Page 1

DATA SHEET

MOS INTEGRATED CIRCUIT

µ

PD16833A

MONOLITHIC QUAD H BRIDGE DRIVER CIRCUIT

DESCRIPTION

The µPD16833A is a monolithic quad H bridge driver IC which uses power MOS FETs in its driver stage. By using the

MOS FETs in the output stage, this driver IC has a substantially improved saturation voltage and power consumption as

compared with conventional driver circuits using bipolar transistors.

A low-voltage malfunction prevention function is provided to prevent the IC from malfunctioning when the supply voltage

drops. By eliminating the charge pump circuit, the current during power-OFF is drastically decreased.

As the package, a 30-pin plastic shrink SOP is employed to enable the creation of compact, slim application sets.

This driver IC can drive two stepping motors at the same time, and is ideal for driving stepping motors in the lens of a

video camera.

FEATURES

• Four H bridge circuits employing power MOS FETs

• Low current consumption by eliminating charge pump

VM pin current when power-OFF: 10 µA MAX. VDD pin current: 10 µA MAX.

• Input logic frequency: 100 kHz

• 3-V power supply

Minimum operating supply voltage: 2.5 V

• Low-voltage malfunctioning prevention circuit

µ

• 30-pin plastic shrink SOP (300 mil) (

PD16833AG3)

ORDERING INFORMATION

Part Number Package

µ

PD16833AG3 30-pin plastic shrink SOP (300 mil)

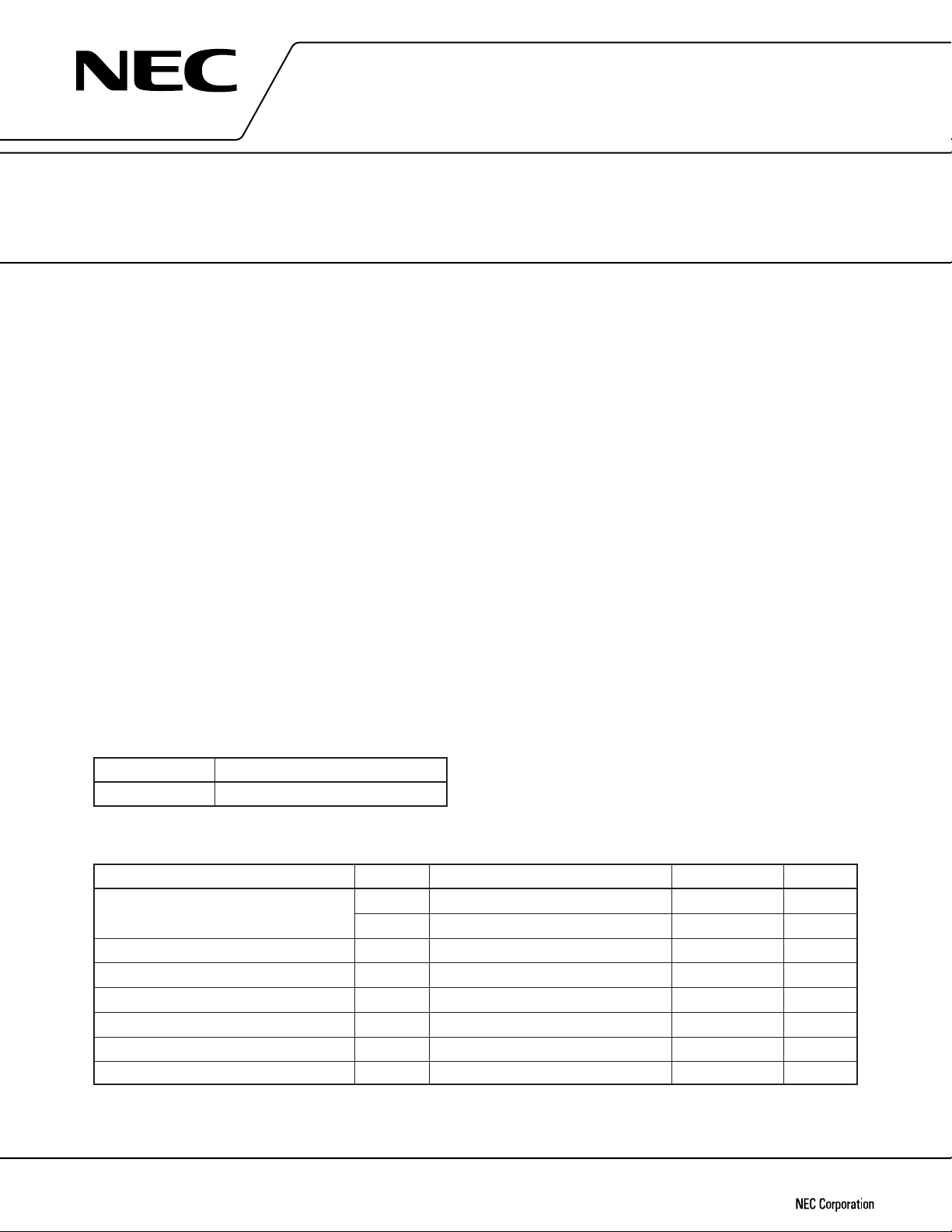

ABSOLUTE MAXIMUM RATINGS (TA = 25 °C)

Parameter Symbol Conditions Rating Unit

Supply voltage VDD –0.5 to +6.0 V

VM –0.5 to +6.0 V

Input voltage VIN –0.5 to VDD + 0.5 V

Note 2

Note 1

IDR (DC) DC ±300 mA

Note 1

The information in this document is subject to change without notice.

IDR (pulse) PW ≤ 10 ms, Duty ≤ 5 % ±700 mA

PT 1.19 W

H bridge drive current

Instantaneous H bridge drive current

Power dissipation

Peak junction temperature TCH (MAX) 150 °C

Storage temperature range Tstg –55 to +150 °C

Notes 1. Permissible current per phase, when mounted on a printed circuit board

2. When mounted on a glass epoxy board (10 cm × 10 cm × 1 mm)

Document No. S13147EJ1V0DS00 (1st edition)

Date Published January 1998 N CP(K)

Printed in Japan

©

1998

Page 2

µ

PD16833A

Recommended Operating Conditions

Parameter Symbol MIN. TYP. MAX. Unit

Supply voltage VDD 2.5 5.5 V

VM 2.7 5.5 V

H bridge drive current IDR –200 200 mA

Logic input frequency

Operating temperature range TA –10 85 °C

Peak junction temperature TCH (MAX) 125 °C

Note

fIN 100 kHz

Note Common to IN and EN pins

DC Characteristics (Unless otherwise specified, VDD = VM = 3.0 V, TA = 25 °C)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

OFF VM pin current IM (OFF) with all control pins at low level 10

VDD pin current IDD with all control pins at low level 10

High-level input current IIH VIN =VDD 0.06 mA

Low-level input current IIL VIN = 0 –1.0

Input pull-down resistor RIND 50 200 kΩ

High-level input voltage VIH VDD = 2.5 V to 5.5 V VDD × 0.7 VDD + 0.3 V

Low-level input voltage VIL VDD = 2.5 V to 5.5 V –0.3 VDD × 0.3 V

H bridge ON resistance

Low-voltage malfunction

prevention circuit operating voltage

Note

RON VDD = VM = 2.7 V to 5.5 V 3.0 Ω

VDDS1 VM = 5.0 V 0.8 2.5 V

–10 °C ≤ TA ≤ +85 °C

VDDS2 VM = 3.0 V 0.65 2.5 V

–10 °C ≤ TA ≤+85 °C

µ

A

µ

A

µ

A

Note Sum of top and bottom ON resistances (@IDR = 100 mA)

AC Characteristics (Unless otherwise specified, VDD = VM = 3.0 V, TA = 25 °C)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

H bridge output circuit turn-ON tONH RM = 20 Ω, Figure 1 0.7 20

time

H bridge output circuit turn-OFF tOFFH 0.2 0.5

time

Rise time tr 0.1 0.4 1.0

Fall time tf 70 200 ns

2

µ

A

µ

A

µ

s

Page 3

µ

PD16833A

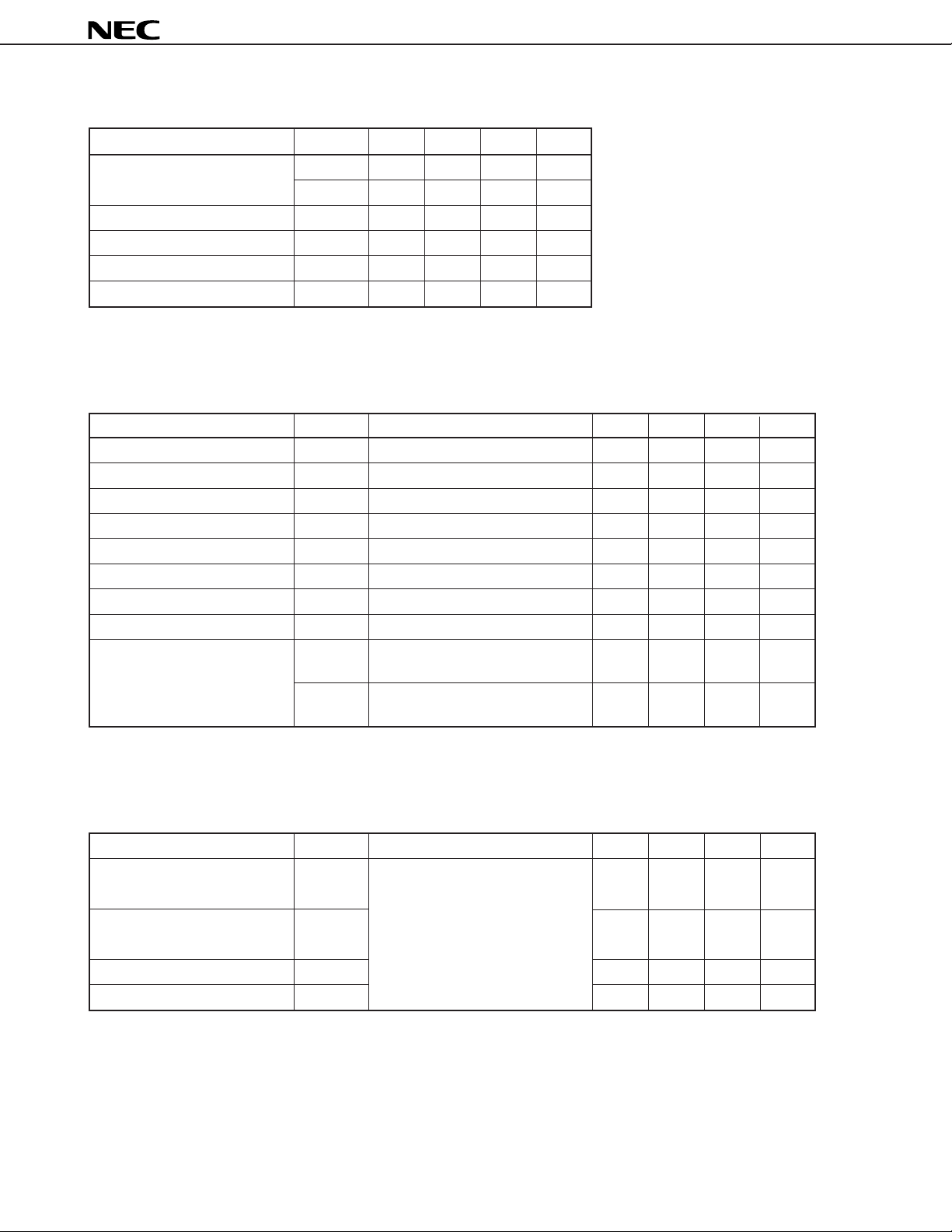

FUNCTION TABLE

Channel 1 Channel 2

EN1 IN1 OUT1A OUT1B EN2 IN2 OUT2A OUT2B

HLH L HLH L

HHL H HHL H

LLZ Z LLZ Z

LHZ Z LHZ Z

Channel 3 Channel 4

EN3 IN3 OUT3A OUT3B EN4 IN4 OUT4A OUT4B

HLH L HLH L

HHL H HHL H

LLZ Z LLZ Z

LHZ Z LHZ Z

H: High level, L: Low level, Z: High impedance IN

PIN CONFIGURATION

NC

1

NC

2

VDD

3

VM1

4

1A

5

PGND

PGND

2A

3A

4A

VM4

IN1

EN1

IN2

EN2

6

7

8

9

10

11

12

13

14

15

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

NC

NC

DGND

NC

1B

PGND

2B

VM2, 3

3B

PGND

4B

EN4

IN4

EN3

IN3

3

Page 4

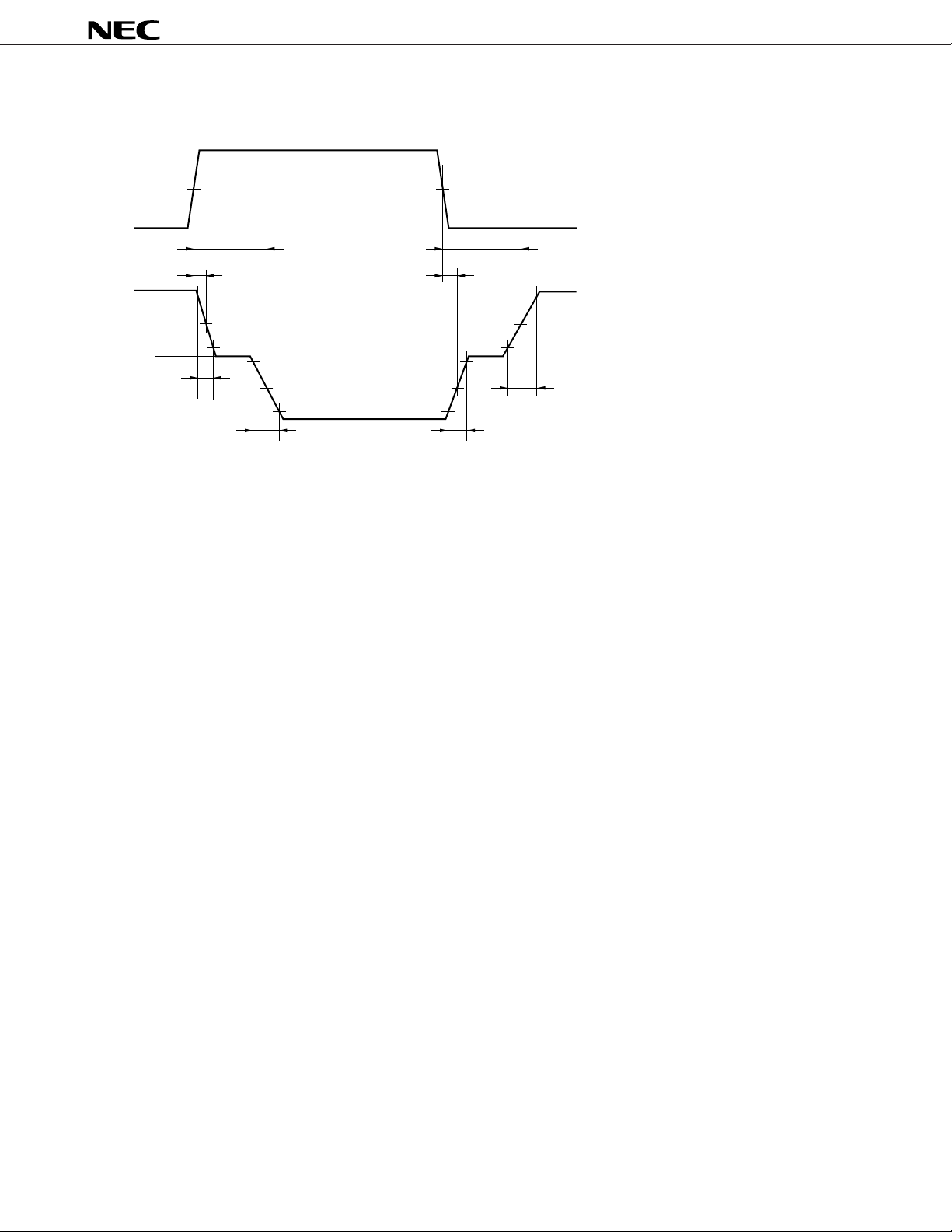

Figure 1. Switching Characteristic Wave

100 %

µ

PD16833A

V

IN

50 % 50 %

0 %

t

t

ON

t

100 %

OFF

90 %

I

DR

0 %

50 %

10 %

–10 %

t

f

–50 % –50 %

–90 % –90 %

t

r

–100 %

ON

t

OFF

100 %

90 %

50 %

10 %

–10 %

t

r

The current flowing in the direction from

OUT_A to OUT_B is assumed to be (+).

f

t

4

Page 5

BLOCK DIAGRAM

µ

PD16833A

IN

EN

EN

NC V

NCNCNCNC

DD

133029272

Low-voltage

malfunction

prevention

circuit

1

12

Control circuit

13

1

H bridge

1

DGND

14

IN

2

Control circuit

15

2

H bridge

2

26

23

24

V

M1

4

1A

5

1B

PGND

6

V

M2, 3

2A

7

2B

IN

EN

IN

EN

DGND

DGND

16

3

Control circuit

17

3

H bridge

3

DGND

18

4

Control circuit

19

4

H bridge

4

28

25

22

11

10

20

21

PGND

8

3A

3B

9

PGND

M4

V

4A

4B

PGND

5

Page 6

6

DD

= VM = 2.7 V to 5.5 V

V

STANDARD CONNECTION EXAMPLE

DC/DC Converter

µ

µ

1 to 10 F

1 to 10 F

Battery

V

M4

V

M2, 3

V

CPU

V

IN

EN

IN

EN

IN

EN

IN

EN

M1

DD

Low-voltage

H bridge 1

malfunction

1

1

2

2

Control

circuit

3

3

4

4

prevention

circuit

Level

shift

circuit

H bridge 2

H bridge 3

H bridge 4

PGND

PGND

PGND

1A

1B

Motor 1

2A

2B

3A

3B

Motor 2

4A

4B

GND

DGND

PGND

µ

PD16833A

Page 7

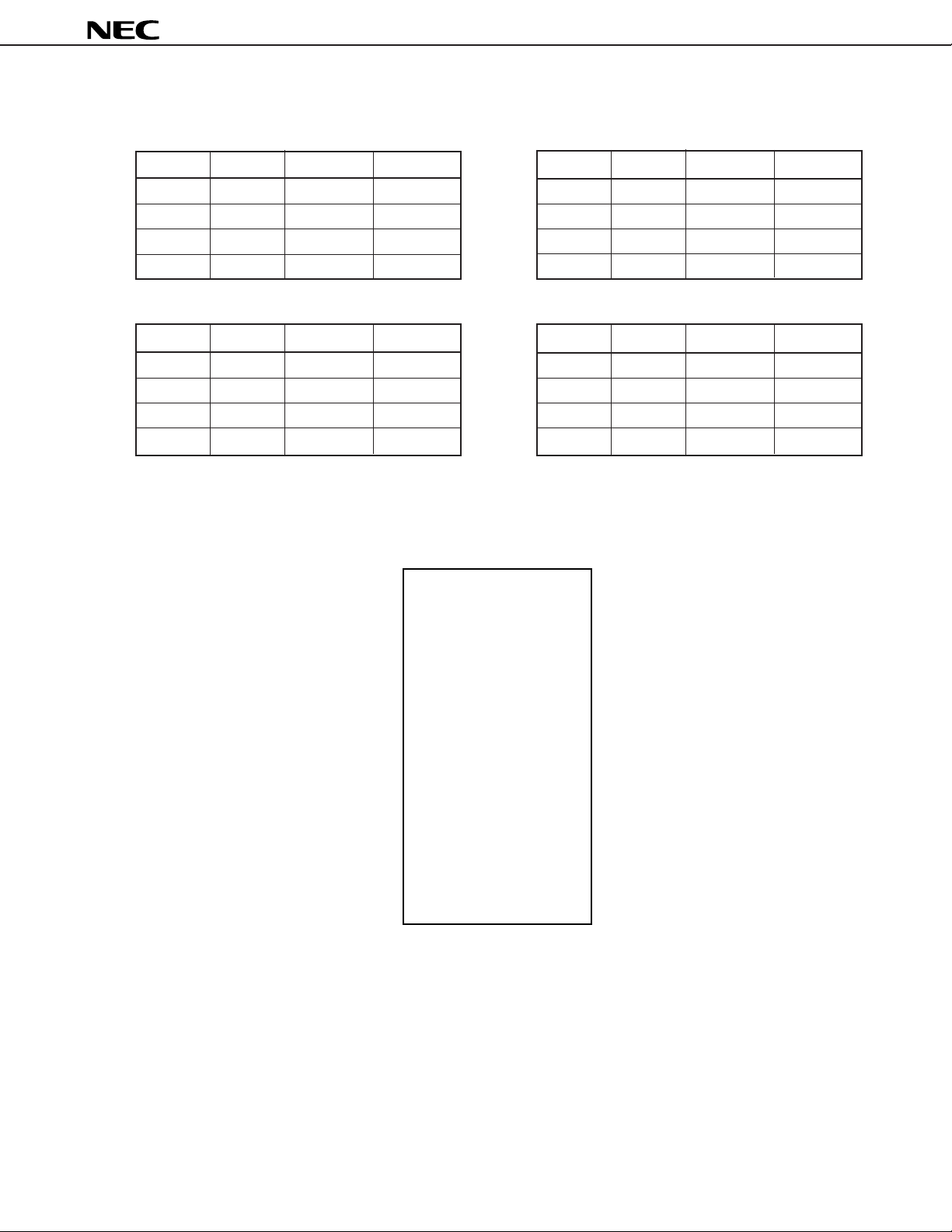

TYPICAL CHARACTERISTICS (TA = 25 °C)

T

vs. TA characteristics

P

1.4

1.2

1.0

(W)

T

0.8

0.6

0.4

Total power dissipation P

0.2

1.19 W

20

µ

( A)

M (OFF)

10

pin current I

M

OFF V

I

M (OFF)

vs. VM characteristics

µ

PD16833A

All control pins at

low level

T

A

= 25 °C

0

–10 0 40 60 80 100 120

Ambient temperature TA (°C) Output block supply voltage VM (V)

IIH/IIL vs. VIN characteristics

100

TA = 25 °C

80

µ

( A)

60

IL

/I

IH

IH

I

40

20

Input current I

I

0

1234

IL

Input voltage V

567

IN

(V)

0

123456

IH/VIL

vs. VDD characteristics

V

T

A

= 25 °C

3

V

(V)

IL

/V

IH

IH

V

IL

2

Input voltage V

1

1234567

Control block supply voltage VDD (V)

7

7

Page 8

200

(kΩ)

150

IND

100

Input pull-down resistor R

50

R

IND

vs. VDD characteristics

TA = 25 °C

(V)

DDS

Low voltage detection voltage V

µ

PD16833A

V

DDS

vs. VM characteristics

3

T

A

= 25 °C

2

1

0

1234 567

DD

Control block supply voltage V

(V)

RON vs. VM characteristics

3

T

A

= 25 °C

I

DR

= 100 mA

(Ω)

ON

2

1

Output ON resistor R

0

234567

1

M

Output block supply voltage V

(V)

0

1234567

M

Output block supply voltage V

R

ON

vs. TA characteristics

(V)

3

M

= 3.5 V

V

I

DR

= 100 mA

(Ω)

ON

2

1

Output ON resistor R

0

–25 0 25 50 75 100

A

Ambient temperature T

(°C)

8

Page 9

µ

PD16833A

Switching time vs. VDD/VM characteristics

1000

800

(ns)

f

/t

r

/t

600

OFF

/t

ON

400

200

Switching time t

0

123456

Supply voltage VDD/VM (V)

RM = 20 Ω

T

A

= 25 °C

ON

t

t

OFF

t

r

t

f

Switching time vs. TA characteristics

1000

DD

= VM = 3 V

V

R

M

= 20 Ω

800

(ns)

f

/t

r

/t

OFF

/t

ON

600

t

ON

t

r

400

t

200

Switching time t

0

7

0

–25 0 25 50 75 100

OFF

t

f

Ambient temperature TA (°C)

9

Page 10

PACKAGE DIMENSION

30 PIN PLASTIC SHRINK SOP (300 mil)

µ

PD16833A

30

115

A

G

F

E

C

D

M

M

N

NOTE

Each lead centerline is located within 0.10

mm (0.004 inch) of its true position (T.P.) at

maximum material condition.

16

detail of lead end

–3°

+7°

3°

H

I

K

B

L

ITEM MILLIMETERS INCHES

A

B

10.11 MAX.

0.51 MAX.

J

P30GS-65-300B-1

0.398 MAX.

0.020 MAX.

C

D

E

F

G

H

I

J

K

L

M

N

0.65 (T.P.)

+0.10

0.30

–0.05

0.125±0.075

2.0 MAX.

1.7±0.1

8.1±0.2

6.1±0.2

1.0±0.2

+0.10

0.15

–0.05

0.5±0.2

0.10

0.10

0.026 (T.P.)

+0.004

0.012

–0.003

0.005±0.003

0.079 MAX.

0.067±0.004

0.319±0.008

0.240±0.008

+0.009

0.039

–0.008

+0.004

0.006

–0.002

+0.008

0.020

–0.009

0.004

0.004

10

Page 11

µ

PD16833A

RECOMMENDED SOLDERING CONDITIONS

It is recommended to solder this product under the conditions described below.

For soldering methods and conditions other than those listed below, consult NEC.

For the details of the recommended soldering conditions of this type, refer to the Semiconductor Device Mounting

Technology Manual (C10535E).

Soldering Method Soldering Conditions

Infrared reflow

VPS

Wave soldering

Peak package temperature: 235 °C, Time: 30 seconds MAX. (210 °C MIN.),

Number of times: 3 MAX., Number of days: None

flux with little chlorine content (chlorine: 0.2 Wt% MAX.) is recommended.

Peak package temperature: 215 °C, Time: 40 seconds MAX. (200 °C MIN.),

(200 °C MIN.), Number of times: 2 MAX., Number of days: None

Flux: Rosin-based flux with little chlorine content (chlorine: 0.2 Wt% MAX.)

is recommended.

Soldering bath temperature: 260 °C MAX., Time: 10 seconds MAX.,

Preheating temperature: 120 °C MAX.,

Number of times: 1, Flux: Rosin-based flux with little chlorine content

(chlorine: 0.2 Wt% MAX.) is recommended.

Note

, Flux: Rosin-based

Note

,

Note The number of storage days at 25 °C, 65% RH after the dry pack has been opened

Caution Do not use two or more soldering methods in combination.

Symbol of Recommended

Soldering

IR35-00-3

VP15-00-2

WS60-00-1

11

Page 12

µ

PD16833A

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in

this document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property

rights of third parties by or arising from use of a device described herein or any other liability arising from use

of such device. No license, either express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on a

customer designated "quality assurance program" for a specific application. The recommended applications of

a device depend on its quality grade, as indicated below. Customers must check the quality grade of each device

before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

Anti-radioactive design is not implemented in this product.

M4 96.5

2

Loading...

Loading...