Page 1

DATA SHEET

MOS INTEGRATED CIRCUIT

µµµµ

PD16520

VERTICAL DRIVER FOR CCD SENSORS

The µPD16520 is a vertical driver for CCD image sensors that has a level conversion circuit and a 3-level output

function. Since it incorporates a CCD vertical register driver equivalent to the µPD16510 (10 channels, consisting of

six 3-level channels and four 2-level channels) and a VOD shutter driver (1 channel), it is ideal as a vertical driver for

multiple-electrode high-pixel CCD transfer type area image sensors employed in digital still cameras.

The µPD16520 uses a CMOS process to achieve optimum transmission delay characteristics for vertical driving of

CCD image sensors, as well as output on-state resistance characteristics. The µPD16520 also supports low-voltage

logic (logic supply voltage: 2.0 to 5.5 V).

FEATURES

CCD vertical register driver: 10 channels (3-level: 6 channels, 2-level: 4 channels)

•

VOD shutter driver: 1 channel

•

High withstand voltage: 33 V Max.

•

Low-output on-state resistance: 30 Ω TYP.

•

Low-voltage input supported (Logic supply voltage: 2.0 to 5.5 V)

•

Latch-up free

•

Same drive capacity as

•

Small package: 38-pin plastic shrink SOP (300 mil)

•

APPLICATIONS

Digital still cameras, digital video cameras, etc.

ORDERING INFORMATION

Part Number Package

PD16520GS-BGG 38-pin plastic shrink SOP (300 mil)

µ

PD16510

µ

The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

Not all devices/types available in every country. Please check with local NEC representative for

availability and additional information.

Document No. S14201EJ1V0DS00 (1st edition)

Date Published May 1999 N CP(K)

Printed in Japan

©

1999

Page 2

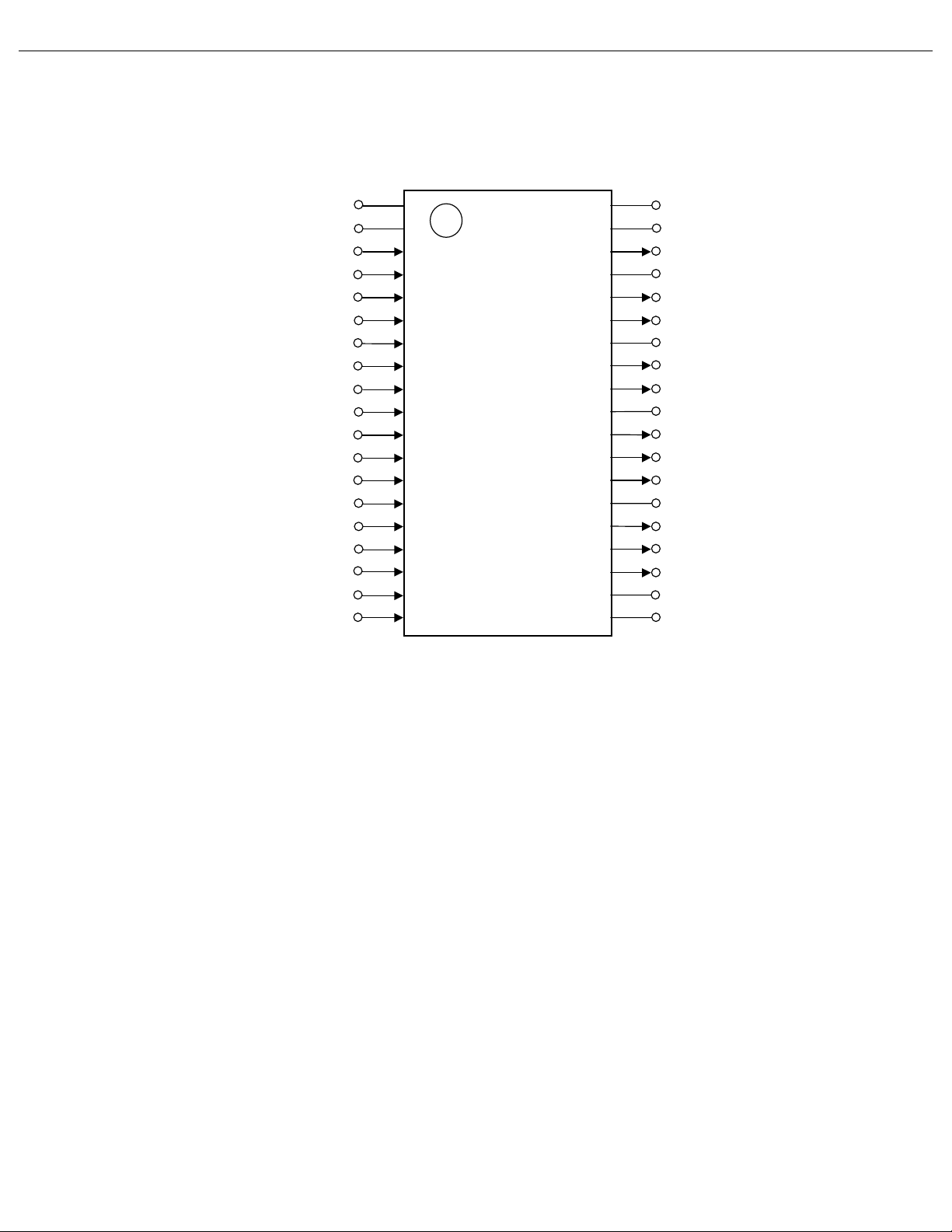

PIN CONFIGURATION (TOP VIEW)

38-pin plastic shrink SOP (300 mil)

•

PD16520GS-BGG

µ

µµµµ

PD16520

GND

Vcc

TI1

TI2

TI3

TI4

TI5

TI6

PG1

PG2

PG3

PG4

PG5

PG6

BI1

BI2

BI3

BI4

SUBI

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

V

SS

VDD1

TO1

VDD2a

TO2

TO3

VDD2a

TO4

TO5

VDD2a

TO6

BO1

BO2

VDD2b

BO3

BO4

SUBO

Vsb

Vss

PIN NAMES

BI1 to BI4: 2 Level Driver Input TO1 to TO6: 3 Level Pulse Output

BO1 to BO4: 2 Level Pulse Output VDD1: Power Supply (VH)

GND: Ground VDD2a: Power Supply (VMa)

PG1 to PG6: 3 Level Driver Input VDD2b: Power Supply (VMb)

SUBI: VOD Shutter Drive Pulse Input VCC: Power Supply (Logic)

SUBO: VOD Shutter Drive Pulse Output Vsb: Power Supply (VHH)

TI1 to TI6: 3 Level Driver Input VSS: Power Supply (VL)

2

Data Sheet S14201EJ1V0DS00

Page 3

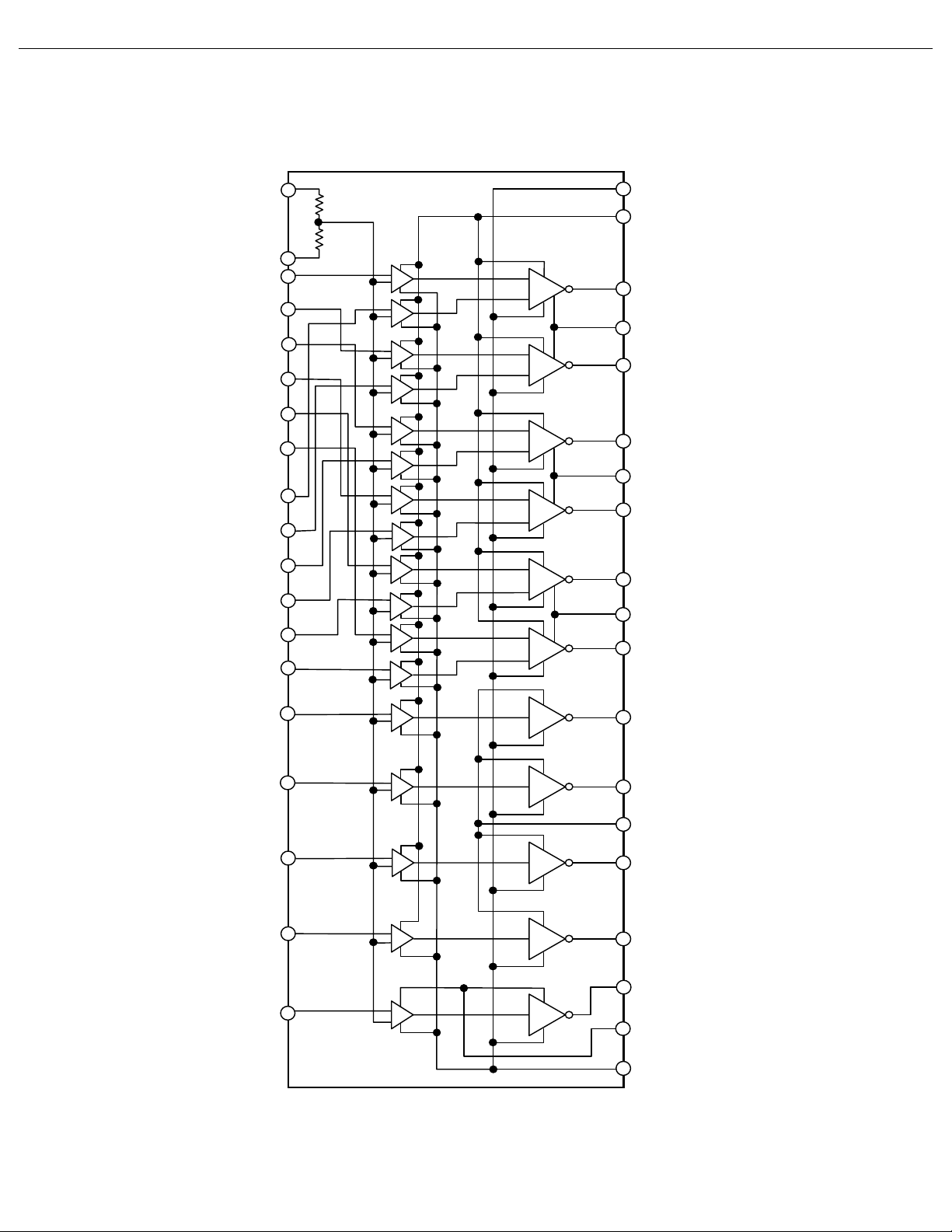

BLOCK DIAGRAM

GND

Vcc

TI1

TI2

TI3

TI4

TI5

TI6

PG1

PG2

PG3

PG4

PG5

PG6

µµµµ

PD16520

Vss

1

2

3

4

5

6

7

8

9

10

11

12

13

14

+

−

+

−

+

−

+

−

+

−

+

−

+

−

+

−

+

−

+

−

+

−

+

−

3 level

3 level

3 level

3 level

3 level

3 level

38

37

36

35

34

33

32

31

30

29

28

VDD1

TO1

VDD2a

TO2

TO3

VDD2a

TO4

TO5

VDD2a

TO6

BI1

BI2

BI3

BI4

SUBI

1

16

17

18

19

+

−

+

−

+

−

+

−

+

−

2 level

2 level

2 level

2 level

2 level

27

26

25

24

23

22

21

20

BO1

BO2

VDD2b

BO3

BO4

SUBO

Vsb

Vss

Data Sheet S14201EJ1V0DS00

3

Page 4

1. PIN FUNCTIONS

Pin No. Pin Name I/O Function

1GND

2V

3TI1 I

4TI2 I

5TI3 I

6TI4 I

7TI5 I

8TI6 I

9PG1 I

10 PG2 I

11 PG3 I

12 PG4 I

13 PG5 I

14 PG6 I

15 BI1 I

16 BI2 I

17 BI3 I

18 BI4 I

19 SUBI I VOD shutter drive pulse input

20 V

21 Vsb

22 SUBO O VOD shutter drive pulse out put

23 BO4 O

24 BO3 O

25 VDD2b

26 BO2 O

27 BO1 O

28 TO6 O 3-level pulse output

29 VDD2a

30 TO5 O

31 TO4 O

32 VDD2a

33 TO3 O

34 TO2 O

35 VDD2a

36 TO1 O 3-level pulse output

37 VDD1

38 V

µµµµ

PD16520

Ground

−

CC

SS

SS

Logic power supply

−

3-level driver input (for charge t ransfer) (See Function

Tables.)

3-level driver input (for charge read) (S ee Function

Tables.)

2-level driver input (for charge t ransfer) (See Function

Tables.)

L

V

power supply

−

VHH power supply (for SUB drive)

−

2-level pulse output

VMb power supply (for 2-level driver)

−

2-level pulse output

VMa power supply (for 3-level driver)

−

3-level pulse output

VMa power supply (for 3-level driver)

−

3-level pulse output

VMa power supply (for 3-level driver)

−

VH power supply

−

L

V

power supply

−

4

Data Sheet S14201EJ1V0DS00

Page 5

µµµµ

PD16520

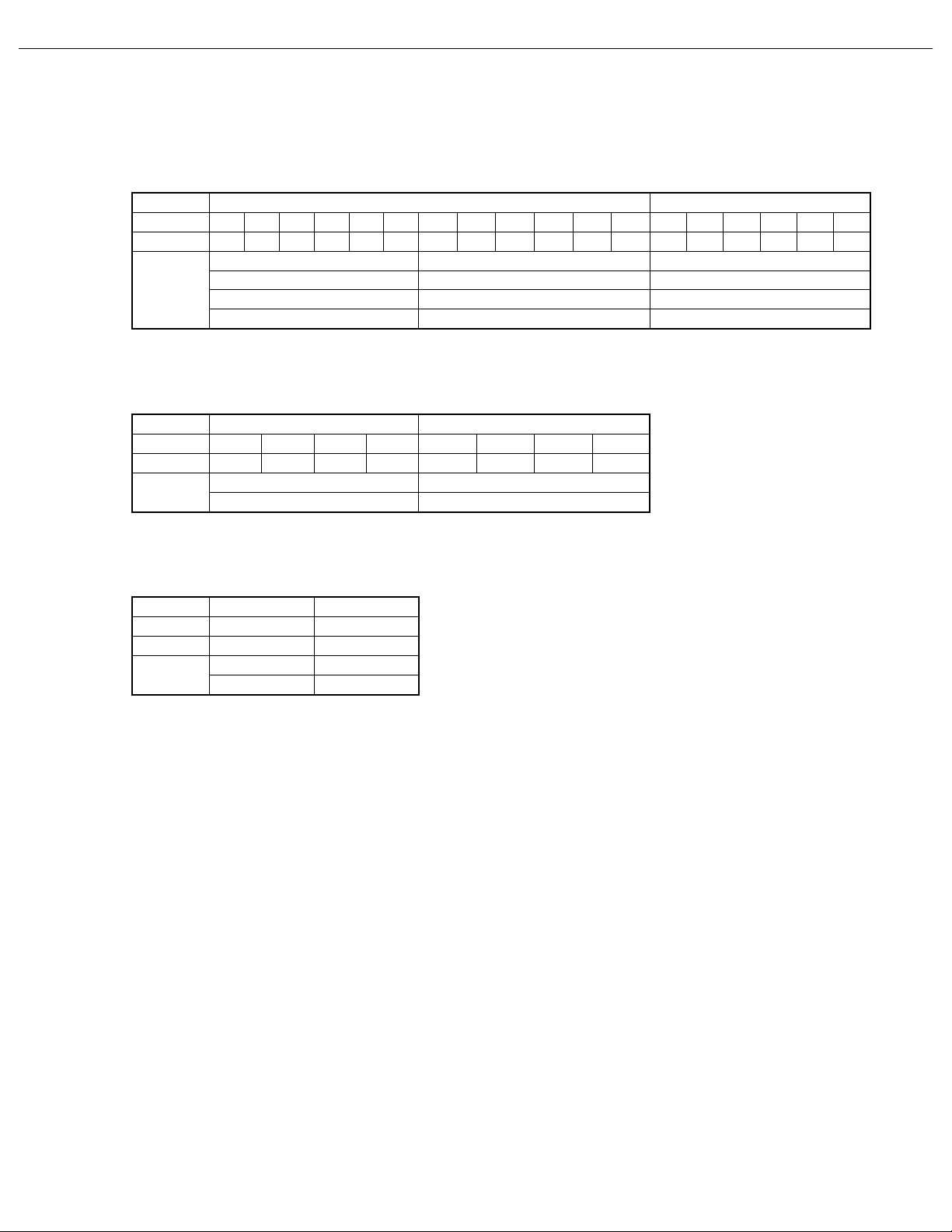

Function Tables

L

= VSS, VMa = VDD2a, VMb = VDD2b, VH = VDD1, VHH = Vsb

V

Pins TO1 to TO6

Input Output

Pin Name TI1 TI2 TI3 TI4 TI5 TI6 PG1 PG2 PG3 PG4 PG5 PG6 TO1 TO2 TO3 TO4 TO5 TO6

Pin No. 34567891011121314363433313028

LLV

LHV

HL V

HH V

H

Ma

L

L

Pins BO1 to BO4

Input Output

Pin Name BI1 BI2 BI3 BI4 BO1 BO2 BO3 BO4

Pin No. 1516171827262423

LV

HV

Mb

L

Pin SUBO

Input Output

Pin Name SUBI SUBO

Pin No. 19 22

LV

HV

HH

L

Data Sheet S14201EJ1V0DS00

5

Page 6

2. ELECTRICAL SPECIFICATIONS

µµµµ

PD16520

Absolute Maximum Ratings (TA = 25

C, GND = 0 V)

°°°°

Parameter Symbol Conditions Ratings Unit

Supply voltage

Input pin voltage V

Operating ambient temperature T

Storage temperature T

Allowable dissipation P

V

CC

V

VDD1 V

VDD2 V

Vsb V

I

A

stg

d

0.0 to −10 V

V

V

SS

SS

SS

SS

−

−

−

−

SS

0.3 to V

0.3 to V

0.3 to V

0.3 to V

−

−

0.3 to V

25 to +85

−

40 to +125

SS

+ 20.0 V

SS

+ 33.0 V

SS

+ 33.0 V

SS

+ 33.0 V

CC

+ 0.3 V

500 mW

C

°

C

°

SS

Caution Product quality may suffer if the absolute maximum rating is exceeded even momentarily for any

parameter. That is, the absolute maximum ratings are rated values at which the product is on the

verge of suffering physical damage, and therefore the product must be used under conditions that

ensure that the absolute maximum ratings are not exceeded.

Recommended Operating Range (T

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Supply voltage

Input voltage, high V

Input voltage, low V

Operating ambient temperature T

SS

Set VDD1 and V

Note

to values that satisfy VDD1-VSS rating.

A

CC

V

VDD1

VDD1-V

VDD2a

VDD2b

SS

V

Vsb-V

IH

IL

A

= 25

C, GND = 0 V)

°°°°

SS

SS

Note

Note

Note

2.0 5.5 V

10.5 15.0 21.0 V

16.5 31.0 V

1.0 +4.0 V

−

1.0 +4.0 V

−

−

10.0

6.0 V

−

31.0 V

CC

0.8V

00.3V

20 +70

−

CC

V

V

CC

V

°

C

6

Data Sheet S14201EJ1V0DS00

Page 7

µµµµ

PD16520

Electrical Specifications

(

Unless otherwise specified, VDD1 = +15 V, VDD2a = 0 V, VDD2b = +1.0 V, Vsb = +21.5 V, VCC = +2.5 V, VSS =

7.0 V, TA = 25

−−−−

Output voltage, high V

Output voltage, low V

Output voltage, sub-high V

Output voltage, sub-low V

Output on-state resistance

Transmission delay ti m e 1 TD1 200 ns

Transmission delay ti m e 2 TD2 200 ns

Transmission delay ti m e 3 TD3

Rise/fall time 1 TP1 500 ns

Rise/fall time 2 TP2 500 ns

Rise/fall time 3 TP3

C, GND = 0 V)

°°°°

Parameter Symbol Conditions MIN. TYP. MAX. Unit

H

Ma

V

Mb

V

L

subH

subL

L

R

M

R

H

R

sub

R

IO = −20 µA VDD1 − 0 .1 VDD1 V

IO = −20 µA VDD2a − 0 . 1 VDD2a VOutput voltage, middle

IO = 20 µA VDD2b VDD2b + 0.1 V

IO = 20 µAVSSV

IO = −20 µAVsb

0.1 Vsb V

−

IO = 20 µAVSSV

SS

+ 0.1 V

SS

+ 0.1 V

IO = 10 mA 20 30

IO = ±10 mA 30 45

IO = −10 mA

30 40

30 40

Ω

Ω

Ω

Ω

No load

See

Figure 2-2 Timing Charts

.

200 ns

See

Figure 2-1 Output Load

Equivalence Circuit

See

Figure 2-2 Timing Charts

.

.

200 ns

Data Sheet S14201EJ1V0DS00

7

Page 8

Figure 2-1. Output Load Equivalence Circuit

(a) Between output pins (b) Between output pin and GND

µµµµ

PD16520

BO2

BO3

BO1

R8

R9

BO2'

BO1'

R7

BO3'

BO4

R10

TO6'

TO6

BO4'

R6

TO5'

R1

TO1

TO1'

R5

TO5

TO4'

R2

TO2'

TO3'

R4

R3

TO2

TO4

TO3

BO2

BO3

BO1

R8

R9

BO3'

BO2'

R7

BO4

R10

BO4'

C8

BO1'

TO6

C10

C9

C7

SUB0

R6

C6

TO6'

TO1'

C1

RGND

R1

C5

C2

TO5'

C11

TO1

TO2'

C3

C4

R5

TO5

TO4'

R2

TO3'

R4

R3

TO2

TO3

TO4

Output Load Capacitance Symbol

TO1' TO2' TO3' TO4' TO5' TO6' BO1' BO2' BO3' BO4' GND

TO1'

−

TO2' C_33

TO3' C_33 C_33

TO4' C_33 C_33 C_33

TO5' C_33 C_33 C_33 C_33

TO6' C_33 C_33 C_33 C_33 C_33

BO1' C_32 C_23 C_32 C_23 C_32 C_23

BO2' C_23 C_32 C_23 C_32 C_23 C_32 C_22

BO3' C_32 C_23 C_32 C_23 C_32 C_23 C_22 C_22

BO4' C_23 C_32 C_23 C_32 C_23 C_32 C_22 C_22 C_22

SUBO

−−−−−−−−−−

8

C_33 C_33 C_33 C_33 C_33 C_32 C_23 C_32 C_23 C1

−

C_33 C_33 C_33 C_33 C_23 C_32 C_23 C_32 C2

−

C_33 C_33 C_33 C_32 C_23 C_32 C_23 C3

−

C_33 C_33 C_23 C_32 C_23 C_32 C4

−

C_33 C_32 C_23 C_32 C_23 C5

−

C_23 C_32 C_23 C_32 C6

−

C_22 C_22 C_22 C7

−

C_22 C_22 C8

−

Data Sheet S14201EJ1V0DS00

C_22 C9

−

C10

C11

Page 9

Output Load Equivalence Circuit Constants

Parameter Symbol Constant

Vertical register serial resistor R1 to R10 0

Vertical register ground resi stor RGND 0

Ω

Ω

Capacitance 1 between vertic al regi ster clocks (3 level-3 level) C_33 0 pF

Capacitance 2 between vertic al regi ster clocks (2 level-2 level) C_22 0 pF

Capacitance 3 between vertic al regi ster clocks (3 level-2 level) C_32 1000 pF

Capacitance 4 between vertic al regi ster clocks (2 level-3 level) C_23 500 pF

Vertical register ground capacitance 1 (3 level) C1 to C6 3000 pF

Vertical register ground capacitance 2 (2 level) C7 to C10 1500 pF

Substrate ground capacitanc e C11 1600 pF

Figure 2-2. Timing Charts

BI1 to BI4

TI1 to TI6

TD1 TD1

µµµµ

PD16520

BO1 to BO4

TO1 to TO6

PG1 to PG6

TO1 to TO6

SUBI

TP1

TD2 TD2

TP2

TP1

TP2

Mb

V

Ma

V

L

V

H

V

Ma

V

SUBO

TD3 TD3

TP3

Data Sheet S14201EJ1V0DS00

TP3

HH

V

L

V

9

Page 10

3. CAUTIONS

3.1 Power ON/OFF Sequence

µµµµ

PD16520

In the

BI4, SUBI) → VCC, so that in the case of voltage conditions: VDD2 > VDD1, input pin voltage (TI1 to TI6, PG1 to

PG6, BI1 to BI4, SUBI) > VCC, an abnormal current flows. Therefore, when turning the power ON/OFF, make sure

that the following voltage conditions are satisfied: VDD2 ≤ VDD1, input pin voltage (TI1 to TI6, PG1 to PG6, BI1 to

BI4, SUBI) ≤ VCC. Also, to minimize the negative potential applied to the SUB pin of the CCD image sensor, following

the power ON/OFF sequence described below.

(1) Power ON

PD16520, a PN junction (diode) exists between VDD2 → VDD1, input pin (TI1 to TI6, PG1 to PG6, BI1 to

µ

<1> Powering ON V

Make sure that input pin voltage (TI1 to TI6, PG1 to PG6, BI1 to BI4, SUBI) ≤ VCC. Also, when Vsb = 2 V,

make sure that VCC reaches the rated voltage.

<2> Powering ON Vsb, VDD1, VDD2a, VDD2b, V

At this time, make SUBI high level (0.8VCC or higher).

CC

SS

Vsb

VDD1

2V

<1> <2>

Vcc

VDD2a, VDD2b

0V

Vss

Time

10

Data Sheet S14201EJ1V0DS00

Page 11

(2) Power OFF

<1> Powering OFF Vsb, VDD1, VDD2a, VDD2b, V

Until VCC power OFF, keep SUBI high level (0.8VCC or higher).

<2> Powering OFF V

Power OFF VCC when Vsb becomes 2 V or lower. At this time, make sure that the input pin voltage (TI1 to

TI6, PG1 to PG6, BI1 to BI4, SUBI) ≤ VCC.

CC

SS

µµµµ

PD16520

Vsb

VDD1

Vcc

VDD2a, VDD2b

Vss

3.2. Recommended Connection of Unused Pins

Handle input pins and output pins that are not used as follows.

Input pin: High level (connect to V

Output pin: Leave open

CC

)

<1>

<2>

2V

0V

Time

Data Sheet S14201EJ1V0DS00

11

Page 12

4. APPLICATION CIRCUIT EXAMPLE

CCD

VSUB (Substrate voltage)

VDD2b

µµµµ

PD16520

1MΩ

+

µ

1 F

µ

0.1 F

Vsb

VDD1

SS

V

CC

V

34

35

36

38

37

SS

V

TO1

VDD1

VDD2a

PD16520GS-BGG

µ

CC

TI1

TI2

V

4

5

3

1

GND

2

TO2

TI3

33

6

TO3

TI4

31

32

VDD2a

TI5

8

7

TO4

TI6

30

9

29

TO5

PG1

10

28

TO6

VDD2a

PG2

PG3

11

27

12

26

BO1

PG4

13

25

BO2

PG5

14

24

BO3

VDD2b

PG6

BI1

15

23

16

22

BO4

BI2

17

21

Vsb

SUBO

BI4

BI3

18

20

SS

V

SUBI

19

µ

0.1 F

µ

0.1 F

µ

0.1 F

µ

0.1 F

µ

0.1 F

12

TG/SSG

Data Sheet S14201EJ1V0DS00

Page 13

5. PACKAGE DRAWING

38-PIN PLASTIC SSOP (300 mil)

µµµµ

PD16520

38 20

detail of lead end

F

G

119

A

P

E

S

C

D

M

M

N

S

B

K

L

H

I

J

NOTE

Each lead centerline is located within 0.10 mm of

its true position (T.P.) at maximum material condition.

ITEM MILLIMETERS

12.7±0.3

A

0.65 MAX.

B

C

0.65 (T.P.)

D

E

F

H

I

J 1.05±0.2

K 0.2

L 0.6±0.2

M

N 0.10

P3°

+0.05

0.37

−0.1

0.125±0.075

1.675±0.125

1.55G

7.7±0.2

5.6±0.2

+0.1

−0.05

0.10

+7°

−3°

P38GS-65-BGG

Data Sheet S14201EJ1V0DS00

13

Page 14

µµµµ

PD16520

6. RECOMMENDED SOLDERING CONDITIONS

The µPD16520 should be soldered and mounted under the following recommended conditions.

For the details of the recommended soldering conditions, refer to the document

Mounting Manual (C10535E)

For soldering methods and conditions other than those recommended below, contact your NEC sales

representative.

µPD16520GS-BGG: 38-pin plastic shrink SOP (300 mil)

•

Soldering Method Soldering Conditions Recommended

Infrared reflow Pac k age peak temperature: 235°C, Time: 30 sec. Max. (at 210°C or higher),

Count: Three times or less

VPS Package peak temperature: 215°C, Time: 40 sec. Max. (at 200°C or higher),

Count: Three times or less

Wave soldering Solder bath t em perature: 260°C, Time: 10 sec. Max., Count: Once,

Preheating temperature: 120°C Max. (package surface temperature)

Partial heating Pin t em perature: 300°C Max., Time: 3 sec . M ax. (per pin row)

.

Table 6-1. Surface Mounting Type Soldering Conditions

Semiconductor Device

Condition Symbol

IR35-00-3

VP15-00-3

WS60-00-1

−

Caution Do not use different soldering methods together (except for partial heating).

14

Data Sheet S14201EJ1V0DS00

Page 15

NOTES FOR CMOS DEVICES

1 PRECAUTION AGAINST ESD FOR SEMICONDUCTORS

Note:

Strong electric field, when exposed to a MOS device, can cause destruction of the gate oxide and

ultimately degrade the device operation. Steps must be taken to stop generation of static electricity

as much as possible, and quickly dissipate it once, when it has occurred. Environmental control

must be adequate. When it is dry, humidifier should be used. It is recommended to avoid using

insulators that easily build static electricity. Semiconductor devices must be stored and transported

in an anti-static container, static shielding bag or conductive material. All test and measurement

tools including work bench and floor should be grounded. The operator should be grounded using

wrist strap. Semiconductor devices must not be touched with bare hands. Similar precautions need

to be taken for PW boards with semiconductor devices on it.

2 HANDLING OF UNUSED INPUT PINS FOR CMOS

Note:

No connection for CMOS device inputs can be cause of malfunction. If no connection is provided

to the input pins, it is possible that an internal input level may be generated due to noise, etc., hence

causing malfunction. CMOS devices behave differently than Bipolar or NMOS devices. Input levels

of CMOS devices must be fixed high or low by using a pull-up or pull-down circuitry. Each unused

DD

pin should be connected to V

being an output pin. All handling related to the unused pins must be judged device by device and

related specifications governing the devices.

or GND with a resistor, if it is considered to have a possibility of

µµµµ

PD16520

3 STATUS BEFORE INITIALIZATION OF MOS DEVICES

Note:

Power-on does not necessarily define initial status of MOS device. Production process of MOS

does not define the initial operation status of the device. Immediately after the power source is

turned ON, the devices with reset function have not yet been initialized. Hence, power-on does

not guarantee out-pin levels, I/O settings or contents of registers. Device is not initialized until the

reset signal is received. Reset operation must be executed immediately after power-on for devices

having reset function.

Data Sheet S14201EJ1V0DS00

15

Page 16

µµµµ

PD16520

• The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

• No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in

this document.

• NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property

rights of third parties by or arising from use of a device described herein or any other liability arising from use

of such device. No license, either express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of NEC Corporation or others.

• Descriptions of circuits, software, and other related information in this document are provided for illustrative

purposes in semiconductor product operation and application examples. The incorporation of these circuits,

software, and information in the design of the customer's equipment shall be done under the full responsibility

of the customer. NEC Corporation assumes no responsibility for any losses incurred by the customer or third

parties arising from the use of these circuits, software, and information.

• While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

• NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on a

customer designated "quality assurance program" for a specific application. The recommended applications of

a device depend on its quality grade, as indicated below. Customers must check the quality grade of each device

before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircraft, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

M7 98. 8

Loading...

Loading...