Page 1

ALEZIO

Reversible air / water heat pump "Split Inverter"

AWHP-V220

EN

User Guide

300026802-001-03

Page 2

Contents

1 Introduction ................................................................................................4

1.1 Symbols used .......................................................4

1.1.1 Symbols used in the manual ...................................4

1.1.2 Symbols used on the equipment .............................4

1.2 Abbreviations and lexicon ...................................5

1.3 General ..................................................................5

1.3.1 Manufacturer’s liability .............................................5

1.3.2 Installer’s liability .....................................................5

1.3.3 User’s liability ..........................................................6

2 Safety instructions and recommendations ..............................................7

2.1 Safety instructions ...............................................7

2.2 Recommendations ................................................7

3 Description ..................................................................................................9

3.1 General description ..............................................9

3.2 Main parts ..............................................................9

3.2.1 Inside module with electrical back-up .....................9

3.2.2 Inside module with hydraulic back-up ...................11

3.3 Control panel .......................................................12

3.3.1 Description of the keys ..........................................12

3.3.2 Description of the display ......................................12

3.3.3 Accessing the menus ............................................13

4 Operating the appliance ..........................................................................15

4.1 Starting the heat pump .......................................15

4.2 Shutting down the heat pump ...........................15

4.3 User settings .......................................................15

4.3.1

4.3.2 Modifying the domestic hot water

4.3.3 Changing the operating mode ...............................17

4.3.4 Forcing the additional heating ...............................17

4.3.5 Hybrid operating mode ..........................................18

Modifying the set room temperature d .................16

temperaturer .......................................................16

4.4 Reading out measured values ...........................19

4.4.1 Energy consumption display .................................20

1

23/04/2013 - 300026802-001-03

Page 3

Contents

5 Checking and maintenance .....................................................................22

5.1 General instructions ...........................................22

5.2 Periodic checks ..................................................22

5.3 Top up the installation with water .....................23

5.4 Bleeding the heating system .............................23

5.4.1 Manual venting ......................................................23

5.4.2 Automatic venting ..................................................24

6 Troubleshooting .......................................................................................25

6.1 Error codes ..........................................................25

6.2 Incidents and solutions ......................................26

7 Technical specifications ..........................................................................28

7.1 Technical specifications ....................................28

7.1.1 Heat pump .............................................................28

7.1.2 Domestic hot water tanks ......................................29

8 Energy savings .........................................................................................30

8.1 Energy savings ...................................................30

8.1.1 Energy-saving advice ............................................30

8.1.2 Room thermostat and settings ..............................30

9 Warranty ....................................................................................................31

9.1 General ................................................................31

9.2 Warranty terms ...................................................31

2

23/04/2013 - 300026802-001-03

Page 4

3

23/04/2013 - 300026802-001-03

Page 5

1 2

M002628-A

AWHP-V220

1 Introduction

1.1 Symbols used

1. Introduction

1.1.1. Symbols used in the manual

In these instructions, various danger levels are employed to draw the

user’s attention to particular information. In so doing, we wish to

safeguard the user’s safety, obviate hazards and guarantee correct

operation of the appliance.

DANGER

Risk of a dangerous situation causing serious physical

injury.

WARNING

Risk of a dangerous situation causing slight physical

injury.

CAUTION

Risk of material damage.

Signals important information.

¼Signals a referral to other instructions or other pages in the

instructions.

1.1.2. Symbols used on the equipment

4

~

Protective earthing

Alternating current

Before installing and commissioning the device, read

carefully the instruction manuals provided.

Dispose of the used products in an appropriate recovery

and recycling structure.

23/04/2013 - 300026802-001-03

Caution: danger, live parts.

Disconnect the mains power prior to any operations.

4

Page 6

1. Introduction

1.2 Abbreviations and lexicon

1.3 General

AWHP-V220

4 MIV: Indoor module

4 HP: Heat pump

4 DHW: Domestic hot water

4 Flow temperature: Temperature of the water circulating in the

radiators or in the underfloor heating

4 Ambient temperature: Temperature inside the house or in a room

4 Room temperature setpoint: Temperature programmed in the

control system that must be reached by the heat pump

4 Forced back-up operation: Function enabling the ignition of a

heating system to complement the heat pump in periods of

extreme cold

1.3.1. Manufacturer’s liability

Our products are manufactured in compliance with the requirements

of the various applicable European Directives. They are therefore

delivered with [ marking and all relevant documentation.

In the interest of customers, we are continuously endeavouring to

make improvements in product quality. All the specifications stated in

this document are therefore subject to change without notice.

It is our responsibility to inform customers, in accordance with Article

L. 113-3 of the Consumer Code, of their obligation to have this

equipment installed by a certified operator whenever the refrigerant

load is more than two kilograms or when a refrigerant connection is

necessary (the case with split systems, even when fitted with a quick

coupling device).

Our liability as the manufacturer may not be invoked in the following

cases:

4 Failure to abide by the instructions on using the appliance.

4 Faulty or insufficient maintenance of the appliance.

4 Failure to abide by the instructions on installing the appliance.

1.3.2. Installer’s liability

The installer is responsible for the installation and inital start up of the

appliance. The installer must respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Carry out installation in compliance with the prevailing legislation

and standards.

4 Perform the initial start up and carry out any checks necessary.

5

23/04/2013 - 300026802-001-03

Page 7

AWHP-V220 1. Introduction

4 Explain the installation to the user.

4 If a maintenance is necessary, warn the user of the obligation to

check the appliance and maintain it in good working order.

4 Give all the instruction manuals to the user.

1.3.3. User’s liability

To guarantee optimum operation of the appliance, the user must

respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Call on qualified professionals to carry out installation and initial

start up.

4 Get your installer to explain your installation to you.

4 Have the required checks and services done.

4 Keep the instruction manuals in good condition close to the

appliance.

This appliance is not intended to be used by persons (including

children) whose physcial, sensory or mental capacity is impaired or

persons with no experience or knowledge, unless they have the

benefit, through the intermediary of a person responsible for their

safety, of supervision or prior instructions regarding use of the

appliance. Care should be taken to ensure that children do not play

with the appliance.

To prevent hazardous situations from arising, if the mains lead is

damaged it must be replaced by the original manufacturer, the

manufacturer’s dealer or another suitably skilled person.

23/04/2013 - 300026802-001-03

6

Page 8

2. Safety instructions and recommendations

2 Safety instructions and

recommendations

2.1 Safety instructions

DANGER

If smoke is released or in case of refrigerant leak:

1. Switch the appliance off.

2. Open the windows.

3. Evacuate the premises.

4. Contact a qualified professional.

AWHP-V220

2.2 Recommendations

WARNING

Depending on the settings of the appliance:

4 The temperature of the radiators may reach 90°C.

4 Do not touch the refrigeration connection pipes with

your bare hands while the appliance is running.

Danger of burns or frost injury.

CAUTION

Do not neglect to service the appliance. Contact a qualified

professional or take out a maintenance contract for the

annual servicing of the appliance.

CAUTION

Before any work, switch off the mains supply to the

appliance.

WARNING

Only qualified professionals are authorised to work on the

appliance and the installation.

4 Have regular checks made to ensure that the water pressure in

the installation is between 1.5 and 2 bar.

4 Ensure that the appliance is accessible at all times for

maintenance purposes.

4 Avoid draining the installation.

4 Never remove or cover labels and rating plates affixed to the

appliance. Labels and rating plates must be legible throughout the

entire lifetime of the appliance.

7

23/04/2013 - 300026802-001-03

Page 9

AWHP-V220 2. Safety instructions and recommendations

4 To guarantee the following functions, select the Off/Antifreeze

mode but do not switch off the appliance:

- Anti blocking of pumps

- Antifreeze protection

4 To take advantage of the guarantee, no modifications must be

made to the appliance.

23/04/2013 - 300026802-001-03

8

Page 10

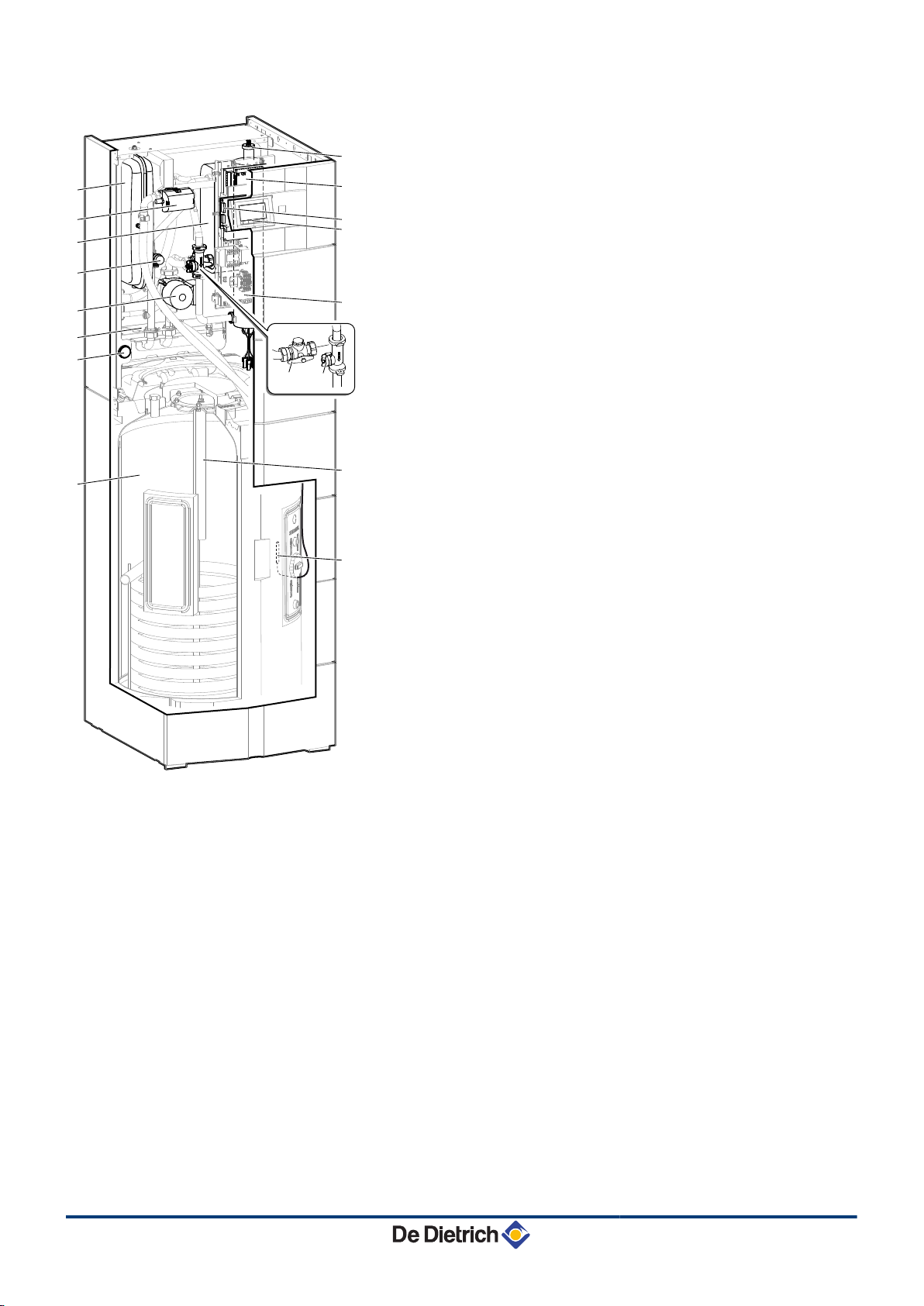

3. Description

3 Description

3.1 General description

AWHP-V220

The ALEZIO V220 heat pump comprises:

4 A reversible outside module for energy production in hot or cold

mode.

4 An inside module with a control panel to handle the thermal

exchange between the R410A fluid and the hydraulic circuit.

The two units are connected by means of refrigeration and electrical

connections.

The inside module handles domestic hot water production.

The system offers the following advantages:

3.2 Main parts

4 The heating circuit is housed in the insulated volume within the

home. There is no danger of the pipes freezing.

4 Thanks to the DC inverter system, the heat pump modulates its

output to adapt to the needs of the home.

4 The control panel uses the outside temperature sensor to adjust

the temperature of the heating circuit according to the outside

temperature.

4 The steel tank is lined with food quality standard enamel vitrified

at 850°C, which protects the tank from corrosion.

4 The coil-shaped heat exchanger welded into the tank is made of

smooth piping, its external surface, which comes into contact with

drinking water, being enamelled.

4 The appliance is insulated by CFC-free polyurethane foam, which

reduces heat losses to a minimum.

4 The outside casing is made of painted steel sheeting.

4 The tank is protected against corrosion by a magnesium anode.

3.2.1. Inside module with electrical back-up

9

23/04/2013 - 300026802-001-03

Page 11

L000243-C

10

12

11

9

13

16

17

5

4

3

2

1

6

7

8

14

15

AWHP-V220 3. Description

Models: MIV-II/EM-ET V220

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Expansion vessel

3-way valve + Motor

Exchanger

Safety valve

Shunt pump

Connection plate

Pressure gauge

DHW tank

Bleed valve

Interface PCB *1

Control system board

Display

Low-loss header with electrical back-up

500 μm filter with isolating valves

Flowmeter

Magnesium anode

DHW sensor

23/04/2013 - 300026802-001-03

10

Page 12

L000244-C

10

12

11

9

13

16

17

5

4

3

2

1

6

7

8

14

15

3. Description AWHP-V220

3.2.2. Inside module with hydraulic back-up

Model: MIV-II/H V220

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Expansion vessel

3-way valve + Motor

Exchanger

Safety valve

Shunt pump

Connection plate

Pressure gauge

DHW tank

Bleed valve

Interface PCB *1

Control system board

Display

Disconnecting cylinder

500 μm filter with isolating valves

Flowmeter

Magnesium anode

DHW sensor

11

23/04/2013 - 300026802-001-03

Page 13

-

)

m

w

r

r

r

d

d

v

c

d

SERVICE

L000308-A

h

j

A B C D

-

m

r

r

ddd

SERVICE

L000309-A

h

j

w

r

v

c

)

AWHP-V220 3. Description

3.3 Control panel

3.3.1. Description of the keys

A

B

C

D

Escape key G

Heating temperature button d or [-]

DHW temperature button r or [+]

S [Enter] Key

3.3.2. Description of the display

Key functions

n

G

d

[-]

r

[+]

®

Back to the previous level without saving the

modifications made.

Central heating function:

Access to the max. heating temperature parameter.

To reduce a value

DHW function:

Access to the heating set point temperature parameter.

To increase a value

Confirmation of the value displayed

or

Access to the selected menu

23/04/2013 - 300026802-001-03

12

Page 14

)

-

m

r

r

ddd

SERVICE

L000310-A

w

r

v

c

h

j

-

m

r

r

d

d

d

SERVICE

L000311-A

w

r

v

c

h

j

)

-

m

r

r

d

d

d

SERVICE

L000312-A

w

r

v

c

h

j

)

-

m

r

r

ddd

SERVICE

L000313-A

A B C D

w

r

v

c

h

j

)

3. Description

n

AWHP-V220

Menus

W

Q

Operating indicators

n

K

a

v

G

w

r

D

a

User menu

Information menu

Installer menu

A manual vent cycle is running / Permanent display of the

Information menu / The screed drying function is active

In stop/antifreeze mode

Compressor on

Electrical or hydraulic back-up running

cooling mode on

DHW mode running

Central heating off

Default active

Forced back-up operation

n

m

d

r

Manual mode

Additional heating

Additional DHW

3.3.3. Accessing the menus

The various menus can be accessed using various key combinations.

1. Press keys C (r) and D simultaneously.

The symbol W flashes.

13

23/04/2013 - 300026802-001-03

Page 15

)

-

m

r

r

ddd

SERVICE

L000314-A

A B C D

w

r

v

c

h

j

AWHP-V220 3. Description

2. Use the B (-) and C (+) keys to scroll through the menus.

3. To confirm, press the D (S) key.

4 Press the key A (G) to exit the menu.

4 If no keys are pressed for 10 seconds, the screen

goes back to the main display without saving the

parameters.

23/04/2013 - 300026802-001-03

14

Page 16

4. Operating the appliance AWHP-V220

4 Operating the appliance

4.1 Starting the heat pump

WARNING

Only a qualified professional may carry out initial start up

or a start up when the heat pump has completely stopped.

When the appliance is switched on, the control panel indicates its

operating mode:

Screen display

r

r + D

w + r

w

/

To modify the operating mode, see chapter:

¼ "Changing the operating mode", page 17.

4.2 Shutting down the heat pump

Operating mode

4 Heating and domestic hot water

4 Swimming pool and domestic hot water

4 Heating

4 Pool

Domestic hot water

Cooling and domestic hot water

Cooling

Shutdown/Frost Protection

WARNING

It is recommended that the heat pump never be completely

shut down.

Antifreeze protection is no longer guaranteed

automatically if the mains supply is switched off.

4.3 User settings

15

If the central heating and the DHW tank are not used for a long period,

we recommend putting the heat pump in shutdown/frost protection

mode.

¼See chapter: "Changing the operating mode", page 17.

In this mode, the installation’s antifreeze protection remains active.

If no buttons are pressed, the settings menus are exited

automatically after 10 seconds, without saving the

parameters.

23/04/2013 - 300026802-001-03

Page 17

)

-

m

r

r

ddd

SERVICE

L000317-A

A C D

w

r

v

c

h

j

B

)

-

m

r

r

ddd

SERVICE

L000318-A

A B C D

w

r

v

c

h

j

)

-

m

r

r

ddd

SERVICE

L000319-A

A C D

w

r

v

c

h

j

B

)

-

m

r

r

ddd

SERVICE

L000320-A

A B C D

w

r

v

c

h

j

AWHP-V220

4. Operating the appliance

4.3.1.

1. Press the B (d) key.

2. Use the B (-) and C (+) keys to modify the value.

Temperature

Room temperature

setpoint

3.

Press the D (®) key to confirm and exit the menu.

Modifying the set room temperature d

Adjustment range Increment Factory

from 15 to 30°C 1 °C 20 °C

When a room thermostat is connected, set the room

thermostat to a value 2 K higher than the room temperature

setpoint d.

setting

4.3.2. Modifying the domestic hot water

temperaturer

1. Press the C (r) key.

2. Use the B (-) and C (+) keys to modify the value.

Temperature

DHW set temperature from 40 to 65°C 1 °C 50 °C

3.

Press the D (®) key to confirm and exit the menu.

Adjustment range Increment Factory setting

23/04/2013 - 300026802-001-03

16

Page 18

)

-

m

r

r

ddd

SERVICE

L000321-A

A B C D

w

r

v

c

h

j

)

-

m

r

r

ddd

SERVICE

L000322-A

A B C D

w

r

v

c

h

j

)

-

m

r

r

ddd

SERVICE

L000323-A

A C D

w

r

v

c

h

j

B

4. Operating the appliance AWHP-V220

4.3.3. Changing the operating mode

1. Press keys C (r) and (D) simultaneously.

The symbol W flashes.

2. To confirm, press the D (S) key.

3. Use the B (-) and C (+) keys to modify the value.

Operating mode

Heating and domestic hot water 1

Heating 2

Domestic hot water 3

Cooling and domestic hot water 4

Cooling 5

Shutdown/Frost Protection 6

Pool 7

Swimming pool and domestic hot water 8

4.

Press the D (®) key to confirm and exit the menu.

Value Screen display

r

+

r

D

+

w

r

w

/

r

4.3.4. Forcing the additional heating

It is impossible to force the additional heating when the off/

antifreeze mode is selected.

It is possible to force use of the additional heating to complement the

heat pump. To force use of the additional heating, perform the

following operations:

1. Press keys A and D simultaneously.

Hold the keys down.

17

23/04/2013 - 300026802-001-03

Page 19

)

-

m

r

r

ddd

SERVICE

L000324-A

A C D

w

r

v

c

h

j

B

)

-

m

r

r

ddd

SERVICE

L000325-A

A B C D

w

r

v

c

h

j

M003105-A

AWHP-V220

4. Operating the appliance

2. Hold the A key down and press the D key successively to choose

the forcing desired.

Display Back-up

+

m

d

+

m

r

+ d +

m

The m symbol disappears from

the display

r

Forcing additional heating for heating

Forcing additional heating for DHW

Forcing additional heating for heating and

DHW

Additional heating forcing deactivated

4.3.5. Hybrid operating mode

CAUTION

The hybrid operating mode is only available for appliances

with hydraulic back-up.

The appliance offers a choice between several hybrid operating

modes. The modes available offer either optimised energy

consumption according to energy cost, or optimised energy

consumption according to primary energy consumption. Both hybrid

operating modes are available via parameter U1. In optimised

primary energy consumption mode, the control system chooses the

generator that consumes the least primary energy. In optimised

energy cost mode, the control system chooses the cheapest

generator according to the coefficient of performance of the heat

pump and according to energy cost.

To access the parameters:

1. Go to the Installer menu .

See chapter: "Accessing the menus", page 13

¼

2. The symbol flashes.

Press the key D (®) to enter the "Installer" menu.

3. Use the B (-)+ and *2 keys to switch from one parameter to

another.

4. Use the B (-) and *2 keys to change the parameter value.

Press the ® key to confirm the setting.

To modify another parameter, repeat the procedure from

step 3.

5. Press the key A (G) to exit the menu.

23/04/2013 - 300026802-001-03

18

Page 20

)

-

m

r

r

ddd

SERVICE

L000315-A

A B C D

w

r

v

c

h

j

4. Operating the appliance

Choosing the hybrid operating mode

n

Parameter Description Adjustment range Increment Factory setting

Hybrid operating mode

0 to 2

1 0

AWHP-V220

(1)

U1

(1) Only available if p3 = 0

4 0 = Off

4 1 = Optimisation of primary energy consumption

4 2 = Optimisation according to energy cost

It is imperative that you input the energy cost parameters

U2 ,U3, U4 to use the hybrid operating mode

optimised according to energy cost.

Energy cost parameters

n

CAUTION

The currency for parameters U2 ,U3, U4 must be the

same. For example: U2 in euro per kWH and U4 in

euro per litre.

Paramters U2, U3 and U4 are available only if U1

= 2

Parameter Description Adjustment range Increment Factory

setting

U2

U3

U4

(1) Only available if p3 = 0

4 For a standard electricity tariff, input parameter U2.

Tariff per kWh of electricity (Off-peak hours)

4 For a Peak Hours / Off-peak Hours electricity tariff, input

(1)

parameters U2 for the Peak Hours tariff and U3 for the

Off-peak Hours tariff.

Fossil energy tariff for the hydraulic back-up.

(1)

4 Gas boiler: Tariff per m3 of gas. For example: €/m

4 Fuel oil fired boiler: Tariff per litre of oil. For example: €/litre

Tariff per kWh of electricity

(1)

3

0.01 to 2.00

0.01 to 2.00

0.01 to 2.50

0.01 0.13

0.01 0.09

0.01 0.9

4.4 Reading out measured values

19

To display the data in the Information menu, proceed as follows:

1. Go to the Information menu Q.

See chapter: "Accessing the menus", page 13

¼

23/04/2013 - 300026802-001-03

Page 21

)

-

m

r

r

ddd

SERVICE

L000316-A

A B C D

w

r

v

c

h

j

AWHP-V220

4. Operating the appliance

2. Use the B (-) and C (+) keys to scroll through the information.

If no buttons are pressed for 10 seconds, the screen goes

back to the main display.

For permanent information display:

When the word SERVICE flashes, press the A (G) and B

(-) keys simultaneously.

The word SERVICE continues to be displayed and no

longer flashes.

3. Press the key A (G) to exit the menu.

If the information SERVICE is not displayed, the screen will

switch back to the main display after 5 seconds.

The following data can be accessed in the information menu:

Parameter

pB

pC

pD

pE

lp

F.jp

Description Unit

4 In heating mode: Heating flow set point temperature

4 In DHW mode: DHW setpoint temperature

4 In cooling mode: Cooling setpoint temperature

4 In swimming pool mode: Pool set temperature

Measured start temperature °C

Domestic hot water temperature measured °C

Outside temperature measured °C

Water flow l/min

Software version

°C

4.4.1. Energy consumption display

Parameter

gB:

gC:

gD:

(1) Display available if the estimated electrical energy consumption function is activated

(2) Cooling mode must be enabled

Description Unit

Estimated consumption of electrical energy in heating mode

Estimated consumption of electrical energy in DHW mode

Estimated consumption of electrical energy in cooling mode

(2)

(1)

(1)

(1)

kWh

kWh

kWh

23/04/2013 - 300026802-001-03

The estimated electricity consumption is displayed in 3 digits. The

fourth digit indicates the scale (x1, x10, x100, x1000).

20

Page 22

)

-

m

r

r

ddd

SERVICE

C004248-A

A B C D

w

r

v

c

h

j

)

-

m

r

r

ddd

SERVICE

C004249-A

A B C D

w

r

v

c

h

j

)

-

m

r

r

ddd

SERVICE

C004250-A

A B C D

w

r

v

c

h

j

)

-

m

r

r

ddd

SERVICE

C004251-A

A B C D

w

r

v

c

h

j

4. Operating the appliance AWHP-V220

Display example Description

The displayed value is 123 kWh. The unit is 1 kWh.

The displayed value is 1230 kWh. The unit is 10 kWh. The fourth digit indicates

the scale x10. Only the first 3 figures are displayed.

The displayed value is 12300 kWh. The unit is 100 kWh. The fourth digit

indicates the scale x100. Only the first 3 figures are displayed.

The displayed value is 123000 kWh. The unit is 1000 kWh. The fourth digit

indicates the scale x1000. Only the first 3 figures are displayed.

21

23/04/2013 - 300026802-001-03

Page 23

T001507-B

AWHP-V220

5 Checking and maintenance

5.1 General instructions

CAUTION

4 An annual inspection is compulsory.

4 We recommend taking out a maintenance contract.

4 Maintenance operations must be done by a qualified

engineer.

4 Only original spare parts must be used.

4 Make certain that the flues and chimneys are

connected, in good condition and not blocked.

4 Do not modify nor block the condensate outlet(s).

4 If a neutralisation system is installed, follow the

instructions delivered with the neutralisation system

for cleaning and servicing of this system.

5. Checking and maintenance

5.2 Periodic checks

WARNING

Only qualified professionals are permitted access to the

inside of the appliance.

If the pressure gauge is not accessible, contact the

installer.

4 Have the installation’s water pressure checked.

If the water pressure is lower than 1 bar, more water should

be added. If necessary, top up the water level in the heating

system (recommended hydraulic pressure between 1,5

and 2,0 bar).

¼See chapter: "Top up the installation with water",

page 23.

4 Carry out a visual check for the presence of any water leaks.

23/04/2013 - 300026802-001-03

22

Page 24

1

2

3

4

T000181-B

1

2

3

4

T000181-B

1

2

3

4

T000181-B

5. Checking and maintenance

4 Open and close the radiator valves several times a year (this

prevents the valves from seizing up).

4 Clean the outside of the heat pump using a damp cloth and a mild

detergent.

5.3 Top up the installation with water

If necessary, top up the water level in the heating system

(recommended hydraulic pressure between 1.5 and 2 bar).

1. Open the valves on all radiators connected to the heating system.

2. Set the room thermostat to as low a temperature as possible.

3. Put the heat pump in shutdown/frost protection mode.

See chapter: "Changing the operating mode", page 17.

¼

4. Open the filling valve .

5. Close the filling valve when the pressure gauge shows a pressure

of 1,5 bar.

6. Put the heat pump in heating mode.

See chapter: "Changing the operating mode", page 17.

¼

7. When the pump has stopped, bleed again and top up the water

pressure.

AWHP-V220

CAUTION

Only qualified professionals are permitted to clean the

inside of the appliance.

5.4 Bleeding the heating system

It is essential that you bleed any air in the calorifier, the conduits or

the taps to prevent the annoying noises likely to be produced during

heating or when tapping water.

5.4.1. Manual venting

1. Open the valves on all radiators connected to the heating system.

2. Put the heat pump in shutdown/frost protection mode.

Filling and bleeding the installation 2 times a year should

be sufficient to obtain an adequate hydraulic pressure. If it

is often necessary to top up the installation with water,

contact your fitter.

See chapter: "Changing the operating mode", page 17

¼

23

23/04/2013 - 300026802-001-03

Page 25

M001495-A

11

22

)

-

m

r

r

ddd

SERVICE

A000917-A

A C D

w

r

v

c

h

j

B

AWHP-V220 5. Checking and maintenance

3. Vent the underfloor heating circuits and the radiators. First vent

the lower floors A and then the upper floors Z.

5.4.2. Automatic venting

The heat pump runs an automatic venting cycle when it is powered

up. Automatic venting takes approximately one minute.

Automatic venting starts up only if the measured DHW

temperature is lower than 25°C.

It is possible to extend automatic venting manually to run for more

than one minute:

1. The word SERVICE flashes when powering up. Press A and B

(d)-keys simultaneously.

An automatic venting cycle begins. The word SERVICE stops

flashing .

2. Press the A and B (d) keys simultaneously to stop the venting

cycle.

¼Consult the installer for more detailed information.

WARNING

After venting, have the installation’s pressure checked.

Top up with water if necessary.

23/04/2013 - 300026802-001-03

24

Page 26

6. Troubleshooting AWHP-V220

6 Troubleshooting

6.1 Error codes

In the event of problems, the control panel displays the symbol a and

an error code.

WARNING

Make a note of the code displayed.

The error code is important for the correct and rapid

diagnosis of the type of malfunction and for any technical

assistance from your installer.

4 To go back to the main display, press the ® button.

4 The symbol a continues to be displayed as long as the error is

present.

4 Browsing is possible in all menus.

Error

codes

err

e[1

e[2

e[3

e[4

e[5

Description Probable causes Checking / solution

Configuration error

flow sensor failure

Outside temperature sensor

fault

The heat pump continues to

operate at maximum

temperature.

Domestic hot water sensor fault

Flow rate fault

Fault on the outdoor module

4 The control system mode is not

compatible with the configuration of the

installer parameters.

4 Sensor defective

4 Sensor not or badly connected

4 Sensor defective

4 Sensor not or badly connected

4 Sensor defective

4 Sensor not or badly connected.

4 The water level and/or pressure are too

low

4 Too much air

4 Fault on the outdoor module 4 Contact the fitter.

4 Contact the fitter.

4 Contact the fitter.

4 Contact the fitter.

4 Contact the fitter.

4 Check the water pressure in

the installation (Pressure

gauge)

4 Completely vent the indoor

module and the installation for

optimum functioning.

25

23/04/2013 - 300026802-001-03

Page 27

AWHP-V220 6. Troubleshooting

6.2 Incidents and solutions

Problem Probable causes Solution

The radiators are cold.

There is no domestic hot

water.

Significant variations in

domestic hot water

temperature

The heat pump is not

working.

The water pressure is too

low (< 1 bar).

The heating temperature

setting is too low.

The heating mode is

deactivated.

The radiator valves are closed.

The heat pump is not operating.

The water pressure is too low (<

1 bar).

The DHW temperature setting

is too low.

The domestic hot water mode is

deactivated.

The energy-saving shower

head is restricting the water

flow.

The heat pump is not operating.

The water pressure is too low (<

1 bar).

Insufficient water supply

The heating temperature

setting is too low.

The heat pump is not operating.

The water pressure is too low (<

1 bar).

An error code appears on the

display.

Not enough water in the

installation.

Water leak.

4 Increase the value of parameter d or, if a room thermostat

is connected, increase the temperature.

¼See chapter: "Modifying the set room

temperature d", page 16.

4 Activate the heating mode.

¼See chapter: "Changing the operating mode",

page 17.

4 Open the valves on all radiators connected to the heating

system.

4 Check that the heat pump is switched on.

4 Check the fuses and switches on the electrical installation.

4 Top up the installation with water.

¼See chapter: "Top up the installation with

water", page 23.

4 Increase the value of parameter r.

¼See chapter: "Modifying the domestic hot water

temperaturer", page 16.

4 Activate the DHW mode.

¼See chapter: "Changing the operating mode",

page 17.

4 Clean the shower head; replace if necessary.

4 Check that the heat pump is switched on.

4 Check the fuses and switches on the electrical installation.

4 Top up the installation with water.

¼See chapter: "Top up the installation with

water", page 23.

4 Check the water pressure in the installation.

4 Open the valve.

4 Increase the value of parameter d or, if a room thermostat

is connected, increase the temperature.

¼See chapter: "Modifying the set room

temperature d", page 16

4 Check that the boiler is switched on.

4 Check the fuses and switches on the electrical installation.

4 Top up the installation with water.

¼See chapter: "Top up the installation with

water", page 23.

4 Correct the error if possible.

¼See chapter: "Error codes", page 25.

4 Top up the installation with water.

¼See chapter: "Top up the installation with

water", page 23.

4 Contact the fitter.

23/04/2013 - 300026802-001-03

26

Page 28

6. Troubleshooting AWHP-V220

Problem Probable causes Solution

The central heating pipe

connections are too tight.

There is air in the heating pipes.

Clicking in the central heating

pipes

4 Contact the fitter.

4 It is essential that you bleed any air in the calorifier, the

conduits or the taps to prevent the annoying noises likely to

be produced during heating or when tapping water.

¼See chapter: "Bleeding the heating system",

page 23

Significant water leak

underneath or in the vicinity

of the heat pump

The water is circulating too

quickly in the central heating

system.

The pipes on the heat pump or

the central heating are

damaged.

4 Contact the fitter.

4 Contact the fitter.

27

23/04/2013 - 300026802-001-03

Page 29

AWHP-V220 7. Technical specifications

7 Technical specifications

7.1 Technical specifications

7.1.1. Heat pump

Conditions of use:

4 Limit operating temperatures in Hot mode:

- Water: +18 °C / +55 °C

- Outside air: -15 °C / +35 °C

4 Limit operating temperatures in Cooling mode:

- Water: +18 °C / +25 °C

- Outside air: +15 °C / +40 °C

4 Maximum operating pressure: 3 bar

AWHP-V220

Calorific output

Performance coefficient (COP)

Absorbed electrical power

Nominal amperage

Calorific output

Performance coefficient (COP)

Absorbed electrical power

Cooling output

Energy efficiency ratio (EER)

Absorbed electrical power

Sound pressure

Nominal water flow (ΔT = 5K)

Manometric height available at

nominal flow rate

Nominal air flow rate

Power voltage of the outdoor unit V 230 V~ 230 V~ 230 V~ 230 V~ 400 V3~ 230 V~ 400 V3~ 230 V~ 400 V3~

Start-up amperage A 5 5 5 5. 3 5 3 6 3

Sound output - Inside

Sound output - Outside

R410A refrigerant kg 2.1 2.5 3.6 5 5 5 5 5 5

Refrigeration connection (LiquidGas)

(1) Hot mode: Outside air temperature +7 °C, Water temperature at the outlet +35 °C. Performances in line with EN 14511-2.

(2) Hot mode: Outside air temperature +2 °C, Water temperature at the outlet +35 °C. Performances in line with EN 14511-2.

(3) Only in reversible versions

(4) Cooling mode: Outside air temperature +35 °C, Water temperature at the outlet +18 °C. Performances in line with EN 14511-2

(5) 5 m from the appliance, free field.

(6) Noise spread by the envelope - Test conducted in accordance with the standard NF EN 12102

(1)

(1)

(1)

(2)

(2)

(3)

(4)

(5)

(6)

(6)

kW 4.1 5.73 8.08 10.87 10.37 13.07 13.07 14.95 14.95

(1)

kWe 0.95 1.46 2.00 2.57 2.50 3.31 3.31 3.91 3.91

A 4.3 6.8 9.3 11.2 6.7 14.8 8.8 17.7 10.1

kW 4 4.45 5.93 7.57 7.57 10.32 10.32 10.38 10.38

(2)

kWe 1.23 1.43 1.90 2.46 2.46 3.37 3.37 3.36 3.36

kW 3.60 5.40 7.94 10.48 10.48 11.74 11.74 11.70 11.70

(4)(3)

kWe 0.77 1.40 1.99 2.24 2.24 2.65 2.65 2.70 2.70

dB(A) 36 36 36 40 40 41 41 41 41

m3/h

mbar 450 400 200 300 300 120 120 - -

m3/h

dB(A) 43.2 43.2 40.4 38.2 38.2 40.2 40.2 43.4 43.4

dB(A) 63.7 63.7 65.2 65.4 65.4 66.8 66.8 69.4 69.4

inch 1/4-1/2 1/4-1/2 3/8-5/8 3/8-5/8 3/8-5/8 3/8-5/8 3/8-5/8 3/8-5/8 3/8-5/8

4 MR 6 MR 8 MR 11 MR 11 TR 14 MR 14 TR 16 MR 16 TR

4.3 3.93 4.03 4.23 4.15 3.95 3.95 3.82 3.82

3.2 3.12 3.12 3.10 3.10 3.10 3.10 3.10 3.10

4.65 3.80 3.99 4.68 4.68 4.43 4.43 4.40 4.40

0.71 1.04 1.47 1.88 1.88 2.36 2.36 2.67 2.67

2100 2100 3000 6000 6000 6000 6000 6000 6000

23/04/2013 - 300026802-001-03

28

Page 30

7. Technical specifications AWHP-V220

AWHP-V220 4 MR 6 MR 8 MR 11 MR 11 TR 14 MR 14 TR 16 MR 16 TR

Max pre-loaded length m 30 30 30 30 30 30 30 30 30

Weight (empty) - Outside module kg 45 45 75 121 135 116 130 116 130

Weight (empty) - Indoor module kg 35 35 35 37 37 37 37 37 37

(1) Hot mode: Outside air temperature +7 °C, Water temperature at the outlet +35 °C. Performances in line with EN 14511-2.

(2) Hot mode: Outside air temperature +2 °C, Water temperature at the outlet +35 °C. Performances in line with EN 14511-2.

(3) Only in reversible versions

(4) Cooling mode: Outside air temperature +35 °C, Water temperature at the outlet +18 °C. Performances in line with EN 14511-2

(5) 5 m from the appliance, free field.

(6) Noise spread by the envelope - Test conducted in accordance with the standard NF EN 12102

7.1.2. Domestic hot water tanks

Technical specifications

Primary circuit (Heating water) Maximum operating temperature °C 85

Maximum operating pressure bar 3

Exchanger capacity L 14

Exchange surface

2

1.7

m

Secondary circuit (domestic water) Maximum operating temperature °C 70

Maximum operating pressure bar 10

Water content L 220

Weight

Shipping weight kg 112

Domestic hot water tank loading time

AWHP-V220 4 MR 6 MR 8 MR 11 MR - 11 TR 14 MR - 14 TR 16 MR - 16 TR

(1)

Heating time

(1) ΔT = 40 K. Outside air temperature: 7 °C. Inside air temperature: 20 °C

2 h 39 min 1 h 42 min 1 h 25 min 1 h 19 min 1 h 16 min 1 h 14 min

29

23/04/2013 - 300026802-001-03

Page 31

AWHP-V220

8 Energy savings

8.1 Energy savings

8. Energy savings

This chapter contains:

4 Energy-saving advice

4 Advice on setting the room thermostat correctly

8.1.1. Energy-saving advice

4 Do not block ventilation outlets.

4 Install reflective panels behind the radiators to prevent heat

losses.

4 Do not cover the radiators. Do not hang curtains in front of the

radiators.

4 Insulate the pipes in rooms that are not heated (cellars and lofts).

4 Close the radiators in rooms not in use.

4 Do not run hot (or cold) water pointlessly.

4 Install a water-saving shower head to save up to 40 % energy.

4 Take showers rather than baths. A bath consumes twice as much

water and energy.

8.1.2. Room thermostat and settings

4 A modulating thermostat, possibly in combination with

thermostatic valve radiators, saves energy and offers

considerable comfort. This combination allows you to set the

temperature on each flow. In the room in which the room

thermostat is installed, do not fit thermostatic valve radiators.

4 Lower the thermostat to approximately 16°C at night or when you

are absent. This reduces heating costs and energy consumption.

4 Lower the room thermostat when you air the rooms.

4 When setting an hourly programmable thermostat, keep in mind

the days you are absent or on vacation.

23/04/2013 - 300026802-001-03

30

Page 32

9. Warranty

9 Warranty

9.1 General

9.2 Warranty terms

AWHP-V220

You have just purchased one of our appliances and we thank you for

the trust you have placed in our products.

Please note that your appliance will provide good service for a longer

period of time if it is regularly checked and maintained.

Your fitter and our customer support network are at your disposal at

all times.

The following provisions are not exclusive of the buyer being able

benefit from the legal provisions applicable regarding hidden defects

in the buyer’s country.

Starting from the purchase date shown on the original fitter’s invoice,

your appliance has a contractual guarantee against any

manufacturing defect.

The length of the guarantee is mentioned in the price catalogue.

The manufacturer is not liable for any improper use of the appliance

or failure to maintain or install the unit correctly (the user shall take

care to ensure that the system is installed by a qualified engineer).

In particular, the manufacturer shall not be held responsible for any

damage, loss or injury caused by installations which do not comply

with the following:

4 applicable local laws and regulations,

4 specific requirements relating to the installation, such as national

and/or local regulations,

4 the manufacturer’s instructions, in particular those relating to the

regular maintenance of the unit,

4 the rules of the profession.

The warranty is limited to the exchange or repair of such parts as have

been recognised to be faulty by our technical department and does

not cover labour, travel and carriage costs.

The warranty shall not apply to the replacement or repair of parts

damaged by normal wear and tear, negligence, repairs by unqualified

parties, faulty or insufficient monitoring and maintenance, faulty

power supply or the use of unsuitable fuel.

31

Sub-assemblies such as motors, pumps, electric valves etc. are

guaranteed only if they have never been dismantled.

The legislation laid down by european directive 99/44/EEC,

transposed by legislative decree No. 24 of 2 February 2002 published

in O.J. No. 57 of 8 March 2002, continues to apply.

23/04/2013 - 300026802-001-03

Page 33

AWHP-V220 9. Warranty

23/04/2013 - 300026802-001-03

32

Page 34

Page 35

Page 36

AD001NU-Ai

DUEDI S.r.l.

DE DIETRICH SERVICE

BDR Thermea (Czech republic) s.r.o

www.duediclima.it

www.dedietrich.cz

Distributore Ufficiale Esclusivo

De Dietrich-Thermique Italia

www.dedietrich-heiztechnik.com

Freecall 0800 / 201608

Jeseniova 2770/56

130 00 Praha 3

+49 (0)25 72 / 9161-0

+49 (0)25 72 / 9161-102

info@remeha.de

Via Passatore, 12 - 12010

San Defendente di Cervasca

CUNEO

+39 0171 857170

+39 0171 687875

info@duediclima.it

+420 271 001 627

info@dedietrich.cz

IT

DE DIETRICH THERMIQUE Iberia S.L.U.

www.dedietrich-calefaccion.es

Av. Princep d’Astúries 43-45

08012 BARCELONA

+34 932 920 520

+34 932 184 709

ES

129164, Россия, г. Москва

Зубарев переулок, д. 15/1

Бизнес-центр «Чайка Плаза»,

офис 309

+7 (495) 221-31-51

CZ

DE DIETRICH THERMIQUE S.A.S

M001476-C

R410AR410A

300026802- 001-03

DEDIETRICH THERMIQUE

57,ruedelaGareF-67580MERTZWILLER-BP 30

© Copyright

All technical and technological information contained in these technical instructions,

as well as any drawings and technical descriptions supplied, remain our property

and shall not be multiplied without our prior consent in writing.

23/04/2013

Loading...

Loading...