Datasheet W6PXD3O-0000, W6NXD3L-0000, W6NXD3K-0000, W6NXD3J-0000, W6NXD0KLSR-0000 Datasheet (CREE)

...Page 1

Effective December 1998 • Revised March 2003 • Page 1

Silicon Carbide

Substrates

Product Specifications

4H Silicon Carbide

(n/p-type)

6H Silicon Carbide

(n/p-type)

Page 2

Page 2 • Effective December 1998 • Revised March 2003

Properties and Specifications for

Silicon Carbide

Applications: • High Frequency Power Devices

• High Power Devices

• High Temperature Devices

• Optoelectronic Devices

• III-V Nitride Deposition

Physical Properties

Polytype Single Crystal 4H Single Crystal 6H

Crystal Structure Hexagonal Hexagonal

Bandgap 3.26 eV 3.03 eV

Thermal Conductivity

(Typical Range)

3.0-3.8 W/cm • K @ 298K

(2.3-2.8 W/cm • K @ 373K)

3.0-3.8 W/cm • K @ 298K

(2.3-2.8 W/cm • K @ 373K)

Lattice Parameters

a=3.073 Å

c=10.053Å

a=3.081 Å

c=15.117Å

Mohs Hardness ~9 ~9

Page 3

Effective December 1998 • Revised March 2003 • Page 3

Product Descriptions

Part Number Options

W X X X X X X - X X X X

0 = No Epitaxy

1 = 1 Layer

2 = 2 Layer

3 = 3 Layer

4 = 4 Layer

5 = 5 Layer

0 = No Epitaxy

S = Standard SiC Epitaxy

T = Thick SiC Epitaxy

0 = Single Side Polish, Si Face Epi Ready

C = Single Side Polish, C Face Epi Ready

D = Double Side Polish, Si Face Epi Ready

G = Double Side Polish, C Face Epi Ready

1 = CMP Polish, Si Face Epi Ready

2 = Double Side CMP Polish, Si Face Epi Ready

0 = Standard Micropipe

S = Select Micropipe

L = Low Micropipe

U = Ultra-Low Micropipe

Resistivity code (see appropriate specification sheet)

0 = On-axis

3 = 3.5° Off-axis

4 = 4.0° Off-axis

8 = 8.0° Off-axis

D = 50.8mm (2.0")

E = 76.2mm (3.0")

P = Production Grade

R = Research Grade

N = N-type

P = P-type

S = Semi-Insulating

T = High Purity Semi-Insulating

4 = 4H

6 = 6H

W= Standard Product

Page 4

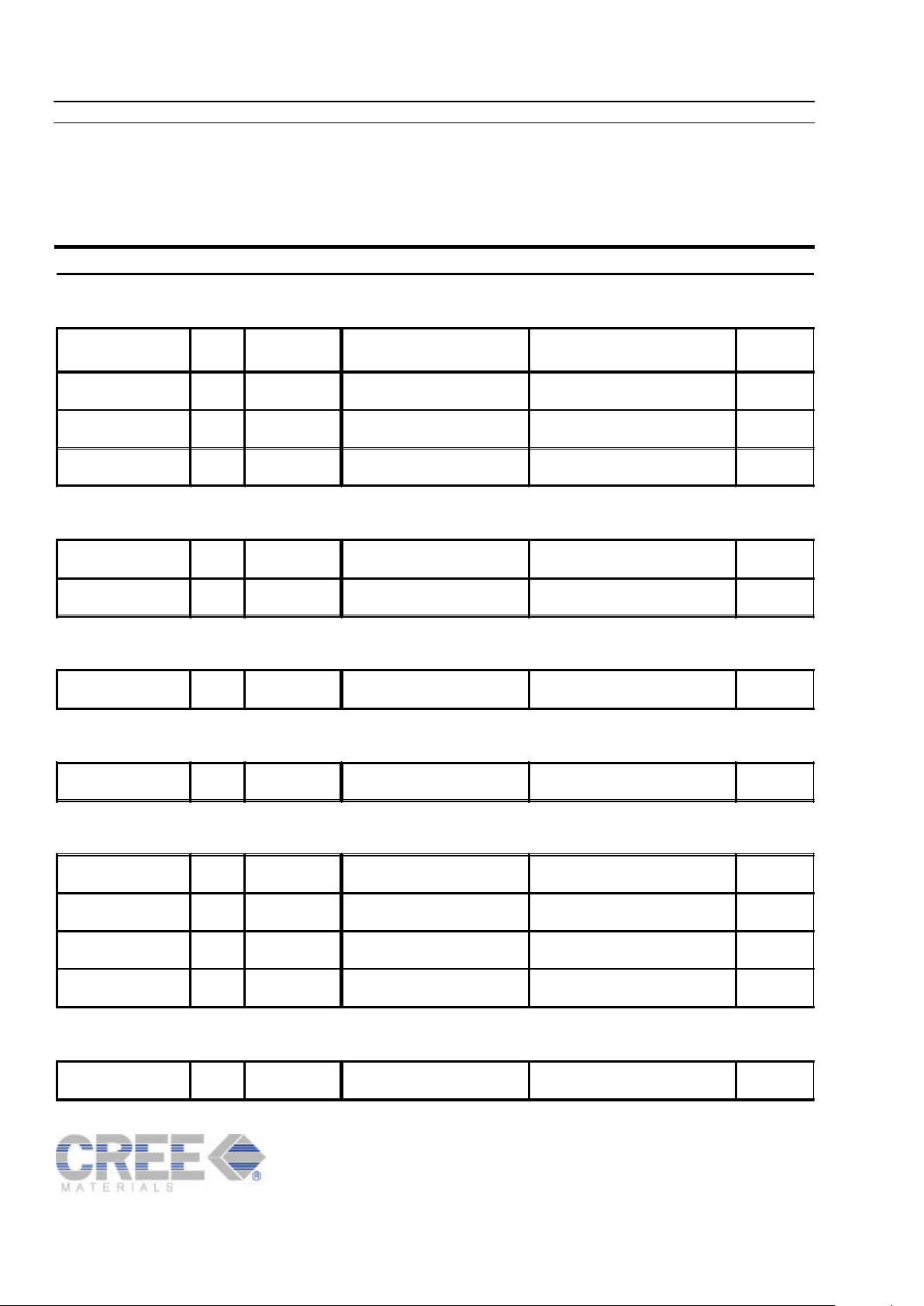

Page 4 • Effective December 1998 • Revised March 2003

Product Descriptions

4H-Silicon Carbide

50.8mm Diameter

STANDARD MICROPIPE DENSITY

Part Number Type Orientation Micropipe Density Resistivity Ohm-cm Range Bin

W4NXD8C-0000 n 8° off 31-100 micropipes/cm

2

0.015-0.028 C

W4NXD8D-0000 n 8° off 31-100 micropipes/cm

2

0.028-0.065 D

W4PXD8G-0000 p 8° off N/A 2.50-8.50 G

SELECT MICROPIPE DENSITY

W4NXD8C-S000 n 8° off 16-30 micropipes/cm

2

0.015-0.028 C

W4NXD8D-S000 n 8° off 16-30 micropipes/cm

2

0.028-0.065 D

LOW MICROPIPE DENSITY

W4NXD8C-L000 n 8° off

[15 micropipes/cm

2

0.015-0.028 C

ULTRA-LOW MICROPIPE DENSITY

W4NRD8C-U000

†

n 8° off

[5 micropipes/cm

2

0.015-0.028 C

SEMI-INSULAT ING

W4SRD0R-0D00 SI on-axis N/A á1E5 R

W4SRD8R-0D00 SI 8° off N/A

á1E5

R

W4TRD0R-0D00 HPSI on-axis N/A

á1E5

R

W4TRD8R-0D00 HPSI 8° off N/A

á1E5

R

LCW SUBSTRATES

W4NRD0X-0000 n on-axis N/A 0.013-0.500 N/A

†

- Contact Cree for availability

Page 5

Effective December 1998 • Revised March 2003 • Page 5

Product Descriptions

4H-Silicon Carbide

76.2mm Diameter

STANDARD MICROPIPE DENSITY

Part Number Type Orientation Micropipe Density Resistivity Ohm-cm Range Bin

W4NXE4C-0D00 n 4° off 31-100 micropipes/cm

2

0.015-0.028 C

W4NXE8C-0D00 n 8° off 31-100 micropipes/cm

2

0.015-0.028 C

W4NRE0X-0D00 n on-axis N/A 0.013-0.500 N/A

SELECT MICROPIPE DENSITY

W4NXE4C-SD00 n 4° off 16-30 micropipes/cm

2

0.015-0.028 C

W4NXE8C-SD00 n 8° off 16-30 micropipes/cm

2

0.015-0.028 C

LOW MICROPIPE DENSITY

W4NXE4C-LD00 n 4° off

[15 micropipes/cm

2

0.015-0.028 C

W4NXE8C-LD00 n 8° off [15 micropipes/cm

2

0.015-0.028 C

SEMI-INSULAT ING (PROTOTYPE)

W4TXE0X-0D00 HPSI on-axis N/A N/A N/A

Page 6

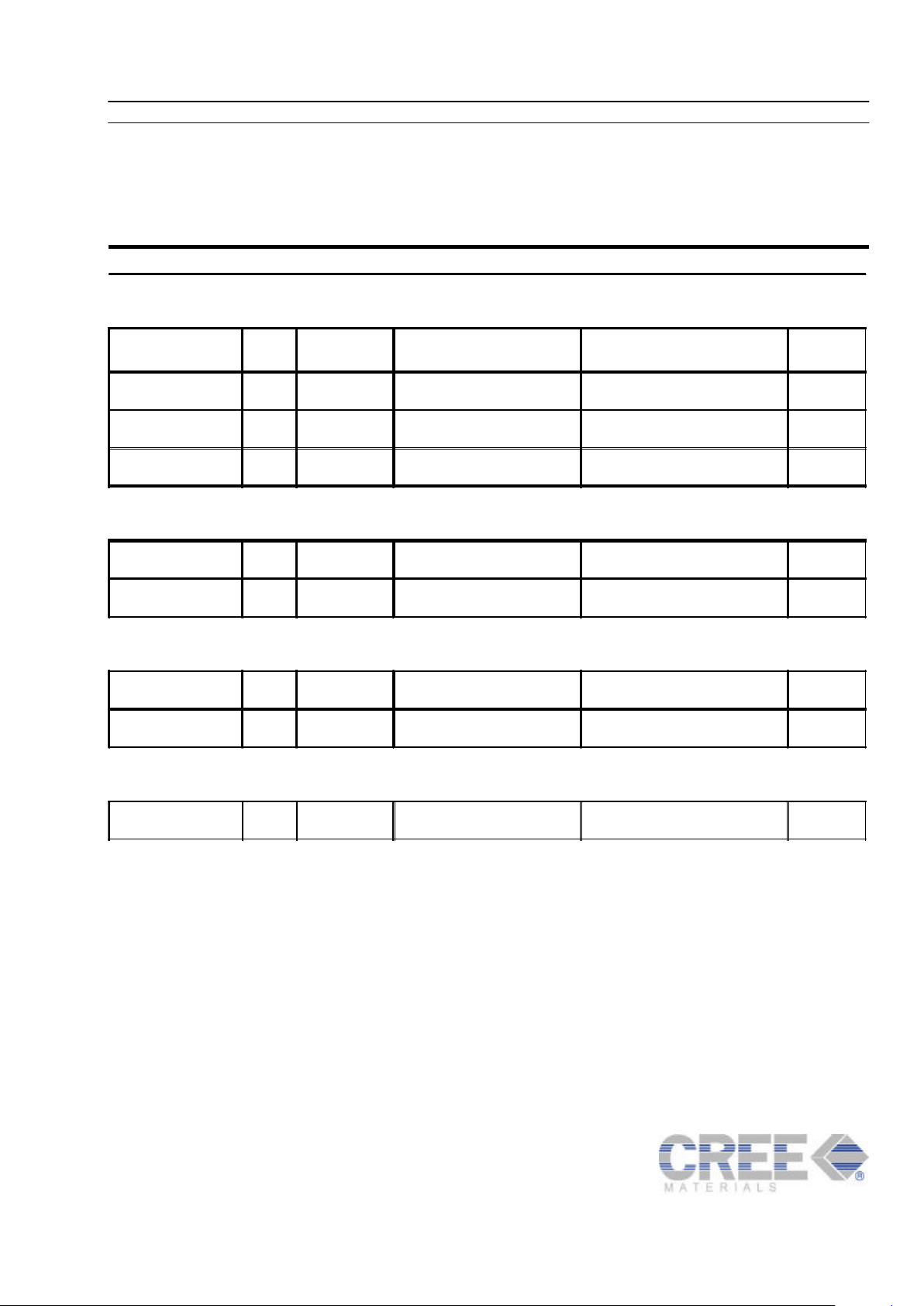

Page 6 • Effective December 1998 • Revised March 2003

Product Descriptions

6H-Silicon Carbide

50.8mm Diameter

76.2mm Diameter

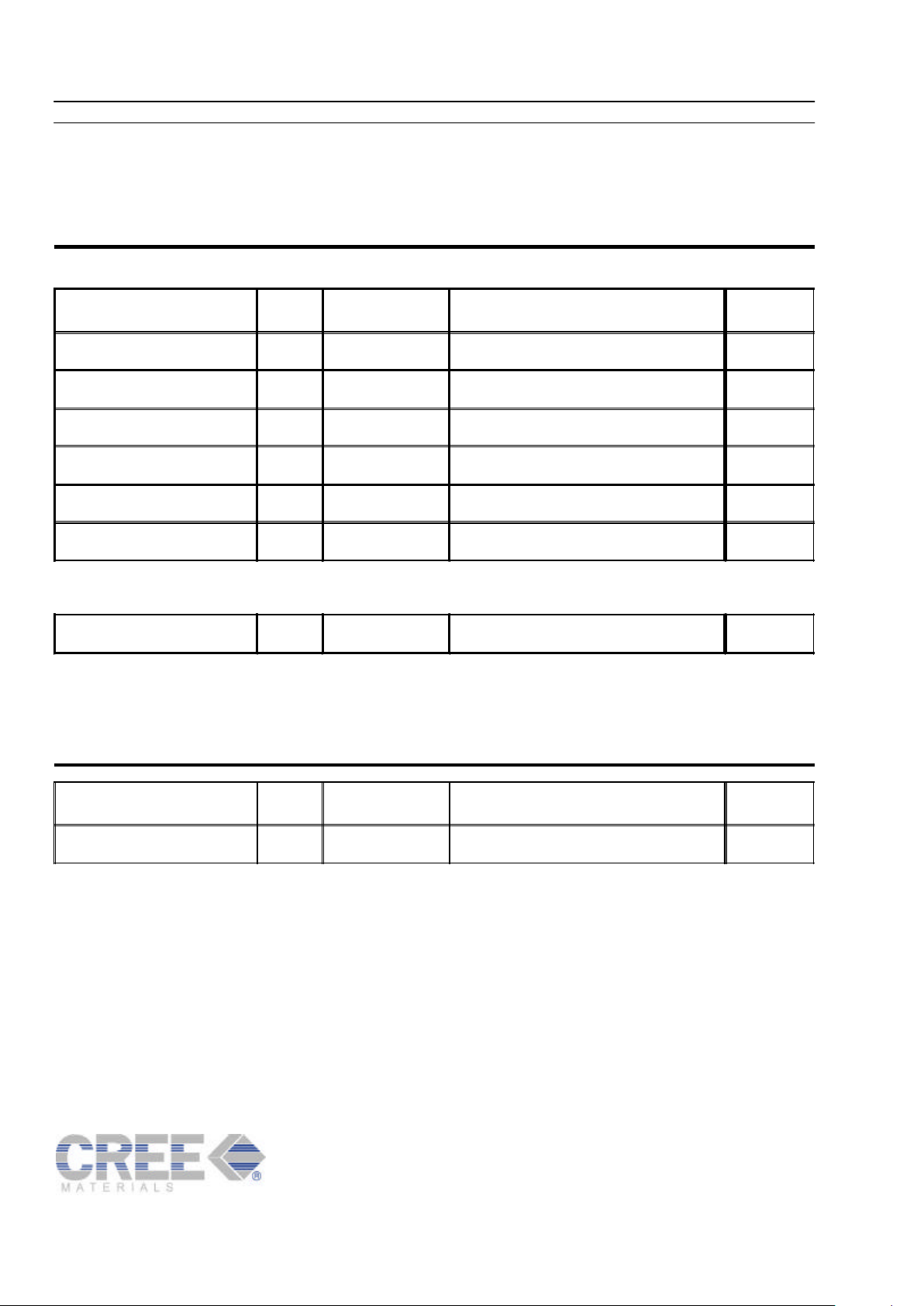

Part Number Type Orientation Resistivity Ohm-cm Range Bin

W6NXD3J-0000 n 3.5° off 0.020-0.040 J

W6NXD3K-0000 n 3.5° off 0.040-0.090 K

W6NXD0K-0000 n on-axis 0.040-0.090 K

W6NXD0KLSR-0000 n on-axis 0.040-0.090 K

W6NXD3L-0000 n 3.5° off 0.090-0.150 L

W6PXD3O-0000 p 3.5° off 1.00-5.00 O

LCW SUBSTRATES

W6NRD0X-0000 n on-axis 0.020-0.200 N/A

Part Number Type Orientation Resistivity Ohm-cm Range Bin

W6NRE0X-0000 n on-axis 0.020-0.200 N/A

Page 7

Effective December 1998 • Revised March 2003 • Page 7

DEFINITION OF DIMENTIONAL PROPERTIES, TERMINOLOGY AND METHODS

Figure 1. Diameter and Primary and Secondary

Flat Dimension

Standard Specifications

Diameter

The linear dimension across the surface of a wafer.

Measurement is performed manually with ANSI

certified digital calipers on each individual wafer (see

Figure 1).

Thickness, Center Point

Measured with ANSI certified non-contact tools at the

center of each individual wafer.

Flat Length

Linear dimension of the flat measured with ANSI

certified digital calipers on a sample of one wafer per

ingot (see Figure 1).

Surface Orientation

Denotes the orientation of the surface of a wafer with

respect to a crystallographic plane within the lattice

structure. Measured with x-ray goniometer on a sample

of one wafer per ingot in the center of the wafer.

Orthogonal Misorientation

In wafers cut intentionally “off orientation,” the angle

between the projection of the normal vector to the

wafers surface onto a {0001} plane and the projection

on that plane of the nearest <1120> direction.

Primary Flat

The primary flat is the {1010} plane with the flat face

parallel to the <1120> direction.

Primary Flat Orientation

The flat of the longest length on the wafer, oriented

such that the chord is parallel with a specified low

index crystal plane. Measured on one wafer per ingot

using Laue back-reflection technique with manual

angle measurement.

Secondary Flat Orientation

A flat of shorter length than the primary orientation

flat, whose position with respect to the primary orientation flat identifies the face of the wafer.

Marking

The carbon face of each individual wafer is laser

marked with OCR compatible font (similar to definitions and characteristics in SEMI M12).

XXXXXXX-XX

Page 8

Page 8 • Effective December 1998 • Revised March 2003

SUBSTRATE PROPERTY CREE STANDARD

Diameter

2.000" ± 0.015"

50.8mm ± 0.38mm

Thickness, Centerpoint

4H and 6H On-Axis

Standard

0.010" ± 0.001"

254.0µm ± 25.4µm

Laser (6H only)

0.0055" ± 0.0015"

140.0µm ± 38.0µm

4H and 6H Off-Axis; Semi-Insulating

0.0145" ± 0.0025"

368.0µm ± 64.0µm

Dopant

n-type: Nitrogen

p-type: Aluminum

Primary Flat Length

0.625" ± 0.065"

15.88mm ± 1.65mm

Secondary Flat Length

0.315" ± 0.065"

8.0mm ± 1.65mm

Cleaved Flat Length (laser substrate only) Nominal 0.4" (10mm)

Surface Orientation

6H and 4H On-Axis {0001} ± 0.5°

6H Off-Axis 3.5° toward <1120> ± 0.5°

4H Off-Axis 8.0° toward <1120> ± 0.5°

Surface Treatment Silicon face polish unless otherwise specified

Orthogonal Misorientation ± 5°

Primary Flat Orientation <1120> ± 5°

Secondary Flat Orientation

Carbon Face 90° CCW from Primary ± 5°

Silicon Face 90° CW from Primary ± 5°

Cleaved Flat Orientation (laser substrate only) 180° from primary flat is {1010} face

Package FLUOROWARE® Single Wafer Container

Standard Specifications

50.8mm Diameter Substrate Specifications

Page 9

Effective December 1998 • Revised March 2003 • Page 9

SUBSTRATE PROPERTY CREE STANDARD

Diameter

3.000" ± 0.015"

76.2mm ± 0.38mm

Thickness, Centerpoint

4H On and Off-Axis

0.0138" ± 0.001"

350.0µm ± 25.4µm

Semi-Insulating

0.0145" ± 0.0025"

368.0µm ± 64.0µm

6H On-Axis

0.010" ± 0.001"

254.0µm ± 25.4µm

Dopant n-type: Nitrogen

Primary Flat Length

0.875" ± 0.125"

22.22mm ± 3.17mm

Secondary Flat Length

0.440" ± 0.060"

11.18mm ± 1.52mm

Surface Orientation

4H and 6H On-Axis {0001} ± 0.5°

4H Off-Axis

4.0° toward <1120> ± 0.5°

8.0° toward <1120> ± 0.5°

Surface Treatment Silicon face polish unless otherwise specified

Orthogonal Misorientation ± 5°

Primary Flat Orientation <1120> ± 5°

Secondary Flat Orientation

Carbon Face 90° CCW from Primary ± 5°

Silicon Face 90° CW from Primary ± 5°

Package FLUOROWARE® Single Wafer Container

Standard Specifications

76.2mm Diameter Substrate Specifications

Page 10

Page 10 • Effective December 1998 • Revised March 2003

STANDARD SPECIFICATIONS FOR POLISHED SILICON CARBIDE

SUBSTRATES - Surface Finish

Standard Specifications

Characteristics Production Grade Research Grade

Edge Chips/Indents by diffuse

lighting

†

None Permitted 2 [ 1.5 mm width & depth

Orange Peel/Pits by diffuse lighting*

G

[ 10% area [ 30% area

Polytype Areas by diffuse lighting*

[ 5% area [ 20% area

Striations by diffuse lighting* 3 allowed [ 3mm each 20 allowed [ 7mm each

Area Contamination (stains) by high

intensity light

None Permitted None Permitted

Cracks by high intensity light None Permitted None Permitted

Hex Plate by high intensity light* Cumulative area <10% Cumulative area <30%

Scratches by high intensity light*

5 scratches to 1x wafer diameter

cumulative length.

8 scratches to 1.5x wafer diameter

cumulative length.

Masking Defects (Mounds)*

Quantitative by 200X Microscopic

Inspection

10 defects in 3 or less of the 9

fields inspected in a cross pattern

10 defects in 5 or less of the 9

fields inspected in a cross pattern

Contamination

Quantitative by 200X Microscopic

Inspection

None in inspected fields None in inspected fields

Cumulative Area Defects*

[ 10% area [ 30% area

Notes:

* Defect limits apply to entire wafer surface except for a 2mm edge exclusion area

G

Pits must be < 2mm in distance from one another to be considered a reject cause

†

Edge chips must be > 0.5mm on R grade material to be considered a reject cause

Page 11

Effective December 1998 • Revised March 2003 • Page 11

Standard Specifications

Orange peel

Visually detectable surface roughening when viewed

under diffuse illumination.

Pits

Individual distinguishable surface anomalies, which

appears as a depression in the wafer surface with a

length-to-width ratio less than 5 to 1, and visible under

high intensity illumination.

Foreign Polytypes (also referred to as “Inclusions” or

“Crystallites”)

Regions of the wafer crystallography which are polycrystalline or of a different polytype material than the

remainder of the wafer, such as 4H mixed in with a 6H

type wafer. Poly regions frequently exhibit color

changes or distinct boundary lines, and are judged in

terms of area percent under diffuse illumination.

Scratches

A scratch is defined as a singular cut or groove into the

frontside wafer surface with a length-to-width ratio of

greater than 5 to 1, and visible under hight intensity

illumination.

Striations

Striations in silicon carbide are defined as linear

crystallographic defects extending down from the

surface of the wafer which may or may not pass

through the entire thickness of the wafer, and generally

follow crystallographic planes over its length.

Total Usable Area

A cumulative subtraction of all noted defect areas from

the frontside wafer quality area within the edge exclusion zone. The remaining percent value indicates the

proportion of the frontside surface to be free of all

noted defects (does not include 2mm edge exclusion).

STANDARD SPECIFICATIONS FOR POLISHED SILICON CARBIDE

SUBSTRATES - Surface Finish

(Area) Contamination

Any foreign matter on the surface in localized areas

which is revealed under high intensity (or diffuse)

illumination as discolored, mottled, or cloudy appearance resulting from smudges, stains or water spots.

Cracks

A fracture or cleavage of the wafer that extends from

the frontside surface of the wafer to the back-side

surface of the wafer. Cracks must exceed 0.010” in

length under high intensity illumination in order to

discriminate fracture lines from allowable crystalline

striations. Fracture lines typically exhibit sharp, thin

lines of propagation, which discriminate them from

material striations.

Edge Chips

Any edge anomalies (including wafer saw exit marks)

in excess of 1.5 mm in either radial depth or width. As

viewed under diffuse illumination, edge chips are

determined as unintentionally missing material from

the edge of the wafer.

Edge Exclusion

The outer 2 mm annulus of the wafer is designated as

wafer handling area and is excluded from surface finish

criteria (such as scratches, pits, haze, contamination,

craters, dimples, grooves, mounds, orange peel and saw

marks).

Hex Plate

Hexagonal shaped platelets on the surface of the wafer

which appear silver in color to the unaided eye, under

diffuse illumination.

Masking Defects (also referred to as “Mound”)

A distinct raised area above the wafer frontside surface

as viewed with diffuse illumination.

Definition of Terminology and Methods

Page 12

Page 12 • Effective December 1998 • Revised March 2003

Epitaxial Specifications for

Silicon Carbide

Notes: • 2mm edge exclusion

• N-type epi layers <20 microns are preceeded by n-type , 1E18, 0.5 micron buffer layer

• N-type epi layers 20 microns are preceeded by n-type , 1E18, 1.0 micron buffer layer

• No buffer layer for p-type epitaxial layers

• Not all doping densities are available in all thicknesses

• Epitaxy on 6H polytype is limited to 10 microns

• Contact Cree Sales for specifications on multi-layer or unique epitaxy requests

STANDARD SPECIFICATIONS FOR SILICON CARBIDE EPITAXIAL WAFER -

50.8mm and 76.2mm SUBSTRATES

Substrate Orientation: Epitaxy is only available for off-axis substrates.

Conductivity n-type p-type

Dopant Nitrogen Aluminum

Net Doping Density ND-N

A

NA-N

D

Silicon Face 9E14 – 1E19/cm

3

9E14 – 1E19/cm

3

Carbon Face 1E16 – 1E19/cm

3

Not Available

Tolerance ± 50% ± 50%

Thickness Range- Silicon Face

0.2-1.0 microns ± 25% of selected thickness ± 25% of selected thickness

1.1-20.0 microns ± 15% of selected thickness ± 15% of selected thickness

20.1-50.0 microns ± 10% of selected thickness ± 10% of selected thickness

Thickness Range- Carbon Face

0.2-1.0 microns ± 25% of selected thickness Not Available

1.0-10.0 microns ± 15% of selected thickness Not Available

á

Page 13

Effective December 1998 • Revised March 2003 • Page 13

Epitaxial Specifications for

Silicon Carbide

Notes: • 2mm edge exclusion

STANDARD SPECIFICATIONS FOR SILICON CARBIDE EPITAXIAL WAFER -

50.8mm and 76.2mm SUBSTRATES

Characteristics

Maximum Acceptability

Limits

Test

Methods

Defect Definitions

(see pgs. 14-15)

Methodology

Large Point Defects

50.8mm 30

Diffuse

Illumination

D1 M1, M2

76.2mm 60

Scratches 10 lines < 2x wafer diameter D2 M1, M2

Dimpling < 5% affected D3 M1, M2

Step Bunching

4° off-axis N/A

D4 M1, M2

8° off-axis < 10% affected

Backside

Cleanliness

95% clean D5 M1, M2

Edge Chips 2 with radius 1.5mm D6 M2

ID Correct/Legible Yes D7 M2

Wafer Flats Yes D7 M2

Epi Defects

50.8mm, 4H 75

Microscopic

D8-D12 M3

50.8mm, 6H 135

76.2mm, 4H 113

76.2mm, 6H 203

Net Doping See Specification Table Hg Probe CV - M4

Thickness See Specification Table

FTIR, SIMS,

SEM

- M5

Page 14

Page 14 • Effective December 1998 • Revised March 2003

Definitions

D1. Large Point Defects

Defects which exhibit a clear shape to the unassisted

eye and are > 50 microns across. These features

include spikes, adherent particles, chips and craters.

Large point defects less than 3 mm apart count as one

defect.

D2. Scratches

Grooves or cuts below the surface plane of the wafer

having a length-to-width ratio of greater than 5 to 1.

Scratches are specified by the number of discrete

scratches times the total length in fractional diameter.

D3. Dimpling

A texture resembling the surface of a golf ball. Specified in % affected area.

D4. Step Bunching

Step bunching is visible as a pattern of parallel lines

running perpendicular to the major flat. If present,

estimate the % of specified area affected.

D5. Backside Cleanliness

Verified by inspecting for a uniform color to the wafer

backside. Note there is a darker region near the center

of some higher doped wafers. Backside cleanliness

specified as percent area clean.

D6. Edge Chips

Areas where material has been unintentionally removed

from the wafer. Do not confuse fractures in epi crown

with edge chips.

D7. ID Correct and Major Wafer Flat

Both should be readily discernible.

Epitaxy Defects

The sum of discrete microscopic defects counted in

specified area. These include 3C inclusions, comet

tails, carrots, particles and silicon droplets.

D8. 3C Inclusions

Regions where step-flow was interrupted during epi

layer growth. Typical regions are generally triangular

although more rounded shapes are sometimes seen.

Count once per occurrence. Two inclusions within 200

microns count as one.

D9. Comet Tails

Comet tails have a discrete head and trailing tail. These

features are aligned parallel to the major flat. Usually,

all comet tails tend to be of the same length. Count

once per occurrence. Two comet tails within 200

microns count as one.

D10. Carrots

Similar to comet tails in appearance except they are

more angular and lack a discrete head. If present, these

features are aligned parallel to the major flat. Usually,

any carrots present tend to be of the same length. Count

once per occurrence. Two carrots within 200 microns

count as one.

D11. Particles

Particles have the appearance of eyes and if present are

usually concentrated at the wafer edges and not within

the specified area. If present, count once per occurrence. Two particles within 200 microns count as one.

D12. Silicon droplets

Silicon droplets can appear as either small mounds or

depressions in the wafer surface. Normally absent, but

if present are largely concentrated at perimeter of

wafer. If present, estimate the % of specified area

affected.

STANDARD SPECIFICATIONS FOR SILICON CARBIDE EPITAXIAL WAFER,

DEFINITIONS, EPITAXY DEFECT DESCRIPTIONS, AND METHODOLOGY

Epitaxial Specifications for

Silicon Carbide

Page 15

Effective December 1998 • Revised March 2003 • Page 15

Methodology

M1. 2mm edge exclusion.

M2. Inspection performed under diffuse illumination.

M3. Microscopic inspection performed at 100X, on an

Olympus BH2 UMA Optical Microscope, or comparable. Inspection pattern detailed in Figure 2.

M4. Net doping is determined in the center of the

wafer using Hg probe CV.

M5. Thickness is determined in the center of the wafer

using FTIR, SIMS, or cross-sectional SEM on available

monitor wafers.

Figure 2. Epi Inspection Pattern

STANDARD SPECIFICATIONS FOR SILICON CARBIDE EPITAXIAL WAFER,

DEFINITIONS, EPITAXY DEFECT DESCRIPTIONS, AND METHODOLOGY

Epitaxial Specifications for

Silicon Carbide

Page 16

Page 16 • Effective December 1998 • Revised March 2003

4600 Silicon Drive

Durham, NC 27703 USA

tel: 919-313-5300

fax: 919-313-5451

e-mail: sales@cree.com

www.cree.com

Copyright © 1998-2003 Cree, Inc. All rights reserved.

Permission is given to reproduce this document provided the entire

document (including this copyright notice) is duplicated.

The information in this document is subject to change without notice.

Cree and the Cree logo are registered trademarks of Cree, Inc.

Version MAT-CATALOG.000

Page 17

Loading...

Loading...