Page 1

PROJECT

S U S T A I N A B L E C O M F O R T

®

C 330 / C 630

en

Installation, User and Service Manual

High-efficiency floor-standing boiler

Page 2

Contents

2 7600532 - v.11 - 13122018

Contents

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Liabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.1 Manufacturer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.2 Installer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.3 User's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Additional documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.1 Symbols used in the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.1 Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.2 Unit categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.1.3 Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.1.4 Factory test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.2.1 C 330 ECO technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.2 C 630 ECO technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Dimensions and connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.1 Boiler type C 330 ECO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.2 Boiler type C 630 ECO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4 Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4 Description of the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.2 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.1 Regulating the water temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.2 Protection against shortage of water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.3 Maximum protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.4 Air pressure differential switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.2.5 Circulating pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3.1 Main components C 330 ECO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.3.2 Main components C 630 ECO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.4 Control panel description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.5 Standard delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.6 Accessories and options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 Before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1 Installation regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 Choice of the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2.1 Data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2.2 Installing the boiler C 330 ECO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2.3 Installing the boiler C 630 ECO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.2.4 Rotating the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2 Hydraulic connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

6.2.1 Rinsing the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2.2 Connecting the heating circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2.3 Connecting the condensate discharge pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.3 Gas connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.4 Air supply/flue gas connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.4.1 Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4.2 Dimensions of flue gas outlet pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.4.3 Length of the air and flue gas pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.4.4 Additional guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4.5 Connecting the flue gas outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Page 3

Contents

7600532 - v.11 - 13122018 3

6.4.6 Air supply connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6.5 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.5.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.5.3 Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.5.4 Access to the connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

6.5.5 Connection options for the standard PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.5.6 PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.6 Filling the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

6.6.1 Water treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

6.6.2 Filling the siphon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.6.3 Filling the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.1 Checklist before commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.1.1 Gas circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.1.2 Hydraulic circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.1.3 Connections for the air and flue gas pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.1.4 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.2 Commissioning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.3 Gas settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.3.1 Checking/setting the combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

7.4 Final instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

8.1 Use of the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.2 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.3 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.4 Frost protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9.1 Changing the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9.2 Displaying the measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.2 Standard inspection and maintenance operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.2.1 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.2.2 Checking the water pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.2.3 Checking the ionisation current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10.2.4 Checking the water quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

10.2.5 Checking the flue gas outlet/air supply connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10.2.6 Checking the gas filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10.2.7 Checking the combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10.2.8 Check the air supply hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.2.9 Checking the dirt trap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

10.2.10 Checking the air box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.2.11 Checking the PS air pressure differential switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10.2.12 Checking the VPS gas leakage control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

10.2.13 Checking the Gps minimum gas pressure switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

10.3 Specific maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

10.3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

10.3.2 Clean the fan and venturi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

10.3.3 Cleaning and inspecting the non-return valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

10.3.4 Replacing the ionisation/ignition electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

10.3.5 Clean the gas filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

10.3.6 Cleaning the burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10.3.7 Cleaning the burner area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10.3.8 Cleaning the heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

10.3.9 Clean the condensate collector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.3.10 Clean the siphon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

10.3.11 Remounting the burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.3.12 Reassembling the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.3.13 Putting the boiler back into operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Page 4

Contents

4 7600532 - v.11 - 13122018

11.1 Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

12 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

12.1 Removal/recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

13 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

13.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

13.2 Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

13.3 Parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

14 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

14.1 ErP information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

14.1.1 Product fiche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

14.2 EC declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Page 5

1 Safety

7600532 - v.11 - 13122018 5

1.1 General safety instructions

For the installer:

1 Safety

Danger

If you smell gas:

1. Do not use naked flames, do not smoke and

do not operate electrical contacts or switches

(doorbell, lighting, motor, lift etc).

2. Shut off the gas supply.

3. Open the windows.

4. Trace possible leaks and seal them off

immediately.

5. If the leak is upstream of the gas meter, notify

the gas company.

Danger

If you smell flue gases:

1. Switch the boiler off.

2. Open the windows.

3. Trace possible leaks and seal them off

immediately.

Caution

After maintenance or repair work, check the

entire heating installation to ensure that there are

no leaks.

For the end user:

Page 6

1 Safety

6 7600532 - v.11 - 13122018

Danger

If you smell gas:

1. Do not use naked flames, do not smoke and

do not operate electrical contacts or switches

(doorbell, lighting, motor, lift etc).

2. Shut off the gas supply.

3. Open the windows.

4. Evacuate the property.

5. Contact a qualified installer.

Danger

If you smell flue gases:

1. Switch the boiler off.

2. Open the windows.

3. Evacuate the property.

4. Contact a qualified installer.

Warning

Do not touch the flue gas pipes. Depending on

the boiler settings, the temperature of the flue gas

pipes can rise to over 60°C.

Warning

Do not touch radiators for long periods.

Depending on the boiler settings, the temperature

of the radiators can rise to over 60°C.

Warning

Be careful when using the domestic hot water.

Depending on the boiler settings, the temperature

of domestic hot water can rise to over 65°C.

Warning

The use of the boiler and the installation by you

as the end-user must be limited to the operations

described in this manual. All other actions may

only be undertaken by a qualified fitter/engineer.

Warning

The condensation drain must not be changed or

sealed. If a condensate neutralisation system is

used, the system must be cleaned regularly in

accordance with the instructions provided by the

manufacturer.

Caution

Ensure that the boiler is regularly serviced.

Contact a qualified installer or arrange a

maintenance contract for the servicing of the

boiler.

Page 7

1.2 Recommendations

7600532 - v.11 - 13122018 7

1 Safety

Caution

Only genuine spare parts may be used.

Important

Regularly check for the presence of water and

pressure in the heating installation.

Danger

This appliance can be used by children aged

eight and above and people with a physical,

sensory or mental disability, or with a lack of

experience and knowledge, provided they are

supervised and instructed in how to use the

appliance in a safe manner and understand the

associated dangers. Children must not be

allowed to play with the appliance. Cleaning and

user maintenance should not be carried out by

children without adult supervision.

Warning

Installation and maintenance of the boiler must be

carried out by a qualified installer in accordance

with local and national regulations.

Warning

The installation and maintenance of the boiler

must be undertaken by a qualified installer in

accordance with the information in the supplied

manual, doing otherwise may result in dangerous

situations and/or bodily injury.

Warning

Removal and disposal of the boiler must be

carried out by a qualified installer in accordance

with local and national regulations.

Warning

If the mains lead is damaged, it must be replaced

by the original manufacturer, the manufacturer's

dealer or another suitably skilled person to

prevent hazardous situations from arising.

Warning

Always disconnect the mains supply and close

the main gas tap when working on the boiler.

Warning

Check the entire system for leaks after

maintenance and servicing work.

Page 8

1 Safety

8 7600532 - v.11 - 13122018

Danger

For safety reasons, we recommend fitting smoke

and CO alarms at suitable places in your home.

Caution

Make sure the boiler can be reached at all

times.

The boiler must be installed in a frost-free area.

If the power cord is permanently connected, you

must always install a main bipolar switch with

an opening gap of at least 3 mm (EN 60335-1).

Drain the boiler and central heating system if

you are not going to use your home for a long

time and there is a chance of frost.

The frost protection does not work if the boiler is

out of operation.

The boiler protection only protects the boiler,

not the system.

Check the water pressure in the system

regularly. If the water pressure is lower than 0.8

bar, the system must be topped up

(recommended water pressure between 1.5 and

2 bar).

1.3

Important

Keep this document near to the boiler.

Important

Only remove the casing for maintenance and

repair operations. Refit all panels when

maintenance work and servicing are complete.

Important

Instruction and warning labels must never be

removed or covered and must be clearly legible

throughout the entire service life of the boiler.

Damaged or illegible instructions and warning

stickers must be replaced immediately.

Important

Modifications to the boiler require the written

approval of De Dietrich.

Liabilities

1.3.1 Manufacturer's liability

Our products are manufactured in compliance with the

requirements of the various Directives applicable. They

are therefore delivered with the

marking and any

Page 9

1 Safety

7600532 - v.11 - 13122018 9

documents necessary. In the interests of the quality of

our products, we strive constantly to improve them. We

therefore reserve the right to modify the specifications

given in this document.

Our liability as manufacturer may not be invoked in the

following cases:

Failure to abide by the instructions on installing and

maintaining the appliance.

Failure to abide by the instructions on using the

appliance.

Faulty or insufficient maintenance of the appliance.

1.3.2

Installer's liability

The installer is responsible for the installation and initial

commissioning of the appliance. The installer must

observe the following instructions:

Read and follow the instructions given in the manuals

provided with the appliance.

Install the appliance in compliance with prevailing

legislation and standards.

Carry out initial commissioning and any checks

necessary.

Explain the installation to the user.

If maintenance is necessary, warn the user of the

obligation to check the appliance and keep it in good

working order.

Give all the instruction manuals to the user.

1.3.3 User's liability

To guarantee optimum operation of the system, you

must abide by the following instructions:

Read and follow the instructions given in the manuals

provided with the appliance.

Call on a qualified professional to carry out installation

and initial commissioning.

Get your installer to explain your installation to you.

Have the required inspections and maintenance

carried out by a qualified installer.

Keep the instruction manuals in good condition close

to the appliance.

Page 10

2 About this manual

10 7600532 - v.11 - 13122018

2 About this manual

2.1 Additional documentation

The boiler can be fitted with various control panels. The selected control

panel is supplied with its corresponding manual.

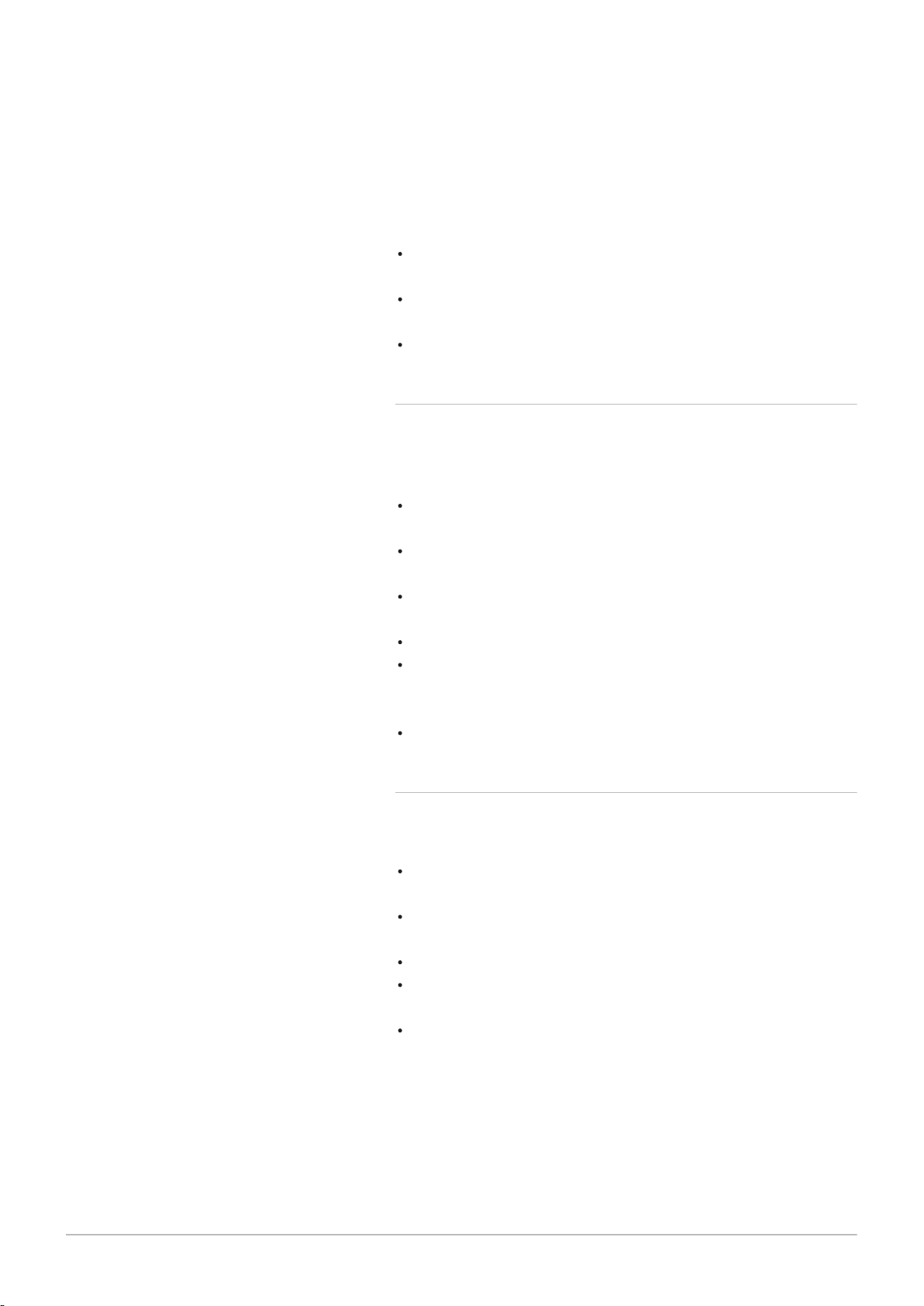

2.2

Symbols used

2.2.1 Symbols used in the manual

This manual uses various danger levels to draw attention to special

instructions. We do this to improve user safety, to prevent problems and to

guarantee correct operation of the appliance.

Danger

Risk of dangerous situations that may result in serious personal

injury.

Danger of electric shock

Risk of electric shock.

Warning

Risk of dangerous situations that may result in minor personal

injury.

Caution

Risk of material damage.

Important

Please note: important information.

See

Reference to other manuals or pages in this manual.

Page 11

3 Technical specifications

7600532 - v.11 - 13122018 11

3.1 Homologations

3.1.1 Certifications

Tab.1 Certifications

CE identification number PIN 0063CL3613

Class NOx

(1)

Type of flue gas connection

6

B23, B

23P

(2)

C33, C53, C63, C

(1) EN 15502–1

(2) When installing a boiler with connection type B23, B

boiler is lowered to

IP20.

3.1.2 Unit categories

3 Technical specifications

93

, the IP rating of the

23P

3.2

Technical data

Tab.2 Unit categories

Category Gas type Connection pressure

(mbar)

I

2H

G20 (H gas) 20

3.1.3 Directives

In addition to the legal requirements and guidelines, the supplementary

guidelines in this manual must also be followed.

Supplements or subsequent regulations and guidelines that are valid at

the time of installation shall apply to all regulations and guidelines

specified in this manual.

3.1.4 Factory test

Before leaving the factory, each boiler is optimally set and tested for:

Electrical safety.

Adjustment of (O2).

Water tightness.

Gas tightness.

Parameter setting.

3.2.1 C 330 ECO technical data

Tab.3 General

C 330 ECO 280 350 430 500 570 650

Number of sections 5 6 7 8 9 10

Nominal output (Pn)

(80/60 °C)

Nominal output (Pn)

(50/30 °C)

Nominal load (Qnh)

(Hi)

min

max

max

min

max

(1)

(1)

kW 279 350 425 497 574 651

261

kW 54

kW 51

(1)

266

65

327

68

333

79

395

82

402

92

461

95

469

106

530

109

539

119

601

122

610

Page 12

3 Technical specifications

12 7600532 - v.11 - 13122018

C 330 ECO 280 350 430 500 570 650

Nominal load (Qnh)

(Hs)

Full load central heating efficiency

min

max

(1)

kW 60

295

75

369

96

445

105

520

121

598

135

677

% 98.0 98.1 98.2 98.3 98.4 98.5

(Hi) (80/60 °C) (92/42/EEC)

Full load central heating efficiency

% 104.8 105.2 105.6 106.0 106.4 106.8

(Hi) (50/30 °C) (EN15502)

Central heating efficiency under

% 94.7 95.3 95.8 96.3 96.8 97.3

part load (Hi)

(Return temperature 60 °C)

Annual efficiency G20 (DIN 4702,

% 109.6 109.5 109.4 109.3 109.2 109.1

Part 8)

Part load central heating efficiency

% 109.2 109.0 108.8 108.6 108.3 108.1

(92/42 EEC)

(Return temperature 30 °C)

(1)

Factory setting

Tab.4 Gas and flue gas data

C 330 ECO 280 350 430 500 570 650

Gas inlet pressure G20 (H gas) min

max

Gas inlet pressure G25 (L gas) min

max

Gas consumption G20 (H gas) min

max

Gas consumption G25 (L gas) min

max

NOx annual emissions G20

O2 = 0% ppm 28.9 31.7 30.6 28.9 30.6 27

mbar 17

30

mbar 17

30

m3/h

5.7

28.1

m3/h

6.6

32.7

17

30

17

30

7.2

35.2

8.4

41.0

17

100

17

100

8.7

42.5

10.1

49.5

17

100

17

100

10.1

49.6

11.7

57.7

17

100

17

100

11.5

57.0

13.4

66.3

17

30

17

30

12.9

64.6

15.0

75.1

EN15502

NOx annual emissions G20

H

i

mg/kWh 51.0 56.0 54.0 51.0 54.0 47.6

EN15502

NOx annual emissions G20

H

s

mg/kWh 46.0 50.0 49.0 46.0 49.0 43.0

EN15502

Flue gas mass flow rate min

max

Flue gas temperature min

max

Maximum counter pressure for flue

Pa

gas outlet

kg/h 91

448

°C 30

80

130 120 130 150 150 150

114

560

30

80

138

676

30

80

160

789

30

80

183

907

30

80

205

1026

30

80

Chimney losses 80/60 °C % 2.3 2.3 2.3 2.3 2.3 2.3

Stoppage loss (EN15502)

(Including heat exchanger insula

tion kit)

(ΔT = 30K)

(1)

W

%

464

0.17

479

0.14

493

0.12

508

0.11

522

0.10

537

0.09

Number of stars (92/42/EEC) 4 4 4 4 4 4

(1) ΔT = (boiler temperature – ambient temperature).

Tab.5 Central heating circuit data

C 330 ECO 280 350 430 500 570 650

Water content l 49 60 71 82 93 104

Water operating pressure min bar 0.8 0.8 0.8 0.8 0.8 0.8

Water operating pressure (PMS) max bar 7 7 7 7 7 7

Water temperature max °C 110 110 110 110 110 110

Operating temperature max °C 90 90 90 90 90 90

Water resistance (ΔT=20K) mbar 113 110 120 110 125 130

Water resistance (ΔT=11K) mbar 374 364 397 364 413 435

Minimum flow

m3/h

3.4 4.2 5.1 5.9 6.8 7.8

Page 13

3 Technical specifications

7600532 - v.11 - 13122018 13

Tab.6 Electrical data

C 330 ECO 280 350 430 500 570 650

Supply voltage V~/Hz 230/50 230/50 230/50 230/50 230/50 230/50

Power consumption – full load max W 279 334 426 543 763 723

Power consumption – part load min W 46 46 58 61 62 55

Power consumption – standby min W 6 6 6 6 6 7

Electrical protection index

(1)

IP X1B X1B X1B X1B X1B X1B

Fuse – main fuse F2 (A) 10 10 10 10 10 10

Fuse – PCB F1 (A) 2 2 2 2 2 2

(1) For a room-sealed system.

Tab.7 Other data

C 330 ECO 280 350 430 500 570 650

Total weight (empty) kg 364 398 433 495 531 568

Average acoustic level

(1)

at a dis

dB(A) 56 56 56 56 56 56

tance of 1 metre from the boiler

Ambient temperature max °C 40 40 40 40 40 40

(1) For a sealed installation

Tab.8 Technical parameters

C 330 ECO 280 350 430 500 570 650

Condensing boiler Yes Yes Yes - - -

Low-temperature boiler

(1)

No No No - - -

B1 boiler No No No - - -

Cogeneration space heater No No No - - -

Combination heater No No No - - -

Rated heat output

Useful heat output at nominal

Prated

P

4

kW 261 327 395 - - -

kW 261 327 395 - - heat output and high tempera

ture operation

Useful heat output at 30% of rat

(2)

P

1

kW 87.6 109.5 132.0 - - ed heat output and low tempera

ture regime

Seasonal space heating energy ef

(1)

ƞ

s

% - - - - - -

ficiency

Useful efficiency at rated heat

ƞ

4

% 88.2 88.3 88.4 - - output and high temperature re

(2)

gime

Useful efficiency at 30% of rated

ƞ

1

% 98.6 98.6 98.5 - - heat output and low temperature

(1)

regime

Auxiliary electricity consumption

Full load

Part load

Standby mode

elmax

elmin

P

SB

kW 0.279 0.334 0.426 - - -

kW 0.060 0.060 0.080 - - -

kW 0.006 0.006 0.006 - - -

Other items

Standby heat loss

Ignition burner power consump

P

stby

P

ign

kW - - - - - -

kW - - - - - tion

Annual energy consumption

Q

HE

kWh

- - - - - -

GJ

Page 14

3 Technical specifications

14 7600532 - v.11 - 13122018

C 330 ECO 280 350 430 500 570 650

Sound power level, indoors

Emissions of nitrogen oxides NO

(1) Low temperature means 30 °C for condensing boilers, 37 °C for low temperature boilers and 50 °C (at heater inlet) for other heating

appliances.

(2) High temperature operation means 60 °C return temperature at heater inlet and 80 °C feed temperature at heater outlet.

L

WA

X

dB 69 69 73 - - -

mg/kWh 46 50 49 - - -

See

Refer to the back cover for contact details.

3.2.2 C 630 ECO technical data

Tab.9 General

C 630 ECO 560 700 860 1000 1140 1300

Number of sections 2x5 2x6 2x7 2x8 2x9 2x10

Nominal output (Pn)

(80/60 °C)

Nominal output (Pn)

(50/30 °C)

Nominal load (Qnh)

(Hi)

Nominal load (Qnh)

(Hs)

Full load central heating efficiency

(Hi) (80/60 °C) (92/42/EEC)

Full load central heating efficiency

(Hi) (50/30 °C) (EN15502)

Central heating efficiency under

part load (Hi)

(Return temperature 60 °C)

Annual efficiency G20 (DIN 4702,

Part 8)

Part load central heating efficiency

(92/42 EEC)

(Return temperature 30 °C)

(1)

Factory setting.

min

max

max

min

max

min

max

(1)

(1)

(1)

(1)

kW 69

522

87

654

123

790

122

922

148

1060

158

1202

kW 558 700 850 994 1148 1303

kW 72

532

kW 80

590

91

666

101

738

128

804

142

890

127

938

141

1040

153

1078

170

1196

162

1220

180

1354

% 98.0 98.1 98.2 98.3 98.4 98.5

% 104.8 105.2 105.6 106.0 106.4 106.8

% 94.7 95.3 95.8 96.3 96.8 97.3

% 109.6 109.5 109.4 109.3 109.2 109.1

% 109.2 109.0 108.8 108.6 108.3 108.1

Tab.10 Gas and flue gas data

C 630 ECO 560 700 860 1000 1140 1300

Gas inlet pressure G20 (H gas) min

max

Gas inlet pressure G25 (L gas) min

max

Gas consumption G20 (H gas) min

max

Gas consumption G25 (L gas) min

max

NOx annual emissions G20

O2 = 0% ppm 28.9 31.7 30.6 28.9 30.6 27

mbar 17

30

mbar 17

30

m3/h

7.6

56.2

m3/h

8.9

65.4

17

30

17

30

9.6

70.4

11.2

82.0

17

100

17

100

13.5

85.0

15.8

99.0

17

100

17

100

13.4

99.2

15.6

115.4

17

100

17

100

16.2

114.0

18.8

132.6

EN15502

NOx annual emissions G20

H

i

mg/kWh 51.0 56.0 54.0 51.0 54.0 47.6

EN15502

NOx annual emissions G20

H

s

mg/kWh 45.9 50.5 48.6 45.9 48.6 42.9

EN15502

Flue gas mass flow rate min

max

kg/h 182

896

228

1120

276

1352

320

1578

366

1814

17

30

17

30

17.2

129.2

19.9

150.2

410

2052

Page 15

3 Technical specifications

7600532 - v.11 - 13122018 15

C 630 ECO 560 700 860 1000 1140 1300

Flue gas temperature min

max

Maximum counter pressure for flue

Pa 130 120 130 130 130 150

°C 30

80

30

80

30

80

30

80

30

80

30

80

gas outlet

Chimney losses 80/60 °C % 2.3 2.3 2.3 2.3 2.3 2.3

Stoppage loss (EN15502)

(Including heat exchanger insula

(ΔT = 30K)

(1)

W

%

928

0.17

958

0.14

986

0.12

1016

0.11

1044

0.10

1074

0.09

tion kit)

(1) ΔT = (boiler temperature – ambient temperature).

Tab.11 Central heating circuit data

C 630 ECO 560 700 860 1000 1140 1300

Water content (per unit) l 49 60 71 82 93 104

Water operating pressure min bar 0.8 0.8 0.8 0.8 0.8 0.8

Water operating pressure (PMS) max bar 7 7 7 7 7 7

Water temperature max °C 110 110 110 110 110 110

Operating temperature max °C 90 90 90 90 90 90

Water resistance (ΔT=20K) (per unit) mbar 113 110 120 110 125 130

Water resistance (ΔT=11K) (per unit) mbar 374 364 397 364 413 435

Minimum flow (per unit)

m3/h

3.4 4.2 5.1 5.9 6.8 7.8

Tab.12 Electrical data

C 630 ECO 560 700 860 1000 1140 1300

Supply voltage V~/Hz 230/50 230/50 230/50 230/50 230/50 230/50

Power consumption – full load max W 558 668 852 1086 1526 1446

Power consumption – part load min W 92 92 116 122 124 110

Power consumption – standby min W 12 12 12 12 12 14

Electrical protection index

(1)

IP X1B X1B X1B X1B X1B X1B

Fuse – main fuse F2 (A) 10 10 10 10 10 10

Fuse – PCB F1 (A) 2 2 2 2 2 2

(1) For a room-sealed system.

Tab.13 Other data

C 630 ECO 560 700 860 1000 1140 1300

Total weight (empty) kg 707 771 837 957 1025 1095

Average acoustic level

(1)

at a dis

dB(A) 58 58 58 58 58 58

tance of 1 metre from the boiler

Ambient temperature max °C 40 40 40 40 40 40

(1) For a sealed installation

Page 16

AD-0000485-01

2 2

1500

1023

130

366 320

1477

447

1293

310

706

592

716

155

2

Ø 250

C

L

920

B

A

Ø 250

1310

353

3 Technical specifications

16 7600532 - v.11 - 13122018

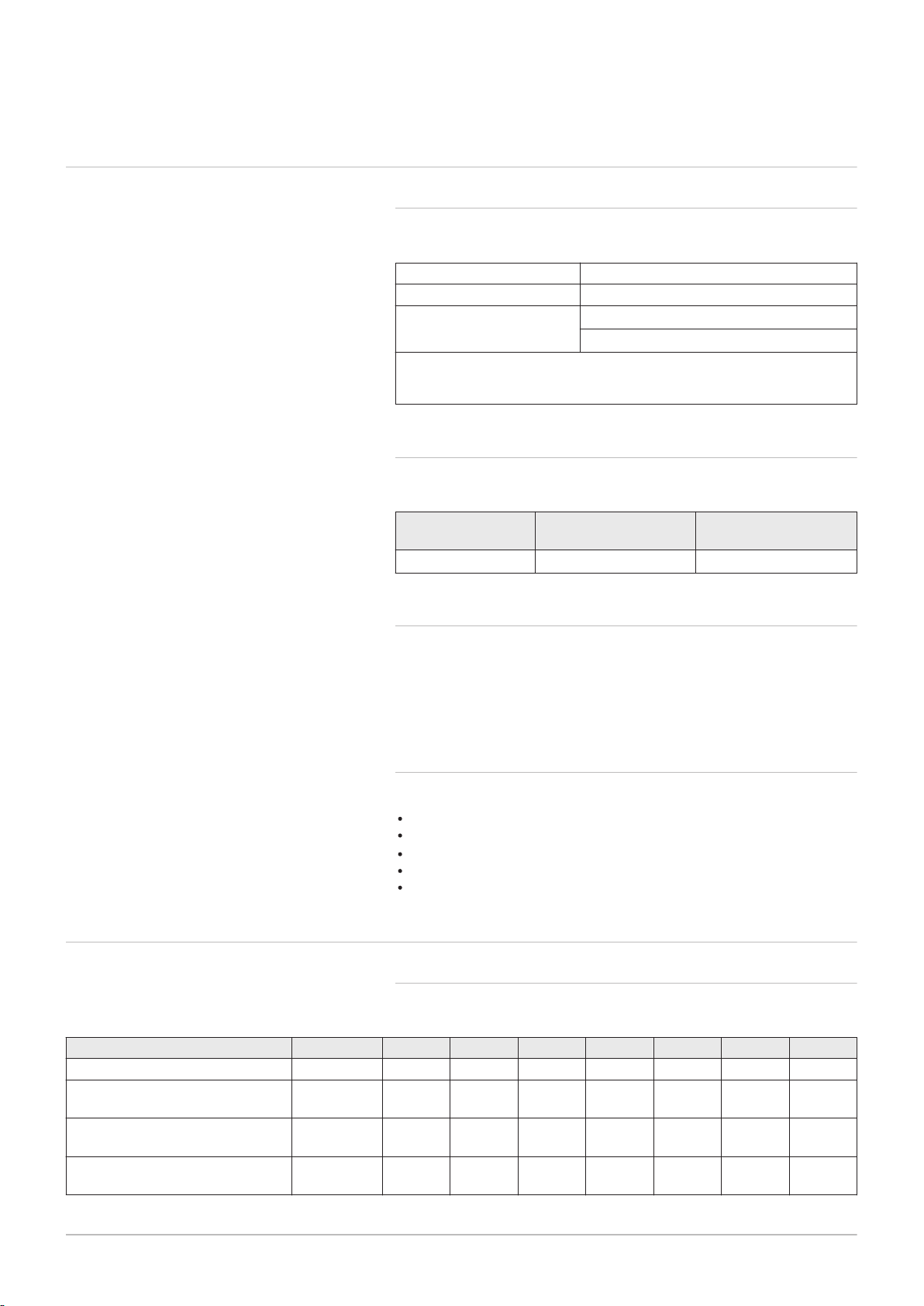

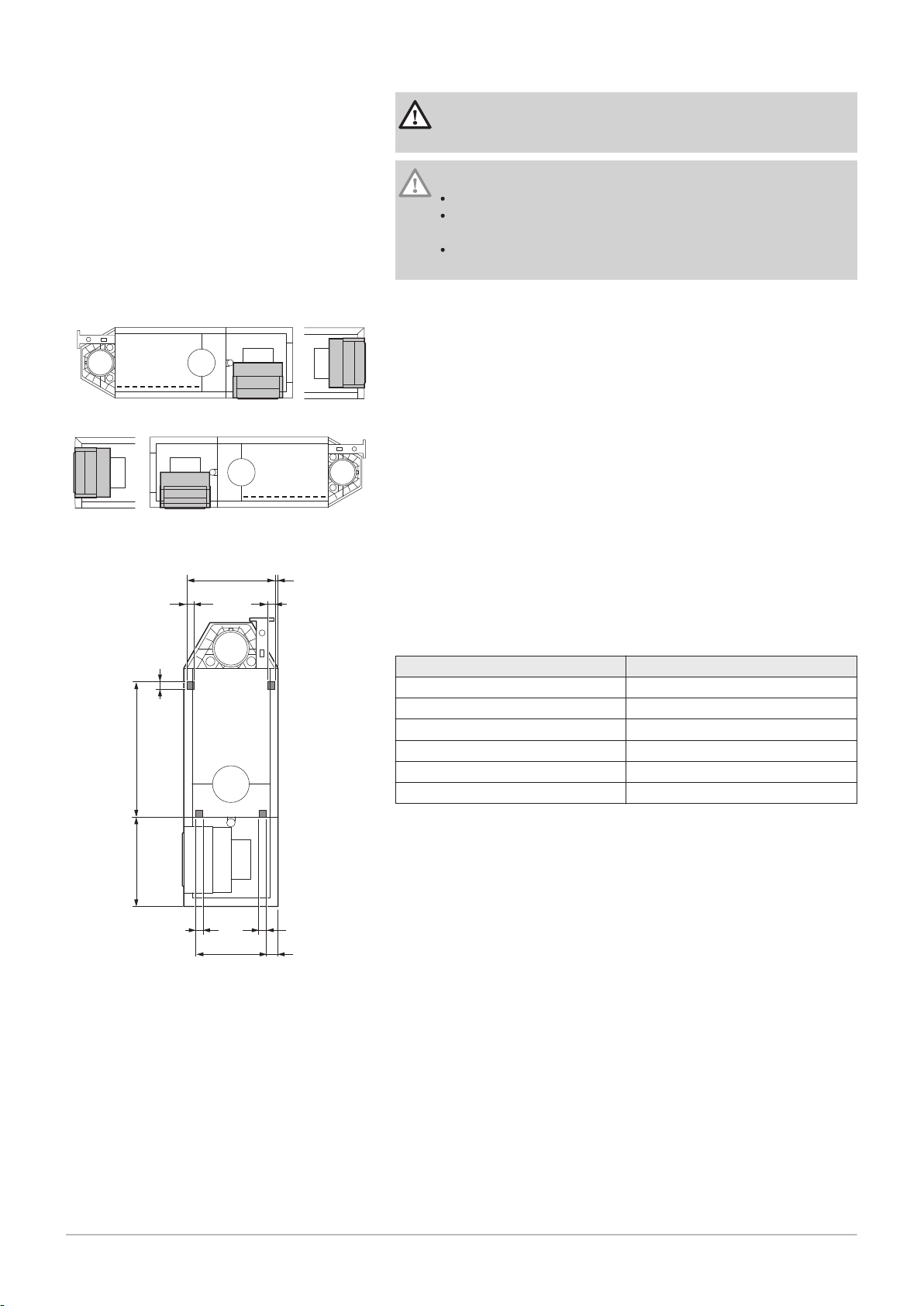

3.3 Dimensions and connections

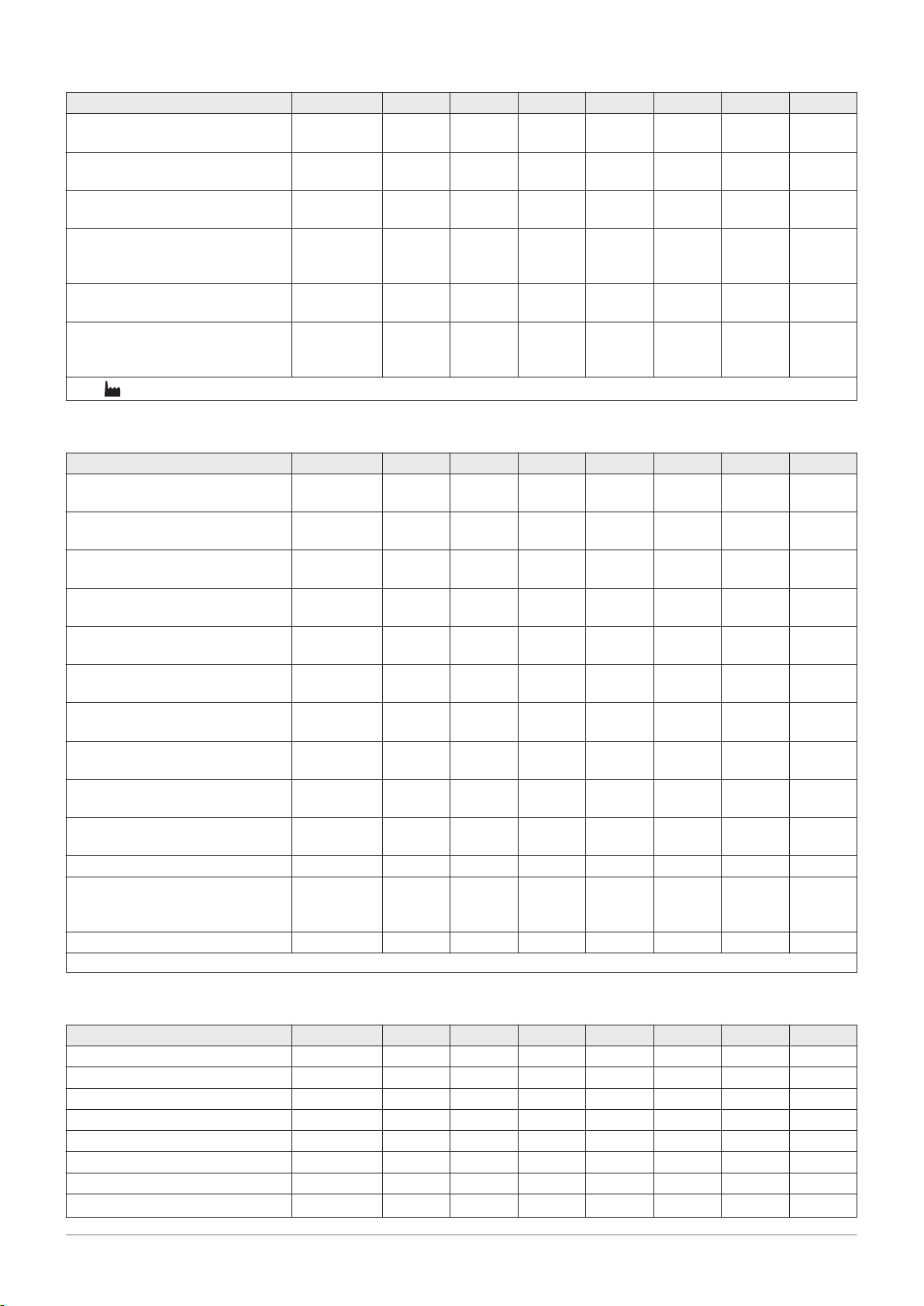

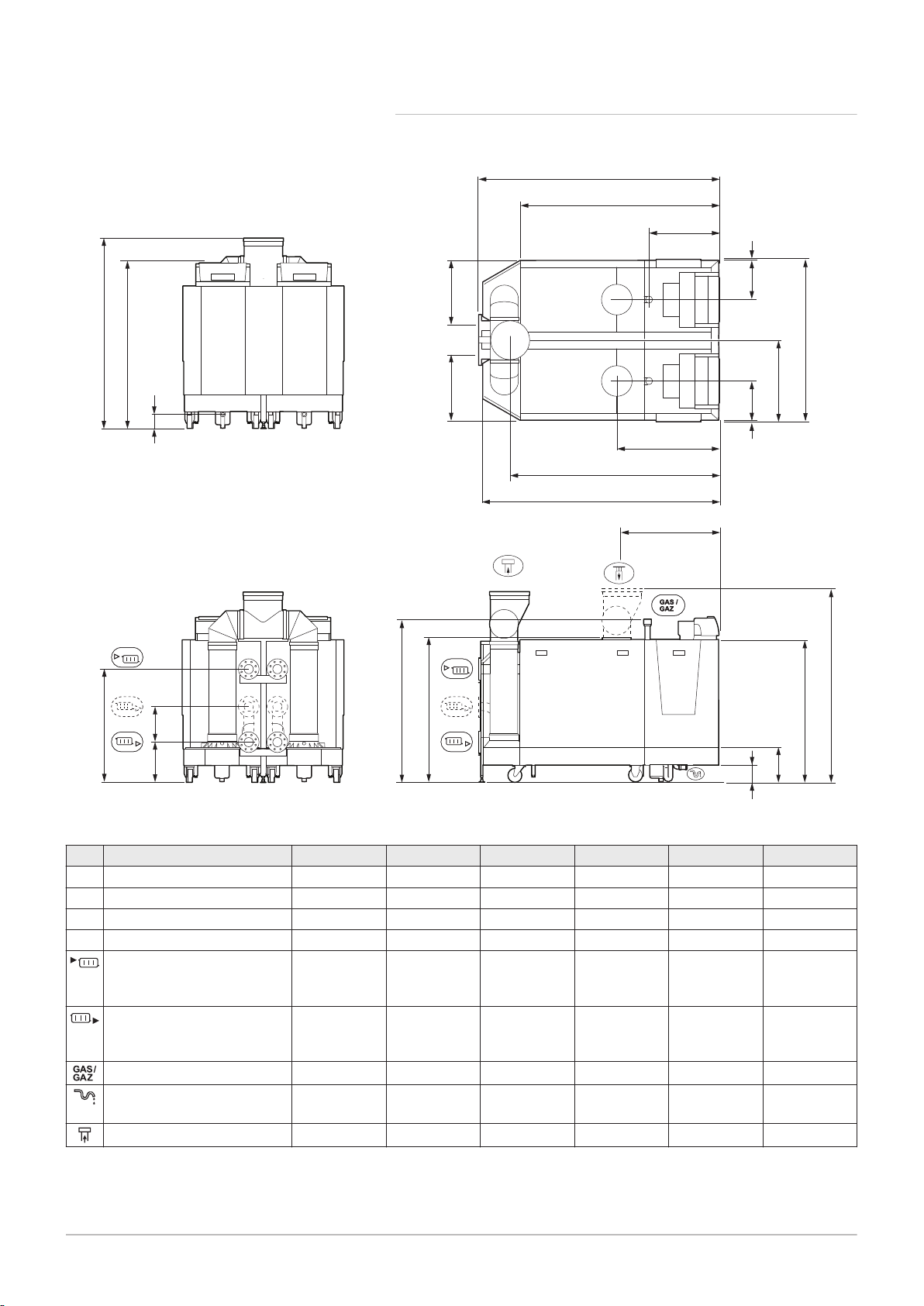

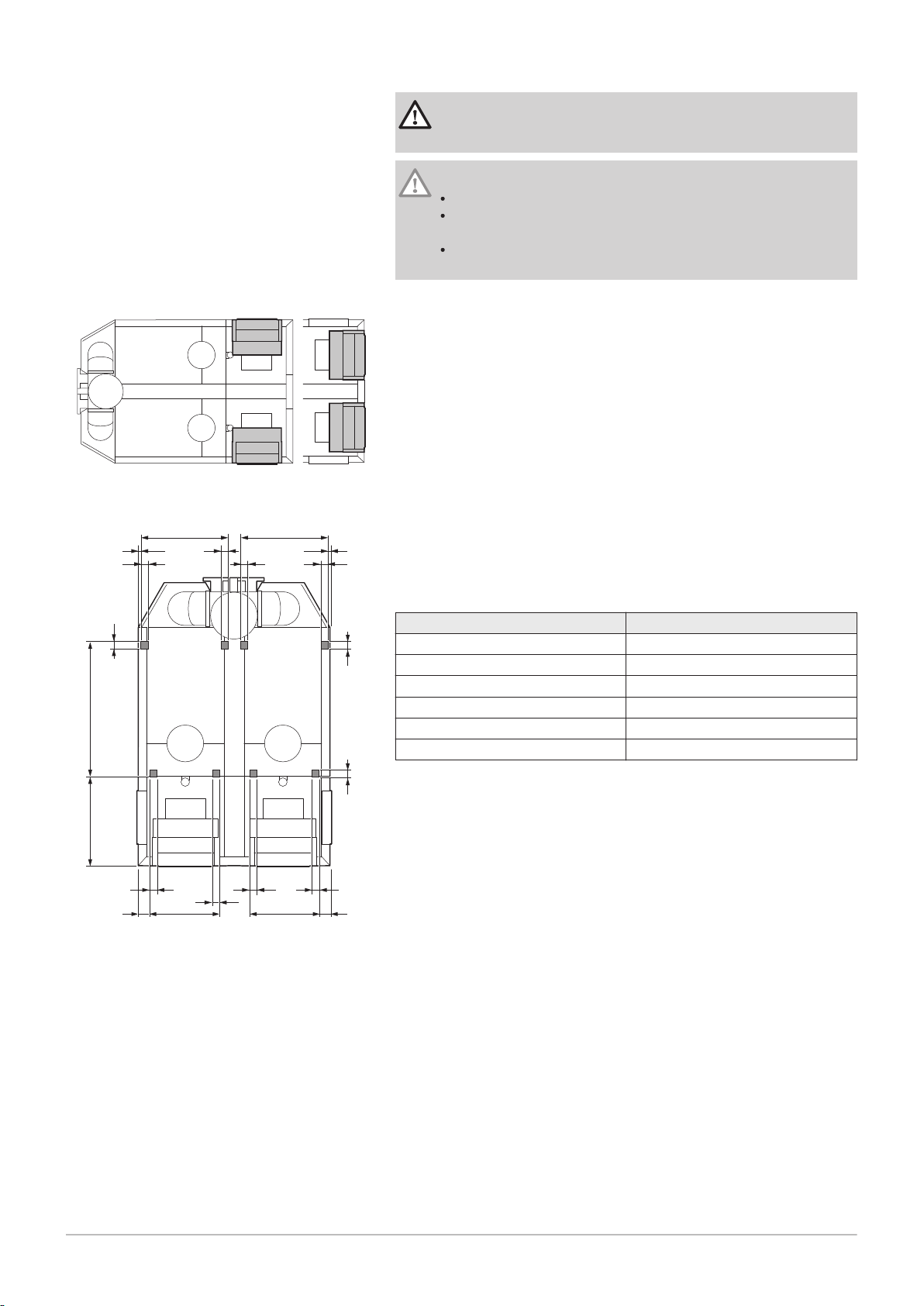

Fig.1 Dimensions C 330 ECO

3.3.1 Boiler type C 330 ECO

C 330 ECO 280 350 430 500 570 650

A 1833 mm 1833 mm 1833 mm 2142 mm 2142 mm 2142 mm

B 1635 mm 1635 mm 1635 mm 1944 mm 1944 mm 1944 mm

C 1862 mm 1862 mm 1862 mm 2172 mm 2172 mm 2172 mm

L 1490 mm 1490 mm 1490 mm 1800 mm 1800 mm 1800 mm

Central heating circuit flow Flange NW

Central heating circuit return Flange NW

Gas connection G2" G2" G2" G2" G2" G2"

Condensation outlet Ø 32 mm (in

80 (DIN

2576)

80 (DIN

2576)

ternal)

Flange NW

80 (DIN

2576)

Flange NW

80 (DIN

2576)

Ø 32 mm (in

ternal)

Flange NW

80 (DIN

2576)

Flange NW

80 (DIN

2576)

Ø 32 mm (in

ternal)

Flange NW

80 (DIN

2576)

Flange NW

80 (DIN

2576)

Ø 32 mm (in

ternal)

Flange NW

80 (DIN

2576)

Flange NW

80 (DIN

2576)

Ø 32 mm (in

ternal)

Flue gas outlet Ø 250 mm Ø 250 mm Ø 250 mm Ø 250 mm Ø 250 mm Ø 250 mm

Air supply Ø 250 mm Ø 250 mm Ø 250 mm Ø 250 mm Ø 250 mm Ø 250 mm

Second return (optional) Flange NW

65 (DIN

2576)

Flange NW

65 (DIN

2576)

Flange NW

65 (DIN

2576)

Flange NW

65 (DIN

2576)

Flange NW

65 (DIN

2576)

Flange NW

80 (DIN

2576)

Flange NW

80 (DIN

2576)

Ø 32 mm (in

ternal)

Flange NW

65 (DIN

2576)

Page 17

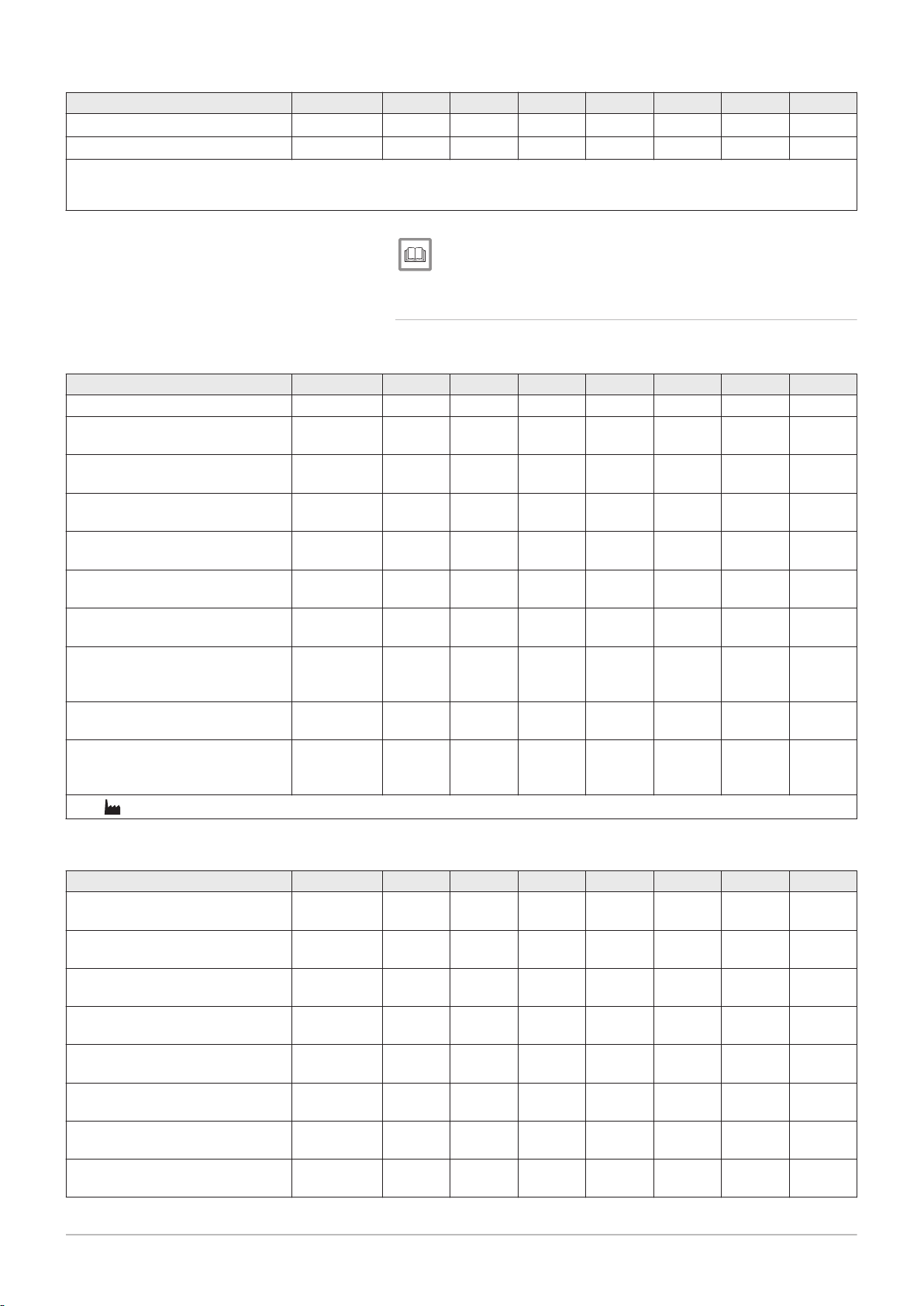

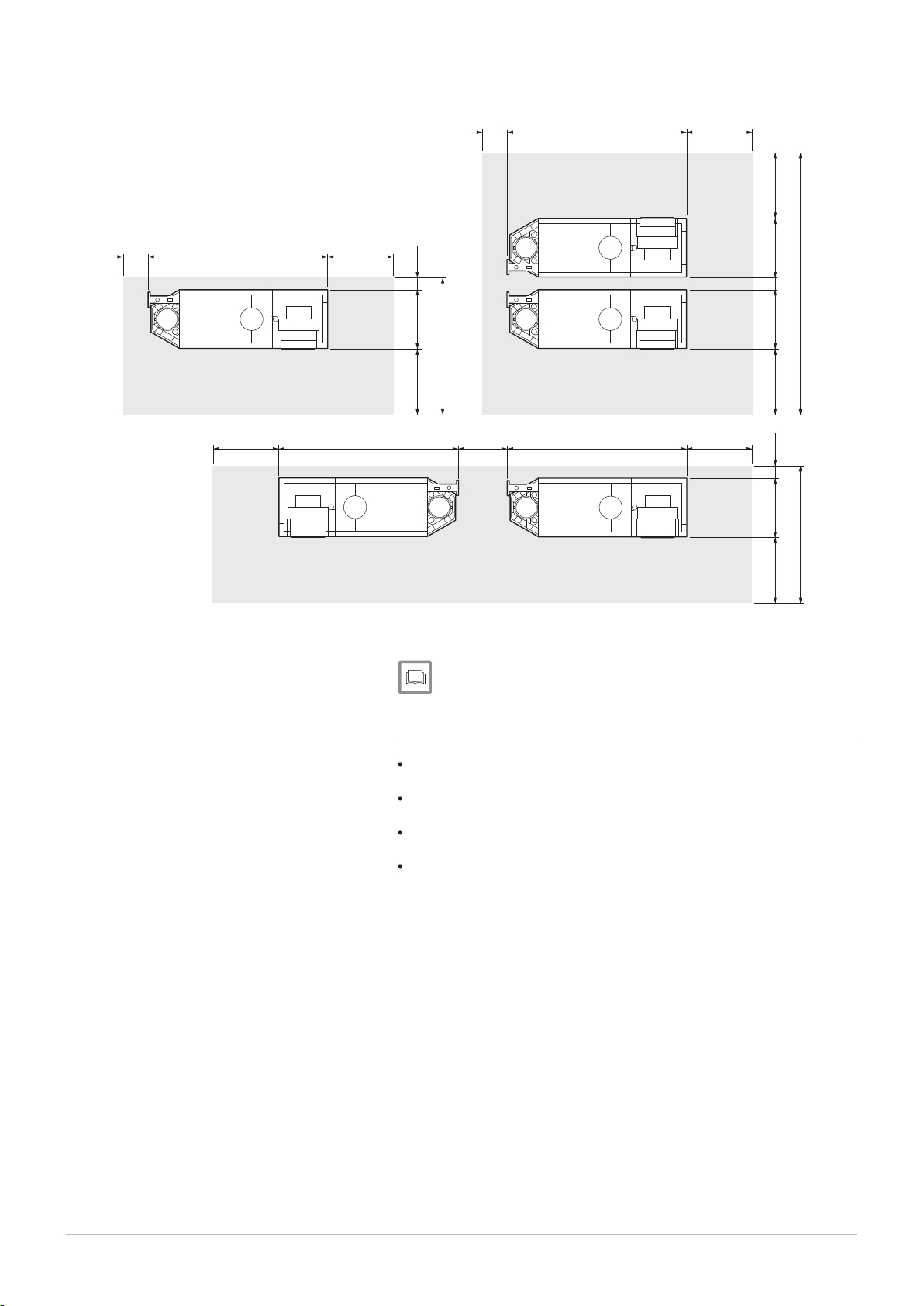

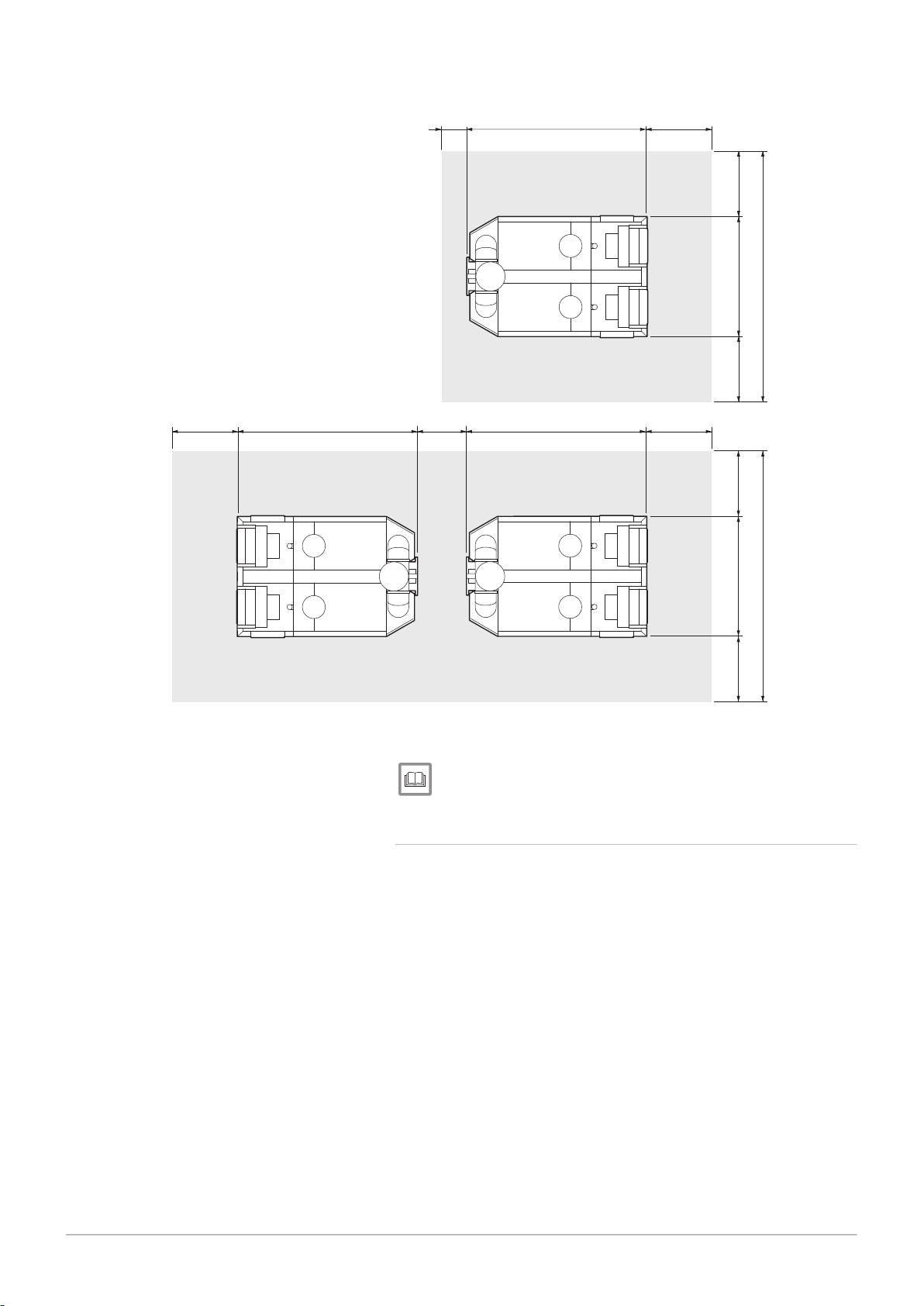

Fig.2 DimensionsC 630 ECO

AD-0000509-01

B

920

869

A

641

L

C

592592

366 320

2 2

1023

1760

1477

1293

310

155

1500

130

1726

1310

8

8353353

722

1460

7600532 - v.11 - 13122018 17

3 Technical specifications

3.3.2 Boiler type C 630 ECO

C 630 ECO 560 700 860 1000 1140 1300

A 1833 mm 1833 mm 1833 mm 2142 mm 2142 mm 2142 mm

B 1582 mm 1582 mm 1582 mm 1892 mm 1892 mm 1892 mm

C 1862 mm 1862 mm 1862 mm 2172 mm 2172 mm 2172 mm

L 1490 mm 1490 mm 1490 mm 1800 mm 1800 mm 1800 mm

Central heating circuit flow Flange NW

80 (DIN

2576)

Central heating circuit return Flange NW

80 (DIN

2576)

Flange NW

80 (DIN

2576)

Flange NW

80 (DIN

2576)

Flange NW

80 (DIN

2576)

Flange NW

80 (DIN

2576)

Flange NW

80 (DIN

2576)

Flange NW

80 (DIN

2576)

Flange NW

80 (DIN

2576)

Flange NW

80 (DIN

2576)

Gas connection G2" G2" G2" G2" G2" G2"

Condensation outlet Ø 32 mm (in

ternal)

Ø 32 mm (in

ternal)

Ø 32 mm (in

ternal)

Ø 32 mm (in

ternal)

Ø 32 mm (in

ternal)

Flue gas outlet Ø 350 mm Ø 350 mm Ø 350 mm Ø 350 mm Ø 350 mm Ø 350 mm

Flange NW

80 (DIN

2576)

Flange NW

80 (DIN

2576)

Ø 32 mm (in

ternal)

Page 18

AD-3001123-01

PCU-06

X06

1 2 3 4

N LL

BL

BR

BR

X07

1 2 3

ION

LN

GY

BL

BK

X02

1 2

Pump

3

LN

P

X50

10 AT

LN

X04 X05

1 10

X11

1 2 3 4

1 4 25

WH

BR

GN

YW

X09

1 2 3 4 5 6

OT

1

On / Off

bL

3 4

RL

5 62

X08

X51

X01

1 2 3

Mains

YW/

GN

BL

BK

BL

BR

BK

BL

YW/

GN

X03

1 92 3 4 5 10 116 7 8 12

WH BL

RD

BK

OR

OR

YW/

WH

BR/

WH

BK/

WH

BL/

WH

SU-01

X10

SCU-D4

J6 J2

N

TS + BB

LN L N

Alim

230 V - 50 Hz

L

N N L

A

+

0-10V

- 4

S CAMB S AMBB S AMPA

3 2 1 2 1 2 1 2 1 2

S SYST

1 2

+ S ECS S EXTTA - S DEP C S DEPB

1 2 1 2 1 2 1 2 1

J9 J8 J8

X06

X07

X08

X02

X03

X11

X09

X04

X10

X05

X01

SU-01

J5

J2

J1

J10

J8

J9

J6

J4

J7

SU-01

3

4

5

1

2

6 7 8 9 10 11 12 13 14 15

16

3 Technical specifications

18 7600532 - v.11 - 13122018

C 630 ECO 560 700 860 1000 1140 1300

Air supply

Air supply manifold

Second return (optional) Flange NW

Ø 250 mm

Ø 350 mm

65 (DIN

2576)

Ø 250 mm

Ø 350 mm

Flange NW

65 (DIN

2576)

Ø 250 mm

Ø 350 mm

Flange NW

65 (DIN

2576)

Ø 250 mm

Ø 350 mm

Flange NW

65 (DIN

2576)

Ø 250 mm

Ø 350 mm

Flange NW

65 (DIN

2576)

Ø 250 mm

Ø 350 mm

Flange NW

65 (DIN

2576)

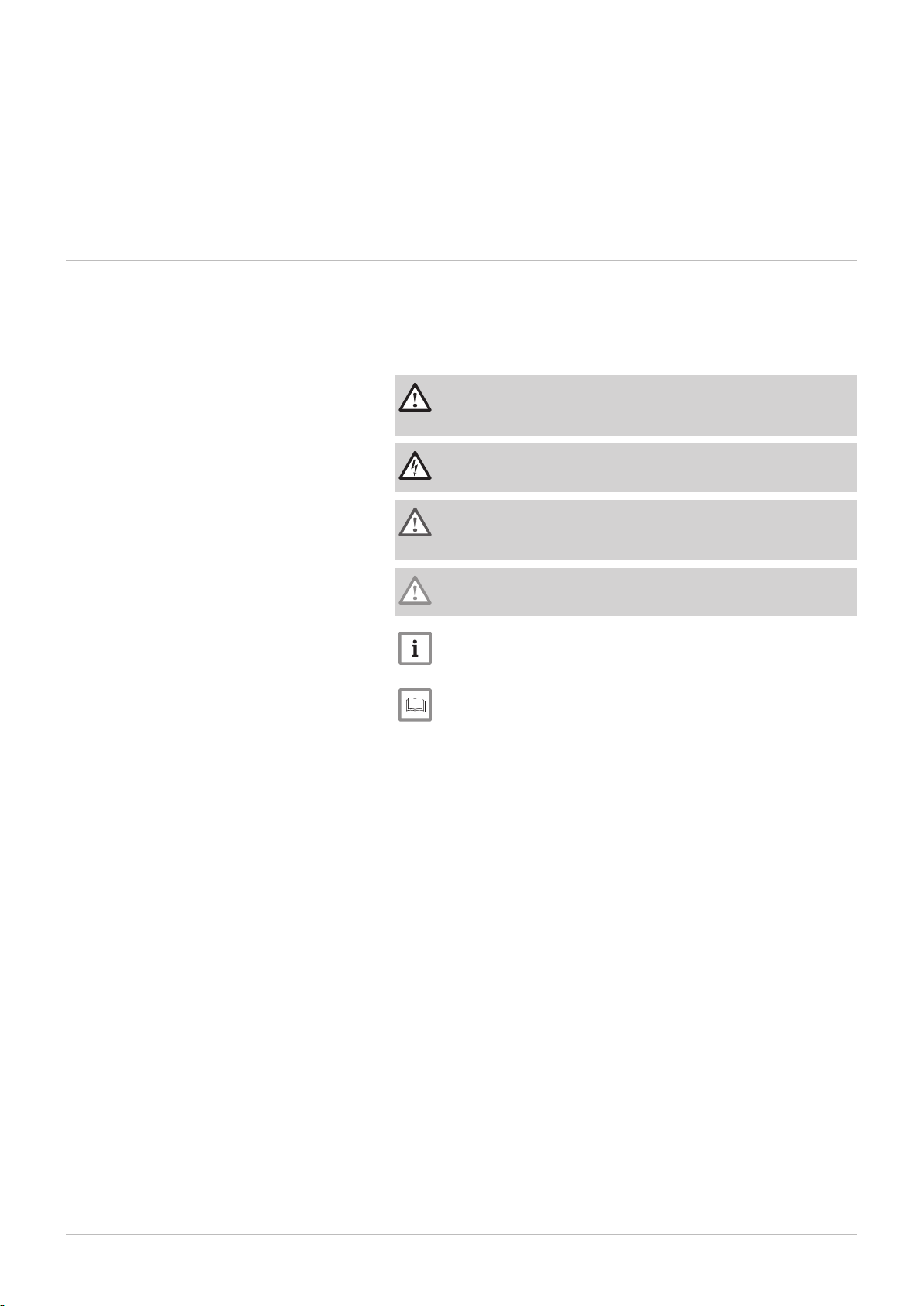

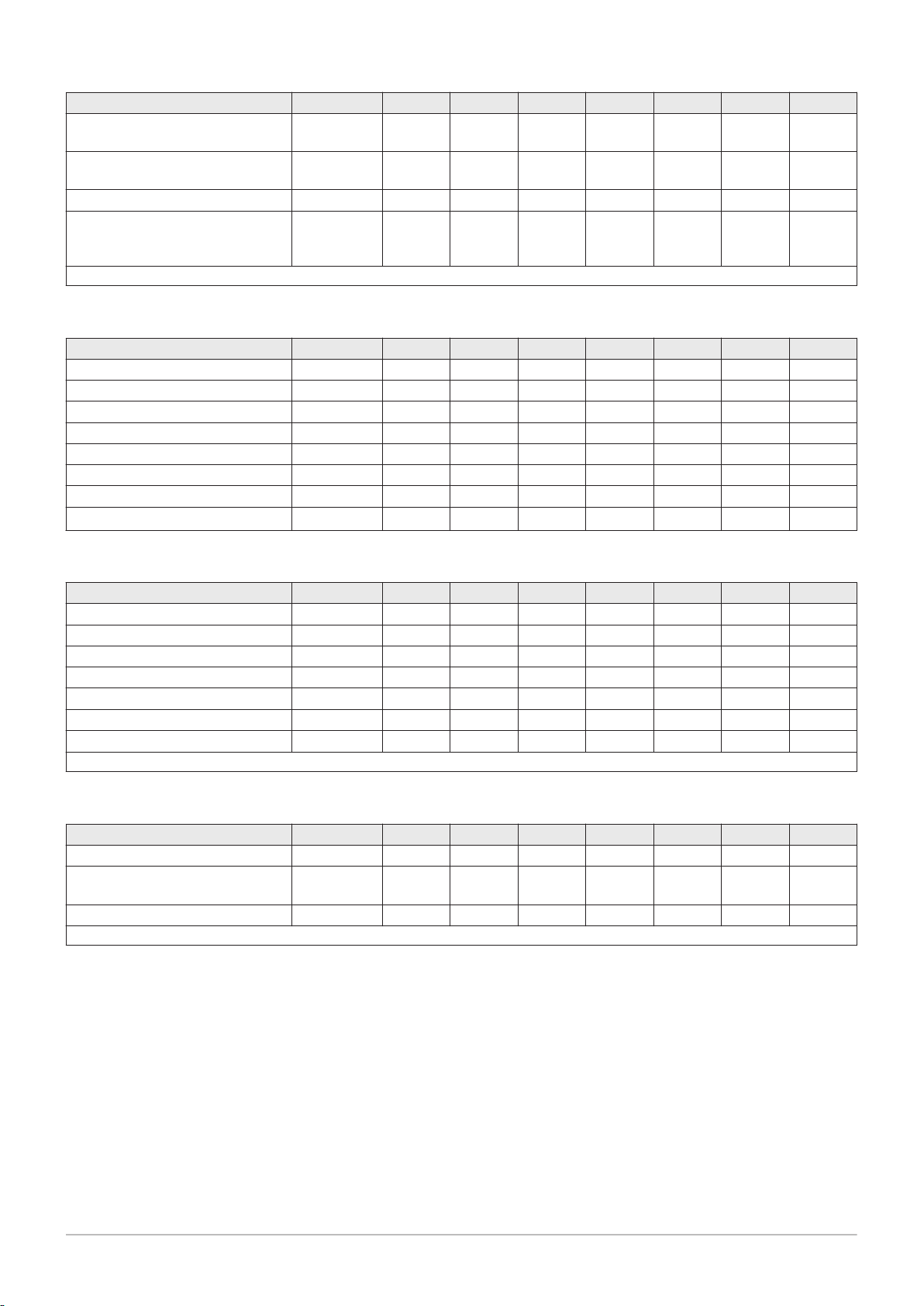

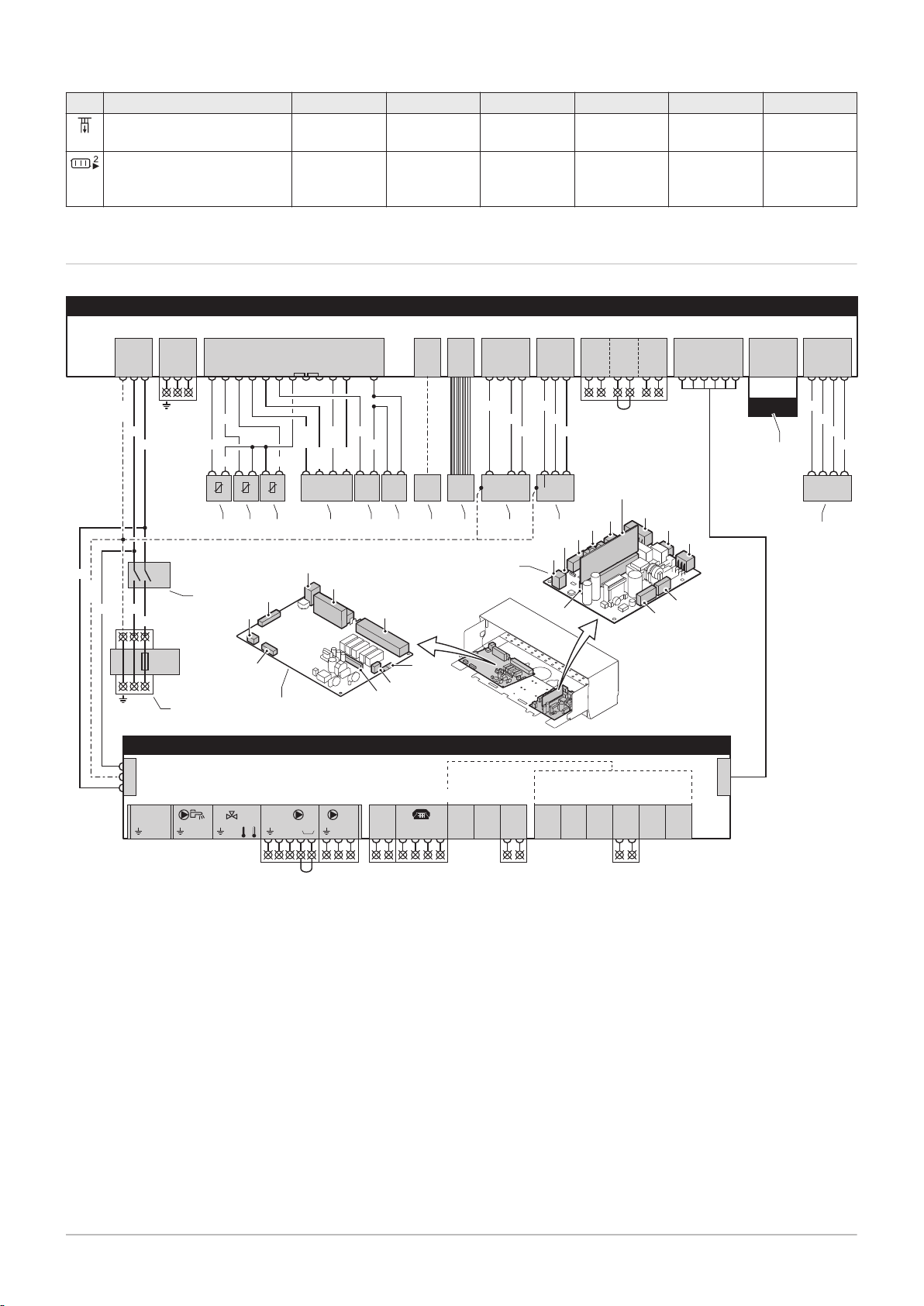

3.4

Electrical diagram

Fig.3 Electrical diagram

1

2

3

4

5

6

7

8

Extended PCB (SCU-D4)

Standard PCB (PCU-06)

Safety PCB (SU-01)

On/Off switch (AU)

Power supply (P)

Flow sensor (Fs)

Heat exchanger temperature sensor (HEs)

Return temperature sensor (RTs)

9

Parameter storage (PSU)

10

High limit switch (HLs)

11

Air pressure differential switch (PS)

12

Computer connection (PC)

13

Control panel (HMI)

14

Gas valve unit (GB)

15

Ignition transformer (IT)

16

Fan (FAN)

Page 19

4 Description of the product

7600532 - v.11 - 13122018 19

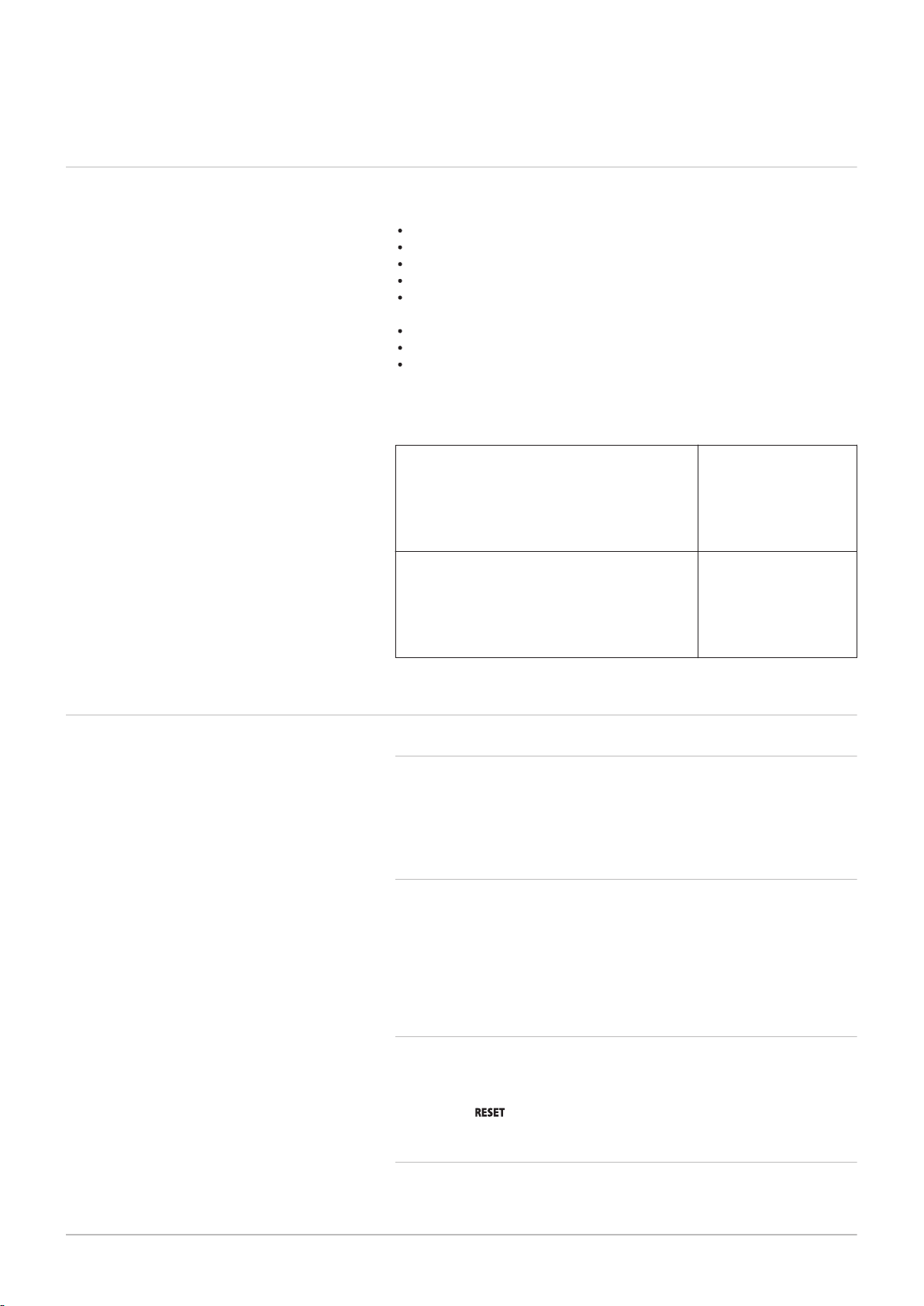

4.1 General description

4 Description of the product

The C 330 ECO / C 630 ECO is a freestanding gas boiler with the

following characteristics:

High-efficiency heating.

Heat exchanger made of cast aluminium sections.

Limited emissions of polluted substances.

Has transport wheels as standard.

Left- or right-hand version of the water and flue gas side connections

possible.

Separable for assembly in boiler room.

DIEMATIC iSystem or IniControl control panel.

The C 630 ECO comprises a left-hand and a right-hand module. These

are combined on the flue gas side (optionally on the air side) and also in

terms of their casing.

The following boiler types are available:

4.2

Operating principle

C 330 ECO 280

C 330 ECO 350

C 330 ECO 430

C 330 ECO 500

C 330 ECO 570

C 330 ECO 650

C 630 ECO 560

C 630 ECO 700

C 630 ECO 860

C 630 ECO 1000

C 630 ECO 1140

C 630 ECO 1300

279 kW output

350 kW output

425 kW output

497 kW output

574 kW output

651 kW output

558 kW output

700 kW output

850 kW output

994 kW output

1148 kW output

1303 kW output

4.2.1 Regulating the water temperature

The boiler is fitted with an electronic temperature control with a flow and

return temperature sensor. The flow temperature can be adjusted between

20°C and 90°C. The boiler modulates back when the set flow temperature

is reached. The switch-off temperature is the set flow temperature + 5°C.

4.2.2 Protection against shortage of water

The boiler is fitted with protection against a shortage of water that is based

on temperature differences (difference in temperature between flow and

return). From ΔT = 25K (factory setting) the boiler reduces its output by

modulating to remain in operation as long as possible. At ΔT ≥ 25K, the

boiler goes into part load. At ΔT > 25 + 5K, the boiler goes into a normal

control stop (blocking).

4.2.3 Maximum protection

The maximum temperature protection shuts the boiler down in the event

that an excessively high water temperature (110 °C) is reached. Once the

cause of the fault has been remedied, the boiler can be unlocked by

pressing the button for 2 seconds.

4.2.4 Air pressure differential switch

Before a start and when the boiler is in operation, the air pressure

differential switch PS measures the difference in pressure between the

measuring points on the back of the heat exchanger p+ and the air box p-.

Page 20

AD-0000521-01

2

1

3

4

5

6

7

8

27

40

28

29

30

32

34

31

33

35

36

37

38

39

11

12

14

13

15

16

17

18

19

20

22

24

26

21

23

25

10

9

4 Description of the product

20 7600532 - v.11 - 13122018

If the pressure difference is greater than 6 mbar, then the boiler will lock

out. Once the cause of the fault has been remedied, the boiler can be

unlocked by pressing the button for 2 seconds.

4.2.5 Circulating pump

The boiler does not have a built-in pump. A circulating pump can be

installed on the connector of the standard control PCB. This can be an

on/off pump or a modulating pump (with 0 - 10 V control).

The pump settings can be changed.

See

Manual for the control panel.

For more information, see

Analogue output (Ctrl), page 44

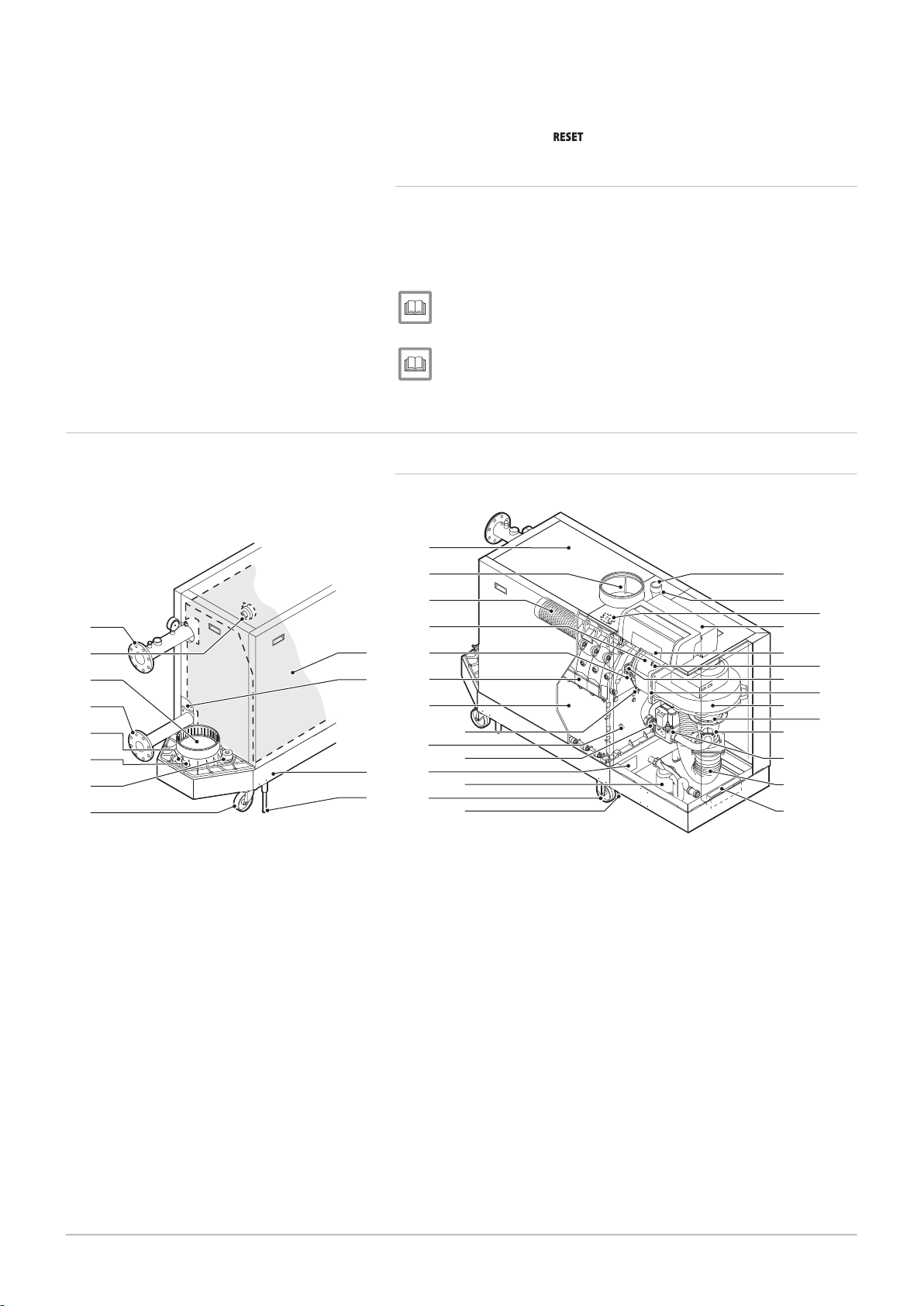

4.3

Main components

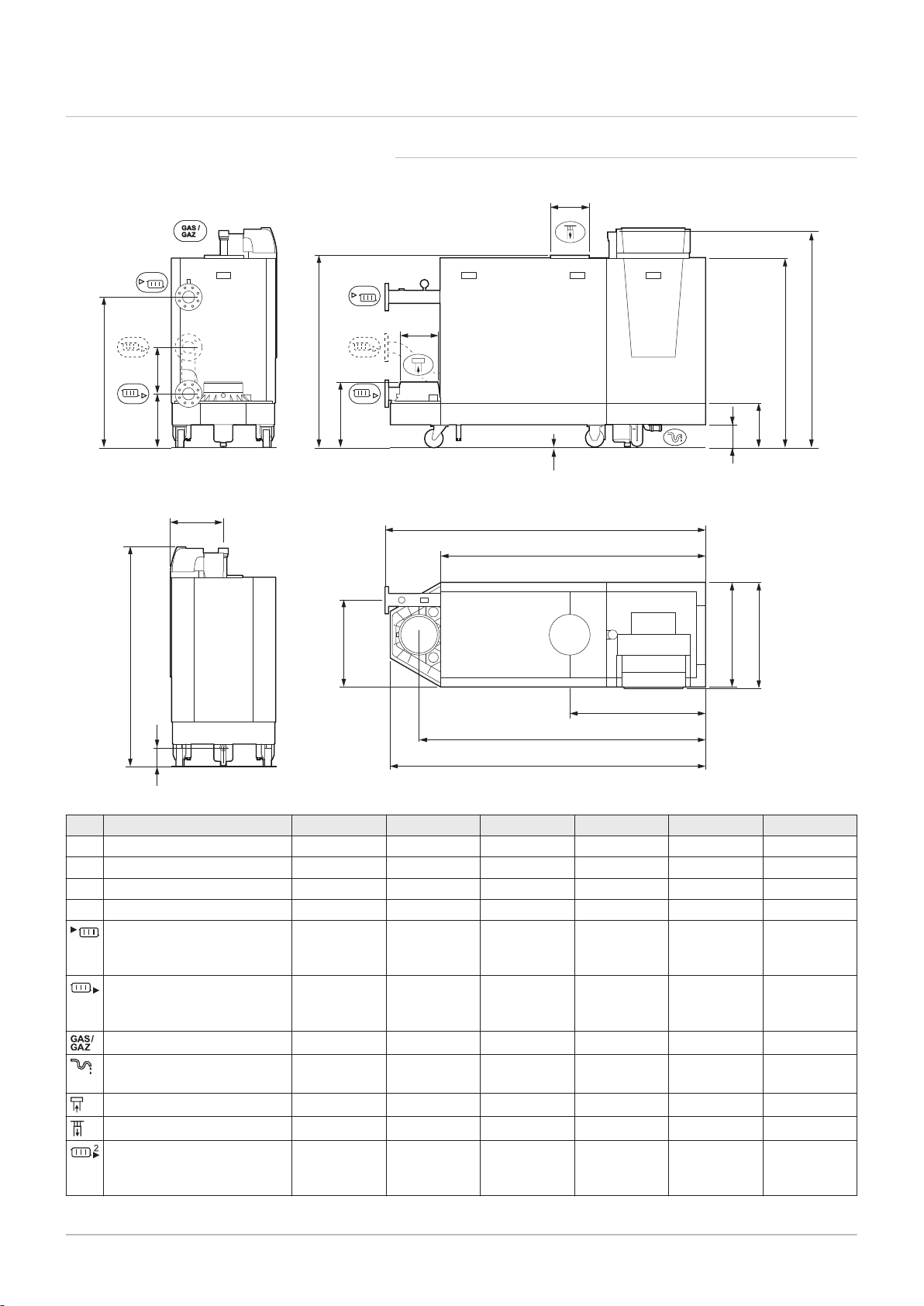

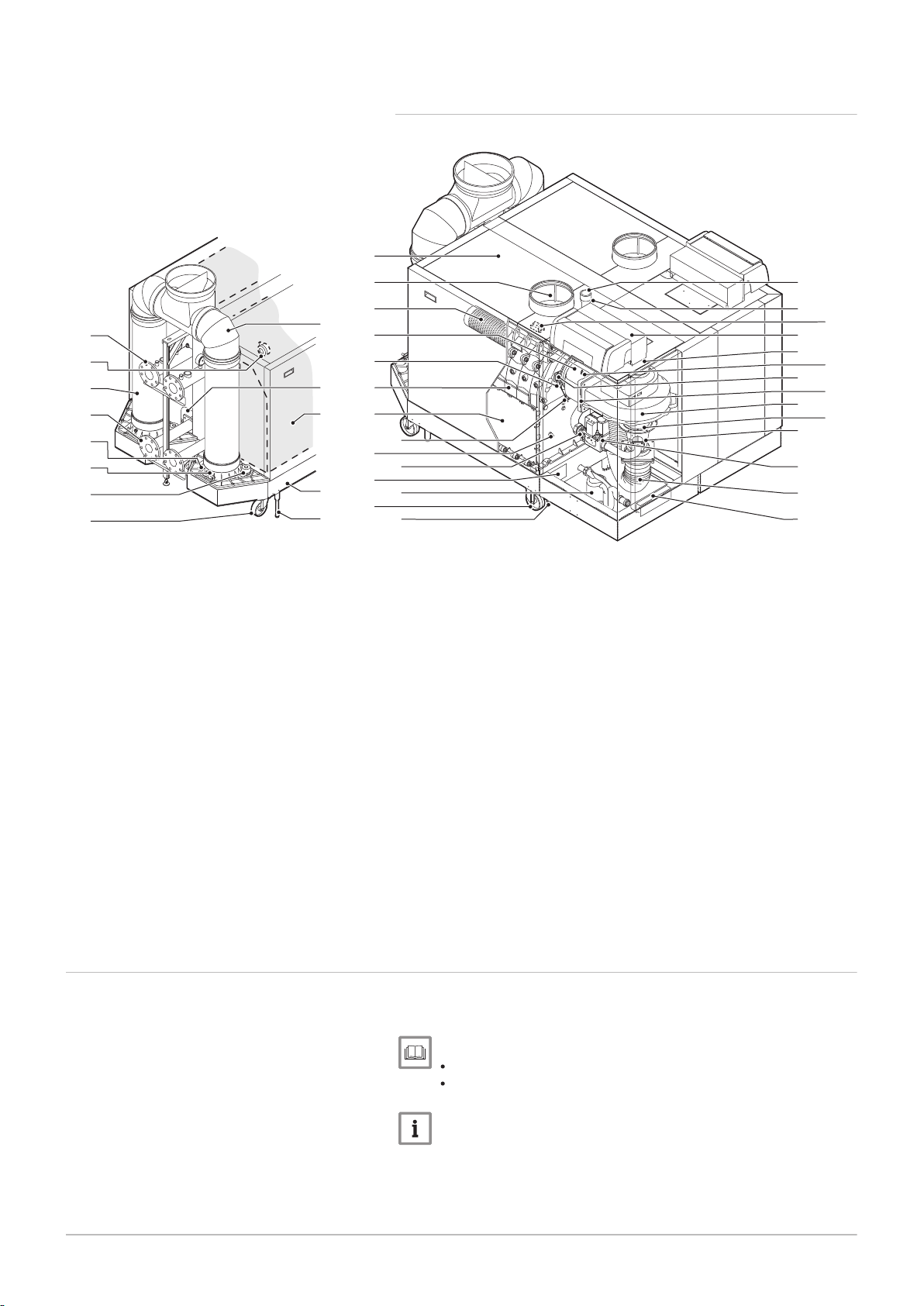

4.3.1 Main components C 330 ECO

Fig.4

C 330 ECO

1

Flow connection

2

Air pressure differential switch

3

Flue gas outlet

4

Return connection

5

Flue gas measuring point

6

Flue gas thermostat (if present)

7

Condensate collector sealant cap

8

Pivoting castor

9

Adjustment bolt

10

Frame

11

Second return connection

12

Heat exchanger insulation kit (if present)

13

Boiler casing

14

Air supply

15

Burner

16

Adapter

17

Ignition/ionisation electrode

18

Heat exchanger

19

Inspection trap

20

Temperature sensor for heat exchanger

21

Return temperature sensor

22

Gas filter

23

Data plate

24

Siphon

25

Transport wheels

26

Adjustment bolt

27

Gas connection

28

Gas pressure measuring point

29

Control panel

30

Installation option for weather-compensated boiler

control

31

Pressure measurement point

32

Flame inspection window

33

Non-return valve

34

Fan

35

Extension piece

36

Venturi

37

Gas valve unit

38

Air supply hose

39

Document holder

40

Ignition transformer

Page 21

Fig.5 C 630 ECO

AD-0000522-01

1

3

4

5

2

6

7

8

27

28

29

30

32

34

31

33

35

36

14

13

15

16

17

18

19

20

22

24

26

21

23

25

10

41

11

12

9

37

38

39

40

7600532 - v.11 - 13122018 21

4 Description of the product

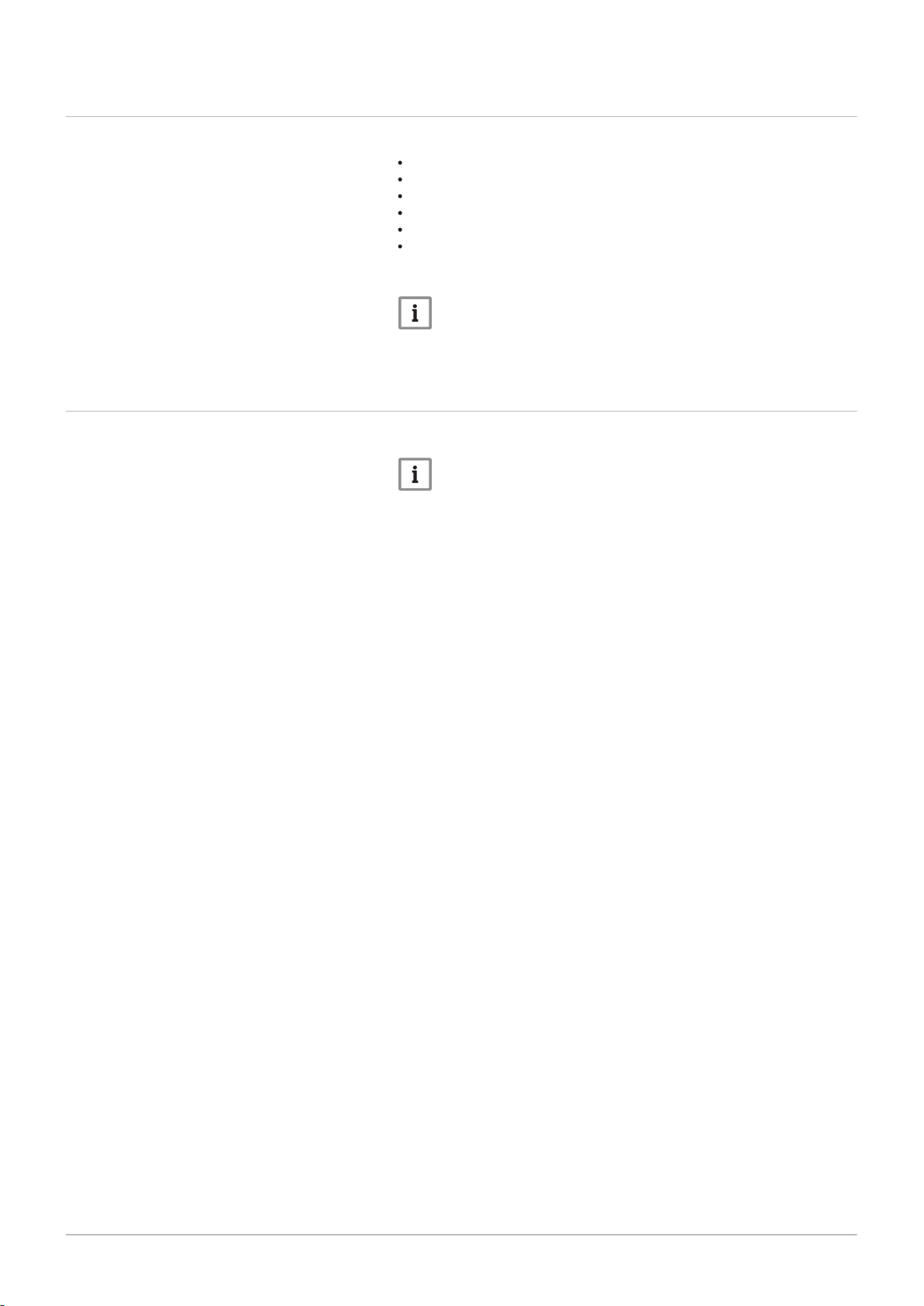

4.3.2 Main components C 630 ECO

1

Flow connection

2

Air pressure differential switch

3

Flue gas outlet

4

Return connection

5

Flue gas measuring point

6

Flue gas thermostat (if present)

7

Condensate collector sealant cap

8

Pivoting castor

9

Adjustment bolt

10

Frame

11

Heat exchanger insulation kit (if present)

12

Flue gas collector

13

Boiler casing

14

Air supply

15

Burner

16

Adapter

17

Ignition/ionisation electrode

18

Heat exchanger

19

Inspection trap

20

Temperature sensor for heat exchanger

21

Return temperature sensor

4.4

Control panel description

The boiler is supplied with a DIEMATIC iSystem or IniControl control

panel. The control panel is mounted in the boiler.

See

Assembly instructions for the control panel.

Manual for the control panel.

Important

For operation of the C 630 ECO boiler: each module has its own

control panel.

22

Gas filter

23

Data plate

24

Siphon

25

Transport wheels

26

Adjustment bolt

27

Gas connection

28

Gas pressure measuring point

29

Control panel

30

Installation option for weather-compensated boiler

control

31

Pressure measurement point

32

Flame inspection window

33

Non-return valve

34

Fan

35

Extension piece

36

Venturi

37

Gas valve unit

38

Air supply hose

39

Document holder

40

Ignition transformer

41

Second return connection

Page 22

4 Description of the product

22 7600532 - v.11 - 13122018

4.5 Standard delivery

The delivery includes:

The boiler

Complete siphon

Filling and drain valve

Gas filter

Documentation

Water quality instructions

Please fit these components in the order described in this manual.

Important

This manual only deals with the standard scope of supply. For the

installation or mounting of any accessories delivered with the

boiler, refer to the corresponding mounting instructions.

4.6

Accessories and options

Various accessories can be obtained for the boiler.

Important

Contact us for more information.

Page 23

5 Before installation

AD-0000487-01

7600532 - v.11 - 13122018 23

5.1 Installation regulations

5 Before installation

Warning

The boiler must be installed by a qualified installer in accordance

with local and national regulations.

5.2

Fig.6

Choice of the location

Position of data plate

5.2.1 Data plate

The identification plate is located behind the boiler casing on the frame,

near the syphon connection. The data plate provides important information

on the boiler specifications such as the model and the device category.

5.2.2

Use the guidelines and the required installation space as a basis for

determining the correct place to install the boiler.

When determining the correct installation area, take account of the

permitted position of the flue gas outlet and/or air supply outlet.

Ensure that there is sufficient space around the boiler for good access

and ease of maintenance.

A technical clearance of at least 80 cm is required at the front (service

side) of the boiler. However, we recommend that the clearance is at

least 100 cm. Above the boiler, we recommend a clearance of at least

40 cm (when using an air inlet filter, the clearance must be at least 65

cm). A minimum of 30 cm is required on the side of the flue gas outlet,

and a minimum of 30 cm is also required on the other side (or 80 cm, if

this is operating side).

Installing the boiler C 330 ECO

Page 24

AD-0000515-01

L

R

I

I

AD-0000486-01

55 55

55 55

663 21,5

531 87,5

673

55

A

5 Before installation

24 7600532 - v.11 - 13122018

Danger

It is forbidden to store, even temporarily, combustible products

and substances in or near the boiler.

Caution

The boiler must be installed in a frost-free area.

An earthed electrical connection must be available close to the

boiler.

A connection to the drain must be present for the condensate

drain close to the boiler.

Fig.7 Left-hand and right-hand versions

Fig.8 Position of the adjustment bolts

L

Left-hand version

R

Right-hand version

I

Inspection trap (service side)

The service side with the inspection trap on the heat exchanger is

considered to be the front of the boiler. The boiler is available in both a

'left-hand' and 'right-hand' version. This means that the hydraulic

connections and the flue gas discharge are situated on either the left or

the right-hand side of the boiler. The control panel is on the front as

standard, but can easily be rotated so that it is on the short side.

The adjustment bolts must be used to make the boiler level and to raise

the wheels off the floor. Turn the adjustment bolts outwards as soon as the

boiler is placed in the correct position. The figure shows the support

surface of the boiler (this is the position of the adjustment bolts).

Tab.14 Dimensions A (mm)

C 330 ECO A (mm)

280 723

350 723

430 723

500 1032

570 1032

650 1032

Page 25

Fig.9 Clearance required

AD-0000506-02

C C

C

800

300

600

800 800

720

1670

800150

720720

3190

800

800

150

720

1670

800150

C

800

300

7600532 - v.11 - 13122018 25

5 Before installation

For the dimensions of C:

See

Boiler type C 330 ECO, page 16

5.2.3 Installing the boiler C 630 ECO

Use the guidelines and the required installation space as a basis for

determining the correct place to install the boiler.

When determining the correct installation area, take account of the

permitted position of the flue gas outlet and/or air supply outlet.

Ensure that there is sufficient space around the boiler for good access

and ease of maintenance.

A technical clearance of at least 80 cm is required at the front (service

side) of the boiler. However, we recommend that the clearance is at

least 100 cm. Above the boiler, we recommend a clearance of at least

40 cm (when using an air inlet filter, the clearance must be at least 65

cm). A minimum of 30 cm is required on the side of the flue gas outlet,

and a minimum of 30 cm is also required on the other side (or 80 cm, if

this is operating side).

Page 26

AD-0000514-02

AD-0000510-01

5555

55

55

21,5

21,5

87,5531

663663

53187,5

673

A

55

55

55

55

55

55

55

5 Before installation

26 7600532 - v.11 - 13122018

Danger

It is forbidden to store, even temporarily, combustible products

and substances in or near the boiler.

Caution

The boiler must be installed in a frost-free area.

An earthed electrical connection must be available close to the

boiler.

A connection to the drain must be present for the condensate

drain close to the boiler.

Fig.10 Position of the control panel

Fig.11 Position of the adjustment bolts

The boiler is not available with a choice between 'left-hand' and 'righthand' versions. The control panel is on the front as standard, but can

easily be rotated so that it is on the short side.

The adjustment bolts must be used to make the boiler level and to raise

the wheels off the floor. Turn the adjustment bolts outwards as soon as the

boiler is placed in the correct position. The figure shows the support

surface of the boiler (this is the position of the adjustment bolts).

Tab.15 Dimensions A (mm)

C 630 ECO A (mm)

560 723

700 723

860 723

1000 1032

1140 1032

1300 1032

Page 27

Fig.12 Clearance required

AD-0000511-02

C

C

C

800

300

600

800

800

1450

3050

800800

1450

3050

800800

7600532 - v.11 - 13122018 27

5 Before installation

For the dimensions of C:

See

Boiler type C 630 ECO, page 17

5.2.4 Rotating the control panel

The control panel is on the front as standard, but can easily be rotated so

that it is on the short side.

Page 28

AD-0000523-01

3 2x

4

90º

5

6

72x

8

9

1

2

AD-0000519-01

1789

800

L

5 Before installation

28 7600532 - v.11 - 13122018

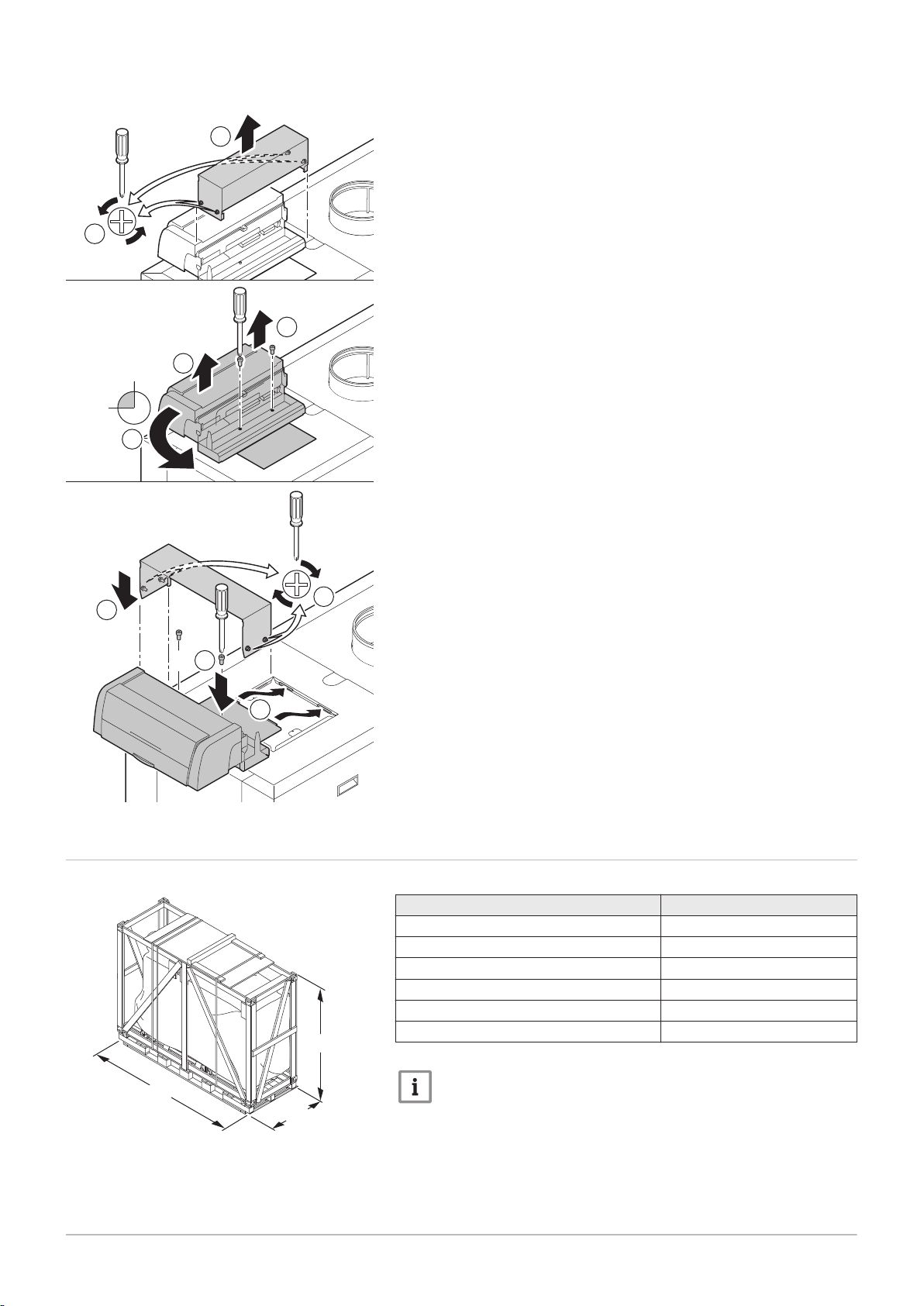

Fig.13 Rotating the control panel

1. Unscrew the 4 lateral retaining screws in the control panel.

2. Remove the protective cover.

3. Unscrew the 2 bottom plate screws.

4. Lift up the control panel with the bottom plate.

5. Turn the control panel and the bottom plate into position on the short

side.

6. Slide the lips of the bottom plate into the appropriate slots.

7. Tighten the 2 bottom plate screws.

8. Replace the protective cover.

9. Tighten the 4 lateral retaining screws again.

5.3

Transport

Fig.14 Boiler package

Tab.16 Boiler package dimensions

C 330 ECO L (mm)

280 1920

350 1920

430 1920

500 2230

570 2230

650 2230

Important

For work on the C 630 ECO boilers: The features and instructions

described apply to each boiler module.

The boiler is supplied fully assembled on a pallet. See the diagram and

table for the dimensions. The base of the package is a pallet 80 cm wide.

This means that it can be transported with a pallet truck or using fourwheel transport boards. Without the packaging, the boiler is 720 mm wide,

Page 29

Fig.15 Transport element

AD-0000507-01

1107

1000

700

L

1000

7600532 - v.11 - 13122018 29

5 Before installation

(without casing 700 mm), meaning that it will fit through all standard

doorways. The boiler has wheels so that, once the packaging has been

removed, it can easily be moved around.

Caution

The wheels are designed for transport purposes only and not for

use when the boiler is in its final position.

If required for internal transport, the boiler can be dismantled into smaller

parts for transport. The boiler can be stripped of:

Casing panels

Gas/air components

The frame section on the control panel side

See drawing and table for the dimensions and weight of the largest

remaining transport element (frame element with heat exchanger and

water connections).

Tab.17 Boiler dimensions and weight

C 330 ECO L (mm) Weight (kg)

280 1160 249

350 1160 283

430 1160 317

500 1469 356

570 1469 390

650 1469 424

See

Refer to the installation manual supplied for information on how to

install the boiler parts.

Page 30

AD-0000488-01

1

3

2

6

4

5

6 Installation

30 7600532 - v.11 - 13122018

6 Installation

6.1 General

Warning

The boiler must be installed by a qualified installer in accordance

with local and national regulations.

6.2

Hydraulic connections

6.2.1 Rinsing the system

Installation must be carried out in accordance with the prevailing

regulations, codes of practice and the recommendations in this manual.

Before a new boiler can be connected to an existing or new system, the

entire system must be thoroughly cleaned and flushed. This step is

absolutely crucial. The flushing helps to remove residue from the

installation process (weld slag, fixing products etc.) and accumulations of

dirt (silt, mud etc.)

Important

Flush the system with a volume of water equivalent to at least

three times the volume of the system.

Flush the DHW pipes with at least 20 times the volume of the

pipes.

6.2.2 Connecting the heating circuit

Important

For C 630 ECO: the properties described and the instructions

apply to each boiler module.

1. Remove the dust caps from the CH flow connection and CH

return connection .

2. Fit the outlet pipe for CH water to the CH flow .

3. Fit the inlet pipe for CH water to the CH return .

4. Connect a safety valve to the boiler's flow connection.

5. Connect the pump to the boiler's return connection.

Always connect the boiler in a way that will guarantee the water flow

through the unit during operation. When the boiler is used in a system with

two return pipes, the return pipe must be used as a cold return. The

second return pipe (if connected) is then used as a hot return. Contact us

for more information.

The flow pipe is fitted with the following components:

Fig.16 Flow pipe

1 Immersion tube for a temperature sensor for an external control

(½").

2 Air vent (⅛").

3 Safety valve connection (1½").

4 Pressure gauge (½").

5 Flow sensor (M6).

6 High-limit thermostat (M4).

Page 31

6 Installation

7600532 - v.11 - 13122018 31

Caution

If using synthetic pipes, follow the manufacturer's (connection)

instructions.

6.2.3 Connecting the condensate discharge pipe

Important

For C 630 ECO: the properties described and the instructions

apply to each boiler module.

1. Fit a plastic drain pipe of Ø 32 mm or larger to the siphon, terminating

in the drain.

Caution

Use only plastic material for the discharge pipe due to the

acidity (pH 2 to 5) of the condensate.

Do not make a fixed connection in order to prevent an

overpressure in the siphon.

2. Fit a stench-trap or siphon in the drain pipe.

Caution

Never seal the condensate drain.

The drain pipe must slope down at least 5 - 10 mm per metre,

the maximum horizontal length is 5 metres.

Condensed water must not be discharged into a gutter.

6.3

6.4

Gas connection

Important

For C 630 ECO: the properties described and the instructions

apply to each boiler module.

Warning

Before starting work on the gas pipes, turn off the main gas tap.

Before installing, check that the gas meter has sufficient

capacity. Take into account the consumption of all appliances.

Notify the local energy company if the gas meter has insufficient

capacity.

1. Remove the dust cap on the gas connection .

2. Fit the gas supply pipe to the gas supply .

3. Also fit a gas isolation valve in this pipe, near the boiler.

Caution

Remove dirt and dust from the gas pipe.

Always perform welding work at a sufficient distance from the

boiler.

The boiler is fitted with a gas filter as standard.

Air supply/flue gas connections

The boiler is suitable for the following types of flue gas connections:

See

Certifications, page 11.

Follow applicable local guidelines when connecting the flue gas discharge

and air supply pipes to the boiler. The diameters of the pipes must be

defined in accordance with the standards in force in your country. The total

resistance of the flue gas outlet and air inlet must not exceed the

maximum acceptable resistance.

Page 32

AD-3001120-01

EN 14471 - T120 P1 W 1 O50 LI E U0

EN 1856-1 - T120 P1 W VxL40045 G(xx)

1

3

2

4

5

6 Installation

32 7600532 - v.11 - 13122018

Important

With room-sealed operation, make sure the dirt trap in the boiler

air supply remains accessible. For example, fit a T piece with an

inspection trap in the air supply pipe directly above the boiler.

With a flue gas connection of two or more C 330 ECO boilers,

certain fan speeds need to be changed. Change the values of

relevant parameters for each boiler in the flue gas connection.

Set them to the values as specified in the parameter table for

the C 630 ECO boiler.

6.4.1 Material

Use the string on the flue gas outlet material to check whether it is suitable

for use on this appliance.

Fig.17 Sample string

1

EN 14471 of EN 1856–1: The material is CE approved according to

this standard. For plastic this is EN 14471, For aluminium and

stainless steel this is EN 1856-1.

2

T120: The material has temperature class T120. A higher number

is also allowed, but not lower.

3

P1: The material falls into pressure class P1. H1 is also allowed.

4

W: The material is suitable for draining condensation water

(W=’wet’). D is not allowed (D=’dry’).

5

E: The material falls into fire resistance class E. Class A to D are

also allowed, F is not allowed. Only applicable to plastic.

Warning

The coupling and connection methods may vary depending on

the manufacturer. It is not permitted to combine pipes, coupling

and connection methods from different manufacturers. This also

applies to roof feed-throughs and common channels.

The materials used must comply with the prevailing regulations

and standards.

Tab.18 Overview of material properties

Version Flue gas outlet Air supply

Material Material properties Material Material properties

Single-wall, rigid

(1)

Plastic

Stainless steel

Thick-walled,

aluminium

(2)

With CE marking

(2)

Temperature class T120 or

higher

Condensate class W (wet)

Plastic

Stainless steel

Aluminium

Pressure class P1 or H1

Fire resistance class E or bet

(3)

ter

(1) according to EN 14471

(2) according to EN 1856

(3) according to EN 13501-1

With CE marking

Pressure class P1 or H1

Fire resistance class E or bet

(3)

ter

Page 33

6.4.2 Dimensions of flue gas outlet pipe

AD-3001094-01

ød

1

AD-0000562-01

L =

7600532 - v.11 - 13122018 33

Warning

The pipes connected to the flue gas adapter must satisfy the

following dimension requirements.

6 Installation

Fig.18 Dimensions of open connection

d

External dimensions of flue gas outlet pipe

1

Tab.19 Dimensions of pipe

d1 (min-max)

250 mm 249 - 251 mm

350 mm 349 - 351 mm

6.4.3 Length of the air and flue gas pipes

The maximum length of the flue gas outlet and air supply channel vary

depending on the appliance type; consult the relevant chapter for the

correct lengths.

Important

When using bends, the maximum chimney length (L) must be

shortened according to the reduction table.

For adaptation to another diameter use approved transitions

Room-ventilated model (B23, B

With a room-ventilated version, the air supply opening stays open; only the

flue gas outlet opening is connected. This will ensure that the boiler

obtains the necessary combustion air directly from the installation area.

23P

)

Fig.19 Room-ventilated version C 330

ECO

Caution

The air supply opening must stay open.

The installation area must be equipped with the necessary air

supply openings. These openings must not be obstructed or

shut off.

If the boiler, in room-ventilated operation, has been set up in a

(very) dusty room, use the air supply filter (accessory).

Use of the air inlet filter is compulsory when the boiler is

exposed to building dust.

L

Length of the flue gas outlet channel to roof feed-through

Flue gas outlet

Tab.20 Maximum length for open design

C 330 ECO

Maximum length L (in metres)

Ø 150 mm Ø 180 mm Ø 200 mm Ø 250 mm

(1)

280 20 50 50 50

350 11 30 50 50