Page 1

DATA SHEET

MOS INTEGRATED CIRCUIT

µ

PD16901

FLASH MEMORY VOLTAGE STEPUP DC/DC CONVERTER IC

The µPD16901 is a DC/DC converter IC which produces a 12 V output from a 5 V input source. The integration

of a control circuit and power MOSFET in the output stage on a single-chip allows a power supply for flash memory

write and erasure to be configured with a reduced number of external components.

FEATURES

• With an on-chip output stage power MOSFET, fewer external components are needed.

• The ALLMOS structure achieves low power consumption.

• Internally set output voltage eliminates the need for adjustment.

• Output can be turned ON/OFF via an external signal.

• A timer latch type overcurrent protection circuit on chip

ORDERING INFORMATION

Part Number Package

µ

PD16901GS 14-pin plastic SOP (300 mil)

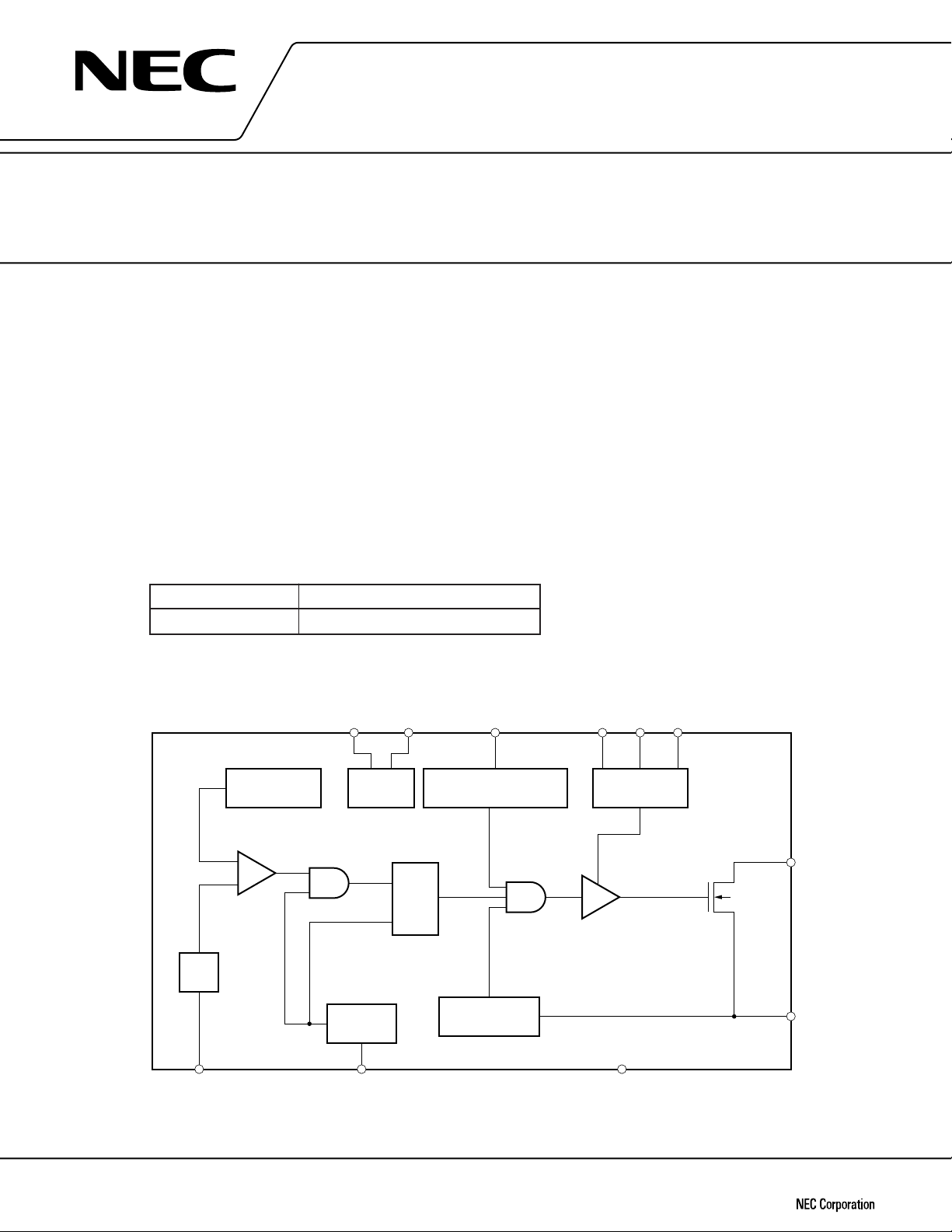

BLOCK DIAGRAM

Reference

voltage circuit

β

ON/OFF V

Startup

circuit

IN

Timer latch short-circuit

protection circuit

F/F

C

DLY

C1HC1LC

Charge pump

circuit

2

V

SW

SW

FB R

The information in this document is subject to change without notice.

Document No. S10643EJ2V0DS00 (2nd edition)

Date Published May 1997 N

Printed in Japan

Oscillation

circuit

T

Overcurrent

detection circuit

GND

C.S.

©

1997

Page 2

ABSOLUTE MAXIMUM RATINGS (TA = 25 ˚C unless specified otherwise)

Item Symbol Condition Rating Unit

Supply voltage VIN 7.0 V

Output voltage VSW 20 V

Total power dissipation PT Note 0.9 W

Operating ambient temperature TA –20 to 85 ˚C

Storage temperature range Tstg –55 to +150 ˚C

Note When 90 mm × 90 mm × 1.6 mm thick glass epoxy board is mounted

RECOMMENDED OPERATING RANGE

Item Symbol MIN. TYP. MAX. Unit

Supply voltage VDD 4.5 5.0 5.5 V

Charge pump capacitor C1, C2 0.033 0.1 0.47

Operating ambient temperature TA 070˚C

µ

F

µ

PD16901

ELECTRICAL SPECIFICATIONS (TA = 25 ˚C, VIN = 5 V unless specified otherwise)

Item Symbol Condition MIN. TYP. MAX. Unit

(Oscillation block)

Oscillation frequency fOSC RT = 68 kΩ 153 167 181 kHz

On duty DUTY 67 %

(Low voltage misoperation preventive circuit)

Operation start voltage VIN(start-up) 3.3 3.7 4.3 V

Operation stop voltage VIN(stop) 2.7 3.2 3.8 V

Hysteresis width VHYS 0.3 0.5 0.7 V

(Overcurrent detection block)

Overcurrent detection voltage VDET 270 300 330 mV

(On/off control block)

ON/OFF pin input voltage VIH 4.5 V ≤ VIN ≤ 5.5 V VIN*0.7 V

VIL 4.5 V ≤ VIN ≤ 5.5 V VIN*0.3 V

ON/OFF pin input current IIL ON/OFF pin voltage = 0 –20 –5 –1

(Charge pump circuit)

Output voltage VCHG 4.5 V ≤ VIN ≤ 5.5 V 8.0 11 V

0 ˚C ≤ TA ≤ 70 ˚C

(Short-circuit protection circuit)

Timer latch pin output current ISCP RT = 68 kΩ 2.0 3.3 4.5

Timer latch detection voltage VDETT 0.85 1.0 1.15 V

(Output block)

Output stage on resistance RDS(ON) IPK = 0.5 A 0.3 0.5 Ω

Output stage leakage current IDSOFF VDS = 20 V 1.0 µA

µ

A

µ

A

2

Page 3

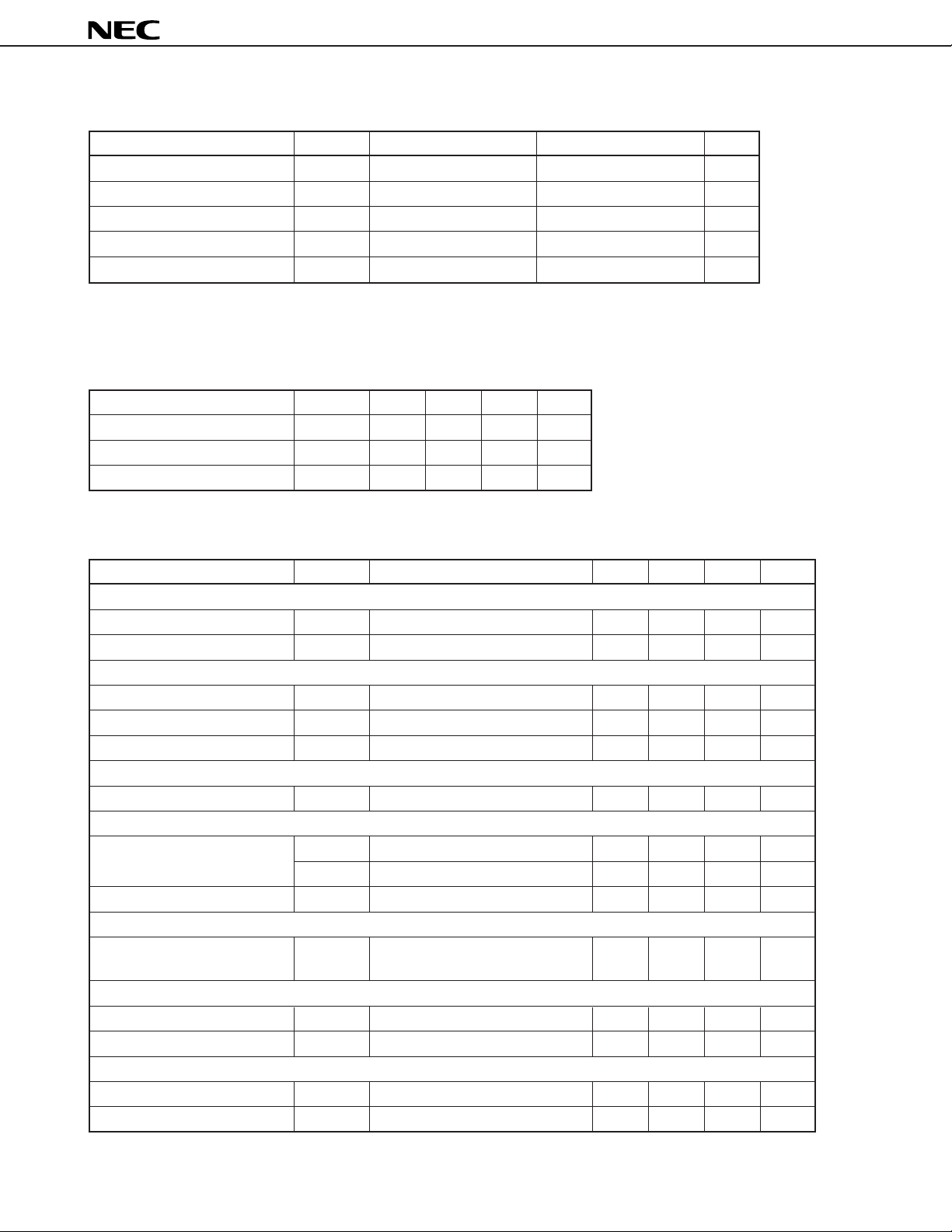

PIN CONFIGURATION (Top View)

C

14

µ

PD16901

V

2

NC11NC10NC9CS8FB

SW

13

12

1

C

2

3

C

1H

V

1L

CC

4

ON/OFF

5

R

6

C

T

DLY

7

GND

CONTROL

3

Page 4

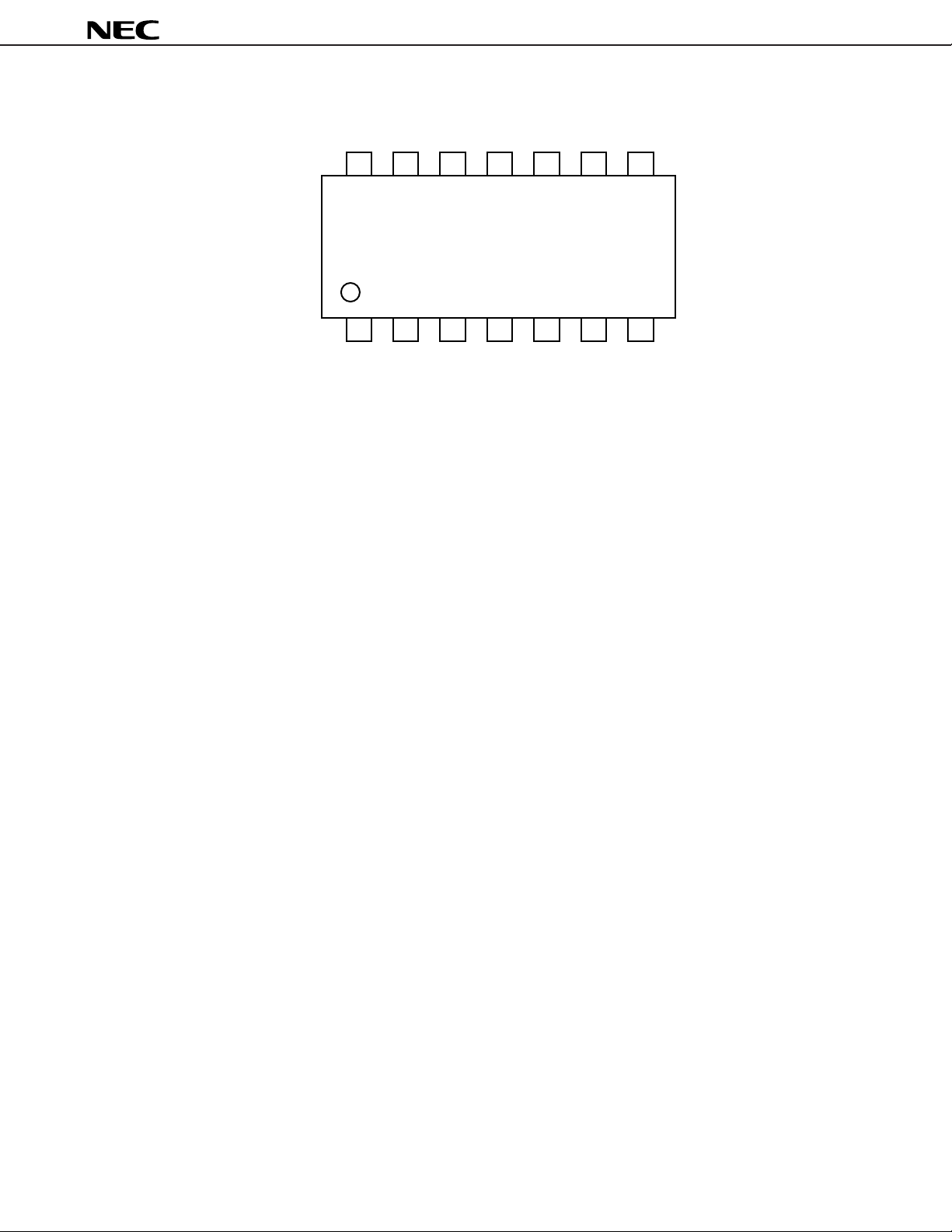

PACKAGE DRAWINGS

14 PIN PLASTIC SOP (300 mil)

14 8

17

detail of lead end

P

µ

PD16901

A

G

F

E

C

M

D

NOTE

Each lead centerline is located within 0.12 mm (0.005 inch) of

its true position (T.P.) at maximum material condition.

M

B

H

I

J

K

L

ITEM MILLIMETERS INCHES

A

10.46 MAX.

B

1.42 MAX.

C

1.27 (T.P.)

D 0.40 0.016

E

F

G

H

I

J

K 0.20

L 0.6±0.2 0.024

M

N

P3° 3°

+0.10

–0.05

0.1±0.1

1.8 MAX.

1.55

7.7±0.3

5.6

1.1

+0.10

–0.05

0.12

0.10

+7°

–3°

P14GM-50-300B-4

0.412 MAX.

0.056 MAX.

0.050 (T.P.)

0.004±0.004

0.071 MAX.

0.061

0.303±0.012

0.220

0.043

0.008

0.005

0.004

+7°

–3°

N

+0.004

–0.003

+0.004

–0.002

+0.008

–0.009

4

Page 5

STANDARD CHARACTERISTIC CURVES

µ

PD16901

PT - TA characteristic

1.4

When mounted on

90 mm × 90 mm × 1.6 mm

glass epoxy board

(W)

T

1.2

1.0

0.9 W

0.8

0.6

0.4

Total Power dissipation P

0.2

0

–20 0 20 40 60 80 100

Ambient temperature TA (˚C)

CC (ON)

- VIN characteristic

I

3.5

TA = 85 ˚C

TA = 0 ˚C

(mA)

CC (ON)

3.0

2.5

2.0

139 ˚C/W

TA = 25 ˚C

85 ˚C

f

OSC

-VIN characteristic

180

175

(kHz)

OSC

170

165

160

Oscillation frequency f

155

3.5 4.0 4.5 5.0 6.0 6.5

5.5

Input voltage VIN (V)

f

OSC

- TA characteristic

180

175

(kHz)

170

OSC

165

T

A

= 25 ˚C

V

IN

= 5 V

1.5

1.0

0.5

Operating circuit current I

0

3.5 4.0 4.5 5.0 6.0 6.5

5.5

Input voltage VIN (V)

DET

- TA characteristic

V

340

(mV)

330

DET

320

310

300

290

280

Overcurrent detection voltage V

270

–20 0 20 40 60 80 100

Ambient temperature TA (˚C)

160

155

Oscillation frequency f

150

145

–20 0 20 40 60 80 100

Ambient temperature TA (˚C)

V

DETT

- TA characteristic

1.12

V

IN

= 5 V VIN = 5 V

(V)

DETT

1.1

1.08

1.06

1.04

1.02

1.0

Timer latch detection voltage V

0.98

–20 0 20 40 60 80 100

Ambient temperature TA (˚C)

5

Page 6

µ

( A)

SCP

µ

PD16901

SCP

- TA characteristic I

I

5

V

IN = 5 V

4

3

140

120

µ

( A)

100

CC (OFF)

80

CC (OFF)

- TA characteristic

IN = 5 V

V

2

1

Timer latch pin output current I

0

–20 0 40 60 100

20

Ambient temperature TA (˚C)

80

60

40

Standby current I

20

0

–20 0 20 40 60 80 100

Ambient temperature TA (˚C)

6

Page 7

STANDARD CONNECTION DIAGRAM

µ

PD16901

4.5 V to 5.5 V

ON/OFF

+

µ

C

33 F

IN

Reference

voltage circuit

β

Oscillation

circuit

FB R

68 kΩ

Startup

circuit

T

C

T

0.1 F

µ

V

IN

C

DLY

Timer latch short-circuit

protection circuit

F/F

Overcurrent

detection circuit

0.1 F

C

µ

C1HC1LC

Charge pump

circuit

GND

C

2

2

0.1 F

µ

L

33 H

µ

1

D

V

SW

SW

+

15 F

µ

C

OUT

C.S.

R

CS

0.3 Ω

Remark The circuit constants and circuit configuration in this connection diagram are shown for illustrative

purposes and not intended for volume production design.

ELECTRICAL SPECIFICATIONS

(as per standard connection diagram. T

Item Symbol Condition MIN. TYP. MAX. Unit

Output voltage VOUT 4.5 V ≤ VIN ≤ 5.5 V 11.52 12.00 12.48 V

Input stability REGIN 4.5 V ≤ VIN < 5.5 V 0.5 %/V

Load stability REGL 0 mA ≤ IO < 140 mA 0.004 %/mA

Conversion efficiency

Operating circuit current ICC IO = 0 3.0 mA

Standby circuit current ICC(OFF) ON/OFF pin voltage = 0 100

Startup voltage VIN(start-up) 3.7 4.3 V

η

A = 25 ˚C, VIN = 5 V, IOUT = 140 mA unless specified otherwise)

0 mA ≤ IO ≤ 140 mA

0 ˚C ≤TA ≤ 60 ˚C

83 %

Remark These specifications are reference values confirmed with the standard connection diagram (without

taking account of variations) and are not intended to guarantee the characteristics of the product as a

DC/DC converter.

µ

A

7

Page 8

STANDARD CHARACTERISTIC CURVES (as per standard connection diagram)

µ

PD16901

- IO characteristic

η

100

VIN = 5.5 V

80

η

VIN = 4.5 V

60

40

20

Conversion efficiency (%)

0

0 25 50 75 125 150100

Output current IO (mA)

V

O

- IO characteristic

13

12.5

(V)

O

12

Output voltage V

11.5

VIN = 5 V

IN

= 5V

V

O (MAX)

- VIN characteristic

I

350

300

(mA)

(MAX)

250

O

200

150

100

50

Maximum output current I

0

3.5 4.0 4.5 5.0 6.0 6.55.5

Input voltage VIN (V)

O

-TA characteristic

V

12.5

VIN = 5.5 V

(V)

O

12

11.5

Output voltage V

TA = 85 °C

TA = 0 °C

VIN = 4.5 V

TA = 25 °C

I

O

= 140 mA

VIN = 5 V

11

0 25 50 75 100

Output current IO (mA)

125 150

11

–20 0 20 40 60 80 100

Ambient temperature TA (°C)

8

Page 9

µ

PD16901

RECOMMENDED SOLDERING CONDITIONS

This product should be soldered and mounted under the conditions recommended below.

For soldering methods and conditions other than those recommended, please contact your NEC sales representative.

For details of recommended soldering conditions, refer to the information document "Semiconductor Device

Mounting Technology Manual."

Soldering Method Soldering Conditions

Infrared reflow Package peak temperature: 235 ˚C; Duration: 30 sec. max. (210 ˚C or above): IR35-00-3

Number of times: Max. 3; Time limit: None

Flux: Rosin type flux with reduced chlorine content (chlorine 0.2 Wt% or less)

is recommended.

VPS Package peak temperature: 215 ˚C; Duration: 40 sec. max. (200 ˚C or above): VP15-00-1

Number of times: 1; Time limit: None

Flux: Rosin type flux with reduced chlorine content (chlorine 0.2 Wt% or less)

is recommended.

Wave soldering Package peak temperature: 260 ˚C or less, Duration: 10 sec. max., WS60-00-1

Preparatory heating temperature: 120 ˚C or less; Number of times: 1

Flux: Rosin type flux with reduced chlorine content (chlorine 0.2 Wt% or less)

is recommended.

Note

Note

Recommended

Condition Symbol

Note For the storage period after unpacking from the dry-pack, storage conditions are max. 25 ˚C, 65% RH.

Caution Use of more than one soldering method should be avoided.

REFERENCE DOCUMENTS

NEC Semiconductor Device Reliability/Quality Control System 10983E

Semiconductor Device Quality Guarantee Guide MEI-1202

Semiconductor Device Mounting Technology Manual C10535E

9

Page 10

[MEMO]

µ

PD16901

10

Page 11

[MEMO]

µ

PD16901

11

Page 12

µ

PD16901

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in

this document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property

rights of third parties by or arising from use of a device described herein or any other liability arising from use

of such device. No license, either express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on a

customer designated "quality assurance program" for a specific application. The recommended applications of

a device depend on its quality grade, as indicated below. Customers must check the quality grade of each device

before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

Anti-radioactive design is not implemented in this product.

M4 96.5

Loading...

Loading...