Page 1

DEA SYSTEM s.r.l.

Via Monte Summano 45/E , 36010 Zanè

(VI) - Italy

Tel.+39.0445.314944 Fax +39.0445.314334

http://www.deasystem.com

e-mail: deasystem@deasystem.com

203B_2

CENTRALE DI COMANDO

I

UNITÉ DE COMMANDE

F

CONTROL UNIT INSTALLATION AND USER’S MANUAL

GB

CENTRAL DE MANDO INSTRUCCIONES DE USO Y DE INSTALACION

E

QUADRO DE COMANDO INSTRUÇÕES DE USO E DE INSTALAÇÃO

P

ISTRUZIONI D’ USO E DI INSTALLAZIONE

INSTRUCTIONS D’UTILISATION ET D’INSTALLATION

Document Number F12031

Rev 01 Date 17/12/02

filename

F1203101.pub

Page 2

203B_2

This booklet is an integral and essential part of the product and must be delivered to the

user. Carefully read the warnings contained inside that provide important information

regarding safety during installation, use and maintenance.

OVERVIEW

The DEA 203B_2 control panel has been designed to control the “DEA SYSTEM” automation devices for both sliding gates powered by 230V single-phase motors, and comes

complete with an inertia limitation system. The widest versatility, easy installation and

complete respect for the European regulations in force regarding electromagnetic compatibility and electric safety are the unit's main characteristics; in particular, DEA SYSTEM ensures conformity to the following European Directives: 89/336/EEC, 73/23/EEC

and subsequent amendments.

DEA SYSTEM reminds all users that the selection, configuration and installation of all the

devices and materials in the entire automation must be performed in respect of the

regulations in force in the nation of installation.

TECHNICAL DATA

Power supply :230V AC +/- 10% 50 Hz

Flashing light output 230V AC 50 Hz max 40W

Gate open signal light/courtesy light output :230V AC 50 Hz max 40W

Auxiliary power supply output :24V AC max 200 mA

Electric lock output :12V AC max 15V A

Max. motor power :500W

Fuse F1 :160 mA 250V

Fuse F2 :5A 250V

Max pause time :80 s

Max work time :160 s

The work time you set must anyway allow to respect the maximum working time admitted for the type of motor you are using. Please refer to the data on the motor label.

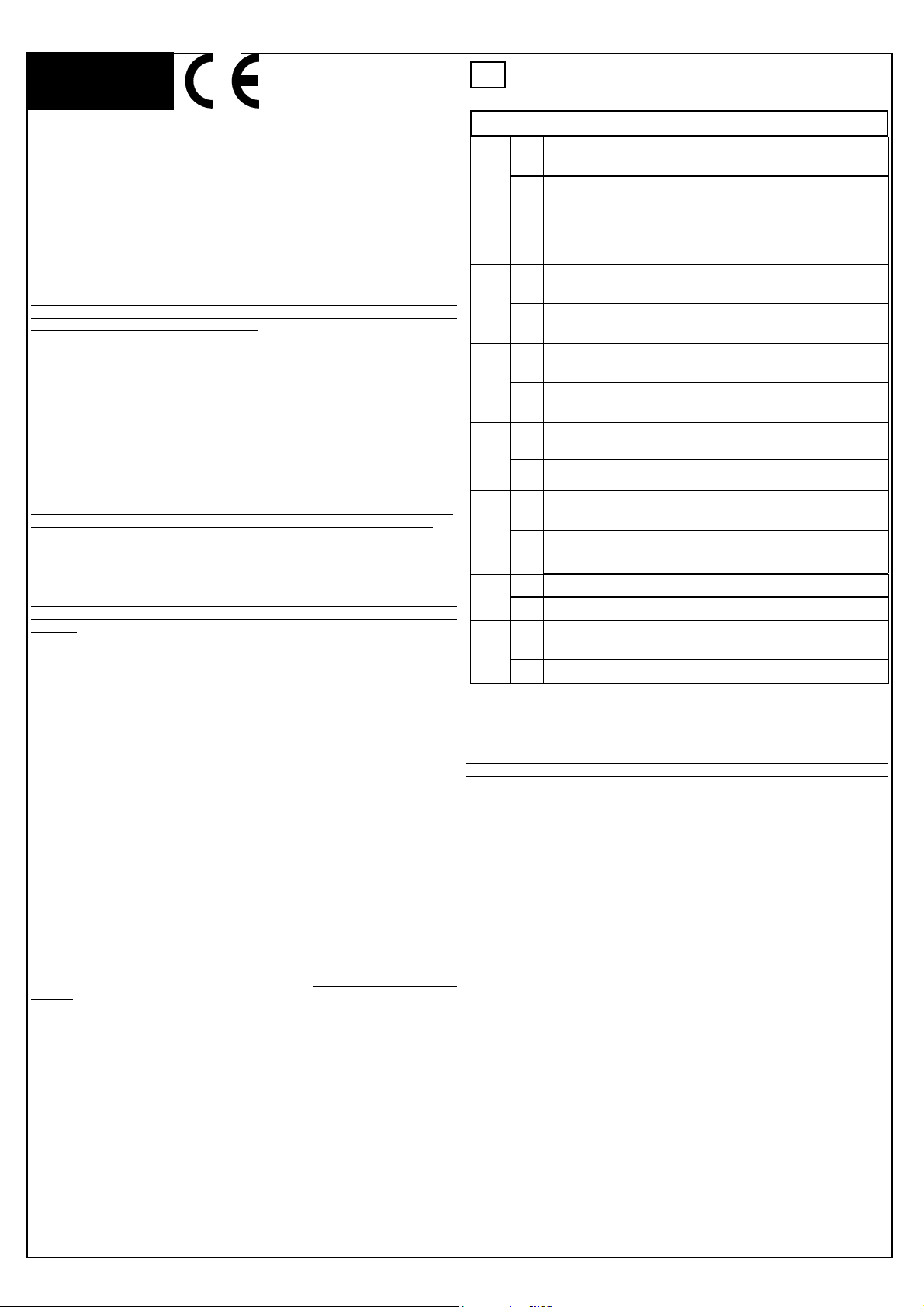

ELECTRICAL SYSTEM CONFIGURATION

(See fig. 1)

IMPORTANT: Any installation, maintenance, cleaning or repair operations on any part

of the automatism must be performed exclusively by qualified personnel, and all such

operations must be performed only after first disconnecting the power supply. Always

keep the 230V cables (power supply, motor, starting condenser, flashing light, courtesy

light) separate from the low voltage cables (controls, electric lock, antenna, and auxiliary power supply) and fasten these latter using adequate clamps near the terminal

boards. Install a multiple pole switch with a contact opening of 3 mm provided with

protection against overloads upstream from the automatism. Use a cable with a minimum section of 3X1.5 mm² (such as H07RN-F type) for the power supply and scrupulously respect all the regulations in force regarding electrical systems in the nation of

installation.

TERMINAL BOARD CONNECTION:

(See fig. 1)

1-2: Power supply: 230V AC +/-10% 50 Hz (F = phase, N = neutral)

3-4 Courtesy light output 230 V AC 50 Hz max 40W (DIP8 = ON)

Gate open indicator light output: 230 V AC 50 Hz max 40W (DIP8 = OFF)

5-6 Flashing light output: 230 V AC 50 Hz max 40W

7-8-9 Motor output (7 = open, 8 = common, 9 = close)

12 Common inputs

13 FCA opening limit-switch input (N.C.) stops the motor's opening stroke

14 FCC closing limit-switch input (N.C.) stops the motor's closing stroke

15 APRE PEDONALE opens the gate to a width of only 1.5 (N.O.)

16 FOTO Photocell Art. 104/105 input (N.C) inverts movement during closing, and

if enabled during opening stops movement

17 STOP stop button input (N.C) stops movement in any situation

18 APRE open/close button input (N.O.) can function in both step-by-step mode

and inversion mode

IMPORTANT: All N.C. inputs not used must be bridged towards the common inputs

terminal.

19 Antenna ground

20 Antenna signal

21-22 Auxiliary power supply output: 24V AC max 200mA

J3 Radio receiver plug-in connector

OPERATION:

TIME SETTING

TCA trimmer for the setting of the automatic closing time, after which the gate will

automatically close again.

TLAV trimmer for the setting of the work time, after which the motor will stop during

both opening and closing.

Whenever the limit-switches are installed, the work time must be set to a value

that is a few seconds higher than the real time required for the stroke of the

motor.

GB

DIP-SWITCHES FUNCTIONS

ON

DIP1

DIP2

DIP3

DIP4

DIP5

DIP6

DIP7

DIP8

It is in any case obligatory to use appropriate safety devices in order to ensure the

impact force limitation values prescribed by the regulations in force in the nation of

installation.

“collectivity” function enabled: does not receive opening pulses

during opening and the gate open pause time

OFF

“collectivity” function disabled: receives opening pulses also during

opening and the gate open pause time

ON Not used

OFF

Not used

ON “step-by-step” program: OPEN->opening, OPEN->stop, OPEN-

>closing...

OFF

“inversion” program: OPEN->opening, OPEN->closing, OPEN>opening...

ON Not used

OFF

Not used

ON Photocell operative also during opening: stops all movement until the

obstacle is removed

OFF

Photocell operative only during closing: inverts direction of movement

ON automatic closing disabled: after opening, it closes again only after

an opening pulse

automatic closing enabled : after opening, and after the pause time

OFF

set, the gate automatically closes again

ON Not used

OFF

Not used

ON Terminals 3-4: courtesy light output 230V AC 50 Hz (delay: 50 sec-

onds)

OFF

Terminals 3-4: gate open signal light output, 230V AC, 50 Hz

Page 3

fig. 1

A

24Vac OUTPUT

M4

R22

F1

FORZ

M5

R32-SENS

R1-TLAV

R2-TCA

ANTENNA

ANTENNE

ANTENNA

RG58

ANTENA

ANTENA

19 2021 22

M3

1 2 3 4 5 6 7 8

18

17

16

15

14

13

12

11

10

2 X 0,5 mm²

APRE N.O.

4 X 0,5 mm²

STOP

PED. N.O.

N.C.

START/APRE

START/OUVRE

START/OPEN

START/ABRE

START/ABRE

BLOCCO

BLOCAGE

STOP

BLOQUE

BLOQUEIO

START PEDONALE

OUVERTURE PIETONS

PEDESTRIAN OPEN

APERTURA PEATONAL

APERTURA PEATONAL

INTERRUTTORE ONNIPOLARE

INTERRUPTEUR OMNIPOLAIRE

OMNIPOLAR CIRCUIT BRAKER

INTERRUPTOR OMNIPOLAR

INTERRUPTOR OMNIPOLAR

2 X 1,5 mm²

3 X 1,5 mm²

F2

1 2 3 4 5 6 7 8 9

M1

L

N

FCA

N.C.

FINECORSA APERURA

BUTÉE DE FIN DE COURSE EN OUVERTURE

2 X 1,5 mm²

OPENING LIMIT SWITCH

FIN DE CARRERA ABERTURA

FIM DE PERCURSO ABERTURA

LAMPEGGIANTE 230Vac 50Hz 40W max

CLIGNOTEUR 230Vac 50Hz 40W max

FLASHING LIGHT 230Vac 50Hz 40W max

LAMPARA INTERMITENTE 230Vac 50Hz 40W max

PISCA - PISCA 230 V. c. a. 50 Hz máx. 40W

M

TX

M2

2

1

3 X 1 mm²

FCC

N.C.

3 X 0,5 mm²

FINECORSA CHIUSURA

BUTÉE DE FIN DE COURSE EN FERMETURE

CLOSING LIMIT SWITCH

FIN DE CARRERA CIERRE

FIM DE PERCURSO FECHAMENTO

2 X 0,5 mm²

FOTOCELLULA art. 104 / 105

PHOTOCELLULE art. 104 /105

POHOTOCELL item 104 /105

FOTOCELLULA art. 104 / 105

FOTOCÉLULA art. 104/105

2 X 0,5 mm²

RX

N.C.

1 2 3 4 5

LUCE DI CORTESIA / SPIA CANCELLO APERTO 230Vac 50Hz 40W max

LAMPE DE COURTOISIE / VOYANT PORTAIL OUVERTE 230Vac 50Hz 40W max

COURTESY LIGHT / OPEN GATE WARNING LIGHT 230Vac 50Hz 40W max

LUZ DE CORTESIA / INDICADOR LUMINOSO PUERTA ABIERTA 230Vac 50Hz 40W max

LUZ DE CORTESIA / INDICADOR LUMINOSO PORTÃO ABERTO 230 V. c. a. 50 Hz máx. 40 W

ATTENZIONE: DEA SYSTEM ricorda tuttavia che la scelta ,la disposizione e l’installazione di tutti i dispositivi e materiali che compongono l’intera automazione deve avvenire in ottemperanza alle normative vigenti nel paese in cui si effettua l’installazione.

ATTENTION: DEA SYSTEM vous rappelle toutefois que le choix, la disposition et l’installation de tous les dispositifs et de tous les matériels qui font partie de l’automation complète doivent être exécutés

conformément aux réglementations en vigueur dans le pays où l’installation sera mise en place.

WARNING: DEA SYSTEM reminds however that the choice and installation of all devices and materials included in the complete automation must respect the legal norms in force in the country where the

system is installed

ATENCIÓN!: DEA SYSTEM, no obstante, recuerda que la elección, la disposición y la instalación de todos los dispositivos y materiales que componen el automatismo debe efectuarse en el cumplimiento

de las normativas en vigor en el país en el que se efectúa dicha instalación.

ATENÇÃO: Entretanto o DEA SYSTEM lembra que a escolha, a disposição e a instalação de todos os dispositivos e materiais que constituem a inteira automação, devem ser efectuadas a obedecer

também as normas em vigor no país onde for instalada.

Loading...

Loading...