Page 1

DATA SHEET

MOS INTEGRATED CIRCUIT

µ

PD16808

MONOLITHIC DUAL H BRIDGE DRIVER CIRCUIT

DESCRIPTION

The µPD16808 is a monolithic dual H bridge driver circuit which employing N-channel power MOS FETs for its driver

stage. By using the power MOS FETs for the output stage, saturation voltage and power consumption are substantially

improved as compared with conventional driver circuits that use bipolar transistors.

Because the dual H bridge driver circuits at the output stage are independent of each other, this IC is ideal as the driver

circuit for a 1- to 2-phase excitation bipolar driving stepping motor for the head actuator of an FDD.

FEATURES

• Low ON resistance (sum of ON resistors of top and bottom FETS)

ON1 = 1.0 Ω TYP. (VM = 5.0 V)

R

RON2 = 1.5 Ω TYP. (VM = 12.0 V)

• Low current consumption: IDD = 0.4 mA TYP.

• Four input modes independently controlling dual H bridge drivers (with 1- to 2-phase excitation selected)

• Motor voltage 12 V/5 V compatible

• Compact surface mount package: 20-pin plastic SOP (300 mil)

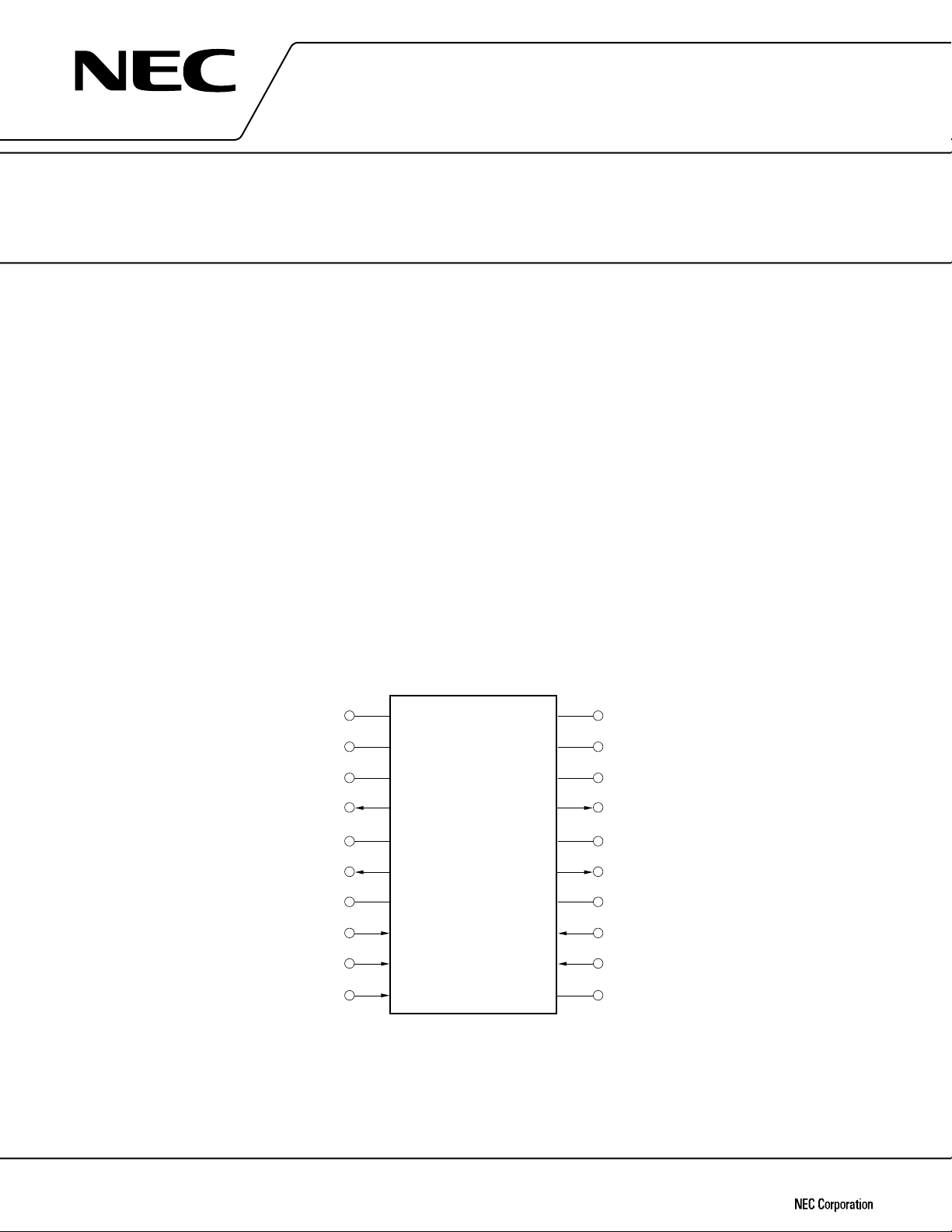

PIN CONFIGURATION (Top View)

C1H

C2L

V

M1

1A

1

PGND

2A

V

DD

IN

1

IN

2

IN

3

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

C1L

C2H

V

G

1B

PGND

2B

V

M2

SEL

4

IN

DGND

2

Document No. S12720EJ2V0DS00 (2nd edition)

Date Published September 1997 N

Printed in Japan

©

1997

Page 2

ORDERING INFORMATION

Part Number Package

µ

PD16808GS 20-pin plastic SOP (300 mil)

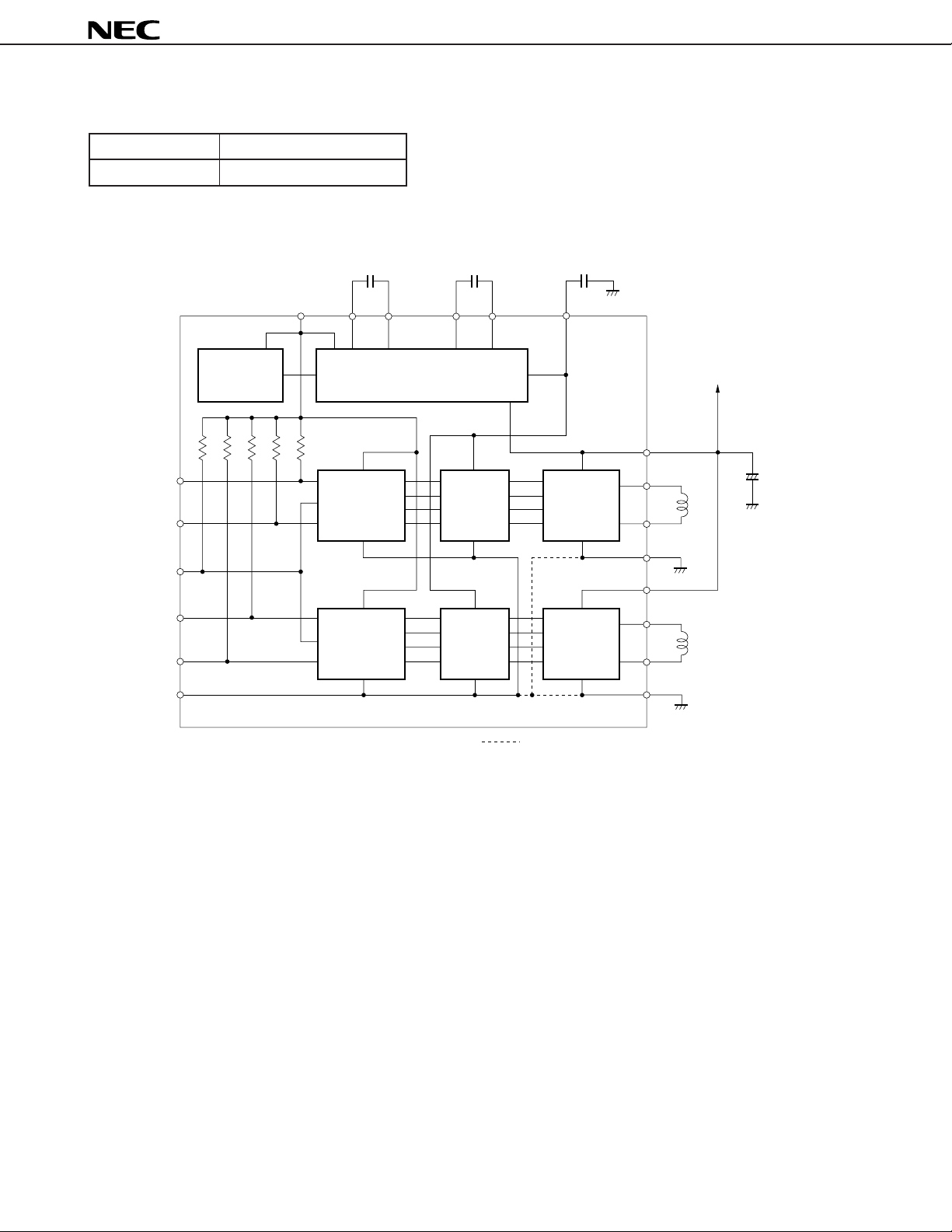

BLOCK DIAGRAM

0.01 F

µ

0.01 F

µ

0.01 F

µ

µ

PD16808

IN

IN

SEL

IN

IN

DGND

C1L C2LC1H C2H

V

DD

OSC

CIRCUIT

1

2

3

4

CHARGE PUMP

CONTROL

CIRCUIT 1

CONTROL

CIRCUIT 2

LEVEL

SHIFT 1

LEVEL

SHIFT 2

V

G

2 × V

“H”

BRIDGE 1

“H”

BRIDGE 2

DD

+ V

M

V

M1

1A

V

M

+

1B

PGND

1

V

M2

2A

2B

2

PGND

Connected in diffusion layer

2

Page 3

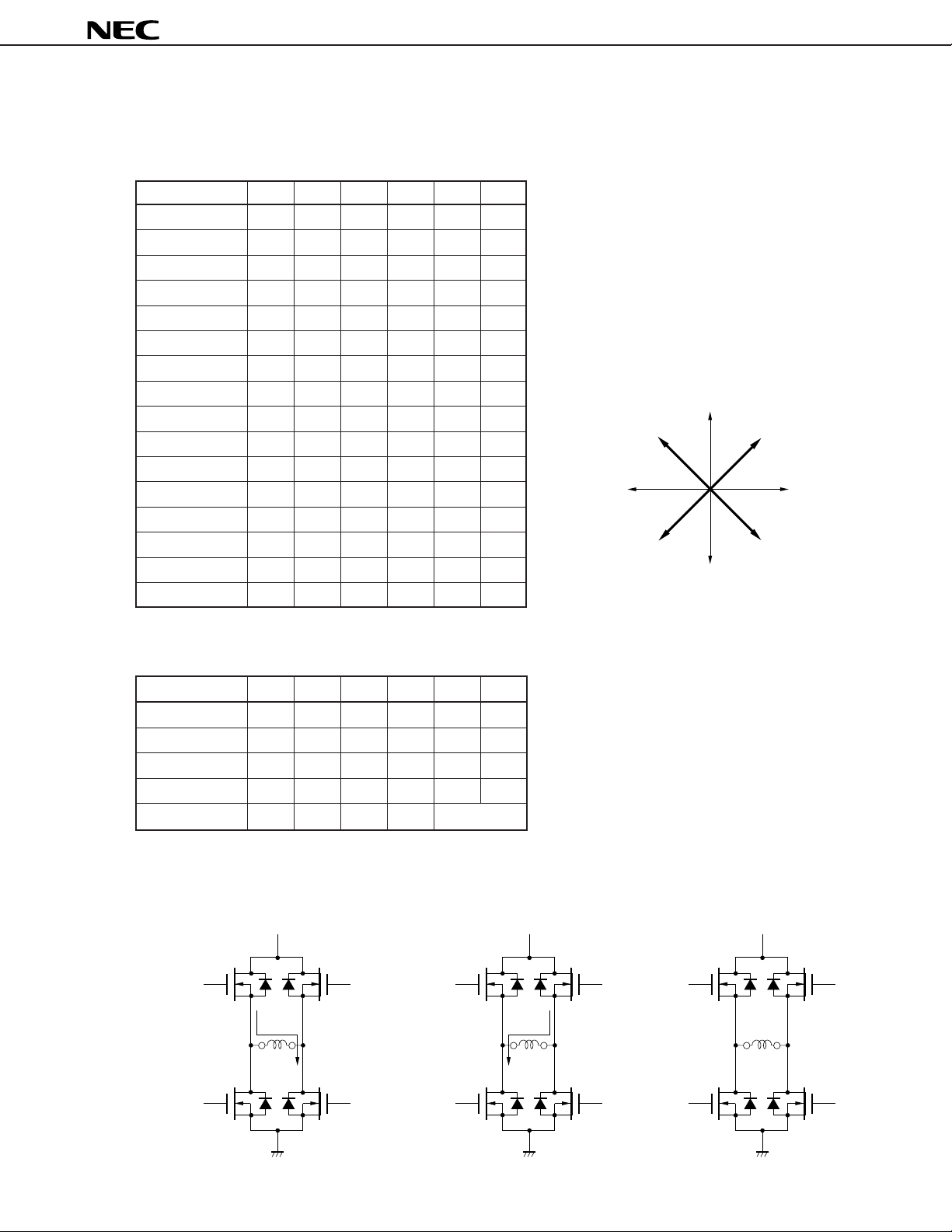

FUNCTION TABLE

• With 1- to 2-phase excitation selected (SEL = High)

µ

PD16808

Excitation Direction

—— LLLLSS

H2R LLLHSR

H2FLLHLSF

—— L L H H S S

H1RLHLLRS

<3> L H L H R R

<2> L H H L R F

H1R LHHHRS

H1F HLLLFS

<4> H L L H F R

<1> HLHLFF

H1FHLHHFS

—— H H L L S S

H2RHHLHSR

H2F HHHLSF

—— HHHHSS

IN1 IN2 IN3 IN4 H1 H2

H2R

<4>

H

1

F

<1>

H

2

F

<2><3>

1

R

H

• With 2-phase excitation selected (SEL = Low)

Excitation Direction

<1> H H × HFF

<2> L H × HRF

<3> L L × HRR

<4> H L × HFR

– ×××L Stop

F: Forward R: Reverse S: Stop ×: Don’t care

IN1 IN3 IN4 IN2 H1 H2

For the excitation waveform timing chart, refer to APPLICATION CIRCUIT EXAMPLE.

FORWARD

M

V

ON

AB

OFF

OFF

ON

OFF

REVERSE

M

V

AB

ON

ON

OFF

STOP

M

V

OFF

AB

OFF

OFF

OFF

3

Page 4

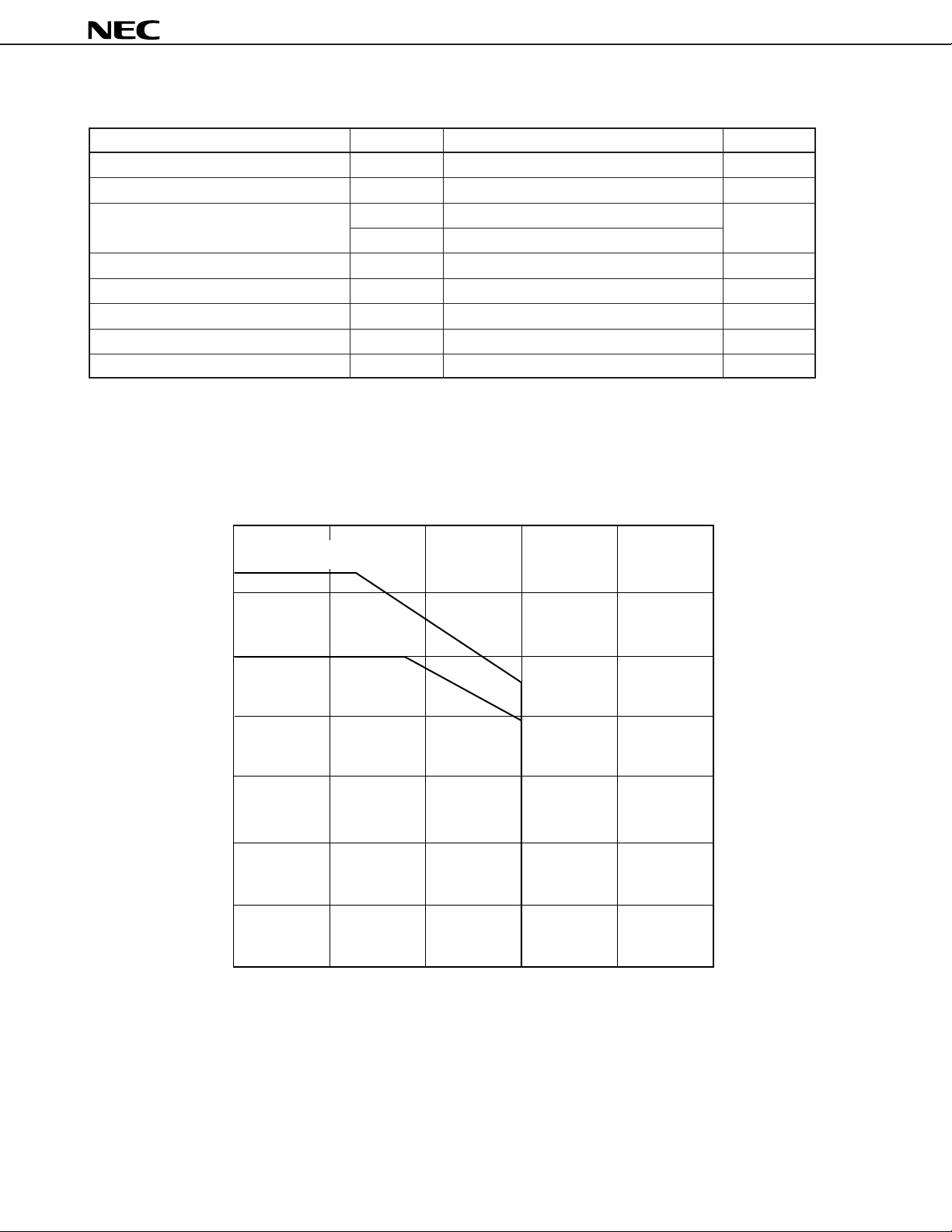

ABSOLUTE MAXIMUM RATINGS (TA = 25 °C)

Parameter Symbol Rating Unit

Supply voltage (motor block) VM –0.5 to +15 V

Supply voltage (control block) VDD –0.5 to +7 V

Power dissipation Pd1 1.0

Pd2 1.25

Instantaneous H bridge driver current ID (pulse) ±1.0

Input voltage VIN –0.5 to VDD + 0.5 V

Operating temperature range TA 0 to 60 °C

Operation junction temperature TjMAX. 150 °C

Storage temperature range Tstg –55 to +125 °C

Note 1

Note 2

Note 2, 3

Notes 1. IC only

2. When mounted on a printed circuit board (100 × 100 × 1 mm, glass epoxy)

3. t ≤ 5 ms, Duty ≤ 40 %

µ

PD16808

W

A

1.4

When mounted

on printed circuid boad

1.2

IC only

1.0

(W)

d

0.8

0.6

Average power dissipation P

0.4

0.2

P

d

– TA Characteristics

0 20 40 60 80 100

Ambient temperature TA (˚C)

4

Page 5

µ

PD16808

RECOMMENDED OPERATING CONDITIONS

Parameter Symbol MIN. TYP. MAX. Unit

Supply voltage (motor block) VM 4.0 5.0 13.2 V

Supply voltage (control block) VDD 4.0 5.0 6.0 V

H bridge driver current

VM = 5.0 V 2-phase excitation

Charge pump capacitance C1 to C3 520nF

Operating temperature TA 060°C

Note

1-/2-phase excitation IDR ± 600 mA

±450

Note When mounted on a printed circuit board (100 × 100 × 1 mm, glass epoxy)

ELECTRICAL SPECIFICATIONS (Within recommended operating conditions unless otherwise specified)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

OFF VM pin current IM VM = 6.0 V, VDD = 6.0 V

VM = 13.2 V, VDD = 6.0 V

VDD pin current IDD Note 2 0.4 1.0 mA

Control pin high-level input IIH TA = 25 °C, VIN = VDD 1.0

current 0 ≤ TA ≤ 60 °C, VIN = VDD 2.0

Control pin low-level input IIL TA = 25 °C, VIN = 0 V –0.18 mA

current 0 ≤ TA ≤ 60 °C, VIN = 0 V –0.25

Control pin input pull-up RIN TA = 25 °C 355065kΩ

resistance 0 ≤ TA ≤ 60 °C2575

Control pin high-level input voltage

Control pin low-level input voltage VIL –0.3 0.8 V

H bridge circuit ON RON1 VDD = 5 V, VM = 5 V 1.0 2.0 Ω

resistance

RON relative accuracy

Charge pump circuit (VG) turn-ON time

H bridge circuit turn-ON time TONH C1 = C2 = C3 = 10 nF 5

H bridge circuit turn-OFF time TOFFH RM = 20 Ω 5

Note 3

VIH 3.0 VDD + 0.3 V

RON2 VDD = 5 V, VM = 12 V 1.5 3.0 Ω

∆

RON1 Excitation direction <2>, <4>

∆

RON2 Excitation direction <1>, <3> ±10

TONG VDD = 5 V, VM = 5 V 0.2 1.0 ms

Note 1

Note 1

Note 4

1.0

1.0 mA

±5%

µ

A

µ

A

µ

s

µ

s

Notes 1. Control pins (IN1, IN2, IN3, IN4): low

2. Control pins (IN

1, IN2, IN3, IN4): high

3. Sum of ON resistances of top and bottom transistors

4. For the excitation direction, refer to FUNCTION TABLE.

5

Page 6

CHARACTERISTIC CURVES

µ

PD16808

RON vs. VDD (= VM) Characteristics

3

(Ω) H bridge ON resistance R

ON

2

1

H bridge ON resistance R

0

4.0 10 11 12 13 145.0 6.0

Supply voltage VDD (= VM) (V)

R

ON

vs. Tj Characteristics

3

RM = 20

Ω

VDD = VM =5.0 V

R

M

= 20 Ω

RON vs. VM Characteristics

3

(Ω)

ON

2

1

H bridge ON resistance R

0

Motor voltage V

M

(V)

RM = 100

VDD = 4.5 V

V

DD

= 5.0 V

DD

= 5.5 V

V

Ω

(Ω)

ON

2

1

0

Operation junction temperature T

50 100 150

j

(˚C)

6

Page 7

Step input

µ

PC2100AGF Stepping Motor Excitation Timing Chart

APPLICATION CIRCUIT EXAMPLE

• Connection with 1-chip FDD LSI

Direction

Internal circumference seek

External circumference seek

PH11

PH21

PH31

µ

PC2100AGF (With 1- to 2-phase excitation selected)

PH41

0.01 F

0.01 F

C2L

LEVEL

SHIFT 1

LEVEL

SHIFT 2

µ

C2H

PH11

PH21

PH31

PH41

IN

IN

V

SEL

IN

IN

0.01 F

µ

C1L

V

DD

OSC

CIRCUIT

1

2

DD

3

4

CONTROL

CIRCUIT 1

CONTROL

CIRCUIT 2

C1H

CHARGE PUMP

DGND

µ

PC2100AGF

7

Connected in diffusion layer

µ

V

G

2 × V

DD

“H”

BRIDGE 1

“H”

BRIDGE 2

+

V

M

V

1A

V

M

M1

+

1B

1

PGND

V

M2

2A

2B

PGND

2

µ

PD16808

Page 8

8

• Connection with 1-chip FDD LSI

The application circuits and their parameters are for reference only and are not intended for use in actual design-ins.

µ

PC2100AGF Stepping Motor Excitation Timing Chart

Step input

SPF0

PH11

PH21

Direction

PH11

PH21

DGND

IN1

IN2

SEL

IN3

IN4

Internal circumference seek

0.01 F

µ

C1L

V

DD

OSC

CIRCUIT

CHARGE PUMP

CONTROL

CIRCUIT 1

CONTROL

CIRCUIT 2

C1H

C2L

LEVEL

SHIFT 1

LEVEL

SHIFT 2

External circumference seek

0.01 F

µ

C2H

0.01 F

V

G

2 × V

“H”

BRIDGE 1

“H”

BRIDGE 2

µ

PC2100AGF (With 2-phase exication selected)

µ

DD

+

V

M

V

1A

V

M

M1

+

1B

1

PGND

V

M2

2A

2B

PGND

2

PC2100AGF

µ

Connected in diffusion layer

µ

PD16808

Page 9

20 PIN PLASTIC SOP (300 mil)

110

µ

PD16808

1120

detail of lead end

P

A

G

F

E

C

D

NOTE

Each lead centerline is located within 0.12 mm (0.005 inch) of

its true position (T.P.) at maximum material condition.

N

M

M

H

I

J

K

B

L

ITEM MILLIMETERS INCHES

A

13.00 MAX.

B

0.78 MAX.

C

1.27 (T.P.)

D 0.40 0.016

E

F

G

H

I

J

K 0.20

L 0.6±0.2 0.024

M

N

P3° 3°

+0.10

–0.05

0.1±0.1

1.8 MAX.

1.55

7.7±0.3

5.6

1.1

+0.10

–0.05

0.12

0.10

+7°

–3°

0.512 MAX.

0.031 MAX.

0.050 (T.P.)

+0.004

–0.003

0.004±0.004

0.071 MAX.

0.061

0.303±0.012

0.220

0.043

+0.004

0.008

–0.002

+0.008

–0.009

0.005

0.004

+7°

–3°

P20GM-50-300B, C-4

9

Page 10

µ

RECOMMENDED SOLDERING CONDITIONS

It is recommended to solder this product under the conditions described below.

For soldering methods and conditions other than those listed below, consult NEC.

Surface mount type

For the details of the recommended soldering conditions of this type, refer to Semiconductor Device Mounting

Technology Manual (C10535E).

PD16808

Soldering Method Soldering Conditions

Infrared reflow

VPS

Wave soldering Solder bath temperature: 260 °C MAX., Time: 10 seconds MAX., WS60-00

Partial heating

Peak package temperature: 230 °C, Time: 30 seconds MAX. (210 °C MIN.),

Number of times: 1, Number of days: None

Peak package temperature: 215 °C, Time: 40 seconds MAX. (200 °C MIN.),

Number of times: 1, Number of days: None

Number of times: 1, Number of days: None

Pin temperature: 300 °C MAX., Time: 10 seconds MAX., –

Number of days: None

Note

Note

Note

Note

Symbol of Recommended

Soldering

IR30-00

VP15-00

Note The number of storage days at 25 °C, 65 % RH after the dry pack has been opened

Caution Do not use two or more soldering methods in combination (except partial heating).

10

Page 11

[MEMO]

µ

PD16808

11

Page 12

µ

PD16808

[MEMO]

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in

this document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property

rights of third parties by or arising from use of a device described herein or any other liability arising from use

of such device. No license, either express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on a

customer designated "quality assurance program" for a specific application. The recommended applications of

a device depend on its quality grade, as indicated below. Customers must check the quality grade of each device

before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

Anti-radioactive design is not implemented in this product.

M4 96.5

2

Loading...

Loading...