Page 1

ADVANCE

S U S T A I N A B L E C O M F O R T

®

AMC

Ireland

en

Installation and Service Manual

Wall-hung gas condensing boilers

AMC 15

AMC 25

AMC 35

AMC 25/28 MI

Diematic Evolution

Page 2

Contents

2 AMC 7686707 - v.01 - 06092018

Contents

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Liabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3.1 Manufacturer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3.2 Installer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.3 User's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Additional documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.1 Symbols used in the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1.1 Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1.2 Unit categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.1.3 Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.1.4 Factory test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.3 Dimensions and connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Description of the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.2 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.1 Automatic refill device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.2 Circulation pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.3 Water flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.4 Skeleton diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.3 Main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.5 Standard delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5 Before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1 Installation regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 Choice of the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2.1 Data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2.2 Location of the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2.3 Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.2 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.2.1 Installing the mounting frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

6.2.2 Positioning the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3 Hydraulic connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.3.1 Rinsing the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.3.2 Water flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.3.3 Connection of the heating circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.3.4 Connection of the water circuit for domestic use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.3.5 Connecting the secondary heating circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.3.6 Disconnecting the secondary heating circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.3.7 Connecting the expansion vessel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.3.8 Connecting the condensate drain pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.4 Gas connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.5 Air supply/flue gas outlet connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

6.5.1 Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.5.2 Requirements for shaft for C93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.5.3 Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.5.4 Dimensions of flue gas outlet pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.5.5 Length of the air and flue gas pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.5.6 Additional guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Page 3

Contents

7686707 - v.01 - 06092018 AMC 3

6.5.7 Connecting the flue gas outlet and air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.6 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.6.1 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.6.2 Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.6.3 Connecting a PC/laptop and diagnostic tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.6.4 Access to the connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

6.6.5 Connection options for the standard PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.6.6 Access to the PCB housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.6.7 Description of the SCB-10 PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

6.7 Connection diagrams PCB SCB-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.7.1 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.7.2 Factory configuration of circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.7.3 Boiler settings with SCB-10 control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.7.4 Connection direct zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.7.5 Connection 1 direct zone + DHW zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.7.6 Connection 1 LLH + 1 direct zone + DHW zone with electrical heating element . . . . . . . . . . . . . . . . . . . . . .51

6.7.7 Connection 1 LLH + 1 direct zone + mixing zone + DHW zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.7.8 Connection 1 LLH + 1 direct zone + mixing zone + DHW zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.7.9 Connection 1 LLH + 1 mixing zone + 1 direct zone + swimming pool + DHW zone . . . . . . . . . . . . . . . . . . . 56

6.7.10 Connection 1 LLH + 3 mixing zones + DHW zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6.7.11 Connection 1 combi–buffer + 1 direct zone + 1 mixing zone + solar collectors . . . . . . . . . . . . . . . . . . . . . . . 60

6.7.12 Connection 1 combi–buffer + 1 direct zone + 1 mixing zone + swimming pool + solar collectors . . . . . . . . . 61

6.7.13 Connection 2 boilers (cascade) + LLH + 1 direct zone + 1 mixing zone + DHW zone . . . . . . . . . . . . . . . . . 63

6.8 Filling the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.8.1 Water quality and water treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

6.8.2 Filling the siphon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.8.3 Filling the system with the automatic refill device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.1 Checklist before commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.1.2 Gas circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.1.3 Hydraulic circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.1.4 Connections for the air and flue gas pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.1.5 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.2 Commissioning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.3 Gas settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.3.1 Adjusting to a different gas type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.3.2 Fan speeds for overpressure applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

7.3.3 Checking/setting combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

7.3.4 Basic setting for the gas/air ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.4 Final instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.4.1 Saving the commissioning settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

8.1 Control panel description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.1.1 Description of the components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.1.2 Description of the home screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

8.1.3 Description of the main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.1.4 Definition of zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

8.1.5 Definition of activity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.2 Use of the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.2.1 Accessing the installer level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

8.2.2 Changing the display settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.2.3 Changing the name and symbol of a zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.2.4 Changing the name of an activity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.2.5 Setting the installer details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

8.2.6 Adjusting the heating curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.2.7 Activating the automatic (re)filling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.2.8 Activating the screed drying program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.3 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.4 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.5 Frost protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

9 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

9.1 Setting the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Page 4

Contents

4 AMC 7686707 - v.01 - 06092018

9.2 List of parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

9.2.1 CU-GH08 control unit settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

9.3 Setting the maximum heat input for CH operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

9.4 Settings SCB-10 print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.4.1 Setting the 0-10 Volt input function of SCB-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.4.2 Analogue temperature regulation (°C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

9.4.3 Configuring a DHW tank with two sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.5 Reading out measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.6 List of measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.6.1 CU-GH08 control unit counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.6.2 CU-GH08 control unit signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.6.3 Status and sub-status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

9.7 Resetting or restoring settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

9.7.1 Resetting the configuration numbers CN1 and CN2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

9.7.2 Carrying out an auto-detect for the CAN matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

9.7.3 Restoring the commissioning settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

9.7.4 Resetting to factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

10.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

10.2 Standard inspection and maintenance operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

10.2.1 Checking the water pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

10.2.2 Checking the expansion vessel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

10.2.3 Checking the ionisation current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

10.2.4 Checking the draw-off capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10.2.5 Check the flue gas outlet/air supply connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

10.2.6 Checking the combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10.2.7 Checking the automatic air vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10.2.8 Checking the safety valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10.2.9 Cleaning the siphon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.2.10 Checking the burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10.3 Specific maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10.3.1 Opening boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

10.3.2 Replacing the ionisation/ignition electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

10.3.3 Cleaning the plate heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

10.3.4 Cleaning the water filter cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

10.3.5 Replacing the three-way valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

10.3.6 Replacing the non-return valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

10.3.7 Finalising work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

10.3.8 Replacing the control PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

10.3.9 Replacing the CB-03 PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

10.3.10 Updating the control panel firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

10.4 Refilling the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

10.4.1 Refilling the system with the automatic refill device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

10.4.2 Activating the automatic refill device (if fitted) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

10.4.3 Topping up the system (manually) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

11.1 Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

11.1.1 Warning codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

11.1.2 Control unit blocking codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

11.1.3 Control unit locking codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

11.2 Error memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

11.2.1 Reading out and clearing the error memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

12 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

12.1 Disposal and recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

13 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

13.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

13.2 Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

13.3 Spare parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

14 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

14.1 EC declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

Page 5

1 Safety

7686707 - v.01 - 06092018 AMC 5

1.1 General safety instructions

1 Safety

Danger

If you smell gas:

1. Do not use naked flames, do not smoke and

do not operate electrical contacts or switches

(doorbell, lighting, motor, lift etc).

2. Shut off the gas supply.

3. Open the windows.

4. Trace possible leaks and seal them off

immediately.

5. If the leak is upstream of the gas meter, notify

the gas company.

Danger

If you smell flue gases:

1.2

1. Switch the boiler off.

2. Open the windows.

3. Trace possible leaks and seal them off

immediately.

Caution

After maintenance or repair work, check the

entire heating installation to ensure that there are

no leaks.

Recommendations

Warning

Installation and maintenance of the boiler must be

carried out by a qualified installer in accordance

with local and national regulations.

Warning

If the mains lead is damaged, it must be replaced

by the original manufacturer, the manufacturer's

dealer or another suitably skilled person to

prevent hazardous situations from arising.

Warning

Always disconnect the mains supply and close

the main gas tap when working on the boiler.

Warning

Check the entire system for leaks after

maintenance and servicing work.

Page 6

1 Safety

6 AMC 7686707 - v.01 - 06092018

Caution

Make sure the boiler can be reached at all

times.

The boiler must be installed in a frost-free area.

If the power cord is permanently connected, you

must always install a main bipolar switch with

an opening gap of at least 3 mm (EN 60335-1).

Drain the boiler and central heating system if

you are not going to use your home for a long

time and there is a chance of frost.

The frost protection does not work if the boiler is

out of operation.

The boiler protection only protects the boiler,

not the system.

Check the water pressure in the system

regularly. If the water pressure is lower than 0.8

bar, the system must be topped up

(recommended water pressure between 1.5 and

2 bar).

1.3

Important

Keep this document near to the boiler.

Important

Only remove the casing for maintenance and

repair operations. Refit all panels when

maintenance work and servicing are complete.

Important

Instruction and warning labels must never be

removed or covered and must be clearly legible

throughout the entire service life of the boiler.

Damaged or illegible instructions and warning

stickers must be replaced immediately.

Important

Modifications to the boiler require the written

approval of De Dietrich.

Liabilities

1.3.1 Manufacturer's liability

Our products are manufactured in compliance with the

requirements of the various Directives applicable. They

are therefore delivered with the marking and any

documents necessary. In the interests of the quality of

our products, we strive constantly to improve them. We

therefore reserve the right to modify the specifications

given in this document.

Page 7

1 Safety

7686707 - v.01 - 06092018 AMC 7

Our liability as manufacturer may not be invoked in the

following cases:

Failure to abide by the instructions on installing and

maintaining the appliance.

Failure to abide by the instructions on using the

appliance.

Faulty or insufficient maintenance of the appliance.

1.3.2 Installer's liability

The installer is responsible for the installation and initial

commissioning of the appliance. The installer must

observe the following instructions:

Read and follow the instructions given in the manuals

provided with the appliance.

Install the appliance in compliance with prevailing

legislation and standards.

Carry out initial commissioning and any checks

necessary.

Explain the installation to the user.

If maintenance is necessary, warn the user of the

obligation to check the appliance and keep it in good

working order.

Give all the instruction manuals to the user.

1.3.3 User's liability

To guarantee optimum operation of the system, you

must abide by the following instructions:

Read and follow the instructions given in the manuals

provided with the appliance.

Call on a qualified professional to carry out installation

and initial commissioning.

Get your installer to explain your installation to you.

Have the required inspections and maintenance

carried out by a qualified installer.

Keep the instruction manuals in good condition close

to the appliance.

Page 8

2 About this manual

8 AMC 7686707 - v.01 - 06092018

2 About this manual

2.1 General

This manual is intended for the installer of a AMC boiler.

Important

The manual is also available on our internet site.

2.2

2.3

Additional documentation

The following documentation is available in addition to this manual:

User manual

Symbols used

2.3.1 Symbols used in the manual

This manual uses various symbols to draw attention to special instructions.

We do this to improve user safety, to prevent problems and to guarantee

correct operation.

Danger

Risk of dangerous situations that may result in serious personal

injury.

Warning

Risk of dangerous situations that may result in minor personal

injury.

Caution

Risk of material damage.

Important

Please note: important information.

See

Reference to other manuals or pages in this manual.

Page 9

3 Technical specifications

7686707 - v.01 - 06092018 AMC 9

3 Technical specifications

3.1 Homologations

3.1.1 Certifications

Tab.1 Certifications

CE identification number PIN 0063CR3604

Class NOx

(1)

Type of connection B23, B

(1) EN 15502–1

3.1.2 Unit categories

Tab.2 Unit categories

Country Category Gas type Connection pressure (mbar)

Ireland II

2H3B/P

G20 (H gas)

G30/G31 (butane/propane)

6

C

13(X)

C

(10)3(X)

23P

, C

33(X)

, C

20

30

, B

(12)3(X)

33

, C

43P

, C

53(X)

, C

63(X)

, C

93(X)

,

3.1.3 Directives

In addition to the legal requirements and guidelines, the supplementary

guidelines in this manual must also be followed.

Supplements or subsequent regulations and guidelines that are valid at

the time of installation shall apply to all regulations and guidelines

specified in this manual.

3.1.4 Factory test

Before leaving the factory, each boiler is optimally set and tested for:

Electrical safety.

Adjustment of (O2).

Domestic hot water function (For combi-boilers only).

Water tightness.

Gas tightness.

Parameter setting.

3.2

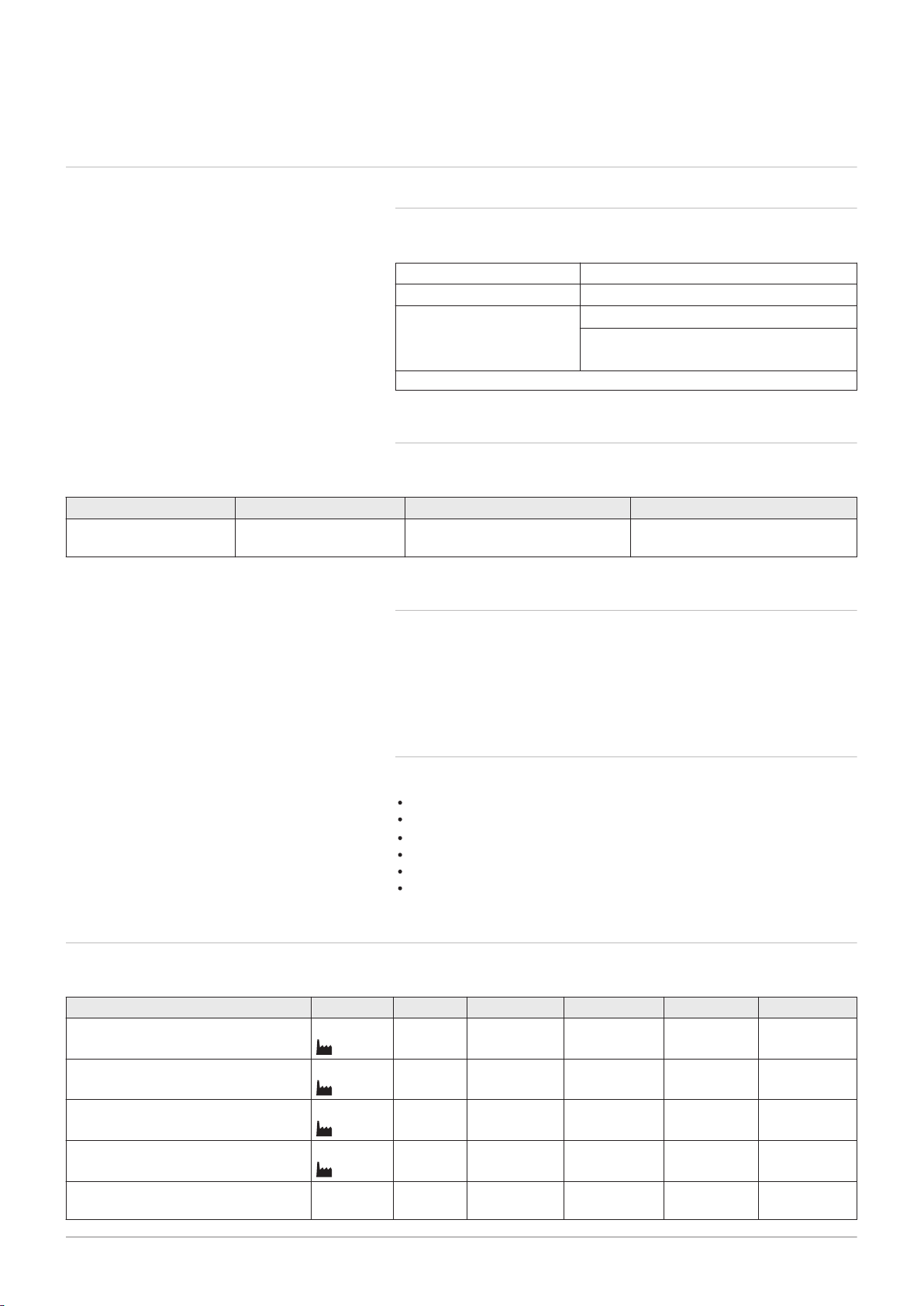

Tab.3 General

AMC 15 25 25/28 MI 35

Nominal output (Pn) for central heat

ing operation (80 °C/60 °C)

Nominal output (Pn) for central heat

ing operation (50/30 °C)

Nominal output (Pn) for DHW opera

tion

Nominal input (Qnh) central heating

operation (Hi)

Nominal input (Qnh) for central heat

ing operation (Hi) Propane

Technical data

min-max

(1)

min–max

(1)

min–max

(1)

min–max

(1)

kW 3.0 - 14.9

14.9

kW 3.4 - 15.8

15.8

kW -

-

kW 3.1 - 15.0

15.0

5.0 - 24.8

24.8

5.6 - 25.5

25.5

-

-

5.2 - 25.0

25.0

5.0 - 24.8

19.9

5.6 - 25.5

20.5

5.0 - 27.8

27.8

5.2 - 25.0

20.1

7.0 - 34.5

7.9 - 35.6

7.3 - 34.8

min-max 5.2 - 15.0 5.9 - 25.0 5.9 - 25.0 7.3 - 34.8

34.5

35.6

-

-

34.8

Page 10

3 Technical specifications

10 AMC 7686707 - v.01 - 06092018

AMC 15 25 25/28 MI 35

Nominal input (Qnh) central heating

operation (Hs)

Nominal input (Qnh) for central heat

ing operation (Hs) Propane

Nominal input (Qnw) for DHW opera

tion (Hi)

Nominal input (Qnw) for DHW opera

tion (Hi) Propane

Nominal input (Qnw) for DHW opera

tion (Hs)

Nominal input (Qnw) for DHW opera

tion (Hs) Propane

Full load central heating efficiency

min–max

(1)

min-max

(1)

min–max

(1)

min–max kW -

min–max

(1)

min–max kW -

kW 3.4 - 16.7

16.7

5.8 - 27.8

27.8

5.8 - 27.8

22.3

8.1 - 38.7

5.8 - 16.7 6.5 - 27.8 6.5 - 27.8 8.1 - 38.7

kW -

-

-

kW -

-

-

-

-

-

5.2 - 28.0

28.0

5.9 - 28.0 -

-

-

-

-

5.8 - 31.1

31.1

6.5 - 31.1 -

-

% 99.3 99.2 99.2 99.1

(Hi) (80/60 °C) (92/42/EEC)

Full load central heating efficiency

% 105.3 102.0 102.0 102.2

(Hi) (50°C/30°C) (EN15502)

Part load central heating efficiency

% 94.9 96.1 96.1 96.3

(Hi) (return temperature 60°C)

Part load central heating efficiency

% 110.2 110.1 110.1 110.6

(Hi) (92/42/EEC) (return temperature

30°C)

Full load central heating efficiency

% 89.4 89.3 89.3 89.2

(Hs) (80/60°C) (92/42/EEC)

Full load central heating efficiency

% 94.8 91.9 91.9 92.0

(Hs) (50°C/30°C) (EN15502)

Part load central heating efficiency

% 85.5 86.5 86.5 86.7

(Hs) (return temperature 60°C)

Part load central heating efficiency

% 99.2 99.1 99.1 99.6

(Hs) (92/42/EEC) (return temperature

30°C)

(1) Factory setting

38.7

-

-

-

-

-

-

Tab.4 Details of gas and flue gas

AMC 15 25 25/28 MI 35

Gas inlet pressure G20 (H gas) min-max mbar 17 - 25 17 - 25 17 - 25 17 - 25

Gas consumption G20 (H gas) min-max

NOx annual emissions G20 (H gas)

O2 = 0% ppm 17 16 16 27

m3/h

0.33 - 1.59 0.55 - 2.65 0.55 - 2.96 0.77 - 3.68

EN15502

NOx annual emissions G20 (H gas)

H

I

mg/kWh 30 28 28 45

EN15502

NOx annual emissions G20 (H gas)

H

s

mg/kWh 27 25 25 41

EN15502

Flue gas quantity min-max kg/h

g/s

5.5 - 25.3

1.5 - 7.0

9.2 - 42.1

2.6 - 11.7

9.2 - 47.1

2.6 - 13.1

12.7 - 57.4

3.5 - 15.9

Flue gas temperature min-max °C 30 - 59 30 - 74 30 - 81 32 - 79

Maximum counter pressure Pa 80 120 130 140

Tab.5 Central heating circuit data

AMC 15 25 25/28 MI 35

Water content l 1.7 1.7 1.7 2.3

Water operating pressure min bar 0.8 0.8 0.8 0.8

Water operating pressure (PMS) max bar 3.0 3.0 3.0 3.0

Water temperature max °C 110.0 110.0 110.0 110.0

Operating temperature max °C 90.0 90.0 90.0 90.0

Page 11

3 Technical specifications

7686707 - v.01 - 06092018 AMC 11

AMC 15 25 25/28 MI 35

Central heating total dynamic head

mbar 585 355 355 231

(ΔT = 20K)

Casing-related losses ΔT 30°C

ΔT 50°C

W 78

136

78

136

78

136

Tab.6 DHW circuit data

AMC 25/28 MI

Specific hot water flow rate D (60°C) l/min 8.2

Specific hot water flow rate D (40°C) l/min 14.5

Pressure difference on tap water side mbar 329

Flow rate threshold

(1)

max l/min 1.5

Water content l 0.33

Operating pressure (Pmw) bar 8

Minimum flow l/min 2

Score stars 3

(1) Minimum amount of water that comes out of the tap to make the boiler start.

Tab.7 Electrical data

AMC 15 25 25/28 MI 35

Supply voltage V~ 230 230 230 230

Power consumption – full load max

(1)

W 67

67

77

77

84

68

54

121

93

93

Power consumption – part load max W 27 26 26 27

Power consumption – standby max W 4 4 4 4

Electrical protection index

(2)

Fuses

(1) Factory setting.

(2) Splashproof; under certain conditions, the boiler may be installed in damp areas, such as bathrooms.

(3) The fuse is located on the CU-GH08 control unit

IP IPX5D IPX5D IPX5D IPX5D

(3)

CU-GH

A 2.5 2.5 2.5 2.5

Tab.8 Other data

AMC 15 25 25/28 MI 35

Minimum mounting weight

(1)

kg 36 36 38 31

Total weight (empty) kg 38 38 40 33

Average acoustic level at a distance

of one metre from the boiler (LPA)

Central

heating op

dB(A) 37

43

-

-

40

44

eration

DHW oper

ation

(1) Without front panel.

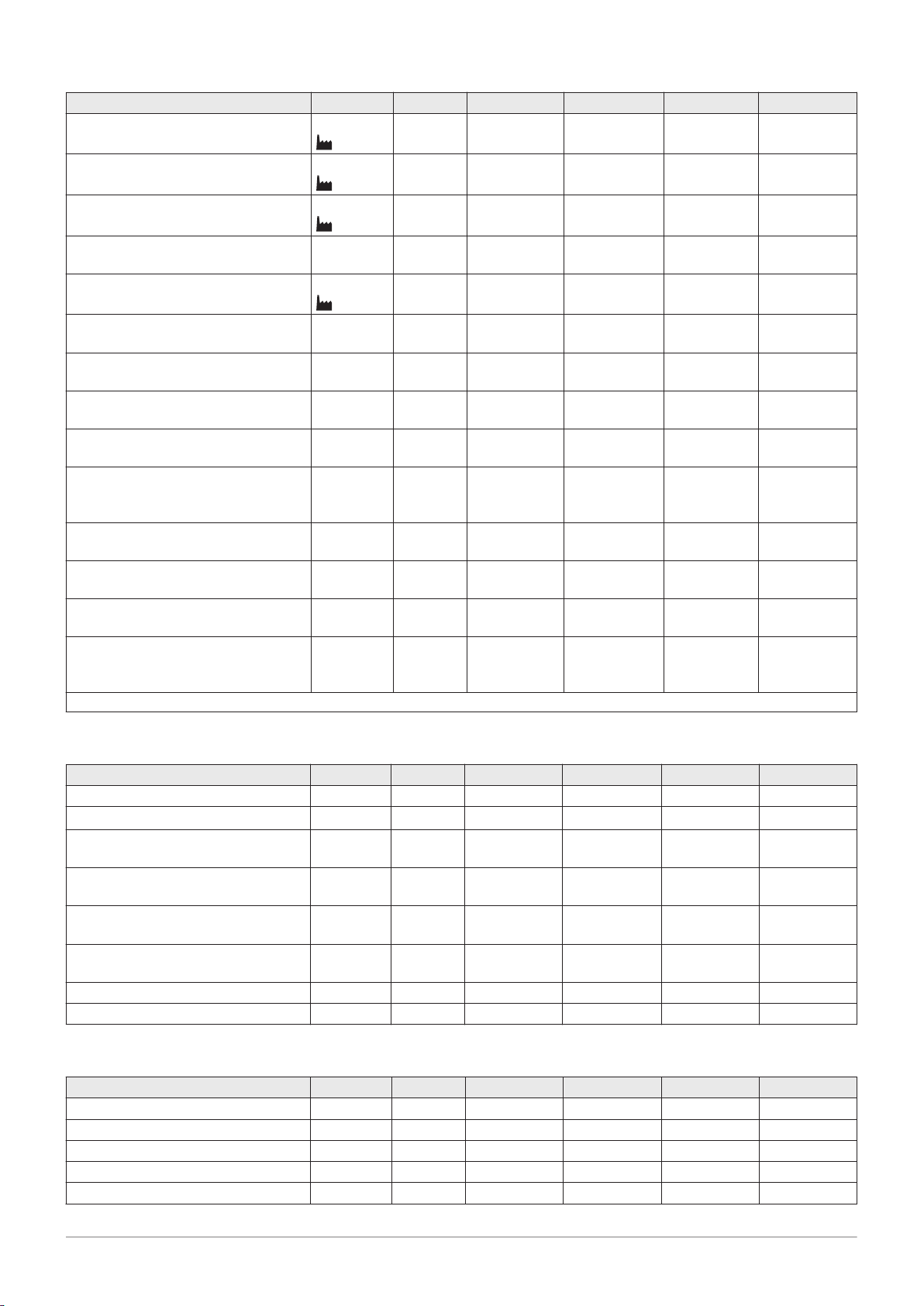

Tab.9 Technical parameters

AMC 15 25 25/28 MI 35

Condensing boiler Yes Yes Yes Yes

Low-temperature boiler

(1)

No No No No

B1 boiler No No No No

Cogeneration space heater No No No No

Combination heater No No Yes No

Rated heat output

Prated

kW 15 25 25 35

31

33

45

-

Page 12

3 Technical specifications

12 AMC 7686707 - v.01 - 06092018

AMC 15 25 25/28 MI 35

Useful heat output at nominal heat

P

4

kW 14.9 24.8 24.8 34.5

output and high temperature oper

(2)

ation

Useful heat output at 30% of rated

P

1

kW 5.0 8.3 8.3 11.6

heat output and low temperature

(1)

regime

Seasonal space heating energy effi

ƞ

s

% 94 94 94 95

ciency

Useful efficiency at rated heat out

put and high temperature regime

Useful efficiency at 30% of rated

ƞ

4

(2)

ƞ

1

% 89.5 89.4 89.4 89.3

% 99.3 99.2 99.2 99.6

heat output and low temperature

(1)

regime

Auxiliary electricity consumption

Full load

Part load

Standby mode

elmax

elmin

P

SB

kW 0.027 0.037 0.037 0.050

kW 0.018 0.017 0.017 0.018

kW 0.004 0.004 0.004 0.004

Other items

Standby heat loss

Ignition burner power consumption

Annual energy consumption

Sound power level, indoors

Emissions of nitrogen oxides NO

P

stby

P

ign

Q

HE

L

WA

X

kW 0.078 0.078 0.078 0.054

kW - - - -

GJ 46 76 76 105

dB(A) 45 51 51 53

mg/kWh 27 25 25 41

Domestic hot water parameters

Declared load profile - - A -

Daily electricity consumption

Annual electricity consumption

Water heating energy efficiency

Daily fuel consumption

Annual fuel consumption

(1) Low temperature means 30°C for condensing boilers, 37°C for low temperature boilers and 50°C (at heater inlet) for other heating appli

ances.

(2) High temperature operation means 60°C return temperature at heater inlet and 80°C feed temperature at heater outlet.

Q

elec

AEC

ƞ

wh

Q

fuel

AFC

kWh - - 0.169 -

kWh - - 37 -

% - - 82.4 -

kWh - - 22.045 -

GJ - - 17 -

See

See the back of this manual for contact information.

Page 13

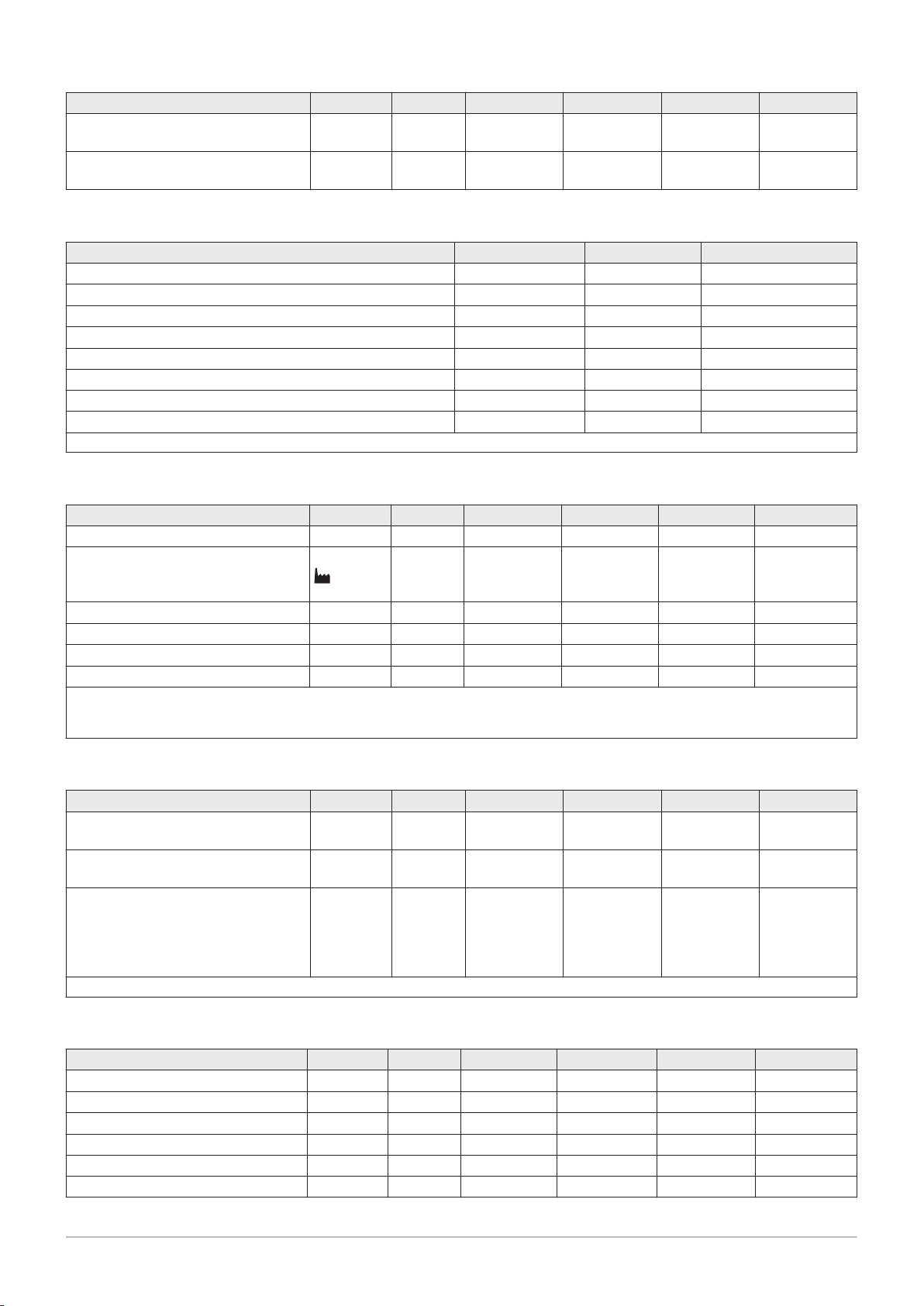

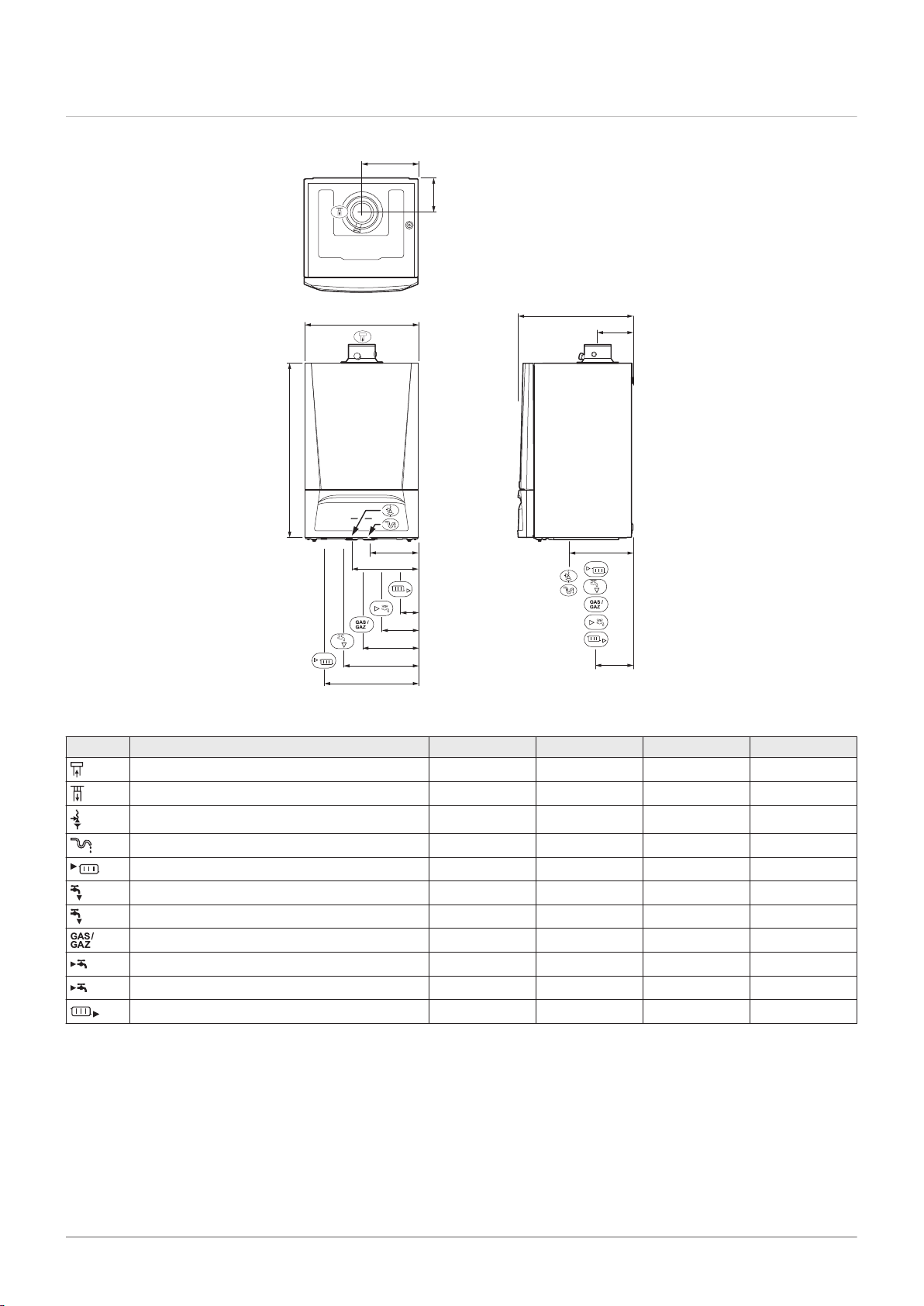

3.3 Dimensions and connections

AD-0001436-02

67

195

265

132

199

266

331

690

450

450

225

140

140

150

255

7686707 - v.01 - 06092018 AMC 13

Fig.1 Dimensions

3 Technical specifications

Tab.10 Connections

AMC 15 25 25/28 MI 35

Connecting the flue gas outlet Ø 60 mm Ø 60 mm Ø 60 mm Ø 60 mm

Connecting the air supply Ø 100 mm Ø 100 mm Ø 100 mm Ø 100 mm

Hose of safety valve Ø 25 mm Ø 25 mm Ø 25 mm Ø 25 mm

Condensation outlet Ø 25 mm Ø 25 mm Ø 25 mm Ø 25 mm

Heating circuit flow (primary circuit) G¾" G¾" G¾" G¾"

Domestic hot water outlet - - G½" -

Heating circuit flow (secondary circuit) G½" G½" - G½"

Gas connection G½" G½" G½" G½"

Domestic cold water inlet - - G½" -

Heating circuit return (secondary circuit) G½" G½" - G½"

Heating return (primary circuit) G¾" G¾" G¾" G¾"

Page 14

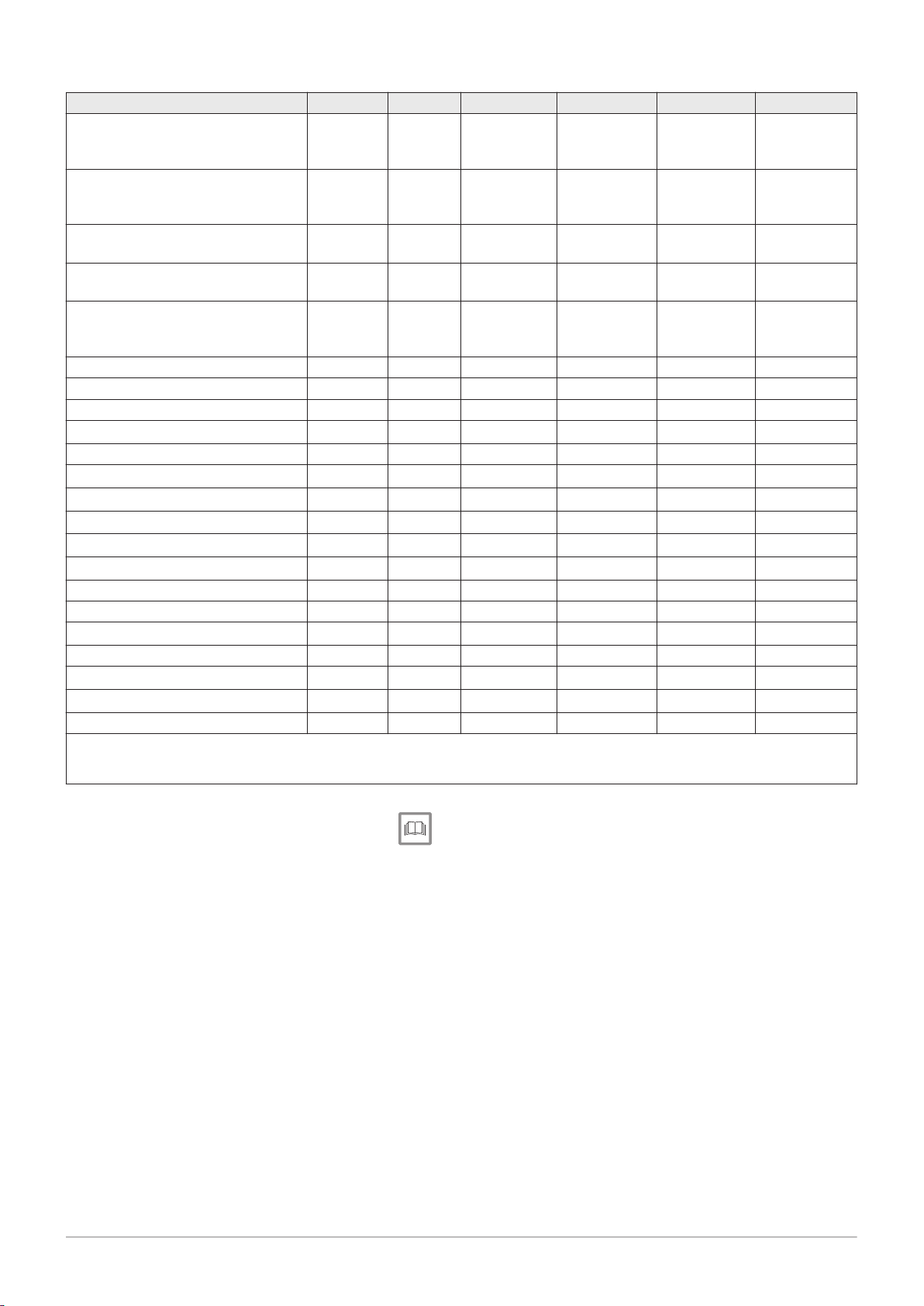

AD-0001240-05

12

BK

BK

1 2

X116

51 6

4

BK

BK

3 1

X112

BK

BK

1 3

X113

9

X111

BK

BK

BK

BK

4 2 3 1

X11

14

X91

BK

BK

BK

BK

1 2 4 5

2 3 8 7 4 10 13 15

2 2

RD

3

BK

1

2

X115

BL

1

23

X114

BK

BK

1 2

X113

X10

4

4 7 2 1096

X8

1

BR

BL

GN/

YW

3 1

2 3

2

X41

X7

2 1 3

WH

BK

RD

1 3 2

X121

X6

1 2

GN/

YW

WH

BL

153

3 4

X21

X5

2

BK

BL

GN/

YW

GY

1 23

X22

3 4 1

X4

1

BK

BK

BK

X91

1 2 3

2 3

CB-03

7 81 2 3 4 5 6

R-Bus ToutBL RL

9 10

Tdhw

X1

X136

1 3 4 52

X131

1 3 4 52 6

X13

1 32 54 1 32 54

321

X134

54

321

X135

54

321

X132

54

6 7 8 9 10 11

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

Spare

X14

1 32

BK

BK

BK

321

X141

22

21

2019

18171615

141312

11

10

8

6

7

9

5

4

3

X11

X13

X12

X4

X3

X10

X8

X7

X14

X6

X5

X3

2 31

X32

1 32

X33

2 31

24

13 X31

2

N L

230V, 50Hz

1

4 132

1 3 42

X01

BR

BL

GN/

YW

BR

BR

BL

BL

GN/

YW

GN/

YW

3 Technical specifications

14 AMC 7686707 - v.01 - 06092018

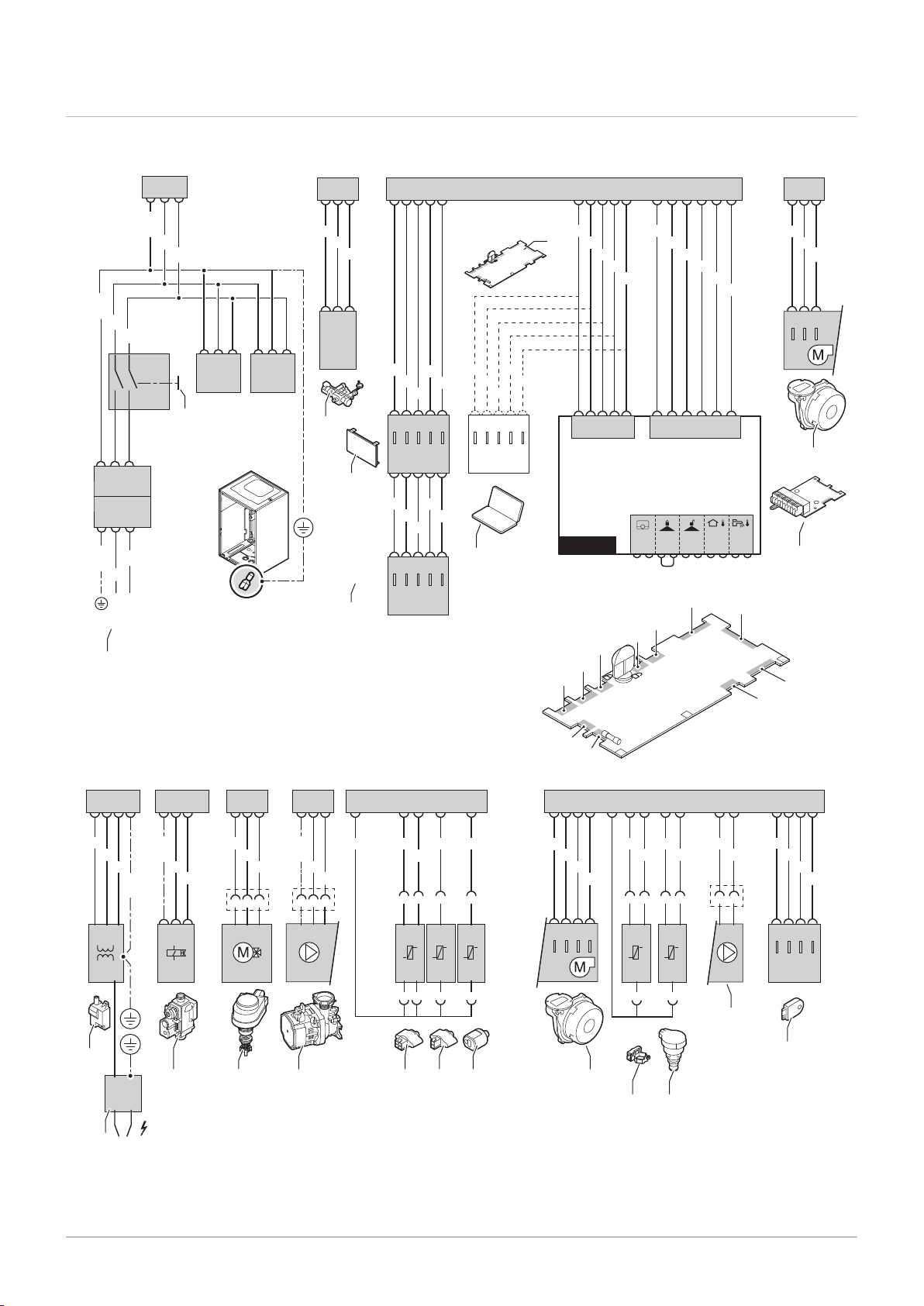

3.4 Electrical diagram

Fig.2 Electrical diagram

Power supply (P)

On/off switch (S)

Automatic refill device

4

5

6

Control unit (CU-GH08)

Display (DIS)

Spare CAN-Bus connection

1

2

3

Page 15

3 Technical specifications

7686707 - v.01 - 06092018 AMC 15

7

Service connection

8

Fan supply

9

CB-03 PCB

10

Ignition transformer (IT)

11

Ionisation/ignition electrode (E)

12

Gas combination block (GB)

13

Three-way valve (3WV)

14

Circulation pump (CH)

15

Flow sensor (FTS)

16

Return sensor (TR)

17

Tap water temperature sensor (TDHW)

18

Fan control (PWM)

19

20

21

22

BK

BL

BR

GN/YW

GY

RD

WH

Flow sensor (FS)

Pressure sensor (PS)

PWM pump

Storage information (CSU)

Black

Blue

Brown

Green/Yellow

Grey

Red

White

Page 16

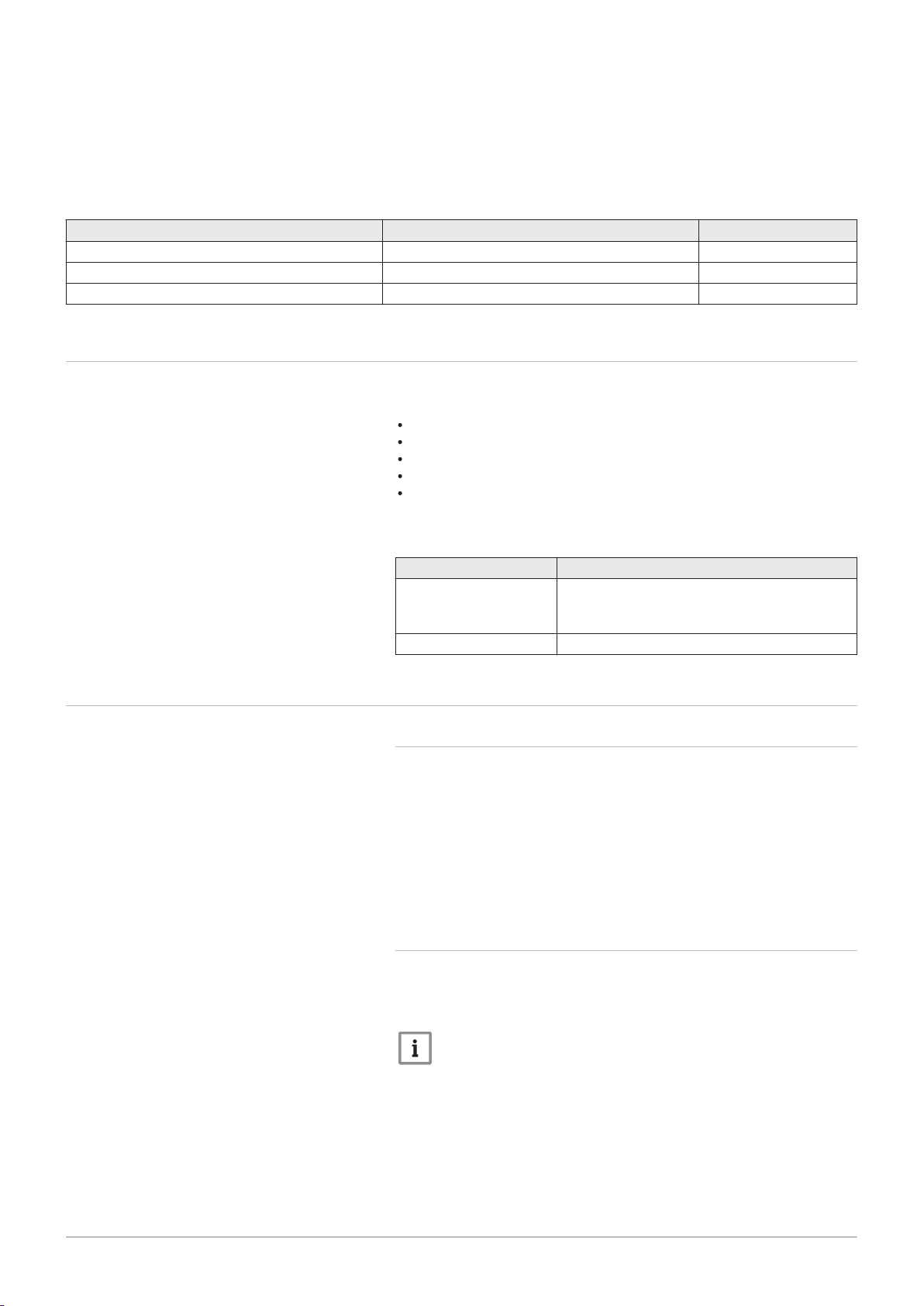

4 Description of the product

16 AMC 7686707 - v.01 - 06092018

4 Description of the product

The AMC boiler is delivered with a combination of the control panel,

control unit and extension PCB. The contents of this manual are based on

the following software and navigation information:

Tab.11 Software and navigation information

Name visible in display Software version

Boiler AMC CU-GH08 1.4

Control panel Diematic Evolution MK3 1.29

PCB SCB-10 SCB-10 0.5

4.1

General description

4.2 Operating principle

The AMC boiler is a wall-mounted gas boiler with the following

characteristics:

High-efficiency heating

Low polluting emissions

Automatic refill device

High-quality electronic control panel

Easier installation and connection thanks to the mounting frame

delivered with the appliance.

The following boiler types are available:

Type Mode

AMC 15

AMC 25

AMC 35

AMC 25/28 MI Heating and production of domestic hot water.

4.2.1

The boiler has an automatic refill device located under the boiler.

The automatic refill device will refill the central heating system whenever

the water pressure is lower than the set minimum. Refilling can be

automatic or semi-automatic. On the semi-automatic setting, refilling will

only start after confirmation by the user. The automatic refill device can

also be used to fill an empty system.

If refilling takes too long or occurs too often (e.g. because the system

leaks), a warning code will appear on the display and refilling will stop.

Automatic refill device

Heating only (option of producing domestic hot

water using a separate hot water appliance).

4.2.2

The energy-efficient, modulating circulation pump is controlled by the

control unit based on ΔT. The graphs show the total dynamic head at

various outputs.

Circulation pump

Important

The benchmark for the efficient circulation pumps is EEI ≤ 0.20.

Page 17

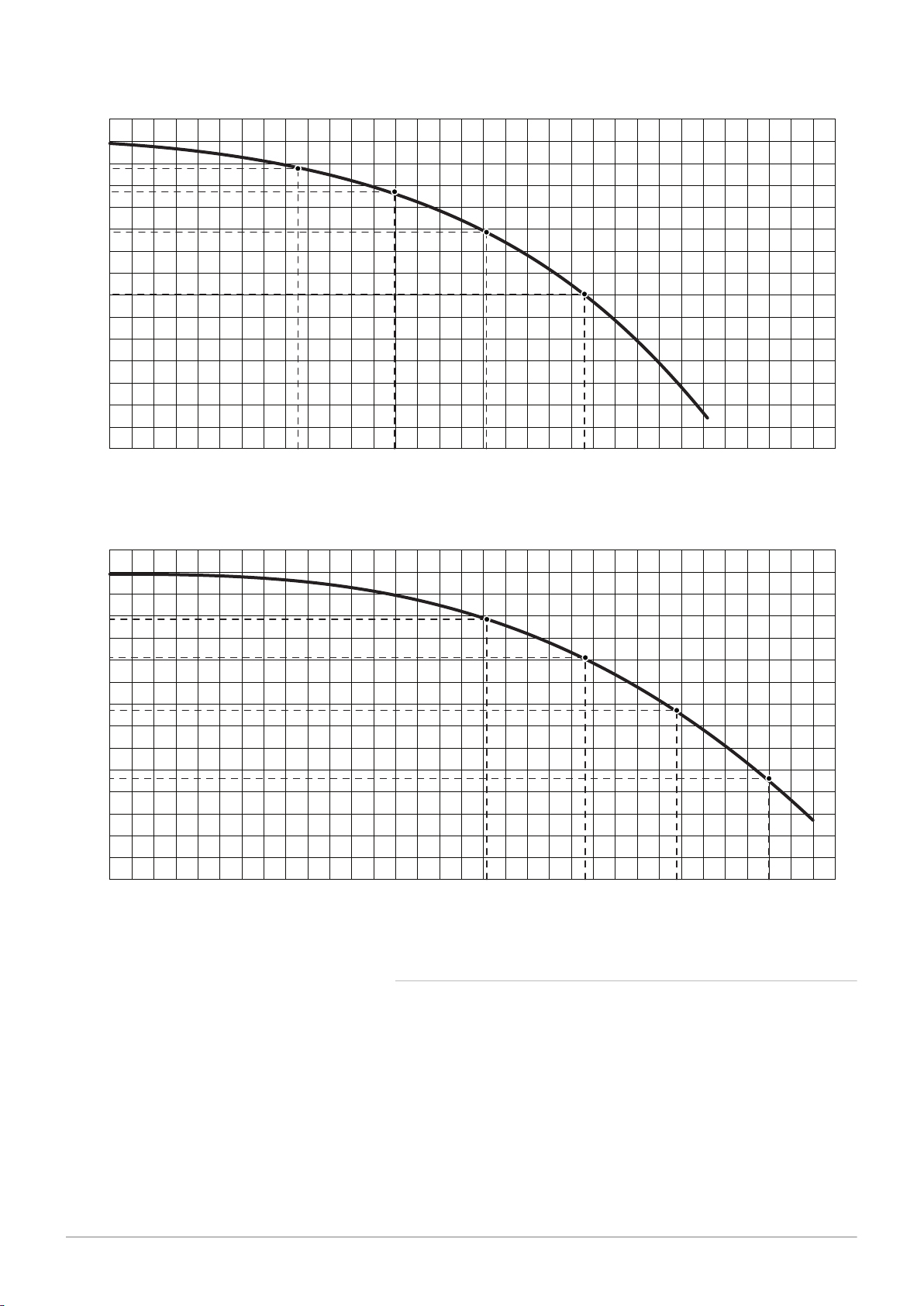

Fig.3 AMC 15 - 25 - 25/28 MI

AD-3000862-02

Q

1600140012001000600 800400200

0

0

100

200

300

400

500

600

H

700

355

25 kW

1080

494

20 kW

860

585

15 kW

650

640

10 kW

430

AD-3000863-02

Q

1600140012001000600 800400200

0

0

100

200

300

400

500

600

H

700

231

35 kW

1500

387

30 kW

1290

508

25 kW

1080

594

20 kW

860

7686707 - v.01 - 06092018 AMC 17

4 Description of the product

H

Total dynamic head CH (mbar)

Fig.4 AMC 35

H

Total dynamic head CH (mbar)

Q

Water flow rate (l/h)

Q

Water flow rate (l/h)

4.2.3 Water flow

The modulating control of the boiler limits the maximum temperature

difference between the flow and return and the maximum rise velocity of

the flow temperature. In addition, a heat exchanger temperature sensor is

mounted to monitor the minimum water flow. As a result, the boiler is

virtually unaffected by low water flow.

Page 18

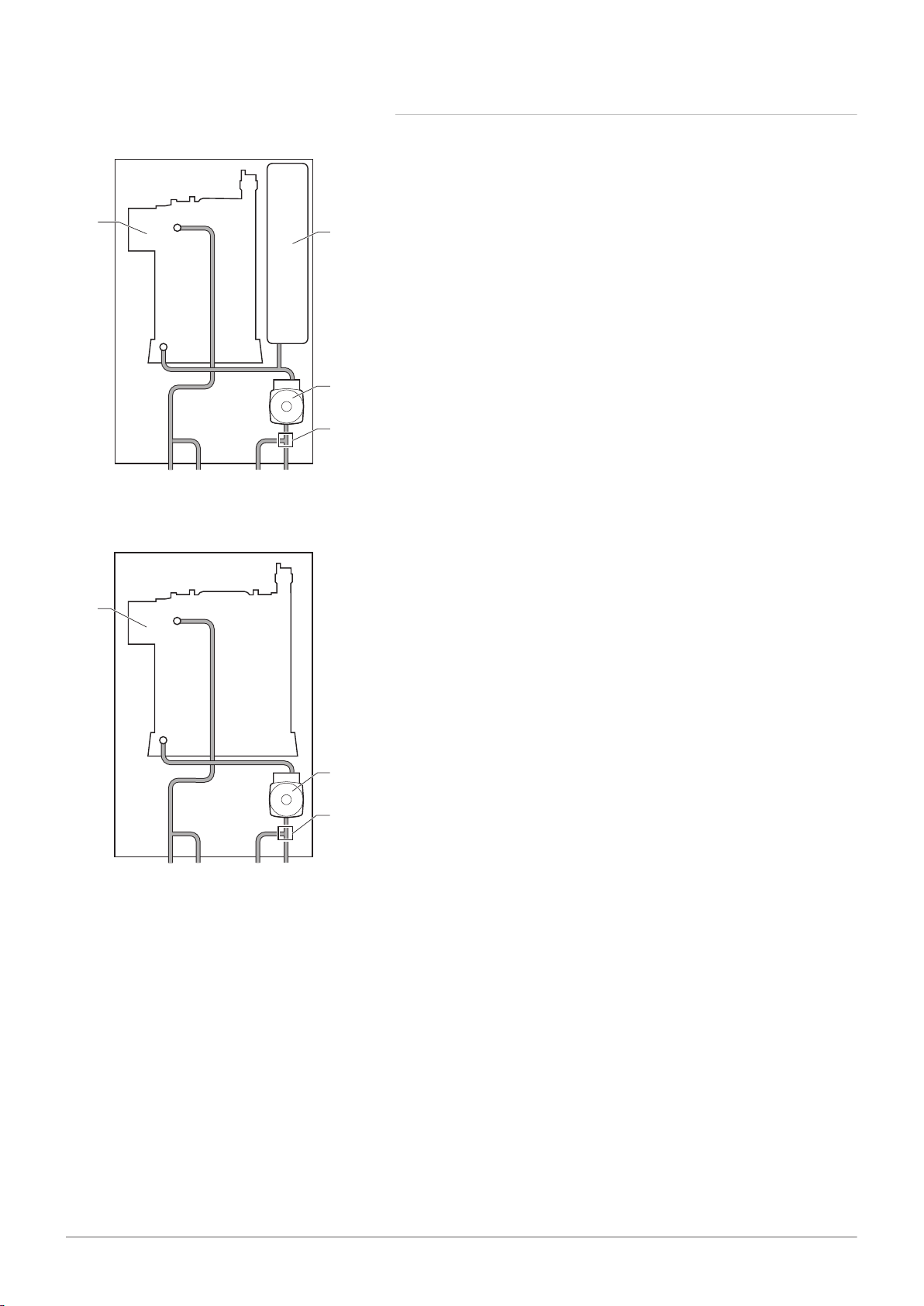

AD-0000428-01

1

8

7

6

2 3 4 5

AD-3000830-01

1

7

6

2 3 4 5

4 Description of the product

18 AMC 7686707 - v.01 - 06092018

4.2.4 Skeleton diagram

Fig.5 AMC 15 - 25

Fig.6 AMC 35

1

Heat exchanger (CH)

2

Heating circuit flow (primary circuit)

3

Heating circuit flow (secondary circuit)

4

Heating return (secondary circuit)

5

Heating return (primary circuit)

6

Three-way valve

7

Circulation pump (CH)

8

Expansion vessel

1

Heat exchanger (CH)

2

Heating circuit flow (primary circuit)

3

Heating circuit flow (secondary circuit)

4

Heating return (secondary circuit)

5

Heating return (primary circuit)

6

Three-way valve

7

Circulation pump (CH)

Page 19

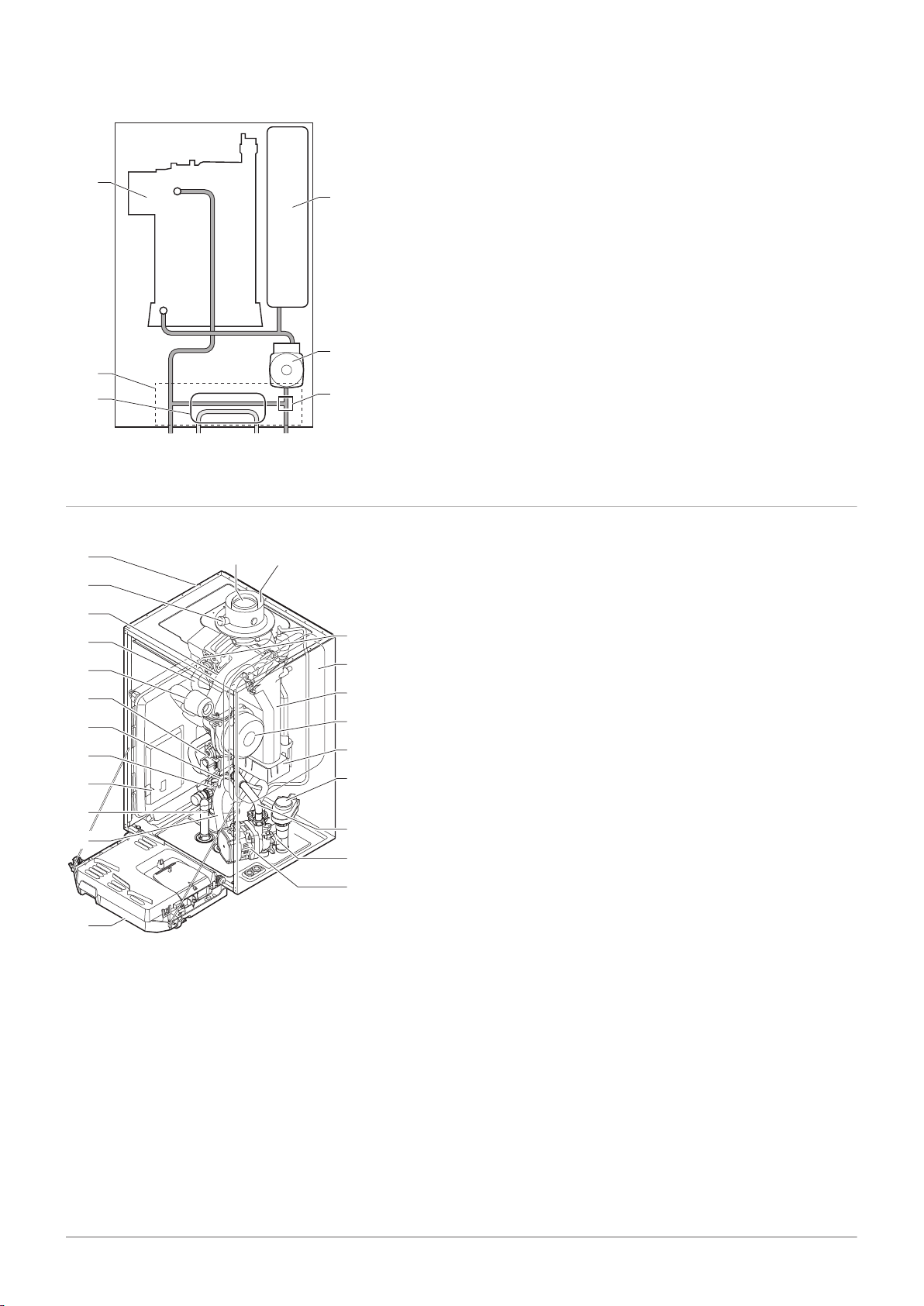

AD-0000419-01

1

2

3

10

9

8

4 5 6 7

AD-0001371-02

2

16

15

14

17

18

19

20

21

22

3

4

5

6

7

8

9

10

11

12

13

1 23

4 Description of the product

7686707 - v.01 - 06092018 AMC 19

Fig.7 AMC 25/28 MI

4.3

Main components

Fig.8 AMC 15 - 25

1

Heat exchanger (CH)

2

Hydroblock

3

Plate heat exchanger (DHW)

4

Central heating circuit flow

5

Domestic hot water outlet

6

Domestic cold water inlet

7

Central heating circuit return

8

Three-way valve

9

Circulation pump (CH)

10

Expansion vessel

1

Flue gas outlet

2

Casing/air box

3

Flue gas measuring point

4

Mixing tube

5

Hydraulic flow pipe

6

Air intake silencer

7

Combined gas valve unit

8

Automatic air vent hose

9

Hydroblock, flow side

10

Housing for PCBs

11

Safety valve hose

12

Siphon

13

Instrument box

14

Circulation pump

15

Hydroblock, return side

16

Return pipe

17

Three-way valve

18

Condensate collector

19

Fan

20

Heat exchanger (CH)

21

Expansion vessel

22

Ionisation/ignition electrode

23

Air supply

Page 20

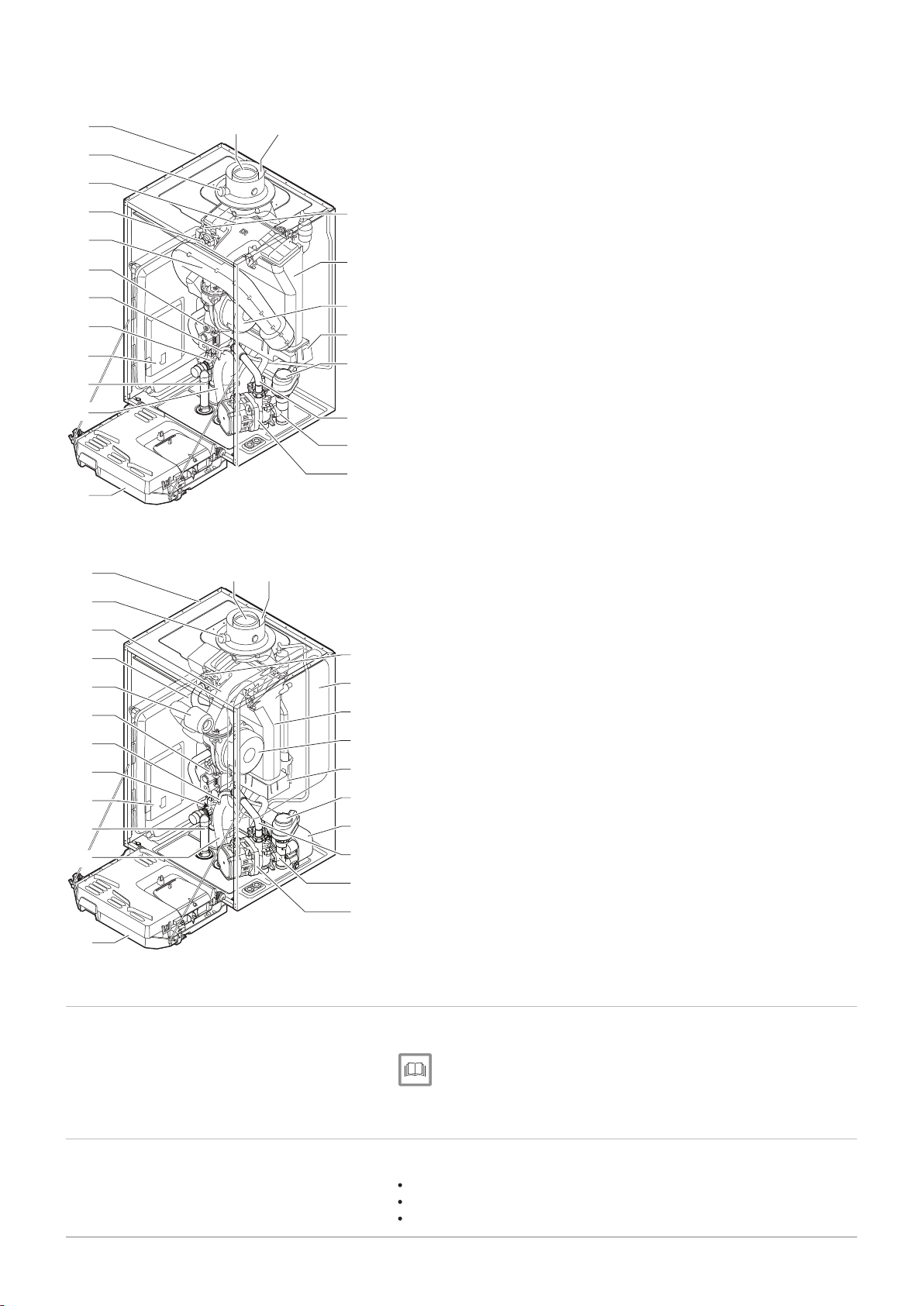

AD-0001372-02

2

15

16

17

14

18

19

20

21

3

4

5

6

7

8

9

13

1

22

10

11

12

AD-0001373-03

2

17

16

15

14

18

19

20

21

22

23

3

4

5

6

8

7

9

10

11

12

13

1 24

4 Description of the product

20 AMC 7686707 - v.01 - 06092018

Fig.9

AMC 35

Fig.10 AMC 25/28 MI

4.4

4.5

Control panel

Standard delivery

1

Flue gas outlet

2

Casing/air box

3

Flue gas measuring point

4

Mixing tube

5

Hydraulic flow pipe

6

Air intake silencer

7

Combined gas valve unit

8

Automatic air vent hose

9

Hydroblock, flow side

10

Housing for PCBs

11

Safety valve hose

12

Siphon

13

Instrument box

14

Circulation pump

15

Hydroblock, return side

16

Return pipe

17

Three-way valve

18

Condensate collector

19

Fan

20

Heat exchanger (CH)

21

Ionisation/ignition electrode

22

Air supply

1

Flue gas outlet

2

Casing/air box

3

Flue gas measuring point

4

Mixing tube

5

Hydraulic flow pipe

6

Air intake silencer

7

Combined gas valve unit

8

Automatic air vent hose

9

Hydroblock, flow side

10

Housing for PCBs

11

Safety valve hose

12

Siphon

13

Instrument box

14

Circulation pump

15

Hydroblock, return side

16

Return pipe

17

Plate heat exchanger (DHW)

18

Three-way valve

19

Condensate collector

20

Fan

21

Heat exchanger (CH)

22

Expansion vessel

23

Ionisation/ignition electrode

24

Air supply

The AMC boiler is supplied with a Diematic Evolution control panel.

For more information, see

Control panel description, page 77

The delivery includes:

The boiler, fitted with a three-core cable

Mounting frame with automatic refill device

Connection kit including cable glands and clamping rings

Page 21

4 Description of the product

7686707 - v.01 - 06092018 AMC 21

Condensate drain hose for siphon and safety valve

Condensates collector

Seal plates for sealing off the lines for the secondary heating circuit if it

is not being used

Documentation

Mounting template

Sticker: This central heating unit is set for ...

This manual only deals with the standard scope of supply. For the

installation or mounting of any accessories supplied with the boiler, please

refer to the mounting instructions delivered with the accessories in

question.

Page 22

AD-0001197-01

AD-0001376-02

450

min.10

0

0

4

5

0

min.

250

m

i

n.

2

5

0

690

5 Before installation

22 AMC 7686707 - v.01 - 06092018

5 Before installation

5.1 Installation regulations

Warning

The boiler must be installed by a qualified installer in accordance

with local and national regulations.

5.2

Choice of the location

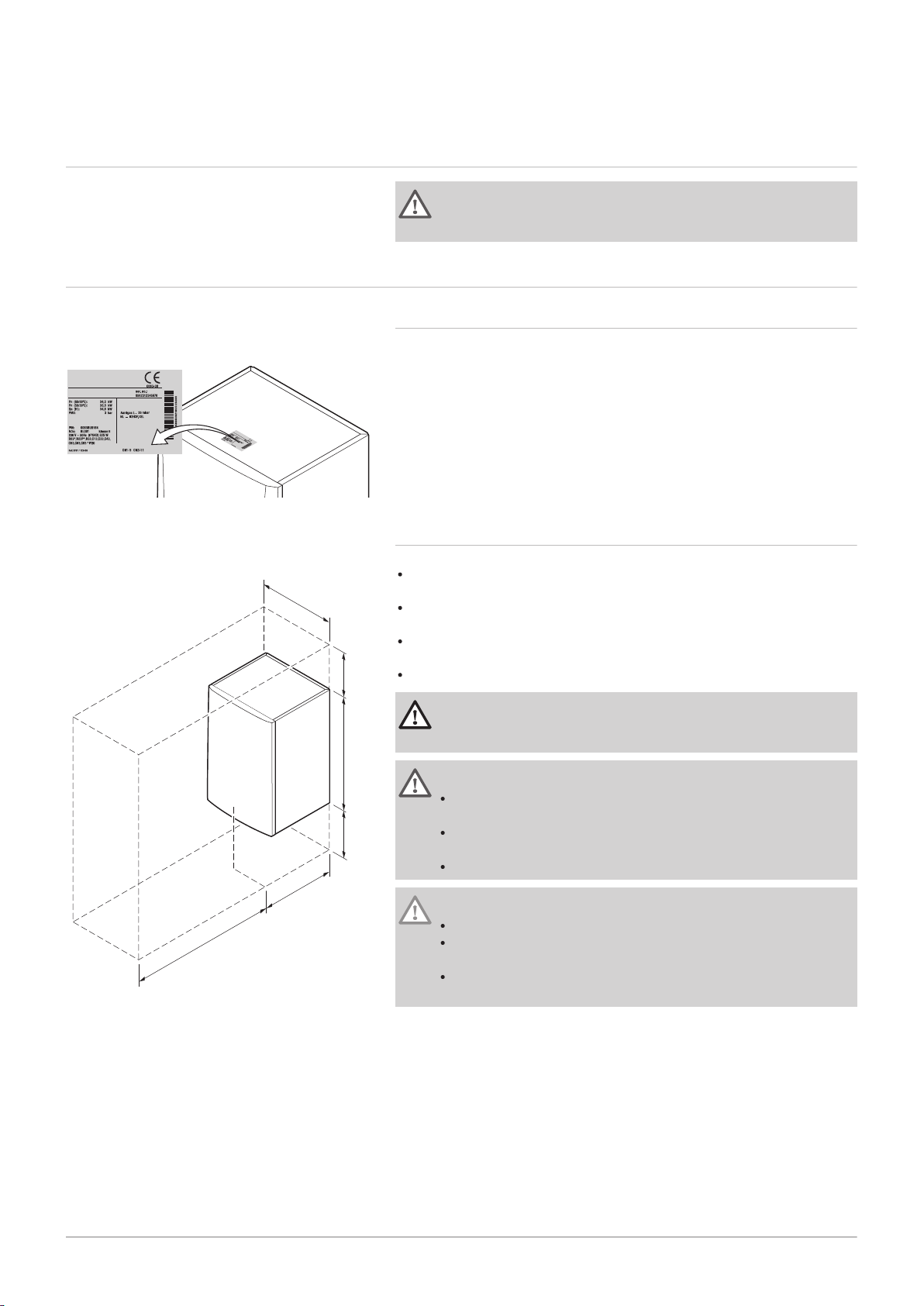

Fig.11 Position of data plate

Fig.12 Installation area

5.2.1 Data plate

The data plate on top of the boiler states the boiler serial number and

important boiler specifications such as the model and gas category. The

configuration numbers CN1 and CN2 codes are also stated on the data

plate.

5.2.2 Location of the boiler

Use the guidelines and the required installation space as a basis for

determining the correct place to install the boiler.

When determining the correct installation area, take account of the

permitted position of the flue gas outlet and/or air supply outlet.

Ensure that there is sufficient space around the boiler for good access

and ease of maintenance.

Mount the boiler onto a flat surface.

Danger

It is forbidden to store, even temporarily, combustible products

and substances in the boiler or near the boiler.

Warning

Fix the appliance to a solid wall capable of bearing the weight of

the boiler when full of water and fully equipped.

Do not place the appliance above a heat source or a cooking

appliance.

Do not locate the boiler in direct or indirect sunlight.

Caution

The boiler must be installed in a frost-free area.

An earthed electrical connection must be available close to the

boiler.

A connection to the drain must be present for the condensate

drain close to the boiler.

Page 23

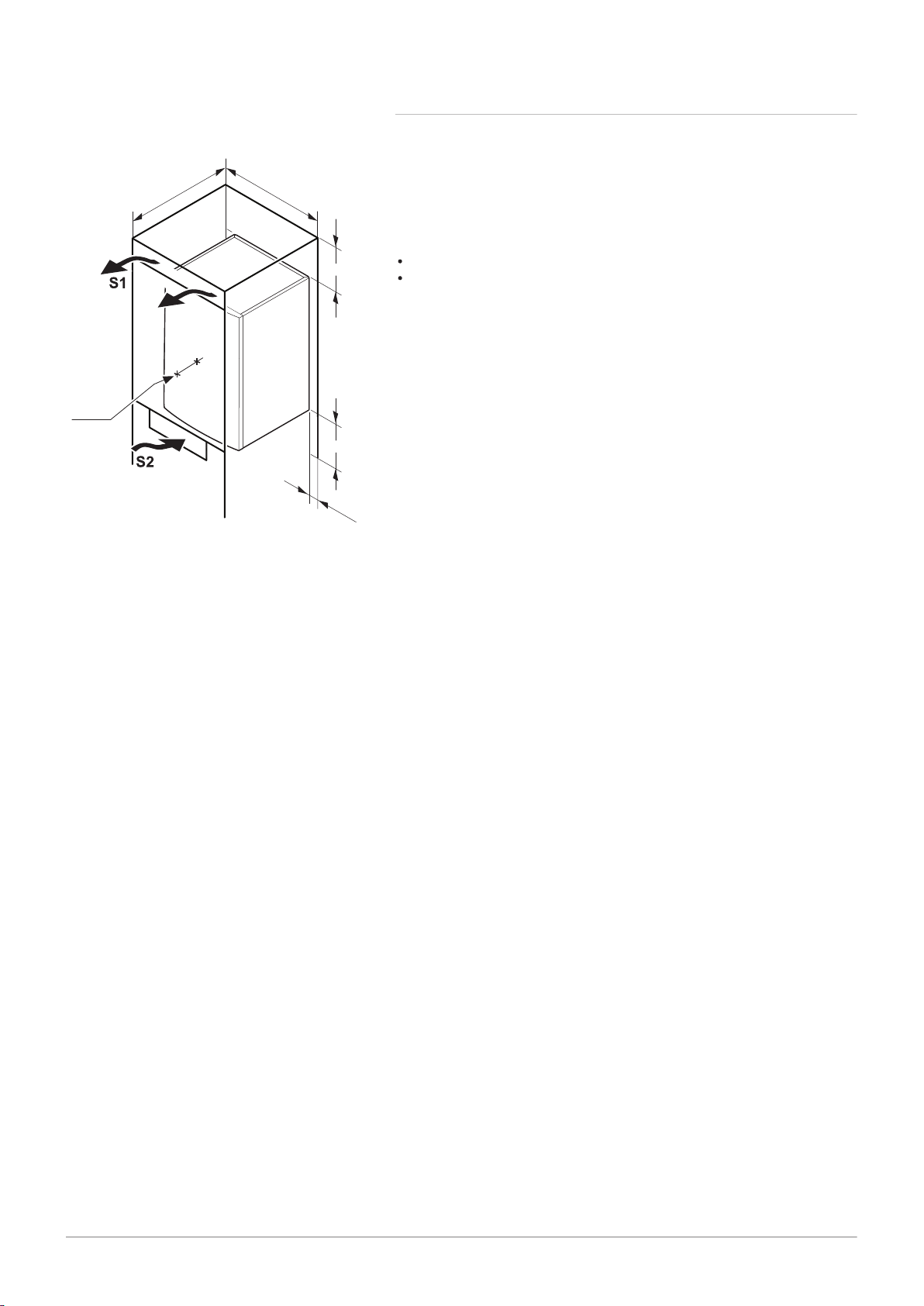

5.2.3 Ventilation

AD-0001377-02

min. 550

min.550

min. 250

50 (2)

min. 250

100

min. (1)

7686707 - v.01 - 06092018 AMC 23

5 Before installation

Fig.13

Space for ventilation

(1)

Distance between the front of the boiler and the internal wall of the

casing.

(2)

Space on either side of the boiler.

If the boiler is installed in a closed casing, observe the minimum

dimensions indicated. Also allow for openings to prevent the following

hazards:

Accumulation of gas

Heating of the casing

Minimum cross section of the openings: S1 + S2 = 150 cm

2

Page 24

AD-0001379-02

76499

0

2

-01

50

57

41

13

152,5

154,5

216

216

2

20

220

2

6,5

120

432

450

6

76

7

6

7

6565

63

50

1

95

690

42

487

715

3

6

100

59

10

(1x)

10

(1x)

1

0

(1x)

104,5

1

04,5

5

1

0

(1

x

)

1

0

(1x)

1

2

3

4

5

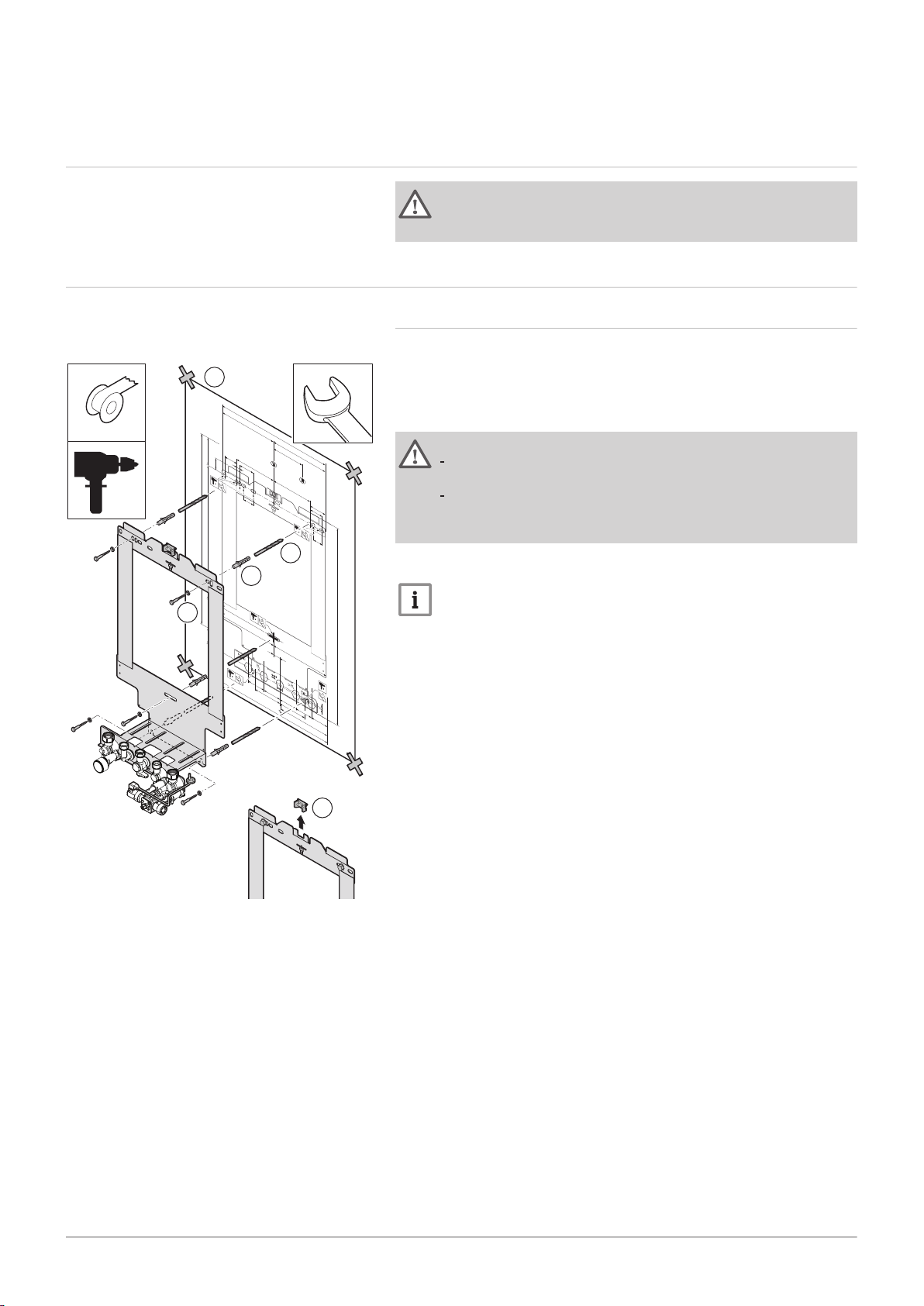

6 Installation

24 AMC 7686707 - v.01 - 06092018

6 Installation

6.1 General

Warning

The boiler must be installed by a qualified installer in accordance

with local and national regulations.

6.2

Preparation

Fig.14 Installing the mounting frame

6.2.1 Installing the mounting frame

The boiler is supplied with a mounting template.

Proceed as follows to hang the mounting frame:

1. Attach the mounting template of the boiler to the wall using adhesive

tape.

Warning

Use a level on the mounting frame to check whether the

mounting template is perfectly horizontal.

Protect the boiler against building dust and cover the flue gas

outlet and air supply connection points. Only remove this cover

to assemble the relevant connections.

2. Drill 3 holes of Ø 10 mm.

Important

The extra holes are intended for use in the event that one of the

two fastening holes is not suitable for correct fastening of the plug.

3. Fit the Ø 10 mm plugs.

4. Attach the mounting frame to the wall with the Ø 8 mm screws

supplied

5. Remove the level from the mounting frame.

Page 25

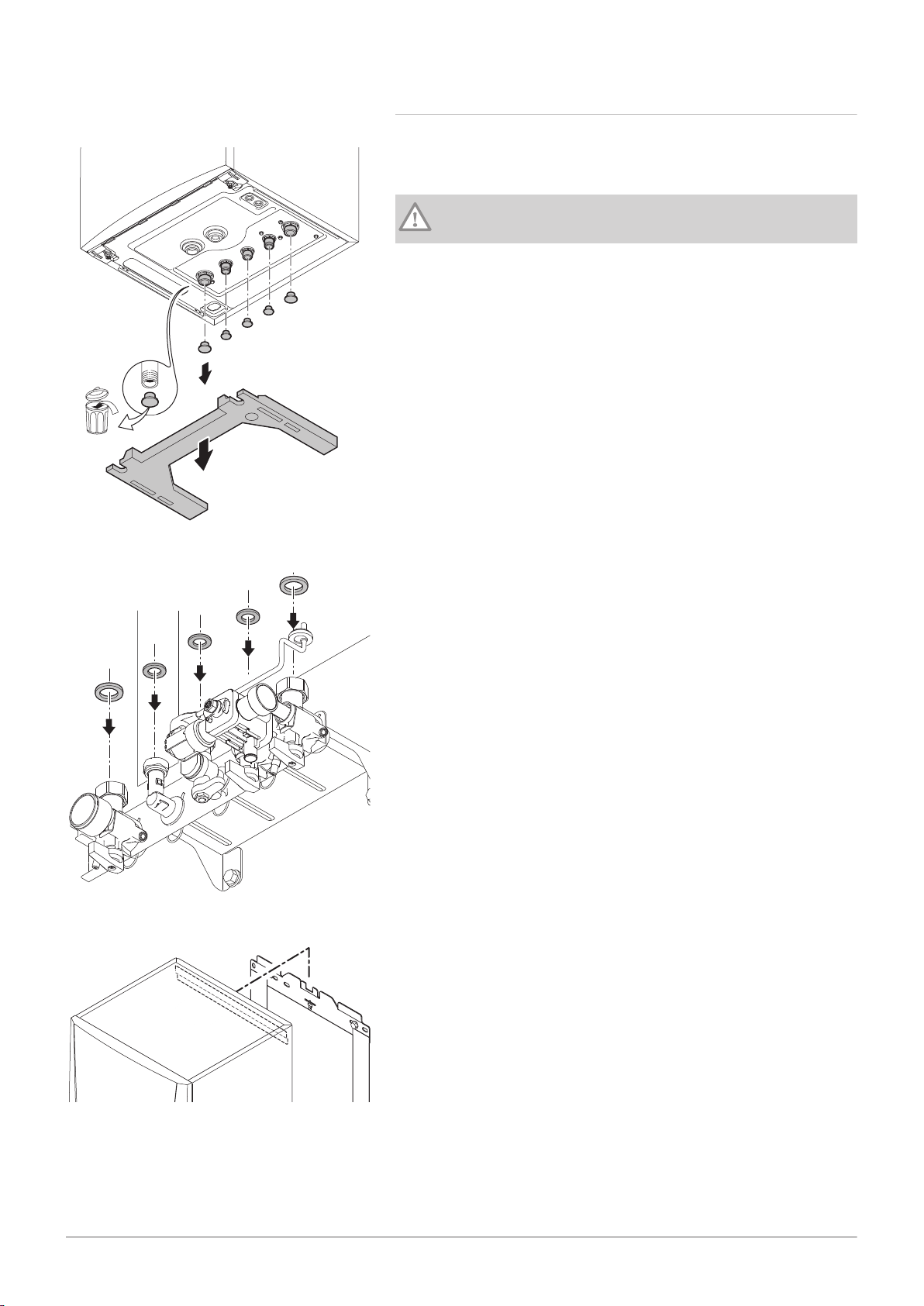

6.2.2 Positioning the boiler

AD-0001380-02

AD-0001381-02

AD-3001203-01

7686707 - v.01 - 06092018 AMC 25

6 Installation

Fig.15 Removing boiler protection

Fig.16 Fitting gaskets

1. Remove the black protective strip on the underside of the boiler.

2. Remove the dust caps from all of the hydraulic inlets and outlets on

the boiler.

Caution

The valve of the filling loop must be closed.

3. Fit a fibre gasket to each joint on the valve plate.

Fig.17 Fitting the boiler

4. Position the boiler above the mounting frame. Gently lower the boiler.

5. Tighten the valve nuts on the boiler.

Page 26

AD-0001383-03

1

2

AD-0001384-03

2

1

6 Installation

26 AMC 7686707 - v.01 - 06092018

6.3 Hydraulic connections

6.3.1 Rinsing the system

Installation must be carried out in accordance with the prevailing

regulations, codes of practice and the recommendations in this manual.

Before a new boiler can be connected to an existing or new system, the

entire system must be thoroughly cleaned and flushed. This step is

absolutely crucial. The flushing helps to remove residue from the

installation process (weld slag, fixing products etc.) and accumulations of

dirt (silt, mud etc.)

Important

Flush the system with a volume of water equivalent to at least

three times the volume of the system. Flush the DHW pipes with a

volume of water equivalent to at least 20 times the volume of the

pipes.

Fig.18 Connecting the heating circuit

6.3.2

Water flow

The boiler's modulating control system limits the maximum difference in

temperature between the heating flow and return, and the maximum

speed at which the flow temperature increases. In this way, the boiler does

not require a minimum water flow rate.

Important

In the case of a combi boiler in an installation in which the flow

can be fully disconnected from the return (e.g. by using

thermostatic valves), a bypass pipe should be fitted or the

expansion vessel placed on the central heating flow pipe.

6.3.3

Connection of the heating circuit

1. Fit the inlet pipe for CH water to the CH return connection .

2. Fit the outlet pipe for CH water to the CH flow connection .

Caution

Carry out any welding work required at a safe distance from the

boiler or before the boiler is fitted.

If using synthetic pipes, follow the manufacturer's (connection)

instructions.

6.3.4 Connection of the water circuit for domestic use

Fig.19 Connecting water circuit for

domestic use

1. Connect the cold water inlet pipe to the domestic cold water

connection .

2. Connect the domestic hot water outlet pipe to the domestic hot water

connection

Page 27

Caution

AD-0001385-04

4

3

2

1

AD-0001207-03

1

2

7686707 - v.01 - 06092018 AMC 27

If using synthetic pipes, follow the manufacturer's (connection)

instructions.

Carry out any welding work required at a safe distance from the

boiler or before the boiler is fitted.

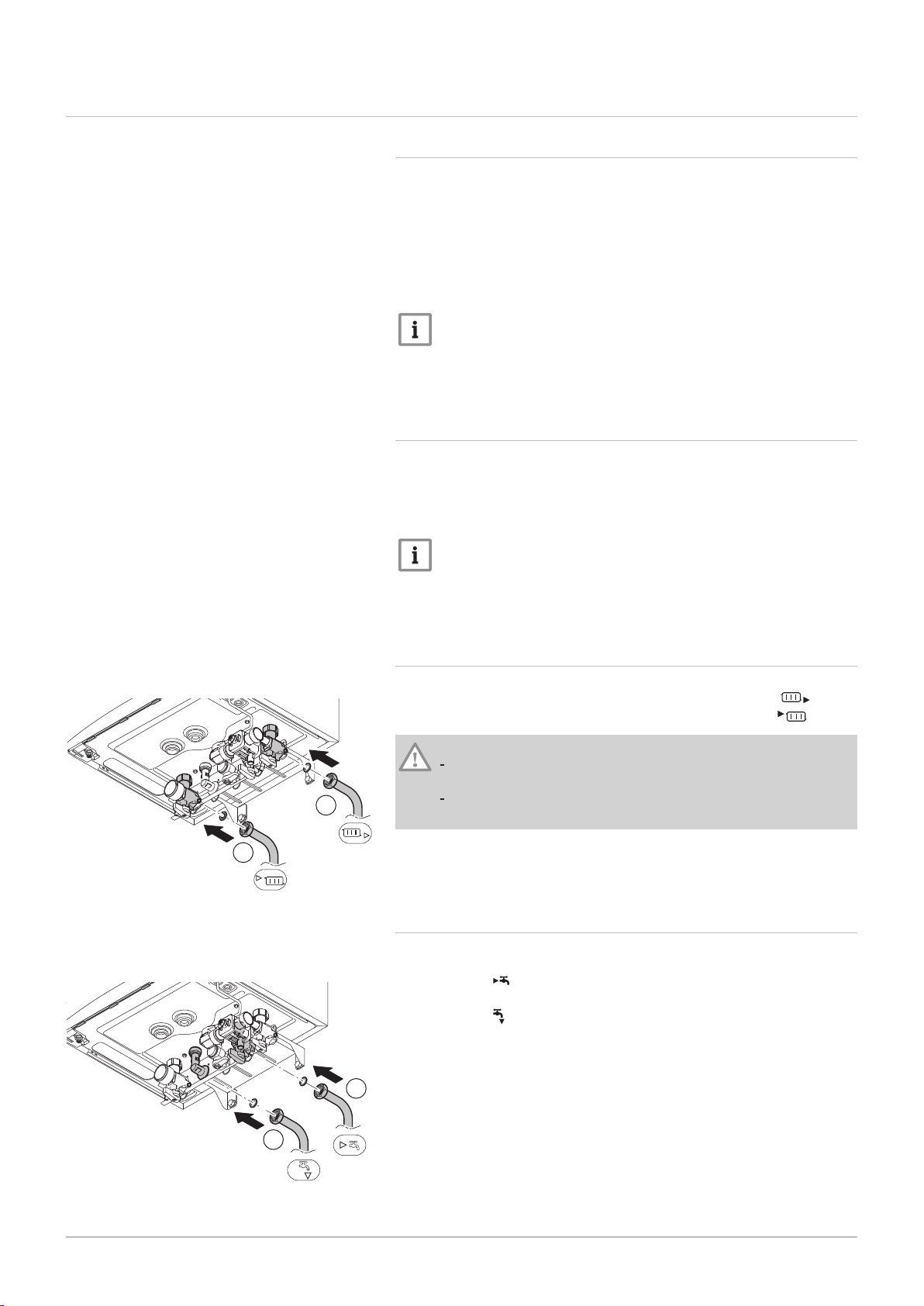

6.3.5 Connecting the secondary heating circuit

6 Installation

Fig.20 Connecting the secondary heating

circuit

Fig.21 Disconnecting the secondary

heating circuit

1. Fit the pipe supplied with the mounting frame to the domestic cold

water connection of the automatic (re)fill device.

2. Connect the domestic cold water inlet to this pipe.

3. Fit the inlet pipe for CH water to the CH return connection .

4. Fit the outlet pipe for CH water to the CH flow connection .

Caution

Carry out any welding work required at a safe distance from the

boiler or before the boiler is fitted.

If using synthetic pipes, follow the manufacturer's (connection)

instructions.

6.3.6

Disconnecting the secondary heating circuit

These connections must be closed off if the secondary heating circuit is

not connected (solo use of the boiler). To do this, proceed as follows:

Important

The blanking plates needed are supplied with the boiler.

1. Remove the secondary heating circuit valves from the mounting

frame.

2. Place a blanking plate in the fitting (G½") and install this on the CH

return connection .

3. Place a blanking plate in the fitting (G½") and install this on the CH

flow connection .

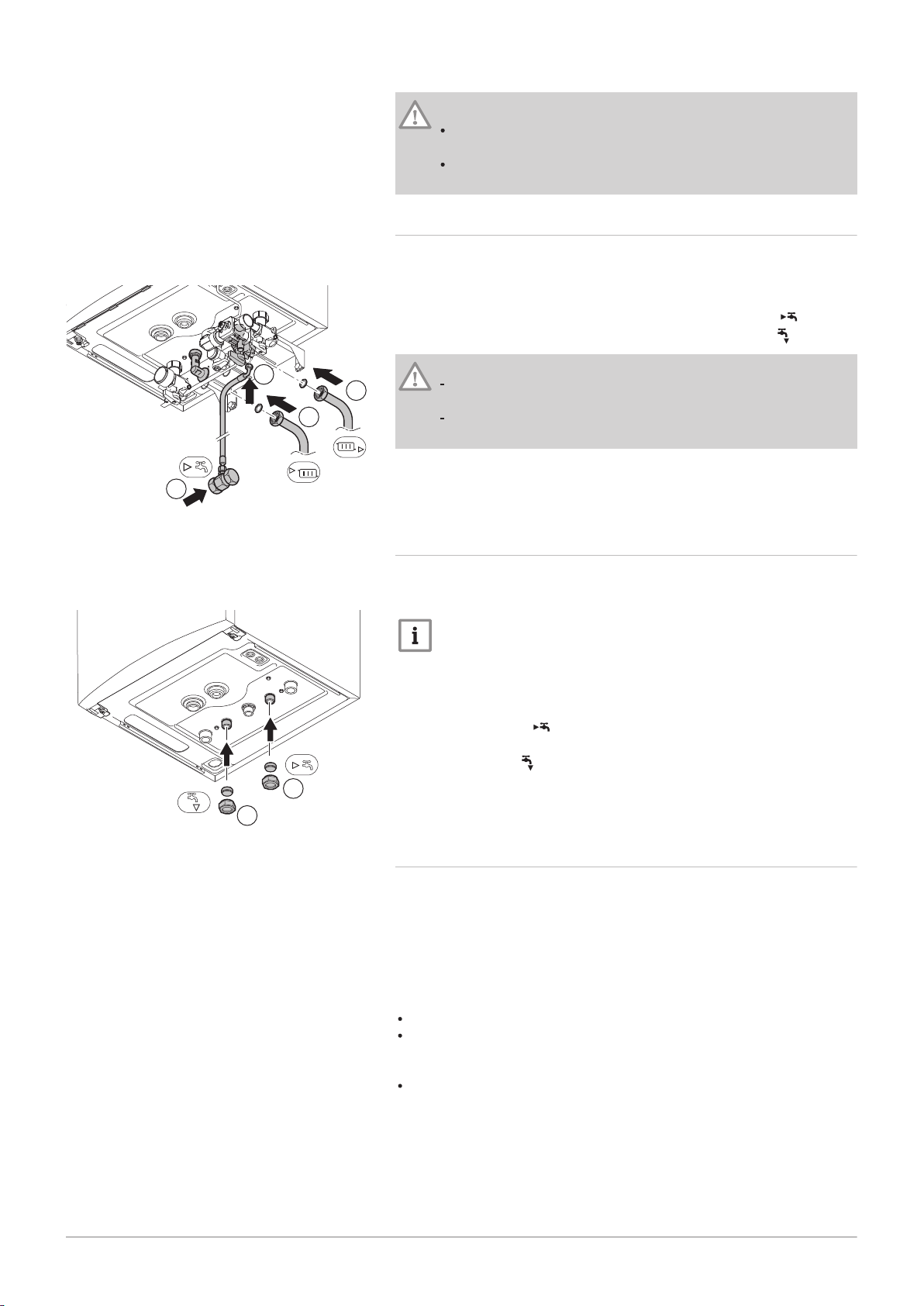

6.3.7 Connecting the expansion vessel

The boiler is fitted as standard with an 12 litre expansion vessel.

If the water volume is greater than 150 litres or the static height of the

system exceeds 5 metres, an additional expansion vessel must be fitted.

Refer to the table below to determine the expansion vessel required for

the system.

Validity terms of the table:

3-bar safety valve

Average water temperature: 70°C

Flow temperature: 80°C

Return temperature: 60°C

The filling pressure in the system is lower than or equal to the inflation

pressure in the expansion vessel.

Page 28

AD-3001204-01

1

2

4

4

3

3

AD-0001387-03

1

6 Installation

28 AMC 7686707 - v.01 - 06092018

Tab.12 Volume of the expansion vessel (litres)

Initial pressurinstae of the ex

pansion vessel

Volume of the system (litres)

100 125 150 175 200 250 300 > 300

0.5 bar 4.8 6.0 7.2 8.4 9.6 12.0 14.4 Volume of the system x 0.048

1 bar 8.0 10.0

(1

14.0 16.0 20.0 24.0 Volume of the system x 0.080

12.0

)

1.5 bar 13.3 16.6 20.0 23.3 26.6 33.3 39.9 Volume of the system x 0.133

(1) Standard configuration.

6.3.8 Connecting the condensate drain pipe

Fig.22 Connecting the condensate

discharge pipe

6.4 Gas connection

1. Fit a plastic drain pipe of Ø 32 mm or larger, terminating in the drain.

Important

Fit a watertrap or siphon in the drain pipe.

2. Insert the condensate collector into the drain pipe.

3. Attach the boiler siphon and safety valve drain hose to the condensate

discharge pipe connection and the safety valve .

4. Slide the hose into the drain pipe.

Caution

Never seal the condensate drain.

The drain pipe must slope down at least 30 mm per metre, the

maximum horizontal length is 5 metres.

Condensed water must not be discharged into a gutter.

For more information, see

Filling the siphon, page 66

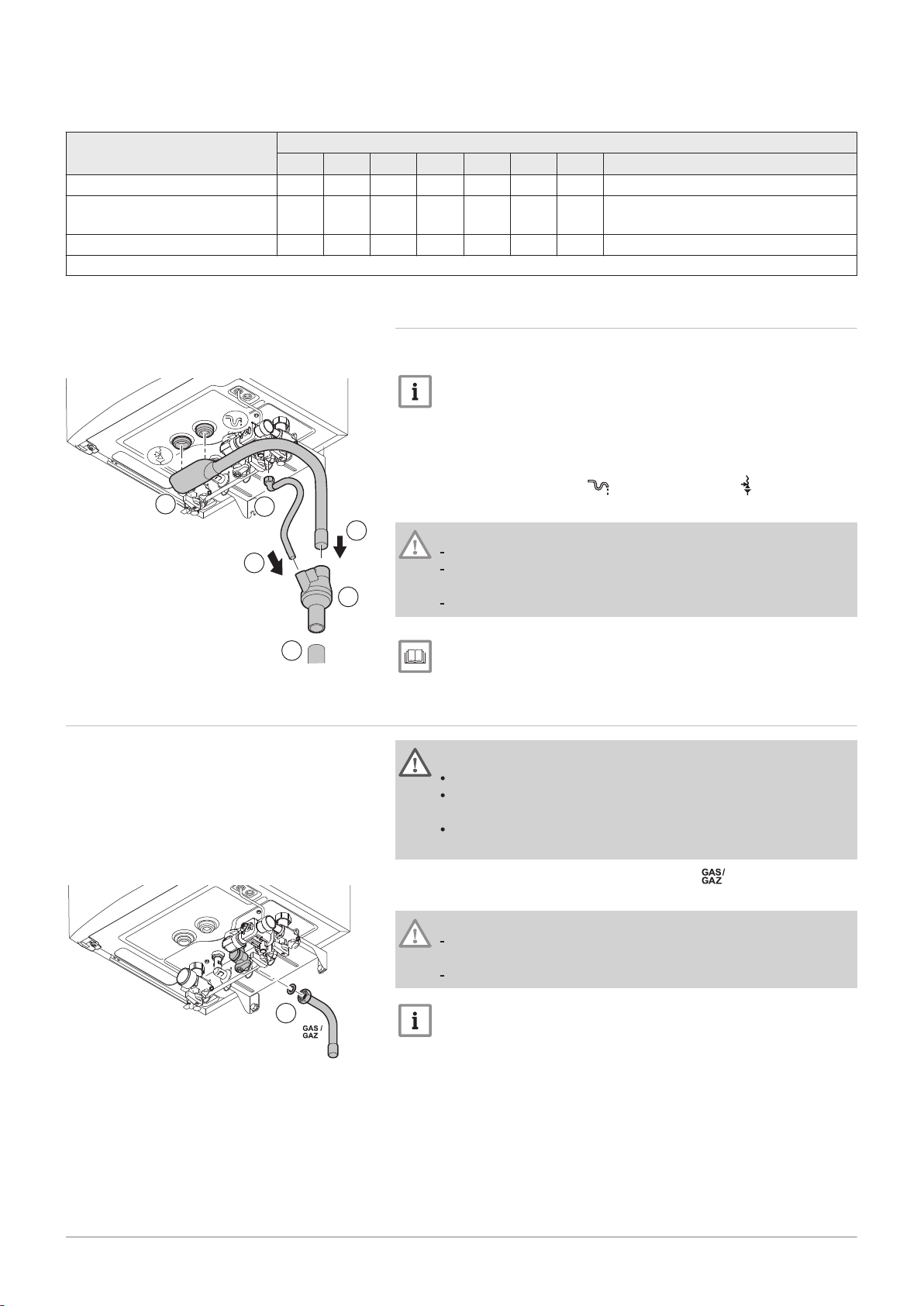

Warning

Before starting work on the gas pipes, turn off the main gas tap.

Before installing, check that the gas meter has sufficient

capacity. Take into account the consumption of all appliances.

Notify the local energy company if the gas meter has insufficient

capacity.

Fig.23 Connecting the gas pipe

1. Fit the gas supply pipe to the gas connection .

2. Fit the gas pipe to the gas tap.

Caution

Always perform welding work at a sufficient distance from the

boiler.

Remove dirt and dust from the gas pipe.

Important

We recommend installing a gas filter to prevent clogging of the

gas valve unit.

Page 29

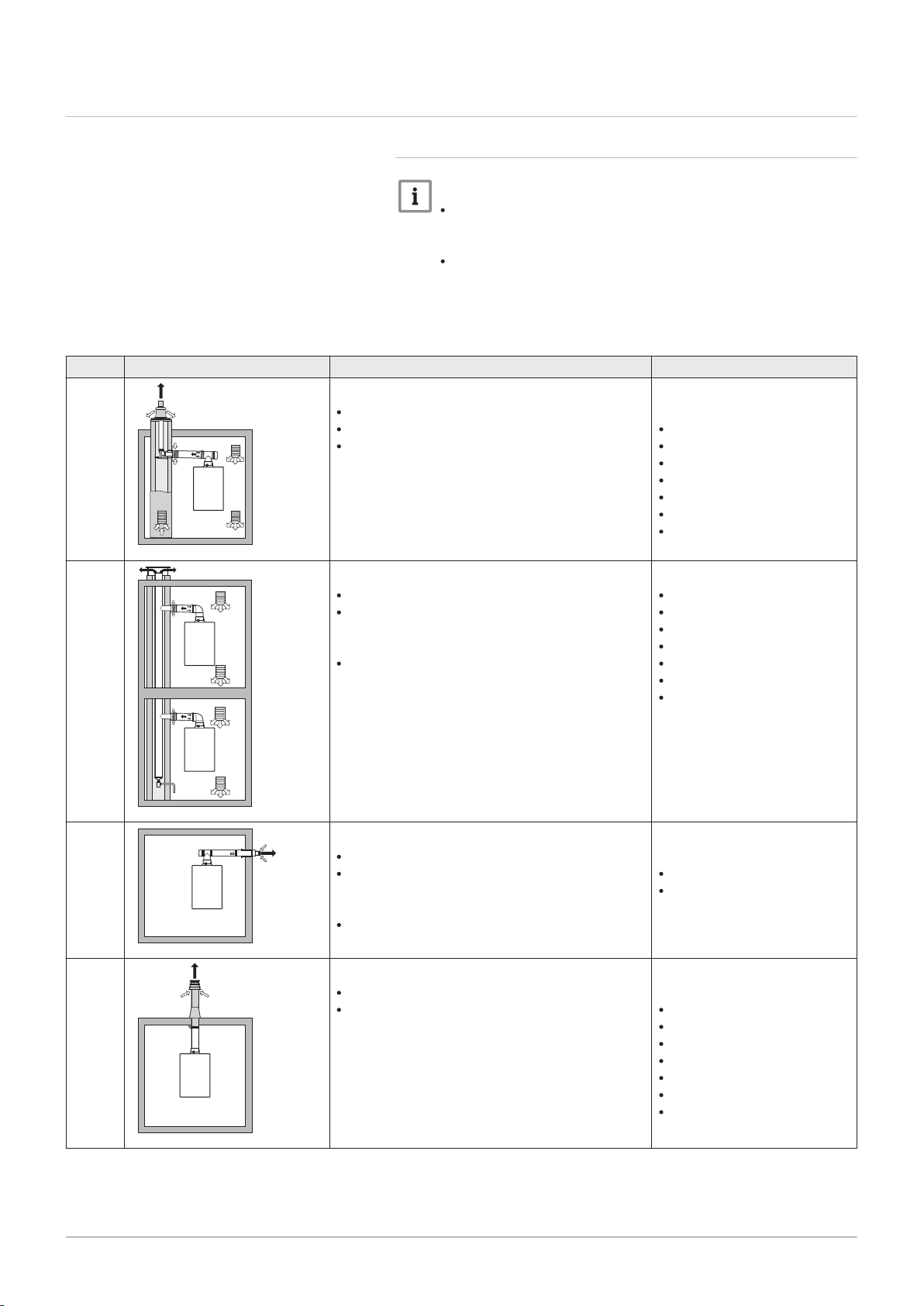

6.5 Air supply/flue gas outlet connections

AD-3000924-01

AD-3000925-01

AD-3000926-01

AD-3000927-01

7686707 - v.01 - 06092018 AMC 29

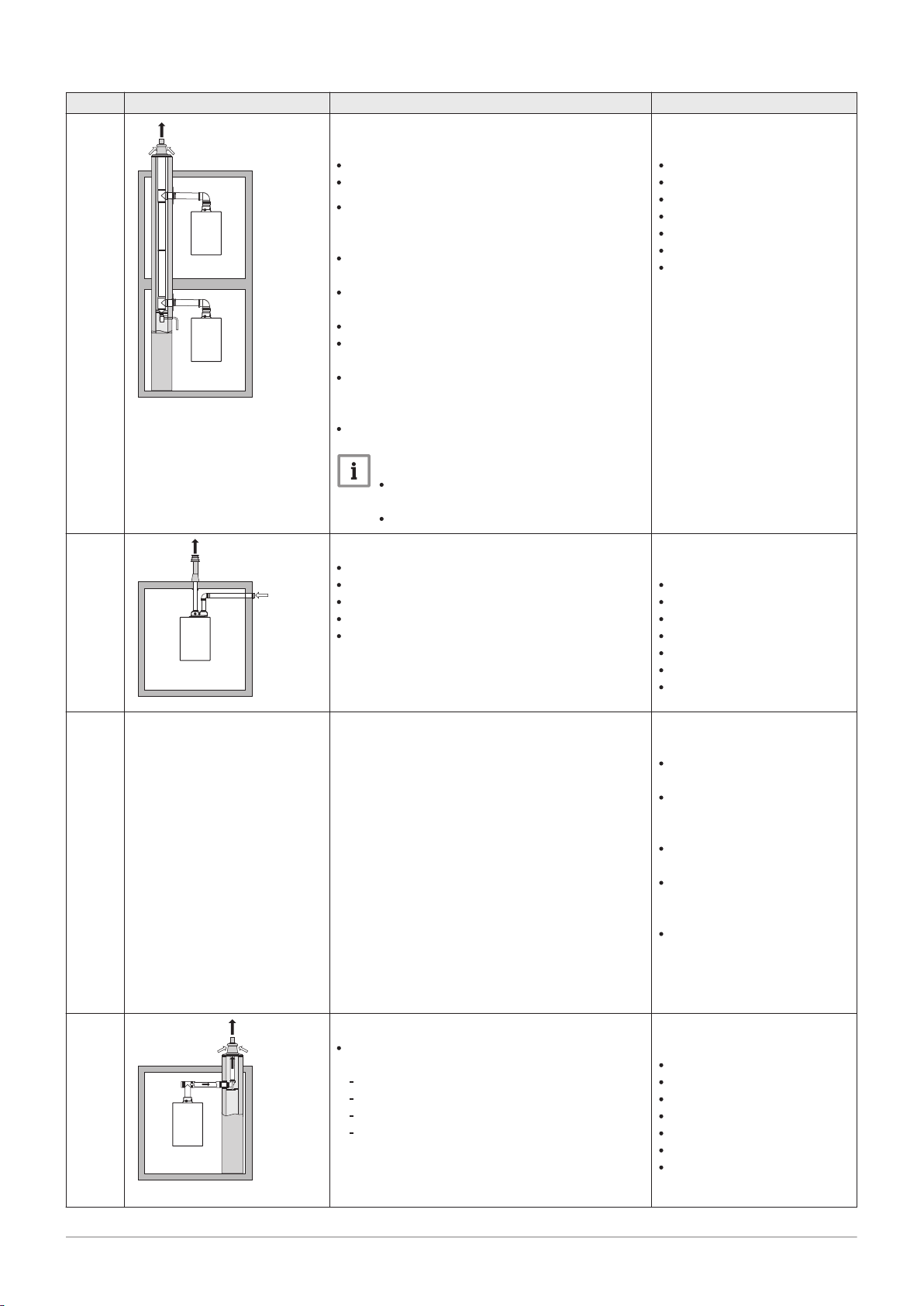

Tab.13 Types of flue gas connections

Type Principle Description

B

23

B

23P

Room-ventilated version

Without down-draught diverter.

Flue gas discharge via the roof.

Air from the installation area.

6.5.1 Classification

Important

The installer is responsible ensuring that the right type of flue

gas outlet system is used and that the diameter and length are

correct.

Always use connection materials and roof terminal supplied by

the same manufacturer. Consult the manufacturer for

compatibility details.

6 Installation

Permitted manufacturers

(1)

Connection material and roof

terminal:

Centrotherm

Cox Geelen

Muelink & Grol

Natalini

Poujoulat

Skoberne

Ubbink

B

C

C

33

13(X)

33(X)

Room-ventilated version

Without down-draught diverter.

Joint flue gas discharge via the roof, with guar

anteed natural draft. (at all times underpressure

in the joint discharge duct)

Flue gas discharge rinsed with air, air from the

installation area (special construction).

Room-sealed version

Discharge in the outside wall.

Inlet opening for the air supply is in the same

pressure zone as the discharge (e.g. a com

bined outside wall feed-through).

Parallel not permitted

Room-sealed version

Flue gas discharge via the roof.

Inlet opening for the air supply is in the same

pressure zone as the discharge (e.g. a concen

tric roof feed-through).

Connection material:

Centrotherm

Cox Geelen

Muelink & Grol

Natalini

Poujoulat

Skoberne

Ubbink

Outside wall terminal and con

nection material:

Cox Geelen

Muelink & Grol

Roof terminal and connection

material

Centrotherm

Cox Geelen

Muelink & Grol

Natalini

Poujoulat

Skoberne

Ubbink

Page 30

AD-3000928-01

AD-3000929-02

AD-3000931-01

6 Installation

30 AMC 7686707 - v.01 - 06092018

Type Principle Description

C

43P

(2)

Combined air supply and flue gas outlet system

(CLV) with overpressure.

Concentric (preferably).

Parallel (if concentric is not possible).

Minimum permitted pressure difference between

the air supply and the flue gas outlet is -200 Pa

(including -100 Pa wind pressure).

The channel must be designed for a nominal

flue gas temperature of 25°C

Place a condensation drain, equipped with a si

phon, at the bottom of the channel.

Maximum permissible recirculation of 10%.

The common outlet should be appropriate for a

pressure of at least 200 Pa.

The roof feed-through must be designed for this

configuration and must cause a draught in the

channel.

A draught diverter is not permitted.

Important

The fan speed must be adapted for

this configuration.

Contact us for more information.

C

53(X)

Connection in different pressure zones

Closed unit.

Separate air supply duct.

Separate flue gas discharge duct.

Discharging into various pressure areas.

The air supply and the flue gas outlet must not

be placed on opposite walls.

Permitted manufacturers

(1)

Connecting material to the

common channel:

Centrotherm

Cox Geelen

Muelink & Grol

Natalini

Poujoulat

Skoberne

Ubbink

Connection material and roof

terminal:

Centrotherm

Cox Geelen

Muelink & Grol

Natalini

Poujoulat

Skoberne

Ubbink

C

C

(3)

63(X)

93(X)

This type of unit is supplied by the manufacturer

without a supply and discharge system.

Room-sealed version

Air supply and flue gas discharge duct in shaft

or ducted:

Concentric.

Air supply from existing duct.

Flue gas discharge via the roof.

Inlet opening for the air supply is in the same

pressure zone as the discharge.

When selecting the material,

please note the following:

Condensed water must flow

back to the appliance

The material must be resist

ant to the flue gas tempera

ture of this appliance.

Maximum permissible recir

culation of 10%.

The air supply and the flue

gas outlet must not be placed

on opposite walls.

Minimum permitted pressure

difference between the air

supply and the flue gas outlet

is -200 Pa (including -100 Pa

wind pressure).

Connection material and roof

terminal:

Centrotherm

Cox Geelen

Muelink & Grol

Natalini

Poujoulat

Skoberne

Ubbink

Page 31

AD-3000959-01

AD-3000930-01

6 Installation

7686707 - v.01 - 06092018 AMC 31

Type Principle Description

C

(10)3(X)

Combined air supply and flue gas outlet system

(CLV) with overpressure

Minimum permitted pressure difference between

the air supply and the flue gas outlet is -200 Pa

(including -100 Pa wind pressure).

The channel must be designed for a nominal

flue gas temperature of 25°C

Place a condensation drain, equipped with a si

phon, at the bottom of the channel.

Maximum permissible recirculation of 10%.

The common outlet should be appropriate for a

pressure of at least 200 Pa.

The roof feed-through must be designed for this

configuration and must cause a draught in the

channel.

A draught diverter is not permitted.

Important

The fan speed must be adapted for

this configuration.

Contact us for more information.