Page 1

Modulens

Gas fired floor-standing condensing boiler

AGC 10/15

AGC 15

AGC 25

AGC 35

EN

User Guide

300026080-001-03

Page 2

Contents

1 Introduction ................................................................................................4

1.1 Symbols used .......................................................4

1.1.1 Symbols used in the manual ...................................4

1.1.2 Symbols used on the equipment .............................4

1.2 Abbreviations ........................................................5

1.3 General ..................................................................5

1.3.1 Manufacturer’s liability .............................................5

1.3.2 Installer’s liability .....................................................6

1.3.3 User’s liability ..........................................................6

1.4 Certifications .........................................................6

2 Safety instructions and recommendations ..............................................7

2.1 Safety instructions ...............................................7

2.2 Recommendations ................................................8

3 Description ..................................................................................................9

3.1 Operating principle ...............................................9

3.1.1 Gas/air setting .........................................................9

3.1.2 Combustion .............................................................9

3.2 Main parts ............................................................10

3.3 Control panel .......................................................11

3.3.1 Description of the keys ..........................................11

3.3.2 Description of the display ......................................12

3.3.3 Browsing in the menus ..........................................15

4 Operating the appliance ..........................................................................16

4.1 Putting the appliance into operation ................16

4.2 Reading out measured values ...........................16

4.3 Changing the settings ........................................18

4.3.1 Setting the set point temperatures ........................18

4.3.2 Selecting the operating mode ...............................19

4.3.3 Forcing domestic hot water production .................20

4.3.4 Setting the contrast and lighting on the

display ...................................................................20

4.3.5 Setting the time and date ......................................21

4.3.6 Selecting a timer programme ................................21

4.3.7 Customising a timer programme ...........................22

1

03/12/2013 - 300026080-001-03

Page 3

Contents

4.4 Installation shutdown .........................................24

4.5 Antifreeze protection ..........................................24

5 Checking and maintenance .....................................................................26

5.1 General instructions ...........................................26

5.2 Periodic checks ..................................................26

6 Troubleshooting .......................................................................................28

6.1 Anti-hunting ........................................................28

6.2 Messages (Code type Bxx or Mxx) ....................28

6.3 Faults (Code type Lxx or Dxx) ...........................30

7 Technical specifications ..........................................................................36

7.1 Technical specifications ....................................36

8 Energy savings .........................................................................................38

8.1 Energy-saving advice .........................................38

8.2 Recommendations ..............................................38

9 Warranty ....................................................................................................39

9.1 General ................................................................39

9.2 Warranty terms ...................................................39

2

03/12/2013 - 300026080-001-03

Page 4

3

03/12/2013 - 300026080-001-03

Page 5

D000241-C

AGC 10/15 AGC 15 AGC 25 AGC 35

1 Introduction

1.1 Symbols used

1. Introduction

1.1.1. Symbols used in the manual

In these instructions, various danger levels are employed to draw the

user’s attention to particular information. In so doing, we wish to

safeguard the user’s safety, obviate hazards and guarantee correct

operation of the appliance.

DANGER

Risk of a dangerous situation causing serious physical

injury.

WARNING

Risk of a dangerous situation causing slight physical

injury.

CAUTION

Risk of material damage.

Signals important information.

¼Signals a referral to other instructions or other pages in the

instructions.

1.1.2. Symbols used on the equipment

4

~

Protective earthing

Alternating current

Before installing and commissioning the device, read

carefully the instruction manuals provided.

Dispose of the used products in an appropriate recovery

and recycling structure.

03/12/2013 - 300026080-001-03

This appliance must be connected to the protective earth.

4

Page 6

1 2

M002628-A

1. Introduction

1.2 Abbreviations

AGC 10/15 AGC 15 AGC 25 AGC 35

Caution: danger, live parts.

Disconnect the mains power prior to any operations.

4 3CE: Collective conduit for sealed boiler

4 DHW: Domestic hot water

4 Interscenario switch: Home automation switch that can be used

to centralise and control several scenarios

4 Hi: Lower heating value LHV (Nett)

4 Hs: Higher heating value HHV (Gross)

4 PPS: Polypropylene hardly inflammable

4 PCU: Primary Control Unit - PCB for managing burner operation

4 PSU: Parameter Storage Unit - Parameter storage for PCBs

PCU and SU

4 SCU: Secondary Control Unit - control panel PCB

4 SU: Safety Unit - Safety PCB

4 3WV: 3-way valve

4 HL: High Load - DHW tank with plate exchanger

4 SL: Standard Load - DHW tank with coil

4 SHL: Solar High Load - Solar DHW tank with plate exchanger

4 SSL: Solar Standard Load - Solar DHW tank with coil

1.3 General

1.3.1. Manufacturer’s liability

Our products are manufactured in compliance with the requirements

of the various applicable European Directives. They are therefore

delivered with [ marking and all relevant documentation.

In the interest of customers, we are continuously endeavouring to

make improvements in product quality. All the specifications stated in

this document are therefore subject to change without notice.

Our liability as the manufacturer may not be invoked in the following

cases:

4 Failure to abide by the instructions on using the appliance.

4 Faulty or insufficient maintenance of the appliance.

4 Failure to abide by the instructions on installing the appliance.

5

03/12/2013 - 300026080-001-03

Page 7

AGC 10/15 AGC 15 AGC 25 AGC 35 1. Introduction

1.3.2. Installer’s liability

The installer is responsible for the installation and inital start up of the

appliance. The installer must respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Carry out installation in compliance with the prevailing legislation

and standards.

4 Perform the initial start up and carry out any checks necessary.

4 Explain the installation to the user.

4 If a maintenance is necessary, warn the user of the obligation to

check the appliance and maintain it in good working order.

4 Give all the instruction manuals to the user.

1.3.3. User’s liability

To guarantee optimum operation of the appliance, the user must

respect the following instructions:

1.4 Certifications

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Call on qualified professionals to carry out installation and initial

start up.

4 Get your installer to explain your installation to you.

4 Have the required checks and services done.

4 Keep the instruction manuals in good condition close to the

appliance.

This appliance is not intended to be used by persons (including

children) whose physcial, sensory or mental capacity is impaired or

persons with no experience or knowledge, unless they have the

benefit, through the intermediary of a person responsible for their

safety, of supervision or prior instructions regarding use of the

appliance. Care should be taken to ensure that children do not play

with the appliance.

To prevent hazardous situations from arising, if the mains lead is

damaged it must be replaced by the original manufacturer, the

manufacturer’s dealer or another suitably skilled person.

03/12/2013 - 300026080-001-03

CE identification no

NOx classification

Type of connection Chimney: B23, B

CE-0085CM0178

5 (EN 297 pr A3, EN 483)

Flue gas outlet: C

C

93(x)

33

13(x)

, C

33(x)

, C

43(x)

, C53, C

83(x)

,

6

Page 8

2. Safety instructions and recommendations AGC 10/15 AGC 15 AGC 25 AGC 35

2 Safety instructions and

recommendations

2.1 Safety instructions

DANGER

If you smell gas:

1. Do not use a naked flame, do not smoke, do not

operate electrical contacts or switches ( doorbell,

light, motor, lift, etc..).

2. Shut off the gas supply.

3. Open the windows.

4. Evacuate the premises.

5. Call your fitter.

DANGER

If you smell flue gases:

1. Switch the appliance off.

2. Open the windows.

3. Evacuate the premises.

4. Call your fitter.

WARNING

Depending on the settings of the appliance:

4 The temperature of the flue gas conduits may exceed

60°C.

4 The temperature of the radiators may reach 85°C.

4 The temperature of the domestic hot water may reach

65°C.

CAUTION

Do not neglect to service the appliance:

4 For completely safe and optimum operation, you

must have your boiler regularly serviced by an

approved installer.

7

03/12/2013 - 300026080-001-03

Page 9

AGC 10/15 AGC 15 AGC 25 AGC 35 2. Safety instructions and recommendations

2.2 Recommendations

WARNING

Only qualified professionals are authorised to work on the

appliance and the installation.

4 Regularly check the water pressure in the installation (minimum

pressure 0.8 bar, recommended pressure between 0.08 and 1.5

bar).

4 Keep the appliance accessible at all times.

4 Never remove or cover labels and rating plates affixed to the

appliance. Labels and rating plates must be legible throughout the

entire lifetime of the appliance.

4 The appliance should be on Summer or Antrifreeze mode rather

than switched off to guarantee the following functions:

- Anti blocking of pumps

- Antifreeze protection

03/12/2013 - 300026080-001-03

8

Page 10

3. Description AGC 10/15 AGC 15 AGC 25 AGC 35

3 Description

3.1 Operating principle

3.1.1. Gas/air setting

Air is sucked in by the fan and the gas injected into the venturi

attached to the fan inlet. The fan rotation speed modulates and adapts

to thermal energy requirements thanks to the temperatures measured

by the various sensors. The gas and air are mixed in the venturi, which

enables operation at a constant ratio. The noise of the venturi is

absorbed by a silencer attached to its inlet. The gas/air mixture is

carried to the burner in the top of the exchanger, guided by the premix channel.

3.1.2. Combustion

The burner heats the heating water circulating in the heat

exchanger. At a return temperature lower than around 55°C, the flue

gases cool down to a temperature lower than the dew point, thus

causing the condensation of the water vapour contained in the flue

gases in the lower section of the heat exchanger. The heat released

during this condensation process (the latent heat or condensing heat)

is also transferred to the heating water. The cooled combustion gases

are evacuated via the combustion gas outlet flue. The condensation

water is evacuated via a siphon.

9

03/12/2013 - 300026080-001-03

Page 11

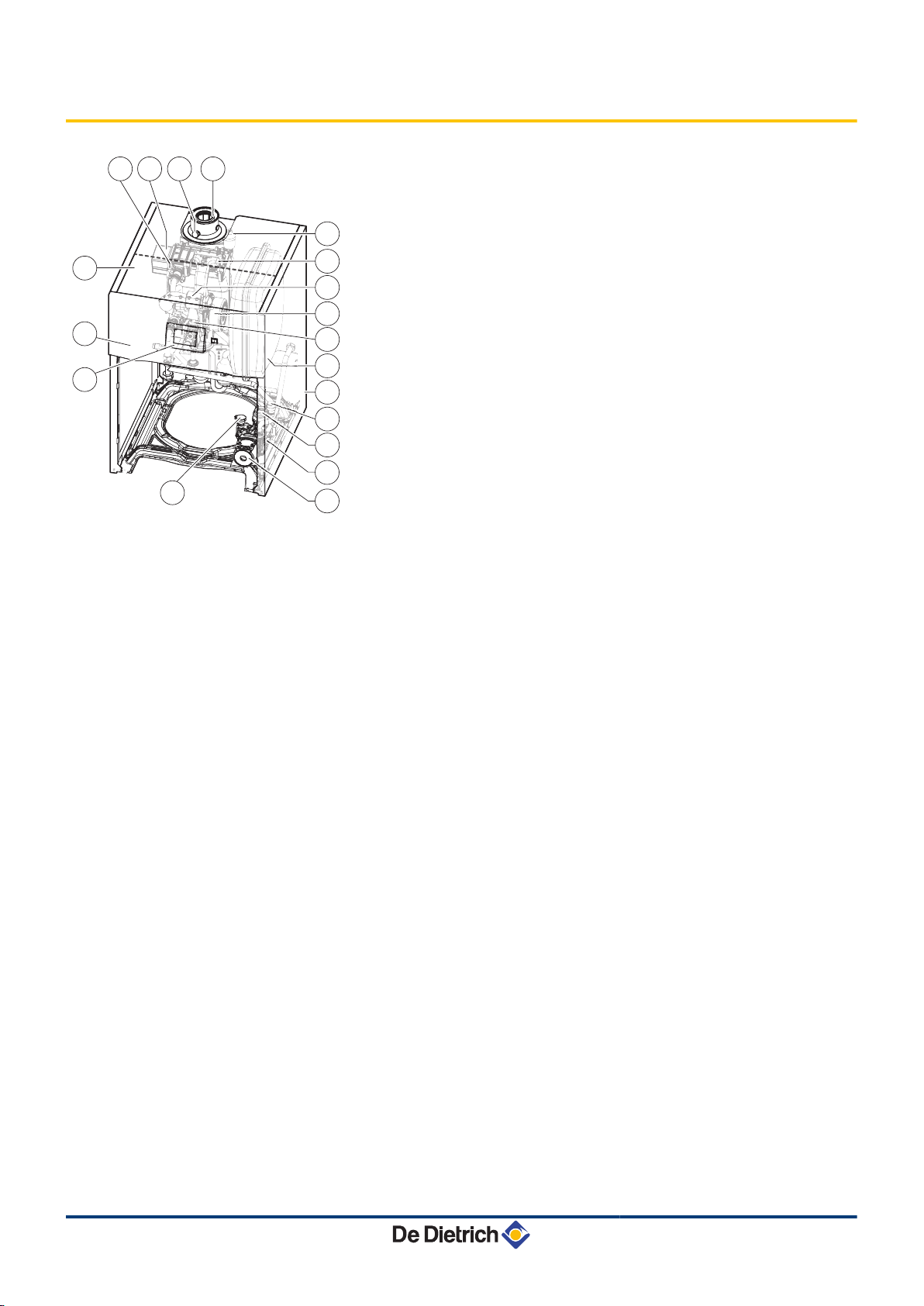

C003072-C

18

19

16

17

15

14

13

12

11

1234

10

9

5

6

7

8

AGC 10/15 AGC 15 AGC 25 AGC 35 3. Description

3.2 Main parts

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Flue gas discharge pipe

Flue gas measuring point

Heat exchanger

Ignition/ionization electrode

Box for the control PCBs

Control panel

Command module

Water pressure sensor

Circulation pump

Hydroblock

3-way valve

Safety valve

Casing

Expansion vessel

Combined venturi and gas valve unit

Fan

Air intake silencer

18

19

Mixer pipe

Automatic air vent

03/12/2013 - 300026080-001-03

10

Page 12

A000866-A

bar

STD

t

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

A

B

C

D

E

F

(

'

3. Description AGC 10/15 AGC 15 AGC 25 AGC 35

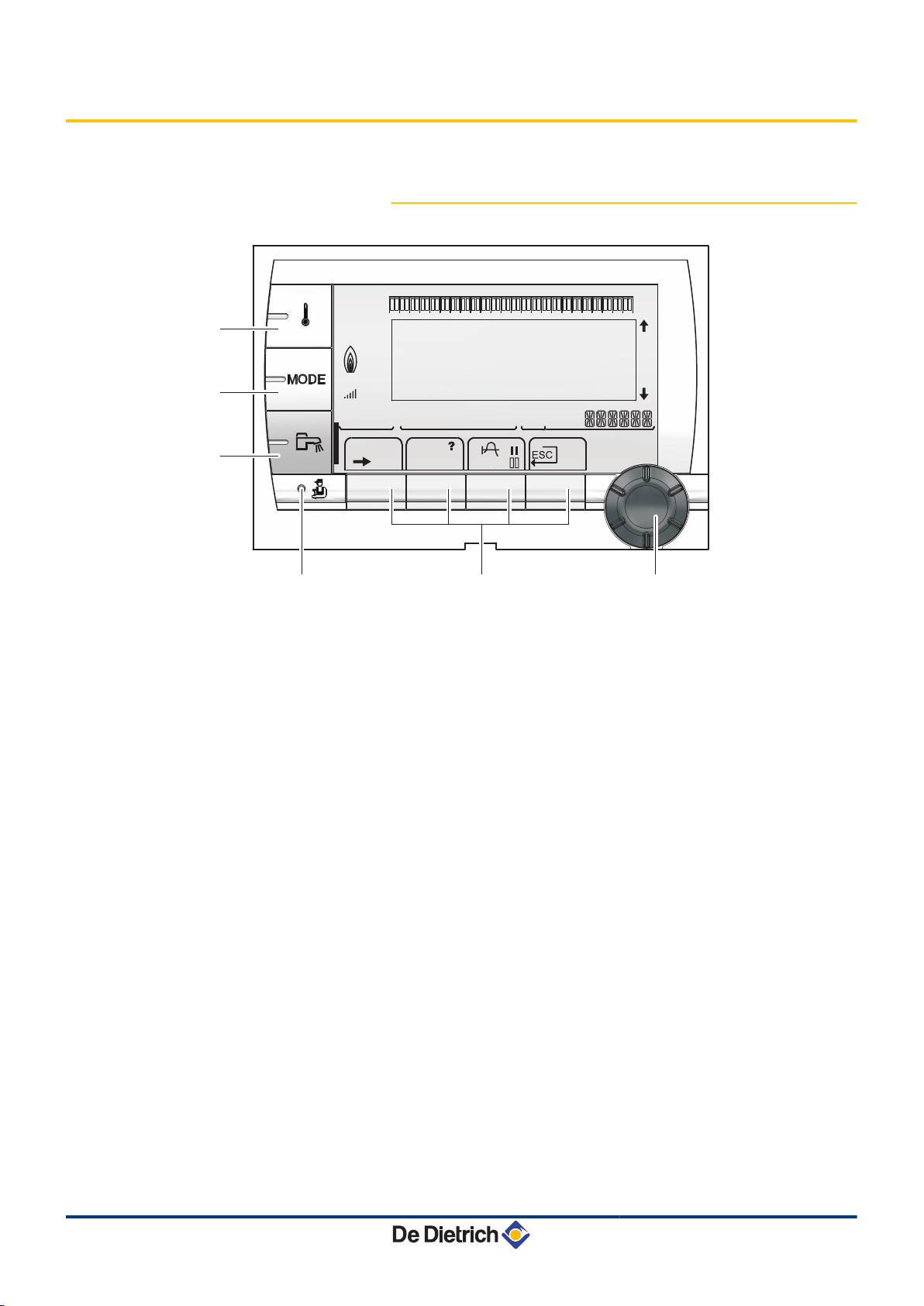

3.3 Control panel

3.3.1. Description of the keys

A

B

C

D

E

F

Temperature setting key (heating, DHW, swimming pool)

Operating mode selection key

DHW override key

Key to access the parameters reserved for the installer

Keys on which the function varies as and when selections

are made

Rotary setting button:

4 Turn the rotary button to scroll through the menus or

modify a value

4 Press the rotary button to access the selected menu

or confirm a value modification

11

03/12/2013 - 300026080-001-03

Page 13

C002705-A

C002704-A

C002703-A

C002702-A

bar

r

STD

(

'

t

0 2 4 6 8 10 12 14 16 18 22 2420

C002696-A

p

b

AUTO

x

c

r

j

L

g

m

bar

STD

t

0 2 4 6 8 10 12 14 16 18 22 2420

C002701-B

p

b

AUTO

x

c

r

j

M

g

m

AGC 10/15 AGC 15 AGC 25 AGC 35 3. Description

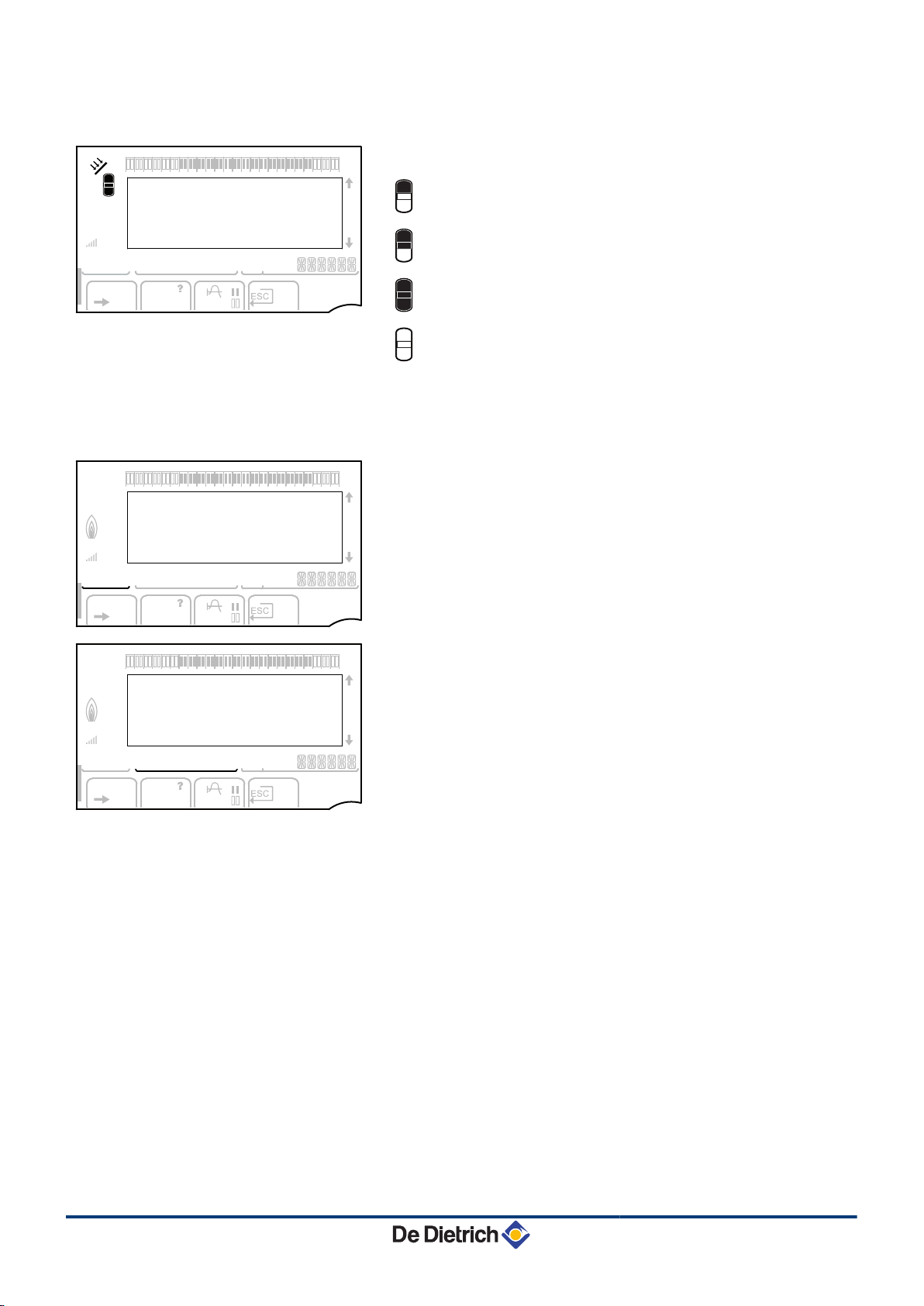

3.3.2. Description of the display

Key functions

n

>

(

’

?

f

STD

b

Access to the various menus

Used to scroll through the menus

Used to scroll through the parameters

The symbol is displayed when help is available

Used to display the curve of the parameter selected

Reset of the time programmes

Selection of comfort mode or selection of the days to be

programmed

v

Selection of reduced mode or deselection of the days to

be programmed

j

ESC

Back to the previous level

Back to the previous level without saving the

modifications made

t

Flame output level

n

Manual reset

The whole symbol flashes: The burner starts up but the

flame is not yet present

Part of the symbol flashes: Output is increasing

Steady symbol: The required output has been reached

Part of the symbol flashes: Output is dropping

03/12/2013 - 300026080-001-03

12

Page 14

L000200-A

L000201-A

L000198-A

L000199-A

bar

STD

t

0 2 4 6 8 10 12 14 16 18 22 2420

L000197-A

p

b

AUTO

x

c

r

j

M

g

m

bar

STD

t

0 2 4 6 8 10 12 14 16 18 22 2420

C002697-B

p

b

AUTO

x

c

r

j

M

g

m

bar

STD

t

0 2 4 6 8 10 12 14 16 18 22 2420

C002698-B

p

b

AUTO

x

c

r

j

M

g

m

3. Description AGC 10/15 AGC 15 AGC 25 AGC 35

Solar (If connected)

n

u

The solar load pump is running

The top part of the tank is reheated to the tank set point

The entire tank is reheated to the tank set point

The entire tank is reheated to the solar tank set point

The tank is not loaded - Presence of the solar control

system

Operating modes

n

p

Summer mode: The heating is off. Domestic hot water

continues to be produced

b

WINTER mode: Heating and domestic hot water working

AUTO

x

m

g

m

Operation in automatic mode according to the timer

programme

Comfort mode: The symbol is displayed when a DAY

override (comfort) is activated

4 Flashing symbol: Temporary override

4 Steady symbol: Permanent override

Reduced mode: The symbol is displayed when a NIGHT

override (reduced) is activated

4 Flashing symbol: Temporary override

4 Steady symbol: Permanent override

Holiday mode: The symbol is displayed when a HOLIDAY

override (antifreeze) is activated

4 Flashing symbol: Holiday mode programmed

4 Steady symbol: Holiday mode active

Manual mode: The boiler operates with the displayed set

point. All of the pumps operate. The 3-way valves are not

controlled.

13

03/12/2013 - 300026080-001-03

Page 15

bar

STD

t

0 2 4 6 8 10 12 14 16 18 22 2420

C002708-A

p

b

AUTO

x

c

r

j

M

g

m

bar

STD

t

0 2 4 6 8 10 12 14 16 18 22 2420

C002707-A

p

b

AUTO

x

c

r

j

M

g

m

bar

STD

t

0 2 4 6 8 10 12 14 16 18 22 2420

C002699-B

p

b

AUTO

x

c

r

j

M

g

m

AGC 10/15 AGC 15 AGC 25 AGC 35 3. Description

System pressure

n

bar

Pressure indicator: The symbol is displayed when a water

pressure sensor is connected.

4 Flashing symbol: The water pressure is insufficient.

4 Steady symbol: The water pressure is sufficient.

l

Water pressure level

4 R: 0,9 to 1,1 bar

4 E: 1,2 to 1,5 bar

4 Z: 1,6 to 1,9 bar

4 A: 2,0 to 2,3 bar

4 l: > 2,4 bar

Domestic Hot Water override

n

A bar is displayed when a DHW override is activated:

4 Flashing bar: Temporary override

4 Steady bar: Permanent override

Other information

n

r

The symbol is displayed when domestic hot water

production is running.

w

Valve indicator: The symbol is displayed when a 3-way

valve is connected.

4 x: 3-way valve opens

4 c: 3-way valve closes

M

The symbol is displayed when the pump is operating.

Name of the circuit for which the parameters are

displayed.

03/12/2013 - 300026080-001-03

14

Page 16

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

L

g

m

#MEASURES

#CHOICE TIME PROG.

#TIME PROGRAM

#SETTING

#TIME .DAY

a

C002220-B-04

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

L

g

m

CURRENT PROG.B

CURRENT PROG.C

P2

P3

a

C002221-C-04

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

L

g

m

CURRENT PROG.C

"Choice of the timeprogram

applied C"

P4

a

C002222-C-04

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

LUNDI 11:45

C002224-D-04

2x

3. Description AGC 10/15 AGC 15 AGC 25 AGC 35

3.3.3. Browsing in the menus

1. To select the desired menu, turn the rotary button.

2. To access the menu, press the rotary button.

To go back to the previous display, press the key j.

3. To select the desired parameter, turn the rotary button.

4. To modify the parameter, press the rotary button.

To go back to the previous display, press the key j.

5. To modify the parameter, turn the rotary button.

6. To confirm, press the rotary button.

To cancel, press key

h

.

7. To go back to the main display, press key j2 times.

It is possible to use the ( and ’ keys instead of the rotary

button.

15

03/12/2013 - 300026080-001-03

Page 17

8 22 2420

l

0

C003159-A

Français - Deutsch - English Italiano - Espanol - Nederlands

- Pycck - Polski - Türk -

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

x

c

r

g

m

ÿ

LANGUE FRANCAIS

C002286-C

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

SUNDAY 11:45

C002219-D-04

AGC 10/15 AGC 15 AGC 25 AGC 35 4. Operating the appliance

4 Operating the appliance

4.1 Putting the appliance into operation

1. Turn on the boiler using the on/off switch.

2. The first time the boiler is powered up, the LANGUAGE menu is

displayed. Select the desired language by turning the rotary

button.

3. To confirm, press the rotary button.

The boiler will begin an automatic venting-programme (which lasts

approx. 3 minutes) and will do this every time the power supply is

isolated. If there is a problem, the error is displayed on the screen.

4. Check the water pressure in the installation shown on the control

panel display.

4.2 Reading out measured values

The various values measured by the appliance are displayed in the

#MEASURES menu.

1. To access user level: Press the > key.

2. Select the menu #MEASURES.

If the water pressure is lower than 0,8 bar, more water

should be added. If necessary, top up the water level in the

heating system (recommended hydraulic pressure

between 1,5 and 2,0 bar).

4

Turn the rotary button to scroll through the menus or

modify a value.

4 Press the rotary button to access the selected menu

or confirm a value modification.

For a detailed explanation of menu browsing, refer to

¼

the chapter: "Browsing in the menus", page 15.

03/12/2013 - 300026080-001-03

16

Page 18

4. Operating the appliance AGC 10/15 AGC 15 AGC 25 AGC 35

User level - Menu #MEASURES

Parameter Description Unit

OUTSIDE TEMP.

ROOMTEMP.A

ROOMTEMP.B

ROOMTEMP.C

BOILER TEMP

PRESSURE

WATER TEMP.

TEMP DHW INST

STOR.TANK.TEMP

(1)

SWIMMING P.T.B

SWIMMING P.T.C

OUTLET TEMP.B

OUTLET TEMP.C

TEMP.SYSTEM

T.DHW BOTTOM

TEMP.TANK AUX

DHW A TEMP.

(1)

TEMP.SOL.TANK

SOLAR.COLL.T.

SOLA.ENERGY

BACK TEMP

FAN SPEED

POWER

HEATCONS.

DHW CONS.

(2)

(2)

NB IMPULS.

Outside temperature °C

(1)

Room temperature of circuit A °C

(1)

Room temperature of circuit B °C

(1)

Room temperature of circuit C °C

Water temperature in the boiler °C

Water pressure in the installation bar (MPa)

(1)

Water temperature in the DHW tank °C

(1)

Instant hot water temperature °C

Water temperature in the storage tank °C

(1)

Water temperature of the swimming pool on circuit B °C

(1)

Water temperature of the swimming pool on circuit C °C

(1)

Temperature of the flow water in circuit B °C

(1)

Temperature of the flow water in circuit C °C

(1)

Temperature of the system flow water if multi-generator °C

(1)

Water temperature in the bottom of the DHW tank °C

(1)

Water temperature in the second DHW tank connected to the AUX circuit °C

Water temperature in the second DHW tank connected to circuit A °C

(1)

Temperature of the hot water produced by solar power (TS) °C

(1)

Solar panel temperature (TC) °C

(1)

Solar energy accumulated in the tank kWh

Temperature of the boiler return water °C

Fan rotation speed rpm

Instantaneous boiler output (0%: Burner off or running at minimum output) %

Estimated boiler energy in heating mode kWh

Estimated boiler energy in DHW mode kWh

Number of burner starts (not restartable)

The meter is incremented by 8 every 8 start-ups

RUNTIME

Number of burner operation hours (not restartable)

h

The meter is incremented by 2 every 2 hours

IN 0-10V

(1)

SEQUENCE

CTRL Software control number

(1) The parameter is only displayed for the options, circuits or sensors actually connected.

(2) The parameter is only displayed if the function is activated (parameter ENERGY METER in the #CONFIGURATION menu)

Voltage at input 0-10 V V

Control system sequence

17

03/12/2013 - 300026080-001-03

Page 19

MODE

C002266-A

AGC 10/15 AGC 15 AGC 25 AGC 35 4. Operating the appliance

4.3 Changing the settings

4.3.1. Setting the set point temperatures

To set the various heating, DHW and swimming pool temperatures,

proceed as follows:

1. Press the C key.

2. To select the desired parameter, turn the rotary button.

3. To modify the parameter, press the rotary button.

To go back to the previous display, press the key j.

4. To modify the parameter, turn the rotary button.

5. To confirm, press the rotary button.

To cancel, press key

h

.

Menu C

Parameter Adjustment range Description Factory setting

DAY TEMP.A

NIGHT TEMP.A

DAY TEMP.B

NIGHT TEMP.B

DAY TEMP.C

NIGHT TEMP.C

DHW TEMP.

(1)

(1)

(1)

(1)

(1)

TEMP.TANK AUX

DHW A TEMP.

(1)

TEMP.SOL.TANK

(2)

SWIMMING P.T.B

SWIMMING P.T.C

WATER T.NIGHT

WATER T.NIGHTAUX

WATER T.NIGHT.A

(1) The parameter is only displayed for the options, circuits or sensors actually connected.

(2) The menu is only displayed if the solar control system is connected

5 to 30 °C Desired room temperature in comfort periods on circuit A 20 °C

5 to 30 °C Desired room temperature in reduced periods on circuit A 16 °C

5 to 30 °C Desired room temperature in comfort periods on circuit B 20 °C

5 to 30 °C Desired room temperature in reduced periods on circuit B 16 °C

5 to 30 °C Desired room temperature in comfort periods on circuit C 20 °C

5 to 30 °C Desired room temperature in reduced periods on circuit C 16 °C

10 to 80 °C Desired domestic hot water temperature in the DHW circuit 55 °C

(1)

10 to 90 °C Desired domestic hot water temperature in the auxiliary circuit 55 °C

10 to 90 °C Desired domestic hot water temperature in circuit A 55 °C

(1)

20 to 80 °C Maximum load temperature of the tank’s solar zone 65 °C

(1)

HG / 0.5 to 39 °C Desired temperature for swimming pool B 20 °C

(1)

HG / 0.5 to 39 °C Desired temperature for swimming pool C 20 °C

10 to 80 °C Desired domestic hot water temperature in the DHW circuit 10 °C

10 to 90 °C Desired domestic hot water temperature in the auxiliary circuit 10 °C

10 to 90 °C Desired domestic hot water temperature in circuit A 10 °C

03/12/2013 - 300026080-001-03

18

Page 20

MODE

C002267-A

4. Operating the appliance AGC 10/15 AGC 15 AGC 25 AGC 35

4.3.2. Selecting the operating mode

To select an operating mode, proceed as follows:

1. Press the MODE key.

2. To select the desired parameter, turn the rotary button.

3. To modify the parameter, press the rotary button.

To go back to the previous display, press the key j.

4. To modify the parameter, turn the rotary button.

5. To confirm, press the rotary button.

To cancel, press key h.

Menu MODE

Parameter Adjustment range Description Factory setting

AUTOMATIQUE

DAY

NIGHT

HOLIDAYS

SUMMER

MANUEL

FORCE AUTO

(1) The start and end days and the number of days are calculated in relation to each other.

(2) The parameter is only displayed if a room sensor is connected.

7/7, xx:xx Comfort mode is forced until the time indicated or all the time (7/7). Present time + 1

7/7, xx:xx Reduced mode is forced until the time indicated or all the time

7/7, 1 to 364 The antifreeze mode is active on all boiler circuits.

(2)

YES / NO An operating mode override is activated on the remote control

The comfort ranges are determined by the timer programme.

(7/7).

Number of days’ holiday: xx

heating OFF: xx:xx

Restarting: xx:xx

The heating is off.

Domestic hot water continues to be produced.

The generator operates according to the set point setting. All of

the pumps operate. Option of setting the set point by simply

turning the rotary button.

(option).

To force all circuits to run on AUTOMATIQUE mode, select

YES.

(1)

(1)

(1)

hour

Present time + 1

hour

Present date + 1

day

19

03/12/2013 - 300026080-001-03

Page 21

MODE

C002268-A

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

SUNDAY 11:45

C002219-D-04

AGC 10/15 AGC 15 AGC 25 AGC 35 4. Operating the appliance

4.3.3. Forcing domestic hot water production

To force domestic hot water production, proceed as follows:

1. Press the r key.

2. To select the desired parameter, turn the rotary button.

3. To modify the parameter, press the rotary button.

To go back to the previous display, press the key j.

4. To modify the parameter, turn the rotary button.

5. To confirm, press the rotary button.

To cancel, press key h.

Menu r

Parameter Description Factory setting

AUTOMATIQUE

COMFORT

The domestic hot water comfort ranges are determined by the timer programme.

Domestic hot water comfort mode is forced until the time indicated or all the time (7/7). Present time + 1 hour

4.3.4. Setting the contrast and lighting on the

display

1. To access user level: Press the > key.

2. Select the menu #SETTING.

4

Turn the rotary button to scroll through the menus or

modify a value.

4 Press the rotary button to access the selected menu

or confirm a value modification.

For a detailed explanation of menu browsing, refer to

¼

the chapter: "Browsing in the menus", page 15.

3. Set the following parameters:

User level - Menu #SETTING

Parameter Adjustment range Description Factory setting Customer setting

CONTRAST DISP.

BACK LIGHT COMFORT

ECO

Adjusting the display contrast.

The screen is illuminated continuously in

daytime periods.

The screen is illuminated for 2 minutes

whenever pressed.

ECO

03/12/2013 - 300026080-001-03

20

Page 22

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

SUNDAY 11:45

C002219-D-04

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

SUNDAY 11:45

C002219-D-04

4. Operating the appliance

AGC 10/15 AGC 15 AGC 25 AGC 35

4.3.5. Setting the time and date

1. To access user level: Press the > key.

2. Select the menu #TIME .DAY.

4 Turn the rotary button to scroll through the menus or

modify a value.

4 Press the rotary button to access the selected menu

or confirm a value modification.

For a detailed explanation of menu browsing, refer to

¼

the chapter: "Browsing in the menus", page 15.

3. Set the following parameters:

User level - Menu #TIME .DAY

(1)

Parameter Adjustment range Description Factory setting Customer setting

HOURS

MINUTE

DAY

DATE

MONTH

YEAR

SUM.TIME AUTO

0 to 23 Hours setting

0 to 59 Minutes setting

Monday to Sunday Setting the day of the week

1 to 31 Day setting

January to December Month setting

2008 to 2099 Year setting

automatic switch to summer time on the last Sunday

AUTO

in March and back to winter time on the last Sunday

in October.

MANU

for countries where the time change is done on other

dates or is not in use.

(1) According to the configuration

4.3.6. Selecting a timer programme

1. To access user level: Press the > key.

2. Select the menu #CHOICE TIME PROG..

21

4

Turn the rotary button to scroll through the menus or

modify a value.

4 Press the rotary button to access the selected menu

or confirm a value modification.

For a detailed explanation of menu browsing, refer to

¼

the chapter: "Browsing in the menus", page 15.

3. To select the desired parameter.

4. Assign the desired timer programme (P1 to P4) to the circuit with

the rotary button.

03/12/2013 - 300026080-001-03

Page 23

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

SUNDAY 11:45

C002219-D-04

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

L

g

m

PROG P2 C

Mo Tu We Th Fr Sa Su

"Display of the timeprogram.

To continuepush on the button"

a

C002228-B-04

AGC 10/15 AGC 15 AGC 25 AGC 35

4. Operating the appliance

User level - Menu #CHOICE TIME PROG.

Parameter Adjustment range Description

CURRENT PROG.A

P1 / P2 / P3 / P4 Comfort programme activated

(Circuit A)

CURRENT PROG.B

P1 / P2 / P3 / P4 Comfort programme activated

(Circuit B)

CURRENT PROG.C

P1 / P2 / P3 / P4 Comfort programme activated

(Circuit C)

4.3.7. Customising a timer programme

1. To access user level: Press the > key.

2. Select the menu #TIME PROGRAM.

4 Turn the rotary button to scroll through the menus or

modify a value.

4 Press the rotary button to access the selected menu

or confirm a value modification.

For a detailed explanation of menu browsing, refer to

¼

the chapter: "Browsing in the menus", page 15.

3. To select the desired parameter.

User level - Menu #TIME PROGRAM

Parameter Time schedule Description

TIME PROG.A PROG P2 A

Timer programme for circuit A

PROG P3 A

PROG P4 A

TIME PROG.B PROG P2 B

Timer programme for circuit B

PROG P3 B

PROG P4 B

TIME PROG.C PROG P2 C

Timer programme for circuit C

PROG P3 C

PROG P4 C

TIME PROG.DHW

TIME PROG.AUX

DHW circuit timer programme

Auxiliary circuit timer programme

4. To select a timer programme to be modified.

To select to days for which the timer programme is to be

5.

modified:

Turn the rotary button to the left until you reach the day desired.

To confirm, press the rotary button.

03/12/2013 - 300026080-001-03

22

Page 24

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

L

g

m

PROG P2 C

Mo Tu

We Th Fr Sa Su

"Select the days to

program"

a

C002229-C-04

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

L

g

m

PROG P2 C

Mo Tu

We Th Fr Sa Su

Set the time program.

a

C002230-E-04

06:00

06:00

4. Operating the appliance AGC 10/15 AGC 15 AGC 25 AGC 35

6.b: Day selection

Press key b / v until the symbol b is displayed.

Turn the rotary button to the right to select the day(s) desired.

: Cancelling the day selection

v

Press key b / v until the symbol v is displayed.

Turn the rotary button to the right to cancel selection of the relevant

day(s).

7. When the days desired for the programme have been selected,

press the rotary button to confirm.

To define the timer ranges for the comfort mode and reduced

8.

mode:

Turn the rotary button to the left until 0:00 is displayed. The first

segment of the graphic bar for the timer programme flashes.

9.b: Comfort mode selection

Press key b / v until the symbol b is displayed.

To select a comfort time range, turn the rotary button to the right.

: Reduced mode selection

v

Press key b / v until the symbol v is displayed.

To select a reduced time range, turn the rotary button to the right.

10.When the times for the comfort mode have been selected, press

the rotary button to confirm.

User level - Menu #TIME PROGRAM

TIME PROG.A

Day Comfort periods / Filling enabled:

Monday 6:00 to 22:00

Tuesday 6:00 to 22:00

Wednesday 6:00 to 22:00

Thursday 6:00 to 22:00

Friday 6:00 to 22:00

Saturday 6:00 to 22:00

Sunday 6:00 to 22:00

TIME PROG.B

Monday 6:00 to 22:00

Tuesday 6:00 to 22:00

Wednesday 6:00 to 22:00

Thursday 6:00 to 22:00

Friday 6:00 to 22:00

Saturday 6:00 to 22:00

Sunday 6:00 to 22:00

TIME PROG.C

Monday 6:00 to 22:00

Tuesday 6:00 to 22:00

Wednesday 6:00 to 22:00

Thursday 6:00 to 22:00

Friday 6:00 to 22:00

Saturday 6:00 to 22:00

Sunday 6:00 to 22:00

P1

_______________

P2 _______________ P3 _______________ P4 _______________

23

03/12/2013 - 300026080-001-03

Page 25

AGC 10/15 AGC 15 AGC 25 AGC 35

User level - Menu #TIME PROGRAM

4. Operating the appliance

TIME PROG.DHW

TIME PROG.AUX

Day Comfort periods / Filling enabled:

P1

_______________

Monday

Tuesday

Wednesday

Thursday

Friday

Saturday

Sunday

Monday

Tuesday

Wednesday

Thursday

Friday

Saturday

Sunday

4.4 Installation shutdown

P2 _______________ P3 _______________ P4 _______________

4.5 Antifreeze protection

CAUTION

Do not switch off the mains supply to the appliance. If the

central heating system is not used for a long period, we

recommend activating the HOLIDAYS mode (to ensure

the anti-grip of the heating pump).

When the heating water temperature in the boiler is too low, the

integrated boiler protection system starts up. This protection functions

as follows:

4 If the water temperature is lower than 7°C, the heating pump starts

up.

4 If the water temperature is lower than 4°C, the boiler starts up.

4 If the water temperature is higher than 10°C, the boiler shuts down

and the circulation pump continues to run for a short time.

4 If the water temperature in the storage tank is less than 4°C, it is

reheated to its set point.

03/12/2013 - 300026080-001-03

24

Page 26

4. Operating the appliance AGC 10/15 AGC 15 AGC 25 AGC 35

CAUTION

4 The antifreeze protection does not function if the

appliance is switched off.

4 The integrated protection system only protects the

boiler, not the installation. To protect the installation,

set the appliance to HOLIDAYS mode.

The HOLIDAYS mode protects:

4 The installation if the outside temperature is lower than 3°C

(factory setting).

4 The room temperature if a remote control is connected and the

room temperature is lower than 6 °C (factory setting).

4 The domestic hot water tank if the tank temperature is lower

than 4 °C (the water is reheated to 10 °C).

To configure the holidays mode: ¼See chapter: "Selecting the

operating mode", page 19.

25

03/12/2013 - 300026080-001-03

Page 27

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

SUNDAY 11:45

TEMP. : 68°

PCU COM.FAIL D27

C002302-D-04

AGC 10/15 AGC 15 AGC 25 AGC 35 5. Checking and maintenance

5 Checking and maintenance

5.1 General instructions

The boiler does not require a lot of maintenance. Nevertheless, we

recommend having the boiler inspected and serviced at regular

intervals.

4 Maintenance and cleaning of the boiler must be carried out at least

once a year by a qualified technician.

4 Have the flues swept at least once a year or more, depending on

the regulations in force in your country.

CAUTION

4 Maintenance operations must be done by a qualified

engineer.

4 We recommend taking out a maintenance contract.

4 Only original spare parts must be used.

4 Make certain that the flues and chimneys are

connected, in good condition and not blocked.

4 Do not modify nor block the condensate outlet(s).

4 If a neutralisation system is installed, follow the

instructions delivered with the neutralisation system

for cleaning and servicing of this system.

5.2 Periodic checks

The boiler displays a message whenever maintenance is necessary.

1. When the message, REVISION, is displayed, press ? to display

the installer’s telephone number (only if the installer has input this

parameter).

2. Contact the fitter.

3. Have the required checks and services done.

4 Check the water pressure in the installation (MEASURE mode).

If the water pressure is lower than 0,8 bar, more water

should be added. If necessary, top up the water level in the

heating system (recommended hydraulic pressure

between 1,5 and 2,0 bar).

03/12/2013 - 300026080-001-03

26

Page 28

T001507-B

1

2

3

4

T000181-B

5. Checking and maintenance AGC 10/15 AGC 15 AGC 25 AGC 35

4 Carry out a visual check for the presence of any water leaks.

4 Open and close the radiator valves several times a year (this

prevents the valves from seizing up).

4 Clean the outside of the boiler using a damp cloth and a light

detergent.

CAUTION

Only a qualified professional is authorised to clean the

inside of the boiler.

27

03/12/2013 - 300026080-001-03

Page 29

AGC 10/15 AGC 15 AGC 25 AGC 35 6. Troubleshooting

6 Troubleshooting

6.1 Anti-hunting

When the boiler is in Anti-short-cycle operating mode, the symbol ?

flashes.

1. Press the "?" key.

The message Operation assured when the restart temperature

will be reached is displayed.

This message is not an error message but an item of

information.

6.2 Messages (Code type Bxx or Mxx)

Code

B00 BL.PSU ERROR

B01 BL.BOILER MAX

B02 BL.HEATING SPEED

Messages Description Checking / solution

In the case of failure, the control panel displays a message and a

corresponding code.

1. Make a note of the code displayed.

The code is important for the correct and rapid diagnosis of the

type of failure and for any technical assistance that may be

needed.

2. Switch the boiler off and switch back on.

The boiler starts up again automatically when the reason for the

blocking has been removed.

3. If the code is displayed again, correct the problem by following the

instructions in the table below:

The PSU PCB is incorrectly

configured

Maximum flow temperature

exceeded

The increase in flow temperature

has exceeded its maximum limit

Parameter error on the PSU PCB

4 Contact the professional who takes care of

maintenance of the appliance

The water flow in the installation is insufficient

4 Check the circulation (direction, pump, valves)

The water flow in the installation is insufficient

4 Check the circulation (direction, pump, valves)

4 Check the water pressure

Sensor error

B07 BL.DT OUTL RET.

03/12/2013 - 300026080-001-03

Maximum difference between

the flow and return temperature

exceeded

4 Contact the professional who takes care of

maintenance of the appliance

The water flow in the installation is insufficient

4 Check the circulation (direction, pump, valves)

4 Check the water pressure

Sensor error

4 Contact the professional who takes care of

maintenance of the appliance

28

Page 30

6. Troubleshooting AGC 10/15 AGC 15 AGC 25 AGC 35

Code Messages Description Checking / solution

B08 BL.RL OPEN

The RL inlet on the PCU PCB

terminal block is open

Parameter error

4 Contact the professional who takes care of

maintenance of the appliance

Bad connection

4 Contact the professional who takes care of

maintenance of the appliance

B09 BL.INV.L/N

B10

BL.SC.IN.OPEN

B11

4 Contact the professional who takes care of maintenance of the appliance

The BL inlet on the PCU PCB

terminal block is open

The contact connected to the BL inlet is open

4 Contact the professional who takes care of

maintenance of the appliance

Parameter error

4 Contact the professional who takes care of

maintenance of the appliance

Bad connection

4 Contact the professional who takes care of

maintenance of the appliance

B13 BL. PCU COM

Communication error with the

SCU PCB

Bad connection

4 Contact the professional who takes care of

maintenance of the appliance

SCU PCB not installed in the boiler

B14 BL.WATER MIS.

B15 BL.GAS PRESS

B16

BL.BAD SU

B17 BL.BAD PSU

B18 BL.BAD PSU

B19 BL.NO CONFIG

B21 BL.COM SU

B22 BL.FLAME LOS

4 Contact the professional who takes care of

maintenance of the appliance

The water pressure is lower than

0,8 bar

Not enough water in the circuit

4 Top up the installation with water

Gas pressure too low Incorrect setting of the gas pressure switch on the SCU

PCB

4 Check that the gas valve is fully opened

4 Contact the professional who takes care of

maintenance of the appliance

The SU PCB is not recognised Wrong SU PCB for this boiler

4 Contact the professional who takes care of

maintenance of the appliance

The parameters saved on the

PCU PCB are impaired

Parameter error on the PCU PCB

4 Contact the professional who takes care of

maintenance of the appliance

The PSU PCB is not recognised Wrong PSU PCB for this boiler

4 Contact the professional who takes care of

maintenance of the appliance

The boiler has not been

configured

The PSU PCB has been changed

4 Contact the professional who takes care of

maintenance of the appliance

Communication error between

the PCU and SU PCBs

Bad connection

4 Contact the professional who takes care of

maintenance of the appliance

No flame during operation No ionization current

B25

BL.SU ERROR

B26 BL.DHW. S.

29

Internal error on the SU PCB

The DHW tank sensor is

disconnected or short circuited

4 Check that the gas valve is fully opened

4 Contact the professional who takes care of

maintenance of the appliance

4 Contact the professional who takes care of

maintenance of the appliance

4 Contact the professional who takes care of

maintenance of the appliance

03/12/2013 - 300026080-001-03

Page 31

bar

1

1

2

2

r

c

STD

(

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

SUNDAY 11:45

TEMP. : 68°

PCU. COM. FAIL. D27

C002604-B-04

AGC 10/15 AGC 15 AGC 25 AGC 35

Code Messages Description Checking / solution

B27 BL.DHW INST

The sensor on the plate

exchanger outlet is disconnected

4 Contact the professional who takes care of

maintenance of the appliance

or short circuited

B28 BL.BAD.CONFIG

An HL tank is detected whilst the

boiler cannot control it.

This message disappears after

10 seconds if the boiler can

4 Wait for 10 seconds to see whether the error persists

4 Contact the professional who takes care of

maintenance of the appliance

control the HL tank

B29 to

B34

M04 REVISION

BL.UNKNOWN Bxx

Incorrect configuration of the

PCU

4 Contact the professional who takes care of

maintenance of the appliance

A service is required The date programmed for the service has been reached

4 If the symbol ? flashes, press key ?. The installer’s

contact details are displayed.

4 Contact the professional who takes care of

maintenance of the appliance

M05 REVISION A

M06

REVISION B

M07 REVISION C

An A, B or C service is required The date programmed for the service has been reached

4 If the symbol ? flashes, press key ?. The installer’s

contact details are displayed.

4 Contact the professional who takes care of

maintenance of the appliance

M20 DISGAS

A boiler vent cycle is underway Switching the boiler on

6. Troubleshooting

FL.DRY.B XX DAYS

FL.DRY.C XX DAYS

FL.DRY.B+C XX

Floor drying is active

XX DAYS = Number of days’

floor drying remaining.

DAYS

M23 CHANGE OUTSI.S

The outside temperature sensor

is defective.

6.3 Faults (Code type Lxx or Dxx)

In the event of operational failure, the control panel flashes and

displays an error message and a corresponding code.

1. Make a note of the code displayed.

The code is important for the correct and rapid diagnosis of the

type of failure and for any technical assistance that may be

needed.

2. Press the t key. If the code is displayed again, switch off the boiler

and then switch it back on.

4 Wait 3 minutes

Floor drying is underway. Heating on the circuits not

concerned is shut down.

4 Contact the professional who takes care of

maintenance of the appliance

Change the outside radio temperature sensor.

03/12/2013 - 300026080-001-03

30

Page 32

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

SUNDAY 11:45

TEMP. : 68°

PCU COM.FAIL D27

C002302-D-04

6. Troubleshooting AGC 10/15 AGC 15 AGC 25 AGC 35

3. Press the ? key. Follow the instructions displayed to solve the

problem.

4. Consult the meaning of the codes in the table below:

Code Faults Cause

of the

fault

L00 PSU FAIL

L01 PSU PARAM FAIL

L02 DEF.OUTLET S.

L03 DEF.OUTLET S.

L04 DEF.OUTLET S.

PCU PSU PCB not connected Bad connection

PCU The safety parameters are incorrect Bad connection

PCU The boiler flow sensor has short-

PCU The boiler flow sensor is on an open

PCU Boiler temp too low Bad connection

Description Checking / solution

PSU PCB faulty

4 Contact the professional who takes care of

maintenance of the appliance

PSU PCB faulty

4 Contact the professional who takes care of

maintenance of the appliance

Bad connection

circuited

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

Bad connection

circuit

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

No water circulation

L05 STB OUTLET

L06 BACK S.FAILURE

31

4 Vent the air in the heating system

4 Check the circulation (direction, pump,

valves)

4 Check the water pressure

PCU Boiler temperature too high Bad connection

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

No water circulation

4 Vent the air in the heating system

4 Check the circulation (direction, pump,

valves)

4 Check the water pressure

PCU The return temperature sensor has

short-circuited

Bad connection

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

03/12/2013 - 300026080-001-03

Page 33

AGC 10/15 AGC 15 AGC 25 AGC 35 6. Troubleshooting

Code Faults Cause

of the

fault

L07 BACK S.FAILURE

L08 BACK S.FAILURE

L09 STB BACK

L10 DT RET-DEP>MAX

PCU The return temperature sensor is on

PCU Return temperature too low Bad connection

PCU Return temperature too high Bad connection

PCU Difference between the flow and

Description Checking / solution

Bad connection

an open circuit

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

No water circulation

4 Vent the air in the heating system

4 Check the circulation (direction, pump,

valves)

4 Check the water pressure

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

No water circulation

4 Vent the air in the heating system

4 Check the circulation (direction, pump,

valves)

4 Check the water pressure

Bad connection

return temperatures insufficient

Sensor fault

L11 DEP-RET>MAX

L12 STB OPEN

PCU Difference between the flow and

return temperatures too great

PCU Maximum boiler temperature

exceeded (STB thermostat

maximum)

4 Contact the professional who takes care of

maintenance of the appliance

No water circulation

4 Vent the air in the heating system

4 Check the circulation (direction, pump,

valves)

4 Check the water pressure

Bad connection

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

No water circulation

4 Vent the air in the heating system

4 Check the circulation (direction, pump,

valves)

4 Check the water pressure

Bad connection

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

No water circulation

4 Vent the air in the heating system

4 Check the circulation (direction, pump,

valves)

4 Check the water pressure

03/12/2013 - 300026080-001-03

32

Page 34

6. Troubleshooting AGC 10/15 AGC 15 AGC 25 AGC 35

Code Faults Cause

of the

fault

L14 BURNER FAILURE

L16

PARASIT FLAME

L17 VALVE FAIL

PCU 5 burner start-up failures No ignition

PCU Detection of a parasite flame Ionization current present even though there is no

PCU Problem on the gas valve SU PCB faulty

Description Checking / solution

4 Contact the professional who takes care of

maintenance of the appliance

Ignition arc, but no flame formation

4 Check that the gas valve is fully opened

4 Contact the professional who takes care of

maintenance of the appliance

Presence of the flame but insufficient ionization

(<3 µA)

4 Check that the gas valve is fully opened

4 Contact the professional who takes care of

maintenance of the appliance

flame

Ignition transformer defective

Gas valve defect

The burner remains very hot: CO2 too high

4 Contact the professional who takes care of

maintenance of the appliance

L34 FAN FAILURE

L35 BACK>BOIL FAIL

L36 I-CURRENT FAIL

L37

SU COM.FAIL

L38 PCU COM.FAIL

L39 BL OPEN FAIL

4 Contact the professional who takes care of

maintenance of the appliance

PCU The fan is not running at the right

speed

Bad connection

Fan defective

4 Contact the professional who takes care of

maintenance of the appliance

PCU Flow and return reversed Bad connection

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

Water circulation direction reversed

4 Check the circulation (direction, pump,

valves)

PCU The flame went out more than 5

times in 24 hours while the burner

was operating

No ionization current

4 Check that the gas valve is fully opened

4 Contact the professional who takes care of

maintenance of the appliance

PCU Communication failure with the SU

PCB

Bad connection

4 Contact the professional who takes care of

maintenance of the appliance

PCU Communication failure between the

PCU and SCU PCBs

Bad connection

SCU PCB not connected or faulty

4 Contact the professional who takes care of

maintenance of the appliance

PCU The BL inlet opened for a short time Bad connection

External cause

Parameter incorrectly set

33

4 Contact the professional who takes care of

maintenance of the appliance

03/12/2013 - 300026080-001-03

Page 35

AGC 10/15 AGC 15 AGC 25 AGC 35 6. Troubleshooting

Code Faults Cause

of the

fault

L40 TEST.HRU.FAIL

L250 DEF.WATER MIS.

L251

MANOMETRE FAIL

D03

OUTL S.B FAIL.

D04

OUTL S.C FAIL.

D05 OUTSI.S.FAIL.

D07 AUX.SENS.FAIL

PCU HRU/URC unit test error Bad connection

PCU The water pressure is too low Hydraulic circuit incorrectly vented

PCU Fault on the water pressure sensor Wiring problem

SCU Circuit B flow sensor fault

SCU Outside temperature sensor fault

SCU Auxiliary sensor fault Bad connection

Description Checking / solution

External cause

Parameter incorrectly set

4 Contact the professional who takes care of

maintenance of the appliance

Water leak

Measurement error

4 Top up with more water if necessary

4 Reset the boiler

The manometer is defect

Sensor pcb defect

4 Contact the professional who takes care of

maintenance of the appliance

Bad connection

Circuit C flow sensor fault

Remarks:

The circuit pump is running.

The 3-way valve motor on the circuit

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

is no longer powered and can be

adjusted manually.

Bad connection

Remarks:

The boiler operates on BOILER

MAX temperature.

The valve setting is no longer

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

ensured but monitoring the

maximum temperature of the circuit

after the valve is ensured.

Valves may be manually operated.

Reheating the domestic hot water

remains ensured.

Sensor fault

D09 DHW S.FAILURE

D11

ROOM S.A FAIL.

D12

ROOM S.B FAIL.

D13

ROOM S.C FAIL.

D14 MC COM.FAIL

03/12/2013 - 300026080-001-03

SCU Domestic hot water sensor fault

Remarks:

Heating of domestic hot water is no

longer ensured.

The load pump operates.

The load temperature of the dhw

tank is the same as the boiler.

SCU A room temperature sensor fault

B room temperature sensor fault

C room temperature sensor fault

Note:

The circuit concerned operates

without any influence from the room

sensor.

SCU Communication failure between the

SCU PCB and the boiler radio

module

4 Contact the professional who takes care of

maintenance of the appliance

Bad connection

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

Bad connection

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

Bad connection

4 Contact the professional who takes care of

maintenance of the appliance

Boiler module failure

4 Contact the professional who takes care of

maintenance of the appliance

34

Page 36

6. Troubleshooting AGC 10/15 AGC 15 AGC 25 AGC 35

Code Faults Cause

of the

fault

D15 ST.TANK S.FAIL

D16

SWIM.B S.FAIL

D16

SWIM.C S.FAIL

D17 DHW 2 S.FAIL

D18 ST.TANK S.FAIL

D19 SOL.COL.S.FAIL

D20 SOL COM.FAIL

SCU Storage tank sensor fault

SCU Swimming pool sensor fault circuit B

SCU Sensor fault tank 2 Bad connection

SCU Solar tank sensor fault Bad connection

SCU Header sensor fault Bad connection

SCU Interruption in communication between the SCU PCB and the solar control system

Description Checking / solution

Bad connection

Note:

The hot water storage tank reheating

operation is no longer assured.

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

Bad connection

Swimming pool sensor fault circuit C

Note:

Swimming pool reheating is always

done during the circuit’s comfort

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

period.

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

D27 PCU COM. FAIL

D32 5 RESET:ON/OFF

D37

TA-S SHORT-CIR

D38 TA-S DISCONNEC

D99 DEF.BAD PCU

4 Contact the professional who takes care of maintenance of the appliance

SCU Communication failure between the SCU and PCU PCBs

4 Contact the professional who takes care of maintenance of the appliance

SCU 5 resets done in less than an hour

4 Switch the boiler off and switch back on

4 If the boiler does not start after several resets (5 attempts possible), contact your

heating engineer and inform him of the error message displayed

SCU The Titan Active System® is short-circuited

4 Contact the professional who takes care of maintenance of the appliance

Remarks:

Domestic hot water production has stopped but can nonetheless be restarted using key

r.

The tank is no longer protected.

If a tank without Titan Active System® is connected to the boiler,check that the TAS

simulation connector (delivered with package AD212) is fitted to the sensor card.

SCU The Titan Active System® is on an open circuit

4 Contact the professional who takes care of maintenance of the appliance

Remarks:

Domestic hot water production has stopped but can nonetheless be restarted using key

r.

The tank is no longer protected.

If a tank without Titan Active System® is connected to the boiler,check that the TAS

simulation connector (delivered with package AD212) is fitted to the sensor card.

SCU The SCU software version does not recognise the PCU connected

35

4 Contact the professional who takes care of maintenance of the appliance

03/12/2013 - 300026080-001-03

Page 37

AGC 10/15 AGC 15 AGC 25 AGC 35 7. Technical specifications

7 Technical specifications

7.1 Technical specifications

Boiler type AGC 10/15 AGC 15 AGC 25 AGC 35

General

Nominal output (Pn)

Heating System (80/60 °C)

Nominal output (Pn)

Heating System (50/30 °C)

Nominal output (Pn)

Heating System (40/30 °C)

Nominal input (Qn)

Heating System (Hi)

Nominal input(Qn)

Heating System (Hs)

Nominal input (Qnw)

DHW System (Hi)

Nominal input (Qnw)

DHW System (Hs)

Heating efficiency under full load (Hi)

(80/60 °C)

Heating efficiency under full load (Hi)

(50/30 °C)

Heating efficiency under partial load

(Hi) (Return temperature 60°C)

Heating efficiency under partial load

(EN 92/42) (Return temperature

30°C)

Data on the gases and combustion gases

Gas consumption - Natural gas H

(G20)

Gas consumption - Natural gas L

(G25)

Gas consumption - Propane G31 minimum-

NOx-Emission (Scrolls forward

EN297A3)

Mass flue gas flow rate minimum-

Flue gas temperature minimum-

Maximum counter pressure

Characteristics of the heating circuit

Water content (ex expansion vessel)

Water operating pressure minimum kPa (bar (MPa)) 80 (0,8) 80 (0,8) 80 (0,8) 80 (0,8)

Water operating pressure (PMS) maximum kPa (bar (MPa)) 300 (3,0) 300 (3,0) 300 (3,0) 300 (3,0)

Water temperature maximum °C 110 110 110 110

Operating temperature maximum °C 90 90 90 90

Electrical characteristics

minimummaximum

minimummaximum

minimummaximum

minimummaximum

minimummaximum

minimummaximum

minimummaximum

- % 96,5 96,5 96,3 96,9

- % 105,3 105,3 102,0 102,2

- % 94,9 94,9 96,1 96,3

- % 108,8 108,5 108,0 108,2

minimummaximum

minimummaximum

maximum

maximum

maximum

kW 3,0 - 10,1 3,0 - 14,5 5,0 - 24,1 6,3 - 34,0

kW 3,4 - 11,2 3,4 - 15,8 5,6 - 25,5 7,0 - 35,9

kW 3,4 - 16,0 3,4 - 16,0 5,6 - 25,9 7,0 - 36.4

kW 3,1 - 10,5 3,1 - 15,0 5,2 - 25,0 6,5 - 35,1

kW 3,4 - 11,7 3,4 - 16,7 5,8 - 27,8 7,2 - 39,0

kW 3,1 - 15,0 3,1 - 15,0 5,2 - 29,3 6,5 - 35,1

kW 3,4 - 16,7 3,4 - 16,7 5,8 - 32,6 7,2 - 39,0

m3/h

m3/h

m3/h

mg/kWh 33 33 38 41

kg/h 5,3 - 25,2 5,3 - 25,2 8,9 - 49,3 11,1 - 57,3

°C 30 - 65 30 - 65 30 - 80 30 - 75

Pa 22 80 120 140

l 1,9 1,9 1,9 2,5

0,33 - 1,59 0,33 - 1,59 0,55 - 3,10 0,69 - 3,71

0,38 - 1,85 0,38 - 1,85 0,64 - 3,61 0,80 - 4,32

0,13 - 0,61 0,13 - 0,61 0,21 - 1,20 0,27 - 1,44

03/12/2013 - 300026080-001-03

36

Page 38

7. Technical specifications AGC 10/15 AGC 15 AGC 25 AGC 35

Boiler type AGC 10/15 AGC 15 AGC 25 AGC 35

Power supply voltage

Power consumption - Full load maximum W 101 101 116 173

Power consumption - Part load maximum W 25 25 25 68

Power consumption - Standby maximum W 4 4 4 4

Electrical protection index

Other characteristics

Weight (empty)

VAC 230 230 230 230

IP21 IP21 IP21 IP21

kg 56 56 56 50

37

03/12/2013 - 300026080-001-03

Page 39

AGC 10/15 AGC 15 AGC 25 AGC 35

8 Energy savings

8.1 Energy-saving advice

8. Energy savings

4 Keep the room in which the boiler is installed well ventilated.

4 Do not block ventilation outlets.

4 Do not cover the radiators. Do not hang curtains in front of the

radiators.

4 Install reflective panels behind the radiators to prevent heat

losses.

4 Insulate the pipes in rooms that are not heated (cellars and lofts).

4 Close the radiators in rooms not in use.

4 Do not run hot (or cold) water pointlessly.

4 Install a water-saving shower head to save up to 40 % energy.

4 Take showers rather than baths. A bath consumes twice as much

water and energy.

8.2 Recommendations

The remote control is available in the following versions:

4 Wire

4 Radio

The setting of the control panel and/or of the remote control has a

considerable influence on energy consumption.

A few tips:

4 In the room in which the room thermostat is installed, it’s advised

not to use thermostatic valve radiators. If a thermostatic valve is

used the valve must be fully opened.

4 Completely closing and opening thermostatic valve radiators

causes undesirable temperature fluctuations. Open and close

thermostatic valves in small steps.

4 Lower the temperature to around 20°C. This reduces heating costs

and energy consumption.

4 Lower the temperature when you air the rooms.

4 When setting a time schedule , bear days when you are absent

and holidays in mind.

03/12/2013 - 300026080-001-03

38

Page 40

9. Warranty

9 Warranty

9.1 General

9.2 Warranty terms

AGC 10/15 AGC 15 AGC 25 AGC 35

You have just purchased one of our appliances and we thank you for

the trust you have placed in our products.

Please note that your appliance will provide good service for a longer

period of time if it is regularly checked and maintained.

Your installer and our customer support network are at your disposal

at all times.

The following provisions are not exclusive of the buyer being able

benefit from the legal provisions applicable regarding hidden defects

in the buyer’s country.

Starting from the purchase date shown on the original installer’s

invoice, your appliance has a contractual guarantee against any

manufacturing defect.

The length of the guarantee is mentioned in the price catalogue.

The manufacturer is not liable for any improper use of the appliance

or failure to maintain or install the unit correctly (the user shall take

care to ensure that the system is installed by a qualified engineer).

In particular, the manufacturer shall not be held responsible for any

damage, loss or injury caused by installations which do not comply

with the following:

4 applicable local laws and regulations,

4 specific requirements relating to the installation, such as national

and/or local regulations,

4 the manufacturer’s instructions, in particular those relating to the

regular maintenance of the unit,

4 the rules of the profession.

The warranty is limited to the exchange or repair of such parts as have

been recognised to be faulty by our technical department and does

not cover labour, travel and carriage costs.

The warranty shall not apply to the replacement or repair of parts

damaged by normal wear and tear, negligence, repairs by unqualified

parties, faulty or insufficient monitoring and maintenance, faulty

power supply or the use of unsuitable fuel.

39

Sub-assemblies such as motors, pumps, electric valves etc. are

guaranteed only if they have never been dismantled.

The legislation laid down by european directive 99/44/EEC,

transposed by legislative decree No. 24 of 2 February 2002 published

in O.J. No. 57 of 8 March 2002, continues to apply.

03/12/2013 - 300026080-001-03

Page 41

AGC 10/15 AGC 15 AGC 25 AGC 35 9. Warranty

03/12/2013 - 300026080-001-03

40

Page 42

Page 43

Page 44

AD001-AI

DUEDI S.r.l.

DE DIETRICH SERVICE

BDR Thermea (Czech republic) s.r.o

www.duediclima.it

www.dedietrich.cz

Distributore Ufficiale Esclusivo

De Dietrich-Thermique Italia

www.dedietrich-heiztechnik.com

Freecall 0800 / 201608

Jeseniova 2770/56

130 00 Praha 3

+49 (0)25 72 / 9161-0

+49 (0)25 72 / 9161-102

info@remeha.de

Via Passatore, 12 - 12010

San Defendente di Cervasca

CUNEO

+39 0171 857170

+39 0171 687875

info@duediclima.it

+420 271 001 627

info@dedietrich.cz

IT

DE DIETRICH THERMIQUE S.A.S

DE DIETRICH THERMIQUE Iberia S.L.U.

www.dedietrich-calefaccion.es

C/Salvador Espriu, 11

08908 L’HOSPITALET de LLOBREGAT

+34 935 475 850

info@dedietrich-calefaccion.es

ES

129164, Россия, г. Москва

Зубарев переулок, д. 15/1

Бизнес-центр «Чайка Плаза»,

офис 309

+7 (495) 221-31-51

CZ

300026080-001-03

DEDIETRICH THERMIQUE

57,ruedelaGareF-67580MERTZWILLER-BP 30

© Copyright

All technical and technological information contained in these technical instructions,

as well as any drawings and technical descriptions supplied, remain our property

and shall not be multiplied without our prior consent in writing.

03/12/2013

Loading...

Loading...