Page 1

DATA SHEET

MOS INTEGRATED CIRCUIT

µµµµ

PD16877

MONOLITHIC QUAD H-BRIDGE DRIVER CIRCUIT

DESCRIPTION

The µPD16877 is monolithic quad H-bridge driver LSI which uses power MOSFETs in the output stages. By using

the MOS process, this driver IC has substantially improved saturation voltage and power consumption as compared

with conventional driver circuits using bipolar transistors.

By eliminating the charge pump circuit, the current during power-OFF is drastically decreased.

In addition, a low-voltage malfunction prevention circuit is also provided that prevents the IC from malfunctioning

when the supply voltage drops.

As the package, a 24-pin plastic TSSOP is adopted to enable the creation of compact, slim application sets.

This driver IC can drive two stepping motor at the same time, and is ideal for driving stepping motors in the lens of

a camcorder.

FEATURES

Four H bridge circuits employing power MOSFETs

Low current consumption by eliminating charge pump

VM pin current when power-OFF: 10 µA MAX. VDD pin current: 10 µA MAX.

Input logic frequency: 100 kHz

3-V power supply

Minimum operating supply voltage: 2.5 V

Low voltage malfunction prevention circuit

24-pin plastic TSSOP (5.72 mm (225))

ORDERING INFORMATION

Part Number Package

µ

PD16877MA-6A5 24-pin plastic TSSOP (5.72 mm (225))

The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

Not all devices/types available in every country. Please check with local NEC representative for

availability and additional information.

Document No. S13964EJ1V0DS00 (1st edition)

Date Published March 2000 N CP(K)

Printed in Japan

©

2000

Page 2

µµµµ

PD16877

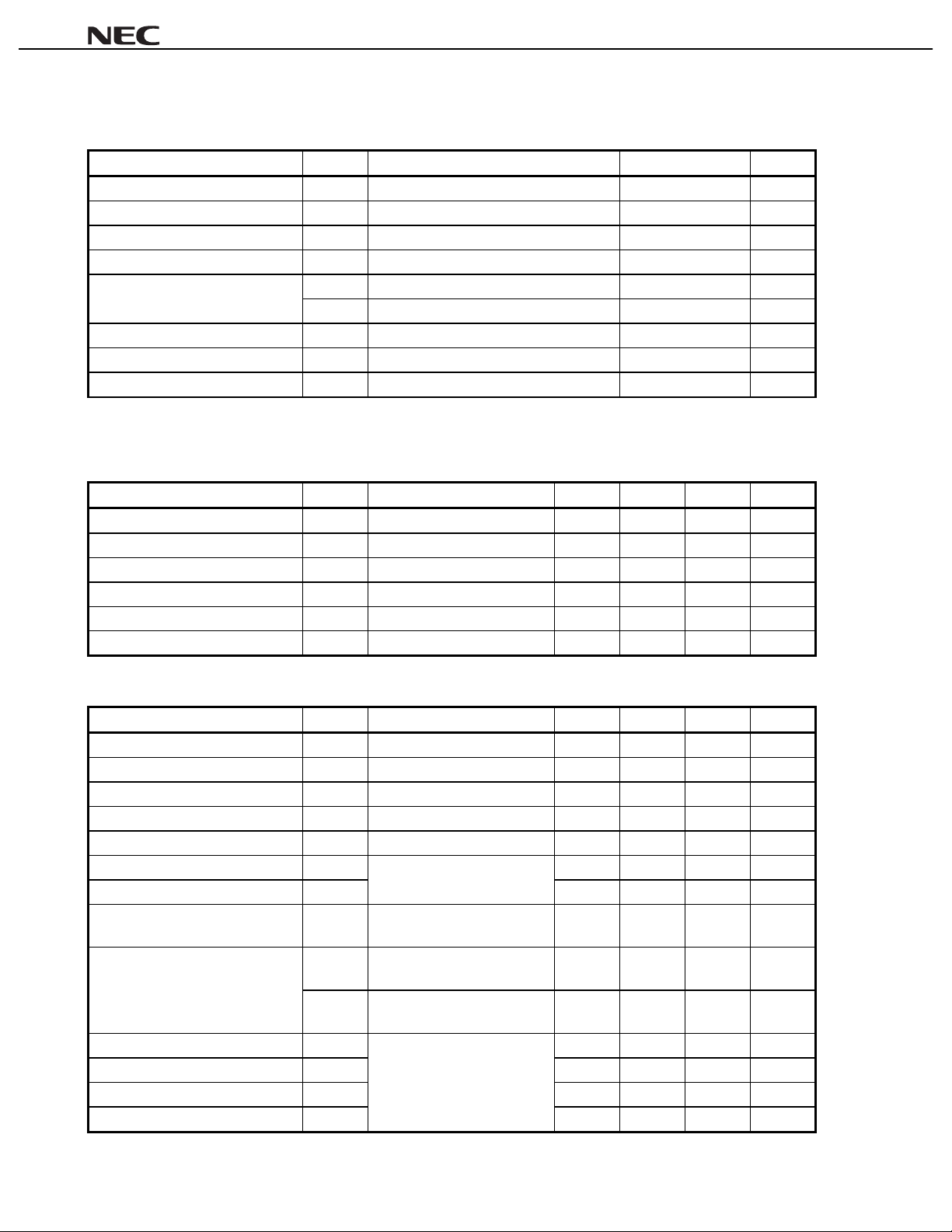

ABSOLUTE MAXIMUM RATINGS (TA = 25

When mounted on a glass epoxy board (10 cm

C)

°°°°

××××

Parameter Symbol Condition Rating Unit

Control block supply v ol t age V

Output block supply v ol tage V

Input voltage V

Output terminal voltage V

Output current

Power consumption P

Peak junction temperature T

Storage temperature range T

DD

M

IN

OUT

D(DC)

I

D(pulse)

I

T

CH(MAX)

stg

DC

PW ≤ 10 ms, Duty ≤ 5%

RECOMMENDED OPERATING CONDITIONS

When mounted on a glass epoxy board (10 cm

Parameter Symbol Condition MIN. TYP. MAX. Unit

Control block supply v ol t age V

Output block supply v ol tage V

Output current I

Operating frequency f

Operating temperature range T

Peak junction temperature T

DD

M

D(DC)

IN

A

CH(MAX)

××××

DC

IN, EN terminal 100 kHz

10 cm

10 cm

1 mm, 15% copper foil)

××××

1 mm, 15% copper foil)

××××

2.5 5.5 V

2.7 5.5 V

0.2 +0.2 A

−

10 85

−

0.5 to +6.0 V

−

0.5 to +6.0 V

−

DD

0.5 to V

−

+ 0.5 V

6.2 V

0.3 A/ch

±

0.7 A/ch

±

0.7 W

150

55 to +150

−

125

C

°

C

°

C

°

C

°

CHARACTERISTICS (Unless otherwise specified, VDD = VM = 3 V, TA = 25

Parameter Symbol Condition MIN. TYP. MAX. Unit

Off state VM pin current I

VDD pin current I

High level input current I

Low level input current I

Input pull down resistance R

High level input voltage V

Low level input voltage V

H-bridge ON resistance R

Low voltage malfunction

prevention circuit operati ng voltage

H bridge output turn-on time t

H bridge output turn-off time t

H bridge output rise time t

H bridge output fall time t

M(OFF)

DD

IH

IL

IND

IH

IL

ON

DDS1

V

DDS2

V

ONH

OFFH

r

f

All control terminal: L l evel 10

All control terminal: L l evel 10

DD

VIN = V

VIN = 0 V

1.0

−

50 200 k

DD

2.5 V ≤ VDD ≤ 5.5 V

0.7 × V

3.0 0.3 × V

−

2.5 V ≤ VM, VDD ≤ 5.5 V

Upper + lower

VM = 5 V

−10°C ≤

VM = 3 V

−10°C ≤

RM = 20

Figure 1

A

T

≤ +85°C

A

T

≤ +85°C

Ω

0.8 2.5 V

0.65 2.5 V

0.1 0.4 1.0

C)

°°°°

0.06 mA

VDD+0.3 V

3.0

0.7 20

0.2 0. 5

70 200 ns

A

µ

A

µ

A

µ

Ω

DD

V

Ω

s

µ

s

µ

s

µ

2

Data Sheet S13964EJ1V0DS00

Page 3

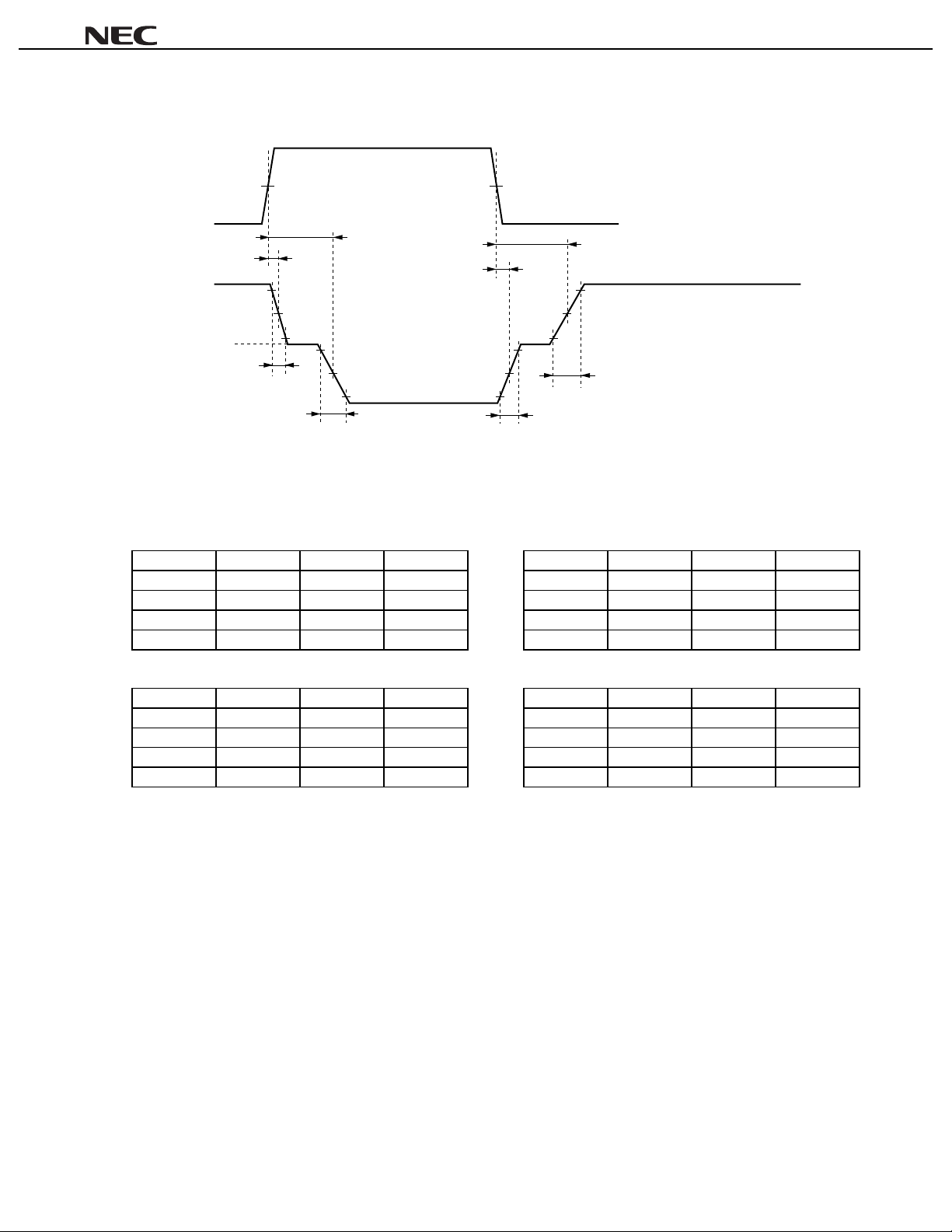

Figure 1. Switching time condition

100%

µµµµ

PD16877

50%

V

IN

50%

0%

t

ONH

t

OFFH

t

OFFH

t

ONH

100% 100%

90% 90%

50%

I

D

0%

t

10% 10%

−10%

f

−50% −50%

−90% −90%

t

r

−100%

50%

−10%

t

r

t

f

The current flowing in the direction from

A

to OUT_B is assumed to be (+).

OUT_

FUNCTION TABLE

Channel 1 Channel 2

1

EN

HLHL HLHL

HHLH HHLH

LLZZ LLZZ

LHZZ LHZZ

IN

1

OUT

1A

OUT

1B

EN

2

IN

2

OUT

2A

OUT

2B

Channel 3 Channel 4

3

EN

HLHL HLHL

HHLH HHLH

LLZZ LLZZ

LHZZ LHZZ

IN

3

OUT

3A

OUT

3B

EN

4

IN

4

OUT

4A

OUT

H: High-level, L: Low-level, Z: High impedance

4B

Data Sheet S13964EJ1V0DS00

3

Page 4

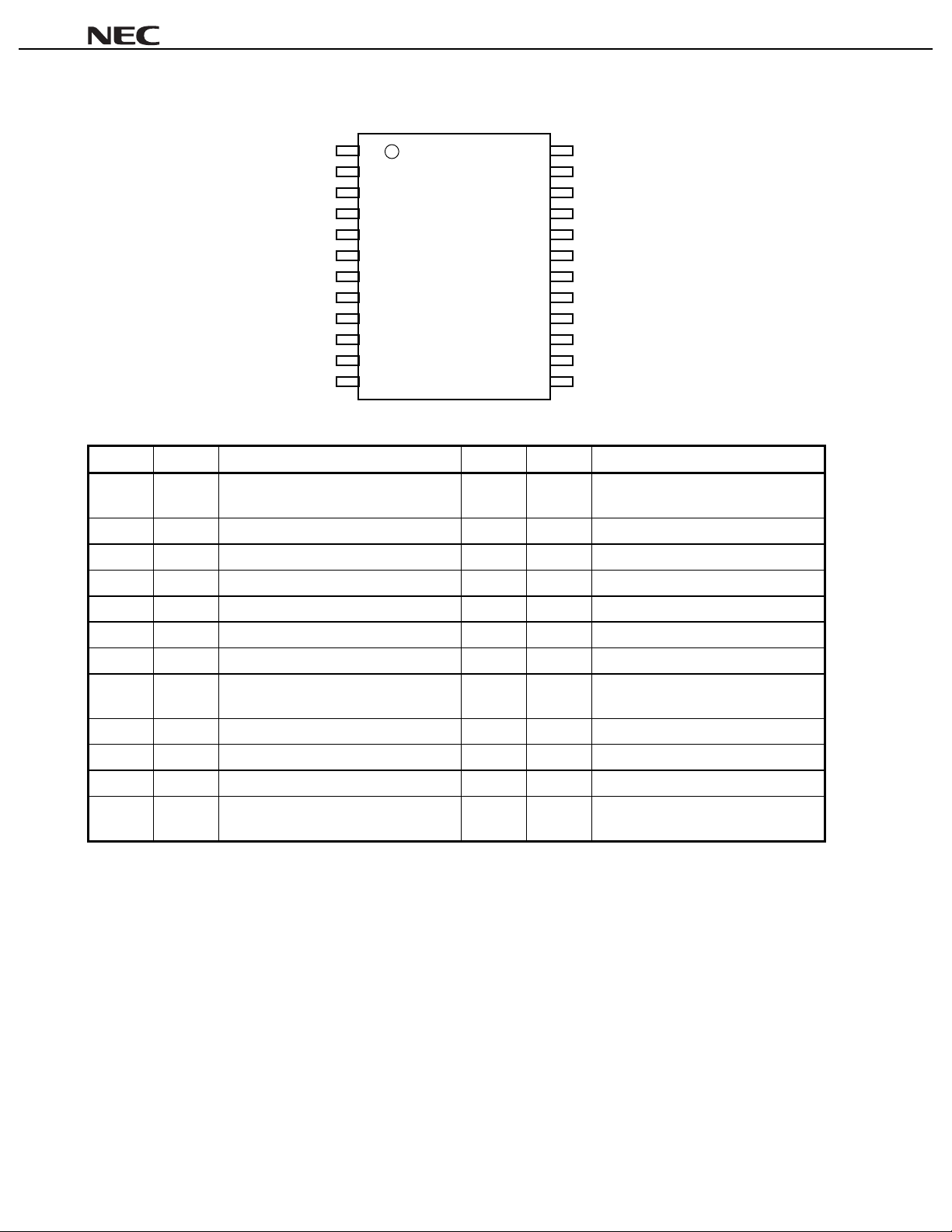

PIN CONNECTION

µµµµ

PD16877

V

OUT

PGND

OUT

OUT

PGND

OUT

V

IN

EN

IN

EN

M1

1

1A

2

3

2A

4

3A

5

6

4A

7

M4

8

1

9

1

10

2

11

2

12

24

23

22

21

20

19

18

17

16

15

14

13

V

DD

OUT

PGND

OUT

V

M23

OUT

PGND

OUT

EN

4

IN

4

EN

3

IN

3

1B

2B

3B

4B

Pin No. Pin name Pin function Pin No. Pin name Pin function

Output block supply v ol tage input

1V

M1

terminal

13 IN

2OUT1AOutput terminal 14 EN

3 PGND Ground terminal 15 IN

4OUT2AOutput terminal 16 EN

5OUT3AOutput terminal 17 OUT

3

Control terminal (channel 3)

3

Enable terminal (channel 3)

4

Control terminal (channel 4)

4

Enable terminal (channel 4)

4B

Output terminal

6 PGND Ground terminal 18 PGND Ground terminal

7OUT4AOutput terminal 19 OUT

Output block supply v ol tage input

8V

M4

terminal

20 V

9IN1Control terminal (channel 1) 21 OUT

10 EN

11 IN

12 EN

1

Enable terminal (channel 1) 22 PGND Ground terminal

2

Control terminal (channel 2) 23 OUT

2

Enable terminal (channel 2) 24 V

3B

Output terminal

Output block supply v ol tage input

M23

terminal

2B

Output terminal

1B

Output terminal

Control block supply v ol t age i nput

DD

terminal

4

Data Sheet S13964EJ1V0DS00

Page 5

BLOCK DIAGRAM

IN

9

EN

10

IN

11

EN

12

µµµµ

PD16877

24

V

Low volatge

DD

malfunction

prevention

circuit

V

M1

1

1

1

Control

circuit (1)

H-bridge

(1)

OUT

OUT

1A

2

1B

23

PGND

3

V

M23

20

2

2

circuit (2)

Control

H-bridge

(2)

OUT

OUT

2A

4

2B

21

13

14

15

16

IN

EN

IN

EN

PGND

22

3

Control

3

circuit (3)

H-bridge

(3)

OUT

OUT

3A

5

3B

19

PGND

6

V

M4

8

4

4

circuit (4)

Control

H-bridge

(4)

OUT

OUT

PGND

4A

7

4B

17

18

Remark

Plural terminal (V

M

, PGND) is not only 1 terminal and connect all terminals.

Data Sheet S13964EJ1V0DS00

5

Page 6

TYPICAL CHARACTERISTICS

µµµµ

PD16877

µ

Total power dissipation PT (W)

0.7

0.6

0.5

1.0

0.8

0.6

0.4

0.2

0

−10 0

T vs. TA characteristics

P

0.7W

20 40 60

Ambient temperature T

DD vs. VDD characteristics

I

178°C/W

80 100 120

A (°C)

T

control : "L"

A = 25°C

µ

OFF state VM Pin current IM (OFF) ( A)

µ

35

30

25

20

15

10

60

50

M (OFF) vs. VM characteristics

I

T

A = 25°C

control : "L"

5

0

Output block supply voltage V

IH, IIL vs. VDD characteristics

I

654321

M (V)

A = 25°C

T

VDD pin current IDD ( A)

Input voltage VIH, VIL (V)

0.4

0.3

0.2

0.1

4.0

3.0

2.0

1.0

0

Control block supply voltage V

IH, VIL vs. VDD characteristics

V

VIH, VIL

40

IH

I

30

Input current IIH IIL ( A)

20

10

IIL

654321

DD (V)

T

A = 25°CTA = 25°C

0

Control block supply voltage V

DDS vs. VM characteristics

V

654321

DD (V)

2.0

VDD (L H)

1.5

VDD (H L)

1.0

0.5

Low voltage detection voltage VDDS (V)

00

Control block supply voltage VDD (V)

6

654321

Data Sheet S13964EJ1V0DS00

654321

Output block supply voltage VM (V)

Page 7

µµµµ

PD16877

t

ONH

, t

OFFH

RON vs. VM characteristics

vs. VM characteristics

1.0

T

A

TA = 25°C

µ

3.0

(Ω)

ON

2.5

µ

( s)

ONH

( s)

OFFH

0.8

t

ONH

= 25°C

2.0

1.5

1.0

H-bridge ON resistance R

0.5

0

Output block supply voltage V

1.0

µ

0.8

µ

( s)

r

( s)

f

0.6

0.1

t

r

, tf vs. VM characteristics

t

r

654321

M

(V)

TA = 25°C

0.6

0.4

t

OFFH

0.2

H-bridge Output turn-on time t

H-bridge Output turn-off time t

0

Output block supply voltage V

M

654321

(V)

H-bridge Output rise time t

H-bridge Output fall time t

0.2

0

Output block supply voltage V

t

f

654321

M

(V)

Data Sheet S13964EJ1V0DS00

7

Page 8

STANDARD CONNECTION EXAMPLE

VDD = VM = 2.7 V to 5.5 V

DC/DC CONVERTER

1 to 10 F

µ

µµµµ

1 to 10 F

µ

PD16877

CPU

VDD

IN1

EN1

IN2

EN2

IN3

EN3

IN4

EN4

control

circuit

low voltage

malfunction

prevention

circuit

level

shift

circuit

VM4

V

H-bridge

(1)

H-bridge

(2)

H-bridge

(3)

H-bridge

(4)

M4VM2 3

PGND

OUT1A

OUT1B

PGND

OUT

PGND

OUT

OUT3B

PGND

OUT

OUT4B

motor1

2A

OUT2B

3A

motor2

4A

8

Data Sheet S13964EJ1V0DS00

Page 9

PACKAGE DIMENSION

24-PIN PLASTIC TSSOP (5.72 mm (225))

µµµµ

PD16877

24

13

detail of lead end

F

G

R

P

L

S

1

A

A'

12

E

H

I

J

S

C

K

SN

DM

NOTE

Each lead centerline is located within 0.10 mm of

its true position (T.P.) at maximum material condition.

M

B

ITEM MILLIMETERS

A

6.65±0.10

6.5±0.1

A'

0.575

B

0.5 (T.P.)

C

0.22±0.05

D

0.1±0.05

E

F

1.2 MAX.

1.0±0.05

G

6.4±0.1

H

I

4.4±0.1

1.0±0.1

J

0.145±0.025

K

L

0.5

0.10

M

0.08

N

P3°

R

S 0.6±0.15

+5°

−3°

0.25

S24MA-50-6A5

Data Sheet S13964EJ1V0DS00

9

Page 10

RECOMMENDED SOLDERING CONDITIONS

Solder this product under the following recommended conditions.

For soldering methods and conditions other than those recommended, consult NEC.

µµµµ

PD16877

For details of the recommended soldering conditions, refer to information document

Mounting Technology Manual”

Soldering Method Soldering Conditions

Package peak temperature: 235°C; Time: 30 secs. max. (210°C min.);

Infrared reflow

VPS

Wave soldering

Number of times: 3 tim es max; Number of day: none;

Flux: Rosin-based flux wi th little chlorine cont ent (chlorine: 0.2Wt% max.) is

recommended.

Package peak temperature: 215°C; Time: 40 secs. max. (200°C min.);

Number of times: 3 tim es max.; Number of day: none;

Flux: Rosin-based flux wi th little chlorine cont ent (chlorine: 0.2 Wt% max.) is

recommended.

Package peak temperature: 260°C; Time: 10 secs. max.;

Preheating temperature: 120°C max.; Number of tim e s: once;

Flux: Rosin-based flux wi th little chlorine cont ent (chlorine: 0.2 Wt% max.) is

recommended.

.

Caution Do not use two or more soldering methods in combination.

“Semiconductor Device

Recommended

Condition Symbol

IR35-00-3

VP15-00-3

WS60-00-1

10

Data Sheet S13964EJ1V0DS00

Page 11

NOTES FOR CMOS DEVICES

1 PRECAUTION AGAINST ESD FOR SEMICONDUCTORS

Note:

Strong electric field, when exposed to a MOS device, can cause destruction of the gate oxide and

ultimately degrade the device operation. Steps must be taken to stop generation of static electricity

as much as possible, and quickly dissipate it once, when it has occurred. Environmental control

must be adequate. When it is dry, humidifier should be used. It is recommended to avoid using

insulators that easily build static electricity. Semiconductor devices must be stored and transported

in an anti-static container, static shielding bag or conductive material. All test and measurement

tools including work bench and floor should be grounded. The operator should be grounded using

wrist strap. Semiconductor devices must not be touched with bare hands. Similar precautions need

to be taken for PW boards with semiconductor devices on it.

2 HANDLING OF UNUSED INPUT PINS FOR CMOS

Note:

No connection for CMOS device inputs can be cause of malfunction. If no connection is provided

to the input pins, it is possible that an internal input level may be generated due to noise, etc., hence

causing malfunction. CMOS devices behave differently than Bipolar or NMOS devices. Input levels

of CMOS devices must be fixed high or low by using a pull-up or pull-down circuitry. Each unused

DD

pin should be connected to V

being an output pin. All handling related to the unused pins must be judged device by device and

related specifications governing the devices.

or GND with a resistor, if it is considered to have a possibility of

µµµµ

PD16877

3 STATUS BEFORE INITIALIZATION OF MOS DEVICES

Note:

Power-on does not necessarily define initial status of MOS device. Production process of MOS

does not define the initial operation status of the device. Immediately after the power source is

turned ON, the devices with reset function have not yet been initialized. Hence, power-on does

not guarantee out-pin levels, I/O settings or contents of registers. Device is not initialized until the

reset signal is received. Reset operation must be executed immediately after power-on for devices

having reset function.

Data Sheet S13964EJ1V0DS00

11

Page 12

µµµµ

PD16877

• The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

• No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in

this document.

• NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property

rights of third parties by or arising from use of a device described herein or any other liability arising from use

of such device. No license, either express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of NEC Corporation or others.

• Descriptions of circuits, software, and other related information in this document are provided for illustrative

purposes in semiconductor product operation and application examples. The incorporation of these circuits,

software, and information in the design of the customer's equipment shall be done under the full responsibility

of the customer. NEC Corporation assumes no responsibility for any losses incurred by the customer or third

parties arising from the use of these circuits, software, and information.

• While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

• NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on a

customer designated "quality assurance program" for a specific application. The recommended applications of

a device depend on its quality grade, as indicated below. Customers must check the quality grade of each device

before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircraft, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

M7 98. 8

Loading...

Loading...