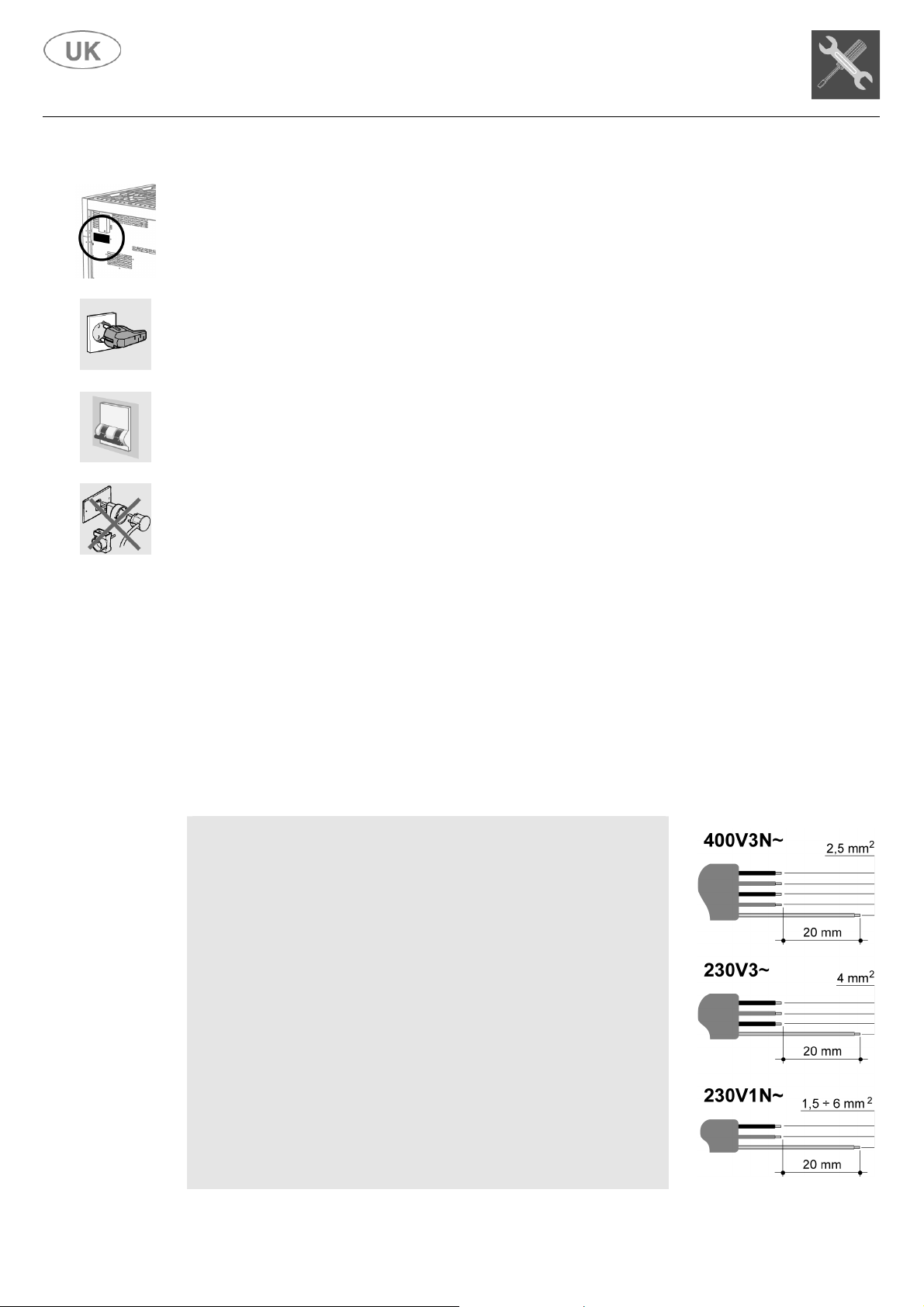

3.4.1 Electric power cable section

According to the type of power supply, use a cable that conforms to the following table.

Running at 400V3N~ (models connected according to DIAGRAM

"A"): use a pentapolar cable type H05RR-F/H05RN-F (cable

measuring 5 x 2.5 mm2).

Running at 230V3~ (models connected according to DIAGRAM

"C" but commutated by the installer according to DIAGRAM

"B"): use a tetrapolar cable type H05RR-F/H05RN-F (cable

measuring 4 x 4 mm2).

Running at 230V1N~ (models connected according to DIAGRAM

"C"): up to 2.9 kW use a tripolar cable type H05RR-F/H05RN-F

(cable measuring 3 x 1.5 mm2); between 2.9 kW and 5.4 kW use a

tripolar cable type H05RR-F/H05RN-F (cable measuring 3 x 2.5

mm2); between 5,4 kW and 7 kW use a tripolar cable type H05RRF/H05RN-F (cable measuring 3 x 4 mm2); over 7 kW use a tripolar

cable type H05RR-F/H05RN-F (cable measuring 3 x 6 mm2).

The end to be connected to the appliance must have the earth wire

(yellow-green) at least 20 mm longer.

The cable type H05RN-F is to be used for the models with fryer,

while cable type H05RR-F for those without fryer.

10

Page 11

Instructions for the installer

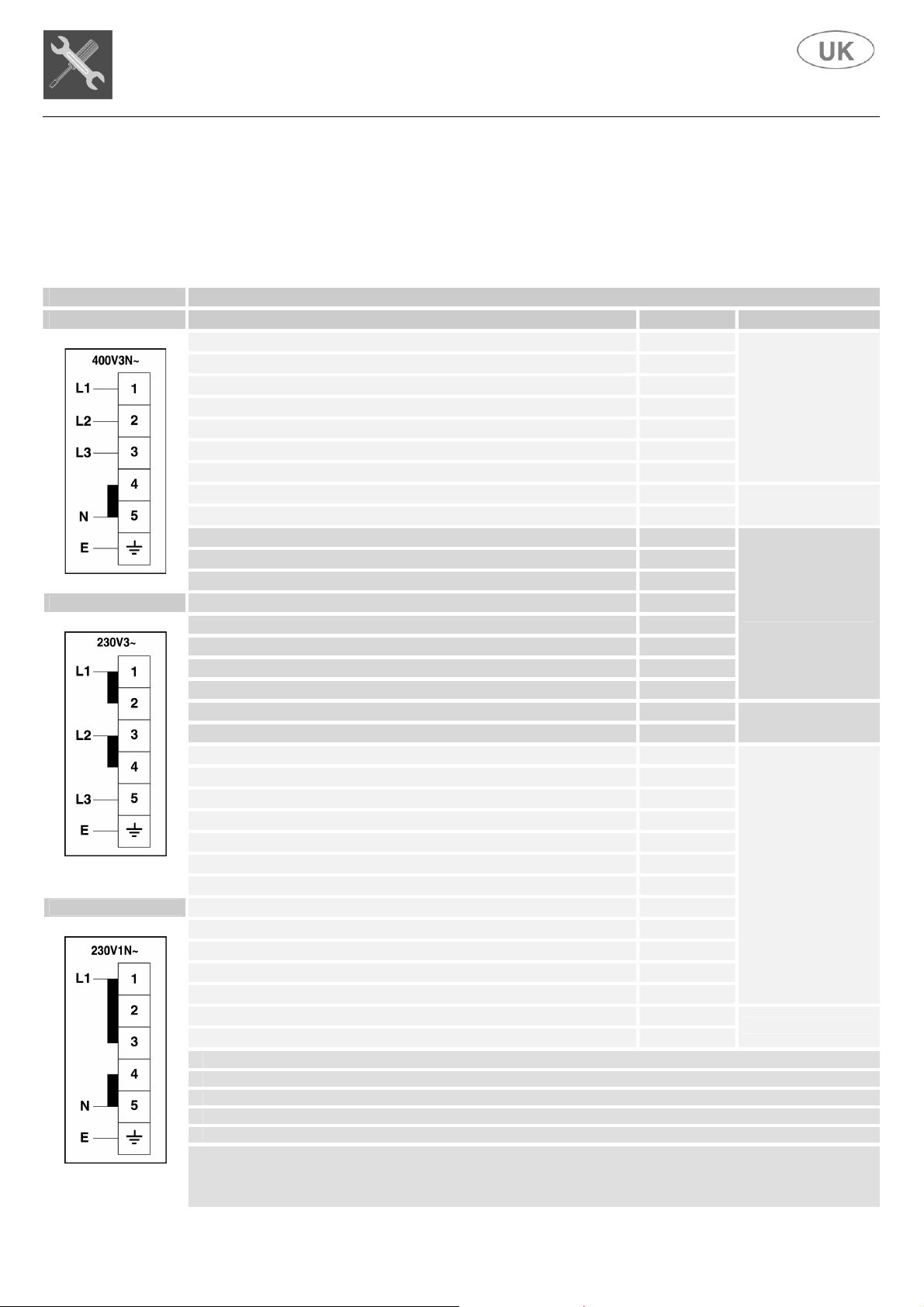

3.4.2 Type of power supply

It is possible to obtain different connections according to the voltage, simply by moving the

unconnected cable ends on the terminal board as shown in the following diagrams.

According to the model, consult the table "C

ONNECTION TO THE TERMINAL BOARD".

DIAGRAM CONNECTION TO THE TERMINAL BOARD

“A” MODEL POWER kW POWER SUPPLY

“B”

“C”

COOKING HOB 4 / 6 / 8 BURNERS 0,006

COOKING HOB 4 / 6 BURNERS + B / T / C 2,4

COOKING HOB 4 / 6 BURNERS + F 2,2

COOKING HOB 4 / 6 BURNERS + G 2,5

COOKING HOB 4 BURNERS + B / T + C 4,8

COOKING HOB 4 BURNERS + B / T + F 4,6

COOKING HOB 4 BURNERS + B / T + G 4,9

VITROCERAMIC HOB (4 HEATING ELEMENTS) 7,6

VITROCERAMIC HOB (5 HEATING ELEMENTS) 9,8

COOKER 4 BURNERS (1 OVEN) 2,2

COOKER 6 / 8 BURNERS (1 OVEN) 2,9

COOKER 4 / 6 BURNERS (1 OVEN) + B / T / C 5,3

COOKER 4 / 6 BURNERS (1 OVEN) + F 5,1

COOKER 4 / 6 BURNERS (1 OVEN) + G 5,4

COOKER 4 BURNERS (1 OVEN) + B / T + C 7,7

COOKER 4 BURNERS (1 OVEN) + B / T + F 7,5

COOKER 4 BURNERS (1 OVEN) + B / T + G 7,8

COOKER VITROCERAMIC HOB (1 OVEN) (4 HEATING ELEMENTS) 9,8

COOKER VITROCERAMIC HOB (1 OVEN) (5 HEATING ELEMENTS) 12,7

COOKER 6 BURNERS (2 OVENS) 3,9

COOKER 8 BURNERS (2 OVENS) 4,6

COOKER 4 BURNERS (2 OVENS) 4,7

COOKER 4 BURNERS (2 OVENS) + B / T / C 6,3

COOKER 4 BURNERS (2 OVENS) + F 6,1

COOKER 4 BURNERS (2 OVENS) + G 6,4

COOKER 6 BURNERS (2 OVENS) + B / T / C 7,0

COOKER 6 BURNERS (2 OVENS) + F 6,8

COOKER 6 BURNERS (2 OVENS) + G 7,1

COOKER 4 BURNERS (2 OVENS) + B / T + C 9,4

COOKER 4 BURNERS (2 OVENS) + B / T + F 9,2

COOKER 4 BURNERS (2 OVENS) + B / T + G 9,5

COOKER VITROCERAMIC HOB (2 OVENS) (5 HEATING ELEMENTS) 13,7

COOKER VITROCERAMIC HOB (2 OVENS) (4 HEATING ELEMENTS) 12,3

B = STEAK GRILL

T = FRY-TOP

C = VITROCERAMIC GRIDDLE

F = DEEP FRYER

G = GRILL

MODELS CONNECTED ACCORDING TO DIAGRAM "A" CAN BE COMMUTATED BY THE INSTALLER ACCORDING TO DIAGRAM

"B".

MODELS CONNECTED ACCORDING TO DIAGRAM "C" CAN BE COMMUTATED BY THE INSTALLER ACCORDING TO DIAGRAM

"A".

DIAGRAM “C”

DIAGRAM “A”

DIAGRAM “C”

DIAGRAM “A”

DIAGRAM “C”

DIAGRAM “A”

11

Page 12

Instructions for the installer

3.4.3 Replacing the electric cable

To replace the electric cable, it is necessary to access the terminal board. It is located on the back

of the appliance, at the top left, as shown in the figure.

To replace the cable, proceed as follows:

• open the terminal board box;

• unscrew the screw A that locks the cable;

• loosen the screw contacts and replace the cable

with one of the same length that corresponds to the

specifications in the table in section “3.4.1 Electric

power cable section”;

• the "yellow-green" earth wire must be connected to

the terminal

and must be approximately 20 mm

longer than the line cables;

• the neutral "blue" wire must be connected to the

terminal marked with the letter N;

• the line wire must be connected to the terminal

marked with the letter L.

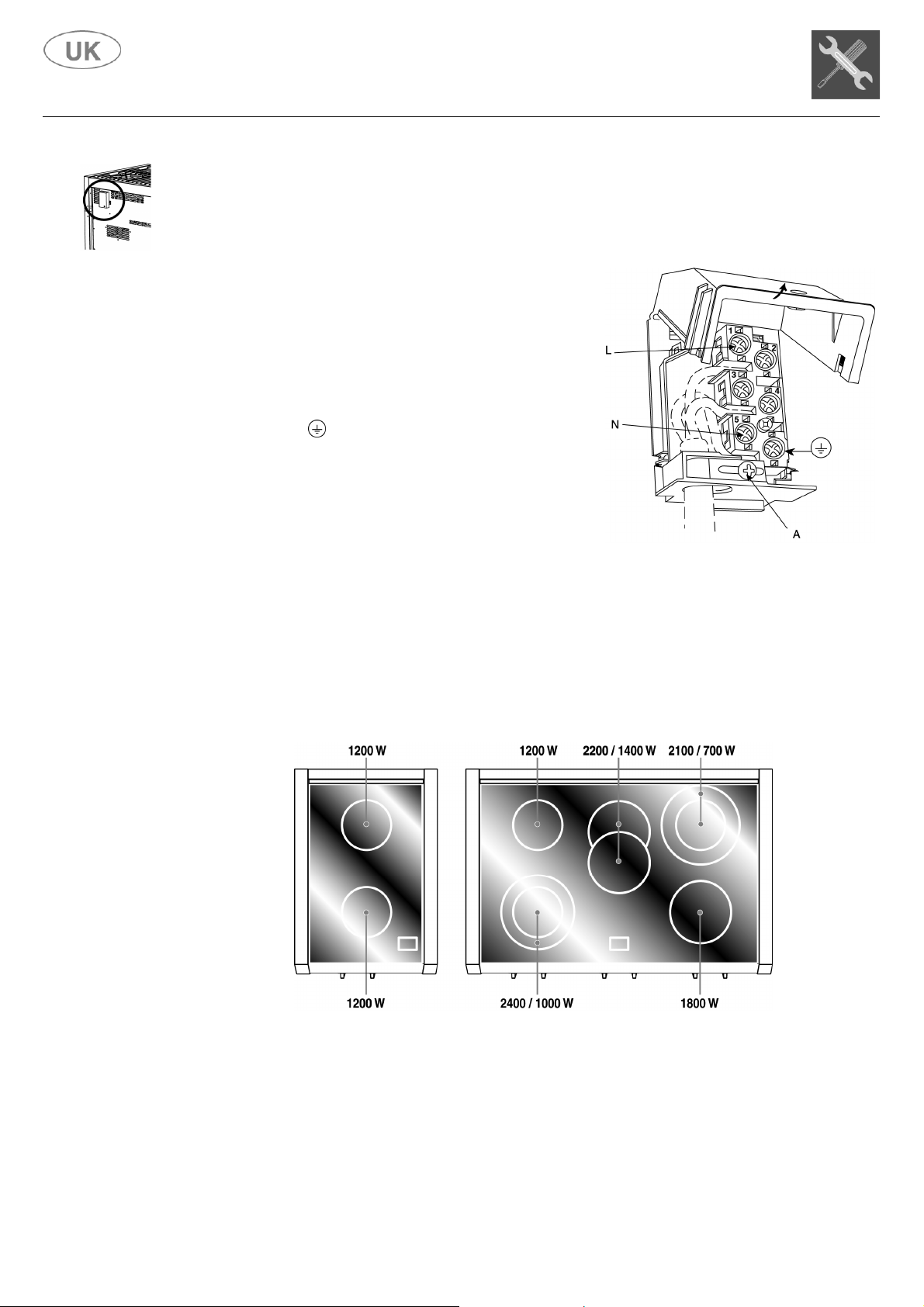

3.5 Power consumption of the vitroceramic hob

The vitroceramic hob has different power consumptions depending on the type of heating element

used. The diagram shows the values of the power consumed.

In the envisaged cases, the first numeric value refers to the total power, whereas the value that

follows the symbol "/" refers to the inside diameter, with the exception of the central heating

element, whose value that follows "/" refers to the outer diameter.

12

3.6 Power consumption of the volcanic rock grill

The volcanic rock grill has a consumption of 2500W. This appliance must therefore be installed

where this power consumption can be ensured in total safety.

Page 13

Instructions for the installer

3.7 Ventilation requirements

The room containing the appliances should have an air supply in accordance with B.S. 5440 part 2.

1. All rooms require an opening window or equivalent, and some rooms will require a permanent

vent as well.

2. For room volumes up to 5m³ an air vent of 100cm² is required.

3. If the room has a door that opens directly to the outside, and the room exceeds 1m³ no air

vent is required.

4. For room volumes between 5m³ and 10m³ an air vent of 50cm² is required.

5. If there are other fuel burning appliances in the same room B.S. 5440 part 2 should be

consulted to determine the air vent requirements.

6. The appliance must not be installed in a bed sitting room of less than 20m or in a bathroom or

shower room.

Windows and permanent vents should therefore not be blocked or removed without first consulting a

Corgi gas installer.

Failure to install appliances correctly is dangerous and could lead to prosecution.

DO NOT install LPG version below ground level. This does not exclude installation into a room, which

equates to a basement on one side of the building, but open to ground level on the opposite side.

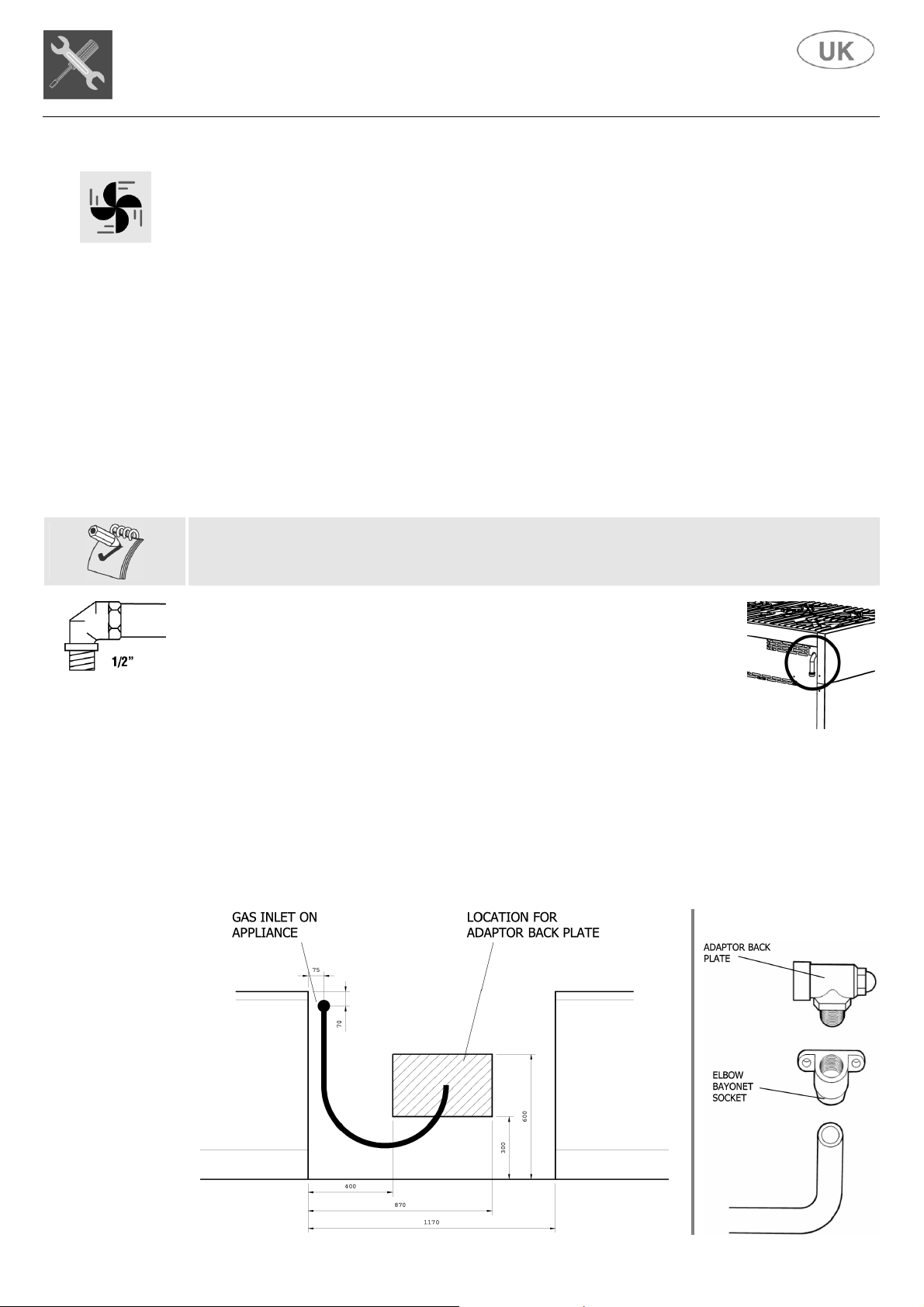

3.8 Gas connection

Gas-powered devices for home use, which are not connected to a conduit for the evacuation of

combustion products, must not cause a concentration of carbon monoxide that could pose a health

risk to the persons exposed in relation to the time of exposure.

We recommend checking that the appliance is properly set up for the type of

gas distributed. The threaded ½" gas connection pipe is located at the rear

on the right hand side of the appliance.

The cooker is designed to match the depth of standard 600mm worktops. An adaptor back plate

should, therefore, be fitted within the shaded area shown to allow the cooker to be pushed in fully

and chased to the wall.

Connection to the cooker should be made with an approved appliance flexible connection to

BS 669. A length of 0.9 to 1.25m is recommended. The length of hose chosen should be such that

when the cooker is in situ, the hose does not touch the floor.

The temperature rise of areas at the rear of the cooker that are likely to come in contact with the

flexible hose do not exceed 70°C.

13

Page 14

Instructions for the installer

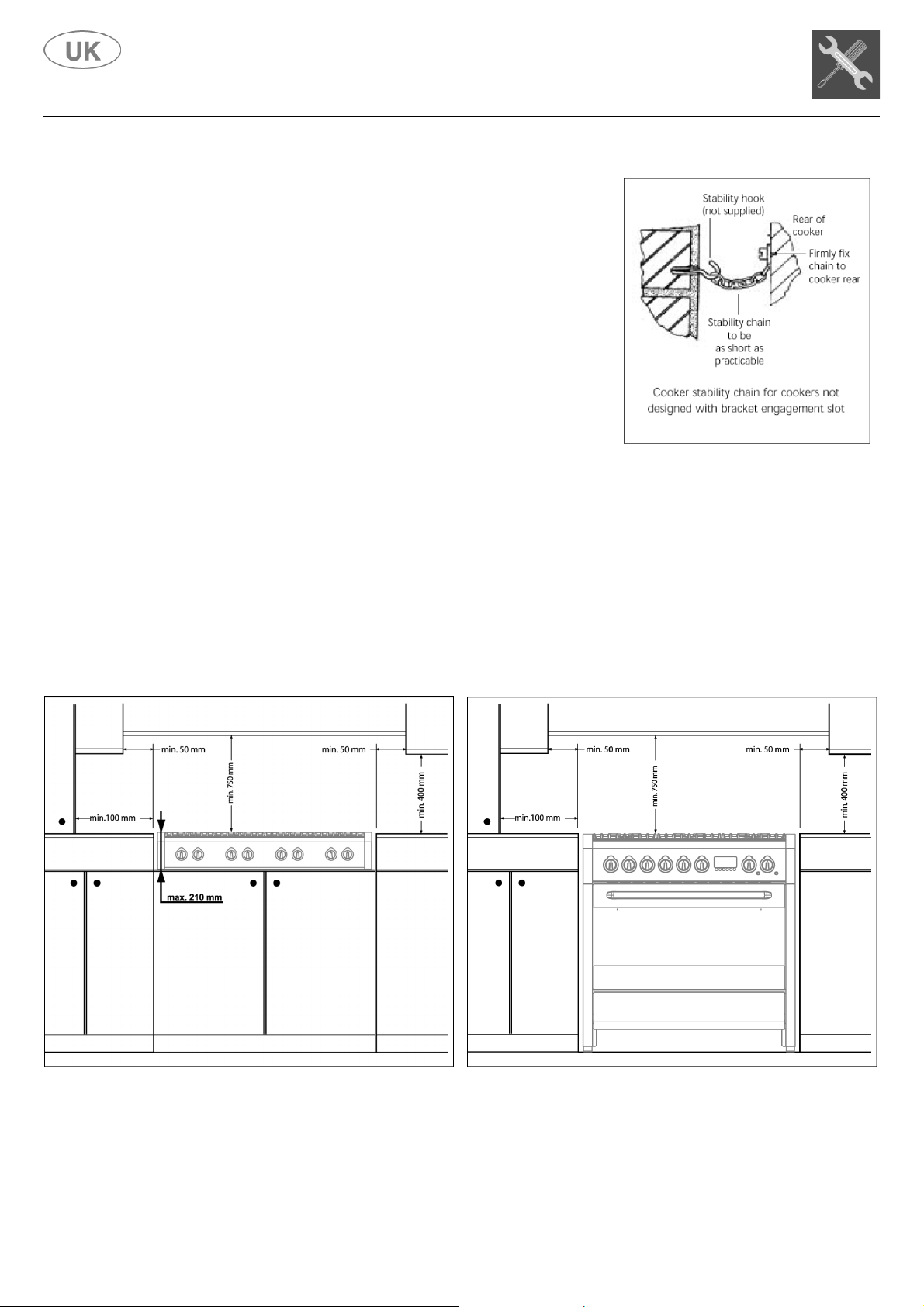

3.9 Stability chain

The cooker is fitted with a stability device such as a

proprietary stability chain as shown and firmly secured to the

fabric of the building.

Whatever the position, remember to leave enough room for

the cooker to be pulled out for cleaning and service.

The wall behind the cooker between the hotplate and 450mm above, and across the width of the

cooker, must be an incombustible material such as ceramic wall tiles.

This appliance is designed not to project in front of standard 600mm worktops (excluding handles).

To achieve the best fit the cooker must be pushed against the wall.

As this appliance is very heavy it should be situated on a suitably hard surface as to ensure

servicing and installation is made possible with minimal impact on the floor surface.

14

Page 15

Instructions for the installer

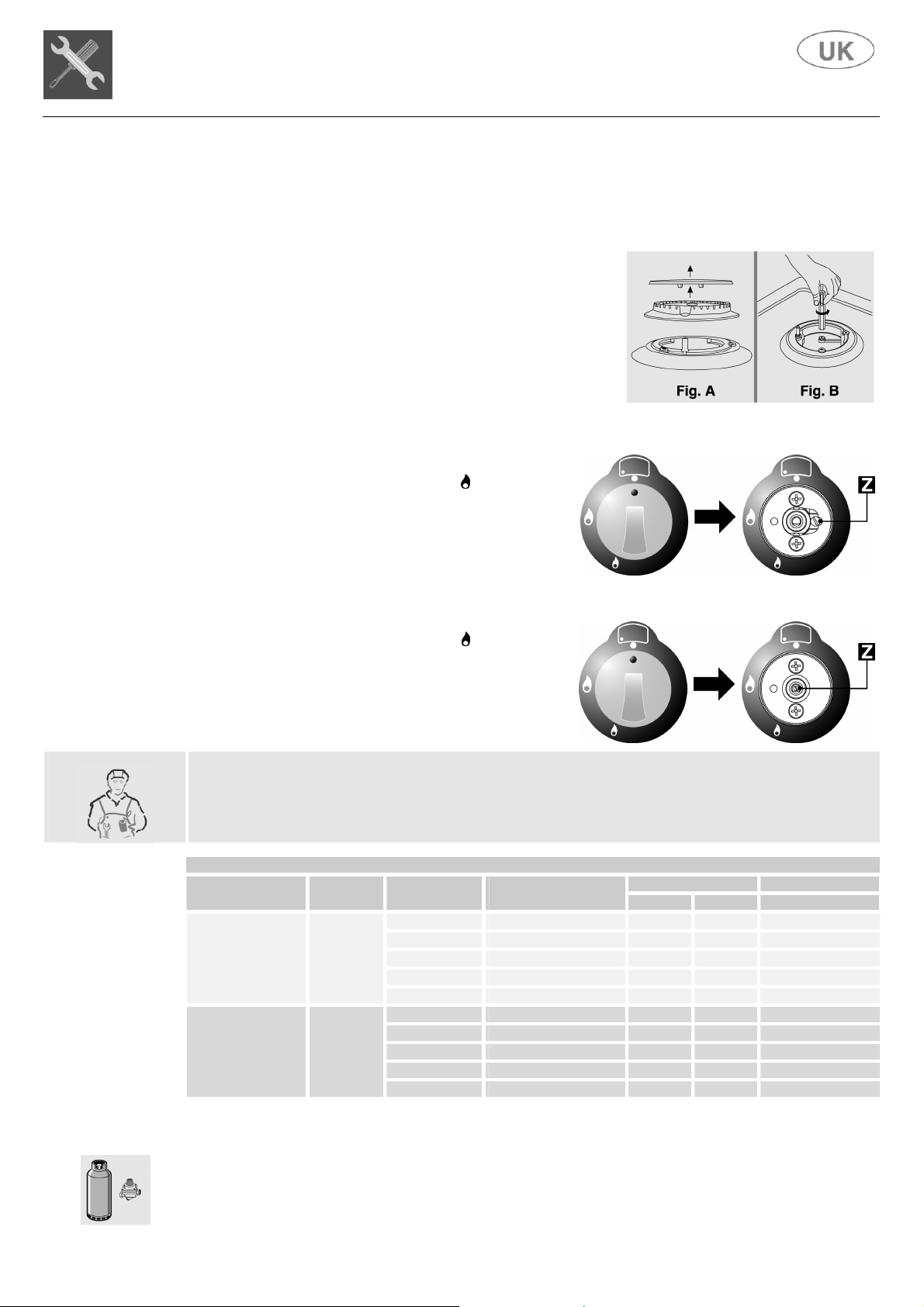

3.10 Gas regulations

If the cooking appliance is set up for a different type of gas than that available, its injectors must

be replaced, the minimum flow regulated. In order to replace the injectors in the cooking hob, it is

necessary to carry out the following operations:

• remove the pan supports;

• remove the burners and burner caps (Fig. A);

• take out the injector (Fig. B) and replace it with one

• replace the gas label (on the rear of the appliance) with

• refit all parts by following the disassembly instructions in

3.10.1 Minimum flow of valved cooking hob taps

• Switch on the burner and turn the control knob

• remove the knob;

• using a screwdriver, adjust the internal screw Z

• refit the knob.

3.10.2 Minimum flow of non-valved cooking hob taps

• Switch on the burner and turn the control knob

• remove the knob;

• insert a small screwdriver into the rod of the tap

• refit the knob.

• Unscrew the adjustment screw Z to increase the flow, or tighten it to reduce the flow.

• The adjustment is correct when the low flame measures approximately 3 or 4 mm.

• When changing quickly from maximum to minimum flow and vice versa make sure that the

3.11 Connecting to LPG

Use a pressure regulator and connect to the cylinder in compliance with the guidelines set out in

standards regulations in force.

suitable for the new type of gas (see "G

INJECTORS TABLE

");

ENERAL

the new one provided with the injectors kit;

reverse order and taking care to position the burner cap

correctly on the burner.

towards the minimum flow position ;

until the correct low flame is obtained;

towards the minimum flow position ;

and adjust the internal screw Z until the correct

low flame is obtained;

flame does not go out.

TYPE OF GAS

NATURAL GAS 20

LPG

BUTANE

PROPANE

mBar NOZZLE NO.

30

28

37

GENERAL INJECTORS TABLE

POSITION TYPE

115 RAPID 3000 750 286 l/h

97 SEMI RAPID 1750 480 167 l/h

72 AUXILIARY 1000 330 95 l/h

128 TRIPLE-RING 3300 1300 314 l/h

94 FISH KETTLE 1900 750 181 l/h

85 RAPID 3000 750 219 g/h

65 SEMI RAPID 1750 480 128 g/h

50 AUXILIARY 1000 330 73 g/h

93 TRIPLE-RING 3300 1300 241 g/h

68 FISH KETTLE 1900 750 138 g/h

BURNERS

POWER Watt CONSUMPTION

MAX. MIN. MAX.

15

Page 16

Instructions for the installer

4. Final operations

4.1 Fixing the free-standing cooking hob

Once the gas pipes and electric cables have been connected, the free-standing cooking hob must

be fixed to the support unit using the brackets A provided and the four screws B.

Make sure that the gas pipes and electric cables are not crushed or obstructed.

4.2 Levelling the cooker to the floor

After having made the electrical and gas hook-ups, level the cooker to the

floor using the adjustable feet that were previously screwed onto the bottom

of the cooker.

Should it be necessary to drag the cooker, screw the feet in completely and carry out the final

regulation only when the other operations are completed.

16

Page 17

Instructions for the user

5. Description of controls

5.1 The front panel

All the commands and controls for the cooking hob and oven are on the front panel.

THE CONTROL PANEL

DESCRIPTION OF HOB BURNER KNOB

The flame is lit by simultaneously pressing and turning the knob anticlockwise to

the low flame symbol .

To regulate the flow of the flame, turn the knob to between the maximum and

minimum settings. Turn off the burner by returning the knob to position .

LAYOUT OF BURNERS – Description of symbols

REAR LEFT

REAR CENTRE LEFT

CENTRE FRONT

FRONT CENTRE LEFT

FRONT LEFT

REAR RIGHT

REAR CENTRE RIGHT

CENTRE REAR

FRONT CENTRE RIGHT

FRONT RIGHT

17

Page 18

Instructions for the user

DESCRIPTION OF THE DEEP FRYER KNOB

The knob of the thermostat that controls the temperature of the heating

element can be adjusted between 0° and 200°C. There are also two warning

lights: the red light signals the deep fryer is working; the orange light

switches on while the appliance is heating. When the preset temperature is

reached, the orange light switches off. If the temperature of the oil should

decrease while frying, the appliance automatically begins to heat and the

orange light switches on until the temperature set on the thermostat knob is

reached.

DESCRIPTION OF FRY-TOP / STEAK GRILL AND GRILL KNOB

FRY-TOP/STEAK GRILL: is equipped with differentiated heating. The entire

cooking surface can be used, or only one of the two halves, front or rear. The

knobs that regulate the energy individually control the temperature of the two

heating elements. A red light indicates that the appliance is heating.

GRILL: two warning lights give essential information on how the appliance is

working. The orange light switches on to indicate that the appliance is

powered (ON). A red light indicates that the heating element is heating up.

LAYOUT OF HEATING ELEMENTS - Description of symbols

REAR

FRONT

DESCRIPTION OF TIMER KNOB (DEEP FRYER AND GRILL)

A spring-loaded timer with bell makes checking the frying time easier. Turn

the knob all the way clockwise to wind the timer. It is possible to set the

required time up to a maximum of 60 min. The bell rings briefly when the

preset time has elapsed. The timer has no effect on the heating of the deep

fryer or the grill.

DESCRIPTION OF VITROCERAMIC HOB KNOBS

Besides the normal knobs that regulate the energy, the

vitroceramic hob is equipped with knobs for differentiated

heating. Settings from 1 to 11 control the heating of the

internal element, setting the knob to the symbol the

outer element also operates.

LAYOUT OF HEATING ELEMENTS - Description of symbols

REAR LEFT

FRONT LEFT

CENTRAL

REAR RIGHT

FRONT RIGHT

18

Page 19

Instructions for the user

DESCRIPTION OF ELECTRIC OVEN KNOBS

The electric oven is controlled by two knobs: function

switch knob and thermostat knob. They allow you to

choose the most suitable type of heating for different

cooking requirements, by switching on the heating

elements appropriately and setting the required

temperature (from 50°C to MAX).

The V setting on the thermostat knob operates the oven fan.

Below the oven knobs there are two warning lights: the red light signals the oven is working; the

orange light indicates that the preset temperature has been reached. The orange light switches on

and off to indicate when the heating automatically kicks in to maintain the temperature inside the oven

at the level set on the thermostat knob.

The oven has an internal light. The light is always on while the oven is working: it can be switched

on while the oven is off, for cleaning purposes, by turning the function switch knob to the symbol

SWITCH ON LIGHT INSIDE OVEN

UPPER AND LOWER

HEATING ELEMENTS

UPPER HEATING ELEMENT

LOWER HEATING ELEMENT

GRILL ELEMENT

DESCRIPTION OF SYMBOLS ON THE FUNCTION SWITCH KNOB

GRILL-FAN ELEMENT

UPPER AND LOWER

HEATING ELEMENTS – FAN

HEATING ELEMENT-CONVECTION

DEFROST

DESCRIPTION OF AUXILIARY ELECTRIC OVEN KNOB

Some cooker models are equipped with an auxiliary electric oven with natural

convection, controlled by a single knob. This allows the user to choose the

most suitable type of heating for different cooking requirements, by switching

on the heating elements appropriately and setting the required temperature

(from 60 to MAX). Using the same knob it is also possible to set the functions

described in the table.

Below the auxiliary oven knob there is an orange light, which indicates when the oven has

reached the set temperature. The orange light switches on and off to indicate when the heating

automatically kicks in to maintain the temperature inside the auxiliary oven at the level set on the

control knob.

The auxiliary oven has an internal light. The light is always on while the oven is working: it can be

switched on while the oven is off, for cleaning purposes, by turning the function switch knob to the

60÷MAX

symbol

.

DESCRIPTION OF SYMBOLS ON AUXILIARY ELECTRIC OVEN KNOB

SWITCH ON LIGHT INSIDE OVEN

UPPER AND LOWER

HEATING ELEMENTS

LOWER HEATING ELEMENT

UPPER HEATING ELEMENT

GRILL ELEMENT + SPIT

19

Page 20

Instructions for the user

DESCRIPTION OF GRILL OVEN KNOB

The electric oven, equipped with function grill with natural convection, is

controlled by a single knob. By positioning the knob appropriately and by

setting the required temperature, both upper and lower heating elements will

switch on. It is possible to set one of the functions described in the table, but

in this case the temperature of the chosen heating element will be

automatically set to the MAX temperature value.

Below the grill oven knob there is an orange light, which indicates when the oven has reached the

set temperature. The orange light switches on and off to indicate when the heating automatically

kicks in to maintain the temperature inside the grill oven at the level set on the control knob.

The grill oven has an internal light. The light is always on while the oven is working: it can be

switched on while the oven is off, for cleaning purposes, by turning the knob to the symbol .

DESCRIPTION OF SYMBOLS

50÷MAX

SWITCH ON LIGHT INSIDE OVEN

UPPER AND LOWER

HEATING ELEMENTS

LOWER HEATING ELEMENT

UPPER HEATING ELEMENT

GRILL ELEMENT

DESCRIPTION OF CONVECTION OVEN KNOB

The convection oven is controlled by a single knob. This allows the user to

choose the most suitable type of heating for different cooking requirements

by setting the required temperature value (from 50°C to MAX).

Turning the knob to the "V" position activates the motorized fan, which aids in the thawing of frozen

foods by recirculating the air inside the oven.

Below the convection oven knob there is an orange light, which indicates when the oven has

reached the set temperature. The orange light switches on and off to indicate when the heating

automatically kicks in to maintain the temperature inside the convection oven at the level set on the

control knob.

The oven has an internal light. The light is always on while the oven is working: it can be switched

on while the oven is off, for cleaning purposes, by turning the knob to the symbol "V".

20

Page 21

Instructions for the user

DESCRIPTION AND USE OF THE END OF COOKING DISPLAY ON THE ELECTRIC OVEN

The end of cooking display electronically checks the operation of the oven. Programming the

display allows the user to set the oven to switch on and off at set times.

TIMER BUTTON

COOKING TIME BUTTON

END OF COOKING BUTTON

MANUAL OPERATION BUTTON

DECREASE VALUE BUTTON

INCREASE VALUE BUTTON

SETTING THE TIME

When using the oven for the first time, or after a power cut, the display flashes regularly indicating

.

Press button

to stop the flashing. Press the value variation buttons or within 5 seconds to

increase or decrease by one minute at a time. Press one of the two value variation buttons until the

current time appears.

Before setting the end of cooking display, it is necessary to select the required function and

temperature. The function P is not enabled.

SEMI-AUTOMATIC COOKING

This setting automatically switches off the oven at the end of the cooking.

Press button

same time the value variation buttons

Release the button

the current time together with symbols AUTO and

and the display lights up showing the figures ; hold down and press at the

or to set the cooking time.

to begin the count of the programmed cooking time and the display shows

.

AUTOMATIC COOKING

This setting switches the oven on and off automatically.

Press button

same time the value variation buttons

Press button

at the same time the value variation buttons

Release the button

together with symbols AUTO and

and the display lights up showing the figures ; hold down and press at the

or to set the cooking time.

to display the sum of the current time plus the cooking time: hold down and press

or to set the end of cooking time.

to begin the programmed count and the display shows the current time

.

After the setting, press button to see the remaining cooking time. Press button to see the end

of cooking time.

END OF COOKING

At the end of the cooking, the oven switches off automatically and at the same time an intermittent

bell rings. After deactivating the bell, the display once again shows the current time together with

symbol

, which signals the oven has returned to manual conditions.

21

Page 22

Instructions for the user

ADJUSTING THE VOLUME OF THE BELL

The volume of the bell can be varied (on 3 levels) while it is operating by pressing button

.

DEACTIVATING THE BELL

The bell automatically stops ringing after seven minutes. It is possible to deactivate it manually by

pressing button

.

After pressing button the oven begins to operate once again: to switch it off, turn the function

switch knob and the thermostat knob to “0”.

It is also possible to deactivate the bell by pressing any one of the function buttons. The oven

switches off regardless of the function or set temperature and the AUTO symbol flashes. To stop

the AUTO symbol flashing, press button

, turn the function selector switch and thermostat to "0".

TIMER

The end of cooking display can also be used as a simple timer.

Using the display as a timer does not interrupt the operation of the oven at the end of the set time.

Press button

the value variation buttons

display shows symbols

and the display shows the figures ; hold down and press at the same time

or . Release the button to begin the programmed count and the

and .

After programming the timer, the display once more shows the current time. To display the time

remaining, press button .

Setting inconsistent values is logically prevented (e.g. the end of cooking display does not accept a

contrast between an end of cooking time and a longer cooking time).

DELETING SET DATA

With the program set, hold down the button of the function you wish to delete while at the same

time reaching value with the value variation buttons or . Deleting the cooking time is

interpreted by the display as the end of the cooking.

MODIFYING SET DATA

The data set for cooking can be modified at any moment by holding down the button of the function

and at the same time pressing the value variation buttons

or .

22

Page 23

Instructions for the user

6. Using the cooking hob

Make sure that the flame caps, the burner caps and the pan supports are fitted correctly.

During normal operations, the appliance heats up considerably. Caution should therefore be used.

Do not allow children to approach the appliance. Do not leave the cooking hob unattended

while it is on.

6.1 Switching on the burners

All the hob burner knobs have the following symbols:

tap closed

high flame

low flame

The low flame setting is found by turning the knob anticlockwise all the way. All intermediate

settings must be selected between the high flame and low flame, never between high flame and

closed.

6.1.1 One-touch lighting

The hob burners are equipped with a "one-touch" lighting system. To switch on one of the burners,

press the knob corresponding to the required burner and turn it anticlockwise to the low setting

Hold down the knob to activate the automatic "one-touch" lighting system. When the burner is on,

hold down the knob for approximately 10 seconds, to allow the safety valve to open. In the event

of a power cut, the burner can also be lit with a match (see section “6.1.2 Manual lighting”).

Should the burner switch off accidentally, the safety thermocouple blocks the gas flow, even when

the tap is open.

Appliances not equipped with safety valve: it is not necessary to hold down the knob (the

burner is immediately operative). Take care, however, as if the flame should go out accidentally,

gas will continue to come out of the burner.

The device should not been activated for longer than 15 seconds. If after that time it fails to

operate stop pressing the knob, open the window and wait 1 minute before trying again. In case

the flame goes out accidentally turn off the knob and do not try to switch on the burner for at least

1 minute.

6.1.2 Manual lighting

To light one of the burners, move a lit match towards the burner, press the corresponding knob and

turn it anticlockwise to the minimum setting

6.2 Switching off the burners

. Release the knob.

At the end of the cooking, return the knob to position .

.

23

Page 24

Instructions for the user

7. Using the deep fryer

During normal operations, the surface of the deep fryer heats up considerably. Do not allow

children to approach the deep fryer. Do not leave the deep fryer unattended while it is on. Oil or

fat in bad condition may burst into flames.

7.1 Before switching on the deep fryer

The first time it is used, the deep fryer may develop an acrid or burnt smell caused by oily residue

from manufacturing that may give unpleasant odours or flavours to fried food. To eliminate this

problem, clean the vat, basket and heating element before use.

Proceed as follows:

• wash the basket in warm water and detergent;

• pour warm water into the deep fryer vat and add detergent for stainless steel surfaces;

• carefully wash the vat and the heating element;

• lift the heating element upwards, rinse and dry;

• lock the heating element by moving the lock system S

towards the left as shown in the figure;

• remove the frying vat, rinse away the soapy water with

running water;

• dry the vat and return it to its working position;

• release the lock system S and lower the heating element

into the vat.

7.2 How to fry

Proceed as follows:

• pour 3 litres of oil into the deep fryer vat. It is also possible to fry with fat: in this case, chop up

approximately 3.5 kg of frying fat.

• Switch on the heating element (see below for relative instructions).

• If using fat, leave it to melt slowly in the deep fryer vat.

To avoid abnormal overheating: until the heating element is completely covered with melted fat,

we recommend switching the heating element on and off repeatedly by using the thermostat knob.

• Heat the oil or fat to a maximum of 190°C. This temperature should not be exceeded,

otherwise the oil or fat would overheat and change consistency.

The heating element should never be switched on unless the frying vat contains the above

mentioned quantity and type of oil or fat.

The appliance is now ready for frying.

Proceed as follows:

• use the thermostat knob to set the required degree of heating: the deep fryer starts to operate

and the red and orange lights switch on;

• wait until the orange light switches off, which means that the frying liquid has reached the

preset temperature;

• place the food to be fried in the basket and lower it very slowly into the frying vat;

24

Page 25

Instructions for the user

• lift the basket periodically to check the frying. When the food is

• hang the basket on the element of the deep fryer (as shown in

Each time the deep fryer has been used, check the level of

frying liquid.

Check the level of frying liquid by lifting out the basket and

checking that the level is between the two minimum and maximum

marks punched on the wall of the frying vat.

The water contained in food goes to the bottom of the frying vat, into the so-called cold area. In this

way, it is practically impossible for the frying liquid to overflow out of the vat. Food particles that

come out of the basket while cooking also go to the cold area.

7.2.1 Tripping of the temperature limiting device

The deep fryer is equipped with a temperature limiting device in the vat. In the event that the frying

liquid temperature exceeds the preset value, this device cuts off the heating (both lights switch

off). To reactivate the heating of the deep fryer, rearm the limiting device manually.

Proceed as follows:

• wait until the frying liquid has cooled down;

• lift the heating element upwards and remove the frying vat from

• press the small red pushbutton on the bottom of the vat

• replace the frying vat into its working position and lower the

• It is now possible to reactivate heating (red and orange lights

Should the appliance unexpectedly turn off after following the above instructions, switch off

the master power switch and contact the Technical Service.

7.3 Indicative frying times

The frying times indicated in the table are approximate and vary according to the condition of the

food and personal taste.

FOOD FRYING TIME HEATING

Chicken (1100 g) 20 min.

Fries (500 g frozen) 6 min. 190°C

Fries (500 g frozen) repeat 2 min. 190°C

Milanese cutlet (370 g) 5 min. 170°C

Sliced onions (approx. 500 g) 5 min. 190°C

7.4 Switching off

After frying, return the thermostat knob to position "0".

crisp as required, remove the basket completely from the frying

liquid and shake it lightly to remove excess liquid;

the figure) and allow to drip.

the deep fryer;

compartment, whose position is shown in the figure;

heating element.

on).

(turn after 10 min.)

190°C

25

Page 26

Instructions for the user

8. Using the fry-top / steak grill

During normal operations, the appliance heats up considerably. Caution should therefore be used.

Do not allow children to approach the appliance. Do not leave the fry-top/steak grill unattended

while it is on.

Depending on the model, the appliance is fitted with a fry-top with smooth griddle, or a steak grill

with lined griddle.

FRY-TOP STEAK GRILL

8.1 Before switching on the fry-top / steak grill

The first time it is used, the fry-top/steak grill griddle may develop an acrid or burnt smell caused by

oily residue from manufacturing that may give unpleasant odours or flavours to food. To eliminate

this problem, clean the griddle as described in section “13.7 Cleaning the fry-top / steak grill” before

use.

8.2 Switching on

The fry-top/steak grill is equipped with differentiated heating. The entire surface of the griddle can

be used, or only one of the two halves, front or rear.

Position the control knob of the heating element to the required setting. The red light switches on

to indicate the appliance is working. Place the food on the griddle and cook as preferred.

8.3 Energy regulator table

The following table offers only indicative values because, according to the thickness and type of

food, as well as personal taste, the heat should be higher or lower.

1 - 4

Maintaining the heat on the griddle

26

5 - 7

8 - 9

10 - 11

After cooking, return the knob to position .

11

8.4 Switching off

For light cooking

To grill

To grill thicker meat

For rapid warming and cleaning

Page 27

Instructions for the user

9. Using the volcanic rock grill

During normal operations, the appliance heats up considerably. Caution should therefore be used.

Do not allow children to approach the appliance. Do not leave the grill unattended while it is on.

9.1 Before switching on the grill

The first time it is used, the grill may develop an acrid or burnt smell caused by oily residue from

manufacturing that may give unpleasant odours or flavours to food. To eliminate this problem,

clean all its components beforehand as described in section “13.8 Cleaning the volcanic rock grill”.

9.2 Switching on

Proceed as follows:

• Remove the cast iron grill very carefully to

avoid breaking it;

• lift the heating element upwards and lock it, by

moving the lock system

S towards the left as

shown in the figure;

• fill the safety vat with the volcanic rock, taking

care to evenly cover the whole surface, so that

it does not go over the edge.

Water (up to 2 litres) can be used in the safety vat instead of volcanic rock. It is advisable to use

water when cooking very fatty meat (e.g. sausage, bacon, etc.), as the meat juices will melt

instantaneously in the water. This method prevents excessive smoke and simplifies the cleaning

operations described in section 13.8.

The heating element should never be switched on unless the safety vat contains the volcanic rock

or water as specified above.

• Release the lock system S and lower the

heating element;

• reposition the cast iron grill over the heating

element as shown in the figure.

The cast iron grill ensures adequate heat

distribution.

• The appliance is ready to be switched on.

Before use, preheat the cast iron grill for 5 or 10 minutes by turning the energy regulator knob to

the maximum setting (11). The red light signals the appliance is working.

• Now turn the energy regulator knob to the required setting (see section “9.3 Energy regulator

table”). Place the food on the cast iron grill and cook as required.

27

Page 28

Instructions for the user

The appliance can also be used in the same way as an “open burner”, which is ideal for

simmering. Only use multi-function pans whose dimensions are compatible with the cooking

surface of the cast iron grill. This type of cooking is ideal for: beef stews, grilled pork, blanquette,

rabbit with beer, tongue.

Proceed as follows:

• preheat the cast iron grill by turning the energy regulator knob to the maximum setting (11) for

a few seconds;

• turn the regulator knob back to the minimum setting (1);

• position the multi-function pan containing the food to be cooked on the cast iron grill;

• put the lid on the pan to keep in humidity or remove to reduce.

9.3 Energy regulator table

The following table offers only indicative values because, according to the thickness and type of

food, as well as personal taste, the heat should be higher or lower.

1 - 4

Maintaining the heat on the cast iron grill

5 - 7

8 - 9

10 - 11

11

For light cooking

To grill

To grill thicker meat

For rapid warming and cleaning

9.4 Switching off

After cooking, return the knob to position .

28

Page 29

Instructions for the user

10. Using the vitroceramic hob

During normal operations, the appliance heats up considerably. Caution should therefore be used.

Do not allow children to approach the appliance. Do not leave the vitroceramic hob unattended

while it is on.

10.1 General warnings

The first time it is heated, the vitroceramic hob may develop an acrid or burnt smell caused by oily

residue from manufacturing, which disappears completely after repeated use.

The vitroceramic hob is fitted with a cooking area with various diameters and power (see section

“3.5 Power consumption of the vitroceramic hob”). Their position is clearly indicated with circles

and the heat is delimited within the diameters marked on the glass.

10.2 Switching on

Position the pan or pot with the food to be cooked inside it on the required heating element.

Turn the energy regulator knob to the required setting. After a few moments, the latent heat light

corresponding to the selected heating element switches on.

If the vitroceramic hob is used to boil water, once it has boiled, turn the energy regulator knob to a

lower setting to prevent the liquid in the pot from boiling over and soiling the surface.

Some knobs are fitted with a supplementary heating setting (griddle with dual heating

element). To activate it, turn the energy regulator knob to position

.

10.3 Switching off

After cooking, return the knob to position

.

The vitroceramic hob features a latent heat light which

reproduces in reduced scale the position of the heating

diameters. This light signals that the surface area is still hot.

Do not clean or touch the surface until the latent heat light has switched off.

29

Page 30

Instructions for the user

11. Using the ovens

11.1 General warnings

When the oven or grill is operating, the outer walls and oven door can become very hot.

Keep children away from the appliance.

Do not allow children to sit on the oven door or play with it.

Do not use the door as a stool.

Do not cook food on the bottom of the oven.

When using the oven for the first time, or after a power cut, the display flashes regularly indicating

. To set the display, refer to section "SETTING THE TIME” on page 21.

Do not attempt to disassemble the oven door without consulting the relative instructions carefully

(refer to section “14.1 Removing the oven door”): the hinges on the oven door may injure the

hands.

HEATING BLOCK OF THE OVEN

If during normal operation the oven interrupts heating and the programmer display begins to flash

and goes to zero, check whether:

• there has been a current interruption.

If the block occurs again after the cooking programme has been restarted, this means that the

safety device has been tripped. This device intervenes in the event of a thermostat fault and

prevents oven overheating. In such case, we recommend that you not try to light the oven again

and that you contact your nearest service centre.

11.2 Drawer and storage compartment

In some models a storage drawer is

provided on the lower part of the cooker

beneath the oven or in the next side

compartment. Use this cabinets only to

store metal cooker accessories.

Do not store inflammable material such as cloths, paper or similar in the drawer and storage

compartment.

11.3 Using the electric multifunction oven

The end of cooking display and the control knobs on the main oven

have no bearing on the operation of the auxiliary oven.

11.3.1 Switching on the oven for the first time

The first time it is used, the oven may smoke or give off

an acrid smell caused by oily residue from manufacturing

that may give unpleasant odours or flavours to food.

Before putting food in the oven, heat to the maximum

temperature for 30-40 minutes with the door closed

and wait until the smoke or odour has stopped.

30

Page 31

Instructions for the user

To prevent any steam in the oven from scalding, proceed as follows:

turn the function switch knob to "0", or to function ; open the door in

two stages: hold it partly open (approx. 5 cm) for 4-5 seconds, then

Should you need to adjust the food, leave the door open for as short a

open it completely.

time as possible to prevent the temperature inside the oven from

lowering to such an extent as to jeopardise cooking.

11.3.2 Traditional cooking

Turn the function switch knob to position and the thermostat knob in correspondence with the

required temperature value. For differentiated heating over or below the food, set the function

selector switch to position

the oven, turn the function switch knob to position

(hot above) or (hot below). For more uniform heating throughout

.

After preheating and putting the food in the oven an air flow between the upper side of the door and

the lower side of the hob may be noticed. In case that does not happen, switch off the

appliance and contact the Technical Service immediately.

11.3.3 Convection cooking

Turn the function switch knob to position ; turn the thermostat knob in correspondence with the

required temperature value.

11.3.4 Cooking with the ventilated grill

Turn the function switch knob to position ; turn the thermostat knob in correspondence with the

maximum temperature value (MAX).

11.3.5 Cooking with the grill + roasting spit

Turn the function switch knob to position ; turn the thermostat knob in correspondence with the

maximum temperature value (MAX). The grill and spit operate at the same time, allowing for

cooking on the spit.

11.3.6 Cooking with the roasting spit

If your oven model has a roasting spit, proceed as follows:

• Slide the meat to be cooked on the spit rod A and secure it with the adjustable forks.

• Hang the hook B at the top of the oven as shown in the figure.

• Place the spit rod A into the hole C in the oven casing; before closing the oven door, make

sure that the rod A is correctly inserted into the hole C (insert the rod and turn it slightly back

and forth).

• Hang the other end of the spit rod to the hook B (the

pulley of the rod A is situated on the handle of the

hook B).

• Close the oven door and activate the spit by turning

the function selector knob to the

position.

• When cooking is completed, open the oven door and

remove the spit rod using the plastic handle D, which

is screwed into the base of the rod A.

11.3.7 Defrosting

Turn the function switch knob to position , turn the thermostat knob to position "0": in this way the

motor fan is activated, which moves the air inside the oven and encourages frozen food to defrost.

11.3.8 Switching off the oven

The oven is switched off by returning the thermostat knob to position "0".

31

Page 32

Instructions for the user

11.4 Using the auxiliary oven with natural convection

The end of cooking display and the control knobs on the main oven

have no bearing on the operation of the auxiliary oven.

The auxiliary oven with natural convection is equipped with:

• a heating element positioned on the base of the oven (at the bottom);

• a heating element positioned on the ceiling of the oven (at the top) +

grill.

11.4.1 Switching on the auxiliary oven for the first time

The first time it is used, the auxiliary oven may smoke or give off an acrid smell caused by oily

residue from manufacturing that may give unpleasant odours or flavours to food. Before putting

food in the oven, heat the auxiliary oven to the maximum temperature for 30-40 minutes with

the door closed and wait until the smoke or odour has stopped.

To start heating the auxiliary oven, select the temperature (from 60 to MAX) or the required

function by turning the thermostat knob.

11.4.2 Cooking with the grill (auxiliary oven)

Turn the thermostat knob to position and let the auxiliary oven preheat for approximately 5

minutes. For correct operations, position the grill shelf on the third guide from the bottom. It is

however possible to vary the position of the grill shelf according to personal taste and different

cooking requirements. Before putting food in the oven, allow it to preheat for 5 minutes. A cooling

system prevents the control knobs from overheating.

11.4.3 Cooking with the spit (auxiliary oven)

Turn the thermostat knob to position and let the auxiliary oven preheat for approximately 5

minutes. In the meantime, proceed as follows:

• insert the food on to the spit rod A taking care to hold it firm with the two forks B, and balancing

it so as to avoid straining the gearmotor;

• place the pulley C of the spit rod onto the support D after

introducing the opposite end into the hole E, until the coupling with

the gearmotor F so that the rod rotates;

• pour a little water into the dripping pan and position it under the spit

rod;

• monitor the cooking from time to time and check the spit rod is

rotating correctly;

• at the end of the cooking, switch off the auxiliary oven by returning

the thermostat knob to position "0";

• remove the spit rod from the auxiliary oven using the knob G and

wearing an oven glove.

11.4.4 Switching off the auxiliary oven

The oven is switched off by returning the thermostat knob to position "0".

32

Page 33

Instructions for the user

11.5 Using the convection electric oven

The end of cooking display and the control knob on the convection oven

have no bearing on the operation of the grill oven.

The convection oven is equipped with a circular heating element with a fan

located on the rear wall of the oven.

11.5.1 Switching on the oven for the first time

The first time it is used, the oven may smoke or give off an acrid smell caused by oily residue from

manufacturing that may give unpleasant odours or flavours to food. Before putting food in the

oven, heat to the maximum temperature for 30-40 minutes with the door closed and wait

until the smoke or odour has stopped.

To prevent any steam in the oven from scalding, proceed as follows:

turn the knob to "0", or to function "V"; open the door in two stages: hold

it partly open (approx. 5 cm) for 4-5 seconds, then open it completely.

time as possible to prevent the temperature inside the oven from

Should you need to adjust the food, leave the door open for as short a

lowering to such an extent as to jeopardise cooking.

11.5.2 Cooking with convection oven

Turn the knob in correspondence with the required temperature value. It is possible to vary the

position of the grill shelf according to personal taste and different cooking requirements.

11.5.3 Switching off the oven

The oven is switched off by returning the knob to position "0".

33

Page 34

Instructions for the user

11.6 Using the grill oven with natural convection

The grill oven knob do not influence the functioning of the convection

oven.

The grill oven with natural convection is equipped with:

• a heating element positioned on the base of the oven (at the bottom);

• a heating element positioned on the ceiling of the oven (at the top) +

grill.

11.6.1 Switching on the grill oven for the first time

The first time it is used, the grill oven may smoke or give off an acrid smell caused by oily residue

from manufacturing that may give unpleasant odours or flavours to food. Before putting food in

the oven, heat the grill oven to the maximum temperature for 30-40 minutes with the door

closed and wait until the smoke or odour has stopped.

It is possible to switch on the heating of the grill oven by turning the knob to the required

temperature (from 50°C to MAX) or function.

11.6.2 Cooking with the grill

Turn the knob to position and let the grill oven preheat for approximately 5 minutes. For correct

operations, position the grill shelf on the second guide from the bottom. It is possible to vary the

position of the grill shelf according to personal taste and different cooking requirements. A cooling

system prevents the control knob from overheating.

11.6.3 Traditional cooking

For differentiated heating over or below the food, set the function selector switch to position

above) or

11.6.4 Switching off the grill oven

The oven is switched off by returning the knob to position "0".

(hot below).

(hot

34

Page 35

Instructions for the user

12. Cooking suggestions

12.1 Suggestions for using the hob burners correctly

The diameter of the base of cooking recipients

should fit the diameter of the burner used (see

Burner

Recipient diameter

adjacent table). The burner flame must never be

wider than the diameter of the recipient. Use

recipients with a flat base. Where possible use

pots with a lid, as this allows less power to be

used. To reduce cooking times for vegetables,

potatoes, etc., use little water.

12.2 Suggestions for using the deep fryer correctly

Rapid from 24 to 26

Semi rapid from 16 to 22

Auxiliary from 8 to 14

Triple-ring from 24 to 26

Fish kettle from 16 to 35

Do not add salt or spices to food while the basket is still positioned above the frying vat, as the oil

or fat would be altered, jeopardising the flavour of subsequent fries.

For large quantities of food, we recommend removing the basket from the frying vat every 1-2

minutes, so that the frying liquid can return to the preset temperature more quickly. The food to be

fried must always be covered by the frying liquid. Should this not be possible (with chicken for

instance), turn it half way through cooking.

At the end of the cooking, remove any food residue from the frying liquid. If, despite the correct

temperature setting, the food is not crisp and the frying liquid is dark, it should be replaced by

carefully following the instructions given in section “13.6.1 Discharging the frying liquid”.

In order to avoid the dangerous combustion of the frying liquid, do not activate the open

burners near the deep fryer.

12.3 Suggestions for using the fry-top / steak grill correctly

The fry-top griddle is smooth, whereas the steak grill is lined and can be used to obtain the typical

rhomboidal pattern together with the delicious flavour of barbecue cooking.

Foods cooked on the fry-top/steak grill have a special taste that does not require the excessive use

of spices. It is possible to cook in different ways. For example, different foods, such as meat and

fish, can be cooked at the same time. Before cooking meat, we recommend treating it with

flavoured oil or marinating it for a few hours.

A little tip: meat should always be salted after cooking on the griddle, so that its juices do not come

out prematurely.

12.4 Suggestions for using the volcanic rock grill correctly

Cooking food on the cast iron grill creates a considerable quantity of smoke. Sometimes, while

cooking very fatty meat, small flames may appear similar to those seen during barbeque cooking

(see section 9.2 for how to solve this problem). Before placing fish on the grill, we recommend

greasing it slightly with oil or melted butter. This will stop the fish sticking to the surface of the grill.

The appliance can also be used in the same way as an “open burner”, which is ideal for

simmering. Only use multi-function pans whose dimensions are compatible with the cooking

surface of the cast iron grill. This type of cooking is ideal for: beef stews, grilled pork, blanquette,

rabbit with beer, tongue (see instructions in section 9.2).

(in cm)

35

Page 36

Instructions for the user

12.5 Suggestions for using the vitroceramic hob correctly

In order to obtain good efficiency and adequate energy consumption, it is essential to use only

recipients that are suitable for electric cooking. The diameter of the base of the recipient must be

the same as the diameter of the outline of the cooking area. Energy is wasted if they do not

correspond.

The base of the recipient must be very thick and perfectly flat. It should also be clean and dry, as

should the glass on the hob.

Do not use cast iron pots or pots with a rough base, as they may scratch the surface.

When using the vitroceramic hob, it must be thoroughly cleaned before switching on the heating

elements.

The glass may be scratched if pans are placed on abrasive residues. Any scratches do not

however jeopardise the cooking procedure.

The ideal thickness for the base of the pans is:

• 2-3 mm in enamelled steel;

• 4-6 mm in stainless steel with double base.

Before cooking food with a high sugar content (e.g. jam), apply a protective product to the cooking

surface to prevent it from being damaged if the food spits or boils over.

12.6 Suggestions for using the oven correctly

The oven allows to optimise cooking. It is possible to cook traditionally, with convection and with

the grill.

The oven door should be completely closed for all types of cooking.

12.6.1 Traditional cooking

With this type of cooking, the heat comes from the top and the bottom. It is therefore preferable to

use the central guides. If the cooking requires a hotter temperature from the bottom or from the top,

use the lower or upper guides. Traditional cooking is recommended for all food that requires high

cooking temperatures, or long brazing times. This system is also recommended when cooking with

recipients made of terracotta, porcelain and similar materials.

36

12.6.2 Convection cooking

With this type of cooking, the food is heated by preheated air that is circulated in the oven thanks to

a fan located on the rear wall of the oven. Heat rapidly and evenly reaches all parts of the oven,

thus enabling different food to be cooked at the same time on different shelves. Humidity is

eliminated from the air and the drier area prevents odours and flavours from being spread and

mixed.

The possibility of cooking on more than one shelf allows you to cook many different dishes at the

same time. Biscuits and mini pizzas can be cooked in three different baking tins. The oven,

however, can also be used for cooking on a single shelf. The lower shelves can be used so that it

is easier to monitor cooking.

Convection cooking is particularly

convenient for bringing frozen food rapidly back to room

temperature, for sterilising preserves or home-made fruit in syrup and, finally, for drying

mushrooms or fruit.

Page 37

Instructions for the user

12.6.3 Cooking with the grill

The heat comes from the top. Almost all meat can be grilled, with the exception of lean game and

dishes such as meat-loaf. Meat and fish to be grilled should be lightly drizzled with oil and placed

on the grid bars, which should be placed in the guides closest to or farthest away from the grill

element, depending on the thickness of the meat, so as to avoid burning the surface and cooking

too little inside.

Suitable for: relatively thin meat; toasted sandwiches.

Pour 1 or 2 glasses of water into the dripping pan to avoid smoke forming due to drops of juice or fat.

While cooking with the grill, the dripping pan should always be positioned in the 1st guide from the

bottom.

12.6.4 Cooking with the ventilated grill

Using the combination of grill and fan .

This type of cooking allows the heat to penetrate gradually inside the food, even though the surface

is directly exposed to the grill.

Suitable for: thicker meat; game-birds.

12.6.5 Cooking meat and fish

Meat to be cooked in the oven should weigh at least 1 kg. Very tender red meat to be cooked rare

(roast beef, fillet, etc.), or which should be well cooked on the outside and preserve all its juices on

the inside, require cooking on high temperatures for a short time (200-250°C). White meat, gamebirds and fish require cooking on low temperatures (150-175°C).

The ingredients for the sauce should only be placed in the baking tin if the cooking time is short,

otherwise, they should be added in the last half hour. Meat can be placed on an ovenproof plate or

directly on the grid bars, below which the dripping pan should be placed to collect the juice. Press

the meat with a spoon to check if it is done. If it is firm, it is cooked.

At the end of the cooking, wait at least 15 minutes before cutting the meat so as not to lose the

juices. Before serving, plates can be warmed in the oven at minimum temperature.

12.6.6 Baking

Beaten mixtures must stick to the spoon because excess fluidity would prolong the cooking time.

Sweets require moderate temperatures (generally between 150-200°C) and require preheating

(approximately 10 minutes). The oven door must not be opened until at least ¾ of the way

through the cooking time.

37

Page 38

Instructions for the user

12.6.7 Recommended cooking tables

Cooking times vary according to the nature, homogeneity and volume of the food. We recommend

monitoring your first attempts and checking the results, as similar results are obtained by cooking