Page 1

®

www.BDTIC.com/Intersil

X9520

Fiber Channel/Gigabit Ethernet Laser Diode Control for Fiber Optic Modules

Data Sheet August 20, 2007

Triple DCP, POR, 2kbit EEPROM Memory,

Dual Voltage Monitors

The X9520 combines three Digitally Controlled

Potentiometers (DCPs), V1/VCC Powe r-on R eset ( POR)

circuitry , tw o programma ble volt ag e monitor inputs with

software and hardware indicators, and integrated EEPROM

with Block Lock™ protection. All functions of the X9520 are

accessed by an industry standard 2-Wire serial interface.

Two of the DCPs of the X9520 may be utilized to control the

bias and modulation currents of the laser diode in a Fiber Optic

module. The third DCP may be used to set other various

reference quantities, or as a coarse trim for one of the other two

DCPs. The 2kbit integrated EEPROM may be used to store

module definition data. The programmable POR circuit may be

used to ensure that V1/VCC is stable before power is applied to

the laser diode/module. The programmable voltage monitors

may be used for monitoring various module alarm levels.

The features of the X9520 are ideally suited to simplifying the

design of fiber optic modules which comply to the Gigabit

Interface Converter (GBIC) specification. The integration of

these functions into one package significantly reduces board

area, cost and increases reliability of laser diode modules.

Features

• Three Digitally Controlled Potentiometers (DCPs)

- 64 Tap - 10kΩ

- 100 Tap - 10kΩ

- 256 Tap - 100kΩ

- Nonvolatile

- Write Protect Function

• 2kbit EEPROM Memory with Write Protect & Block Lock

• 2-Wire Industry Standard Serial Interface

- Complies to the Gigabit Interface Converter (GBIC)

specification

• Power-on Reset (POR) Circuitry

- Programmable Threshold Voltage

- Software Selectable Reset Timeout

- Manual Reset

• Two Supplementary Voltage Monitors

- Programmable Threshold Voltages

• Single Supply Operation

- 2.7V to 5.5V

• Hot Pluggable

• 20 Ld Package

-TSSOP

• Pb-free available (RoHS compliant)

FN8206.2

Ordering Information

PART

PART NUMBER

X9520V20I-A X9520V IA Optimized for 3.3V system monitoring** -40 to +85 20 Ld TSSOP MDP0044

X9520V20I-AT1* X9520V IA Optimized for 3.3V system monitoring** -40 to +85 20 Ld TSSOP MDP0044

X9520V20I-AT2* X9520V IA Optimized for 3.3V system monitoring** -40 to +85 20 Ld TSSOP MDP0044

X9520V20I-B X9520V IB Optimized for 5V system monitoring** -40 to +85 20 Ld TSSOP MDP0044

X9520V20I-BT1* X9520V IB Optimized for 5V system monitoring** -40 to +85 20 Ld TSSOP MDP0044

X9520V20IZ-A (Note) X9520V ZIA Optimized for 3.3V system monitoring** -40 to +85 20 Ld TSSOP (Pb-free) MDP0044

X9520V20IZ-AT1* (Note) X9520V ZIA Optimized for 3.3V system monitoring** -40 to +85 20 Ld TSSOP (Pb-free) MDP0044

X9520V20IZ-AT2* (Note) X9520V ZIA Optimized for 3.3V system monitoring** -40 to +85 20 Ld TSSOP (Pb-free) MDP0044

X9520V20IZ-B (Note) X9520V ZIB Optimized for 5V system monitoring** -40 to +85 20 Ld TSSOP (Pb-free) MDP0044

X9520V20IZ-BT1* (Note) X9520V ZIB Optimized for 5V system monitoring** -40 to +85 20 Ld TSSOP (Pb-free) MDP0044

* Please refer to TB347 for details on reel specifications.

** For details, see DC Operating characteristics

NOTE: These Intersil Pb-free plastic packaged products employ special Pb-free material sets; molding compounds/die attach materials and 100%

matte tin plate PLUS ANNEAL - e3 termination finish, which is RoHS compliant and compatible with both SnPb and Pb-free soldering operations.

Intersil Pb-free products are MSL classified at Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J

STD-020.

MARKING

PRESET (FACTOR Y SHIPPED) TRIPx

THRESHOLD LEVELS (x = 2, 3)

TEMP. RANGE

(°C) PACKAGE

PKG.

DWG. #

™

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2005-2007. All Rights Reserved

Page 2

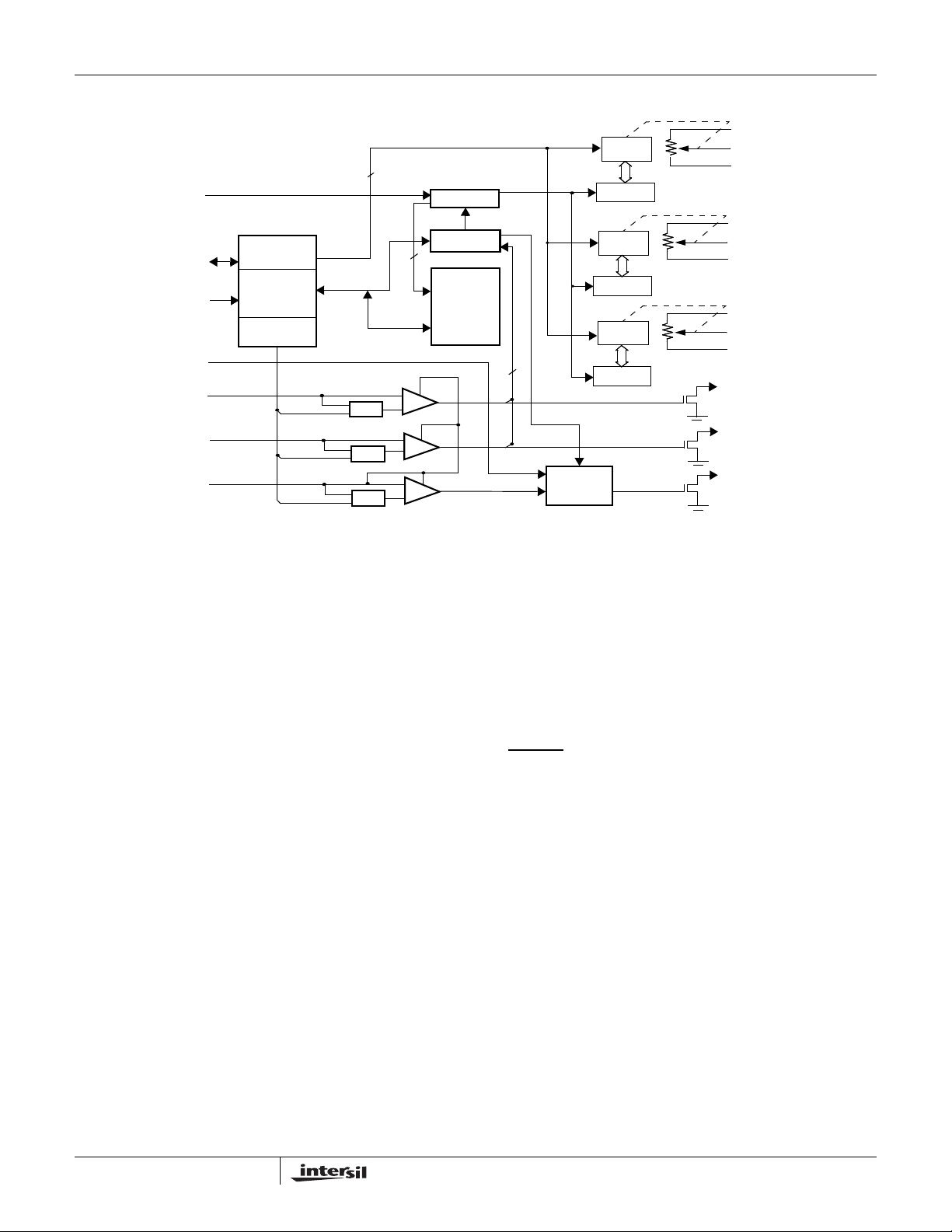

Block Diagram

www.BDTIC.com/Intersil

WP

SDA

SCL

MR

V3

V2

V1/VCC

DATA

REGISTER

COMMAND

DECODE &

CONTROL

LOGIC

THRESHOLD

RESET LOGIC

8

VTRIP

VTRIP

VTRIP

X9520

R

WIPER

COUNTER

REGISTER

6 - BIT

NONVOLATILE

PROTECT LOGIC

CONSTAT

REGISTER

4

2kbit

EEPROM

ARRAY

2

-

+

3

-

+

2

POWER-ON /

+

-

1

LOW VOLTAGE

RESET

GENERATION

MEMORY

WIPER

COUNTER

REGISTER

7 - BIT

NONVOLATILE

MEMORY

WIPER

COUNTER

REGISTER

8 - BIT

NONVOLATILE

MEMORY

R

R

R

H1

R

W1

R

L1

R

H2

R

W2

R

L2

V3RO

V2RO

V1RO

H0

W0

L0

Detailed Device Description

The X9520 combines three Intersil Digitally Controlled

Potentiometer (DCP) devices, V1/VCC power-on reset

control, V1/VCC low voltage reset control, two

supplementary voltage monitors, and integrated EEPROM

with Block Lock™ protection, in one package. These

functions are suited to the control, support, and monitoring of

various system parameters in Fiber Channel/Gigabit

Ethernet fiber optic modules, such as in Gigabit Interface

Converter (GBIC) applications. The combination of the

X9520 fucntionality lowers system cost, increases reliability,

and reduces board space requirements using Intersil’s

unique XBGA™ packaging.

Two high resolution DCPs allow for the “set-and-forget”

adjustment of Laser Driver IC parameters such as Laser

Diode Bias and Modulation Currents. One lower resolution

DCP may be used for setting sundry system parameters

such as maximum laser output power (for eye safety

requirements).

Applying voltage to V

which allows the V1RO output to go HIGH, until the supply

the supply voltage stabilizes for a period of time (selectable

via software). The V1RO output then goes LOW. The Low

Voltage Reset circuitry allows the V1RO output to go HIGH

when V

falls below the minimum VCC trip point. V1RO

CC

remains HIGH until V

Manual Reset (MR) input allows the user to externally trigger

the V1RO output (HIGH).

activates the Power-on Reset circuit

CC

returns to proper operating level. A

CC

Two supplementary Voltage Monitor circuits continuously

compare their inputs to individual trip voltages. If an input

voltage exceeds it’s associated trip level, a hardware output

(V3RO, V2RO) are allowed to go HIGH. If the input voltage

becomes lower than it’s associated trip level, the

corresponding output is driven LOW. A corresponding binary

representation of the two monitor circuit outputs (V2RO and

V3RO) are also stored in latched, volatile (CONSTAT)

register bits. The status of these two monitor outputs can be

read out via the 2-wire serial port.

An application of the V1RO output may be to drive the

“ENABLE

” input of a Laser Driver IC, with MR as a

“TX_DISABLE” input. V2RO and V3RO may be used to

monitor “TX_FAULT” and “RX_LOS” conditions respectively.

Intersil’s unique circuits allow for all internal trip voltages to

be individually programmed with high accuracy. This gives

the designer great flexibility in changing system parameters,

either at the time of manufacture, or in the field.

The memory portion of the device is a CMOS serial

EEPROM array with Intersil’s Block Lock™ protection. This

memory may be used to store fiber optic module

manufacturing data, serial numbers, or various other system

parameters. The EEPROM array is internally organized as x

8, and utilizes Intersil’s proprietary Direct Write™ cells,

providing a minimum endurance of 1,000,000 cycles and a

minimum data retention of 100 years.

The device features a 2-Wire interface and software protocol

allowing operation on an I

2

C™ compatible serial bus.

2

FN8206.2

August 20, 2007

Page 3

X9520

www.BDTIC.com/Intersil

Pinout

X9520

(20 LD TSSOP)

TOP VIEW

R

R

R

V3RO

MR

WP

SCL

SDA

V

H2

W2

V3

SS

1

2

3

L2

4

5

6

7

8

9

10

V1/VCC

20

V1RO

19

18

V2RO

17

V2

R

16

15

14

13

12

11

L0

R

W0

R

H0

R

H1

R

W1

R

L1

NOT TO SCALE

Pin Descriptions

TSSOP NAME FUNCTION

1R

2R

3RL2Connection to other end of resistor array for (the 256 Tap) DCP 2.

4 V3 V3 Voltage Monitor Input. V3 is the input to a non-inverting voltage comparator circuit. When the V3 input is higher than the

5 V3RO V3 RESE T Output. This open drain output makes a transition to a HIGH level when V3 is greater than V

6 MR Manual Reset. MR is a TTL level compatible input. Pulling the MR pin active (HIGH) initiates a reset cycle to the V1RO pin

7 WP Write Protect Control Pin. WP pin is a TTL level comp atible input. When held HIGH, Write Protection is enabled. In the enabled

8 SCL Serial Clock. This is a TTL level compatible input pin used to control the serial bus timing for data input and output.

9 SDA Serial Data. SDA is a bidirectional TTL level compatible pin used to transfer data into and out of the device. The SDA pin input

10 Vss Ground.

11 R

12 R

13 R

14 R

15 R

16 R

17 V2 V2 Voltage Monitor Input. V2 is the input to a non-inverting voltage comparator circuit. When the V2 input is greater than the

18 V2RO V2 RESET Output. This open drain output makes a transition to a HIGH level when V2 is greater than V

Connection to end of resistor array for (the 256 Tap) DCP 2.

H2

Connection to terminal equivalent to the “Wiper” of a mechanical potentiometer for DCP 2.

w2

threshold voltage, V3RO makes a transition to a HIGH level. Connect V3 to VSS when not used.

V

TRIP3

and goes LOW

when V3 is less than VTRIP3. There is no delay circuitry on this pin. The V3RO pin requires the use of an external “pull-up”

TRIP3

resistor.

(V1/VCC RESET Output pin). V1RO will remain HIGH for time t

reset time can be selected using bits POR1 and POR0 in the CONSTAT Register. The MR pin requires the use of an external

after MR has returned to it’s normally LOW state. The

purst

“pull-down” resistor.

state, this pin prevents all nonvolatile “write” operations. Also, when the Write Protection is enabled, and the device Block Lock

feature is active (i.e. the Block Lock bits are NOT [0,0]), then no “write” (volatile or nonvolatile) operations can be performed

in the device (including the wiper position of any of the integrated Digitally Controlled Potentiometers (DCPs). The WP pin

uses an internal “pull-down” resistor, thus if left floating the write protection feature is disabled.

buffer is always active (not gated). This pin requires an external pull up resistor.

Connection to other end of resistor for (the 100 Tap) DCP 1.

L1

Connection to terminal equivalent to the “Wiper” of a mechanical potentiometer for DCP 1.

w1

Connection to end of resistor array for (the 100 Tap) DCP 1.

H1

Connection to end of resistor array for (the 64 Tap) Digitally Controlled Potentiometer (DCP) 0.

H0

Connection to terminal equivalent to the “Wiper” of a mechanical potentiometer for DCP 0.

W0

Connection to the other end of resistor array for (the 64 Tap) DCP 0.

L0

threshold voltage, V2RO makes a transition to a HIGH level. Connect V2 to VSS when not used.

V

TRIP2

, and goes LOW

when V2 is less than V

external “pull-up” resistor.

TRIP2

. There is no power-up reset delay circuitry on this pin. The V2RO pin requires the use of an

TRIP2

3

FN8206.2

August 20, 2007

Page 4

X9520

www.BDTIC.com/Intersil

Pin Descriptions (Continued)

TSSOP NAME FUNCTION

19 V1RO V1/VCC RESET Output. This is an active HIGH, open drain output which becomes active whenever V1/VCC falls below

20 V1/VCC Supply Voltage.

V

. V1RO becomes active on power-up and remains active for a time t

TRIP1

be changed by varying the POR0 and POR1 bits of the internal control register). The V1RO pin requires the use of an external

“pull-up” resistor. The V1RO pin can be forced active (HIGH) using the manual reset (MR) input pin.

after the power supply stabilizes (t

purst

purst

can

Principles of Operation

Serial Interface

SERIAL INTERFACE CONVENTIONS

The device supports a bidirectional bus oriented protocol.

The protocol defines any device that sends data onto the

bus as a transmitter, and the receiving device as the

receiver. The device controlling the transfer is called the

master and the device being controlled is called the slave.

The master always initiates data transfers, and provides the

clock for both transmit and receive operations. Therefore,

the X9520 operates as a slave in all applications.

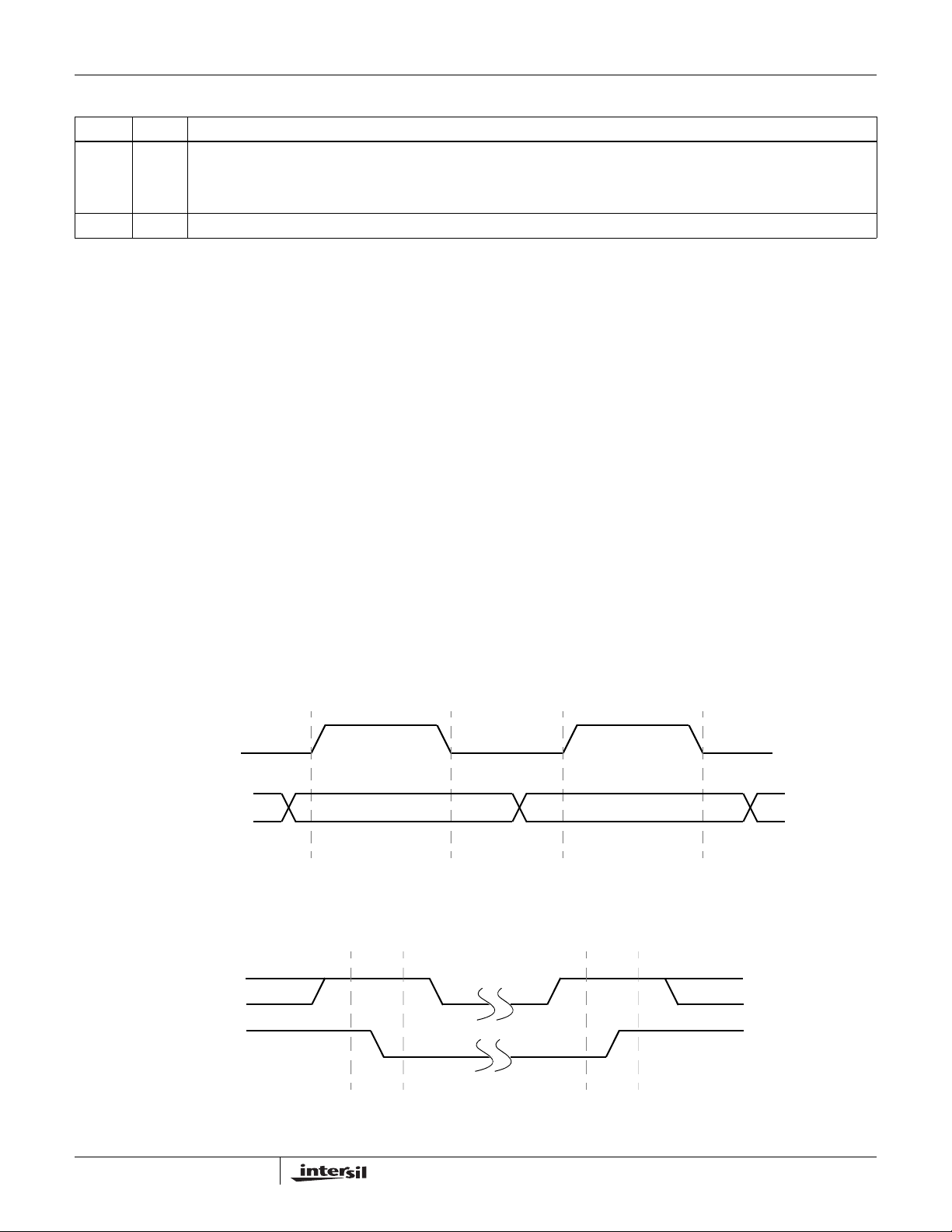

SERIAL CLOCK AND DATA

Data states on the SDA line can change only while SCL is

LOW. SDA state changes while SCL is HIGH are reserved

for indicating START and STOP conditions. See Figure 1.

On power-up of the X9520, the SDA pin is in the input mode.

SERIAL START CONDITION

All commands are preceded by the START condition, which

is a HIGH to LOW transition of SDA while SCL is HIGH. The

device continuously monitors the SDA and SCL lines for the

START condition and does not respond to any command

until this condition has been met. See Figure 2.

SERIAL STOP CONDITION

All communications must be terminated by a STOP condition,

which is a LOW to HIGH transition of SDA while SCL is HIGH.

The STOP condition is also used to place the device into the

Standby pow er mode after a read sequence. A STOP

condition can only be issued after the transmitting device has

released th e bu s . See Figure 2.

SCL

SDA

SCL

SDA

DATA STABLE DATA CHANGE DATA STABLE

FIGURE 1. VALID DATA CHANGES ON THE SDA BUS

START STOP

FIGURE 2. VALID START AND STOP CONDITIONS

4

FN8206.2

August 20, 2007

Page 5

SCL from

www.BDTIC.com/Intersil

SCL

Master

from

Master

Data Output from

Transmitter

Data Output from

Receiver

X9520

81 9

START ACKNOWLEDGE

FIGURE 3. ACKNOWLEDGE RESPONSE FROM RECEIVER

SERIAL ACKNOWLEDGE

An ACKNOWLEDGE (ACK) is a software convention used to

indicate a successful data transfer . The transmitting device,

either master or slave, will release the bus after transmitting

eight bits. During the ninth clock cycle, the receiver will pull the

SDA line LOW to ACKNOWLEDGE that it received the eight

bits of data. Refer to Figure 3.

The device will respond with an ACKNOWLEDGE after

recognition of a START condition if the correct Device

Identifier bits are contained in the Slave Address Byte. If a

write operation is selected, the device will respond with an

ACKNOWLEDGE after the receipt of each subsequent eight

bit word.

In the read mode, the device will transmit eight bits of data,

release the SDA line, then monitor the line for an

ACKNOWLEDGE. If an ACKNOWLEDGE is detected and

no STOP condition is generated by the master, the device

will continue to transmit data. The device will terminate

further data transmissions if an ACKNOWLEDGE is not

detected. The master must then issue a STOP condition to

place the device into a known state.

Device Internal Addressing

Addressing Protocol Overview

The user addressable internal components of the X9520 can

be split up into three main parts:

• Three Digitally Controlled Potentiometers (DCPs)

• EEPROM array

• Control and Status (CONSTAT) Register

Depending upon the operation to be performed on each of

these individual parts, a 1, 2 or 3 Byte protocol is used. All

operations however must begin with the Slave Address Byte

being issued on the SDA pin. The Slave address selects the

part of the X9520 to be addressed, and specifies if a Read or

Write operation is to be performed.

It should be noted that in order to perform a write operation

to either a DCP or the EEPROM array, the Write Enable

Latch (WEL) bit must first be set (See “BL1, BL0: Block Lock

protection bits - (Nonvolatile)” on page 13.)

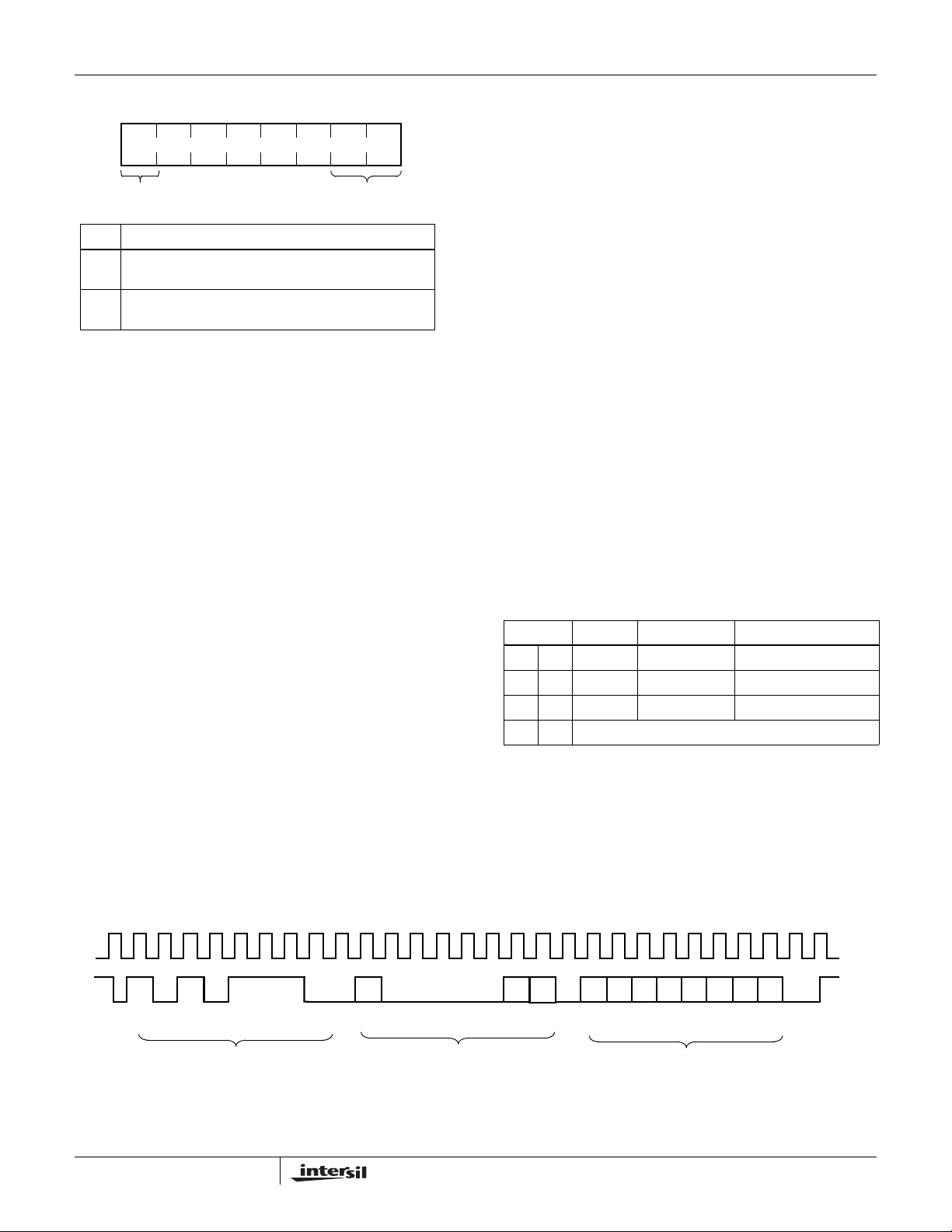

Slave Address Byte

Following a START condition, the master must output a

Slave Address Byte (Refer to Figure 4). This byte consists of

three parts:

• The Device Type Identifier which consists of the most

significant four bits of the Slave Addre ss (SA7 - SA4). The

Device Type Identifier must always be set to 1010 in order

to select the X9520.

• The next three bits (SA3 - SA1) are the Internal Device

Address bits. Setting these bits to 000 internally selects

the EEPROM array, while setting these bits to 111 selects

the DCP structures in the X9520. The CONSTAT Register

may be selected using the Internal Device Address 010.

• The Least Significant Bit of the Slave Address (SA0) Byte

is the R/W

performed on the device being addressed (as defined in

the bits SA3 - SA1). When the R/W

operation is selected. A “0” selects a WRITE operation

(Refer to Figure 4.)

5

bit. This bit defines the operation to be

bit is “1”, then a READ

FN8206.2

August 20, 2007

Page 6

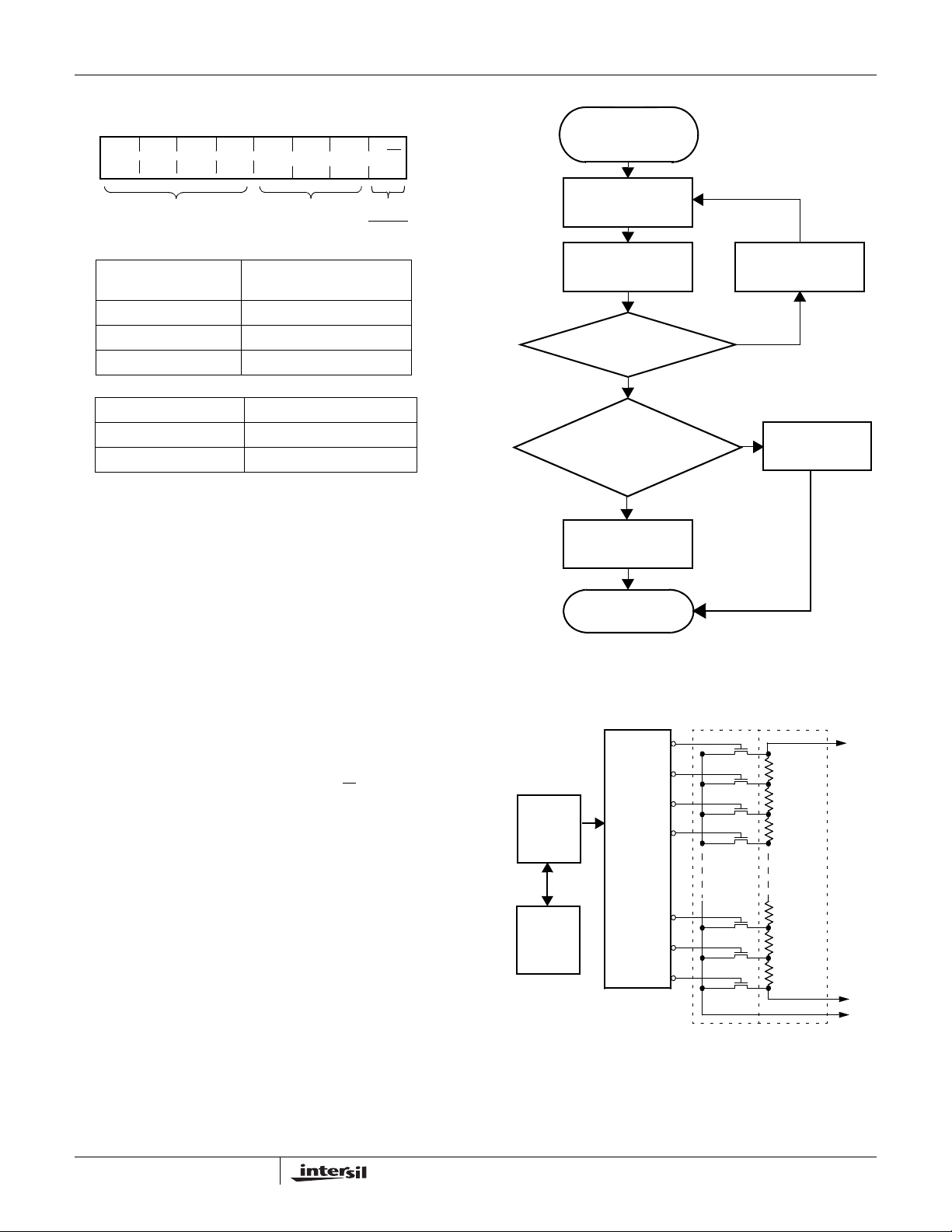

x

X9520

www.BDTIC.com/Intersil

SA6SA7

SA5

1010

DEVICE TYPE

IDENTIFIER

INTERNAL ADDRESS

(SA3 - SA1)

000 EEPROM Array

010 CONSTAT Register

111 DCP

BIT SA0 OPERATION

0WRITE

1 READ

FIGURE 4. SLAVE ADDRESS FORMAT

SA3 SA2

SA4

INTERNAL

DEVICE

ADDRESS

INTERNALL Y ADDRESSED

SA1

DEVICE

SA0

R/W

READ/

WRITE

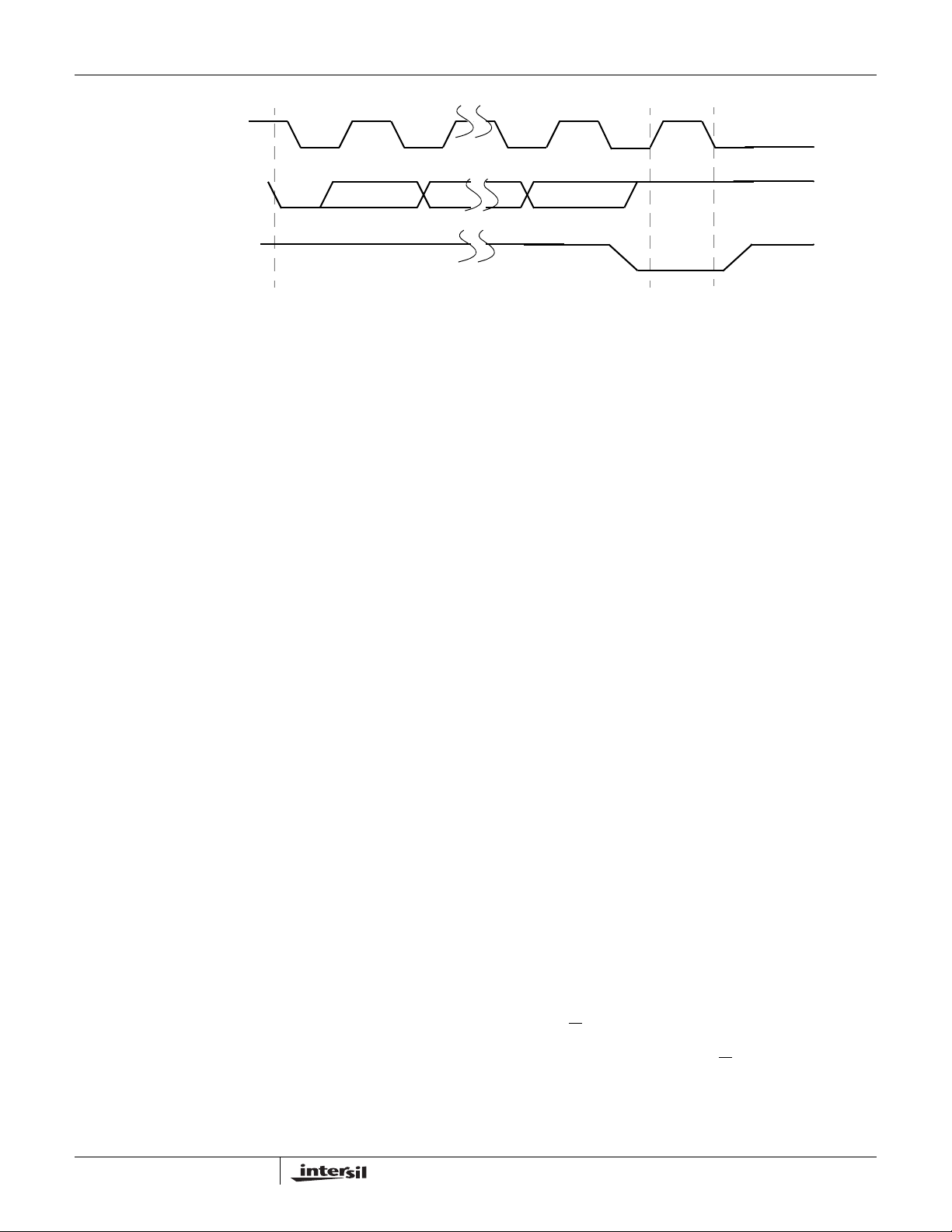

Nonvolatile Write Acknowledge Polling

After a nonvolatile write command sequence (for either the

EEPROM array, the Non Volatile Memory of a DCP (NVM),

or the CONSTAT Register) has been correctly is sued

(including the final STOP condition), the X9520 initiates an

internal high voltage write cycle. This cycle typically requires

5 ms. During this time, no further Read or Write commands

can be issued to the device. Write Acknowledge Polling is

used to determine when this high voltage write cycle has

been completed.

Byte load completed

by issuing STOP.

Enter ACK Polling

Issue START

Issue Slave Address

Byte (Read or Write)

ACK

returned?

YES

High Voltage Cycle

complete. Continue

command sequence?

YES

Continue normal

Read or Write

command sequence

PROCEED

FIGURE 5. ACKNOWLEDGE POLLING SEQUENCE

NO

NO

ssue STOP

I

Issue STOP

T o perform acknowledge polling, the master issues a ST AR T

condition followed by a Slave Address Byte. The Slave

Address issued must contain a valid Internal Device

Address. The LSB of the Slave Address (R/W

) can be set to

either 1 or 0 in this case. If the device is still busy with the

high voltage cycle then no ACKNOWLEDGE will be

returned. If the device has completed the write operation, an

ACKNOWLEDGE will be returned and the host can then

proceed with a read or write operation (Refer to Figure 5.).

Digitally Controlled Potentiometers

DCP Functionality

The X9520 includes three independent resistor arrays.

These arrays respectively contain 63, 99 and 255 discrete

resistive segments that are connected in series. The

physical ends of each array are equivalent to the fixed

terminals of a mechanical potentiometer (R

inputs - where x = 0,1,2).

6

and RLx

Hx

WIPER

COUNTER

REGISTER

(WCR)

NON

VOLATILE

MEMORY

(NVM)

N

DECODER

2

1

0

FIGURE 6. DCP INTERNAL STRUCTURE

“WIPER”

FET

SWITCHES

RESISTOR

ARRAY

R

Hx

R

Lx

R

W

FN8206.2

August 20, 2007

Page 7

V1/VCC

www.BDTIC.com/Intersil

t

0

trans

X9520

t

purst

FIGURE 7. DCP POWER

V1/VCC (Max)

V

TRIP1

t

MAXIMUM WIPER RECALL TIME

At both ends of each array and between each resistor

segment there is a CMOS switch connected to the wiper

(R

) output. Within each individual array, only one switch

x

w

may be turned on at any one time. These switches are

controlled by the Wiper Counter Register (WCR) (See Figure

6). The WCR is a volatile register.

On power-up of the X9520, wiper position data is

automatically loaded into the WCR from its associated Non

Volatile Memory (NVM) Register. The table below shows the

Initial Values of the DCP WCR’s before the contents of the

NVM is loaded into the WCR.

DCP INITIAL VALUES BEFORE RECALL

R0/64 TAP VH/TAP = 63

100 TAP VL/TAP = 0

R

1/

256 TAP VH/TAP = 255

R

2/

The data in the WCR is then decoded to select and enable

one of the respective FET switches. A “make before break”

sequence is used internally for the FET switches when the

wiper is moved from one tap position to another.

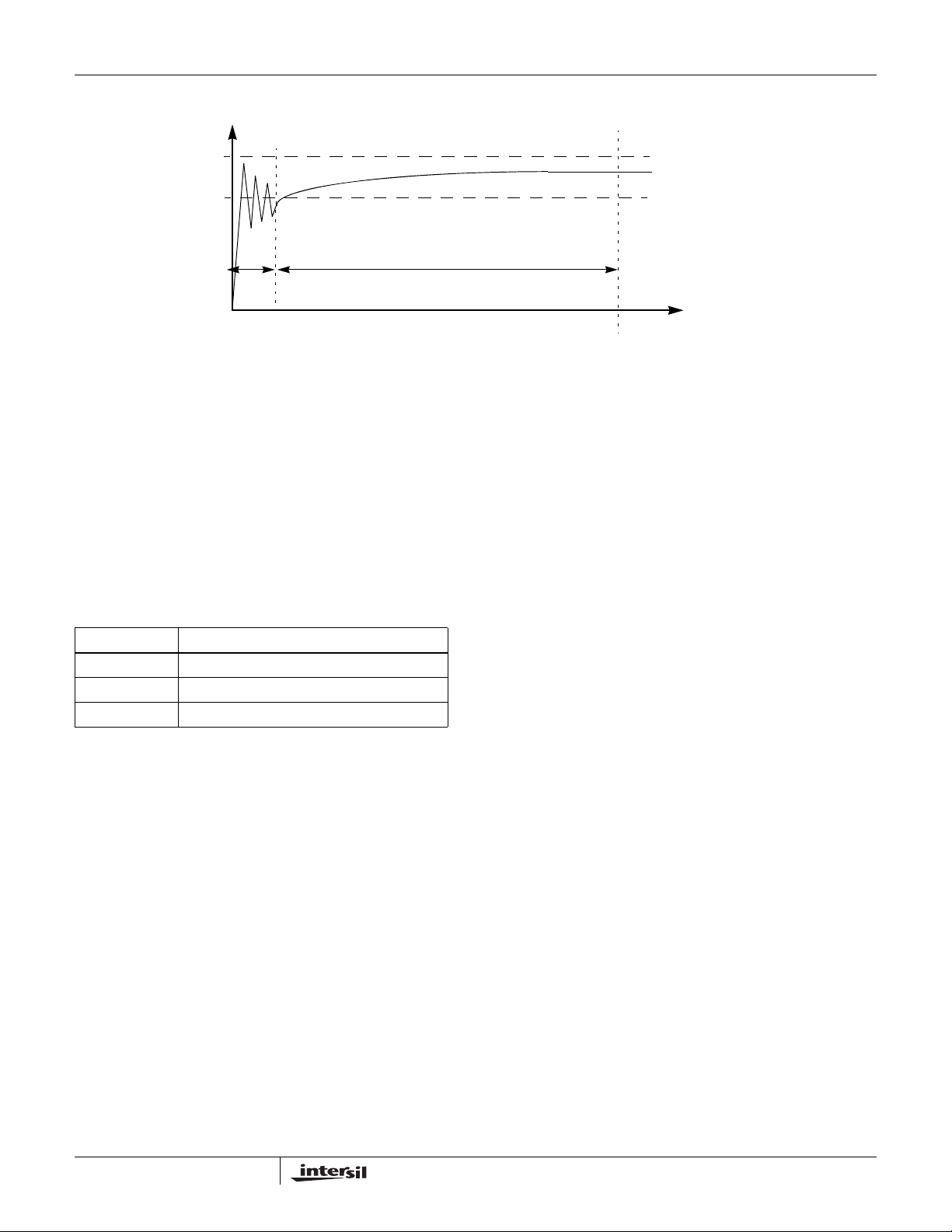

Hot Pluggability

Figure 7 shows a typical waveform that the X9520 might

experience in a Hot Pluggable situation. On power-up,

V1/VCC applied to the X9520 may exhibit some amount of

ringing, before it settles to the required value.

The device is designed such that the wiper terminal (R

recalled to the correct position (as per the last stored in the

DCP NVM), when the voltage applied to V1/VCC exceeds

V

time, set in the CONSTAT Register - See “Control and Status

Register” on page 12.).

Therefore, if

to settle above V

terminal position is recalled by (a maximum) time:

for a time exceeding t

TRIP1

t

trans

(the Power-on Reset

purst

is defined as the time taken for V1/VCC

(Figure 7): then the desired wiper

TRIP1

t

trans

Wx

) is

+

t

. It should be noted that t

purst

system hot plug conditions.

is determined by

trans

DCP Operations

In total there are three operations that can be performed on

any internal DCP structure:

• DCP Nonvolatile Write

• DCP Volatile Write

• DCP Read

A nonvolatile write to a DCP will change the “wiper position”

by simultaneously writing new data to the associated WCR

and NVM. Therefore, the new “wiper position” setting is

recalled into the WCR after V1/VCC of the X9520 is powered

down and then powered back up.

A volatile write operation to a DCP however, changes the

“wiper position” by writing new data to the associated WCR

only. The contents of the associated NVM register remains

unchanged. Therefore, when V1/VCC to the device is

powered down then back up, the “wiper position” reverts to

that last position written to the DCP using a nonvolatile write

operation.

Both volatile and nonvolatile write operations are executed

using a three byte command sequence: (DCP) Slave

Address Byte, Instruction Byte, followed by a Data Byte (See

Figure 9).

A DCP Read operation allows the user to “read out” the

current “wiper position” of the DCP, as stored in the

associated WCR. This operation is ex ecu ted using the

Random Address Read command sequence, consisting of

the (DCP) Slave Address Byte followed by an Instruction

Byte and the Slave Address Byte again (Refer to Figure 10.).

Instruction Byte

While the Slave Address Byte is used to select the DCP

devices, an Instruction Byte is used to determine which DCP

is being addressed.

7

FN8206.2

August 20, 2007

Page 8

X9520

www.BDTIC.com/Intersil

I5I6I7 I4 I3 I2 I1 I0

00WT 0 0 0 P1 P0

WRITE TYPE

†

WT

0 Select a Volatile Write operation to be performed on the

DCP pointed to by bits P1 and P0

1 Select a Nonvolatile Write operation to be performed on

the DCP pointed to by bits P1 and P0

†

This bit has no effect when a Read operation is being performed.

FIGURE 8. INSTRUCTION BYTE FORMAT

DESCRIPTION

DCP SELECT

The Instruction Byte (Figure 8) is valid only when the Device

Type Identifier and the Internal Device Address bits of the

Slave Address are set to 1010111. In this case, the two

Least Significant Bit’s (I1 - I0) of the Instruction Byte are

used to select the particular DCP (0 - 2). In the case of a

Write to any of the DCPs (i.e. the LSB of the Slave Address

is 0), the Most Significant Bit of the Instruction Byte (I7),

determines the Write Type (WT) performed.

If WT is “1”, then a Nonvolatile Write to the DCP occurs. In

this case, the “wiper position” of the DCP is changed by

simultaneously writing new data to the associated WCR and

NVM. Therefore, the new “wiper position” setting is recalled

into the WCR after V1/VCC of the X9520 has been powered

down then powered back up

If WT is “0” then a DCP Volatile Write is performed. This

operation changes the DCP “wiper position” by writing new

data to the associated WCR only. The contents of the

associated NVM register remains unchanged. Therefore,

when V1/VCC to the device is powered down then back up,

the “wiper position” reverts to that last written to the DCP

using a nonvolatile write operation.

DCP Write Operation

A write to DCPx (x = 0,1,2) can be performed u sing the three

byte command sequence shown in Figure 9.

In order to perform a write operation on a particular DCP, the

Write Enable Latch (WEL) bit of the CONSTA T Re gi ster

must first be set (See “BL1, BL0: Block Lock protection bits (Nonvolatile)” on page 13.)

The Slave Address Byte 10101110 specifies that a Write to a

DCP is to be conducted. An ACKNOWLEDGE is returned by

the X9520 after the Slave Address, if it has been received

correctly.

Next, an Instruction Byte is issued on SDA. Bits P1 and P0

of the Instruction Byte determine which WCR is to be written,

while the WT bit determines if the Write is to be volatile or

nonvolatile. If the Instruction Byte format is valid, another

ACKNOWLEDGE is then returned by the X9520.

Following the Instruction Byte, a Data Byte is issued to the

X9520 over SDA. The Data Byte contents is latched into the

WCR of the DCP on the first rising edge of the clock signal,

after the LSB of the Data Byte (D0) has been issued on SDA

(See Figure 34).

The Data Byte determines the “wiper position” (which FET

switch of the DCP resistive array is switched ON) of the

DCP. The maximum value for the Data Byte depends upon

which DCP is being addressed (see Table below).

P1 - P0 DCPX # TAPS MAX DATA BYTE

00 x = 0 64 3Fh

0 1 x = 1 100 Refer to Appendix 1

1 0 x = 2 256 FFh

11 Reserved

Using a Data Byte larger than the values specified above

results in the “wiper terminal” being set to the highest tap

position. The “wiper position” does NOT roll-over to th e

lowest tap position.

For DCP0 (64 Tap) and DCP2 (256 Tap), the Data Byte

maps one to one to the “wiper position” of the DCP “wiper

10101110

S

T

A

R

T

SLAVE ADDRESS BYTE

A

WT 0 0 0 0 0 P1 P0 A

C

K

INSTRUCTION BYTE

FIGURE 9. DCP WRITE COMMAND SEQUENCE

C

K

8

D7 D6 D5 D4 D3 D2 D1 D0

DATA BYTE

S

A

T

C

O

K

P

FN8206.2

August 20, 2007

Page 9

X9520

www.BDTIC.com/Intersil

terminal”. Therefore, the Data Byte 00001111 (1510)

corresponds to setting the “wiper terminal” to tap position 15.

Similarly, the Data Byte 00011100 (28

) corresponds to

10

setting the “wiper terminal” to tap position 28. The mapping

of the Data Byte to “wiper position” data for DCP1 (100 Tap),

is shown in “Appendix 1” . An example of a simple C

language function which “translates” between the tap

position (decimal) and the Data Byte (binary) for DCP1, is

given in “Appendix 2” .

It should be noted that all writes to any DCP of the X9520

are random in nature. Therefore, the Data Byte of

consecutive write operations to any DCP can differ by an

arbitrary number of bits. Also, setting the bits P1 = 1, P0 = 1

is a reserved sequence, and will result in no

ACKNOWLEDGE after sending an Instruction Byte on SDA.

The factory default setting of all “wiper position” settings is

with 00h stored in the NVM of the DCPs. This corresponds

to having the “wiper teminal”

tap position, Therefore, the resistance between

R

is a minimum (essentially only the Wiper Resistance,

LX

R

).

W

R

(x = 0,1,2) at the “lowest”

WX

R

WX

and

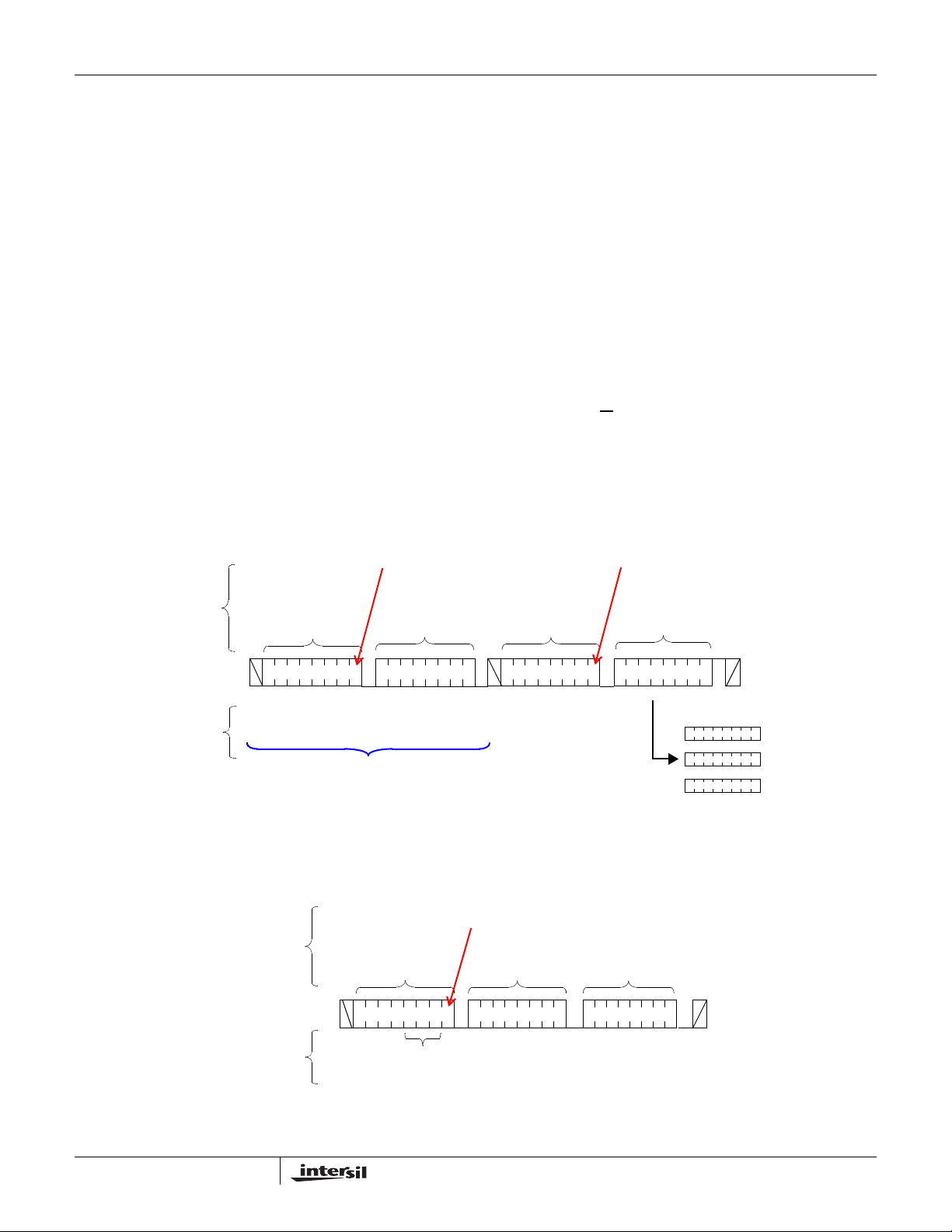

DCP Read Operation

A read of DCPx (x = 0,1,2) can be performed using the three

byte random read command sequence shown in Figure 10.

The master issues the START condition and the Slave

Address Byte 10101110 which specifies that a “dummy”

write” is to be conducted. This “dummy” write operation sets

which DCP is to be read (in the preceding Read operation).

An ACKNOWLEDGE is returned by the X9520 after the

Slave Address if received correctly. Next, an Instruction Byte

is issued on SDA. Bits P1-P0 of the Instruction Byte

determine which DCP “wiper position” is to be read. In this

case, the state of the WT bit is “don’t care”. If the Instruction

Byte format is valid, then another ACKNOWLEDGE is

returned by the X9520.

Following this ACKNOWLEDGE, the master immediately

issues another START condition and a valid Slave address

byte with the R/W

ACKNOWLEDGE followed by Data Byte, and finally, the

master issues a STOP condition. The Data Byte read in this

operation, corresponds to the “wiper position” (value of the

WCR) of the DCP pointed to by bits P1 and P0.

bit set to 1. Then the X9520 issues an

Signals from the

Master

SDA Bus

Signals from the

Slave

S

t

a

r

t

101 11100

Signals from the

Master

SDA Bus

Signals from the

Slave

Slave

Address

WRITE Operation

S

Instruction

Byte

t

a

Slave

Address

r

t

P

W

00 000

T

A

C

K

“Dummy” write

FIGURE 10. DCP READ SEQUENCE

S

t

a

Slave

r

Address

t

10100000

Internal

Device

Address

FIGURE 11. EEPROM BYTE WRITE SEQUENCE

P

1

WRITE Operation

A

C

K

0

A

C

K

Address

Byte

101 11110

A

C

K

READ Operation

Data Byte

A

C

K

Data

Byte

S

t

o

p

--

-

MSB

“-” = DON’T CARE

S

t

o

p

A

C

K

LSB

DCPx

x = 0

x = 1

x = 2

9

FN8206.2

August 20, 2007

Page 10

X9520

www.BDTIC.com/Intersil

S

Signals from the

Master

SDA Bus

Signals from the

Slave

t

a

Slave

r

Address

t

10100000

A

C

K

FIGURE 12. EEPROM PAGE WRITE OPERATION

It should be noted that when reading out the data byte for

DCP0 (64 Tap), the upper two most significant bit s are

“unknown” bits. For DCP1 (100 Tap), the upper most

significant bit is an “unknown”. For DCP2 (256 Tap) however,

all bits of the data byte are relevant (See Figure 10).

2KBIT EEPROM ARRAY

Operations on the 2kbit EEPROM Array, consist of either 1,

2 or 3 byte command sequences. All operations on the

EEPROM must begin with the Device Type Identifier of the

Slave Address set to 1010000. A Read or Write to the

EEPROM is selected by setting the LSB of the Slave

Address to the appropriate value R/W

(Read = “1”,

Write = ”0”).

In some cases when performing a Read or Write to the

EEPROM, an Address Byte may also need to be specified.

This Address Byte can contain the values 00h to FFh.

EEPROM BYTE WRITE

In order to perform an EEPROM Byte Write operation to the

EEPROM array, the Write Enable Latch (WEL) bit of the

CONSTAT Register must first be set (See “BL1, BL0: Block

Lock protection bits - (Nonvolatile)” on page 13.)

For a write operation, the X9520 requires the Slave Address

Byte and an Address Byte. This gives the master access to

any one of the words in the array. After receipt of the

Address Byte, the X9520 responds with an

ACKNOWLEDGE, and awaits the next eight bits of data.

After receiving the 8 bits of the Data Byte, it again responds

with an ACKNOWLEDGE. The master then terminates the

transfer by generating a STOP condition, at which time the

X9520 begins the internal write cycle to the nonvolatile

memory (See Figure 1 1). During this internal write cycle, the

X9520 inputs are disabled, so it does not respond to any

requests from the master. The SDA output is at high

impedance. A write to a region of EEPROM memory which

has been protected with the Block-Lock feature (See “BL1,

BL0: Block Lock protection bits - (Nonvolatile)” on page 13.),

suppresses the ACKNOWLEDGE bit after the Address Byte.

S

t

o

p

A

C

K

Address

Byte

(2 < n < 16)

Data

(1)

A

C

K

A

C

K

Data

(n)

EEPROM Page Write

In order to perform an EEPROM Page Write operation to the

EEPROM array, the Write Enable Latch (WEL) bit of the

CONSTAT Register must first be set (See “BL1, BL0: Block

Lock protection bits - (Nonvolatile)” on page 13.)

The X9520 is capable of a page write operation. It is initiated

in the same manner as the byte write operation; but instead

of terminating the write cycle after the first data byte is

transferred, the master can transmit an unlimited number of

8-bit bytes. After the receipt of each byte, the X9520

responds with an ACKNOWLEDGE, and the address is

internally incremented by one. The page address remains

constant. When the counter reaches the end of the page, it

“rolls over” and goes back to ‘0’ on the same page.

For example, if the master writes 12 bytes to the page

starting at location 11 (decimal), the first 5 bytes are written

to locations 11 through 15, while the last 7 bytes are written

to locations 0 through 6. Afterwards, the address counter

would point to location 7. If the master supplies more than 16

bytes of data, then new data overwrites the previous data,

one byte at a time (See Figure 13).

The master terminates the Data Byte loading by issuing a

STOP condition, which causes the X9520 to begin the

nonvolatile write cycle. As with the byte write operation, all

inputs are disabled until completion of the internal write

cycle. See Figure 12 for the address, ACKNOWLEDGE, and

data transfer sequence.

Stops and EEPROM Write Modes

Stop conditions that terminate write operations must be sent

by the master after sending at least 1 full data byte and

receiving the subsequent ACKNOWLEDGE signal. If the

master issues a STOP within a Data Byte, or before the

X9520 issues a corresponding ACKNOWLEDGE, the X9520

cancels the write operation. Therefore, the contents of the

EEPROM array does not change.

10

FN8206.2

August 20, 2007

Page 11

7 BYTES

www.BDTIC.com/Intersil

X9520

5 bytes

5 BYTES

ADDRESS = 6

FIGURE 13. EXAMPLE: WRITING 12 BYTES TO A 16-BYTE PAGE STARTING AT LOCATION 11.

SIGNALS FROM

THE MASTER

SDA BUS

SIGNALS FROM

THE SLAVE

FIGURE 14. CURRENT EEPROM ADDRESS READ SEQUENCE

10

S

T

A

R

T

1 0 00001

EEPROM Array Read Operations

Read operations are initiated in the same manner as write

operations with the exception that the R/W

bit of the Slave

Address Byte is set to one. There are three basic read

operations: Current EEPROM Address Read, Random

EEPROM Read, and Sequential EEPROM Read.

Current EEPROM Address Read

Internally the device contains an address counter that

maintains the address of the last word read incremented by

one. Therefore, if the last read was to address n, the next

read operation would access data from address n+1. On

power-up, the address of the address counter is undefined,

requiring a read or write operation for initialization.

Upon receipt of the Slave Address Byte with the R/W

to one, the device issues an ACKNOWLEDGE and then

transmits the eight bits of the Data Byte. The master

terminates the read operation when it does not respond with

an ACKNOWLEDGE during the ninth clock and then issues

a STOP condition (See Figure 14 for the address,

ACKNOWLEDGE, and data transfer sequence).

It should be noted that the ninth clock cycle of the read

operation is not a “don’t care.” To terminate a read operation,

the master must either issue a STOP condition during the

ninth cycle or hold SDA HIGH during the ninth clock cycle

and then issue a STOP condition.

bit set

ADDRESS POINTER

ENDS HERE

ADDRESS = 7

SLAVE

ADDRESS

ADDRESS = 11

10

ADDRESS = 15

10

S

T

O

P

10

1

A

C

K

DATA

Another important point to note regarding the “Current

EEPROM Address Read” , is that this operation is not

available if the last executed operation was an access to a

DCP or the CONSTAT Register (i.e.: an operation using the

Device Type Identifier 1010111 or 1010010). Immediately

after an operation to a DCP or CONSTAT Register is

performed, only a “Random EEPROM Read” is available.

Immediately following a “Random EEPROM Read” , a

“Current EEPROM Address Read” or “Sequential EEPROM

Read” is once again available (assuming that no access to a

DCP or CONSTAT Registe r occur in the interim).

Random EEPROM Read

Random read operation allows the master to access any

memory location in the array. Prior to issuing the Slave

Address Byte with the R/W

first perform a “dummy” write operation. The master issues

the START condition and the Slave Address Byte, receives

an ACKNOWLEDGE, then issues an Address Byte. This

“dummy” Write operation sets the address pointer to the

address from which to begin the random EEPROM read

operation.

After the X9520 acknowledges the receipt of the Address

Byte, the master immediately issues another START

condition and the Slave Address Byte with the R/W

one. This is followed by an ACKNOWLEDGE from the

X9520 and then by the eight bit word. The master terminates

bit set to one, the master must

bit set to

11

FN8206.2

August 20, 2007

Page 12

X9520

www.BDTIC.com/Intersil

WRITE Operation

Address

0

A

C

K

“Dummy” Write

Byte

Signals from the

Master

SDA Bus

Signals from the

Slave

S

t

Slave

a

r

Address

t

1 0 00001

FIGURE 15. RANDOM EEPROM ADDRESS READ SEQUENCE

the read operation by not responding with an

ACKNOWLEDGE and instead issuing a STOP condition

(Refer to Figure 15.).

A similar operation called “Set Current Address” also exists.

This operation is performed if a STOP is issued instead of

the second START shown in Figure 15. In this case, the

device sets the address pointer to that of the Address Byte,

and then goes into standby mode after the STOP bit. All bus

activity will be ignored until another START is detected.

Sequential EEPROM Read

Sequential reads can be initiated as either a current address

read or random address read. The first Data Byte is

transmitted as with the other modes; however, the master

now responds with an ACKNOWLEDGE, indicating it

requires additional data. The X9520 continues to output a

Data Byte for each ACKNOWLEDGE received. The master

terminates the read operation by not responding with an

ACKNOWLEDGE and instead issuing a STOP condition.

The data output is sequential, with the data from address n

followed by the data from address n + 1. The address counter

for read operations increments through the entire memory

contents to be serially read during one operation. At the end of

S

t

Slave

a

Address

r

READ Operation

S

t

o

p

t

1 0 00001

A

C

K

the address space the counter “rolls over” to address 00h and

the device continues to output data for each

ACKNOWLEDGE received (Refer to Figure 16.).

1

A

C

K

Data

Control and Status Register

The Control and Status (CONSTAT) Register provides the

user with a mechanism for changing and reading the status

of various parameters of the X9520 (See Figure 17).

The CONSTAT regi ster is a combination of both volatile and

nonvolatile bits. The nonvolatile bits of the CONSTAT

register retain their stored values even when V1/VCC is

powered down, then powered back up. The volatile bits

however, will always power-up to a known logic state “0”

(irrespective of their value at power-down).

A detailed description of the function of each of the

CONST AT register bits follows:

WEL: WRITE ENABLE LATCH (V OLATILE)

The WEL bit controls the Write Enable status of the entire

X9520 device. This bit must first be enabled before ANY

write operation (to DCPs, EEPROM memory array, or the

CONSTAT register). If the WEL bit is not first enabled, then

ANY proceeding (volatile or nonvolatile) write operation to

Signals from the

Master

SDA Bus

Signals from the

Slave

Slave

Address

000

A

C

K

1

A

C

K

Data

(1)

FIGURE 16. SEQUENTIAL EEPROM READ SEQUENCE

Data

(2)

A

C

K

12

A

C

K

Data

(n-1)

(n is any integer greater than 1)

Data

(n)

S

t

o

p

FN8206.2

August 20, 2007

Page 13

NV

www.BDTIC.com/Intersil

CS3

CS2 CS1 CS0

BL0BL1

RWEL

NV

WEL

POR0

NV

CS6CS7 CS4

CS5

POR1

NV

BIT(S) DESCRIPTION

WEL Write Enable Latch bit

RWEL Register Write Enable Latch bit

V2OS V2 Output Status flag

V3OS V3 Output Status flag

BL1 - BL0 Sets the Block Lock partition

POR1 - POR0 Sets the Power-on Reset time

NOTE: Bits labelled NV are nonvolatile (See “CONTROL AND STATUS REGISTER”).

V3OS

V2OS

FIGURE 17. CONSTAT REGISTER FORMAT

DCPs, EEPROM array, as well as the CONSTAT register, is

aborted and no ACKNOWLEDGE is issued after a Data

Byte.

The WEL bit is a volatile latch that powers up in the disabled,

LOW (0) state. The WEL bit is enabled/set by writing

00000010 to the CONSTA T register . Once enabled, the WEL

bit remains set to “1” until either it is reset to “0” (by writing

00000000 to the CONSTAT register) or until the X9520

powers down, and then up again.

Writes to the WEL bit do not cause an internal high voltage

write cycle. Therefore, the device is ready for another

operation immediately after a STOP condition is executed in

the CONSTAT Write command sequence (See Figure 18).

RWEL: REGISTER WRITE ENABLE LATCH (VOLATILE)

The RWEL bit controls the (CONSTAT) Register Write

Enable status of the X9520. Therefore, in order to write to

any of the bits of the CONSTAT Register (except WEL), the

RWEL bit must first be set to “1”. The RWEL bit is a volatile

bit that powers up in the disabled, LOW (“0”) state.

It must be noted that the RWEL bit can only be set, once the

WEL bit has first been enabled (See "CONSTAT Register

Write Operation").

The RWEL bit will reset itself to the default “0” state, in one

of three cases:

• After a successful write operation to any bits of the

CONSTAT registe r ha s been completed (See Figure 18).

• When the X9520 is powered down.

• When attempting to write to a Block Lock protected region

of the EEPROM memory (See "BL1, BL0: Block Lock

protection bits - (Nonvolatile)").

X9520

BL1, BL0: BLOCK LOCK PROTECTION BITS (NONVOLATILE)

The Block Lock protection bits (BL1 and BL0) are used to:

• Inhibit a write operation from being performed to certain

addresses of the EEPROM memory array

• Inhibit a DCP write operation (changing the “wiper

position”)

The region of EEPROM memory which is protected/locked is

determined by the combination of the BL1 and BL0 bits

written to the CONSTAT register. It is possible to lock the

regions of EEPROM memory shown in the table below:

PROTECTED ADDRESSES

BL1 BL0

0 0 None (Default) None (Default)

0 1 C0h - FFh (64 bytes

1 0 80h - FFh (128 bytes

1 1 00h - FFh (256 bytes) All

(SIZE)

) Upper 1/4

) Upper 1/2

PARTITION OF

ARRAY LOCKED

If the user attempts to perform a write operation on a

protected region of EEPROM memory, the operation is

aborted without changing any data in the array.

When the Block Lock bits of the CONSTAT register are set to

something other than BL1 = 0 and BL0 = 0, then the “wiper

position” of the DCPs cannot be changed - i.e. DCP write

operations cannot be conducted:

BL1 BL0 DCP WRITE OPERATION PERMISSABLE

0 0 YES (Default)

01 NO

10 NO

11 NO

The factory default setting for these bits are BL1 = 0, BL0 = 0.

IMPORTANT NOTE: If the Write Protect (WP) pin of the

X9520 is active (HIGH), then all nonvolatile write operations

to both the EEPROM memory and DCPs are inhibited,

irrespective of the Block Lock bit settings (See "WP: Write

Protection Pin").

POR1, POR0: POWER-ON RESET BITS – (NONVOLATILE)

Applying voltage to V

activates the Power-on Reset circuit

CC

which holds V1RO output HIGH, until the supply voltage

stabilizes above the V

t

(See Figure 30).

PURST

threshold for a period of time,

TRIP1

The Power-on Reset bits, POR1 and POR0 of the CONSTAT

register determine the t

delay time of the Power-on

PURST

Reset circuitry (See "Vol t age Monitoring Functions"). These

bits of the CONSTAT register are nonvolatile, and therefore

power-up to the last written state.

13

FN8206.2

August 20, 2007

Page 14

SCL

www.BDTIC.com/Intersil

SDA

X9520

S

1 010010R/WA

T

A

R

T

SLAVE ADDRESS BYTE

FIGURE 18. CONSTAT REGISTER WRITE COMMAND SEQUENCE

11111111 A

C

K

ADDRESS BYTE

The nominal Power-on Reset delay time can be selected

from the following table, by writing the appropriate bits to the

CONSTAT register:

POR1 POR0 POWER-ON RESET DELAY (T

0 0 50ms

0 1 100ms (Default)

1 0 200ms

1 1 300ms

PUV1RO

)

The default for these bits are POR1 = 0, POR0 = 1.

V2OS, V3OS: VOLTAGE MONITOR STATUS BITS

(VOLATILE)

Bits V2OS and V3OS of the CONSTAT register are latched,

volatile flag bits which indicate the status of the Voltage

Monitor reset output pins V2RO and V3RO.

At power-up the VxOS (x = 2,3) bits default to the value “0”.

These bits can be set to a “1” by writing the appropriate value to

the CONSTAT register. To provide consistency between the

VxRO and VxOS however, the status of the VxOS bits can only

be set to a “1” when the corresponding VxRO output is HIGH.

Once the VxOS bits have been set to “1”, they will be reset to

“0” if:

• The device is powered down, then back up

• The corresponding VxRO output becomes LOW

CONSTAT Register Write Operation

The CONST AT register is access ed using the Slave Address

set to 1010010 (Refer to Figure 4.). Following the Slave

Address Byte, access to the CONSTAT register requires an

Address Byte which must be set to FFh. Only one data byte

is allowed to be written for each CONSTAT register Write

operation. The user must issue a STOP, after sending this

byte to the register, to initiate the nonvolatile cycle that

stores the BP1, BP0, POR1 and POR0 bits. The X9520 will

not ACKNOWLEDGE any data bytes written after the first

byte is entered (Refer to Figure 18.).

CS7 CS6

C

K

CONSTAT REGISTER DATA IN

CS5 CS4 CS3

CS2 CS1

CS0

A

S

C

T

K

O

P

Prior to writing to the CONSTAT register, the WEL and

RWEL bits must be set using a two step process, with the

whole sequence requiring 3 steps.

• Write a 02H to the CONSTAT Register to set the Write

Enable Latch (WEL). This is a volatile operation, so there

is no delay after the write. (Operation preceded by a

ST ART and ended with a STOP).

• Write a 06H to the CONSTAT Re gister to set the Register

Write Enable Latch (RWEL) AND the WEL bit. This is also a

volatile cycle. The zeros in the data byte are required.

(Operation preceded by a STAR T and ended with a ST OP).

• Write a one byte value to the CONSTAT Register that has

all the bits set to the desired state. The CONSTAT register

can be represented as qxyst01r in binary, where xy are the

Voltage Monitor Output Status (V2OS and V3OS) bits, st

are the Block Lock Protection (BL1 and BL0) bits, and qr

are the Power-on Reset delay time (t

PUV1RO

) control bits

(POR1 - POR0). This operation is proceeded by a START

and ended with a STOP bit. Since this is a nonvolatile

write cycle, it will typically take 5ms to complete. The

RWEL bit is reset by this cycle and the sequence must be

repeated to change the nonvolatile bits again. If bit 2 is set

to ‘1’ in this third step (qxys t11r) then the R WEL bit is set,

but the V2OS, V3OS, POR1, POR0, BL1 and BL0 bits

remain unchanged. Writing a second byte to the control

register is not allowed. Doing so aborts the write operation

and the X9520 does not return an ACKNOWLEDGE.

For example, a sequence of writes to the device CONSTAT

register consisting of [02H, 06H, 02H] will reset all of the

nonvolatile bits in the CONSTAT Register to “0”.

It should be noted that a write to any nonvolatile bit of

CONST AT register will be ignored if the Write Protect pin of

the X9520 is active (HIGH) (See "WP: Write Protection Pin").

CONSTAT Register Read Operation

The contents of the CONST A T Register can be read at any time

by performing a random read (See Figure 19). Using the Slave

Address Byte set to 10100101, and an Address Byte of FFh.

Only one byte is read by each register read operation. The

X9520 resets itself after the first byte is read. The master should

supply a STOP condition to be consistent with the bus protocol.

After setting the WEL and/or the RWEL bit(s) to a “1”, a

CONST AT register read operation may occur, without

interrupting a proceeding CONSTAT register write operation.

14

FN8206.2

August 20, 2007

Page 15

X9520

www.BDTIC.com/Intersil

WRITE Operation

0

A

C

K

“Dummy” Write

Address

Signals from the

Master

SDA Bus

Signals from the

Slave

S

t

Slave

a

r

Address

t

0 1 0 0 1 011 0 1 0 0 1 0

FIGURE 19. CONSTAT REGISTER READ COMMAND SEQUENCE

Data Protection

There are a number of levels of data protection features

designed into the X9520. Any write to the device first

requires setting of the WEL bit in the CONSTAT register. A

write to the CONSTAT register itself, further requires the

setting of the RWEL bit. Block Lock protection of the device

enables the user to inhibit writes to certain regions of the

EEPROM memory, as well as to all the DCPs. One further

level of data protection in the X9520, is incorporated in the

form of the Write Protection pin.

Byte

A

C

K

S

t

a

r

t

V1/VCC

V1RO

Address

MR

Slave

READ Operation

CS7 … CS0

1

A

C

K

0 Volts

0 Volts

0 Volts

Data

S

t

o

p

V

TRIP1

WP: Write Protection Pin

When the Write Protection (WP) pin is active (HIGH), it

disables nonvolatile write operations to the X9520.

The table below (X9520 Write Permission Status)

summarizes the effect of the WP pin (and Block Lock), on

the write permission status of the device.

Additional Data Protection Features

In addition to the preceding features, the X9520 also

incorporates the following data protection functionality:

• The proper clock count and data bit sequence is required

prior to the STOP bit in order to start a nonvolatile write

cycle.

Voltage Monitoring Functions

V1/VCC Monitoring

The X9520 monitors the supply voltage and drives the V1RO

output HIGH (using an external “pull up” resistor) if V1/VCC

is lower than V

HIGH until V1/VCC exceeds V

t

. After this time, the V1RO pin is driven to a LOW

PURST

state. See Figure 30.

For the Power-on/Low Voltage Reset function of the X9520,

the V1RO output may be driven HIGH down to a V1/VCC of

1V (V

RVALID

threshold. The V1RO output will remain

TRIP1

for a minimum time of

TRIP1

). See Figure 30. Another feature of the X9520,

t

PURST

FIGURE 20. MANUAL RESET RESPONSE

is that the value of t

may be selected in software via

PURST

the CONSTAT register (See “POR1, POR0: Power-on Reset

bits – (Nonvolatile)” on page 13.).

It is recommended to stop communication to the device

while V1R0 is HIGH. Also, setting the Manual Reset (MR)

pin HIGH overrides the Power-on/Low Voltage circuitry and

forces the V1RO output pin HIGH (See "MR: Manual

Reset").

MR: Manual Reset

The V1RO output can be forced HIGH externally using the

Manual Reset (MR) input. MR is a de-bounced, TTL

compatible input, and so it may be operated by connecting a

push-button directly from V1/VCC to the MR pin.

V1RO remains HIGH for time t

after MR has returned

PURST

to its LOW state (See Figure 20). An external “pull down”

resistor is required to hold this pin (normally) LOW.

15

FN8206.2

August 20, 2007

Page 16

X9520 Write Permission Status

www.BDTIC.com/Intersil

X9520

BLOCK

LOCK BITS

DCP VOLATILE WRITE

BL0 BL1 VOLATILE BITS

x11NONONONONO

1x1NONONONONO

0 0 1 YES NO NO NO NO

x 1 0 NO NO Not in locked region YES YES

1 x 0 NO NO Not in locked region YES YES

0 0 0 YES YES Yes (All Array) YES YES

WP

PERMITTED

DCP NONVOLATILE

WRITE PERMITTED

WRITE TO EEPROM

PERMITTED

WRITE TO CONSTAT REGISTER

PERMITTED

NONVOLATILE

BITS

precision/tolerance is required, the X9520 trip points may be

adjusted by the user, using the steps detailed below.

Setting a V

Voltage (x = 1,2,3)

TRIPx

Vx

V

TRIPx

0V

There are two procedures used to set the threshold voltages

VxRO

0V

V1/VCC

V

TRIP1

0 Volts

(x = 2,3)

FIGURE 21. VOLTAGE MONITOR RESPONSE

V2 Monitoring

The X9520 asserts the V2RO output HIGH if the voltage V2

exceeds the corresponding V

21). The bit V2OS in the CONSTAT register is then set to a

“0” (assuming that it has been set to “1” after system

initilization).

The V2RO output may remain active HIGH with V

1V.

threshold (See Figure

TRIP2

down to

CC

(V

higher or lower than the present value. For example, if the

present V

new voltage can be stored directly into the V

however, the new setting is to be lower than the present

setting, then it is necessary to “reset” the V

before setting the new value.

Setting a Higher V

To set a V

than the present threshold, the user must apply the desired

V

(V1/VCC, V2 or V3). Then, a programming voltage (Vp) mus t

be applied to the WP pin before a START condition is set up on

SDA. Next, issue on the SDA pin the Slave Address A0h,

followed by the Byte Address 01h for V

V

program V

operation initiates the programming sequence. Pin WP must

then be brought LOW to complete the operation (See Figure

23). The user does not have to set the WEL bit in the

), depending if the threshold voltage to be stored is

TRIPx

is 2.9 V and the new V

TRIPx

Voltage (x = 1,2,3)

TRIPx

threshold to a new voltage which is higher

TRIPx

threshold voltage to the corresponding input pin

TRIPx

, and 0Dh for V

TRIP2

. The STOP bit following a valid write

TRIPx

, and a 00h Data Byte in order to

TRIP3

TRIPx

TRIPx

TRIP1

is 3.2 V, the

TRIPx

cell. If

voltage

, 09h for

CONSTAT register before performing this write sequence.

V3 Monitoring

The X9520 asserts the V3RO output HIGH if the voltage V3

exceeds the corresponding V

21). The bit V3OS in the CONSTAT register is then set to a

“0” (assuming that it has been set to “1” after system

initilization).

The V3RO output may remain active HIGH with V

1V.

V

Thresholds (x = 1,2,3)

TRIPx

The X9520 is shipped with pre-programmed threshold

(V

) voltages. In applications where the required

TRIPx

thresholds are different from the default values, or if a higher

threshold (See Figure

TRIP3

down to

CC

Setting a Lower V

In order to set V

value, then V

TRIPx

TRIPx

procedure described below. Once V

then V

can be set to the desired voltage using th e

TRIPx

procedure described in “Setting a Higher V

Resetting the V

To reset a V

TRIPx

Voltage (x = 1,2,3).

TRIPx

to a lower voltage than the present

must first be “reset” according to the

has been “reset”,

TRIPx

Voltage”.

TRIPx

Voltage (x = 1,2,3).

TRIPx

voltage, apply the programming voltage

(Vp) to the WP pin before a ST ART condition is set up on SDA.

Next, issue on the SDA pin the Slave Address A0h followed

by the Byte Address 03h for V

0Fh for V

reset V

TRIPx

, followed by 00h for the Data Byte in order to

TRIP3

. The STOP bit following a valid write operation

TRIP1

, 0Bh for V

TRIP2

, and

16

FN8206.2

August 20, 2007

Page 17

X9520

www.BDTIC.com/Intersil

initiates the programming sequence. Pin WP must then be

brought LOW to complete the operation (See Figure 23).The

user does not have to set the WEL bit in the CONSTAT

register before performing this write sequence.

After being reset, the value of V

becomes a nominal

TRIPx

value of 1.7V .

V

The accuracy with which the V

Accuracy (x = 1,2,3).

TRIPx

thresholds are set, can

TRIPx

be controlled using the iterative process shown in Figure 24.

If the desired threshold is less that the present threshold

voltage, then it must first be “reset” (See "Resetting the

VTRIPx Voltage (x = 1,2,3).").

The desired threshold voltage is then applied to the appropriate

input pin (V1/VCC, V2 or V3) and the procedure described in

Section “Setting a Higher V

V1/VCC

V2, V3

Voltage“ must be followed.

TRIPx

V

TRIPx

Once the desired V

threshold has been set, the error

TRIPx

between the desired and (new) actual set threshold can be

determined. This is achieved by applying V1/VCC to the

device, and then applying a test voltage higher than the desired

threshold voltage, to the input pin of the voltage monitor circuit

whose V

was programmed. For example, if V

TRIPx

set to a desired level of 3.0 V , then a test voltage of 3.4 V may

be applied to the voltage monitor input pin V2. In the case of

setting of V

then only V1/VCC need be applied. In all

TRIP1

cases, care should be taken not to exceed the maximum input

voltage limits.

After applying the test voltage to the voltage monitor input

pin, the test voltage can be decreased (either in discrete

steps, or continuously) until the output of the voltage monitor

circuit changes state. At this point, the error between the

actual/measured, and desired threshold levels is calculated.

For example, the desired threshold for V

is set to 3.0 V,

TRIP2

and a test voltage of 3.4 V was applied to the input pin V2 (after

V

P

TRIP2

was

WP

SCL

WP

SDA

SCL

SDA

01234567

A0h

A0h

†

S

T

A

R

T

01234567

S

T

A

R

T

01234567

†

FIGURE 22. SETTING V

FIGURE 23. RESETTING THE V

01h† sets V

†

sets V

09h

0Dh† sets V

V

P

01234567

03h† Resets

0Bh† Resets

0Fh† Resets

VTRIP1

VTRIP2

VTRIP3

TRIP1

TRIP2

TRIP3

TRIPX

TRIPx

01234567

00h

Data Byte

TO A HIGHER LEVEL (X = 1,2,3).

01234567

†

00h

Data Byte

LEVEL

†

†

All others Reserved.

†

All others Reserved.

17

FN8206.2

August 20, 2007

Page 18

X9520

www.BDTIC.com/Intersil

applying power to V1/VCC). The input voltage is decreased,

and found to trip the associated output level of pin V2RO from a

LOW to a HIGH, when V2 reaches 3.09 V . From this, it can be

calculated that the programming error is 3.09 - 3.0 = 0.09 V.

If the error between the desired and measured V

TRIPx

is

less than the maximum desired error, then the programming

process may be terminated. If however, the error is greater

than the maximum desired error, then another iteration of the

V

programming sequence can be performed (using the

TRIPx

calculated error) in order to further increase the accuracy of

the threshold voltage.

If the calculated error is gr eate r than zero, th en th e V

TRIPx

must first be “reset”, and then programmed to the a value equal

V

TRIPx

NO

Desired V

present value?

V

TRIPx

Programming

TRIPx

YES

Execute

Reset

Sequence

to the previously set V

the case that the error is less than zero, then the V

be programmed to a value equal to the previously set V

minus the calculated error. If it is

TRIPx

TRIPx

TRIPx

plus the absolute value of the calculated error.

Continuing the previous example, we see that the calculated

error was 0.09V. Since this is greater than zero, we must first

“reset” the V

threshold, then apply a voltage equal to the

TRIP2

last previously programmed voltage, minus the last previously

calculated error. Therefore, we must apply V

TRIP2

= 2.91 V to

pin V2 and execute the programming sequence.

Using this process, the desired accuracy for a particular

V

threshold may be attained using a successive

TRIPx

number of iterations.

Note: X = 1,2,3.

Let: MDE = Maximum Desired Error

<

Desired Value

+

MDE

Acceptable

Error Range

–

MDE

Error = Actual - Desired

must

New Vx applied =

Old Vx applied

+ | Error |

Error < MDE

FIGURE 24. V

Set Vx = desired

Execute

Set Higher

Sequence

Apply VCC & Voltage

> Desired V

Decrease Vx

NO

–

TRIPx

switches?

Actual V

- Desired V

SETTING/RESET SEQUENCE (X = 1,2,3)

V

TRIPx

V

TRIPx

to Vx

TRIPx

Output

YES

TRIPx

TRIPx

= Error

| Error | < | MDE |

DONE

Error >MDE

New Vx applied =

Old Vx applied

Execute

Reset

Sequence

+

- | Error |

V

TRIPx

18

FN8206.2

August 20, 2007

Page 19

X9520

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Temperature under Bias. . . . . . . . . . . . . . . . . . . . . . . .-65 to +135°C

Voltage on WP pin (With respect to Vss). . . . . . . . . . . .-1.0 to +15V

Voltage on other pins (With respect to Vss). . . . . . . . . . . -1.0 to +7V

| Voltage on RHx– Voltage on RLx |

(x = 0,1,2. Referenced to Vss) . . . . . . . . . . . . . . . . . . . . . V1/VCC

DC Output Current (SDA,V1RO,V2RO,V3RO) . . . . . . . . . . . . . 5mA

Supply Voltage Limits

(Applied V1/VCC voltage, referenced to Vss) . . . . . . . 2.7 to 5.5V

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product reliability and

result in failures not covered by warranty.

DC Operating Characteristics

SYMBOL PARAMETER TEST CONDITIONS/NOTES MIN TYP MAX UNIT

(Note 1) Current into VCC Pin

I

CC1

(Note 2) Current into VCC Pin

I

CC2

I

LI

I

ai

I

LO

V

TRIP1PR

V

TRIPxPR

V

TRIP1

(Note 6)

V

TRIP2

(Note 6)

V

TRIP3

(Note 6)

I

Vx

V

(Note 7) Input LOW Volt age (SCL, SDA, WP, MR) -0.5 0.8 V

IL

(Note 7) Input HIGH Voltage (SCL,SDA, WP, MR) 2.0 V

V

IH

V

OLx

NOTES:

1. The device enters the Active state after any START, and remains active until: 9 clock cycles later if the Device Select Bits in the Slave Address

Byte are incorrect; 200ns after a STOP ending a read operation; or t

2. The device goes into Standby: 200ns after any STOP, except those that initiate a high voltage write cycle; t

voltage cycle; or 9 clock cycles after any START that is not followed by the correct Device Select Bits in the Slave Address Byte.

3. Current through external pull up resistor not included.

V

4.

IN

V

5.

OUT

6. See Ordering Information Table.

7. V

IL

(X9520: Active)

Read memory array (Note 3)

Write nonvolatile memory

(X9520:Standby)

With 2-Wire bus activity (Note 3)

No 2-Wire bus activity

Input Leakage Current (SCL, SDA, MR) VIN (Note 4) = GND to V

Input Leakage Current (WP) 10 μA

Analog Input Leakage VIN = VSS to VCC with all other analog inputs floating 1 10 µA

Output Leakage Current (SDA, V1RO,

V2RO, V3RO)

V

Programming Range 2.75 4.70 V

TRIP1

V

Programming Range (x = 2,3) 1.8 4.70 V

TRIPx

Pre - programmed V

Pre - programmed V

Pre - programmed V

V2 Input leakage current

V3 Input leakage current

V1RO, V2RO, V3RO, SDA Output Low

Voltage

= Voltage applied to input pin.

= Voltage applied to output pin.

Min. and VIH Max. are for reference only and are not tested.

threshold Factory shipped default option A

TRIP1

threshold Factory shipped default option A

TRIP2

threshold Factory shipped default option A

TRIP3

= 400kHz

f

SCL

= V

V

SDA

MR = Vss

WP = Vss or Open/Floating

V

V

(Note 2)

Factory shipped default option B

Factory shipped default option B

Factory shipped default option B

V

Others = GND or V

I

SINK

CC

= V

SCL

OUT

SDA

(when no bus activity else f

CC

(Note 5) = GND to V

= V

SCL

= 2.0mA 0.4 V

Storage Temper ature . . . . . . . . . . . . . . . . . . . . . . . . . .-65 to +150°C

Pb-free reflow profile . . . . . . . . . . . . . . . . . . . . . . . . . .see link below

http://www.intersil.com/pbfree/Pb-FreeReflow.asp

Recommended Operating Conditions

Industrial Temperature Range . . . . . . . . . . . . . . . . . .-40°C to +85°C

= 400kHz)

SCL

CC.

X9520 is in Standby

CC.

= VCC

CC

after a STOP ending a write operation.

WC

2.85

4.55

1.65

2.85

1.65

2.85

after a STOP that initiates a high

WC

0.1 10 μA

0.1 10 μA

3.0

4.7

1.8

3.0

1.8

3.0

0.4

1.5

50

50

3.05

4.75

1.85

3.05

1.85

3.05

1

1

+0.5 V

CC

mA

μA

V

V

V

μA

19

FN8206.2

August 20, 2007

Page 20

X9520

www.BDTIC.com/Intersil

AC Characteristics

SYMBOL PARAMETER

f

SCL

(Note 5) Pulse width Suppression Time at inputs 50 ns

t

IN

(Note 5) SCL LOW to SDA Data Out Valid 0.1 0.9 μs

t

AA

t

BUF

t

LOW

t

HIGH

t

SU:STA

t

HD:STA

t

SU:DAT

t

HD:DAT

t

SU:STO

tDH (Note 5) Data Output Hold Time 50 ns

(Note 5) SDA and SCL Rise Time 20 +.1Cb (Note 2) 300 ns

t

R

(Note 5) SDA and SCL Fall Time 20 +.1Cb (Note 2) 300 ns

t

F

t

SU:WP

t

HD:WP

Cb (Note 5) Capacitive load for each bus line 400 pF

SCL Clock Frequency 0 400 kHz

Time the bus free before start of new transmission 1.3 μs

Clock LOW Time 1.3 μs

Clock HIGH Time 0.6 μs

Start Condition Setup Time 0.6 μs

Start Condition Hold Time 0.6 μs

Data In Setup Time 100 ns

Data In Hold Time 0 μs

Stop Condition Setup Time 0.6 μs

WP Setup Time 0.6 μs

WP Hold Time 0 μs

(See Figure 27, Figure 28, Figure 29)

400kHz

UNITSMIN MAX

AC TEST CONDITIONS

Input Pulse Levels 0.1VCC to 0.9V

Input Rise and Fall Times 10ns

Input and Output Timing Levels 0.5V

Output Load See Figure 25

CC

CC

Nonvolatile Write Cycle Timing

SYMBOL PARAMETER MIN TYP (Note 1) MAX UNITS

(Note 4) Nonvolatile Write Cycle Time 5 10 ms

t

WC

Capacitance (T

SYMBOL PARAMETER MAX UNITS TEST CONDITIONS

(Note 5) Output Capacitance (SDA, V1RO, V2RO, V3RO) 8 pF V

C

OUT

(Note 5) Input Capacitance (SCL, WP, MR) 6 pF VIN = 0V

C

IN

NOTES:

1. Typical values are for T

2. Cb = total capacitance of one bus line in pF.

3. Over recommended operating conditions, unless other wise specified.

is the time from a valid STOP condition at the end of a write sequence to the end of the self-timed internal nonvolatile write cycle. It is the

4. t

WC

minimum cycle time to be allowed for any nonvolatile write by the user, unless Acknowledge Polling is used.

5. This parameter is not 100% tested.

= +25°C, f = 1.0MHz, VCC = 5V)

A

= 25°C and VCC = 5.0V.

A

OUT

= 0V

20

FN8206.2

August 20, 2007

Page 21

X9520

www.BDTIC.com/Intersil

Potentiometer Characteristics

SYMBOL PARAMETER TEST CONDITIONS/NOTES

R

TOL

V

RHx

V

RLx

P

R

R

W

I

W

C

H/CL/CW

End to End Resistance Tolerance -20 +20 %

RH Terminal Voltage (x = 0,1,2) Vss V

RL Terminal Voltage (x = 0,1,2) Vss V

Power Rating (Note 1) (Note 6) R

DCP Wiper Resistance IW = 1mA, VCC = 5 V, V

= 10kΩ (DCP0, DCP1) 10 mW

TOTAL

= 100kΩ (DCP2) 5 mW

R

TOTAL

V

= Vss (x = 0,1,2).

RLx

= 1mA, VCC = 2.7 V , V

I

W

= Vss (x = 0,1,2)

V

RLx

RHx

Wiper Current (Note 6) 4.4 mA

Noise R

Absolute Linearity (Note 2) R

Relative Linearity (Note 3) R

R

Temperature Coefficient R

TOTAL

= 10kΩ (DCP0, DCP1) mV/

TOTAL

= 100kΩ (DCP2) mV/

R

TOTAL

w(n)(actual)

w(n+1)

TOTAL

R

TOTAL

- R

w(n)(expected)

- [R

]-1+1MI

w(n)+MI

= 10kΩ (DCP0, DCP1) ±300 ppm/°C

= 100kΩ (DCP2) ±300 ppm/°C

Potentiometer Capacitances (Note 6) See Figure 26. 10/10/25 pF

RHx

=VCC,

= VCC,

LIMITS

MIN TYP MAX UNITS

CC

CC

V

V

200 400 Ω

400 1200 Ω

√(Hz)

√(Hz)

-1 +1 MI

(4)

(4)

t

wr

Wiper Response time (Note 6) See Figure 34. 200 μs

NOTES:

1. Power Rating between the wiper terminal R

2. Absolute Linearity is utilized to determine actual wiper resistance versus, expected resistance = (R

and the end terminals RHX or RLX - for ANY tap position n, (x = 0,1,2).

WX(n)

(actual) - R

wx(n)

(expected)) = ±1 Ml

wx(n)

Maximum (x = 0,1,2).

3. Relative Linearity is a measure of the error in step size between taps = R

4. 1 Ml = Minimum Increment = R

5. Typical values are for T

= 25°C and nominal supply voltage.

A

/(Number of taps in DCP - 1).

TOT

Wx(n+1)

- [R

+ Ml] = ±1 Ml (x = 0,1,2)

wx(n)

6. This parameter is periodically sampled and not 100% tested.

V