DeDietrich C230 ECO-A 120, C230 ECO-A 160, C230 ECO-A 200 Installation, Operating And Service Manual

ENG

10/2012

De Dietrich C230 ECO-A Series

Gas-Fired Condensing Hot Water Boiler

Models

C230 ECO-A 80

C230 ECO-A 120

C230 ECO-A 160

C230 ECO-A 200

Installation,

Operating and

service manual

Important

This is a category II or IV boiler,

only use an approved type ‘BH’

vent or equivalent, consult the

venting section in this manual.

Warning: Before you operate this boiler, read this manual carefully and take extra precautions to all safety

and warning symbols or important items. The installation and service manual is part of the documentation

along with the boiler. The installer is required to explain your heating system and boiler operating

instructions.

Notice: Please read this manual and retain for future reference. Improper installation, adjustment, alteration,

service or maintenance can cause injury, loss of life or property damage. Refer to this manual for assistance

or additional information or consult a qualified installer, service agency or the gas supplier.

Table of contents C230 ECO-A

3

Table of contents

Preface 7

1 Introduction 8

1.1 Pictograms used 8

1.2 Important instructions 8

2 Safety 9

3 Boiler description 10

3.1 General description 10

3.2 Boiler layout 11

3.3 Operating principle 12

3.4 Boiler Control 12

3.4.1 Temperature control 12

3.4.2 Low water level protection 12

3.4.3 Maximum protection 13

3.4.4 Frost protection 13

4 Installation 14

4.1 Standards and certifications 14

4.2 Regulations governing installation 14

4.3 Scope of delivery and installation 15

4.4 Installation and service clearances 17

5 Water-side connections 19

5.1.1 Flue gas condensation discharge 19

5.1.2 Water treatment 19

5.1.3 Circulation pump 20

5.1.4 Water flow 20

5.1.5 Water pressure 20

5.1.6 Safety relief valve 21

5.1.7 Water system layout 21

6 Gas-side connections 23

6.1 Gas connection 23

6.2 Gas pressure 23

6.3 Gas/air ratio control 24

7 Flue gas discharge and air supply 25

7.1 General 25

7.1.1 Boiler Venting Types 25

7.1.2 Venting options 26

7.1.3 Vent Termination Inlet/Outlets 26

7.1.4 Combustion Air Supply Requirements 26

7.1.5 Conventional Chimney Venting & CLV system Application Requirements 27

7.1.6 Direct Vent-Sealed Combustion Application 31

7.1.7 Co-venting – Retrofitting 34

7.1.8 Vent terminations installation precautions 34

8 Control and electrical connections 36

8.1 General 36

8.1.1 Boiler control 36

8.1.2 Modulating controls general 37

8.1.3 Modulating room control 37

8.2 Wiring diagrams 38

8.3 Electrical specifications 40

8.3.1 Mains voltage 40

8.3.2 Control box 40

8.3.3 Fuse ratings 40

8.4 Electrical connection options 41

8.4.1 Connection options of standard control unit (PCU-01) 41

8.4.2 On/off control (OT) 41

8.4.3 Modulating controls (OT) 41

8.4.4 External interlock (BL) 41

8.4.5 Input release (RL) 42

8.4.6 Circulation pump (Pump) 42

8.5 Connection options for the optional 0 - 10 V control PCB (IF-01) 42

8.5.1 Connection status (Nc) 42

8.5.2 OTm connection 42

8.5.3 Analogue input (0 - 10 V) 43

8.5.4 Analogue input (0 - 10 V) 44

8.6 Connection options for the optional 0 - 20 mA control PCB 45

8.6.1 Connection status (Nc) 45

8.6.2 OTm connection 45

8.6.3 Analogue input (0 - 20 mA) 45

8.6.4 Analogue input (0 - 20 mA) 46

8.7 Connection options of the optional expanded control/protection PCB (SCU-S01) 47

8.7.1 Flue gas damper control (FgV) 47

8.7.2 Hydraulic valve control (HdV) 47

8.7.3 External gas valve control (EgV) 47

8.7.4 Operation signal and failure signal (Nc / No) 47

8.7.5 Water pressure sensor (Wps) 47

8.7.6 Outside temperature sensor (Tout) 48

8.7.7 Minimum gas pressure switch (Gps) 48

8.7.8 Gas leakage control (VPS; only for 230- 160 and 230- 200 boilers) 48

9 Commissioning 49

9.1 Control panel 49

9.1.1 Normal start-up procedure 49

9.1.2 Fault during start-up procedure 50

9.1.3 Reading current values 51

9.1.4 Adjusting the boiler to the system 52

9.1.5 Changing parameters at user level (without access code) 53

9.1.6 Changing parameters at service level (with access code) 53

9.1.7 Resetting factory settings 56

9.1.8 Setting manual operation ( symbol) 57

9.2 Commissioning 57

9.3 Taking the boiler out of operation 60

9.3.1 Boiler with frost protection, out of operation for a long time 60

9.3.2 Boiler without frost protection, out of operation for a long time 60

10 Inspection and maintenance 62

10.1 General 62

10.2 Combustion check of the boiler 62

10.2.1 Corrective maintenance 63

10.2.2 Cleaning the fan 63

10.2.3 Cleaning the heat exchanger (flue gas side) 65

10.2.4 Cleaning the burner 66

10.3 Cleaning the trap 66

10.4 Checking the ignition electrode 66

10.5 Checking for leaks 67

10.6 Checking water pressure 67

10.7 Putting boiler back into operation 67

4

Table of contents C230 ECO-A

11 Control stops and faults 68

11.1 General 68

11.2 Control stops and faults 68

11.3 Control stop codes 68

11.4 Fault codes 71

11.5 Control stop - and fault memory 74

11.5.1 Reading faults 75

11.5.2 Deleting control stops or faults 76

12 Service parts 77

12.1 General 77

12.2 Exploded views 78

13 Technical specifications 83

13.1 Technical data 83

14 Efficiency information 84

14.1 Unit usable efficiency (HR efficiency) 84

14.2 Water-side efficiency 84

14.3 Zero-load losses 84

15 General information 85

15.1 Description of specifications 85

15.2 Accessories 85

15.3 Services 86

16 Application data 87

16.1 General 87

16.2 Air and flue gas application options 87

16.3 Hydraulic application options 87

16.4 Control options 87

16.5 Gas application options 87

17 Checklists (records) 88

17.1 Checklist for commissioning (Commissioning record) 88

17.2 Checklist for annual inspection (inspection record) 88

17.3 Checklist for maintenance (maintenance record) 89

5

Preface C230 ECO-A

Preface

This installation and service manual, which contains a lot of practical

information about the De Dietrich C230 ECO-A, a High efficiency

central heating unit, is mainly intended for installers. It contains

important instructions for safe and trouble-free operation of the boiler

before commissioning and during operation.

Read these instructions carefully before putting the boiler into

operation, familiarize yourself with its control functions, operation and

strictly observe the instructions given. Failure to do so may invalidate

warranty or prevent the boiler from operating. The following boiler

models are available:

C230 ECO-A 80 (3 sections; 297 MBH (87 kW))

C230 ECO-A 120 (4 sections; 359 MBH (105 kW))

C230 ECO-A 160 (5 sections; 567 MBH (166 kW))

C230 ECO-A 200 (6 sections; 683 MBH (200 kW))

Installation and any service, maintenance or reparation of this product

may only be done by a licensed heating technician, trained in and

experienced with hot water boiler installation and gas combustion. The

product must be installed according to all national and local codes

having jurisdiction. Canadian installation must conform to CSA B149 &

US installation ANSI Z223.1.

If you have any questions, need more information or require an

engineer to call on site, please contact our technical help line

1.800.943.6275 Monday thru Friday 08:00 - 17:00 EST.

When contacting De Dietrich America's with a problem on the boiler,

please provide the following information: the boiler type, Serial No

(located on the bottom of the casing), and the symptoms or fault code

(the fault code is a series of flashing digits in the display panel).

The data published in this manual is based on the latest information

(at date of publication) and may be subject to revisions.

We reserve the right to continuous development in both design and

manufacture, therefore any changes to the materials or technology

employed may not be retrospective nor may we be obliged to adjust

earlier supplies accordingly.

7

1 Introduction C230 ECO-A

1 Introduction

1.1 Pictograms used

The following pictograms are used in this document to emphasize

certain instructions. This is in order to increase your personal safety

and to safeguard the technical reliability of the boiler. The pictograms

used are:

Useful advice.

Important instruction for carrying out an action.

Possible risk of personal injury or material damage

to boiler, building or environment.

Possible risk of electrical shocks. Serious personal

injury may occur.

1.2 Important instructions

The boiler must be installed in a frost-free area.

Work on the boiler

Installation, commissioning, maintenance and repair work may only be

carried out by suitably qualified specialist installers in accordance with

the applicable national and local standards and guidelines. Always

disconnect the mains supply and close the main gas cock when

working on the boiler. Check the entire system for leaks after

maintenance and servicing work.

Casing panels may only be removed for maintenance and servicing

purposes. Refit all panels on completion of maintenance and servicing

work.

Instructions and warning labels on the boiler must never be

removed or covered and must be clearly legible throughout the entire

service life of the boiler. Replace damaged or illegible instruction and

warning labels immediately. Generally applicable safety instructions

related to accident prevention must be consulted in addition to the

information supplied in this manual.

Boiler modifications and spare parts

The boiler must not be modified or non OEM spare parts fitted without

the written approval of De Dietrich Boilers.

Keep this document near the boiler.

8

C230 ECO-A 2 Safety

2 Safety

Adhere strictly to the specific safety instructions.

Can you smell gas? Proceed as follows:

Do not smoke and avoid fire and sparks.

Do not operate electrical switches.

Close the gas cock.

Open doors and windows.

Warn those present and leave the building together.

Do not use any phone in the building.

Call your gas supplier once your outside the building. If you

cannot reach them, call the fire department.

Can you smell flue or combustion gases? Proceed as follows:

Isolate the mains power supply from the boiler.

Open doors and windows.

Trace possible leaks and seal them off.

Do not use the boiler, if any part has been under water

Immediately call your service company to inspect the boiler and

replace any part of the control or gas controls.

The boiler casing is not designed for supporting other items, damage

to the casing will result if used for supporting or suspending items. Do

not walk or use the boiler casing as a ladder.

9

3 Boiler description C230 ECO-A

3 Boiler description

3.1 General description

The De Dietrich C230 ECO-A is a pre-assembled, free standing, gas

fired, high efficiency condensing boiler. The sectional cast aluminium

heat exchanger and other major components are contained within a

sealed air box. This forms the main boiler casing with a removable

inspection hatch for maintenance purposes. All electrical and

electronic controls are contained within the instrument panel mounted

on top of the boiler.

The flue gas outlet, combustion air inlet, flow, return and gas

connections are located on top of the boiler with a condensate

connection at low level on the right hand side.

The boiler is suitable for room sealed or open flue applications and

has been designed for central heating and indirect hot water

production at working pressures not exceeding 100 psi (7 bar). It must

be installed on a fully pumped system and is suitable for use on

sealed installations.

The premix gas burner with its gas/air ration control system ensures

clean, trouble free operation with higher than average efficiencies

109% (NCV) in the condensing mode combined with ultra low NO

x

and minimum CO emissions. The standard control package allows

actual and set values to be read and adjusted on the built-in digital

display which also provides normal operating and fault code

indication.

An intelligent, advanced boiler control (Comfort Master) continuously

monitors the boiler conditions, varying the heat output to suit the

system load. The control is able to react to external “negative”

influences in the rest of the system (flow rates, gas/air supply

problems) maintaining boiler output for as long as possible without

resorting to a lockout condition. At worst the boiler will reduce its

output and/or shutdown (shut off mode) awaiting the “negative"

conditions to return to normal before restarting.

The Comfort Master control cannot override the standard flame safety

controls.

10

C230 ECO-A 3 Boiler description

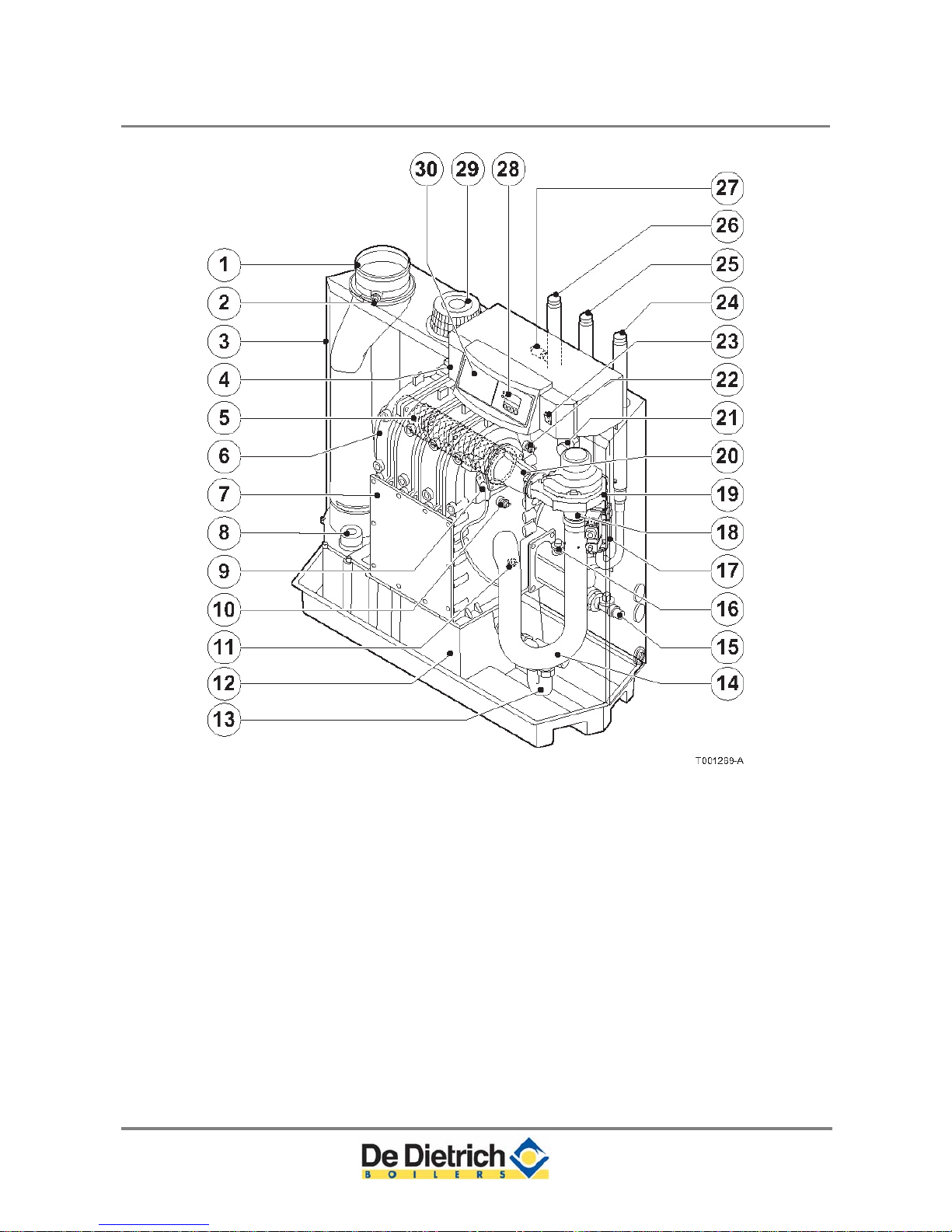

3.2 Boiler layout

Fig. 1 Cross-section

1. Flue gas discharge 11. Return temperature sensor 21. Flue gas switch

2. O2/CO2 measuring point

12. Condensate collector 22. Flow temperature sensor

3. Air box 13. Condensate trap 23. On/off

4. Control panel 14. Air silencing tube 24. Gas connection

5. Burner 15. Filling and drain cock 25. Return connection

6. Heat exchanger 16. Water pressure switch (option) 26. Flow connection

7. Inspection hatch 17. Gas multiblock 27. Thermostat pocket

8. Inspection hatch for condensate

collector

18. Venturi 28. Display

9.Ignition pin 19. Fan 29. Combustion air supply

10. Boiler heath exchanger sensor 20.Mixing tube

30. Facility for built-in weather

compensator

11

3 Boiler description C230 ECO-A

3.3 Operating principle

Combustion air is drawn into the closed air box through the air inlet

from the plant room (open flued) or from outside via the eccentric flue

system (room sealed) by the boiler gas/air supply fan.

Depending on demand (under the dictates of flow/return sensor and

other external/internal control inputs), the Comfort Master system

determines the boiler output, which directly controls the volume of

mixed gas and air to the premix burner. This mixture is initially ignited

by the combined ignitions & ionization probe, which monitors the state

of the flame. Should the flame be unstable or not ignite within the preset safety time cycle, the controls will shut the boiler down requiring

manual intervention to reset the boiler. The digital display will indicate

a flashing fault code confirming the reason for the failure.

The products of combustion in the form of hot flue gases are forced

through the heat exchanger transferring their heat to the system water

(the flue gas temperature is reduced to approximately 9

°F (5 °C)

above the temperature of the system return water). Then they are discharged

via the condensate collector, vertically through the 5.9” (150 mm) flue gas

connection to the atmosphere.

Because of the low flue gas exit temperature there will be a vapor cloud

formed at the flue gas terminal - this is not smoke, simply water vapor formed

during the combustion process.

If the controls allow the flow and therefore return temperature to fall below

dew point (131 °F (55 °C)) this water vapor will begin to condense out in the

boiler, transferring its latent heat into the system water, increasing the output

of the boiler without increasing the gas consumption. Condensation formed

within the boiler and flue system is discharged from the boiler to an external

drain via the drain pan/siphon supplied.

3.4 Boiler Control

3.4.1 Temperature control

The C230 ECO-A is equipped with electronic temperature control

based on flow, return and boiler block temperature sensors. The flow

temperature is adjustable between 68 and 194°F (20 and 90°C)

(factory setting 176°F (80°C)).

3.4.2 Low water level protection

The C230 ECO-A is equipped with low water protection based on

temperature difference measurements and temperature increase

measurements. In some jurisdictions this internal function may not be

acceptable, a separate low water cut-off (LWCO) safety device will be

needed.

This function safeguards the boiler only, a separate control is needed

for the system.

12

C230 ECO-A 3 Boiler description

3.4.3 Maximum protection

The maximum protection switches the unit off if the water temperature

is too high (230°F (110°C)) and interlocks it on the control box. Once

the fault has been remedied, the unit can be reset using the reset-

key.

3.4.4 Frost protection

The unit must be installed in a frost-free area to prevent freezing of

the condensate drain pipe. If the temperature of the heating water

drops too much, the built-in unit protection activates.

13

4 Installation C230 ECO-A

4 Installation

4.1 Standards and certifications

Installation, commissioning, maintenance and repair work must

only be carried out by a suitably qualified specialist.

Installations must conform to national and local codes having

jurisdiction. Canadian installation must conform to CSA B149 &

US installation ANSI Z223.1.

The Gas 230 ECO-A boiler or any of its components do not contain

crystalline silica.

The boiler is certified to use natural gas only with a gas supply of

< 0.5 psig or a gas supply pressure range of 7-14” w.c. [17-35

mbar] max.

The Gas 230 ECO-A boilers are certified with the burner control

unit Comfort Master. Consult local codes having ju

risdiction for

other requirements.

All installation must provid

e a fitted safety relief valve on the boiler

supply piping, without any obstructions or valves. The safety relief

valve needs to be piped to a nearby drain that will avoid personal

injury or damage to property. The relief valve must be sized

according to the minimum relief capacity as listed on the boiler

nameplate. Consult local or national code having jurisdictions

regarding the relief valve piping arrangement.

The condensate is very aggressive and can be harmful to some

drain systems, neutralization of the condensate may be

necessary, consult local codes.

The boiler requires an adequate supply of combustion air, unless

the boiler is a sealed combustion system. The boiler needs a

clean combustion air source according to CSA B149 & ANSI Z223

gas codes.

4.2 Regulations governing installation

Installation and maintenance must be done by a qualified

professional, in compliance with prevailing local and national

regulations.

Gas Installation Code CSA B 149 & ANSI Z223.1 (NFPA 54)

In addition to the above regulations, this boiler must be installed in

compliance with:

National & local building codes

ASME CSD-1 as required

CSA & NEC electrical codes

Other Regulations

The C230 ECO-A is a CSA certified boiler and must not be modified or

installed in any way contrary to this Installation manual.

Manufacturer’s Instructions must NOT be taken as overriding statutory

obligations.

14

C230 ECO-A 4 Installation

4.3 Scope of delivery and installation

The boiler is supplied fully assembled and protected. The boiler is

placed on a pallet ( 28" (70 cm) x 51" (130 cm) x 57" (145 cm)), which

can be transported with a pallet truck, hand truck, forklift truck or 4wheel transport boards. The packaging passes through all standard

doors (minimum width of 29" (74.5 cm)).

The boiler is installed as follows:

Position the pallet with the boiler in the boiler room;

Remove the fixing bands and all other packaging (some

components are packaged in the polystyrene cap);

Lift the boiler from the pallet;

Slide the boiler into the required position, using the recessed

handles in the boiler base;

Cover the boiler and do not operate it while dust creating

construction processes or insulation to the pipe work etc. are

carried out in the plant room.

Install the boiler such that the gas ignition system components are

protected from water (dripping, spraying, rain, etc.) during

operation and service.

Do not install the boiler on carpet or other combustible materials.

Do not install the boiler near combustible constructions, vent

connector, and steam and hot-water pipes.

15

4 Installation C230 ECO-A

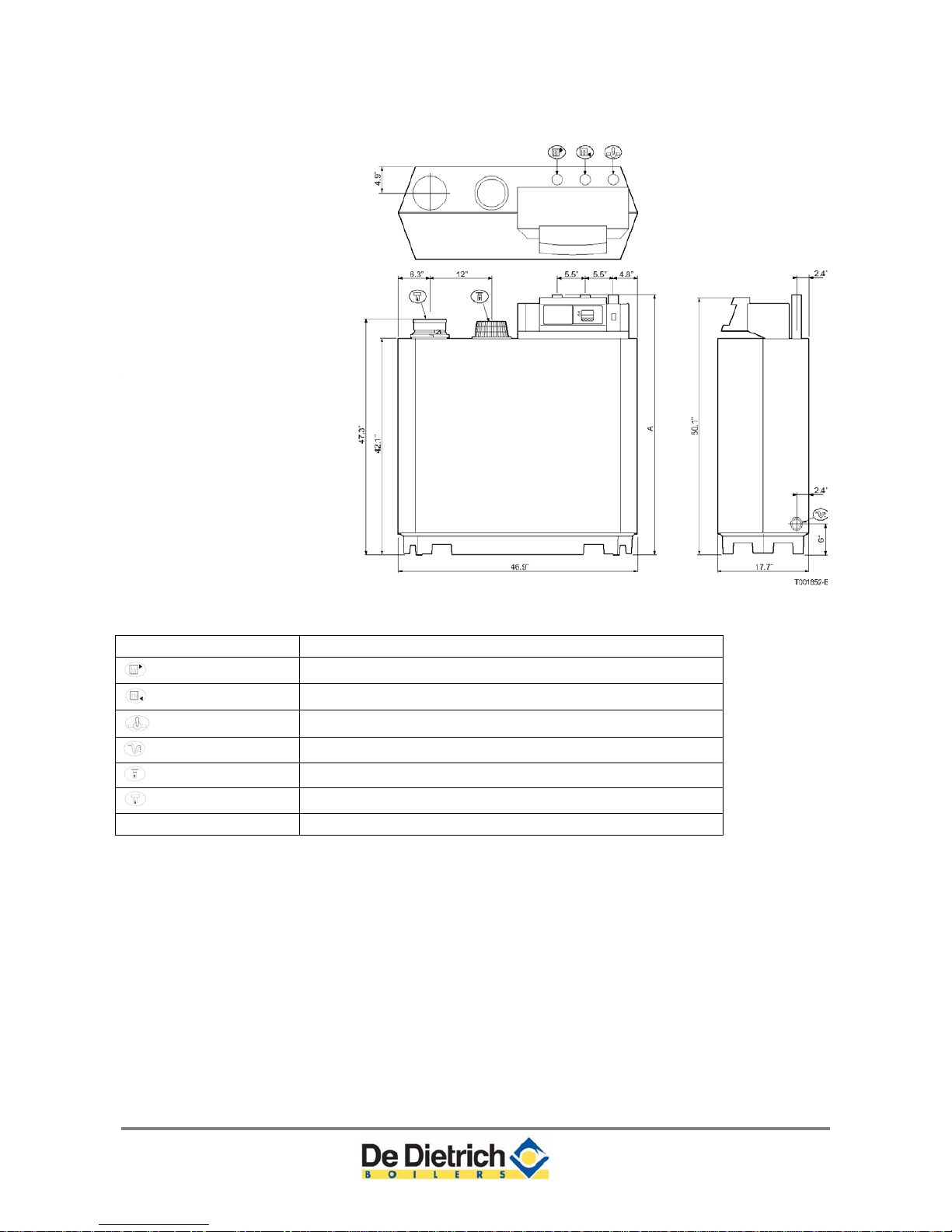

Dimensions

Fig. 2 Elevation drawings

Connection C230 ECO-A 80/120/160/200

Flow

2” NPT thread (do not remove the adapter, pipe is non-NPT)

Return

2” NPT thread (do not remove the adapter, pipe is non-NPT)

Gas connection

2” NPT thread (do not remove the adapter, pipe is non-NPT)

Condensate drain

1.26" (32 mm) external

Combustion air supply

5.91" (150 mm)

Flue gas outlet

5.91" (150 mm)

Dimension “A”

52½” (1330 mm)

16

C230 Eco-A 4 Installation

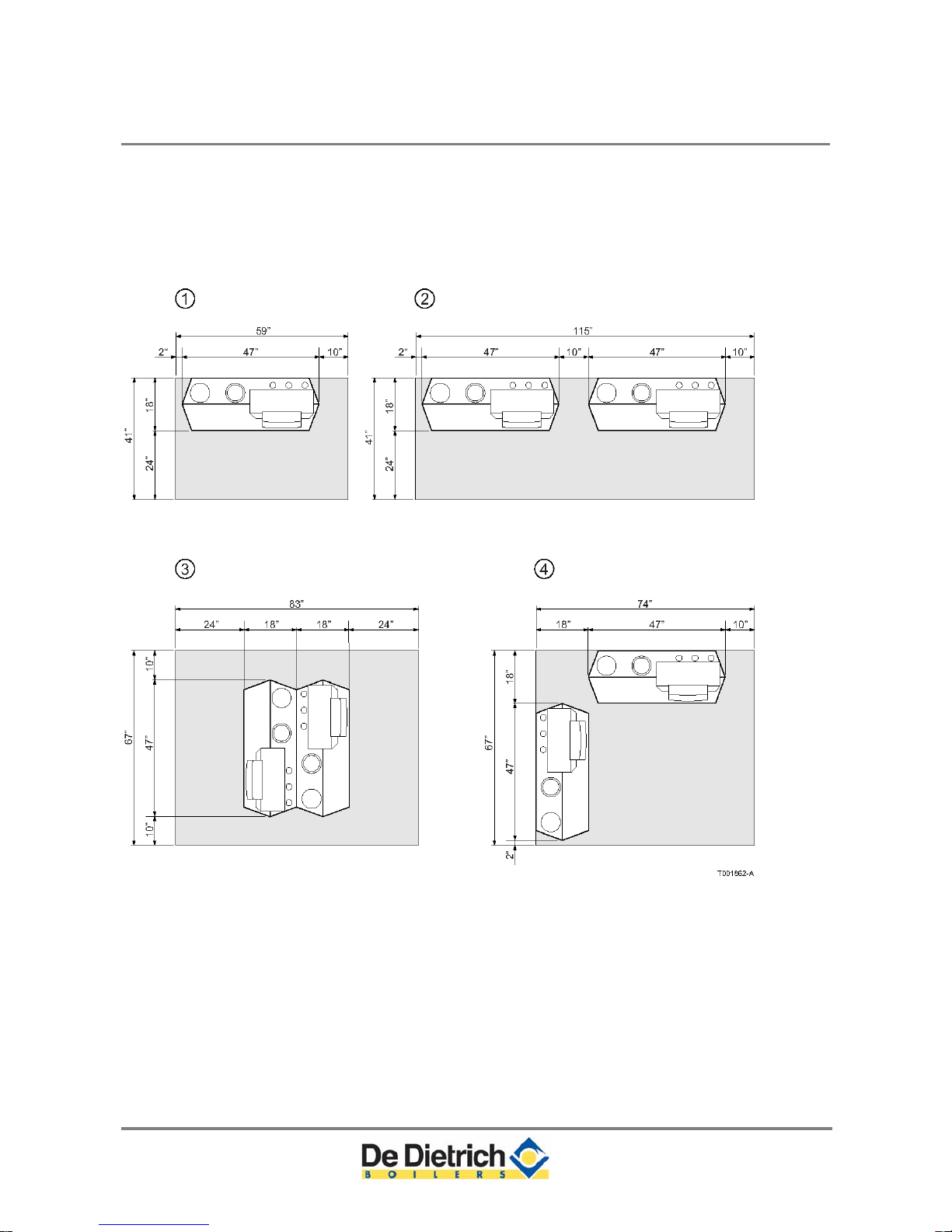

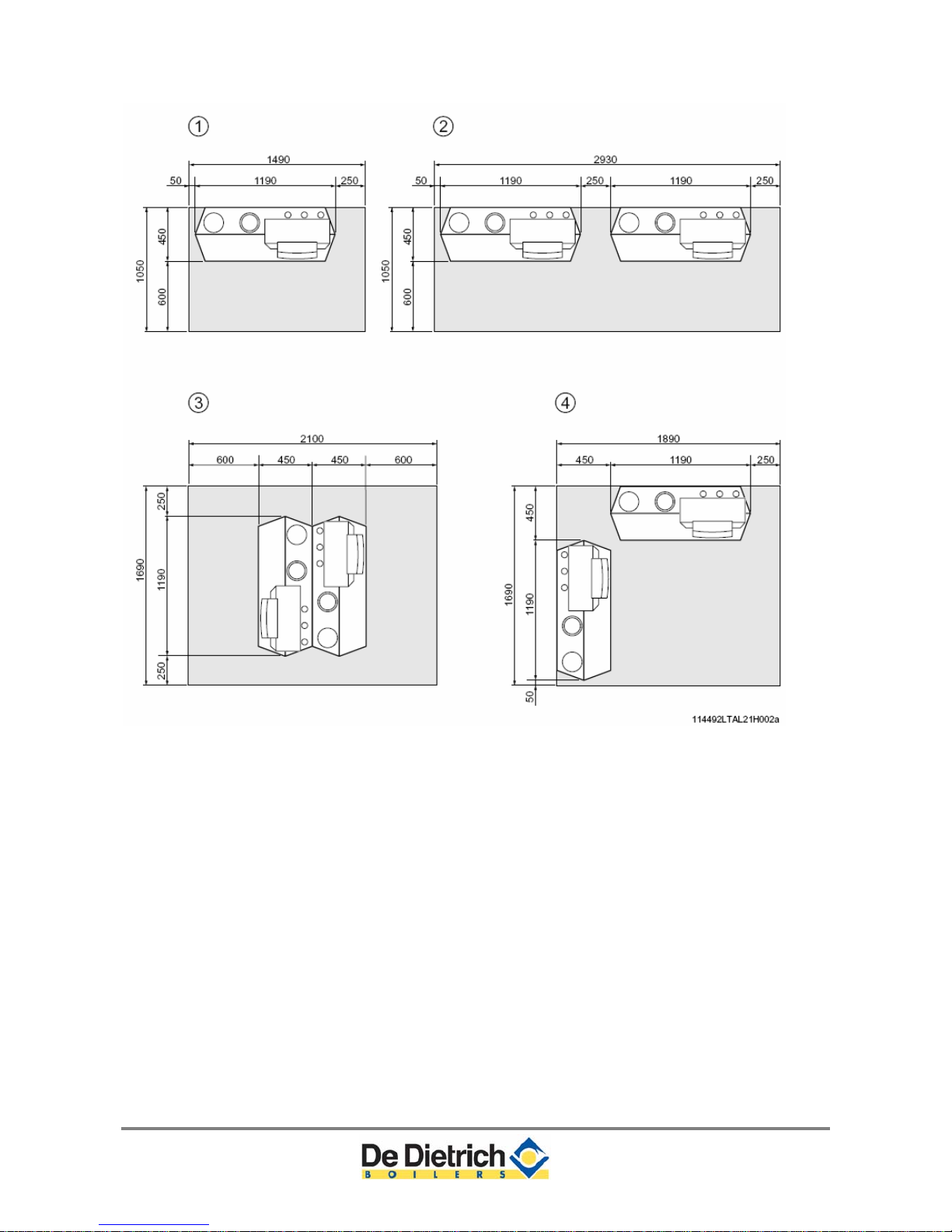

4.4 Installation and service clearances

Clearance of at least 24" (600 mm) is required at the front of the

boiler. However, we recommend a clearance of 40" (1 m). We

recommend a clearance of at least 16" (400 mm) above the boiler

control panel, at least 2" (50 mm) on the left side and at least 10" (25

cm) on the right side in connection with condensed water discharge.

Install a gas cock in the immediate vicinity of/above the boiler.

17

4 Installation C230 ECO-A

Fig. 3 Boiler room installation options (in inches and mm)

18

C230 ECO-A 5 Water-side connections

5 W ater-side connections

5.1.1 Flue gas condensation discharge

Discharge the condensate water directly into a city water drain. In

view of the acidity level of the condensate (pH between 3 and 5), use

only materials that can resist flue gas condensation for the discharge

pipe. The use of neutralizer shall be considered for older drains or

where local codes require.

After assembly, fill the trap with clean water. Make an open

connection with the drain. The discharge pipe must slope down by at

least 3"/100" (30 mm/m). Condensed water must not be discharged

into gutters or rain water down pipes.

5.1.2 Water treatment

Use untreated tap water only to fill the heating system.

The pH value of the system water must be between 7 and 9.

If water treatment is used, the chemicals used shall comply with

the water quality requirements and must not affect cast aluminium

boilers. Follow the manufacturer’s instructions given.

For further information a special document about water quality

regulations is available from De Dietrich America's. The regulations

mentioned in this document must be followed.

As most systems contain a variety of metals, it is considered good

practice to provide some form of water treatment in order to prevent or

reduce the following:

Metallic corrosion

Formation of scale and sludge

Microbiological contamination

Chemical changes in the untreated system water

All scale or calcium deposits, will reduce the efficiency of the boiler

and should be prevented.

Suitable chemicals and their use should be discussed with a specialist

water treatment company prior to carrying out any work

(environmental aspects, health aspects). The specification of the

system and manufacturers recommendations must be taken into

account, along with the age and condition of the system. New systems

should be flushed thoroughly to remove all traces of flux, debris,

grease and metal swarf generated during installation. Take care with

old systems to ensure any black metallic iron oxide sludge and other

corrosive residues are removed, again by power flushing, ensuring

that the system is drained completely from all low points.

19

5 Water-side connections C230 ECO-A

Please ensure that the new boiler plant is not in circuit when the

flushing takes place, especially if cleansing chemicals are used to

assist the process.

It is important to check the inhibitor concentration after installation,

system modifications, filling the system and every service in

accordance with these instructions.

For the correct dosage and the suitability of inhibitors for use with our

boilers and for further information on water treatment or system

cleaning we advise you to contact a water treatment company who is

experienced with our boilers.

5.1.3 Circulation pump

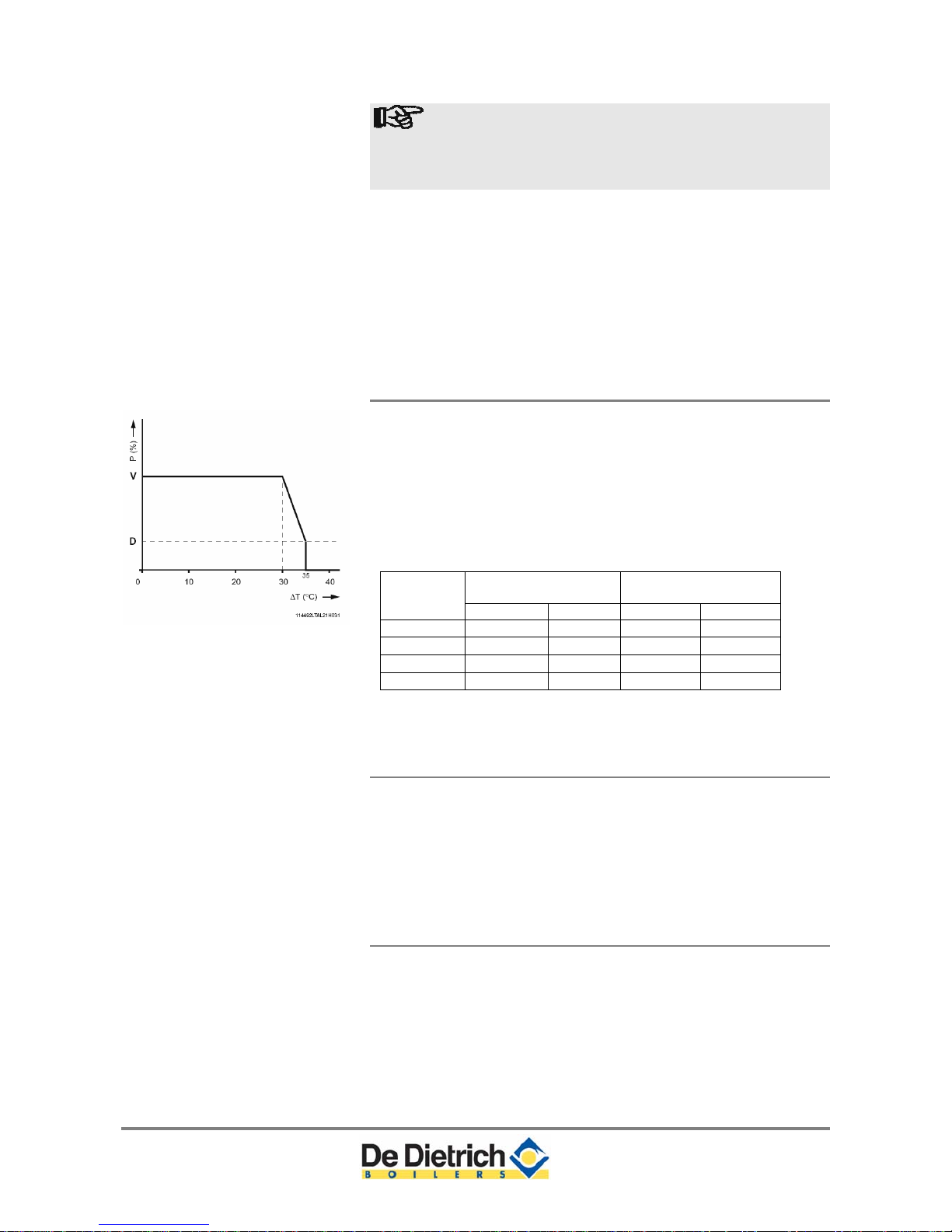

Fig. 4 Output control characteristic

V = full load P = heat output

D = part load ∆T = temperature

difference

The boiler is equipped with a pump switch to connect an

external circulation pump. This pump is run once every 24

hours to prevent sticking (24 hour pump operation).

Only on/off pumps can be controlled. For connections, see

Section 8.4.6.

The hydrauli

c resistance for the various output options of the

boiler is as follows:

Hydraulic resistance

at a dT of 36°F (20°C)

Hydraulic resistance

at a dT of 18°F (10°C)

Boiler

model

mbar psi mbar psi

C230 80

165 2.39 545 7.90

C230 120

135 1.96 446 6.47

C230 160

170 2,47 562 8.15

C230 200

180 2,61 595 8.63

5.1.4 Water flow

The maximum temperature difference between flow and return, and

the maximum rate of rise of the flow temperature and boiler block

temperature are limited by the boiler's modulating controls. As a

result, the boiler is virtually unaffected by low water flow. However for

a continuous supply of heat, the boiler requires a minimum flow of

30% of the nominal flow at the relevant design temperatures.

5.1.5 Water pressure

The boiler is suitable for a maximum working pressure of 100 psi (6.8

bar) according to ASME MWAP = 100 psi. The minimum operating

pressure shall not be less than < 11.6 psi (0.8 bar).

20

C230 ECO-A 5 Water-side connections

5.1.6 Safety relief valve

A safety relief valve NB certified with V or HV & CRN symbols, must

be installed within 20 inches on the boiler supply piping without any

obstructions. The relief valve must not be smaller than 3/4 inch and

not larger than 4 inch. The pressure shall not exceed 10% above the

MAWP and must be of an automatic reset type. The valve opening

must be routed away so that no injury or damage to property will

result. Consult local codes. When replacing the valve, the relief

capacity must be more than the minimum relief capacity shown on the

boiler rating plate.

5.1.7 Water system layout

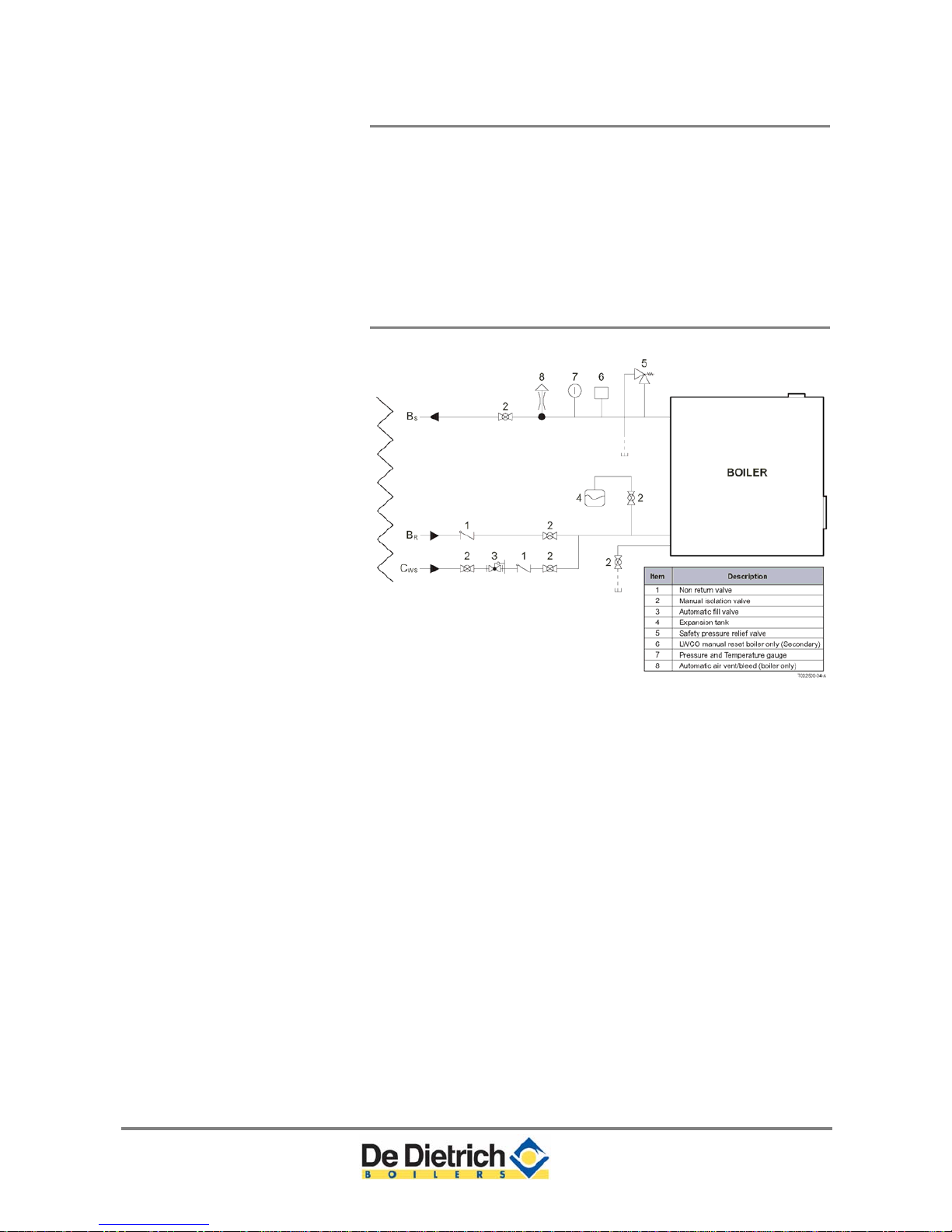

Fig. 5 Boiler water connections (minimum)

The above piping diagram illustrates the minimum boiler system

controls needed, the by-pass system is not necessary, but can be

used in multiple heating temperature circuits.

The boiler if installed above radiation (heating circuits below the

boiler) or as required by local codes or authorities having jurisdiction

must install a low water cut-off safety device, The LWCO is not a

standard scope of supply, but is available as an option. The boiler has

been approved and has found to be in compliance to the LWCO

protection, provided the factory pre-set high limit and flow

temperatures are not altered and the modulating controls are used

and no minimum flow is required as the Comfort master system will

monitor these conditions and reduce the boiler output, finally shutting

down until the flow conditions improve, As a result, the boiler is

virtually unaffected by low water flow. Although boiler flow and content

protection is provided, does not safeguard the entire heating system,

additional low water content and temperature safety control maybe

needed in certain jurisdictions.

21

5 Water-side connections C230 ECO-A

It is strongly recommended that a decoupling device is installed to

isolate the boiler during non working times and/or when the system or

boiler flow is unknown

When the boiler is connected to a refrigeration system, it must be

installed so the chilled medium is piped in parallel with the boiler with

appropriate valves to prevent the chilled medium from entering the

boiler.

The boiler piping system of a hot water boiler connected to heating

coils located in air handling units where they may be exposed to

refrigeration air circulation must be equipped with flow control valves

or other automatic means to prevent gravity circulation of the boiler

water during cooling operations.

22

C230 ECO-A 6 Gas-side connections

6 Gas-side connections

6.1 Gas connection

The boiler is suitable for use with natural gas and propane*. For other

types of natural gas, consult our Technical department. All gas

appliances must, by law, be installed by competent persons. Failure to

install appliances correctly could lead to prosecution.

It is in your own interest and that of safety to ensure that the law is

complied with.

The gas connection is at the top of the boiler. We recommend

installing a gas filter in the gas supply pipe to avoid pollution of the

gas multiblock. The gas filter's resistance must not be so high that the

minimum inlet gas pressure can no longer be achieved.

Gas installation instructions

1.

A main gas shutoff valve should be connected to the boiler within

accessible area and within hand reach.

2. A sedime

nt trap must be installed upstream of the main gas

shutoff valve.

3. The boiler gas train (valve) does not require venting or bleeding, a

VPS can be used in jurisdiction where required.

The boiler and the individual shutoff valve must be leak tested

according to local and national gas installation codes B149 & ANSI

Z223.1. If the leak pressure testing exceeds 1/2 psi (35 mbar) the

boiler and the individual gas shutoff valve shall be isolated and

disconnect during this test.

* OEM gas conversion kit required (optional).

6.2 Gas pressure

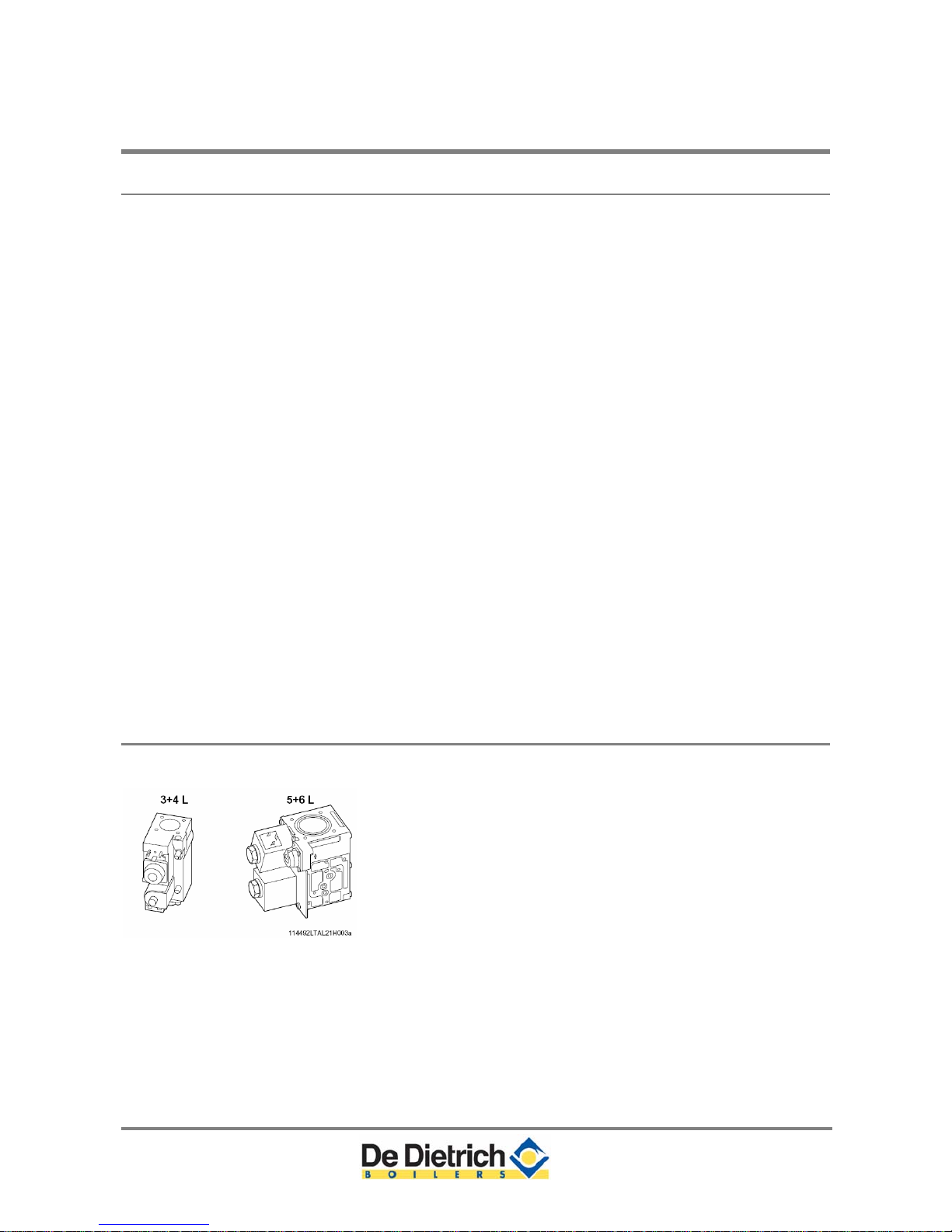

Fig. 6 Gas multiblocks

The boiler has been factory set and tested to natural gas (G20) with an inlet pressure of 7 inches w.c.(17 mbar).

Higher gas supply pressure(s) require a separate service regulator.

Natural gas supply inlet pressure range 3.5 - 14 inches w.c. (< 0.5

psi) [8.7 - 35 mbar) is required.

For propane (LPG), an inlet pressure of 8 - 13 inches w.c. (< 0.5

psi) [20 - 32 mbar) is required.

23

6 Gas-side connections C230 ECO-A

Gas system pressure checks

The boiler main gas cock shutoff valve and piping must be

isolated from any gas piping pressure testing in excess of 0.5 psi

(35 mbar).

The boiler main gas cock shutoff valve and piping must be

isolated by closing the main gas cock shutoff valve during gas

piping pressure testing less than 0.5 psi (35 mbar).

The boiler main gas piping and gas train must be leak tested prior

to placing the boiler in operation.

6.3 Gas/air ratio control

The boiler has a zero governor gas valve. This gas valve maintains

the ratio between the gas and air quantities in the burner at a constant

level under variable loads. This ensures clean and reliable combustion

and high efficiency across the entire load range. There is no need to

vent the gas valve.

24

C230 ECO-A 7 Flue gas discharge and air supply

7 Flue gas discharge and air supply

7.1 General

The C230 ECO-A is suitable for both conventional room-supplied or

sealed combustion. Sealed combustion terminals should comply with

the local and national codes. Any horizontal pipe-work in the flue gas

discharge system should slope towards the boiler. Horizontal pipework in the air supply system should slope towards the supply

opening and may require a drain point at the low point. Care should

be taken when locating flue exit positions as a vapor plume will be

visible when the boiler is operational (flue gas temperature will be less

than 170°F [77°C] resulting in the water vapor condensing out on

contact with the air).

Provisions for combustion and ventilation air in accordance with

section 5.3, Air for Combustion and Ventilation, of the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, or Sections 7.2, 7.3 or 7.4 of the

Natural Gas and Propane Installation Code, CAN/CSA B149.1, or

applicable provisions of the local building codes.

For boilers for connection to gas vents or chimneys, vent installation

shall be in accordance with Part 7, Venting of Equipment, of the

National Fuel Gas Code, ANSI Z223.1/NFPA 54, or Section 7, Venting

Systems and Air Supply for Appliances, of the Natural Gas and

Propane Installation Code, CAN/CSA B149.1, or applicable provisions

of the local building codes.

The venting system shall be installed in accordance with the boiler

manufacturer’s installation instructions.

The horizontal portions of the venting system shall be supported to

prevent sagging. Follow the instructions of the supplier of the venting

system.

7.1.1 Boiler Venting Types

Flue gas venting

Use only an approved gas vent category II and IV type “BH” (AL29-4C

stainless steel vent material). Plastic vent material (CPVC/PVC) can

be used where local/national codes allow.

Conventional Chimney Applications

A vertical chi

mney-vent system with the air supply, required for

combustion, provided within the boiler room or combustion air sour

ce

provided into the room.

CLV – Direct Vent (Sealed Combustion) Systems Applications

Vertical o

r horizontal venting systems for both, the flue gases and

combustion ai

r operating at two different pressure zones or vent

terminal locations.

25

7 Flue gas discharge and air supply C230 ECO-A

Sidewall Vented & Direct Vent [Sealed Combustion] Applications

A horizontal vent system with the air supply, required for combustion,

provided within the boiler room or combustion air sources provided

into the room.

7.1.2 Venting options

The standard delivery of the C230 ECO-A boiler can be installed with

any of the venting options listed above. See each respective section

for details; discard the air intake grill when using sealed combustion

vent systems.

7.1.3 Vent Termination Inlet/Outlets

The vent terminals must be installed to provide suitable protection

against wind, rain, snow or blockage along with a rodent/debris

screen. See section 7.1.5, 7.1.6 and 7.1.7 for other requirements.

Conve

ntional chimney application tapered cone (finishing cone), and

sidewall or direct vent requi

re a termination TEE or 90º elbow fitting.

7.1.4 Combustion Air Supply Requirements

The boiler requires a clean, fresh and adequate supply of combustion

air, failure to provide sufficient combustion air supply will result in

carbon monoxide (CO) production that could lead to personal injury

including loss of life or damage to boiler or property. Do not store any

flammable liquids, fluids, vapors or materials near the vicinity of the

boiler.

Special attention

Quality of combustion air

Dust, fumes, corrosive elements, hydrocarbons, other unknown

containments

Paint, beauty, automotive etc. shops

The flue gas vent pipe must be airtight and watertight. Horizontal

sections of the venting must slope downward towards the boiler ½”

per linear foot [42 mm/m] and adequate vent support must be

provided.

Room combustion air supply requirements

The boiler must be provided with an adequate combustion air supply,

the combustion air supply requirem

ents must be determined and sized

in accordance to national and local codes having jurisdiction. CSA

B149 & ANSI Z223.1 – More than one combustion air source may be

required. An optional air intake filter should be fitted air intake housing

(recommendation).

Air supply venting materials

Aluminium, st

ainless steel or PVC/CPVC (UL 181 or ULc S-110 class

1).

26

C230 ECO-A 7 Flue gas discharge and air supply

Air supply structure

The air supply pipe must also be airtight. Horizontal sections in the air

supply must slope away from the boiler towards the supply opening

and incorporate a drain connection if the route rises from a lower

point. It is necessary to provide an easily removable air vent for

maintenance reasons.

7.1.5 Conventional Chimney Venting & CLV system

Application Requirements

The boiler should never be operated in a negative building pressure.

Caution should be exercised with exhaust fans, air handling & other

devices, that could affect the buildings air pressure or combustion air

supply. All venting must be arranged to avoid and prevent the

accumulation of flue gas condensation. Where necessary, have

means provided for drainage of condensate.

An improperly sealed venting system could result in carbon monoxide

poisoning; ensure adequate support and fastening of the system.

Ensure venting can safely exhaust all flue gases to the outside in a

safe and effective manner. Do not puncture or drill holes in any portion

of the venting, the boiler is equipped with a pressure and emission

test port.

Precautions for Co-venting

Only co-vent this boiler with another, category II or IV, appliance.

When co-venting the C230 ECO-A boiler a vent damper is required.

Co-venting with other appliances shall conform and be sized in

accordance to local and national codes [CSA B149 & ANSI Z223.1]

according to appropriate tables in Part II of the above mentioned

codes.

Venting lengths must not exceed the minimum and maximum

equivalent lengths shown in the following two tables. Any horizontal

runs of the venting must slope towards the boiler ½” per linear foot.

27

Loading...

Loading...