Page 1

Regulation

C003674-B

VM iSystem

EN

User Guide

300028026-001-A

Page 2

Contents

1 Introduction ................................................................................................4

1.1 Symbols used .......................................................4

1.2 Abbreviations ........................................................4

1.3 General ..................................................................4

1.3.1 Manufacturer's liability .............................................4

1.3.2 Installer's liability .....................................................5

1.3.3 User's liability ..........................................................5

1.4 Certifications .........................................................6

2 Description ..................................................................................................7

2.1 Description of the keys ........................................7

2.2 Description of the display ....................................8

2.2.1 Key functions ...........................................................8

2.2.2 Flame symbol ..........................................................8

2.2.3 Solar (If connected) .................................................8

2.2.4 Operating modes .....................................................9

2.2.5 Domestic Hot Water override ..................................9

2.2.6 Other information ..................................................10

3 Operating the appliance ..........................................................................11

3.1 Browsing in the menus ......................................11

3.2 Reading out measured values ...........................12

3.3 Changing the settings ........................................13

3.3.1 Setting the set point temperatures ........................13

3.3.2 Selecting the operating mode ...............................14

3.3.3 Forcing domestic hot water production .................15

3.3.4 Setting the contrast and lighting on the

display ...................................................................15

3.3.5 Setting the time and date ......................................16

3.3.6 Selecting a timer programme ................................16

3.3.7 Customising a timer programme ...........................17

3.3.8 Setting an annual clock .........................................19

1

17/11/2011 - 300028026-001-A

Page 3

Contents

3.4 Installation shutdown .........................................21

3.5 Frost protection ..................................................21

4 Troubleshooting .......................................................................................22

4.1 Messages (type code Mxx) ................................22

4.2 Faults ...................................................................22

5 Warranty ....................................................................................................25

5.1 General ................................................................25

5.2 Warranty terms ...................................................25

2

17/11/2011 - 300028026-001-A

Page 4

3

17/11/2011 - 300028026-001-A

Page 5

VM iSystem

1 Introduction

1.1 Symbols used

1. Introduction

In these instructions, various danger levels are employed to draw the

user's attention to particular information. In so doing, we wish to

safeguard the user's safety, obviate hazards and guarantee correct

operation of the appliance.

DANGER

Risk of a dangerous situation causing serious physical

injury.

WARNING

Risk of a dangerous situation causing slight physical

injury.

1.2 Abbreviations

1.3 General

CAUTION

Risk of material damage.

Signals important information.

¼ Signals a referral to other instructions or other pages in the

instructions.

4 DHW: Domestic hot water

4 3WV: 3-way valve

1.3.1. Manufacturer's liability

17/11/2011 - 300028026-001-A

Our products are manufactured in compliance with the requirements

of the various applicable European Directives. They are therefore

delivered with [ marking and all relevant documentation.

4

Page 6

1. Introduction

VM iSystem

In the interest of customers, we are continuously endeavouring to

make improvements in product quality. All the specifications stated in

this document are therefore subject to change without notice.

Our liability as the manufacturer may not be invoked in the following

cases:

4 Failure to abide by the instructions on using the appliance.

4 Faulty or insufficient maintenance of the appliance.

4 Failure to abide by the instructions on installing the appliance.

1.3.2. Installer's liability

The installer is responsible for the installation and inital start up of the

appliance. The installer must respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Carry out installation in compliance with the prevailing legislation

and standards.

4 Perform the initial start up and carry out any checks necessary.

4 Explain the installation to the user.

4 If a maintenance is necessary, warn the user of the obligation to

check the appliance and maintain it in good working order.

4 Give all the instruction manuals to the user.

1.3.3. User's liability

To guarantee optimum operation of the appliance, the user must

respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Call on qualified professionals to carry out installation and initial

start up.

4 Get your fitter to explain your installation to you.

4 Have the required checks and services done.

4 Keep the instruction manuals in good condition close to the

appliance.

This appliance is not intended to be used by persons (including

children) whose physcial, sensory or mental capacity is impaired or

persons with no experience or knowledge, unless they have the

benefit, through the intermediary of a person responsible for their

safety, of supervision or prior instructions regarding use of the

appliance. Care should be taken to ensure that children do not play

with the appliance.

5

17/11/2011 - 300028026-001-A

Page 7

VM iSystem 1. Introduction

1.4 Certifications

This product complies to the requirements to the european directives

and following standards:

4 2006/95/EC Low Voltage Directive. Reference Standard:

EN60.335.1.

4 2004/108/EC Electromagnetic Compatibility Directive. Generic

standards: EN1000-6-3 , EN 61000-6-1.

17/11/2011 - 300028026-001-A

6

Page 8

C003672-B

bar

STD

0 2 4 6 8 10 12 14 16 18 22 2420

AUTO

A

B

C

D

E

F

J

H

G

2. Description VM iSystem

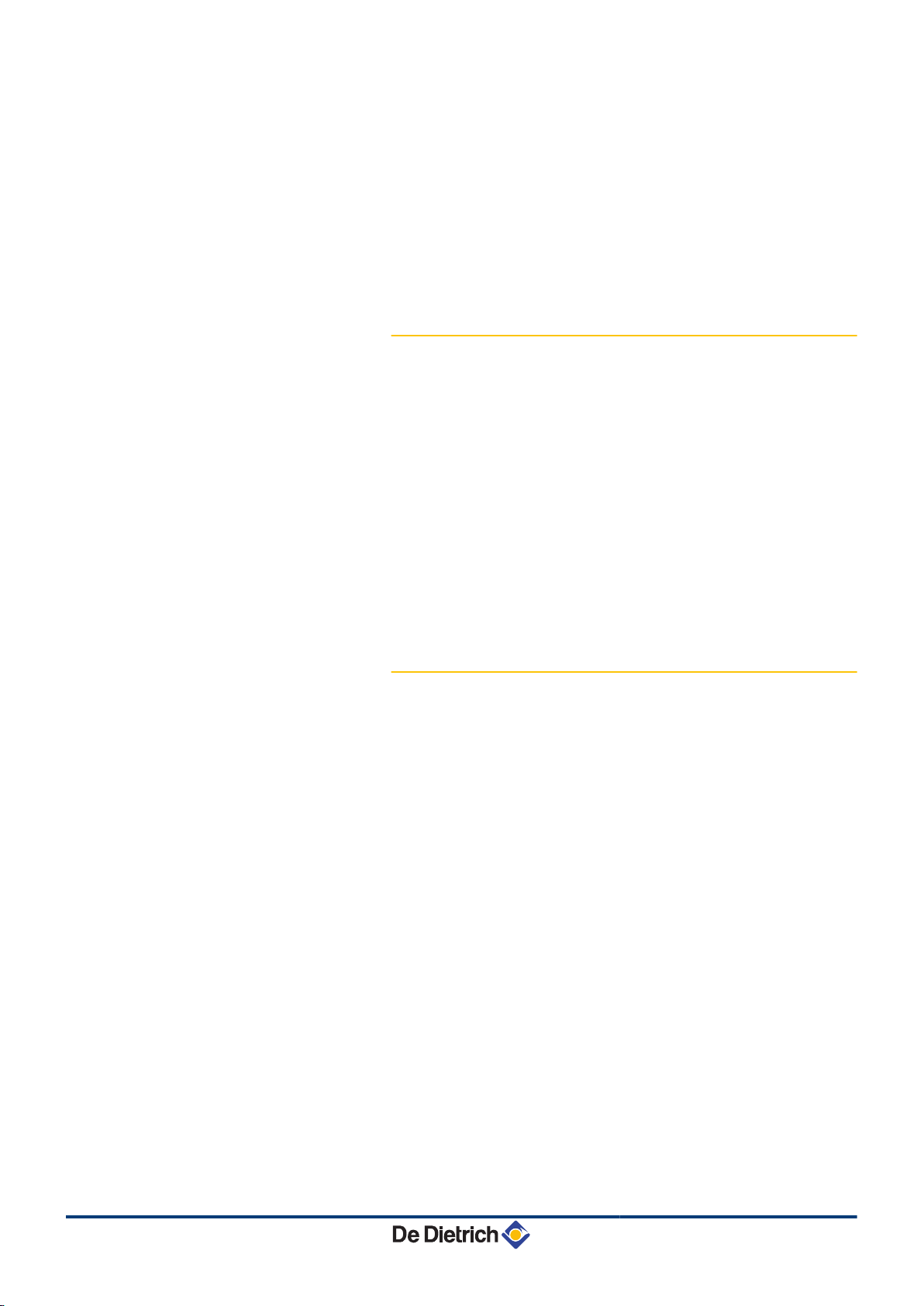

2 Description

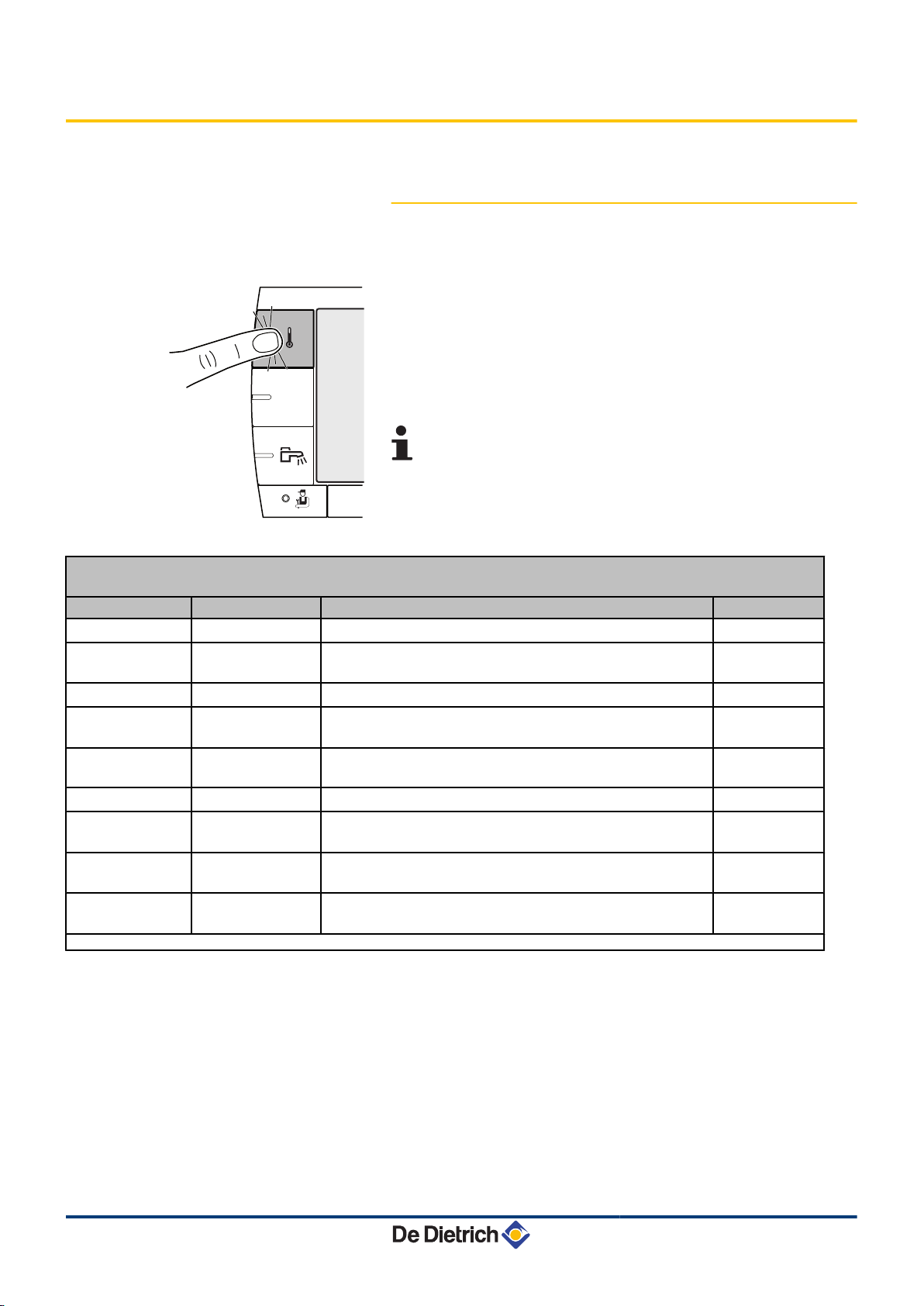

2.1 Description of the keys

A

B

C

D

E

F

G

H

J

Temperature setting key (heating, DHW, swimming pool)

Operating mode selection key

DHW override key

Key to access the parameters reserved for the installer

Keys on which the function varies as and when selections

are made

Rotary setting button:

4 Turn the rotary button to scroll through the menus or

modify a value

4 Press the rotary button to access the menu selected

or confirm a value modification

Button AUTO/MANU

Fuse

Button ON/OFF

7

17/11/2011 - 300028026-001-A

Page 9

L000200-A

L000201-A

L000198-A

L000199-A

bar

r

STD

(

'

t

0 2 4 6 8 10 12 14 16 18 22 2420

C002696-A

p

b

AUTO

x

c

r

j

L

g

m

bar

STD

t

0 2 4 6 8 10 12 14 16 18 22 2420

C002701-B

p

b

AUTO

x

c

r

j

M

g

m

bar

STD

t

0 2 4 6 8 10 12 14 16 18 22 2420

L000197-A

p

b

AUTO

x

c

r

j

M

g

m

VM iSystem 2. Description

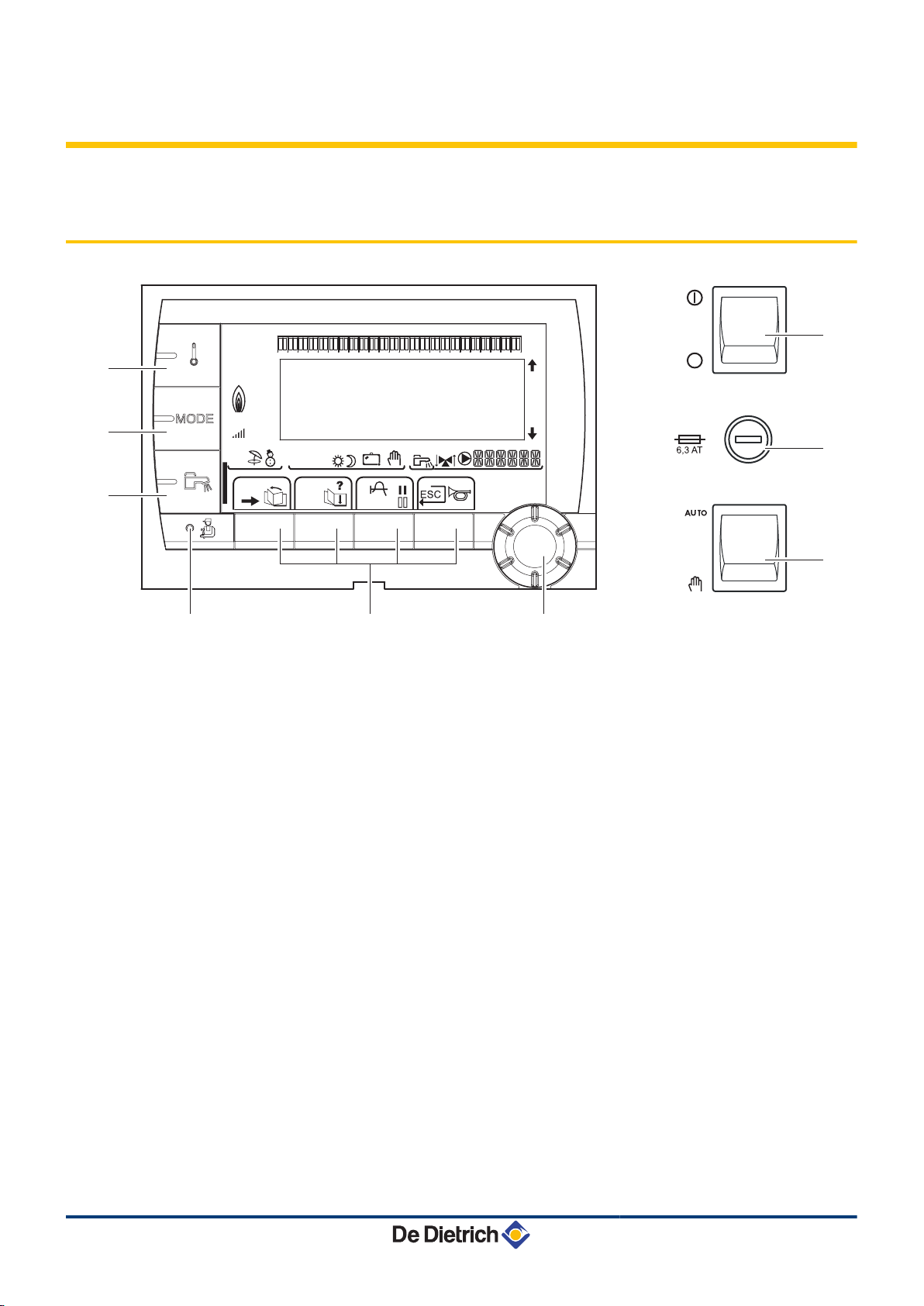

2.2 Description of the display

2.2.1. Key functions

>

(

'

?

f

STD

b

Access to the various menus

Used to scroll through the menus

Used to scroll through the parameters

The symbol is displayed when help is available

Used to display the curve of the parameter selected

Reset of the time programmes

Selection of comfort mode or selection of the days to be

programmed

v

Selection of reduced mode or deselection of the days to

be programmed

j

ESC

Back to the previous level

Back to the previous level without saving the

modifications made

2.2.2. Flame symbol

4 The symbol is displayed: The burner is operating.

4 The symbol is not displayed: The burner is off.

17/11/2011 - 300028026-001-A

2.2.3. Solar (If connected)

u

The solar load pump is running

The top part of the tank is reheated to the tank set point

The entire tank is reheated to the tank set point

The entire tank is reheated to the solar tank set point

The tank is not loaded - Presence of the solar control

system

8

Page 10

bar

STD

t

0 2 4 6 8 10 12 14 16 18 22 2420

C002697-B

p

b

AUTO

x

c

r

j

M

g

m

bar

STD

t

0 2 4 6 8 10 12 14 16 18 22 2420

C002698-B

p

b

AUTO

x

c

r

j

M

g

m

bar

STD

t

0 2 4 6 8 10 12 14 16 18 22 2420

C002707-A

p

b

AUTO

x

c

r

j

M

g

m

2. Description VM iSystem

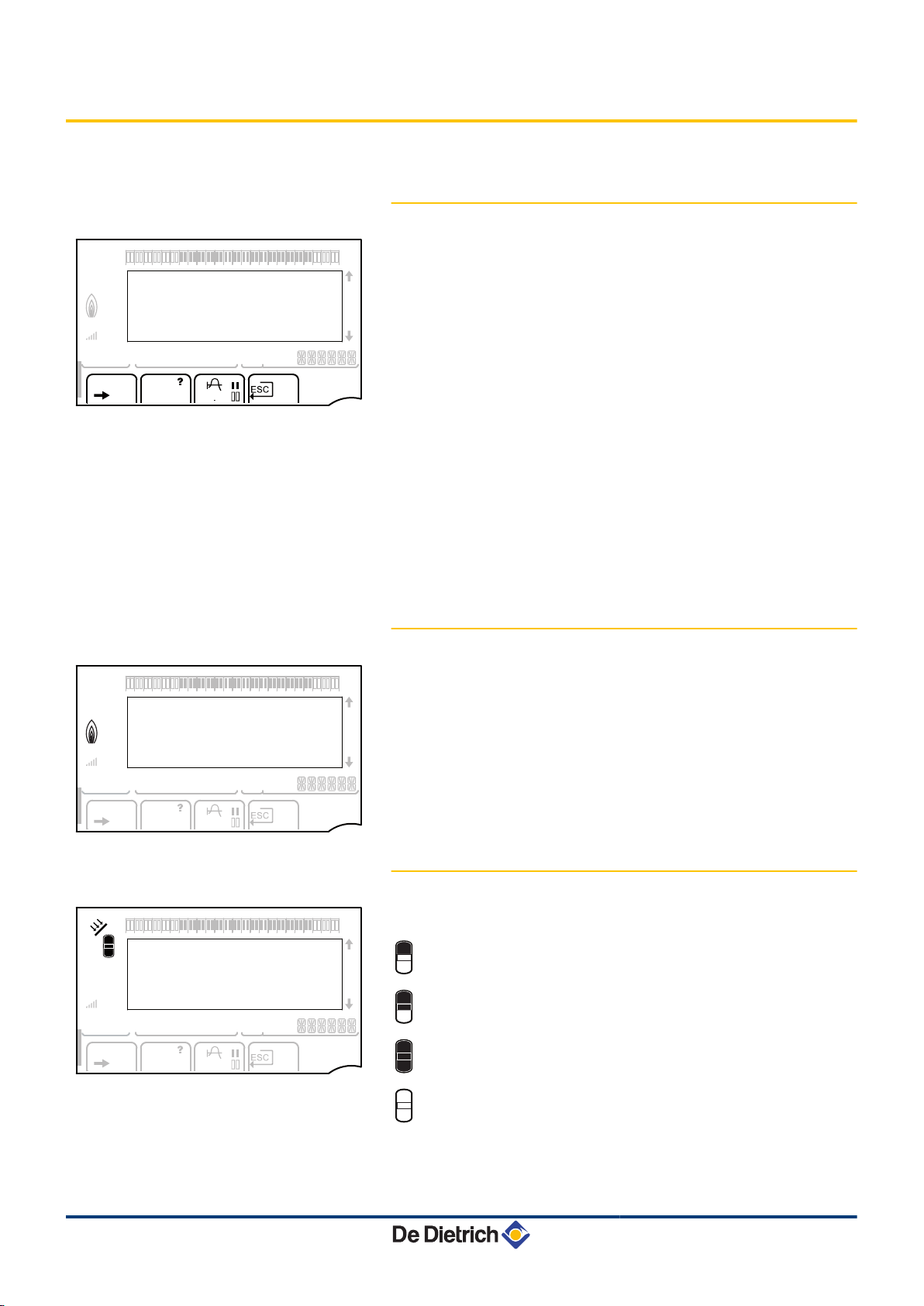

2.2.4. Operating modes

p

b

AUTO

x

m

g

Summer mode: The heating is off. Domestic hot water

continues to be produced

WINTER mode: Heating and domestic hot water working

Operation in automatic mode according to the timer

programme

Comfort mode: The symbol is displayed when a DAY

override (comfort) is activated

4 Flashing symbol: Temporary override

4 Steady symbol: Permanent override

Reduced mode: The symbol is displayed when a NIGHT

override (reduced) is activated

4 Flashing symbol: Temporary override

4 Steady symbol: Permanent override

Holiday mode: The symbol is displayed when a HOLIDAY

override (antifreeze) is activated

4 Flashing symbol: Holiday mode programmed

4 Steady symbol: Holiday mode active

m

Manual mode

2.2.5. Domestic Hot Water override

A bar is displayed when a DHW override is activated:

4 Flashing bar: Temporary override

4 Steady bar: Permanent override

9

17/11/2011 - 300028026-001-A

Page 11

bar

STD

t

0 2 4 6 8 10 12 14 16 18 22 2420

C002699-B

p

b

AUTO

x

c

r

j

M

g

m

VM iSystem 2. Description

2.2.6. Other information

r

w

M

The symbol is displayed when domestic hot water

production is running.

Valve indicator: The symbol is displayed when a 3-way

valve is connected.

4 x : 3-way valve opens

4 c : 3-way valve closes

The symbol is displayed when the pump is operating.

Name of the circuit for which the parameters are

displayed.

17/11/2011 - 300028026-001-A

10

Page 12

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

L

g

m

#MEASURES

#CHOICE TIME PROG.

#TIME PROGRAM

#SETTING

#TIME .DAY

a

C002220-B-04

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

L

g

m

CURRENT PROG.B

CURRENT PROG.C

P2

P3

a

C002221-C-04

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

L

g

m

CURRENT PROG.C

"Choice of the timeprogram

applied C"

P4

a

C002222-C-04

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

LUNDI 11:45

C002224-D-04

2x

3. Operating the appliance VM iSystem

3 Operating the appliance

3.1 Browsing in the menus

1. To select the desired menu, turn the rotary button.

2. To access the menu, press the rotary button.

To go back to the previous display, press the key j.

3. To select the desired parameter, turn the rotary button.

4. To modify the parameter, press the rotary button.

To go back to the previous display, press the key j.

5. To modify the parameter, turn the rotary button.

6. To confirm, press the rotary button.

To cancel, press key

h

.

7. To go back to the main display, press key j2 times.

It is possible to use the ( and ' keys instead of the rotary

button.

11

17/11/2011 - 300028026-001-A

Page 13

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

SUNDAY 11:45

C002219-D-04

VM iSystem 3. Operating the appliance

3.2 Reading out measured values

The various values measured by the appliance are displayed in the

#MEASURES menu.

1. To access user level: Press the > key.

2. Select the menu #MEASURES.

4 Turn the rotary button to scroll through the menus or

modify a value.

4 Press the rotary button to access the menu selected

or confirm a value modification.

For a detailed explanation of menu browsing, refer

¼

to the chapter: "Browsing in the menus", page 11.

User level - #MEASURES menu

Parameter Description Unit

OUTSIDE TEMP.

ROOMTEMP. B

ROOMTEMP. C

BOILER TEMP.

WATER TEMP.

STOR.TANK.TEMP

(1)

SWIMMING P.T.B

(1)

SWIMMING P.T.C

(1)

OUTLET TEMP. B

(1)

OUTLET TEMP. C

(1)

SYSTEM TEMP.

T.DHW BOTTOM

(1)

TEMP.TANK AUX

(1)

TEMP.SOL.TANK

(1)(2)

SOLAR.COLL.T.

(2)

SOLA.ENERGY

(2)

IN 0-10V

(1)(2)

CTRL Software control number

(1) The parameter is only displayed for the options, circuits or sensors actually connected.

(2) According to the configuration

17/11/2011 - 300028026-001-A

Outside temperature °C

(1)

Room temperature of circuit B °C

(1)

Room temperature of circuit C °C

(2)

Water temperature in the boiler °C

(1)

Water temperature in the DHW tank °C

Water temperature in the storage tank °C

Water temperature of the swimming pool on circuit B °C

Water temperature of the swimming pool on circuit C °C

Temperature of the flow water in circuit B °C

Temperature of the flow water in circuit C °C

(1)

Temperature of the system flow water if multi-generator °C

Water temperature in the bottom of the DHW tank °C

Water temperature in the second DHW tank connected to the AUX circuit °C

Temperature of the hot water produced by solar power (TS) °C

(1)

Solar panel temperature (TC) °C

(1)

Solar energy accumulated in the tank kWh

Voltage at input 0-10 V V

12

Page 14

MODE

C002266-A

3. Operating the appliance VM iSystem

3.3 Changing the settings

3.3.1. Setting the set point temperatures

To set the various heating, DHW and swimming pool temperatures,

proceed as follows:

1. Press the C key.

2. To select the desired parameter, turn the rotary button.

3. To modify the parameter, press the rotary button.

To go back to the previous display, press the key j.

4. To modify the parameter, turn the rotary button.

5. To confirm, press the rotary button.

To cancel, press key

h

.

Menu C

Parameter Adjustment range Description Factory setting

(1)

DAY TEMP. B

NIGHT TEMP. B

(1)

DAY TEMP. C

NIGHT TEMP. C

(1)

TEMP.SOL.TANK

(1)

WATER TEMP.

TEMP.TANK AUX

(1)

SWIMMING P.T.B

(1)

SWIMMING P.T.C

(1)

(1) The parameter is only displayed for the options, circuits or sensors actually connected.

5 to 30 °C Desired room temperature in comfort periods on circuit B 20 °C

5 to 30 °C Desired room temperature in reduced periods on circuit B 16 °C

(1)

5 to 30 °C Desired room temperature in comfort periods on circuit C 20 °C

5 to 30 °C Desired room temperature in reduced periods on circuit B 16 °C

20 to 80 °C Maximum load temperature of the tank's solar zone 60°C

(1)

10 to 80 °C Desired domestic hot water temperature in the DHW circuit 55 °C

10 to 80 °C Desired domestic hot water temperature in the auxiliary circuit 55 °C

5 to 39 °C Desired temperature for swimming pool B 20 °C

5 to 39 °C Desired temperature for swimming pool C 20 °C

13

17/11/2011 - 300028026-001-A

Page 15

MODE

C002267-A

VM iSystem 3. Operating the appliance

3.3.2. Selecting the operating mode

To select an operating mode, proceed as follows:

1. Press the MODE key.

2. To select the desired parameter, turn the rotary button.

3. To modify the parameter, press the rotary button.

To go back to the previous display, press the key j.

4. To modify the parameter, turn the rotary button.

5. To confirm, press the rotary button.

To cancel, press key h.

Menu MODE

Parameter Adjustment range Description Factory setting

AUTOMATIQUE

DAY

NIGHT

HOLIDAYS

SUMMER

MANUEL

FORCE AUTO

(1) The start and end days and the number of days are calculated in relation to each other.

(2) According to the configuration

(2)

7/7, xx:xx Comfort mode is forced until the time indicated or all the time (7/7). Present time + 1

7/7, xx:xx Reduced mode is forced until the time indicated or all the time (7/7). Present time + 1

7/7, 1 to 365 The antifreeze mode is active on all boiler circuits.

YES / NO An operating mode override is activated on the remote control

The comfort ranges are determined by the timer programme.

Number of days' holiday: xx

heating OFF: xx:xx

Restarting: xx:xx

The heating is off.

Domestic hot water continues to be produced.

The generator operates according to the set point setting. All of the

pumps operate. Option of setting the set point by simply turning the

rotary button.

(option).

To force all circuits to run on AUTOMATIQUE mode, select YES.

(1)

(1)

(1)

hour

hour

Present date + 1

day

17/11/2011 - 300028026-001-A

14

Page 16

MODE

C002268-A

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

SUNDAY 11:45

C002219-D-04

3. Operating the appliance VM iSystem

3.3.3. Forcing domestic hot water production

To force domestic hot water production, proceed as follows:

1. Press the r key.

2. To select the desired parameter, turn the rotary button.

3. To modify the parameter, press the rotary button.

To go back to the previous display, press the key j.

4. To modify the parameter, turn the rotary button.

5. To confirm, press the rotary button.

To cancel, press key h.

Menu r

Parameter Description Factory setting

AUTOMATIQUE

COMFORT

The domestic hot water comfort ranges are determined by the timer programme.

Domestic hot water comfort mode is forced until the time indicated or all the time (7/7). Present time + 1 hour

3.3.4. Setting the contrast and lighting on the

display

1. To access user level: Press the > key.

2. Select the menu #SETTING.

4

Turn the rotary button to scroll through the menus or

modify a value.

4 Press the rotary button to access the menu selected

or confirm a value modification.

For a detailed explanation of menu browsing, refer

¼

to the chapter: "Browsing in the menus", page 11.

3. To set the following parameters:

User level - Menu #SETTING

Parameter Adjustment range Description Factory setting Customer setting

CONTRAST DISP.

BACK LIGHT COMFORT

ECO

Adjusting the display contrast.

The screen is illuminated continuously in

daytime periods.

The screen is illuminated for 2 minutes

whenever pressed.

ECO

15

17/11/2011 - 300028026-001-A

Page 17

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

SUNDAY 11:45

C002219-D-04

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

SUNDAY 11:45

C002219-D-04

VM iSystem

3.3.5. Setting the time and date

1. To access user level: Press the > key.

2. Select the menu #TIME .DAY.

4 Turn the rotary button to scroll through the menus or

modify a value.

4 Press the rotary button to access the menu selected

or confirm a value modification.

For a detailed explanation of menu browsing, refer

¼

to the chapter: "Browsing in the menus", page 11.

3. To set the following parameters:

3. Operating the appliance

User level - Menu #TIME .DAY

(1)

Parameter Adjustment range Description Factory setting Customer setting

HOURS

MINUTE

DAY

DATE

MONTH

YEAR

SUM. TIME: AUTO

0 to 23 Hours setting

0 to 59 Minutes setting

Monday to Sunday Setting the day of the week

1 to 31 Day setting

January to December Month setting

2008 to 2099 Year setting

automatic switch to summer time on the last Sunday

AUTO

in March and back to winter time on the last Sunday

in October.

MANU

for countries where the time change is done on

other dates or is not in use.

(1) According to the configuration

3.3.6. Selecting a timer programme

1. To access user level: Press the > key.

2. Select the menu #CHOICE TIME PROG..

17/11/2011 - 300028026-001-A

4

Turn the rotary button to scroll through the menus or

modify a value.

4 Press the rotary button to access the menu selected

or confirm a value modification.

For a detailed explanation of menu browsing, refer

¼

to the chapter: "Browsing in the menus", page 11.

3. To select the desired parameter.

User level - Menu

Parameter Adjustment range Description

CURRENT PROG.B

CURRENT PROG.C

#CHOICE TIME PROG.

P1 / P2 / P3 / P4 Comfort programme activated

(Circuit B)

P1 / P2 / P3 / P4 Comfort programme activated

(Circuit C)

4. Assign the desired timer programme (P1 to P4) to the circuit with

the rotary button.

16

Page 18

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

SUNDAY 11:45

C002219-D-04

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

L

g

m

PROG P2 C

Mo Tu We Th Fr Sa Su

"Display of the timeprogram.

To continuepush on the button"

a

C002228-B-04

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

L

g

m

PROG P2 C

Mo Tu

We Th Fr Sa Su

"Select the days to

program"

a

C002229-C-04

3. Operating the appliance

3.3.7. Customising a timer programme

1. To access user level: Press the > key.

2. Select the menu #TIME PROGRAM.

4 Turn the rotary button to scroll through the menus or

modify a value.

4 Press the rotary button to access the menu selected

or confirm a value modification.

For a detailed explanation of menu browsing, refer

¼

to the chapter: "Browsing in the menus", page 11.

3. To select the desired parameter.

User level - Menu #TIME PROGRAM

Parameter Time schedule Description

TIME PROG.B PROG P2 B

PROG P3 B

PROG P4 B

TIME PROG.C PROG P2 C

PROG P3 C

PROG P4 C

TIME PROG.DHW

TIME PROG.AUX

Timer programme for circuit B

Timer programme for circuit C

DHW circuit timer programme

Auxiliary circuit timer programme

VM iSystem

4. To select a timer programme to be modified.

To select to days for which the timer programme is to be

5.

modified:

Turn the rotary button to the left until you reach the day desired.

To confirm, press the rotary button.

6.b : Day selection

Press key b / v until the symbol b is displayed.

Turn the rotary button to the right to select the day(s) desired.

: Cancelling the day selection

v

Press key b / v until the symbol v is displayed.

Turn the rotary button to the right to cancel selection of the relevant

day(s).

7. When the days desired for the programme have been selected,

press the rotary button to confirm.

17

17/11/2011 - 300028026-001-A

Page 19

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

L

g

m

PROG P2 C

Mo Tu

We Th Fr Sa Su

Set the time program.

a

C002230-E-04

06:00

06:00

VM iSystem 3. Operating the appliance

To define the timer ranges for the comfort mode and reduced

8.

mode:

Turn the rotary button to the left until 0:00 is displayed. The first

segment of the graphic bar for the timer programme flashes.

9.b : Comfort mode selection

Press key b / v until the symbol b is displayed.

To select a comfort time range, turn the rotary button to the right.

: Reduced mode selection

v

Press key b / v until the symbol v is displayed.

To select a reduced time range, turn the rotary button to the right.

10.When the times for the comfort mode have been selected, press

the rotary button to confirm.

User level - Menu #TIME PROGRAM

TIME PROG.B

TIME PROG.C

TIME PROG.DHW

TIME PROG.AUX

Day Comfort periods / Filling enabled:

P1

P2 _______________ P3 _______________ P4 _______________

_______________

Monday 6:00 to 22:00

Tuesday 6:00 to 22:00

Wednesday 6:00 to 22:00

Thursday 6:00 to 22:00

Friday 6:00 to 22:00

Saturday 6:00 to 22:00

Sunday 6:00 to 22:00

Monday 6:00 to 22:00

Tuesday 6:00 to 22:00

Wednesday 6:00 to 22:00

Thursday 6:00 to 22:00

Friday 6:00 to 22:00

Saturday 6:00 to 22:00

Sunday 6:00 to 22:00

Monday

Tuesday

Wednesday

Thursday

Friday

Saturday

Sunday

Monday

Tuesday

Wednesday

Thursday

Friday

Saturday

Sunday

17/11/2011 - 300028026-001-A

18

Page 20

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

SUNDAY 11:45

C002219-D-04

3. Operating the appliance

VM iSystem

3.3.8. Setting an annual clock

The annual clock is used to programme up to 10 heating stop periods

over one year. The circuits selected for this stop are in Antifreeze

mode during the period chosen.

1. To access user level: Press the > key.

2. Select the menu #ANNUAL PROG.

4 Turn the rotary button to scroll through the menus or

modify a value.

4 Press the rotary button to access the menu selected

or confirm a value modification.

For a detailed explanation of menu browsing, refer

¼

to the chapter: "Browsing in the menus", page 11.

3. To select the desired parameter.

OFF

No stop

B

circuit B

C

circuit C

B+C

circuit B, C

SU

DHW circuit

B+E

circuit B and DHW

C+E

circuit C and DHW

ALL

circuit B, C and DHW

4. Set the start date and the end date of the shutdown selected.

5. To deactivate a shutdown, select the shutdown and set to OFF.

6. To select another shutdown, press the ' button.

Annual programme (Factory setting)

Stop no. Circuit concerned Start date End date

1

2

3

4

5

6

7

8

9

10

For example: Customised programming

Stop no. Circuit concerned Start date End date

1

2

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

AC

AC

01-01 01-01

01-01 01-01

01-01 01-01

01-01 01-01

01-01 01-01

01-01 01-01

01-01 01-01

01-01 01-01

01-01 01-01

01-01 01-01

01-11 10-11

20-12 02-01

19

If setting STOP: OFF, the stop is deactivated and the start and end

dates are not displayed.

17/11/2011 - 300028026-001-A

Page 21

VM iSystem 3. Operating the appliance

User level - Menu #ANNUAL PROG

STOP N 1:

STOP N 2:

STOP N 3:

STOP N 4:

STOP N 5:

STOP N 6:

STOP N 7:

STOP N 8:

STOP N 9:

STOP N 10:

BEG.DATE N 01

BEG.MONTH N 01

END DATE N 01

END MONTH N 01

BEG.DATE N 02

BEG.MONTH N 02

END DATE N 02

END MONTH N 02

BEG.DATE N 03

BEG.MONTH N 03

END DATE N 03

END MONTH N 03

BEG.DATE N 04

BEG.MONTH N 04

END DATE N 04

END MONTH N 04

BEG.DATE N 05

BEG.MONTH N 05

END DATE N 05

END MONTH N 05

BEG.DATE N 06

BEG.MONTH N 06

END DATE N 06

END MONTH N 06

BEG.DATE N 07

BEG.MONTH N 07

END DATE N 07

END MONTH N 07

BEG.DATE N 08

BEG.MONTH N 08

END DATE N 08

END MONTH N 08

BEG.DATE N 09

BEG.MONTH N 09

END DATE N 09

END MONTH N 09

BEG.DATE N 10

BEG.MONTH N 10

END DATE N 10

END MONTH N 10

Description Factory setting Adjustment range

Selection of the circuit stopped

Setting start date of the stop 01 1-31

Setting start month of the stop 01 1-12

Setting end date of the stop 01 1-31

Setting end month of the stop 01 1-12

Selection of the circuit stopped

Setting start date of the stop 01 1-31

Setting start month of the stop 01 1-12

Setting end date of the stop 01 1-31

Setting end month of the stop 01 1-12

Selection of the circuit stopped

Setting start date of the stop 01 1-31

Setting start month of the stop 01 1-12

Setting end date of the stop 01 1-31

Setting end month of the stop 01 1-12

Selection of the circuit stopped

Setting start date of the stop 01 1-31

Setting start month of the stop 01 1-12

Setting end date of the stop 01 1-31

Setting end month of the stop 01 1-12

Selection of the circuit stopped

Setting start date of the stop 01 1-31

Setting start month of the stop 01 1-12

Setting end date of the stop 01 1-31

Setting end month of the stop 01 1-12

Selection of the circuit stopped

Setting start date of the stop 01 1-31

Setting start month of the stop 01 1-12

Setting end date of the stop 01 1-31

Setting end month of the stop 01 1-12

Selection of the circuit stopped

Setting start date of the stop 01 1-31

Setting start month of the stop 01 1-12

Setting end date of the stop 01 1-31

Setting end month of the stop 01 1-12

Selection of the circuit stopped

Setting start date of the stop 01 1-31

Setting start month of the stop 01 1-12

Setting end date of the stop 01 1-31

Setting end month of the stop 01 1-12

Selection of the circuit stopped

Setting start date of the stop 01 1-31

Setting start month of the stop 01 1-12

Setting end date of the stop 01 1-31

Setting end month of the stop 01 1-12

Selection of the circuit stopped

Setting start date of the stop 01 1-31

Setting start month of the stop 01 1-12

Setting end date of the stop 01 1-31

Setting end month of the stop 01 1-12

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF, B, C, B+C, SU, B+E, C+E, ALL

OFF, B, C, B+C, SU, B+E, C+E, ALL

OFF, B, C, B+C, SU, B+E, C+E, ALL

OFF, B, C, B+C, SU, B+E, C+E, ALL

OFF, B, C, B+C, SU, B+E, C+E, ALL

OFF, B, C, B+C, SU, B+E, C+E, ALL

OFF, B, C, B+C, SU, B+E, C+E, ALL

OFF, B, C, B+C, SU, B+E, C+E, ALL

OFF, B, C, B+C, SU, B+E, C+E, ALL

OFF, B, C, B+C, SU, B+E, C+E, ALL

17/11/2011 - 300028026-001-A

20

Page 22

3. Operating the appliance VM iSystem

3.4 Installation shutdown

CAUTION

Do not switch off the mains supply to the appliance. If the

central heating system is not used for a long period, we

recommend activating the HOLIDAYS mode (to ensure

the anti-grip of the heating pump).

3.5 Frost protection

CAUTION

4 The antifreeze protection does not function if the

appliance is switched off.

4 To protect the installation, set the appliance to

HOLIDAYS mode.

The HOLIDAYS mode protects:

4 The installation if the outside temperature is lower than 3°C

(factory setting).

4 The room temperature if a remote control is connected and the

room temperature is lower than 6 °C (factory setting).

4 The domestic hot water tank if the tank temperature is lower

than 4 °C (the water is reheated to 10 °C).

To configure the holidays mode: ¼ See chapter: "Selecting the

operating mode", page 14.

21

17/11/2011 - 300028026-001-A

Page 23

bar

1

1

2

2

r

c

STD

(

'

t

v

0 2 4 6 8 10 12 14 16 18 22 2420

p

b

AUTO

x

c

r

j

M

g

m

SUNDAY 11:45

TEMP. : 68°

PCU COM.FAIL D27

C002302-D-04

VM iSystem 4. Troubleshooting

4 Troubleshooting

4.1 Messages (type code Mxx)

The module may display the following messages:

Code

Messages Description Checking / solution

no.

FL.DRY.B XX DAYS

FL.DRY.C XX DAYS

FL.DRY.B+C XX DAYS

M30 BL.COM.MODBUS

M31 BL.SYSTEM NETWORK

4.2 Faults

Floor drying is active

XX DAYS = Number of days' floor

drying remaining.

No communication with the master

regulation by the network

MODBUS.

Incorrect configuration of the

network MODBUS.

If a malfunction occurs, the module flashes and displays an error

message and a corresponding code.

1. Make a note of the code displayed.

The code is important for the correct and rapid diagnosis of the

type of failure and for any technical assistance that may be

needed.

2. Press the ? key. Follow the instructions displayed to solve the

problem.

3. Consult the meaning of the codes in the table below:

Floor drying is underway. Heating on the circuits not

concerned is shut down.

4 Contact the professional who takes care of

maintenance of the appliance.

Contact the professional who takes care of

maintenance of the appliance.

Contact the professional who takes care of

maintenance of the appliance.

17/11/2011 - 300028026-001-A

22

Page 24

4. Troubleshooting VM iSystem

Code Faults Description Checking / solution

D03

OUTL S.B FAIL.

D04

OUTL S.C FAIL.

Circuit B flow sensor fault

Circuit C flow sensor fault

Remarks:

The circuit pump is running.

The 3-way valve motor on the circuit is no longer

Bad connection

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

powered and can be adjusted manually.

D05 OUTSI.S.FAIL.

Outside temperature sensor fault

Remarks:

The set point of the appliance is equal to the

maximum.

The valve setting is no longer ensured but

Bad connection

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

monitoring the maximum temperature of the circuit

after the valve is ensured.

Valves may be manually operated.

Reheating the domestic hot water remains

ensured.

D07 SYST.SENS.FAIL.

System sensor fault Bad connection

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

D09 DHW S.FAILURE

Domestic hot water sensor fault

Remarks:

Heating of domestic hot water is no longer

ensured.

The load pump operates.

Bad connection

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

The load temperature of the dhw tank is the same

as the boiler.

D12

ROOM S.B FAIL.

D13

ROOM S.C FAIL.

D14 MC COM.FAIL

B room temperature sensor fault

C room temperature sensor fault

Note:

The circuit concerned operates without any

influence from the room sensor.

Break in communication between the iSystem

module and the boiler radio module

Bad connection

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

Bad connection

4 Check the link and the connectors

Boiler module failure

D15 ST.TANK S.FAIL

D16 SWIM.P.B. S.FAIL

SWIM.P.C. S.FAIL

D17 DHW 2 S.FAIL

D18 ST.TANK S.FAIL

D19 SOL.COL.S.FAIL

23

4 Change the boiler module

Storage tank sensor fault

Note:

The hot water storage tank reheating operation is

no longer assured.

Swimming pool sensor fault circuit B

Swimming pool sensor fault circuit C

Note:

Pool reheating is independent of its temperature.

Bad connection

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

Bad connection

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

Sensor fault tank 2 Bad connection

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

Solar tank sensor fault Bad connection

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

Header sensor fault Bad connection

Sensor fault

4 Contact the professional who takes care of

maintenance of the appliance

17/11/2011 - 300028026-001-A

Page 25

VM iSystem 4. Troubleshooting

Code Faults Description Checking / solution

D20 SOL COM.FAIL

Interruption in communication between the SCU PCB and the solar control system

4 Contact the professional who takes care of maintenance of the appliance

D50 DEF.COM.OTH

D51 DEF XX:SEE BOIL.

Break in communication between the iSystem

module and the boiler control panel.

An error is displayed on the boiler control panel.

4 Contact the professional who takes care of

maintenance of the appliance.

4 Refer to the boiler's installation and service

manual.

17/11/2011 - 300028026-001-A

24

Page 26

5. Warranty

5 Warranty

5.1 General

5.2 Warranty terms

VM iSystem

You have just purchased one of our appliances and we thank you for

the trust you have placed in our products.

Please note that your appliance will provide good service for a longer

period of time if it is regularly checked and maintained.

Your fitter and our customer support network are at your disposal at

all times.

The following provisions are not exclusive of the buyer being able

benefit from the legal provisions applicable regarding hidden defects

in the buyer's country.

Starting from the purchase date shown on the original fitter's invoice,

your appliance has a contractual guarantee against any

manufacturing defect.

The length of the guarantee is mentioned in the price catalogue.

The manufacturer is not liable for any improper use of the appliance

or failure to maintain or install the unit correctly (the user shall take

care to ensure that the system is installed by a qualified engineer).

In particular, the manufacturer shall not be held responsible for any

damage, loss or injury caused by installations which do not comply

with the following:

4 applicable local laws and regulations,

4 specific requirements relating to the installation, such as national

and/or local regulations,

4 the manufacturer's instructions, in particular those relating to the

regular maintenance of the unit,

4 the rules of the profession.

The warranty is limited to the exchange or repair of such parts as have

been recognised to be faulty by our technical department and does

not cover labour, travel and carriage costs.

The warranty shall not apply to the replacement or repair of parts

damaged by normal wear and tear, negligence, repairs by unqualified

parties, faulty or insufficient monitoring and maintenance, faulty

power supply or the use of unsuitable fuel.

25

Sub-assemblies such as motors, pumps, electric valves etc. are

guaranteed only if they have never been dismantled.

The legislation laid down by european directive 99/44/EEC,

transposed by legislative decree No. 24 of 2 February 2002 published

in O.J. No. 57 of 8 March 2002, continues to apply.

17/11/2011 - 300028026-001-A

Page 27

VM iSystem 5. Warranty

17/11/2011 - 300028026-001-A

26

Page 28

AD001-AF

DUEDI S.r.l.

www.duediclima.it

Distributore Ufficiale Esclusivo

De Dietrich-Thermique Italia

Via Passatore, 12 - 12010

San Defendente di Cervasca

CUNEO

+39 0171 857170

+39 0171 687875

info@duediclima.it

IT

DE DIETRICH THERMIQUE Iberia S.L.U.

DE DIETRICH THERMIQUE S.A.S

www.dedietrich-calefaccion.es

Av. Princep d’Astúries 43-45

08012 BARCELONA

+34 932 920 520

+34 932 184 709

ES

3000280 26 - 00 1- A

DEDIETRICH THERMIQUE

57,ruedelaGareF-67580MERTZWILLER-BP 30

© Copyright

All technical and technological information contained in these technical instructions,

as well as any drawings and technical descriptions supplied, remain our property

and shall not be multiplied without our prior consent in writing.

17/11/2011

Loading...

Loading...