Page 1

5 BIT PROGRAMMABLE SYNCHRONOUS BUCK

FEATURESFEATURES

Dual Layout Compatible with HIP6004A

Designed to meet Intel specification of VRM8.4

for Pentium III

On board DAC programs the output voltage

from 1.3V to 3.5V. The US3011 remains on for

VID code of (11111).

Loss less Short Circuit Protection

Synchronous operation allows maximum

efficiency

Patented architecture allows fixed frequency

operation as well as 100% duty cycle during

dynamic load

Over Voltage Protection Output

Soft Start

High current totem pole driver for direct

driving of the external Power MOSFET

Power Good function

APPLICATIONSAPPLICATIONS

Pentium III & Pentium II processor DC to DC converter application

Low cost Pentium with AGP

US3011

CONTROLLER IC

PRELIMINARY DATASHEET

DESCRIPTIONDESCRIPTION

The US3011controller IC is specifically designed to meet

Intel specification for latest Pentium III microprocessor applications as well as the next generation P6 family processors. These products feature a patented topology that in combination with a few external components

as shown in the typical application circuit ,will provide in

excess of 20A of output current for an on- board DC/DC

converter while automatically providing the right output

voltage via the 5 bit internal DAC.These devices also

features, loss less current sensing by using the Rds-

on of the high side Power MOSFET as the sensing

resistor, a Power Good window comparator that switches

its open collector output low when the output is outside

of a ±10% window and an OVP output. Other features of

the device are ; Undervoltage lockout for both 5V and

12V supplies , an external programmable soft start function as well as programming the oscillator frequency by

using an external capacitor.

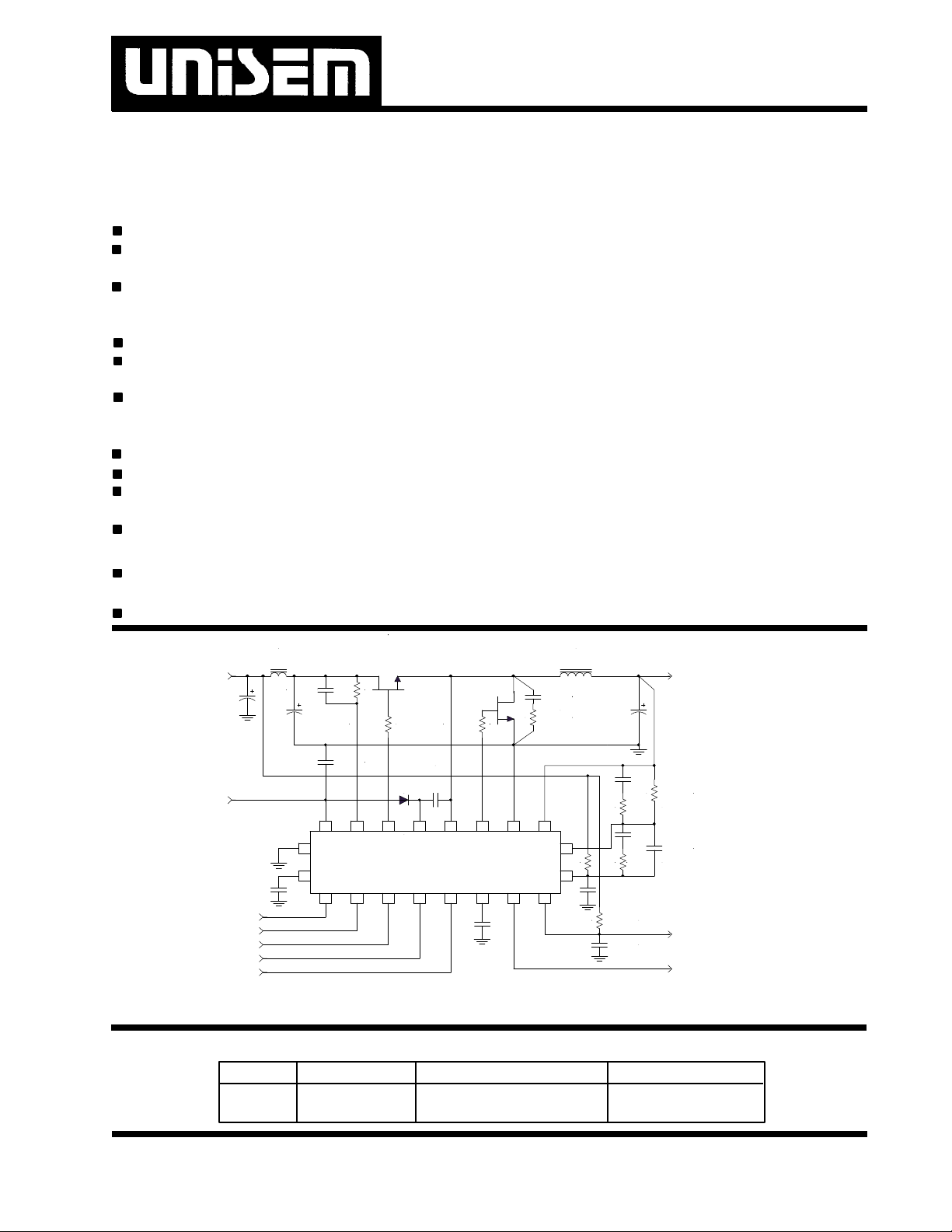

TYPICAL APPLICATIONTYPICAL APPLICATION

5V

C1

12V

Notes: Pentium II and Pentium III are

trade marks of Intel Corp.

L1 L2

C5 R1

C3

1882

NC/Gnd

11

SS

3

C2

VID4

VID3

VID2

VID1

VID0

Q1

R2 R3

C6

D1 C4

14

HDrv LDrv

CS+ Gnd NC/Sen

D3 D2D4 D1 D0

7

Boot

US3011

6155134

PACKAGE ORDER INFORMATIONPACKAGE ORDER INFORMATION

Ta (°C) Device Package VID Voltage Range

0 TO 70 US3011CW 20 pin Plastic SOIC WB 1.3V to 3.5V

CS-V12 NC/

C7

Q2

171216201

V5/Comp

OVP PGdCt/Rt

19

C8

R4

Vfb

10

9

C10

C11

R9

R7

C12

C13

R5

C9

R8

R6

C14

3011app1-1.1

Power Good

OVP

Rev. 1.3

12/8/00

4-1

Page 2

US3011

ABSOLUTE MAXIMUM RATINGSABSOLUTE MAXIMUM RATINGS

V5 supply Voltage ........................................... 7V

V12 Supply Voltage ............................................ 20V

Storage Temperature Range ................................. -65 TO 150°C

Operating Junction Temperature Range .......... 0 TO 125°C

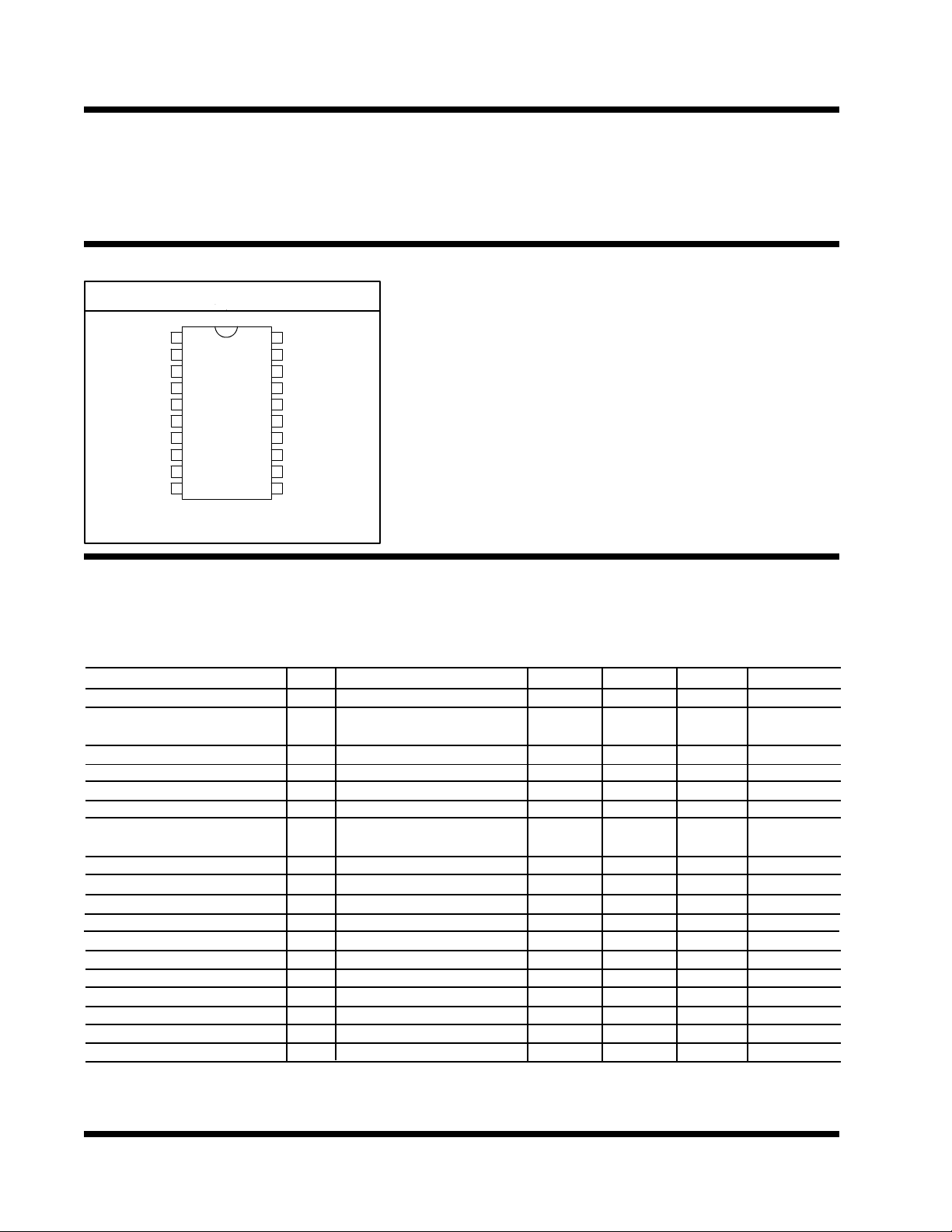

PACKAGE INFORMATIONPACKAGE INFORMATION

20 PIN WIDE BODY PLASTIC SOIC (W)

TOP VIEW

1

NC

2

CS+

3

SS

4

D0

5

D1

6

D2

7

D3

8

D4

9

V5

10

Vfb

θJA =85°C/W

20

Ct

19

OVP

18

V12

17

LDrv

16

Gnd

15

NC

14

HDrv

13

CS-

12

PGd

11

NC

ELECTRICAL SPECIFICATIONSELECTRICAL SPECIFICATIONS

Unless otherwise specified ,these specifications apply over ,V12 = 12V, V5 = 5V and Ta=0 to 70°C. Typical values

refer to Ta =25°C. Low duty cycle pulse testing are used which keeps junction and case temperatures equal to the

ambient temperature.

PARAMETER SYM TEST CONDITION MIN TYP MAX UNITS

VID Section

DAC output voltage 0.99Vs Vs 1.01Vs V

(note 1)

DAC Output Line Regulation 0.1 %

DAC Output Temp Variation 0.5 %

VID Input LO 0.4 V

VID Input HI 2 V

VID input internal pull-up 27 kΩ

resistor to V5

Power Good Section

Under voltage lower trip point Vout ramping down 0.89Vs 0.90Vs 0.91Vs V

Under voltage upper trip point Vout ramping up 0.92Vs V

UV Hysterises .015Vs .02Vs .025Vs V

Over voltage upper trip point Vout ramping up 1.09Vs 1.10Vs 1.11Vs V

Over voltage lower trip point Vout ramping down 1.08Vs V

OV Hysterises .015Vs .02Vs .025Vs V

Power Good Output LO RL=3mA 0.4 V

Power Good Output HI RL=5K pull up to 5V 4.8 V

Soft Start Section

Soft Start Current CS+ =0V , CS- =5V 10 uA

4-2

Rev. 1.3

12/8/00

Page 3

US3011

UVLO Section

UVLO Threshold-12V Supply ramping up 9.2 10 10.8 V

UVLO Hysterises-12V 0.3 0.4 0.5 V

UVLO Threshold-5V Supply ramping up 4.1 4.3 4.5 V

UVLO Hysterises-5V 0.2 0.3 0.4 V

Error Comparator Section

Input bias current 2 uA

Input Offset Voltage -2 +2 mV

Delay to Output Vdiff=10mV 100 nS

Current Limit Section

C.S Threshold Set Current 160 200 240 uA

C.S Comp Offset Voltage -5 +5 mV

Hiccup Duty Cycle Css=0.1 uF 2 %

Supply Current

Operating Supply Current CL=3000pF

V5 20

V12 14 mA

Output Drivers Section

Rise Time CL=3000pF 70 100 nS

Fall Time CL=3000pF 70 130 nS

Dead band Time CL=3000pF 100 200 300 nS

Oscillator Section

Osc Frequency Ct=150pF 190 220 250 Khz

Osc Valley 0.2 V

Osc Peak V5 V

Over Voltage Section

OVP Drive Current 50 mA

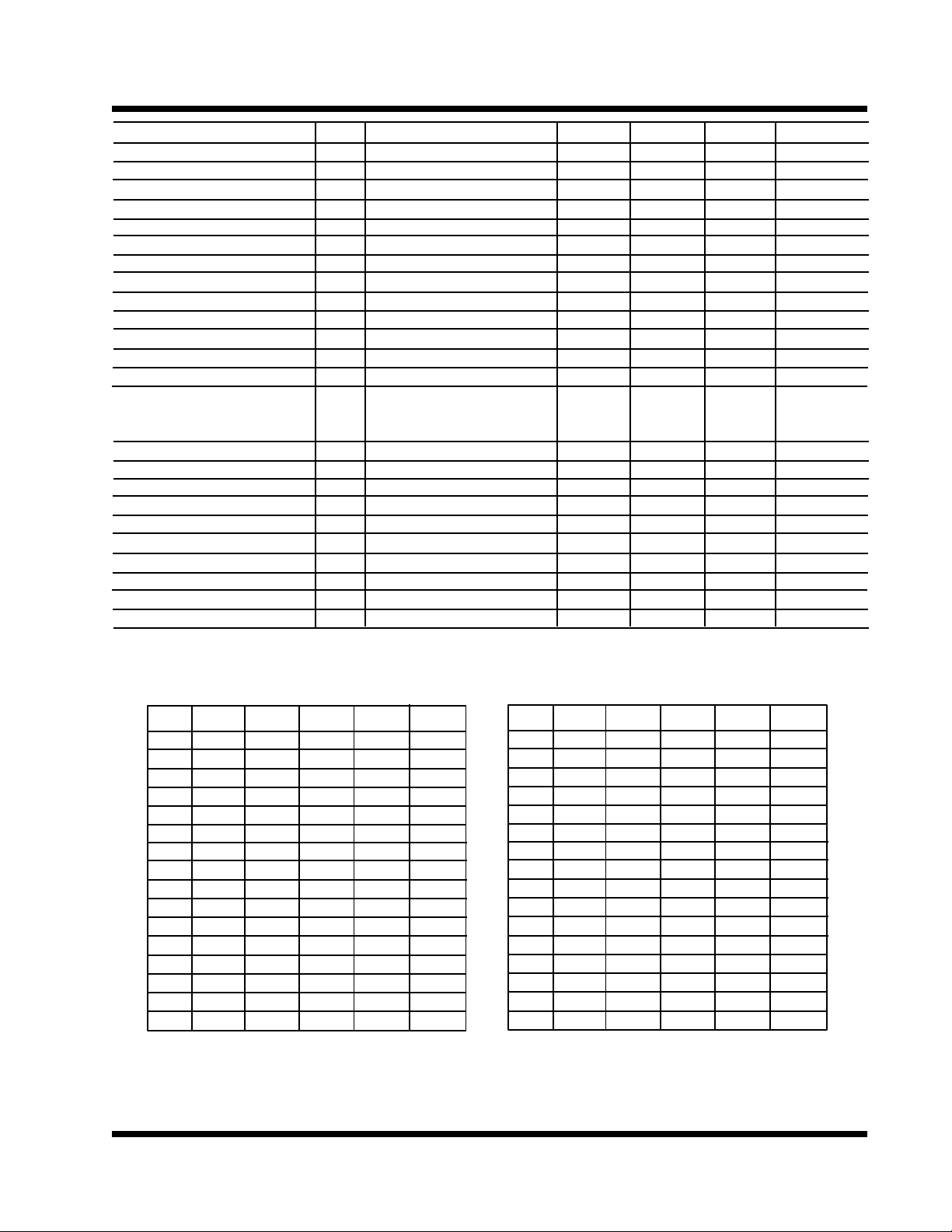

Note 1: Vs refers to the set point voltage given in Table 1.

D4 D3 D2 D1 D0 Vs D4 D3 D2 D1 D0 Vs

0 1 1 1 1 1.30 1 1 1 1 1 2.0

0 1 1 1 0 1.35 1 1 1 1 0 2.1

0 1 1 0 1 1.40 1 1 1 0 1 2.2

0 1 1 0 0 1.45 1 1 1 0 0 2.3

0 1 0 1 1 1.50 1 1 0 1 1 2.4

0 1 0 1 0 1.55 1 1 0 1 0 2.5

0 1 0 0 1 1.60 1 1 0 0 1 2.6

0 1 0 0 0 1.65 1 1 0 0 0 2.7

0 0 1 1 1 1.70 1 0 1 1 1 2.8

0 0 1 1 0 1.75 1 0 1 1 0 2.9

0 0 1 0 1 1.80 1 0 1 0 1 3.0

0 0 1 0 0 1.85 1 0 1 0 0 3.1

0 0 0 1 1 1.90 1 0 0 1 1 3.2

0 0 0 1 0 1.95 1 0 0 1 0 3.3

0 0 0 0 1 2.00 1 0 0 0 1 3.4

0 0 0 0 0 2.05 1 0 0 0 0 3.5

Table 1 - Set point voltage vs. VID codes

Rev. 1.3

12/8/00

4-3

Page 4

US3011

PIN DESCRIPTIONSPIN DESCRIPTIONS

PIN# PIN SYMBOL

4 D0

5 D1

6 D2

7 D3

8 D4

12 PGd

10 Vfb

2 CS+

13 CS3 SS

20 Ct

16 Gnd

17 LDrv

14 HDrv

18 V12

9 V5

19 OVP

15,11 NC

Pin Description

LSB input to the DAC that programs the output voltage. This pin can be pulled up externally by a 10k resistor to either 3.3V or 5V supply.

Input to the DAC that programs the output voltage.This pin can be pulled up externally by

a 10kΩ resistor to either 3.3V or 5V supply.

Input to the DAC that programs the output voltage.This pin can be pulled up externally by

a 10k resistor to either 3.3V or 5V supply.

MSB input to the DAC that programs the output voltage.This pin can be pulled up externally by a 10k resistor to either 3.3V or 5V supply.

This pin selects a range of output voltages for the DAC.

This pin is an open collector output that switches LO when the output of the converter is

not within ±10% (typ) of the nominal output voltage.When PWRGD pin switches LO the

sat voltage is less than 0.4V at 3mA.

This pin is connected directly to the output of the Core supply to provide feedback to the

Error comparator.

This pin is connected to the Drain of the power MOSFET of the Core supply and it

provides the positive sensing for the internal current sensing circuitry. An external resistor programs the C.S threshold depending on the Rds of the power MOSFET. An external

capacitor is placed in parallel with the programming resistor to provide high frequency

noise filtering.

This pin is connected to the Source of the power MOSFET for the Core supply and it

provides the negative sensing for the internal current sensing circuitry.

This pin provides the soft start for the switching regulator. An internal current source

charges an external capacitor that is conected from this pin to the GND which ramps up

the outputs of the switching regulator, preventing the outputs from overshooting as wellas

limiting the input current. The second function of the Soft Start cap is to provide long off

time for the synchronous MOSFET or the Catch diode (HICCUP) during current limiting.

This pin programs the oscillator frequency in the range of 50 kHZ to 500kHZ with an

external capacitor connected from this pin to the GND.

This pin serves as the ground pin and must be conected directly to the ground plane. A

high frequency capacitor (0.1 to 1 uF) must be connected from V5 and V12 pins to this

pin for noise free operation.

Output driver for the synchronous power MOSFET.

Output driver for the high side power MOSFET.

This pin is connected to the 12 V supply and serves as the power Vcc pin for the output

drivers.A high frequency capacitor (0.1 to 1 uF) must be connected directly from this pin

to GND pin in order to supply the peak current to the power MOSFET during the transitions.

5V supply voltage.

Over voltage comparator output.

No connect

4-4

Rev. 1.3

12/8/00

Page 5

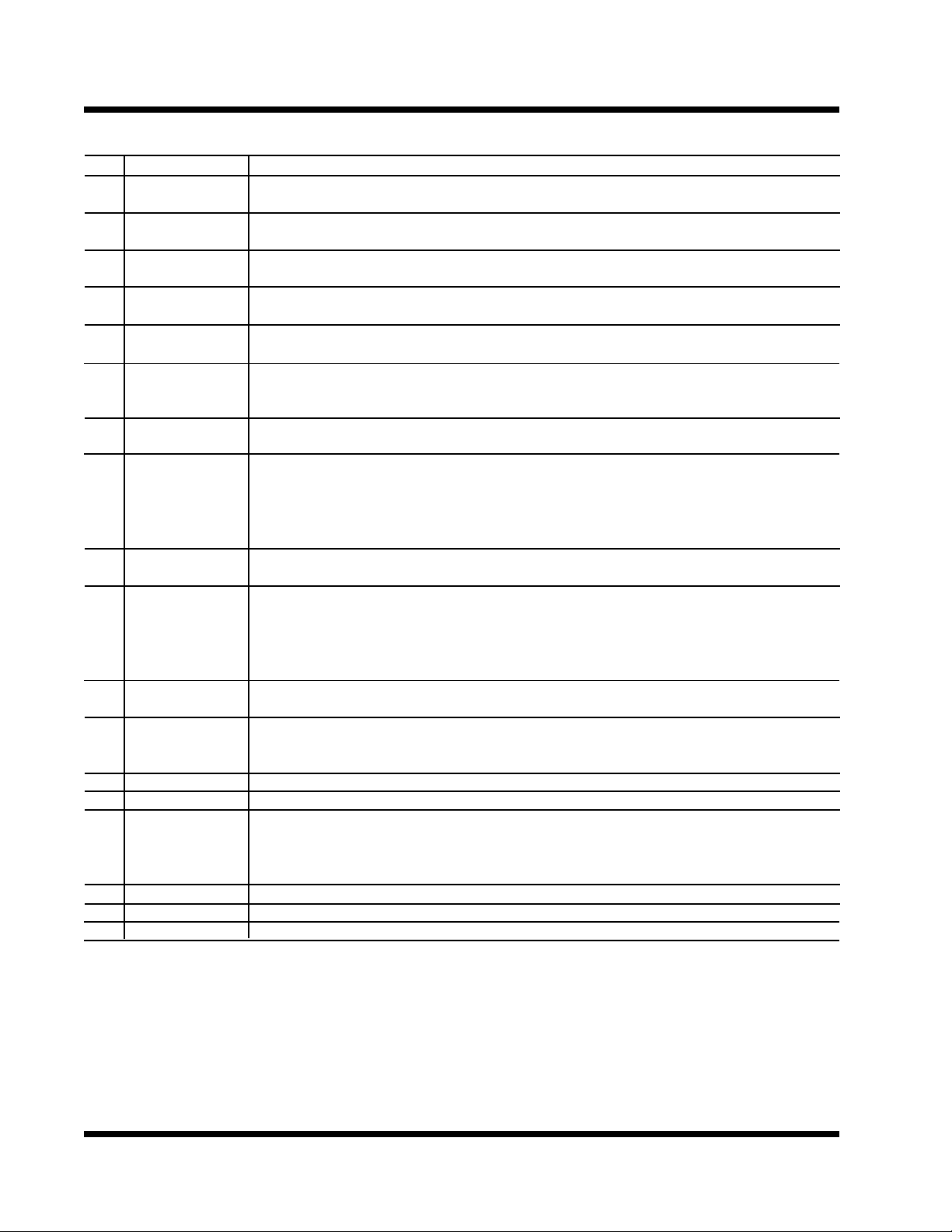

BLOCK DIAGRAMBLOCK DIAGRAM

US3011

V12

V5

D0

D1

D2

D3

D4

OVP

Gnd

UVLO

5Bit

DAC,

Ctrl

Logic

1.18Vset

Enable

Vset

Enable

+

Slope

Comp

Soft

Start &

Fault

Logic

Vset

Enable

Osc

Enable

PWM

Control

Over

Current

200uA

1.1Vset

0.9Vset

V12

V12

3011Ablk1-1.1

Vfb

HDrv

LDrv

CSCS+

Ct

SS

PGd

Rev. 1.3

12/8/00

Figure 1 - Simplified block diagram of the US3011.

4-5

Page 6

US3011

TYPICAL APPLICATIONTYPICAL APPLICATION

SYNCHRONOUS OPERATION

(Dual Layout with HIP6004B)

12V

C1

VID4

VID3

VID2

VID1

C2

L1

C3

R13

C5 R1

1882

NC/Gnd

11

SS

3

Q1

Q2

R2 R3

C6

D1 C4

14

155134171216201

HDrv LDrv

CS+ Gnd NC/Sen

Boot

CS-V12 NC/

US3011

V5/Comp

D3 D2D4 D1 D0

6

7

C7

OVP PGdCt/Rt

19

C8

R4

Vfb

10

L2

R10 R11

C15

R5

9

C9

C11

R7

C12

R8

R6

C14

3011app1-1.3

VID0

Typical application of US3011 in an on board DC-DC converter providing the Core supply for

microprocessor.

C10

R9

C13

Vcore5V

R12

Vcc3

Power Good

Table of components that need to be modified to make the dual layout work for US3011

and HIP6004B.

Part # R5 R7 R8 R9 C4 C7 C9 C11 C12 C13 D1

HIP6004B O V V V V O O V V V V

US3011 S O O V O V V O O O O

S - Short O - Open V - See Unisem or Harris parts list for the value.

4-6

Rev. 1.3

12/8/00

Page 7

US3011

US3011and HIP6004B Dual Layout Parts List

Ref Desig Description Qty Part # Manuf

Q1 MOSFET 1 IRL3103s, TO263 package IR

Q2 MOSFET 1 IRL3103D1S, TO263 package IR

L1 Inductor 1 L=1uH, 5052 core with 4 turns of Micro Metal

1.0mm wire

L2 Inductor 1 L=2.7uH, 5052B core with 7 turns of Micro Metal

1.2mm wire

C1 Capacitor, Electrolytic 1 10MV470GX, 470uF,10V Sanyo

C2,9 Capacitor, Ceramic 2 1uF, 0603

C3 Capacitor, Electrolytic 2 10MV1200GX, 1200uF,10V Sanyo

C5 Capacitor, Ceramic 1 220pF, 0603

C6 Capacitor, Ceramic 1 1uF, 0805

C7 Capacitor, Ceramic 1 150pF, 0603

C8 Capacitor, Ceramic 1 1000pF, 0603

C10 Capacitor, Electrolytic 6 6MV1500GX, 1500uF,6.3V Sanyo

C14 Capacitor, Ceramic 1 0.1uF, 0603

C15 Capacitor, Ceramic 1 4.7uF, 1206

R1 Resistor 1 3.3kΩ, 5%, 0603

R2,3,4 Resistor 3 4.7Ω, 5%, 1206

R5 Resistor 1 0Ω, 0603

R6 Resistor 1 10kΩ, 5%, 0603

R9 Resistor 1 100 Ω, 1%, 0603

R10 Resistor 1 220Ω, 1%, 0603

R11 Resistor 1 330Ω, 1%, 0603

R12 Resistor 1 22kΩ, 1%, 0603

R13 Resistor 1 10Ω, 5%, 0603

Note 1: R10, R11, C15, R9, and R12 set the Vcore 2% higher for level shift to reduce CPU Transient Voltage.

Rev. 1.3

12/8/00

4-7

Page 8

US3011

Application InformationApplication Information

An example of how to calculate the components for the

application circuit is given below.

Assuming, two sets of output conditions that this regulator must meet,

a) Vo=2.8V , Io=14.2A, ∆Vo=185mV, ∆Io=14.2A

b) Vo=2V , Io=14.2A, ∆Vo=140mV, ∆Io=14.2A

The regulator design will be done such that it meets the

worst case requirement of each condition.

Output Capacitor Selection

The first step is to select the output capacitor. This is

done primarily by selecting the maximum ESR value

that meets the transient voltage budget of the total ∆Vo

specification. Assuming that the regulators DC initial

accuracy plus the output ripple is 2% of the output voltage, then the maximum ESR of the output capacitor is

calculated as :

100

≤ =

ESR

1427.

The Sanyo MVGX series is a good choice to achieve

both the price and performance goals. The 6MV1500GX

, 1500uF, 6.3V has an ESR of less than 36 mΩ typ .

Selecting 6 of these capacitors in parallel has an ESR

of ≈6 mΩ which achieves our low ESR goal.

Other type of Electrolytic capacitors from other manufacturers to consider are the Panasonic “FA” series or

the Nichicon “PL” series.

Reducing the Output Capacitors Using Voltage Level

Shifting Technique

The trace resistance or an external resistor from the output

of the switching regulator to the Slot 1 can be used to

the circuit advantage and possibly reduce the number

of output capacitors, by level shifting the DC regulation point when transitioninig from light load to

full load and vice versa. To accomplish this, the out-

put of the regulator is typically set about half the DC

drop that results from light load to full load. For example,

if the total resistance from the output capacitors to the

Slot 1 and back to the GND pin of the device is 5mΩ and

if the total ∆I, the change from light load to full load is

14A, then the output voltage measured at the top of the

resistor divider which is also connected to the output

capacitors in this case, must be set at half of the 70 mV

or 35mV higher than the DAC voltage setting.

m

Ω

This intentional voltage level shifting during the load transient eases the requirement for the output capacitor ESR

at the cost of load regulation. One can show that the

new ESR requirement eases up by half the total trace

resistance. For example, if the ESR requirement of the

output capacitors without voltage level shifting must be

7mΩ then after level shifting the new ESR will only need

to be 8.5mΩ if the trace resistance is 5mΩ (7+5/2=9.5).

However, one must be careful that the combined “voltage level shifting” and the transient response is still within

the maximum tolerance of the Intel specification. To insure this, the maximum trace resistance must be less

than:

Rs≤ 2(Vspec - 0.02*Vo - ∆Vo)/∆I

Where :

Rs=Total maximum trace resistance allowed

Vspec=Intel total voltage spec

Vo=Output voltage

∆Vo=Output ripple voltage

∆I=load current step

For example, assuming:

Vspec=±140 mV=±0.1V for 2V output

Vo=2V

∆Vo=assume 10mV=0.01V

∆I=14.2A

Then the Rs is calculated to be:

Rs≤ 2(0.140 - 0.02*2 - 0.01)/14.2=12.6mΩ

However, if a resistor of this value is used, the maximum

power dissipated in the trace (or if an external resistor is

being used) must also be considered. For example if

Rs=12.6 mΩ , the power dissipated is

(Io^2)*Rs=(14.2^2)*12.6=2.54W. This is a lot of power to

be dissipated in a system. So, if the Rs=5mΩ, then the

power dissipated is about 1W which is much more acceptable. If level shifting is not implemented, then the

maximum output capacitor ESR was shown previously

to be 7mΩ which translated to ≈ 6 of the 1500uF,

6MV1500GX type Sanyo capacitors. With Rs=5mΩ, the

maximum ESR becomes 9.5mΩ which is equivalent to

≈ 4 caps. Another important consideration is that if a

trace is being used to implement the resistor, the

power dissipated by the trace increases the case

temperature of the output capacitors which could

seriously effect the life time of the output capacitors.

Output Inductor Selection

The output inductance must be selected such that under low line and the maximum output voltage condition,

the inductor current slope times the output capacitor

ESR is ramping up faster than the capacitor voltage is

4-8

Rev. 1.3

12/8/00

Page 9

US3011

drooping during a load current step. However if the inductor is too small , the output ripple current and ripple

voltage become too large. One solution to bring the ripple

current down is to increase the switching frequency ,

however that will be at the cost of reduced efficiency and

higher system cost. The following set of formulas are

derived to achieve the optimum performance without

many design iterations.

The maximum output inductance is calculated using the

following equation :

L = ESR * C * ( Vinmin - Vomax ) / ( 2* ∆I )

Where :

Vinmin = Minimum input voltage

For Vo = 2.8 V , ∆I = 14.2 A

L =0.006 * 9000 * ( 4.75 - 2.8) / (2 * 14.2) = 3.7 uH

Assuming that the programmed switching frequency is

set at 200 KHZ , an inductor is designed using the

Micrometals’ powder iron core material. The summary

of the design is outlined below :

The selected core material is Powder Iron , the

selected core is T50-52D from Micro Metal wounded

with 8 Turns of # 16 AWG wire, resulting in 3 uH

inductance with ≈ 3 mΩ of DC resistance.

Assuming L = 3 uH and the switching frequency ; Fsw =

200 KHZ , the inductor ripple current and the output

ripple voltage is calculated using the following set of

equations :

T = 1/Fsw

T ≡ Switching Period

D ≈ ( Vo + Vsync ) / ( Vin - Vsw + Vsync )

D ≡ Duty Cycle

Ton = D * T

Vsw ≡ High side Mosfet ON Voltage = Io * Rds

Rds ≡ Mosfet On Resistance

Toff = T - Ton

Vsync ≡ Synchronous MOSFET ON Voltage=Io * Rds

∆Ir = ( Vo + Vsync ) * Toff /L

∆Ir ≡ Inductor Ripple Current

∆Vo = ∆Ir * ESR

∆Vo ≡Output Ripple Voltage

In our example for Vo = 2.8V and 14.2 A load , Assuming IRL3103 MOSFET for both switches with maximum

on resistance of 19 mΩ, we have :

T = 1 / 200000 = 5 uSec

Vsw =Vsync= 14.2*0.019=0.27 V

D ≈ ( 2.8 + 0.27 ) / ( 5 - 0.27 + 0.27 ) = 0.61

Ton = 0.61 * 5 = 3.1 uSec

Toff = 5 - 3.1 = 1.9 uSec

∆Ir = ( 2.8 + 0.27 ) * 1.9 / 3 = 1.94 A

∆Vo = 1.94 * .006 = .011 V = 11 mV

Power Component Selection

Assuming IRL3103 MOSFETs as power components,

we will calculate the maximum power dissipation as follows:

For high side switch the maximum power dissipation

happens at maximum Vo and maximum duty cycle.

Dmax ≈ ( 2.8 + 0.27 ) / ( 4.75 - 0.27 + 0.27 ) = 0.65

Pdh = Dmax * Io^2*Rds(max)

Pdh= 0.65*14.2^2*0.029=3.8 W

Rds(max)=Maximum Rds-on of the MOSFET at 125°C

For synch MOSFET, maximum power dissipation happens at minimum Vo and minimum duty cycle.

Dmin ≈ ( 2 + 0.27 ) / ( 5.25 - 0.27 + 0.27 ) = 0.43

Pds = (1-Dmin)*Io^2*Rds(max)

Pds=(1 - 0.43) * 14.2^2 * 0.029 = 3.33 W

Heatsink Selection

Selection of the heat sink is based on the maximum

allowable junction temperature of the MOSFETS. Since

we previously selected the maximum Rds-on at 125°C,

then we must keep the junction below this temperature.

Selecting TO220 package gives θjc=1.8°C/W ( From the

venders’ datasheet ) and assuming that the selected

heatsink is Black Anodized , the Heat sink to Case thermal resistance is ; θcs=0.05°C/W , the maximum heat

sink temperature is then calculated as :

Ts = Tj - Pd * (θjc + θcs)

Ts = 125 - 3.82 * (1.8 + 0.05) = 118 °C

With the maximum heat sink temperature calculated in

the previous step, the Heat Sink to Air thermal resistance (θsa) is calculated as follows :

Assuming Ta=35 °C

∆T = Ts - Ta = 118 - 35 = 83 °C Temperature Rise

Above Ambient

θsa = ∆T/Pd

θsa = 83 / 3.82 = 22 °C/W

Next , a heat sink with lower θsa than the one calculated in the previous step must be selected. One way to

do this is to simply look at the graphs of the “Heat Sink

Temp Rise Above the Ambient” vs. the “Power Dissipation” given in the heatsink manufacturers’ catalog and

select a heat sink that results in lower temperature rise

than the one calculated in previous step. The following

heat sinks from AAVID and Thermaloy meet this criteria.

Co. Part #

Thermalloy 6078B

AAVID 577002

Rev. 1.3

12/8/00

4-9

Page 10

US3011

If, F= kHz :

200

200

10

Following the same procedure for the Schottcky diode

results in a heatsink with θsa = 25 °C/W. Although it is

possible to select a slightly smaller heatsink, for simplicity the same heatsink as the one for the high side

MOSFET is also selected for the synchronous MOSFET.

Switcher Current Limit Protection

The PWM controller uses the MOSFET Rds-on as the

sensing resistor to sense the MOSFET current and compares to a programmed voltage which is set externally

via a resistor (Rcs) placed between the drain of the

MOSFET and the “CS+” terminal of the IC as shown in

the application circuit. For example, if the desired current limit point is set to be 22A and from our previous

selection, the maximum MOSFET Rds-on=19mΩ, then

the current sense resistor, Rcs is calculated as :

Vcs=IcL*Rds=22*0.019=0.418V

Rcs=Vcs/Ib=(0.418V)/(200uA)=2.1kΩ

Where: Ib=200uA is the internal current setting of the

device

Switcher Timing Capacitor Selection

The switching frequency can be programmed using an

external timing capacitor. The value of Ct can be approximated using the equation below:

−

5

×

35 10

SW

T

SW

.

≈

C

T

:

min

=

F

Where

C =Ti g Capacitor

F Switching Frequency

Slot 1 and back to the GND pin of the device is 5mΩ and

if the total ∆I, the change from light load to full load is

14A, then the output voltage measured at the top of the

resistor divider which is also connected to the output

capacitors in this case, must be set at half of the 70 mV

or 35mV higher than the DAC voltage setting. To do this,

the top resistor of the resistor divider, Rtop is set at 100Ω,

and the bottom resistor, Rb is calculated. For example,

if DAC voltage setting is for 2.8V and the desired output

under light load is 2.835V, then Rb is calculated using

the following formula :

Rb= 100*{Vdac /(Vo - 1.004*Vdac)} [Ω]

Rb= 100*{2.8 /(2.835 - 1.004*2.800)} = 11.76 kΩ

Select 11.8 kΩ , 1%

Note: The value of the top resistor must not exceed

100ΩΩ. The bottom resistor can then be adjusted to raise

the output voltage.

Soft Start Capacitor Selection

The soft start capacitor must be selected such that during the start up when the output capacitors are charging

up, the peak inductor current does not reach the current

limit treshold. A minimum of 1uF capacitor insures this

for most applications. An internal 10uA current source

charges the soft start capacitor which slowly ramps up

the inverting input of the PWM comparator Vfb3. This

insures the output voltage to ramp at the same rate as

the soft start cap thereby limiting the input current. For

example, with 1uF and the 10uA internal current source

the ramp up rate is (∆V/ ∆t)=I/C = 1V/100mS. Assuming that the output capacitance is 9000uF, the maximum start up current will be:

I=9000uF*(1V/100mS)=0.09A

Input Filter

SW

5

35 10

C pF

Switcher Output Voltage Adjust

As it was discussed earlier,the trace resistance from

the output of the switching regulator to the Slot 1 can be

used to the circuit advantage and possibly reduce the

number of output capacitors, by level shifting the DC

regulation point when transitioninig from light load to full

load and vice versa. To account for the DC drop, the

output of the regulator is typically set about half the DC

drop that results from light load to full load. For example,

if the total resistance from the output capacitors to the

.

T

≈

−

×

×

175

=

3

4-10

It is highly recommended to place an inductor between

the system 5V supply and the input capacitors of the

switching regulator to isolate the 5V supply from the

switching noise that occurs during the turn on and off of

the switching components. Typically an inductor in the

range of 1 to 3 uH will be sufficient in this type of application.

Switcher External Shutdown

The best way to shutdown the part is to pull down on the

soft start pin using an external small signal transistor

such as 2N3904 or 2N7002 small signal MOSFET. This

allows slow ramp up of the output, the same as the power

up.

Rev. 1.3

12/8/00

Page 11

US3011

Layout Considerations

Switching regulators require careful attention to the layout of the components, specifically power components

since they switch large currents. These switching components can create large amount of voltage spikes and

high frequency harmonics if some of the critical components are far away from each other and are connected

with inductive traces. The following is a guideline of how

to place the critical components and the connections

between them in order to minimize the above issues.

Start the layout by first placing the power components:

1) Place the input capacitors C3 and the high side

mosfet ,Q1 as close to each other as possible

2) Place the synchronous mosfet,Q2 and the Q1 as

close to each other as possible with the intention that

the source of Q1 and drain of the Q2 has the shortest

length.

3) Place the snubber R4 & C7 between Q1 & Q2.

4) Place the output inductor ,L2 and the output capacitors ,C10 between the mosfet and the load with output

capacitors distributed along the slot 1 and close to it.

5) Place the bypass capacitors, C6 and C9 right next to

12V and 5V pins. C6 next to the 12V, pin 18 and C9

next to the 5V, pin 9.

6) Place the IC such that the pwm output drives, pins

14 and 17 are relatively short distance from gates of Q1

and Q2.

7) If the ouput voltage is to be adjusted, place resistor

dividers close to the feedback pin.

Note 1: Although, the device does not require resistor

dividers and the feedback pin can be directly connected

to the output, they can be used to set the outputs slightly

higher to account for any output drop at the load due to

the trace resistance. See the application note.

8) Place timing capacitor C7 close to pin20 and soft

start capacitor C2 close to pin 3.

Component connections:

Note : It is extremely important that no data bus

should be passing through the switching regulator

section specifically close to the fast transition nodes

such as PWM drives or the inductor voltage.

Using 4 layer board, dedicate on layer to GND, another

layer as the power layer for the 5V, 3.3V and Vcore.

Connect all grounds to the ground plane using direct vias to the ground plane.

Use large low inductance/low impedance plane to connect the following connections either using component

side or the solder side.

a) C3 to Q1 Drain

b) Q1 Source to Q2 Drain

c) Q2 drain to L2

d) L2 to the output capacitors, C10

e) C10 to the slot 1

f) Input filter L1 to the C3

Connect the rest of the components using the shortest

connection possible

Rev. 1.3

12/8/00

4-11

Loading...

Loading...