Page 1

High Efficiency Decathlon (HD)

Series Gas Fryers

Service & Parts Manual

HDC, CFHDC, SCFHDC,

FPHDC, Y/KSCF/C/HC, BK1814

(High Efficiency Common Cabinet

Decathlon Fryers)

Dean, a member of the Commercial Food Equipment Service Association, recommends using

CFESA Certified Technicians.

PRINTED IN THE UNITED STATES

OF AMERICA

24-Hour Service Hotline

1-800-551-8633

*8196314*

APRIL 2011

Page 2

Please read all sections of this manual and retain for future reference.

This product has been certified as commercial cooking equipment and MUST be installed by

professional personnel as specified. Installation, maintenance and repairs should be performed

by your FRYMASTER AUTHORIZED SERVICE AGENCY.

DANGER

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other cooking appliance.

DANGER

Instructions explaining procedures to be followed MUST be posted in a prominent location in

the event the operator detects a gas leak. This information can be obtained from the local gas

company or gas supplier.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

DANGER

Safe and satisfactory operation of your equipment depends on proper installation. Installation

MUST conform with local codes, or in absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1; The Natural Gas Installation Code, CAN/CGA-B149.1; The Propane Installation

Code, CAN/CGA-B149.2; or The latest edition of the National Electric Code, N.F.P.A. 70.

NOTICE

If, during the warranty period, the customer uses a part for this Manitowoc Food Service

equipment other than an unmodified new or recycled part purchased directly from Frymaster

and Dean, or any of its authorized service centers, and/or the part being used is modified from

its original configuration, this warranty will be void. Further, Frymaster and Dean and its

affiliates will not be liable for any claims, damages or expenses incurred by the customer which

arise directly or indirectly, in whole or in part, due to the installation of any modified part and/or

part received from an unauthorized service center.

DANGER

The crumb tray in fryers equipped with a filter system must be emptied into a fireproof container

at the end of frying operations each day. Some food particles can spontaneously combust if left

soaking in certain shortening material. Additional information can be obtained in the filtration

manual included with the system.

DANGER

The front ledge of the fryer is not a step. Do not stand on the fryer. Serious injury can result

from slips or contact with the hot oil.

Page 3

WARNING

Drawings and photos used in this manual are intended to illustrate operational, cleaning and

technical procedures and may not conform to on-site management operational procedures.

WARNING

No structural material on the fryer should be altered or removed to accommodate placement of

the fryer under a hood. Questions? Call the Frymaster and Dean Service Hotline at 1-800-551-

8633.

This equipment is to be installed in compliance with the basic plumbing code of The Building

Officials and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation

Manual of the Food and Drug Administration.

COMPUTERS

FCC

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

1) This device may not cause harmful interference, and 2) This device must accept any interfere nce

received, including interference that may cause undesired operation. While this device is a verified Class

A device, it has been shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set out by the

ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A et B

prescrites dans la norme NMB-003 edictee par le Ministre des Communcations du Canada.

DANGER

THIS PRODUCT CONTAINS CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE

CANCER AND/OR BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

Operation, installation, and servicing of this product could expose you to airborne particles of

glasswool or ceramic fibers, crystalline silica, and/or carbon monoxide. Inhalation of airborne

particles of glasswool or ceramic fibers is known to the State of California to cause cancer.

Inhalation of carbon monoxide is known to the State of California to cause birth defects or other

reproductive harm.

WARNING

Do not bang fry baskets or other utensils on the fryer’s joiner strip. The strip is present to seal

the joint between the fry vessels. Banging fry baskets on the strip to dislodge shortening will

distort the strip, adversely affecting its fit. It is designed for a tight fit and should only be

removed for cleaning.

Page 4

High Efficiency Decathlon (HD) Series Gas Fryers

Service and Parts Manual

TABLE OF CONTENTS

1. SERVICE PROCEDURES……..……..……………………………………………...

1.1 Functional Description............................................................................................1-1

1.2 Accessing Fryers for Service...................................................................................1-7

1.3 Cleaning the Gas Valve Vent Tube (if applicable)................................................1-9

1.4 Adjusting Burner Manifold Gas Pressure.............................................................1-9

1.5 Adjusting the Pilot Flame......................................................................................1-10

1.6 Calibrating the Thermatron Controller and Backup Thermostat....................1-10

1.7 Replacing Fryer Components...............................................................................1-11

1.8 Troubleshooting and Problem Isolation..............................................................1-28

1.9 Troubleshooting Guides........................................................................................1-36

1.10 Wiring Diagrams....................................................................................................1-37

1.11 Probe Resistance Charts........................................................................................1-51

2. PARTS LIST…….…………………………………..………………………………

2.1 Decathlon(HDC) Primary Components................................................................2-1

2.2 Orifices ....................................................................................................................2-13

2.3 Additional Optional Components and Controllers.............................................2-14

2.4 Drain Components .................................................................................................2-16

2.5 Oil Return System..................................................................................................2-20

2.6 Additional Oil Return Components.....................................................................2-22

2.7 Oil Disposal (Popeye's)..........................................................................................2-24

2.8 Oil Return Wand....................................................................................................2-25

2.9 Over-the-Top Oil Return System.........................................................................2-26

2.10 Filtration Components...........................................................................................2-27

2.11 Basket Lift Components........................................................................................2-34

2.12 Accessories ..............................................................................................................2-36

2.13 Fasteners (Screws, Nuts, Bolts).............................................................................2-37

2.14 Flexlines...................................................................................................................2-38

APPENDIX: Pre-Common Cabinet HD65 Parts List..................................................2-39

Page 5

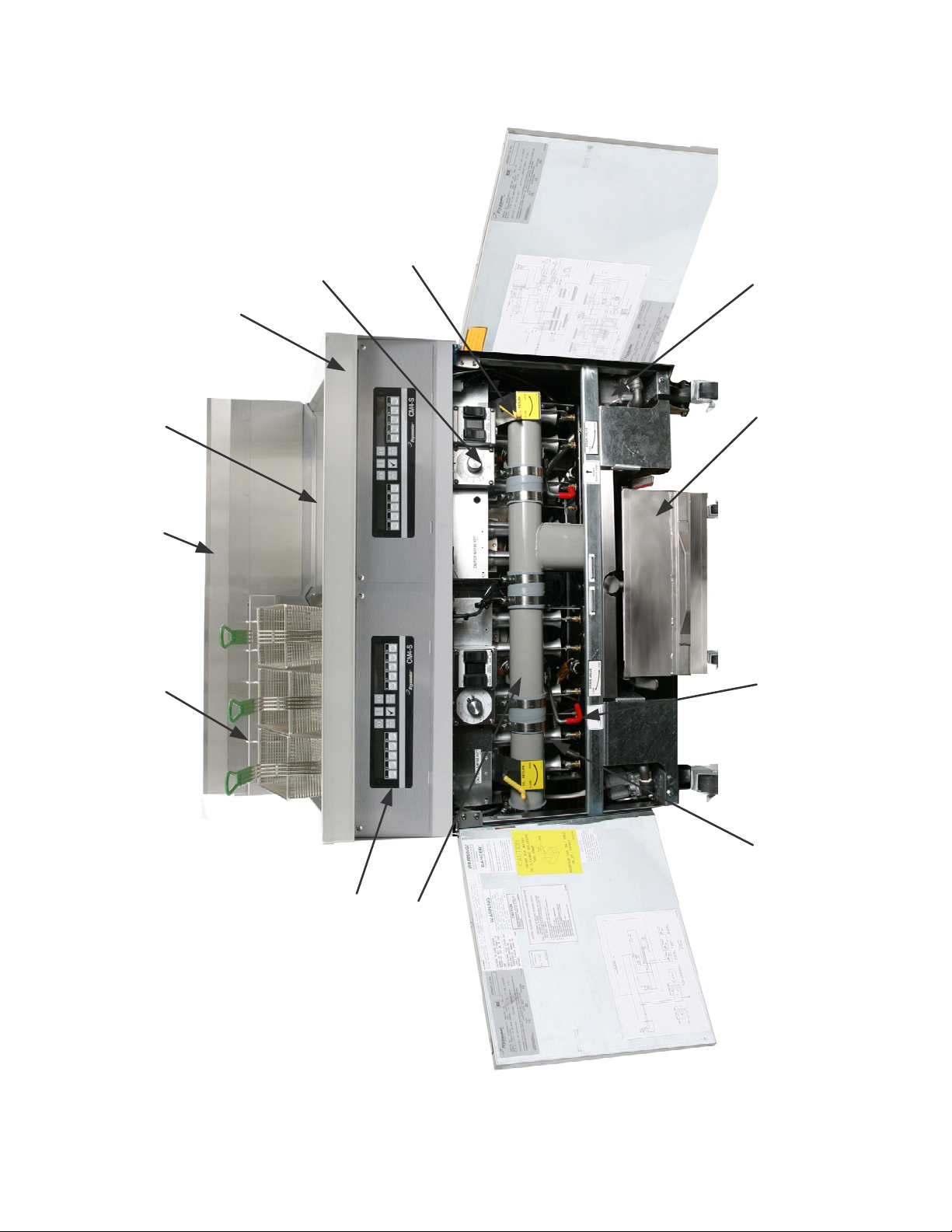

Flue Cap

Top Cap

Electronic

Operating

Thermostat

Oil Return Handle

Gas Valve

Filter Unit

configuration and date of manufacture.

Basket Hanger Frypot

Drain Valve Handle (Red)

Oil Return Handle (Yellow)

Drain Flush Handle (Blue)

Burners

Note: The appearance of your fryer may differ slightly from that shown depending upon

Controller

Drain Tubes

FINDING YOUR WAY AROUND THE DEAN HIGH EFFICIENCY DECATHLON

Page 6

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.1 Functional Description

High Efficiency Decathlon (HD) Series gas fryers contain a welded stainless steel frypot heated by

gas flames diffused evenly through tubes built into the frypot.

Flames originate from orifices in a burner manifold positioned beneath cast-steel burners. The

burners are positioned in the tube openings at the front of the frypot. The diameter of the orifices

differs for natural and LP gas as indicated in the accompanying table.

GAS INFORMATION (Altitudes of 2000 feet or less)

MODEL

HD50G 95

HD60/63/65G 125

INPUT

(BTU)

GAS

TYPE

NAT

LP

NAT

LP

ORIFICE

MM

(INCH)

2.26(#43)

1.40(#54)

2.26(#43)

1.40(#54)

ORIFICE

PART NO.

810-2938

810-2939

810-2938

810-2939

QTY

4

4

5

5

EQUIPMENT

PRESSURE

MBAR

10

27.5

10

27.5

INCH W.C.

4

10

4

10

An electromechanical gas valve regulates gas flow to the manifold. HD Series gas fryers are

equipped with either a 24V valve system. Unit configurations include either a pilot ignition system

or an electronic ignition system.

1-1

Page 7

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.1 Functional Description (cont.)

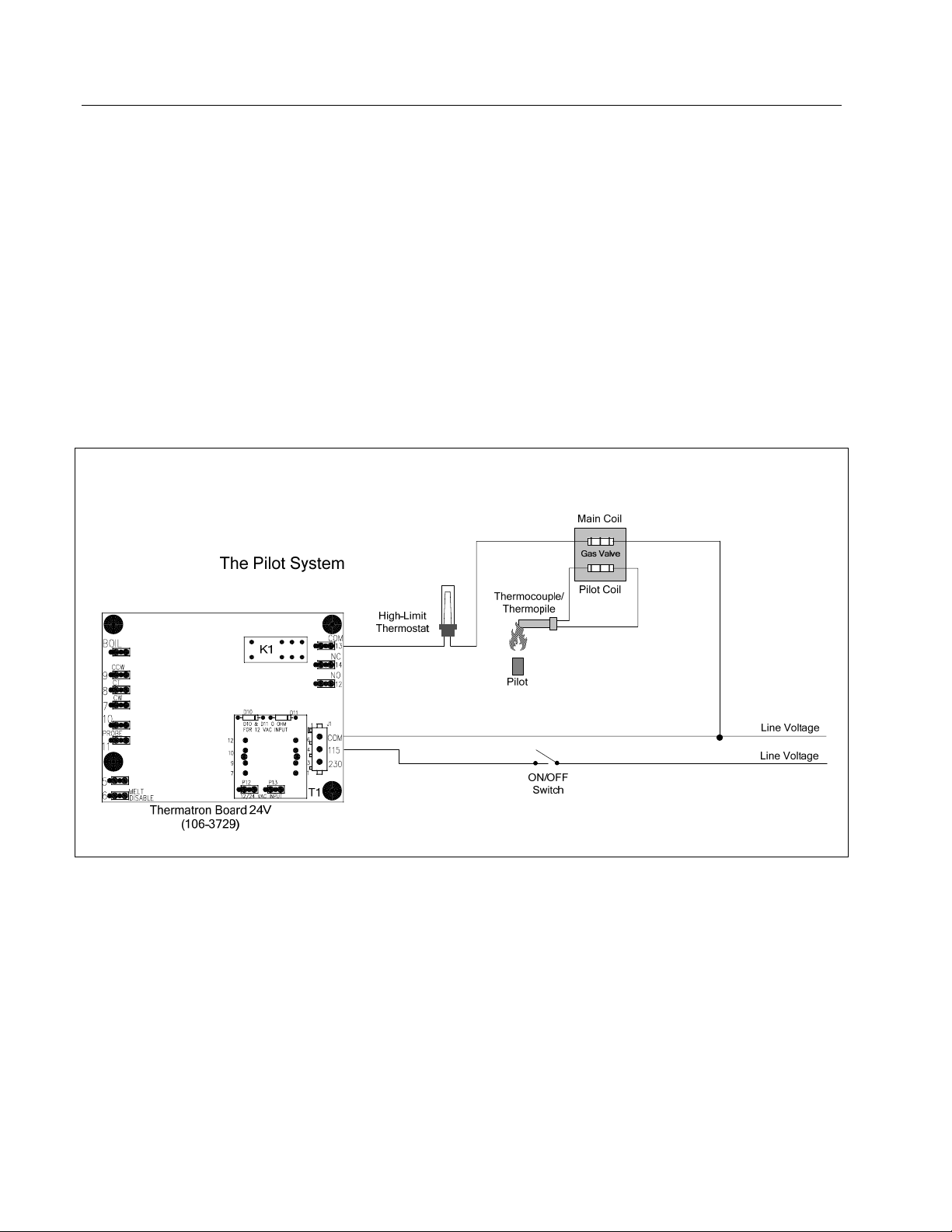

Pilot System Configuration

The pilot system is comprised of the pilot orifice, pilot hood, and a thermopile (some systems

incorporate a thermocouple). The pilot serves two purposes: light the burner and heat the

thermopile. In operation, the thermopile is in contact with the pilot flame and generates millivolts.

The millivolt output energizes the gas valve pilot coil, which in turn opens the pilot valve. If the

pilot flame is extinguished, the gas valve pilot coil loses voltage and the pilot valve closes. The

main valve of the gas valve will not open if the pilot valve is not open. The pilot flame must be

manually lit when the fryer is first placed into operation. A separate 24V circuit, activated by the

fryer ON/OFF switch, provides voltage through the Thermatron to the gas valve main coil, which

opens the main valve.

Electronic Ignition Configuration

In units configured for electronic ignition, an ignition module connected to an ignitor assembly

replaces the pilot system. The ignition module performs three important functions: It provides an

ignition spark, supplies voltage to the gas valve, and proofs the pilot flame.

The module contains a 90-second time delay circuit and a coil that activates the gas valve. The

ignitor assembly consists of a spark plug, a pilot, and a flame sensor element.

1-2

Page 8

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

Electronic Ignition Configuration (cont.)

At start-up the ON/OFF switch is placed in the ON position, supplying 12 VDC to the heat control

circuitry in the controller or controller and to one side of the heat relay coil on the interface board. If

resistance in the temperature probe indicates the temperature in the frypot is below 180°F (82°C),

the current flows through a melt cycle circuit where a timer switch alternately closes for 3 seconds

and opens for 24 seconds. If the temperature is 180°F (82°C) or above, the current flows through a

heat circuit, bypassing the timer switch. In either case, current is supplied to the other leg of the heat

relay coil which then closes an electronic switch in the 24 VAC circuit to provide current to the

ignition module. NOTE: The listed melt cycle times and exit temperature pertain to the Compu-Fry

controller only.

Circuitry in the ignition module sends 24 VAC current to the gas valve via a normally closed highlimit switch and a drain safety switch. Simultaneously, the module causes the ignitor to spark for up

to 90 seconds to light the pilot flame. A flame sensor verifies that the pilot is lit by measuring the

flow of microamps through the flame. If the pilot does not light (or is extinguished), current to the

ignition module is interrupted, preventing the main valve from opening, and the ignition module

"locks out" until the power switch is turned OFF, then back ON.

A temperature probe monitors the temperature in the frypot. When the programmed setpoint

temperature is reached, resistance in the probe causes the heat cycle circuitry in the controller to

interrupt current flow through the heat relay. This in turn interrupts the 24 VAC current to the

ignition module, resulting in closure of the gas valve.

NOTE: Unlike previous modules, microamp readings on these black modules will move up and

down as the module pulses on and off and this is an indication that the module is functioning.

Control Options

HD Series gas fryers may be equipped with Thermatron controls, Compu-Fry controllers, 3-Lane

controllers or FAST controllers.

In fryers equipped with Thermatron controls, the fryer is turned on and off by means of a rocker

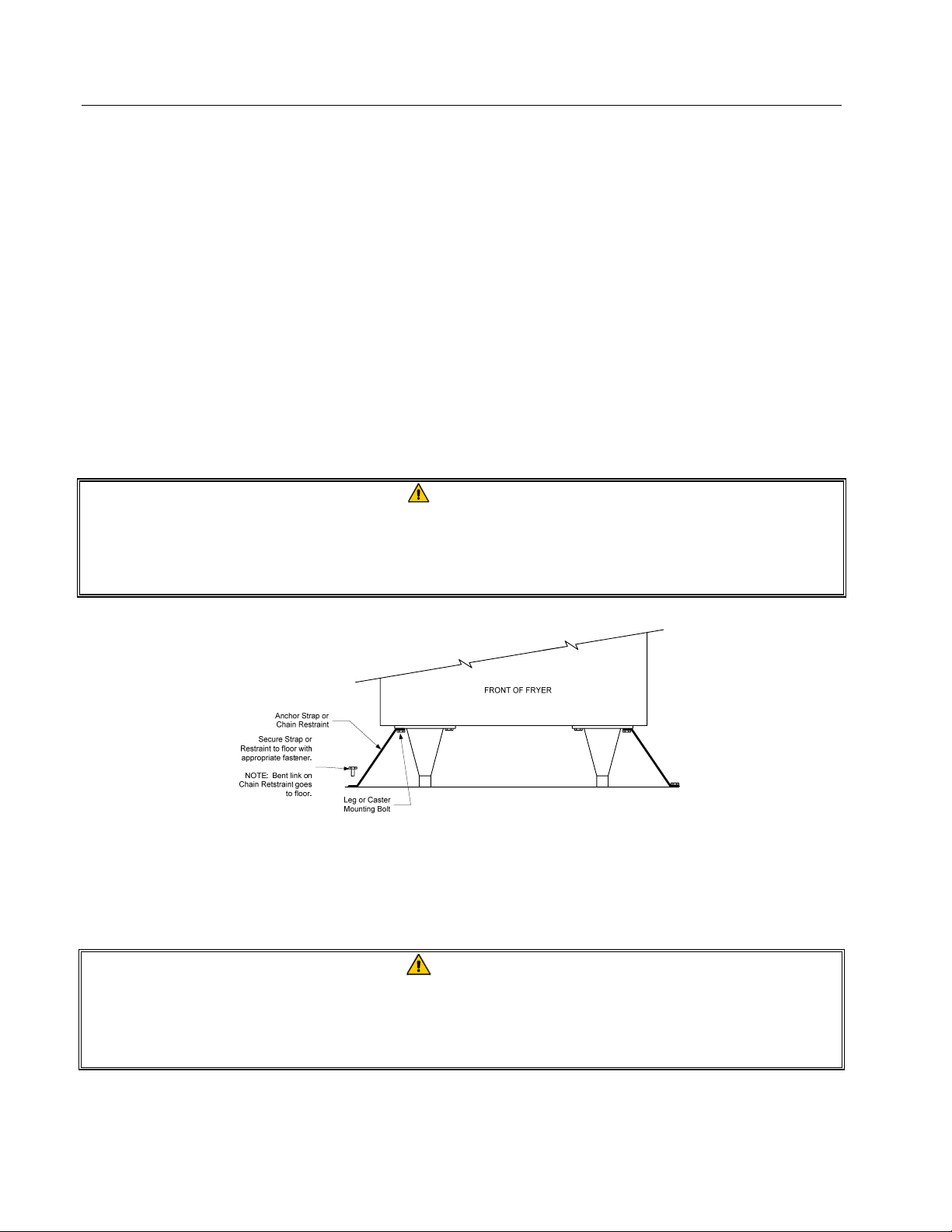

switch and the temperature is set by adjusting a potentiometer. An interface board is located in the

component box (shield) behind the control panel (controller-equipped) or a Thermatron board is

located in a component box inside the cabinet (Thermatron-equipped).

Interface Boards

The interface board provides a link between the controller/controller and the fryer’s individual

components without requiring excessive wiring, and allows the controller to execute commands

from one central point. Two types of interface boards may be used in HD Series gas fryers; the type

used depends on the fryer configuration.

In units configured for electronic ignition and constant pilot, P/N 826-2434 is used; in units

configured with a manually lit pilot (non-electronic ignition), P/N 826-2425 is used.

1-3

Page 9

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

Interface Boards (cont.)

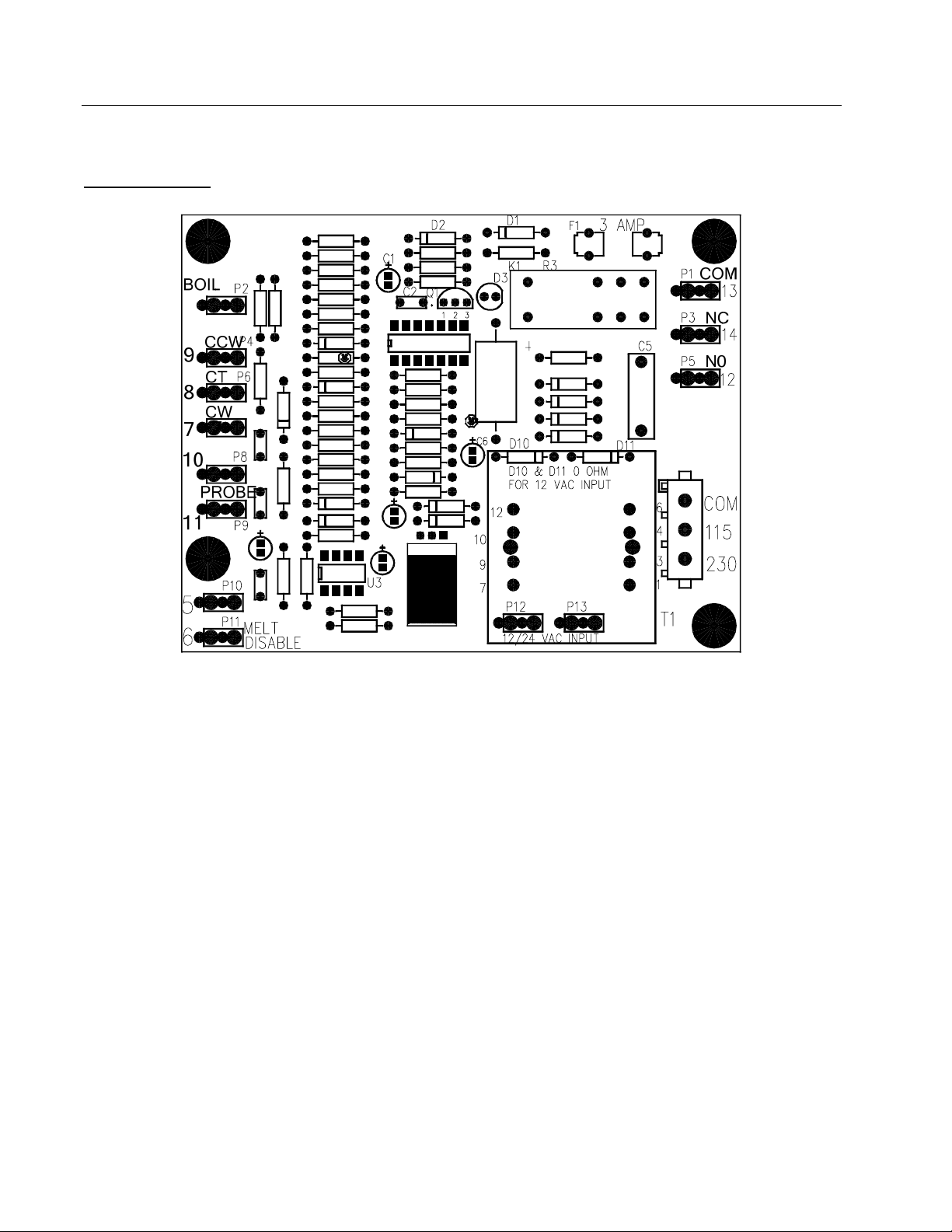

106-3729 (24V): These boards are used in HD fryers equipped with Thermatron control systems.

THERMATRON BOARD P/N 106-3729

Thermatron systems incorporate a temperature probe, a potentiometer, and a temperature control

circuit board. This system is more accurate and reliable than a standard thermostat. The temp erature

probe measures oil temperature via resistance (ohms); as oil temperature rises, resistance decreases.

The potentiometer sets the oil temperature via resistance (ohms). The temperature control circuit

board compares the resistance from the probe and potentiometer and cycles the burner on and off as

necessary.

1-4

Page 10

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

Interface Boards (cont.)

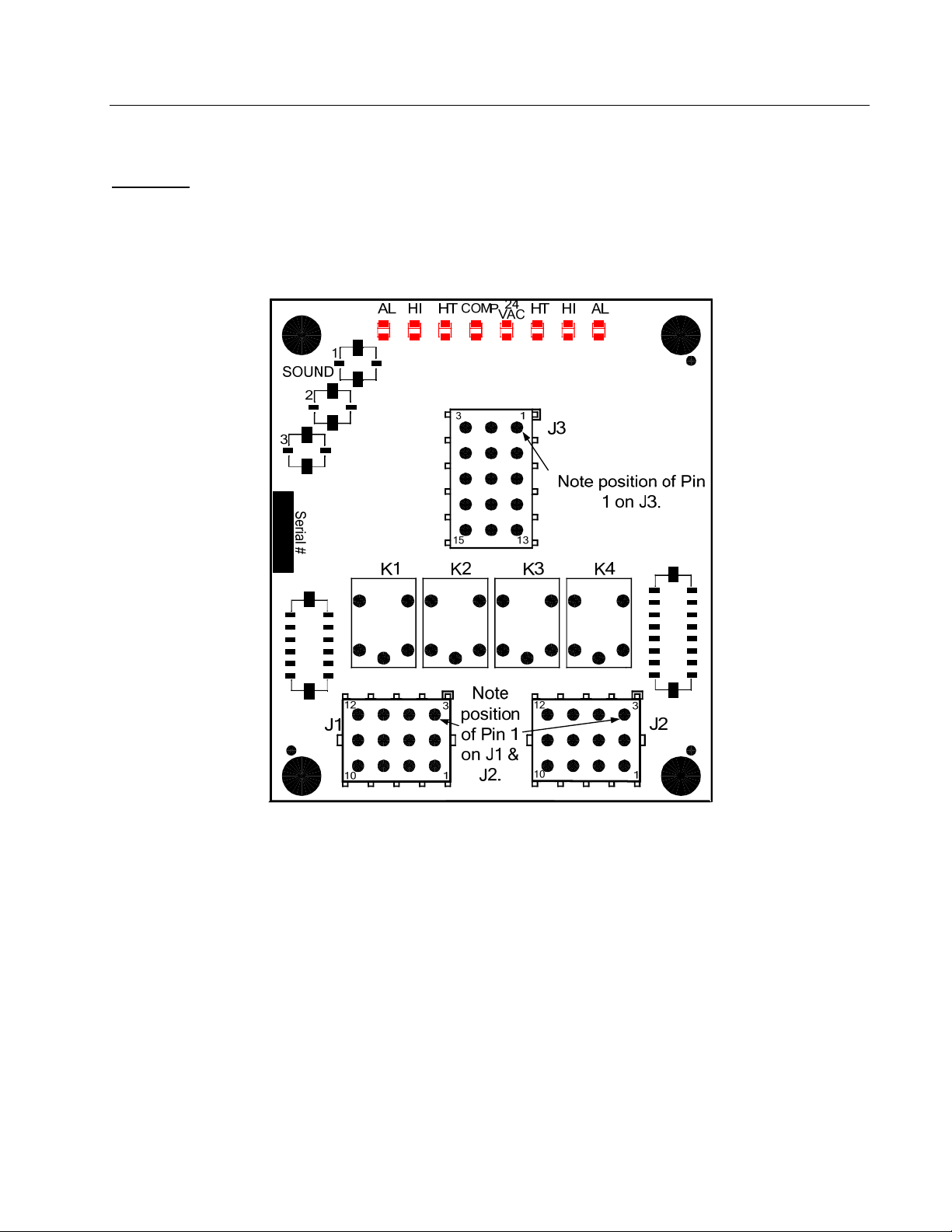

826-2434: These interface boards are used in HD fryers equipped with electronic ignition and

constant pilot.

INTERFACE BOARD P/N 826-2434

Used on fryers equipped with electronic ignition and constant pilot.

1-5

Page 11

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

Interface Boards (cont.)

FREQUENTLY USED TEST POINTS FOR HIGH EFFICIENCY DECATHLON (HD) FRYER S

106-6669 INTERFACE BOARD

Test Meter Setting Pins Test Results

12VAC Power to Controller 50 VAC Scale 1 and 3 on J3 12-18

12VDC Power to Right BL Relay 50 VDC Scale 4 on J2 and 5 on J2 12-18

12VDC Power to Left BL Relay 50 VDC Scale 7 on J1 and 5 on J2 12-18

24VAC Power to High-Limit 50 VAC Scale 6 on J2 and GROUND 22-28

24VAC Power 50 VAC Scale 2 on J2 and GROUND 22-28

24VAC Power To 24VAC Gas Valve 50 VAC Scale 7 on J2 and GROUND 22-28

Probe Resistance* R x 1000 Ohms 10 and 11 on J2 **

* Disconnect 15-pin harness from controller before testing probe circuit.

** See Probe Resistance Chart at the end of this chapter.

HIGH EFFICIENCY DECATHLON (HD) FRYER

LED DIAGNOSTIC LIGHTS

(106-6669 INTERFACE BOARD)

CMP

24V

HI

HT

AL

Indicates power from 12V transformer.

Indicates power from 24V transformer.

Indicates output (closed) from latch relay (K4).

Indicates output from heat relay (K3).

Indicates output (open) from latch relay (K4).

The board contains four relays. K3 is the heat relay and K4 is the latch relay. K1 and K2 are only

used in "dual" or "split" pot applications.

NOTE: On factory-original units not equipped with basket lifts and on service interface boards, the

board will have no basket lift relays installed.

1-6

Page 12

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

Thermostats

Different types of thermostats are used in High Efficiency Decathlon Series gas fryers, depending on

fryer configuration.

Fryers equipped with a Thermatron use a dial to adjust temperature. In this configuration, the probe

resistance varies inversely with the temperature. As the temperature rises, resistance decreases at a

non-linear rate. A chart is located at the end of this chapter.

Fryers equipped with controller controls have a temperature probe. In this configuration, the probe

resistance varies directly with the temperature. As the temperature rises, resistance increases at a

rate of approximately 2 ohms for every 1°F (approximately 3.7 ohms for every 1°C). Circuitry in the

controller monitors the probe resistance and controls burner firing when the resistance exceeds or

falls below programmed temperatures (setpoints). The temperatures are programmed by means of a

keypad on the face of the controller.

All HD Series gas fryers are equipped with a high-limit thermostat. In the event that the fryer fails

to control the oil temperature, the high-limit thermostat prevents the fryer from overheating to flash

point. The high-limit thermostat acts as a normally closed power switch that opens when exposed to

temperatures above 450°F/232°C.

1.2 Accessing Fryers for Service

DANGER

Moving a fryer filled with cooking oil may cause spilling or splattering of the hot

liquid. Follow the draining instructions included with the fryer before attempting to

relocate a fryer for servicing.

1. Shut off the gas supply to the unit. Unplug the power cords. Remove any attached restraining

devices.

2. Disconnect the unit from the gas supply.

3. Relocate the fryer for service accessibility.

4. After servicing is complete, reconnect the unit to the gas supply, reattach restraining devices, and

plug in the electrical cords.

DANGER

No structural material on the fryer should be altered or removed to accommodate

placement of the fryer under a hood. Questions? Call the Frymaster Dean Service

Hotline at 1-800-551-8633.

1-7

Page 13

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

Restraints

Once the fryer has been positioned at the frying station, use a carpenter’s level placed across the top

of the frypot to verify that the unit is level, both side-to-side and front-to-back.

To level fryers equipped with legs, the bottom of the legs can be screwed out up to one inch for leveling.

Legs should also be adjusted so that the fryer(s) are at the proper height in the frying station.

For fryers equipped with casters, there are no built-in leveling devices. The floor where the fryers

are installed must be level.

When the fryer is leveled in its final position, install the restraints provided with the unit to limit its

movement so that it does not depend on or transmit stress to the electrical conduit or connection.

Install the restraints in accordance with the provided instructions (see illustration below). If the

restraints are disconnected for service or other reasons, they must be reconnected before the fryer is

used.

DANGER

Adequate means must be provided to limit the movement of this appliance without

depending on or transmitting stress to electrical conduits or gas supply line. A

restraint kit is provided with the fryer. If the restraint kit is missing contact your

local Frymaster Factory Authorized Service Center (FASC) for part number 826-0900.

NOTE: If you need to relocate a fryer installed with legs, remove all weight from each leg

before moving. If a leg becomes damaged, contact your service agent for immediate repair or

replacement.

DANGER

Hot oil can cause severe burns. Avoid contact. Under all circumstances, oil must be

removed from the fryer before attempting to move it to avoid oil spills, falls, and

severe burns. This fryer may tip and cause personal injury if not secured in a

stationary position.

1-8

Page 14

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.3 Cleaning the Gas Valve Vent Tube (if applicable)

1. Set the fryer power switch and the gas valve to the OFF position.

2. Carefully unscrew the vent tube from the gas valve. NOTE: The vent tube may be straightened

for ease in removal.

3. Pass a piece of wire through the tube to remove any obstruction. Remove the wire and blow

through the tube to ensure it is clear.

4. Reinstall tube and bend so that the opening is pointing downward.

1.4 Adjusting Burner Manifold Gas Pressure

WARNING

This task should be performed by qualified service personnel only.

1. Ensure that the gas valve knob is in the OFF position.

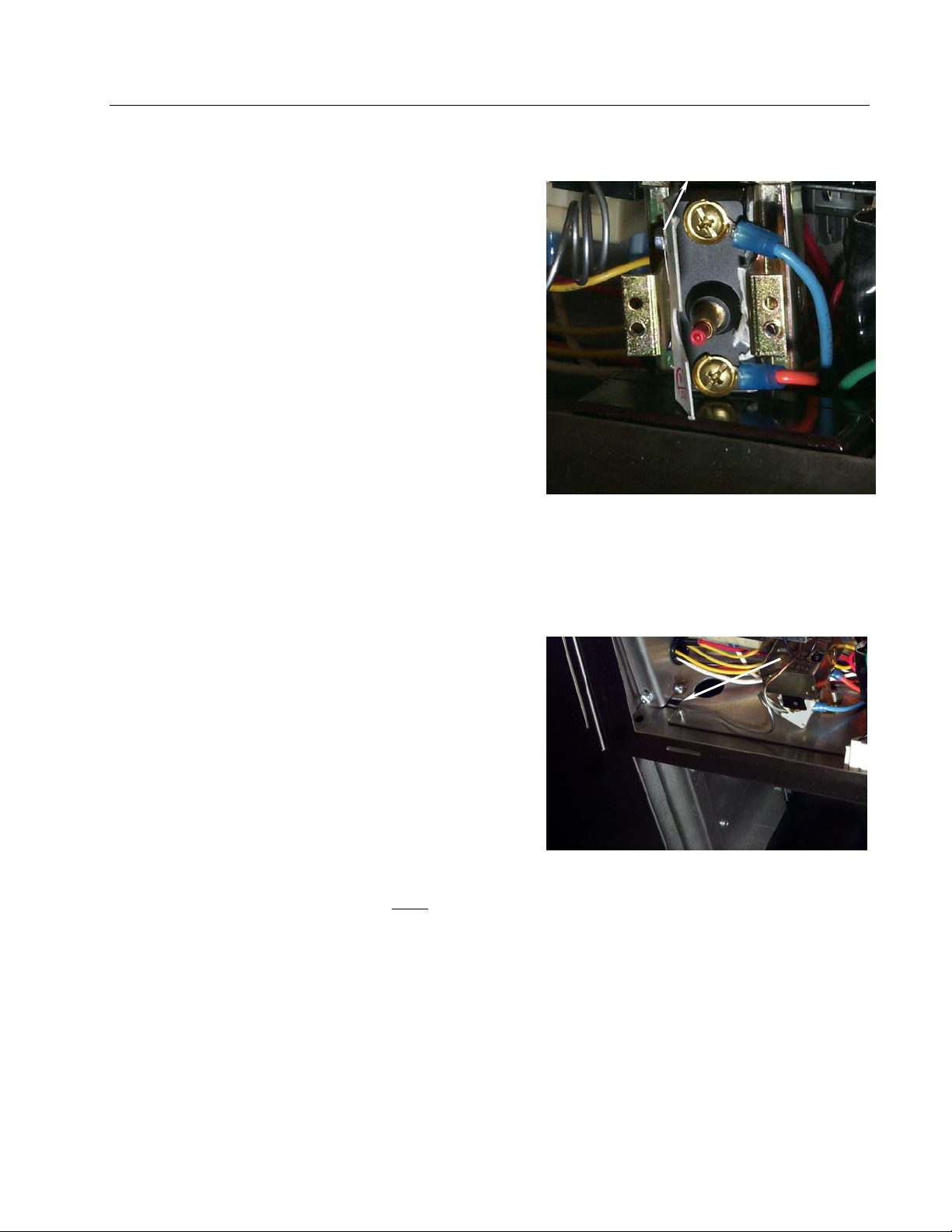

2. Remove the pressure tap plug from the gas valve (see arrows in photos below for location).

Pilot Ignition Valve

(Line Voltage)

Electronic

Ignition Valve

3. Insert the manometer fitting into the pressure tap hole.

4. Place the gas valve in the ON position then place the fryer power switch in the ON position.

When the burner lights and continues to burn, check the gas pressure reading against the table on

page 1-1.

5. To adjust burner gas pressure, remove the cap from the gas valve regulator and adjust to correct

pressure.

6. Place the fryer power switch and the gas valve in the OFF position. Remove the manometer

fitting from the pressure tap hole and reinstall the pressure tap plug.

1-9

Page 15

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.5 Adjusting the Pilot Flame

1.5.1 Main Pilot

1. Remove the cap from the pilot adjustment screw hole on the gas valve.

2. Using a small, flat-tipped screwdriver, turn the pilot adjusting screw counterclockwise to

increase length of flame or clockwise to decrease length of flame. Adjust to obtain a flame from

1 inch to 1½ inches long.

3. Reinstall the pilot adjustment screw cap.

1.5.2 Trailing Pilot

Unlike older Decathlon units, current production HD units do not have a trailing pilot adjustment.

1.6 Calibrating the Thermatron

1. Fill the frypot to the lower OIL-LEVEL line with cooking oil. If solid shortening is used, it must

be melted before starting the calibration procedure.

2. Ensure the fryer ON/OFF switch is in the OFF position and light the pilot.

3. Place the fryer ON/OFF switch in the ON position. Set the potentiometer dial to 325°F (162°C).

4. Allow the oil to equalize at setpoint temperature. This is evident when the burners have cycled

on and off several times.

5. Insert a thermometer or pyrometer into the frypot within 3 inches of the probe bulb. Ensure the

tip of the thermometer/pyrometer does not touch the frypot burner tube.

6. If the temperature on the thermometer is higher or lower than 325°F (162°C), the knob is out of

calibration.

7. Calibrate the knob by first loosening the setscrews and slowly turning the knob to match the

temperature reading of the thermometer. Tighten the setscrews, ensuring the knob does not

move on the shaft during tightening.

8. Allow burners to cycle on and off several times, then recheck oil temperature as described in

Step 5. If the thermostat dial temperature matches the thermometer temperature, the thermostat

is calibrated. If not, repeat Step 7.

1-10

Page 16

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7 Replacing Fryer Components

1.7.1 Replacing the Controller

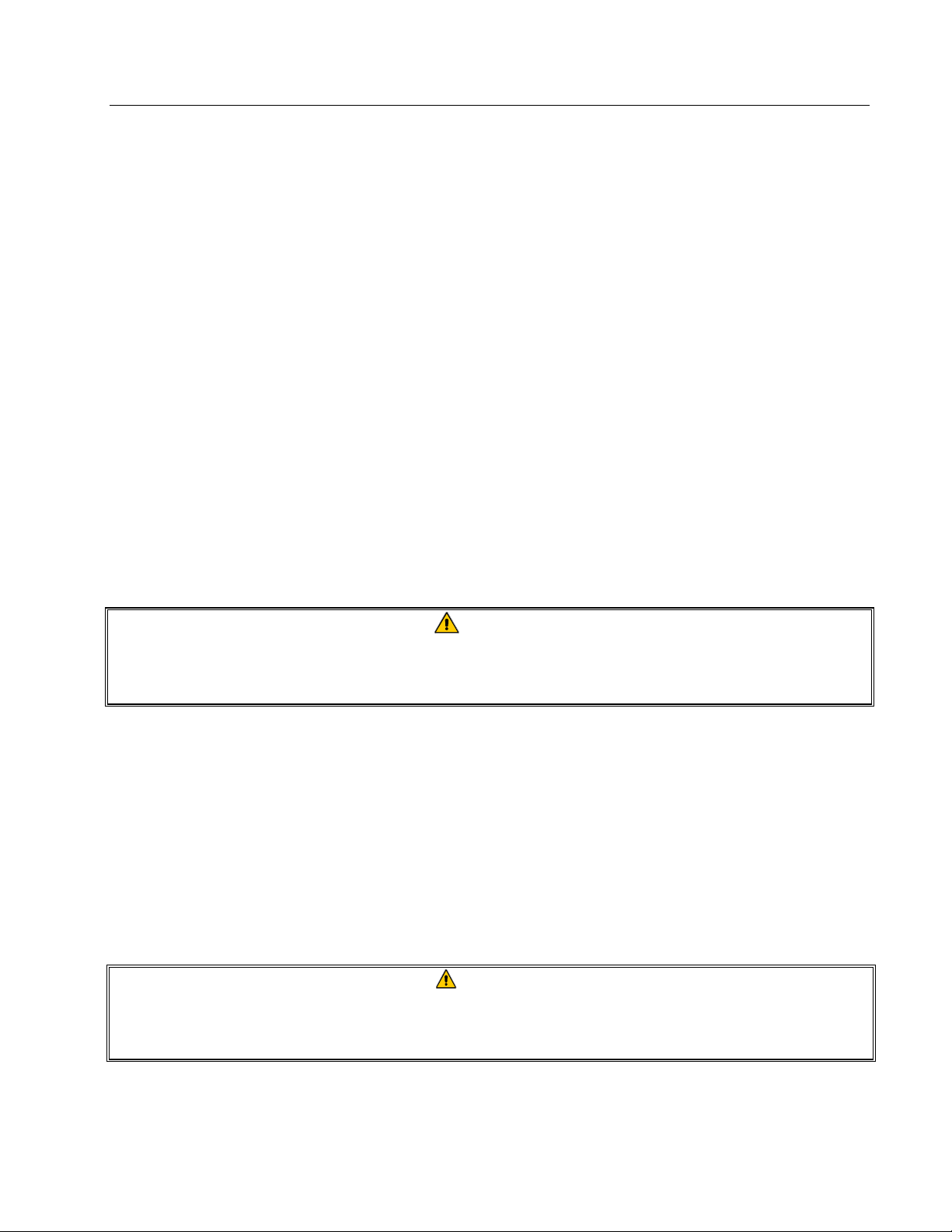

1. Disconnect the fryer from the electrical

supply.

2. Unscrew the two controller panel screws.

The controller panel is hinged at the bottom

and will swing open from the top.

3. Unplug the fryer wiring harness and ground

wire from the back of the controller.

4. Remove the controller by lifting it from the

hinge slots in the fryer control panel frame.

5. Reverse the procedure to install a new

controller.

Computer panel in “down” position.

Disconnect the 15-pin connector and ground

wire (arrows) from the computer.

1-11

Page 17

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7.2 Replacing the Temperature Probe; Controller-equipped Fryers

1. Disconnect the fryer from the electrical supply.

2. Drain cooking oil from the frypot. Allow the

frypot to cool completely before proceeding.

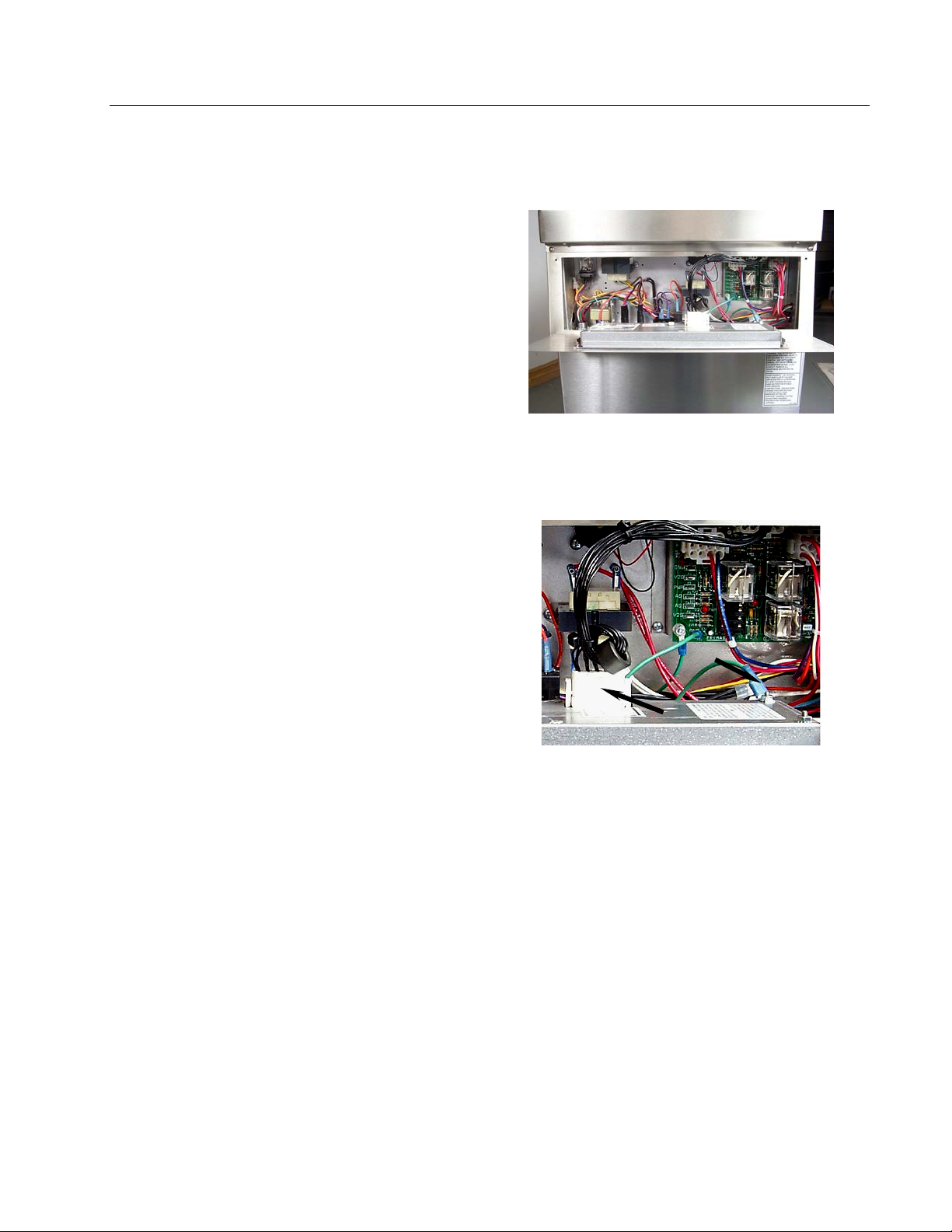

3. Remove fryer door for easier access to the

temperature probe. First, remove top hinge

from bracket. Then, lift door off bottom

hinge pin.

Remove the fryer door for easier access to the

temperature probe.

4. Disconnect the probe harness connector

(arrow). Use a pin pusher to remove plug

from probe wires (probe side only). Retain

the plug for re-assembly on new probe.

5. Remove the drain manifold. Only the drain

tubes directly blocking the frypot being

Disconnect the two-pin probe harness

connector (arrow).

replaced require removal.

- Remove the nuts holding the drain valve

strap onto the drain tube stud.

- Disconnect the Teflon tube at the back of

the center dump tube piece and any other

components attached to the tubes,

including drain flush flexlines.

- Loosen the nut on each clamp holding the

rubber boots and drain sections together.

Remove the nuts, Teflon tube (not pictured), clamp,

boot, and drain tubes.

- Carefully remove the tubes by pulling

down at an angle, straight out of the drain

valves, and working them gently out of

the rubber boots. Set aside for

reassembly.

1-12

Page 18

)

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7.2 Replacing the Temperature Probe; Controller-equipped Fryers (cont.)

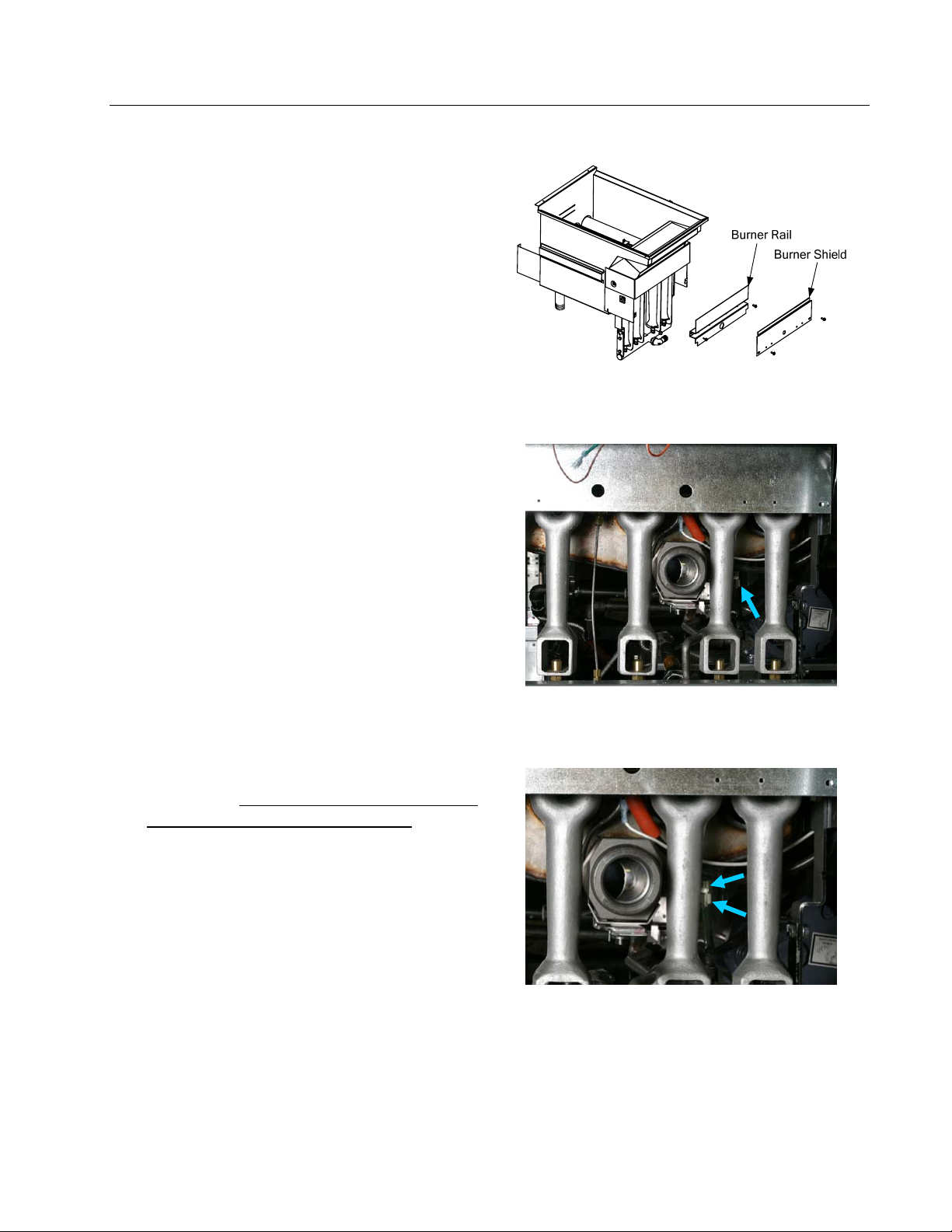

6. Remove the burner shield by loosening the

screw on each end.

7. Remove the burner rail by loosening the

screw on each end. The burner rail secures

the burners in the burner manifold. Be

careful to ensure that the burners do not fall

out of the gas manifold, as they might be

damaged and dented.

Remove the burner rail and burner shield.

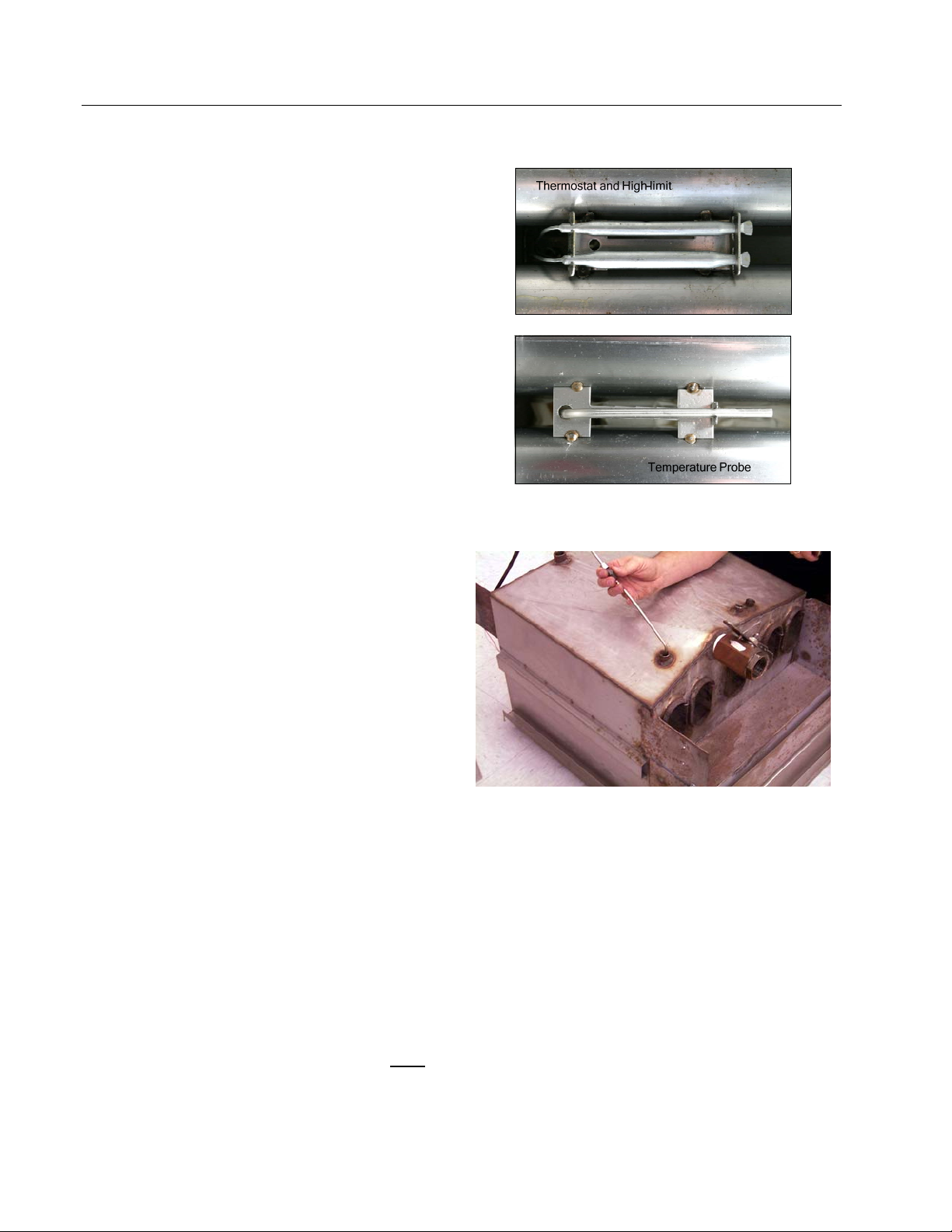

8. Remove the burners to gain access to the

temperature probe and to ease frypot

removal. Lean each burner slightly away

from the frypot to clear the burner seal

(metal box attached to frypot). Then, pull

the burner up and off of the orifice. The

burners should be easy to remove and do

not require force.

9. Loosen and unscrew the compression nut

Remove burners to gain access to temperature

probe (arrow).

and the pass-through nut completely from

the frypot. Proceed to the next step before

removing the probe from the frypot.

Loosen and unscrew completely the compression

nut (bottom arrow), then the pass-through nut (top

arrow

.

1-13

Page 19

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7.2 Replacing the Temperature Probe; Controller-equipped Fryers (cont.)

10. Locate the temperature probe inside the

frypot.

11. The temperature probe can be removed

through the bottom of the frypot as follows:

Ensure the two-pin connector has been

Locate the temperature probe.

removed from the probe wiring harness

(step 4, above). Carefully bend the two tabs

(one forward and toward the back) so the

probe will clear the tabs. Remove the

harness insulation. The probe can be pulled

through the frypot from the bottom

(complete step 7, above, prior to removing

probe).

12. Carefully remove the probe from the frypot.

As the probe is removed, tilt the probe at an

angle to facilitate removal (curved probes

only).

After removing the probe mounting hardware, the

temperature probe can be removed through the

bottom of the frypot. Retain the mounting hardware

for reassembly.

13. Follow the steps on the next page to install

the new temperature probe.

IMPORTANT: When installing new probe, use

Loctite PST567 or equivalent pipe thread sealant

on threads and ensure probe is positioned properly

with the mounting hardware installed prior to

tightening the compression nut. Once tightened,

the probe cannot be repositioned.

1-14

Page 20

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

Installing the New Temperature Probe:

1. Feed the probe wire through the probe nipple from the top side of the frypot.

2. Loosely install the bladder nut.

3. Mount the probe into the mounting hardware. Carefully bend the two tabs back into alignment to

retain probe.

4. Tighten the bladder nut.

5. Install the insulation and plug.

1.7.3 Replacing the High-limit Thermostat

1. Turn fryer off and drain oil from the frypot. Allow the frypot to cool completely before

proceeding.

2. Perform steps 1-4 in Section 1.7.1, Replacing the Controller.

3. Remove fryer door for easier access to the temperature probe. First, remove top hinge from

bracket. Then, lift door off bottom hinge pin.

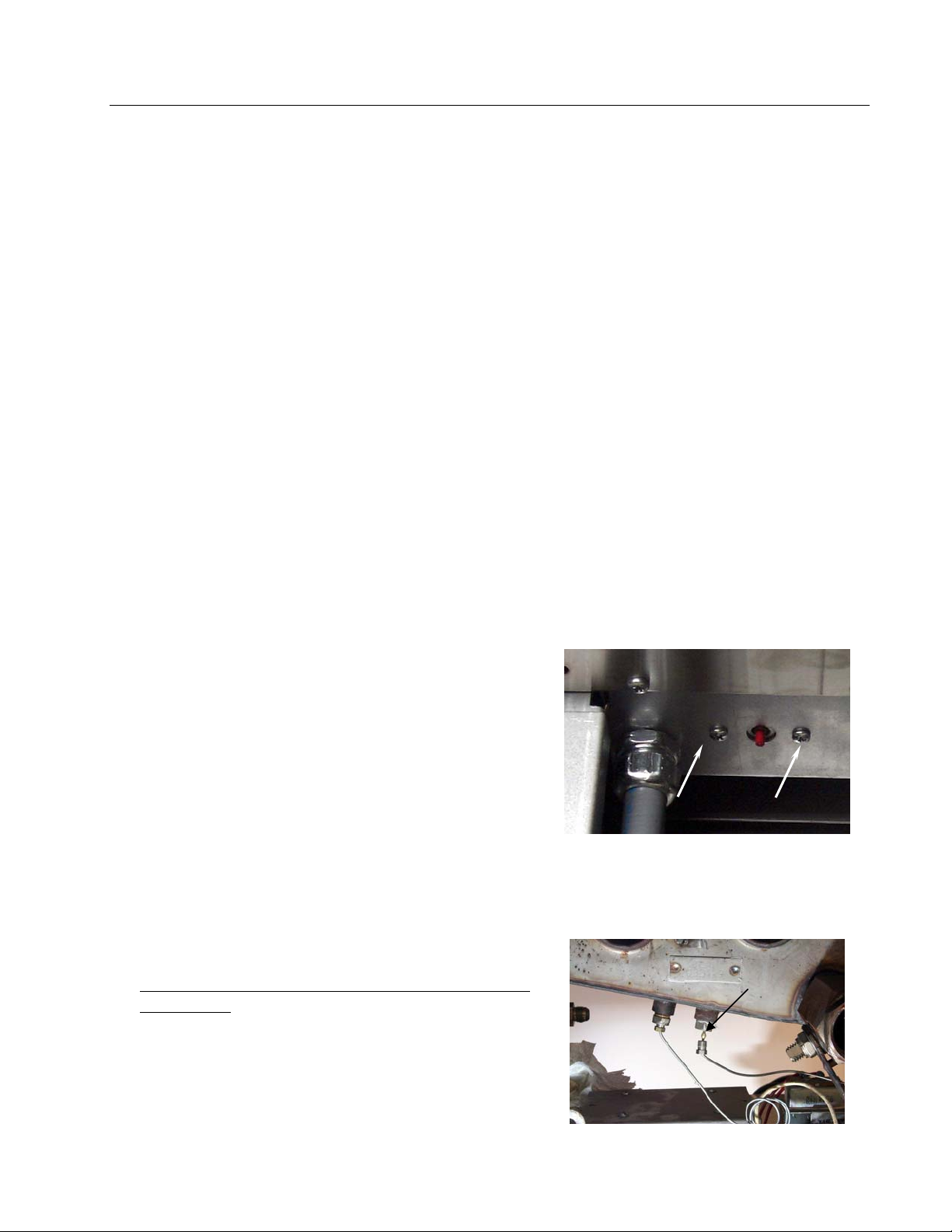

4. Remove two screws securing the high-limit

mounting-bracket. Do not disconnect wires from

high-limit at this time.

5. Loosen and completely unscrew the compression

Remove screws (arrows) securing high-limit to

fryer.

nut, then the pass-through nut on the frypot bottom.

Proceed to the next step before removing high-limit

from frypot.

Compression nut unscrewed. Unscrew

the pass-through nut (arrow).

1-15

Page 21

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7.3 Replacing the High-limit Thermostat (cont.)

6. Locate the high-limit probe inside the frypot.

Carefully bend the outer tab at the rear of the high

limit until the high limit can slid back and out of the

retaining bracket.

7. Carefully pull high-limit capillary tube and bulb out

of the frypot from the bottom.

Remove high-limit capillary tube and bulb

from the bottom of the frypot.

Locate the high-limit probe.

1-16

Page 22

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7.3 Replacing the High-limit Thermostat (cont.)

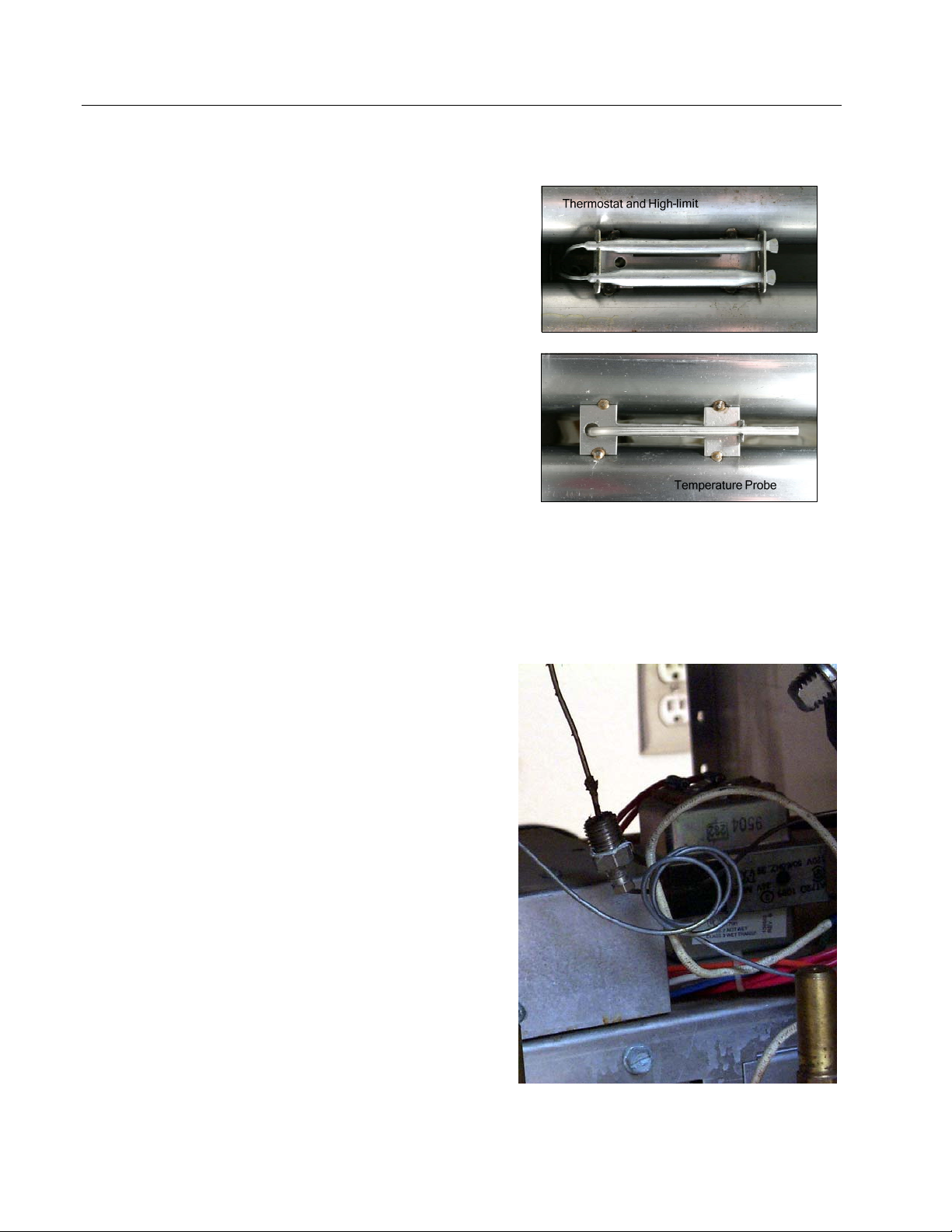

8. Mark and disconnect wires at the high-limit in the

component box.

9. Remove high-limit from fryer by pulling the

capillary tube and bulb through the component box

opening (arrow). This may require removal of the

control panel frame.

10. Reverse the above steps for high-limit installation.

IMPORTANT: When installing new high-limit,

ensure the capillary tube and bulb are positioned

properly with tab back in alignment prior

to tightening

the compression nut. Once tightened, the capillary

tube cannot be repositioned.

Mark and disconnect high-limit wiring

(arrows). Reconnect wires to the same

terminals on the replacement high-limit.

Component box opening (arrow).

1-17

Page 23

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7.4 Replacing Rocker Switches

1. Disconnect the fryer from the electrical supply.

2. If switches are located in a control box within the fryer, remove the six screws securing the

switch panel to the control box. Do not allow the switch panel to hang from the switch wiring

harness or other wires.

1-18

Page 24

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7.4 Replacing Rocker Switches (cont.)

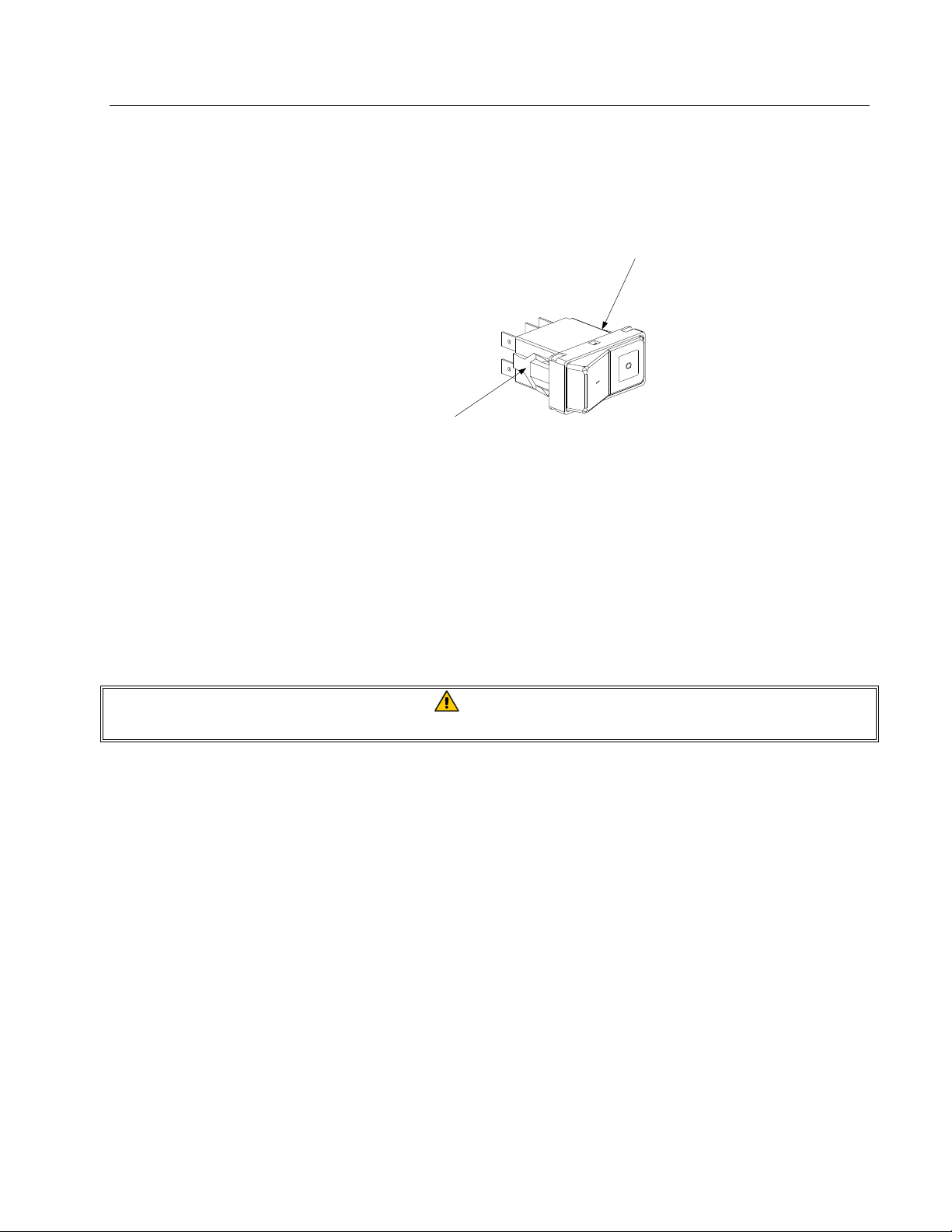

3. Depress the retaining clips (see illustration below) and push the switch out of the slot. If there is

a switch-guard present, retain it for installation of the replacement switch.

Depress clips on each

side to remove switch

from control panel.

4. Remove wires one at a time from the switch being removed and connect to the replacement

switch until all wires are transferred.

5. Reverse the above steps for reassembly.

1.7.5 Replacing the Gas Valve

DANGER

Drain the frypot or remove the handle from the drain valve before proceeding further.

1. Disconnect fryer from electrical and gas supplies.

2. Disconnect the wires from the gas valve terminal block, marking each wire to facilitate

reconnections. For 120VAC gas valves, disconnect the black wire from the high-limit, then

remove the bobtail connecting the white wire.

3. Remove the high-limit thermostat wire from the gas valve pilot coil (all but 120 VAC valves).

4. Remove the pilot gas line fitting from the gas valve.

5. Remove the pipe union collars to the left and right of the gas valve and remove the valve.

6. Remove the pipefitting from the old gas valve and install on the replacement valve, using Loctite

PST567 or equivalent pipe thread sealant on threads. Do not apply sealant to the first two pipe

threads. Doing so will clog and damage the gas valve.

7. Reverse steps 1-5 to install the replacement gas valve.

1-19

Page 25

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7.6 Replacing the Pilot Assembly

1. Remove the pilot tubing from the bottom of the pilot assembly.

2. If the pilot is an electronic ignition pilot, disconnect the ignition cable and the sense wire.

3. Remove the pilot mounting screw(s) from the pilot mounting bracket and remove the pilot.

4. Reverse the procedure to replace the pilot assembly.

NOTE: The above procedure is applicable to standing pilot, electronic ignition, and

trailing pilot assemblies.

1.7.7 Replacing the Frypot

1. Open fryer doors and remove filter pan (if applicable). Ensure controller and all power switches

are off. Drain and dispose of or store oil from all frypots prior to moving fryer.

DANGER

Hot cooking oil will cause severe burns. Never attempt to move this appliance when

filled with hot cooking oil or to transfer hot cooking oil from one container to

another.

2. Turn gas valve off, then turn gas off at supply valve or meter. Disconnect supply line from gas

manifold at rear of fryer.

NOTE: If restraints are installed on the fryer, disconnect restraints prior to disconnecting

the gas supply line.

3. Unplug fryer from electrical supply source.

4. Remove fryer door for easier access to the temperature probe. First, remove top hinge from

bracket. Then, lift door off bottom hinge pin.

5. Remove the basket hanger from the flue cap by lifting

up and off of fryer. Some units may have a built-in

flue deflector on the basket hanger. Units with basket

lifts will require the removal of the lift arms prior to

removing the basket hanger.

1-20

Removing the basket hanger from the flue cap.

Page 26

g

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7.7 Replacing the Frypot (cont.)

6. Remove the top cap. It is held in place by one screw on

each side of the fryer. If the fryer has a controller on

the front, the top cap may also be held in place by two

screws on the front of each pot. FPHD65 units may

have two screws on each end of the top cap.

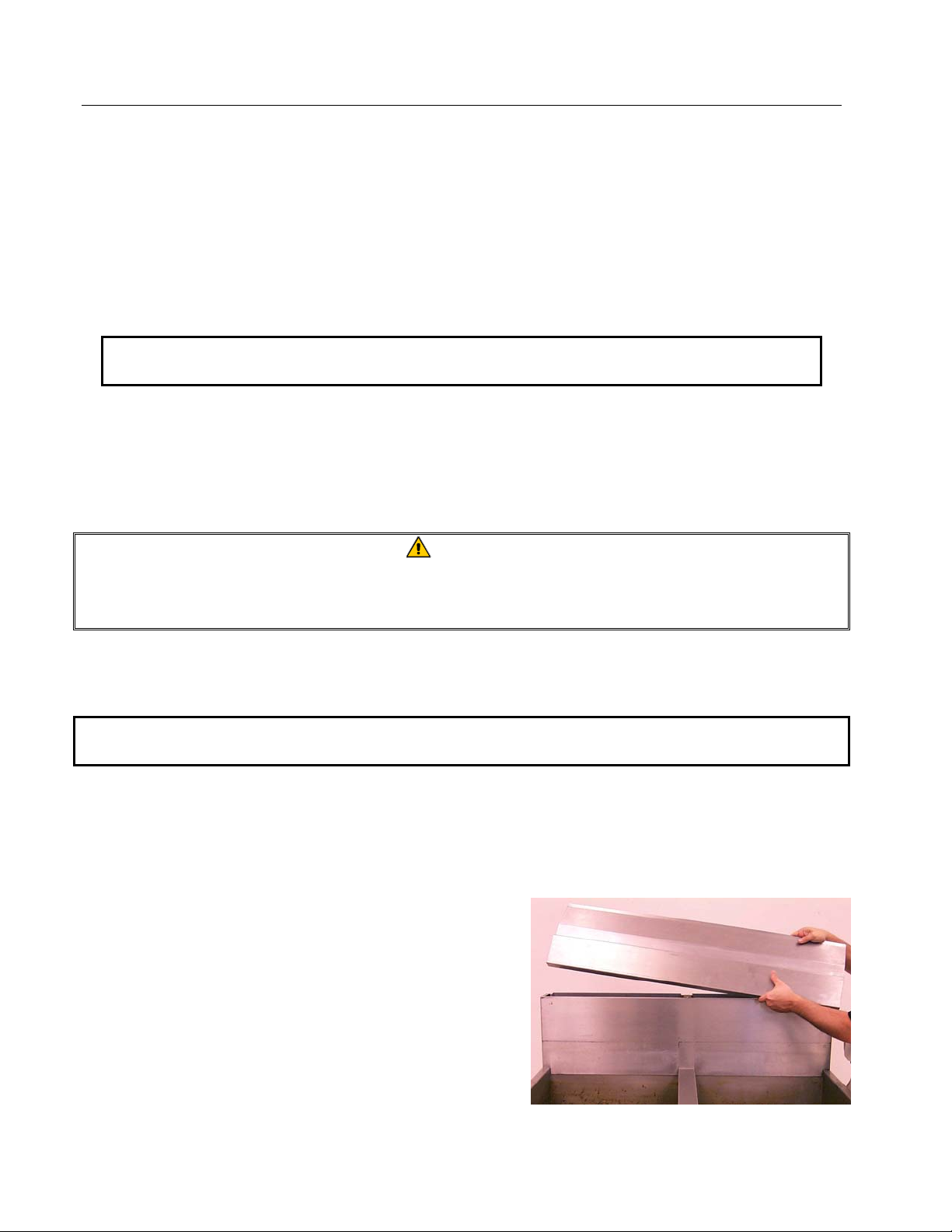

7. Remove the joiner strips on either side of the frypot. Be

careful not to bend the joiner strip during removal.

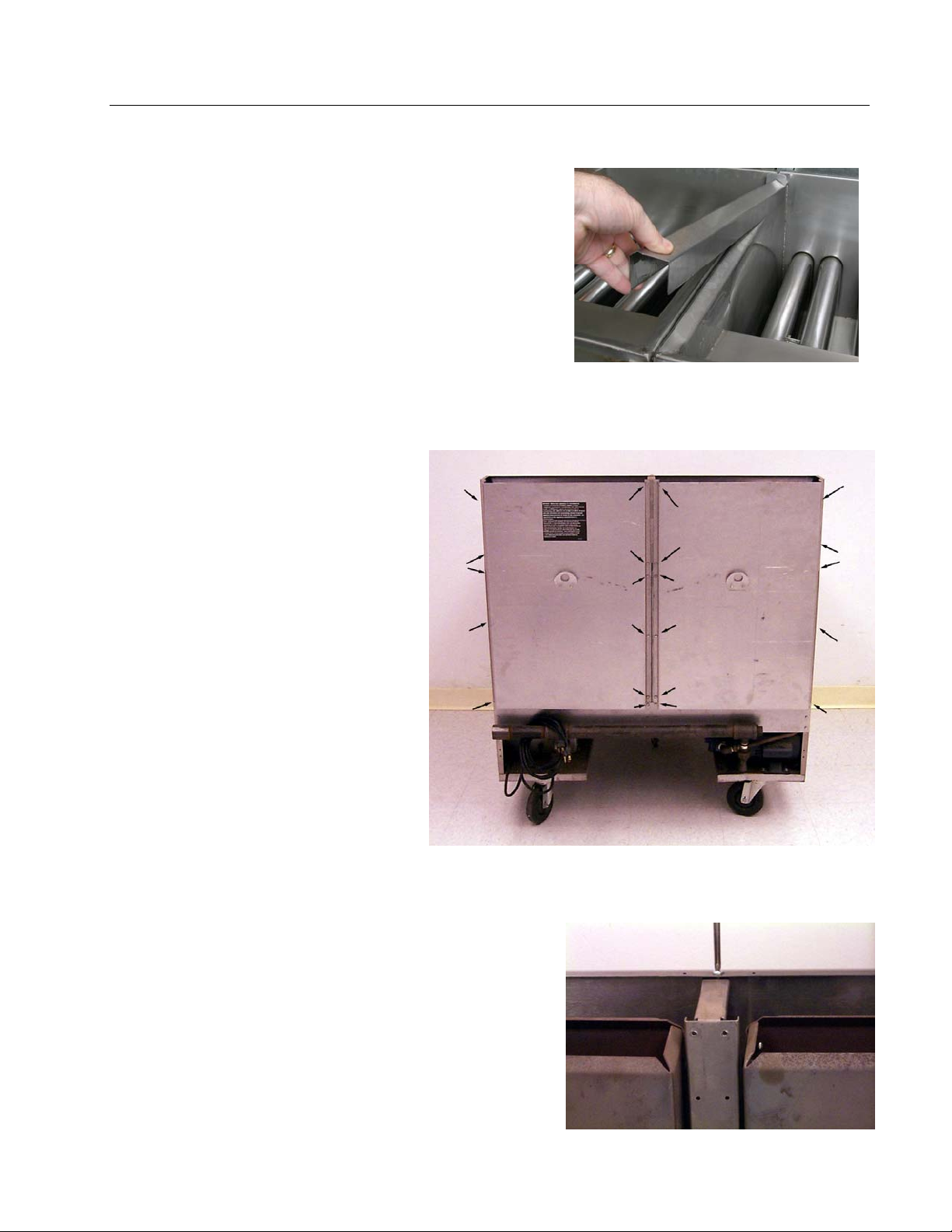

8. Remove back panels of the fryer.

There may be both upper and lower

panels and several screws secure

them. Screw location and orientation

will vary according to fryer model.

Typical screw locations on the back panel (may vary by

model).

9. Remove screw securing brace (and back panel) to the

flue cap. Support the brace with hand while removing

screw to prevent brace from falling away. Remove

brace and set aside for reassembly.

Removin

the joiner strip.

Removing brace holding back panel to flue

cap.

1-21

Page 27

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7.7 Replacing the Frypot (cont.)

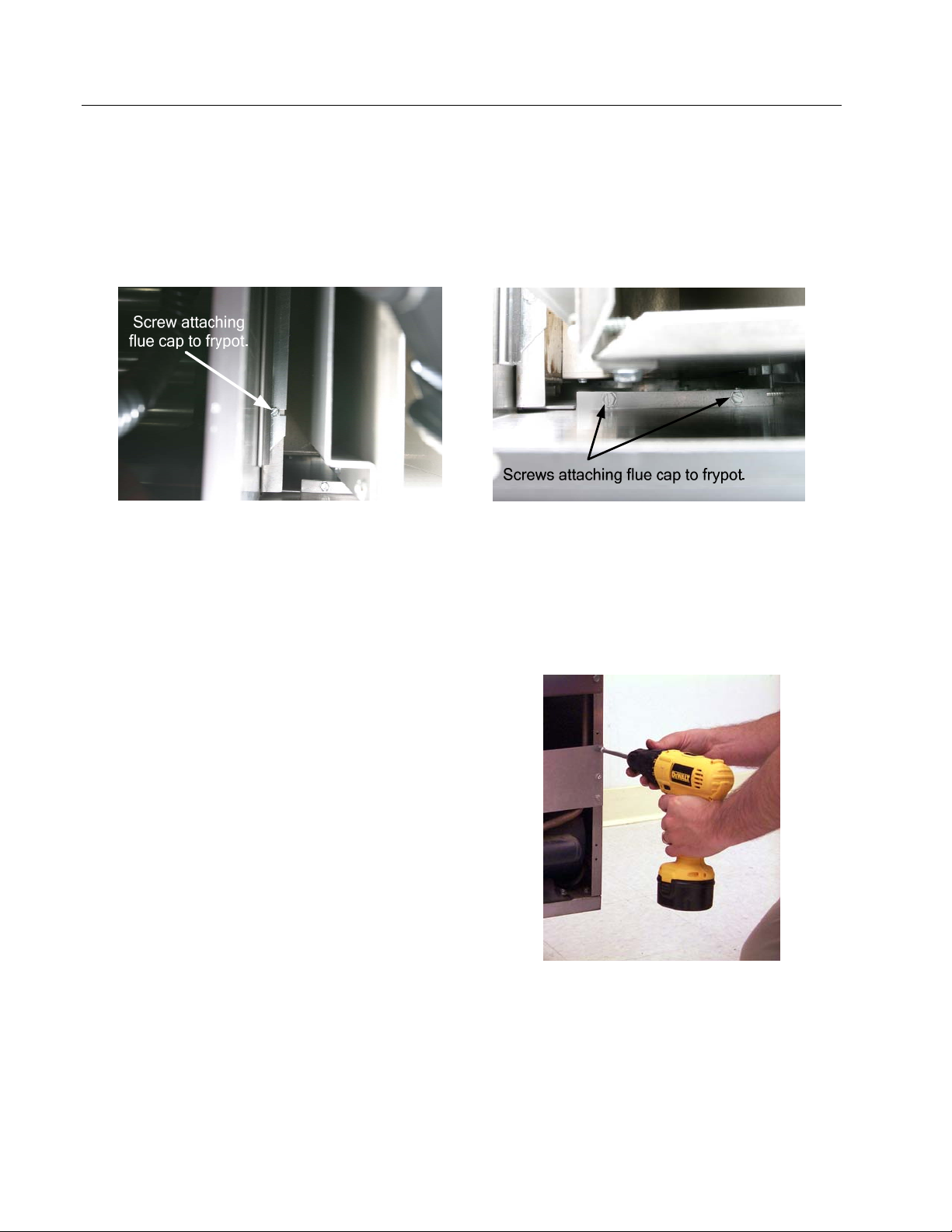

10. Remove screws securing flue cap to frypot (access from above; a nut-driver with an extension or

long screwdriver is required). Use care not to drop the screws into the flues. If this happens, the

screws can be retrieved when the flue is removed (Step 12). Use a screwdriver or similar tool to

free flue cap from frypots. Remove flue cap by lifting up and off of fryer.

Remove the screws (arrow) securing the flue cap

to the frypot on the long edge. There will be two or

three screws depending on configuration. (view

from above, looking down into flue)

11. Remove gas manifold pipe for access to gas

manifold shield by disconnecting at the unions.

Ensure gas supply is shut off and supply line is

disconnected prior to removing. Set gas

manifold aside. Remove screws securing gas

manifold shield. Remove shield to access oilreturn plumbing components connected to the

frypots.

NOTE: For units without built-in filtration

skip the steps pertaining to removal and

replacement of oil-return plumbing.

Remove the screws (arrows) securing the flue

cap to the frypot on the short edge. There will be

two screws on each end of the flue. (view from

above, looking down into flue)

Removing gas manifold shield.

1-22

Page 28

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7.7 Replacing the Frypot (cont.)

12. Remove screws securing flue to frypot (access

from above; a nut-driver with an extension or

long screwdriver is required). Retrieve any

screws dropped into the flue during removal of

the flue cap and frypot bracket.

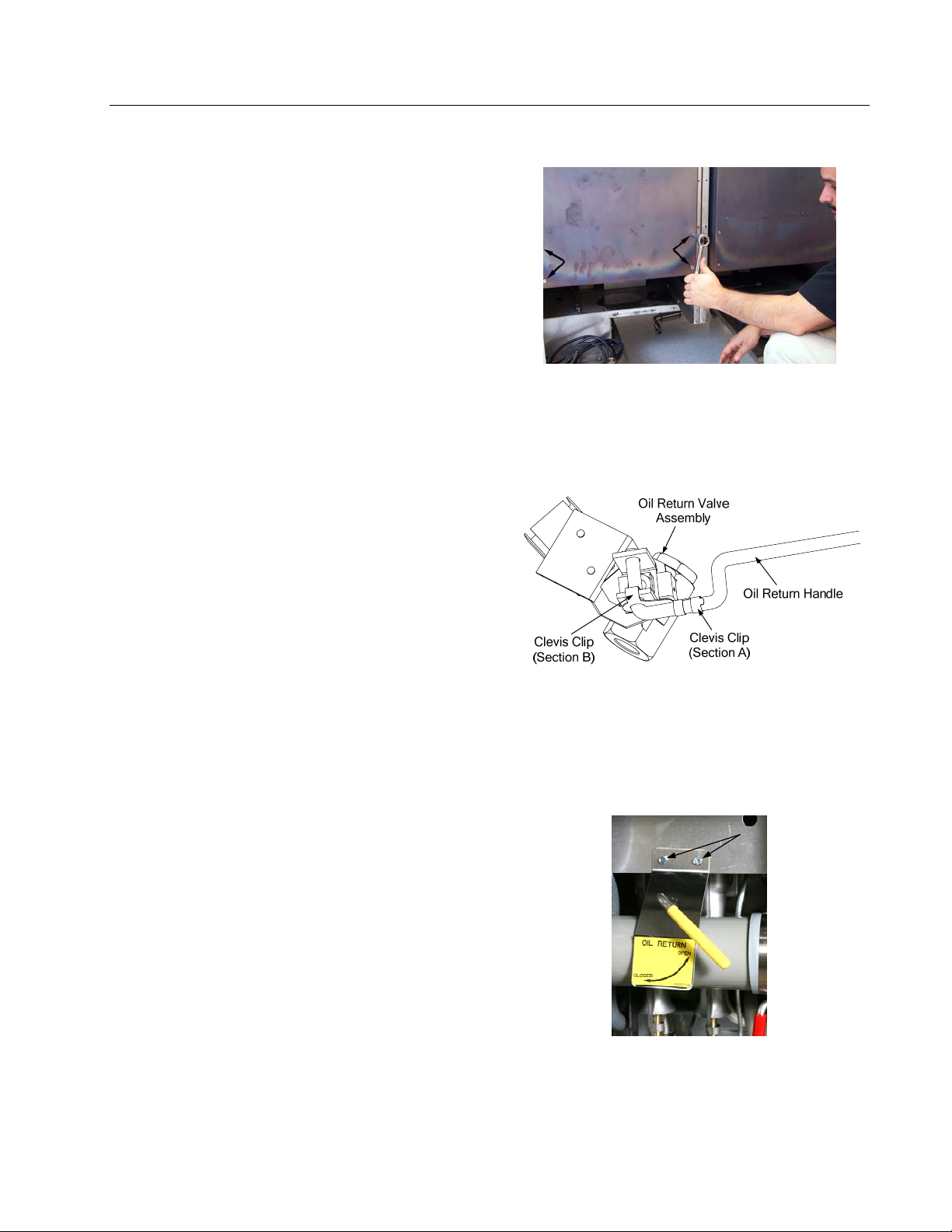

13. Remove the clevis clip and oil return handle

rod from the oil return valve at the rear of the

fryer. Slip Section A of the clevis clip off of

the oil return handle by pulling up on the rings.

Slide the oil return handle out of the bracket

and Section B of the clevis clip. Repeat for the

drain flush handle (if applicable).

14. Loosen the two screws on the front of the oil

return handle bracket at the front of the fryer.

Remove the bracket and handle and set aside

for reassembly. Repeat for the drain flush

handle (if applicable).

Removing bolts (arrows) securing flue to

frypot.

Disconnect oil-return handle from clevis clip

and valve.

Oil-return handle bracket and screws.

1-23

Page 29

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7.7 Replacing the Frypot (cont.)

15. Remove the drain manifold. Only the drain

tubes directly blocking the frypot being

replaced require removal.

- Remove the nuts holding the drain valve

strap onto the drain tube stud.

- Disconnect the Teflon tube at the back of

the center dump tube piece and any other

components attached to the tubes,

including drain flush flexlines.

- Loosen the nut on each clamp holding the

rubber boots and drain sections together.

- Carefully remove the tubes by pulling

down at an angle, straight out of the drain

valves, and working them gently out of the

rubber boots. Set aside for reassembly.

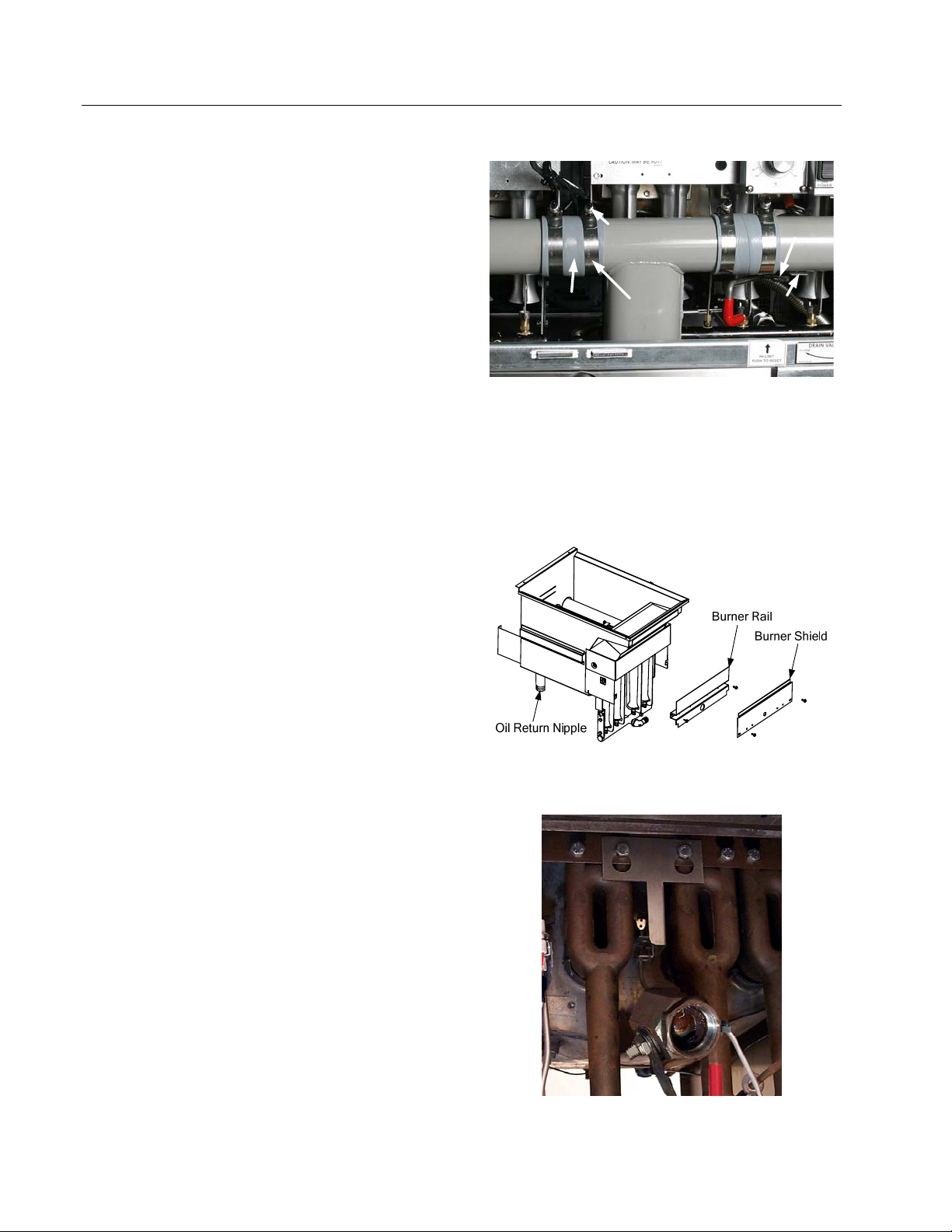

16. Remove the nipple attaching the oil return line

to the bottom of the frypot at the rear of the

fryer using a wrench. This may require

removal of other pieces of the oil return

manifold, as needed.

17. Remove the burner shield by loosening the

screw on each end.

18. Remove the burners to gain access to the

temperature probe and to ease removal. Remove

one burner at a time. Loosen the two screws

attaching the burner to the burner rail. Slide the

burner up until the heads of the two screws reach

the round key holes and lean it slightly toward

from the frypot to clear the burner rail and seal

(metal box attached to frypot). Then, pull the

burner up and off of the orifice. The burners

should be easy to remove and do not require

force.

19. Remove the burner rail when all burners have

been uninstalled. Loosen the screws on each

end of the rail and set it aside.

Valve

Stud &

Boot

Nut

Clamp

Strap

Drain manifold parts.

Oil-return nipple, burner shield, and burner rail.

Remove drain valve handle and

burners from fryer.

1-24

Page 30

yp

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7.7 Replacing the Frypot (cont.)

20. If the fryer is equipped with drain-valve microswitches, mark the wires and microswitch

terminals, then disconnect wires from the switch. Secure the wires to prevent damage when

frypot is removed.

Left: Microswitch wires marked for removal (ensure microswitch

terminals are marked the same as the wires removed). Right:

Microswitch mounted to drain valve.

21. Remove the drain valve handle by loosening

the drain valve nut and removing attached

hardware. Depending on placement and

configuration, the valve may be turned in a

different direction than pictured.

22. Remove the pilot assembly from the frypot.

Remove the drain valve nut and attached

hardware.

- If trailing pilot, disconnect the pilot supply

line from the trailing pilot valve on the

burner manifold.

Remove the mounting screw(s) to detach the pilot

assembly from the pilot bracket.

Remove the pilot assembly from the pilot bracket

on the fr

ot.

1-25

Page 31

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7.7 Replacing the Frypot (cont.)

23. Remove the temperature probe from frypot. (See Section 1.7.2, Replacing the Temperature

Probe: Controller–equipped Fryers, for specific instructions.)

24. Remove the high-limit from the frypot (see Section 1.7.3, Replacing the High-limit Thermostat).

25. Remove bolts from brackets securing burner

manifold to frypot. Leave the manifold in

place.

Removing bolts (arrows) from burner manifold

support brackets (both sides). Leave the burner

manifold in place after removing bolts.

26. Using a sharp knife or box-cutter, cut the

silicon seal around the frypot. Use care not

to scratch stainless steel surfaces.

1-26

Cutting frypot seal prior to frypot removal.

Page 32

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7.7 Replacing the Frypot (cont.)

27. Ensure wires and tubes will not be caught

on the frypot when it is removed.

28. Remove frypot from fryer by lifting up

and out.

29. Position the frypot upside down on a

suitable work surface.

30. Record position of the valve stem in

relation to the frypot prior to removing

the drain valve. If equipped, remove

microswitches and mounting hardware

from valve prior to removal. Using a

suitable wrench, remove the drain valve

from the frypot. Use Loctite PST567

sealant when installing drain valve on

replacement frypot.

31. Remove all other hardware and

accessories from the frypot.

32. Reverse the above steps to install the

replacement frypot.

33. Add a bead of silicon around the edges of

the new frypot, sealing the seam where

the frypot and the cabinet meet. Only do

this when the frypot is completely

installed.

Lifting frypot from fryer.

Removing drain valve from frypot.

1-27

Page 33

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8 Troubleshooting and Problem Isolation

Because it is not feasible to include every issue that might occur, this section is intended to provide

technicians with a general knowledge of the broad problem categories associated with this

equipment and the probable causes of each. With this knowledge, the technician should be able to

isolate and correct any problem encountered.

You are likely to encounter problems in these broad categories:

1. ignition failure,

2. improper burner function,

3. improper temperature control,

4. improper controller function,

5. improper filtration function,

6. frypot leakage, and

7. basket lift malfunction.

The probable causes of each category are discussed in the following sections. Troubleshooting

guides are included in Section 1.9 to assist in identifying some of the more common problems.

1.8.1 Ignition Failure

Ignition failure occurs when the ignition module fails to sense a flame within the 60-second time

delay period and locks out. Turn the fryer off, locate and fix the problem, then turn fryer back on to

clear the module lock.

There are three primary reasons for ignition failure, listed in order of probability:

1. The gas and electrical power supplies,

2. The electronic circuits, or

3. The gas valve.

The Gas and Electrical Power Supplies

The main indicators that the gas or electrical power supply is the cause of ignition failure are as

follows: an entire battery of fryers fails to light, and/or there are no indicator lights illuminated on

the fryer experiencing ignition failure. Verify that the quick disconnect hose is properly connected,

the fryer is plugged in, the main gas supply valve is open, and the circuit breaker for the fryer

electrical supply is not tripped.

1-28

Page 34

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8.1 Ignition Failure (cont.)

The Electronic Circuits

If gas and electrical power are supplied to the fryer, the next most likely cause of ignition failure is a

problem in the 24 VAC circuit of fryers equipped with electronic ignition systems, or in the pilot

system for those without electronic ignition. If the fryer is equipped with a SUFF/UFF filtration

system, verify that the drain valve is fully closed. (The valve is equipped with a microswitch that

must be closed for power to reach the gas valve. The valve handle can appear to be closed when the

microswitch is open.) If the valve is fully closed, or the fryer does not have a filtration system, refer

to the troubleshooting guides in this chapter.

The Gas Valve

If the problem is not in the 24 VAC circuit or pilot system, it is most likely in the gas valve. Before

replacing the gas valve, refer to the troubleshooting guides in this chapter.

1.8.2 Improper Burner Function

In these instances, the burner ignites but exhibits abnormal characteristics, such as popping,

incomplete lighting of the burner, fluctuating flame intensity, and flames “rolling” out of the fryer.

Popping indicates delayed ignition. In most cases, the main gas valve is opening, but the burner is

not immediately lighting. When ignition does take place, excess gas ignites rapidly rather than

smoothly.

The primary causes of popping are:

1. low or fluctuating gas pressure,

2. misdirected or weak pilot flame,

3. clogged burner orifices,

4. clogged burners,

5. inadequate make-up air,

6. heat damage to the controller or ignition module,

7. an out-of-adjustment igniter or broken ignition wire,

8. a defective ignition module,

9. missing or misaligned burners,

10. clogged vent tube (causing incorrect gas pressure), or

11. make-up air is blowing down the flue.

1-29

Page 35

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8.2 Improper Burner Function (cont.)

If popping occurs only during peak operating hours, the problem may be incorrect or fluctuating gas

pressure. Verify that the incoming gas pressure (pressure to the gas valve) is in accordance with the

appropriate requirements listed in the Installation and Operation manual that came with the fryer,

and that the pressure remains constant throughout all hours of usage. Refer to Adjusting Burner

Manifold Pressure in Section 1.4 if burner manifold pressure is suspected of being incorrect.

If popping is consistent during all hours of operation, verify that the pilot is properly positioned

above the burner orifice and that the pilot pressure is correct. Correct pilot pressure is indicated by a

flame 1 to 1½" long. Also verify that igniter is properly adjusted (electrode tip 1/8" from pilot hood

corner). Refer to Section 1.5 for pilot adjustment procedure.

Clogged burners or burner orifices are also likely causes of delayed ignition. Clogged burners are

indicated by uneven flame or partial flame on the burner face. Clogged orifices are indicated by no

flame.

Another cause of popping is an insufficient air supply or drafts that are blowing the pilot flame away

from the burner. Check for "negative pressure" conditions in the kitchen area. If air is flowing into

the kitchen area, this indicates that more air is being exhausted than is being replenished and the

burners may be starved for air.

If the fryer’s gas and air supplies are okay, the problem most likely is with one of the electrical

components. Examine the ignition module for signs of melting, distortion, or discoloration due to

excessive heat build-up in the fryer. Also, examine the controller for the same conditions. This

condition usually indicates improper flue performance. A melted or distorted ignition module is

automatically suspect and should be replaced, but unless the condition causing excessive heat in the

fryer is corrected, the problem is likely to recur.

Next, ensure the ignition wire is tightly connected at both ends and examine it for obvious signs of

damage. Again, if damage is due to excessive heat in the fryer, that problem must also be corrected.

Check for proper operation by disconnecting the wire from the igniter, inserting the tip of a

screwdriver into the terminal, and holding it near the frame of the fryer as the power switch is placed

in the "ON" position. A strong, blue spark should be generated for at least 60 seconds.

DANGER

MAKE SURE YOU ARE HOLDING THE INSULATED HANDLE OF THE SCREWDRIVER

AND NOT THE BLADE. THE SPARKING CHARGE IS APPROXIMATELY 25,000

VOLTS.

Ensure the gap setting of the igniter is correct (electrode tip 1/8" from pilot hood corner).

1-30

Page 36

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8.2 Improper Burner Function (cont.)

Burners lighting on the left side only may be caused by a trailing pilot problem (four- and five-tube

frypots) or improper burner manifold pressure.

Fluctuating flame intensity is normally caused by either improper or fluctuating incoming gas

pressure, but may also be the result of variations in the kitchen atmosphere. Verify incoming gas

pressure in the same way as for "popping,” discussed in the preceding paragraphs. Variations in the

kitchen atmosphere are usually caused by air conditioning and/or ventilation systems starting and

stopping during the day. As air conditioning/ventilation systems start and stop, the pressure in the

kitchen may change from positive or neutral to negative, or vice versa. Changes in airflow patterns

may affect flame intensity.

Flames "rolling" out of the fryer are usually an indication of negative pressure in the kitchen and

make up air blowing down the flue. Air is being sucked out of the fryer enclosure and the flames are

literally following the air. If negative pressure is not the cause, check for high burner-manifold gas

pressure in accordance with the procedures in Section 1.4. An obstructed flue, which prevents the

fryer from properly exhausting, may also be the cause.

Excessively noisy burners may indicate that the burner gas pressure is too low, the tube diffusers are

defective or burned out, or it may simply be that the gas valve vent-tube is blocked (if applicable). If

the gas pressure is correct, the tube diffusers are intact and in good condition, and the vent-tube is

unobstructed (if applicable), the gas valve regulator is probably defective.

1.8.3 Improper Temperature Control

Temperature control is a function of several interrelated components, including the melt cycle. Each

must operate correctly. The principal component is the temperature probe. Depending upon the

specific configuration of the fryer, other components may include the interface board, the

controller/controller itself, and the ignition module.

Improper temperature control problems can be categorized into melt cycle problems and failure to

control at setpoint.

In fryers equipped with a Thermatron, the problem will be with the thermostat. Possible causes are

that the thermostat is out of calibration or defective. Refer to Section 1.6 for instructions on

calibrating the thermostat.

In fryers equipped with controllers, the problem may be with the temperature probe, the interface

board, or the controller. Refer to the troubleshooting guides in this chapter.

1-31

Page 37

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8.4 Improper Controller Function

Sensitivity or "Stretch Time." Sensitivity—or stretch time—is a programmable feature that

increases the cook time countdown based on variations in the oil temperature from the setpoint (e.g.,

when cold product is dropped into the oil, causing the oil temperature to drop).

The sensitivity for each product button has 10 settings (0 through 9). A "0" sensitivity setting will

disable the feature (no change in cooking time), while a nine will provide the highest sensitivity or

the most change. The correct sensitivity for any product is based on the product type, its density, the

setpoint temperature, and the customer’s own requirements.

Common Controller Complaints. Most problems concerning controllers have to do with

programming them. There are four common complaints. The complaints, their causes, and

corrective actions are as follows for the Dean Compu-Fry controller:

1. Fryer constantly displays " ".

Cause: Setpoint incorrect or missing.

Corrective Action: Press 1 6 5 0, enter the correct setpoint using keypad, then press and

then this to lock in the setpoint.

2. Temperature is displayed in Celsius.

Cause: Controller is programmed to display in Celsius.

Corrective Action: Press 1 6 5 8.

3. Temperature is constantly displayed.

Cause: Controller is programmed for constant temperature display.

Corrective Action: Press 1 6 5 L.

4. Controller times down too slowly or too quickly.

Cause: Controller is compensating for oil temperature via the sensitivity setting.

Corrective Action: Reprogram sensitivity setting for each product in accordance with

programming instructions in the Compu-Fry Operation and Programming manual, P/N 819-

5865.

1-32

Page 38

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8.5 Improper Filtration Function

The majority of filtration problems arise from operator error. One of the most common errors is

placing the filter paper on the bottom of the filter pan rather than over the filter screen. Anytime the

pump is running, but no oil is being filtered, check the installation and size of the filter paper. Verify

that the O-rings on the slip-connection are in good condition. Missing or worn O-rings allow the

pump to suck air, decreasing its efficiency.

If the pump motor overheats, the thermal overload will trip and the motor will not start until it is

reset. If the pump motor does not start, press the red reset switch located on the rear of the motor.

Also, reset the filter circuit breaker located under the fryer control panel. If the pump then starts,

something caused the motor to overheat. The pump most likely overheated for one of the following

reasons:

• Shortening was solidified in the pan or filter lines.

• Multiple frypots were filtered one-after-another. Allow the pump to cool for 30 minutes before

using again.

• The operator attempted to filter unheated oil. Cold oil is thick and will cause the pump motor to

work harder and overheat.

If the motor runs, but the pump does not, the pump is blocked. Incorrectly sized or installed paper

allows food particles and sediment to pass through the filter pan and into the pump. When sediment

enters the pump, the gears bind and cause the motor to overheat, tripping the thermal overload.

Solidified shortening in the pump will produce the same result. A pump seized by debris or hard

shortening must be disassembled, cleaned, and reassembled in the following manner:

1. Disconnect power to the filter system.

2. Remove the front cover of the pump to access the gears inside, if the pump is accessible while

still inside the cabinet. If the front cover is not accessible, the pump must be removed from the

pump motor (disconnect input/output plumbing from the pump prior to removing it). Remove

three setscrews to disengage the pump from the motor.

3. Prior to reassembly, the inside housing must be clean and free of any sediment or debris. If not,

the gears will bind again after reassembly.

Remove these bolts to

remove pump cover.

NOTE:

The pump cover in

current production units

is held in place by four

(4) bolts.

Remove debris or hardened

shortening to free gears.

1-33

Page 39

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8.5 Improper Filtration Function (cont.)

Incorrectly sized or installed paper will allow food particles and sediment to pass through and clog

the suction tube on the bottom of the filter carriage. Particles large enough to block the suction tube

may indicate that the crumb tray is not being used.

Pan blockage can also occur if shortening is left in the pan and allowed to solidify. Heater strips (if

equipped) on the oil return plumbing are designed to prevent solidification of shortening left in the

plumbing. Heater strips will not melt or prevent solidification of shortening in the pan.

Remove blockage by forcing it out with an auger or drain snake. DO NOT use compressed air or

other pressurized gases to force out the blockage.

The SUFF/UFF filtration systems use microswitches attached to handles for each vat. They are

wired in parallel and provide the 24 VAC required to activate the pump relay coil when the handles

are moved to the ON position. The activated pump relay coil pulls the pump motor switch in,

supplying power to the pump motor.

Filter systems equipped with oil-return heater tape are wired into the 120 VAC source, and remain

energized as long as the unit is plugged in and power remains constant. Heater tape should receive

constant power all day and all night; it should not be connected to a power supply that is turned off

at night.

1.8.6 Frypot Leakage

Frypot leaks are almost always due to improperly sealed high-limit, thermostats/temperature probe

and drain fittings. When installed or replaced, each of these components must be sealed with Loctite

PST567 sealant or equivalent to prevent leakage. In very rare cases, a leak may develop along one

of the welded edges of the frypot, or where the tube is welded to the frypot. When this occurs, the

frypot must be replaced.

If the sides or ends of the frypot are coated with oil, the most likely cause is spillage over the top of

the frypot rather than leakage.

Frypot locations (indicated by arrows)

where potential leaks could occur.

1-34

Page 40

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8.7 Improper Basket Lift Function

Bell-Crank Basket Lifts

Most High Efficiency Decathlon Series gas fryers are

equipped with a bell-crank style basket lift. A cam and a

bell crank are connected to the basket lift arm by a flat metal

link. The cam is attached to a drive motor. The motor rotates

the cam, raising or lowering the lift arm linked to the bell

crank. A roller-activated microswitch is used to limit travel.

When the roller in the microswitch is in contact with the cam,

the motor is energized. As the cam rotates, the roller loses

contact with the cam and the motor power circuit is broken,

de-energizing the motor.

Timing circuitry in the controller initiates and stops

basket lift operation. When the product button is pressed,

the timing circuitry activates a coil in the basket lift relay

to supply power to the motor. The microswitch stops the

motor at the lift’s lower travel limit and the switch

contacts are reversed. At the end of the programmed

cooking time, the timing circuit activates the coil once

more and the lift rises until the microswitch again loses

contact with the cam, opening the motor power circuit and

stopping the motor.

Problems with the bell-crank basket lift system can be

grouped into two categories:

• binds and jams or

• motor and gear wear.

Binds and jams. Noisy, jerky, or erratic lift movement is

usually due to lack of lubrication. Apply a light coat of

Lubriplate or similar lightweight white grease to the

connection points to correct the problem.

Motor Problems. If power is reaching the motor but the

motor fails to run, the motor is burned out and must be

replaced.

Back view of bell-crank basket lift.

Bell-crank basket-lift arms.

1-35

Page 41

b

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.9 Troubleshooting Guides

The following troubleshooting guides are intended to assist service technicians in quickly isolating

the probable causes of equipment malfunctions by following a logical, step-by-step process.

PROBLEM

Burner will not ignite.

Light in ON/OFF switch

is not illuminated.

A. ON/OFF switch is off. A. Turn ON/OFF switch on.

PROBABLE CAUSES CORRECTIVE ACTION

ON/OFF switch is on,

ut the switch light is not

illuminated.

ON/OFF switch is on and

the switch light is

illuminated, but there is

no output to gas valve.

No burner flame.

A. No voltage at switch. A. Ensure line voltage is present at the

switch.

A. Drain microswitch circuit (filter-

equipped units) is open.

B. Voltage is present at ON/OFF switch,

but continuity of the switch in ON

position is not "0.”

C. Continuity of thermostat is not "0" (oil

temperature is at least 15°F below

electronic thermostat setting).

D. Gas valve is suspect. D. Go to "No burner flame" section.

C. Gas valve is known to be good, but

there is not 24 VAC (120VAC on

systems so equipped) at the gas valve

terminals.

A. Ensure drain valve is fully closed and

microswitch is functioning. Replace

microswitch if defective.

B. ON/OFF switch is defective. Replace

switch with a known working switch.

C. Thermostat(s) is/are defe ctive.

Replace defective thermostat with a

known working thermostat.

D. Inspect electronic sensor (while still in

frypot) for damage. Replace if bent,

dented, or cracked. Inspect leads for

fraying, burning, breaks, and/or kinks.

If found, remove and replace

thermostat(s). Remove leads from

terminal block, allow oil to cool 15°F

(8°C) below thermostat setting, and

check continuity. If continuity is not

"0,” then thermostat has failed.

Replace thermostat(s).

Fluctuating or erratic

lighting of burner flame.

Electronic/operating

thermostat will not adjust

to correct temperature.

A. Incoming gas supply pressures are not

within range [Natural- 6-14" W.C.

(1.49-3.49 kPa); Propane- 11-14"

W.C. (2.74-3.49 kPa)]

B. Air in gas supply lines (new

installation).

A. Electronic/operating thermostat is out

of calibration.

A. Inspect gas supply to fryer. Repair

and/or replace faulty components

(defective supply shut-off valves,

incorrect piping size, etc.)

B. Allow unit to cy cle on and off for

approximately 30 minutes to force air

from gas manifold and lines.

A. Calibrate electronic/operating

thermostat. Replace if calibration is

not possible.

1-36

Page 42

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10 Wiring Diagrams

Note: The diagrams in this section depict wiring as of the date of manual publication.

It may not reflect design changes made to the equipment after publication. Refer to

the wiring diagram affixed to the unit when actually troubleshooting this equipment.

1.10.1 Controller Dean Common Cabinet

805-1545 B

1-37

Page 43

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10.2 Wingstreet Common Cabinet

805-1599 B

1-38

Page 44

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10.3 BK1814 Main Wiring Diagram prior after Sep. 2010

1-39

Page 45

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10.4 BK1814 Main Wiring Diagram prior to Sep. 2010

1-40

Page 46

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10.5 BK1814 RAM Wiring Diagram

1-41

Page 47

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

1.10.6 Filter Box

CHAPTER 1: SERVICE PROCEDURES

1-42

Page 48

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10.7 Thermatron Controller

1-43

Page 49

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10.8 FAST Controller prior to Feb 09

1-44

Page 50

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10.9 FAST Controller Non-CE after Feb 09

1-45

Page 51

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10.10 FAST Controller CE after Feb 09

1-46

Page 52

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10.11 FAST Controller India

1-47

Page 53

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10.12 KFC-1 Controller

1-48

Page 54

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10.13 CM4S Controller

1-49

Page 55

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10.14 Constant Pilot, FAST Ready

1-50

Page 56

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.11 Probe Resistance Charts

Thermatron Probe Resistance Chart

° Celsius ° Fahrenheit Ohms (±3%)

21 70 108130

27 80 84606

32 90 66721

38 100 53020

43 110 42452

49 120 34206

54 130 27735

60 140 22641

66 150 18588

71 160 15349

77 170 12741

82 180 10635

88 190 8925

93 200 7527

99 210 6391

104 220 5470

110 230 4705

116 240 4030

121 250 3441

127 260 2967

132 270 2583

138 280 2255

143 290 1977

149 300 1729

154 310 1496

160 320 1320

166 330 1170

171 340 1051

177 350 942

182 360 840

188 370 750

193 380 676

199 390 605

204 400 541

Controller Probe Resistance Chart

° Celsius ° Fahrenheit

21 70 1080

27 80 1101

32 90 1122

38 100 1143

43 110 1164

49 120 1185

54 130 1206

60 140 1226

66 150 1247

71 160 1268

77 170 1289

82 180 1309

88 190 1330

93 200 1350

99 210 1371

104 220 1391

110 230 1412

116 240 1432

121 250 1453

127 260 1473

132 270 1493

138 280 1514

143 290 1534

149 300 1554

154 310 1574

160 320 1594

166 330 1614

171 340 1634

177 350 1654

182 360 1674

188 370 1694

193 380 1714

199 390 1734

204 400 1754

Ohms (±3%)

1-51

Page 57

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 2: PARTS LIST

2.1 High Efficiency Common Cabinet Decathlon (HDC) Primary Components

2.1.1 Decathlon HD50 Primary Components

18

3

15

10

12

4

6

5

2

9

1

7

8

14

22

13

11

17

16

19

20

21

2-1

Page 58

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 2: PARTS LIST

Each section is labeled by size (e.g., D50) and parts are not interchangeable between different sized fryers. The parts in this manual

are for use on Common Cabinet style fryer.

If you have any questions, call the Frymaster and Dean 24-Hour Service Hotline, 1-800-551-8633.

2.1.1 Decathlon HD50 Primary Components

ITEM PART # DESCRIPTION

1 826-3009 Frypot - S/S

2

3

* 810-0705

* 810-0703

4 230-4900 Diffuser Assembly

5

6 810-3356 Burner, High Efficiency

7 220-5287 Bracket, Burner Mounting

8 200-9063 Shield, Burner Heat

9

10 231-2060 Side Panel, Left Side

11 232-2060 Side Panel, Right Side

12

*

*

*

13

14

106-5433 x1 (Single)

106-5956 x3 (3-battery)

106-6333 x4 (4-battery)

106-7631 x5 (5-battery)

15

230-1848 x1 (Single)

230-1812 x2 (2-battery)

230-1841 x3 (3-battery)

230-1875 x4 (4-battery)

230-2434 x5 (5-battery)

16 106-7542SP Door Assembly (Left or Right)

17

* 810-2346 Magnetic Catch, Door

* 230-4998 Hinge, One-piece

18

210-1595 Single (SCFHD50, 823-4075 with deflector)

210-3131 Double (SCFHD50, 823-4074 with deflector)

19 810-0356 Caster, Plate-mount, 5" without Brake

* 826-1117 Caster Kit, Plate-mount, 5" without Brake (includes mounting hardware)

20 810-0357 Caster, Plate-mount, 5" with Brake

* 826-1118 Caster Kit, Plate-mount, 5" with Brake (includes mounting hardware)

* 810-0944 Caster, Plate-mount, 3" with Brake

* 810-1494 Caster, Plate-mount, 4" without Brake

* 106-7649 Cordset, 10' Power

21 810-2411 Leg, Single Bolt Mount (black)

* 810-3169 Leg Package, 4 Bolt Mount (4 per set)

22 823-3248 Leg Support Assembly

* Not illustrated.

►►► See Orifices, Section 2.2

See Additional Components and Controllers, Section 2.3

1

⁄

Tube,

Tube,

" x 23" Pilot Gas Supply (one-piece gasline)

4

1

⁄

" x 17½" Pilot Gas Supply (one-piece gasline)

4

►►► See Drain Components, Section 2.4

See Additional Components and Controllers, Section 2.3

Cabinet Back

220-1847 x1 (Single)

220-1806

220-1838

x2 (2-battery)

x3 (3-battery)

823-5932 Joiner Strip

Top Cap

106-5955 x2 (2-battery)

Flue Cap

210-8077 Handle, Door

Basket Lifts

2-2

Page 59

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 2: PARTS LIST

2.1.2 Decathlon HD60/63 Primary Components

18

3

15

10

12

4

6

5

2

9

1

7

8

14

22

13

11

17

16

19

20

21

2-3

Page 60

1

1

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 2: PARTS LIST

2.1.2 Decathlon HD60/63 Primary Components (cont.)

ITEM PART # DESCRIPTION

1 106-9632 Frypot - S/S

* 106-9634 Frypot - S/S (Single HD60 without filtration)

* 823-5742SP Frypot - S/S (Single HD60 without filtration, Red Robin)

* 106-9638SP Frypot - S/S (Single HD63 without filtration)

* 823-6314 Frypot - S/S (Single HD63 without filtration, Red Robin)

2

3

* 810-0705 Tube,

* 810-0703 Tube,

* 810-0703 Tube, Pilot Gas Supply, 1⁄4" x 17.50" (one-piece gasline)

4 230-1431 Diffuser Assembly

5

6 810-3356 Burner, High Efficiency

7 220-5152 Burner Bracket

8 200-8748 Shield, Burner Heat

9

* 810-0691 Vent Tube

10 231-2311SP Side Panel, Left Side

11 232-2311SP Side Panel, Right Side

* 221-2737 Side Panel, Left Side (Filter Ready)

* 222-2737 Side Panel, Right Side (Filter Ready)

* 823-5744 Side Panel, with Splash Panel (660/363/663)

12

220-1851 x1 (Single)

220-1828 x2 (2-battery)

220-3702 x2, without Deflector (2-battery)

220-4518 x1, without Deflector (3-battery)

13 210-3017 Joiner strip

14

106-5434 x1 (Single)

106-5953 x2 (2- and 6-battery)

106-6080 x3 (3- and 6-battery)

106-4683 x4 (4- and 6-battery)

15

230-3078 x1 (Single)

230-1833 x2 (2-battery)

230-1890 x3 (3-battery)

230-1891 x4 (4-battery)

230-1890 x3 (6-battery)

230-1891 x4 (6-battery)

16 106-4309SP Door Assembly, left or right

17 210-8077 Handle, Door

* 810-2346 Magnet, Door

* 230-4998 Hinge, One-piece

* Not illustrated.

►►► See Orifices, Section 2.2

See Additional Components and Controllers, Section 2.3

⁄4" x 23" Pilot Gas Supply (one-piece gasline)

⁄4" x 17½" Pilot Gas Supply (one-piece gasline)

►►► See Drain Components, Section 2.4

See Additional Components and Controllers, Section 2.3

Cabinet Back (One-piece)

Top Cap

Flue Cap

2-4

Page 61

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 2: PARTS LIST

2.1.2 Decathlon HD60/63 Primary Components (cont.)

ITEM PART # DESCRIPTION

18

210-2737SP Single (60/63/65, 823-3649 with deflector)