Page 1

DATA SHEET

MOS INTEGRATED CIRCUIT

µµµµ

PD16856

MONOLITHIC CD-ROM 3-PHASE SPINDLE MOTOR DRIVER

The µPD16856 is a CD-ROM 3-phase spindle motor driver consisting of a CMOS controller and MOS bridge

outputs.

By employing 3-phase full-wave PWM as the drive method and MOS FETs at the output stage, it has been

possible to reduce the power consumption of the µPD16856 ever further than the conventional linear drive drivers

that use bipolar transistors.

By using a 30-pin shrink SOP package, a more compact-size has been achieved.

FEATURES

• Supply voltage for controller block: 5 V, supply voltage for output block: 12 V

3 V input available for the input interface

• Low on-state resistance (total on-state resistance of upper and lower MOS FETs) RON = 1.3 Ω (TYP.)

• Low power consumption due to 3-phase full-wave PWM drive method

• On-chip hole bias switch (linked with STB pin)

• On-chip IND (FG) pulse switching function, 1-phase output or 3-phase composite output

• START/STOP pin included, acting as a brake during STOP

• Standby pins included, turning off internal circuit in standby

• Low current consumption: IDD = 3 mA (Max.), IDD

• On-chip thermal shutdown circuit

• On-chip current limiting circuit; reference voltage can be set externally

• On-chip low voltage malfunction prevention circuit

• On-chip reverse rotation prevention circuit

• 30-pin plastic shrink SOP (300 mil)

ORDERING INFORMATION

Part Number Package

µ

PD16856GS 30-pin shrink SOP (0.8-mm pi t ch, 300 mil)

(ST)

= 1 µA (Max.)

Document No. S13447EJ1V0DS00 (1st edition)

Date Published April 1999 N CP(K)

Printed in Japan

The information in this document is subject to change without notice.

©

1999

Page 2

µµµµ

PD16856

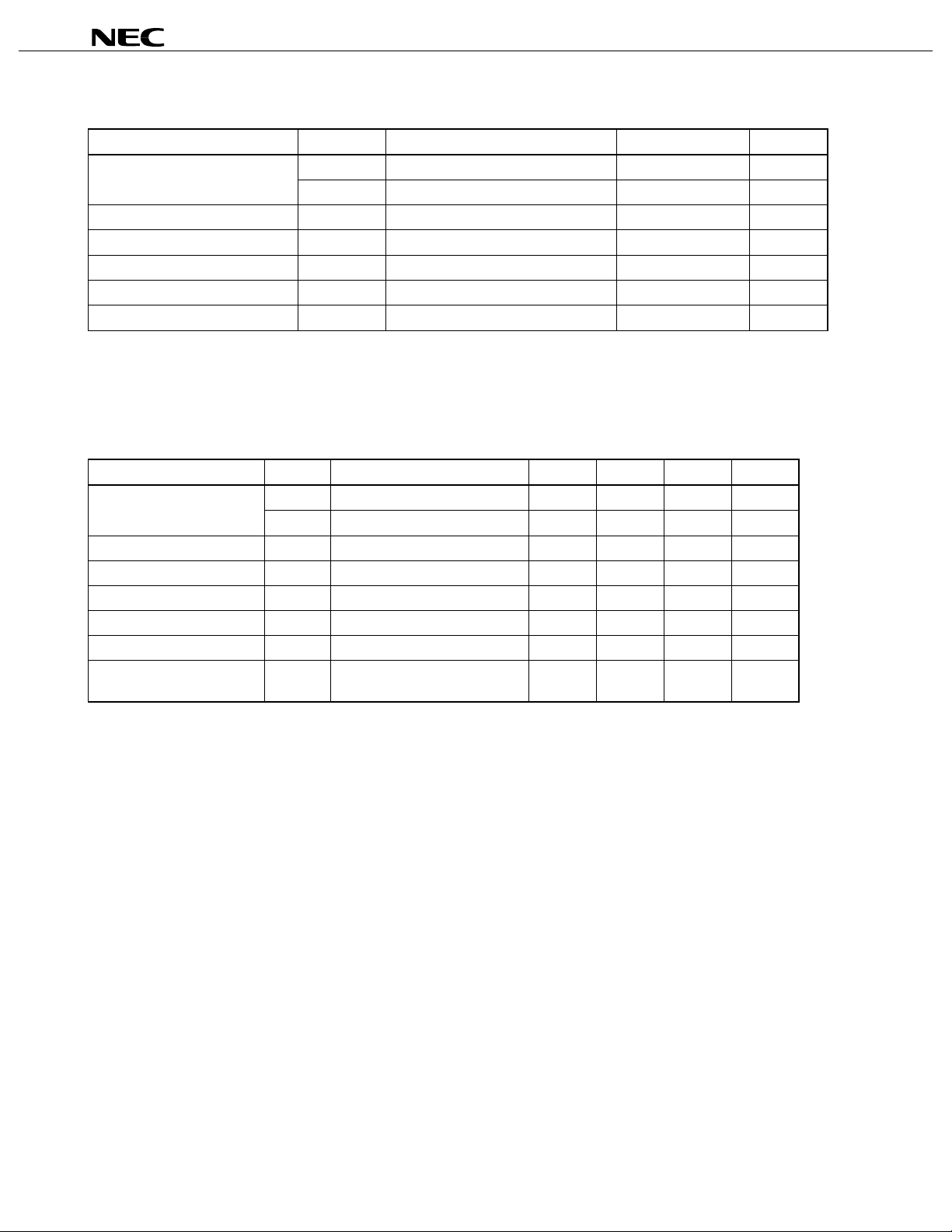

ABSOLUTE MAXIMUM RATINGS (TA = 25

Parameter Symbol Conditions Ratings Unit

DD

Supply voltage

Input voltage V

Instantaneous output c urrent

Power consumption

Note 2

Note 1

Peak channel temperature T

Storage temperature range T

Notes 1.

Allowable current per phase while on-board

When mounted on glass epoxy board (100 mm × 100 mm × 1 mm)

2.

V

M

V

IN

DR (pulse)

I

T

P

CH (MAX)

stg

RECOMMENDED OPERATING RANGE

Parameter Symbol Conditions MIN. TYP. MAX. Unit

DD

V

M

V

Output current (DC) I

Instantaneous output c urrent IDR

Hole bias current I

IND pin output current I

CL pin input voltage V

Operating temperature

range

DR (DC)

HB

FG

CL

A

T

(pulse)

PW ≤ 5 ms, Duty ≤ 10%

C)

°°°°

PW ≤ 5 ms, Duty ≤ 30%

0.5 to +6.0 V

−

0.5 to +13.5 V

−

DD

0.5 to V

−

+ 0.5 V

2.0 A/phase

±

1.0 W

150

55 to +150

−

4.5 5.0 5.5 VSupply voltage

10.8 12.0 13.2 V

0.5 A/Phase

±

1.5 A/Phase

±

10 15 mA

0

2.5

±

5mA

±

0.1 0.4 V

20 75

−

C

°

C

°

C

°

2

Data Sheet S13447EJ1V0DS00

Page 3

µµµµ

PD16856

ELECTRICAL SPECIFICATIONS (UNLESS OTHERWISE SPECIFIED, TA = 25

C, VDD = 5 V, VM = 12 V)

°°°°

Parameter Symbol Conditions MIN. TYP. MAX. Unit

[General]

Current consumption 1 (during operation) I

DD

Current consumption (in standby) IDD

(ST)

STB = V

STB = GND 1.0

DD

1.5 3.0 mA

[ST/SP, STB, REV, FGsel]

Input voltage, high V

Input voltage, low V

Input pull-down resistor R

IH

IL

IND

1.8 V

120 k

DD

0.8 V

[Controller block]

Triangle wave oscillation frequency f

PWM

CT = 100 pF 75 kHz

[Hole amplifier]

Common mode input voltage range V

Hysteresis volt age V

Input bias current I

Hch

Hhys

Hbias

1.0 3.5 V

VH = 2.5 V 15 mV

1.0

[Hole bias block]

Hole bias voltage V

HB

IHB = 10 mA 0.3 0.5 V

[FG output]

IND-pin voltage, high V

IND-pin voltage, low V

FG_H

FG_L

IFG = −2.5 mA 4.0 V

IFG = +2.5 mA 0.5 V

[Output block]

Output on-state resistance (upper stage +

lower stage)

Leakage current during OFF IDR

Output turn-on time t

Output turn-off time t

R

ONH

OFFH

ON

(OFF)

IDR = 200 mA

A

T

= −20°C to +75°C

1.3 1.8

In standby 10

RM = 5

Ω

Star connection

1.0 2.0

1.0 2.0

[Torque command]

Control reference input voltage range ECR 0.3 4.0 V

Control input voltage range EC 0.3 4.0 V

Input current I

Input voltage differenc e ECR-EC

IN

Note

DUTY = 100% 1.0 V

30 50

Dead zone (+) EC_d+ 1.5 V ≤ ECR ≤ 2.5 V 0 50 100 mV

Dead zone (−)EC_d

1.5 V ≤ ECR ≤ 2.5 V 0

−

50

−

100 mV

−

[Overcurrent detection bl ock]

Input offset volt age V

IO

15 +15 mV

−

A

µ

V

Ω

A

µ

Ω

A

µ

s

µ

s

µ

A

µ

Dead zone not included.

Note

Remarks 1.

The thermal shutdown circuit (T.S.D.) operates with T

The low-voltage malfunction prevention circuit (UVLO) operates with a voltage of 4 V

2.

CH

> 150°C.

Data Sheet S13447EJ1V0DS00

TYP

.

3

Page 4

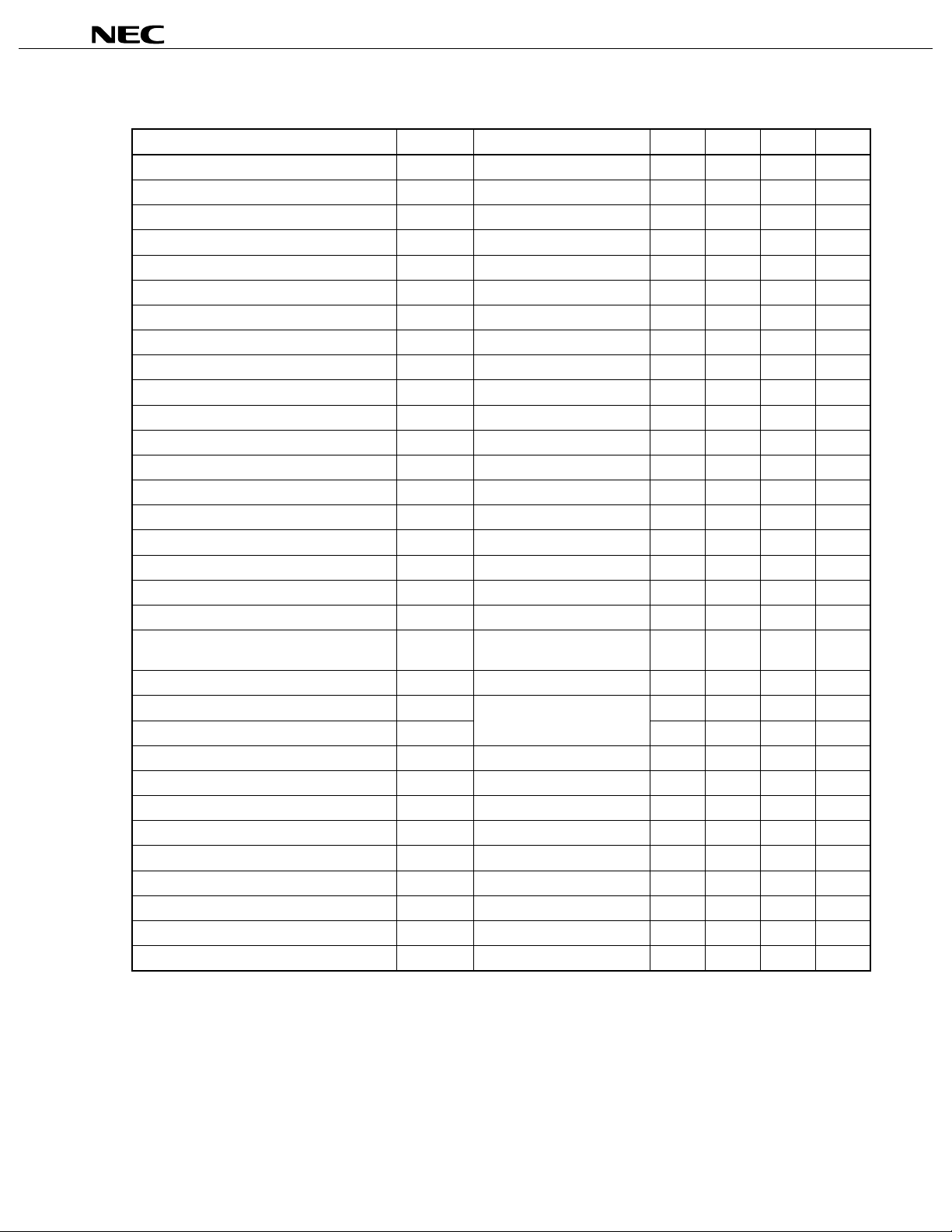

PIN FUNCTIONS

Package: 30-pin Shrink SOP (300 mil)

µµµµ

PD16856

IND

STB

V

V

OUT2

RF

RF

OUT1

V

V

OUT0

RF

RF

SEN

I

CL

1

2

3

M

4

M

5

6

7

8

9

M

10

M

11

12

13

14

15

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

EC

ECR

DD

V

CT

H2+

H2–

H1+

H1–

H0+

H0–

HB

FGsel

ST/SP

REV

GND

Pin No. Pin Name Pin Function

1 IND Index signal out put pin

2 STB Standby operation input pin

3V

4V

M

M

Supply input pin for motor block (12 V)

Supply input pin for motor block (12 V)

5 OUT2 Motor connection pin

6 RF 3-phase bridge common pin

7 RF 3-phase bridge common pin

8 OUT1 Motor connection pin

9V

10 V

M

M

Supply input pin for motor block (12 V)

Supply input pin for motor block (12 V)

11 OUT0 Motor connection pin

12 RF 3-phase bridge common pin

13 RF 3-phase bridge common pin

14 I

SEN

Sense resistor connection pin

15 CL Overcurrent detection voltage input pin

16 GND GND pin

17 REV Reverse rotation input pin (reverse brake pin)

18 ST/SP Start/stop input pin

19 FGsel IND pulse selection pin

20 HB Hole bias pin

21 H0

−

Hole signal input pin

22 H0+ Hole signal input pin

23 H1

−

Hole signal input pin

24 H1+ Hole signal input pin

25 H2

−

Hole signal input pin

26 H2+ Hole signal input pin

27 CT Oscillation frequency setup c apacitor connection pin

28 V

DD

Controller block supply i nput pi n (5 V)

29 ECR Control reference voltage input pi n

30 EC Control voltage input pin

Caution When there is more than one pin of the same kind of pin (VM and RF), all pins should be connected

to their targets.

4

Data Sheet S13447EJ1V0DS00

Page 5

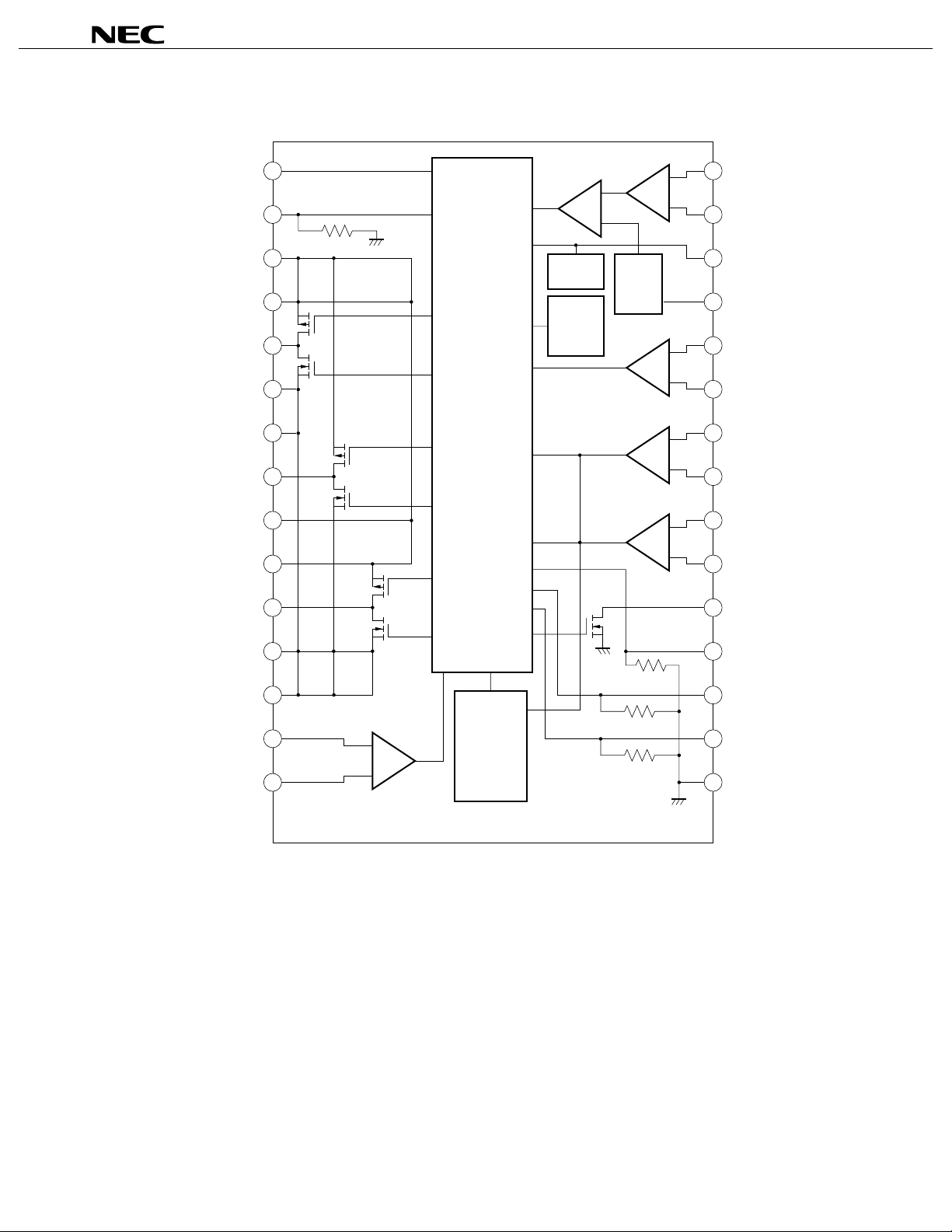

BLOCK DIAGRAM

µµµµ

PD16856

IND

STB

V

V

OUT2

RF

RF

OUT1

V

V

OUT0

RF

1

2

M

3

M

4

Q5

5

UVLO

T.S.D

OSC

+

30

29

28

27

26

EC

ECR

V

DD

C

T

H2+

Q6

6

Phase

–

25

H2–

excitation

pulse

7

generator

+

24

H1+

Q3

8

–

23

H1–

Q4

M

9

M

10

+

–

22

21

H0+

H0–

Q1

11

12

Q2

Ganged

with STB

20

19

HB

FGsel

I

RF

SEN

13

14

Reverse

rotation

18

17

ST/SP

REV

detection

CL

15

circuit

16

GND

Caution When there is more than one pin of the same kind of pin (VM and RF), all pins should be connected

to their targets.

Data Sheet S13447EJ1V0DS00

5

Page 6

TOTAL POWER DISSIPATION VS. AMBIENT TEMPERATURE CHARACTERISTICS

P

T

vs. TA Characteristics

1.4

While mounted on a 100 mm ×

100 mm × 1.0 mm glass epoxy board

1.2

µµµµ

PD16856

Remark

(W)

T

1.0

0.8

0.6

Total power dissipation P

0.4

0.2

0

–20 0 25 50 75 100 125 150

1.0 W

25˚C

125˚C/W

Ambient temperature T

75˚C

A

(˚C)

It is possible to apply a maximum of 1 W of power when the ambient temperature is 25°C or lower.

When the ambient temperature is higher than 25°C, derate based on the above chart.

It is possible to apply 0.6 W to the IC when the ambient temperature is 75°C, which is within recommended

ambient temperature conditions.

6

Data Sheet S13447EJ1V0DS00

Page 7

µµµµ

PD16856

STANDARD CHARACTERISTICS CURVES (UNLESS OTHERWISE SPECIFIED, TA = 25

IDD and IDD (ST) vs. VDD Characteristics

2.0

µ

1.0

Circuit current IDD (mA)

Circuit current in standby IDD (ST) ( A)

0

4.5 5.0 5.5

Controller block supply voltage VDD (V) Controller block supply voltage VDD (V)

2.0

IDD

IDD (ST)

VIH and VIL vs. VDD Characteristics

(ST/SP, REV, STB, and FGsel pins)

IIN vs. VDD Characteristics (EC and ECR pins)

50

µ

40

30

20

10

Torque command block input current IIN ( A)

0

4.5 5.0 5.5

20

IIN

VHhys vs. VDD Characteristics

(Hole Amplifier Input)

C)

°°°°

EC, ECR = 4 V

VH = 2.5 V

IL (V)

1.5

VIH

Input voltage, high VIH (V)

Input voltage, low V

1.0

4.5 5.0 5.5

100

50

PWM oscillation frequency fPWM (kHz)

VIL

Controller block supply voltage VDD (V)

fPWM vs. VDD Characteristics

fPWM

VIL

CT = 100 pF

15

Hole amplifier hysteresis voltage VHhys (mV)

10

4.5 5.0 5.5

Controller block supply voltage VDD (V)

RON vs. TA Characteristics

1.5

1.0

Output on-state resistance RON (Ω)

VHhys

VDD = 5 V

RON

0

4.5 5.0 5.5

Controller block supply voltage VDD (V)

Data Sheet S13447EJ1V0DS00

0.5

30 40 50 60 70

Operating ambient temperature T

A (V)

7

Page 8

FUNCTION OPERATION TABLE

(1) ST/SP = “H”

Input Signal Circuit Operation Mode Source → Sink

CMP0 CMP1 CMP2 PWM

H H L H Operation

HHL LBrake

H L L H Operation

HLLLBrake

H L H H Operation

HLHLBrake

L L H H Operation

LLHLBrake

L H H H Operation

LHHLBrake

L H L H Operation

LHLLBrake

Brake: Regenerates via the high-side Pch MOS FET channel.

(2) ST/SP = “L”

Input Signal Circuit Operation Mode

CMP0 CMP1 CMP2 PWM

−−−−

Short brake

Short brake: Turns the high-side MOS FET on and the low-side MOS FET off.

W → V

W → U

V → U

V → W

U → W

U → V

µµµµ

PD16856

(3) Torque Command

The curve shown below is the relationship to torque of the difference (ECR – EC) between the control reference

voltage (ECR) and the control voltage (EC).

Duty cycle

Normal direction torque

→ ECR–EC (+)(–)

–100%

Reverse direction torque

Stops after detecting reverse rotation

Note

The reverse drive current flows in the high-side Pch

MOS FET channel on reverse rotation.

Reverse Rotation Pin Volt age (REV)

LH

ECR > EC Normal rotation Reverse rotation

ECR < EC Reverse rotation

Note

Stop

100%

Note

8

Data Sheet S13447EJ1V0DS00

Page 9

µµµµ

PD16856

(4) Standby Mode

The setting of the standby mode allows the power supply in the device to be turned off forcibly.

The status of outputs from pins in standby is high impedance (H-bridge all OFF). In addition it is possible to

reduce the circuit current since the internal oscillation block stops.

When the stop operation is executed by the standby pin during normal operation, the motor is stopped by inertia

force.

When the normal status is reset, it takes several tens of

STB Pin Operation Mode

H Normal operation mode

L Standby mode

s to be activated.

µ

Data Sheet S13447EJ1V0DS00

9

Page 10

TIMING CHART

(1) Hole Signal Input

H

0

H

1

H

2

(2) CMP Signal (FGsel = L: IND1, FGsel = H: IND2)

µµµµ

PD16856

CMP0

CMP1

CMP2

IND1

IND2

(3) Selection of Output MOS FET Drive and Comparator (A Blank Indicates Switch OFF)

Q1 SW SW ON ON SW SW ON ON

Q2 SW SW SW SW

Q3 SW ON ON SW SW ON ON SW SW

Q4 SW SW SW SW SW

Q5 ON ON SW SW ON ON SW SW ON

Q6 SW SW SW SW

10

Data Sheet S13447EJ1V0DS00

Page 11

(4) Motor Drive Waveform

PWMOUT0 PWM

µµµµ

PD16856

PWM

PWMOUT1 PWM

PWMOUT2 PWM

Data Sheet S13447EJ1V0DS00

11

Page 12

APPLICATION CIRCUIT EXAMPLE

5 V

µµµµ

PD16856

+

µµ

15 F

controller

controller

EC

ECR

30

29

DD

V

28

UVLO

200 Ω

100 pF

CTH2+

27

OSC

HW

26

T.S.D

HU

HV

CPU

CPU

CPU

200 Ω

H2–

H1+

H1–

H0+

H0–

HB

FGsel

ST/SP

REV

GND

25

24

23

22

21

20

19

18

17

16

+

–

+

–

+

–

pulse

Phase

excitation

generator

Ganged

with STB

rotation

Reverse

detection

circuit

Remark

Q1

Q2

Q4

Q3

Q5

Q6

5

6

7

RF

RF

OUT2

Motor W phase

8

9

MVM

V

OUT1

Motor V

phase

10

11

OUT0

Motor U

phase

12

RF

13

RF

1.8 kΩ

FIL

R

14

SEN

I

330 pF

S

R

15

CL

FIL

C

CL

V

0.3 V

0.3 Ω

12 V

+

47 F

1

2

IND

STB

CPU

controller

3

MVM

V

4

To eliminate noise during PWM, it is recommended to insert a tantalum capacitor between VM and GND

(47

F in the above figure).

µ

Moreover, set VCL and RS to values within the ratings.

This circuit is for reference only and is not intended for use in mass production.

12

Data Sheet S13447EJ1V0DS00

Page 13

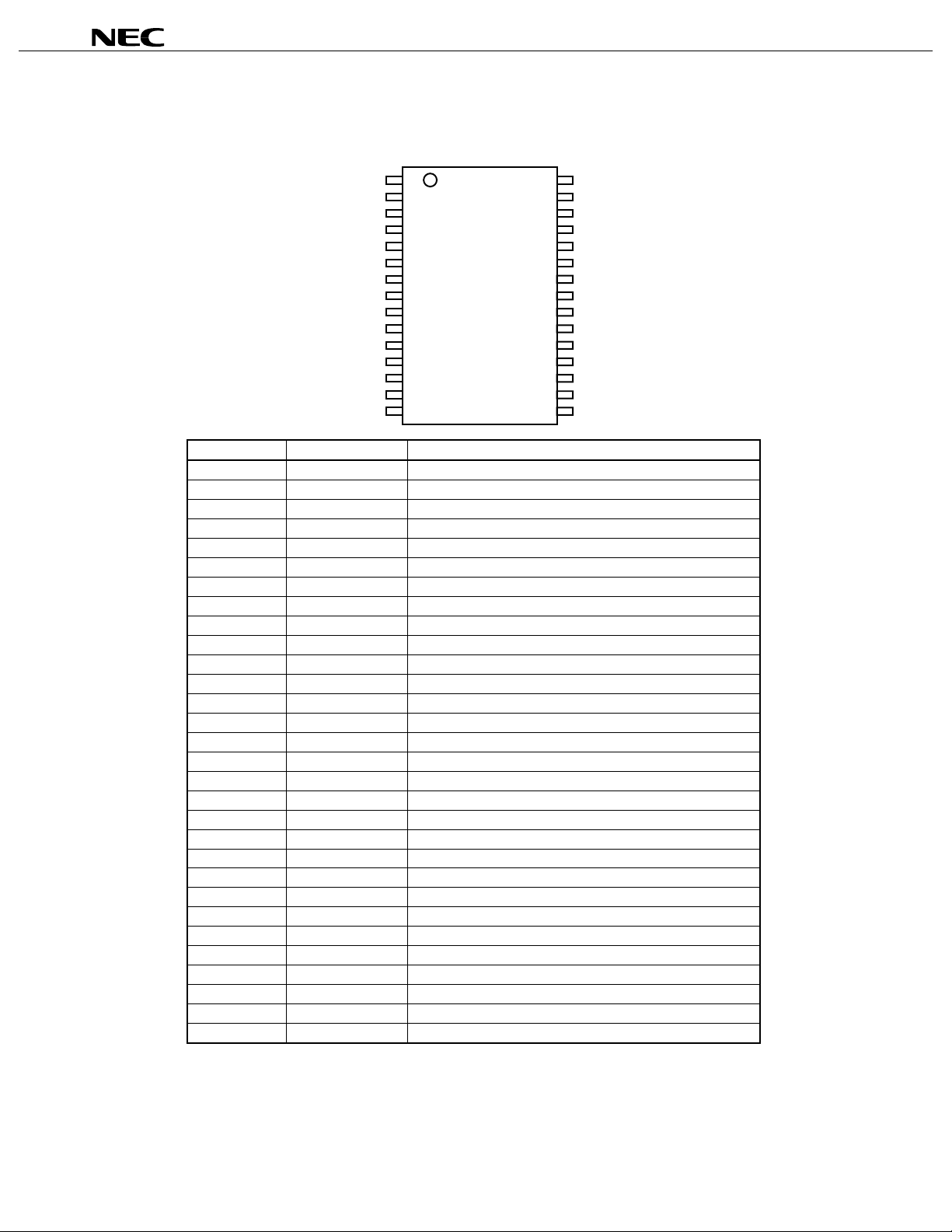

PACKAGE DRAWING

30-Pin Plastic Shrink SOP (300 mil) (Unit: mm)

30

16

Detail of lead end

+7

-3

3˚

µµµµ

PD16856

115

1.55±0.1

1.8 MAX.

0.1±0.1

0.8

0.35

13.0 MAX.

+0.10

–0.05

0.10

+0.10

0.9 MAX.

0.10

M

–0.05

0.20

0.6±0.2

7.7±0.3

5.6±0.2

1.05±0.2

Data Sheet S13447EJ1V0DS00

13

Page 14

µµµµ

RECOMMENDED SOLDERING CONDITIONS

PD16856 should be soldered and mounted under the following recommended conditions. For soldering methods

µ

and conditions other than those recommended below, contact your NEC sales representative.

PD16856

For the details of the recommended soldering conditions, refer to the document

•

Technology Manual (C10535E)

Soldering Method Soldering Conditions Recommended

Infrared reflow Package peak temperat ure: 235°C, Time: 30 sec. Max. (at 210°C or higher),

Count: three times or less, Exposure limit: none

with little chlorine c ontent (chlorine: 0.2 Wt% Max.) is recommended

VPS Package peak temperature: 215°C, Time: 40 sec. Max. (at 200°C or higher),

Count: three times or less, Exposure limit: none

with little chlorine c ontent (chlorine: 0.2 Wt% Max.) is recommended

Wave soldering Package peak temperature: 260°C, Time: 10 sec. Max . , Proheating

temperature: 120°C Max., Count: once, Fl ux: Rosin-based flux with l i t tle

chlorine content (chlorine: 0.2 Wt% Max.) is recommended

After opening the dry pack, store it at 25°C or less and 65% RH or less for the allowable storage period.

Note

.

Note

, Flux: Rosin-based flux

Note

, Flux: Rosin-based flux

Semiconductor Device Mounting

Condition Symbol

IR35-00-3

VP15-00-3

WS60-00-1

Caution Do not use different soldering methods together.

14

Data Sheet S13447EJ1V0DS00

Page 15

µµµµ

PD16856

Regional Information

Some information contained in this document may vary from country to country. Before using any NEC

product in your application, pIease contact the NEC office in your country to obtain a list of authorized

representatives and distributors. They will verify:

•

Device availability

•

Ordering information

•

Product release schedule

•

Availability of related technical literature

•

Development environment specifications (for example, specifications for third-party tools and

components, host computers, power plugs, AC supply voltages, and so forth)

•

Network requirements

In addition, trademarks, registered trademarks, export restrictions, and other legal issues may also vary

from country to country.

NEC Electronics Inc. (U.S.)

Santa Clara, California

Tel: 408-588-6000

800-366-9782

Fax: 408-588-6130

800-729-9288

NEC Electronics (Germany) GmbH

Duesseldorf, Germany

Tel: 0211-65 03 02

Fax: 0211-65 03 490

NEC Electronics (UK) Ltd.

Milton Keynes, UK

Tel: 01908-691-133

Fax: 01908-670-290

NEC Electronics Italiana s.r.l.

Milano, Italy

Tel: 02-66 75 41

Fax: 02-66 75 42 99

NEC Electronics (Germany) GmbH

Benelux Office

Eindhoven, The Netherlands

Tel: 040-2445845

Fax: 040-2444580

NEC Electronics (France) S.A.

Velizy-Villacoublay, France

Tel: 01-30-67 58 00

Fax: 01-30-67 58 99

NEC Electronics (France) S.A.

Spain Office

Madrid, Spain

Tel: 91-504-2787

Fax: 91-504-2860

NEC Electronics (Germany) GmbH

Scandinavia Office

Taeby, Sweden

Tel: 08-63 80 820

Fax: 08-63 80 388

NEC Electronics Hong Kong Ltd.

Hong Kong

Tel: 2886-9318

Fax: 2886-9022/9044

NEC Electronics Hong Kong Ltd.

Seoul Branch

Seoul, Korea

Tel: 02-528-0303

Fax: 02-528-4411

NEC Electronics Singapore Pte. Ltd.

United Square, Singapore 1130

Tel: 65-253-8311

Fax: 65-250-3583

NEC Electronics Taiwan Ltd.

Taipei, Taiwan

Tel: 02-2719-2377

Fax: 02-2719-5951

NEC do Brasil S.A.

Electron Devices Division

Rodovia Presidente Dutra, Km 214

07210-902-Guarulhos-SP Brasil

Tel: 55-11-6465-6810

Fax: 55-11-6465-6829

J99.1

Data Sheet S13447EJ1V0DS00

15

Page 16

µµµµ

PD16856

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in this

document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a device described herein or any other liability arising

from use of such device. No license, either express, implied or otherwise, is granted under any patents,

copyrights or other intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on

a customer designated "quality assurance program" for a specific application. The recommended applications

of a device depend on its quality grade, as indicated below. Customers must check the quality grade of each

device before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

Anti-radioactive design is not implemented in this product.

M4 96. 5

Loading...

Loading...