Page 1

FEATURES

■ Low power consumption

■ 2.5GHz input

■ 144 frequencies, 1MHz steps (20MHz crystal)

■ Forms complete phase locked loop using external

VCO and loop components

■ Serially programmed via 3 wire bus

■ Contains anti-modulation circuit

■ Part of DE6038 Chip-set (WL600C, WL102)

ORDERING INFORMATION

WL800/KG/TP1R

The WL800 is a low power single chip frequency synthesiser.

The circuit is fabricated on Mitel Semiconductor HG process

and operates from a supply voltage of 2.7 - 3.6V. It is designed

to work with the Mitel Semiconductor WL600C RF and IF

circuit and the WL102 WLAN controller chip which together

make up the DE6038 frequency hopping Wireless Local Area

Network (WLAN) transceiver.

RELATED DOCUMENTS

WL600C, WL102 datasheets

TQFP 32

Fig.1 Pin connections - top view

PIN 1 IDENT

ABSOLUTE MAXIMUM RATINGS

Supply Voltage Vcc 4VDC

Transmit/Receive and -0.5VDC to Vcc +0.5VDC

Standby Input

Prescaler Inputs Pins 30 &31 No DC. Externally Capacitively

Coupled.

Output Current (any output) TBD mA

Junction temperature Tj 150°C

ESD protection: 2kV

Operating temperature -20 to +85°C

WL800

2.5GHz Frequency Synthesiser

Preliminary Information

DS4583 1.6 October1997

Page 2

2

WL800

PIN REFERENCE TYPE DESCRIPTION

1 VCC1 VCC Power for serial data bus

2 CS-DATA IN Channel Data in (Synth Programming)

3 CS-CLK IN Data Clock (Synth Programming)

4 CS-LOADB IN Data Enable (Synth Programming)

5 STDBYB IN Power down control Active = Logic 1 Standby = logic 0

6 VEE1 GND Ground connection

7 ISET Set modulation current

8 ICP Set charge pump current

9 VEE3 GND Ground connection

10 TXD IN Modulation data in

11 COM CAP Compensation capacitor for modulation data

12 RCOMP OUT Resistor for V/I converter

13 IDOUT OUT Modulation data out

14 TXRXB IN Transmit/Receive control Transmit = Logic 1 Receive = Logic 0

15 VARICAP OUT Control V to varicap in VCO

16 VCC3 VCC Power for charge pump and loop amplifier and modulator

17 LOOPFILTER OUT Loop filter out (Loop Filter Components)

18 CPUMPREF Charge pump reference voltage

19 CPUMPOUT OUT Charge pump out (Loop Filter Components)

20 VEE2 GND Ground connection

21 SYSCLK OUT Reference (system) clock out

22 XTAL Crystal connection (Differential)

23 XTALB Crystal connection (Differential)

24 VCC2 VCC Power for reference oscillator

25 FREF OUT Reference frequency monitor

26 LKCAP Lock detect capacitor

27 LCKDETB OUT Lock detect output

28 FV OUT VCO frequency / (NM+A) monitor

29 VEE5 GND Ground connection

30 VCC VCC Power for prescaler, AM counter Ref divider, phase detector and

lock detector

31 VCOIPB IN Prescaler IN32 VCOIP IN Prescaler IN+

DEVICE PIN OUT

Page 3

3

WL800

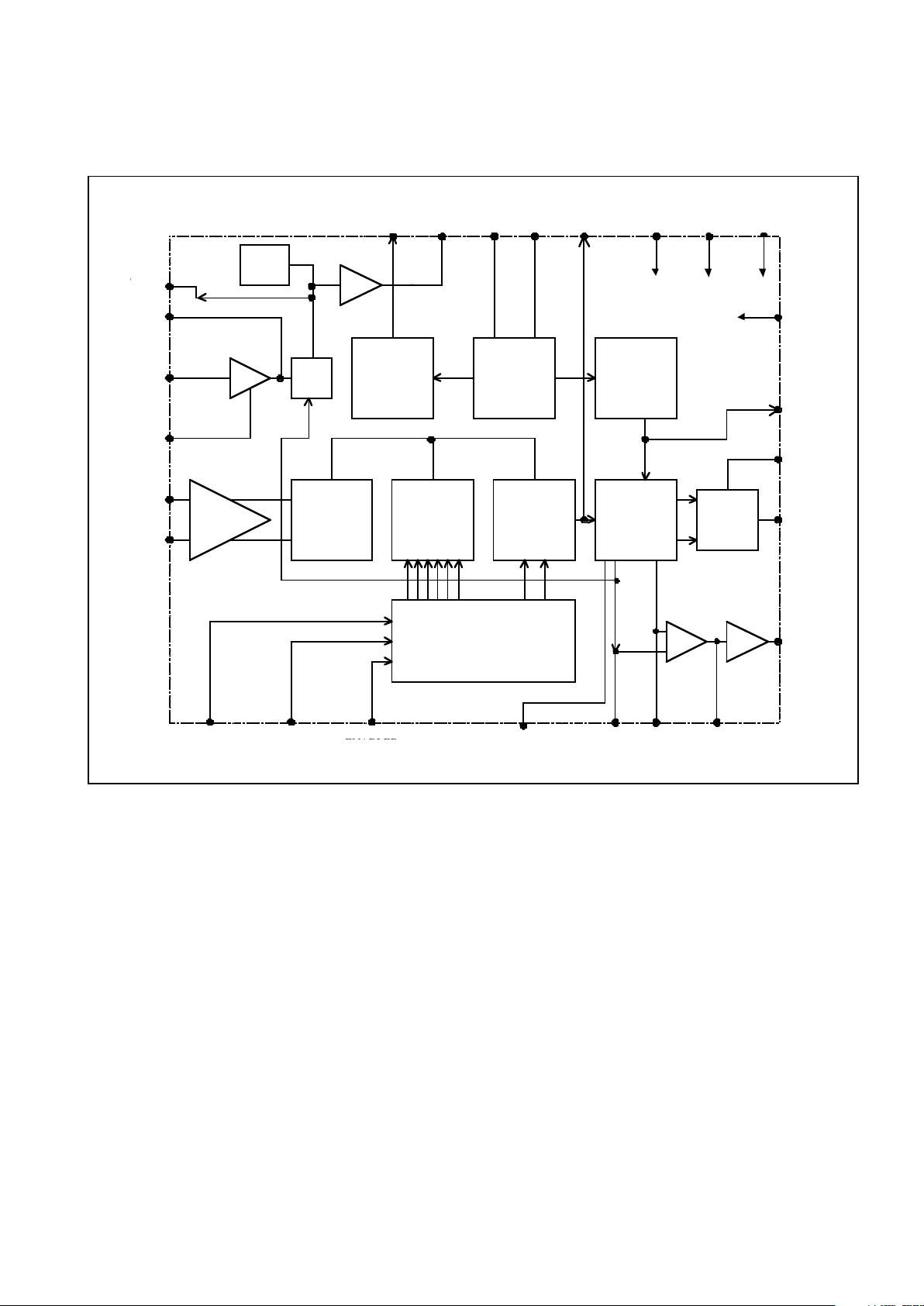

PRE-SCALER A COUNTER

PHASE DET

& CHARGE

PUMP

INPUT REGISTER

M COUNTER

REFERENCE

OSC

DIVIDE

BY 20

REF OUT

BUFFER

LOCK

DETECT

PRE

AMP

DATA

BUFFER

1,16,24,30

Vcc

6,9,20,29

Vee

STANDBY

5

14

TXRXB

DATA

2

CLK

3

ENABLEB

4

VCOIP

32

VCOIPB

31

DIN

10

IDOUT

13

ISET

7

21

REF

OUT

23

XTAL122XTAL2

LKCAP

26

LKDETB

27

CPUMP

REF

18

VARICAP

15

LOOP

FILTER

17

CPUMP

OUT

19

MOD

COMP

COMP

11

ICP

8

FREF

25

28

FV

12

RCOMP

VCAP

CHARGE

CAP

BUFFER

1/3

SYSCLK

STDBYB

LCKDETB

COMPCAP

TXD

CS-DATA CS-CLK

CS-LOADB

B

Fig. 1 WL800 block diagram

XTALB

Page 4

4

WL800

ELECTRICAL CHARACTERISTICS

These characteristics are guaranteed over the following conditions (unless otherwise stated):

T

AMB

= -20°C, to +85°C, Vcc = 2.7V to 3.6V

Characteristic Value Unit Condition

MIN TYP MAX

Supply current (total)

Transmit 37 50 mA

Receive 35 50 mA

Supply current in standby 3 5 mA

PROGRAMMING INPUTS

Logic low voltage 0 0.4 V

Logic high voltage 0.8Vcc Vcc V

Input current 1 µA Input level high

Data clock frequency (1/tclock) 20 MHz See Fig. 2

Data/Enable set up time (t set up) 10 ns See Fig. 2

Enable hold time (t enable) 10 ns See Fig. 2

Positive clock pulse width (tp) 20 ns See Fig. 2

Negative clock pulse width (t neg) 20 ns See Fig. 2

STANDBY INPUT

Logic low input voltage 0 0.8 V Circuit powered down

Logic high input voltage Vcc -0.7 Vcc V Circuit powered up

Input current 100 150 µA Circuit powered up

-150 µA Circuit powered down

Standby to operate time 3 µs *References operational (see note 1)

TX/RX INPUT

Logic low input voltage 0 0.8 V Receive mode

Logic high input voltage Vcc -0.7 Vcc V Transmit mode

Input current 10 µA

REFERENCE OUTPUT

Reference output frequency 20 MHz With 20MHz crystal

Reference clock output voltage 200 250 300 mVp-p With 15pF load

Reference output impedance 600 Ohms

Mark Space ratio -2% 50/50 +2% With 15pF load

Rise time 15 ns

Fall time 15 ns

Crystal Drive Levels required 200 mV Pins 22,23 differential

Page 5

5

WL800

ELECTRICAL CHARACTERISTICS (continued)

These characteristics are guaranteed over the following conditions (unless otherwise stated):

T

AMB

= -20°C, to +85°C, Vcc = 2.7V to 3.6V

Characteristic Value Unit Condition

MIN TYP MAX

LOCK DETECT CIRCUIT

Smoothing capacitor charge/ 80 110 150 µA Determined by application.

discharge current

Threshold voltage Vcc-0.3 V On smoothing capacitor

Output high voltage 1.8 Vcc V I out = 10µA

Output low voltage Vee 0.5 V I out = 0 µA

PHASE DETECTOR AND

CHARGE PUMP

Comparison frequency 1 MHz Divided crystal reference

Charge pump output current ±1 mA Rpin 8 = 10k

Up down current matching 5 %

Reference voltage V

cc-1.05 Vcc-0.7 V

CHARGE PUMP OP-AMP

First Stage:

High output voltage 2.4 V

Low output voltage 0.3 V

Second Stage:

Filter drive amplifier output current ±1mA

Filter drive amp output swing 0.77 Vp-p

PRESCALER

Input drive voltage 40 200 mV rms

Maximum operating frequency 3 GHz

Input Impedance 330Ω

0.5pF

TRANSMIT DATA INPUT

Logic low -60 -100 µA Rsource=20k

Logic high +60 +100 µA

TX DATA OUT

Logic 0 output current 25 50 100 µA Set by external resistor on pin 7

Logic 1 output current 200 nA Leakage Current

Output current in receive mode 25 µA Equal to 0.5 mod current

Page 6

6

WL800

ELECTRICAL CHARACTERISTICS (continued)

These characteristics are guaranteed over the following conditions (unless otherwise stated):

T

AMB

= -20°C, to +85°C, Vcc = 2.7V to 3.6V

Characteristic Value Unit Condition

MIN TYP MAX

MOD. CURRENT INPUT

Mod current set pin current 25 µA Set by external resistor on pin 7.

R = 47k

COMPENSATION CAP PIN

Compensation current -25 µA Set by external resistor on

pin 7. R=47k.

Compensation current matching 2 % Compensation capacitor 8.2nF

Compensation capacitor voltage CPRef - CPRef CPRef V Receive mode

0.02 +0.02

Compensation capacitor voltage 88 98 +110 mV 1 MHz data, 32bits ‘0’

-120 -98 -88 mV 1 MHz data, 32bits ‘1’

VCAP CHARGE

Settling Time 100 µs Receive mode

Charging Current 20 mA Receive mode.

Vcap initially at 0 V.

Offset Voltage 15 mV Receive mode.

COMPENSATION VtoI

(CAPBUFFER+RCOMP)

Compensation current into Loop +52.08 nA Per 1us of databit 0

Filter -52.08 nA Per 1us of databit 1

Max. Compensation current 1.666 mA for 32 bits(1) at 1MHz

CAPACITOR BUFFER

Offset Voltage 15 mV

External Resistor RCOMP 58000 Ohms

Note: 1. Standby to operate time refers to the time for internal current references to become operational.

Page 7

7

WL800

FUNCTIONAL DESCRIPTION

Reference Frequency

The reference frequency is generated using a 20MHz

crystal in conjunction with an on chip oscillator maintaining

circuit. A buffer circuit provides a low level voltage output

signal at the crystal frequency to drive the logic in the protocol

and control chip. The crystal frequency is divided by 20 to

provide the reference signal to the phase comparator.

Counters / Dividers

An external oscillator is used to feed the input of the

preamplifier in the synthesiser, (this isolates the counters from

the oscillator and reduces the level of drive signal required by

the synthesiser). The output of the preamplifier drives a dual

modulus prescaler with ratios of 48/49, which in turn then

drives the standard A-M counter arrangement. The A counter

then provides the modulus control signal back to the

prescaler. The counter system has an overall division ratio

given by the formula MN+A where N is the lower divide ratio

of the prescaler (48).

The divide ratio of the M and A counters is programmable

to allow the oscillator to be tuned over the required frequency

range of 144 channels at 1MHz spacing. The M count ratio can

be programmed over the range 49 to 52 and the A counter from

1 to 48 giving a total divide ratio from 2353 to 2544 which is

greater than necessary to tune the required frequency range.

Programming

The programming data for the synthesiser is entered via a

three wire serial data bus consisting of Enable, Clock and Data

signals.

The enable signal is taken low at the start of the programming sequence and remains low for the duration of the 8 serial

data bits. A positive clock edge is required to strobe each data

bit into the input register. When all 8 data bits are entered, the

enable pin is taken high forcing the counters to zero and

preloading the new count data when the counter is next

clocked . The charge pump is disabled for a short period after

the enable pin goes low to prevent glitch energy being transferred to the VCO.

Phase Detectors

A conventional digital phase frequency detector incorporating dead band suppression is used in conjunction with a

charge pump to steer the VCO. An internal op-amp maintains

the charge pump pin at the same voltage as the charge pump

reference by virtual earth principles. The op-amp is split into

two parts with the first section having a relatively low current

drive capability but including the high gain stages of the

amplifier. The second stage has a controlled voltage gain of

1/3 but high input impedance and low output impedance. This

minimises loading to the high output impedance of the first

stage and provides sufficient drive current via the loop filter to

maintain virtual earth at the charge pump output. The output

from the first stage is designed to swing close to the positive

and negative rails so as to provide maximum voltage swing to

the varactor controlling the VCO. A compensating capacitor

can be connected to this point to stabilise the amplifier.

A lock detect output (active low) is provided to give an

indication to the controller that the phase locked loop is locked,

preventing transmission on illegal frequencies.

Antimodulation

The WL800 contains a data buffer circuit which accepts

transmit data from the CMOS controller circuit and converts

the CMOS input to a tristate current output for driving the

transmit spectrum shaping filter. The buffer gives zero current

for a logic “1” input, a high current (+2I) for a logic “0” and a

current midway between the two (+I) for use during the

transmit amplifier power up/down period and during receive.

This function prevents the synthesiser centring its frequency

on either a logic “1” or “0” and removes the possibility of overmodulation at the start of a transmission. The amplitude of the

output current and therefore modulation index of the radio is

controlled by an external resistor connected to ground.

A data compensation path is included which counteracts the

tendency of the PLL to drift back to centre frequency when the

data is non-white. This is achieved by charging an external

capacitor with a current +I when data is low, and discharging

it by a current -I when data is high. The capacitor voltage,

which then represents an integrated form of the data is

converted to a current via a buffer and an external resistor

(RCOMP), and fed into the Loop Filter in addition to the Phase

Detector output. During Receive Mode, the capacitor is

charged to the Charge Pump Reference voltage.

Page 8

8

WL800

WL800 PROGRAMMING

Frequency A counter M counter 6 bit binary A bit binary M

MHz Value Value Value d0-d5 Value d6-d7

2357 5 49 101000 00

2358 6 49 011000 00

2400 48 49 000011 00

2401 1 50 100000 10

2448 48 50 000011 10

2449 1 51 100000 01

2496 48 51 000011 01

2497 1 52 100000 11

2498 2 52 010000 11

2499 3 52 110000 11

2500 4 52 001000 11

Notes: 1.The binary data is in reverse order.

2.The data is programmed with bit d7 first and d0 last

d0 d1 d2 d3 d4 d5 d6 d7

A counter M counter

DATA

CLOCK

DATA

ENABLE

t set up

t enable

t clock

tp

t neg

TIMING DIAGRAM

Fig. 2 Timing diagram

CS_LOADB

CS_DATA

CS_CLK

Page 9

9

WL800

CONTROL SIGNALS

Control Line Logic ‘0’ Logic ‘1’

STDBYB Standby Active

TXRXB Receive Transmit

LCKDETB Locked Unlocked

Page 10

Page 11

M Mitel (design) and ST-BUS are registered trademarks of MITEL Corporation

Mitel Semiconductor is an ISO 9001 Registered Company

Copyright 1999 MITEL Corporation

All Rights Reserved

Printed in CANADA

TECHNICAL DOCUMENTATION - NOT FOR RESALE

World Headquarters - Canada

Tel: +1 (613) 592 2122

Fax: +1 (613) 592 6909

North America Asia/Pacific Europe, Middle East,

Tel: +1 (770) 486 0194 Tel: +65 333 6193 and Africa (EMEA)

Fax: +1 (770) 631 8213 Fax: +65 333 6192 Tel: +44 (0) 1793 518528

Fax: +44 (0) 1793 518581

http://www.mitelsemi.com

Information relating to products and services furnished herein by Mitel Corporation or its subsidiaries (collectively “Mitel”) is believed to be reliable. However, Mitel assumes no

liability for errors that may appear in this publication, or for liability otherwise arising from the application or use of any such information, product or ser vice or for any infringement of

patents or other intellectual property rights owned by third parties which may result from such application or use. Neither the supply of such information or purchase of product or

service conveys any license, either express or implied, under patents or other intellectual property rights owned by Mitel or licensed from third parties by Mitel, whatsoever.

Purchasers of products are also hereby notified that the use of product in certain ways or in combination with Mitel, or non-Mitel furnished goods or services may infringe patents or

other intellectual property rights owned by Mitel.

This publication is issued to provide information only and (unless agreed by Mitel in writing) may not be used, applied or reproduced for any purpose nor form par t of any order or

contract nor to be regarded as a representation relating to the products or services concerned. The products, their specifications, services and other information appearing in this

publication are subject to change by Mitel without notice. No warranty or guarantee express or implied is made regarding the capability, performance or suitability of any product or

service. Information concerning possible methods of use is provided as a guide only and does not constitute any guarantee that such methods of use will be satisfactory in a specific

piece of equipment. It is the user’s responsibility to fully determine the performance and suitability of any equipment using such information and to ensure that any publication or

data used is up to date and has not been superseded. Manufacturing does not necessarily include testing of all functions or parameters. These products are not suitable for use in

any medical products whose failure to perform may result in significant injury or death to the user. All products and materials are sold and services provided subject to Mitel’s

conditions of sale which are available on request.

Loading...

Loading...