Page 1

Features

• High output voltage and wide bandwidth; optimal for

use in fH(horizontal deflection frequency) = 100 kHz

class monitors.

(f = 130 MHz –3 dB at V

OUT

= 40 Vp-p)

• SIP molded 15-pin package houses three amplifier

channels.

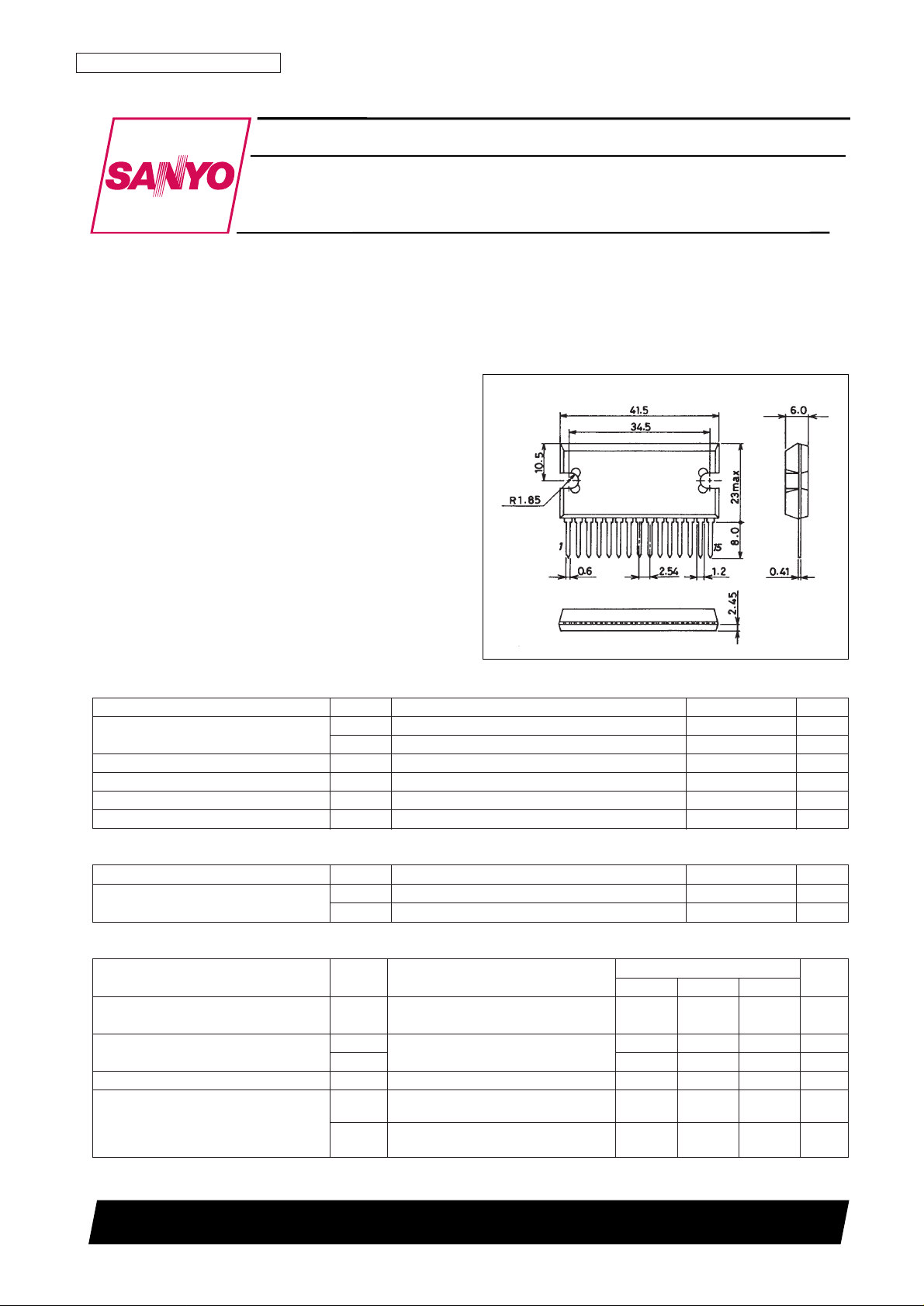

Package Dimensions

unit: mm

2127A

Wideband Output Module (Video Pack)

Ordering number : EN5548A

83097HA (OT)/03096HA (OT) No. 5548-1/4

[VPS13]

SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquarters

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110 JAPAN

CRT Display Video Output Amplifier,

High-Voltage/Wideband Amplifier

VPS13

Parameter Symbol Conditions Ratings Unit

Maximum supply voltage

V

CC

max 90 V

V

BB

max 15 V

Allowable power dissipation Pd max With an ideal heat sink at Tc = 25°C 30 W

Maximum junction temperature Tj max 150 °C

Maximum case temperature Tc max 100 °C

Storage temperature Tstg –20 to +110 °C

Specifications

Absolute Maximum Ratings at Ta = 25°C

Parameter Symbol Conditions Ratings Unit

Recommended supply voltage

V

CC

80 V

V

BB

10 V

Operating Conditions at Ta = 25°C

Parameter Symbol Conditions

Ratings

Unit

min typ max

Frequency band (–3 dB) f

c

V

CC

= 80 V, VBB= 10 V, CL= 10 pF

130 MHz

V

IN

(DC) = 3.2 V, V

OUT

(p-p) = 40 V

Impulse response

t

r

V

CC

= 80 V, VBB= 10 V, CL= 10 pF 3.5 ns

t

f

V

IN

(DC) = 3.2 V, V

OUT

(p-p) = 40 V 2.9 ns

Voltage gain VG (DC) 13 15 17 double

I

CC

(1)

V

CC

= 80 V, VBB= 10 V, VIN(DC) = 2.9 V,

47 mA

Current drain

f = 10 MHz clock, CL= 10 pF, V

OUT

(p-p) = 40 V

ICC(2)

V

CC

= 80 V, VBB= 10 V, VIN(DC) = 2.9 V,

85 mA

f = 130 MHz clock, CL= 10 pF, V

OUT

(p-p) = 40 V

Electrical Characteristics at Ta = 25°C (for a single channel)

Page 2

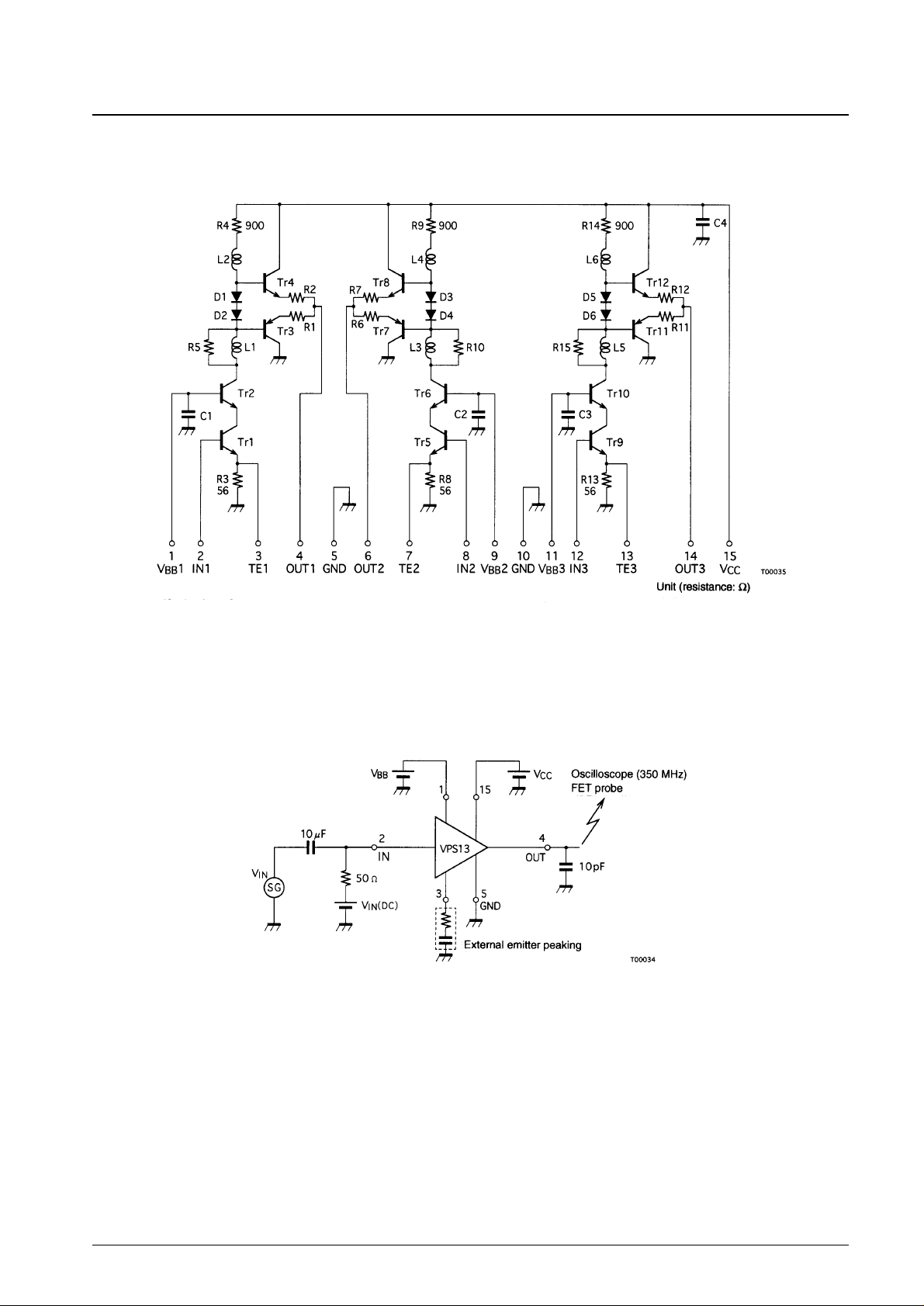

Internal Equivalent Circuit

Test Circuit (for a single channel)

No. 5548-2/4

VPS13

Page 3

Thermal Design

Since the VPS13 includes three channels as shown in the circuit diagram on page 2, we first consider a single channel.

The chip temperature of each transistor under actual operating conditions is determined using the following formula.

Tj = (Tri) = θj-c (Tri) × Pc (Tri) + ∆Tc + Ta (°C).......................(1)

θ

j-c (Tri) : Thermal resistance of an individual transistor

Pc(Tri) : Collector loss for an individual transistor

∆Tc : Case temperature rise

Ta : Ambient temperature

The θj-c (Tri) for each chip is: θj-c (Tr1) = 35°C/W

θ

j-c (Tr2) to (Tr4) = 30°C/W.......................................................(2)

Although the loss for each transistor in a video pack varies with frequency and is not uniform, if we assume the

maximum operating frequency, f = 130 MHz (clock), then the chip with the largest loss will be transistor 3 (Tr3) of the

emitter-follower stage. From the Pd-f (clock) figure we see that loss will be 22% of the total loss for a single channel:

Pc (emitter-follower stage)

(f = 130 MHz)

= Pd (1ch)

(f = 130 MHz)

× 0.22 [W] (3)

Here, we must select a heat sink with a capacity θh such that the Tj of these transistors does not exceed 150°C. Equation

(4) below gives the relationship between θh and ∆Tc.

∆Tc = Pd (Total) ×θh..................................................................(4)

The required θh is calculated using this equation and equation (1).

No. 5548-3/4

VPS13

Page 4

No. 5548-4/4

VPS13

VPS13 Thermal Design Example

Conditions: Using an fH= 100 kHz class monitor, fV= 130 MHz (clock)

VCC= 80 V, VBB= 10 V, V

OUT

= 40 Vp-p (CL= 10 pF)

Here we consider the case where this class of monitor is operated up to Ta = 60°C at a maximum clock frequency of

f = 130 MHz.

As mentioned previously, the chip with the largest loss is transistor 3 (Tr3) of the emitter-follower stage. Determining

that value gives:

Pc (emitter-follower stage) = 6.8 × 0.22 ≈ 1.5 [W] .....................(5)

Now, determine ∆Tj by substituting the value for θj-c in equation (5).

∆Tj = 1.5 × 30 = 45 [°C]

Here, ∆Tj < 50°C, and we need only consider cases where Tc < 100 °C. Therefore, we must design a θh for the heat sink

such that the Tc < 100°C condition holds when three channels are operating at maximum levels, i.e., Pd(TOTAL) =

Pd(one channel) × 3.

∆Tc will be 100 – 60 = 40 °C, and therefore:

θ

h = ∆Tc ÷ Pd (TOTAL) = 40 ÷ (6.8 × 3) = 2.0, i.e. θh = 2.0 °C/W

In actual practice, the ambient temperature and operating conditions will allow a heat sink smaller than that indicated by

this calculation to be used. Therefore, design optimization taking the actual conditions and the above data into account is

also required.

This catalog provides information as of August, 1997. Specifications and information herein are subject to

change without notice.

■ No products described or contained herein are intended for use in surgical implants, life-support systems, aerospace

equipment, nuclear power control systems, vehicles, disaster/crime-prevention equipment and the like, the failure of

which may directly or indirectly cause injury, death or property loss.

■ Anyone purchasing any products described or contained herein for an above-mentioned use shall:

➀

Accept full responsibility and indemnify and defend SANYO ELECTRIC CO., LTD., its affiliates, subsidiaries and

distributors and all their officers and employees, jointly and severally, against any and all claims and litigation and all

damages, cost and expenses associated with such use:

➁

Not impose any responsibility for any fault or negligence which may be cited in any such claim or litigation on

SANYO ELECTRIC CO., LTD., its affiliates, subsidiaries and distributors or any of their officers and employees

jointly or severally.

■ Information (including circuit diagrams and circuit parameters) herein is for example only; it is not guaranteed for

volume production. SANYO believes information herein is accurate and reliable, but no guarantees are made or implied

regarding its use or any infringements of intellectual property rights or other rights of third parties.

VCC(V) VBB(V) V

OUT

(V) VO(center)

80 10 40 45

Loading...

Loading...